Page 1

Toll-free Phone:

800-324-5190

Phone:

858-657-9800

Fax:

858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

Copyright 2014

07773A DCN6833

Teledyne Advanced Pollution Instrumentation

27 January 2014

07773A DCN6933

A-3

OPERATION MANUAL

MODEL 751H

HIGH PERFORMANCE

ZERO AIR GENERATOR

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Page 2

Page 3

Part No.

Rev

Name/Description

07773

A

Model 751H Manual (this manual)

07839

A

Model 751H Spare Parts List (Appendix A of this manual)

078370100

A

Model 751H Interconnect List (Appendix B of this manual)

07837

A

Model 751H Interconnect Diagram (Appendix B of this manual)

Date

Rev

DCN

Description

27 Jan 2014

A

6833

Initial Release

ABOUT THIS MANUAL

This Model 751H High Performance Zero Air Generator operation manual is comprised of

multiple documents as listed below.

Please read this manual in its entirety before making any attempt to operate the instrument.

NOTE

REVISION HISTORY

Model 751H User Manual, PN 07773

07773A DCN6833

i

Page 4

ii 07773A DCN6833

Page 5

CAUTION

This instrument should only be used for the purpose and in the manner described in

this manual. If you use this instrument in a manner other than that for which it was

intended, unpredictable behavior could ensue with possible hazardous

consequences.

NEVER use any gas analyzer to sample combustible gas(es)!

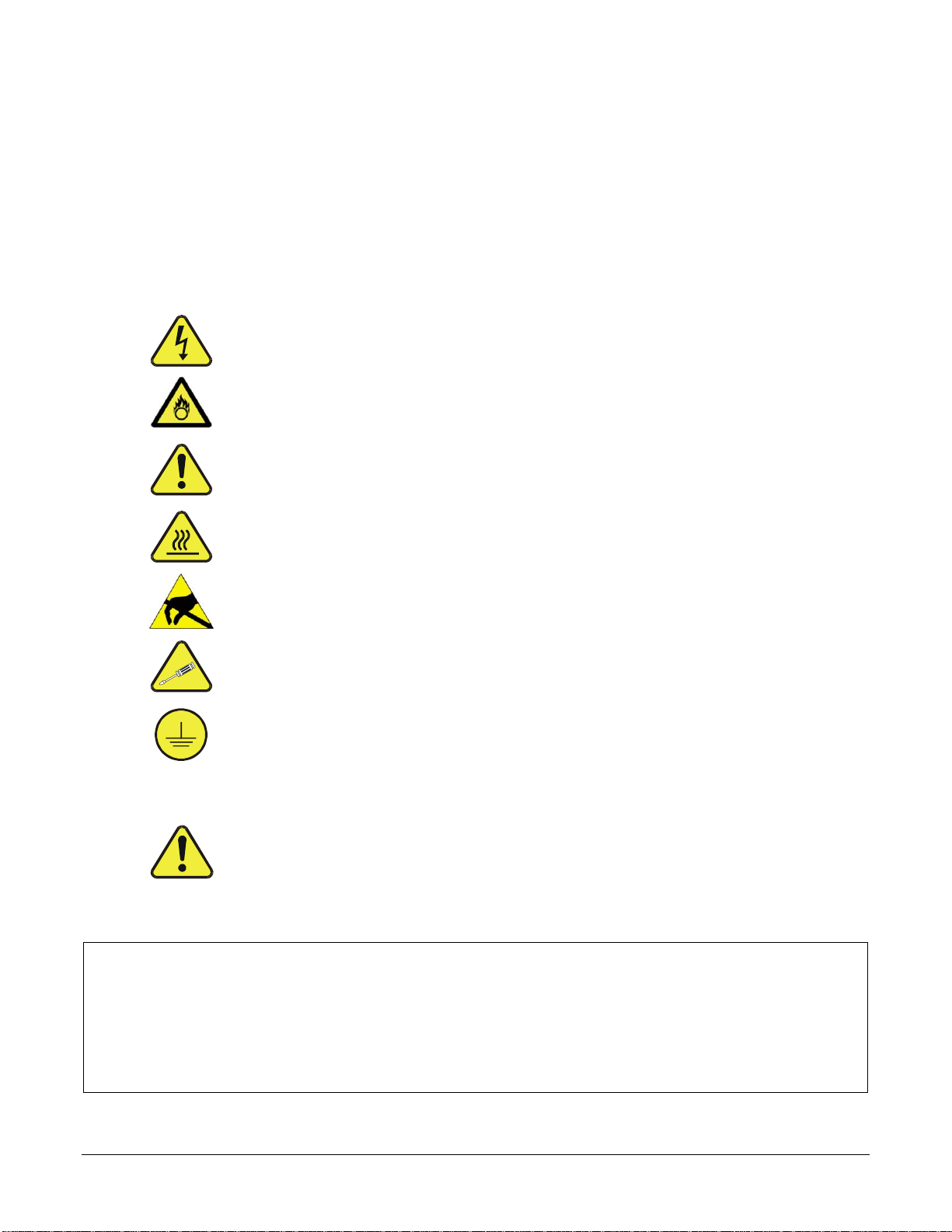

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message for specific

information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without protection or proper tools

could result in damage to the part(s) and/or the instrument.

Technician Symbol: All operations marked with this symbol are to be performed by

qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central safety grounding

point for the instrument.

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of avoiding personal

injury or instrument damage. Please read these messages carefully. Each safety message is associated

with a safety alert symbol, and are placed throughout this manual and inside the instrument. The symbols

with messages are defined as follows:

Note

For Technical Assistance regarding the use and maintenance of this instrument or any

other Teledyne API product, contact Teledyne API’s Technical Support Department:

Telephone: 800-324-5190

Email: sda_techsupport@teledyne.com

or access any of the service options on our website at http://www.teledyne-api.com/

07773A DCN6833 iii

Page 6

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans

protection ou sans les outils appropriés pourrait entraîner des

dommages aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce

symbole doivent être effectuées uniquement par du personnel de

maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le

point central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière décrite

dans ce manuel. Si vous utilisez cet instrument d’une autre manière que

celle pour laquelle il a été prévu, l’instrument pourrait se comporter de façon

imprévisible et entraîner des conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz

combustibles!

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans le but d’éviter

des blessures corporelles ou d’endommager les instruments. Veuillez lire attentivement ces consignes.

Chaque consigne de sécurité est représentée par un pictogramme d’alerte de sécurité; ces pictogrammes

se retrouvent dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux consignes

suivantes :

iv 07773A DCN6833

Page 7

CAUTION – Avoid Warranty Invalidation

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling and

packing instructions and Return Merchandise Authorization (RMA) procedures when

returning parts for repair or calibration may void your warranty. For anti-ESD

handling and packing instructions please refer to the manual, Fundamentals of ESD,

PN 04786, in its “Packing Components for Return to Teledyne API’s Customer

Service” section. The manual can be downloaded from our website at

http://www.teledyne-api.com under Help Center > Product Manuals in the Special

Manuals section. RMA procedures are under Help Center > Return Authorization.

