Page 1

LEADS Addendum

For use with the following user manuals:

Model T700 Manual PN 06873

Model 700E Manual PN 05621

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION (TAPI)

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone: 858-657-9800

Fax: 858-657-9816

Email: api-sales@teledyne.com

Website: http://www.teledyne-api.com/

Copyright 2010-2012 05780A DCN6493

Teledyne Advanced Pollution Instrumentation 06 June 2012

Page 2

Page 3

LEADS Addendum

INTRODUCTION

The LEADS version of Models T700 and 700E software includes support for Dasibi “Dot” serial

data commands, operational “Levels”, and for driving external devices via contact closure

control outputs. Further an optional bolt-on valve driver assembly allows the control of external

valves using these control outputs. Generally a LEADS equipped Model T700 or 700E will be

used in conjunction with a XENO data logger that collects and buffers data between the various

calibrators, analyzers and met gear at an air monitoring station and a remotely located central

data analysis facility.

LEADS is a data collection and analysis system for meteorological and environmental data. It

can be used to integrate data and control instrumentation from several different manufacturers.

However the first and most prevalent implementation of the LEADS system was done for

TNRCC using Dasibi 5008 calibrators. Due to the desire to be backwards compatible with

existing LEADS systems the “Dot” commands and “Levels” were added to the M700, M700E,

and T700. For more information on the LEADS system please go to http://www.meteostar.com/

.

05780A DCN6493 1

Page 4

LEADS Addendum

FRONT PANEL DISPLAYS

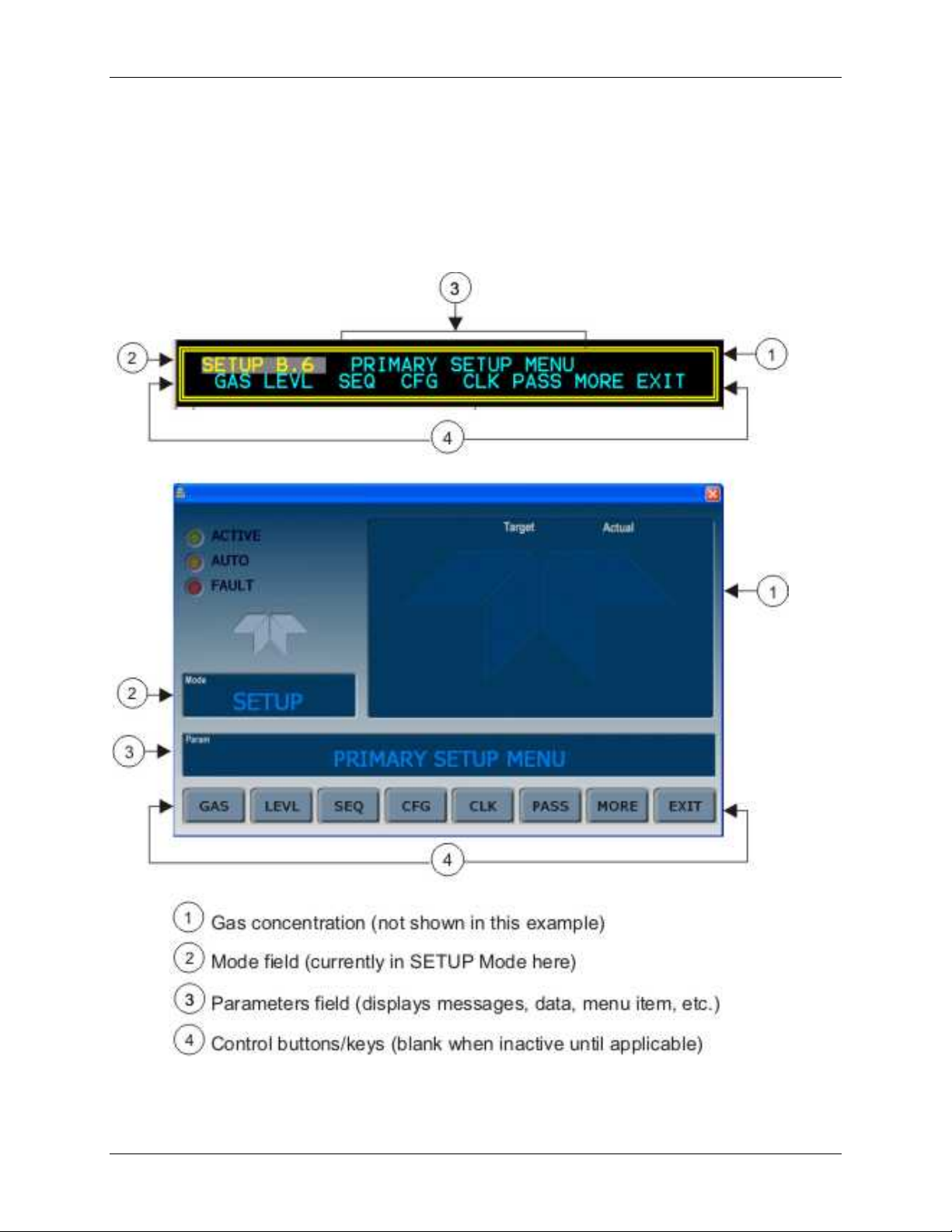

The examples illustrated in this addendum show the front panel display of the Model 700E. The

information is the same for the Model T700, but the front panel display is a capacitive touch

screen whose interface looks significantly different from that of the Model 700E. The following

illustration shows where on a T700 front panel display you will find the same information that is

shown in the 700E front panel display:

2 05780A DCN6493

Page 5

LEADS Addendum

DOT COMMANDS

The Dasibi “Dot” commands form a text-based (ASCII) data protocol that is transmitted between

a control computer (XENO data logger in this case) and a calibrator or ambient gas analyzer

over an RS-232 connection. The details of the protocol are beyond the scope of this document,

but in its simplest form the protocol is based on a two or three digit integer preceded by a

control-A and a period (.) and then followed by a “!” and a two digit checksum. For example:

^A.xxx!nn

For further information on dot commands please contact TAPI Technical Support.

A Model T700 or 700E equipped with LEADS software can be simultaneously operated over the

same COM port using standard TAPI serial data commands and is compatible with APIcom.

APIcom versions 3.7.3 and after include an added feature that allows a user to edit, upload and

download level tables.

LEVELS

A level is a combination of an action, concentration value, if applicable, an output flow rate and

a configuration for one or both of two status output words. Up to twenty levels can be defined

and used with the Model T700 or 700E using a range of numbers from 0-98; level 99 is reserved

for standby. The actions that are possible with levels include Generate gas, conduct a Gas

Phase Titration (GPT), conduct a Gas Phase Titration Pre Set (GPTPS) or Manual operation of

the calibrator’s mass flow controllers and, or ozone generator, if installed. Unlike the sequences

in a T700/M700/M700E, levels do not include time information such as start time or duration;

rather, levels must be executed either by an operator at the calibrator’s front panel or through a

serial data operation over the RS-232 or Ethernet ports.

GENERATING A GAS USING A LEVEL FROM THE FRONT PANEL

To run an existing defined level press GEN, then LEVL

Then select the desired level by pressing the buttons below the 10’s or 1’s digit and finally the

ENTR button.

05780A DCN6493 3

Page 6

LEADS Addendum

CREATING AND EDITING LEVELS

To create a new level or edit an existing level press SETUP and then LEVL

If no level exists or you wish to add a level press INS. If you wish to edit a level then press

PREV or NEXT to select the level you wish to change.

4 05780A DCN6493

Page 7

LEADS Addendum

Select what activity you wish to undertake with the level by pressing the PREV and NEXT

buttons and then the ENTR button. Please consult the manual for your respective calibrator for

more information on GPT, GPTPS and MANUAL modes.

Then select what gas you wish to flow by pressing the gas button (Zero, O3, NO, SO2, etc.)

repeatedly until you get the gas you wish. Then using the buttons below the concentration

value enter the concentration that you wish to flow; pressing the button below the units display

allows you to change the units of operation.

Please note that unless the calibrator

includes an optional ozone generator

you will not get O3 as a selection, and

unless a gas has been setup under the SETUP|GAS|SOURCE GAS CONFIG menu there will

be no selection for the gas of interest. Please see the manual for your respective calibrator for

more information on this.

After selecting the desired gas by pressing the ENTR button,you will be prompted by the

analyzer to input the total amount of gas that you wish to flow. Using the buttons below the

relevant digit to change the value and then press ENTR.

05780A DCN6493 5

Page 8

LEADS Addendum

If you are creating a new level, then you will be prompted to assign the action to a level (0-99).

Press the EDIT button and then the buttons below the 0 and 10’s to select the level you wish to

use, then ENTR to store the level and level number.

At this point you will have set the type of action, the type of gas and the flow rate out of the

analyzer for the new or modified level.

To configure the status block, which determines which of the rear panel CONTROL OUTPUTS

are energized, press the SET> key. If the status block is disabled press the EDIT key, then the

ON key, and then the ENTR key.

Edit the status block bit pattern by selecting the appropriate bit using the <CH and CH> buttons

and by pressing the button below the [1], or [0] button. Press ENTR to store the configuration.

The Most Significant Bit (MSB) is the first bit on the left and corresponds with CONTROL

OUTPUT-1 on the rear panel. In turn the MSB corresponds with VALVE DRIVE-1 on the

optional external valve driver option attached to the calibrator’s rear panel.

To select the second status block press SET> and follow the steps above. The second status

block does not correspond to any physical output but is used to communicate status over the

serial data port.

