Teledyne T201 User Manual

MANUAL ADDENDUM

MODEL T201

AMMONIA ANALYZER

(For use with the T200 Operators Manual, P/N 06858)

TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

(TELEDYNE-API)

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

TOLL-FREE: 800-324-5190

FAX: 858-657-9816

TEL: 858-657-9800

E-MAIL: api-sales@teledyne.com

WEB SITE: www.teledyne-api.com

Copyright 2011-2013

Teledyne Advanced Pollution Instrumentation

07271B DCN6646

05 February 2013

ABOUT THIS MANUAL

This addendum is to be used in conjunction with the T200 NOx Analyzer

manual, p/n 06858; for operating the T201 analyzer; it includes

document(s) as listed below.

Part No. Name/Description

07356 T201 Spare Parts List (in Section 7.0)

Note: Please refer to our Website or Sales for more recent updates.

Note

We recommend that this manual and the T200 manual be read in their

entirety before any attempt is made to operate the instrument.

REVISION HISTORY

T201 Addendum, PN 07271

Date To Rev DCN Change Summary

2013 Feb 05 B 6646 Correct CE value

2012 May 07 A 5910 Initial Release

07271B DCN6646 i

This page intentionally left blank.

ii 07271B DCN6646

Teledyne API Model T201 NH3 Analyzer Operator Manual T201 Ammonia Analyzer

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose

of avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol, and are

placed throughout this manual; the safety symbols are also located inside the

instrument. It is imperative that you pay close attention to these messages, the

descriptions of which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message for

specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without

protection or proper tools could result in damage to the part(s) and/or the

instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central

safety grounding point for the instrument.

CAUTION

This instrument should only be used for the purpose and in the manner described

in this manual. If you use this instrument in a manner other than that for which it

was intended, unpredictable behavior could ensue with possible hazardous

consequences

Technical Assistance regarding the use and maintenance of this instrument or any other

Teledyne API product can be obtained by contacting Teledyne API’s Technical Support

Department:

or by accessing various service options on our website at http://www.teledyne-api.com/

.

NEVER use any gas analyzer to sample combustible gas(es)!

Note

Telephone: 800-324-5190

Email: sda_techsupport@teledyne.com

07271B DCN6646 iii

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du

présent manuel dans le but d’éviter des blessures corporelles ou

d’endommager les instruments. Veuillez lire attentivement ces consignes.

Chaque consigne de sécurité est représentée par un pictogramme d’alerte

de sécurité; ces pictogrammes se retrouvent dans ce manuel et à l’intérieur

des instruments. Les symboles correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans

protection ou sans les outils appropriés pourrait entraîner des dommages

aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce symbole

doivent être effectuées uniquement par du personnel de maintenance

qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le

point central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière décrite

dans ce manuel. Si vous utilisez cet instrument d’une autre manière que

celle pour laquelle il a été prévu, l’instrument pourrait se comporter de

façon imprévisible et entraîner des conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz

combustibles!

iv 07271B DCN6646

TABLE OF CONTENTS

MODEL T201 AMMONIA ANALYZER.............................................................I

CONSIGNES DE SÉCURITÉ.........................................................................IV

1.0 T201 AMMONIA ANALYZER.................................................................7

1.1 Theory of Operation...................................................................................................... 10

1.1.1 Minimizing PMT Drift.......................................................................................... 11

1.1.2

1.2

1.3 Sample Filtration........................................................................................................... 12

1.4 T201 Analyzer Specifications.......................................................................................13

2.0 CALIBRATION PROCEDURE .............................................................15

2.1 Zeroing the Analyzer .................................................................................................... 16

2.2 Spanning the Analyzer with Nitric Oxide Gas ............................................................. 17

2.3 Spanning the Analyzer with Ammonia Gas.................................................................. 19

3.0 CONFIGURABLE ANALOG OUTPUT OVERVIEW ...........................25

4.0 MAINTENANCE SCHEDULE...............................................................27

4.1 M501 NH3 Maintenance............................................................................................... 27

