OPERATING INSTRUCTIONS FOR

Model 7500ZA

NDIR Infrared Gas Analyzer

P/N M7500ZA

4/09/14

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Model 7500ZA

Copyright © 2014 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91748.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, an d serves as a to ol by whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

NDIR Gas Analyzer

Specific Model Information

It is not recommended that this instrument be used for analysis on

any other gas or gas mixture than that specified at the time of purchase.

The analyzer is set up and calibrated at the factory for a specific

application using a known gas mixture that is representative of the

customers’ process. Using this instrument to analyze any other gas

mixture may result in interference and possible measurement error.

Consult the factory for additional information for gas analysis not

specified at the time of purchase.

Instrument Serial Number: _______________________

Measurable

Species:

Range 1:

Range 2:

Span Gas 1:

Span Gas 2:

Zero Gas:

NO

SO2

CO2

CO

CH4

O2

Fuel Cell

ZrO2

Built-In External

Background:

Teledyne Analytical Instruments iii

Model 7500ZA

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

No

Symbol

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments iv

NDIR Gas Analyzer

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Model 7500ZA

Additional Caution on Safety

To operate the analyzer properly, be sure to read “Caution on

Safety” carefully.

The descriptions listed here provide important information on safety.

Be sure to observe them at all times. Th ese safety p recau tions are classified

into 3 levels: “DANGER,” “CAUTION” and “PROHIBITION”.

”

Improper handling may cause dangerous

DANGER

CAUTION

situations that may result in death or serious

injury.

Improper handling may cause dangerous

situations that may result in medium-level

troubles, minor injury, or property damage.

Items which must not be done are indicated.

PROHIBITION

Caution on installation and transport of analyzer

DANGER

CAUTION

The unit is not of explosion-proof. Do not use it in an

atmosphere of explosive gases. Otherwise, serio us

accidents including explosion or fire may result.

For installation, observe the rule on it given in the

instruction manual, and select a place where the

weight of analyzer can be supported. Installation in

an inadequate place may cause turnover or falling,

resulting in injury.

Be sure to wear protective gloves when lifting the

analyzer. Lifting it with bare hands may result in

injury.

Be sure to fix the cover before transporting the

analyzer. Transportation in unstable state may result

in injury.

Teledyne Analytical Instruments vi

NDIR Gas Analyzer

The gas analyzer is heavy. To transport the

analyzer, please use a hand cart or equivalent. Avoid

carrying analyzer by hand as much as possible.

Doing so may cause injury.

Take care not to let cable chips and other foreign

objects enter the unit during installation work.

Otherwise, fire, failure, or malfunction may result.

Caution on piping

Be sure to observe the following

DANGER

precautions while installing piping. Improper

piping may result in gas leakage.

If the leaking gas contains a toxic

component, serious accidents may re sult. If

it contains combustible gases, explosion or

fire may result.

Connect pipes correctly referring to the

instruction manual.

Discharge the exhaust gas outdoors to

prevent it from remaining within the

sampling device or indoors.

Relieve the exhaust gas fro m the an alyzer t o

the atmospheric pressure to prevent buildup

of undesirable pressure to the analyzer.

Otherwise, piping within the analyzer may be

disconnected, resulting in gas leakage.

Use pipes and pressure reducing valves to

which no oil/grease is attached to the

piping. Otherwise, fire may result.

Caution on wiring

Be sure to turn off the power before

DANGER

installing wiring. Otherwise, electric shock

may result.

Be sure to perform protective earth ground

connection. Otherwise, electric shock or

failure may result.

Select a proper wiring material that satisfies

Teledyne Analytical Instruments vii

Model 7500ZA

the ratings of the instrument. Otherwise,

electric shock or fire may result.

Be sure to connect a power supply of

correct rating. Otherwise, fire may result.

Caution on use

Be sure to read the instruction manual for

DANGER

CAUTION

reference gases before handling reference gases

such as calibration gas to use them properly.

Leaving the analyzer unused for a long time or

restarting it after long-term suspension requires

procedures different from normal operation or

suspension procedures. Be sure to follow the

instructions in each instruction manual.

Otherwise, intended performance may not be

achieved. Also, accidents or injury may result.

Do not operate the analyzer for a long time with

its cover left open. Otherwise, dust, foreign

matter, etc. may contaminate the internal walls,

thereby causing faults.

PROHIBITION

Do not touch the input/output terminals with

metal or finger. Otherwise, electric shock or

injury may result.

Do not smoke or use flames near the analyzer.

Otherwise, fire may result.

Do not allow water to enter the analyzer.

Otherwise, electric shock or internal fire may result.

Caution on maintenance and check

DANGER

Before performing work with the cover of the

analyzer open for maintenance and check, be sure

to purge completely not only within the analyzer but

also measuring gas lines using nitrogen or air.

Otherwise, poisoning, fire, or explosion may result

due to gas leakage.

Teledyne Analytical Instruments viii

NDIR Gas Analyzer

CAUTION

Be sure to observe the following to perform work

safely, avoiding electric shock or injury.

Remove the watch and other metallic objects before

work.

Do not touch the instrument with wet hands.

If the fuse is blown, eliminate the cause and replace

it with the one of the same capacity and type.

Otherwise, electric shock or accidents may result.

Do not use replacement parts other than those

specified by the manufacturer. Otherwise, intended

performance may not be achieved and accidents or

failures may result.

Dispose replacement parts such as maintenance

parts as incombustibles according to the local waste

disposal regulations.

Teledyne Analytical Instruments ix

Model 7500ZA

Table of Contents

Specific Model Information ......................................................... iii

Safety Messages .......................................................................... iv

Additional Caution on Safety ...................................................... vi

List of Figures ............................................................................ xiv

List of Tables ............................................................................... xv

Introduction ................................................................................... 1

1.1 Overview 1

1.2 Typical Applications 2

Items included with the Analyzer ................................................. 3

2.1 Confirmation of delivered items 3

2.2 Name and Description of Analyzer 4

Installation ..................................................................................... 7

3.1 Installation Conditions 8

3.2 Installation 8

3.2.1 Installation of Analyzer Main Frame 8

3.3 Piping 9

3.4 Sampling 12

3.4.1 Sample Gas Conditioning 12

3.4.2 Sample Gas Flow 12

3.4.3 Preparation of Standard Gas 12

3.4.4 Internal Purging of the Instrument Housing 13

3.4.5 Pressure at Sample Outlet 13

3.4.6 Example Configuration of Sample System 14

3.5 Electrical Connections 15

Operation ..................................................................................... 25

4.1 Preparation for operation 25

4.2 Warm-up Operation and Normal Operation 25

Teledyne Analytical Instruments x

NDIR Gas Analyzer

Display And Operation Panels ................................................... 27

5.1 Front Panel Description 27

5.2 Overview of Display and Operation Panels 29

5.3 Outline of Display Screen 30

5.4 Basic Operation 34

Settings and Calibration ............................................................. 35

