Page 1

Getting Started

Manual

WaveRunner 6 Zi

and 12-Bit HRO

Oscilloscopes

Page 2

Page 3

WaveRunner 6 Zi and

12-Bit HRO Oscilloscopes

Getting Started Manual

January 2013

Page 4

© 2013 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials other than for

internal sales and distribution purposes is strictly prohibited. Clients may distribute and

duplicate Teledyne LeCroy documentation for their own internal educational purposes.

WaveRunner 6 Zi and Teledyne LeCroy are registered trademarks of Teledyne LeCroy, Inc.

Windows is a registered trademark of Microsoft Corporation. Other product or brand names

are trademarks or requested trademarks of their respective holders. Information in this

publication supersedes all earlier versions. Specifications subject to change without notice.

Warranty

NOTE: THE WARRANTY BELOW REPLACES ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS,

OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR USE. TELEDYNE LECROY SHALL NOT BE

LIABLE FOR ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER IN

CONTRACT OR OTHERWISE. THE CUSTOMER IS RESPONSIBLE FOR THE TRANSPORTATION

AND INSURANCE CHARGES FOR THE RETURN OF PRODUCTS TO THE SERVICE FACILITY.

TELEDYNE LECROY WILL RETURN ALL PRODUCTS UNDER WARRANTY WITH TRANSPORT

PREPAID.

The oscilloscope is warranted for normal use and operation, within specifications, for a

period of three years from shipment. Teledyne LeCroy will either repair or, at our option,

replace any product returned to one of our authorized service centers within this period.

However, in order to do this we must first examine the product and find that it is defective

due to workmanship or materials and not due to misuse, neglect, accident, or abnormal

conditions or operation.

Teledyne LeCroy shall not be responsible for any defect, damage, or failure caused by any of

the following: a) attempted repairs or installations by personnel other than Teledyne LeCroy

representatives or b) improper connection to incompatible equipment, or c) for any damage

or malfunction caused by the use of non-Teledyne LeCroy supplies. Furthermore, Teledyne

LeCroy shall not be obligated to service a product that has been modified or integrated

where the modification or integration increases the task duration or difficulty of servicing

the oscilloscope. Spare and replacement parts, and repairs, all have a 90-day warranty.

The oscilloscope's firmware has been thoroughly tested and is presumed to be functional.

Nevertheless, it is supplied without warranty of any kind covering detailed performance.

Products not made by Teledyne LeCroy are covered solely by the warranty of the original

equipment manufacturer.

922136-00 Rev A

January 2013

Page 5

Getting Started Manual

922136-00 Rev A

i

TABLE OF CONTENTS

Welcome ............................................................................................... 1

How This Manual Is Organized ............................................................... 2

Safety Instructions ................................................................................. 3

Symbols ................................................................................................... 3

Precautions ............................................................................................. 3

Operating Environment .......................................................................... 4

Cooling .................................................................................................... 4

Cleaning .................................................................................................. 5

Calibration............................................................................................... 5

Power ...................................................................................................... 6

Hardware .............................................................................................. 8

The Front of Your Oscilloscope ............................................................... 8

I/O Panel ............................................................................................... 12

The Back of Your Oscilloscope .............................................................. 14

Basic Controls ...................................................................................... 17

Hardware and Software Controls ......................................................... 17

Front Panel Controls ............................................................................. 18

Front Panel Control Groupings ............................................................. 19

Probe / Signal Connection Interfaces .................................................... 31

Probe Interfaces.................................................................................... 31

ProBus Interface ................................................................................... 32

Probes ................................................................................................... 33

Passive Probe Compensation ............................................................... 34

Display Dashboard ............................................................................... 35

Screen Layout, Groupings, and Controls .............................................. 35

Menu Bar .............................................................................................. 35

The Quick Access Toolbar ..................................................................... 36

The Signal Display Grid ......................................................................... 36

Trace Descriptor Labels ........................................................................ 39

B

Page 6

WaveRunner 6 Zi and 12-Bit HRO Oscilloscopes

ii

922136-00 Rev A

Dialog Area ............................................................................................ 42

Shortcut Toolbar ................................................................................... 48

Message Bar .......................................................................................... 49

Turning on Channels and Traces ............................................................50

Timebase ..............................................................................................51

Overview ............................................................................................... 51

Timebase Setup and Control ................................................................. 51

Sampling Modes ...................................................................................52

Overview ............................................................................................... 52

Selecting a Sampling Mode ................................................................... 52

Single-shot Sampling Mode .................................................................. 52

Sequence Sampling Mode – Working with Segments .......................... 53

RIS Sampling Mode for Higher Sampling Rates .................................... 59

Roll Mode .............................................................................................. 60

Vertical .................................................................................................61

Overview ............................................................................................... 61

Channel Controls ................................................................................... 61

Actions for Trace C1 Buttons ................................................................ 63

Pre-Processing Controls ........................................................................ 64

Trigger ..................................................................................................68

Overview ............................................................................................... 68

Trigger Types ......................................................................................... 69

Trigger Settings ..................................................................................... 73

Trigger Setup ......................................................................................... 74

TriggerScan............................................................................................ 79

Viewing Waveforms ..............................................................................83

Display ................................................................................................... 83

Persistence ............................................................................................ 87

WaveStream Display Mode................................................................... 89

Adjusting Trace Intensity ...................................................................... 90

Page 7

Getting Started Manual

922136-00 Rev A

iii

Zooming Waveforms ............................................................................ 91

Overview ............................................................................................... 91

Zooming a Single Channel ..................................................................... 92

Touch-and-Drag Zooming ..................................................................... 94

Quickly Zooming Waveforms ................................................................ 94

Measuring with Cursors ....................................................................... 95

Overview ............................................................................................... 95

Cursor Types ......................................................................................... 95

Cursors Setup ........................................................................................ 95

Measurement Parameters .................................................................... 99

Overview ............................................................................................... 99

Parameter Setup ................................................................................. 100

Measure Modes .................................................................................. 101

Help Markers ...................................................................................... 102

Measurement Parameter Analysis ...................................................... 104

Overview ............................................................................................. 104

Creating and Viewing a Histogram ..................................................... 106

Creating and Viewing a Trend ............................................................. 112

Creating a Track View ......................................................................... 113

Pass-Fail Parameter Testing ................................................................ 114

Math ................................................................................................. 121

Math Traces and Functions Overview ................................................ 121

Math Setup ......................................................................................... 122

Mask Testing ..................................................................................... 124

Creating a Mask .................................................................................. 124

Quick Access to Pass/Fail Setup Dialogs ............................................. 125

Removing a Mask from the Display .................................................... 126

Right-Hand Dialogs ............................................................................. 126

WaveScan Overview .......................................................................... 127

Signal Views ........................................................................................ 128

B

Page 8

WaveRunner 6 Zi and 12-Bit HRO Oscilloscopes

iv

922136-00 Rev A

Search Modes ..................................................................................... 129

Parameter Measurements .................................................................. 129

Sampling Mode ................................................................................... 129

Customization Overview ..................................................................... 130

Documenting Work with LabNotebook ................................................ 131

Overview ............................................................................................. 131

LabNotebook Dialog ............................................................................ 131

Save/Recall ......................................................................................... 136

Overview ............................................................................................. 136

Saving and Recalling Setups ................................................................ 137

Saving and Recalling Waveforms ........................................................ 138

Utilities .............................................................................................. 143

Utilities Setup ...................................................................................... 143

Disk Utilities ........................................................................................ 156

Preferences ......................................................................................... 158

System Recovery Tool ......................................................................... 164

Restoring Software Using Acronis® ..................................................... 164

Reference ........................................................................................... 168

Specifications ...................................................................................... 168

Certifications ....................................................................................... 168

End-User License Agreement for Teledyne LeCroy® X-Stream Software

............................................................................................................ 171

Windows® License Agreement ............................................................ 182

Contact Teledyne LeCroy .................................................................... 183

Index .................................................................................................. 184

Page 9

Getting Started Manual

922136-00 Rev A

1

Welcome

Thank you for purchasing a Teledyne LeCroy product. We're certain you'll

be pleased with the detailed features so unique to our instruments.

With 16 times more resolution, unmatched accuracy and impressive signal

fidelity, Teledyne LeCroy High Resolution Oscilloscopes are a new breed of

instrument delivering more vertical resolution, unmatched accuracy,

impressive signal fidelity, and true 12 bit vertical resolution.

