Teledyne T640 User Manual

Toll-free Phone:

800-324-5190

Phone:

+1 858-657-9800

Fax:

+1 858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

User Manual

Model T640

PM Mass Monitor

© TELEDYNE API (TAPI)

9970 CARROLL CANYON ROAD

SAN DIEGO, CALIFORNIA 92131-1106

USA

Copyright 2016-2018 08354B DCN7877

Teledyne Advanced Pollution Instrumentation 29 June 2018

NOTICE OF COPYRIGHT

© 2016-2018 Teledyne Advanced Pollution Instrumentation. All rights reserved.

TRADEMARKS

All trademarks, registered trademarks, brand names or product names appearing in

this document are the property of their respective ow ners and are used herein for

identification purposes only.

08354B DCN7877 Teledyne API T640 PM Mass Monitor i

SAFETY MESSAGES

Do Not Touch: Touching some parts of the instrument without protection

Important safety messages are provided throughout this manual for the purpose of avoiding personal

injury or instrument damage. Please read these messages carefully. Each safety message is associated

with a safety alert symbol, and are placed throughout this manual; the safety symbols are also located

inside the instrument. It is imperative that you pay close attention to these messages, the descriptions of

which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the acc ompanying message for

specific information.

CAUTION: Hot Surface Warning

or proper tools could result in damage to the part(s) a nd/or the

instrument.

Technician Symbol: All operations marked with t hi s symbol are to be

performed by qualified maintenance personnel only .

Electrical Ground: This symbol inside the instrum ent marks the central

safety grounding point for the instrument.

CAUTION

This instrument should only be used for the purpose and in the manner described

in this manual. If you use this instrument in a manner other than that for which it

was intended, unpredictable behavior could ensue with possible hazardous

consequences.

NEVER use any TAPI analyzer to sample combustible gas(es)!

For Technical Assistance regarding the use and maintenance of this instrument or any ot her Teledyne API

product, contact Teledyne API’s Technical S upport Department:

Telephone: 800-324-5190

Email: sda_techsupport@teledyne.co m

or access any of the service options on our website at http://www.teledyne-api.com/

08354B DCN7877 Teledyne API T640 PM Mass Monitor ii

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans protection ou

Pictogramme « technicien » : Toutes les opérations portant ce symbole doivent

Mise à la terre : Ce symbole à l’intérieur de l’instrum ent détermine le point central

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans le but d’éviter

des blessures corporelles ou d’endommag er les instruments. Veuillez lire attentivement ces consignes.

Chaque consigne de sécurité est représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se

retrouvent dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux consignes

suivantes:

complémentaire pour des renseignements spécif i ques

sans les outils appropriés pourrait entraî ner des dommages aux pièces ou à

l’instrument.

être effectuées uniquement par du personnel de mai ntenance qualifié.

de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière décrite dans ce

manuel. Si vous utilisez cet instrument d’une autre manière que celle pour laquelle il

a été prévu, l’instrument pourrait se comporter de f açon imprévisible et entraîner des

conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz combustibles!

08354B DCN7877 Teledyne API T640 PM Mass Monitor iii

WARRANTY

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should

equipment failure occur, TAPI assures its customers that prompt service and support

will be available. (For the instrument-specific warranty period, please refer to the

“Limited Warranty” section in the Terms and Conditions of Sale on our website at:

http://www.teledyne-api.com.

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands

ready to provide on-site or in-plant service at reasonable rates similar to those of

other manufacturers in the industry. All maintenance and the first level of field

troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be

repaired to the extent and according to the current terms and conditions of the

respective equipment manufacturer’s warr anty.

PRODUCT RETURN

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling and packing

instructions and Return Merchandise Authorizat ion (RMA) procedures when returning

parts for repair or calibration may void your warranty. For anti-ESD handling and packing

instructions please refer to the manual, Fundamentals of ESD, PN 04786, in its “Packing

Components for Return to Teledyne API’s Customer Service” section. The manual can

be downloaded from our website at http://www.teledyne-api.com; RMA procedures are

under Return Authorization.

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center.

After the repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com

CAUTION – Avoid Warranty Invalidation

08354B DCN7877 Teledyne API T640 PM Mass Monitor iv

ABOUT THIS MANUAL

operating the instrument.

This user manual, part number 08354, provides instructions for the setup,

installation, and operation of the T640 Real-time Continuous PM Monitor.

Support manuals, such as electrostatic discharge (ESD) prevention and various

communications, are available o n the TAPI website http://www.teledyne-api.com

under Product Manuals.

We recommend that all users read this manual in its entirety before

08354B DCN7877 Teledyne API T640 PM Mass Monitor v

TABLE OF CONTENTS

Safety Messages ...................................................................................................................................... ii

WARRANTY ............................................................................................................................................ iv

About This Manual ................................................................................................................................... v

Table of Contents .................................................................................................................................... vi

List of Figures .......................................................................................................................................... vii

List of Tables ........................................................................................................................................... ix

1. INTRODUCTION, SPECIFICATIONS, APPROVALS, AND COMPLIANCE ......................................... 10

Specifications .................................................................................................................................. 10

EPA Designation ............................................................................................................................. 11

Safety .............................................................................................................................................. 11

EMC ................................................................................................................................................ 12

2. INSTALLATION AND HARDWARE SETUP .......................................................................................... 12

Unpacking ....................................................................................................................................... 12

List of Standard Items .......................................................................................................... 13

List of Optional Accessories ................................................................................................. 13

Ventilation Clearance ........................................................................................................... 16

Instrument Layout ........................................................................................................................... 16

Front Panel ........................................................................................................................... 16

Rear Panel ........................................................................................................................... 17

Internal Layout ..................................................................................................................... 18

Height Dimensions ............................................................................................................... 19

Connections and Startup ................................................................................................................. 20

Power Connection ................................................................................................................ 20

Communications Interface Connections .............................................................................. 21

Aerosol Sample Conditioner (ASC) Connect i ons and Installation ....................................... 21

Inlet Installation .................................................................................................................... 25

Indoor/Outdoor Installation .............................................................................................................. 27

Shelter Installation with Roof Penetration ............................................................................ 27

Outdoor Enclosure Installation ............................................................................................. 31

Pneumatics ...................................................................................................................................... 33

Display and Menu Navigation ......................................................................................................... 35

Startup and Functional Checks ....................................................................................................... 36

Startup .................................................................................................................................. 36

Functional Checks of Operating Parameters ....................................................................... 36

Initial Sensor Checks and Adjustments ................................................................. 37

3. SOFTWARE SETUP AND OPERATION ............................................................................................... 37

Menu System Overview .................................................................................................................. 37

Configuration and Setup ................................................................................................................. 38

HomeScreen ........................................................................................................................ 38

