Teledyne T200 User Manual

User Manual

Toll-free Phone:

+ 800-324-5190

Phone:

+1 858-657-9800

Fax:

+1 858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

Model T200

NO/NO2/NOX Analyzer

with NumaView™ software

ELEDYNE API (TAPI)

© T

9970 CARROLL CANYON ROAD

SAN DIEGO, CALIFORNIA 92131-1106

USA

Copyright 2019

Teledyne API

083730200A DCN7962

11 March 2019

NOTICE OF COPYRIGHT

© 2019 Teledyne API (TAPI). All rights reserved.

TRADEMARKS

All trademarks, registered trademarks, brand names or product names appearing in

this document are the property of their respective owners and are used herein for

identification purposes only.

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software i

SAFETY MESSAGES

Do Not Touch: Touching some parts of the instrument without

Important safety messages are provided throughout this manual for the purpose of

avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol and is placed

throughout this manual; the safety symbols are also located inside the instrument. It

is imperative that you pay close attention to these messages, the descriptions of

which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message

for specific information.

CAUTION: Hot Surface Warning

protection or proper tools could result in damage to the part(s)

and/or the instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the

central safety grounding point for the instrument.

CAUTION

This instrument should only be used for the purpose and in the

manner described in this manual. If you use this instrument in a

manner other than that for which it was intended, unpredictable

behavior could ensue with possible hazardous consequences.

NEVER use any gas analyzer to sample combustible gas(es)!

For Technical Assistance regarding the use and maintenance of this instrument or

any other Teledyne API product, contact Teledyne API’s Technical Support

Department:

Telephone: +1 800-324-5190

Email: api-techsupport@teledyne.com

or access any of the service options on our website at http://www.teledyne-api.com/

ii Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la

Ne pas toucher : Toucher à certaines parties de l’instrument

Pictogramme « technicien » : Toutes les opérations portant ce

Mise à la terre : Ce symbole à l’intérieur de l’instrument

Des consignes de sécurité importantes sont fournies tout au long du présent manuel

dans le but d’éviter des blessures corporelles ou d’endommager les instruments.

Veuillez lire attentivement ces consignes. Chaque consigne de sécurité est

représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se retrouvent

dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux

consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

consigne complémentaire pour des renseignements

spécifiques

MISE EN GARDE : Surface chaude

sans protection ou sans les outils appropriés pourrait entraîner

des dommages aux pièces ou à l’instrument.

symbole doivent être effectuées uniquement par du personnel

de maintenance qualifié.

détermine le point central de la mise à la terre sécuritaire de

l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la

manière décrite dans ce manuel. Si vous utilisez cet instrument

d’une autre manière que celle pour laquelle il a été prévu,

l’instrument pourrait se comporter de façon imprévisible et

NE JAMAIS utiliser un analyseur de gaz pour échantillonner

entraîner des conséquences dangereuses.

des gaz combustibles!

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software iii

WARRANTY

Failure to comply with proper anti

handling and packing instructions and Return Merchandise

Authorization (RMA) procedures when returning parts for repair or

calibration may void your warranty. For anti

packing instructions please refer to

ESD, PN 04786, in its

API’s Customer Service”

from our website at

can also be found on our website

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should

equipment failure occur, TAPI assures its customers that prompt service and support

will be available. (For the instrument-specific warranty period, please refer to the

“Limited Warranty” section in the Terms and Conditions of Sale on our website at

the following link: http://www.teledyne-api.com/terms_and_conditions.asp).

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready

to provide on-site or in-plant service at reasonable rates similar to those of other

manufacturers in the industry. All maintenance and the first level of field

troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be

repaired to the extent and according to the current terms and conditions of the

respective equipment manufacturer’s warranty.

PRODUCT RETURN

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center. After

the repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com/terms_and_conditions.asp

CAUTION – Avoid Warranty Invalidation

http://www.teledyne-api.com. RMA procedures

iv Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

-Electro-Static Discharge (ESD)

-ESD handling and

the manual, Fundamentals of

“Packing Components for Return to Teledyne

section. The manual can be downloaded

.

ABOUT THIS MANUAL

COULD DAMAGE INSTRUMENT AND VOID WARRANTY

IMPACT ON READINGS OR DATA

Provides information pertinent to the proper care,

This manual is comprised of multiple documents, in PDF format, as listed below.

Part No. Name/Description

083730200 T200 NO/NO2/NOx Analyzer with NumaView™ software (this

n/a MODBUS Registers, Appendix A

069110000 T200 Interconnect Diagram, Appendix B

Support manuals, such as electrostatic discharge (ESD) prevention, are available on

the TAPI website http://www.teledyne-api.com

manual)

.

Note

CONVENTIONS USED

In addition to the safety symbols as presented in the Safety Messages page, this

manual provides special notices related to the careful and effective use of the

instrument and related, pertinent information.

ATTENTION

Important

Note

We recommend that all users read this manual in its entirety

before operating the instrument.

This special notice provides information to avoid damage

to your instrument and possibly invalidate the warranty.

Provides information about that which could either affect

accuracy of instrument readings or cause loss of data.

operation or maintenance of the instrument or its parts.

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software v

TABLE OF CONTENTS

Safety Messages ...................................................................................................................................... ii

Warranty .................................................................................................................................................. iv

Table of Contents .................................................................................................................................... vi

List of Figures .......................................................................................................................................... xi

List of Tables .......................................................................................................................................... xiii

1. INTRODUCTION, SPECIFICATIONS, APPROVALS, & COMPLIANCE ............................................... 15

Specifications .................................................................................................................................. 15

EPA Designation ............................................................................................................................. 16

Safety .............................................................................................................................................. 16

EMC ................................................................................................................................................ 16

Other Certifications ......................................................................................................................... 17

2. GETTING STARTED .............................................................................................................................. 18

Unpacking ....................................................................................................................................... 18

Ventilation Clearance ........................................................................................................... 19

Instrument Layout ........................................................................................................................... 20

Front Panel ........................................................................................................................... 20

Rear Panel ........................................................................................................................... 21

Internal Chassis ................................................................................................................... 23

Connections and Startup ................................................................................................................. 25

Electrical Connections ......................................................................................................... 25

Connecting Power ................................................................................................. 25

Connecting Analog Inputs (Option) ....................................................................... 26

Connecting Analog Outputs ................................................................................... 27

Current Loop Analog Outputs (Option 41) Setup .................................................. 28

Connecting the Status Outputs (Digital Outputs) .................................................. 29

Connecting the Control Inputs (Digital Inputs) ....................................................... 30

Concentration Alarm Relay (Option 61) ................................................................ 31

Connecting Communications Interfaces ................................................................ 31

Pneumatic Connections ....................................................................................................... 37

Critical Tubing, Pressure, Venting and Exhaust Requirements ............................ 38

Basic Connections from Calibrator ........................................................................ 39

Connections w/Ambient Zero/Ambient Span (Z/S) Valves (OPT 50A) ................. 40

Connections w/Ambient Zero/Pressurized Span Valves (OPT 50B)..................... 42

Zero Scrubber and Internal Span Source (IZS) (OPT 50G) .................................. 44

Gas Conditioner Options ....................................................................................... 47

Pneumatic Flow Diagrams ................................................................................................... 47

Startup, Functional Checks and Calibration ........................................................................ 52

Startup ................................................................................................................... 53

Alerts: Warnings and Other Messages .................................................................. 54

Functional Checks ................................................................................................. 55

Calibration.............................................................................................................. 55

Menu Overview ............................................................................................................................... 56

Home Page .......................................................................................................................... 57

Dashboard ............................................................................................................................ 59

Alerts .................................................................................................................................... 60

Calibration ............................................................................................................................ 61

Utilities .................................................................................................................................. 62

Setup .................................................................................................................................... 62

Setup Menu: Features/Functions Configuration ............................................................................ 63

Setup>Data Logging (Data Acquisition System, DAS) ........................................................ 63

Configuring Trigger Types: Periodic ...................................................................... 65

vi Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

Configuring Trigger Types: Conditional ................................................................ 66

Downloading DAS (Data Acquisition System) Data .............................................. 66

Setup>Events ....................................................................................................................... 67

Editing or Deleting Events ..................................................................................... 69

Using Events as Triggers for Data Logging ........................................................... 70

Setup>Dashboard ................................................................................................................ 70

Setup>AutoCal (with Valve Option) ..................................................................................... 71

Setup>Vars .......................................................................................................................... 71

Setup>Homescreen ............................................................................................................. 72

Setup>Digital Outputs .......................................................................................................... 73

Setup>Analog Outputs ......................................................................................................... 74

Manual Calibration of Voltage Range Analog Outputs .......................................... 76

Manual Adjustment of Current Range Analog Outputs ......................................... 77

Setup>Instrument ................................................................................................................. 78

Setup>Comm (Communications) ....................................................................................... 79

COM1/COM2 ....................................................................................................... 79

TCP Port1 ............................................................................................................ 80

TCP Port2 ............................................................................................................ 80

TCP Port3 ............................................................................................................ 80

Network Settings ................................................................................................. 80

Transferring Configuration to Other Instruments ............................................................................ 82

3. COMMUNICATIONS AND REMOTE OPERATION ............................................................................... 83

Data Terminal/Communication Equipment (DTE DCE) .................................................................. 83

Modes, Baud Rate and Serial Communication ............................................................................... 83

Serial Communication: RS-232 ............................................................................................ 84

Serial Communication: RS-485 (Option) ............................................................................. 84