WARRANTY

WARRANTY POLICY (02024G)

Teledyne Advanced Pollution Instrumentation (TAPI), a business unit of Teledyne

Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should equipment

failure occur, TAPI assures its customers that prompt service and support will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready to

provide on-site or in-plant service at reasonable rates similar to those of other manufacturers

in the industry. All maintenance and the first level of field troubleshooting are to be

performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be repaired to the

extent and according to the current terms and conditions of the respective equipment

manufacturer’s warranty.

Product Return

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center. After the

repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at http://www.teledyneapi.com/terms_and_conditions.asp

07773A DCN6833 v

Page 8

TABLE OF CONTENTS

ABOUT THIS MANUAL ........................................................................................................... I

REVISION HISTORY ............................................................................................................... I

SAFETY MESSAGES ............................................................................................................. III

1 INTRODUCTION ....................................................................................... 9

1.1 PREFACE ................................................................................................................... 9

1.2 751H FEATURES ........................................................................................................ 9

2 SPECIFICATIONS AND APPROVALS ................................................... 11

2.1 SPECIFICATIONS....................................................................................................... 11

2.2 APPROVALS AND CERTIFICATIONS ............................................................................. 12

2.2.1 Safety .............................................................................................................. 12

2.2.2 EMC ................................................................................................................. 12

3 GETTING STARTED .............................................................................. 13

3.1 UNPACKING ............................................................................................................. 13

3.2 INSTALLATION .......................................................................................................... 13

3.3 INSTRUMENT PANEL ................................................................................................. 14

3.4 ELECTRICAL AND PNEUMATIC CONNECTIONS .............................................................. 15

3.4.1 ELECTRICAL................................................................................................... 15

3.4.2 PNEUMATICS ................................................................................................. 15

3.5 POWER-UP .............................................................................................................. 16

3.6 STORAGE AND TRANSPORTATION .............................................................................. 16

3.7 EXPENDABLE KITS (OPT 42A) .................................................................................. 17

3.8 FLOW RESTRICTOR (OPT 72B) ................................................................................ 17

4 OPERATION ........................................................................................... 19

4.1 OVERVIEW ............................................................................................................... 19

4.2.1 Intake Filter ...................................................................................................... 22

4.2.2 Compressor ..................................................................................................... 22

4.2.3 Cooling Coil ..................................................................................................... 22

4.2.4 Water Trap ....................................................................................................... 22

4.2.5 Water Drain Valve ........................................................................................... 22

4.2.6 Pressure Relief Valve ...................................................................................... 23

4.2.7 Regenerative Dryer .......................................................................................... 23

4.2.8 Pressure Sensor .............................................................................................. 23

4.2.9 Pressure Regulator .......................................................................................... 24

vi 07773A DCN6833

Page 9

4.2.10 Hydrocarbon (HC) Scrubber ......................................................................... 24

4.2.11 NO-NO2 Scrubber ......................................................................................... 25

4.2.12 Charcoal Scrubber ........................................................................................ 25

4.2.13 Carbon Monoxide (CO) Scrubber ................................................................. 25

4.2.14 Final Filter ..................................................................................................... 25

4.2.15 Pressure Gauge............................................................................................ 25

4.2.16 Controller ...................................................................................................... 25

4.2.17 Dewpoint Sensor .......................................................................................... 27

4.2.18 Instrument Panel Indicator Lights ................................................................. 27

5 MAINTENANCE ...................................................................................... 29

5.1 SCHEDULE ............................................................................................................... 29

5.2 MAINTENANCE MODE................................................................................................ 30

5.3 CLEANING ................................................................................................................ 30

5.4 CHECKING TUBING ................................................................................................... 30

5.5 REPLACING THE CHARCOAL SCRUBBER MEDIA ........................................................... 31

5.6 REPLACING THE NO - NO

5.7 REPLACING THE CO SCRUBBER ................................................................................ 32

5.8 REPLACING THE HYDROCARBON (HC) SCRUBBER ...................................................... 33

5.9 SERVICING THE REGENERATIVE DRYER ..................................................................... 34

5.10 CHANGING THE REGENERATIVE DRYER’S 4-WAY VALVE .......................................... 37

5.11 LEAK CHECK ......................................................................................................... 37

5.12 FILTER ELEMENT REPLACEMENT ............................................................................ 38

5.12.1 Intake Filter ................................................................................................... 38

5.12.2 Final Filter ..................................................................................................... 38

SCRUBBER MEDIA ............................................................ 32

2

6 TROUBLESHOOTING ............................................................................ 41

APPENDIX A - SPARE PARTS .......................................................................................... A-1

APPENDIX B - SCHEMATICS ........................................................................................... B-1

LIST OF FIGURES

FIGURE 3-1: 751H STARTUP CONNECTIONS .......................................................................................... 14

FIGURE 4-1: PNEUMATIC DIAGRAM ......................................................................................................... 20

FIGURE 4-2: PLAN VIEW .......................................................................................................................... 21

FIGURE 4-3: INSTRUMENT PANEL ............................................................................................................ 21

FIGURE 4-4: CONTROL BOARD LAYOUT .................................................................................................. 26

FIGURE 5-1: REGENERATIVE DRYER ....................................................................................................... 36

07773A DCN6833 vii

Page 10

LIST OF TABLES

TABLE 2-1: SPECIFICATIONS ................................................................................................................... 11

TABLE 4-1: POWER AND DEWPOINT CONDITION INDICATORS ................................................................ 27

TABLE 5-1: MAINTENANCE SCHEDULE .......................................................................................... 29

TABLE 6-1: TROUBLESHOOTING .............................................................................................................. 41

viii 07773A DCN6833

Page 11

1 INTRODUCTION

1.1 Preface

The 751H is an excellent source of clean, dry air for dilution calibrators. It also may be

used as a source of purge air for permeation tube ovens, zero air for ozone generators,

or combustion air for FID analyzers. The 751H has an oil-free and diaphragm-free

pump that pushes air through a pre-cooler and water trap that removes moisture, and

passes the air through a regenerative, heatless dryer for final drying. The pump then

routes the dry air through multiple scrubbers that remove SO2, NO, NO2, O3, H2S, CO,

and Hydrocarbons; the outlet air passes through a final filter to assure a clean, dry,

analytical zero air supply.

The regenerative dryer removes water and produces gas with a dewpoint of less than

-20°C (up to 10 SLPM flow rate) independent of the inlet dewpoint, and assists in the

removal of other gases, greatly increasing the life of the chemical scrubbers. The 751H

is an ideal accessory to the Model T700 Mass Flow Calibrator or Model 702 Single

Point Calibrator as a zero air source for analyzers.

1.2 751H Features

Regenerative, heatless dryer for maintenance-free water removal independent of

inlet dewpoint

Long life scrubbers for SO2, NO, NO2, O3, H2S, CO, and Hydrocarbons

Automatic water drain

May be used to provide combustion air for FID

Source of purge air for permeation tube ovens

Source of zero air for Ozone Generators

07773A DCN6833

9

Page 12

Introduction Teledyne API M751H High Performance Zero Air Generator

This page intentionally left blank.

