Page 1

instruction

manual

Model 8800T

TRACE MOISTURE ANALYZER

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 2

8800T User’s Manual

i

Page 3

8800T User’s Manual

8800T User’s Manual Table of Contents

1.0 Overview of the 8800T .................................................1

2.1 Precautions using the sensor .........................................3

2.2 Sensor Technical Specifications ...................................4

2.3 Sensor Installation & Sampling Techniques .................4

2.3.1 In-situ Installation ......................................................5

2.3.2 Extractive Installation ................................................7

2.4 Troubleshooting unexpected readings ..........................9

3.1 Precautions using the 8800T .......................................13

3.1.1 Electromagnetic Compatibility Considerations .......13

3.2 Instrument Technical Specifications ...........................14

3.3 Installation ..................................................................15

3.3.1 Mechanical Installation ............................................15

3.3.2 Electrical Installation ...............................................16

3.4 Operating the Instrument ............................................17

3.4.1 Starting up ................................................................17

3.4.2 Display Conventions ................................................17

3.4.3 Push Buttons ............................................................19

3.4.4 Operating State ........................................................19

3.4.4.1 Viewing Dewpoint Mode ......................................20

3.4.4.2 Viewing Temperature at the Sensor ......................20

3.4.4.3 Start Calibration (SpanCheck™) Mode ................21

3.4.4.4 Viewing Serial Number Mode ..............................24

3.4.5 SetUp State ..............................................................24

3.5 Troubleshooting the Instrument ..................................28

Appendix A: Operating State User Interface flowchart ....31

Appendix B: Set-Up State User Interface flowchart .........32

Appendix C: 8800T Mechanical Drawing ........................34

Appendix D: 8800T Electrical Connections .....................35

Appendix E: Sensor/SpanCheck™ Theory of Operation .36

Appendix F: Pressure Correction ......................................39

Appendix G: Current vs. Dewpoint ..................................40

ii

Page 4

8800T User’s Manual

Appendix H: Uncertainty in LBS & ppmV calculations ..43

Appendix I: Sensor Response Time ..................................44

Appendix J: Return Authorization Request ......................45

iii

Page 5

Section 1: Introduction

1.0 Overview of the 8800T

The 8800T is a microprocessor based 4-20mA loop powered

(2 wire) hygrometer, for measuring moisture content in

gases in the range from -100°C to +20°C. The measurement

is displayed on the instrument’s custom LCD, and is transmitted by varying the current drawn (4-20mA) from the

power supply. The current varies linearly proportional to the

selected measurement units. An optional digital output is

available which modulates/demodulates the 4-20mA loop

line without interfering with its operation. With this option

the 8800T is capable of communicating with properly

equipped Personal Computers or other RS-232 capable controllers. Three front panel buttons provide the user with a

wide variety of features. The 8800T’s advanced design

allows it to be housed in a small stainless steel enclosure

behind the sensor probe, thus the instrument and sensor are

a single integrated unit.

The 8800T uses the Teledyne HTF™ sensor which is encapsulated in sintered stainless steel, thus it is capable of coming into contact with a wide variety of environments.

However one should keep in mind that the sensor is a sensitive device and it should be handled accordingly.

page 1

Page 6

8800T User’s Manual

page 2

Page 7

Section 2: Sensor and Sampling Techniques

2.1 Precautions using the sensor

The Teledyne HTF™ Al2O3 sensor is designed and field

proven to be highly reliable, rugged and maintenance free.

However the user should consider the following precautions:

• To avoid the need for prolonged dry-down (when

expecting to measure dewpoints dryer than -65ºC), do

not expose the sensor to room air longer than necessary

(1 - 2 minutes). Thus, do not open the sensor container

before you are ready to install the sensor.

• The sensor container has desiccant to keep the sensor

dry during shipping and to avoid damage due to condensation. Close the container immediately after removing

the sensor to avoid degradation of the desiccant.

• Do not throw away the sensor container, you may use it

again to transport the sensor between locations, to store

it between uses or to ship it back to the factory for certification. The container can be attached to the loop cable,

by trapping the cable with the lid strap.

• Do not expose the sensor to corrosive gases such as

gases containing chlorine, ammonia or HCl. (SO2 can

be monitored when the moisture content is low).

• Except for the XTR65W sensor:

1. Do not expose the sensor to liquid water, as it may get

damaged.

2. Do not breathe directly onto the sensor, as condensation may form which could damage the sensor element.

• Do not install the sensor near heat sources such as radiators or air ducts.

• Do not install the sensor in places subject to extreme

mechanical vibration or shock. If this is not avoidable,

use resilient mounting. If in doubt, call your representa-

page 3

Page 8

8800T User’s Manual

tive.

• Do not disassemble the porous metal filter encapsulation, as this will damage the sensor and void your factory warranty.

• Prior to installation of the probe, ensure that no contaminants are present in the system (e.g. oil, liquid water).

2.2 Sensor Technical Specifications

Type: .................................Hyper Thin Film high capacitance Al2O3.

Dewpoint range:

XTR-100........................-148°F to +68°F (-100°C to +20°C)

XTR-65..........................-85°F to +68°F (-65°C to +20°C).

Capacitance:......................15nF to 200nF.

Accuracy:..........................±5.5°F (±3°C).

Repeatability:....................±0.9°F (±0.5°C).

Response time:..................see graph in Appendix I.

Temperature range:...........-10°C to +70°C.

Sample Flow range:

(linear velocity @ 1ATM):Static to 100m/s.

Storage temperature:. ........-40°F to+176°F (-40°C to +80°C).

Mechanical:.......................encapsulated in 100µ sintered stainless steel.

Calibration method: ..........SpanCheck™, sensor saturates at dewpoint above

+68°F (+20°C). NIST/NPL traceable multi-point

factory calibration available optionally.

2.3 Sensor Installation & Sampling Techniques

Keep in mind that the moisture content at the sensor is not

only due to the moisture of the gas being measured, but also

due to desorption of water from tubing, trapped moisture (at

the interconnection points, valves, filters and other hygroscopic materials in the system), leaks in the system, and others. Thus the measurement may vary from the expectation,

and therefore care should be taken in choosing the sampling

technique utilized in the measurement. Factors such as gas

pressure, flow rate, materials of construction, length and

page 4

Page 9

Section 2: Sensor and Sampling Techniques

diameter of tubing, number of interconnecting fittings, dead

space in tubing and manifolds; will influence the measurement value and response time.

The high capacitance HTF™ sensors can be installed either

directly in the line to be sampled (in-situ), or in a slip stream

of a sample system (extractive).

To assure a long and accurate performance of the sensor, it

should be protected from contaminants such as liquids

(water, oil etc.), and particulates. The sintered stainless steel

sensor encapsulation protects from particulates larger than

100 microns, finer particulates (e.g. from degraded desiccant or rust) should be filtered with a particulate filter with

suitable capability, do not use hygroscopic filter materials.