Ethernet ........................................................................................................................................... 84

Communications Protocols ............................................................................................................. 85

MODBUS ............................................................................................................................. 85

MODBUS Com Port Configuration ........................................................................ 85

Hessen ................................................................................................................................. 87

Hessen Com Port Configuration ............................................................................ 87

Hessen Settings Configuration .............................................................................. 88

Hessen Gas List Configuration .............................................................................. 90

4. CALIBRATION ........................................................................................................................................ 91

Important Precalibration Information ............................................................................................. 91

Calibration Requirements .................................................................................................... 91

Zero Air ................................................................................................................................ 92

Calibration (Span) Gas ........................................................................................................ 92

Span Gas for Multipoint Calibration ..................................................................................... 93

Physical Range Measurements ........................................................................................... 93

Interferents ........................................................................................................................... 94

NO2 Permeation Tubes ........................................................................................................ 94

Data Recording Devices ...................................................................................................... 95

NO2 Conversion Efficiency (CE) .......................................................................................... 95

Calibration Procedures .................................................................................................................... 95

Calibration and Check Procedures for Basic Configuration ................................................ 96

Zero Calibration Check and Actual Calibration ..................................................... 97

Span Calibration Check and Actual Calibration .................................................... 97

Calibration and Check Procedures with Valve Options Installed ......................................... 98

Use of Zero/Span Valve with Remote Contact Closure ........................................ 98

Automatic Zero/Span Cal/Check (Auto Cal) ................................................................................... 99

Calibration Quality Analysis .......................................................................................................... 101

Conversion Efficiency (CE) Check ................................................................................................ 102

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software vii

Simplified GPT Data Sheet .................................................................................. 104

EPA Protocol Calibration ............................................................................................................... 105

5. MAINTENANCE AND SERVICE .......................................................................................................... 106

Maintenance Schedule .................................................................................................................. 106

Predictive Diagnostics ................................................................................................................... 108

Operational Health Checks ........................................................................................................... 109

Software/Firmware Updates .......................................................................................................... 109

Remote Updates ................................................................................................................ 109

Manual Reload/Update Procedures ................................................................................... 110

Instrument Display Calibration (for earlier instruments)..................................................... 111

Time Zone Changes ...................................................................................................................... 112

Hardware Maintenance Procedures ............................................................................................. 113

Replacing the Sample Particulate Filter ............................................................................. 113

Changing the O3 Dryer Particulate Filter ............................................................................ 114

Changing the Ozone Cleanser Chemical .......................................................................... 115

Maintaining the External Sample Pump (Pump Pack) ....................................................... 118

Rebuilding the Pump ........................................................................................... 118

Replacing the Scrubber ....................................................................................... 118

Changing the Internal Span Gas Generator Permeation Tube ......................................... 118

Changing the External Zero Air Scrubber (OPT 86C) ....................................................... 119

Changing or Cleaning the NO2 Converter .......................................................................... 122

Cleaning the Reaction Cell ................................................................................................ 124

Servicing Critical Flow Orifices .......................................................................................... 126

Checking for Light Leaks ................................................................................................. 128

Checking for Pneumatic Leaks ........................................................................................ 129

Simple Vacuum Leak and Pump Check ............................................................ 129

Detailed Pressure Leak Check .......................................................................... 129

Performing Flow Checks/Calibrations ............................................................... 130

Service and Troubleshooting ........................................................................................................ 132

Fault Diagnosis with Alerts ................................................................................................. 133

Fault Diagnosis With Dashboard Functions ....................................................................... 136

Using the Diagnostic Signal I/O Functions ........................................................................ 137

Using the Analog Output Channels.................................................................................... 138

Using the Internal Electronic Status LEDs ......................................................................... 139

CPU Status Indicator ........................................................................................... 139

Relay PCA Watchdog and Status LEDs .............................................................. 139

Flow Problems ................................................................................................................... 141

Sample Flow is Zero or Low ................................................................................ 141

Ozone Flow is Zero or Low .................................................................................. 143

High Flow ............................................................................................................. 144

Sample Flow is Zero or Low but Analyzer Reports Correct Flow ........................ 144

Calibration Problems .......................................................................................................... 145

Negative Concentrations ..................................................................................... 145

Absence of Analyzer Response to Sample Gas ................................................. 146

Unstable Zero and Span ...................................................................................... 146

Inability to Span - Deactivated SPAN Button ...................................................... 147

Inability to Zero - Deactivated ZERO Button ....................................................... 147

Non-Linear Response .......................................................................................... 148

Discrepancy Between Analog Output and Display .............................................. 149

Discrepancy Between NO and NOX Slopes ....................................................... 149

Other Performance Problems ............................................................................................ 149

Excessive Noise .................................................................................................. 150

Slow Response .................................................................................................... 150

Auto Zero Warnings ............................................................................................. 150

viii Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

Subsystem Check for Troubleshooting .............................................................................. 151

AC Main Power .................................................................................................... 152

DC Power Supply ................................................................................................ 152

I2C Bus ................................................................................................................. 153

LCD/Display Module ............................................................................................ 153

Relay PCA ........................................................................................................... 154

Motherboard ........................................................................................................ 154

Pressure / Flow Sensor Assembly ...................................................................... 156

CPU ..................................................................................................................... 157

RS-232 Communications ..................................................................................... 158

NO2 à NO Converter ........................................................................................ 159

Photomultiplier Tube (PMT) Sensor Module ..................................................... 161

PMT Preamplifier Board .................................................................................... 161

High Voltage Power Supply (HVPS) ................................................................. 162

PMT Temperature Control PCA ........................................................................ 163

O3 Generator ..................................................................................................... 163

Internal Span Gas Generator and Valve Options .............................................. 164

Temperature Sensor .......................................................................................... 164

Service Procedures .......................................................................................................... 165

Disk-On-Module Replacement Procedure ......................................................... 166

O3 Generator Replacement ............................................................................... 167

Sample and Ozone Dryer Replacement ............................................................ 167

PMT Sensor Hardware Calibration .................................................................... 168

Replacing the PMT, HVPS or TEC .................................................................... 170

Removing / Replacing the Relay PCA from the Instrument .............................. 173

Frequently Asked Questions ......................................................................................................... 174

Technical Assistance .................................................................................................................... 175

6. PRINCIPLES OF OPERATION ............................................................................................................ 176

Measurement Principle ................................................................................................................. 176

Chemiluminescence Creation in the Reaction Cell ............................................................ 176

Chemiluminescence Detection in the Reaction Cell .......................................................... 178

The Photo Multiplier Tube (PMT) ........................................................................ 178

Optical Filter......................................................................................................... 178

NOX and NO2 Determination .............................................................................................. 179

Auto Zero ........................................................................................................................... 180

Measurement Interferences ............................................................................................... 181

Direct Interference ............................................................................................... 182

Third Body Quenching ......................................................................................... 183

Light Leaks .......................................................................................................... 183

Reaction Cell Temperature Control ..................................................................... 183

Pneumatic Operation .................................................................................................................... 184

Sample Gas Flow ............................................................................................................... 184

Vacuum Manifold ................................................................................................. 185

Sample Gas Flow Valves and Routing ................................................................ 186

Flow Rate Control - Critical Flow Orifices .......................................................................... 186

Critical Flow Orifice .............................................................................................. 187

Locations and Descriptions of Critical Flow Orifices ........................................... 187

Ozone Gas Generation and Air Flow ................................................................................. 189

The O3 Generator ................................................................................................ 190

Ozone Generator Dry Air Supply ......................................................................... 190

Ozone Supply Air Filter ........................................................................................ 192

Ozone Destruct .................................................................................................... 192

Pneumatic Sensors ............................................................................................................ 193

Sample Pressure Sensor ..................................................................................... 193

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software ix

Vacuum Pressure Sensor .................................................................................... 193

Sample Gas Flow Calculation ............................................................................. 194

O3 Supply Air Flow Sensor .................................................................................. 194

Electronic Operation ...................................................................................................................... 195

Overview ............................................................................................................................ 195

CPU .................................................................................................................................... 197

Motherboard ....................................................................................................................... 198

A to D Conversion ............................................................................................... 198

Sensor Inputs....................................................................................................... 198

Thermistor Interface ............................................................................................ 199

Analog Outputs .................................................................................................... 199

External Digital I/O ............................................................................................... 200

Internal Digital I/O ................................................................................................ 200

I2C Data Bus ........................................................................................................ 200

Power-Up Circuit ................................................................................................. 200

Relay PCA .......................................................................................................................... 200

Status LED’s ........................................................................................................ 203

Watchdog Circuitry .............................................................................................. 203

Valve Control ....................................................................................................... 203

Heater Control ..................................................................................................... 204

Thermocouple Inputs and Configuration Jumper (JP5) ...................................... 205

Sensor Module .............................................................................................................................. 207

Photo Multiplier Tube (PMT) ......................................................................................................... 207

PMT Preamplifier ............................................................................................................... 208

PMT Cooling System ......................................................................................................... 210

TEC Control Board .............................................................................................. 211

Pneumatic Sensor Board .............................................................................................................. 212

Power Supply/Circuit Breaker ....................................................................................................... 212

AC Power Configuration .................................................................................................... 214

AC Configuration – Standard Heaters (JP2) ....................................................... 215

AC Configuration – Heaters for Option Packages (JP6) ..................................... 216

Front Panel Touchscreen/Display Interface .................................................................................. 217

LVDS Transmitter Board .................................................................................................... 218