10 07773A DCN6833

Page 13

Parameter

Specification

Output

10 SLPM at 30 psig

Max delivery pressure

30 psig

Dewpoint

< -20 C

Dryer

Regenerative heatless dryer with lifetime of greater than 5 years

Output Concentration

SO2 <0.025 ppb

NO <0.025 ppb

NO2 <0.025 ppb

O3 <0.3 ppb

CO < 10 ppb

HC < 0.25 ppb

Compressor

Single-cylinder, internal long-life, oil-less piston pump

Dimensions

9” x 22” x 13.8” (229 x 559 x 351 mm)

Weight

47 lbs (21.3 kg)

Operating Temp

5-40 C

Power

Typical Power Consumption

110-120 V~ 60 Hz, 4.0 A

220-240 V~ 50 Hz, 3.0 A

320 W

425 W

Environmental Conditions

Installation Category (Over Voltage Category ) II Pollution Degree 2

Intended for Indoor Use Only at Altitudes 2000m

Mains Supply Voltage Fluctuations not to exceed ± 10% of the

nominal voltage.

Transient Over Voltages according to Over Voltage Category II

2 SPECIFICATIONS AND APPROVALS

2.1 Specifications

Table 2-1: Specifications

07773A DCN6833

11

Page 14

Specifications and Approvals Teledyne API M751H High Performance Zero Air Generator

2.2 Approvals and Certifications

The Teledyne-API Model 751H Zero Air Generator was designed, tested and certified for Safety

and Electromagnetic Compatibility (EMC). This section presents the compliance statements for

those requirements and directives. For additional certifications, please contract Technical

Support at 1-800-324-5190 or sda_techsupport@teledyne.com.

2.2.1 Safety

IEC/EN 61010-1:2010 (3rd Edition), Safety requirements for electrical equipment for

measurement, control and laboratory use.

CE: 2006/95/EC, Low-Voltage Directive

2.2.2 EMC

IEC/EN 61326-1, Class A Emissions/Industrial Immunity

EN55011 (CISPR 11), Group 1, Class A Emissions

FCC 47 CFR Part 15B, Class A Emissions

CE: 2004/108/EC, Electromagnetic Compatibility Directive

12 07773A DCN6833

Page 15

CAUTION

TO AVOID PERSONAL INJURY, ALWAYS USE TWO PERSONS TO

LIFT AND CARRY THE 751H.

CAUTION

TO AVOID PERSONAL INJURY OR DAMAGE TO THE INSTRUMENT,

ALWAYS OPERATE THE 751H WITH THE LID OPEN.

3 GETTING STARTED

This section provides instructions on the proper installation and power up of the

751H. Refer to Figure 4-2 for the instrument layout and Table 2-1 for the

specifications.

NOTE

Due to mounting screws through its case, the 751H is not considered waterproof.

3.1 Unpacking

1. Remove the 751H from its shipping carton.

2. Verify that there is no shipping damage. If there are signs of damage, immediately

advise the shipper, then Teledyne API.

3. Open the lid and check for damage inside.

4. Check the line voltage and frequency label on the instrument to ensure that it

matches the local power source.

3.2 Installation

The basic 751H is a portable, self-contained instrument; there are no installation

instructions other than to ensure adequate support for its weight. However, the

connections must be made to the instrument panel and drain port with the lid open

(see Section 3.4 for connection instructions).

07773A DCN6833

13

Page 16

Getting Started Teledyne API M751H High Performance Zero Air Generator

3.3 Instrument Panel

Figure 3-1 shows the components in the Model 751H instrument layout that are

pertinent to starting up the instrument.

Figure 3-1: 751H Startup Connections

14 07773A DCN6833

Page 17

Teledyne API M751H High Performance Zero Air Generator Getting Started

CAUTION

ENSURE THAT THE POWER CORD IS PROPERLY GROUNDED

AND ADEQUATELY RATED FOR THE SPECIFIED POWER

RATING OF THIS INSTRUMENT (SEE SPECIFICATIONS TABLE).

3.4 Electrical and Pneumatic Connections

3.4.1 ELECTRICAL

NOTE

To maintain compliance with EMC standards, it is required that the power cord

length be no greater than 3 meters.

With the power switch in the “OFF” position, connect the power cord from the AC

input connection to the proper power source.

3.4.2 PNEUMATICS

Make the following pneumatic connections:

DRAIN (1/4” swage-type bulkhead union) - Connect 1/4” diameter tubing to the water-

out fitting (refer to Figure 4-2) to avoid the occasional spurts of water ejecting from

the fitting. Ensure the tubing is long enough that the water ejects outside the

instrument.

ZERO AIR OUT (1/4” swage-type bulkhead union) - Connect the AIR OUT port of the

751H to the INLET fitting of the Model 700 Calibrator with clean 1/4” TFE tubing.

Keep this line as short as possible to minimize pressure drops. . The pressure in this

line is adjustable, but should normally be 30 ± 5 psig.

07773A DCN6833 15

Page 18

Getting Started Teledyne API M751H High Performance Zero Air Generator

NOTE

If the 751H has been unused for several days, it may take 30-60 minutes for

the DEWPOINT LED to light green. However, for ultra-low-level calibrations,

running the instrument for several hours could be beneficial for achieving

stability and thoroughly scrubbing contaminants.

3.5 Power-Up

COOLING FAN Requirements

The instrument panel cooling fan draws air IN and requires at least 6” (150 mm) of

clearance for proper operation.

NOTE:

DO NOT BLOCK THE COOLING FAN; ALWAYS KEEP LID OPEN WHEN

INSTRUMENT IS RUNNING.

1. Turn on the instrument panel POWER SWITCH (Figure 3-1).

2. The instrument panel POWER LED should come on.

3. The cooling fan should start immediately.

4. The compressor should start after a few seconds delay. The delay is to allow the

control board to measure the local line frequency.

5. After 30 to 60 seconds, the instrument panel pressure gauge should read 30

psig.

6. When the DEWPOINT LED is lit green, it indicates that the 751H is producing

clean dry air.

3.6 Storage and Transportation

If the 751H will not be used for an extended period of time or will be transported, the

following procedure applies:

1. Turn off the 751H.

2. Wait approximately 1 minute.

3. Turn on the 751H. The water drain valve will switch into the open position and

vent any accumulated water through the water drain. (Standing H20 will cause

corrosion)

4. Turn the 751H off.

16 07773A DCN6833

Page 19

Teledyne API M751H High Performance Zero Air Generator Getting Started

This shut down process will vent any water that has accumulated in the coalescing

filter. It will prevent this water from passing into the 751H in the event that the

instrument is inverted during storage or shipment.

3.7 Expendable Kits (OPT 42A)

A one-year supply of replacement particulate filters and consumable scrubber media

is available from Teledyne API as Option 42A. Refer to Appendix B for a list of

expendables.