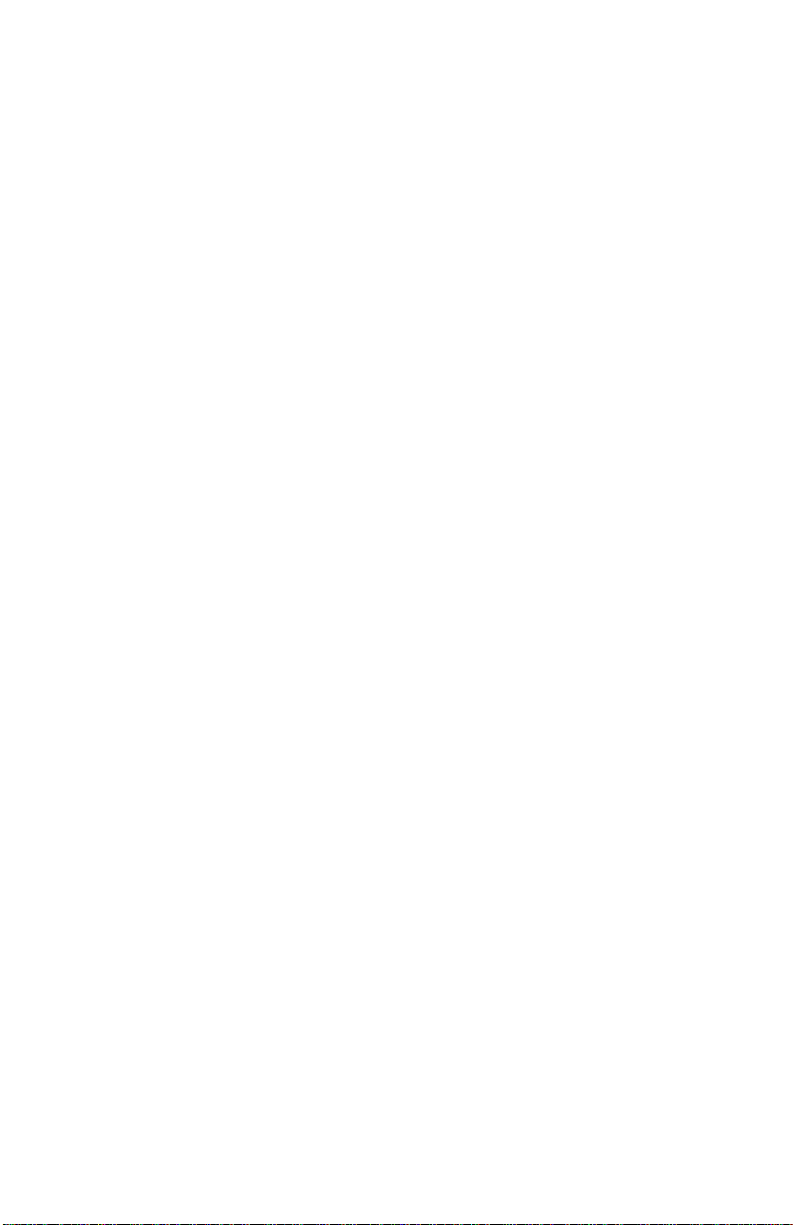

2.3.1 In-situ Installation

In-situ installation is recommended only for measurements

where the gas pressure is expected to vary little, the gas is

expected to be free of contaminants, the gas temperature is

wit hin the oper a ting s pec if ic at ions of the se nsor , a nd th e re is

no chance of liquids coalescing. Examples of applications

suited for in-situ installations are: pure gases, output of desiccant dryers (for instrument air), glove boxes, etc. For most

other applications in-situ installation should be avoided for

the following reasons:

• Sample conditioning is almost always necessary to

avoid exposure of the sensor to liquid water and other

contaminants, such as hydrocarbons, which may damage the sensor or affect accuracy over time.

• Variations in line pressure affect the reading of the sen-

sor because dewpoint varies with pressure.

• If the gas line is under pressure, it is more likely that

water condensation occurs which may damage the sensor.

page 5

Page 10

8800T User’s Manual

• Under a pressurized system removal of the sensor with-

out the installation of isolation valves can be dangerous.

If in-situ installation is required, bypass mounting is preferable; make sure to install the sensor at the upper surface of

the gas line to minimize its exposure to liquid water, should

condensation occur, the XTR65W sensor is best suited for

these applications. Also consider the need to isolate (depressurize) before installing or removing the sensor.

4-20mA loop cable

Main

Gas Line

8800T

oint Transmitter

Think

Read

Safety

www.xentaur.com

Mo

In-Line Installation, Sensor

Se

Manual

Measuring at Line Pressure

Ma

NOT RECOMMENDED

4-20mA loop cable

8800T

oint Transmitter

Think

Read

Safety

www.xentaur.com

Mo

Se

Bypass Installation, Sensor

Manual

Ma

Measuring at Line Pressure

Safety shut-off Valve

Safety shut-off Valve

Sample Cell

Bypass

Main

Gas Line

Control

Valve *

* maintain differential pressure to provide adequate flow through sample cell

page 6

Page 11

Section 2: Sensor and Sampling Techniques

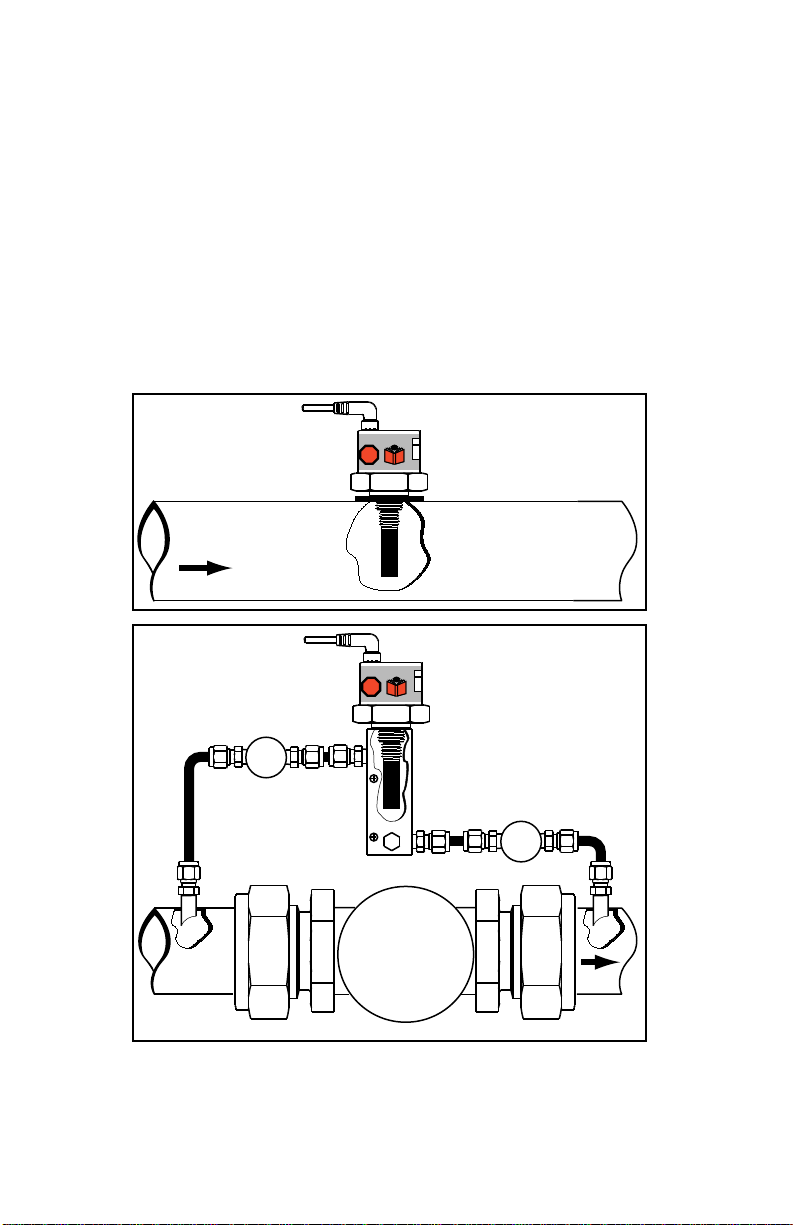

2.3.2 Extractive Installation

For extractive installations we recommend our sample system ESS, which may be equipped with a variety of features,

such as: isolation valve, coalescing or particulate filter,

pressure regulator , calibration sample injection or ext raction

port, pressure gauge, flow meter, weatherproof enclosure.

Refer to the ESS literature for more information.

If the resources to make your own sample system are available, the following two diagrams may be used as a guideline

to configure a simple system.

4-20mA loop cable

Safety shut-off Valve

oint Transmitter

Think

Safety

8800T

Read

Manual

www.xentaur.com

Exhaust

Mo

Se

Ma

Regulator or

Needle Valv e

Main

Gas Line

4-20mA loop cable

Regulator or

Needle Valv e

Main

Gas Line

Sample Cell

Extractive Installation, Sensor

Measuring at Line Pressure

8800T

oint Transmitter

Mo

Se

Think

Read

Manual

Safety

Ma

www.xentaur.com

Exhaust

Sample Cell

Extractive Installation, Sensor

Measuring at Ambient Pressure

page 7

Page 12

8800T User’s Manual

It is generally recommended to measure at ambient pressure

for the following reasons:

• The readings will not be affected by variations in line

pressure.

• The risk of exposing the sensor to liquid water is signif-

icantly reduced.

• ppm readings are computed for a pressure of one atmo-

sphere (1 bar); and have to be corrected using software

in the instrument, or a pressure nomograph, or calcula-

tor if the sensor is measuring at different pressures.

If readings at line pressure are necessary, it is recommended

to measure at ambient pressure and to use the instrument’s

pressure compensation feature to calculate the dewpoint at

line pressure. See appendix F.

Please make sure that:

• The sample is taken from the upper surface of the main

gas line. This avoids problems with contamination. The

sample should be taken away from pipe line walls where

flow rates may be low, and dewpoint changes may lag.