Front Panel Touchscreen/Display Interface PCA .............................................................. 218

Software Operation ....................................................................................................................... 218

Adaptive Filter .................................................................................................................... 219

Temperature/Pressure Compensation (TPC) .................................................................... 219

Calibration - Slope and Offset ............................................................................................ 220

Glossary ............................................................................................................................................... 221

x Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

LIST OF FIGURES

Figure 2-1. Front Panel Layout ................................................................................................................... 20

Figure 2-2. Rear Panel Layout, Base Unit (options include additional pneumatic ports) ........................... 21

Figure 2-3. Internal Chassis Layout with IZS Option .................................................................................. 23

Figure 2-4. Internal Layout with Other Options ........................................................................................... 24

Figure 2-5. Analog In Connector ................................................................................................................. 26

Figure 2-6. Analog Output Connector ......................................................................................................... 27

Figure 2-7. Current Loop Option Installed on the Motherboard .................................................................. 28

Figure 2-8. Status Output Connector for Digital Outputs ............................................................................ 29

Figure 2-9. Energizing the Control Inputs ................................................................................................... 30

Figure 2-10. Concentration Alarm Relay ..................................................................................................... 31

Figure 2-11. Rear Panel Connector Pin-Outs for RS-232 Mode ................................................................ 32

Figure 2-12. Default Pin Assignments for CPU COM Port Connector (RS-232) ........................................ 33

Figure 2-13. Jumper and Cables for Multidrop Mode ................................................................................. 35

Figure 2-14. RS-232 Multidrop PCA Option Host/Analyzer Interconnect Diagram .................................... 36

Figure 2-15. Gas Line Connections from Calibrator – Basic Configuration ................................................ 39

Figure 2-16. Gas Line Connections from Bottled Span Gas – Basic Configuration ................................... 39

Figure 2-17. Rear Panel Layout with Z/S Valve Options (OPT 50A) .......................................................... 40

Figure 2-18. Gas Line Connections with Z/S Valves Option (OPT 50A) .................................................... 41

Figure 2-19. Rear Panel Layout with Ambient Zero/Pressurized Span Valves (OPT 50B) ........................ 42

Figure 2-20. Gas Line Connection w/Ambient Zero/Pressurized Span Valves Option (OPT 50B) ............ 43

Figure 2-21. Rear Panel Layout with Internal Span Source (IZS) (OPT 50G) ........................................... 44

Figure 2-22. Gas Line Connection w/Zero Scrubber and Internal Span Source (IZS) Option (OPT 50G) . 45

Figure 2-23. Pneumatic Connections for Precision Calibration when IZS Generator Present ................... 45

Figure 2-24. Pneumatics, Basic Configuration............................................................................................ 48

Figure 2-25. Pneumatics with Zero/Span Valves Option (OPT 50A) .......................................................... 49

Figure 2-26. Pneumatics with Ambient Zero/Pressurized Span Valves (OPT 50B) .................................. 50

Figure 2-27. Pneumatics with the Internal Span Gas Generator Option (OPT 50G).................................. 51

Figure 2-28. Pneumatics for Sample Conditioner Option (OPT 86A) ......................................................... 52

Figure 2-29. Status Screens at Startup ....................................................................................................... 53

Figure 2-30. Home Page Example .............................................................................................................. 53

Figure 2-31. Viewing Active Alerts Page ..................................................................................................... 54

Figure 2-32. Sample Dashboard Page ....................................................................................................... 55

Figure 2-33. User Interface Orientation ...................................................................................................... 57

Figure 2-34. Concentration and Stability Graph (top) and Meter Graph (bottom) ...................................... 58

Figure 2-35. Dashboard Page ..................................................................................................................... 59

Figure 2-36. Navigating to the Active Alerts Page ...................................................................................... 60

Figure 2-37. Active Alerts Cleared .............................................................................................................. 61

Figure 2-38. Utilities>Alerts Log of Active and Past Alerts and Events ...................................................... 61

Figure 2-39. Datalog Configuration, New Log Page ................................................................................... 63

Figure 2-40. Datalog Configuration, Existing Log ....................................................................................... 63

Figure 2-41. Creating a New Data Log ....................................................................................................... 64

Figure 2-42. Datalog Periodic Trigger Configuration .................................................................................. 65

Figure 2-43. Datalog - Conditional Trigger Configuration ........................................................................... 66

Figure 2-44. DAS Download Page .............................................................................................................. 66

Figure 2-45. Events List .............................................................................................................................. 67

Figure 2-46. Event Configuration ................................................................................................................ 68

Figure 2-47. Configured Event Sample ....................................................................................................... 69

Figure 2-48. Edit or Delete an Event ........................................................................................................... 69

Figure 2-49. Dashboard Display and Configuration .................................................................................... 70

Figure 2-50. Homescreen Configuration ..................................................................................................... 72

Figure 2-51. Digital Outputs Setup .............................................................................................................. 73

Figure 2-52. Analog Output Configuration Example ................................................................................... 74

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software xi

Figure 2-53. Analog Outputs Group Calibration Screen ............................................................................. 75

Figure 2-54. Analog Outputs Manual Calibration Screen (AOUT2 Example) ............................................. 75

Figure 2-55. Setup for Checking / Calibrating DCV Analog Output Signal Levels ..................................... 76

Figure 2-56. Setup for Checking / Calibration Current Output Signal Levels ............................................. 77

Figure 2-57. Alternative Setup Using 250Ω Resistor for Checking Current Output Signal Levels ............. 78

Figure 2-58. Communications Configuration, Network Settings ................................................................. 80

Figure 2-59. Configuration Transfer ............................................................................................................ 82

Figure 3-1. MODBUS via Ethernet .............................................................................................................. 85

Figure 3-2. MODBUS via Serial Communication (example) ....................................................................... 86

Figure 3-3. Serial Communication, Setting Hessen Protocol ...................................................................... 87

Figure 3-4. Hessen Gas List Configuration ................................................................................................. 90

Figure 4-1. Multi-Point Calibration Page ..................................................................................................... 96

Figure 4-2. Zero and Span Calibration Screens ......................................................................................... 98

Figure 4-3. Auto Cal Page........................................................................................................................... 99

Figure 5-1: Report Generation Page ......................................................................................................... 109

Figure 5-2. Remote Update Page ............................................................................................................. 110

Figure 5-3. Manual Update Page (and other utilities) ............................................................................... 110

Figure 5-4. Touchscreen Calibration Page ............................................................................................... 111

Figure 5-5. Time Zone Change Requirements ......................................................................................... 112

Figure 5-6. Replacing the Particulate Filter............................................................................................... 113

Figure 5-7. Particle Filter on O3 Supply Air Dryer ..................................................................................... 115

Figure 5-8. Ozone Cleanser Assembly ..................................................................................................... 116

Figure 5-9. Zero Air Scrubber Assembly ................................................................................................... 121

Figure 5-10. NO2 Converter Assembly...................................................................................................... 123

Figure 5-11. Reaction Cell Assembly ........................................................................................................ 125

Figure 5-12. Critical Flow Orifice Assembly .............................................................................................. 126

Figure 5-13. Flow Calibration Menu .......................................................................................................... 131

Figure 5-14. CPU Status Indicator ............................................................................................................ 139

Figure 5-15. Relay PCA Status LEDS Used for Troubleshooting ............................................................. 140

Figure 5-16. Location of DC Power Test Points on Relay PCA ................................................................ 153

Figure 5-17. Typical Set Up of Status Output Test ................................................................................... 155

Figure 5-18. Pressure / Flow Sensor Assembly........................................................................................ 156

Figure 5-19. Pre-Amplifier Board Layout .................................................................................................. 169

Figure 5-20. Sensor Assembly .................................................................................................................. 171

Figure 5-21. Relay PCA with AC Relay Retainer In Place ........................................................................ 173

Figure 5-22. Relay PCA Mounting Screw Locations ................................................................................. 173

Figure 6-1. Reaction Cell with PMT Tube and Optical Filter ..................................................................... 178

Figure 6-2. Sensitivity Spectrum ............................................................................................................... 179

Figure 6-3. NO2à NO Conversion ............................................................................................................ 179

Figure 6-4. Pneumatic Flow during the Auto Zero Cycle .......................................................................... 181

Figure 6-5. Vacuum Manifold, Standard Configuration ............................................................................. 185

Figure 6-6. Flow Control Assembly & Critical Flow Orifice ....................................................................... 187

Figure 6-7. Location of Flow Control Assemblies & Critical Flow Orifices ................................................ 188

Figure 6-8. Ozone Generator Principle ..................................................................................................... 190

Figure 6-9. Semi-Permeable Membrane Drying Process ......................................................................... 191

Figure 6-10. Sample Dryer ........................................................................................................................ 191

Figure 6-11. Electronic Block Diagram ..................................................................................................... 195

Figure 6-12. CPU Board ............................................................................................................................ 197

Figure 6-13. Relay PCA Layout (P/N 045230100) .................................................................................... 201

Figure 6-14. Relay PCA P/N 045230100 with AC Relay Retainer in Place .............................................. 202

Figure 6-15. Heater Control Loop Block Diagram. .................................................................................... 205

Figure 6-16. Thermocouple Configuration Jumper (JP5) Pin-Outs .......................................................... 206

Figure 6-17. Basic PMT Design ................................................................................................................ 207

Figure 6-18. PMT Preamp Block Diagram ................................................................................................ 209

xii Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

Figure 6-19. Typical Thermo-Electric Cooler ............................................................................................ 210