3.8 Flow Restrictor (OPT 72B)

An external flow restrictor is available in order to run the 751H without a calibrator or

other external restriction. It is connected to the outlet fitting and restricts the air flow to

9 SLPM, allowing the 751H to build adequate backpressure to operate.

07773A DCN6833 17

Page 20

Getting Started Teledyne API M751H High Performance Zero Air Generator

This page intentionally left blank,

18 07773A DCN6833

Page 21

4 OPERATION

4.1 Overview

Refer to Figure 4-1 for a diagram of the 751H pneumatic flow.

The 751H dries and scrubs ambient air to produce zero air. To accomplish this, first

the compressor draws air in through the intake filter and compresses it. At the

compressor outlet, the air is under pressure and hot from the compression. The

relative humidity is high as a result of the high pressure.

The air is conducted through the cooling coil where heat is removed by transfer to the

cooling fan air. With the high pressure and the temperature reduced to ambient level,

the relative humidity is at its highest. At this point, the air is usually supersaturated.

From the coil, the wet air passes through a coalescing filter where the excess water is

separated and settles in the bottom of the filter. The controller periodically opens the

solenoid drain valve allowing the water to be expelled through a drain fitting.

The partially dried air enters the Regenerative Dryer which removes essentially all the

remaining water and a portion of the other contaminants. The pressure relief valve

may open occasionally and can be loud but this is a normal part of the operation for

the 751H.

As the air leaves the dryer, its pressure is controlled to 30 psig by an air pressure

regulator mounted on the instrument panel. This maintains a constant pressure at the

calibrator inlet and is displayed by the pressure gauge on the 751H instrument panel.

For a final clean-up, the dry, regulated air enters the specific scrubbers/filters as

follows:

1. The Hydrocarbon scrubber where Hydrocarbons are catalytically converted to

CO2 and water.

2. The NO scrubber where NO is oxidized to NO2.

3. The activated charcoal scrubber where the NO2, O3, SO2 and H2S are absorbed.

4. The CO scrubber, where CO is catalytically oxidized to CO2.

5. The clean dry air passes through a fine particulate filter and leaves the 751H

through the instrument panel bulkhead union (Zero Air Out).

07773A DCN6833

19

Page 22

Operation Teledyne API M751H High Performance Zero Air Generator

751H Chassis

10LPM Pump

Pressure

Regulator

“AIR IN”

Drain Valve

Condenser

4-Way

Valve

Regen Dryer

Inlet Filter

BA

Pressure

Gauge

0 60

30

HC Scrubber

Purafil Scrubber

Charcoal Scrubber

CO Scrubber

DFU

Filter

“ZERO AIR OUT”

Cooling Coil

Dewpoint

Sensor

“DRAIN OUT”

Relief Valve

Coalescer

Pressure Relief

Valve

Figure 4-1: Pneumatic Diagram

Figure 4-2 and Figure 4-3 are illustrations of the 751H plan view and a close-up of its

instrument panel, respectively.

20 07773A DCN6833

Page 23

Teledyne API M751H High Performance Zero Air Generator Operation

Figure 4-2: Plan View

Figure 4-3: Instrument Panel

07773A DCN6833 21

Page 24

Operation Teledyne API M751H High Performance Zero Air Generator

CAUTION

THE WATER/AIR SPRAY LEAVING THE DRAIN FITTING SPURTS AT

A HIGH VELOCITY AND MUST BE CONDUCTED AWAY FROM ANY

SENSITIVE COMPONENTS.

4.2 Components

This section describes the main components and their functions (not all components

are visible from the plan view).

4.2.1 Intake Filter

The intake filter is a serviceable assembly that houses a screen filter. Maintenance

instructions are provided in Section 5 of this manual.

4.2.2 Compressor

The compressor is a single-cylinder oscillating piston type driven by a split capacitor

AC motor. The compressor is dry; that is, there are no lubricants which can

contaminate the compressed air. The pistons are sealed by flexible TFE piston rings,

and after a short run-in period to seat the rings, should last for years. There are no

diaphragms.

The compressor is mounted on a sub-plate which is supported on four tuned vibration

isolators.

4.2.3 Cooling Coil

The cooling coil consists of several turns of copper tubing coiled through which the

cooling fan blows outside air.

4.2.4 Water Trap

The water trap is a coalescing type. Supersaturated air enters the trap and is rapidly

swirled causing the water droplets to deposit on a membrane where the drops

coalesce and gather in a puddle at the bottom of the filter bowl.

4.2.5 Water Drain Valve

The water drain valve is a stainless steel solenoid-operated valve through which

accumulated water is drained from the filter. The valve is sequenced by the controller

and is pulsed open every minute to remove water from the filter bowl.

The operation cycle has been preset at the factory and is not adjustable.

22 07773A DCN6833

Page 25

Teledyne API M751H High Performance Zero Air Generator Operation

CAUTION – SAFETY HAZARD

DO NOT ADJUST THE RELIEF VALVE!

(Contact TAPI Technical Support if there is any concern about proper function).

4.2.6 Pressure Relief Valve

The pressure relief valve is a safety device designed to limit the maximum pressure

to which the 751H can be subjected. It is set to open at 75-80 psig. This can be quite

loud when the valve opens and sounds like steam escaping. This is normal operation

and does not mean there is a problem with the unit.

4.2.7 Regenerative Dryer

The Regenerative Dryer consists primarily of two parallel columns of molecular sieve,

in which alternately one column is scrubbing the air while the other is being

regenerated.

The Regenerative Dryer needs no warm-up and operates at full efficiency as soon as

the 751H is turned on. The molecular sieve is not consumed and is good for the life

of the instrument.

When the 751H is turned on, a four-way solenoid-operated valve directs high

pressure air to one of the two columns and vents the other column to atmosphere.

Virtually all the water in the high-pressure air is trapped by the molecular sieve. A

portion of the dried air is expanded to atmospheric pressure through a flow controller

and passes in reverse through the second column. By expanding the air, the volume

increases, thus enabling a small amount of dry purge air to evaporate the entrained

water in the second column. The wet purge air leaving the column is routed through a

stainless steel solenoid-operated valve and exhausted through the drain fitting. This

valve will periodically close when the four-way valve switches columns to maintain

system pressure. The majority of the dry air from the first column is conducted on to

the pressure regulator.

The controller toggles the four-way valve at a predetermined interval and the columns

alternate their function. This cycling rate has been selected to provide the optimum

balance of scrubbing efficiency and air usage and is not adjustable.

4.2.8 Pressure Sensor

The pressure sensor senses the system pressure directly following the regenerative

dryer and controls four-way valve action through the control board.

07773A DCN6833 23

Page 26

Operation Teledyne API M751H High Performance Zero Air Generator

WARNING

THE 751H NOMINAL DELIVERY PRESSURE IS 30 PSIG. NEVER SET

THE DELIVERY PRESSURE HIGHER THAN 35 PSIG. TO DO SO MAY

CAUSE DAMAGE TO THE 751H AND INJURY TO THE OPERATOR.

CAUTION

THE AIR LEAVING THE SCRUBBER IS AT 300 C (575 F).