Dashboard ............................................................................................................................ 39

Alerts .................................................................................................................................... 40

Utilities>Datalog View .......................................................................................................... 40

Utilities>Alerts Log ............................................................................................................... 40

Utilities>USB Utilities (Downloads and Updates) ................................................................ 41

Downloading DAS (Data Acquisition System) Data .............................................. 42

Updating Software/Firmware ................................................................................. 42

Transferring Configuration to Other Instrume nts ................................................... 44

Generating a Report .............................................................................................. 45

Setup>Data Logging ............................................................................................................ 45

Creating a User-Defined Data Log ........................................................................ 46

Configuring Trigger Types ..................................................................................... 47

Downloading DAS (Data Acquisition System) Data .............................................. 48

Setup>Events ....................................................................................................................... 49

Creating User-Defined Events ............................................................................... 50

08354B DCN7877 Teledyne API T640 PM Mass Monitor vi

Editing or Deleting Events ..................................................................................... 51

Setup>Dashboard ................................................................................................................ 51

Setup>VARS (Variables) ................................................................................................... 52

Setup>Homescreen ........................................................................................................... 53

Setup>Instrument ............................................................................................................... 54

Instrument Display Calibration (for Earlier In st ruments) ..................................... 54

Instrument Date/Time Adjustments ..................................................................... 56

Setup>Comm (Communications Setup) ............................................................................ 57

TCP Port1 ............................................................................................................ 57

TCP Port2 ............................................................................................................ 57

Network Settings ................................................................................................. 59

Operation ......................................................................................................................................... 60

4. SENSOR CHECKS AND ADJUSTMENTS ............................................................................................ 60

Ambient Temperature Sensor Check .............................................................................................. 61

Pressure Sensor Check and Calibration ......................................................................................... 62

Sample Flow Cal (5-LPM) ............................................................................................................... 63

Bypass Flow Cal (11.67-LPM) ........................................................................................................ 64

PMT Adjustment .............................................................................................................................. 65

Leak Check ..................................................................................................................................... 67

5. MAINTENANCE AND SERVICE ............................................................................................................ 68

Maintenance Schedule .................................................................................................................... 68

Maintenance Procedures ................................................................................................................ 69

Cleaning the T640 Inlet ........................................................................................................ 69

Cleaning the US EPA PM10 Inlet ........................................................................................ 70

Changing the Disposable Filter Unit (DFU) ......................................................................... 71

Checking Pump Performance .............................................................................................. 72

Checking the Volume Flow .................................................................................................. 72

Cleaning the Optical Chamber and the RH/T Sensor .......................................................... 73

Inspecting the Sampling Line ............................................................................................... 78

Checking for Leaks .............................................................................................................. 78

Troubleshooting and Service .......................................................................................................... 79

Fault Diagnosis .................................................................................................................... 79

Flow Problems ..................................................................................................................... 80

Calibration Problems ............................................................................................................ 80

Technical Assistance ........................................................................................................... 81

6. PRINCIPLES OF OPERATION .............................................................................................................. 81

Sampling System ............................................................................................................................ 82

Inlet ...................................................................................................................................... 82

Aerosol Sample Conditioner (ASC) ..................................................................................... 82

Optical particle Sensor ......................................................................................................... 82

Flow Sensor and Pump Control ........................................................................................... 82

Electronic Block Diagram ................................................................................................................ 83

APPENDIX A – Warranty Repair Questionnaire .................................................................................... 84

APPENDIX B – Menu Hierarchy ............................................................................................................ 86

LIST OF FIGURES

Figure 2-1. T640 Typical Set of Included Hardware ................................................................................... 14

Figure 2-2. 640x Option Typical Set of Included Har dware ........................................................................ 15

Figure 2-3. Front Panel Layout ................................................................................................................... 16

Figure 2-4. T640 Rear Panel....................................................................................................................... 17

Figure 2-5. T640 with 640x Option Rear Panel........................................................................................... 17

Figure 2-6. T640 Internal Layout, with 640x Option Components .............................................................. 18

08354B DCN7877 Teledyne API T640 PM Mass Monitor vii

Figure 2-7. Top View of Inlet Nozzle ........................................................................................................... 21

Figure 2-8. Inlet Nozzle Adapter for ASC Connectio n ................................................................................ 22

Figure 2-9. Collar for Lower Flange ............................................................................................................ 22

Figure 2-10. Set Screws for ASC ................................................................................................................ 23

Figure 2-11. Collar and ASC Adapter Support............................................................................................ 23

Figure 2-12. Ambient Temperature Probe and ASC Connections (T640 with 640X Option shown) .......... 24

Figure 2-13. T640 Sample Head (5-LPM) and ASC Asse m bl y .................................................................. 25

Figure 2-14. 640X Option Inlet and ASC Assembly .................................................................................... 26

Figure 2-15. Ambient Temperature Sensor Probe In stalled into Radiation Shield ..................................... 26

Figure 2-16. T640 Inlet Tube and Slip Coupler Assem bly .......................................................................... 28

Figure 2-17. 640x Inlet Tube and Slip Coupler Assembly .......................................................................... 29

Figure 2-18. T640 Inlet and Sample Line Assembly ................................................................................... 29

Figure 2-19. 640x Inlet and Sample Line Assembly ................................................................................... 30

Figure 2-20. T640 Rooftop Sample Inlet and Extension Tubing Installation .............................................. 30

Figure 2-21. T640 (left) and 640x (right) Outdoor E nclosures Assembled ................................................. 32

Figure 2-22. T640 Pneumatics .................................................................................................................... 33

Figure 2-23. T640 with 640X Option Pneumatics ....................................................................................... 34

Figure 2-24. Sample Home Screen with Orientation .................................................................................. 35

Figure 2-25. Concentration Graph and Meter Graph .................................................................................. 36

Figure 3-1. Home Configuration thru Home Page Shortcut ........................................................................ 39

Figure 3-2. Dashboard ................................................................................................................................ 39

Figure 3-3. Alerts Log .................................................................................................................................. 40

Figure 3-4. USB Utility Pages ..................................................................................................................... 41

Figure 3-5: Das download Page ............................................................................................................ 42

Figure 3-6: Remote Update Page .......................................................................................................... 43

Figure 3-7: Manual Update Page (and other utilities) ............................................................................ 43

Figure 3-8: Configuration Transfer ........................................................................................................ 44

Figure 3-9: Report Generation Page ..................................................................................................... 45

Figure 3-10. Datalog Configuration, New Log Page ................................................................................... 45

Figure 3-11. Datalog Configuration, Existing Log ....................................................................................... 46

Figure 3-12. Creating a New Data Log ....................................................................................................... 46

Figure 3-13. Datalog Periodic Trigger Configurati on .................................................................................. 47