Figure 6-20. PMT Cooling System Block Diagram ................................................................................... 211

Figure 6-21. Power Distribution Block Diagram ........................................................................................ 213

Figure 6-22. Location of AC power Configuration Jumpers ...................................................................... 214

Figure 6-23. Typical Set Up of AC Heater Jumper Set (JP2) ................................................................... 215

Figure 6-24. Typical Jumper Set (JP2) Set Up of Heaters ...................................................................... 216

Figure 6-25. Front Panel and Display Interface Block Diagram ................................................................ 217

Figure 6-26. Basic Software Operation ..................................................................................................... 218

LIST OF TABLES

Table 1-1. Specifications ............................................................................................................................. 15

Table 2-1. Ventilation Clearance ................................................................................................................. 19

Table 2-2. Rear Panel Description .............................................................................................................. 22

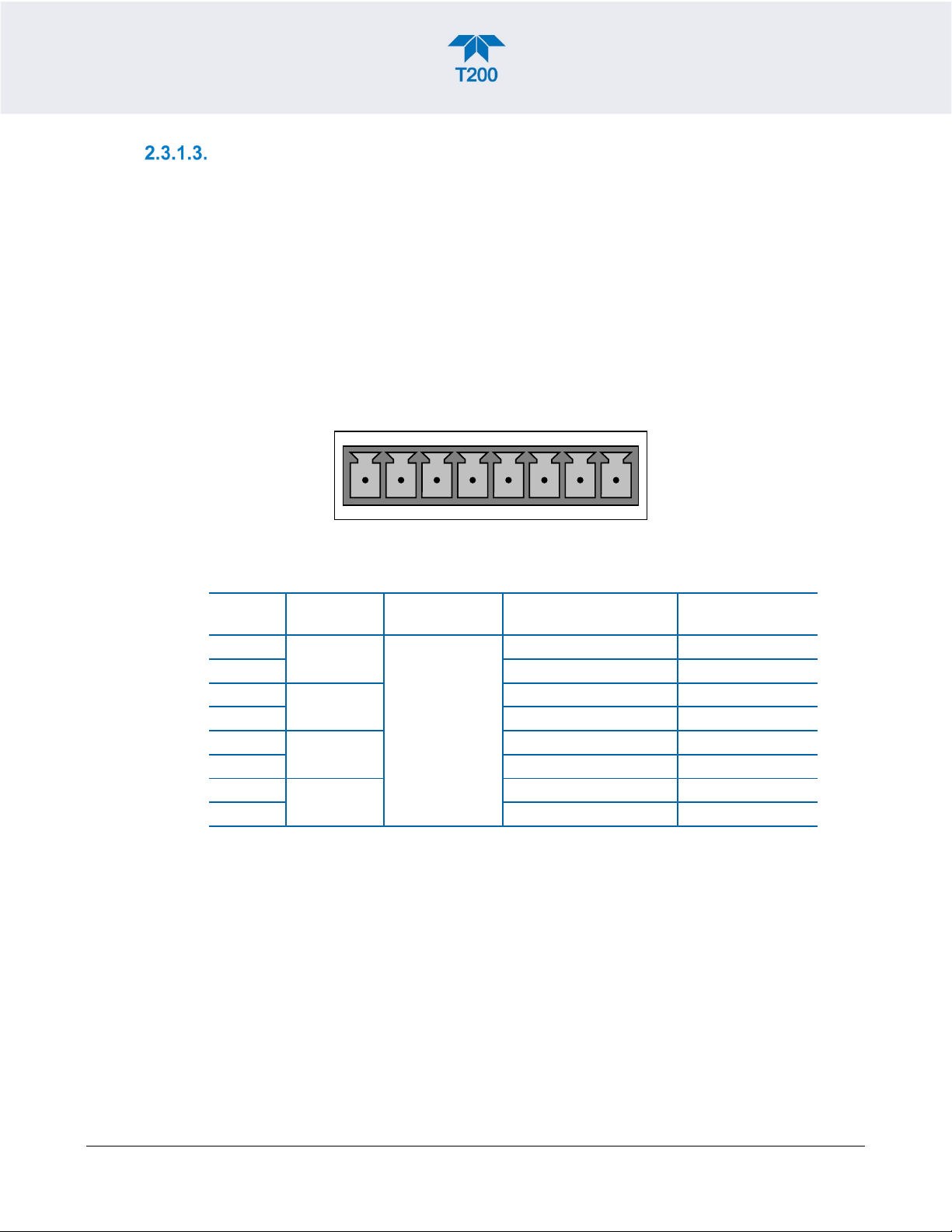

Table 2-3. Analog Input Pin Assignments ................................................................................................... 26

Table 2-4. Analog Output Pin Assignments ................................................................................................ 27

Table 2-5. Status Output Pin Assignments ................................................................................................. 30

Table 2-6. Control Input Pin Assignments .................................................................................................. 31

Table 2-7. Zero/Span Valves Operating States (OPT 50A) ........................................................................ 49

Table 2-8. Ambient Zero/Pressurized Span Valve Operating States (OPT 50B) ....................................... 50

Table 2-9. IZS Valve Option Operating States (OPT 50G) ......................................................................... 51

Table 2-10. Menu Overview ........................................................................................................................ 56

Table 2-11. Utilities Submenu Descriptions ................................................................................................ 62

Table 2-12. List of Variables with Descriptions ........................................................................................... 71

Table 2-13. Analog Output Voltage/Current Range .................................................................................... 75

Table 2-14. Voltage Tolerances .................................................................................................................. 76

Table 2-15. Current Loop Output Check ..................................................................................................... 78

Table 2-16. Setup>Instrument Menu .......................................................................................................... 78

Table 2-17. COM1/COM2 Configuration ..................................................................................................... 79

Table 2-18. LAN/Ethernet Configuration Properties ................................................................................... 81

Table 3-1. Ethernet Status Indicators ......................................................................................................... 84

Table 3-2. Teledyne API's Hessen Protocol Response Modes .................................................................. 88

Table 3-3. Hessen Status Flags and Default Bit Assignments ................................................................... 89

Table 3-4. Hessen Gas List Definitions ....................................................................................................... 90

Table 4-1. AUTO CAL States .................................................................................................................... 100

Table 4-2. Auto Cal Setup Combinations .................................................................................................. 100

Table 4-3. Auto Cal Programming Sequence Execution .......................................................................... 101

Table 4-4. Calibration Data Quality Evaluation ......................................................................................... 102

Table 5-1. Maintenance Schedule ............................................................................................................ 107

Table 5-2. Predictive Uses for Dashboard Functions ............................................................................... 108

Table 5-3. Warning Alerts, Fault Conditions and Possible Causes .......................................................... 133

Table 5-4. Dashboard Functions - Indicated Failures ............................................................................... 137

Table 5-5. Analog Outputs as Diagnostic Tools....................................................................................... 138

Table 5-6. Relay PCA Watchdog and Status LED Failure Indications ..................................................... 140

Table 5-7. DC Power Test Point and Wiring Color Codes ........................................................................ 152

Table 5-8. DC Power Supply Acceptable Levels ...................................................................................... 153

Table 5-9. Relay PCA Control Devices ..................................................................................................... 154

Table 5-10. Control Input Pin Assignments and Corresponding Signal I/O Functions ............................. 155

Table 6-1. List of Interferents .................................................................................................................... 181

Table 6-2. Valve Cycle Phases ................................................................................................................ 186

Table 6-3. Gas Flow Controls ................................................................................................................... 188

Table 6-4. Relay PCA Status LED’s ......................................................................................................... 203

Table 6-5. Thermocouple Configuration Jumper (JP5) Pin-Outs .............................................................. 206

Table 6-6. Power Configuration for Standard AC Heaters (JP2) .............................................................. 215

Table 6-7. Power Configuration for Optional Heaters (JP6) ..................................................................... 216