6.1 Range Switch 35

6.1.1 Setting the Range Switch Mode 35

6.1.2 Manual Range Mode 36

6.1.3 Range Identification Contacts 36

6.2 Calibration Setting 37

6.2.1 Setting the Span Gas Concentration 37

6.2.2 Manual Zero Calibration 38

6.2.3 Setting the Calibration Range 40

6.2.4 Setting the Component/Range for Auto Calibration 42

6.3 Alarm setting 44

6.3.1 Setting Alarm Parameters 44

6.3.2 Hysteresis Setting 46

6.3.3 Peak Alarm Setting 47

6.4 Setting Up the Auto Calibration 49

6.4.1 Auto Calibration 49

6.4.2 Forced Run/Stop Of Auto Calibration 52

6.4.2.1 Execution of auto calibration (only once) 52

6.4.2.2 Forced stop of auto calibration 53

6.5 Setting Auto Zero Calibration 55

6.5.1 Auto Zero Calibration 55

6.5.2 Forced Run/Stop of Auto Zero Calibration 57

6.5.2.1 Execution of auto zero calibration (only once) 58

6.5.2.2 Forced stop of auto zero calibration 58

6.6 Parameter Setting 60

6.7 Maintenance Mode 68

6.7.1 Sensor Input Value screen 68

Teledyne Analytical Instruments xi

Model 7500ZA

6.7.2 Error Log screen 68

6.7.3 Calibration Log screen 69

6.7.4 Output Adjustment Screen 70

6.7.5 Other Parameter 71

6.8 Calibration 73

6.8.1 Zero Calibration 73

6.8.2 Span Calibration 74

7. Maintenance ............................................................................ 75

7.1 Daily Check 75

7.2 Daily Check And Maintenance Procedures 76

7.3 Long Term Maintenance 76

7.4 Cleaning the Sample Cell 78

7.4.1 Sample Cell Disassembly 78

7.4.1.1 Pipe Cell Removal (See Fig. 7-1) 79

7.4.1.2 Block Cell Removal (See Fig. 7-2) 80

7.4.1.3 Removing the Measuring Unit 82

7.4.2 Cleaning the Sample Cell 82

7.5 Fuse Replacement 84

8. Error Messages ....................................................................... 85

8.1 Troubleshooting 86

8.2 Error Log File 87

9. Specifications .......................................................................... 89

9.1 General Specifications 89

9.1.1 Standard Specifications 89

9.1.2 Standard Functions 93

9.1.3 Optional Functions 94

9.1.4 Performance 98

9.1.5 EC Directive Compliance 98

9.1.6 Requirements for Sample Gas 99

9.1.7 Installation Requirements 100

9.2 Table 1 Measurable Component and Range - Availability

Check Table 101

Teledyne Analytical Instruments xii

NDIR Gas Analyzer

9.3 Code Symbols 106

9.4 Outline Diagram 109

Teledyne Analytical Instruments xiii

Model 7500ZA

List of Figures

Figure 2-1A: Model 7500ZA Front Panel ......................................... 4

Figure 2-1B: Model 7500ZA Rear Panel ......................................... 5

Figure 7-1: Measuring Unit Configuration (Pipe Cell) .................... 79

Figure 7-2: Measuring Unit Configuration (Block Cell) .................. 81

Figure 7-3: Measuring Unit with 2-Component Block and Pipe Cell83

Teledyne Analytical Instruments xiv

NDIR Gas Analyzer

List of Tables

Table 7.1 Maintenance and Check Table ...................................... 76

Table 8-1: Error Messages ............................................................ 85

Teledyne Analytical Instruments xv

Model 7500ZA

DANGER

COMBUSTIBLE GAS USAGE

This is instrument is approved as an intrinsically safe gas

analyzer for use in a category (ia) Group IIC hazardous area.

This approval only to the equipment specified installed in

accordance with the information contained within this

manual. It is the customer's responsibility to ensure safety

especially when combustible gases are being analyzed since

the potential of gas leaks always exist.

WARNING

The customer should ensure that the principles of operating

of this equipment is well understood by the user and that the

instrument as well as any approved support equipment is

properly installed. Misuse of this product in any manner,

tampering with its components, or unauthorized substitution

of any component may adversely affect the certification and

the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments xvi

NDIR Gas Analyzer Introduction

Introduction

1.1 Overview

The Model 7500ZA is designed to measure the concentration of

NO, SO

different atomic molecules have a different absorption spectrum in the

infrared band and the intensity of absorption is determined by the

Lambert-Beer law.

, CO2, CO and CH4 in a sample gas based on the principle that

2

When equipped with the optional O

sensor, the Model 7500ZA is

2

capable of measuring up to 5 components simultaneously or up to 4

components if O2 sensor is not installed.

The Model 7500ZA is a microprocessor based analyzer with a large

LCD display, superior accuracy and a multitude of functions suitable for

applications such as:

• Combustible gas emissions from boilers or incinerators

• Steel gas analysis (blast furnace, steel converter, thermal

treatment furnace, sintering (pellet equipment) etc.

• Coke furnace

• Storage and maturity of vegetable and fruit,

• Biochemistry (microbe) (fermentation)

• Air pollution monitoring [incinerator, exhaust gas

desulfurization, denitration], automotive emission (excluding

tester)

• Disaster prevention (detection of explosive gas and toxic gas,

combustion gas analysis of new building material)

• Agricultural

• Chemical analysis (petroleum refinery plant, petroleum

chemistry plant, gas generation plant)

• Environmental analysis

• Physical and chemical research

Teledyne Analytical Instruments 1

Introduction Model 7500ZA

1.2 Typical Applications

The Model 7500ZA is a microprocessor based analyzer with a large

LCD display, superior accuracy and a multitude of functions suitable for

a variety of applications including:

• Combustible gas emissions from boilers or incinerators

• Steel gas analysis (blast furnace, steel converter, thermal

treatment furnace, sintering (pellet equipment) etc.

• Coke furnace

• Storage and maturity of vegetable and fruit,

• Biochemistry (microbe) (fermentation)

• Air pollution monitoring (incinerator, exhaust gas

desulfurization, denitration)

• automotive emission (excluding tester)

• Disaster prevention (detection of explosive gas and toxic gas,

combustion gas analysis of new building material)

• Agricultural

• Chemical analysis (petroleum refinery plant, petroleum

chemistry plant, gas generation plant)

• Environmental analysis

• Physical and chemical research

Teledyne Analytical Instruments 2

NDIR Gas Analyzer Items Included with Analyzer

Items included with the Analyzer

2.1 Confirmation of delivered items

• The following items are included with you analyzer.

Analyzer

Fuse (2pcs))

Std: IEC127-2

05x20 mm

250V/2A SB

Analog Output Connector (1)

25 pin D-sub male

M2.6x4 mm

Instruction Manual

External Input Connector (1)

(External O2/External Zirconia Sensor as

specified)

Digital Input Connector

(3 max with the no. of DIO when digital

I/O function is specified).

Teledyne Analytical Instruments 3

Items Included with Analyzer Model 7500ZA

RS-484 Connector

(1) (when provided with communications

function)

9 pin D-sub connector male

M2.6 x 4 mm

Ferrite Core

(1) for power cable (When terminal block

for power supply is specified)

Power Supply Cord (1) (when power input

is specified)

•

2.2 Name and Description of Analyzer

The operator interface is shown in Figure 2-1A and the various

connections to the instrument are shown in figure 2-1B.

Figure 2-1A: Model 7500ZA Front Panel

Teledyne Analytical Instruments 4

NDIR Gas Analyzer Operation

Figure 2-1B: Model 7500ZA Rear Panel

Teledyne Analytical Instruments 5

Items Included with Analyzer Model 7500ZA

[Blank page]

Teledyne Analytical Instruments 6

NDIR Gas Analyzer Instalation

Installation

Installation of the Model 7500ZA NDIR Analyzer includes:

Unpacking

Mounting

Gas connections

Electrical connections

Calibration

DANGER: THIS UNIT IS NOT AN EXPLOSION-PROOF

INSTRUMENT. DO NOT USE IT IN A PLACE WITH

EXPLOSIVE GASES TO PREVENT EXPLOSION, FIRE

OR OTHER SERIOUS ACCIDENTS.

CAUTION: ENTRUST THE INSTALLATION, MOVEMENT OR RE-

INSTALLATION TO A SPECIALIST OR THE

SUPPLIER. A POOR INSTALLATION MAY CAUSE

ACCIDENTAL TIPOVER, ELECTRIC SHOCK, FIRE,

INJURY, ETC.

• The gas analyzer is heavy. It should be installed with utmost

care. Otherwise, it may tip over or fall, causing accident or

injury.

• For lifting the gas analyzer, be sure to wear protective gloves.

Using bare hands may result in injury.

• This unit should be installed in an environment conforming to

the conditions noted in the instruction manual. Otherwise,

electric shock, fire or other malfunction of the unit may occur.

• During installation, care should be taken to keep the unit free

from entry of chips, dust, and debris. Otherwise, it may cause

fire, trouble or malfunction of the unit.

The analyzer is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the transmitter

and inspect it for damage. Immediately report any damage to the

shipping agent.

Teledyne Analytical Instruments 7

Installation Model 7500ZA

3.1 Installation Conditions

To install the analyzer for optimum performance, select a location

that meets the following conditions;

1. This instrument is designed for rack mounting in a standard 19”

equipment rack.

2. Indoor use only.

3. Vibration-free.

4. Free of dust and debris and obstruction around the analyzer.

5. AC power: 100V to 240 VAC

Operating voltage: 85V to 264V AC

Rated frequency: 50/60 Hz

Power consumption: 100 VA max.

