Page 1

OPERATING INSTRUCTIONS FOR

Model 7600

NDIR Infrared Gas Analyzer

P/N M7600

ECO:

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Page 2

Model 7600

Copyright © 2005 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/ Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/ Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Teledyne Analytical Instruments ii

Page 3

Infrared Gas Analyzer

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Page 4

Model 7600

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

No

Symbol

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments iv

Page 5

Infrared Gas Analyzer

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

TI/AI at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model 7600

Table of Contents

List of Figures ...............................................................................x

List of Tables...............................................................................xii

Introduction.................................................................................15

1.1 Overview 15

1.2 Main Features of the Analyzer 15

1.3 Options Available 17

1.4 Applications 17

1.5 Description of the Main Unit 18

Installation................................................................................... 21

2.1 Unpacking the Analyzer 21

2.2 Choosing a Location 22

2.3 Mounting the Analyzer 23

2.4 Mounting the Input/Output Terminal Module 23

2.5 Gas Connections 25

2.5.1 Internal Piping Diagram 25

2.5.2 External Piping Diagram 27

2.5.3 Gas Conditioning 28

2.5.4 Flowrate 29

2.5.5 Preparation of Calibration Gas 29

2.5.6 Purging the Analyzer 30

2.5.7 Sample Gas Pressure 30

2.5.8 Example configuration of gas sampling system 30

2.6 Electrical Connections 32

2.6.1 Power Inlet 32

2.6.2 Input/Output Terminal Module 33

2.7 Testing the System 34

Teledyne Analytical Instruments vi

Page 7

Infrared Gas Analyzer

Operation .....................................................................................35

3.1 General Information 35

3.2 Display and Available Menus 36

3.3 The Display Screen 38

3.3.1 Measurement Mode 38

3.3.2 Setting/Selection Screen 40

3.4 Basic Operation 41

3.5 Setting Up the Analyzer in the User Mode 42

3.5.1 Switch Ranges 42

3.5.1.1 Manual Range Switching 43

3.5.1.2 Range identification contact operation 44

3.5.1.3 Remote Range Selection 45

3.5.1.4 Autoranging 46

3.5.2 Calibration Parameters 46

3.5.2.1 Calibration Value 46

3.5.2.2 Setting of Manual Zero Calibration 48

3.5.2.3 Setting of calibration range 50

3.5.2.4 Setting of auto calibration component/range 51

3.5.3 Alarm Setting 53

3.5.3.1 Configuring the Alarms 55

3.5.3.2 Hysteresis Setting 56

3.5.4 Setting of Auto Calibration 58

3.5.4.1 Auto Calibration 58

3.5.4.2 Gas Flow Time Setting 59

3.5.4.3 Cycle Setting Range 60

3.5.4.4 Remote Start 62

3.5.4.5 Forced Run/Stop of Auto Calibration 62

3.5.5 Setting of Auto Zero Calibration 65

3.5.5.1 Auto Zero Calibration 65

3.5.5.2 Forced run/stop of auto zero calibration 68

3.5.6 Peak Alarm Setting 70

3.5.7 Parameter Setting 73

Teledyne Analytical Instruments vii

Page 8

Model 7600

3.5.7.1 Output Hold 75

3.5.7.2 Average Value Reset: 78

3.5.7.3 Response Time 79

3.5.7.4 Average Period 79

3.5.7.5 Backlight Timer 80

3.5.7.6 Maintenance mode 81

3.6 Maintenance Mode 82

3.6.1 Sensor Input Value 83

3.6.2 Error Log 84

3.6.3 Calibration Log 84

3.6.4 Optical Adjustment 85

3.6.5 Moisture Interference Adjustment 86

3.6.6 Output Adjustment Screen 86

3.6.7 Other Parameters 87

3.7 Calibration 90

3.7.1 Zero Calibration 90

3.7.2 Span Calibration 91

Maintenance ................................................................................93

4.1 Routine Maintenance 93

4.2 Daily Check and Maintenance Procedures 93

4.3 Analyzer Maintenance 94

4.3.1 Sample Cell Cleaning 94

4.3.2 Cleaning the Cell Block 97

4.4 Optical Zero Adjustment 99

4.5 Moisture Interference Compensation Adjustment 102

4.6 Error Messages 104

4.6.1 Error Log File 106

4.6.2 Error Log Screen 106

4.6.3 Deleting Error Hstory 107

Appendix.................................................................................... 109

A.1 SPECIFICATIONS 109

A.2 Standard Functions 111

Teledyne Analytical Instruments viii

Page 9

Infrared Gas Analyzer

A.3 Optional Functions 115

A.4 Performance: 116

A.5 Standard Requirements for Sample Gas 117

A.6 Installation Requirements 118

A.7 EC Directive Compliance 118

A.8 Terminal Block Connections 119

A.9 Description on Terminal Block 120

Index...........................................................................................125

Teledyne Analytical Instruments ix

Page 10

Model 7600

List of Figures

Figure 1-1: Model 7600A Infrared Gas Analyzer...........................16

Figure 1-2: Model 7600 Description..............................................19

Figure 2-1: Slide Rail Mounting Dimensions .................................23

Figure 2-2: Input/Output Terminal Module.....................................24

Figure 2-3: Mounting the I/O Module............................................. 24

Figure 2-4: Internal Piping with Single or Dual Measuring Units ... 26

Figure 2-5: External Piping with Single Inlet and Outlet................27

Figure 2-6: External Piping with Two Pair of Inlet/Outlet (1).......... 28

Figure 2-7: External Piping with Two Pair of Inlet/Outlet (2).......... 28

Figure 2-8: Five Component Analysis System .............................. 31

Figure 2-9: Model 7600 Electrical Connections.............................32

Figure 2-10: Noise Suppression.................................................... 33

Figure 2-11: I/O Cable Connection................................................ 33

Figure 3-1: Front Panel of the Model 7600.................................... 35

Figure 3-2: Interface Keys on the Front Panel...............................35

Figure 3-3: Display Modes and Menu Hierarchy...........................37

Figure 3-4: Example Screen—5 Component Analysis 12

Channels................................................................................38

Figure 3-5: Setting/Selection Screen Areas .................................. 41

Figure 3-6: Hysteresis Example for a High Limit Alarm................. 57

Figure 3-7: Example Auto Calibration ........................................... 61

Figure 3-8: Example Auto Zero Calibration................................... 67

Figure 3-9: Peak Alarm Example ..................................................72

Figure 3-10: Output Hold for Manual Calibration........................... 75

Teledyne Analytical Instruments x

Page 11

Infrared Gas Analyzer

Figure 3-11: Output Hold for Auto Calibration ...............................76

Figure 3-12: Output Hold for External Hold ...................................76

Figure 3-13: Average Value Reset................................................79

Figure 3-14: Example Average Period ..........................................80

Figure 4-1: Top Cover Removal....................................................95

Figure 4-2: Sample Cell Removal..................................................95

Figure 4-3: Sample Cell.................................................................96

Figure 4-4: IR Window Assembly..................................................97

Figure 4-5: Detector Secure Nut....................................................98

Figure 4-6: Cell Block Assembly....................................................99

Figure 4-7: Optical Adjustment Display for Dual Optical System

Option...................................................................................100

Figure 4-8: Optical Zero Adjustment............................................101

Figure 4-9: Beam Adjustment Plate.............................................102

Figure 4-10: Bubbler Apparatus ..................................................103

Figure 4-11: The Error Log Screen..............................................107

Teledyne Analytical Instruments xi

Page 12

Model 7600

List of Tables

Table 2-1: Correspondence of Measured Components and

Measuring Units..................................................................... 27

Table 2-2: Zero and Span Gas......................................................29

Table 4.1 Troubleshooting and Maintenance................................ 93

Table 4-2: Components of Optical Adjustment Screen ............... 100

Table 4-3: Error Messages .......................................................... 104

Teledyne Analytical Instruments xii

Page 13

Infrared Gas Analyzer

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

WARNING

Since the use of this instrument is beyond the control of

Teledyne Instruments/ Analytical Instruments, referred as

TI/AI, no responsibility by TI/AI, its affiliates, and agents for

damage or injury from misuse or neglect of this equipment is

implied or assumed.

Teledyne Analytical Instruments xiii

Page 14

Model 7600

Teledyne Analytical Instruments xiv

Page 15

Infrared Gas Analyzer Introduction

Introduction

1.1 Overview

The Model 7600 Infrared Gas Analyzer is a microprocessor based

infrared gas analyzer used to measure the concentration of NO, SO

CO

, CO and CH4 contained in sample gas. It is based on the principle

2

that different molecular species have unique absorption spectrum in the

infrared, and the intensity of absorption is determined by the LambertBeer law.

In addition to the infrared analyzer, the Model 7600 can also be

equipped with a built-in compact paramagnetic O2 sensor or employ an

external zirconia oxygen sensor to increase to 5 the number of

simultaneous component species the unit can analyze.

,

2

Teledyne's Series 7600 Infrared (IR) Gas Analyzer is conveniently

packaged in either a 19" rack mount or NEMA-4 wall mount enclosure.

The NEMA-4 enclosure can be X or Z-purged to satisfy hazardous area

installation requirements.

A high-sensitivity mass flow type twin detector is used for infrared

measurements. By utilizing a single beam, double path design in

conjunction with a serial dual-layer transmission detector, the Series

7600 delivers long term, drift-free performance.

The concentration of the desired gases is displayed on a large, easyto-read back-lit LCD. Figure 1-1 shows the standard rack mountable

Model 7600. The user interface is very intuitive and the menu / mode

selection buttons, which are readily accessible, provide the operator with

dynamic control and extensive diagnostic capabilities.

1.2 Main Features of the Analyzer

The Model 7600 Infrared Gas Analyzer is designed for accurate

and reliable gas analysis and is easy to operate. The following features

are standard on the 7600 instrument:

Teledyne Analytical Instruments 15

Page 16

Introduction Model 7600

Figure 1-1: Model 7600A Infrared Gas Analyzer

• Simultaneous measurement of up to five components

• Excellent long-term stability

• Large, easy to read LCD display showing all simultaneous

measurements and computations

• Slide-out, chassis design to facilitate any optical or

maintenance adjustments required to fine tune analyzer

performance (7600A)

• Multiple, in-depth on-screen analyzer functions easily

accessible using the front-panel user interface buttons

• Follow & Hold output signal control (during calibration)

• Remote range change control

• Low / Hi limit alarms

• Range ID signals

• Auto-calibration with user adjustable frequency and gas flow

time setting programming capabilities

• Remote auto-calibration initiation

• Auto-calibration status contacts

Teledyne Analytical Instruments 16

Page 17

Infrared Gas Analyzer Introduction

• Instrument or calibration error contact outputs

• Extra functions included such as average value computation,

O2 conversion

• Pump ON/OFF contact

1.3 Options Available

• Percent O

detector — Paramagnetic (built-in) or ZrO2

2

(externally installed), user preference

• O

correction (the conversion of measured CO and SO2

2

readings into values at standard O2 concentration). Consult

factory for more detail for this function.

