Page 1

Manual Addendum

Model T360U

CO2 Analyzer

(Addendum to T360 Manual, PN 07272)

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION (TAPI)

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone: 858-657-9800

Fax: 858-657-9816

Email: api-sales@teledyne.com

Website: http://www.teledyne-api.com/

Copyright 2013 07273A DCN6707

Teledyne Advanced Pollution Instrumentation 09 July 2013

Page 2

Page 3

ABOUT THIS ADDENDUM

This addendum, part number 07273, is to be used in conjunction with the Model T360 operation

manual, part number 07272. Where operation of the Model T360U diverges from that of the

Model T360, this addendum takes precedence.

Please note that the T360 operation manual contains important SAFETY messages and the

WARRANTY information for this instrument. It is strongly recommended that you read the

T360 operation manual in its entirety as well as this addendum, before operating the instrument.

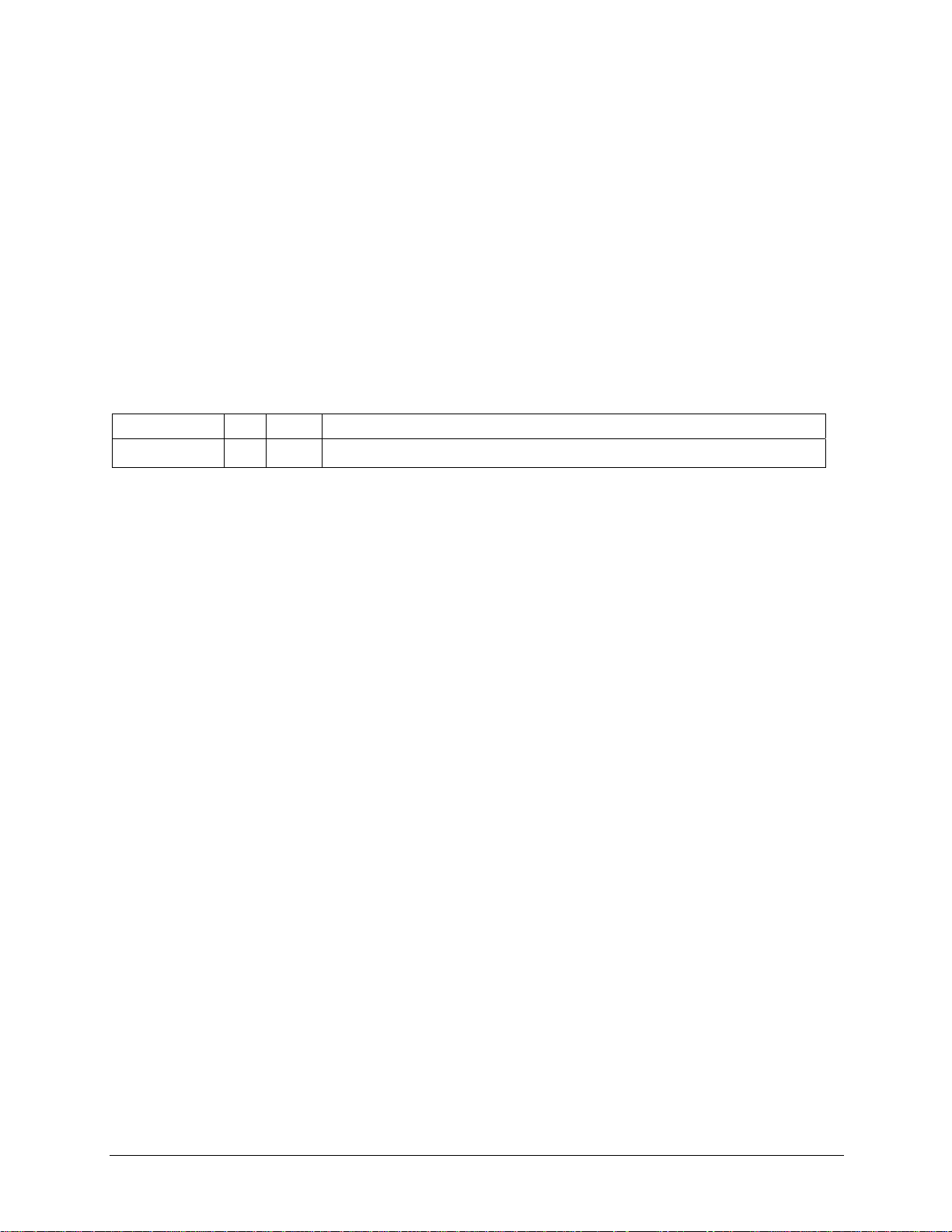

REVISION HISTORY

Date Rev DCN Change Summary

09 July 2013

6707 T-Series initial release

A

i

Page 4

This page intentionally left blank

ii

Page 5

TABLE OF CONTENTS

About This Addendum ................................................................................................................ i

Revision History.......................................................................................................................... i

Table of Contents ......................................................................................................................iii

1. Overview ........................................................................................................................... 5

2. Specifications and Agency Approvals ...............................................................................5

3. Electrical Connections....................................................................................................... 6

4. Pneumatic Connections .................................................................................................... 7

4.1. Basic and Zero/Span Valve Option Configurations.......................................................8

4.2. Making the Pneumatic Connections............................................................................10

5. RelayAlarm Outputs (Standard configuration) ................................................................ 11

6. Relay Alarm Outputs (Air Products Configuration).......................................................... 11

7. Control inputs (Air Products Configuration only) .............................................................11

Figures

Figure 4-1. T360U Pneumatic Flow Diagram...............................................................................................7

Figure 4-2. Pneumatic Connections–Basic Configuration ............................................................................8

Figure 4-3. Pneumatic Connections–Configuration with Zero/Span Valve Option....................................... 9

Tables

Table 2-1. T360U Specifications and Agency Approvals.............................................................................. 5

Table 4-1. Model T360U Pneumatic Connections ........................................................................................9

Spare Parts List........................................................................................................................................... 13

iii

Page 6

This page intentionally left blank.

iv

Page 7

1. OVERVIEW

The Model T360U is a close derivative of the Model T360 CO Analyzer. The main

differences are as follows:

The optical bench is longer (14 m), making the instrument more sensitive at low CO

levels.