4.2 Replacing the Catalytic Cartridge................................................................................. 28

4.3 Replacing the Thermocouple........................................................................................ 29

4.4 AutoZero Flow Check................................................................................................... 31

5.0 ALARMS AND CAUTIONS ..................................................................33

5.1 Alarm ............................................................................................................................ 33

5.2 Caution.......................................................................................................................... 33

6.0 CALCULATING MOLY CONVERTER EFFICIENCIES ......................35

6.1 Purpose.......................................................................................................................... 35

6.2 Tools ............................................................................................................................. 35

6.3 Parts............................................................................................................................... 35

6.4 Procedure ...................................................................................................................... 35

7.0 T201 SPARE PARTS LIST...................................................................39

Purging the Reaction Cell..................................................................................... 11

Special Considerations For Ammonia Measurement ................................................... 12

LIST OF FIGURES

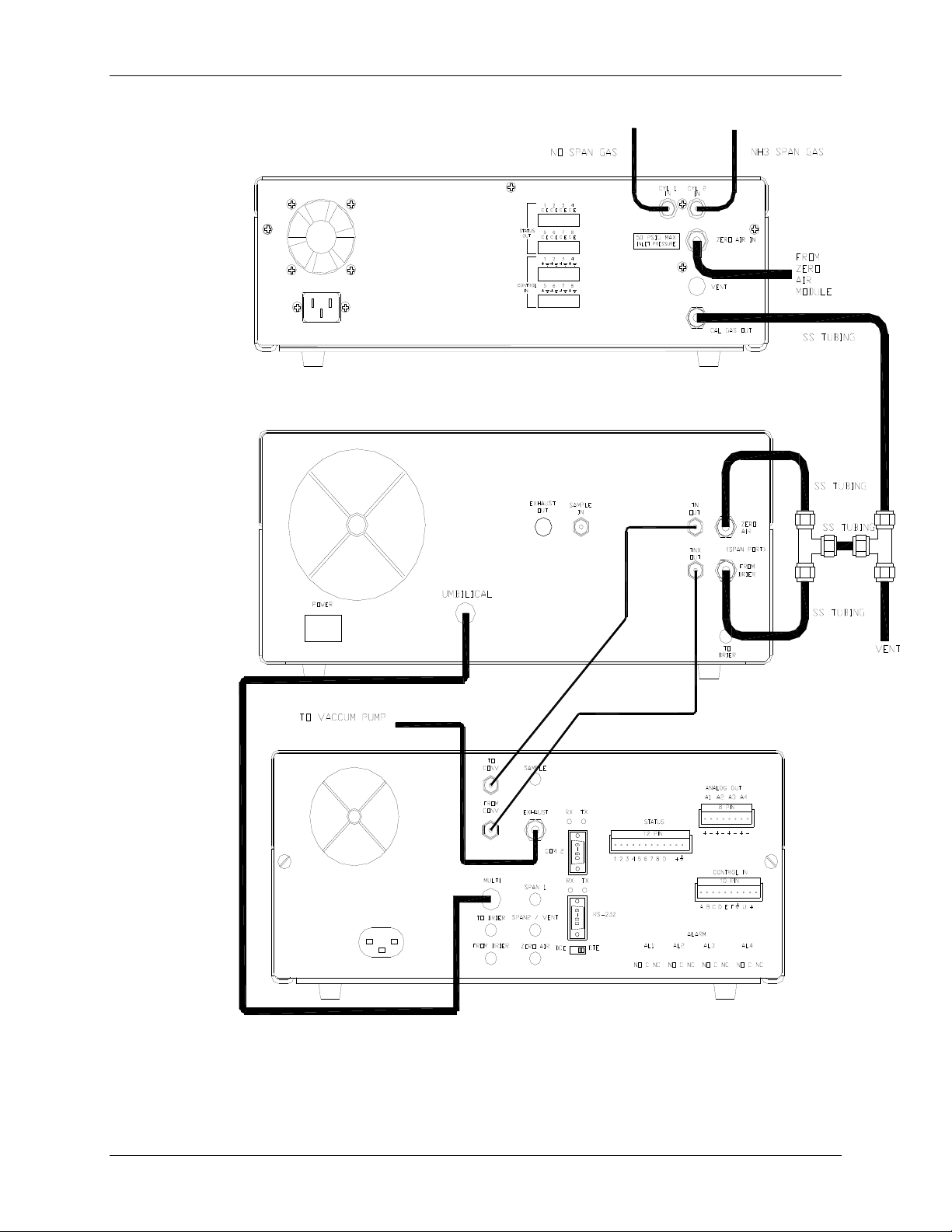

Figure 1-1. T201 Pneumatic Connection Diagram w/External Calibrator Option (ECO)..8