• Communication functions:

• RS-232C (9 pins D-Sub connector)

• Half-duplex bit serial

• Modbus protocol

1.4 Applications

The Model 7600 Infrared Gas Analyzer is a versatile analytical

instrument tool and is ideally suited for multi-parameter gas analysis

requirements for applications such as:

• Combustion control within the power, pulp and paper, steel,

and cement industries

• Heat treating / Inert gas blanketing atmosphere control

• Bulk-gas impurity analysis within the air separation industry

• Anaerobic digester / Bio-gas / Land-fill gas analysis

• Vent gas analysis of oxyhydrochlorination reactors (EDC)

• Off-gas analysis on PTA and Maleic Anhydride reactors

• Fluid Catalytic Cracker (FCC) regeneration gas analysis

• Ammonia / Fertilizer process gas stream analysis

• Continuous Emissions Monitoring Systems (CEMS)

Teledyne Analytical Instruments 17

Page 18

Introduction Model 7600

• Biochemistry and fermentation,

• Automotive emission analysis

• Explosive and toxic gas analysis

• Chemical analysis

• Refinery operation

• Research applications

1.5 Description of the Main Unit

Teledyne's Series 7600 Infrared Gas Analyzer measures the

concentration of NO, SO2, CO2, CO, and CH4 in a gas mixture on a

continuous basis. The Series 7600 can also be supplied with an oxygen

sensor, which allows the simultaneous measurement of oxygen

concentration as well. The NEMA-4 enclosure can be X or Z-purged to

satisfy hazardous area installation requirements.

The system uses a high-sensitivity mass flow type twin detector for

infrared measurements. A single beam, double path optical bench is

installed in conjunction with a serial dual-layer transmission detector.

The concentration of the desired gases is displayed on a large, easyto-read backlit LCD. The user interface is very intuitive and the menu /

mode selection buttons, which are readily accessible, provide the

operator with dynamic control and extensive diagnostic capabilities. See

Figure 1-2.

The front panel mounted power switch turns the instrument on and

off while the display switch controls power to the display.

Front panel mounted handles make sliding the instrument out of the

panel rack or enclosure a simple task for easy maintenance.

Teledyne Analytical Instruments 18

Page 19

Infrared Gas Analyzer Introduction

Figure 1-2: Model 7600 Description

Gas connections for the 7600 instrument are made on the rear panel

of the instrument using the ¼” NPT fittings installed. The standard

instrument has two measuring units and a pair of inlet/outlet gas

connections exist for each unit. See Section 2.5 Gas Connections.

A power receptacle on the rear panel accepts the three-prong power

cable supplied with the instrument. The Model 7600 operates on 100240 VAC 50/60 Hz power. The power inlet conforms to EN60320

Protection Class 1 specifications.

Teledyne Analytical Instruments 19

Page 20

Introduction Model 7600

Teledyne Analytical Instruments 20

Page 21

Infrared Gas Analyzer Installation

Installation

Installation of the analyzer includes:

1. Unpacking the system.

2. Choosing a suitable location

3. Mounting the analyzer

4. Mounting the terminal module

5. Installing gas connections

6. Making electrical connections

7. Testing the installation.

CAUTION: READ THIS CHAPTER IN ITS ENTIRETY BEFORE

INSTALLING THE SYSTEM.

FOR INDOOR USE ONLY.

2.1 Unpacking the Analyzer

The Model 7600 Infrared Gas Analyzer is shipped with the

following components:

• 7600 Analyzer

• Input/Output terminal module set

• Connection cable

• Power cable

• Fuse (2)

• Cell window mounting tool

• Slide rail (2)*

• Relay board for auto calibration*

• Relay board connection cable*

• Instruction manual

Teledyne Analytical Instruments 21

Page 22

Installation Model 7600

* These optional items are included if specified at the time of purchase

As soon as you receive the instrument, carefully unpack and inspect

the analyzer and components for damage. Immediately report any

damage to the shipping agent. The analyzer is shipped with all the

materials you need to install and prepare the system for operation.

2.2 Choosing a Location

CAUTION: THIS UNIT IS NOT EXPLOSION-PROOF. DO NOT

INSTALL IT IN A LOCATION WHERE EXPLOSIVE OR

FLAMMABLE GASES ARE PRESENT.

Select an installation location that meets the following criteria:

• This instrument should be rack mounted, or mounted in a

steel enclosure.

• Indoor location.

• Vibration-free.

• Not exposed to direct sunlight.

• Clean and non-cluttered space.

• Depending on the options selected at the time of purchase,

the model 7600 requires an AC power source of 100V to

240V AC.

• Operating voltage: 85V to 264V AC

• Rated frequency: 50/60 Hz

• Power consumption: 250 VA max.

• Plug: Comformity to EN60320 class I type 3-pin inlet

• Operation conditions:

• Ambient temperature: -5° to 45°C

• Ambient humidity: 90 % RH or less, no condensation

Teledyne Analytical Instruments 22

Page 23

Infrared Gas Analyzer Installation

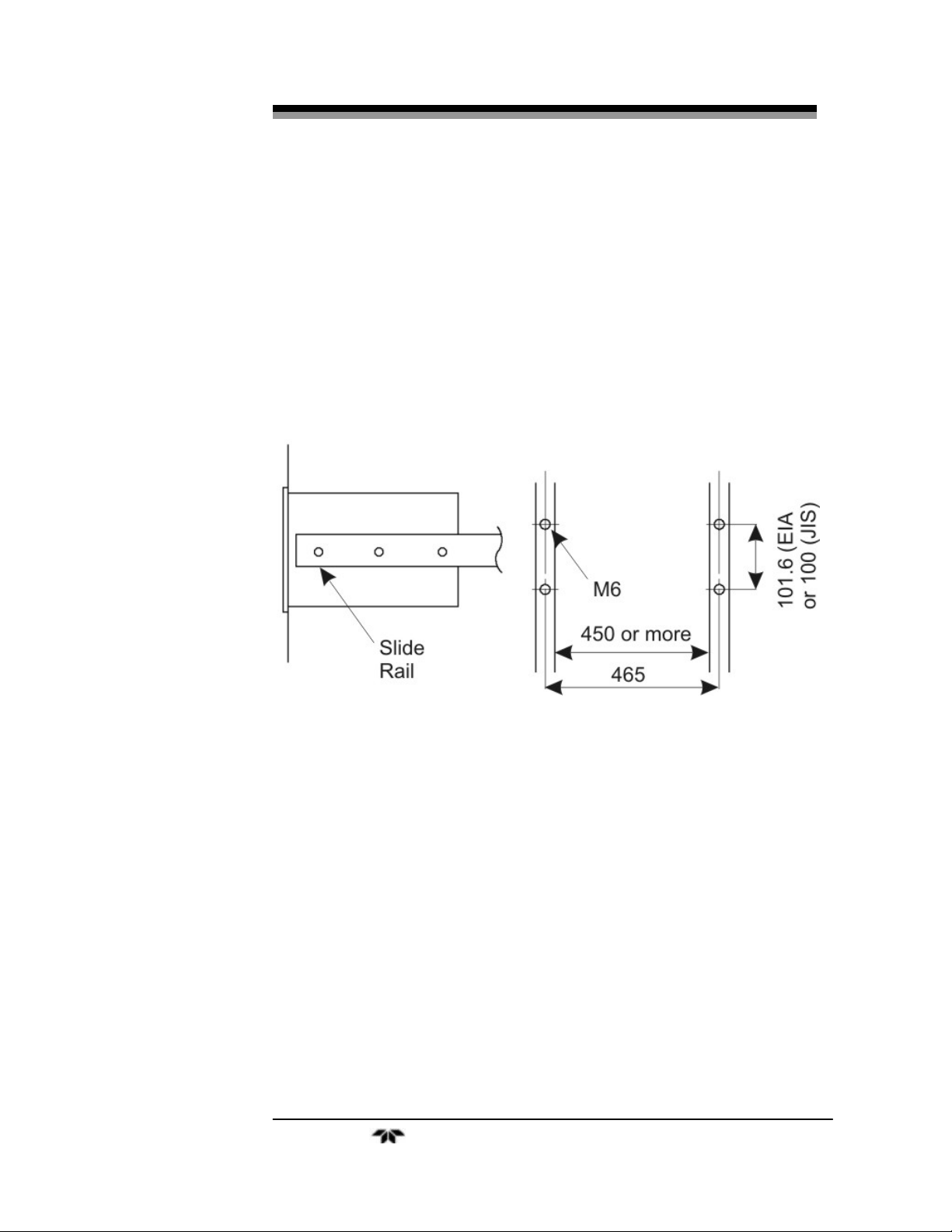

2.3 Mounting the Analyzer

The 19” rack mountable 7600 analyzer is designed for either a

guide rail or slide rail mounting within a rack or cabinet. The guide rail

method supports the weight of the instrument from the bottom and can

be used when there is adequate space for removing the top cover for

maintenance. The slide rail mount supports the instrument from sliders

mounted on the side of the instrument as shown in Figure 2-1. The

instrument is then able to slide out of the rack or enclosure for required

access during maintenance.

Figure 2-1: Slide Rail Mounting Dimensions

2.4 Mounting the Input/Output Terminal Module

The input/output module is the electronic interface that handles the

various signals to and from the analyzer. It consists of up to five

terminal blocks, a communications connector, a cable connector, and a

solenoid drive output connector mounted together on a single mounting

plate. See Figure 2-2.

Mount the input/output terminal module to the rack or cabinet panel

using the six M4 screws supplied. For grounding, see Figure 2-3.

Note: To avoid noise generated from external units, mount the

I/O terminal module mounting plate to the panel making

sure there is adequate metal contact for continuity at the

Teledyne Analytical Instruments 23

Page 24

Installation Model 7600

mounting surface. Connect the panel to the same ground

as the analyzer main unit.

Figure 2-2: Input/Output Terminal Module

Figure 2-3: Mounting the I/O Module

Teledyne Analytical Instruments 24

Page 25

Infrared Gas Analyzer Installation

2.5 Gas Connections

Gas connections are made on the rear panel of the analyzer. Adhere

to the following guidelines when making gas connections:

• Use a corrosion resistant tube such as Teflon, stainless or

polyethylene to connect the instrument to a sampling system.

Even if there is a danger of corrosion, refrain from using

rubber or soft vinyl tubing. This would result in instrument

inaccuracies due to gas absorption by the piping materials.

• Pipe connection port is Rc1/4 female thread (or NPT1/4).

Piping should be cut as short as possible for quicker

response. About 4 mm inner diameter is recommended.

• Keep out dust and debris from the tubing and connections .

Always use clean tubing and fittings.

Connect the gas tube as follows:

• Sample gas inlet: Attach the sample gas tube to the inlet

fitting. The sample gas should be filtered and dehumidified

before passing into the analyzer. This port is also used to

connect the zero and span calibration gases.

• The gas flow should be constant within the range of 0.5

L/min ±0.2 L/min.

• Sample gas outlet: Sample gas exits the analyzer through

the gas out port at atmospheric pressure. Exhaust gases must

be vented safely.

• Purge gas inlet: This connection is used for purging the

inside of the analyzer. Purging is not always required. See

Section 2.5.6 Purging the Analyzer. When required, use dry

N

or instrumentation air for the purge gas. Use a flow rate of

2

1L/min or greater).

2.5.1 Internal Piping Diagram

Note: When the purge gas inlet is provided, an internal

connection to measuring unit 2 is installed.