This WaveRunner6 Zi and 12-Bit HRO Getting Started Manual is designed

to cover important safety and installation information for your

oscilloscope, along with standard procedures so you're quickly working on

waveforms. The Teledyne LeCroy website at teledynelecroy.com maintains

the most current specification information and the online help file on your

instrument may be accessed for more comprehensive documentation.

Sections of the online help residing on your oscilloscope may be printed

and transferring the help file itself to a USB memory device is a fairly

common procedure. For details on how to access your online help file can

be found in a .pdf file on the desktop of your oscilloscope or you can search

for Operator's Manual for Zi Oscilloscopes on the Teledyne LeCroy website

at teledynelecroy.com.

When your product is delivered, verify that all items on the packing list or

invoice copy have been shipped to you. Contact your nearest Teledyne

LeCroy customer service center or national distributor if anything is missing

or damaged. If there is something missing or damaged, and you do not

contact us immediately, we cannot be responsible for replacement.

We truly hope you enjoy using Teledyne LeCroy's fine products.

Sincerely,

David C. Graef

Teledyne LeCroy Corporation

Vice President and Chief Technology Officer

B

Page 10

WaveRunner 6 Zi and 12-Bit HRO

2

922136-00 Rev A

How This Manual Is Organized

First, we cover your instrument's unique hardware and software features in

the following sections:

Hardware

Basic Controls

Probe and Signal Connection Interfaces

Display Dashboard

Turning on Channels and Traces

Essential Core Oscilloscope Functions

This section covers the essential Teledyne LeCroy oscilloscope core

functions, such as:

Timebase

Sampling Modes

Vertical

Trigger

Viewing

Zooming

Measuring

Math

Masks

Customization

LabNotebook

Save/Recall

Utilities

Reference

The Reference section is set aside and covers items like Certifications, how

to Contact Teledyne LeCroy for Support, and to always maintains the most

current specification information. The website should always be checked

for frequent updates.

Page 11

Getting Started Manual

922136-00 Rev A

3

CAUTION of potential damage to instrument, or WARNING of

potential for bodily injury. Attend to the accompanying

information to protect against personal injury or damage. Do

not proceed until conditions are fully understood and met.

High voltage. Risk of electric shock.

Measurement ground connection.

Safety (protective) ground connection.

Alternating Current.

Standby Power (front of instrument).

Safety Instructions

This section contains instructions that must be observed to keep the

instrument operating in a correct and safe condition. You are required to

follow generally accepted safety procedures in addition to the precautions

specified in this section. The overall safety of any system incorporating

this instrument is the responsibility of the assembler of the system.

Symbols

These symbols appear on the instrument's front or rear panels and in its

documentation to alert you to important safety considerations.

Precautions

Use proper power cord. Use only the power cord shipped with this

instrument and certified for the country of use.

Maintain ground. This product is grounded through the power cord

grounding conductor. To avoid electric shock, connect only to a grounded

mating outlet.

Connect and disconnect properly. Do not connect/disconnect probes or

test leads while they are connected to a voltage source.

B

Page 12

WaveRunner 6 Zi and 12-Bit HRO

4

922136-00 Rev A

Observe all terminal ratings. Do not apply a voltage to any input (C1, C2,

C3, C4 or EXT) that exceeds the maximum rating of that input. Refer to the

front of the oscilloscope for maximum input ratings.

Use only within operational environment listed. Do not use in wet or

explosive atmospheres.

Use indoors only.

Keep product surfaces clean and dry.

Do not block the cooling vents. Leave a minimum six-inch (15 cm) gap

between the instrument and the nearest object. Keep the underside clear

of papers and other objects.

Do not remove the covers or inside parts. Refer all maintenance to

qualified service personnel.

Do not operate with suspected failures. Do not use the product if any part

is damaged. Obviously incorrect measurement behaviors (such as failure to

calibrate) might indicate impairment due to hazardous live electrical

quantities. Cease operation immediately and sequester the instrument

from inadvertent use.

Operating Environment

Temperature: 5 to 40 °C.

Humidity: Maximum relative humidity 80 % for temperatures up to

31° C decreasing linearly to 50 % relative humidity at 40° C (or at the upper

operational temperature limit).

Altitude: Up to 10,000 ft (3,048 m) at or below 25° C.

Cooling

The instrument relies on forced air cooling with internal fans and vents.

Take care to avoid restricting the airflow to any part of the oscilloscope.

Around the sides and rear, leave a minimum of 15 cm (6 inches) between

the instrument and the nearest object. At the bottom, the oscilloscope feet

(up or down) provide adequate clearance.

CAUTION. Do not block oscilloscope vents. Always keep the area

beneath the oscilloscope clear of paper and other items.

Page 13

Getting Started Manual

922136-00 Rev A

5

The instrument also has internal fan control circuitry that regulates the fan

speed based on the ambient temperature. This is performed automatically

after start-up.

Cleaning

Clean only the exterior of the oscilloscope using a damp, soft cloth. Do not

use harsh chemicals or abrasive elements. Under no circumstances

submerge the instrument or allow moisture to penetrate it. Avoid electric

shock by unplugging the power cord from the AC outlet before cleaning.

CAUTION. Do not attempt to clean internal parts. Refer to qualified

service personnel.

Calibration

The oscilloscope is calibrated at the factory prior to being shipped. The

recommended calibration interval is one year. Calibration should be

performed by qualified personnel only.

The oscilloscope software includes automatic and manual calibration

functions.

CAUTION. It is required that all inputs be removed from the

oscilloscope prior to performing a manual calibration.

Schedule an annual factory calibration as part of your regular maintenance.

Extended warranty, calibration, and upgrade plans are available for

purchase. Contact your Teledyne LeCroy sales representative or

customersupport@teledynelecroy.com to purchase a service plan.

B

Page 14

WaveRunner 6 Zi and 12-Bit HRO

6

922136-00 Rev A

Power

AC Power Source

100-240 VAC (+/-10%) at 50/60 Hz (+/-5%)

100-120 VAC (+/-10%) at 400 Hz (+/-5%)

Installation Category: 300V CAT II

Manual voltage selection is not required because the instrument

automatically adapts to line voltage.

Power Consumption

8-BIT MODELS:

Power Consumption (Nominal): 425 Watts (425 VA)

Max Power Consumption (with all PC peripherals, active probes connected

to 4 channels, and MSO active): 500 Watts (500 VA)

12-BIT MODELS:

Power Consumption (Nominal): 325 Watts (325 VA)

Max Power Consumption (with all PC peripherals, active probes connected

to 4 channels, and MSO active): 425 Watts (425 VA)

Power consumption in Standby Mode: 15 Watts

Power and Ground Connections

The instrument is provided with a 10A/250V 18AWG rated grounded cord

set containing a molded three-terminal polarized plug and a standard

IEC320 (Type C13) connector for making line voltage and safety ground

connections.

The AC inlet ground is connected directly to the frame of the instrument.

For adequate protection again electric shock, connect to a mating outlet

with a safety ground contact.

WARNING. Interrupting the protective conductor inside or outside

the oscilloscope, or disconnecting the safety ground terminal,

creates a hazardous situation. Intentional interruption is prohibited.

Page 15

Getting Started Manual

922136-00 Rev A

7

Standby Power

The Standby Power button controls the operational state of the

oscilloscope. Press the button to switch the instrument On or into Standby

mode (Off).

Always use the Power button or the File > Shutdown menu option to

execute a proper shut down process and preserve settings before powering

down.

Powering off does not disconnect the oscilloscope from the AC power

supply. The only way to fully power down the instrument is to shut down

then unplug the AC power cord from the outlet. We recommend

unplugging the instrument if it will be unused for a long period of time.

B

Page 16

WaveRunner 6 Zi and 12-Bit HRO

8

922136-00 Rev A

Number and Description

1. Power Button

2. Channel Inputs

3. EXT Input and

AUX Output

connectors

4. Ground Connector

and Probe

Calibration Hook

5. USB Connections

and Teledyne

LeCroy Bus Port

6. Front Panel

Control

7. Rotating Display

Release Switch

8. Touch Screen

Stylus

Hardware

The Front of Your Oscilloscope

Numbered labels on this image correspond with descriptions on the

following table.

Page 17

Getting Started Manual

922136-00 Rev A

9

Rotating and Tilting the Display

The display panel allows for Rotation and Tilting adjustments. These

adjustments allow you to position your instrument with unmatched

versatility.

Rotate and Tilt your display using the following instructions:

Note: Your oscilloscope should always be firmly planted on a solid supporting

surface at all times.

ROTATING THE DISPLAY

Rotate the display by firmly grasping the left side of the display. Use your

thumb to push upward on the release switch (on the front-left side of the

display), and then use your wrist to forcibly rotate the display in an

upward, clockwise twisting motion until the display locks into portrait

position.