The instrument has a user-selectable full scale range of 0-100 PPB to 0-100 PPM of

.

CO

2

The rear panel has an extra pneumatic port for the exhaust of the purge gas to the

GFC wheel.

Because the T360U is a close derivative of T360, the Model T360 Operation Manual

continues to be valid as the reference manual covering the details of the instrument’s

components and operation.

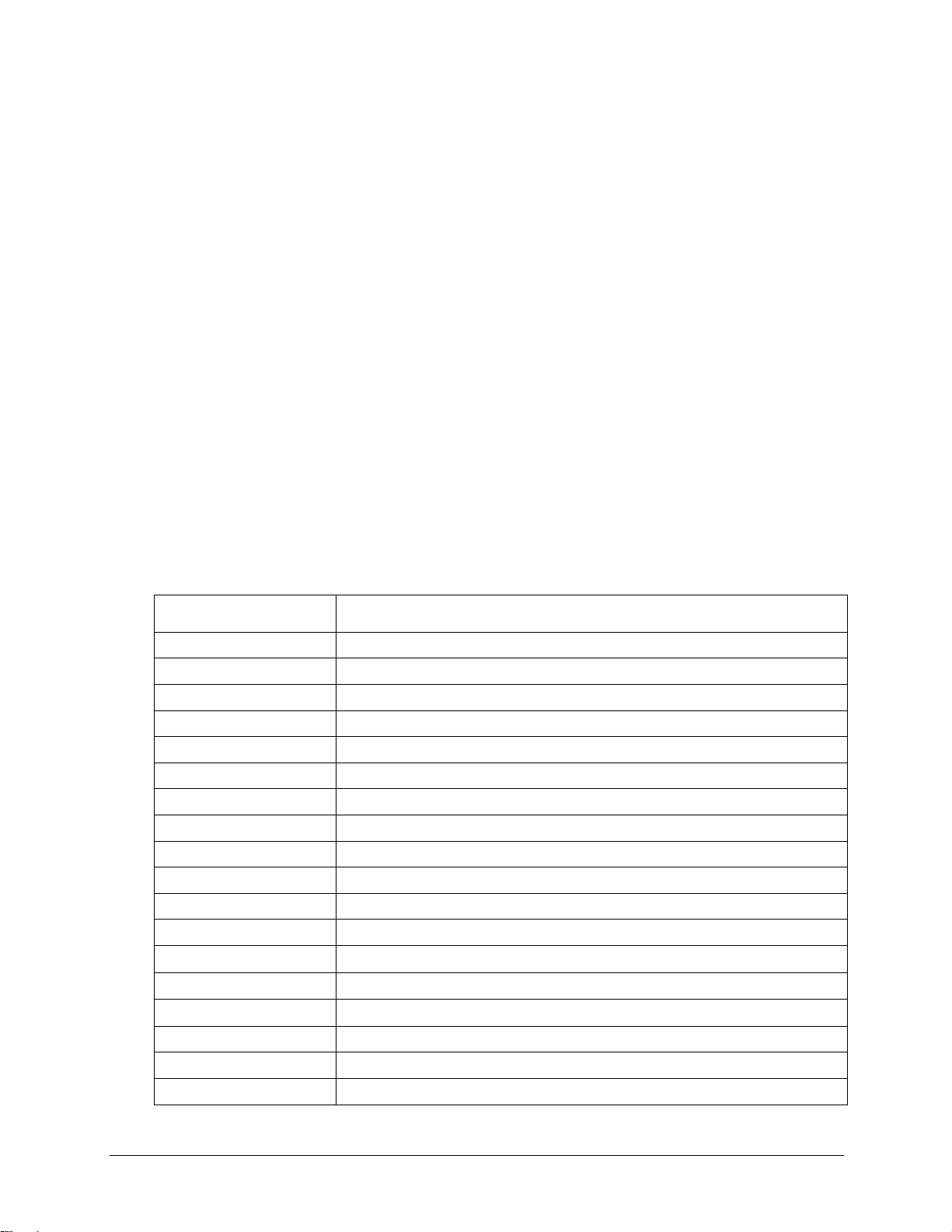

2. SPECIFICA TIONS AND AGENCY APPROVALS

Table 2-1 presents the specification parameters and values, as well as agency approvals.