Teledyne Analytical Instruments 25

Page 26

Installation Model 7600

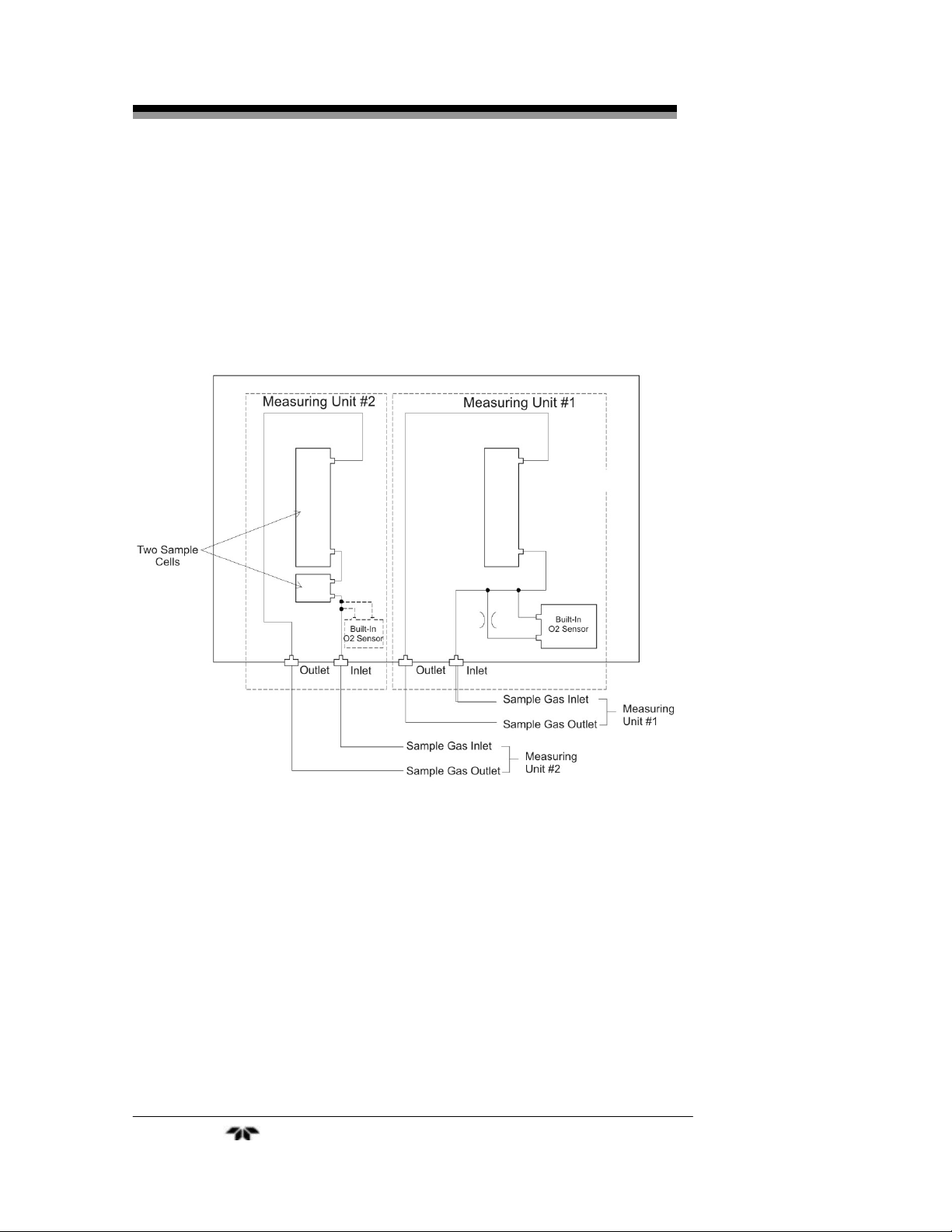

An internal piping diagram for an instrument with one or two

measuring units is shown in Figure 2-4. When there are two measuring

units, if a built-in oxygen sensor is used, it must be installed in

measuring unit 2. The diagram shows the combination of two cells used

in measuring unit #2. This is possible by combining ranges. When a

single measuring unit is used, there is only a single inlet and outlet gas

connection.

Figure 2-4: Internal Piping with Single or Dual Measuring Units

Depending on the options chosen, the analyzer can be configured in

several ways. Table 2-1 lists the possible configurations for single and

dual measuring units with 1 to 4 component meters.

Teledyne Analytical Instruments 26

Page 27

Infrared Gas Analyzer Installation

/

/

Table 2-1: Correspondence of Measured Components and Measuring

Units

Measuring components Measuring unit 1 Measuring unit 2

1-component meter for NO,

SO

, CO2, CO and CH4

2

2-component meter for

NO/SO

and CO

2

2

CO

2-component meter for

Each component None

2

CO

2

None

NO/SO

CO

NO CO

NO/CO

3-component meter for

NO/SO

/CO

2

4-component meter for

NO/SO

/CO2/CO

2

NO/SO

NO/SO

CO

2

CO2/CO

2

2.5.2 External Piping Diagram

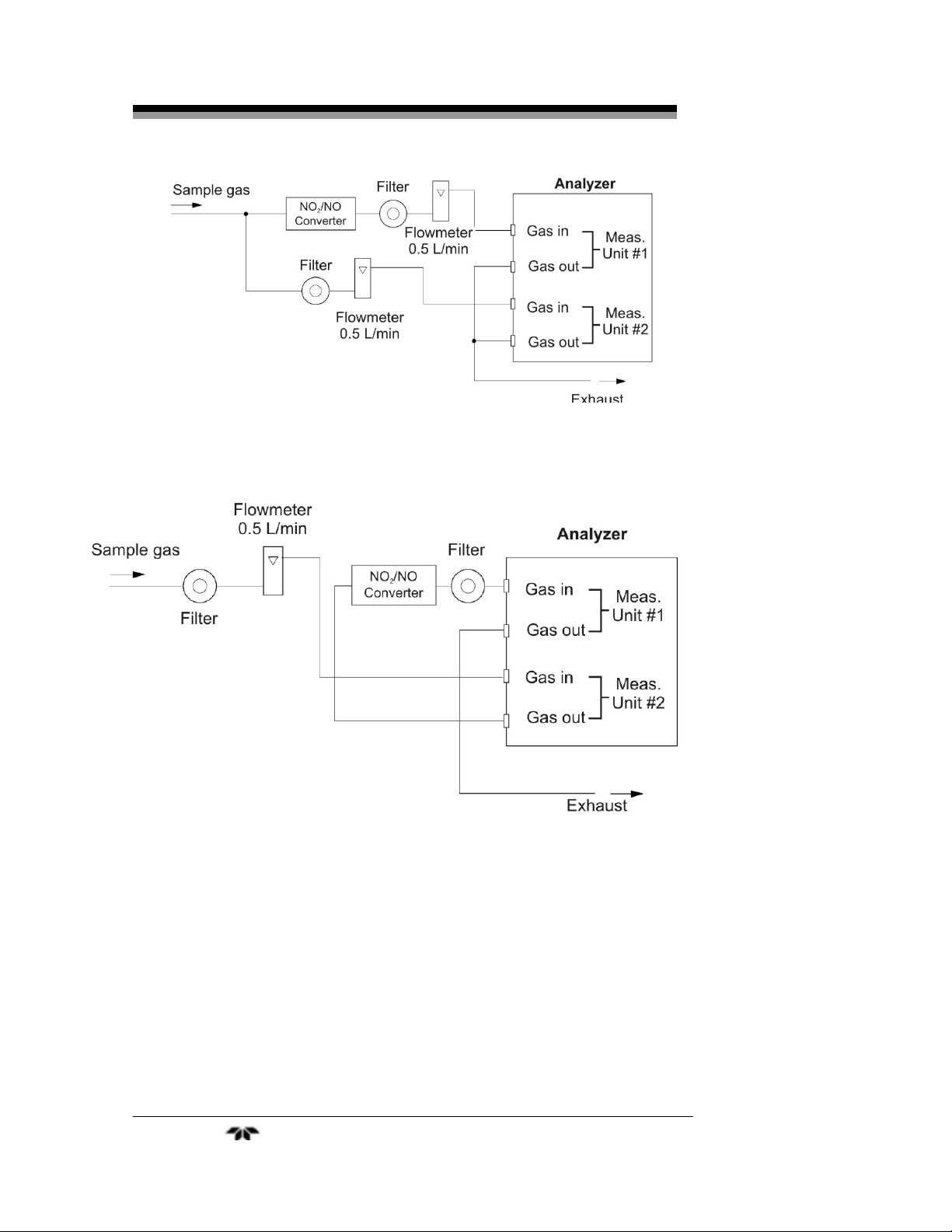

There are several ways to bring sample gas to the analyzer

depending on the number of inlet/outlet gas connections on your

instrument Recommended piping diagrams are shown in Figures 2-5, 26 and 2-7. Figure 2-5 is a schematic for an instrument with a single pair

of inlet/outlet gas connections. Figures 2-6 and 2-7 are used when there

are two pair of inlet/outlet connections. Note that a NO2/NO converter

is used when NO measurement is used for NOx analysis.

Figure 2-5: External Piping with Single Inlet and Outlet

Teledyne Analytical Instruments 27

Page 28

Installation Model 7600

Figure 2-6: External Piping with Two Pair of Inlet/Outlet (1)

Figure 2-7: External Piping with Two Pair of Inlet/Outlet (2)

2.5.3 Gas Conditioning

For optimum performance, the sample gas should be treated as

follows:

• A filter should be installed to remove any dust or particles in

the sample gas. For a final stage filter, use a filter that can

remove dust particles of 0.3 μm.

Teledyne Analytical Instruments 28

Page 29

Infrared Gas Analyzer Installation

• The dew point of the sample gas must be lower than the

ambient temperature to avoid condensation in the analyzer. If

vapor is contained in the sampling gas, the dew point should

be lowered to 0°C by using a dehumidifier.

• If SO

mist is contained in the sample gas, use a mist filter or

2

cooler to remove the SO2 mist. Other mists should be

removed by using an appropriate mist filter or cooler.

• Corrosive gases such as Cl

, F2 and HCl, if contained in the

2

sample gas in considerable amounts, will shorten the life of

the instrument.

• Sample gas temperature should be within 0 to 50°C. Hot gas

should not be fed directly into the instrument.

2.5.4 Flowrate

Use a flowrate of 0.5L/min ±0.2L/min. The sample system should

be designed to avoid any flow fluctuation during measurement.

Use a flowmeter to observe the flow reading as shown in the

external piping diagrams of Figures 2.5, 2.6 and 2.7.

2.5.5 Preparation of Calibration Gas

Routine calibration using calibration gases is required for

optimizing the performance of this instrument. Once a week is a

suggested calibration frequency. Table 2-2 indicates the zero and span

gas required for calibration.

Table 2-2: Zero and Span Gas

Zero gas

Span gas

other than for

O

2

Span gas for

analysis

O

2

Teledyne Analytical Instruments 29

Analyzer without

O

2

N

gas N2 gas Dry air

2

Gas concentration

of 90% or more of

full scale

NA

Analyzer with built-in

O2

Gas concentration of

90% or more of full

scale

Gas concentration of

90% or more of full

scale

Gas concentration of 90%

or more of full scale

1 to 2% O

Analyzer with external

zirconia O2 sensor

2

Page 30

Installation Model 7600

2.5.6 Purging the Analyzer

In general, purging the analyzer is not required unless one of the

following cases apply:

• A combustible gas component is contained in sample gas.

• Corrosive gas is contained in the atmospheric air at the

installation site.

• The same gas as the sample gas component is contained in

the atmospheric air at the installation site.

In the above situations, the inside of analyzer should be purged

with instrument air or N2. Use a purge flow rate of about 1 L/min.

Use a filter to remove dust or mist from the purge gas.

2.5.7 Sample Gas Pressure

The sample gas pressure at the outlet should be atmospheric

pressure.