Rotating the display from landscape (horizontal) to portrait (vertical) positioning.

B

Page 18

WaveRunner 6 Zi and 12-Bit HRO

10

922136-00 Rev A

Note: For models without a latch on the left side of the display, grip the same side

firmly and rotate in an upward, clockwise twisting motion. The track clicks in and

out of the two positions without the use of the latch.

The user interface then adjusts its layout from landscape (horizontal) to

portrait (vertical). This setup is ideal for viewing high-amplitude signals.

The Rotating Display shown in portrait layout position.

Reverse the process by grasping the now upper side of the display. Again,

use your thumb to push upward on the release switch; but, now use your

wrist to forcibly rotate the display in a downward, counter-clockwise

twisting motion until the display locks back into landscape position.

The user interface then adjusts the layout back from portrait (vertical) to

landscape (horizontal).

Page 19

Getting Started Manual

922136-00 Rev A

11

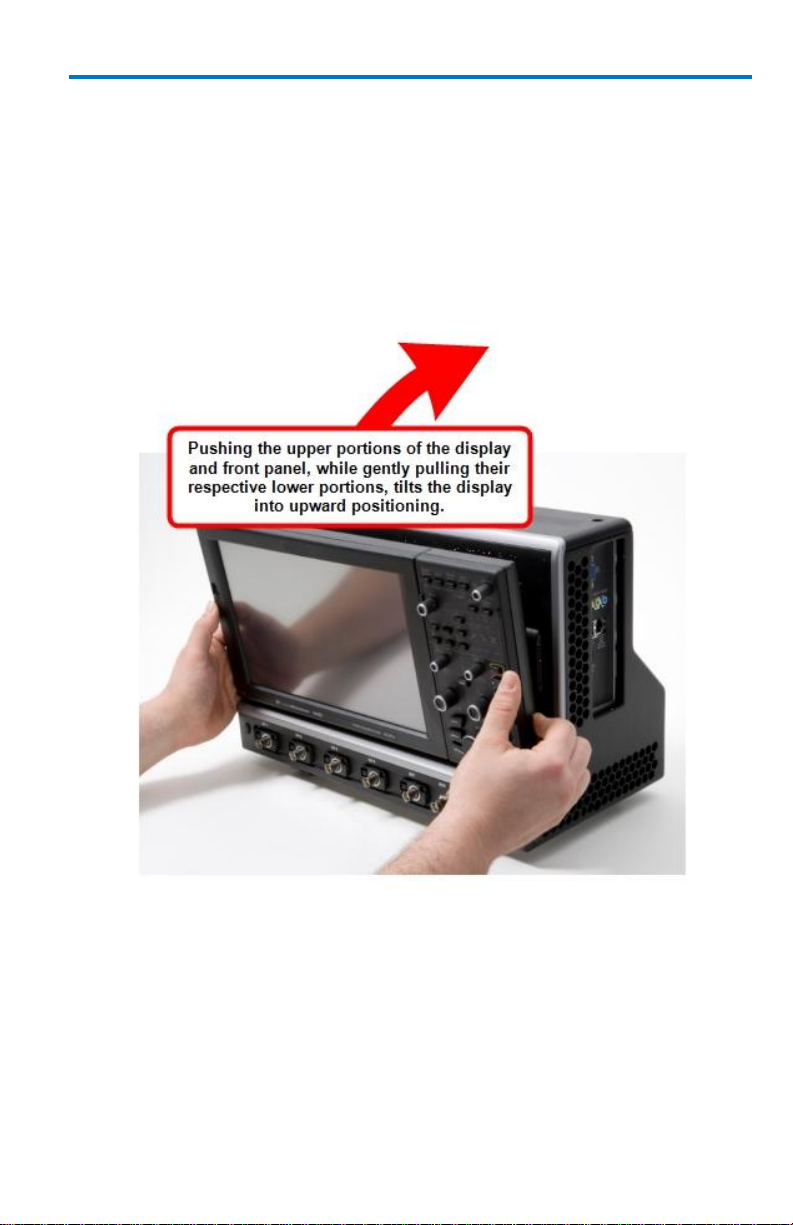

TILTING THE DISPLAY

The display can be tilted (while in either Landscape or Portrait mode) into

Upward or Downward positioning for convenience.

Tilt the display by firmly grasping the far left side of the display and the far

right side of the front panel. Use your wrists to forcibly tilt the display by

pushing the upper-portions forward (to tilt upward) or the lower-portions

backward (to tilt downward) until the desired positioning is reached.

Tilting the display by pushing the upper-portions of the display/front panel

forward - tilting the display from downward to upward positioning.

B

Page 20

WaveRunner 6 Zi and 12-Bit HRO

12

922136-00 Rev A

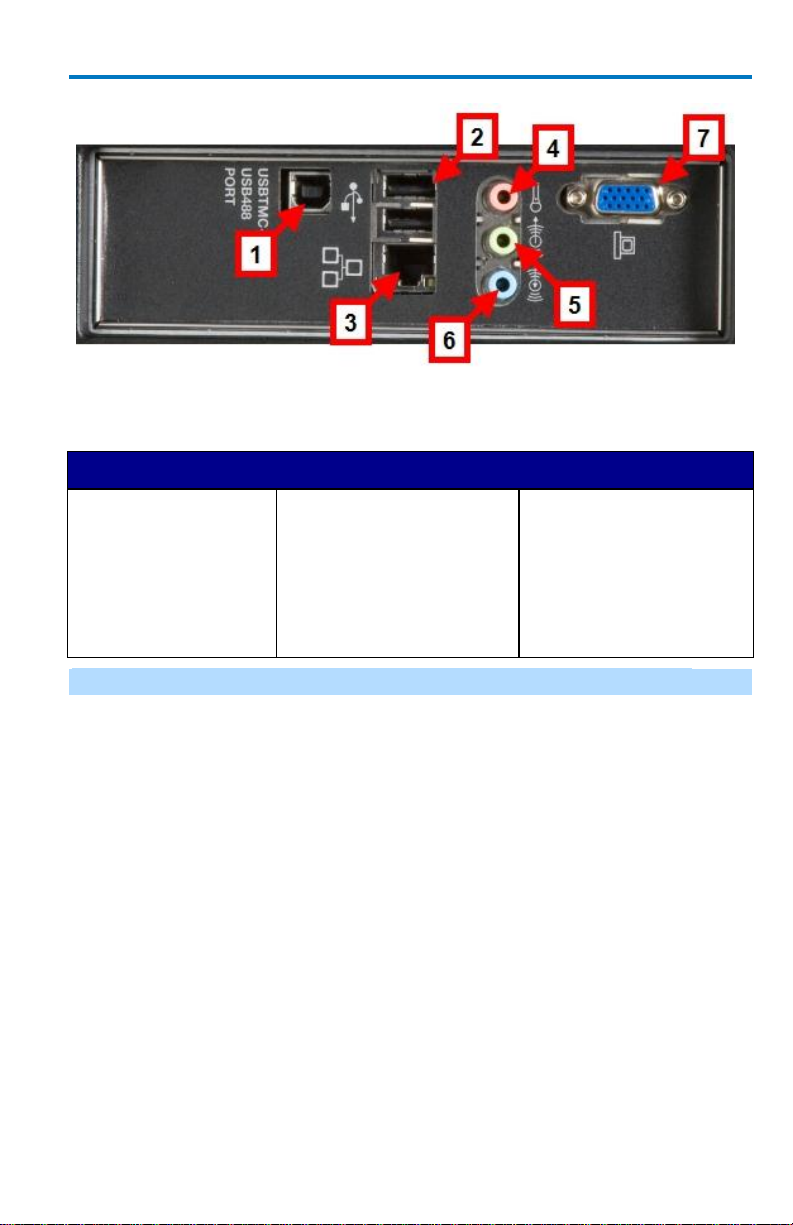

I/O Panel

The I/O Panel is located on the right side (facing) of the instrument as

follows:

Note: A Teledyne LeCroy Bus (LBUS) connection is located on the The Front of

Your Oscilloscope (on page 3).

Page 21

Getting Started Manual

922136-00 Rev A

13

Number and Description

1. USB488

Connection

2. USB A

Connections

3. Ethernet Port

4. Microphone

Connection

5. Speaker

Connection

6. Line In

Connection

7. External VGA

Monitor

Connection

Numbered labels on the following I/O Panel image correspond with

descriptions on the following table.

Note: Contact a system administrator when connecting to any internal LAN.

