Page 1

TA660A / TA660CA

PCI / CPCI

BUS Analyzer-Exerciser

User’s Manual

Revision 4.0, Compatible with Software Revision 4.X

Catalyst

Enterprises, Inc.

1439 Torrington Court

San Jose, CA. 95120

Phone 408.268.4145

Fax 408.268.8280

http://www.catalyst-ent.com

©2000

Page 2

TA660 User's Manual Catalyst Enterprises, Inc

ii

Page 3

TA660 User's Manual Catalyst Enterprises, Inc

Table of Contents

INTRODUCTION .........................................................................................................................................1

WHAT'S IN THIS MANUAL.........................................................................................................................1

OVERVIEW....................................................................................................................................................1

OPTIONAL AUXILIARY PCI CONNECTOR............................................................................................2

TA660 ANALYZER CARD...........................................................................................................................3

STATUS LED FUNCTION DESCRIPTION...............................................................................................3

RECEIVING AND INSPECTING YOUR ANALYZER....................................................................4

UNPACKING YOUR ANALYZER.................................................................................................................4

INSTALLING YOUR ANALYZER .........................................................................................................5

HARDWARE INSTALLATION.......................................................................................................................5

SOFTWARE INSTALLATION.........................................................................................................................6

TA660 OVERVIEW......................................................................................................................................7

TA660 CONFIGURATIONS.......................................................................................................................... 7

STATE ANALYZER ONLY.......................................................................................................................7

STATE & TIMING ANALYZER................................................................................................................7

STATE ANALYZER & EXERCISER..........................................................................................................7

PERFORMANCE ANALYSIS.....................................................................................................................8

STATISTICAL ANALYSIS.........................................................................................................................8

SPECIAL CAPABILITIES........................................................................................................................... 9

LAUNCHING YOUR TA660 ...................................................................................................................11

OPERATING IN SIMULATION MODE ........................................................................................................12

LPT PORT SETTING...................................................................................................................................13

CONFIGURATION MENU......................................................................................................................14

SYSTEM CLOCK.........................................................................................................................................15

ENABLING V OLTAGE CHECK...................................................................................................................15

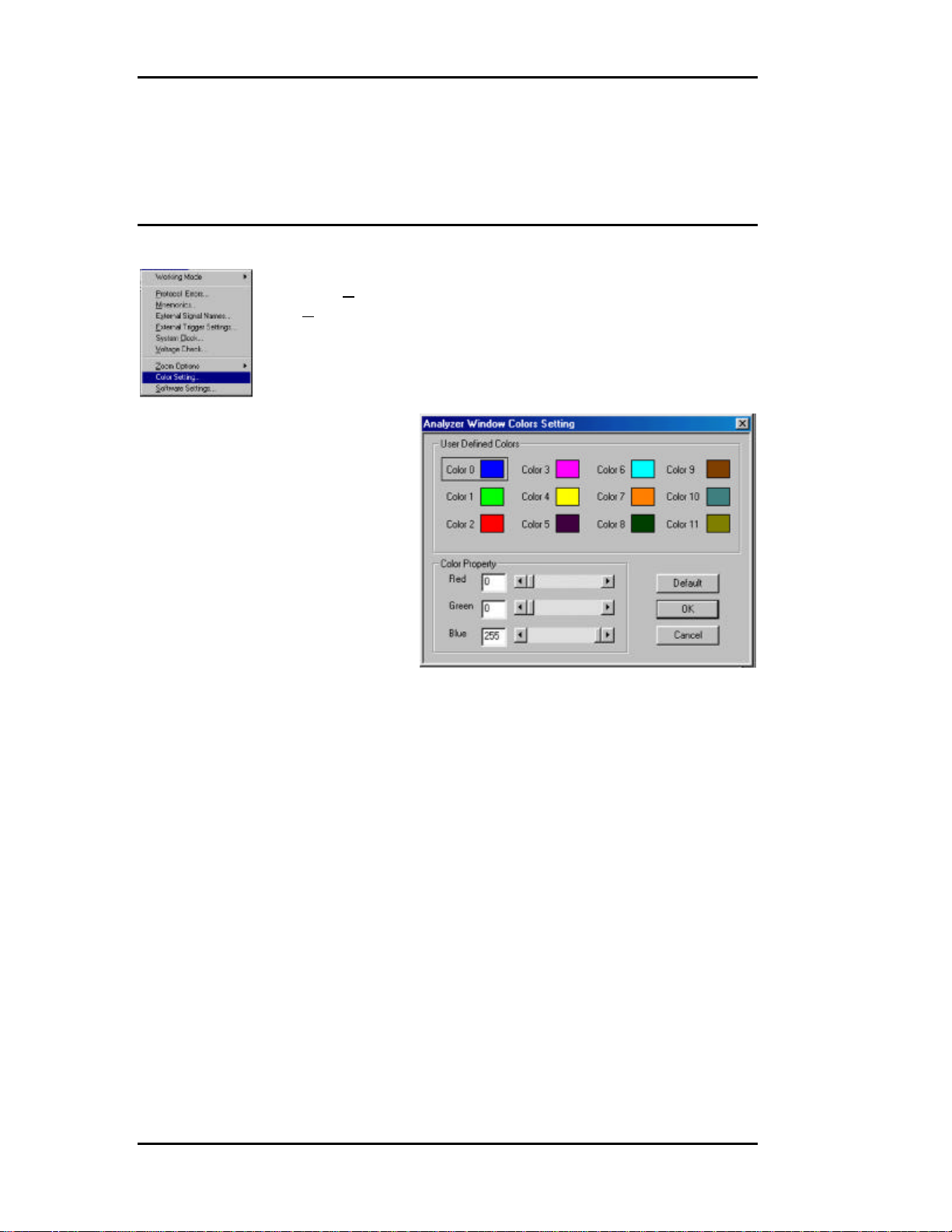

ANALYZER WINDOW COLORS.................................................................................................................16

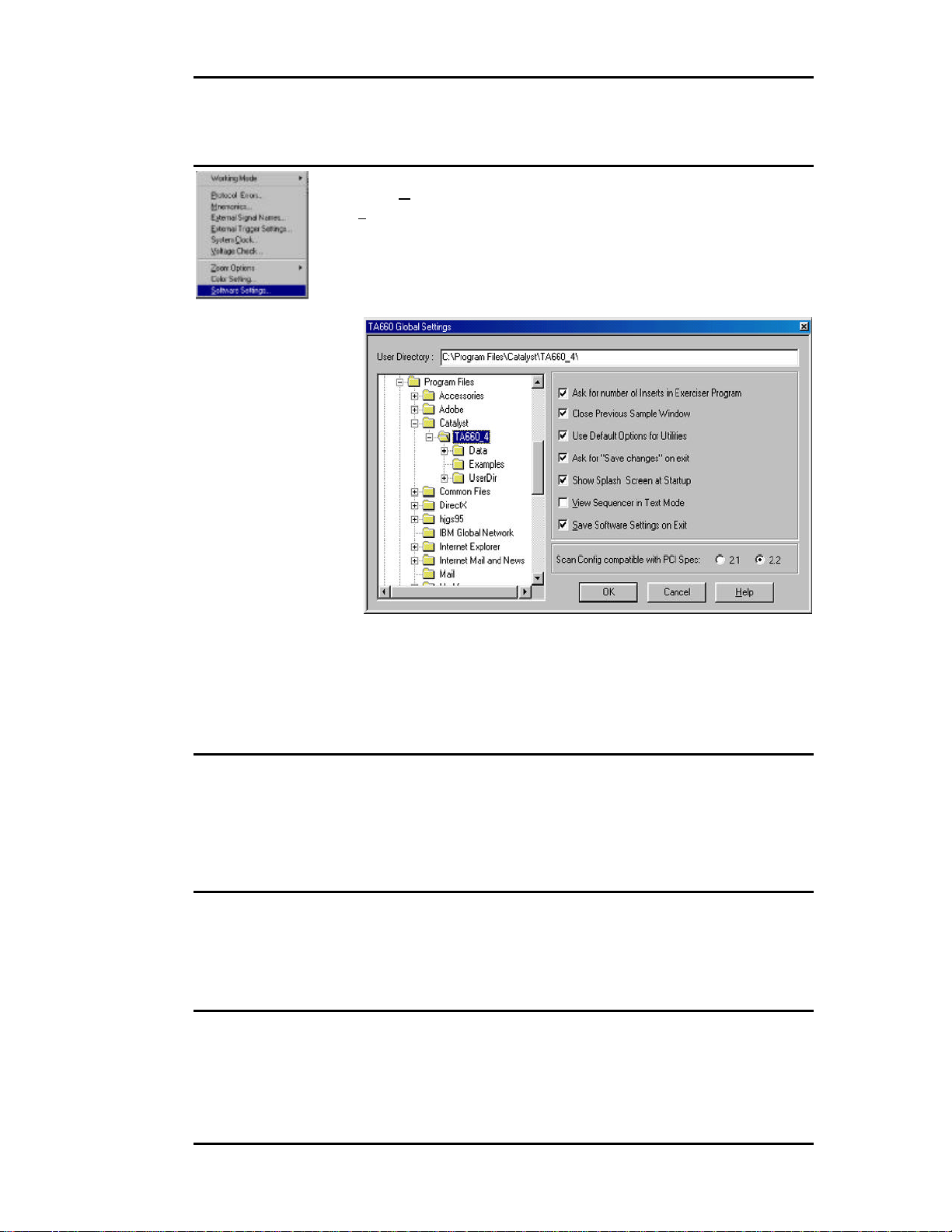

G LOBAL SOFTWARE SETTINGS................................................................................................................17

PROTOCOL ERRORS...................................................................................................................................17

EXTERNAL SIGNAL NAMES...................................................................................................................... 17

EXTERNAL TRIGGER SETTINGS................................................................................................................17

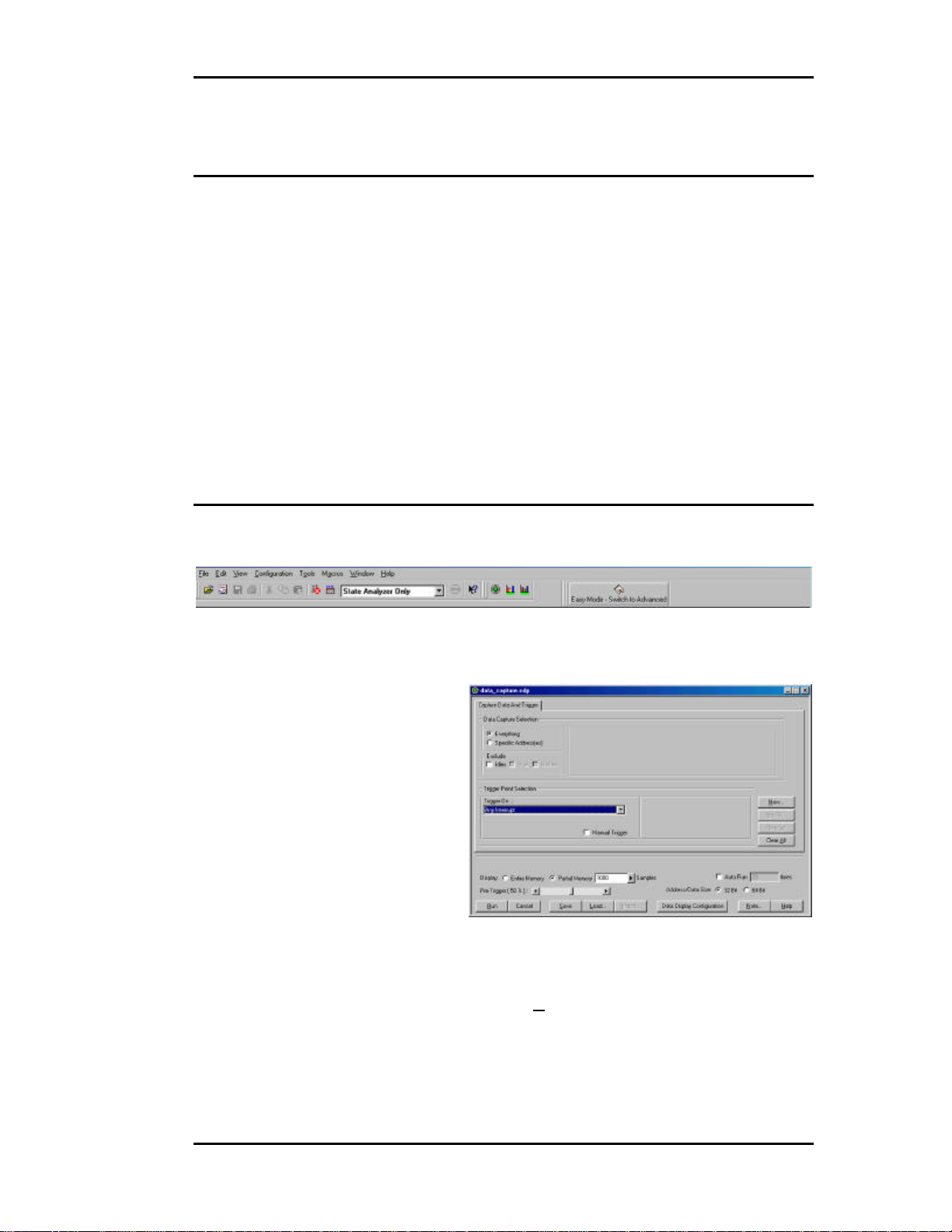

EASY MODE................................................................................................................................................19