Figure 3-14. Datalog - Conditional Trigger Configuration ........................................................................... 48

Figure 3-15. DAS Data Utility ...................................................................................................................... 48

Figure 3-16. Events Page ........................................................................................................................... 49

Figure 3-17. Event Configuration ................................................................................................................ 50

Figure 3-18. Existing Event for Viewing or Editing ...................................................................................... 51

Figure 3-19. Dashboard Configuration ........................................................................................................ 51

08354B DCN7877 Teledyne API T640 PM Mass Monitor viii

Figure 3-20. VARS Configuration Page ...................................................................................................... 52

Figure 3-21. Home Configuration thru Setup Menu .................................................................................... 53

Figure 3-22. Touchscreen Calibration Page ............................................................................................... 54

Figure 3-23. Date and Time Configuration Page ........................................................................................ 56

Figure 3-24. Communications Configuration, Net work Settings ................................................................. 59

Figure 4-1. Leak-Check/Flow-Audit Adaptor Kit.......................................................................................... 61

Figure 4-2. Pressure Cal Menu ................................................................................................................... 62

Figure 4-3. Sample Flow Cal Menu ............................................................................................................ 63

Figure 4-4. Bypass Flow Cal Menu ............................................................................................................. 64

Figure 4-5. PMT Adjustment Menu ............................................................................................................. 65

Figure 4-6. Leak Check Menu ..................................................................................................................... 67

Figure 5-1. T640 Inlet (standard) ................................................................................................................ 69

Figure 5-2. 640X Option Disassembly ........................................................................................................ 70

Figure 5-3. Opening the Front Panel .......................................................................................................... 71

Figure 5-4. Internal DFU ............................................................................................................................. 71

Figure 5-5. External DFU, (with 640X Option only) .................................................................................... 72

Figure 5-6. Maintenance: Optics Chamber Windows ................................................................................. 76

Figure 5-7. Maintenance: Final Dusting ...................................................................................................... 76

Figure 6-1. T640 with 640X Option Electronic Block Diagram .................................................................... 83

LIST OF TABLES

Table 1-1. Specifications ............................................................................................................................. 10

Table 2-1. Ventilation Clearance ................................................................................................................. 16

Table 3-1. Setup>Instrument Menu ............................................................................................................ 54

Table 3-2. T640 MODBUS Register ........................................................................................................... 57

Table 3-3. LAN/Ethernet Configuration Prope rt i es ..................................................................................... 59

Table 5-1. Maintenance Schedule .............................................................................................................. 68

Table 5-2. Alerts and Recommendations .................................................................................................... 79

Appendix A: Warranty Repair Questionnaire

Appendix B: Menu Hierarchy

08354B DCN7877 Teledyne API T640 PM Mass Monitor ix

1. INTRODUCTION, SPECIFICATIONS,

PARAMETER

SPECIFICATION

Flow Rate

640X Option

5.0-LPM + 11.67-LPM bypass flow

1 Ethernet: 10/100Base-T (supports MODBUS and HTTP polling pr otocols)

Minimum Resolution (data rate): 10 seconds , user-definable

APPROV ALS, AND COMPLIANCE

The Teledyne API Model T640 with 640X Option is a real-time, continuous

particulate matter (PM) mass monitor that uses scattered light spectrometry for

measurement. The T640 measures 2.5 PM, and the 640X Option measures 2.5, 10,

and coarse PM.

SPECIFICATIONS

Table 1-1 presents the T640 PM Mass Monitor specifications.

Table 1-1. Specifications

Measurement Principle 90° white-light scattering

Light Source Polychromatic LED

Particle Size Resolution 0.18 – 20µm over 256 channels, combined to 64 channels for mass calculation

PM Mass Resolution

Measurement Range

Mass Measurement & Display

Resolution

Precision +/- 0.5 µg/m3 (1-hr average)

0.1 – 10,000 µg/m3

0.1 µg/m3

Lower Detectable Limit < 0.1 µg/m3 (1-hr average)

Mass Concentration Accuracy

T640

640X Option

T640

Flow Accuracy Within +/-1%; (Typically within +/- 0.5%)

AC Power

Instrument

External pump

(640X Option only)

Communication

Data Storage 4 Gb memory allows for >1 year of data storage

Exceeds US EPA Class III PM2.5

Exceeds US EPA US EPA PM10 FEM and Class III PM2.5 & PM10-2.5 FEM

performance requirements for additive and multiplicative bias compar ed to FRM

samplers

5.0-LPM

Rating Typical Power Consumption

110-120 V, 60 Hz 3.0 A

220V-240V, 50/60 Hz 3.0 A

110-120 V, 60 Hz 3.0 A

220V-240V, 50/60 Hz 3.0 A

2 USB device ports

<120 W (at 120 VAC)

<120 W (at 120 VAC)

<360 W (at 120 VAC)

<360 W (at 120 VAC)

08354B DCN7877 Teledyne API T640 PM Mass Monitor 10

PARAMETER

SPECIFICATION

Dimensions

5.0 LPM Model T640 monitor (PM2.5)

EQPM-0516-236

16.7 LPM Model T640 with 640X option monitor (PM2.5)

EQPM-0516-238

16.7 LPM Model T640 with 640X option monitor (PM10-

2.5)

16.7 LPM Model T640 with 640X option monitor (PM10)

EQPM-0516-239

ASC (heater tube)

ASC w/T640 inlet

ASC w/640X Option inlet

Optional external shelter

Weight

Operating Conditions

Operating temperature

Ambient temperature

Ambient Relative Humidity

Sample Humidity Control

Environmental Conditions Installation Category (Over voltage Category) II Pollution Degree 2

1

As defined by the US EPA

H x W x D: 7" x 17" x 14" (178 x 432 x 356 mm)

43” (1092 mm) above the lid

53.5” (1359 mm) above the lid

70” (1778 mm) above the lid

HxWxD: 45” x 25” x 25” (1143 x 635 x 635 mm)

19 lbs (8.6 kg)

w/ T640 ASC + inlet 27 lbs (12.2 kg);

w/ 640X Option ASC + inlet 30 lbs (13.6 kg)

0 - 50°C, non-condensing

-40 - 60°C

0 - 100%

Aerosol Sample Conditioner (ASC) 24VDC 90W (max) heater controlled to

35% RH

For outdoor use only, to ≤ 5000 m altitude

2

At constant temperature and pressure

EPA DESIGNATION

SAFETY

TAPI’s Model T640 PM Mass Monitor and its options are officially designated as

US EPA Federal Equivalent Methods (FEMs) for determining compliance with

particulate matter mass concentration National Ambient Air Quality Standards

(NAAQS). The US EPA designation numbers are as follows:

EQPM-0516-240

The official List of Designated Reference and Equivalent Methods is published in

the U.S. Federal Register: http://federalregister.gov/a/2016-16578

. .