B

Page 22

WaveRunner 6 Zi and 12-Bit HRO

14

922136-00 Rev A

The Back of Your Oscilloscope

The AC Power Plug is located on the back panel of your instrument.

Removable Hard Drive Option

The WaveRunner 6 Zi and 12-Bit HRO have a removable hard drive option

available. The remainder of this topic explains how to properly remove and

reinstall the WaveRunner 6 Zi and 12-Bit HRO removable hard drive.

PLEASE NOTE THE FOLLOWING:

The WaveRunner 6 Zi and 12-Bit HRO removable hard drive option

must be specified when ordering and installed at the Teledyne

LeCroy factory. Contact your Teledyne LeCroy representative for

details using Contact Teledyne LeCroy for Support.

When this option is ordered, a removable hard drive is installed

inside your oscilloscope and an additional removable hard drive is

also provided.

Never attempt to extract a removable hard drive without powering

down your instrument first.

Page 23

Getting Started Manual

922136-00 Rev A

15

WARNING. Only removable hard drives supplied by Teledyne LeCroy

should ever be used in your instrument. Teledyne LeCroy drives bear

a Teledyne LeCroy sticker and serial number indicating the intended

oscilloscope model with which it's supposed to be used.

When extracting your removable hard drive (if you have this option) handturn and remove the screws, and then remove the cover from the back of

your oscilloscope.

B

Page 24

WaveRunner 6 Zi and 12-Bit HRO

16

922136-00 Rev A

Now, un-tuck and gently pull the tab to unplug the hard drive from its

connection and remove it from the slot.

When reinstalling your removable hard drive, be sure its placed back into

the slot in the correct direction. Firmly press the drive into place securing

its internal connection to your oscilloscope.

Page 25

Getting Started Manual

922136-00 Rev A

17

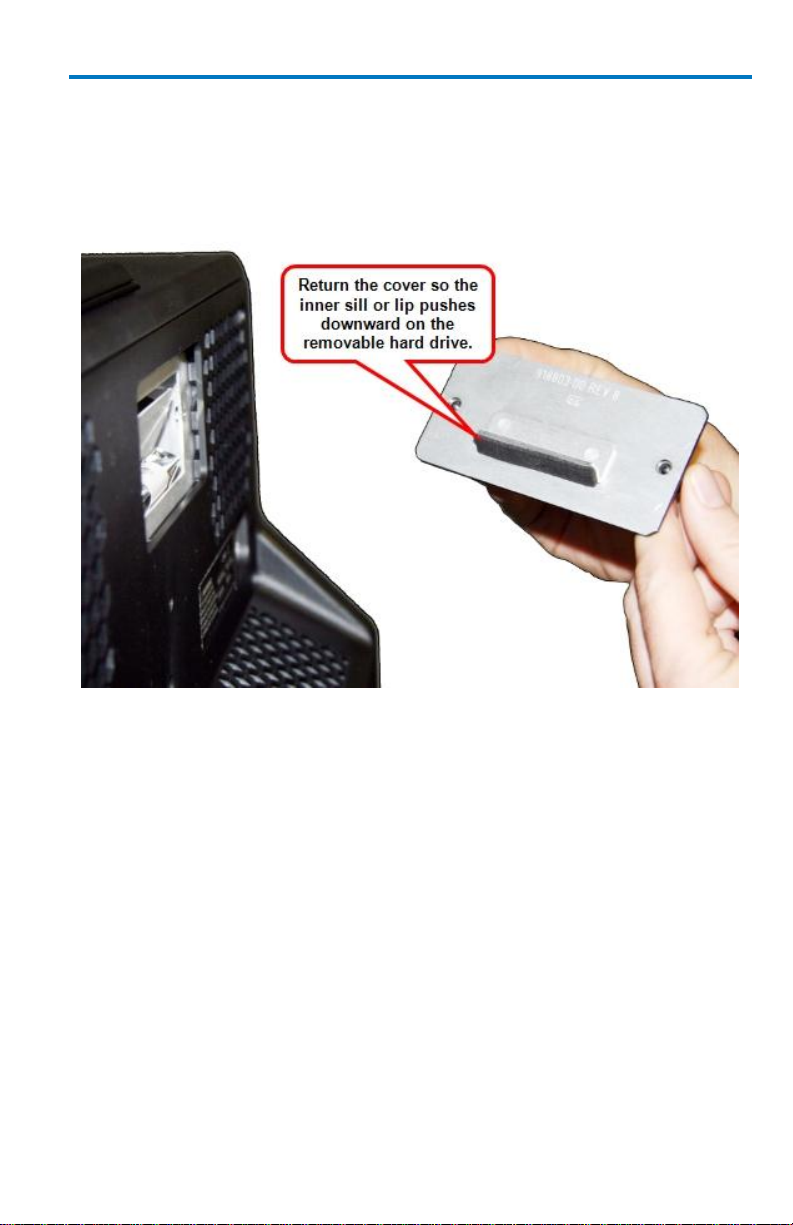

Finally, to make sure the removable hard drive cover is returned in the

correct direction to the back of your oscilloscope, a sill or lip on the inside

of the cover should be situated so it pushes downward on the removable

hard drive.

Basic Controls

Hardware and Software Controls

The following Basic Control topics cover the general usage of the hardware

buttons located on the oscilloscope's front panel and the screen control

interface elements of the software.

B

Page 26

WaveRunner 6 Zi and 12-Bit HRO

18

922136-00 Rev A

Front Panel Controls

Note: Many specific Front Panel Controls directly correspond with Screen Layout

Controls. For example, the Print front panel general control button corresponds

with the Hardcopy function at Utilities → Utilities Setup → Hardcopy.

The following picture shows the Front Panel Control.

Front panel for WaveRunner 6 Zi and 12-Bit HRO oscilloscopes.

Page 27

Getting Started Manual

922136-00 Rev A

19

Front Panel Control Groupings

The front panel is divided into sections based on various functions. The

following topics explain these sections in more detail.

Miscellaneous Controls and WaveStream Indicator

This topmost section of the front panel provides the following functions:

Touch Screen - By default this button's blue backlit LED is ON and

the touch screen is enabled. By pressing this button and turning off

the LED, the touch screen is then disabled.

Print - Press this button and it automatically executes the based on

the settings you've made as described in Printing and Hardcopy

Functions (on page 147).

You can set the oscilloscope to automatically spool directly to a

printer, to a file, an email (with attachment), or to the clipboard.

Scope Setup - Press once and the Scope Setup flyout menu is shown.

The Scope Setup flyout menu quickly provides access to Auto Setup,

C1 Find Scale, C2 Find Scale, C3 Find Scale, C4 Find Scale, and

Default Setup buttons. These functions perform various automatic

setup configurations to your instrument. This corresponds to the

Auto Setup... selection on the menu bar from the Vertical,

Timebase, or Trigger menus.

Press the Auto Setup... button on the flyout menu to perform a full

auto setup. Press a Channel Find Scale button on the flyout menu to

perform a quick auto setup for that channel only.

B

Page 28

WaveRunner 6 Zi and 12-Bit HRO

20

922136-00 Rev A

Press the AUTO SETUP... front panel button twice to perform the last

selection from the Auto Setup... flyout menu (the default is to

perform a full auto setup).

If Auto Setup is run when no channels are turned on, all channels are

affected. When more than one channel is turned on, the first

channel with a signal applied to it is automatically set up for edge

triggering.

Perform an autosetup of all these functions together by pressing the

Auto Setup... front panel button.

Clear Sweeps - Press to clear data from multiple sweeps

(acquisitions) including: persistence trace displays, averaged traces,

parameter statistics, and Histicons. During waveform readout,

cancels readout. This is the same as pressing Clear Sweeps on the

Measure → Measure Setup... or Math → Math Setup dialogs.

WaveStream - Indicates when WaveStream mode is ON. Refer to

WaveStream Mode (on page 89) for more information.

Intensity - Press to toggle between WaveStream OFF and ON for

Analog Persistence and WaveStream ON for Color Persistence. When

you turn the knob, if WaveStream is ON, the WaveStream display

intensity changes. When you turn the knob, if WaveStream is OFF,

changes the Intensity setting. Corresponds with the screen menu

selection: Display → Display Setup (on page 84).

Page 29

Getting Started Manual

922136-00 Rev A

21

Trigger Front Panel Controls

Level - Pressing this button sets the trigger level to 50%. Turn the

knob to change the trigger threshold level. The threshold level is

indicated on the Trigger label.