INSTANT DATA CAPTURE & TRIGGER ....................................................................................................19

iii

Page 4

TA660 User's Manual Catalyst Enterprises, Inc

SELECTIVE DATA CAPTURE................................................................................................................22

DATA CAPTURE & TRIGGER EXAMPLES...........................................................................................23

DATA CAPTURE OPTIONS....................................................................................................................24

PERFORMANCE ANALYSIS........................................................................................................................25

TRACE S TATISTICS....................................................................................................................................27

OBTAINING TRACE STATISTICS..........................................................................................................27

TRACE ANALYSIS OPTIONS.................................................................................................................31

EXERCISE AND CAPTURE..........................................................................................................................33

DEFINING AN EXERCISER PROGRAM..................................................................................................33

CREATING A DATA BLOCK FILE.........................................................................................................35

EDITING FILES IN ASCII...........................................................................................................................37

EXERCISER UTILITIES ............................................................................................................................... 38

DUMP MEMORY....................................................................................................................................38

READ/MODIFY WRITE .........................................................................................................................38

WRITE READ VERIFY...........................................................................................................................39

ADDRESS TEST ...................................................................................................................................... 40

TA660 AS MEMORY.............................................................................................................................42

SCAN CONFIGURATION REGISTERS....................................................................................................44

G ENERATE TRAFFIC AND MEASURE PERFORMANCE ........................................................................... 46

G ENERATE TRAFFIC AND MEASURE TRACE STATISTICS.....................................................................47

PERFORM TIMING ANALYSIS...................................................................................................................49

TIMING VIOLATION CAPTURE ............................................................................................................49

SEARCH FOR SETUP & HOLD LIMITS................................................................................................. 51

ADVANCED MODE...................................................................................................................................53

CAPTURE DATA PROJECT..................................................................................................................53

PROGRAMMING THE EXERCISER.............................................................................................................55

SETTING EXERCISER OPTIONS............................................................................................................58

SET INTERRUPTS................................................................................................................................... 60

DEFINING EVENT PATTERNS.................................................................................................................... 61

DEFINING AN EVENT PATTERN........................................................................................................... 62

PROGRAMMING THE SEQUENCER............................................................................................................ 64

DEFINING A BOOLEAN EXPRESSION................................................................................................... 66

PROGRAMMING THE SEQUENCER AS TEXT ....................................................................................... 67

SET TRIGGER.............................................................................................................................................. 69

V IRTUAL ADDRESS TRIGGER................................................................................................................... 70

STATE & TIMING ANALYZER..................................................................................................................71

iv

Page 5

TA660 User's Manual Catalyst Enterprises, Inc

SEARCH FOR SETUP & HOLD LIMITS................................................................................................. 73

PERFORMANCE ANALYSIS ................................................................................................................75

REAL-TIME ANALYSIS...............................................................................................................................75

PERFORMING A PRE-DEFINED ANALYSIS...........................................................................................76

CREATING A NEW ANALYSIS PROJECT .............................................................................................76

SETTING ANALYSIS OPTIONS:..............................................................................................................77

DEFINING EVENT PATTERNS ................................................................................................................78

WRITING AND EDITING ANALYSIS EQUATIONS....................................................................................79

PROGRAMMING THE EXERCISER........................................................................................................... 80

SAVED PERFORMANCE ANALYSIS REVIEW .............................................................................81

TRACE S TATISTICS....................................................................................................................................82

CREATING A NEW TRACE PROJECT ...................................................................................................82

SETTING TRACE OPTIONS.................................................................................................................... 83

DEFINING EVENT PATTERNS ................................................................................................................84

PROGRAMMING THE EXERCISER........................................................................................................... 84

DEFINING EQUATIONS .........................................................................................................................84

RUNNING THE TRACE PROJECT ............................................................................................................84

EXAMPLE FILES .......................................................................................................................................85

COMPLIANCE DEVICE TEST.............................................................................................................87

EXECUTING A COMPLIANCE DEVICE TEST ............................................................................................88

SETTING THE COMPLIANCE TEST O PTIONS.......................................................................................89

EXECUTING A SAVED CONFIGURATION.................................................................................................90

EXAMPLE TEST ..........................................................................................................................................90

PROGRAM DEVICE.....................................................................................................................................94

DISPLAY MANIPULATION...................................................................................................................95

ADDING AND REMOVING SIGNALS FOR DISPLAY.................................................................................97

LATENCY REPORT .....................................................................................................................................99

USING THE CURSORS.................................................................................................................................99

JUMP WITHIN DATA DISPLAY...............................................................................................................101

USING ZOOM IN THE WAVE WINDOW ..................................................................................................102

ZOOM O PTIONS...................................................................................................................................102

USER DEFINED DISPLAY CONFIGURATION..........................................................................................102

SEARCH......................................................................................................................................................103

CONVERTING CAPTURED DATA .................................................................................................. 109

CONVERT TO TEXT .................................................................................................................................109

v

Page 6

TA660 User's Manual Catalyst Enterprises, Inc

CONVERT TO EXCEL............................................................................................................................110

CAPTURE A SCREEN................................................................................................................................112

TOOLS TO ANALYZE CAPTURED DATA................................................................................... 113

COMPARE ..................................................................................................................................................113

FILTERING CAPTURED DATA.................................................................................................................115

SPECIAL SETUPS...................................................................................................................................118

PROTOCOL ERRORS.................................................................................................................................118

NUMBER OF ERRORS...........................................................................................................................121

PROTOCOL ERROR TYPE....................................................................................................................121

MNEMONICS.............................................................................................................................................123

DISPLAYING PATTERNS MATCHING MNEMONICS.........................................................................124

EXTERNAL SIGNALS/TRIGGER...............................................................................................................125

MACROS....................................................................................................................................................128

SYSTEM ADMINISTRATION............................................................................................................131

MULTIPLE USERS.....................................................................................................................................131

TROUBLESHOOTING.......................................................................................................................... 132

HARDWARE NOT FOUND....................................................................................................................132

NO TRIGGER .........................................................................................................................................132

APPENDIX A TA660 C-API............................................................................................................... 133

APPENDIX B ............................................................................................................................................ 145

TA660CA COMPACTPCI CARD...................................................................................................145

STATUS LED FUNCTION DESCRIPTION................................................................................................146

POWER JUMPER CONFIGURATION.........................................................................................................146

vi

Page 7

TA660 User's Manual Catalyst Enterprises, Inc

Caution:

Introduction

What's In This Manual

This manual describes the installation and operation of your Catalyst

PCI Bus Analyzer / Exerciser. Examples of some typical applications

are included.

The terms TA660 and PCI analyzer thereafter are used for referring to

both PCI and CompactPCI analyzers (see Appendix B).

Overview

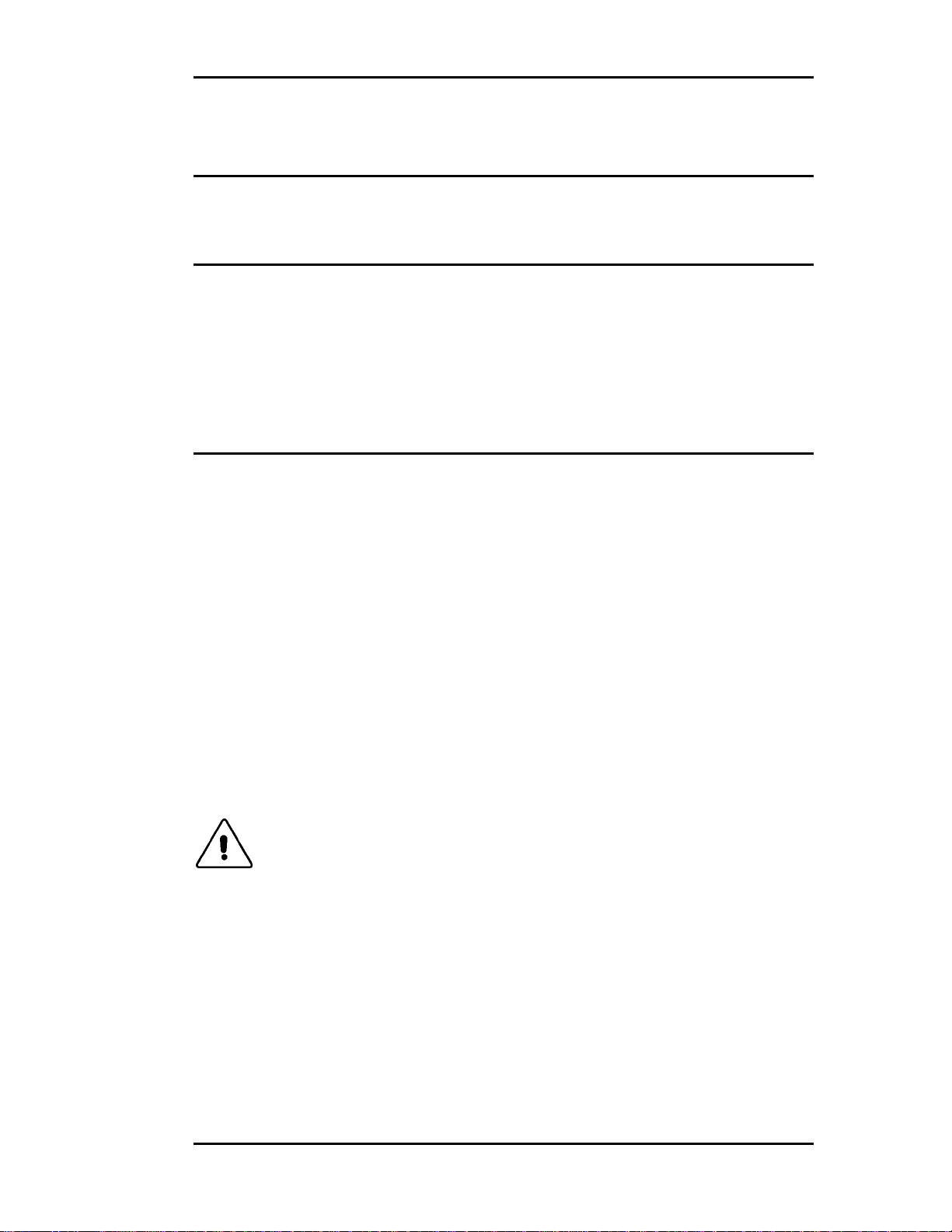

Your TA660 PCI Bus Analyzer is a powerful and versatile analysis

tool that will permit you to debug and characterize PCI designs

operating on any PCI system architecture . To perform analysis you

simply install the analyzer card in a PCI slot in the target machine and

connect it to the host computers Bi-directional parallel port using the

25 pin parallel cable, provided with your analyzer. A typical setup

may include a Host and a Target systems interconnected via the

parallel port with the analyzer card installed in the Target Machine

and a Windows based host running the analysis software.

If your target machine operates under Windows it may also act as the

host. In this case, the analyzer card and the analysis software reside in

the same machine and require you to connect the analyzer card to the

Host high-speed parallel port using the 25 pin parallel cable. See

Figure 1.

Operating the analyzer in this mode, however, may impact

Performance Analysis measurement accuracy since the

analyzer software runs in the same system space as the

application software. For a precise Performance Analysis it

is recommended that you use a separate Host system.

1

Page 8

TA660 User's Manual Catalyst Enterprises, Inc

Figure 1 Target and Host Operating in the Same Machine

Optional Auxiliary PCI connector

The PCI Bus Analyzer Card incorporates a PCI connector on top

which extends the system PCI bus and allows other PCI cards to be

plugged into the analyzer for development or production testing. This

feature allows the analyzer to monitor the same point-to-point signals

such as REQ# & GNT# on the card under test without requiring any

external connections. In this mode, both the analyzer and the card

under test require only one PCI slot. Special design methodology has

been incorporated to minimize any reflections, delay or cross-talk.

This feature only exists on the TA660A PCI analyzer and not on the

Compact PCI version.