6. Operating conditions:

Ambient temperature : -5° to 45°C (max. 40°C when two optical

units are used, and the power supply is more than 200V AC)

7. Maintenance space:

When analyzer is installed by itself, adhere to the

diagram to make sure there is adequate space to

remove the cover for maintenance.

When the analyzer is installed as an unit, See

Section 3.2.1

8. A circuit breaker that meets IEC60947-1 and

IEC60947-3 specifications should be installed.

9. A breaker should be installed near the analyzer

where an operator can access it.

10. A label that clearly identifies the breaker should be visible.

11. The breaker rating should meet the analyzer rating max 2A and

conform to all necessary approvals.

3.2 Installation

3.2.1 Installation of Analyzer Main Frame

Installation methods for the analyzer main unit is shown below.

Teledyne Analytical Instruments 8

NDIR Gas Analyzer Instalation

• The analyzer weight must be supported at the bottom of the

casing.

• The analyzer should be installed in a place where ambient

temperature is within -5 to 45°C (max. 40°C when two optical

units are used, and the power supply is more than 200V AC), and

temperature fluctuation during operation is minimum.

• Where vibration is unavoidable, protect the analyzer from

vibrating. If necessary, install rubber or other vibration absorbing

material around the case to isolate any vibration from the support

structure.

3.3 Piping

Observe the following items when making gas connections to the

rear panel:

• Piping should be connected to the gas inlets and outlets at the

rear panel of the analyzer.

• Use a corrosion resistant tubing comprised of Teflon, stainless

steel or polyethylene to connect the instrument to a sampling

system. Even if there is a danger of corrosion, refrain from using

rubber or soft vinyl tubing. These materials will cause inaccurate

indication due to gas absorption from the tubing.

• Pipe connection port fittings are NPT 1/4” female thread (or 1/4”

RC). Piping should be cut as short as possible for optimum

response. About 4 mm inner diameter is recommended.

Teledyne Analytical Instruments 9

Installation Model 7500ZA

• Entry of dust into the instrument may result in poor performance.

Use clean tubing and couplings.

•

Sample inlet: Attach clean, dry sample gas to the inlet port.

Note that the calibration gases ( zero and span)

also connect to this port.

Input gas flow t should be constant within the

range of 0.5 L/min ±0.2 L/min.

Sample outlet: Attach tubing for exhausting sample or calibration

gases. The exhaust line should be directed to an

appropriate safe vent depending on the nature of

the sample/calibration gas used.

Purge gas inlet: Used to connect a purge gas for purging the

internal housing of the analyzer. Use dry N

or

2

instrument air for purge gas. (Flow rate is 1L/min

or more. Keep dust or moisture/mist from

entering the purge line.

CAUTION: THIS INSTRUMENT IS DESIGNED TO HANDLE

HAZARDOUS GASES. WHENEVER A FITTING IS

OPENED, USE A NEW FERRULE AND CONE TO

SECURE A GAS TIGHT SEAL. EACH FITTING MUST

BE LEAK CHECKED WHENEVER A CONNECTION

HAS BEEN OPENED OR DISTURBED IN ANY

MANNER.

The internal piping diagram for the Model 7500ZA is shown

below.

Teledyne Analytical Instruments 10

NDIR Gas Analyzer Instalation

Correspondence between measured components and the optical

units is as follows:

Measured

Components

Single measured species:

, CO

2

2

2

2

, CO or CH4

2

/ CO

/ CO

NO, CO

Two measured species:

CO

Two measured species:

NO/CO, NO/SO

Three measured species:

NO/ SO

Four measured species:

NO/ SO

Optical Bench 1 Optical Bench 2

Single component None

CO

/CO None

2

NO/CO CO/SO

NO SO

NO/CO SO

/CO

2

/CO

2

2

Teledyne Analytical Instruments 11

Installation Model 7500ZA

3.4 Sampling

3.4.1 Sample Gas Conditioning

1. Dust from the sampling gas should be completely removed using

a filter. For the final stage filter, use a filter that removes dust

particles down to 0.3µm.

2. Dew point must be lower than the ambient temperature. If vapor

is contained in the sample, dew point should be lowered to 2°C

using a dehumidifier.

3. If SO3 mist is present in the sample gas, use a mist filter or

cooler to remove the SO3 mist. Other mists should be removed

using a mist filter or gas dryer.

4. Corrosive gases such as Cl2, F2 and HCl, if present in

considerable amounts, will shorten the life of component parts.

5. Sample gas temperature should be within 0 to 50°C. Do not flow

hot gas directly into the instrument.

3.4.2 Sample Gas Flow

Sample flow should be 0.5L/min ± 0.2L/min. Avoid any flow

fluctuation during measurement. Observe the flow reading using the

flowmeter provided as shown in the example of the sampling system

configuration (Item 3.4.6).

3.4.3 Preparation of Standard Gas

Routine calibration is required once a week using span and zero

calibration gases to keep the instrument performing optimally. Prepare a

standard gas cylinder for zero calibration and span calibration per the

table below.

Without O

2

Sensor

Zero Gas N2 N

Span gas other

than for O

2

Gas with

concentration

Built-in O

2

Sensor

2

(O

of 99.9 to 100

2

vol% for reverse

range O

measurement.)

Gas with

concentration of

2

External O

2

Sensor

Dry air

Gas with

concentration of

Teledyne Analytical Instruments 12

NDIR Gas Analyzer Instalation

Without O

2

Sensor

measurement. of 90 to 100% on

the measuring

range

Span gas for O2

measurement

—

Built-in O

2

Sensor

90 to 100% on

the measuring

range.

Gas with conc. of

90 to 100% on

the measuring

range or

atmospheric air

(21% O

(O

95.5 vol% for

reverse range O

measurement.)

).

2

gas of 95 to

2

90 to 100% on

the measuring

range.

O

2

3.4.4 Internal Purging of the Instrument Housing

The internal housing does need not be purged except under the

following conditions:

External O

2

Sensor

gas at 1 to 2%

2

1. A combustible gas component is contained in the sample gas.

2. Corrosive gas is contained in the atmospheric air at the

installation site.

3. The same gas as the sample gas component is contained in the

atmospheric air at the installation site.

In such cases, the analyzer housing should be purged with the

instrument air or dry N

.

2

The purge flow rate should be set to about 1L/min. The purge gas

must be free of dust and moisture.

3.4.5 Pressure at Sample Outlet

Pressure at the sample gas outlet should be atmospheric pressure.

Make sure there are no kinks or obstructions in the exhaust line.

Teledyne Analytical Instruments 13

Installation Model 7500ZA

3.4.6 Example Configuration of Sample System

The following illustrates a typical sample system configuration for

five component gas measurement monitoring a combustion exhaust gas

from boiler, refuse incinerator, etc.

Contact TAI for other system configurations to match your specific

application.

Name Description Name Description

(1) Gas extractor

(2) Mist filter

(3) Safety drain trap

(4) Gas aspirator For aspiration of the

Teledyne Analytical Instruments 14

Gas extractor with a

heating type stainless

steel filter of standard

mesh 40µm.

Removes drain, mist,

and dust.

The safety drain trap is

divided into two spaces

for positive and

negative pressure. It

monitors

and adjusts the sample

gas pressure.

sample gas

8) Flowmeter

9) Reference gas

10) Zirconia O

sensor

2

Adjusts and monitors

the flow rate of the

sample gas.

Reference gas used for

calibrating zero and

span of the analyzer,

depending on the

measured gas.

External zirconia

oxygen sensor used for

NDIR Gas Analyzer Instalation

Name Description Name Description

(5) Electronic gas

cooler

(6) Solenoid valve

(7) Membrane filter

3.5 Electrical Connections

CAUTION: To prevent electric shock or fire:

Dries the moisture in

the sample gas to a

dew point of approx.

2°C

Used for flowing the

calibration gas.

PTFE filter used to

eliminate fine dust

particles.

(11) NO

converter

2

/NO

measuring the oxygen

concentration in

sample gas.

(Not used when O

sensor is built-in.)

Added to NOx Analyzer.

A special catalyst

material is used for

efficient conversion of

to NO

NO

2

2

Turn off the power before wiring.

Always use a protective earth connection.

Select a proper wiring material that satisfies the

ratings of the instrument. • Be sure to connect a

power supply of correct rating.

The power terminal block and external input/output connector are

installed on the rear panel. Refer to the diagram below.