READY and TRIG'D Indicators - The READY indicator is lit when the

trigger is armed. TRIG'D is lit momentarily when a trigger occurs. A

fast trigger rate causes the light to stay lit continuously.

Setup - Press once to open the Trigger Setup... dialog. Corresponds

with screen menu selection: Trigger → Trigger Setup.... Press the

Trigger SETUP front panel button again to close the Trigger Setup...

dialog.

Trigger Scan - Pressing the Trigger Scan button opens the

TriggerScan dialog to help you quickly find rare waveform glitches

and anomalies.

Source - This button directly selects through the available Source

field values (C1, C2, C3, C4, Dig, EXT, and Line) usually accessed on

the Setup section of the main Trigger dialog.

Slope - This button directly selects through the available Slope field

values (Positive, Negative, or Either) usually accessed on the Setup

section of the main Trigger dialog.

Coupling - This button directly selects through the available

Coupling field values - DC, AC, LFR (Low-Frequency Rejection), or

B

Page 30

WaveRunner 6 Zi and 12-Bit HRO

22

922136-00 Rev A

HFR (High-Frequency Rejection) - usually accessed on the Setup

section of the main Trigger dialog.

Auto - Press to turn on Auto Trigger mode, which triggers the

oscilloscope after a time-out, even if the trigger conditions are not

met.

Normal - Press to turn on Normal Trigger mode, which triggers the

oscilloscope each time a signal is present that meets the conditions

set for the type of trigger selected.

Single - Press to turn on Single Trigger mode, which arms the

oscilloscope to trigger once (single-shot acquisition) when the input

signal meets the trigger conditions set for the type of trigger

selected. If the scope is already armed, it will force a trigger.

Stop - Press to prevent the scope from triggering on a signal. If you

boot up the instrument with the trigger in Stop mode, a no trace

available message is shown. Press the Trigger AUTO front panel

button to display your trace.

Page 31

Getting Started Manual

922136-00 Rev A

23

Horizontal Front Panel Controls

Note: Horizontal front panel controls can be applied to signals, Math, Zoom, or

Memory traces. See Math, Zoom, and Memory Indicators and Controls (on

page 25) for more information.

Delay - Press to toggle between a zero horizontal delay value and

the previous horizontal delay value. Turn to change the horizontal

delay value.

Time/Div - Turn to set the time/division of the oscilloscope timebase

(acquisition system). When using this Horizontal control on a Math,

Zoom, or Memory trace, you can press this button to toggle

between fixed and variable adjustments. Turn the knob to change

the value.

B

Page 32

WaveRunner 6 Zi and 12-Bit HRO

24

922136-00 Rev A

Vertical Front Panel Controls

Note: Vertical front panel controls can be applied to signals, Math, Zoom, or

Memory traces. See Math, Zoom, and Memory Indicators and Controls (on

page 25) for more information.

Channels - The channel buttons (1 - 4 and Digital) control both

channel ON/OFF and which channel is active for the Vertical Offset

and Volts/Div knobs controls. If a channel is OFF, pressing that

channel button turns it on and makes it active. If a channel button is

ON, pressing that channel button makes it active, and then pressing

it a second time turns it OFF.

Offset - Press to toggle between a zero vertical offset value and the

previous vertical offset value for the selected channel. Turn to

change the vertical offset value for the selected channel.

Gain - Press to toggle between fixed and variable gain adjustment.

Turn to change the gain value.

Page 33

Getting Started Manual

922136-00 Rev A

25

Math, Zoom, and Memory Indicators and Controls

When pressed, the Zoom automatically creates a Zoom trace of all

active channels. Math and Memory traces must first be enabled on

their respective dialogs in Math → Math | Memory Setup... for use

by the front panel controls.

When Math, Zoom, or Memory traces are enabled - see Math →

Math | Zoom | Memory Setup..., respectively - the corresponding

indicator light illuminates and the Horizontal and Vertical controls

specifically control the Math, Zoom, or Memory trace.

The Push - Variable function on the Time/Div front panel control for

Horizontal only applies to Math, Zoom, or Memory traces and not

Channels. Press the button to toggle between fixed and variable

adjustments or turn the knob to change the value.

The WavePilot Control Area and The SuperKnob

The WavePilot Control Area contains buttons that correspond to specific

functions. These function buttons are used together with the SuperKnob to

provide increased instrument control at your fingertips.

The SuperKnob is a joystick-like knob in the center of the WavePilot Control

Area used to make selections or provide specific values.

B

Page 34

WaveRunner 6 Zi and 12-Bit HRO

26

922136-00 Rev A

The SuperKnob shown on the WavePilot Control Area.

SUPERKNOB FIELD CONTROL AND THE ADJUST HELP FLYOUT MENU

Whenever you access a non-text entry or file browsing control on a dialog,

the Adjust Help Flyout menu is shown.

The Probe Attenuation control value being changed using the SuperKnob.

Control values can be adjusted using the touch screen, a connected mouse,

or by use of the SuperKnob. Turning the SuperKnob moves through

available control values and, as indicated by the Help Flyout menu, pressing

the SuperKnob provides Toggle Variable functionality; meaning, fine and

coarse adjustments (if available for the particular control) may be selected

for use.

The WavePilot Control Area provides powerful control of Cursors, Decode,

WaveScan, History, LabNotebook, and Spectrum by their respective

function buttons on the front panel. Based on the function button selected,

additional functions are then available on the SuperKnob.

Page 35

Getting Started Manual

922136-00 Rev A

27

PLEASE NOTE THE FOLLOWING:

Not all functions have a function assigned to each (or any) left, right,

up, or down SuperKnob control. Some only have one or two

controls. Deactivated SuperKnob control directions are shown as unlabeled and grayed-out on respective Help Flyout menus.

The name of the current mode being used is shown vertically on the

left side of the Help Flyout menu.

When a function button is pressed and the SuperKnob control

changes, a corresponding clearly-labeled, Help Flyout menu

indicates additional functions available when using the SuperKnob to

joystick in left, right, up, or down directions.

The Table Mode Help Flyout menu for the Spectrum Function button.

Some models have Table and Zoom LED indicators along with

Adjust. Others have only an Adjust LED with Zoom and Table

buttons containing backlit LEDs.

ZOOM AND TABLE BUTTONS

The Zoom and Table buttons may (or may not) provide additional control

for a specific WavePilot funciton you have selected.

Zoom Button

With the Zoom button selected (for a function that has the Zoom control)

you can twist the SuperKnob dial to adjust the zoom value for your

displayed waveform.

Table Button

With the Table control selected (for a function that has the Table control)

you can joystick up or down to Page Up or Down through the table results.

You can also twist the SuperKnob dial to sequentially navigate each row of

the table results.

B

Page 36

WaveRunner 6 Zi and 12-Bit HRO

28

922136-00 Rev A

CURSORS

Use the SuperKnob to adjust Cursors by pressing the Cursors function

button. Once pressed, the Cursors Help Flyout menu is shown.

Note: For more information about the use of Cursors, see Measuring with

Cursors (on page 95).

Horizontal, Off, and Vertical

Pressing the Cursor Function button moves through states for Horizontal

Absolute, Horizontal Relative, Vertical Absolute, Vertical Relative, and

Off.

LED's surrounding the SuperKnob provide visual indication of cursor status

as follows:

When opposing LED's (Top/Bottom and Left/Right) are lit, the

cursors are in a Relative state.

When no LED's surrounding the SuperKnob are lit, the cursors are in

an Absolute or Off state.

Using the SuperKnob with Cursors

The SuperKnob joystick is used for cursor control while in Horizontal and

Vertical states in the following manner:

Horizontal - Cursors Help Flyout menu is shown with instructions for

left and right joystick use of the SuperKnob described as Leftmost

and Rightmost. When either is selected, you can twist the

SuperKnob to adjust the respective cursor.

Vertical - Cursors Help Flyout menu is shown with instructions for

left and right joystick use of the SuperKnob described as Topmost

and Bottommost. When either is selected, you can twist the

SuperKnob to adjust the respective cursor.

Pushing the SuperKnob button changes the cursor control from the

two available states with the added state of tracking (moving the

pair together in parallel).

You can force cursors to swap identities in the event where one is

adjusted past the level of its other extreme. Meaning, if you were to

adjust a bottommost cursor above its respective topmost cursor, the

bottommost would then become the topmost and vice versa.

Note: Zoom and Table buttons are not used for Cursors.

Page 37

Getting Started Manual

922136-00 Rev A

29

DECODE

When first pressing the Decode function button, the Serial Decode dialog is

shown. Subsequent presses of the Decode function button produce the

following results:

If you haven't enabled a Decode signal, it Closes the Serial Decode

dialog.