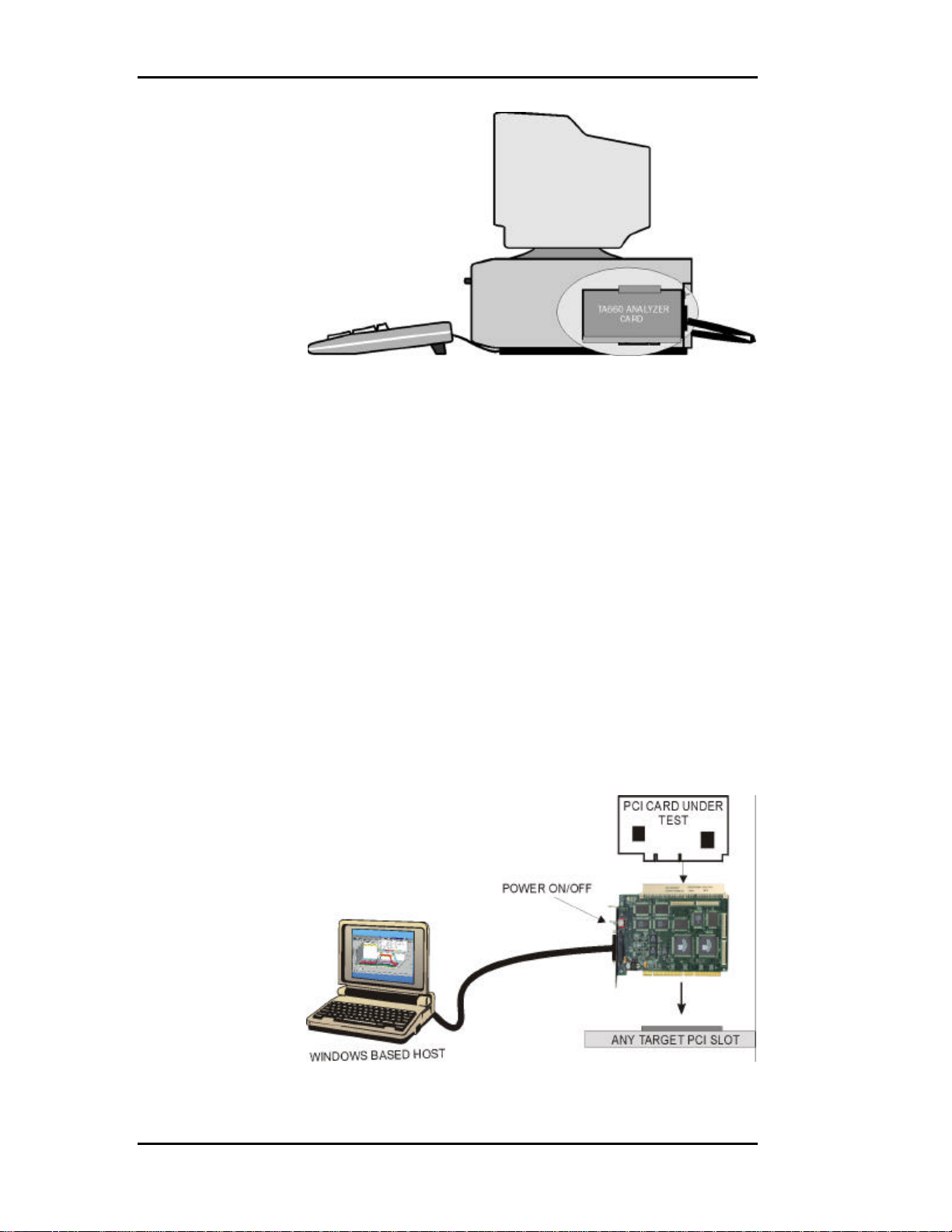

Figure 2 illustrates such a test setup. An On-Off switch on the

analyzer card enables and disables the power and signal connections

between the system and the card under test allowing rapid cycling of

the test cards without shutting off the system power.

Figure 2 Testing a PCI Bus Card

2

Page 9

TA660 User's Manual Catalyst Enterprises, Inc

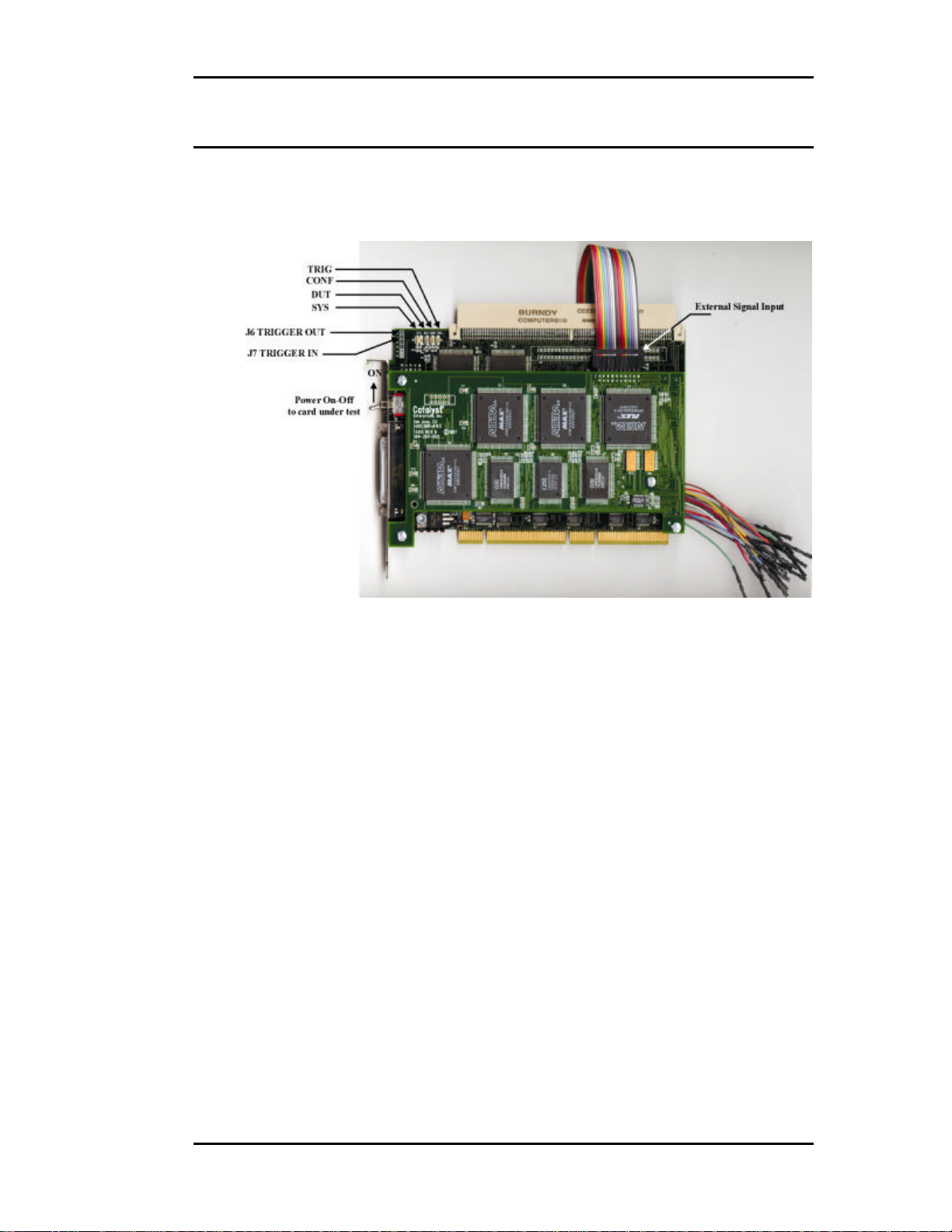

TA660 Analyzer Card

Figure 3 shows a TA660 PCI Analyzer card identifying Status LED

locations, external trigger input and output connections and the

external signal input connector with the supplied cable attached.

Figure 3 TA660 PCI Analyzer Card

Status LED Function Description

SYS When green Indicates if the system voltages are within 5%

of their value. If any of +5V, +3.3V, +12V drop more than

5% the SYS LED turns red. SYS LED also comes up red as

a test on power on and then if the voltages are okay it turns

green once the software is executed. To enable voltages for

sensing see on page 15.

DUT Indicates that the voltage to the DUT is on. In this case the

user may not remove or insert any card in to the top

connector of the TA660.

CONF Indicates that TA660 has been recognized and configured

by the software, therefore the parallel port link is working.

TRIG Indicates that the analyzer has met the trigger condition and

is awaiting for the defined post-trigger data to be captured.

For TA660CA Compact PCI analyzer/exerciser LED status information see APPENDIX

B TA660CA CompactPCI Card.

3

Page 10

TA660 User's Manual Catalyst Enterprises, Inc

Receiving and Inspecting Your

Analyzer

Your analyzer includes the following components:

Analyzer card identified in the packing list

Software on CDROM

Bi-directional parallel port host interface card

DB-25 Cable, parallel port connection

User’s Manual

Cable for external signals

Unpacking Your Analyzer

Inspect the received shipping container for any visible damage. In the

event of visible damage, retain all shipping materials until all of the

contents per the packing list have been checked for completeness and

absence of damage. Unpack the shipping container and account for

each item on the packing list. Visually inspect each item for damage.

In the event of damage notify the shipper and Catalyst Enterprises.

4

Page 11

TA660 User's Manual Catalyst Enterprises, Inc

Installing Your Analyzer

Hardware Installation

1. Make sure that the Target Machine is powered down.

2. Remove the case from your machine in accordance with the

instructions supplied for it.

3. Install the Analyzer card in any available PCI slot and secure the

mounting bracket to the chassis with the mounting screw.

Warning: Make sure to take precautions to avoid static electricity

discharge damage to the Analyzer Card by using a

grounding strap or touching a grounded metal surface just

prior to handling the analyzer card. Avoid touching any

components and handle card by the edges only.

4. Interconnect the Analyzer DB-25 connector to the Host system Bi-

directional parallel port using the provided DB-25 pin cable.

Host and Target Same The Analyzer may be used in a configuration such that the

Host and Target are the same machine.

Bi-Directional Port The Analyzer requires that The Host parallel port support

Bi-directional data transfers. See LPT Port Setting for

verifying that your parallel port supports and/or is set to a

Bi-directional mode. If the parallel port on your Host

system does not support Bi-directional data transfers you

must then install the parallel port card supplied with your

analyzer in a spare ISA slot and connect to it.

Port Configuration The parallel port card supplied with your analyzer is pre

configured for LPT2 (H278). If the Host system is using this

address for its printer port, you must then change the jumper

configuration on the ISA parallel card to H378 (LPT1).

5

Page 12

TA660 User's Manual Catalyst Enterprises, Inc

Software Installation

On systems operating under Windows 95, 98, NT or 2000:

1. Insert the CD ROM.

2. The installation will automatically start the setup unless the auto Run

is turned off, in that case select the CDROM from “My Computer”

and click on setup.

3. After the warning for closing all other programs and before starting

the installation, the Install Component selection window will open as

shown in Figure 4.

Windows NT If you are operating under Windows NT, be sure to select

the NT driver for installation. If the host system operating

software is not Windows NT, this selection will be

automatically Deselected.

Figure 4 Install Component Selection

4. Select the desired components for installation.

5. Click Next to complete the installation.

NT driver Restart If you installed the NT driver you must restart your

computer before you can use your analyzer software.

Error Message If you get an error message during installation of the NT

driver consult your system administrator. Your system may

6

Page 13

TA660 User's Manual Catalyst Enterprises, Inc

be setup to only allow an administrator level to copy such

driver files.

TA660 Overview

The TA660 PCI Bus Analyzer/Exerciser has a convenient, easy to use

Easy Mode that allows you to perform 95% of your PCI bus data

capture & trigger without any programming.

An Advanced Mode offers you a powerful programming capability

for complex triggering.

The TA660 incorporates an Exerciser that generates bus transactions

to exercise the bus as a master or target while allowing you to monitor

and capture the resulting performance.

A Timing Analyzer capability is also included that allows the user to

capture bus timing violations.

Additionally, the TA660 includes Performance Analysis for realtime and statistical measurement as well as comprehensive Device

Compliance Test capabilities.

TA660 Configurations

The TA660 may be operated in one of 3 configurations, each offering

a convenient Easy Mode which requires no programming:

State Analyzer Only

To perform a variety of data capture and trigger and bus analysis.

State & Timing Analyzer

To perform timing analysis for possible violation and to characterize

Setup & Hold limits on all or selected signals.

State Analyzer & Exerciser

To perform Device compliance testing, characterize a PCI device by

emulating various bus cycles & terminations, injecting errors and

generating traffics to measure the PCI bus response. The exerciser

may be used as a bus master to test and debug new designs.

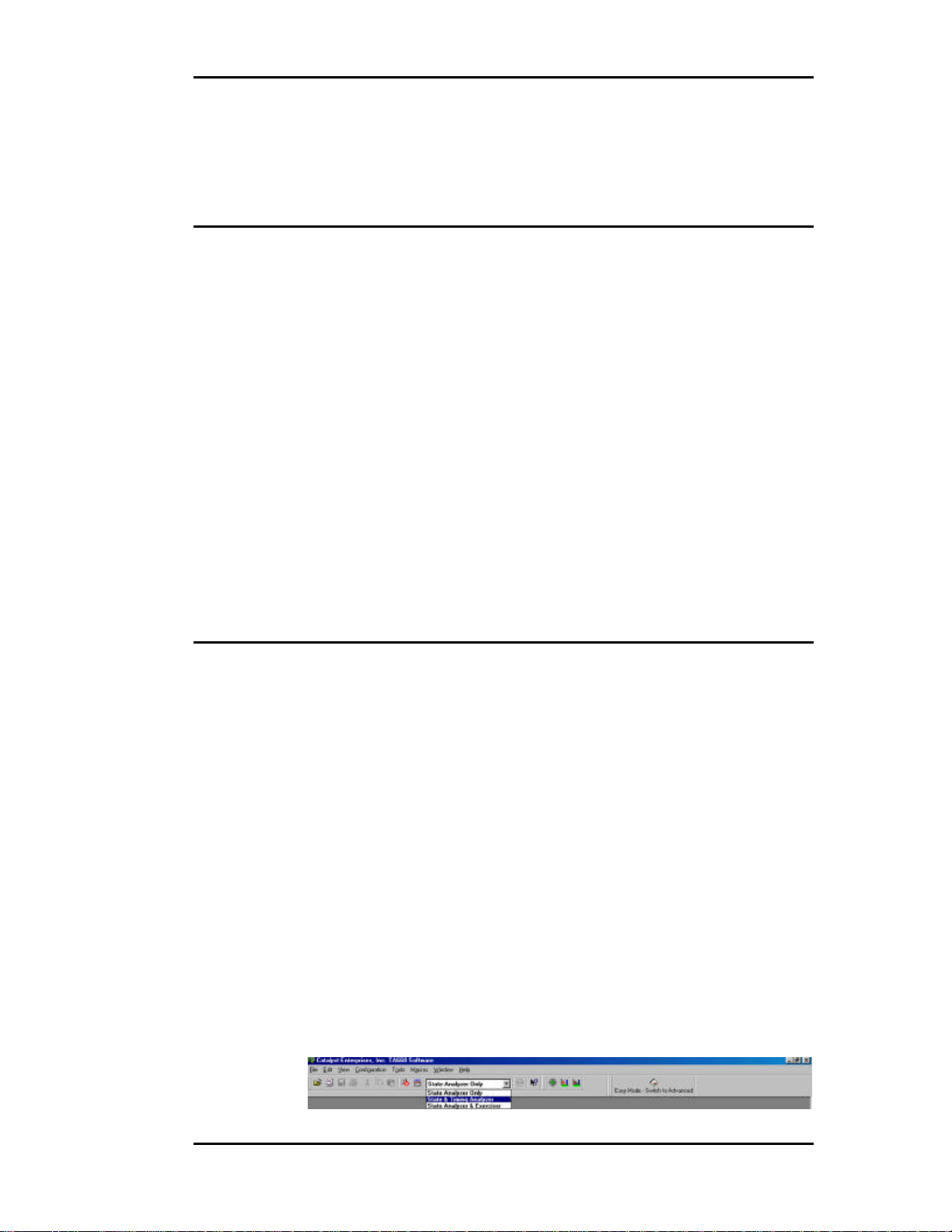

The operating configuration is selectable on the Main Menu Bar.