• For dewpoints dryer than -40°F, use stainless steel tub-

ing only. Copper tubing is acceptable for dewpoints wet-

ter than -40°F. Do not use plastic, rubber or tygon tubing

under any circumstances, as measurements would be

incorrect and/or response time slow due to water reten-

tion inside these materials.

• Try to run pipes to the sensor upwards, so that contami-

nants tend to fall back into the main line.

• Keep the length of the sample line to the sensor as short

as possible.

• Use small diameter pipes (1/4” or 1/8” OD).

• Use sufficient flow rates (e.g. 1 l/min with 6 feet of 1/8”

piping is adequate). The flow rate will influence the sys-

tems’ response time.

page 8

Page 13

Section 2: Sensor and Sampling Techniques

• Do not install any devices upstream of the sensor, such

as other measuring systems, flow meters etc., which are

not absolutely necessary as these are potential leak

sources.

• Installation of a coalescing and / or particulate filter

ahead of the sensor is desirable to prevent any liquid or

particulate contamination of the sensor.

• If filters are used upstream of the sensor, make sure

these contain non-hygroscopic filter materials only.

• If pressure regulators, shut off valves etc. are used

upstream of the sensor, make sure these do not contain

rubber or other hygroscopic materials.

2.4 Troubleshooting unexpected readings

If erroneous readings are suspected on a newly acquired

instrument, compare the serial number engraved on the sensor sintered filter, to the one stored in the instrument memory. The two should be the same; if they are not, the

instrument may not be calibrated with the installed sensor.

To troubleshoot other problems, identify the unexpected

reading category in the following table, and consider the

possible causes and appropriate diagnostic action and remedy.

page 9

Page 14

8800T User’s Manual

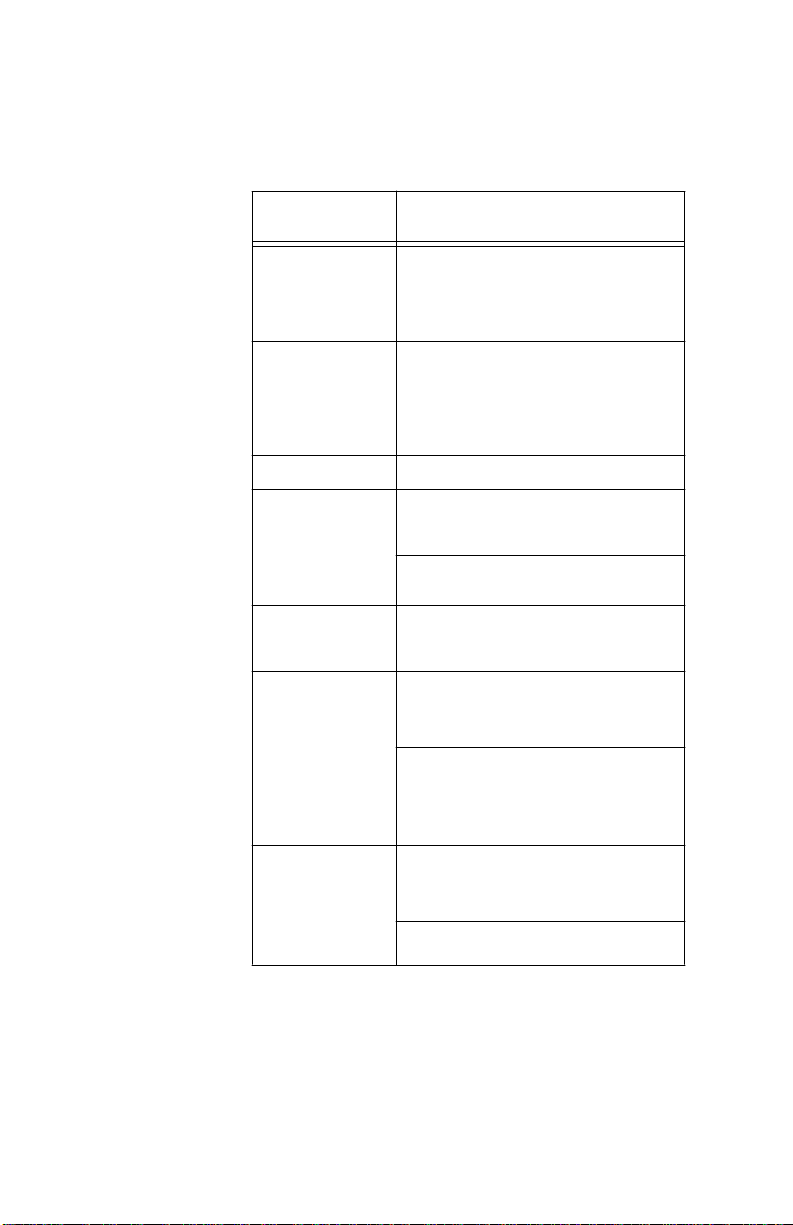

Troubleshooting unexpected readings (table spans 2 pages)

Symptom Possible Cause

Reading is not

changing

Slow Response

Dry Reading SpanCheck™ wrongly set, or faulty sensor.

We t Read ing

Display Shows

Condensation in sample system.

1. Water vapor in the system.

2. Flow rate too low.

3. Sample pipe too large and/or too long.

4. Unsuitable sample pipe material.

5. Leaks

6. Hygroscopic materials in sample system

Leak in system or use of unsuitable pipe.

Comparison of readings with manual cooledmirror instrument.

Prolonged exposure to wet gas.

6$7

Display Shows

1. In st ru men t F a i lu re

6+5

2.Short circuited sensor.

Display Shows

231

1. In st ru men t fai lu re.

2. Open circuit on sensor.

For non-sensor related problems (e.g. no reading on instrument) refer to section 3.5

page 10

Page 15

Section 2: Sensor and Sampling Techniques

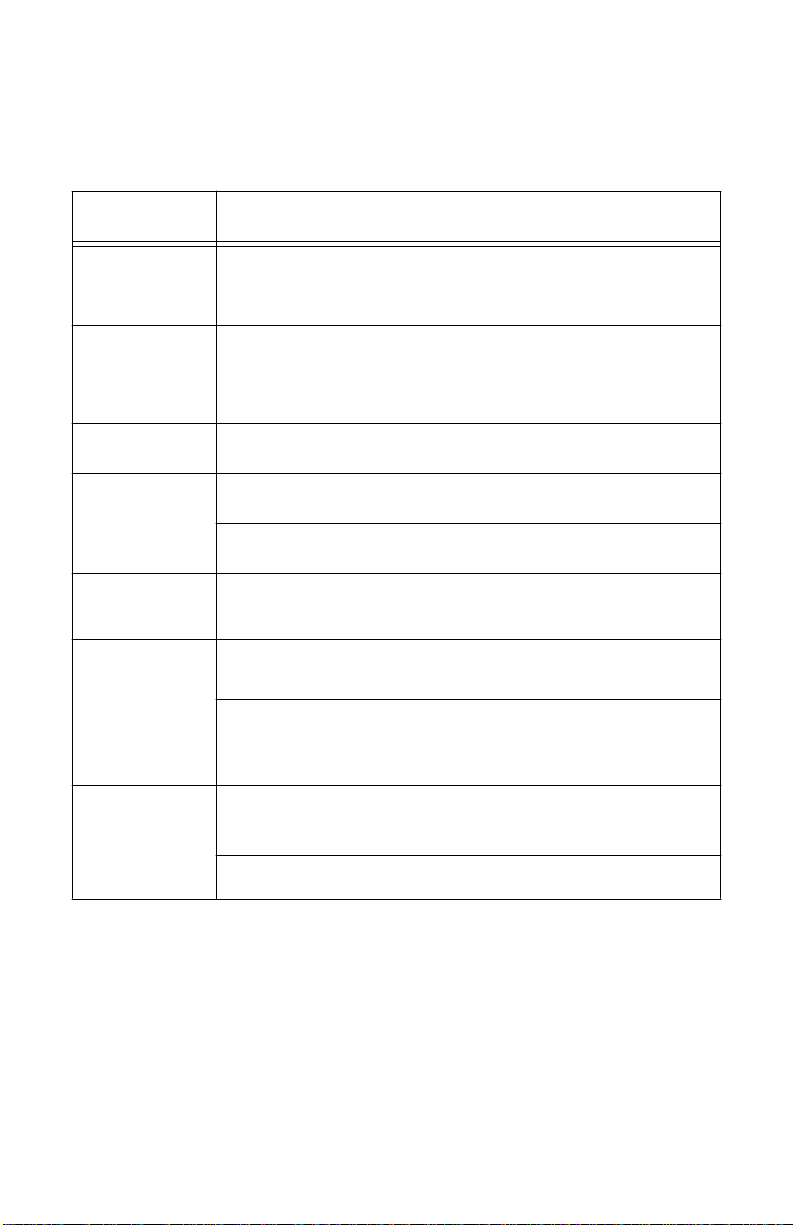

Troubleshooting unexpected readings (continued from previous page)

Symptom Diagnostic/Remedy

Reading is not

changing

Slow Response

Dry Reading Veri fy SpanCheck™, or return sensor for full calibration to your representative.