2.5.8 Example configuration of gas sampling system

A typical system configuration with five component gas analysis

for monitoring combustion exhaust gas from boiler, refuse incinerator,

etc. is shown in Figure 2-8. Contact Teledyne for specific application

system configuration or further information.

The system shown is comprised of:

• Model 7600—with dual measuring unit option and external

zirconia oxygen sensor.

• Gas Extractor—with stainless steel filter of standard mesh 40

μm equipped with integral heater.

• Mist Filter—to remove condensate, mist and dust from the

sample before it enters the analyzer.

• Safety Drain Trap—with two compartments for positive and

negative pressure. It monitors and adjusts the sample gas

pressure.

• Gas Aspirator—to aspirate the sample gas.

• Electronic Gas Cooler—used to dry the sample gas to a dew

point of approximately 2°C (35.6°F).

Teledyne Analytical Instruments 30

Page 31

Infrared Gas Analyzer Installation

• Solenoid Valve—for introducing calibration gas and

OFF/ON flow of sample gas.

• Membrane Filter—PTFE filter for rempval of fine dust

particles.

• Flowmeter—adjusts and monitors the sample gas flowrate.

• Standard Gas—a bank of calibration gases used for setting

zero and span of the analyzer for each species monitored.

• Zirconia Sensor— an external zirconia sensor is used for

measuring the oxygen concentration in the sample gas. Some

instruments use a built-in paramagnetic oxygen sensor

instead aof an external zirconia sensor.

• NO

/NO Converter—added to the NO analysis circuit which

2

uses an efficient catalyst for converting NO2 to NO for

analysis.

Figure 2-8: Five-Component Analysis System

Teledyne Analytical Instruments 31

Page 32

Installation Model 7600

2.6 Electrical Connections

2.6.1 Power Inlet

The power inlet for the Model 7600 is located on the rear panel as

shown in Figure 2-9. The proper 3-prong power cord has been supplied

with your instrument. Connect the power cable to the power inlet.

Figure 2-9: Model 7600 Electrical Connections

The Model 7600 requires 100-240 VAC 50/60 Hz power.

Avoid installing this instrument near an electrical unit that

generates electrical noise such as a high frequency furnace or electric

welder. If using the instrument near such a noise-generating unit is

unavoidable, use a separate power line to avoid noise.

Mount a noise suppressor such as varister or spark killer as shown

in Figure 2-10 to the noise generating unit when noise is generated from

relays or solenoid valves. The suppressor must be mounted near the

noise generating source, or it will have no effect.

Teledyne Analytical Instruments 32

Page 33

Infrared Gas Analyzer Installation

Figure 2-10: Noise Suppression

2.6.2 Input/Output Terminal Module

Use the supplied cable to interface the I/O Module to the analyzer.

Plug the cable connector into the receptacle at the rear panel of the

analyzer and the receptacle on the PC board of the input/output module.

Make sure that the ferrite core attached to the I/O cable goes to the

analyzer. See Figures 2-9 and 2-11.

Figure 2-11: I/O Cable Connection

The I/O Module carries various input and output signals. A detailed

list of these signals and pinout information is given in the Appendix.

Teledyne Analytical Instruments 33

Page 34

Installation Model 7600

2.7 Testing the System

After the analyzer has been installed with gas and electrical

connections but prior to powering up the unit make sure you have:

• Installed the unit correctly

• Checked the gas connections for leaks

Once the above checks have been made, you can connect the power

source and turn the analyzer on using the power switch on the front

panel. Allow the analyzer to warm up for four hours.

When the instrument is first turned on, you will see the

measurement screen. While in the warm up stage, the readings are

inaccurate. They may even be above the upper limit of range, however,

this is not an error.

After the analyzer has come to equilibrium (approximately four

hours after first powering up) the instrument is ready to be configured

and calibrated for your process. This is described in Section 3.

Teledyne Analytical Instruments 34

Page 35

Infrared Gas Analyzer Operation

Operation

3.1 General Information

This section describes the front panel interface of the analyzer.

Figure 3-1 Shows the Model 7600 Infrared Gas Analyzer front

panel. The user interface consists of 8 membrane switch buttons or keys,

a power ON/OFF switch and a display ON/OFF switch. The 8 user keys

are shown in Figure 3-2 and described below.

Figure 3-1: Front Panel of the Model 7600

Figure 3-2: Interface Keys on the Front Panel

Teledyne Analytical Instruments 35

Page 36

Operation Model 7600

MODE key: Used to switch the mode.

LEFT/RIGHT

Arrow key:

UP key: Used to change the selected item by moving the

DOWN key: Used to change the selected item by moving the

ESC key: Used to return to a previous screen or cancel the

ENT key: Used for confirmation of selected item or value, and

ZERO key: Used for zero calibration.

SPAN key: Used for spancalibration.

Used to change the selected item by moving the

cursor and numeral digit.

cursor and to increase a numeric value.

cursor and to decrease a numeric value.

setting midway.

for performing a calibration.

3.2 Display and Available Menus

The display on the Model 7600 has two modes: measurement mode

and user mode. To change between modes, press the MODE key.

In the measurement mode, the display indicates the composition of

the sample gas. Up to 12 channels of output are available although the

screen only shows 5 channels at a time. To see additional channels,

scroll down or up using the UP or DOWN keys.

Calibration is performed from the measurement mode by pressing

ZERO or SPAN. See Section 3.7 Calibration.

Teledyne Analytical Instruments 36

Page 37

Infrared Gas Analyzer Operation

Figure 3-3: Display Modes and Menu Hierarchy

Teledyne Analytical Instruments 37

Page 38

Operation Model 7600

The user mode is where the operator configures the instrument and

sets up various parameters for the intended application. From the user

mode the following menus are available:

• Switch Ranges

• Calibration Parameters

• Alarm Setting

• Setting of Auto Calibration

• Setting of Auto Zero Calibration

• Setting of Peak Alarm

• Parameter Setting

Figure 3-3 shows the overall structure of the Model 7600 display

and menu hierarchy.

3.3 The Display Screen

3.3.1 Measurement Mode

The measurement mode screen is the default mode when the power is

turned on. It displays component and concentration information about the

process. The screen depends on the number of components. Figure 3-4 is an

example of a measurement mode screen for an instrument configured for

NO, SO2, CO2, CO and O2 analysis with a 12 channel output.

Figure 3-4: Example Screen—5 Component Analysis 12 Channels

Teledyne Analytical Instruments 38

Page 39

Infrared Gas Analyzer Operation

p

(Upp

)

p

play

The numbered call outs in Figure 3-4 refer to:

No. Name Function

(1) Component

display

(2) Concentration

display

(3) Range display Displays range values.

(4) Unit display Displays unit with ppm and vol %.

(5) Peak alarm

com

onent

(6) Peak alarm

concentration

(7) Peak alarm

times

(8) Peak alarm

unit dis

Displays component of instantaneous

value, corrected instantaneous value,

corrected average value, etc.

Displays measured value of concentration.

Displays peak alarm component.

Displays peak alarm concentration display.

er limit value

Displays the alarm times exceeding the

eak value.

Displays units of peak alarm with times/H.

Instantaneous value and concentration value:

The concentration display of Ch (component) where sampling

components such as “CO

”, “CO” or “O2 are displayed in the component

2

display, indicates current concentration values of the measured

components contained in gas that is now under measurement.

O

correction concentration values:

2

Ch components where “cv**” is displayed as “cv CO” in the

component display are calculated values. They are obtained from the

following equation by setting sampling components, O2 instantaneous/

concentration values and O2 correction reference value (see item 6.8).

On-21

output Correction ×

⎛

=

⎜

⎝

⎞

Cs

⎟

Os21

−

⎠

Teledyne Analytical Instruments 39

Page 40

Operation Model 7600

Where:

On: The value of the O

correction reference value (Value set by

2

application)

Os: Oxygen concentration (%)

Cs: Concentration of relevant measured component. Note that Os

does not exceed the O

See Section 3.6

The corrected sampling components are NO

limit value set in “Other Parameter”

2

Maintenance Mode.

, SO2 and CO only.

X

O

2 correction concentration average value:

In the Ch (component) and O2 average value where “CV/AV **” is

displayed as “ AV CO” in the component display, a value obtained by

averaging O

correction concentration value or O2 average value in a

2

fixed time is output every 30 seconds.

Averaging time can be changed between 1 minute and 59 minutes

or 1 hour and 4 hours according to the average time settings (See

Section 3.5.7

Parameter Setting).

The set time is displayed as “1h” , for instance, in the range display.

* The measurement ranges of O

correction concentration value and O2

2

correction concentration average value are the same as that of the

measuring components. Also, the measurement range of O

value is the same as that of O

.

2

average

2

3.3.2 Setting/Selection Screen

The setting/selection screen is configured as shown in Figure 3-5:

In the status display area, the current status is displayed.

•

In the message display area, messages associated with

•

operation are displayed.

In the setting item and selection item display area, items or

•

values to be set are displayed, as required. To work in a

particular area, move the cursor to any item by using the UP,

DOWN and LEFT/RIGHT keys.

Teledyne Analytical Instruments 40

Page 41

Infrared Gas Analyzer Operation

Figure 3-5: Setting/Selection Screen Areas

3.4 Basic Operation

Measurement mode

The measurement mode is the default mode of the instrument and

appears when the unit is first turned on. It displays information about the

process being analyzed such as: channel number, component species

analyzed, concentration or calculated value, etc. In this mode, the

display can show up to 5 channels on a single screen. To view additional

channels, scroll down by pressing the DOWN key or back up using the

UP key. Each press scrolls the screen by one channel. You can also

calibrate the instrument from this mode by pressing the appropriate

ZERO or SPAN button. See Section 3.7

Calibration.

User mode displays:

In the user mode you can:

Switch ranges

•

Set calibration parameters

•

Adjust alarm settings

•

Teledyne Analytical Instruments 41

Page 42

Operation Model 7600

• Set up the Auto Calibration feature

Setup an auto zero calibration

•

Adjust the peak alarm parameter Setting.

•

These settings are described in Section 3.5.

To enter the user mode from the measurement mode, press the

MODE key. To return to the measurement mode, press the MODE key

again or ESC.

3.5 Setting Up the Analyzer in the User Mode

3.5.1 Switch Ranges

From the Switch Ranges menu you can:

a.

Manually select a desired range for any channel.

b.

Use the remote range switch contacts to select a range.

c.

Select autoranging.

To enter the Switch Ranges menu:

1.

Press the MODE key to enter the user mode.

Teledyne Analytical Instruments 42

Page 43

Infrared Gas Analyzer Operation

2. Move the cursor to the “Switch Ranges” option and press

ENT. The “Channel Selection” screen appears.

Move the cursor by pressing the UP/DOWN keys to the

3.

desired channel and press ENT.

There are 3 range switch modes in the second column to select from:

MR: Manual selection

RR: Remote range switch

AR: Autoranging

The selected range switch mode is highlighted for the channel you

selected.

4. Press the UP/DOWN keys to toggle between the

available switch modes.

5. Then press the ENT key to confirm the selection.

3.5.1.1 MANUAL RANGE SWITCHING

To manually switch between analysis ranges:

1.

Select the MR option from the Switch Range screen and

press the ENT key.

Teledyne Analytical Instruments 43

Page 44

Operation Model 7600

Move the highlight of the cursor to range selection and

2.

select the desired range using the UP/DOWN keys. The

highlighted arrow indicates the currently selected range.