7

Page 14

TA660 User's Manual Catalyst Enterprises, Inc

Performance Analysis

The TA660 provides continuous Real-Time performance analysis that

operates with Pre-defined or User-defined analysis files. On-board

dual ported FIFOs interface between the counters and the host system

for transferring the measured data in real-time without ever having to

stop the counters. This feature provides a very complete and accurate

event count of up to 533 MB/Sec. An implementation of twelve

counters with up to 32 bits allows a virtually unlimited count of

events.

TA660A includes 12 counters, 8 of which may be programmed to

monitor the primary bus activities and the other 4 may used for

connection to point-to-point signals or the secondary bus.

Your TA660 includes complete setups to measure the most typical

parameters as well as giving you the ability to create your own setup.

Real time Performance Analysis allows you to count actual data

transfers for any agent or agents matching user specified address,

measure and report bus utilization efficiencies, throughput, latencies

and retries, on-the-fly.

You may use real time Performance Analysis simultaneously with the

exerciser to generate traffic on the bus and measure performance of

the target.

Performance Analysis results are presented in a Twelve-color display

that you may customize with your own color preferences and may be

recorded in graphical format for later review or demonstration.

Measurement intervals are selectable from 500 µsec to 10 minutes.

Statistical Analysis

Statistical Analysis is implemented by capturing data in memory and

then performing software post processing.

Statistical Analysis measures and reports on Min, Max and Average

occurrences for several different parameters such as Latencies, Retry,

Data Transfers, Command Utilization, Bus Utilization and various

Target Terminations.

The PCI Analyzer (Allowing the Master card to be plugged into

the expansion slot on top) can also measure latencies from request

to the 1st data transfer including all of the retries in between.

The data capture & trigger for post processing may be initiated per

user defined events on the bus, therefore yielding a very repetitive and

consistent result.

8

Page 15

TA660 User's Manual Catalyst Enterprises, Inc

The parameters measured may be selected for graphical display on the

screen and may be saved as graphical or list files for later review.

In the exerciser mode the TA660 can initiate data transfer to a target

while the trace statistics measures the latency response of the target.

Special Capabilities

Several other features are included in the TA660 such as Protocol

Errors, Mnemonics, Device Compliance Testing. Please refer to the

appropriate sections for each of these features.

9

Page 16

TA660 User's Manual Catalyst Enterprises, Inc

10

Page 17

TA660 User's Manual Catalyst Enterprises, Inc

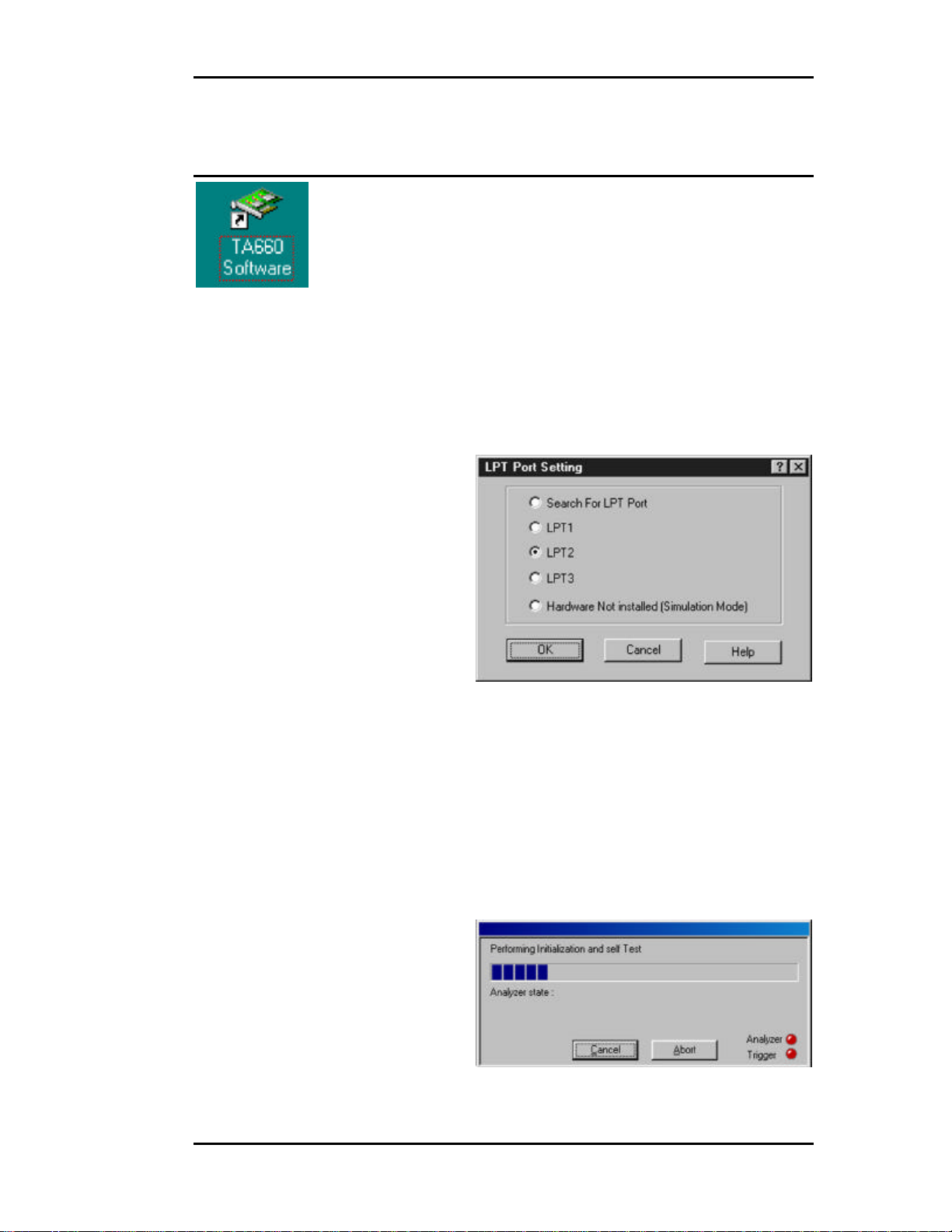

Launching Your TA660

Double click the TA660 Icon in the Program Manager Window.

The TA660 software is pre-configured at the factory to look for LPT2

as the selected port for the analyzer. If the software finds this port

connected to the analyzer program will launch immediately otherwise

the software will ask you to specify which LPT port is connected to

the hardware.

If you have connected your hardware to a different port, select the

that port and click OK to launch the analyzer program.

Find LPT Port If you are not sure which LPT port your hardware is

connected to, click “Search For LPT Port” and let the

software automatically locate the LPT port that is connected

to the hardware. Once the correct LPT port is detected the

analyzer program will launch, perform initialization,

perform a self test and display the analyzer tool bar as

shown in Figure 5

11

Page 18

TA660 User's Manual Catalyst Enterprises, Inc

Figure 5 Analyzer Tool Bar

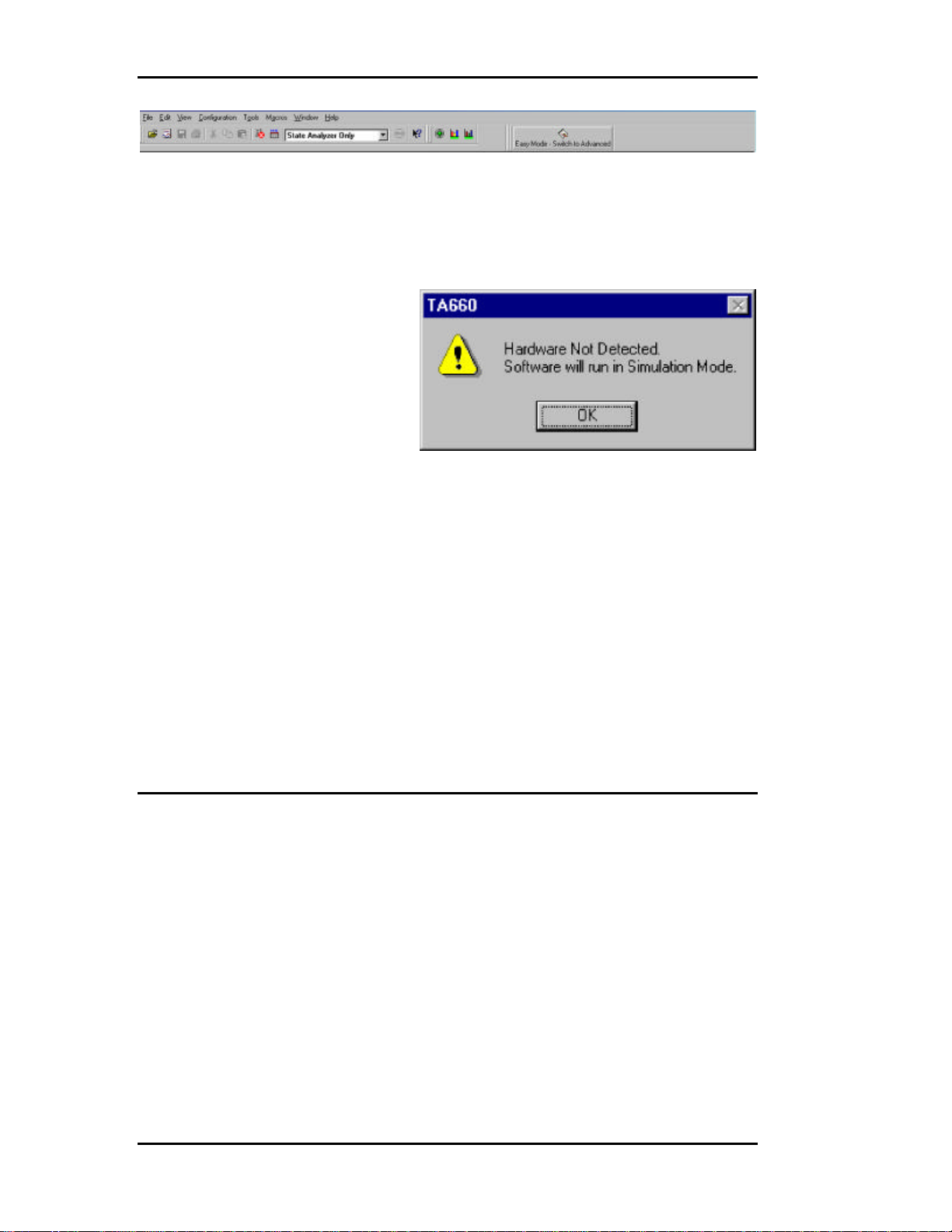

In the event that no LPT port connected to the hardware is found, the

software will display the Hardware Not Detected message. To

configure an LPT port see LPT Port Setting on page 13

Simulation Mode Clicking OK in this dialog box will launch the analyzer

software to operate in the simulation mode.

LPT Port Problems If your analyzer hardware is connected to an LPT port and

there is power to the analyzer, but you are still getting the

message Hardware Not Detected then see the section on

LPT Port setting below.

Bi-directional Port The host system LPT port must be a Bi-directional port. See

LPT Port Setting below.

Launch Problems In the event that you experience difficulties in launching

your software, please see section on LPT Port Setting.

Operating in Simulation Mode

Your system will operate in the Simulation Mode as default if the

hardware is not detected, however, you may operate in Simulation

Mode directly without installing the analyzer hardware. To operate

without hardware, select Hardware Not Installed (Simulation

Mode) in the LPT Port Setting dialog box and click OK.

The Analyzer program will launch and display the tool bar as shown

in Figure 5, but with the limitation that the analyzer will display

previously captured bus data.

Limitations The Simulation mode lets you try all of the available

functions, but keep in mind that the system is not

capturing any real data and is displaying pre-captured

results.

12

Page 19

TA660 User's Manual Catalyst Enterprises, Inc

LPT Port Setting

Your system parallel port may not necessarily be set to a Bidirectional mode even if your system supports this mode.

Port not Configured If you continue to get a Hardware Not Detected even if

you have set the required LPT port, please check your

system setting for your parallel port.