We t Read ing

Display Shows

6$7

Display Shows

6+5

Display Shows

Condensation will occur if the temperature of the sample system, at any point is below

(colder) the dewpoint temperature of the sample gas. Once having formed, the sample

reaching the sensor will have a dewpoint equal to the temperature of the condensation,

regardless of the dewpoint of the sample at the sample point.

It is usually more satisfactory to bleed a sample gas at atmospheric pressure through

the sensor sampling chamber, and to use 1/8” (3mm) o.d. sample pipe.

See below re: sample pipe material, also see section 2.3

Cure the leak, or replace unsuitable pipe with copper or stainless steel. Flexible connections should be made with PTFE pipe. NEVER use rubber or plastic pipe.

This type of indicator reads about 10°C dry at about -50°C dewpoint due to temperature gradi ent s wit hin the de vi ce. Th e error in cr ease s at drier levels.

Dry the sensor, install sensor in either a known dry gas stream i.e. instrument quality

air or dry nitroge n, or place sensor in a dry can or bottle of desiccan t an d seal the container from outside air (the shipping container is designed for this purpose)

Remove (unscrew) sensor, if the instrument still reads

instrum ent. Howeve r , if the instrument rea ds

Remove (unscrew) sensor and note that the meter reading returns to

sensor, or apply approximately 20V DC, between the center pin & the filter body of

the sensor, MOMEN T AR ILY with the s ensor in a known dry condition. Pola rit y is not

important, but the contact MUST be very brief or the sensor may be damaged.

Remove (unscrew) the sensor. Short the center contact of the 8800T sensor connection

to the case, if the ins trumen t read s

the instrument for service.

231

the problem is in the sensor, otherwise return

6+5

the problem is with the

6+5

then check possible cause #2

. Use a new

231

231

Check sensor connection or replace sensor.

page 11

Page 16

8800T User’s Manual

page 12

Page 17

Section 3: Instrument

3.1 Precautions using the 8800T

The 8800T uses state-of-the-art microelectronics to provide

a miniature full functioning instrument. The user should

consider the following precautions when using any sensitive

electronic device.

• Do not install the unit near heat sources such as radia-

tors or air ducts.

• Do not install the unit in places subject to extreme

mechanical vibration or shock. If this is not avoidable,

use resilient mounting. If in doubt, call your representa-

tive.

• Observe the appropriate electrical safety codes and reg-

ulations

• If weather proofing is required consult your representa-

tive for an optional cover.

3.1.1 Electromagnetic Compatibility Considerations

The 8800T has been designed and verified by testing to

meet the requirements of the EC Council EMC Directive

89/336/EEC, for Industrial, Scientific & Medical equipment. The sensor ground (8800T housing) is isolated from

the 4-20mA loop, however they are also shunted with a

2000pF capacitor and a 33V Transient Voltage Suppressor;

this prevents electrostatic buildup, noise pick-up, and in

conjunction with the internal fuse protects the instrument

from over-voltage inputs. Please consider the following

electromagnetic interference issues during installation:

• In order to provide an acceptable noise environment for

the 8800T or any other digital equipment in the proxim-

ity of inductive loads, it is recommended that there be

varistors placed across the inductors to keep down the

high voltage spikes during transitions.

page 13

Page 18

8800T User’s Manual

• Any circuitry which is activated by relay contacts

should account for the contact bounce, one simple

debouncing method is placing a capacitor across the

relay contacts.

• AC power wiring should be routed as far away from the

8800T and its wiring as practical.

3.2 Instrument Technical Specifications

Enclosure:.........................Stainless Steel, optional weather proof cover is avail-

able.

Dimensions & Weight:......~2”Dia. x ~4.75” long including sensor & connector

(see appendix C) 0.5lbs.

Pressure operating range:..Standard:.....500 PSI (34 bar).

Optional:.....5,000 PSI (340 bar).

Mechanical connections:...14mm x 1.25mm threads, and ¾”-16 threads.

Electrical connections:......2.1mm x 5.5mm (12mm minimum barrel length)

power jack, with retainer.

Cable:................................Two conductor cable, 12’ (~4m) provided.

Power Requirements:........10 to 33 VDC polarity independent, the instrument

draws 4-20mA depending on measured dewpoint.

Input resolution:................0.1°C dewpoint.

Indicators:.........................3.5 digit LCD with custom legends.

Engineering units:. ............°C,°F, PPM, LBS H

Controls:............................3 push buttons, user’s selections are stored in

EEPROM.

Outputs:.............................Analog and digital outputs are available from the

8800T.

A. 4-20mA drawn by the instrument from the power

supply. The 4-20mA is linear to the selected engi-

neering units, the range is programmable. Output

resolution is 0.1°C dewpoint.

B. The instrument can supply digital output by

modulating the 4-20mA loop line. The timing and

format of the data conforms to RS-232, however to

interface to a PC or other RS-232 device an optional

adapter is required.

In the digital mode the 8800T can be remotely

operated and the dewpoint as well as temperature

O/mm scf,gm H2O/M3.

2

page 14

Page 19

Section 3: Instrument

(and pressure if installed) can be read.

In the digital mode multiple units can operate on

the same loop cable as a multi-channel instrument.

Alarms:..............................The 4-20mA signal or the digital output may be used

by an external device to operate relays.

Isolation:...........................Sensor and case are isolated from the current loop

but are shunted with a 33V transorb and 2000pF

capacitor.

3.3 Installation

3.3.1 Mechanical Installation

The 8800T has two thread sizes for mounting to the sample

cavity (consult the sensor installation section) where the

dewpoint will be measured. Various adapters are available

for direct connection into existing system openings. Ask

your representative for a Sample Cell, if you do not have the

ability to provide an appropriate sample cavity mounting. If

the ¾”x16 thread is used then the 8800T will seal against the

wall of the sample cell with the provided Viton A O-ring. If

the 14mm x 1.25 spark plug thread is used then an additional Viton gasket must be installed to provide the proper

seal. Ask your representative for this gasket, it is available

free of charge. The 8800T is light enough such that either

thread will mechanically support the whole instrument. To

prevent any leaks, tighten the 8800T into the sample cavity,

with a

metal-to-metal contact.

Since the tightened positioning of the 8800T is unpredictable, its front panel may be rotated (360°) to allow easy

reading of the display. Press down gently on the spring

loaded face plate and turn it to the desired position.

The sensor can be removed from the 8800T by unscrewing

it. Make sure that the sensor is securely fastened to the

” wrench, 1/8 turn past finger-tight to assure

17/

8

page 15

Page 20

8800T User’s Manual

8800T (the tension washer should be compressed), so that it

does not come loose during use.

3.3.2 Electrical Installation

The 8800T will operate properly with 10VDC to 33VDC at

its input, if this voltage is exceeded the internal fuse may

blow. When selecting the power supply voltage do not

neglect the drop across any current measurement resistor

and wiring in the loop. The connector is a standard 2.1mm x

5.5mm (12mm minimum barrel length) DC power jack, an

internal diode bridge accommodates either polarity. The

8800T may be powered using an off-the-shelf wall transformer with 2.1mm connector, or from a power supply

using the provided connectorized cable. The provided cable

is terminated with a connector which has a retainer, the

retainer may be used to secure the connector to the 8800T

thus avoiding accidental disconnection.

The 8800T will draw 4mA to 20mA from the power supply

depending on the dewpoint being measured. The dewpoints

corresponding to 4mA and to 20mA are user selectable, in

between the current will vary linearly to the selected engineering units, see appendix G.

Various strategies for interfacing with the 8800T are shown

in Appendix D.

Please observe good electrical safety and grounding practices when connecting any electrical equipment; connecting

one end (e.g. negative) of the power supply to earth ground

is advisable.