If you have enabled a Decode signal, it Closes the Serial Decode

dialog and disables the Decode signal.

If you have enabled a Decode signal, and the Serial Decode dialog is

closed or a different dialog is currently opened (say, the Zoom

dialog), the Serial Decode dialog is Opened.

Zoom and Table Buttons for Decode

The Zoom and Table buttons are used as described in The WavePilot

Control Area and The SuperKnob Overview (on page 25). Decode tables

are shown beneath the main display area.

WAVESCAN

When first pressing the WaveScan function button, the WaveScan dialog is

shown with table data showing in a column to the left of the main display

area. Subsequent presses of the WaveScan function button produce the

following results:

WaveScan is turned On and you click Close on the WaveScan dialog

or open a different dialog (say, the Zoom dialog), and then click the

WaveScan function button, the WaveScan dialog is Opened.

WaveScan is turned Off and the WaveScan dialog is Closed.

The Zoom and Table buttons are used as described in The WavePilot

Control Area and The SuperKnob Overview (on page 25).

HISTORY

When first pressing the History function button, the History dialog is

shown with table data showing in a column to the left of the main display

area. Subsequent presses of the History function button produce the

following results:

History is turned On and you click Close on the History dialog or

open a different dialog (say, the Zoom dialog), and then click the

History function button, the History dialog is Opened.

B

Page 38

WaveRunner 6 Zi and 12-Bit HRO

30

922136-00 Rev A

History is turned Off and the History dialog is Closed.

On the History dialog, a Capacity control is provided.

Note: A default value for the Capacity control is generated based on your

instrument's specific Acquisition Memory Setting (it also varies based on specific

setups, configurations, and settings at any given time).

The Zoom and Table buttons are used as described in The WavePilot

Control Area and The SuperKnob Overview (on page 25).

LABNOTEBOOK

When first pressing the LabNotebook function button, the LabNotebook

dialog is shown. The button toggles between opening and closing the

LabNotebook dialog - unless you already have LabNotebook entries stored.

With LabNotebook entries already stored subsequent presses of the

LabNotebook function button:

opens the LabNotebook dialog and your first My Notebook Entry is

shown on the display area in Preview mode.

closes the LabNotebook dialog and the My Notebook Entry preview.

As mentioned, with LabNotebook entries already stored a subsequent

press of the LabNotebook function button shows the preview along with

the dialog. You can then turn the SuperKnob to move through entries

shown in My Notebook Entries on the LabNotebook dialog. Pushing the

SuperKnob performs a Flashback (Recall) of the stored entry selected in the

My Notebook Entries on the LabNotebook dialog.

Note: Zoom and Table buttons are not used for LabNotebook.

SPECTRUM

When first pressing the Spectrum function button, the Spectrum dialog is

shown with table data showing in a column to the left of the main display

area. Subsequent presses of the Spectrum function button produce the

following results:

Spectrum Analysis is turned Off and the SpectrumAnalyzer dialog is

Closed.

Spectrum Analysis is turned On and you click Close on the

SpectrumAnalyzer dialog or open a different dialog (say, the Zoom

dialog), and then click the Spectrum function button, the

SpectrumAnalyzer dialog is Opened.

Page 39

Getting Started Manual

922136-00 Rev A

31

Zoom and Table buttons are used as described in The WavePilot Control

Area and The SuperKnob Overview (on page 25). In addition, a spectrum-

specific Table control functionality Centers the Frequency of your

displayed waveform when the SuperKnob is pressed based on the

particular Frequency row you have selected from the Spectrum table

displayed to the left of the main display area.

The Table Help Flyout menu for the Spectrum Function button.

Probe / Signal Connection Interfaces

Probe Interfaces

Teledyne LeCroy oscilloscopes utilize one or more proprietary probe

interfaces providing a complete measurement solution from probe tip to

oscilloscope display. Compared to standard BNC and Probe Ring interfaces,

this intelligent interconnection between your instrument and the probe or

accessory eliminates the guesswork and errors that occur when probe

settings are made manually, and also offers the following important signal

fidelity advantages:

Upon connection to the oscilloscope channel, the probe is

recognized and some setup information, such as input coupling and

attenuation, is performed automatically.

System (probe plus oscilloscope) gain settings are automatically

calculated and displayed based on the probe attenuation.

Active probes typically provide automatic matching of probe to

oscilloscope response using probe response data stored in an onboard EEPROM. This ensures the best possible combined probe plus

oscilloscope channel frequency response without requiring the user

to perform any de-embedding procedure.

B

Page 40

WaveRunner 6 Zi and 12-Bit HRO

32

922136-00 Rev A

Probe interfaces differ in bandwidth, so the interfaces contained on your

oscilloscope depend on the bandwidth rating of the oscilloscope model you

purchased.

When a probe is connected, it is recognized and an additional tab with the

probe model name is displayed to the right of the C1 tab.

The channel dialog layout showing Input A's ProLink interface controls setup

after connection.

This additional tab contains specific information on the connected probe.

In addition, default values for the probes coupling and attenuation (which

may not be changed) are automatically downloaded from the probe, and

these settings along with other attributes are shown on the corresponding

probe dialog.

The dialog showing the connected probe's control attributes.

ProBus Interface

The ProBus interface contains a 6-pin power and communication

connection and a BNC signal connection to the probe. It offers both 50 Ω/1

MΩ input impedance and provides probe power and control for a wide

range of probes such as high impedance passive probes, high impedance

active probes, current probes, high voltage probes, and differential probes.

ProBus also includes sense rings for detecting passive probes. The ProBus

interface may also have a BNC-terminated cable connected directly to it.

Page 41

Getting Started Manual

922136-00 Rev A

33

ProBus is based on a BNC connector and, depending on the exact BNC

connector used and the oscilloscope design, is rated for up to 4 GHz with

50 Ω coupling or up to 1 GHz for 1 MΩ coupling (depending on the exact

model purchase).

Probes

Teledyne LeCroy offers a variety of passive and active probes for use with your XStream oscilloscope. Visit teledynelecroy.com for specifications and ordering

information.

Current Probes - Current Probes measure the current passing

through a wire; current probes do not use the traditional probing

style of placing a tip onto a test point. Instead, a wire is placed inside

the jaw of the probe, which allows the probe to measure the current

(in Amps).

Active Probes - There are two different types of active probes:

single-ended and differential.

Single-Ended - A single-ended active probe is associated with

measuring voltages at high frequencies. Measurement with an active

probe requires a test point and a ground point. The ground (also

called earth) acts as a zero reference for the test point

measurement.

Differential Probes - Differential active probes are like two probes in

one. Instead of measuring a test point in relation to a ground point

(like single-ended active probes), differential probes measure the

difference in voltage of a test point in relation to another test point.

Passive Probes - Passive probes measure voltages at lower

frequencies (<500 MHz). They have higher input capacitance (input

C) and do not need power to operate (unlike active probes). At

higher frequencies, higher input capacitance loads the test circuit,

attenuating the signal. This is why active probes are used in high

frequency applications. Passive probes also measure voltage in

reference to ground.

High Voltage Probes - These are active, single-ended probes

designed to safely measure high voltages. They measure the voltage

in reference to ground.

B

Page 42

WaveRunner 6 Zi and 12-Bit HRO

34

922136-00 Rev A

Passive Probe Compensation

Passive probes must be compensated to flatten overshoot. This is

accomplished by means of a trimmer at the connector end of the probe.

1. Attach the connector end of your passive probe to any channel.

2. Connect the probe end to the CAL output connector at the front of

the oscilloscope. Ground the probe.

3. Adjust the trim pot at the connector end of the probe until the

square wave is as flat as possible.

Page 43

Getting Started Manual

922136-00 Rev A

35

Display Dashboard

Screen Layout, Groupings, and Controls

The instrument's screen is divided into the following main sections:

Menu Bar

Signal Display Grid

Descriptor Labels

Dialog(s)

The Message Bar

Note: Many front panel controls directly correspond with screen layout controls.

For example, the Print front panel general control button corresponds with the

Hardcopy function set from Utilities → Utilities Setup → Hardcopy.

Menu Bar

The top of the screen contains a menu bar of commonly used functions.

Whenever you touch one of these buttons and make a selection from its

drop-down menu, the dialog area at the bottom of the screen displays the

corresponding dialog.

Specific Menu Bar functions are referenced using arrow-separated path

descriptions. For example, the Save Setup function is referenced as File →

Save Setup....