To set the parallel port :

1. Restart your computer and during boot, press F1 key to enter Setup

(some systems may use a different key than F1, please consult your

system manual).

2. Once in setup select the Advanced, then Peripheral Configuration

and then Parallel Port Mode.

3. Select the Parallel Port to be configured. If your system supports Bi-

directional mode you must have choices for at least one of the

following:

Bi-directional, ECP or EPP, preferably Bi-directional first

then ECP and last EPP.

Note that Standard or Compatible modes are not a Bidirectional mode.

4. When finished with the configuration press ESC to exit setup and

save the new configuration.

Supplied Card If your system does not support a Bi-directional mode of

operation or if you like to keep the system port for printer

then you may use the Bi-directional parallel card provided

with your analyzer.

13

Page 20

TA660 User's Manual Catalyst Enterprises, Inc

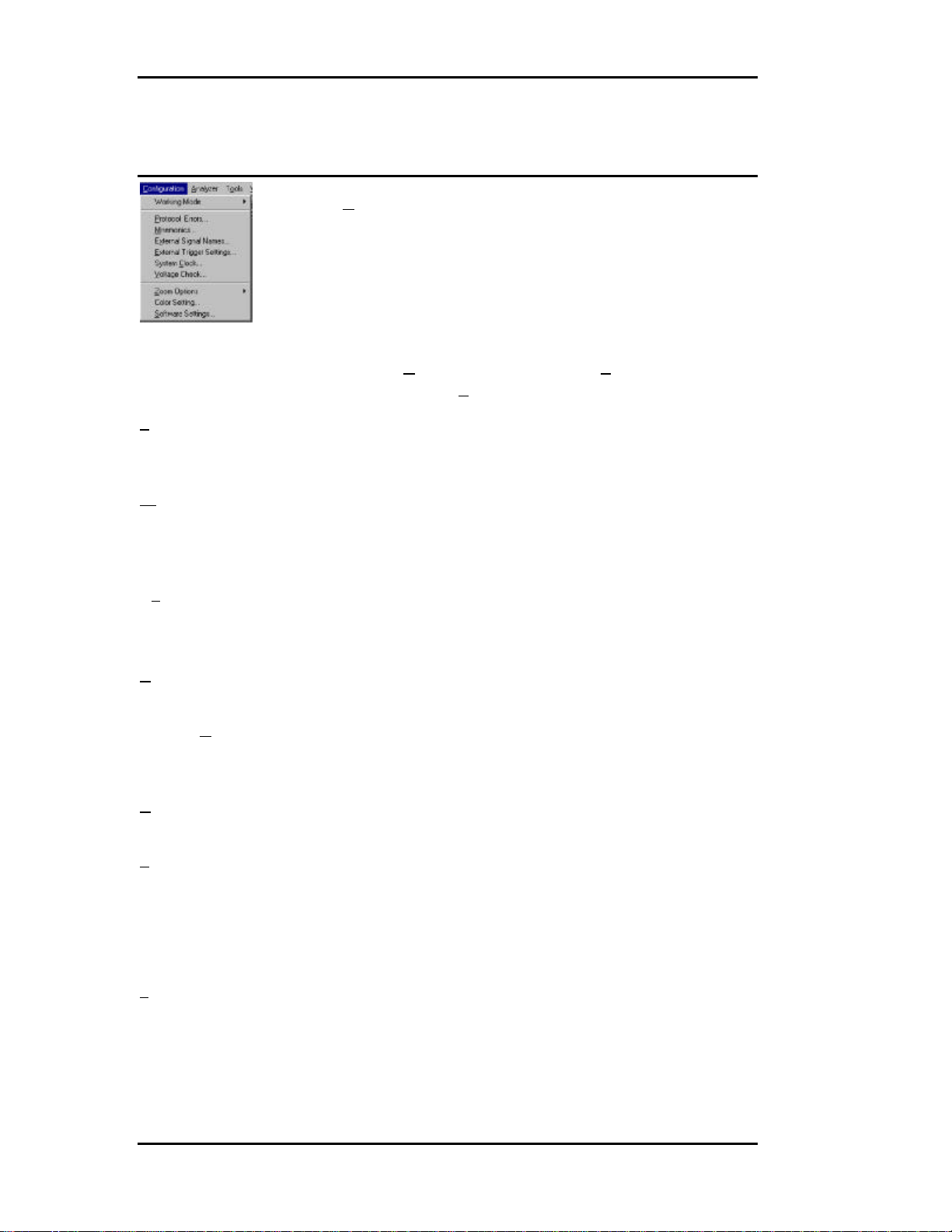

Configuration Menu

Click Configuration on the main menu bar to display the

various configuration options.

Working Mode Allows you to select the analyzer configuration. The choices

are, State Analyzer Only, State & Timing Analyzer or

State Analyzer & Exerciser.

Protocol Errors Used to configure a Protocol Errors mask for use in

triggering on protocol errors. See Protocol Errors on page

118

Mnemonics Used to define Mnemonics. Mnemonics may be used to

display user assigned names to specific patterns, in search a

pattern in the display or filter data patterns from a display.

See Mnemonics on page 123.

External Signal Names Allows users to assign specific names to external signals for

display for display purposes. See External Signals on

page 126.

External Signal/Trigger Settings Allows you to configure external input and

output triggers. See External Signals/Trigger on page 125.

System Clock Only used to set the system frequency for TA660 boards.

TA660A and TA660CA boards automatically detects the

system frequency. See System Clock on page 15.

Voltage Check Used to select or deselect the voltages to be monitored for

tolerance compliance. See on page 15.

Zoom Options Used to select zoom about X or Y cursor or between X and

Y cursor when displaying a Wave data capture window. See

Using Zoom in the Wave Window on page 102

Color Setting Used to set custom color combinations for the Analyzer

Performance Analysis Window.

Software Settings Used to set global software user preferences. See Global

Software Settings on page 17.

14

Page 21

TA660 User's Manual Catalyst Enterprises, Inc

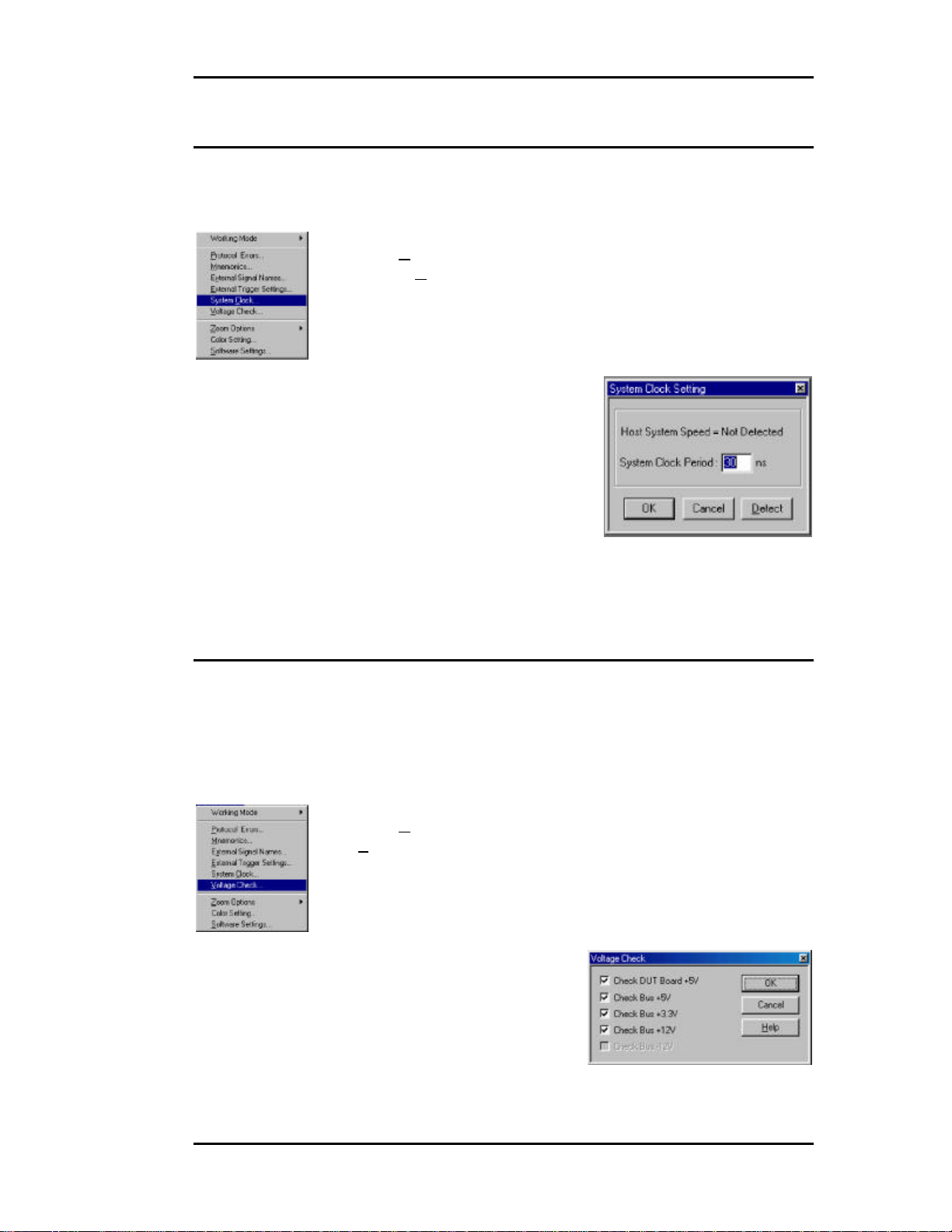

System Clock

When the TA660A software is first executed it automatically detects

the system clock frequency and updates the screen. For earlier

models, TA660 boards, you must set the frequency as follows:

Click Configuration on the main menu bar and then select

System Clock . . . to open the System Clock Setting dialog box

and type in the frequency.

Display Function Only The system clock setting only set the time tag resolution in

the captured data display windows.

Enabling Voltage Check

The TA660 is capable of monitoring the critical voltages on your PCI

bus. TA660 monitors a 5% drop in voltage for selected voltages and

turns the SYS status LED from green to red if any of the voltages

drop by 5%.

To select voltages for monitoring:

Click Configuration on the main menu bar and then select

Voltage Check . . . to open the Voltage Check dialog box.

15

Figure 6 Voltage Check Dialog Box

Page 22

TA660 User's Manual Catalyst Enterprises, Inc

Check the boxes next to the voltages that you wish to be monitored

and click OK.

Analyzer Window Colors

Click Configuration on the main menu bar and then select

Color Setting . . . to open the Analyzer Window colors setting

dialog box.

This color setting is used for the graph display in Performance

Analysis and Trace Statistics Analysis.

16

Page 23

TA660 User's Manual Catalyst Enterprises, Inc

Global Software Settings

Click Configuration on the main menu bar and then select

Software Settings . . . to open the Global Settings dialog box.

Figure 7 Global Software Settings Dialog Box

Check the options that suit your needs and click OK.

Protocol Errors

To trigger on protocol errors immediately in Easy Mode, see Protocol

Errors on page 23 and for Advanced Mode operation see Protocol

Errors on page 118

External Signal Names

To assign unique names to external signals see External Signals

on page 126

External Trigger Settings

To set external trigger parameters see External Signals/Trigger on

page 125

17

Page 24

TA660 User's Manual Catalyst Enterprises, Inc

18

Page 25

TA660 User's Manual Catalyst Enterprises, Inc

Easy Mode

The Easy Mode offers you the capability to perform 95% of your bus analysis tests

without the need for any programming. When operating in the Easy Mode your analyzer

can perform the following:

• Capture data and trigger on bus protocol immediately.

• Perform Timing Violation detection and a search for Setup/Hold

limits.

• Capture bus activity while exercising the bus.

• Do Performance analysis on PCI bus activity.

• Compute Statistics on selected parameters.

• Perform Compliance Device test.

Instant Data Capture & Trigger

Make sure that the TA660 is in the State Analyzer Only configuration and is operating

in the Easy Mode as shown on the Main Menu bar below.

1. Click the Green button on the Main Menu bar to open the Capture

Data and Trigger dialog box shown in Figure 8.