Table 2-1. T360U Specifications and Agency Approvals

PARAMETER SPECIFICATION

Ranges User selectable to any full scale range from 0-100 ppb to 0-100 ppm

Measurement Units ppb, ppm, µg/m3, mg/m3 (user selectable)

Zero Noise ≤ 2.5 ppb RMS

Span Noise < 0.5% of reading RMS over 5 ppm

Lower Detectable Limit < 5 ppb

(1)

Zero Drift (24 hours) < 0.25 ppm

Span Drift (24 hours) < 0.5% of reading

Linearity 1% of full scale

Precision 0.5% reading

Lag Time <10 sec

(1)

Rise/Fall Time <60 sec to 95%

Sample Flow Rate 800 cc/min. ± 10%

Temperature Range

5 - 40C operating

Humidity Range 0-95% RH, Non-Condensing

Temp Coefficient

< 0.05 % of reading per C (5 ppb/C minimum)

Voltage Coefficient < 0.05 % of reading per V

Dimensions (HxWxD) 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight 40 lb (18.1 kg)

(1)

(1) (3)

(2)

(2) (4)

(5)

(1) (5)

(1)

2

5

Page 8

PARAMETER SPECIFICATION

AC Power 100 – 120V 50/60 Hz (120W)

220 – 240 V 50/60 Hz (144W)

Environmental

Installation Category (Over voltage Category) II Pollution Degree 2

Conditions

Standard I/O

1 Ethernet: 10/100Base-T

2 RS-232 (300 – 115,200 baud)

2 USB device ports

8 opto-isolated digital status outputs

6 opto-isolated digital control inputs

4 analog outputs

Optional I/O

1 USB com port

1 RS485

8 analog inputs (0-10V, 12-bit)

4 digital alarm outputs

Multidrop RS232

3 4-20mA current outputs

Analog Output

1 part in 4096 of selected full-scale voltage

Resolution

Certifications CE: IEC 61010-1:2001, EN61326 - Class A

1

As defined by the USEPA

2

At constant temperature and voltage

3

Or 0.2 ppm, whichever is greater

4

Or 0.1 ppm, whichever is greater

5

Above 10 ppm range, otherwise 0.2 ppm for lower ranges

3. ELECTRICAL CONNECTIONS

Follow the instructions for unpacking, inspecting, and making electrical connections

presented in the T360 operation manual.

6

Page 9

4. PNEUMATIC CONNECTIONS

This section provides information on the pneumatic configurations. Figure 4-1 shows the

basic pneumatic flow of the T360U.

Figure 4-1. T360U Pneumatic Flow Diagram

7

Page 10

e

t

g

4.1. BASIC AND ZERO/SPAN VALVE OPTION CONFIGURATIONS

CAUTION

Sample and calibration gases should only come into contact with PTFE

Do NOT operate without first removing dust plugs from rear panel fixtures.

To prevent dust from entering the gas flow channels, your analyzer was shipped with small

plugs inserted into each of the pneumatic fittings on the back panel. Remove these dust

plugs and store for future use before proceeding.

Figure 4-2 illustrates the most common configuration for gas supply and exhaust lines to

the Model T360U Analyzer. Figure 4-3 illustrates the pneumatic connections for optional

configuratio

n with zero/span valves. Table 4-1 describes the pneumatic ports.

(Teflon), FEP, glass, stainless steel or brass.

NOTE

Note that the flowmeter

could also be configured upstream of the instrument. Since most

flowmeters are calibrated at ambient pressure, ensure that the flow going through the flow

meter is at ambient pressure, when it is placed upstream.

Nee dl e v alv e,

set flow to 800

cc/min (+/- 10%)

Flowmeter

10-30 psig

CO2 free

as

Sampl

Exhaus

Ve nt Spa n

Pressure Span

Zero

To Purge

Chassis

Fr o m Pu r ge

Sample/

Cal gas

Pressure

regulator (set

to 10-15 psig

output)

Figure 4-2. Pneumatic Connections–Basic Configuration

8

Page 11

Pressure

Sample

gas

regulator, set

output to 5-10

psig

Needle valve,

set flow to 800

cc /mi n (+/- 10%)

Flowme ter

Sample

Exhaust

Chassis

Ve n t S p an

Pressure Span

Zero

To Purg e

Fro m Purge

Span ga s

CO2 free

gas

Pressure

Regulator (5-10

psig output)

Pressure

Regular (5-10

psig output)

Needle valve,

set flow to 800

cc/min (+/10%)

Needle valve,

set flow to 800

cc/min (+/10%)

10-30 psig

CO2 free gas

Figure 4-3. Pneumatic Connections–Configuration with Zero/Span Valve Option

Table 4-1. Model T360U Pneumatic Connections

Rear Panel Label Function

Connect a gas line from the source of sample gas here.

SAMPLE

Calibration gasses are also inlet here on units without

zero/span valve option installed.

EXHAUST

PRESSURE SPAN

Connect an exhaust gas line of not more than 10 meters

long here.

On units with zero/span valve option installed, connect a

gas line to the source of calibrated span gas here.

VENT SPAN Not used

ZERO

On units with zero/span valve option installed, attach a

gas line to the source of zero air here.

This inlet supplies purge air to the GFC wheel housing

TO PURGE

Connect a source of dried air that has been scrubbed of

CO

.

2

This exhausts purge air from the GFC wheel housing.

FROM PURGE

Connect an exhaust gas line of not more than 10 meters

long here.

9

Page 12

4.2. MAKING THE PNEUMATIC CONNECTIONS

CAUTION

Venting should be outside the shelter or immediate area surrounding the

instrument.

1. Attach a sample inlet line to the sample inlet port. The SAMPLE input line should not

be more than 2 meters long.

2. Attach sources of zero air and span gas

3. Span Gas is a gas specifically mixed to match the chemical composition of the type

of gas being measured at near full scale of the desired measurement range.

In the case of CO

measurements made with the Teledyne Instruments Model

2

T360U Analyzer it is recommended that you use a gas calibrated to have a CO

content equaling 80% of the range of compositions being measured.

EXAMPLE: If the application is to measure between 0 ppm and 50 ppm, an

appropriate Span Gas would be 40 ppm. If the application is to measure between

0 ppm and 100 ppm, an appropriate Span Gas would be 80 ppm.