After the installation is complete, proper detection by the

user’s equipment of the 4-20mA out put, may be tested using

the Analog Output test feature of the 8800T, see section

3.4.5.6.

page 16

Page 21

Section 3: Instrument

3.4 Operating the Instrument

3.4.1 Starting up

The instrument is ready for use as soon as the power cable is

installed. When power is applied the instrument will initialize its program and for a moment display

enter the Operating State. If the MODE button is held

pressed while the instrument is performing its power-up initialization, it will enter the Set-Up State, which allows the

user to select operating variables of the instrument.

To accommodate a variety of installation possibilities, the

8800T front panel may be rotated (360°) by gently pressing

down on the spring loaded face plate and turning it to the

desired position.

3.4.2 Display Conventions

1. To display characters with the 7 segment numeric dis-

play, the following pseudo-alphanumerics are used:

Numbers:

0 123456789

, then it will

;(1

Letters:

ABCDEFGH IJ LNOPQRSTUXYZ

$%&'( ) *+, -/12345678;<=

Symbols:

?-.

"

2. The instrument will indicate whether a particular mode

lets you change a parameter by showing the word

“SET” in the upper left corner of the display. Be careful

page 17

Page 22

8800T User’s Manual

+20°C

-100°C

+68°F

-148°F

23,612 ppmV

0.013,849

ppmV

2,000,000

0.000,000,1

1104.2

lbs H

2

O/mmSCF

0.000,921,15

lbs H

2

O/mmSCF

17.688

grams H

2

O/meters

3

0.000,014,75

grams H

2

O/meters

3

not to change any parameter inadvertently.

3. °C°F appear simultaneously, to indicate the sensors’

attenuation in decibels.

4. Values larger than ±1999 or smaller than ±0.01 are dis-

±3

played in powers of 10

-3

“10

” will appear above and to the right of the dis-

. As required, either a “10 3” or

played value, the value will be rounded off to 3½ digits.

The display will show

(out of ranGe), if the num-

51*

ber to be displayed is larger than 1,999,000. Twelve

examples follow; for each the number and units desired

to be displayed are shown in

italics,

depicted immedi-

ately below them is the resultant 3½ digit LCD display:

3

DEWPOINT

x10

˚C

DEWPOINT

˚F

DEWPOINT

PPM

DEWPOINT

LBS

DEWPOINT G/M

DEWPOINT

3

-3

x10

PPM

DEWPOINT

x10

LBS

-3

page 18

DEWPOINT

DEWPOINT G/M

˚C

x10

3

˚F

DEWPOINT

-3

Page 23

Section 3: Instrument

3.4.3 Push Buttons

Three push buttons are located on the front panel.

Teledyne 8800T

SET %

HILO

TEMP

DEWPOINT PSI G/M³ LBS

MODE button UP button DOWN button

x10¯³

PPM

˚C˚F

Each button is marked with an icon engraved above it.

In general the MODE button navigates through the different

user options “Modes”; the UP and DOWN buttons modify

the units, values or choices in the selected mode. Refer to

the flow diagrams in Appendix A for detailed overview of

button functionality. A button may be held down for a prolonged time, for accelerated incrementing or decrementing

of numeric values.

3.4.4 Operating State

Upon power up, the unit performs certain initialization tests

(see table in section 3.5), and enters the ‘Operating State’, in

the Viewing Dewpoint mode. Depressing the ‘MODE’ button will change modes (see appendix A) in the following

order: nViewing Dewpoint ‹ oViewing Temperature ‹

Start Calibration ‹ qViewing Serial Number ‹ (back to)

p

Viewing Dewpoint. The unit will return to Viewing Dew-

n

point mode if no buttons are pressed for 30 seconds, unless

it is performing a calibration.

page 19

Page 24

8800T User’s Manual

3.4.4.1 Viewing Dewpoint Mode

In this mode the user can view the dewpoint, this is indicated by the presence of the ‘DEWPOINT’ legend on the

lower left of the display. The available engineering units in

which to view the moisture content are °C, °F, PPM, LBS

3

and G/M

; the UP and DOWN buttons scroll back and forth

through these units in respective order. The °C and °F are

dewpoint readings. The PPM is parts per million by volume

computed at the sensor pressure (more about pressure in

3

appendix F). The LBS and G/M

are pounds of water per

million standard cubic feet and grams of water per standard

cubic meters, both in Natural Gas, they are computed

according to data derived by IGT Research Bulletin 8, taking into account sensor pressure.

Note that the analog output is linear to the selected engineering units, therefore be mindful that while scrolling

through various units the analog output may change even

though the measured dewpoint is stable.

The PSI legend flashes at the bottom of the display, when

there is pressure correction in the computation of the displayed values, refer to appendix F.

3.4.4.2 Viewing Temperature at the Sensor

In this mode the user can view the thermodynamic temperature at the dewpoint sensor inside the sampling chamber,

this is indicated by the flashing ‘TEMP’ legend on the lower

left of the display. The available units in which to view the

temperature are °C and °F. The UP and DOWN buttons

switch back and forth between these units.

Pressing the MODE button changes to the Start Calibration

Mode.

page 20

Page 25

Section 3: Instrument

3.4.4.3 Start Calibration (SpanCheck™) Mode

The instrument is calibrated at the factory with the sensor it

is shipped with and does not need to be re-calibrated prior

to installation.

Instrument calibration is recommended in approximately 12

month intervals, and the XTR65W sensor should be re-calibrated after prolonged exposure to liquid water. Simply follow steps 1 - 7 of the procedure below, removing the sensor

from the sample gas stream. Make sure the gas stream is

depressurized before removing the sensor to avoid injury.

It is recommended to keep the sensor exposure to room air

as short as possible to avoid super saturation of the sensor.

While super saturation is not damaging to the sensor, it will

prolong the initial dry-down time after you install the sensor

in the sample stream. Therefore, remove the sensor from the

packaging container only after you are ready to proceed

with the calibration procedure and install the sensor in the

sample stream immediately after the calibration procedure

is completed. If you are not ready to use the sensor right

away after calibration, put the sensor back in the shipping

container for dry storage.

The instrument must be calibrated with the sensor it will be

used with. The calibration procedure takes advantage of the

designed saturation level (DSL) feature of the sensor and is

executed by the instrument computer, by performing the following steps:

1. If the instrument is locked and a calibration is

attempted; it will display

and will not perform the

/2&

calibration. To unlock the instrument consult section

3.4.5.9.

page 21

Page 26

8800T User’s Manual

2. Push the MODE key a few times until the display shows

.

&$/

3. Press the UP button. The display will show

, prompt-

&1)

ing you to confirm that you want to start the calibration

procedure. You can abort the calibration procedure by

pressing the MODE key.

4. Remove the sensor from its packaging container so that

the porous metal filter is visible and the sensor is

exposed to in-hand micro-climate. Close the packaging

container as soon as you have removed the sensor to

avoid degradation of the desiccant inside of the container. You may want to re-use the container at a later

date.

5. Push the UP button again to confirm that you want to

start the calibration procedure. The display will flash

$&

for 60 seconds, while the sensor is saturating. Make sure

you keep the sensor exposed to in-hand micro-climate

until the display shows

(1'

.

6. After 60 seconds, the display will flash the selected sen-

sor type (see “

Selecting a sensor type 3.4.5.2

”) and then

the instrument will calculate the slope and offset of the

sensor curve while displaying the calculations and then

will display

for a few seconds, after which the

(1'

instrument will automatically go into measuring mode.

The sensor calibration is completed. (The display may

flash

, indicating that the sensor has super-saturated.

6$7

As soon as the sensor is exposed to an atmosphere with

a dewpoint lower than the saturation dewpoint, the display will indicate the dewpoint measured by the sensor.)

The display may show alternating

6(1

and

/2

as an

in dica tion t h at the mea sure d capa cit ance is too low to be

from a saturated sensor, in this case make sure that the

sensor is fully engaged into the 8800T, and repeat the

page 22

Page 27

Section 3: Instrument

calibration procedure.

7. Install the sensor in the sample cell or adapter fitting or

put it back into the packaging container for later use.

The instrument will retain the calibration even if the power

is turned off.

Under certain conditions, an over (super) saturated sensor

may need to be completely dried out before a calibration is

performed. Symptoms of these conditions are a sensor that

will not go through the SpanCheck™ function to the

(1'

display, or a sensor that will not dry down after calibration.

To dry, install sensor in either a known dry gas stream i.e.

instrument quality air or dry nitrogen, or place sensor in a

dry can or bottle of desiccant and seal the container from

outside air (the shipping container is designed for this purpose). After a minimum dry out period of 24 hours, proceed

with the calibration procedure of your choice.

SpanCheck™ calibrates sensors by using micro climates.