THIS COPPER COIL AND THE CASING CAN BE VERY HOT.

4.2.9 Pressure Regulator

The pressure regulator is set at 30 psig at the factory except for specially modified

units. Should adjustment be desired, the regulator is accessible on the instrument

panel. The adjustment knob has a push-pull locking ring which should be reengaged

after making an adjustment to prevent the knob from turning under vibration.

When the 751H is used with the Teledyne API Model 700 Calibrator, the pressure

should be between 28 and 32 psig. The Model 700 calibrator requires that its air

source be stable and not subject to compressor-induced pressure surges or pressure

variations with flow.

4.2.10 Hydrocarbon (HC) Scrubber

The High Purity Hydrocarbon Scrubber catalytically converts hydrocarbons to carbon

dioxide and water. The scrubber consists of a cylindrical cartridge which contains a

preheat chamber and the pelletized precious-metal catalyst. The cartridge is heated

by a band heater with an integral type-K thermocouple and is housed in a stainless

steel casing with appropriate thermal insulation. The cartridge temperature is

maintained by the instrument’s controller. The control board reads the thermocouple

voltage, compensates for cold-junction temperature and modulates the heater to

maintain a constant cartridge temperature.

The operating temperature of the cartridge is 300ºC. The temperature can be verified

by measuring the thermocouple voltage at the two terminal blocks of J17 (labeled

“HC Scrubber” in Figure 4-4). At 300ºC, the thermocouple voltage is 11.2 mV in an

ambient temperature of 25ºC (11.4 mV at 20º and 11.0 mV at 30º). While the

controller compensates for cold-junction temperature in controlling the heater, the

thermocouple voltage at the terminal block is not compensated, so allowance must

be made for ambient temperature when converting the voltage to cartridge

temperature.

The catalyst is proprietary. It theoretically should never need changing. However, in

the event it were to become contaminated or poisoned, we recommend that the

scrubber be replaced.

24 07773A DCN6833

Page 27

Teledyne API M751H High Performance Zero Air Generator Operation

WARNING

DANGEROUS VOLTAGES EXIST ON THE CONTROLLER BOARD.

4.2.11 NO-NO2 Scrubber

The NO scrubber uses Purafil® to oxidize NO to NO2. Purafil® has a finite life and we

recommend that it be replaced annually or sooner if the level of NO in the air is high.

4.2.12 Charcoal Scrubber

Activated charcoal removes NO2, O3, SO2 and H2S. The charcoal should be replaced

annually or sooner if there are high atmospheric levels of these contaminants, or if

the calibrator zero air shows signs of a positive drift.

4.2.13 Carbon Monoxide (CO) Scrubber

The CO scrubber catalytically oxidizes CO to CO2. The catalyst is proprietary and

operates at room temperature; theoretically, it should never need changing. However,

in the event it were to become contaminated or poisoned, we recommend that the

scrubber be replaced.

4.2.14 Final Filter

The final filter, located adjacent to the instrument panel, retains any particulates

released by the 751H. The filter rating is 99.99% removal of 0.1 micron particles. If

the filter becomes restricted, it should be replaced.

4.2.15 Pressure Gauge

The pressure gauge shows the regulated air pressure available to a calibrator. The

gauge will usually indicate 30 psig. If the flow demand from the calibrator changes,

the regulator needs to be adjusted to display the correct pressure on the gauge. It is

normal for the gauge needle to not rest at zero when the system is not under

pressure.

4.2.16 Controller

All functions of the 751H are managed by the Control board (Figure 4-4), which

provides connections for all switched and non-switched AC components, AC input,

and the instrument panel power switch/circuit breaker.

Switched components include the regenerative dryer valve, the water drain

valve, and the relief valve.

Non-switched components include the HC scrubber, the fan, the LED board

and the pump.

07773A DCN6833 25

Page 28

Operation Teledyne API M751H High Performance Zero Air Generator

Provision for voltage configuration is via a jumper plug (J5). All electrical connections

are made by quick release connectors to aid in servicing. Refer to Figure 4-4 for the

layout and to Appendix B for the interconnect and other drawings.

The 751H Control PCB is microcontroller based and provides the following functions:

Cycles the four-way valve of the Regenerative Dryer.

Cycles the water drain solenoid valve.

Cycles the relief valve in response to the pressure sensor.

Cycles the Regenerative Dryer four-way valve and momentarily opens the water

drain solenoid valve at compressor startup. This reduces the pressure at the

compressor outlet to facilitate compressor starting.

LED D13 flashes at 1 second intervals as an indication that the controller is

functioning, and a watchdog timer is enabled to prevent any power line disturbances

from halting the processor.

Figure 4-4: Control Board Layout

26 07773A DCN6833

Page 29

Teledyne API M751H High Performance Zero Air Generator Operation

Power

Indicator

Dew Point

Indicator

Instrument State

Green

Green

Power ON, Dewpoint GOOD

Green

Yellow

Power ON, Dewpoint CAUTION

Green

Red

Power ON, Dewpoint BAD

Green

Red-Flashing

Power ON, Dewpoint CRITICAL

Alternating

Yellow –

Green

Representative

of Dewpoint

State

Maintenance Mode. 24hr Dewpoint Fault

Override

Red-Flashing

Yellow

Temperature Fault.

Red-Flashing

Red

Dew Point Fault.

4.2.17 Dewpoint Sensor

The dewpoint sensor ensures that the Regenerative Dryer maintains a dewpoint less

than -20°C (up to the maximum flow rate). This will increase the life of the chemical

scrubbers. When the dewpoint drops below -20°C, the green LED (dewpoint

indicator) on the instrument panel will light green, indicating that the air is dry.

4.2.18 Instrument Panel Indicator Lights

Multicolor indicator lights for both the power state and dewpoint state relay diagnostic

information and instrument mode to the user.

Table 4-1: Power and Dewpoint Condition Indicators

07773A DCN6833 27

Page 30

Operation Teledyne API M751H High Performance Zero Air Generator

This page intentionally left blank.

28 07773A DCN6833

Page 31

WARNING

There are high voltages present while the 751H is plugged in.

CAUTION

The operations outlined in this section are to be performed by

qualified maintenance personnel only.

Date Instrument was received:_____________________

Item

Charcoal

Scrubber

NO-NO2

Scrubber

(Purafil)

CO Scrubber

HC Scrubber

Regenerative

Dryer

Intake and

Final Filters

Recommended

Frequency

Annually

Annually

When

Contaminated

When

Contaminated

When

Contaminated

When

Contaminated

Refer to Section

5.5

5.6

5.7

5.8

5.9

5.12

Month

January

February

March

April

May

June

July

August

September

October

November

December

5 MAINTENANCE

5.1 Schedule

Before performing any maintenance, cycle the power on/off and drain any water that

may be present (refer to instructions for “Storage and Transportation” in Section 3.6).

Table 5-1 presents the maintenance schedule.

Table 5-1: Maintenance Schedule

07773A DCN6833

29

Page 32

MAINTENANCE Teledyne API M751H High Performance Zero Air Generator

CAUTION

Do not loosen any tubing connection while the 751H is running.