Zero Air is similar in chemical composition to the earths atmosphere but scrubbed of

all components that might affect the analyzer’s readings. In the case of CO

measurements this means CO

less than 0.1 ppm of CO2 and Water Vapor.

2

2

Zero Air can be purchased in pressurized canisters or created using a Teledyne

Instruments Model 701 Zero Air Generator in combination with a canister of

indicating soda-lime.

4. Attach an exhaust line to the exhaust outlet port.

The exhaust from the analyser and vent lines should be vented to atmospheric

pressure using maximum of 10 meters of ¼” PTFE tubing.

5. Attach a source of dried air scrubbed of CO2 to the purge inlet port

The source of purge gas should be at least 10 psig and capable of maintaining a flow

of at least 1 liter/min.

2

10

Purge source gas pressure should not exceed 30 psig

6. Once the appropriate pneumatic connections have been made, check all pneumatic

fittings for leaks.

Page 13

5. RELAY ALARM OUTPUTS (STANDARD CONFIGURATION)

There are 4 relay alarm outputs (AL1-AL4) on the rear panel.

AL1 is for system okay,

AL2 is for concentration limit 1 exceeded and

AL3 is for concentration limit 2 exceeded.

AL4 is not used

The relay alarm output AL1 is enabled all the time, whereas the AL2 and AL3 can be

enabled/disabled by going into the diagnostics menu (with 929 password), then factory options, then

turning conc. Alarm Relays ON or OFF.

When the concentration alarm relays are enabled, concentration alarms status is no longer

available through the “Status output” pins. So, either the alarm relays or the status bits could

be used to monitor the concentration alarms but not both at the same time. The default

factory setting is to enable the concentration alarm relays.

The AL1 relay is energized when the system is okay and de-energized when the system has

a fault. The AL2 and AL3 relays energize when the corresponding concentration limits are

exceeded.

6. RELAY ALARM OUTPUTS (AIR PRODUCTS CONFIGURATION)

There are 4 relay alarm outputs (AL1-AL4) on the rear panel.

AL1 is for “system okay”,

AL2 is for “high range status” and

AL3 is for “zero calibration status”

AL4 is not used

The AL1 relay is energized when the system is okay and de-energized when the system has

a fault. The AL2 relay is energized when the high auto-range is in use and and AL3 relays

energize when the the instrument is in zero calibration mode.

7. CONTROL INPUTS (AIR PRODUCTS CONFIGURATION ONLY)

An additional control input is available on this instrument. Control input “C” is used to

select the range for remote calibration. When input C is low, the instrument selects high

range during contact closure calibration.

11

Page 14

This page intentionally left blank.