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software xiii

Appendix A – MODBUS Registers

Appendix B – Interconnect Wiring Diagram

xiv Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

1. INTRODUCTION, SPECIFICATIONS, APPROVALS, &

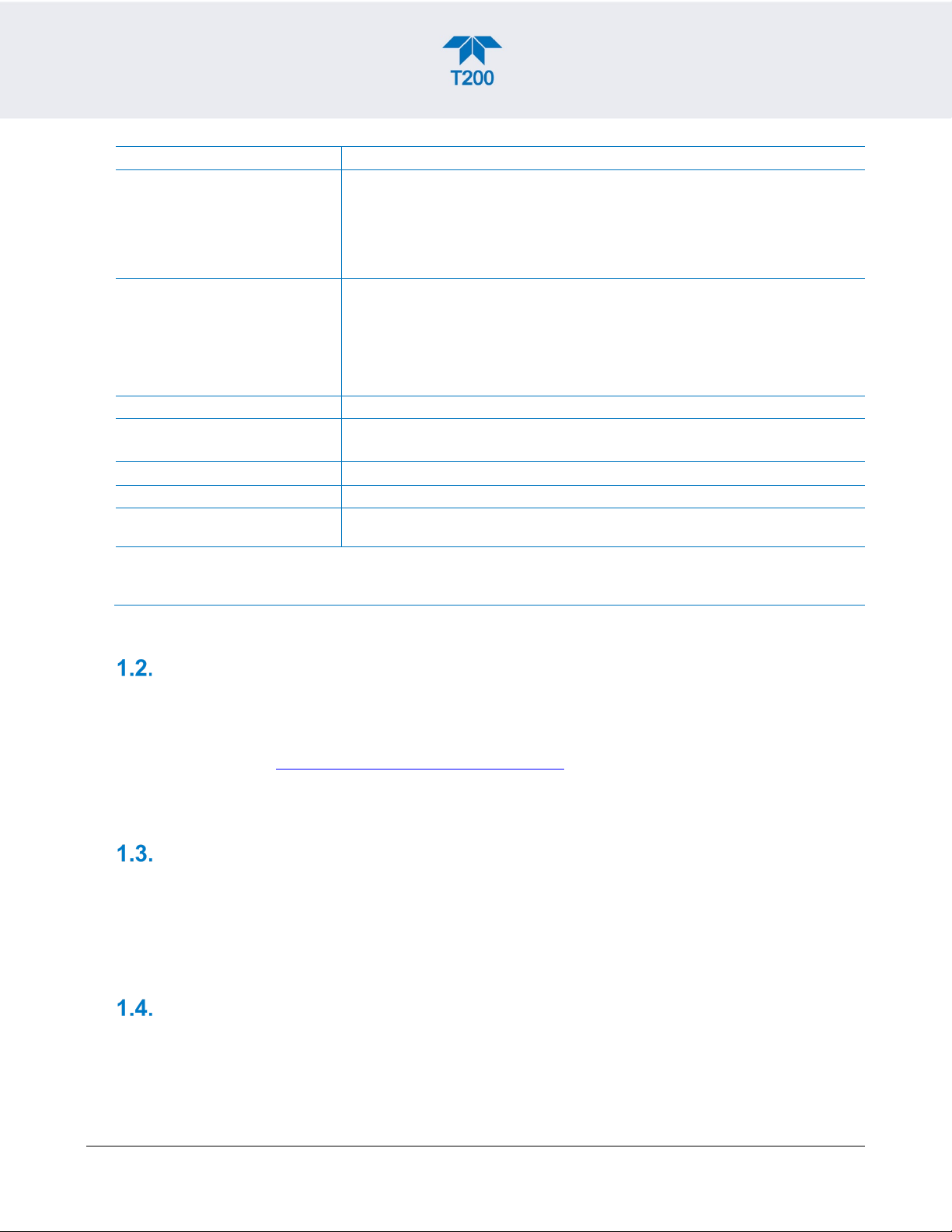

PARAMETER

SPECIFICATION

Min/Max Range

Span Drift

< 0.5% of Full Scale (at constant temperature and voltage) /24 hours

AC Power

Rating

220-240 V~, 50/60 Hz, 3.0 A

Typical Power Consumption

110 W

10V, 5V, 1V, 0.1V (selectable)

All Ranges with 5% Under/Over Range

Analog Output Resolution

1 part in 4096 of selected full-scale voltage

Recorder Offset

COMPLIANCE

Teledyne API’s Model T200 (also referred to as T200) NO/NO2/NOX Analyzer uses

chemiluminescence detection (see Principles of Operation, Section 6, this manual),

coupled with state-of-the-art microprocessor technology to provide the sensitivity, stability

and ease of use needed for ambient or dilution CEM monitoring requirements of nitric

oxide (NO), nitrogen dioxide (NO

high accuracy and dependability, the T200 tracks operational parameters and issues

warnings if they fall outside diagnostic limits, as well as stores easily retrievable data.

Proprietary software allows configurable data acquisition capability that can be triggered

conditionally or periodically, enabling operators to perform predictive diagnostics and

enhanced data analysis by tracking parameter trends. Reports can be downloaded onto a

USB flash drive or via the I/O ports. Operators can also view real-time graphing with one

touch of the interface screen.

) and total nitrogen oxides (NOx). Along with providing

2

SPECIFICATIONS

Table 1-1. Specifications

(Physical Analog Output)

Measurement Units ppb, ppm, µg/m3, mg/m3 (selectable)

Zero Noise1 < 0.2 ppb (RMS)

Span Noise1 < 0.5% of reading (RMS) above 50 ppb

Lower Detectable Limit 2 0.4 ppb

Zero Drift < 0.5 ppb (at constant temperature and voltage) /24 hours

Lag Time

Rise/Fall Time1 < 60 seconds to 95%

Linearity 1% of full scale

Precision 0.5% of reading above 50 ppb

Sample Flow Rate 500 cc/min ± 10%

1

Min: 0-50 ppb Full Scale

Max: 0-20,000 ppb Full Scale (selectable, dual ranges supported)

20 seconds

110-120 V~, 60 Hz, 3.0 A

100 W

Analog Output Ranges

± 10%

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 15

PARAMETER

SPECIFICATION

Standard I/O

1 Ethernet: 10/100Base-T

2 RS-232 (300 – 115,200 baud)

4 analog outputs

3 4-20mA current outputs

Environmental Conditions

Installation Category (Over voltage Category) II Pollution Degree 2

Intended for Indoor Use Only at Altitudes ≤ 2000m

2 USB device ports

8 opto-isolated digital status outputs (7 defined, 1 spare)

6 opto-isolated digital control inputs (4 defined, 2 spare)

Optional I/O 1 USB com port

1 RS485

8 analog inputs (0-10V, 12-bit)

4 digital alarm outputs

Multidrop RS232

Dimensions H x W x D 7" x 17" x 23.5" (178mm x 432 mm x 597 mm)

Weight Analyzer: 40 lbs (18 kg)

External Pump Pack: 15 lbs (7 kg)

Operating Temperature Range

Humidity Range 0-95% RH non-condensing

1

As defined by the US EPA.

2

Defined as twice the zero noise level by the US EPA.

All specifications are based on constant conditions.

5 - 40 °C (with US EPA approval)

EPA DESIGNATION

Teledyne API’s Model T200 nitrogen oxides analyzer is officially designated as US EPA

Federal Reference Method (FRM), Designation Number RFNA-1194-099. The official

List of Designated Reference and Equivalent Methods is published in the U.S. Federal

Register

and configurations.

– http://www3.epa.gov/ttn/amtic/criteria.html, and specifies the instrument’s settings

SAFETY

IEC/EN 61010-1:2010 (3rd Edition), Safety requirements for electrical equipment for

measurement, control, and laboratory use.

CE: 2006/95/EC, Low-Voltage Directive

EMC

IEC/EN 61326-1, Class A Emissions/Industrial Immunity

FCC 47 CFR Part 15B, Class A Emissions

CE: 2004/108/EC, Electromagnetic Compatibility Directive

16 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

OTHER CERTIFICATIONS

EU: EN14211 TÜV Rheinland

QAL1 Certified: EN15267

MCerts: Sira MC050068/11

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 17

2. GETTING STARTED

To avoid personal injury, always use two persons to lift and

COULD DAMAGE INSTRUMENT AND VOID WARRANTY

COULD DAMAGE INSTRUMENT AND VOID WARRANTY

Note

materials for future use if/when the instrument should be

api.com.

This section addresses unpacking, connecting, and initializing the instrument, getting an

overview of the menu system, and setting up/configuring the functions.

UNPACKING

carry the analyzer.

ATTENTION

CAUTION - GENERAL SAFETY HAZARD

Printed Circuit Assemblies (PCAs) are sensitive to electro-static

discharges too small to be felt by the human nervous system. Failure

to use Electro-Static Discharge (ESD) protection when working with

electronic assemblies will void the instrument warranty. Refer to the

manual, Fundamentals of ESD, PN 04786, which can be downloaded

from our website at http://www.teledyne-api.com

.

ATTENTION

Do not operate this instrument without first removing dust plugs from

SAMPLE and EXHAUST ports on the rear panel.

Teledyne API recommends that you store shipping containers

and

returned to the factory for repair and/or calibration service. See

Warranty statement in this manual and Return Merchandise

Authorization (RMA) on our Website at

http://www.teledyne-

Verify that there is no apparent external shipping damage. If damage has occurred, please

advise the shipper first, then Teledyne API.

Included with your instrument is a printed record of the final performance characterization

performed on your instrument at the factory. This record, titled Final Test and Validation

Data Sheet, is an important quality assurance and calibration record and should be placed

in the quality records file for this instrument.

18 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

AREA

MINIMUM REQUIRED CLEARANCE

10 cm / 4 in

2.5 cm / 1 in

With no power to the unit, carefully remove the top cover of the instrument and check for

internal shipping damage by carrying out the following steps:

1. Carefully remove the top cover and check for internal shipping damage.

a. Remove the screws located on the instrument’s sides.

b. Slide the cover backward until it clears the instrument’s front bezel.

c. Lift the cover straight up.

2. Inspect the interior of the instrument to ensure all circuit boards and other

components are intact and securely seated.

3. Check the connectors of the various internal wiring harnesses and

pneumatic hoses to ensure they are firmly and securely seated.

4. Verify that all of the optional hardware ordered with the unit has been

installed. These are listed on the paperwork accompanying the instrument.

WARNING – ELECTRICAL SHOCK HAZARD

Never disconnect PCAs, wiring harnesses or electronic

subassemblies while under power.

VENTILATION CLEARANCE

Whether the instrument is set up on a bench or installed in a rack, be sure to leave sufficient

ventilation clearance.