Please contact your representative if you have any questions

about how to create such micro climates.

A perfectly acceptable and accurate for calibration microclimate may be created for the XTR100 and XTR65 sensors

by cupping the sensor in the palm of one’s hand during the

SpanCheck™ procedure. Remember that the micro-climate

does not have to be accurate, it just has to be higher than the

designed saturation level. The dewpoint of the micro-climate within the fingers is usually higher than the dewpoint

of the room air and probably well above the +20°C upper

range of the sensor. On a dry day one may need to exhale in

the hand before cupping the sensor to guarantee a high dewpoint. The sensor should be warmed up close to body temperature before performing this procedure. Care must be

page 23

Page 28

8800T User’s Manual

12

345

XSN

taken that the sensor temperature is not below the temperature of the hand, as in such case condensation could occur

and super saturate the sensor. For the same reason, avoid

exhaling directly onto the sensor.

3.4.4.4 Viewing Serial Number Mode

In this mode the user can view the serial number of the sensor calibrated and shipped with the instrument. This number

is also engraved on the stainless steel sintered filter of the

sensor element. The display shows the serial number by

alternately displaying

and the number. If the number is

;61

larger than 1999 then it is displayed in 2 parts, first part is

3

the thousands signified by the x10

legend in the upper right

corner of the display and the second part is the units. For

example serial number 12345 will be shown as:

3

x10

Pressing the UP and DOWN buttons simultaneously resets

the instrument, this is useful for restarting in the set-up state

(by holding the MODE button), in installations where

power can not be turned on and off easily.

Pressing the MODE button changes the unit to the Viewing

Dewpoint Mode.

3.4.5 SetUp State

To enter the Setup State power-up the unit (or reset it from

the serial number Mode), and hold the MODE key pressed

while the unit is initializing. Refer to Appendix B for a flow

page 24

Page 29

Section 3: Instrument

diagram of the SetUp State.

The setup state provides nine capabilities, each one controlled from its own mode. Depressing the MODE button

navigates through the modes in the following order: nSelect Alternate Display Units ‹ oSelect Sensor Type ‹ pSet

Measured Attenuation of Sensor at a Low Dewpoint ‹ qSet

the Low Dewpoint at which the Attenuation was measured ‹

Set the Calibration Mid-range Adjust ‹ sPerform a Test

r

and Verification of the Analog Output ‹ tSet dewpoint corresponding to 4mA of Analog Output ‹ uSet dewpoint corresponding to 20mA of Analog Output ‹ vLock/Unlock the

instrument ‹ (back to) nSelect Alternate Display Units.

These nine functions are explained in their respective sections which follow.

unlocked instrument

Changes can be made only to an

, the changes are stored (when the

MODE button is pressed) and retained even if the unit is

turned off.

1.

Display of alternate units

: In this mode, a second engineering unit can be chosen to be displayed alternating

with the engineering unit selected in the operating state,

for example, a dewpoint can be displayed alternating

with the sample temperature, or dewpoint can be alternately shown in °C and in PPM.

2.

Selecting the sensor type

: In this mode the user can

select the software matching the type of sensor installed

in the instrument;

3&4

Adjusting low end sensor attenuation and dewpoint

: XTR-100 (-100°C to +20°C);

;7

: XTR-65 (-65°C to +20°C).

;7

These modes are used to enter a data pair representing a

low dewpoint and the sensor attenuation measured at

this low dewpoint. (see Sensor Theory of Operation

appendix E). This data pair should not be modified

unless the sensor is replaced. The sensor shipping con-

:

page 25

Page 30

8800T User’s Manual

tainer is labeled with the proper values.

5.

Calibration Adjustment

: In this mode the user can

enter a sensor specific Adjustment Value to improve the

instruments’ accuracy in the range of -50°C to -10°C,

this adjustment has very little or no effect outside this

range. The Calibration Adjustment Value is printed on

the shipping container supplied with the sensor, or may

be derived if the sensor can be exposed to a known reference.

Deriving an Adjustment Value

①

: If the adjustment

value for your sensor is not known, contact your representative and follow the instructions in paragraph B on

the next page. If the value is not available, then it may

be derived using a manual method, provided that a

moisture calibration lab is available.

The calibration must be done in the range of -25°C to

-20°C (attempting to calibrate outside this range may

cause inaccuracies), the dewpoint must be kept stable

during calibration and it must be measured accurately

by a reference instrument such as a chilled mirror. One

must also note the state of pressure compensation and

turn it on or off as applicable to the reference.

The necessary steps are described below (also refer to

the Set-Up State flow diagram in Appendix B):

a. Make sure that the low attenuation and low dewpoint

are correctly entered for this sensor.

b. SpanCheck™ the sensor.

c. Dry-down the sensor for at least 12 hrs.

d. Expose the sensor to the known dewpoint (-25°C to

-20°C), for a sufficient time (at least 30 min.)

e. Go to t he

&$/$'-

mode and press the UP button, the

display will show the current value, in the range of -1.99

to +1.99 followed by blinking horizontal lines.

page 26

Page 31

Section 3: Instrument

f. Observe the display, if the buttons are not being

pressed; the display will every few seconds show for a

short duration the dewpoint as being computed at the

moment (utilizing the current cal-adjust value in the

computation).

g. Use the UP or DOWN buttons to modify the caladjust value and observe the alternately displayed dewpoint. Perform this adjustment until the dewpoint

matches the value shown by the reference instrument.

h. Press the MODE button to go to the next mode, this

will save the new cal-adjust value, and it will be retained

even if power is turned off.

Entering a known Adjustment Value

②

: If the sensor is

being replaced an adjustment value should be supplied

with the sensor, to enter it into the instrument:

a. Go to t he

&$/$'-

mode and press the UP button, the

display will show the current value, in the range of -1.99

to +1.99 followed by blinking horizontal lines, ignore

the alternately displayed dewpoint.

b. Use the UP or DOWN buttons to modify the caladjust value as necessary.

c. Press the MODE button to go to the next mode, this

will save the new cal-adjust value, and it will be retained

even if power is turned off.

2), 3), 4) and 5) are set at the factory and need only be

modified when a sensor is changed.

6.

Testing the analog output

: By pushing the UP or

DOWN buttons, the user forces the analog output to its

low and high values, respectively. This facilitates the

hook-up and testing of the user’s monitoring equipment.

7&8

Output range setting

: These modes are used to set

dewpoints corresponding to the low and/or high end of

page 27

Page 32

8800T User’s Manual

the current loop output, refer to appendix G.

9.

Lock/Unlock the instrument

: This mode is used to

block access to parameter settings, protecting the instrument from unauthorized or inadvertent changes of

parameters. Attempting to change settings while instrument is locked will display

/2&

To unlock the instrument press the UP button, to lock

the instrument press the DOWN button. Pressing the

MODE button will navigate back to the Select Alternate

Display Units mode.

Pressing and holding either the UP or DOWN button,

will save the lock or unlock setting depending on the

button, and reset the instrument. This feature is useful if

it is difficult to power off the instrument.

Note: It is imperative that one returns the instrument to

the locked mode to avoid unauthorized changes.

3.5 Troubleshooting the Instrument

This instrument performs diagnostic tests on power up as

well as once every two minutes. The table that follows,

depicts all possible error/unexpected messages that may be

displayed on the instrument. For each message the table has

explanations for the reason, and if necessary a suggested

action to remedy it.

page 28

Page 33

Section 3: Instrument

DISPLAY EXPLANATION REQUIRED ACTION

LO

(55

HI

(55

%

(55

&6)

(55$'

(555()

/2%$7

LO

51*

TEMP

HI

51*

TEMP

231

6$7

6+5

'%

6(1/2

(55((3

/2&

51*

°C(

w/flashing

DEWPOINT

flashing

PSI

when

dew

;(1

Legend:

PROM check sum failed.

RAM write/read te st failed. cycle power

Unidentified power-up failure. if problem persists,

EEPROM Check Sum Failed. return to your representative

power on tests

converter failure.

A/D

erence voltage for A/D out of spec.

Ref

Low supply

Instrument low

has been excee ded . make sure that th e unit is at a

Instrument high

has been excee ded .

Sensor circuit is

Sensor is

Sensor circuit is

Trying to calculate dewpoint for

voltage.

erature

temp

eratur e

temp

open

urated. sensor troubleshooting

sat

shor

undefined sensor.

e

rang

system tests once per 2 min.

e

rang

.

ted. section

dewpoint display tests

Trying to calibrate an undefined

fo r s erv ice.

check input voltage 10-33VDC

temperature of -10°C to +70°C.

see table in

select sensor and

SpanCheck.

see Calibration instructions.

sensor.

sor reading is ‘

Sen

rated sensor, for SpanCheck.