Comply with Code of Federal Regulations, Title 40 (downloadable from the U.S.

Government Publishing Office at http://www/gpo.gov/fdsys/

) and with Quality

Assurance Guidance documents (available on the EPA website,

http://www.epa.gov/ttn/amtic/qalist.html). Give special attention to specific

regulations regarding methods for determining particulate matter.

IEC/EN 61010-1:2010 (3rd Edition), Safety requirements for electrical equipment

for measurement, control, and laboratory use.

CE: 2006/95/EC, Low-Voltage Directive

08354B DCN7877 Teledyne API T640 PM Mass Monitor 11

EMC

IEC/EN 61326-1, Class A Emissions/Industrial Immunity

EN55011 (CISPR 11), Group 1, Class A Emissio ns

FCC 47 CFR Part 15B, Class A Emissions

CE: 2004/108/EC, Electromagnetic Compatibil i t y Directive

2. INST ALLATION AND HAR DWARE SETUP

This section addresses the procedures for unpacking the instrument and inspecting

for damage, presents clearance specifications for proper ventilation, and shows the

instrument layout.

UNPACKING

Verify that there is no apparent external shipping damage. If damage has occurred,

please advise the shipper first, then contact Teledyne API.

Included with your instrument is a printed record of the final performance

characterization performed on your instrument at the factory. This record,

titledT640/640x Mass Monitor Test Data Sheet, is an important quality assuran ce

and calibration record and should be placed in the quality records file for this

instrument.

WARNING – ELECTRICAL SHOCK HAZARD

Never disconnect PCAs, wiring harnesses or electronic

08354B DCN7877 Teledyne API T640 PM Mass Monitor 12

subassemblies while under power.

With no power to the unit, carefully remove the top cover of the instrument and

check for internal shipping damage by carrying out the following steps:

1. Carefully remove the top cover and check for internal shipping damage.

a. Remove the cover screws located on the sides of the instrument.

b. Slide the cover backward until it clears the instrument’s front bezel.

c. Lift the cover straight up.

2. Inspect the interior to ensure all circuit boards an d ot her components are

intact and securely seated.

3. Check the connectors of the various internal wirin g harnesses and pneumatic

hoses to ensure they are firmly and securely seated.

4. Using the paperwork accompanying the instrument, verify that all of the

standard and optional hardware ordered with the unit has been installed.

These are listed on the paperwork accompanyi ng the instrument.

LIST OF STANDARD ITEMS

• Model T640 Instrument with power cord and Test Data Sheet:

• SpanDust

• Aerosol Sample Conditioner (ASC) Tube (~43” long)

• Ambient Temperature Sensor Cable (25’) with ra diation shield and mounting

bracket

• Internal Temperature Sensor Cable (4’) – for performing flow sensor

calibrations from inside shelter without having to di sconnect the normally

installed ambient temperature sensor cable

• CD with operating manuals

TM

bottle with calibration certificate

LIST OF OPTIONAL ACCESSORIES

• Sample head, 5LPM (for T640 base model; PM2.5 FEM)

o Sample Head

o Water collection jar

o ~6” upper inlet tube

• T640 base model extension tube kit

o 8’ long aluminum tube (5/8” OD) with locking collar

o Roof flange with 5/8” cord grip and ¼” cord grip (for am bient temp sen sor

cable)

o Slip coupler (5/8” ID)

• 640x option

o US EPA PM10 inlet, 16.7 LPM

o Outer extension tube (~12” length)

o Inner extension tube (~8” length)

o External vacuum pump pack, 120 or 220V AC with tubing

o Bypass flow splitter / adapter (usually pre-installed onto the ASC from

the factory)

o ¼” black bypass flow tubing

• 640x extension tube kit

o 8’ long aluminum tube (1” OD)

o Step down adapter (1 ¼ ” ID to 1” ID)

o Slip coupler (1” ID)

o Roof flange with 1” cord grip and ¼” cord grip (for ambient t em p sensor

cable)

o Slip coupler (5/8” ID, 1 ¼” OD)

• Support tripod with cord grips for 5/8” or 1” OD tubes

• Leak check / flow audit adapter kit

08354B DCN7877 Teledyne API T640 PM Mass Monitor 13

Figure 2-1. T640 Typical Set of Included Hardware

08354B DCN7877 Teledyne API T640 PM Mass Monitor 14

Figure 2-2. 640x Option Typical Set of Included Hardware

08354B DCN7877 Teledyne API T640 PM Mass Monitor 15

VENTILATION CLEARANCE

AREA

MINIMUM REQUIRED CLEARANCE

Whether the Monitor is set up on a be nch or installe d in an instrument rack, be sure

to leave sufficient ventilation clearance.