PLEASE NOTE THE FOLLOWING:

B

Page 44

WaveRunner 6 Zi and 12-Bit HRO

36

922136-00 Rev A

For common oscilloscope operations, you don't need to use the top menu

bar (since you can access most dialogs from the Front Panel or from the

Descriptor Labels). However, it is the only way to access setup or other

dialogs for Display Setup, Save or Recall Waveform, Save or Recall Setups,

Print Setup, Vertical (Channel), Horizontal, or Trigger Status, Memory

(Reference Waveform) Setup, Pass/Fail Setup, or Utilities and Preferences

Setup....

The Quick Access Toolbar

The Quick Access portion of the toolbar is located on the right side of the

menu bar. It contains the Rotate Display button.

When the display is rotated, touch this button to adjust the user interface

to a portrait layout. The button toggles from portrait layout back to

landscape.

For additional information on rotating and tilting the display, refer to

Hardware and Software Controls (on page 17).

The Signal Display Grid

The grid area is divided into 8 vertical divisions and 10 horizontal divisions

just like any other oscilloscope. Set up the signal display area by touching

Display → Display Setup... from the menu bar.

The Display dialog offers a choice of grid combinations and can also set the

grid intensity.

Page 45

Getting Started Manual

922136-00 Rev A

37

There are several indicators on the grid to help you understand the

following:

Trigger Delay - This indicator is located along the bottom edge of the

grid. Trigger delay allows you to see the signal prior to the trigger

time.

All trigger delay values (including post-trigger delay, shown here) are

displayed in the Timebase Descriptor Label. Zero delay is the

horizontal center of the oscilloscope display.

The default setting (Time) is for delay readout (in seconds) and to

move proportionately when the timebase knob is turned. If you

want to set delay (Div) to a fixed position on the grid, and then have

it stay fixed as the timebase changes, go to Utilities → Preference

Setup... and select the Acquisition dialog to make the setting.

Post-trigger Delay - This is indicated by a left-pointing arrow to the

lower-left of the grid. Pre-trigger delay is indicated by a rightpointing arrow to the lower-right of the grid.

B

Page 46

WaveRunner 6 Zi and 12-Bit HRO

38

922136-00 Rev A

Trigger Level - This indicator is located at the right edge of the grid.

It tracks the trigger level as you reposition the trace up or down, or

change scale. When triggering is stopped, a hollow arrow indicates

where the new level ends up when triggering resumes.

Push the LEVEL knob to reset the level to 50%.

Zero Volts Level - This indicator is located at the left edge of the

grid. Change the zero volts level by turning the vertical OFFSET knob.

Push the knob to reset the indicator to the middle of the grid.

Signal Display Grid Pop-Up Menu

On the Signal Display Grid, the Pop-up menu provides assistance while using the

oscilloscope.

Clicking on a waveform opens a pop-up menu. From this pop-up menu, you

can perform the following functions:

Open the Setup dialog for the trace

Turn the trace descriptor label off

Open the Math dialog for the trace

Open the Measure dialog for the trace

Annotate the selected trace

Page 47

Getting Started Manual

922136-00 Rev A

39

Trace Descriptor Labels

Shown just beneath the grid display, these boxes provide a summary of

your channel, timebase, and trigger settings.

When a trace is selected its corresponding descriptor label is shown

highlighted.

The C1 Trace Descriptor Label is selected; C2 is not.

Make vertical or horizontal channel adjustments by touching the respective

label. The setup dialog for the function is shown beneath.

Channel trace labels show the vertical settings for the trace and cursor

information (if cursors are in use). The title bar of the label includes

indicators for (SinX)/X interpolation, waveform inversion (INV), deskew

(DSQ), coupling (DC/GND), bandwidth limiting (BWL), and averaging (AVG).

These indicators have a long and short form, respectively.

Besides channel traces, math and parameter measurement labels are also

displayed. Labels are displayed only for traces that are turned on.

Vertical and horizontal trace descriptor (labels) are displayed below the

grid. They provide a summary of your channel, timebase, and trigger

settings. Make vertical or horizontal channel adjustments by touching the

respective label. The setup dialog for the function is shown beneath.

TimeBase trace descriptor labels show the trigger delay setting, time per

division, and sampling information.

B

The long and short forms of trace descriptor indicators.

Page 48

WaveRunner 6 Zi and 12-Bit HRO

40

922136-00 Rev A

Trigger trace descriptor labels show the trigger mode (Auto, Normal, or

Stopped). It also shows the coupling (DC), trigger type (Edge), source (C1),

level (0 mV), and slope (Positive).

Setup information for horizontal cursors, including the time between

cursors and the frequency, is shown beneath the TimeBase and Trigger

trace descriptor labels.

Actions for Trace Buttons

You can access the same functions as the ones produced when using the

Signal Display Grid Pop-Up menu just by clicking a trace-descriptor label,

which shows its corresponding dialog. From the respective dialog, you're

able to access the same functions as Actions for Trace X buttons.

Open the Setup dialog for the trace.

Open the Math dialog for the trace.

Open the Measure dialog for the trace.

Annotate the selected trace.

For more information, see the Actions for Trace Buttons section of Dialog

Area (on page 42).

Annotating Traces

The instrument gives you the ability to add an identifying label, bearing

your own text, to a waveform display:

Page 49

Getting Started Manual

922136-00 Rev A

41

For each waveform, you can create multiple labels and turn them all on or

all off. Also, you can position them on the waveform by dragging or by

specifying an exact horizontal position.

Touch the waveform you want to annotate right on the display grid, and

then touch Set label... on the pop-up menu. A dialog box opens in which to

create the label. The first time creating a waveform label, Label1 is

provided as default text when the Add label button is touched.

From this pop-up you can edit existing annotations, change the label

placement on the waveform, add labels, remove labels, and toggle the

visibility. The following bullets show you how.

B

Page 50

WaveRunner 6 Zi and 12-Bit HRO

42

922136-00 Rev A

If you are modifying an existing label, under Labels touch the label

you want to change.

Note: If the dialog for the trace you want to annotate is currently

displayed, you can touch the label button at the bottom to display the

Trace Annotation setup dialog.

You may place a label anywhere you want on the waveform. Labels are

numbered sequentially according to the order in which they are added,

and not according to their placement on the waveform.

If you want to change the label's text, touch inside the Label Text

field. A pop-up keyboard appears for you to enter your text. Touch

O.K. on the keyboard when you are done. The edited text

automatically appears in the label on the waveform.

Precisely place the label by touching inside the Horizontal Pos. field

and provide a horizontal value, using the pop-up numeric keypad.

Add another label by touching the Add label button. Delete a label

by selecting the label from the list, and then touching the Remove

label button.

Make labels visible by touching the View labels checkbox.

Dialog Area

The lower portion of your oscilloscope screen is where information is

shown, selections are made, and data is input. These screens are organized

into tabular displays, subtabs, or pop-up dialogs. The dialog area is

controlled by Touch Screen Controls and Front Panel Controls.

Touch Screen Controls

Various touch screen user interface controls are provided for easily

entering data. Their functionality is described in this topic and you'll see

them referenced throughout the documentation.

Page 51

Getting Started Manual

922136-00 Rev A

43

POP-UP SELECTOR CONTROLS

When Pop-Up selector controls are touched, sometimes a very small box is

shown right inside the control - as in the following control for Coupling on

the C1 dialog.

Pop-Up Selector Control for smaller values.

Other times, a larger box is shown after touching a control. This larger PopUp has categorical buttons along the left column along with labels (and

sometimes descriptions) for the selectable entry values.

B

Pop-Up Selector Control for values with varied types.

Page 52

WaveRunner 6 Zi and 12-Bit HRO

44

922136-00 Rev A

TEXT ENTRY CONTROLS

Most controls can be touched once and you can then provide a value using

an attached (or double-touch/click to use the Virtual, on-screen) keyboard.

Text entry field for LabNotebook using the Virtual Keyboard.

Page 53

Getting Started Manual

922136-00 Rev A

45

FOLDER/FILE BROWSING CONTROLS

These controls allow for navigation to or from folders (on the hard drive or

memory device) for retrieving or storing items such as waveforms,

LabNotebook entries, to name a few.

Note: The instrument's hard disk is partitioned into drive C: and drive D:. Drive C:

contains the Windows operating system and the instrument application software.

Drive D: is intended for data files.

B

Folder/File Browsing recall waveform controls.

Page 54

WaveRunner 6 Zi and 12-Bit HRO

46

922136-00 Rev A

FLYOUT MENU CONTROLS

Flyout Menus provides a variety of solutions for a particular main area of

functionality. It does this by providing a set of buttons subdividing the

control into more specific functions on the right-side of the display.