12

Page 15

T360U SPARE PARTS LIST

13

07273A DCN6707

Ref PN 07460, 05 Apr 2013, 14:24

PARTNUMBER DESCRIPTION

037600000 AKIT, EXP KIT, SODA LIME CH47

037860000 ORING, TEFLON, RETAINING RING, 47MM (KB)

039060100 ASSY, PRESSURE TRANSDUCER

039260501 DETECTOR, CO2, w/BANDPASS FILTER*

040010000 ASSY, FAN REAR PANEL (B/F)

040030300 PCA, PRESS SENSORS w/SW49

040370000 ASSY, CO SCRUBBER

041350000 PCA, RELAY BOARD, CO(KB)

042680000 ASSY, VALVE (SS)

042690000 ASSY, VALVE , 2-WAY, 12V

042890100 ASSY, PUMP CONFIG PLUG, 100-115V/60 HZ

043250100 ASSY, PWR CONF, 100-120V/60HZ, IR

043250300 OPTION, PWR CONF, 220-240V/50HZ, IR

043250400 OPTION, PWR CONF, 220-240V/60HZ, IR

045930000 ASSY, PURGE REGULATOR

050110000 THERMAL PAD, HEATSINK, CENTER

052560000 PCA, OPTO-INTERRUPTER

052830200 ASSY, MOTOR HUB, MR7

055010000 ASSY, MTR WHL HEATER w/THERM, 200W

058021100 PCA, MOTHERBD, GEN 5-ICOP(KB)

066970000 PCA, INTRF. LCD TOUCH SCRN, F/P

067240000 CPU, PC-104, VSX-6154E, ICOP *(KB)

067300000 PCA, AUX-I/O BD, ETHERNET, ANALOG & USB

067300100 PCA, AUX-I/O BOARD, ETHERNET

067300200 PCA, AUX-I/O BOARD, ETHERNET & USB

067900000 LCD MODULE, W/TOUCHSCREEN(KB)

068810000 PCA, LVDS TRANSMITTER BOARD

069500000 PCA, SERIAL & VIDEO INTERFACE BOARD

072150000 ASSY. TOUCHSCREEN CONTROL MODULE

072850000 KIT, T360U MANUAL

074610100 DOM, w/SOFTWARE, STD, T360U*

074620100 DOM, w/SOFTWARE, STD,GFC7000TU,AIR PROD*

077480300 ASSY, PMP, INT, Univ-V, 9 OC

037250000 ASSY, STRIP HEATER

036110400 PCA, SYNC DEMOD, (KB)

033560000 MIRROR, FIELD, 32 PASS, (KB)

033520000 MIRROR, OBJECT, 32 PASS, (KB)

032960000 PCA, SYNC DEMOD, PROGRAM, LONG BENCH

019340600 ASSY, SAMPLE THERMISTOR, SS

016910000 AKIT, EXP KIT, CO CATALYST

016300600 ASSY, SAMPLE FILTER, 47MM, ANG BKT, 5UM

016290000 WINDOW, SAMPLE FILTER, 47MM (KB)

010800000 OUTPUT MIRROR, REPLICATED(KB)

010790000 INPUT MIRROR, REPLICATED(KB)

009840300 ASSY, SHUT-OFF VALVE, (KB)

009690100 AKIT, TFE FLTR ELEM (FL6, 30=1) 47mm

009690000 AKIT, TFE FLTR ELEM (FL6 100=1) 47mm

009560201 GF WHEEL, CO2, (KB)

009550500 ASSY, SOURCE

Page 16

T360U SPARE PARTS LIST

14

07273A DCN6707

Ref PN 07460, 05 Apr 2013, 14:24

009450300 ASSY, ZERO/SPAN VALVES, CO

006110200 ASSY, MOTOR WHEEL HEATER

003291500 ASSY, THERMISTOR, BENCH/WHEEL

003290500 ASSY, THERMISTOR, BENCH

001761300 ASSY, FLOW CTRL, .010, 1/8", SS

001760400 ASSY, FLOW CTL, 800CC, 1/4" CONN-B

000941000 CD, ORIFICE, .013 BLUE/GREEN (KB)

000940600 CD, ORIFICE, .010 BROWN (KB)

077490300 ASSY, PMP, INT, 100V, 9 OC

CN0000073 POWER ENTRY, 120/60 (KB)

CN0000458 PLUG, 12, MC 1.5/12-ST-3.81 (KB)

CN0000520 PLUG, 10, MC 1.5/10-ST-3.81 (KB)

FL0000001 FILTER, SS (KB)

HW0000020 SPRING

HW0000036 TFE TAPE, 1/4" (48 FT/ROLL)

HW0000090 SPRING, SS, LONG

HW0000101 ISOLATOR

HW0000379 SEAL, GFC MOTOR

HW0000453 SUPPORT, CIRCUIT BD, 3/16" ICOP

HW0000685 LATCH, MAGNETIC, FRONT PANEL (KB)

KIT000219 AKIT, 4-20MA CURRENT OUTPUT

OP0000009 WINDOW (KB)

OR0000001 ORING, 2-006VT *(KB)

OR0000002 ORING, 2-023V

OR0000034 ORING, 2-011V FT10

OR0000039 ORING, 2-012V (KB)

OR0000041 ORING, 2-136V

OR0000047 ORING, 2-007V

OR0000077 ORING, 2-018V

OR0000088 ORING, 2-011S, 40 DURO

OR0000094 ORING, 2-228V, 50 DURO VITON(KB)

OR0000096 ORING, 2-532V

OR0000097 ORING, 2-119S

PS0000011 PWR SUPPLY, SW, +5V, +/-15V, 40W (KB)

PS0000024 COVER ENCLOSURE KIT,LPX 40/60 (KB)

PS0000025 PWR SUPPLY, SW, 12V, 40W (KB)

PU0000022 REBUILD KIT, FOR PU20 & 04241 (KB)

SW0000025 SWITCH/CIR BRK, VDE, CE *(KB)

SW0000026 SENSOR, PRES, 0-15, PSIA (OBS)