Table 2-1. Ventilation Clearance

Back of the instrument

Sides of the instrument

Above and below the instrument

INSTRUMENT LAYOUT

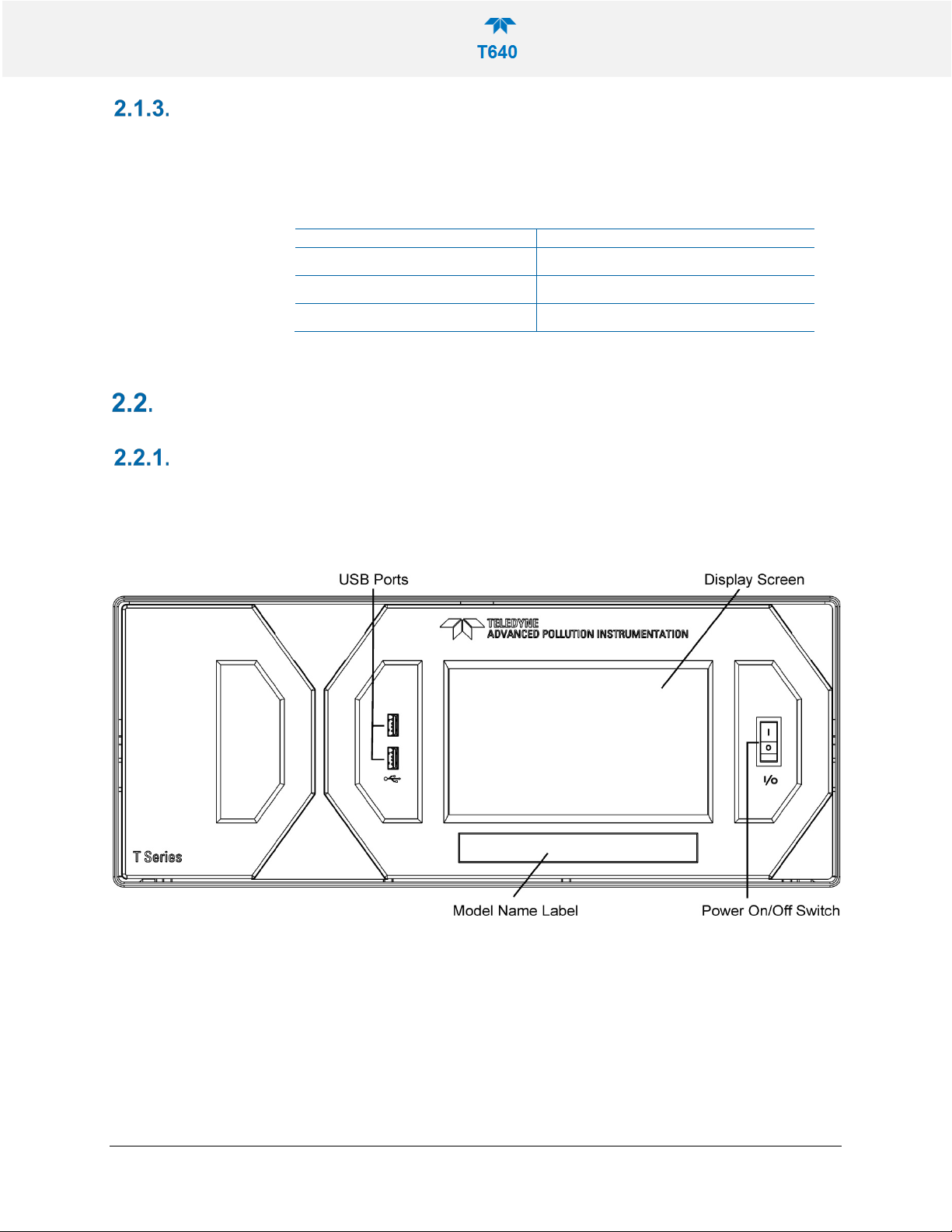

FRONT PANEL

Figure 2-3 shows the front panel layout, which has th e display screen, two USB

ports for peripheral device connections: mouse and keyboard as alternatives to the

touchscreen interface, or flash drive for uploads/downloads (devices not inc luded).

10 cm / 4 in

2.5 cm / 1 in

2.5 cm / 1 in

08354B DCN7877 Teledyne API T640 PM Mass Monitor 16

Figure 2-3. Front Panel Layout

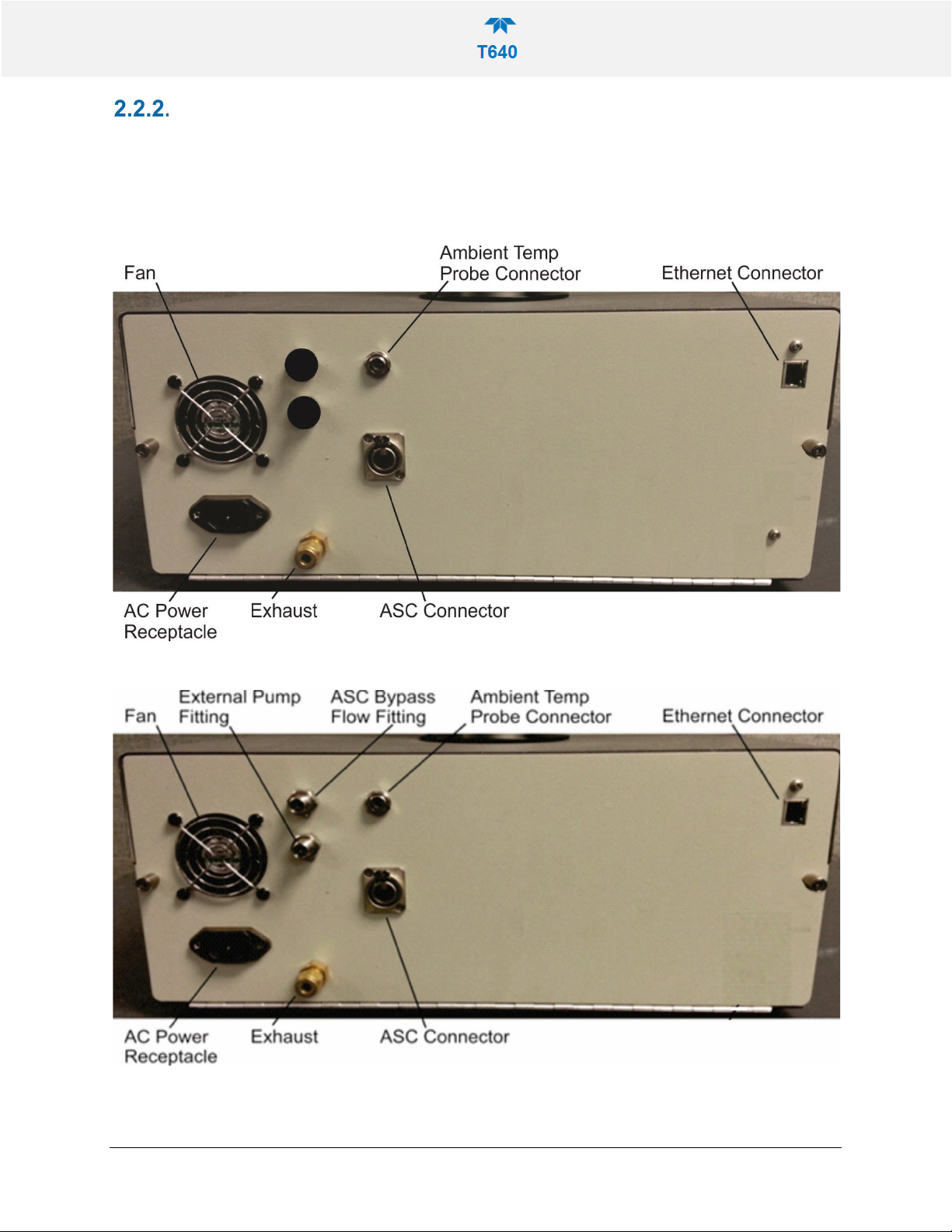

REAR PANEL

The rear panel shows fittings and connectors for the monitor’s functions as well as

connectors for communication.