ROM write cycle not completed.

EEP

Attempting to modify a

number can not be displayed in 3.5 digits.

°F)

An XTR-65 sensor is measuring less

w to be a satu-

too’ lo

Calibration. tests

if this persists, return for service.

ked unit. unlock unit, see set-up mode.

loc

than -70°C or -94°F dewpoint.

miscellaneous

Pressure correction is enabled.

Turn on message,

denotes alternately flashing messages.

Xen

taur (

Greek Ξ

=X)

page 29

Page 34

8800T User’s Manual

The instrument contains a fuse which may open if the

instrument is subjected to voltages exceeding the specifications. Under these circumstances the unit display will be

blank and the instrument will not draw any current when

powered up. The fuse is not user replaceable, therefore the

8800T must be sent to your representative for servicing.

page 30

Page 35

Appendices

SEN/2LO

AC/_AC

CNF/AC?

CAN

/

Appendix A: Operating State User Interface flowchart

Power ON initialization

and sign on message

30 seconds anywhere

other than calibration

without a key press

Viewing

Dewpoint

Viewing

Sensor

Temperature

Calibration

Menu

Viewing

Serial

Number

Teledyne 8800T

DEWPOINT

PSI

select

units

Teledyne 8800T

TEMP

select

units

Teledyne 8800T

SET

Teledyne 8800T

a flashing

PSI legend

means pressure

correction is

being applied,

see appendix F

˚C

˚F

Press together to

RESET the Instrument.

Then quickly press and hold

MODE to go to Set-Up State.

1sec.

Confirm

SpanCheck™

1 minute

Sensor

Reading

OK

Teledyne 8800T

SET

numbers calculating

calibration

Teledyne 8800T

Teledyne 8800T

SET

Teledyne 8800T

SET

Too Low

few

seconds

Teledyne 8800T

SET

Teledyne 8800T

SET

1 sec.

Cancel Calibration (calibration values are not changed)

2 sec.

Values Stored

New Calibration

LEGEND: 1. Arrows leading out from below a button depict the flow as a result of

pressing the button.

2. Arrows leading out of other locations depict flow as a result of

completing a function or a time-out.

3. A slash '

' in the display area, is used to depict two alternately

shown (flashing back and forth) messages.

page 31

Page 36

8800T User’s Manual

LOC

ALT/DSP

SEN/XT1

DB/

CAL/ADJ

A.0./TST LO/BAT

A.O./RNG/

XT1 XT6 DB

Appendix B: Set-Up State User Interface flowchart

CAUTION! These parameters are set

properly at the factory, to correspond to

the shipped sensor. Do not modify them

unless you are replacing the sensor.

appears when changing

settings of a locked instrument

XTR-100 XTR-65 attenuation

+/- 0.01 units

If no buttons pressed

for 3 seconds the dew

is shown for a moment.

SET

Power-Up with

MODE key pressed

blank ˚F ˚C ppm LBS G/M3 Temp˚F Temp˚C%PSI ˚C˚F

Choose alternate units to show when displaying dewpoint

SET

Factory default is blank (there is no alternate display).

Choose Sensor type

SET

page 32

Set measured attenuation at a known low dewpoint

˚C˚F

SET

LO

+/- 0.01dB

Set low dewpoint for the above set attenuation

˚C

SET

LO

DEWPOINT

+/- 0.1˚C

Calibration Midrange Adjust

SET

Page 37

Appendices

/

A.0./TST LO/BAT

A.O./RNG/

A.O./RNG/

UN/LOC

User Interface Flow Diagram - Set-Up State (continued from previous page

Ensure minimum voltage at LPDT

to be 10VDC, when drawing 20mA

Too

Low

Test

Voltage

Current Loop

OK

Test Analog Output

4mA

20mA

HILO

+/- 0.1˚C

Set dewpoint corresponding to low end of analog output

Factory default is -100˚C

˚C

SET

LO

SET

+/- 0.1˚C

Lock or unlock the instrument

Set dewpoint corresponding to high end of analog output

Factory default is 20˚C

˚C

When locked instrument parameters can not be changed.

Prolonged press of either button will reset the unit

Factory default is locked.

Lock

Unlock

HI

SET

)

' in the display area, is used to depict two alternately

page 33

LEGEND: 1. Arrows leading out from below a button depict the flow as a result of

pressing the button.

2. A slash '

shown (flashing back and forth) messages.

Page 38

8800T User’s Manual

m

Appendix C: 8800T Mechanical Drawing

˚

0

6

3

y

l

e

e

r

f

s

e

t

a

t

o

r

l

e

n

a

p

t

n

o

r

f

DC Power Jack

oint Transmitter

Think

Safety

Power Jack screw-on retainer

1.750"

x10¯³

PPM

˚C˚F

SET %

HILO

TEMP

DEWPOINT PSI G/M³ LBS

Teledyne 8800T

Read

Manual

www.teledyne-ai.com

Mo

Se

Ma

8

/

7

flats for 1 " wrench

5/16"-24

tension washer

3/4"-16

sintered stainless steel,

unscrew to remove.

Removable Sensor encapsulated

in 100

Viton A O-ring

14mm x 12.5mm

2.230" 1.850" 0.600"

page 34

Page 39

Appendix D: 8800T Electrical Connections

W

Methods of Using and Interfacing the 8800T

Operation with Wall Transformer

Dewpoint viewed on Instrument Display

10-33VDC

120V

or

220V

Wall Transformer

Operation with DC Power Supply

Dewpoint viewed on Instrument Display

and available as 4-20mA output

maintain

10-33VDC here

VDC

4-20mA

oint Transmitter

Think

Read

Safety

www.xentaur.com

oint Transmitter

Think

Read

Safety

www.xentaur.com

Mo

Se

Manual

Ma

Mo

Se

Manual

Ma

Operation with Relay Option Board

Dewpoint viewed on Instrument Display

and available as 4-20mA output

Relay Option Board

Provides two

independent Relays

with programmable

trip point and

hysteresis

DC or AC supply

Operation with Remote Option Board

Dewpoint viewed on Instrument Display

and available on remote

Display

Buttons

Relays

Voltage or Current

Output

RS-232 Output

Power Supply

4-20mA

Appendices

oint Transmitter

Mo

Se

Think

Read

Manual

Safety

Ma

www.xentaur.com

oint Transmitter

Mo

Se

Think

Read

Manual

Safety

Ma

www.xentaur.com

Operation with DC Power Supply

Dewpoint viewed on Instrument Display

and available as Voltage output

12-33VDC

0.4 - 2V output

100

oint Transmitter

Think

Read

Safety

www.xentaur.com

85 - 265VAC

Operation with Multichannel Option Board

Dewpoint viewed on each Instrument Display

and available on remote interface

Multichannel

Option Board

Mo

Se

Manual

Ma

multiple units connected on the same two wires

oint Transmitter

oint Transmitter

Think

Think

Safety

Safety

www.xentaur.com

Read

Read

www.xentaur.com

Manual

Manual

Mo

Se

Ma

Ma

page 35

RS-232C

to Computer

DC or AC supply

Mo

Se

oint Transmitter

Think

Safety

Read

www.xentaur.com

Manual

Mo

Se

Ma

Page 40

8800T User’s Manual

Appendix E: Sensor/SpanCheck™ Theory of Operation

The Sensor is constructed as a capacitor whose dielectric

consists of porous Aluminum Oxide as well as the gas that

has entered in the pores of the Aluminum Oxide. The plates

(electrodes) of this capacitor are an aluminum substrate and

a porous gold layer deposited on top of the Aluminum

Oxide, the porous gold electrode allows transfer of gases

into or out of the Aluminum Oxide pores.

The capacitance due to the Aluminum Oxide is always constant, while the capacitance due to the gas varies according

to the gas content and pressure. Since the dielectric constant

of water is orders of magnitude larger than that of any gases

being measured, the quantity of water vapor present in the

pores changes the capacitance of the sensor to a much

greater extent than any other system variable. For the same

reason (the extremely large dielectric constant of the water

molecule), any capacitance variations arising from the Aluminum Oxide, such as changes due to temperature, are

insignificant in relation to the capacitance due to the water

content. Thus the sensor capacitance varies greatly in proportion to the water content in the surrounding gas. The sensor is designed such that the relationship of the quantity of

water and the resultant capacitance has an "S" shaped curve.