Press ENT to accept the selection. Measurement is now

3.

carried out using the selected range.

Note: If “RR” or “AR” is selected as range switch mode, manual

range selection as described above is not possible

The range for O2 correction value, O2 correction average

value, and O2 average value is automatically switched if

the corresponding instantaneous value range is switched.

To abort the range selection, press the ESC key and the setting

operation is made invalid and the previous screen appears.

3.5.1.2 RANGE IDENTIFICATION CONTACT OPERATION

In all of the range switch modes (MR, RR, AR), the status of the

range identification relay contact corresponding to each Ch (component)

is closed when Range 1 is selected, and open when Range 2 is selected.

Note that even if the range is switched while a hold of measurement

is in place, for instance, by a remote hold contact input or the hold of

measurement value during calibration, the range identification contact

maintains the contact state immediately before the hold. After stop of the

hold, the contact state of the current range is resumed.

Teledyne Analytical Instruments 44

Page 45

Infrared Gas Analyzer Operation

3.5.1.3 REMOTE RANGE SELECTION

The range can be selected remotely if a remote switch has been

installed. To use this feature, the range mode must be switched in the

display to RR (Remote Range) .

To configure the instrument for remote range selection:

1.

Press the MODE key to enter the user mode.

Move the cursor to the “Switch Ranges” option and press

2.

ENT. The “Channel Selection” screen appears.

Move the cursor by pressing the UP/DOWN keys to the

3.

desired channel and press ENT.

The selected range switch mode is highlighted for the channel you

selected.

4. Press the UP/DOWN keys to toggle between the

available switch modes until RR is displayed.

5. Press the ENT key to accept the selection.

Teledyne Analytical Instruments 45

Page 46

Operation Model 7600

3.5.1.4 AUTORANGING

The Model 7600 can be set to autorange where the instrument will

select the analysis range automatically. To use the autorange feature, AR

must be selected for the switch mode. Note that each channel is

independent so that autoranging can be used for some or all of the

available channels. the remaining channels can be configured to manual

or remote switching.

To setup autoranging use the same procedure as Section 3.5.1.1

except you must select AR for the switch mode on the channel or

channels you want to autorange.

3.5.2 Calibration Parameters

The next menu choice from the user screen is the Calibration

Parameters menu. Here calibration settings can be configured for your

particular application. There are 4 submenus in the Calibration

Parameters menu. They are:

•

Calibration Value—set the concentration of calibration gas

About ZERO Calibration—set each or all components to be

•

zero calibrated during a manual zero calibration.

About Calibration Range—sets whether each component

•

during a zero or span calibration should be calibrated with a

single or dual range.

•

Auto Calibration Components/Range— select the component

and range with which auto calibration is to be performed.

3.5.2.1 CALIBRATION VALUE

This submenu allows you to set the concentration of the standard

gas (zero and span) for each channel used for calibration.

To enter the Calibration Value submenu:

1.

From measurement mode, press the MODE key to

display the user mode.

2.

Point the cursor to “Calibration Parameters” by pressing

the UP or DOWN key.

3. Press the ENT key to enter the Calibration Parameters

menu.

Teledyne Analytical Instruments 46

Page 47

Infrared Gas Analyzer Operation

4. In the “Calibration Parameters” screen that appears, point

the cursor to “Calibration Value” by pressing the UP or

DOWN key. Press the ENT key.

To change the concentration of a calibration gas:

1.

Point the cursor to the channel you want to set by using

UP or DOWN key. Press the ENT key.

the

2.

Select the concentration item you want to set by pressing

the UP or DOWN or SIDE key. Press the ENT key, and

the selected value is highlighted.

Enter the calibration gas concentration values (zero and

3.

span). For any numerical value entry, press the UP or

DOWN key to increase or decrease a single digit. Select

the next digit by pressing the SIDE key.

4.

When the concentration is correct, save the entry by

pressing the ENT key. The saved value becomes valid

from the next calibration process.

Teledyne Analytical Instruments 47

Page 48

Operation Model 7600

Note: Enter settings that correspond to each range. If a zirconia

type O2 sensor is used, select 21.00 for the field of Zero

(when air is used), and select the concentration listed on

the cylinder if the air contained in a cylinder is used.

To close the calibration concentration value setting process or

cancel this mode midway, press the ESC

key. The previous screen will

return.

Setting range of values:

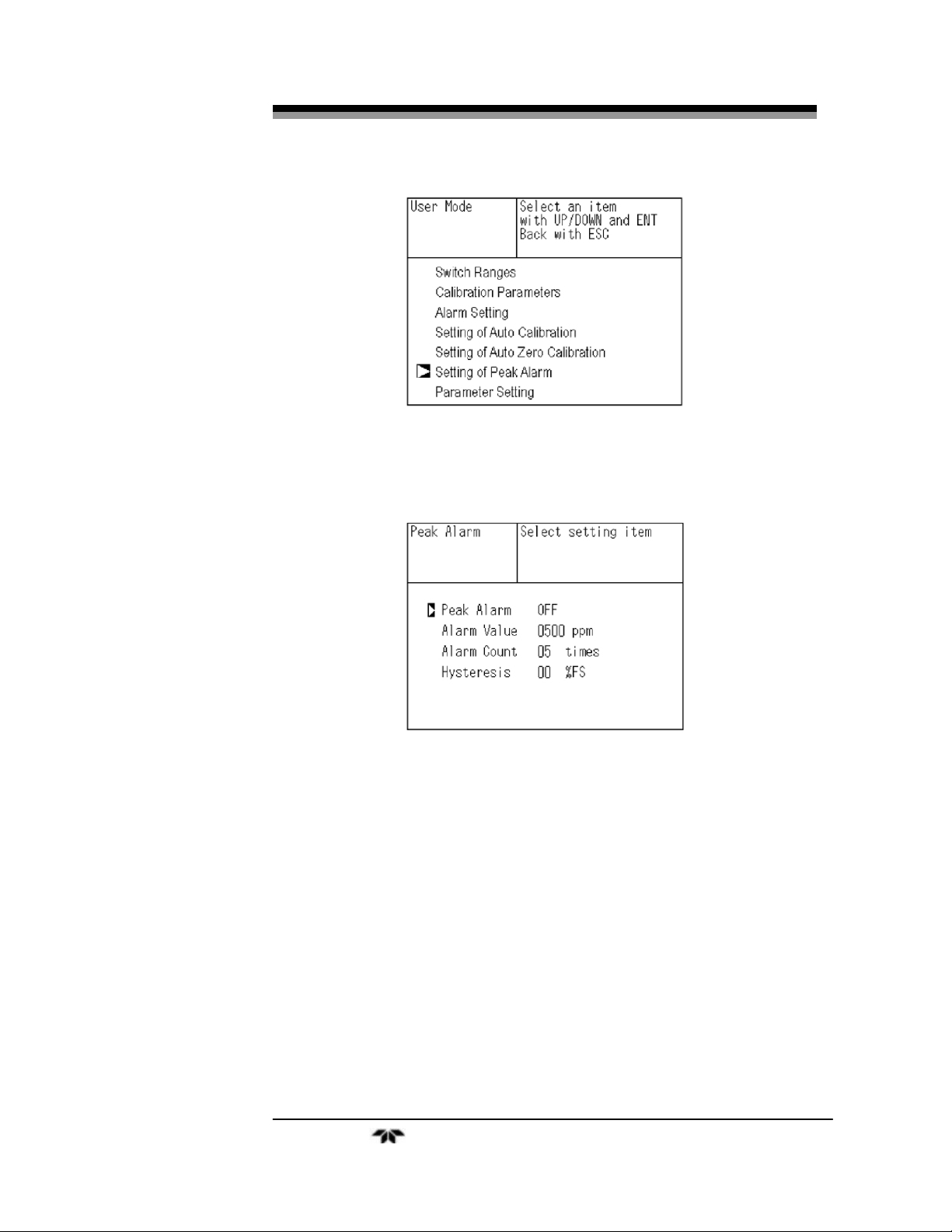

For NOx, SO2, CO2, CO, CH\4, external O2 measurement and built-

in paramagnetic O

sensors, the setting range for span gas is 1 to 105%

2

of full scale. The instrument will not accept values outside of this range.