Table 2-1. Ventilation Clearance

Back of the instrument

Sides of the instrument 2.5 cm / 1 in

Above and below the instrument

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 19

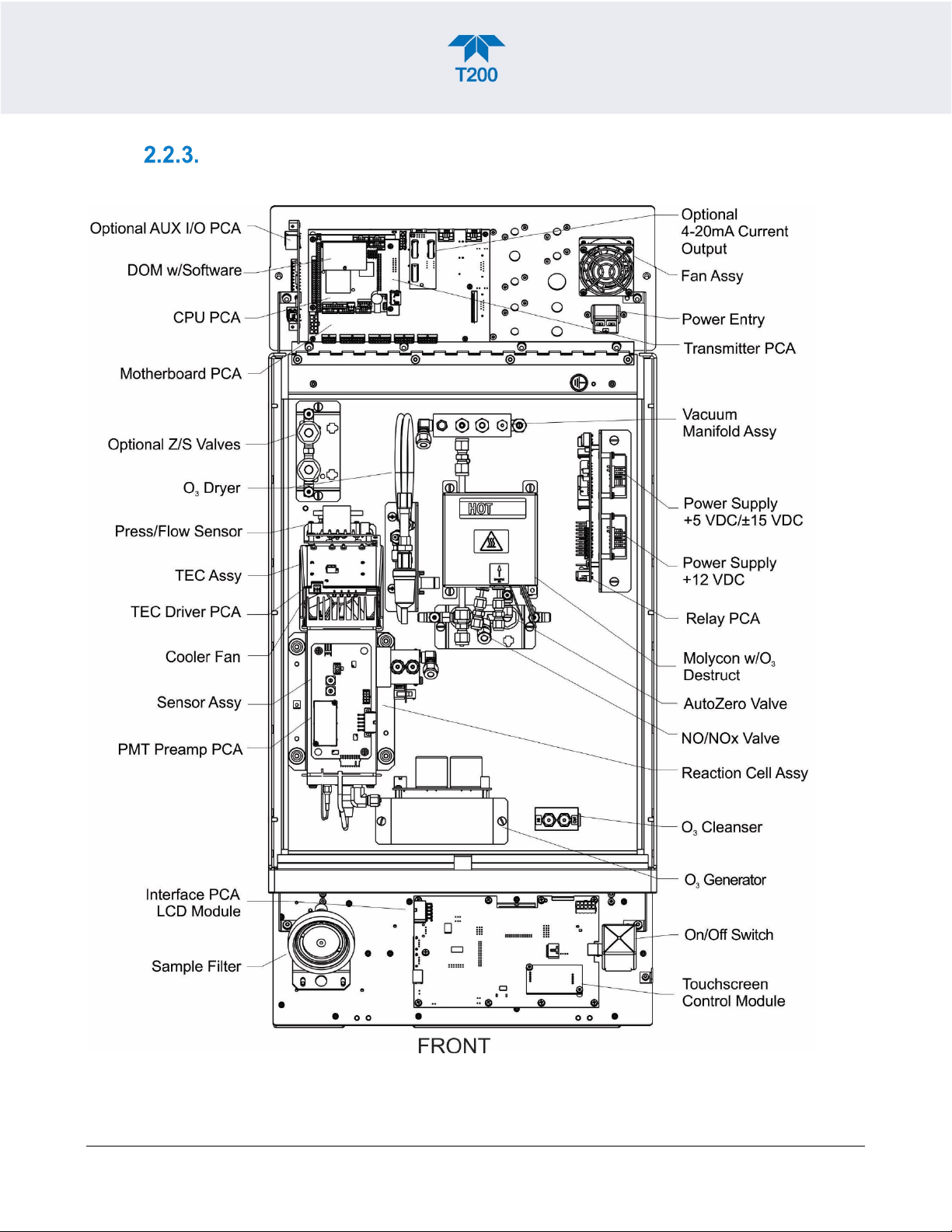

INSTRUMENT LAYOUT

Instrument layout includes front panel, rear panel connectors, and the internal chassis layout.

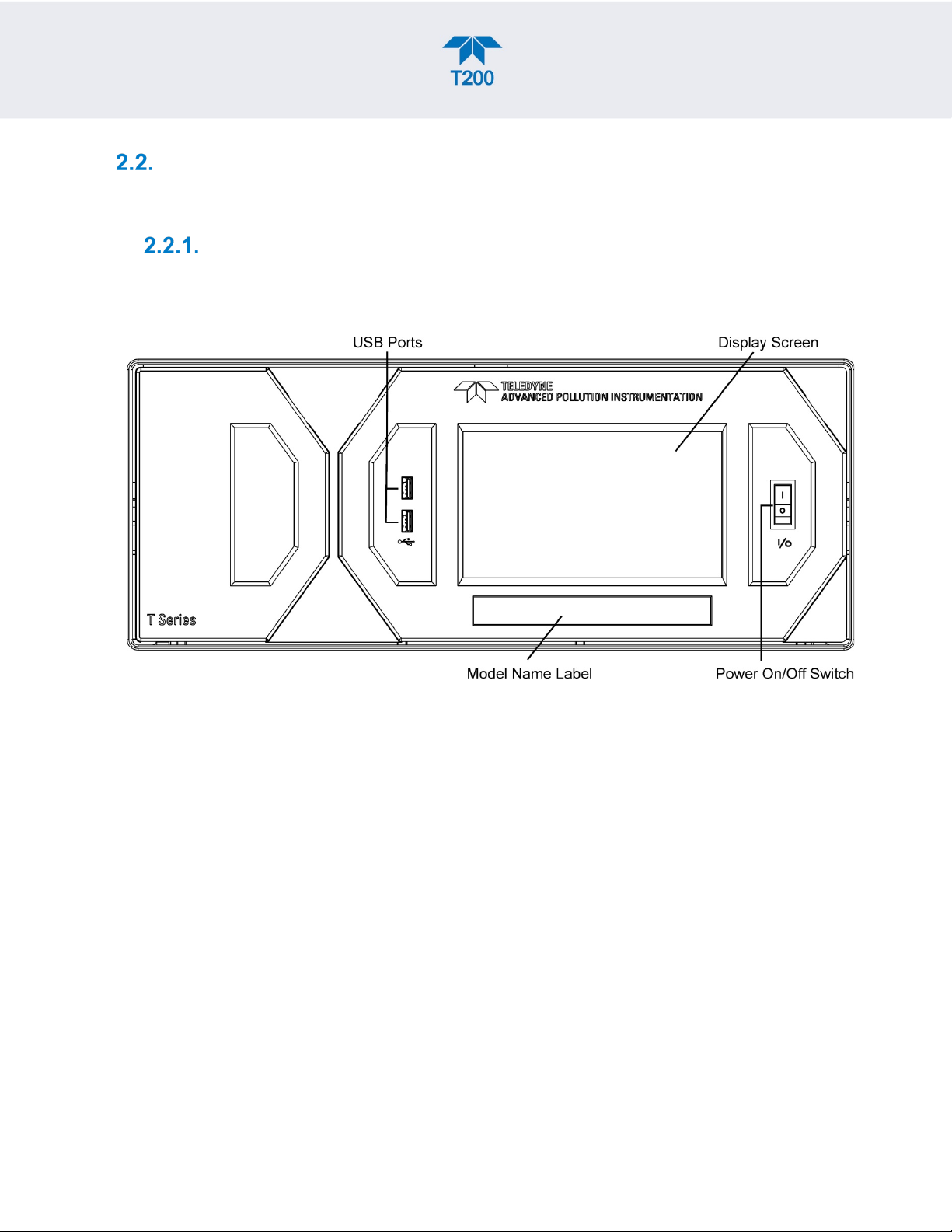

FRONT PANEL

The front panel (Figure 2-1) includes two USB ports for peripheral device connections,

which can be used with mouse and keyboard as alternatives to the touchscreen interface,

or with flash drive for uploads/downloads (devices not included).