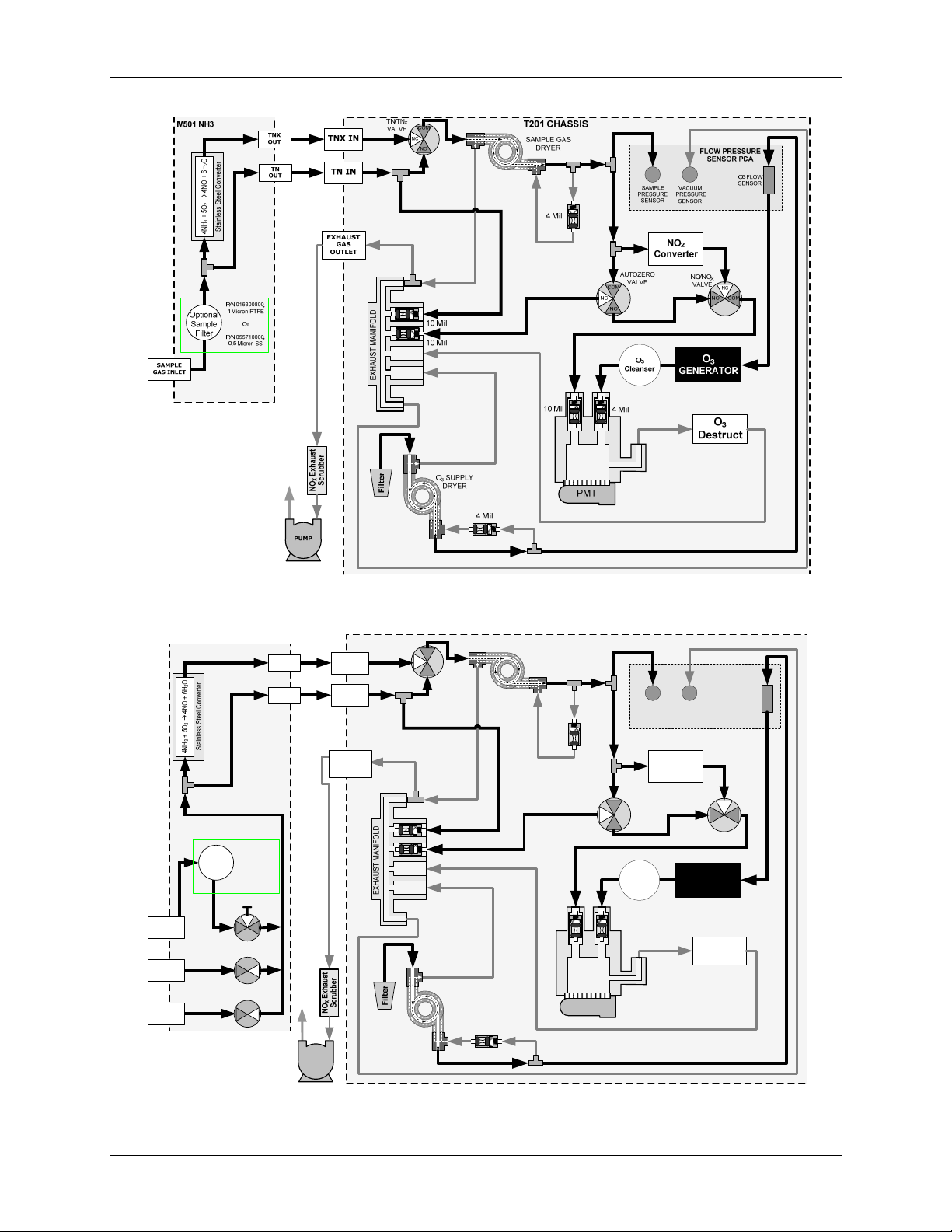

Figure 1-2. T201 and M501 NH

Figure 1-3. T201 and M501 NH3 with Zero and Span Valve Options Pneumatic Flow....9

Figure 3-1. Analog Output Connector............................................................................25

Figure 4-1. Catalytic Cartridge ......................................................................................28

Figure 4-2. Thermocouple Location...............................................................................29

Pneumatic Flow...........................................................9

3

LIST OF TABLES

Table 1-1. T201 Operating Specifications.....................................................................13

Table 2-1. Zero Calibration Procedure – Zero Gas through the SAMPLE Port.............16

Table 2-2. Zero Calibration Procedure - Zero

Table 2-3. NO Calibration Procedure – NO Gas through the SAMPLE Port

07271B DCN6646 v

Gas through ZERO Port.........................17

.................18

Table 2-4. NO Calibration Procedure - NO Gas through the SPAN Port....................... 19

Table 2-5. Confirming Ammonia Converter Efficiency................................................... 21

Table 2-6. NH3 Calibration Procedure – NH3 Gas through the SAMPLE Port...............22

Table 2-7. NH3 Calibration Procedure – NH3 Gas through the SPAN Port....................23

Table 3-1. Analog Output Data Default Settings ...........................................................25

Table 3-2. Analog Output Pin-Outs

Table 4-1. Preventative Maintenance Schedule

...............................................................................26