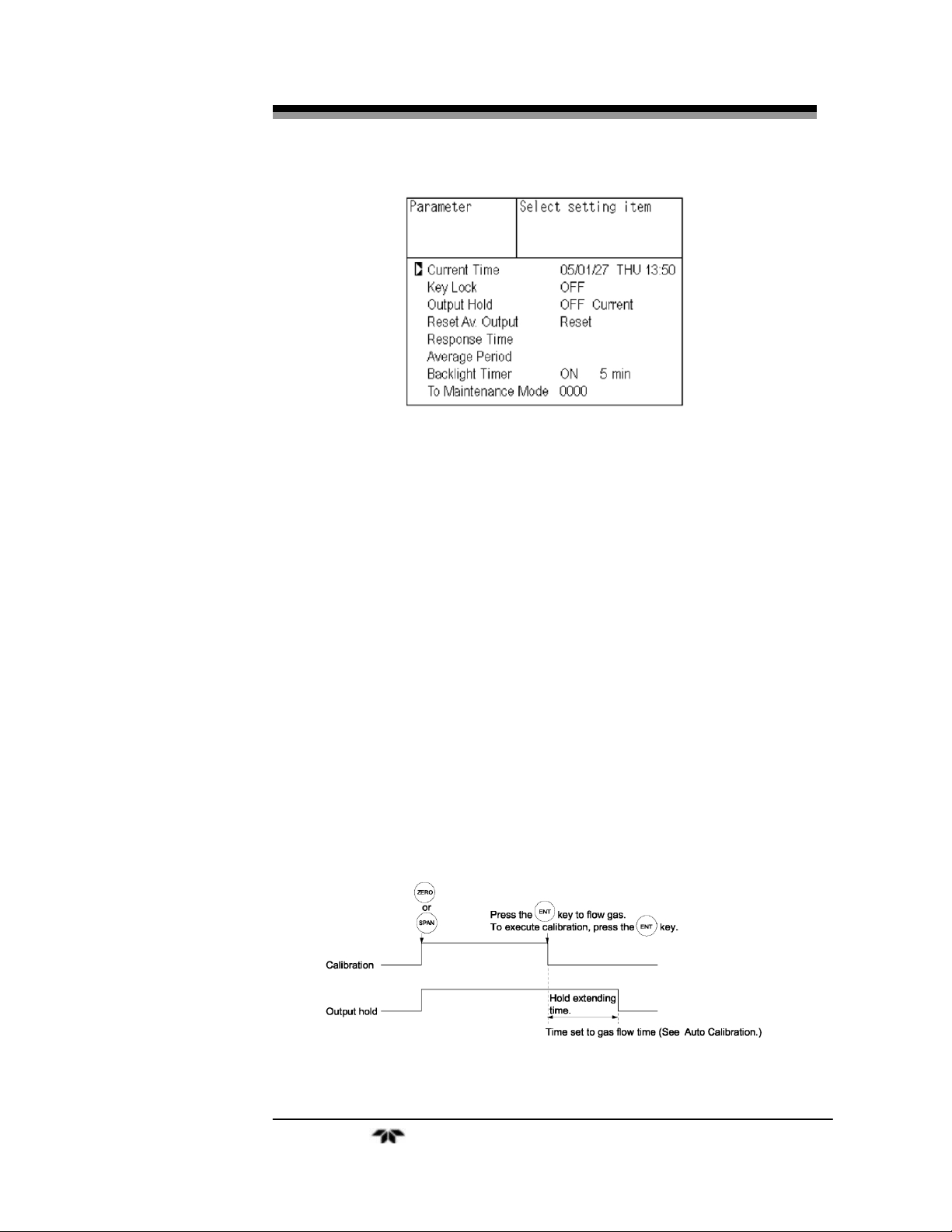

For external Zirconia O

sensors, the setting range for zero gas is 5

2

to 25 vol % and span from 0/01 to 5 vol %

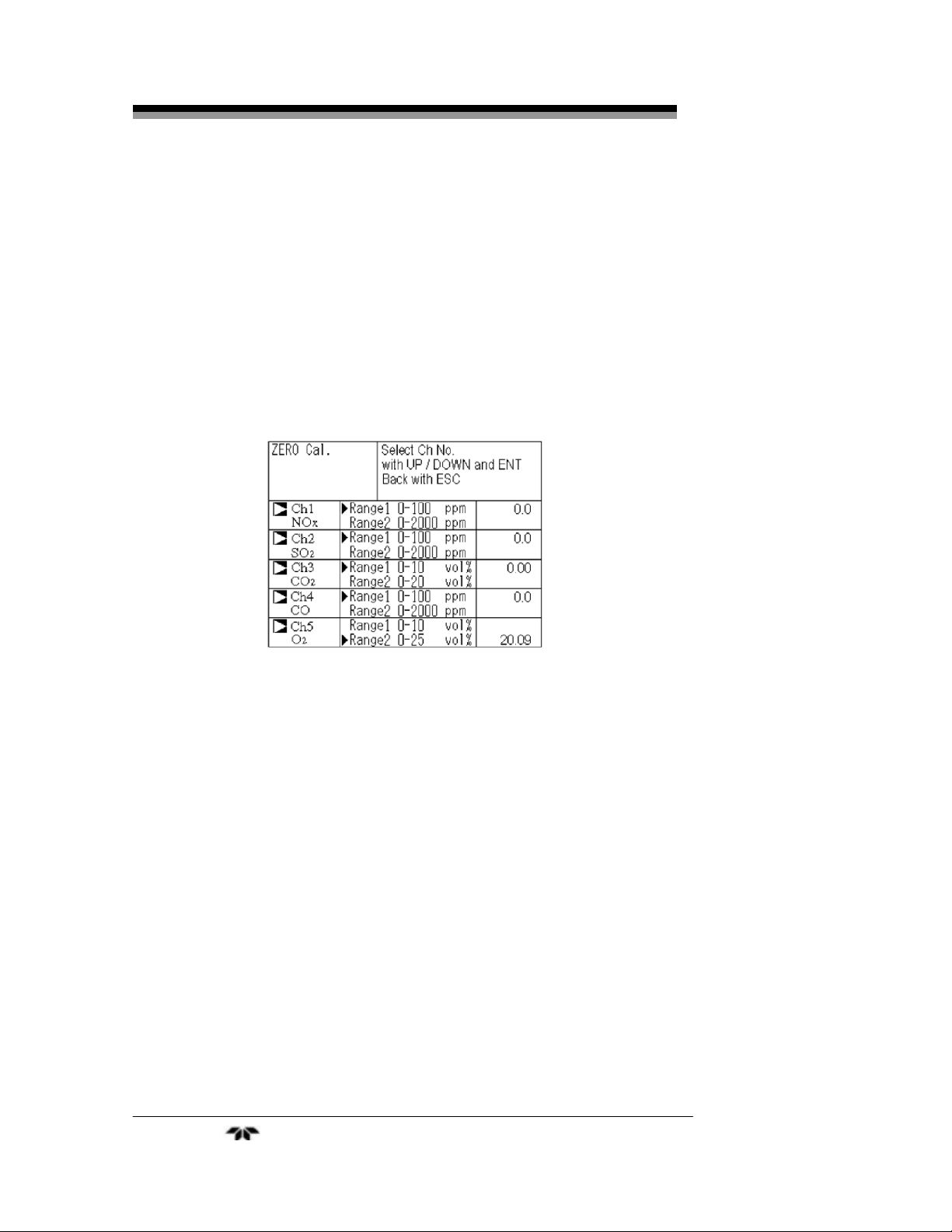

3.5.2.2 SETTING OF MANUAL ZERO CALIBRATION

When zero calibration is performed manually, you can choose

whether all components are to be calibrated simultaneously or each

component calibrated while selecting one by one.

This is configured from the About Zero submenu of the Calibration

Parameters menu. To get to the About Zero submenu:

1.

From the measurement mode, press the MODE key to

display the user mode.

2.

Point the cursor to “Calibration Parameters” by pressing

the UP or DOWN key and press the ENT key.

3.

In the “Calibration Parameters” screen that appears, point

the cursor to “About ZERO Calibration” by pressing the

UP or DOWN key. Press the ENT key.

Teledyne Analytical Instruments 48

Page 49

Infrared Gas Analyzer Operation

This brings up the Cal. Settings ZERO Cal. screen where you can

set whether all components or individually selected components are

zeroed during a manual zero calibration. The choices are:

•

at once—these components will be zeroed simultaneously

during a manual zero.

each—these components will be zeroed individually during a

•

manual zero.

To change the manual zero setting:

1.

In the “Cal. Settings ZERO Cal.” screen, point the cursor

to the channel you want to set by using the UP or DOWN

key. Press the ENT key.

2.

Select “at once” or “each” by pressing the UP or DOWN

key to toggle between the two options. Press the ENT

key when the desired option is displayed.

To close the Cal. Settings ZERO Cal. screen or cancel this mode

midway, press the ESC

Example:

key. The previous screen will return.

The options “each” or “at once” can be determined for each

channel.

When the setting is “each”, select the channel on the manual

•

zero calibration screen (see Section 3.7) and perform a zero

calibration. Only that component is zeroed.

•

When the setting is “at once”, performing a manual

calibration (see Section 3.7) will zero calibrate all

components tagged “at once”. You will notice on the manual

Teledyne Analytical Instruments 49

Page 50

Operation Model 7600

zero calibration screen that all there are cursors on all

components where “at once” is set.

Note: When the cylinder air or atmospheric air is used for the

zero gas, select “at once.”

3.5.2.3 SETTING OF CALIBRATION RANGE

Use the “About Calibration Range” submenu to configure the

instrument for calibration on one or two ranges for a channel.

To set calibration one or both ranges:

1.

From the measurement mode, press the MODE key to

display the user mode.

Point the cursor to “Calibration Parameters” by pressing

2.

the UP or DOWN key and press the ENT key.

In the “Calibration Parameters” screen that appears, point

3.

the cursor to “About Calibration Range” by pressing the

UP or DOWN key. Press the ENT key.

In the next screen that appears, point the cursor to the

4.

channel you want to set by pressing the UP or DOWN

key then press the ENT key.

On the “calibration range selection” screen that appears,

5.

select “both” or “current” by pressing the UP or DOWN

key.

If “both” is selected, zero or span calibration is performed

with Range 1 and Range 2 of the selected channel.

If “current” is selected, zero or span calibration is

Teledyne Analytical Instruments 50

Page 51

Infrared Gas Analyzer Operation

performed only for the range displayed when calibration

of the selected channel is performed.

Press the ENT

6.

key after the selection, and the specified

calibration is set.

To close the calibration range selection screen or cancel this mode

midway, press the ESC key. The previous screen will return.

Note: To perform calibration for “both,” set the same calibration

gas concentration for both ranges.

After setting the calibration range to “both”, you will notice in

the Manual Calibration screen (see Section 3.7), that there are cursors

next to both ranges whereas there would only be a single cursor next to

the range for calibration if “current” was set. For example, if channel 1

and channel 4 were set to “both” then cursors will appear in both ranges

of Ch1 and Ch4 in the Manual Calibration screen shown below.

3.5.2.4 SETTING OF AUTO CALIBRATION COMPONENT/RANGE

This menu is used to select the channel and the range in which auto

calibration is to be performed. If a channel has been set to autoranging

Teledyne Analytical Instruments 51

Page 52

Operation Model 7600

(AR), it will be calibrated in the range set in this menu when auto

calibration is performed. From this menu you can enable or disable the

auto calibration feature.

To navigate to the Auto Calibration Components/Range menu:

1.

From the measurement mode, press the MODE key to

display the user mode.

Point the cursor to “Calibration Parameters” by pressing

2.

the UP or DOWN key and press the ENT key.

In the “Calibration Parameters” screen that appears, point

3.

the cursor to “Auto Calibration Components/Range” by

pressing the UP or DOWN key. Press the ENT key.

In the “Calibration Parameters” screen that appears, point

4.

the cursor to “Auto Calibration Components / Range” by

pressing the UP or DOWN key. Then press the ENT key.

To set the range used for auto calibration:

1.

In the “Auto Calibration Components / Range” selection

screen that appears, point the cursor to the channel whose

Teledyne Analytical Instruments 52

Page 53

Infrared Gas Analyzer Operation

range you want to set using the UP or DOWN key. Then

press the ENT.

2.

The cursor next to the range of the selected channel is

highlighted. Select the range to be calibrated using the

UP or DOWN key. Then press the ENT key. The auto

calibration will be performed on the selected range.

Channels which have been set for autoranging (AR) will undergo

the auto calibration and manual calibration on the range selected here.

Once the calibration has started, the range will automatically switch and

on completion of the calibration, the original range is resumed.

The range identification contact is interlocked with the range after

the switch. However if the hold setting is set to “ON” the contact status

before calibration is maintained.

To ENABLE/DISABLE the auto calibration feature:

1.

With the cursor next to the range of the selected channel

you want to enable or disable for autocalibration (see

steps 1 and 2 above), use the SIDE key to highlight the

“enable” or “disable” option.

Use the UP or DOWN keys to toggle between the two

2.

options then select the desired status by pressing ENT.

To close the Auto Calibration Components/Range screen or cancel

this mode midway, press the ESC key. The previous screen will return.

Note: The order in which the Zero and Span calibrations are

performed in the auto calibration routine are different. For

the zero calibration, the calibration is performed according

to the order in which the channels were set to “enable”. For

Span, the calibration begins with the lowest channel

number first and proceeds sequentially to the highest

channel number set to “enable”.