At the extremely dry end the curve is asymptotic to the

capacitance due to the Aluminum Oxide and the gas, while

at the very wet end the curve is asymptotic to the capacitance due to water molecules packed extremely tightly (saturated) in the pores of the Aluminum Oxide. This upper end

is an excellent indication of the total pore volume; while the

lower end of the curve is an indication of the distance

between, and area of the capacitor plates (electrodes), this is

the intrinsic capacitance of the sensor. Therefore knowing

these two points, a sensor can be calibrated with compensa-

page 36

Page 41

Appendices

tion for small manufacturing deviations.

As the sensor is used in real world applications, it is

exposed to various elements and stress; like any other sensor it may over time drift from calibration. However one

must note that the intrinsic capacitance will not change with

use because it is based simply on the dielectric constant of

Al

and the distance between, & area of the plates (elec-

2O3

trodes), thus the original factory measured values will

always be valid. What may change is the pore volume, due

to clogging with contaminants, residual oxidation, metal

migration, etc. Thus to re-calibrate the sensor the instrument

needs only to "know" the capacitance at the wet end of the

curve. As discussed previously the capacitance at the wet

end approaches asymptotically a saturated pore capacitance,

therefore if the sensor is saturated (the exact water content

will not be important since the curve is asymptotic), then the

instrument can measure the capacitance and re-calibrate the

sensor. This is refered to as SpanCheck™. The advantages

of this unique capability of Teledyne sensors and instruments

are obvious in time and cost savings for re-calibration, as

well as ease of sensor replacement.

Teledyne HTF™ Sensor: Dewpoint vs. Capacitance Response Curve

200

Saturated Capacitance Asymtote of New Sensor

Saturated Capacitance Asymtote of Aged Sensor

160

rCurve

nsor Curve

120

Aged Se

New Senso

80

Capacitance (nF)

40

0

Dry Capacitance Asymtote of New & Aged Sensor

-80

-60

-40

Dewpoint Reference ˚C

-20

0

20

page 37

Page 42

8800T User’s Manual

page 38

Page 43

Appendix F: Pressure Correction

Appendices

Sensor Pressure

is used in the context that this is the pressure inside the sampling chamber when performing the

measurement, i.e. it is the operating pressure of the sensor.

Gas Pressure

is use d in th e c ontex t that this is the pr essur e at

which the dewpoint is to be calculated.

Pressure Correction

is used in the context that the values

displayed signify the moisture content at some pressure (we

refer to this as the ‘Gas Pressure’) different from the pres-

3

sure at the sensor. Note that PPM, LBS and G/M

readings

are by definition unaffected by pressure correction because

only the pressure at the sensor affects their value. While °C

and °F are affected by pressure correction by reporting what

the dewpoint would be at the Gas Pressure when the dewpoint is what is measured at the pressure at the sensor. However, this also implies that whether pressure correction is

3

applied or not the PPM, LBS and G/M

readings are

affected by the setting of the sensor pressure.

The factory default settings are: 14.7psi for both sensor and

gas pressure and pressure correction disabled.

When Pressure correction is disabled all dewpoints are

computed by assuming that both Sensor and Gas Pressures

are 14.7psi.

As all Teledyne dewpoint meters, the 8800T is equipped with

the necessary software to perform pressure correction.

However, for the lack of space, the 8800T does not have a

Pressure Correct button. Therefore the user can not set or

enable Pressure Correction, this must be done at the factory .

Consult with your representative.

page 39

Page 44

8800T User’s Manual

Appendix G: Current vs. Dewpoint

The current being pulled by the 8800T, varies with the dewpoint being measured by the 8800T. To use the current to

calculate the value of the dewpoint measurement, one must

know the settings of the low and high ends of the analog

output range, then:

4

–

()

I

----------------------------------------L+=

D

where:I = current drawn by 8800T loop in mA.

= value of High end of Analog Output range

H

converted to sele cted engineering units

= value of Low end of Analog Output range

L

converted to sele cted engineering units

= dewpoint measured by instrument in selected

D

engineering units.

()×

HL

16

–

Consult section 3.4.5.7&8 and/or appendix B, to check and

set the Analog Output low and high ranges; the factory

default settings are -100°C and +20°C respectively.

For example a unit with factory default settings, drawing

12mA is computed to be measuring a dewpoint of -40°C:

12 4

–

()

----------------------------------------------------------- -

20 100

–

–

()

()×

16

100

–

+

()

40

–=

Note that the computation is such that the current is linear to

the selected engineering units. Hence, selecting ppmV or

LBS or G/M3 units, will cause the analog output to be linearly proportional to those units (approximately logarithmically proportional to dewpoint), refer to the graph that

follows. Naturally selecting °C or °F will cause the analog

output to be linearly proportional to dewpoint.

When monitoring in ppmV or LBS or G/M3, the analog

output low & high ranges may have to be adjusted to pro-

page 40

Page 45

Appendices

vide a useful output. Consider an example where the area of

interest to be monitored is 10 to 100 ppmV, and the analog

output is set up with the factory defaults of -100°C to +20°C

(which is 0.014 to 23612 ppmV); then the current loop output will vary only from ~4.1 to ~4.2 mA in the area of interest (consult with the graph on the following page). In most

instances this would be an unacceptable output for proper

monitoring of the measurement. In this example the user

should adjust the analog output low & high ranges such that

the output range is better suited to the measurement of 10 to

100 ppmV. It may be useful to select the low and high

ranges to be 5 and 150 ppmV respectively, thus out of range

conditions will be detected properly. Then the low range

will be set to 5ppmV which is -65.5°C dewpoint, and the

high range will be set to 150ppmV which is -38.5°C dewpoint. Now the current loop output will be 4.55 to 14.48 mA

in the range of 10 to 100 ppmV, the ~10mA variation is

more than sufficient for a good measurement by the user’s

equipment. One may carry out similar calculations for LBS

or G/M3 and choose the appropriate settings. While making

these computations it may be useful to obtain a copy of

Teledyne’s dewpoint calculator, this is a Microsoft Windows™ program which simplifies the process of converting

dewpoint measurement units. It is available at www.Tel-

edyne-ai.com. If you are not certain how to carry out such calculations send, by e-mail to Teledyne@Teledyne-ai.com or by fax to

(626) 961-2538, your system specifics, and some one will

get back to you with appropriate analog output settings.

In general, if the dewpoint is monitored in °C or °F, there is

no need to change the factory default -100°C to +20°C settings, because the 4-20mA provides sufficient resolution to

measure the output better than the specified accuracy of the

sensor.

page 41

Page 46

8800T User’s Manual

Relationship of 4-20mA output and instrument reading in ppmV or LBS

289.1 LBS = 0˚C = 6063.8 ppmV

49.3 LBS = -20˚C = 1019.3 ppmV

Low AO range = -100˚C High AO range = +20˚C

Instrument reading in ppmV

0.56 LBS = -60˚C = 10.66 ppmV

10 100 1000 10000

8mA

12mA

20mA

4/20 mA output

1.97 LBS = -50˚C = 38.83 ppmV

High AO range = -38.5˚C

5mA

4.5mA

page 42

Instrument reading in LBS of H2O / million cubic feet

Low AO range = -65.5˚C

0.1 1 10 100 1000

4.1mA

Page 47

Appendices

Appendix H: Uncertainty in LBS & ppmV calculations

48

44

38

34

29

24

19

15

900

800

700

600

500

400

300

1000

10

5

2.5

O / mmscf

2

1

Calculated LBS H

0.5

0.25

0.1

Uncertainty of LBS & ppmV calculations due to +/-3˚C measurment accuracy

0.05

-65

-60

-55

-50

-45

-40

-35

-30

-25

-20

Dewpoint +3˚C

Dewpoint -3˚C

-75

-70

200

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

1

0.9

0.8

0.7

0.6

0.5

-80

Measured Dewpoint ˚C

Calculated ppmV

page 43

Page 48

8800T User’s Manual

Appendix I: Sensor Response Time

100

95

90

85

80

after 48hrs of equilibrium

(dp)

Sensors to a Step-change (DOWN)

3

O

2

at time 0, to -62.2 ˚C

(dp)

from -39.4 ˚C

Response Time of TAI Al

0

5

1015202530354045505560657075808590

65% of step change

% of step change

75

70

65

60

55

50

45

Time (minutes)

40

35

30

25

20

15

10

5

95% of step change

0

95

100

105

page 44

Page 49

Teledyne, 16830 Chestnut St., City of Industry, CA 91748 Tel: (626) 934-1500

Loading...

Loading...