Teledyne Analytical Instruments 15

Installation Model 7500ZA

(1) Power Supply (standard terminal 1 to 2)

Connect the power supply to the power terminal, and connect the ground

wire to the grounding terminal (standard terminal 3). Be sure to provide

a protective earth connection. Use solderless terminals (for M4) for

connection to the terminals (power and earth). See the figure below.

For the infrared gas analyzer, install an accessory ferrite core (to

the power supply terminal stand side) on the AC power supply wiring

line. See below.

CAUTION: AFTER WIRING IS COMPLETE, BE SURE TO

REPLACE THE PROTECTIVE COVER OVER THE

TERMINAL BLOCKS.

Note: Avoid installing this instrument near an electrical unit (high

frequency furnace or electric welder) that generates

electrical noise. If using the instrument near such a noise

generating unit is unavoidable, use a different power line.

Mount a noise suppressor such as varistor or spark

quencher to the noise

generating unit when

source of noise is due to

relays or solenoid valves.

See accompanying figure.

Mount the suppressor

near the noise source;

otherwise its effect will be

diminished.

Teledyne Analytical Instruments 16

NDIR Gas Analyzer Instalation

(2) Analog output signal: Analog output connector (A/O)

Output signal : 4 to 20 mA DC or 0 to 1 V DC (selected when

ordering) Minus lines for the insulation and signal

are common from the ground and internal circuit.

Allowable load : 4 to 20 mA DC, 550Ω or less

0 to 1 V DC, 100kΩ or more

The analog output signals of the instrument are not isolated

individually. It is recommended to isolate the signals individually to

eliminate the interference from unwanted signals or other external

interference, especially if the cable exceeds 30 meters or leads to

outdoors.

(3) O2 Sensor Input: External input connector (A/I)

Input signal:

External zirconia O

sensor: Zirconia O2 sensor signal (Fuji ZFK7

2

output)

External O

sensor: 0 to 1 VDC (DC input resistor of 1MW or

2

more)

Teledyne Analytical Instruments 17

Installation Model 7500ZA

• Used when the external zirconia O

sensor or the external O2

2

sensor is ordered. It is not required or used if the analyzer has a

built-in O2 sensor.

• Connect the dedicated connector (accessory) to the output of the

external zirconia sensor or the external O2 sensor (shipped

separately).

• When using an external O2 sensor, the input signal should be 0 to

1 VDC with respect to the O2 full scale of the analyzer. The O2

concentration display, output, and O2 correction can then be

performed correctly.

Note: The O2 sensor input is not isolated. TAI recommends that it

be isolated when an external O2 analyzer is installed

remote from the analyzer. The zirconia O2 sensor should

be installed at a location that is as close to the analyzer as

possible.

The figure below shows how to connect the O

signal to the

2

dedicated connector (accessory).

Teledyne Analytical Instruments 18

NDIR Gas Analyzer Instalation

(4) Contact input/output (DIO): digital input/output connector

(DIO 1 to 3)

Contact input signal : Voltage is applied from the external 12 to 24 V

DC, max 15mA.

Photo-coupler isolation (from each DI and

ground)

Contact capacity : C contact relay output 24V/1A AC/DC

resistive load

Teledyne Analytical Instruments 19

Installation Model 7500ZA

Teledyne Analytical Instruments 20

NDIR Gas Analyzer Instalation

• Isolated output (from each DO and ground)

To avoid external interference, the wiring from the analog output

signal, O2 sensor input and contact input should be run separately from

that of power supply and contact output.

Note: Avoid excess noise generated by other nearby equipment,

by grounding the analyzer and using properly shielded

cables.

(5) Communication: RS-485 connector

(6) Timing of Contact Output for Calibration

1. Manual calibration: (See “Item 6.8 Calibration” if the analyzer is

equipped with the auto calibration feature).

Teledyne Analytical Instruments 21

Installation Model 7500ZA

2. Automatic calibration:

(See also Section 6.4: Automatic Calibration Settings)

Teledyne Analytical Instruments 22

NDIR Gas Analyzer Instalation

[Blank page]

Teledyne Analytical Instruments 23

NDIR Gas Analyzer Operation

Operation

4.1 Preparation for operation

Tube and wiring check

• Double-check if tubes of the gas sampling and exhaust ports are

correctly connected.

• Double-check for proper wiring.

4.2 Warm-up Operation and Normal Operation

(1) Operation Procedure

1. Turn ON the power switch on the left side when facing the front

panel of the analyzer unit. The measurement screen will appear

on the front display panel in a few seconds.

2. The instrument warm-up time is about 4 hours after which the

instrument will produce an accurate measurement.

Note: During the warm-up stage, the concentration reading may

be above the upper range limit. When this occurs, the

indication will display as a series of four dashes. However,

this is not an error.

3. During the warm up period, you can set the various instrument

parameters as described in Section 6: Setting and Calibration.

4. After the warm-up period, perform the zero/span calibration as

described in Section 6.8 Calibration.

5. After calibrating the analyzer, introduce sample gas into the

analyzer and allow the lines to purge before accepting the

measurement value.

Teledyne Analytical Instruments 25

Installation Model 7500ZA

[Blank page]

Teledyne Analytical Instruments 26

NDIR Gas Analyzer Display and Operation Panels

Display And Operation Panels

This section describes the display unit and operation panel on the

Model 7500ZA as well as the various functions available to the user.

5.1 Front Panel Description

Display unit: The measurement screen and the setting items are

displayed.

Operation panel: The operator interface panel is shown below.

Teledyne Analytical Instruments 27

Display and Operation Panels Model 7500ZA

Name Description Name Description

(1) MODE key Used to switch the mode. (5) ESC key Used to return to the

previous screen or

cancel the setting

midway.

(2) SIDE key

(3) UP key

(4) DOWN key

Used to change the selected item (by

moving the cursor) and the numeral

digit.

Used to change the selected item (by

moving the cursor) and to increase the

numeral value.

Used to change the selected item (by

moving the cursor) and to decrease

the numeral value.

(6) ENT key Used for confirmation of

selected items or

values, and for

execution of calibration.