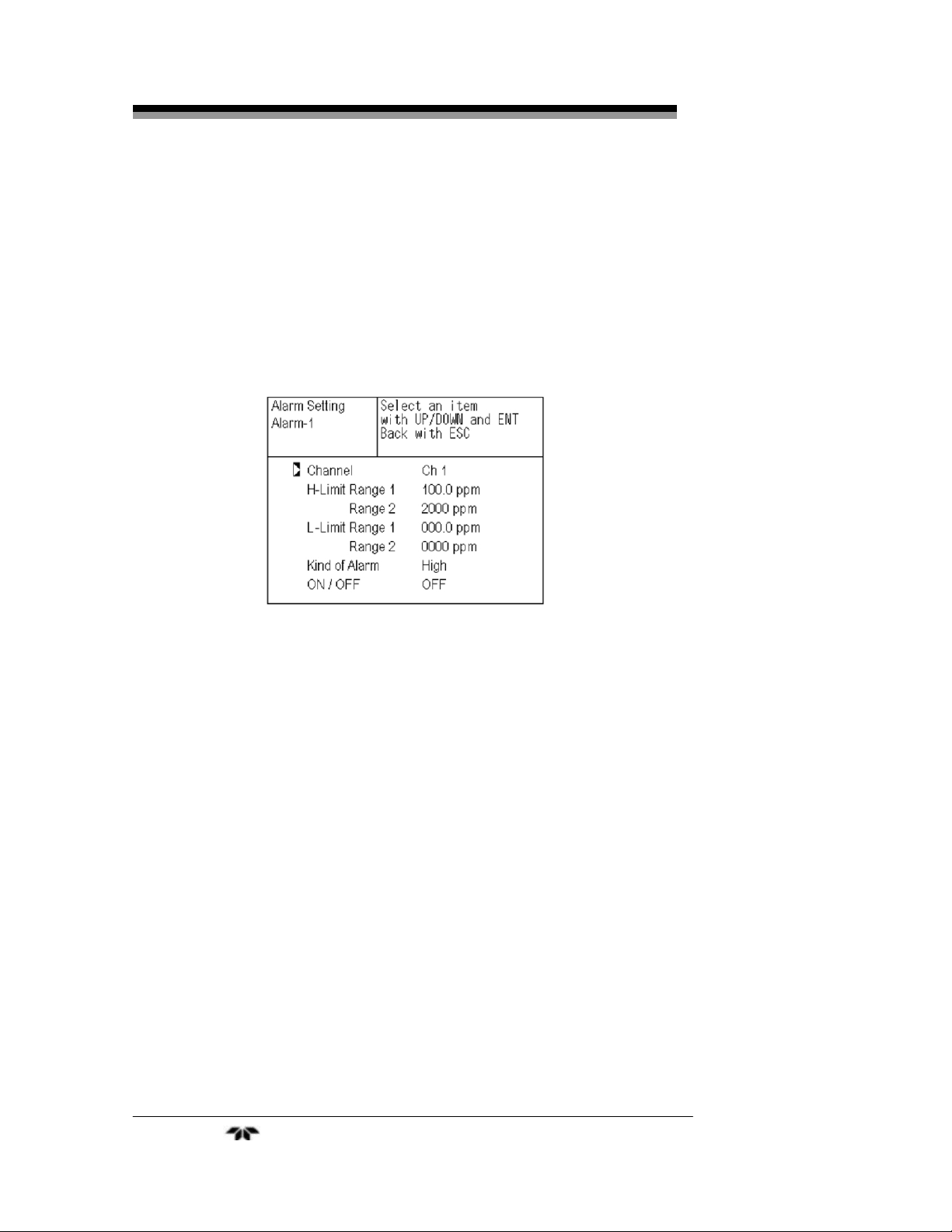

3.5.3 Alarm Setting

The Model 7600 is equipped with 6 alarms (5 or 6 concentration

and a power failure alarm). The alarm configuration and settings can be

assigned to any channel and adjusted at any time by entering the user

mode and navigating to the Alarm Setting submenu. Arbitrary 6 alarm

contact outputs are used which can be configured as:

Teledyne Analytical Instruments 53

Page 54

Operation Model 7600

• High Limit: sets the upper value (concentration) above which

the alarm will trigger. Has an on-screen display.

Low Limit: sets a lower value (concentration) below which

•

the alarm will trigger. Has an on-screen display

•

High or Low Limit: triggers an alarm when the concentration

is above the high limit or below the low limit.

High-High: sets the upper value (concentration) above which

•

the alarm will trigger.

Low-Low: sets a lower value (concentration) below which

•

the alarm will trigger.

Power Failure: (Alarm 6 only) normally closed contacts open

•

when power is removed.

Configuring the alarms involves:

Selecting the alarm type

•

Assigning it to a channel

•

Establishing setpoints (concentration alarms only)

•

Enabling or disabling it

•

A channel can be configured for multiple alarms.

ON/OFF enables the alarm function if set at ON, or disables the

alarm function if set at OFF. The H-limit value cannot be set below the

L-limit value, and the L-limit value cannot be set above the H-limit

value.

If it is desired to set the H-limit value below the L-limit value

already stored in the memory, reduce the L-limit value beforehand, and

vice versa.

A typical on-screen display for a High alarm is shown below.

When the H-limit alarm occurs, the “H-alarm” message comes on

in the field of relevant channel. Similarly for L-alarm. There is no screen

display for the HH-alarm”, and “LL-alarm” but otherwise, they function

like the H and L limit alarms.

Teledyne Analytical Instruments 54

Page 55

Infrared Gas Analyzer Operation

CAUTION: ALARMS ARE INACTIVE FOR 10 MINUTES AFTER

TURNING ON POWER.

3.5.3.1

CONFIGURING THE ALARMS

Note: To change an alarm setting, first set the alarm ON/OFF

setting to OFF, and then change the value.

1. From the measurement mode, press the MODE key to

display the user mode.

Point the cursor to “Alarm Setting” by pressing the UP or

2.

DOWN key and press the ENT key.

In the “Alarm Setting” screen that appears, point the

3.

cursor to the alarm number you want to set (1 through 6)

using the UP or DOWN key. Press the ENT key when the

cursor is on the alarm number you desire.

Teledyne Analytical Instruments 55

Page 56

Operation Model 7600

4. The alarm item selection screen will appear where you

can select the alarm type, assign it to a channel, define

setpoints, and enable or disable the alarm. Use the UP or

DOWN keys until the cursor is aligned with the desired

function and press the ENT key.

Note: Setpoints are adjustable form 0 to 100% of fullscale

however they must be defined so that H-limit value > L-limit

value and that (H-limit value- L-limit value) > hysteresis.

After setting the last feature, store the values by pressing

5.

ENT again.

To close the Alarm Setting screen or cancel this mode midway,

press the ESC key. The previous screen will return.

3.5.3.2 HYSTERESIS SETTING

The hysteresis setting is used prevent chattering of an alarm output

near the alarm setpoint. The hysteresis value range is 0-20% of fullscale

on any analysis range. Figure 3-6 shows the hysteresis width (in %

fullscale) set for a high limit alarm.

Teledyne Analytical Instruments 56

Page 57

Infrared Gas Analyzer Operation

Figure 3-6: Hysteresis Example for a High Limit Alarm

An alarm output is turned ON if measurement value exceeds the

upper limit value as shown in Figure 3-6. Once the alarm output has

been turned ON, it is not turned OFF until the process value falls below

the hysteresis width.

Note: The hysteresis setting is common to all alarms.

To set the hysteresis value:

1.

From the “Alarm No. Selection” screen, point the cursor

to “Hysteresis” by pressing the UP or DOWN key then

press ENT.

In the “Hysteresis Value Setting” screen that appears,

2.

enter hysteresis values using the UP or DOWN keys to

increment or decrement a digit. Use the SIDE key to

move to the next digit. When finished, press ENT.

Teledyne Analytical Instruments 57

Page 58

Operation Model 7600

To close the “Hysteresis Setting” or cancel the mode midway, press

the ESC key. A previous screen will return.

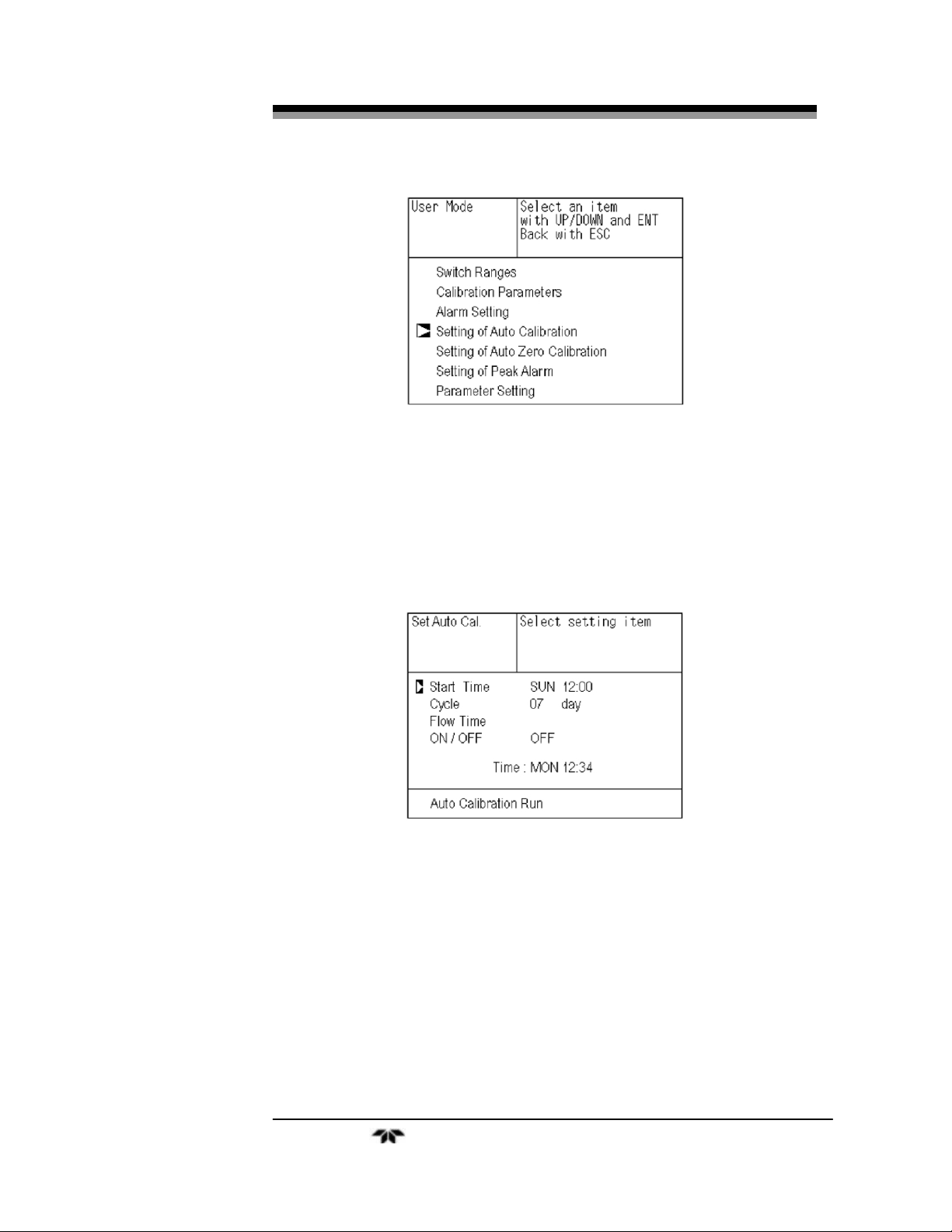

3.5.4 Setting of Auto Calibration

3.5.4.1 AUTO CALIBRATION

Auto calibration is automatically carried out when zero and span

calibrations are set.

In this menu you can set when and how frequent the auto

calibration is performed. You also enable or disable the auto calibration

feature here.

Description of setting items:

Start Time: Setting at the first calibration (day of the week, hour,

minute)

Cycle: A period between the start time of one calibration and

another (unit: hour/day)

Flow Time: The time required for replacement by calibration gas.

Time required for replacement of sample gas after the

calibration is completed (Set by calibration gas.)

ON/OFF: Enable/disable the auto calibration feature.

Note: Before changing the settings of auto calibration, set the

ON/OFF to OFF.

To change the settings:

3.

From the measurement mode, press the MODE key to

display the user mode.

4.

Point the cursor to “Setting of Auto Calibration” by

pressing the UP or DOWN key and press the ENT key.