CAUTION

BEFORE WORKING ON THE 751H PLUMBING TURN OFF THE

751H, WAIT FOR THE PRESSURE GAUGE TO READ ZERO. (THIS

MAY REQUIRE THAT YOU LOOSEN THE INSTRUMENT PANEL

BULKHEAD UNION TO ALLOW THE AIR TO BLEED AWAY.)

5.2 Maintenance Mode

When changing the media of the Charcoal Scrubber (Section 5.5) and the NO-NO2

Scrubber (Section 5.6), the new media will contain some moisture due to humidity in

the ambient air, consequently triggering a dewpoint fault condition. Placing the 751H

in Maintenance Mode will override the fault for 24 hours, allowing time to thoroughly

dry the new media before resuming normal operation of the 751H. (In high humidity

environments this may take longer).

To activate Maintenance Mode, first follow the instructions for changing the media. At

the step when instructed to place the instrument in Maintenance Mode, locate the

hole in the bulkhead of the Instrument Panel. This hole is lined up with the

Maintenance Mode button on the Control Board (Figure 4-4); pass a blunt instrument

with a small diameter through the hole and press the button.

5.3 Cleaning

1. Occasionally, depending upon the local conditions, check the inside of the 751H

for excessive dirt or dust.

2. Particularly, check the cooling fan, cooling coil and compressor fan inlet.

3. Remove any dirt or dust with a vacuum cleaner.

Do not use an air jet. This will only redistribute the dirt and will not remove it.

5.4 Checking Tubing

1. Under the vibration of the compressor, it is possible for some parts of the TFE

tubing to abrade against nearby objects. This is most likely to occur with the

tubing directly attached to the compressor.

2. Check to see if any signs of abrasion are present, and, if so, re-dress the tubing.

3. If any section of tubing appears to be heavily abraded, remove and replace it.

30 07773A DCN6833

Page 33

Teledyne API M751H High Performance Zero Air Generator MAINTENANCE

WARNING

EVEN THOUGH THE INSTRUMENT PANEL POWER SWITCH IS

OFF, THERE IS LINE VOLTAGE PRESENT AT THE POWER ENTRY

TERMINALS, POWER SWITCH TERMINALS AND ON THE

CONTROL BOARD. FOR ADDED SAFETY, REMOVE THE POWER

CORD FROM THE INSTRUMENT PANEL RECEPTACLE.

5.5 Replacing the Charcoal Scrubber Media

Before emptying the used charcoal, wearing a dust mask is recommended as a

preventive measure since it is possible that some charcoal dust may rise when

emptying and refilling the canister.

1. Turn off the 751H and wait for the pressure to go to zero.

2. Remove the 1/4” tubing connected to the top of the scrubber canister.

3. Release the fastening strap to free the canister.

4. Remove the 1/4” tubing connected to the bottom of the canister.

5. Unscrew the cap of the canister.

6. Remove the pad from the top of the canister.

7. Pour out the charcoal and dispose of it properly.

8. Refill the canister with fresh charcoal, up to 3/8” to 1/4” from the top. Rap the

sides of the canister gently to settle the charcoal and add more as necessary.

9. Replace the pad on top of the charcoal.

10. Wipe any charcoal dust from the top edge of the canister. This is the surface

which seals against the gasket.

11. Check that the gasket is in place in the cap.

12. Replace the cap and tighten it “hand-tight”.

13. Reconnect the lower 1/4” tube connection.

14. Reattach the canister with the fastening strap.

15. Reconnect the upper 1/4” tube.

16. Enable “maintenance mode” (Section 5.2) which will bypass the dewpoint

warnings during scrubber drying.

17. After the compressor is turned on, it may be wise to check the scrubber for leaks

(see Section 5.11).

07773A DCN6833 31

Page 34

MAINTENANCE Teledyne API M751H High Performance Zero Air Generator

NOTE

After replacing the material in these scrubbers it can take up to 48 hours for

the material to dry out before the 751H is functioning optimally.

CAUTION

THE SCRUBBER MAY BE HOT.

5.6 Replacing the NO - NO2 Scrubber Media

This procedure is identical to the charcoal scrubber replacement procedure except

that the canister should be refilled with Purafil .

5.7 Replacing the CO Scrubber

The CO scrubber is attached to the bulkhead adjacent to the instrument panel

(Figure 4-2). This is not a heated scrubber. It is secured with four screws through the

body of the scrubber into the panel.

1. Turn off power and unplug the 751H.

2. Remove the Charcoal and NO-NO2 scrubbers to gain access to the hardware.

3. Disconnect the tubing and remove the four screws to remove the scrubber.

4. With a wrench, remove the two fittings from the top of the scrubber cartridge.

5. Pick out the retaining screens.

6. Shake out the catalyst beads and dispose. No special disposal methods

required.

7. Pour in new catalyst to 1/2” from the top of the bores. Tap the cartridge sides

gently to settle the beads and top up to the 1/2” level.

8. Return the retainer screens.

9. Replace the TFE tape on the two unions and replace the unions in the cartridge.

10. Reassemble the scrubber and reattach it to the panel.

11. Reconnect the tubing and receptacle.

12. Turn on the 751H and perform a leak check (see Section 5.11).

32 07773A DCN6833

Page 35

Teledyne API M751H High Performance Zero Air Generator MAINTENANCE

CAUTION

WAIT FOR THE SCRUBBER TO COOL. THE SCRUBBER CASING

AND THE COPPER COOLING COIL WILL BE VERY HOT.

CAUTION

ENSURE THAT THE COPPER COOLING COIL DOES NOT TOUCH

ANY WIRE OR CABLE.

CAUTION

BE SURE THAT YOU USE A TELEDYNE API-SUPPLIED, PURGED

SCRUBBER. OTHERWISE, DOWNSTREAM COMPONENTS MAY BE

DAMAGED. AN UNPURGED HYDROCARBON SCRUBBER

PRODUCES A LOT OF WATER WHEN FIRST TURNED ON.

5.8 Replacing the Hydrocarbon (HC) Scrubber

1. Turn off power and unplug the 751H power cord.

2. Remove the six screws which secure the chassis to the case.

3. Remove the chassis assembly from the case.

4. Remove the cover, exposing the pump and HC scrubber.

5. Disconnect the HC scrubber power at the Controller.

6. Unplug the thermocouple from the control board.

7. Disconnect the pneumatic connections at the REGULATOR OUTLET AND AT

THE COPPER COOLING COIL INLET, using 1/2 and 9/16 wrenches.

5. Loosen the four captive screws holding the scrubber to the chassis.

6. Lift out the scrubber.

7. Install a new Teledyne API-supplied scrubber (these are purged at the factory)

and tighten the four captive screws.

8. Attach and tighten the pneumatic connections.

9. Reconnect the wiring from the scrubber to the control board.

11. Plug the thermocouple into the control board.

12. Turn on the 751H.

13. Connect a millivolt meter to J17 (labeled “HC Scrubber” in Figure 4-4) on the

temperature controller.