Figure 2-1. Front Panel Layout

20 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

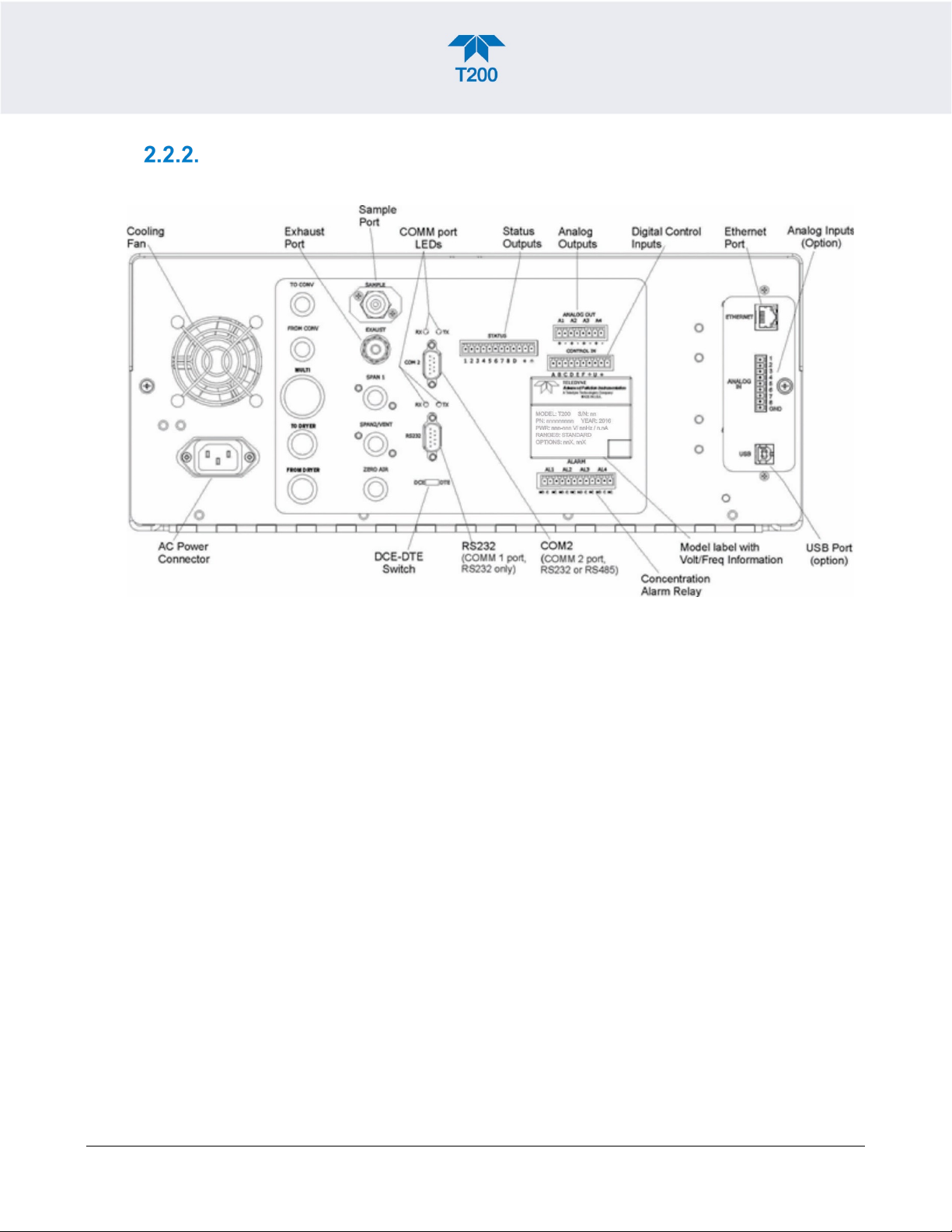

REAR PANEL

Figure 2-2 shows the layout of the rear panel.

Figure 2-2. Rear Panel Layout, Base Unit (options include additional pneumatic ports)

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 21

Table 2-2. Rear Panel Description

TO CONV

CONTROL IN

COMPONENT FUNCTION

cooling fan

AC power

connector

Model/specs label

Pulls ambient air into chassis through side vents and exhausts through rear.

Connector for three-prong cord to apply AC power to the analyzer.

CAUTION! The cord’s power specifications (specs) MUST comply with the power

specs on the analyzer’s rear panel Model number label

Identifies the analyzer model number and provides power specs

(not used)

FROM CONV

MULTI

TO DRYER

FROM DRYER

SAMPLE

EXHAUST

SPAN 1

SPAN2/VENT

ZERO AIR

RX TX

COM 2

RS-232

DCE DTE

STATUS

ANALOG OUT

(not used)

(not used)

(not used)

Outlet for internal sample gas dryer; connect to external zero air scrubber (for IZS options

only).

Connect a gas line from the source of sample gas here.

Calibration gases can also enter here on units without zero/span/shutoff valve options

installed.

Connect an exhaust gas line of not more than 10 meters long here that leads outside the

shelter or immediate area surrounding the instrument. The line must be ¼” tubing or

greater.

On units with zero/span/shutoff valves option installed, connect a gas line to the source of

calibrated span gas here.

On units with pressurized span valve option, used for venting.

Internal Zero Air: On units with zero/span/shutoff valves option installed but no internal zero

air scrubber attach a gas line to the source of zero air here.

LEDs indicate receive (RX) and transmit (TX) activity on the when blinking.

Serial communications port for RS-232 or RS-485.

Serial communications port for RS-232 only.

Switch to select either data terminal equipment or data communication equipment during

RS-232 communication.

For outputs to devices such as Programmable Logic Controllers (PLCs).

For voltage or current loop outputs to a strip chart recorder and/or a data logger.

For remotely activating the zero and span calibration modes.

ALARM

ETHERNET

ANALOG IN

USB

Model Label

Option for concentration alarms and system warnings.

Connector for network or Internet remote communication, using Ethernet cable

Option for external voltage signals from other instrumentation and for logging these signals

Connector for direct connection to laptop computer, using USB cable.

Includes voltage and frequency specifications

22 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

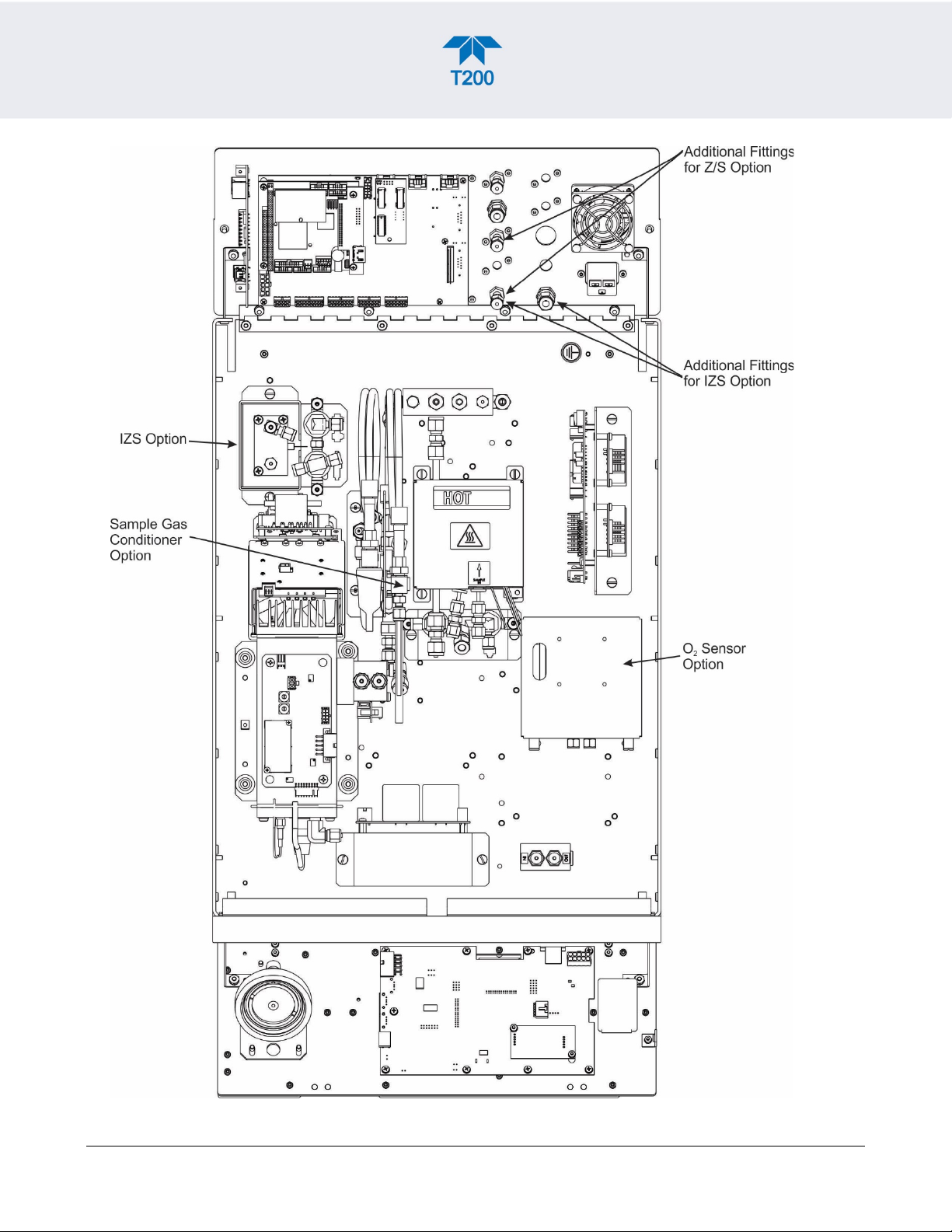

INTERNAL CHASSIS

Figure 2-3 and Figure 2-4 show internal chassis configurations with different options.

Figure 2-3. Internal Chassis Layout with IZS Option

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 23

Figure 2-4. Internal Layout with Other Options

24 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

CONNECTIONS AND STARTUP

To maintain compliance with EMC standards, cable length

Do not operate with cover off.

This section presents the electrical (Section 2.3.1) and pneumatic (Section 2.3.2)

connections for setting up and preparing the instrument for operation (Section 2.3.3).

ELECTRICAL CONNECTIONS

Note

must be go greater than 3 meters for all I/O connections.

WARNING – Electrical Shock Hazard

• High Voltages are present inside the instrument’s case.

• Power connection must have functioning ground connection.

• Do not defeat the ground wire on power plug.

• Turn off instrument power before disconnecting or connecting

electrical subassemblies.

•

CAUTION – Avoid Damage to the Instrument

Ensure that the AC power voltage matches the voltage indicated on

the instrument’s model/specs label before plugging it into line

power.

CONNECTING POWER

Attach the power cord between the instrument’s AC power connector and a power outlet

capable of carrying at least the rated current at your AC voltage range and ensure that it is

equipped with a functioning earth ground. It is important to adhere to all safety and

cautionary messages.