............................................................27

Table 4-2. M501 NH3 Converter Rebuild Parts List.......................................................28

Table 4-3. Flow Check ..................................................................................................31

vi 07271B DCN6646

1.0 T201 AMMONIA ANALYZER

This manual is to be used in conjunction with the T200 NOx Analyzer

manual, p/n 06858 supplied with this instrument. It is important that you

familiarize yourself with the workings of the NOx analyzer before

proceeding with NH3 measurements.

The T201 ammonia analyzer consists of a modified T200 nitrogen oxide

analyzer and an M501 NH3 ammonia converter. The analyzer measures

the following individual gas concentrations: TNx (NH

(NO and NO2) and NO in the sample gas.

and NOx), NOx

3

Note

The

The

ammonia concentration is calculated by subtracting the NOX

reading from the TNx measurement.

nitrogen dioxide concentration is calculated by subtracting the NO

reading from the NO

measurement.

x

The instrument comes in three pneumatic configurations:

The T201 with External Calibrator Option (ECO) is shown in

Figure 1-1.

The basic system is shown in Figure 1-2.

The T201 with Zero/Span valves is shown in Figure 1-3.

For a T201 analyzer with Zero/Span option you must connect the umbilical

cord P/N 02255 between the analyzer and the external M501 NH3 converter

assembly.

If the analyzer is purchased without the Zero/Span option then the zero and

span calibration gases must be individually applied to the Sample port.

Remember, the gases must be clean/dry and supplied at ambient pressure.