(7) ZERO key Used for zero

calibration

(8) SPAN key Used for span

calibration

Teledyne Analytical Instruments 28

NDIR Gas Analyzer Display and Operation Panels

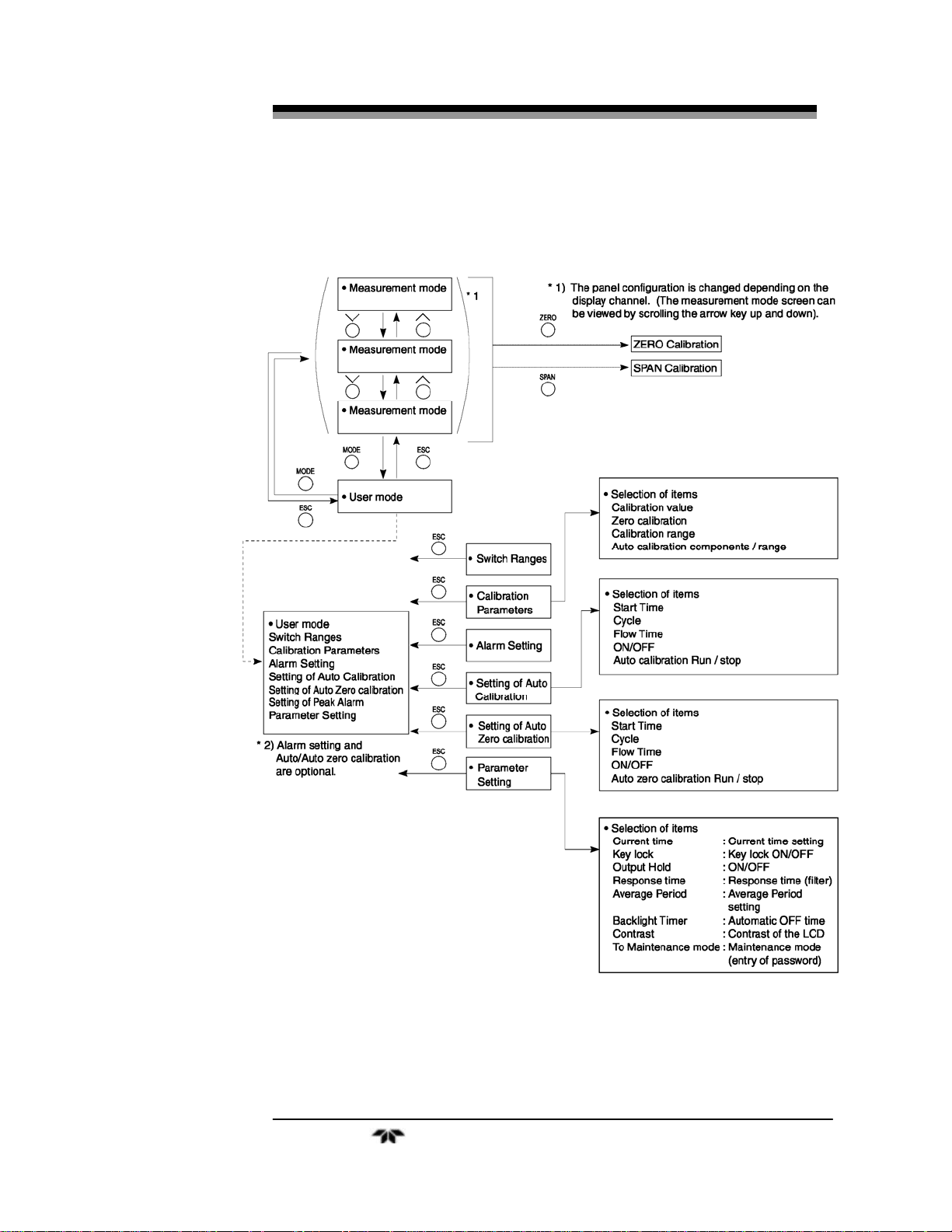

5.2 Overview of Display and Operation Panels

Teledyne Analytical Instruments 29

Display and Operation Panels Model 7500ZA

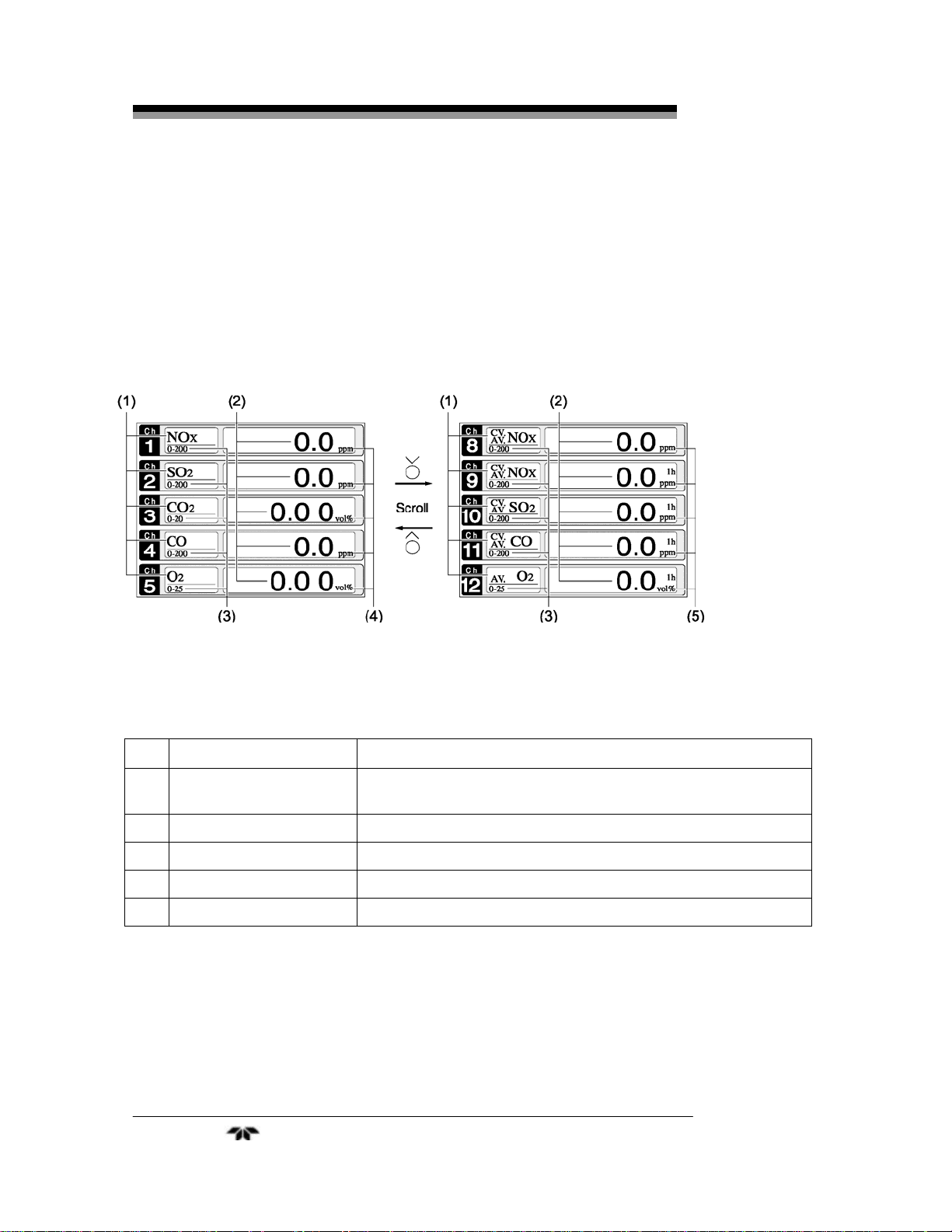

5.3 Outline of Display Screen

(1) Measurement mode screen (appears when the power is

turned on)

The measurement screen depends on the number of components.

The following screen configuration is shown as an example for NO,

SO2, CO2, CO and O2 (output: 12 channels).

Scroll the UP and DOWN keys to display more than 5 channels.

No. Name Function

(1) Component display Displays the component of instantaneous value, corrected

instantaneous value, corrected average value, etc.

(2) Concentration display Displays the measured value of concentration.

(3) Range display Displays the range values.

(4) Unit display Displays the unit with ppm or mg/m3 and vol%.

(5) Average time display Displays the average time.

• Instantaneous value and concentration value:

• The concentration display of Ch (component) where sampling

components such as “CO2”, “CO” and “O2” are displayed in the

component display, are the current concentration values of the

measured components contained in sample gas under test.

Teledyne Analytical Instruments 30

NDIR Gas Analyzer Display and Operation Panels

• O2 corrected concentration values:

• Ch components in which “cv**” is displayed as “cv CO” in the

display are calculated values derived from the following

equation. Refer to Section 6.7 Maintenance Mode - Other

Parameter.

)21(

O

C

n

C

s

)21(

O

s

where:

On: The value of the O2 correction reference value (set by application)

Os: Oxygen concentration (Vol%)

Cs: Concentration of relevant measured component.

Note that Os does not exceed the O2 limit value set in Section

6.7 Maintenance mode - Other parameter.

C: Sample gas concentration (O2 corrected).

The corrected sampling components are NOX , SO2 and CO only.

• O2 corrected concentration average value:

In the Ch (component) and O2 average value where “CV/AV **” is

displayed as “ CV/AV CO” in the component display, a value obtained by

averaging O

corrected concentration value or O2 average value in a

2

fixed time is output every 30 seconds.

Averaging time can be changed between 1 to 59 minutes or 1 to 4

hours according to the average time settings (See Section 6.7, Parameter

Setting).

(The averaging set time is displayed as “1h”, for instance, in the

range display).

* The measurement ranges for O

correction concentration value

2

and O2 correction concentration average value are the same as

the measuring components. Also, the measurement range of the

average value is the same as for O2.

O

2

Teledyne Analytical Instruments 31

Display and Operation Panels Model 7500ZA

(2) Setting/Selection Screen

The setting/selection screen is configured as shown below:

• In the status display area, the current display item is displayed.

• In the message display area, messages associated with operation

are displayed.

• In the setting item and selection item display area, items or

values to be set are displayed, as required. To navigate through

the fields, move the cursor to any item using the UP, DOWN and

SIDE keys.

Teledyne Analytical Instruments 32

NDIR Gas Analyzer Display and Operation Panels

(3) Contents of Measured Channel (Ch)

The following table gives measurement channels and their contents

according to the symbols.

•

Teledyne Analytical Instruments 33

Display and Operation Panels Model 7500ZA

5.4 Basic Operation

Measurement mode

The measurement mode can display up to

5 channels in a single screen. If 5 channels or

more are to be displayed in a single screen,

press the UP or DOWN key to scroll the

channels one by one.