Figure 8 Capture Data and Trigger Dialog Box

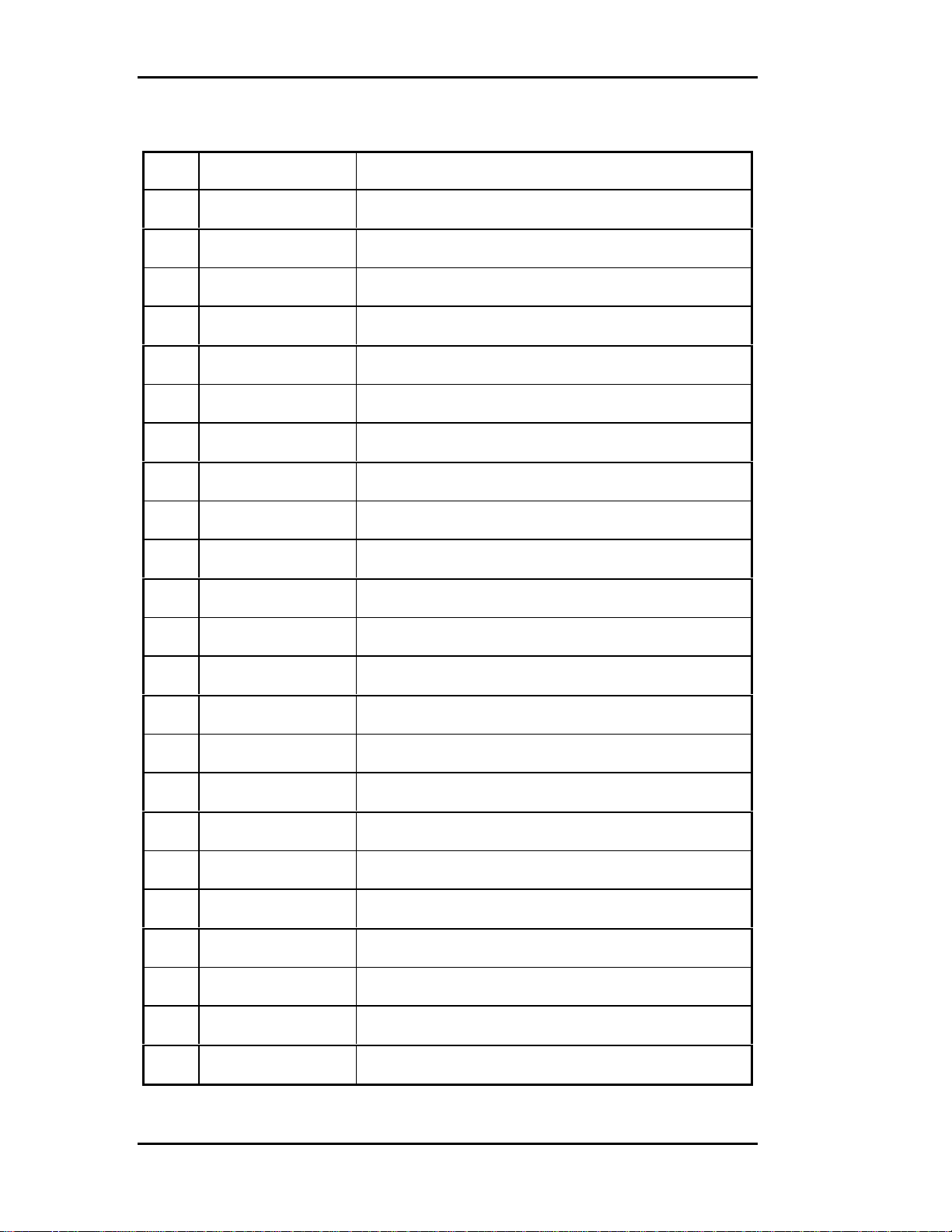

2. Select a Pre-Defined Trigger Point (See Table 1) from the Trigger

On dropdown list and click Run. Wait to capture data and to view

result. Figure 9 and Figure 10 show a typical Wave and List result

display.

19

Page 26

TA660 User's Manual Catalyst Enterprises, Inc

Table 1 Pre-Defined Trigger Points

0 Address Triggers on specified address

1 Any Interrupt Trigger when any interrupt occurs

2 Burst Longer Triggers when the burst is longer than nnn times

3 Burst Shorter Triggers when the burst is shorter than nnn times

4 DMA Transfers Triggers when data burst is transferred

5 Data at Address Triggers on specified data at address

6 External Input Trg. Triggers on external input trigger

7 GNT# Triggers when GNT# is asserted

8 Master Abort Triggers when a master abort occurs

Occurrence of SERR#

9

or PERR#

Triggers when error SERR# or PERR# occurs

10 Protocol Error Triggers when any PCI protocol error is detected

11 REQ# Triggers when REQ# is asserted

12 Reset De-asserted Triggers when reset is de-asserted

13 Assert – De-assert Signal xxx asserted and then de-asserted nnn times

14 Asserted Signal xxx asserted for more than nnn times

15 De-assert – Assert

16 De-asserted Signal xxx de-asserted for more than nnn times.

17 Signal Shorter Triggers when signal xxx is shorter than nnn times

18 Target Abort Triggers when a target aborts

19 Target Disconnect Triggers when a target disconnects

20 Target Retry Triggers when a target Retry occurs

21 Target Retry nnn times

Signal xxx de-asserted and then asserted for more than nnn

times

Triggers when a consecutive target Retry occurs more than

nnn times

22 Target Termination Triggers on target termination, combination

23 Vendor & Device ID Triggers on Vendor & Device ID access.

20

Page 27

TA660 User's Manual Catalyst Enterprises, Inc

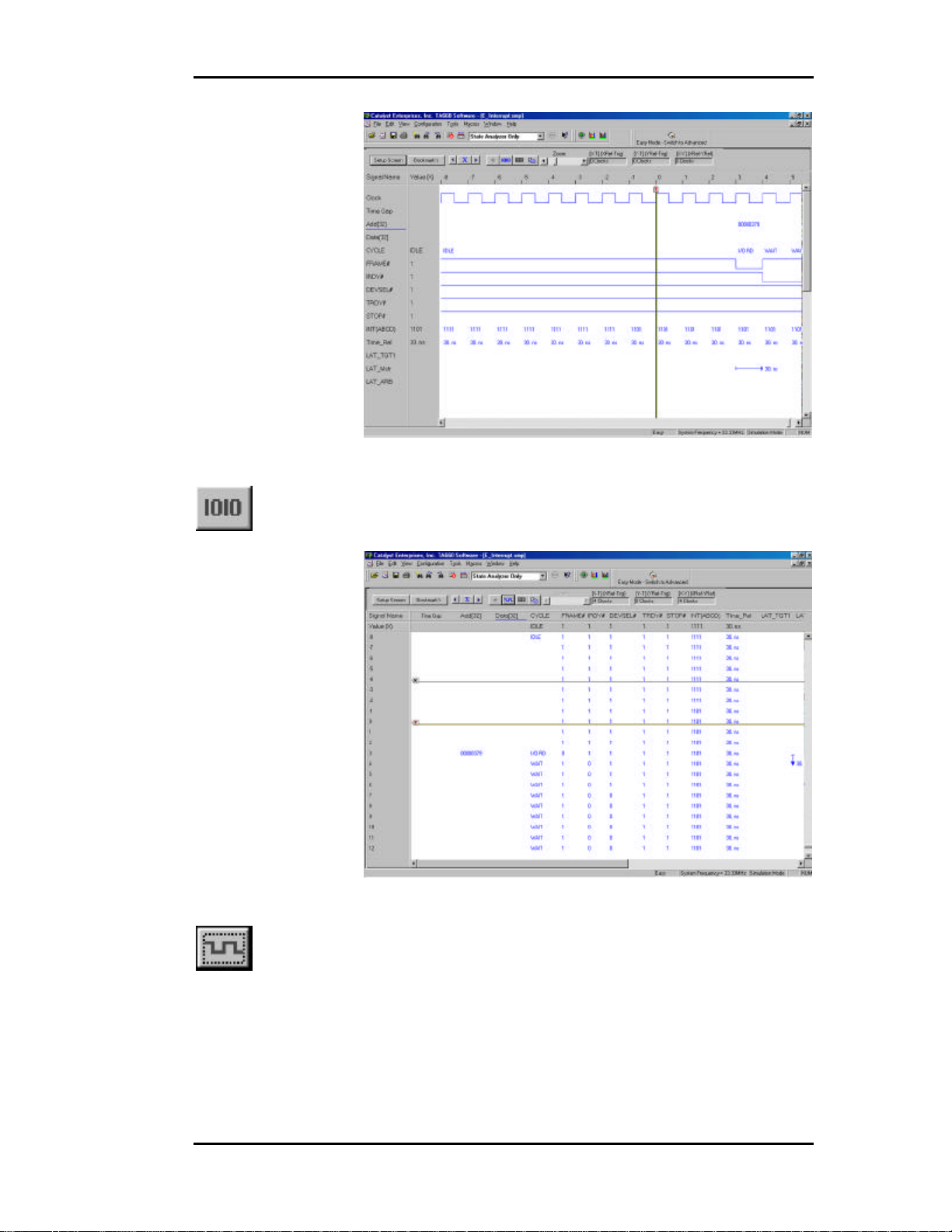

Figure 9 Wave File Output Display

To view the result as a list file output display, click the List

button.

Figure 10 List File Output Display

To return to the wave file output display, click the Wave button.

21

Page 28

TA660 User's Manual Catalyst Enterprises, Inc

Selective Data Capture

You may refine your data capture by checking the Data Capture

Selection as Specific Addresses .

Figure 11 Capture Data At Specific Addresses Dialog Box

Selecting this option allows you to specify data capture at up to 3

address ranges with a specific associated command that is selected

from the CBE# dialog box. To open the CBE Type dialog box click

the ellipses button next to the Command edit box.

Figure 12 CBE Select Dialog Box

22

Page 29

TA660 User's Manual Catalyst Enterprises, Inc

Data Capture & Trigger Examples

The capture data and trigger dialog box changes depending on the

type of Trigger On chosen. The following are some examples.

Signal on shorter than nnn times. When this Trigger On selection is chosen,

note the additional List Box for selecting a signal and the

Edit Box for specifying the number of times.

Figure 13 Specify Signal And Number of Times

Protocol Errors When this Trigger On selection is chosen, note the PE

button next to the Trigger On list box. Clicking this button

opens the Protocol Error mask.

Figure 14 Trigger on Protocol Error

23

Page 30

TA660 User's Manual Catalyst Enterprises, Inc

Data Capture Options

Memory Display You may limit the captured data display to a specific

number of samples by checking Partial Memory and

entering the number of Samples to be captured or, you may

check entire memory to allow the capture for the entire

memory.

Pre-Trigger Pre-Trigger is set by default at 50% which defines the

percentage of data to be captured before and after the

triggering event. You may change this percentage by

dragging the slider to the desired value.

Pre-Trigger Data: The capture of the specified percentage of the data prior to

the triggering event cannot be guaranteed and may in some

cases be 0. This can occur in cases where the triggering

event occurs before the required number pre-trigger event

data can be stored. In these cases the data display will show

fewer than the specified data points prior to the triggering

event. For more detail see Set Trigger on page 69.

Manual Trigger Select this option when you wish to manually interrupt the

data capture based on some external event. With this option

selected, data will be continually captured to memory and

overwritten as required until you stop the data capture.

Continuous Mode Continually captures data for the number of times specified.

A separate data file is generated each time that a capture is

performed.

Exclude Cycles To simplify the captured data display you may check the

options to exclude, Idles, Wait States and Retries.

24

Page 31

TA660 User's Manual Catalyst Enterprises, Inc

Performance Analysis

Click the Performance Analysis Icon on the menu bar to open

the Performance Analysis dialog box.

Figure 15 Easy Mode Performance Analysis Dialog Box

To perform an immediate Performance Analysis:

1. Click the down arrow next to the Performance Analysis Group list

box and select one of the four available analysis groups.

2. Select the parameters for analysis from the Available Items list.

3. Select the counters mode, Reset or Accumulate and click Run.

Reset/Accumulate With Reset selected, the measurement

counters are reset at the beginning of

each interval. With Accumulative

selected, the measurement counters

will continue to add up.

Save Settings To save the measurement setup, first select Save to open the

Save As Dialog Box, enter a new file name to save as a

*.pep file and click Save.

25

Page 32

TA660 User's Manual Catalyst Enterprises, Inc

Figure 16 Performance Analysis Result

Save Results If you would like to save the analysis results, click Save to

File enter the number of samples you wish to save and the

name of the output file.

Review Results For instructions on reviewing a saved performance analysis

file, see Saved Performance Analysis Review on page 81.

26

Page 33

TA660 User's Manual Catalyst Enterprises, Inc

Trace Statistics

Trace Statistics analysis is implemented by capturing data in memory

and then post processing it with software. The analysis software is

capable of measuring important parameters such as Minimum and

Maximum latency occurrences for any target or user defined specific

target, command utilization such as how many times an I/O write

versus I/O read occurs or, how many times memory commands occur.

Available Trace Analysis parameters that may be selected for a report

are listed on page 31.

Obtaining Trace Statistics

Click the Trace Statistics Icon on the menu bar to open the

Trace Statistics dialog box.

1. Select a Trigger Point from the Trigger On dropdown list and then

select the Trace Statistics tab to set the trace statistics options. For a

list of available choices see Trace Analysis Options on page 31.

27

Page 34

TA660 User's Manual Catalyst Enterprises, Inc

Figure 17 Easy Mode Trace Statistics Dialog Box

Selecting Parameters Select the parameters to be measured from the Analyze List

Of shown in Figure 17. Move the selected parameter to the

right window for software to perform interrogation on that

parameter during post processing by clicking the =>> button

next to the Of edit box. Parameters may be defined as

minimum, average, maximum or count and or percent

depending on which unit applies. Parameters may also be

defined, if applicable, by address type.

Number of Samples Set the amount of data to be captured in the memory for

post processing for each interval. The larger the number of

samples the more time is required for downloading and

processing, Therefore you should select an optimum

number of samples to be captured to memory such as 1000.

This takes about one second to process. If your application

requires more data then a larger number should be entered.

Update Interval If a small number of data samples is expected to be

captured, say 1000, and the application does not require

repeated measurement, you may want to sample data once

every 5 or 10 seconds by changing the Update Interval to 5

or 10 seconds as required. The larger of the two number of

data samples or faster update rate will be the dominating

setup for data capture time.

2. When all the parameters have been specified, click Run to capture

the specified data and perform the trace statistics determination.