VA0000014 REGULATOR

WR0000008 POWER CORD, 10A

Page 17

Interconnect List, T360U

0

6

6

6

6

6

6

p

p

p

p

p

p

p

p

p

p

p

p

p

2

2

2

2

2

2

2

2

2

p

p

p

p

p

p

p

p

A

15

07273A DCN6707

Reference: 073640100A

Cable PN Signal Assembly PN J/P Pin Assembly PN J/P Pin

03995 CBL, MOTOR TO RELAY PCA

04023010

04146 CBL, SYNC DEMOD

04671 CBL, MOTHERBOARD TO XMITTER BD (MULTIDROP OPTION)

06737 CBL, I2C TO AUX I/O PCA (ANALOG IN OPTION)

ATX- Motherboard 058021100 J106 1 AUX I/O PCA 067300000 J2 1

06738 CBL, CPU COM to AUX I/O (USB OPTION)

06738 CBL, CPU COM to AUX I/O (MULTIDROP OPTION)

RXD CPU PCA 067240000 COM1 1 Xmitter bd w/Multidrop069500000 J3 1

06739 CBL, CPU ETHERNET TO AUX I/O PCA

ATX- CPU PCA 067240000 LAN 1 AUX I/O PCA 067300100 J2 1

06741 CBL, CPU USB TO LCD INTERFACE PCA

GFC Drive - A Relay PCA 041350000 J6 1 GFC Motor 052380200 P1 1

GFC Drive - B Relay PCA 041350000 J6 2 GFC Motor 052380200 P1 2

Motor Return Relay PCA 041350000 J6 3 GFC Motor 052380200 P1 3

Chassis Gnd Relay PCA 041350000 J6 4 GFC Motor 052380200 P1 4

CBL, I2C, RELAY BOARD TO MOTHERBOARD

I2C Serial Clock Motherboard 058021100 P107 3 Relay PCA 041350000 P3 1

I2C Serial Data Motherboard 058021100 P107 5 Relay PCA 041350000 P3 2

I2C Reset Motherboard 058021100 P107 2 Relay PCA 041350000 P3 4

I2C Shield Motherboard 058021100 P107 6 Relay PCA 041350000 P3 5

DGND Opto Pickup 05032 or 0525

Segmentg Gate Opto Pickup 05032 or 0525

No Connection Opto Pickup 05032 or 0525

DGND Opto Pickup 05032 or 0525

M/R Gate Opto Pickup 05032 or 0525

+5V Opto Pickup 05032 or 0525

GND Motherboard 058021100 P12 2 Xmitter bd w/Multidrop069500000 J4 2

RX0 Motherboard 058021100 P12 14 Xmitter bd w/Multidro

RTS0 Motherboard 058021100 P12 13 Xmitter bd w/Multidro

TX0 Motherboard 058021100 P12 12 Xmitter bd w/Multidro

CTS0 Motherboard 058021100 P12 11 Xmitter bd w/Multidro

RS-GND0 Motherboard 058021100 P12 10 Xmitter bd w/Multidro

RTS1 Motherboard 058021100 P12 8 Xmitter bd w/Multidro

CTS1/485- Motherboard 058021100 P12 6 Xmitter bd w/Multidro

RX1 Motherboard 058021100 P12 9 Xmitter bd w/Multidro

TX1/485+ Motherboard 058021100 P12 7 Xmitter bd w/Multidro

RS-GND1 Motherboard 058021100 P12 5 Xmitter bd w/Multidro

RX1 Motherboard 058021100 P12 9 Xmitter bd w/Multidro

TX1/485+ Motherboard 058021100 P12 7 Xmitter bd w/Multidro

RS-GND1 Motherboard 058021100 P12 5 Xmitter bd w/Multidro

ATX+ Motherboard 058021100 J106 2 AUX I/O PCA 067300000 J2 2

LED0 Motherboard 058021100 J106 3 AUX I/O PCA 067300000 J2 3

ARX+ Motherboard 058021100 J106 4 AUX I/O PCA 067300000 J2 4

ARX- Motherboard 058021100 J106 5 AUX I/O PCA 067300000 J2 5

LED0+ Motherboard 058021100 J106 6 AUX I/O PCA 067300000 J2 6

LED1+ Motherboard 058021100 J106 8 AUX I/O PCA 067300000 J2 8

RXD1 CPU PCA 067240000 COM1 1 AUX I/O PCA 0673000 or -0

DCD1 CPU PCA 067240000 COM1 2 AUX I/O PCA 0673000 or -0

DTR1 CPU PCA 067240000 COM1 3 AUX I/O PCA 0673000 or -0

TXD1 CPU PCA 067240000 COM1 4 AUX I/O PCA 0673000 or -0

DSR1 CPU PCA 067240000 COM1 5 AUX I/O PCA 0673000 or -0

GND CPU PCA 067240000 COM1 6 AUX I/O PCA 0673000 or -0

CTS1 CPU PCA 067240000 COM1 7 AUX I/O PCA 0673000 or -0

RTS1 CPU PCA 067240000 COM1 8 AUX I/O PCA 0673000 or -0

RI1 CPU PCA 067240000 COM1 10 AUX I/O PCA 0673000 or -0

DCD CPU PCA 067240000 COM1 2 Xmitter bd w/Multidro

DTR CPU PCA 067240000 COM1 3 Xmitter bd w/Multidro

TXD CPU PCA 067240000 COM1 4 Xmitter bd w/Multidro

DSR CPU PCA 067240000 COM1 5 Xmitter bd w/Multidro

GND CPU PCA 067240000 COM1 6 Xmitter bd w/Multidro

CTS CPU PCA 067240000 COM1 7 Xmitter bd w/Multidro

RTS CPU PCA 067240000 COM1 8 Xmitter bd w/Multidro

RI CPU PCA 067240000 COM1 10 Xmitter bd w/Multidro

ATX+ CPU PCA 067240000 LAN 2 AUX I/O PCA 067300100 J2 2

LED0 CPU PCA 067240000 LAN 3 AUX I/O PCA 067300100 J2 3

ARX+ CPU PCA 067240000 LAN 4 AUX I/O PCA 067300100 J2 4

ARX- CPU PCA 067240000 LAN 5 AUX I/O PCA 067300100 J2 5

LED0+ CPU PCA 067240000 LAN 6 AUX I/O PCA 067300100 J2 6

LED1 CPU PCA 067240000 LAN 7 AUX I/O PCA 067300100 J2 7

LED1+ CPU PCA 067240000 LAN 8 AUX I/O PCA 067300100 J2 8

GND CPU PCA 067240000 USB 8 LCD Interface PCA 066970000 JP9

LUSBD3+ CPU PCA 067240000 USB 6 LCD Interface PCA 066970000 JP9