•

•

•

•

•

User mode displays

• Switch Ranges

• Calibration Parameters

• Alarm Setting

• Setting of Auto Calibration

• Setting of Auto Zero Calibration

• Parameter Setting.

• Press the UP or DOWN key to move

the cursor to the desired function.

• Select the function by pressing the

ENT (ENTER) key. The screen display

will change to that of the selected

function.

• Each function is described in Chapter

6. Settings and Calibration.

Teledyne Analytical Instruments 34

NDIR Gas Analyzer Settings and Calibration

Settings and Calibration

6.1 Range Switch

6.1.1 Setting the Range Switch

Mode

The range switch has three modes:

• Manual (MR)

• Remote (RR)

• Auto Ranging (AR)

To set the range switch mode:

1. Press the MODE key while in

measurement mode to display the

User mode screen.

2. Move the cursor to “Switch

Ranges” and press the ENT key.

3. In the “Channel Selection” screen

that appears, move the cursor by

pressing the UP or DOWN key,

and select Ch (component).

4. Then press the ENT key.

5. The selected range switch mode

will be highlighted. Press the UP

or DOWN key to select the

desired mode.

6. Then press the ENT key to

confirm the selection.

7. If “MR” is selected, the cursor

moves to “Range Switch.”

Teledyne Analytical Instruments 35

Settings and Calibration Model 7500ZA

6.1.2 Manual Range Mode

The analysis range for the measured component can be switched

manually as follows:

1. (1) Select “MR” as range switch mode,

and then press the ENT key.

2. Using the UP/DOWN keys, move the

cursor to the desired range selection.

The highlighted arrow indicates the

currently selectable range.

3. Select it by pressing the ENT key, and

analysis will be carried out in that

range.

Note: If “RR” or “AR” is selected as range

switch mode, this operation cannot

be performed.

The ranges for O2 correction

value,O2 correction average value,

and O2 average value are

automatically switched according to

the instantaneous value range

switch settings. (Same as for “RR”

or “AR”.)

To return to the previous screen, press the

ESC key. If ESC is pressed in the middle of

an entry or before the ENT key was pressed

to accept a setting, it will reject the current

selection and return you the display to the

previous screen without making the changes .

6.1.3 Range Identification Contacts

The contacts for range identification on each channel are closed

when Range 1 is active, and open when Range 2 is active.

If the measurement value is held by a remote contact input or

during calibration and range switch conditions are met, the contact status

will change only after the hold condition is removed.

Teledyne Analytical Instruments 36

NDIR Gas Analyzer Settings and Calibration

6.2 Calibration Setting

This mode is used to set

calibration parameters such as span

and zero gas concentration,

calibration range, and auto

calibration settings and range.

When <User Mode> The

“Calibration Parameters” screen that

appears, the data shown at right is

illustrated.

6.2.1 Setting the Span Gas

Concentration

This screen allows you to set

the cal gas concentrations for zero

and span on each Ch used for

calibration.

1. Select < User mode > →

< Calibration parameters >

→ < Calibration value >.

The “Calibration Value

Settings” screen will appear.

2. Select the Ch you want to

change by pressing the UP or

DOWN key. Then press the

ENT key and cursor moves

to the first editable parameter

within that field.

3. Select the concentration item

you want to set (Zero or

Span) by pressing the UP,

DOWN or SIDE (>) key.

The SIDE key only functions

within the selected channel.

Press the ENT key when the

cursor is in the desired field.

The first digit of the

parameter is highlighted.

Teledyne Analytical Instruments 37

Settings and Calibration Model 7500ZA

4. Enter calibration gas concentration for zero and span. Use the UP

or DOWN key to increment or decrement the displayed value

one digit at a time. When the correct number is displayed for that

digit, use the SIDE key to move to the next digit and repeat the

increment/decrement process with the UP/DOWN keys.

5. After setting, save the entry by pressing the ENT key. The saved

value becomes valid with the next calibration event.

Note: Enter calibration parameters settings for each range. If a

zirconia O2 sensor is installed, select 21.00 for the Zero if

air is used for calibration, and use the concentration listed

on the cylinder for the span value.

After saving the calibration values entered, close the Calibration

Parameter screen by pressing ESC. This will return the display to the

previous screen.

Note: Pressing ESC during an entry (before pressing ENT) will

abort the entry leaving the previous entry intact.

Calibration parameter range of value

NOx, SO2, CO2, CO, CH4, external and built in O2 sensor:

Span: 1-105% of full scale

External O2 sensor:

Zero: 0-25%

Span: 0.1%-5% (vol.)

Reverse Range:

Zero: 100% (vol.)

Span: 95.25-95.00% (vol.) O

2

The settings cannot be performed beyond the range limits.

6.2.2 Manual Zero Calibration

When setting the zero calibration in manual mode, you can set all

components simultaneously or one by one.

Teledyne Analytical Instruments 38

NDIR Gas Analyzer Settings and Calibration

1. Select < User mode > → < Calibration parameters > → < Zero

calibration >. The Zero

Calibration screen will

appears as shown.

2. Select the Ch you want

to change using the UP

or DOWN key and then

press the ENT key. The

setting content becomes

highlighted.

3. Choose whether you

want to set the zero

values all together or

individually by toggling

“at once” or “each”

with the UP or DOWN

key. Each channel that

is set to “at once” will be zero-calibrated at the same time.

4. When “each” is selected, the specific Ch (component) can be

selected and zero-calibrated individually. Press the ENT key

after making the choice and the specified calibration is

performed.

To close the Manual Zero Calibration screen, press ESC. This will

return the display to the previous screen.

Note: Pressing ESC during an entry (before pressing ENT) will

abort the entry leaving the previous entry intact.

Example:

Set each Ch (component) to either “each” or “at once” using the steps

above.

Setting “each”

Select the Ch (component) on the manual zero calibration screen and

then perform the zero calibration.

Setting “at once”

In a manual zero calibration, Ch (components) for which “at once”

are selected will simultaneously be zero-calibrated.

Teledyne Analytical Instruments 39

Settings and Calibration Model 7500ZA

6.2.3 Setting the Calibration Range

This mode is used to set whether the channels use one or both of

the calibration ranges.

1. From the Calibration Parameters screen, select Calibration

Range. The following screen appears.

Teledyne Analytical Instruments 40

NDIR Gas Analyzer Settings and Calibration

2. Select the Ch you want to change by pressing the UP or DOWN

key, then press the ENT key. The setting content is highlighted.

3. Toggle between “both” or “current” using the UP or DOWN key.

If “both” is selected, zero or span calibration will be

performed on both Range 1 and Range 2 on the selected Ch

when the calibration is performed.

If “current” is selected, zero or span calibration will be performed

only for the range displayed when calibration is performed.

4. Press the ENT key after the selection, and the specified

calibration is performed.

To close the Calibration Range Settings screen or to abort the entry

midway, press the ESC key. The previous screen will return.

Example:

Ch1

NOx

Ch 2

SO2

Ch1: Range 1 and Range 2 are calibrated together

Ch2: Only the currently displayed range is calibrated

Note: When “both” is selected, the same calibration gas

Range 1: 0 to 200 ppm

Range 2: 0 to 2000 ppm

Range 1: 0 to 200 ppm

Range 2: 0 to 2000 ppm

concentration must be used for both ranges.

both

current

Teledyne Analytical Instruments 41

Settings and Calibration Model 7500ZA

6.2.4 Setting the Component/Range for Auto Calibration

In this section you can select the Ch (component) and the range to

calibrate on for those components that have the auto ranging (AR)

feature enabled.

1. From the User Mode screen

select < Calibration

parameters > → < Auto

calibration component/range >.

The “Auto Calibration

Component Range” screen

appears as shown.

2. Select the Ch you want to

change by pressing the or the

key. Press the ENT key. The

cursor will be highlighted in

the selected channel.

3. Select the range you want to

use as the main calibration

range by pressing the UP or

DOWN key to move to the

desired range.

4. Press the ENT key, and

subsequent calibrations will be

performed on the selected

range when either auto

calibration or auto zero

calibration is requested.

Note regarding Auto Calibration

Component/Range Selection

The auto calibration or manual

calibration of the component for

which auto ranging (AR) is in effect

will be performed on the range that is

selected here. In this case, once the

calibration is started, the range is

automatically switched, and on

completion of the calibration, the

original range is resumed.