6 05780A DCN6493

Page 9

LEADS Addendum

Press ENTR or EXIT depending on whether you have enabled and, or edited the second status

block. Press Exit until you return to either the SETUP or GENERATE menus

To edit, insert or delete another level press the PREV or NEXT keys to select the level that you

wish to change and then press the EDIT buttons and follow the steps from above.

OPTION 73, EXTERNAL VALVE DRIVER

An external valve driver assembly, Option 73, is available that can drive up to 8, 16-watt valves

based on the condition of the status block bits described above. The option, pictured below,

consists of a custom Printed Circuit Assembly (PCA) that mounts to the back of the calibrator

and a universal AC-to-DC power supply. Depending upon the capacity of the external supply

either four (standard) or eight valves can be simultaneously energized.

05780A DCN6493 7

Page 10

LEADS Addendum

The PCA is constructed such that it plugs through the rear panel into the Control Output

connector, J1008, on the calibrator’s motherboard (please see the manual for your calibrator

for details). When one of the Control Outputs is energized, it causes the base of the

associated PNP valve driver transistor, U1 through U8 to be taken to ground and thereby into

the emitter-collector junction into full conduction. Please note that this interface sources

current to the valves rather than previous versions that sinks

current from an external supply

DC

through the valve in question.

Valves should be connected between one of the Valve Drive outputs and one

of the Return pins.

The external power supply must be connected to the Valve Driver Interface

using the +12V coaxial input connector on the rear top right of the assembly.

The external supply in turn must be connected to 85-264V, 47-63Hz mains.

The Valve Driver Outputs are mapped one-for-one to the Control Outputs 1 through 8 and can

be manually actuated for troubleshooting using the Signal-I/O diagnostic function in the

calibrator’s software. However, the drive outputs are mapped In reverse to the status control

bits such that Bit-0 (LSB) is valve drive 8 and Bit-7 is valve drive 1. (Schematics attached).

8 05780A DCN6493

Page 11

54321

6

CN_643

JP1

D

C

4 HEADER

1

3

2

+12V

DD_71 CB_32 CA_182

D1

D2

CN_497

15

16

17

18

19

20

21

22

23

10

24

11

25

12

26

13

27

14

28

P1008

1

2

3

4

5

6

7

8

9

F1

2.70A

2.70A

F2

+12b

+12a

C2

+

1000

+12b

R1

1100

D3

GRN

D7

GRN

3

2

54678

1

U1

FPFS2P103A

C1

+

1000

RS_356

DD_62

R2

1100

D4

GRN

D8

GRN

3

2

54678

1

U2

FPFS2P103A

R3

1100

D5

GRN

D9

GRN

3

2

54678

1

U3

FPFS2P103A

R4

1100

D6

GRN

D10

GRN

3

2

54678

IC_307

1

U4

FPFS2P103A

CN_617

JP2

1

2

3

4

5

6

7

8

9

10

11

12

Weidmuller152286

D

C

B

A

Printed Documents Are Uncontrolled

1 2 3 4 5 6

IMCV 1,5/14-G-3,81

R5

1100

U8

FPFS2P103A

3

2

54678

R6

1100

1

U7

FPFS2P103A

3

2

54678

1

R7

1100

U6

FPFS2P103A

3

2

54678

1

R8

1100

U5

FPFS2P103A

3

2

54678

1

DCN 4295

Title

SCH, External Valve Interface PCA 05697

Number RevisionSize

B

Date: 8-Dec-2006 Sheet of

File: N:\PCBMGR\05696.leads.rear.panel.adapter.dn\Protel\05696.ddbDrawn By:

05698

B

21

B

A

Page 12

54321

6

D

P1020 mates with positions 7 & 8 of J1020 on motherboard

J1020

1

2

HEADER 2

CN0000226

C

AnalogOut4+

AnalogOut4-

P1020

1

3

2

4

IMCV 1,5/2-G-3,81

CN0000645

J1004

1

2

3

4

5

6

7

8

9

10

10 HEADER

CN0000395 CN0000395

P1004

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

9

19

10

20

IMCV 1,5/10-G-3,81

CN0000564 CN0000564

J1006

1

2

3

4

5

6

7

8

9

10

10 HEADER

P1006

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

9

19

10

20

IMCV 1,5/10-G-3,81

D

C

B

A

Printed Documents Are Uncontrolled

1 2 3 4 5 6

J1017

1

2

3

4

5

6

7

8

9

10

11

12

12 HEADER

CN0000394

SysOK+

StatusReturn

DigGrnd

P1017

1

13

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

22

11

23

12

24

IMCV 1,5/12-G-3,81

CN0000565

DCN 4295

Title

SCH, External Valve Interface PCA 05697

Number RevisionSize

B

Date: 8-Dec-2006 Sheet of

File: N:\PCBMGR\05696.leads.rear.panel.adapter.dn\Protel\05696.ddbDrawn By:

05698

B

A

B

22

Loading...

Loading...