28

Page 35

TA660 User's Manual Catalyst Enterprises, Inc

29

Figure 18 Trace Statistics Result

Figure 19 Trace Statistics Report

Page 36

TA660 User's Manual Catalyst Enterprises, Inc

Save Measurements All measurements may also be saved and reviewed later,

select SAVE and specify the output file name. The results

may be selected and reviewed from the View option on the

Main Menu bar.

30

Page 37

TA660 User's Manual Catalyst Enterprises, Inc

Trace Analysis Options

Latency Target *Number of waits due to TRDY before first data

phase

Latency Master *Number of waits due to IRDY not asserted

Latency Arbiter Number of clocks from REQ to GNT (master

board must be plugged on top of the TA660)

Efficiency Efficiency in percent for the duration of the

captured data

Target Efficiency *Number of TRDY# asserted over DEVSEL#

asserted

Master Efficiency * Number of IRDY# asserted over DEVSEL#

asserted

Throughput Mb/Sec Number of data transferred over time

Bus Utilization Number of cycles DEVSEL# asserted over time

IDLE Number of IDLE cycles

No of Data Transfer/Address *Size of data burst

Wait Number waits or wait time in percent

Int Ack Number of INT ACK

I/O *Total number of I/O Commands

I/O RD *Number of I/O Read Commands

I/O WR *Number of I/O Write Commands

Memory *Number of Memory Commands

Mem RD *Number of Memory Read

Mem WR *Number of Memory Writes

Configuration *Number of Configuration Cycles

CFG RD *Number of Configuration Read

CFG WR *Number of Configuration Write

MEM RM *Number of Memory Read Multiple

DU ADD *Number of Dual Address Commands

MEM RL *Number of Memory Read Line Commands

MEM W&I *Number of Memory Write and Invalidate

Total No of Data *Number of Data Transferred during capture

RETRY *Number of Target Retry

TABORT *Number of Target Aborts

DIS+DATA *Number of target disconnect + data

DIS-DATA *Number of target disconnect - data

MABORT *Number of Master aborts

Latency, REQ# to Data Latency time from REQ# asserted until data

transferred, including retries

DEVSEL Speed Reports Target Decode speed

* Indicates a total or number at specified address or an address range

31

Page 38

TA660 User's Manual Catalyst Enterprises, Inc

32

Page 39

TA660 User's Manual Catalyst Enterprises, Inc

Exercise and Capture

Make sure that the TA660 is in the State Analyzer & Exerciser configuration and is

operating in the Easy Mode as shown on the Main Menu bar below.

Click the Green Icon on the Main Menu bar to open the Capture

Data and Trigger dialog box shown in Figure 20.

Figure 20 Capture Data and Trigger Dialog Box

The data capture and trigger operation behaves identically to that in

the State Analyzer Only configuration with the exception that bus

signals are generated by an exerciser program that you define.

Defining an Exerciser Program

1. Click on the Exerciser Program tab to open the Exerciser Program

definition dialog box as shown in Figure 21.

33

Page 40

TA660 User's Manual Catalyst Enterprises, Inc

Figure 21 Exerciser Program Definition Dialog Box

2. Define up to 10 exerciser program lines by selecting a command

type, data to be written or a previously defined data block if

applicable, target address, and data size.

3. Click Run to perform data capture and trigger with exerciser

generated signals.

Figure 22 Wave File Output

34

Page 41

TA660 User's Manual Catalyst Enterprises, Inc

Creating a Data Block File

To create an exerciser data file click the Data Block Icon on the

Main Menu bar to open the Data File dialog box shown in Figure

23.

Figure 23 Data File Definition Dialog Box

Click New Data Block in the Data File Definition dialog box to enter

a data block (“Data Block 0”) in the Data Blocks area. With the new

data block highlighted you may define a specific block pattern or

create a walking bit type pattern.

Fixed Data Pattern Click the Define Pattern button to open the Define Data

Pattern dialog box.

Figure 24 Define Data Pattern Dialog Box

Enter a pattern and select the number of times that that pattern is to be

repeated and click OK.

Multiple Line Pattern You may define a block of multiple lines that can be

automatically repeated. Figure 25 shows the definition of a

two line pattern to be repeated 3 times. To add a new line,

enter the data in the edit box and then click on the down

arrow to include it in the list.

35

Page 42

TA660 User's Manual Catalyst Enterprises, Inc

Figure 25 Define Multiple Line Pattern

Figure 26 shows the resulting block pattern where the defined pattern

is replicated 3 times.

Figure 26 Resulting Multiple Line Pattern

Walking Data Pattern Click the Fill With Walking Bits button to open the Fill

With Walking Bits dialog box as shown in Figure 27.

Figure 27 Fill With Walking Bits Dialog Box

Enter the walking bit options desired and the number of times the data

pattern is to be written and click OK.

Figure 28 is an example of a walking bit “1” set in a direction of left

to right to be written 4 times.

36

Page 43

TA660 User's Manual Catalyst Enterprises, Inc

Figure 28 Walking Bit Data File Example

To save the newly created Data file click Close click Yes In the Save

Changes to the Data File? Dialog box.

Enter a file name name.dat in the Save As dialog box and click Save .

The newly created data file is now available for use with the current

exerciser program.

Editing Files in ASCII

You may view and edit all exerciser program files as ASCII by using

a text editor such as Notepad or Wordpad. The following figures

show examples of exerciser program files opened using Wordpad.

Figure 29 Sample Data File

37

Figure 30 Sample Exerciser File

Page 44

TA660 User's Manual Catalyst Enterprises, Inc

Exerciser Utilities

Dump Memory

To perform a memory dump select Dump Memory from the

Exerciser dropdown list on the menu bar. This will open the

Dump Memory dialog box.

Enter a Start address and an End address or Count and click OK to

perform a memory dump as selected.

The resulting memory dump will be displayed as shown in Figure 32.

Read/Modify Write

To perform read/modify write select Read/Modify Write . . .

from the Exerciser dropdown list on the menu bar. This will open

the Read/Modify Write dialog box.

Figure 31 Dump Memory Dialog Box

Figure 32 Dump Memory Result

38

Page 45

TA660 User's Manual Catalyst Enterprises, Inc

Figure 33 Read/Modify Write Dialog Box

1. Enter an address the contents of which you wish to modify in the

Current Address edit box.

2. Enter the value to be written to that address in the New Value edit

box.

NOTE: This feature makes the TA660 to be a bus master and

may be used to read or write any registers or memory contents

of a target device without having to set the programming menu.

Write Read Verify

To perform write read verify select Write/Read Verify . . .from

the Exerciser dropdown list on the menu bar. This will open the

Write/Read verify dialog box.

Figure 34 Write/Read Verify Dialog Box

1. Select the command type from the Command dropdown list, enter

the Target address, BE and either the data to be written or a

previously defined data block and a DMA size.

39

Page 46

TA660 User's Manual Catalyst Enterprises, Inc

2. Click Compile to generate the executable code as shown in Figure

35.

Figure 35 Write/Read Verify Compiled Program

3. To perform Read/Write verification click Run.

Address Test

1. Enter the starting address to be tested and the number of addresses

(Length) to be tested.

Figure 36 Write/Read Verification Result

To perform an Address Test select Address Test from the

Exerciser dropdown list on the menu bar to open the Address Test

Program dialog box..

40

Page 47

TA660 User's Manual Catalyst Enterprises, Inc

Figure 37 Address Test Program Dialog Box

2. Click the ellipses button next to the Length edit box to set the

Read/Write properties, click OK and then Compile & Run. The test

results are displayed as in Figure 39.

Figure 38 Set Read Write Compile Mode Dialog Box

Figure 39 Address Test Result

41

Page 48

TA660 User's Manual Catalyst Enterprises, Inc

TA660 as Memory

TA660 can be used as a target memory so that a master device can write and read to and

from it to see if the master can perform write and read operation properly.

To perform this test, select TA660 as Memory, identify an address to

the TA660 that us not used by the system memory or any agent in the

system, and identify the last address or the number of bytes to write

and read.

Figure 40 TA660 As Memory Dialog Box

Once "OK" is entered another message informs the user to perform

the write instruction by the master. TA660 stays in running mode

until the master writes data.

Once the data has been transferred, the TA660 captures the data as

target memory and displays it on the screen for verification of write.

At this time the user may execute the "Run" from this menu to put the

42

Page 49

TA660 User's Manual Catalyst Enterprises, Inc

TA660 in write mode so the master device can read the data from it to

verify the read operation.

43

Page 50

TA660 User's Manual Catalyst Enterprises, Inc

Scan Configuration Registers

To perform a configuration scan select S can Configuration

Registers from the Exerciser dropdown list on the menu bar.

The system will search for PCI devices on the bus and display the

configuration as shown in Figure 41. All devices on the bus are

reported. To see information on additional devices click Next>.

Figure 41 Configuration Header Display Dialog Box

You may edit all of the parameters displayed in white, if your

hardware allows it. Edit the field and then click on the "Write PCI

Configuration to this Device" button.

To save configuration read all devices, find your device and save it to

a file.

PCI 2.1 or PCI 2.2 Specification Scan check may be performed to either the

PCI 2.1 or PCI 2.2 specification. The selection of which

specification is made on the Software Global Settings dialog

box. To set these options click Configuration on the main

menu bar and then choose Software Settings.

44

Page 51

TA660 User's Manual Catalyst Enterprises, Inc

Device Compliance To perform an immediate device compliance on a device,

see Compliance Device Test on page 87.

45

Page 52

TA660 User's Manual Catalyst Enterprises, Inc

Generate Traffic and Measure Performance

Make sure that the TA660 is in the State Analyzer & Exerciser configuration and is

operating in the Easy Mode as shown on the Main Menu bar below.

Performance Analysis with exerciser requires you to define an

exerciser program as described in Defining an Exerciser Program on

page 33.

Click the Performance Analysis Icon on the menu bar to open

the Performance Analysis dialog box as shown in Figure 42.

Figure 42 Performance Analysis with Exerciser

To perform Performance Analysis with the exerciser:

1. Define the exerciser program, such as reading or writing to a known

memory location(s).

2. Click the Performance Analysis Tab and set up the Performance

Analysis as described in Performance Analysis on page 25.

3. Click Run.

46

Page 53

TA660 User's Manual Catalyst Enterprises, Inc

Generate Traffic and Measure Trace Statistics

Make sure that the TA660 is in the State Analyzer & Exerciser configuration and is

operating in the Easy Mode as shown on the Main Menu bar below.

Click the Trace Statistics Icon on the menu bar to open the

Trace Statistics dialog box as shown in Figure 43.

Figure 43 Trace Statistics With Exerciser

To obtain Trace Statistics with the exerciser:

1. Set the trace statistics options and the Trigger Point as described in

Obtaining Trace Statistics on page 27.

2. Click the Exerciser Tab and define the Exerciser Program as

described in Defining an Exerciser Program on page 33.

3. When all the parameters have been specified, click Run to capture

the specified data and perform the statistics reporting.

47

Page 54

TA660 User's Manual Catalyst Enterprises, Inc

48

Page 55

TA660 User's Manual Catalyst Enterprises, Inc

Perform Timing Analysis

Make sure that the TA660 is in the State & timing Analyzer configuration and is

operating in the Easy Mode as shown on the Main Menu bar below.

In this mode you may immediately detect and capture timing

violations on all bus signals. Any bus "glitch" of 1.5 ns or greater is

captured as a timing violation.

You may also perform a Setup/Hold Limits search on any or all PCI

bus signals by using a convenient signal mask.

To perform an immediate timing analysis, click the Timing

Violation Icon to open the Timing Violation Analysis dialog box.

Figure 44 Timing Violation Analysis Dialog Box

Timing Violation Capture

1. Set the desired data capture options such as Pre-Trigger %, Display

Memory etc. and click Run.

The occurrence of the first timing violation will cause a trigger and

open the Timing Violation Results display as shown in Figure 45.

49

Page 56

TA660 User's Manual Catalyst Enterprises, Inc

Figure 45 Timing Violation Results Display

50

Page 57

TA660 User's Manual Catalyst Enterprises, Inc

Search for Setup & Hold Limits

To search for setup and hold limits click the Setup/Hold Limits

search Icon to open the Setup and Hold Limits Mask definition

dialog box.

Figure 46 Setup and Hold Limits Mask Definition Dialog Box

Select the signals that you wish to ignore in the search and then click

Search. At the completion of the search the result is displayed as

shown in Figure 47.

Figure 47 Setup and Hold Limits Search Result

51

Page 58

TA660 User's Manual Catalyst Enterprises, Inc

52

Page 59

TA660 User's Manual Catalyst Enterprises, Inc

Advanced Mode

The Advanced Mode expands the analyzer capability by allowing you to program special

custom debugging projects and define complex triggering levels. Such projects are

programmed by defining and the sequencer menus.

The State & Timing analyzer configuration, in addition to the special programming with

event and sequencer files, also expands the Timing Violation Analysis by allowing you to

chose leading and trailing edge timing values.

With this expanded capability you may perform all of the same analysis functions as in

the Easy Mode but with much customization.

• Setup complex triggering level to Capture data and trigger using

custom projects.

• Perform timing characterization timing violation detection.

• Capture bus activity and the device under test response under

different conditions using the exerciser.

• Do Performance analysis on PCI bus activities.

• Measure and report Statistics on selected parameters.

Easy Mode Access As a convenience to allow you to get a quick snapshot of

bus activity, the Advanced Mode menu bar includes the Red

Easy mode button.