LUSBD3- CPU PCA 067240000 USB 4 LCD Interface PCA 066970000 JP9

VCC CPU PCA 067240000 USB 2 LCD Interface PC

FROM TO

J2 1 Sync Demod 032960000 JP4 6

J2 2 Sync Demod 032960000 JP4 5

J2 3 Sync Demod 032960000 JP4 4

J2 4 Sync Demod 032960000 JP4 3

J2 5 Sync Demod 032960000 JP4 2

J2 6 Sync Demod 032960000 JP4 1

069500000 J4 14

069500000 J4 13

069500000 J4 12

069500000 J4 11

069500000 J4 10

069500000 J4 8

069500000 J4 6

069500000 J4 9

069500000 J4 7

069500000 J4 5

069500000 J4 9

069500000 J4 7

069500000 J4 5

J3 1

J3 2

J3 3

J3 4

J3 5

J3 6

J3 7

J3 8

J3 10

069500000 J3 2

069500000 J3 3

069500000 J3 4

069500000 J3 5

069500000 J3 6

069500000 J3 7

069500000 J3 8

069500000 J3 10

066970000 JP9

Page 18

Interconnect List, T360U

A

A

A

A

A

A

A

A

9

9

9

9

9

y

A

y

A

g

g

g

g

g

g

g

p

p

p

p

p

r

r

16

07273A DCN6707

Reference: 073640100A

Cable PN Signal Assembly PN J/P Pin Assembly PN J/P Pin

06746 CBL, MB TO 06154 CPU

06809 CBL ASSY, DC POWER TO MOTHERBOARD

06810 CBL, DC POWER & SIGNAL DISTRIBUTION

06811 CBL ASSY, BENCH HEATER

Wheel Heater Relay PCA 041350000 P3 1 Wheel Heater 055010000 P1 1

06812 CBL, BLOWER HTR CONFIG

06813 CBL, MOTHERBOARD TO THERMISTORS

GND Motherboard 058021100 P12 2 Shield

RX0 Motherboard 058021100 P12 14 CPU PCA 067240000 COM1 1

RTS0 Motherboard 058021100 P12 13 CPU PCA 067240000 COM1 8

TX0 Motherboard 058021100 P12 12 CPU PCA 067240000 COM1 4

CTS0 Motherboard 058021100 P12 11 CPU PCA 067240000 COM1 7

RS-GND0 Motherboard 058021100 P12 10 CPU PCA 067240000 COM1 6

RTS1 Motherboard 058021100 P12 8 CPU PCA 067240000 COM2 8

CTS1/485- Motherboard 058021100 P12 6 CPU PCA 067240000 COM2 7

RX1 Motherboard 058021100 P12 9 CPU PCA 067240000 COM2 1

TX1/485+ Motherboard 058021100 P12 7 CPU PCA 067240000 COM2 4

RS-GND1 Motherboard 058021100 P12 5 CPU PCA 067240000 COM2 6

RX1 Motherboard 058021100 P12 9 CPU PCA 067240000 485 1

TX1/485+ Motherboard 058021100 P12 7 CPU PCA 067240000 485 2

RS-GND1 Motherboard 058021100 P12 5 CPU PCA 067240000 485 3

DGND Relay PCA 041350000 J14 1 Motherboard 058021100 J15 1

+5V Relay PCA 041350000 J14 2 Motherboard 058021100 J15 2

AGND Relay PCA 041350000 J14 3 Motherboard 058021100 J15 3

+15V Relay PCA 041350000 J14 4 Motherboard 058021100 J15 4

AGND Relay PCA 041350000 J14 5 Motherboard 058021100 J15 5

-15V Relay PCA 041350000 J14 6 Motherboard 058021100 J15 6

+12V RET Relay PCA 041350000 J14 7 Motherboard 058021100 J15 7

+12V Relay PCA 041350000 J14 8 Motherboard 058021100 J15 8

Chassis Gnd Relay PCA 041350000 J14 10 Motherboard 058021100 J15 9

+12V RET Blower Fan 1 058790000 1 Relay PCA 041350000 J12 7

+12V Blower Fan 1 058790000 2 Relay PCA 041350000 J12 8

+12V RET Blower Fan 2 058790000 1 Relay PCA 041350000 J12 7

+12V Blower Fan 2 058790000 2 Relay PCA 041350000 J12 8

+5V LCD Interface PC

DGND LCD Interface PC

+5V LCD Interface PC

SDA LCD Interface PC

SCL LCD Interface PC

DGND LCD Interface PC

Shield LCD Interface PC

+12V Ret Fan 040010000 P1 1 Relay PCA 041350000 J11 7

+12V Fan 040010000 P1 2 Relay PCA 041350000 J11 8

AGND Flow Module 0400303 or -0

+15V Flow Module 0400303 or -0

Cell Pressure Flow Module 0400303 or -0

Pump Vaccum Flow Module 0400303 or -0

Sample Flow Flow Module 0400303 or -0

Measure Sync Demod 032960000 J3 1 Motherboard 058021100 J109 4

PD Temp Sync Demod 032960000 J3 2 Motherboard 058021100 J109 1

Reference Sync Demod 032960000 J3 5 Motherboard 058021100 J109 3

AGND Sync Demod 032960000 J3 6 Shield

Dark Switch Sync Demod 032960000 J3 4 Motherboard 058021100 J108 16

Sync Error Sync Demod 032960000 J3 7 Motherboard 058021100 J108 4

Etest Sync Demod 032960000 J3 8 Motherboard 058021100 J108 8

AC Return Relay PCA 041350000 P3 4 Wheel Heater 055010000 P1 2

Bench Htr, 115V Rela

Bench Htr, 230V Rela

AC Return Relay PCA 041350000 P3 4 Bench Htr 037250000 P1 3

Chassis Gnd Relay PCA 041350000 P3 5

Config Jumper Oven Htr 1 058810000 HTR1 1 Blower Htr Confi

Config Jumper Oven Htr 1 058810000 HTR1 2 Blower Htr Confi

Config Jumper Oven Htr 2 058810000 HTR2 1 Blower Htr Confi

Config Jumper Oven Htr 2 058810000 HTR2 2 Blower Htr Confi

Config Jumper Blower P4 1 Blower Htr Confi