Teledyne Analytical Instruments 58

Page 59

Infrared Gas Analyzer Operation

5. In the “Setting of Auto Calibration” screen that appears,

point the cursor to any item you want to set by pressing

UP or DOWN key. Press the ENT key.

the

6. In the “Auto Calibration Parameter Setting” screen that

appears, perform the value entry or the setting. For the

value entry or setting change, use the UP or DOWN key.

To change the setting, use the SIDE key to move the

cursor to the right.

After changing the setting, press the ENT key to accept

7.

the change. Auto calibration will now be carried out

using the entered setting value.

To close the “Setting of Auto Calibration” or cancel the mode

midway, press the ESC key. A previous screen will return.

3.5.4.2 GAS FLOW TIME SETTING

In this submenu you select the gas whose flow time is to be

changed. The flow time range is from 60 to 900 seconds. The initial

value is set for 300 seconds.

Teledyne Analytical Instruments 59

Page 60

Operation Model 7600

To set the flow time:

1.

Place the cursor next to “Flow Time,” then press the ENT

key.

On the flow time setting screen that appears, use the UP

2.

and DOWN keys to move the cursor to the gas whose

settings you want to change, then press ENT.

The highlighted value can be changed. Change the value

3.

by pressing the UP or DOWN key, and then move the

cursor to the right by pressing the SIDE key.

After changing the value, press the ENT key.

4.

5.

Press the ESC key to return to the automatic calibration

setting screen.

Note: Only the channels used are displayed on this screen. The

Ex. time is the output signal hold extension time after the

completion of calibration. It is valid only when the hold

setting is set to “ON.” The Ex. time set here is also used in

a manual calibration.

The auto calibration contacts are closed during an auto calibration

event.

3.5.4.3 CYCLE SETTING RANGE

The cycle range is settable from 1 to 99 hours or 1 to 40 days. The

initial value is set at 7days.

Note: When an auto calibration starts, the measurement screen

automatically appears.

Teledyne Analytical Instruments 60

Page 61

Infrared Gas Analyzer Operation

Any operation other than “Stop Auto Calibration” (see

Section 3.5.4.5) is not permitted during auto calibration.

“Stop Auto Calibration” cannot be performed when the key

lock is ON.

To cancel auto calibration, set the key lock to OFF and

then execute “Stop Auto Calibration”.

Auto Calibration Example

Start Time SUN 12:00

Cycle 1 day

Flow Time Zero 350 sec

Ch1 Span 350 sec

Ch1 Span 350 sec

Ch1 Span 350 sec

Ch1 Span 300 sec

Ch1 Span 300 sec

EX. time 300 sec

ON/OFF ON

Figure 3-7 shows the auto calibration with the above settings.

Figure 3-7: Example Auto Calibration

Teledyne Analytical Instruments 61

Page 62

Operation Model 7600

When a channel enabled for auto calibration is in the calibration

mode, a message indicating ZERO cal. or SPAN cal. will appear on the

measurement screen. For example, if channels 1 and 2 have the auto

calibration setting enabled, when the calibration event takes place, both

channels 1 and 2 will indicate ZERO cal. when the zero calibration is

being performed. Zero calibrations are performed first and all enabled

channels will zero simultaneously.

When the zero calibrations are finished, channel 1 will enter the

span calibration followed by channel 2.

3.5.4.4 REMOTE START

An auto calibration is always available by keeping the remote start

input closed for at least 1.5 seconds. The remote start can initiate an auto

calibration whether the parameter setting is ON or OFF.

3.5.4.5 FORCED RUN/STOP OF AUTO CALIBRATION

Auto calibration can be performed manually or forcibly stopped

while the calibration is performed.

Teledyne Analytical Instruments 62

Page 63

Infrared Gas Analyzer Operation

3.5.4.5.1 MANUAL EXECUTION OF AUTO CALIBRATION

To perform the auto calibration cycle manually:

1.

From the measurement mode, press the MODE key to

display the user mode.

2.

Point the cursor to “Setting of Auto Calibration” by

pressing the UP or DOWN key and press the ENT key.

3.

In the “Setting of Auto Calibration” item selection screen

that appears, point the cursor to “Auto Calibration Run”

by pressing the

UP or DOWN keys. Press the ENT

key.

“Run” is highlighted, displaying a message to confirm the

4.

execution of auto calibration. Press the ENT key to

execute the auto calibration, or press the ESC key to

cancel.

3.5.4.5.2

FORCIBLY END AN AUTO CALIBRATION

To abort an auto calibration event:

Teledyne Analytical Instruments 63

Page 64

Operation Model 7600

5. From the measurement mode, press the MODE key to

display the user mode.

6.

Point the cursor to “Setting of Auto Calibration” by

pressing the UP or DOWN key and press the ENT key.

In the “Setting of Auto Calibration” item selection screen

7.

that appears, point the cursor to “Auto Calibration Run”

by pressing the

UP or DOWN keys. Press the ENT

key.

“Stop” is highlighted, displaying a message to confirm

8.

the stop of auto calibration. Press the ENT key to stop the

auto calibration, or press the ESC key to cancel the abort.

Note: During auto calibration, the keys are inoperable other than

key lock ON/OFF and “Stop Auto Calibration.”

When the key lock is set to ON, even the “Auto Calibration

Stop” is locked out. To stop “Auto Calibration” forcedly, set

the key lock to OFF and then execute “Auto Calibration

Stop” as detailed above.

Teledyne Analytical Instruments 64

Page 65

Infrared Gas Analyzer Operation

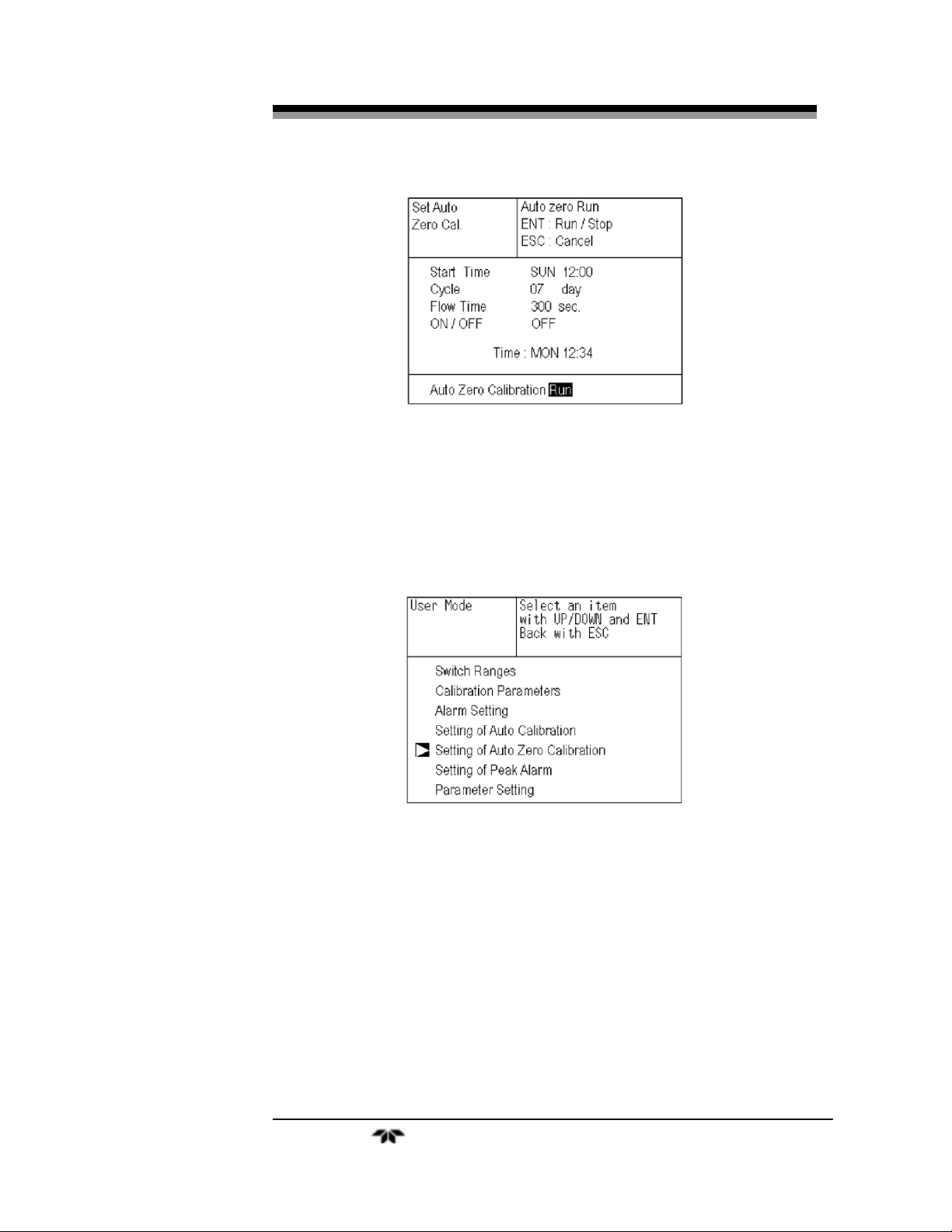

3.5.5 Setting of Auto Zero Calibration

3.5.5.1 AUTO ZERO CALIBRATION

Auto zero calibration is automatically carried out when the zero

calibration is set. Components for which a calibration is to be made are

determined by setting of auto calibration component in Section 3.5.3.

Similar to the menu choices and operation of the auto calibration, in

this menu you can set when and how frequent the auto zero calibration is

performed. You also enable or disable the auto zero calibration feature

here.

Description of setting items:

Start Time: Setting at the first calibration (day of the week, hour,

minute)

Cycle: A period between the start time of one calibration and

another (unit: hour/day)

Flow Time: The time required for replacement by calibration gas.

Time required for replacement of sample gas after the

calibration is completed (Set by calibration gas.)

ON/OFF: Enable/disable the auto calibration feature.

Note: Before changing the settings of auto calibration, set the

ON/OFF to OFF.

To change the settings:

1.

From the measurement mode, press the MODE key to

display the user mode.

Point the cursor to “Setting of Auto Zero Calibration” by

2.

pressing the UP or DOWN key and press the ENT key.

Teledyne Analytical Instruments 65

Page 66

Operation Model 7600

3. In the “Setting of Auto Zero Calibration” screen that

appears, point the cursor to any item you want to set by

pressing the

UP or DOWN key. Press the ENT key.

4. In the “Auto Zero Calibration Parameter Setting” screen

that appears, perform the value entry or the setting. For

the value entry or setting change, use the UP or DOWN

key. To change the setting, use the SIDE key to move the

cursor to the right.

After changing the setting, press the ENT key to accept

5.

the change. Auto zero calibration will now be carried out

using the entered setting value.

To close the “Setting of Auto Calibration” or cancel the mode

midway, press the ESC key. A previous screen will return.

The contacts for the auto zero calibration are closed during auto

zero calibration.

Auto Zero Calibration Example

Start Time SUN 12:00

Cycle 12 hour

Flow Time 300 sec

ON/OFF ON

Figure 3-8 shows the auto zero calibration with the above settings.

Teledyne Analytical Instruments 66

Page 67

Infrared Gas Analyzer Operation

Figure 3-8: Example Auto Zero Calibration

Note: When an auto zero calibration starts, the measurement

screen automatically appears.

Any operation other than “Stop Auto Zero Calibration” (see

Section 3.5.4.5 is not permitted during auto calibration.

“Stop Auto Zero Calibration” cannot be performed when

the key lock is ON.

To cancel auto zero calibration, set the key lock to OFF