Figure 2-4. T640 Rear Panel

Figure 2-5. T640 with 640x Option Rear Panel

08354B DCN7877 Teledyne API T640 PM Mass Monitor 17

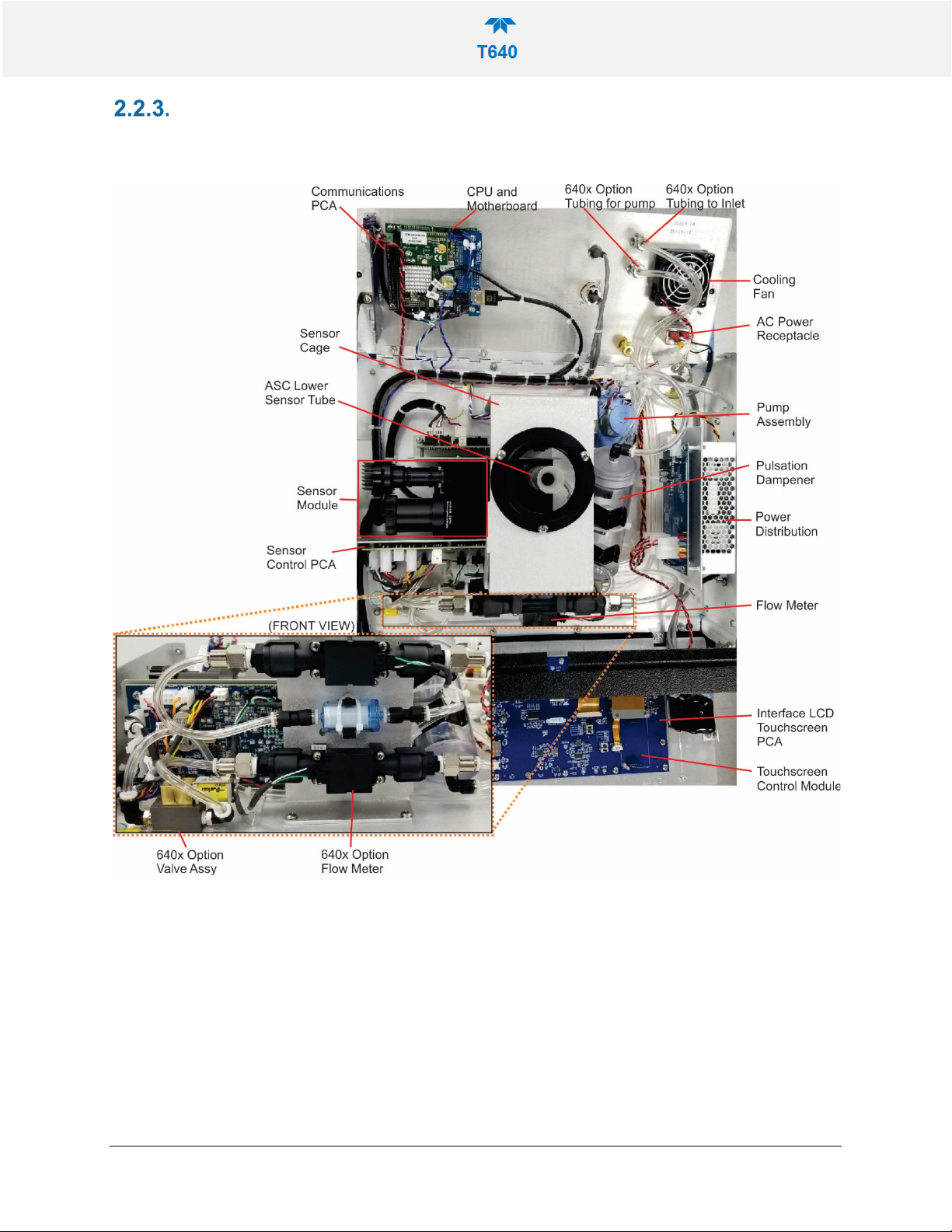

INTERNAL LAYOUT

Below shows the main components and assemblies of the monitor.

Figure 2-6. T640 Internal Layout, with 640x Option Components

08354B DCN7877 Teledyne API T640 PM Mass Monitor 18

HEIGHT DIMENSIONS

T640 Chassis = 7

-in tall

For indoor shelter installation, the

height is 43-in + 3-in for the upper

sampling tube (which goes into the

inlet in this picture) that couples to

the extens ion tube, making

46-in

total above the ins trument lid.

T640 ASC = 43-in tall above the

chassis lid.

T640 Inlet = 10.5-in tall

PM10 Inlet = 15.5-in tall

T640 Chassis = 7-in tall

For indoor shelter installation, the

height is 43-in + 10-in for the PM10

extension tube + 6-i n for the slip

coupler fittings (not shown here)

that couple to the extens ion tube,

making 59-in total above the

instrument lid. Allow extra space

above for sliding tubing on/off the

fittings.

T640 ASC = 43-in tall above the

chassis lid.

T640:

640x:

08354B DCN7877 Teledyne API T640 PM Mass Monitor 19

CONNECTIONS AND STARTUP

Do not operate with cover off.

the instrument’s model/specs label before plugging it into line power.

Note

This section presents the various connections for setup and preparing the

instrument for operation (Section 2.6).

WARNING: ELECTRICAL SHOCK HAZARD

• High Voltages are present inside the instrument.

• Ensure that the power cord being used is capable of carrying the

power rating of the instrument (see rear panel label).

• Power connection must have functioning ground connection.

• Do not defeat the ground wire on power plug.

• Turn off instrument power before disconnecting or connecting

electrical subassemblies.

•

CAUTION – AVOID DAMAGE TO THE INSTRUMENT

Do not operate under conditions outside the environmental

specifications. Operating this instrument under different

environmental conditions, such as corrosive or explosive

environments, electric or electromagnetic fields, areas of ionizing

radiation, or areas conducive to shock or vibration, could damage or

destroy the instrument.

CAUTION – AVOID DAMAGE TO THE INSTRUMENT

Ensure that the AC power voltage matches the voltage indicated on

To maintain compliance with EMC standards, any cable length must

be no greater than 3 meters for all communication connections.

POWER CONNECTION

Adhering to the warning messages previously introduced (Section 2.3), insert the

power cord between the instrument’s AC power connector and a properly rated

power outlet.

08354B DCN7877 Teledyne API T640 PM Mass Monitor 20

COMMUNICATIONS INTERFACE CONNECTIONS

IMPORTANT

instrument’s performance.

For network or Internet communication with the instrument, connect an Ethernet

cable from the analyzer’s rear panel Ethernet i nterface connector to an Ethernet

port. Although the analyzer is shipped with DHCP enabled by default, it should be

manually assigned a static IP address. See Section 3.2.13. The USB ports are f or

other utilities described later in this manual.

AEROSOL SAMPLE CONDITIONER (ASC) CONNECTIONS AND

INSTALLATION

The ASC requires an inlet nozzle adapter fo r in stallation.