Observe that the Heater Relay LED (D8) starts blinking at 11.2 mV (300ºC) and

that the thermocouple voltage holds steady.

14. When all traces of water have disappeared from the 751H output, the output

may be reconnected to the analyzer.

07773A DCN6833 33

Page 36

MAINTENANCE Teledyne API M751H High Performance Zero Air Generator

5.9 Servicing The Regenerative Dryer

It is unlikely that the Regenerative Dryer should ever need service. Should the

molecular sieve become contaminated by oil or other external contaminants, the

scrubber will need to be cleaned and recharged. Refer to Figure 5-1.

NOTE

Wearing a dust mask could be helpful as a preventive measure since the

molecular sieve may be dusty.

1. Turn off the 751H and turn on again and remove any water in bowl.

2. Unplug the instrument from electrical service.

3. Allow the pressure to bleed to zero.

4. Remove the two pneumatic connections and the electrical connection from the 4way manifold.

5. Remove the dryer from the chassis by undoing the four captive screws in the

scrubber base.

6. Remove the 4-way valve bracket from the upper manifold and let the valve hang

loose attached to the lower manifold. (If the valve needs to be replaced, see

Section 5.10 for procedures).

7. Remove the three nuts on top of the upper manifold.

8. Remove the upper manifold.

9. Remove the two dryer columns from the bottom manifold.

10. Change the four o-rings in the circular grooves in the upper and lower manifolds.

11. Remove the retainer pads from the top end of each dryer column and dump the

molecular sieve into a suitable waste receptacle.

12. Remove the retainer pads from the bottom end of each dryer column.

13. Wipe out the inside of the dryer columns with a clean dry cloth.

14. Examine the surface and ports in the upper and lower manifolds. If there is an

accumulation of dirt or corrosion, disassemble the manifolds and clean them. If

not, proceed with the next step.

15. Place new, clean retainer pad in the bottom end of each dryer column, pushing

in until the pads are at the retainer rings.

16. Invert the columns so that the open ends (top) are up.

17. Pour new, clean molecular sieve into each column, up to 1/4” from the top. Rap

the side gently, (with a screw-driver handle, for instance) to settle the molecular

sieve, and then top up to the 1/4” mark again.

18. Place new, clean retainer pads into the top of each column to the retainer ring.

34 07773A DCN6833

Page 37

Teledyne API M751H High Performance Zero Air Generator MAINTENANCE

19. Wipe the ends of the columns. These are the surfaces which seal against the

o-rings.

20. Set the bottom of the columns into the lower manifold. Ensure that they are in

the grooves and not caught up on the edge.

21. Place the upper manifold on top of the two columns. Ensure that the columns are

in the grooves. (Wiggle the columns sideways to ensure that the columns are

trapped in the grooves.)

22. Replace the nuts and lock-washers on the three tie rods BUT DO NOT TIGHTEN

THEM.

23. Push down hard in the center of the upper manifold with one hand and fingertighten the nuts until you feel a soft resistance.

24. With a wrench, tighten each nut in turn, 1/2 turn at a time. This will ensure that all

the nuts are tightened evenly. If the nuts are tightened unevenly, the column orings may not seal and you may cause damage to the sealing surfaces.

25. Examine the fit of the columns in the manifold groove one more time.

26. Re-attach the 4-way valve bracket.

27. Return the dryer to the 751H chassis and tighten the four captive screws.

28. Reconnect the two pneumatic fittings and the valve power cord.

29. Plug in and turn on the 751H.

30. Check the dryer for leaks (see Section 5.11).

If no leaks are detected, the 751H is ready for operation.

07773A DCN6833 35

Page 38

MAINTENANCE Teledyne API M751H High Performance Zero Air Generator

Figure 5-1: Regenerative Dryer

36 07773A DCN6833

Page 39

Teledyne API M751H High Performance Zero Air Generator MAINTENANCE

.

WARNING

ENSURE TO UNPLUG THE POWER CORD PRIOR TO

PERFORMING ANY LEAK CHECK PROCEDURE

NOTE

This procedure checks the majority of the components and fittings. If you

believe that there is still a leak, please contact Technical Support:

(858) 657-9800.

5.10 Changing the Regenerative Dryer’s 4-Way Valve

1. Remove the Regenerative Dryer from the chassis as described in Section 5.9

above.

2. Disconnect the two tubing connections and the electrical connection to the 4-way

valve.

3. Remove the 4-way valve bracket from the regenerative upper manifold.

4. Remove the 4-way valve from the bracket.

5. Attach a new valve, complete with tube fittings and muffler(s).

6. Attach the bracket to the upper manifold.

7. Connect the electric cable and two pneumatic fittings.

8. Re-install the dryer in the 751H chassis and tighten the four captive base screws.

5.11 Leak Check

1. Power off the unit and unplug the power cord.

2. Cap the zero out fitting and the drain port fitting.

3. Disconnect the line to the dewpoint sensor manifold and cap it.

4. Plug in the power cord, power on the unit, and allow it to run for one minute (until

it’s pressurized).

5. Turn off the power switch and wait five minutes. The reading on the instrument

panel pressure gauge should not change.

07773A DCN6833 37

Page 40

MAINTENANCE Teledyne API M751H High Performance Zero Air Generator

5.12 Filter Element Replacement

5.12.1 Intake Filter

To service the intake filter (Figure 4-2):

1. Turn the filter cap counter-clockwise and remove from the filter housing.

2. Remove the filter screen and use compressed air to blow out any debris.

3. Reseat the filter screen inside the filter housing.

4. Return the cap to the filter housing and secure in place with a clockwise turn.

If the screen is damaged, then replace the intake filter assembly (TAPI P/N FL51).

5.12.2 Final Filter

To replace the disposable Final filter unit (Figure 4-2):

1. Remove the disposable filter unit (DFU) from the retainer clip.

2. Release the tubing at each end of the DFU by pressing the spring-loaded quickconnects toward the DFU and pulling the tubing away.

3. Dispose of the used DFU.

4. Reinsert the tubing into each end of the new DFU (Teledyne API P/N FL50),

pushing in tightly to secure.

5. Secure the new filter unit into the retainer clip.

38 07773A DCN6833

Page 41

Teledyne API M751H High Performance Zero Air Generator TROUBLESHOOTING

CAUTION – Avoid Warranty Invalidation

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling

may void your warranty. For anti-ESD handling instructions please refer to the

manual, Fundamentals of ESD, PN 04786, which can be downloaded from our

website at http://www.teledyne-api.com under Help Center > Product Manuals

in the Special Manuals section.

Problem

Probable Cause

Corrective Action

Power light does not come on.

Unplugged power cord.

Plug in power cord at both ends.

Incorrect line voltage.

Refer to Table 3-1 for the correct

line voltage.

Tripped power switch/circuit

breaker.

Reset power switch/circuit

breaker.

Compressor does not start

(after 10 seconds).

AIR IN filter is plugged.

Clean or replace the filter.

Compressor fan is jammed.

Check for any mechanical

obstruction.

Pump is not connected to

controller.