CAUTION

Do not pressurize the Sample/Span/Zero port above ambient

07271B DCN6646 7

T201 Ammonia Analyzer Teledyne API Model T201 NH3 Analyzer Operator Manual

Figure 1-1. T201 Pneumatic Connection Diagram w/External Calibrator Option (ECO)

8 07271B DCN6646

Teledyne API Model T201 NH3 Analyzer Operator Manual T201 Ammonia Analyzer

SAMPLE

GAS

INLET

ZERO AIR

INLET

SPAN GAS

INLET

M501NH3

Optional

Sample

Filter

P/N 016300800,

1 Micron PTFE

Or

P/N 055710000,

0.5 Micron SS

Sample

NC

COM

NO

Zero Gas

NC

Span Gas

NC

Figure 1-2. T201 and M501 NH3 Pneumatic Flow

Valve

Valve

Valve

TN/TN

X

VALVE

TNX

OUT

OUT

TNX IN

TN

TN IN

EXHAUST

GAS

OUTLET

COM

NC

NO

10 Mil

10 Mil

Gas

O3SUPPLY

DRYER

4 Mil

T201 CHASSIS

SAMPLE GAS

DRYER

4 Mil

10 Mil

PMT

NC

COM

NO

4 Mil

SAMPLE

PRESSURE

SENSOR

AUTOZERO

VALVE

O

3

Cleanser

VACUUM

PRESSURE

SENSOR

NO

2

Converter

GENERATOR

FLOW PRESSURE

SENSOR PCA

NO/NO

X

VALVE

NC

COM

NO

O

3

O

3

Destruct

O3 FLOW

SENSOR

PUMP

Figure 1-3. T201 and M501 NH3 with Zero and Span Valve Options Pneumatic Flow

07271B DCN6646 9

T201 Ammonia Analyzer Teledyne API Model T201 NH3 Analyzer Operator Manual

1.1 THEORY OF OPERATION

Note

The Teledyne-API Model T201 analyzer measures ammonia by oxidizing

it to nitric oxide by the following reaction:

4NH3 + 5O2 4NO + 6H2O

The resulting nitric oxide is then measured by the chemiluminescent

reaction with ozone. Consult Section 10.1 in the T200 manual (provided

with this instrument) for more details on the nitric oxide measurement.

The analyzer uses two converters to oxidize the different sample gases. A

high temperature catalytic converter, the M501 NH3, converts NH3 and

NOx into NO creating the TNx channel. A second converter, housed inside

the T201 analyzer and consisting of heated molybdenum, converts all of

the NOx in the sample to NO producing the NOx channel. The nitric oxide

channel is measured while bypassing both the M501 NH3 and

molybdenum converter. A Nafion® drier operated in reflux mode, is

installed prior to the molybdenum converter and the AutoZero valve. The

drier removes ammonia and water from the switched stream. The

ammonia would have otherwise been converted by the molybdenum and

registered as NOx. This location provides the drier with continuous flow,

thereby allowing it to stabilize faster.

Due to the Nafion® drier, the analyzer has a maximum ammonia range of

2.0 PPM.

Note

The calculated gas concentrations, ammonia and nitrogen dioxide, are

computed from the differences between the measured channels, as

outlined in the following equations:

NO (Nitric Oxide) Concentration = Measured

(Total Nitrogen) Concentration = Measured (NH3 + NO2 + NO)

TN

x

(Total Nitrogen – Ammonia) Concentration = Measured

NO

x

(NO

+ NO)

2

(Ammonia) Concentration = Calculated as follows:

NH

3

[(TNx - NOx) / (NH

(Nitrogen Dioxide) Concentration = Calculated as follows:

NO

2

[(NOx – NO) / (NO

nitrogen dioxide efficiency factor (NO2_CE_FACTOR1) must be

The

calculated by conducting a GPT (gas phase titration) as described in Section

8.3.3 of the T200 manual and Section 6.0 of this manual. This value gives a

good indica

into nitric oxide. In a properly functioning analyzer the value should be close

to 1.0. It is recommended that the molybdenum efficiency be checked every

three months.

tion of how well the molybdenum is converting nitrogen dioxide

_CE_FACTOR1)]

3

_CE_FACTOR1)]

2

10 07271B DCN6646

Teledyne API Model T201 NH3 Analyzer Operator Manual T201 Ammonia Analyzer

The ammonia converter efficiency factor (NH3_CE_FACTOR1) is

discussed in more detail in Section 2.3 of this manual. The conversion

efficiency of the M501 NH3 should be checked prior to starting long term

tests. Both efficiency factors can be accessed through the analyzer VARS

MENU.