Config Jumper Blower P4 2 Blower Htr Confi

Shield Blower Htr Confi

+5V Ref Motherboard 058021100 J27 6 Bench Temp Snsr 003290500 P1 1

Bench Temp Motherboard 058021100 J27 13 Bench Tem

+5V Ref Motherboard 058021100 J27 5 Wheel Tem

Wheel Temp Motherboard 058021100 J27 12 Wheel Tem

+5V ref Motherboard 058021100 J27 1 Shield

+5V Ref Motherboard 058021100 J27 7 Sam

Sample Temp Motherboard 058021100 J27 14 Sam

LCD Interface PC

Shield Motherboard 058021100 J109 9

PC

PC

Motherboard 058021100 J27 2 Oven Thermisto

Motherboard 058021100 J27 9 Oven Thermisto

FROM TO

066970000 J14 1 Relay PCA 041350000 J12 2

066970000 J14 2 Relay PCA 041350000 J11 1

066970000 J14 3 Relay PCA 041350000 J11 2

066970000 J14 5 Motherboard 058021100 J106 2

066970000 J14 6 Motherboard 058021100 J106 6

066970000 J14 7 Motherboard 058021100 J106 1

066970000 J14 8 Relay PCA 041350000 J12 1

066970000 J14 10

J4 3 Relay PCA 041350000 J11 3

J4 6 Relay PCA 041350000 J11 4

J4 4 Motherboard 058021100 J109 5

J4 2 Motherboard 058021100 J109 6

J4 5 Motherboard 058021100 J109 2

041350000 P3 2 Bench Htr 037250000 P1 1

041350000 P3 3 Bench Htr 037250000 P1 2

Plug059180000 PLUG 1

Plug059180000 PLUG 2

Plug059180000 PLUG 4

Plug059180000 PLUG 5

Plug059180000 PLUG 4

Plug059180000 PLUG 2

Plug059180000 PLUG 3

Snsr 003290500 P1 2

Snsr 003291500 P1 1

Snsr 003291500 P1 2

le Temp Snsr019340600 P1 1

le Temp Snsr019340600 P1 2

058800000 P1 1

058800000 P1 2

Page 19

Interconnect List, T360U

A

A

17

07273A DCN6707

Reference: 073640100A

Cable PN Signal Assembly PN J/P Pin Assembly PN J/P Pin

06814 CBL ASSY, SYNC DEMOD , DC POWER

DGND Relay PCA 041350000 J15 1 Sync Demod 032960000 J2 1

+5V Relay PCA 041350000 J15 2 Sync Demod 032960000 J2 2

AGND Relay PCA 041350000 J15 3 Sync Demod 032960000 J2 3

+15V Relay PCA 041350000 J15 4 Sync Demod 032960000 J2 4

AGND Relay PCA 041350000 J15 5 Sync Demod 032960000 J2 5

-15V Relay PCA 041350000 J15 6 Sync Demod 032960000 J2 6

+12V ret Relay PCA 041350000 J15 7 Blower Fan 058780000 J1 1

+12V Relay PCA 041350000 J15 8 Blower Fan 058780000 J1 2

06815 CBL ASSY, AC POWER

AC Line Power Entry CN0000073 L Power Switch SW0000025 L

AC Neutral Power Entry CN0000073 N Power Switch SW0000025 N

Power Grnd Power Entry CN0000073 Shield

Power Grnd Power Entry CN0000073 Chassis

AC Line Switched Power Switch SW0000025 L PS2 (+12) 068020000 SK2 1

AC Neu Switched Power Switch SW0000025 N PS2 (+12) 068020000 SK2 3

Power Grnd Power Entry CN0000073 PS2 (+12) 068020000 SK2 2

AC Line Switched Power Switch SW0000025 L PS1 (+5, ±15) 068010000 SK2 1

AC Neu Switched Power Switch SW0000025 N PS1 (+5, ±15) 068010000 SK2 3

Power Grnd Power Entry CN0000073 PS1 (+5, ±15) 068010000 SK2 2

AC Line Switched Power Switch SW0000025 L Relay 041350000 J1 1

AC Neu Switched Power Switch SW0000025 N Relay 041350000 J1 3

Power Grnd Power Entry CN0000073 Relay 041350000 J1 2

06816 CBL ASSY, DC POWER

+15 PS1 068010000 SK1 6 Relay PCA 041350000 J13 4

+5 PS1 068010000 SK1 1 Relay PCA 041350000 J13 3

DGND PS1 068010000 SK1 3 Relay PCA 041350000 J13 1

AGND PS1 068010000 SK1 4 Relay PCA 041350000 J13 5

-15 PS1 068010000 SK1 5 Relay PCA 041350000 J13 6

+12 PS2 068020000 SK1 1 Relay PCA 041350000 J13 8

+12 RET PS2 068020000 SK1 3 Relay PCA 041350000 J13 7

06817 CBL, RELAY BD TO SOURCE

IR Source Drv Relay PCA 041350000 J16 1 IR Source 009550500 P1 1

IR Source Drv Relay PCA 041350000 J16 2 IR Source 009550500 P1 2

06818 CBL ASSY, 12V VALVE CBLS

+12 Relay PCA 041350000 J7 6 Zero/Span Vlv 009450500 P1 1

Zero/Span Drv Relay PCA 041350000 J7 8 Zero/Span Vlv 009450500 P1 2

+12 Relay PCA 041350000 J7 2 Samp/Cal Vlv 009450400 P1 1

Samp/Cal Drv Relay PCA 041350000 J7 4 Samp/Cal Vlv 009450400 P1 2

+12 Relay PCA 041350000 J7 1 Shutoff Valve 009450500 P1 1

Shutoff Vlv Relay PCA 041350000 J7 3 Shutoff Valve 009450500 P1 2

+12 Relay PCA 041350000 J7 5 Autoref Valve 009450500 P1 1

Aref Valve Relay PCA 041350000 J7 7 Autoref Valve 009450500 P1 2

WR256 CBL, TRANSMITTER TO LCD INTERFACE PCA

LCD Interface PC

FROM TO

066970000 J15 Transmitter PC

068810000 J1

Page 20

18

07273A DCN6707

This page intentionally left blank.

Page 21

07273A DCN6707

19

Loading...

Loading...