Teledyne Analytical Instruments 42

NDIR Gas Analyzer Settings and Calibration

The range identification contact is interlocked with the range after

the switch. However, if the hold setting is set to “ON,” the contact status

before calibration is maintained.

5. Press the SIDE key in the state described in (3), and the

highlight is toggled between “enable” and “disable” auto

calibration.

6. Select “enable” of “disable” by pressing the UP or DOWN key.

7. Then press the ENT key to save your selection.

To close the Auto Calibration Settings screen or to abort the entry

midway, press the ESC key. The previous screen will return.

Auto Calibration Operation

Auto calibration is performed under the following rules.

1. Zero calibration is performed at the same time, for the Ch

(component) in which “enable” is selected at the time of auto

calibration and auto zero calibration.

2. Span calibration is performed in the order from smallest Ch No.,

for the Ch (component) that have “enable” set in the Auto

Calibrations Setting screen.

Note: ZERO calibrations for components which have been set to

“enable” in the Auto Calibration Settings screen (above)

are performed in batch irrespective of the description in

“6.2.2 Manual Zero Calibration.”

Teledyne Analytical Instruments 43

Settings and Calibration Model 7500ZA

6.3 Alarm setting

6.3.1 Setting Alarm Parameters

The High/Low limit concentration alarms

are user adjustable. Five different alarm contact

outputs can be used. The setting range is 0100% full scale for each range.

To change the alarm setting, set the alarm

ON/OFF setting to OFF, and then change the

value.

1. Enter the “Alarm Setting” screen from

the user mode. The screen shown on the

right will display. Use the UP or DOWN

keys to move the cursor to the desired

Alarm No. or hysteresis. Then press

ENT.

2. After selecting the alarm the screen

shown at the right will display. Use the

UP or DOWN keys until the cursor is

aligned with the desired item and press

ENT.

Note: Set the values so that H-limit value >

L-limit value and that (H-limit value L-limit value) > hysteresis.

In the case where reverse range O

2

measurements are used set the

values so that L-limit value > H-limit

value.

When “0” is set, the alarm is inactive.

3. After setting the parameters, press ENT

to save the settings.

To close the Alarm Settings screen or to

abort the entry midway, press the ESC key. The

previous screen will return.

Teledyne Analytical Instruments 44

NDIR Gas Analyzer Settings and Calibration

Alarm Setting Descriptions

The alarm contact number can be assigned to any channel.

Channels can also have multiple alarms assigned to them.

Channel: Channel setting targeted for alarm.

H-Limit value: Sets the high limit value (concentration) for

alarm.

L-Limit value: Sets the low limit value (concentration) for alarm.

Kind of Alarm: Select either High limit alarm, Low limit alarm,

and High limit or Low limit alarm, HH limit

alarm, and LL limit alarm.

High, HH: Alarm contact closes when above

H-limit alarm.

Low, LL: Alarm contact closes when below

L-limit alarm.

High or Low: Alarm contact closes when above

H-limit value or below lower limit

value.

ON/OFF: Enables the alarm function when set to ON, or

disables it if set to OFF.

Note: The H-limit value cannot be set below the L-limit value, and

the L-limit value cannot be set above the H-limit value.

If it is desired to set the H-limit value below the L-limit

value already stored in the memory, reduce the L-limit

value beforehand, and vice versa for setting the low limiot

above the high limit.

Note: After turning on power, the alarm logic trigger is inactive for

10 minutes.

When an H-limit alarm occurs, the

“H-alarm” message displays in the relevant

component field. Other alarm displays are:

L-alarm for Low-limit alarm, HHalarm for high limit alarm, HH-alarm for

high-high alarm, and LL-alarm for lowlow alarm.

Teledyne Analytical Instruments 45

Settings and Calibration Model 7500ZA

6.3.2 Hysteresis Setting

The alarm hysteresis can be set or changed to prevent chattering of

an alarm output about its alarm set point. To set or change the alarm

hysteresis:

1. Navigate to the “Alarm Setting” screen and

then move the cursor to “Hysteresis” using

the UP or DOWN key. Then press ENT to

display the screen shown at the right.

2. From this screen enter the hysteresis values

by increasing or decreasing the value using

the UP or DOWN keys. Move the cursor to

the next digit with the SIDE key. When the

value is correct, press ENT to save.

The hysteresis can be set from 0-20% full

scale on the selected range.

To close the Hysteresis Settings screen or to

abort the entry midway, press the ESC key. The

previous screen will return.

Note: The hysteresis is common to all alarms (components).

Hysteresis in peak alarm setting described in Item 6.3.3

should be set separately.

Hysteresis (In case of upper limit alarm)

An alarm output is turned ON if the measured value exceeds the

upper limit value as shown below. Once the alarm output has been

turned ON, it is not turned OFF until the indication falls below the

hysteresis width from the upper limit value.

Teledyne Analytical Instruments 46

NDIR Gas Analyzer Settings and Calibration

6.3.3 Peak Alarm Setting

When the peak number of times CO concentration exceeds the upper

limit value during measurement reaches the set number, an alarm is provid ed.

The peak alarm and this setting screen

appear only when an option is added.

1. Press the MODE key while in the

Measurement mode, and the User

mode appears.

2. Using the UP or DOWN keys move

the cursor to “Setting of Peak

Alarm”. Then press ENT.

3. In the “Peak Alarm Setting”

selection screen that appears, point

the cursor to any item you want to set

using the UP or DOWN key. Then

press ENT.

4. Enter numeric values using the UP or

DOWN keys. The setting will be

saved after pressing the ENT key.

Description of Setting Items

Peak Alarm : ON/OFF of peak alarm

Alarm Value : If measuring value exceeds

the set alarm value, a peak

counter increments by 1

time.

Alarm Count : When the alarm value is

exceeded this many times per

hour, the peak count alarm is

activated (closed).

Hysteresis : To prevent possible

chattering when the

measuring value may exceed

the set peak concentration by

only 1 time, the peak count

has an allowance in the

hysteresis width.

Teledyne Analytical Instruments 47

Settings and Calibration Model 7500ZA

Setting Range

Alarm value: 10-1000 ppm → 5 ppm step (initial value: 500 ppm)

Alarm count: 1- 99 times/hr → (initial value: 5 times)

Hysteresis : 0-20 % FS → (initial value: 0% of full scale)

[% FS] represents the percentage with the CO range regarded as

100%.

Action of Peak Alarm

If the CO concentration exceeds the alarm value, counting will

begin. If the number of peaks is over the set times per hour, a peak alarm

contact output becomes closed (ON). If it is less than the set times per

hour, it is open (OFF). Since 5 peaks /hour is exceeded in the crosshatched area marked (1) in the above graph, the peak count alarm is

turned ON. Since peaks of more than 5 per hour occur at the interval

between (1) and (2), the peak count alarm remains ON whereas at (2),

peaks are reduced to 4 per hour, and the alarm is turned OFF.

Like the hysteresis of the alarm setting, the hysteresis prevents

possible chattering when a measured gas fluctuates about the alarm

value.

* The peak alarm counting logic is not performed during the first 10

minutes after the power is turned ON.

Teledyne Analytical Instruments 48

NDIR Gas Analyzer Settings and Calibration

Releasing peak count alarm

To release the peak count alarm, set the peak alarm to OFF.

Turning on the peak alarm initiates the count at 0.

6.4 Setting Up the Auto Calibration

6.4.1 Auto Calibration

Auto calibration is automatically carried out at the time when zero

span calibration are set. Before changing

the setting of auto calibration, set the

auto calibration function to OFF.

1. Enter the “Setting of Auto

Calibration” screen from the user

mode, and the display shown at

right appears. Use the UP and

DOWN keys to align the cursor

with the desired item and then

press the ENT key.

2. In the “Set Auto Cal” screen that

appears, enter the values for the

various settings. To make a value

entry or change, use the UP and

DOWN keys to increment or

decrement the value on digit at a

time. Use the SIDE key to move

the cursor to the next digit.

When all the settings are correct,

press the ENT key to save them.

Subsequent auto calibrations will

use the saved settings.

Description of Auto Cal Settings

• Start Time : Setting for the first

calibration event (day of the

week, hour, minute)

Teledyne Analytical Instruments 49

Settings and Calibration Model 7500ZA

• Cycle : The period between the start time of one calibration and

the next (unit: hour/day)

• Flow Time : The time required for purging with calibration gas.