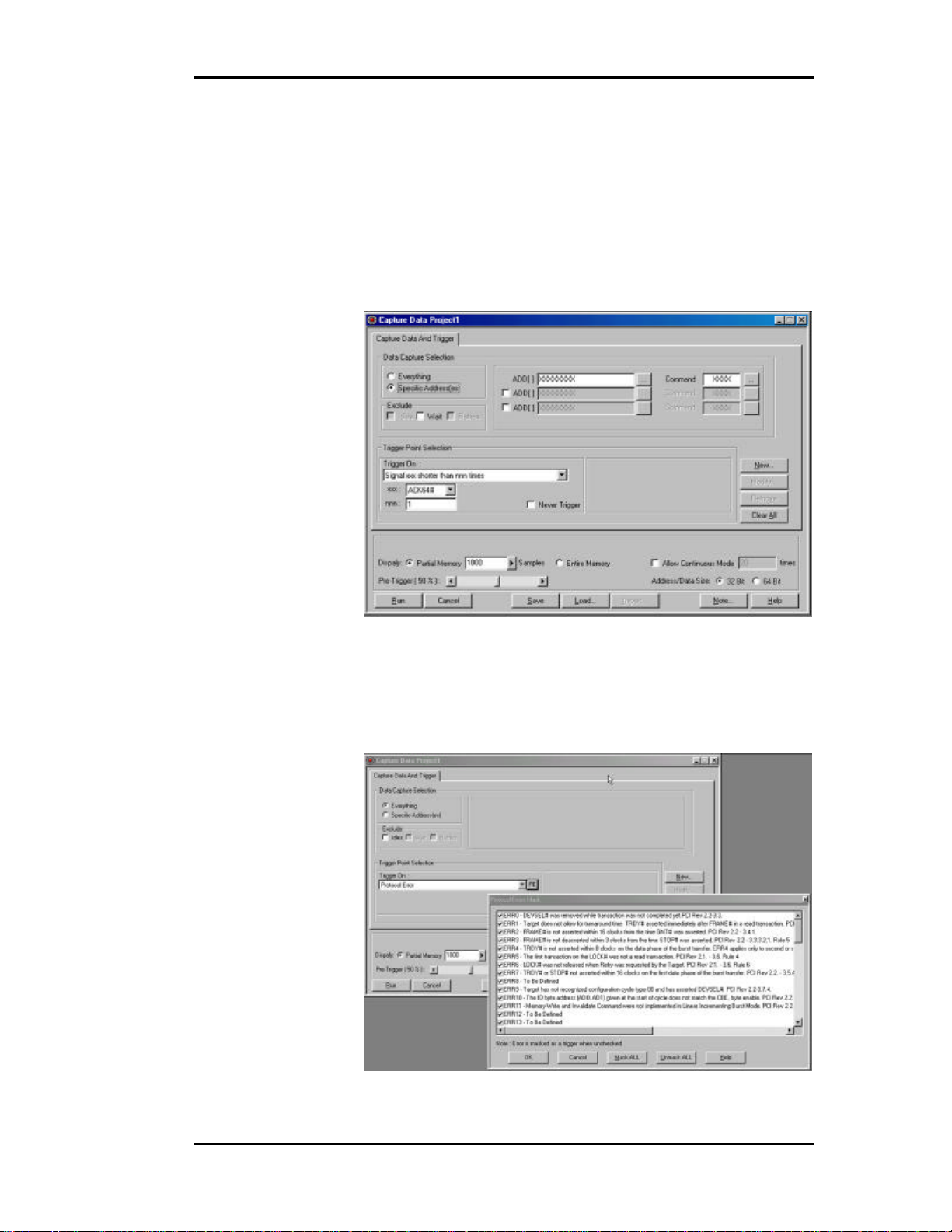

Capture Data Project

Make sure that the TA660 is in the State Analyzer & Exerciser configuration and is

operating in the Advanced Mode as shown on the Main Menu bar below.

1. Click the Black button on the Main Menu bar to open the Custom

Project dialog box shown in Figure 48.

For a custom project you must program/define:

• An Exerciser Program

• A set of Events

• A sequencer Program

Example Files Your analyzer includes a set of pre-defined Project, Event

and sequencer files. You may load a complete Project or

import Events and Sequencer programs to perform pre-

53

Page 60

TA660 User's Manual Catalyst Enterprises, Inc

determined tasks. For more detail see Example Files on

page 85.

Figure 48 Custom Project Dialog Box/Exerciser Program

54

Page 61

TA660 User's Manual Catalyst Enterprises, Inc

Programming the Exerciser

Make sure that the Exerciser Program Tab is selected on the Custom Project Dialog box

as shown in Figure 48. To program the Exerciser:

1. The Exerciser Program dialog box opens as default with one active

program line. You may add additional active program lines by

clicking Add.

Insert Program Line To insert a new program line between previously added

active program lines, position the cursor below the line

where you want to insert the new line and click the Insert

button.

2. Select a command such as MEM Write from the command

dropdown list for each active program line.

Available Exerciser Commands

Interrupt ACK

Special Cycle

I/O Read

I/O Write

MEM Read

MEM Write

CONFIG Read

CONFIG Write

MEM Read Multiple

MEM Read Line

MW & Invalidate

DAC : I/O Read

DAC : I/O Write

DAC : MEM Read

DAC : MEM Write

DAC : MEM Read Multi

DAC : MEM Read Line

DAC : MW & Invalidate

No Termination TA660 to Transfer data as

Target without termination.

Disconnect with data TA660 to Generate Disconnect

as Target at the last data phase.

Disconnect without data Generate disconnect after the

last data phase.

Target Abort with data Generate Target Abort at the

last data phase.

Target Abort without data Generate Target Abort after the

last data phase.

55

Page 62

TA660 User's Manual Catalyst Enterprises, Inc

3. Each of the commands when selected will generate a corresponding

bus cycle.

4. Enter a TARGET ADDRESS that you would like to write to and

enter the DATA to be written to that address.

TA660 Address as Target When a Target command is chosen from the available

COMMAND list a "TA660 Address as Target" button

appears on the Exerciser Program Tab. Click this button to

open the Base Address Setting Dialog Box.

Figure 49 Target Base Address Setting

Setting the Base Address Enter the base address and click OK. You must use

this address in your master program to read or write

from TA660.

Burst Data Writes For burst data write operations requiring multiple data you

may select a previously created data file from a list of Data

Files by clicking Browse and selecting a pre-defined data

file, or create a new data file by clicking Data Block. See

Creating a Data Block File on page 35.

Padding/Bus Utilization Checking Insert Idle and entering the number of idles

desired will insert Idle states at the end of each compiled

command. See Figure 51. With adding idles at the end of

commands the TA660 can be precisely controlled on how

long it would be utilizing the bus.

56

Page 63

TA660 User's Manual Catalyst Enterprises, Inc

32/64 Bit Addressing To set 32 or 64 bit addressing mode click the button next to

the DMA size edit box to open the Program Line Properties

dialog box shown in Figure 50.

Figure 50 Program Line Properties Dialog Box

5. Set Exerciser options as described in Setting Exerciser Options on

page 58.

6. When done, click Compile . . . to generate the executable exercise

code as displayed in

Figure 51 Compiled Output File With Padding

Forcing Errors : All signals displayed in blue may be changed to force errors

and anomalies.

Wait States Wait states may be inserted by pointing the cursor on the

line where a Wait State is desired and then clicking Insert.

Looping You may define a loop by clicking in the Loop Start column

next to the program line where you wish for the loop to start

and in the Loop End column next to the program line where

you wish for the loop to end. For the loop to execute, you

must enable the loop option when setting the Exerciser

Options.

57

Page 64

TA660 User's Manual Catalyst Enterprises, Inc

Forcing an Interrupt You may force interrupts for a specific number of clocks

during the program execution by double clicking in the Int#

field for that line and then setting the interrupts in the Int#

dialog box.

Figure 52 Setting Interrupts

Setting Exerciser Options

You may set the exerciser options globally for all input program types or locally on the

Exerciser Programming window.

To set the exerciser options globally, click Exerciser on the menu

bar and select Options from the dropdown list to open the

exerciser dialog box as shown in Figure 53.

Figure 53 Exerciser Options Dialog Box

Set Options Enabled Selecting the exerciser options menu globally from the

menu bar enables the option setting for both, Master and

Target program files. When setting exerciser options from

the Exerciser Program window, only the options that are

58

Page 65

TA660 User's Manual Catalyst Enterprises, Inc

required by the selected commands are enabled. For

example, if you are using Master commands only, the

Target options are grayed out.

Looping To run an exerciser program in a loop, set Loop Master or

Loop Target or both as applicable. To loop a fixed number

of times, set the Loop Counter to On and enter the number

of loops to execute. Setting the loop counter to Off will

cause the program to loop indefinitely.

On Target Disconnect Options

Use Same Transaction Completes from the disconnect

point on, regardless of the

number of times the target

issues a disconnect. The TA660

will take it from where the

target disconnect was issued and

try to complete the transaction

from that point on.

Use Next Transaction The TA660 will bypass all of

the transactions in the current

command and will jump to the

transaction for the next

command.

On Target Retry Options

Infinite Retry The TA660 will retry the

Advance to Next The TA660 will bypass the

Master Abort on No DEVSEL# Options

Disabled The FRAME# will stay asserted

Enabled The TA660 will issue a Master

Master Assert FRAME#

Regardless of Grant Once the TA660 is set to

current command until the

target transfers data.

current command and go to the

next transaction for the next

command.

indefinitely and the TA660 will

not issue a Master ABORT.

ABORT on the 5th clock if no

DEVSEL# is asserted.

become a master, it asserts the

frame and starts the transaction

regardless of the status of the

GNT#.

59

Page 66

TA660 User's Manual Catalyst Enterprises, Inc

After Grant Asserted The TA660 will request the bus

and start the transaction only

after the GNT# is asserted.

Master Completes Transaction at Time Out

Disabled The TA660 continues to

complete the transaction for

however many clocks it takes

regardless of GNT# being

deasserted.

Enabled The TA660 completes the

current transaction as soon as

possible after GNT# is

deasserted.

Set Interrupts

Setting interrupts may be done in two ways, 1) From a compiled program for a specified

number of clocks or 2) Outside of a compiled program, indefinitely until reset by the user

again. To set it indefinitely:

To set one or more interrupts click Exerciser on the menu bar

and then select Set Interrupts from the dropdown list to open the

Set Interrupt dialog box.

Figure 54 Set Interrupts Dialog Box

Select the interrupts that you wish to set and click OK.

Continuous Setting, Outside Program Setting the interrupts in this manner

sets them continuously until you uncheck them.

Limited Duration, Inside Program You may set one or more interrupts for one or

more program steps when running compiled Program files.

See Forcing an Interrupt on page 58.

60

Page 67

TA660 User's Manual Catalyst Enterprises, Inc

Defining Event Patterns

An Event pattern defines the PCI bus signals, including address, data and control signals

to:

• Define the data capture manipulation.

• Set a trigger in the sequencer.

• Define events that are used for Performance Analysis and Bus

Utilization measurement.

You may define up to 8 events identified as follows:

EV1 - EV8 8 Events with identical capability.

XGRP0 - XGRP3 Events based on external signals.

DEFAULT NAMES EV1 - EV8 are default event names that may be changed to

a user defined descriptive name for reference in the

Sequencer and Performance analysis displays.

PCI SIGNALS All PCI bus signals are included except JTAG which is used

for boundary scan testing.

EXTERNAL The TA660 supports 16 external signals that are all sampled

and captured in memory in synch with the PCI bus signals.

61

Page 68

TA660 User's Manual Catalyst Enterprises, Inc

Defining an Event Pattern

1. Click the Event Patterns tab to open the Event Pattern Definition

dialog box.

Figure 55 Event Pattern Definition Dialog Box

To enter a parameter or edit a previously entered parameter, doubleclick in the appropriate data field to open a corresponding dialog box,

enter the required data, and click OK. The changes entered will be

reflected in the edited data field.

Keyboard Edit You may also edit all of the data fields by using the

keyboard by moving through the available data fields using

the arrow keys and pressing Enter on the desired field to

either open the associated dialog box or to change the

contents from X to 0 to 1.

For example, to define EV1 as a CUSTOM event, double click first in

the EV1 field and then in each of the data fields that you wish to

define to set the required parameters in the corresponding dialog box.

Set Default To set all of the PCI signals to the default value of don’t

care, X, for any given event EVx, position the highlighted

cursor anywhere in that row and hit the “del” key.

Set Transfer Type The transfer type selection dialog box shown in Figure 56

controls the pre-determined signal settings and address

62

Page 69

TA660 User's Manual Catalyst Enterprises, Inc

limits based upon the XFER type selected. For example,

with A32 selected as shown, the address field is

automatically limited to 32 bits, a limited CBE dialog as

shown in Figure 57 is enabled, 64 bit settings in the PAR

dialog and the R/G dialog are grayed out. Additionally the

IDSEL, FRAME#, IRDY#, DEVSEL#, TRDY# and

STOP# are pre-defined and unchangeable.

Figure 56 Transfer Type Selection Dialog Box

Figure 57 Limited CBE Dialog Box

Figure 58 Event File Setup for XFER Type A32

63

Page 70

TA660 User's Manual Catalyst Enterprises, Inc

Programming the Sequencer

The sequencer is used for data capture manipulation, generating

complex triggering on bus events and starting the exerciser (if

required).

The TA660 Sequencer includes 32 states, S0 to S31. The Sequencer

always starts at S0. Each state can be programmed to go to any other