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 25

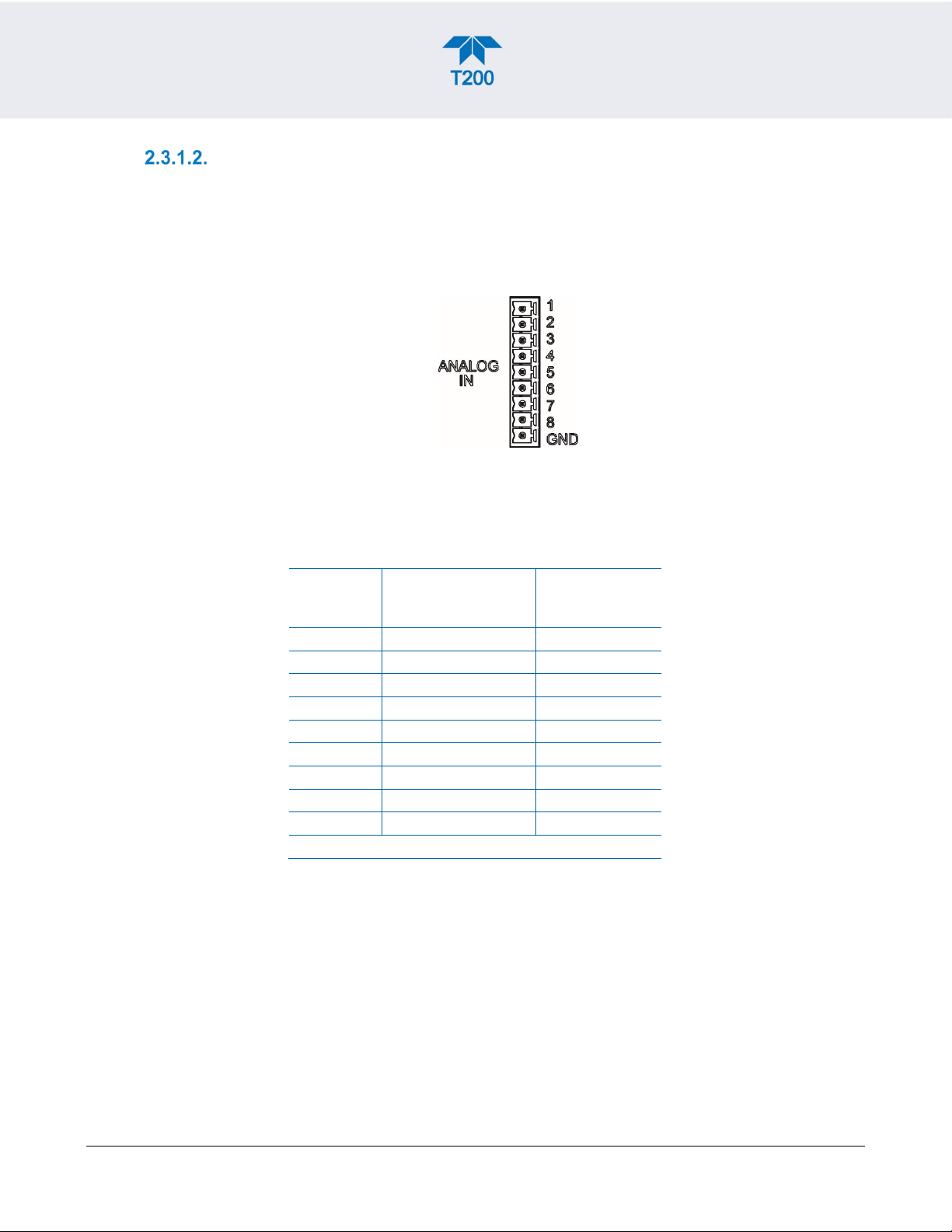

CONNECTING ANALOG INPUTS (OPTION)

DAS/DATA

PARAMETER1

3

Analog input # 3

Channel 3

The Analog In connector option is used for measuring external voltage signals from other

instrumentation (such as meteorological instruments) and for logging these signals in the

analyzer’s internal data acquisition system, the Data Logger (Section 2.5.1). The input

voltage range for each analog input is 0-10 VDC and input impedance is nominally 20kΩ

in parallel with 0.1µF.

Figure 2-5. Analog In Connector

Assignments for the Analog In connector pins 1 through 8 (Table 2-3) are configurable

through the Setup>Ext Analog Inputs menu (visible with installed option).

Table 2-3. Analog Input Pin Assignments

PIN DESCRIPTION

1 Analog input # 1 Channel 1

2 Analog input # 2 Channel 2

4 Analog input # 4 Channel 4

5 Analog input # 5 Channel 5

6 Analog input # 6 Channel 6

7 Analog input # 7 Channel 7

8 Analog input # 8 Channel 8

GND Analog input Ground N/A

1

See Section 2.5.1 to set up the Data Logger.

LOGGER

26 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 083730200A DCN7962

CONNECTING ANALOG OUTPUTS

ANALOG OUT

A1 A2 A3 A4

+ - + - + - + -

ANALOG

OUTPUT

STANDARD

VOLTAGE OUTPUT

CURRENT

LOOP OPTION

The rear panel Analog Output channels A1 through A4 can be mapped to reflect various

operating values in the analyzer, including concentration values, temperatures, pressures,

etc. These mappings are not configured by default and must be set by the user.

An optional Current Loop output (Section 2.3.1.4) is available for A1, A2 and A3 only.

To access these signals attach a strip chart recorder and/or data-logger to the appropriate

analog output connections on the rear panel of the analyzer.

Configure through the Setup>Analog Outputs menu (Section 2.5.8)

Figure 2-6. Analog Output Connector

Table 2-4. Analog Output Pin Assignments

PIN

1

2 Ground I Out 3

4 Ground I Out 3

4 Ground I Out 7

8 Ground Not Available

A1

A2

A3

A4

SIGNAL OUT

User-selected

through the

Setup>Analog

Outputs menu.

V + I Out +

V + I Out +

V + I Out +

V + Not Available

083730200A DCN7962 Teledyne API T200 NO/NO2/NOx Analyzer with NumaView™ Software 27

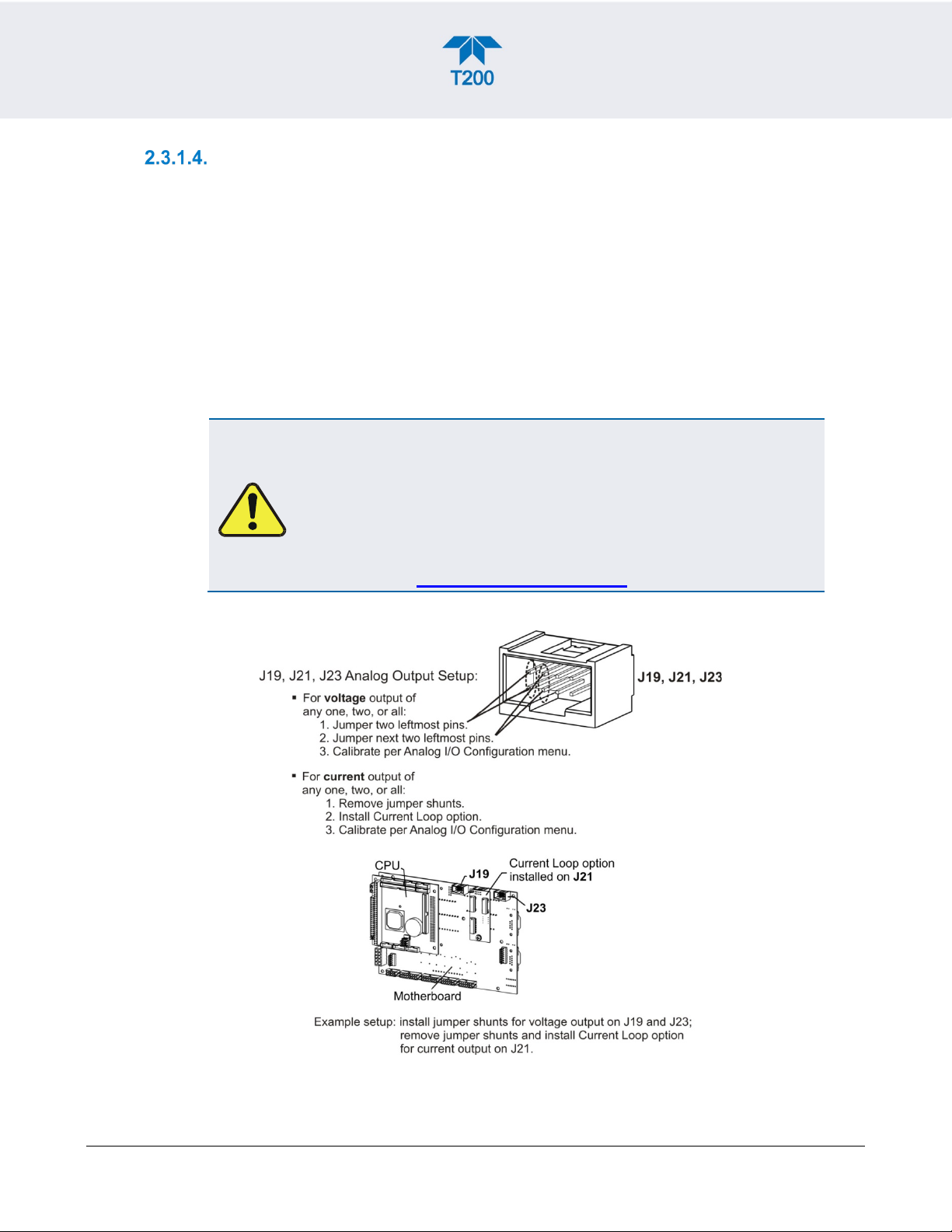

CURRENT LOOP ANALOG OUTPUTS (OPTION 41) SETUP

our website at http://www.teledyne-api.com.