IMPACT ON READINGS OR DATA

The black inlet nozzle to the optical sensor is specific to the

instrument and is not interchangeable with other T640

instruments. Use caution when handling and contact TAPI Tech

Support if this piece is ever damaged as it could affect the

08354B DCN7877 Teledyne API T640 PM Mass Monitor 21

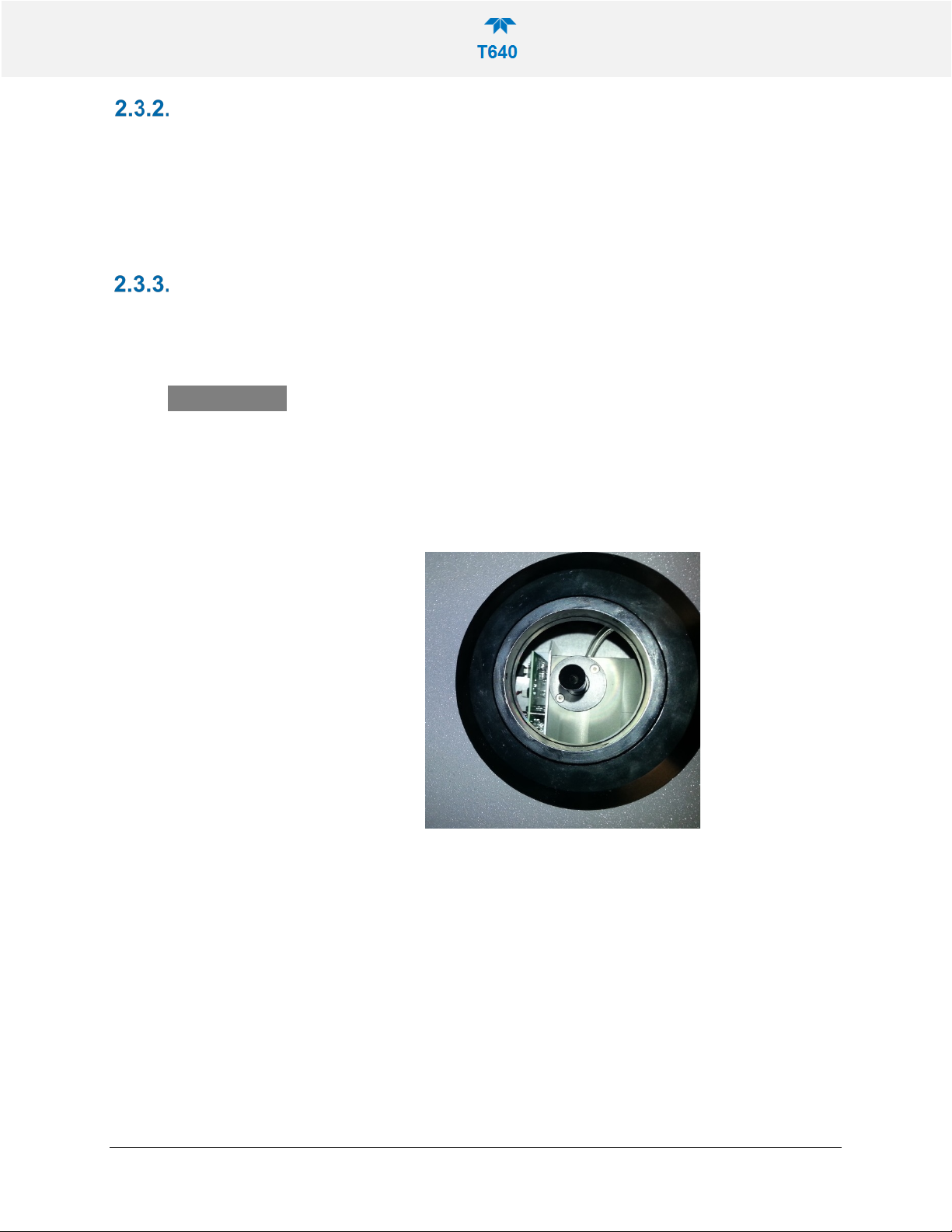

Figure 2-7. Top View of Inlet Nozzle

1. Slide the aluminum adapter over the black inlet nozzle, ensuring its base is

flush with the top of the optical sensor.