Time required for replacement of sample gas after the calibration

is completed (Set by calibration gas. See the next page.)

• ON/OFF: Turns the auto calibration feature ON or OFF.

To close the Auto Cal Settings screen or to abort the entry midway,

press the ESC key. The previous screen will return.

Gas flow time setting

1. With the cursor on “Flow Time”, press the ENT key to bring up

the Flow Time screen.

2. Move the cursor to the gas

you want to change by

pressing the UP or DOWN

key, and then press ENT.

3. The highlighted value can be

changed by pressing UP or

DOWN key, and then using

the SIDE key move the

cursor to the right to alter the

next digit.

4. After changing the value,

press the ENT key to save

the setting.

5. Press the ENT key again to

return to the Auto Cal Setting screen.

Note: Only the channels used are displayed on this screen. The

Ex. time sets the output signal hold extension time that

follows the completion of calibration. It is valid only when

the hold setting is set to “ON.” The Ex. time set here is also

the hold extension time used in a manual calibration.

Teledyne Analytical Instruments 50

NDIR Gas Analyzer Settings and Calibration

Auto calibration status contact output is closed during auto

calibration (NO side), and is open in other cases.

Example:

Start Time Sun 12:00

Cycle 1 day

Flow Time Zero 350 sec

CH 1 Span

CH 2 Span 350 sec

CH 3 Span 350 sec

CH 4 Span

CH 5 Span

350 sec

300 sec

300 sec

Ex. Time 300 sec

ON/OFF ON

Thus, with the above settings:

Setting Range:

Cycle: 1-99 hours or 1-40 days (default value—7days)

Flow Time: 60-90 sec (default value—300 sec)

Teledyne Analytical Instruments 51

Settings and Calibration Model 7500ZA

Caution: When an auto calibration starts, the measurement

screen appears automatically.

Any operation other than “Stop Auto Calibration”

(see Item 6.4.2) is not permitted during auto

calibration. “Stop Auto Calibration” cannot be

performed with the key lock to ON.

To force a cancel of the auto calibration, set the

key lock to OFF and then execute “Stop Auto

Calibration”.

Turn power OFF and then ON again at the time set

as the next start time in auto calibration, and then

repeat it in the set cycle.

Remote Start

Whether the auto calibration is set at ON or OFF, an auto

calibration is always available via a remote start input.

6.4.2 Forced Run/Stop Of Auto Calibration

Auto calibration can be performed just once or forcibly stopped

while the calibration is in process

6.4.2.1 EXECUTION OF AUTO

CALIBRATION

(ONLY ONCE)

1. In the “Set Auto Cal

screen, move the cursor

to “Auto Cal Run” using

the UP or DOWN key,

then press ENT.

2. “Run” is highlighted,

displaying a message to

Teledyne Analytical Instruments 52

NDIR Gas Analyzer Settings and Calibration

confirm the execution of auto calibration. Press the ENT key to

execute the auto calibration or press the ESC key to cancel.

6.4.2.2 FORCED STOP OF AUTO

CALIBRATION

This mode is used to stop the

auto calibration forcibly.

1. In the “Set Auto Cal” screens

point the cursor to “Auto

Calibration Stop” using the

“UP or DOWN key. Then

press ENT. (“Auto Calibration

Stop” appears when this

screen is selected while auto

calibration is performed.)

2. “Stop” is highlighted, displaying a

message to confirm the stop of auto

calibration. Press the ENT key to stop the

auto calibration or press the ESC key to

cancel the stop auto cal action.

“Auto Calibration” screen

Example

When Ch 1 and Ch2 are enabled for auto

calibration (see Section 6.2.4):

• Zero calibration

A message, “Zero cal.” blinks at Ch1 and

Ch2.

• Ch1 span calibration

A message, “Span cal.” blinks at Ch1.

• Ch2 span calibration

A message, “Span cal.” blinks at Ch2.

Teledyne Analytical Instruments 53

Settings and Calibration Model 7500ZA

Caution: During an auto calibration, all key operations are

not permitted other than key lock ON/OFF and

“Auto Calibration Stop.”

When the key lock is ON, the “Auto Calibration

Stop” is locked out as well.

To stop “Auto Calibration” forcedly, set the key

lock to OFF and then execute “Auto Calibration

Stop.”

Teledyne Analytical Instruments 54

NDIR Gas Analyzer Settings and Calibration

6.5 Setting Auto Zero Calibration

6.5.1 Auto Zero Calibration

Zero calibration can be performed automatically using the settings

applied in this screen.

The channels for which auto calibration is to be performed are

determined by the auto calibration settings described in Section 6.2.4.

Before changing any of the auto zero calibration settings, set the

auto zero calibration to OFF.

1. Enter the “Set Auto Zero Cal”

screen from the user mode. The

screen shown at the right will

appear.

2. Use the UP or Down keys to

move the cursor to the desired

item and press the ENT key. In

the “Set Auto Zero” screen that

appears, set the desired

parameter using use the UP or

DOWN key to

increment/decrement the value

and the SIDE key to move to the

next digit or field.

After the setting is correct, press

the ENT key to save the settings.

The next auto zero calibration

will use the entered values.

Description of Auto Zero Settings

• Start Time : Setting for the first

calibration event (day of the

week, hour, minute)

• Cycle : The period between the

start time of one calibration and

the next (unit: hour/day)

Teledyne Analytical Instruments 55

Settings and Calibration Model 7500ZA

• Flow Time: The time required for purging with calibration gas.

Time required for replacement of sample gas after the calibration

is completed (Set by calibration gas. See the next page.)

• ON/OFF: Turns the auto calibration feature ON or OFF.

To close the Auto Zero Settings screen or to abort the entry

midway, press the ESC key. The previous screen will return.

Auto Calibration Status Relay Contacts

The auto calibration status contact output is closed during auto zero

calibration (NO side), and open during normal operation.

Example

Start Time

Cycle

Flow Time

ON/OFF

SUN 12:00

12 hour

300 sec

ON

For an auto zero calibration using the above settings:

In this example, Ch1 through Ch5 are enabled, as shown in Section

6.2.4 “Setting the Component/Range for AutoCalibration.

Teledyne Analytical Instruments 56

NDIR Gas Analyzer Settings and Calibration

Setting the Range

Cycle 1 to 99 hours or 1to 40 days (default: 7 days

Flow Time 60 to 900 sec (default: 300 sec.)

Caution: When an auto zero calibration starts, the

measurement screen automatically appears.

Any operation other than “Auto Zero Calibration

Stop” (see Item 6.5.2) is not permitted during auto

zero calibration. “Auto Zero Calibration Stop”

cannot be performed with the key lock set to ON.

To forcibly cancel auto zero calibration, set the

key lock to OFF and then execute “Auto Zero

Calibration Stop”.

If the auto calibration period and auto zero

calibration period overlap, the auto calibration is

retained, ignoring the auto zero calibration of that

period.

When the hold setting is set to ON, the hold time

for auto calibration contact and measurement

value output signal is extended after calibration

for gas purging.

Remote Start

A remote start input will begin a calibration event regardless of

whether the auto zero calibration is set to ON or OFF.

6.5.2 Forced Run/Stop of Auto Zero Calibration

Auto zero calibration can be performed just once, or auto zero

calibration can be forcibly stopped during calibration.

Teledyne Analytical Instruments 57

Settings and Calibration Model 7500ZA

6.5.2.1 EXECUTION OF AUTO ZERO CALIBRATION (ONLY ONCE)

1. In the “Setting of Auto Zero

Calibration” screen that

appears, point the cursor to

“Run” by pressing the UP

or DOWN key. Then press

ENT.

2. “Run” is highlighted,

displaying a message to

confirm execution of auto

zero calibration. Press the

ENT key to execute the

calibration, or the ESC key

to cancel.

6.5.2.2 FORCED STOP OF AUTO ZERO CALIBRATION

This mode is used to forcibly cancel an auto zero calibration event.

1. In the “Setting of Auto Zero

Calibration” screen that

appears, point the cursor to

“Stop” by pressing the UP

or DOWN key, then press

ENT. (“Auto Zero

Calibration Stop” appears

when the screen is selected

while auto zero calibration

is performed.)

2. “Stop” is highlighted,

displaying a message to

confirm the stop of auto

zero calibration.