The actual formula for computation of the gas concentrations is more

complicated than the above equations, as it includes sample, reaction cell

pressure changes and averaging the PMT signal. Then the zero offset and

slopes are applied to the separate channels (TN

, NOx, NO) to determine

x

the concentrations. Concentration compensation occurs while the variable

TP_FACTOR under the VARS MENU is switched ON. Otherwise the

displayed concentration is uncompensated. It is recommended that

the variable TP_FACTOR remain on at all times.

1.1.1 Minimizing PMT Drift

In order to account for PMT drift in the analyzer, the AutoZero valve

switches once a minute allowing the analyzer to read zero background.

The AutoZero valve directs the sample gas stream to completely bypass

the reaction cell, while simultaneously filling the reaction cell with Ozone

for dark noise measurement. This is then subtracted as a measurement

offset from the raw PMT concentration signal. This process improves zero

baseline stability by minimizing the effect of PMT sensor drift.

1.1.2 Purging the Reaction Cell

As with many chemical reactions the conversion of ammonia in the

presence of other oxides of nitrogen is complicated. It is important to note

that the valve DWELL time for an AZERO measurement has a default

setting of 8 seconds. Shortening this value may not allow enough time to

properly purge the reaction cell of excess nitric oxide from the previous

measurements.

In the molybdenum converter operating at 315

reactions are taking place:

Mo + NO2 MoO3 + NO ~100% Efficiency

The M501 NH3 ammonia converter operates at 825oC. At this high

temperature, several reactions occur:

NO NO Loss = ~ 3%

NO

NO Efficiency = ~97%

2

NH

NO Efficiency = ~97%

3

NH

NO2 Efficiency = ~5%

3

o

C the following significant

07271B DCN6646 11

T201 Ammonia Analyzer Teledyne API Model T201 NH3 Analyzer Operator Manual

As can be seen from the above reactions, the calculation of the ammonia

concentration and overall calibration of the instrument must be done

carefully, if accurate ammonia concentrations are to be measured.

1.2 SPECIAL CONSIDERATIONS FOR AMMONIA MEASUREMENT

Ammonia is a difficult gas to measure due to its chemical characteristics.

The gas tends to adsorb onto surfaces and diffuse into many materials. The

following precautions should be observed when designing ammonia

sampling systems and connecting them to the T201 analyzer:

Do NOT use copper tubing or fittings designed for household plumbing.

Use ONLY Chromatography grade (cleaned, passivated) stainless steel

tubing.

Use ONLY glass for sample inlet manifold.

ALWAYS keep the tubing from the M702SS calibrator to th e analyzer

as short as possible. USE stainless steel tubing throughout, especially

from the ammonia calibration bottle to the calibrator.

If possible HEAT the sample line and DRY the sample gas.

Sample filters will cause response delays on both the rise and fall of the

sample signal.

These rules apply also to your calibrator’s internal plumbing. It is highly

recommended that you use a M702SS calibrator in conjunction with the

T201. The calibrator has stainless steel plumbing throughout. The T700

calibrator contains Teflon tubing and internal MFC’s that can be affected by

the ammonia gas, therefore, the T700 calibrator is not recommend for use

with the T201 analyzer. It is important to keep the sampling system well

maintained.

1.3 SAMPLE FILTRATION

The instrument can be provided with an optional stainless steel sample

filter P/N 05571. For minimum response time operation, the instrument

should be supplied with clean sample gas at ambient pressure.

An additional filter resides in the T201 pneumatic pathway. The filter is a

¼” diameter stainless steel sintered filter used to protect the reaction cell

flow control orifice from plugging. This filter will plug rapidly if

contaminated sample gas is not filtered before entering the analyzer.

Note

12 07271B DCN6646

In situations where the sample gas is known to be contaminated with

particulate material, it is advisably to add extra filtration. However, it must be

noted that the response time is directly extended through filter additions.

Loading...

Loading...