An example of Flyout Menu Controls is seen in the Setup front panel

button.

Setup Flyout Menu control.

Page 55

Getting Started Manual

922136-00 Rev A

47

PRECISION DATA ENTRY CONTROLS

Certain fields requiring precise value entry assist you by having precision

entry means. When these controls are selected, you can provide values as

follows:

Keyboard

Touch inside a text entry control and you can manually type the value in

using an attached (or double-touch/click to use the Virtual, on-screen)

keyboard.

Slider Bar

Some models provide what is known as a Slider Bar along the bottom of

the screen when a keyboard is attached to the instrument. The Slider Bar

allows you to select your entered value by moving a horizontal slider (left

to right provides low to high amounts).

Pop-Up Keypad

Some models provide a pop-up Keypad when you touch twice in the same

control. A keypad button is also provided on the slider bar (on models that

have the slider bar) which shows the pop-up keypad when touched.

B

Text entry field for LabNotebook using the Virtual Keyboard.

Page 56

WaveRunner 6 Zi and 12-Bit HRO

48

922136-00 Rev A

For many controls, once the Pop-Up Keypad is shown the Front Panel

Controls (on page 18) can be used to adjust the value in the pop-up. The

Pop-Up contains Up and Down arrow buttons, Set to Max, Default, and

Min buttons, and the Keypad itself for providing your value.

The slider bar also has a handy default value button for quickly entering the

default for the control.

Default and Keypad Buttons on the Slider Bar are only shown on 7, 8, and 9

Zi models (with a keyboard attached).

UNIQUE WaveRunner 6 Zi and 12-Bit HRO and 12-Bit HRO FEATURE: The 6

Zi and 12-Bit HRO provides touch-screen interface controls in a different manner.

See The WavePilot Control Area and The SuperKnob Overview in the online

help.

Shortcut Toolbar

Several dialogs contain common functions accessible from a row of buttons

that can save you having to select the respective function from the menu

bar or the Signal Display Grid Pop-Up Menu.

For example, at the bottom of the Channel Setup dialog, these buttons

(sometimes labeled as Actions) perform the following functions:

Measure - Opens the Measure menu. You can then select a

parameter from this menu without leaving the Channel Setup dialog.

The parameter automatically appears below the grid.

Zoom - Creates a zoom trace of the channel trace whose dialog is

currently displayed.

Math - Opens the Math menu. You can then select a math function

from this menu without leaving the Channel Setup dialog. A math

trace of the channel whose dialog is currently open is automatically

displayed.

Page 57

Getting Started Manual

922136-00 Rev A

49

Decode - Opens the main Serial Decode dialog where protocol

option measurements can be applied to signals.

Store - Loads the channel trace into the next available memory

location (M1 to M4).

Find Scale - Automatically performs a vertical scaling that fits the

waveform into the grid.

Next Grid - Automatically moves the channel trace whose dialog is

currently open onto the next grid. If you have only one grid

displayed, a new grid will be created automatically, and the trace

moved.

Note: This button is not available on all oscilloscope models.

Label - Enables you to attach identifying labels to your waveforms.

The labels are preserved when the waveform is saved as a

LabNotebook entry and when saved to file.

Probe Cal - Cable Deskew - Opens the Probes Cal. dialog where

various Gain, Offset, Skew, Source, and Advanced controls are

available for probe signal calibration.

Another example is seen in the buttons appearing at the bottom of the

Measure Px dialogs. The button may be selected in order to display the

functions named on the buttons (sometimes labeled as Actions):

Using these buttons allow you to remain in the Measure dialog while

setting up a Math trace on a parameter measurement.

Message Bar

At the bottom of the oscilloscope display is a narrow message bar. The

current date and time are displayed at the far right. Status, error, or other

messages are also shown in this area.

B

Actions for Trace buttons on the Cx dialog.

Page 58

WaveRunner 6 Zi and 12-Bit HRO

50

922136-00 Rev A

Turning on Channels and Traces

PLEASE NOTE THE FOLLOWING:

If you want to display each trace on its own grid automatically,

enable Autogrid by touching Display → Autogrid from the menu bar.

You can turn channels on and off using the software, for more

information see Vertical Overview (on page 61)

On the front panel, press a channel select button to display the trace

descriptor label for that input channel and turn on the channel.

Turn on a math function trace by touching Math → Math Setup...

from the menu bar. Touch the corresponding On checkbox to

activate the desired trace.

You can also quickly create traces (and turn on the trace label) for

math functions and memory traces, without leaving the Vertical

Adjust dialog, by touching the icons at the bottom of the Vertical

Adjust dialog.

Whenever you turn on a channel, math, or memory trace using either the

menu bar or trace descriptor label, the dialog at the bottom of the screen

automatically switches to the vertical setup or math setup dialog for that

selection.

You can configure your traces from here, including math setups.

The Trace Dialog is shown on the lower (dialog) portion of the screen. The

tab is labeled with the corresponding channel number as follows:

Page 59

Getting Started Manual

922136-00 Rev A

51

Timebase

Overview

You can access Timebase settings using the front panel Horizontal controls,

the Timebase → Horizontal Setup... on the menu bar, or by touching the

Timebase trace descriptor label. The main Timebase dialog is then shown

and contains sections for Sampling Mode, Timebase Mode, and Real Time

Memory.

A section specifically used for combining channels is located on the far

right of the main Timebase dialog. This section varies based on your

oscilloscope model.

Timebase Setup and Control

1. With the Timebase dialog showing, touch inside the Time/Division

data entry control and provide a value using your preferred input

control method. Additional information on using the touch screen

controls can be found in the Dialog Area (on page 42).

2. Touch inside the Delay data entry control and provide a value.

B

Page 60

WaveRunner 6 Zi and 12-Bit HRO

52

922136-00 Rev A

Sampling Modes

Overview

Depending on your timebase, you can choose Single-shot Sampling Mode

(below), also known as Real Time mode, Sequence Sampling Mode (on page

53), or RIS Sampling Mode (on page 59) mode sampling.

Newer instruments offer Roll Mode (on page 60)

Some instruments also offer Roll Mode (on page 60).

Selecting a Sampling Mode

1. Touch Timebase → Horizontal Setup... from the menu bar.

2. In the Timebase dialog, touch a Sample Mode button.

3. If you chose Sequence Mode, touch the Sequence tab. The

Sequence dialog is shown. Use the following controls to provide

details for controls such as Number of Segments, Enable Timeout,

Timeout (value), Display Mode, and Show Sequence Trigger Times.

Single-shot Sampling Mode

Basic Capture Technique

A single-shot acquisition is a series of digitized voltage values sampled on

the input signal at a uniform rate. It is also a series of measured data values

associated with a single trigger event. The acquisition is typically stopped a

defined number of samples after this event occurs: a number determined

by the selected trigger delay and measured by the timebase. The

waveform's horizontal position (and waveform display in general) is

determined using the trigger event as the definition of time zero.

You can choose either a pre- or post-trigger delay. Pre-trigger delay is the

time from the left-hand edge of the display grid forward to the trigger

event, while post-trigger delay is the time back to the event. You can

sample the waveform in a range starting well before the trigger event up to

the moment the event occurs. This is 100% pre-trigger, and it allows you to

Page 61

Getting Started Manual

922136-00 Rev A

53

see the waveform leading up to the point at which the trigger condition

was met and the trigger occurred. (The instrument offers up to the

maximum record length of points of pre-trigger information.) Post-trigger

delay, on the other hand, allows you to sample the waveform starting at

the equivalent of 10,000 divisions after the event occurred.

On fast timebase settings, the maximum single-shot sampling rate is used.

But for slower timebases, the sampling rate is decreased and the number

of data samples maintained.

The relationship between sample rate, memory, and time can be simply

defined as:

Capture Interval = 1/Sample Rate X Memory

and

Capture Interval/10 = Time Per Division

Sequence Sampling Mode – Working with

Segments

Using Sequence Mode, thousands of trigger events can be stored as

segments into the oscilloscope's memory (the exact number depends on

oscilloscope model and memory options). This is ideal when capturing

many fast pulses in quick succession or when capturing few events

separated by long time periods. The instrument can capture complicated

sequences of events over large time intervals in fine detail, while ignoring

the uninteresting periods between the events. You can also make time

measurements between events on selected segments using the full

precision of the acquisition timebase.

Sequence mode offers a number of unique capabilities:

You can acquire up to four channels simultaneously.

You can minimize dead time between trigger events for consecutive

segments.

You can view time stamps for acquisitions.