Connect the pump to the

controller.

Pump relay (K4) is open.

Replace the controller.

Instrument vibrates

excessively.

Compressor shock isolator screws

are loose.

Tighten the screws.

The tubing attached to the

compressor is vibrating against a

component.

Adjust the placement of the

tubing.

Pressure does not increase to

30 psig.

Air demand too high. Maximum air

flow is 10 SLPM.

No action. Pressure will increase

as flow demand decreases.

Air Inlet impeded.

Remove the inlet filter and check

for impediment or replace filter.

Pressure regulator is set too low.

Adjust the pressure on the

instrument panel. (Please see

Warning Note at end of this

table).

Air leakage.

Check for leaks. (Section 5.11).

Pump has low output pressure.

Rebuild pump (see sticker on

pump for rebuild kit PN).

6 TROUBLESHOOTING

This section presents possible problems and their causes and solutions.

Table 6-1: Troubleshooting

07773A DCN6833 41

Page 42

TROUBLESHOOTING Teledyne API M751H High Performance Zero Air Generator

Problem

Probable Cause

Corrective Action

Output pressure surges.

Pressure regulator is set too high

and pegged.

Adjust pressure regulator down.

Output air is not “Zero”.

Scrubbers may be contaminated.

Replace the scrubbers.

Output air is not dry.

4-way valve is jammed; only one

column is being used.

Check to ensure the valve is

plugged in; replace the valve.

Reflux flow controller is plugged.

Replace the upper manifold

assembly.

Molecular sieve is contaminated.

Replace the molecular sieve.

CAUTION

THE 751H NOMINAL DELIVERY PRESSURE IS 30 PSIG.

NEVER SET THE DELIVERY PRESSURE HIGHER THAN 35 PSIG.

TO DO SO MAY CAUSE DAMAGE TO THE 751H AND INJURY TO

THE OPERATOR.

42 07773A DCN6833

Page 43

Note

Use of replacement parts other than those supplied by TAPI may result in noncompliance with European standard EN 61010-1.

Note

Due to the dynamic nature of part numbers, please refer to the Website at

http://www.teledyne-api.com or call Technical Support at 800-324-5190 for more

recent updates to part numbers.

APPENDIX A - SPARE PARTS

07773A DCN6833 A-1

Page 44

This page intentionally left blank.

A-2 07773A DCN6833

Page 45

078390000 751H SPARE PARTS LIST Revision A

PART NUMBER DESCRIPTION

005960000 MEDIA, ACTIVATED CHARCOAL KIT

005970000 MEDIA, PURAFIL KIT

006900000 FELT PADS FOR REGEN DRIER

006900100 FELT PADS FOR SCRUBBER CANISTERS

016920000 MEDIA, MOLECULAR SIEVE KIT

018490000 PRESSURE GAGE

040370000 CO SCRUBBER ASSEMBLY

057270000 GASKET FOR SCRUBBER CANISTERS

077830100 PCA, CONTROL BOARD, 751H

077990000 PUMP ASSY, 115V/60HZ, 751H

077990100 PUMP ASSY, 230V/50HZ, 751H

078580000 ASSY, WATER DROP VALVE 751H

078600000 ASSY, DRYER RELIEF VALVE 751H

078610000 ASSY, 12VDC FAN 751H

FL0000007 FILTER, COALESCING

FL0000050 FILTER, DFU, KYNAR

FL0000051 FILTER, INTAKE, 751H

HW0000439 BULKHEAD SCRUBBER MOUNT

OR0000035 O-RINGS FOR REGEN DRIER

PU0000099 REBUILD KIT, PUMP, 751H

07773A DCN6933

A-3

Page 46

This page intentionally left blank.

A-4

07773A DCN6933

Page 47

APPENDIX B - SCHEMATICS

07773A DCN6833 B-1

Page 48

This page intentionally left blank.

B-2 07773A DCN6833

Page 49

Interconnect List 751H

Revision Description Checked Date DCN

A Production Release RH 10/6/2013 6768

Cable Part

#

Signal Assembly PN J/P Pin Assembly PN J/P Pin

077940100 Cbl Assy, Front Panel LED Indicator, 751X

PWR RED LED Front Panel LED Board 077890000 J1 1 Control Board 077830000 J11 1

PWR GREEN LED Front Panel LED Board 077890000 J1 2 Control Board 077830000 J11 2

RH RED LED Front Panel LED Board 077890000 J1 7 Control Board 077830000 J11 3

GND Front Panel LED Board 077890000 J1 4 Control Board 077830000 J11 4

GND Front Panel LED Board 077890000 J1 3 Control Board 077830000 J11 5

RH GREEN LED Front Panel LED Board 077890000 J1 6 Control Board 077830000 J11 6

077990000 Assy, Pump. 115V~, 751H

AC Line Assy, Pump. 115V~ 077990000 L Control Board 077830000 J8 1

AC Neutral Assy, Pump. 115V~ 077990000 N Control Board 077830000 J8 2

Power Gnd Assy, Pump. 115V~ 077990000 G Control Board 077830000 J8 3

077990100 Assy, Pump. 230V~, 751H

AC Line Assy, Pump. 230V~ 077990100 L1 Control Board 077830000 J8 1

AC Neutral Assy, Pump. 230V~ 077990100 L2 Control Board 077830000 J8 2

Power Gnd Assy, Pump. 230V~ 077990100 G Control Board 077830000 J8 3

078580000 Assy, Water Drop Valve, T701X/751X

+12V RET Water Drop Valve 078580000 EXT/J16 1 Control Board 077830000 J16 1

+12V Water Drop Valve 078580000 EXT/J16 2 Control Board 077830000 J16 2

078590000 Cbl Assy, 4-Way Shuttle Valve, T701X/751H

+12V RET 4-Way Shuttle Valve 078590000 P13 1 Control Board 077830000 J13 1

+12V 4-Way Shuttle Valve 078590000 P13 2 Control Board 077830000 J13 2

CONNECTION FROM

CONNECTION TO

07773A DCN6833

B-3

Page 50

B-4

07773A DCN6833

This page intentionally left blank.

Page 51

The information hereon is the property of

API and is submitted in strictest

confidence for reference only.

Unauthorized use by anyone for any othe

rpurposese is prohibited. This document

or any information contained in it may be

duplicated without proper authorization.

Printed Documents are Uncontrolled

Everywhere look

ADVANCED POLLUTION INSTRUMENTATION

J1

DC

AC

J7

FAN

FA10

J11

J17

J3

HEATER

SCRUBBER

PUMP

J1

J8

J2

J2

J1

J15

J19

077830000

SWITCH

AC POWER

ENTRANCE

AC POWER

CONTROL BOARD

PS48

J13

J16

J1

J1

J5

078670000 (115V)

CONFIG

078670100 (230V)

T751H

DRIER

RELIEF

VALVE

WATER

DROP

VALVE

FRONT

PANEL

LED

THERMISTOR

TEMP

751H

PLUG

4-WAY

SHUTTLE

VALVE

07773A DCN6833

B-5

Loading...

Loading...