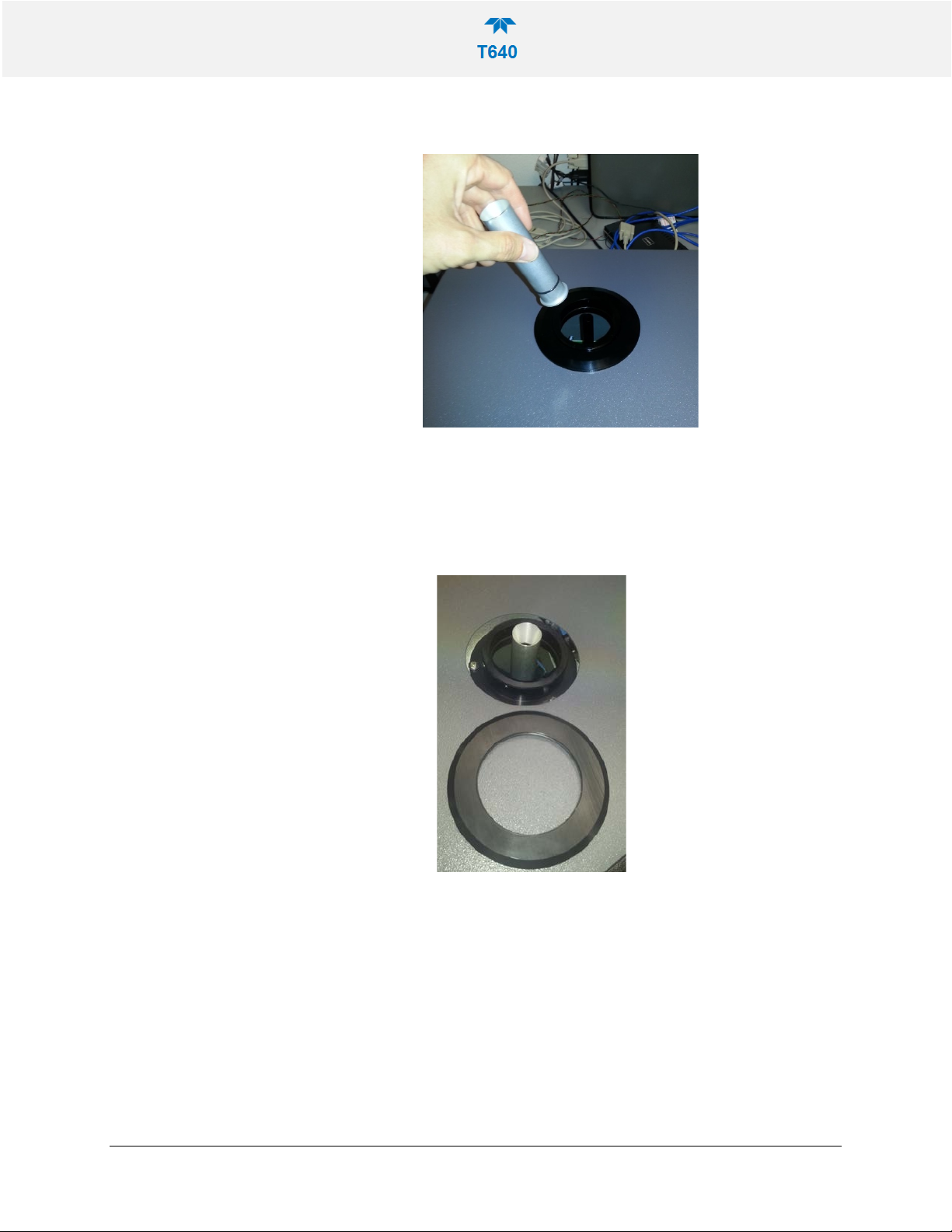

Figure 2-8. Inlet Nozzle Adapter for ASC Connection

2. Remove collar from lower flange of the instrument as shown:

Figure 2-9. Collar for Lower Flange

08354B DCN7877 Teledyne API T640 PM Mass Monitor 22

3. Identify the three openings on the lower flange ASC support and insert set

screws on them. Use a 1/16” Hex/Allen Wrench. Do not tighten them at this

point.

Figure 2-10. Set Screws for ASC

4. Replace collar over lower flange/ASC support:

Figure 2-11. Collar and ASC Adapter Support

5. Carefully place ASC over sample inlet making sure it properly seated by

applying sufficient pressure to slide past the internal o-rings at the base of the

inlet nozzle adapter. Be sure the ASC is oriented squarely, by using a plumb

bob or level:

08354B DCN7877 Teledyne API T640 PM Mass Monitor 23

6. Once the ASC is leveled, set screws should be hand tightened until snug. Do

not over-tighten; the screws should be relatively easy to loosen when

necessary. Press slightly on instrument top cover to allow more clearance if

needed. Do not use thread locker.

7. Connect the ASC power and communications cable to the rear panel of the

T640 labeled ASC Connector (or IADS Connector in some cases).

8. Locate the 25’ temperature sensor cable (15’ in some cases). Pl ug the ambient

temperature probe connector into its respective rear panel electrical port.

Figure 2-12. Ambient Temperature Probe and ASC Connections (T640 with

640X Option shown)

08354B DCN7877 Teledyne API T640 PM Mass Monitor 24

INLET INSTALLATION

1. To complete the installation now will depend on whether t he instrument is being

installed in an Outdoor Enclosure or Walk-in Shelter. If performing testing in a

laboratory, you can proceed with attaching the inlet.

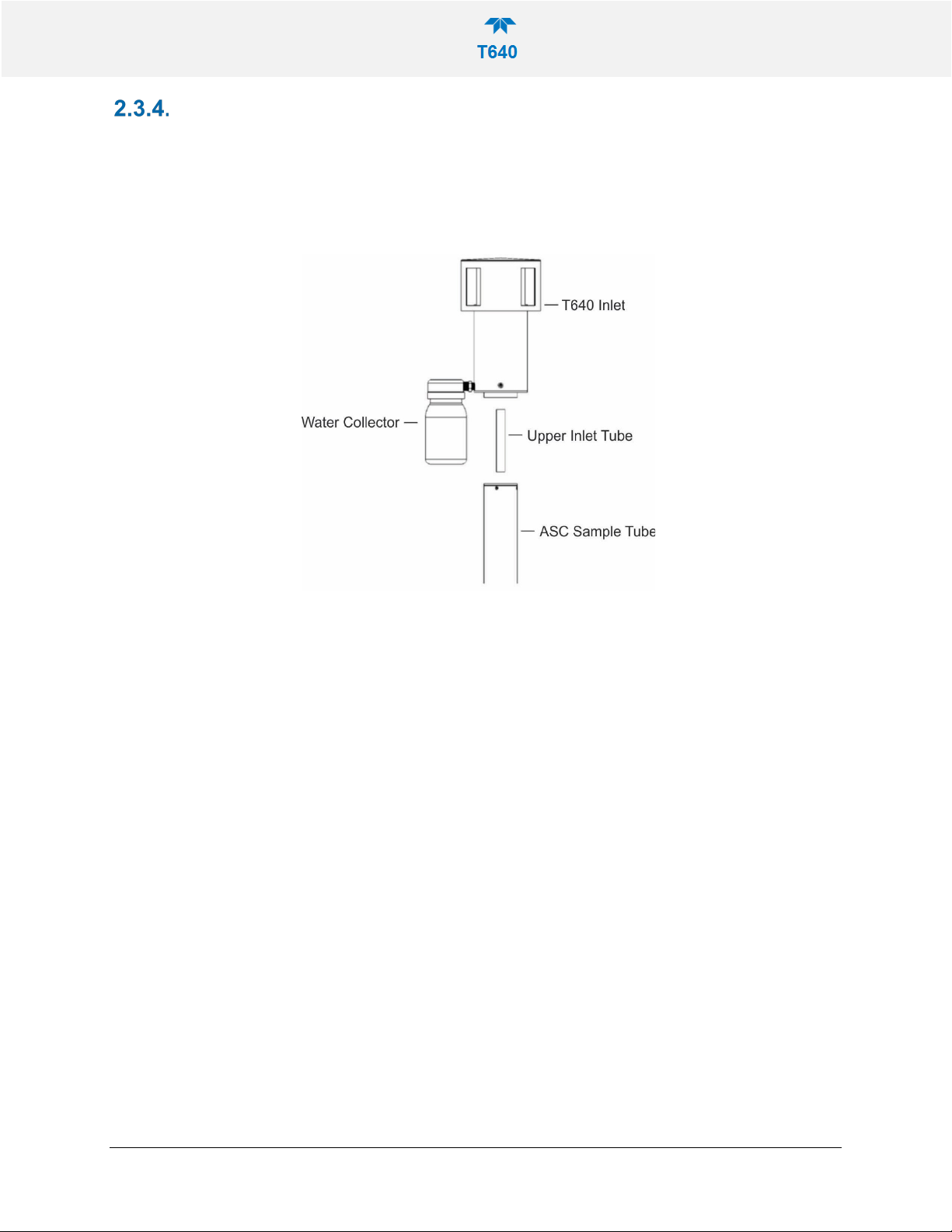

2. For the T640, assemble the inlet and the ASC as depicted below ( Figure 2-13.

T640 Sample Head (5-LPM) and ASC Assembly).

Figure 2-13. T640 Sample Head (5-LPM) and ASC Assembly

08354B DCN7877 Teledyne API T640 PM Mass Monitor 25

Loading...

Loading...