Page 1

Teledyne Analytical Instruments

OPERATING INSTRUCTIONS FOR

Model 6750

Total Organic Carbon Analyzer

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

P/N M

ECO:

Page 2

Model 6750

Teledyne Analytical Instruments ii

Copyright © 2005 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/ Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/ Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Page 3

Total Organic Carbon Analyzer

Teledyne Analytical Instruments iii

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Page 4

Model 6750

Teledyne Analytical Instruments iv

Safety Messages

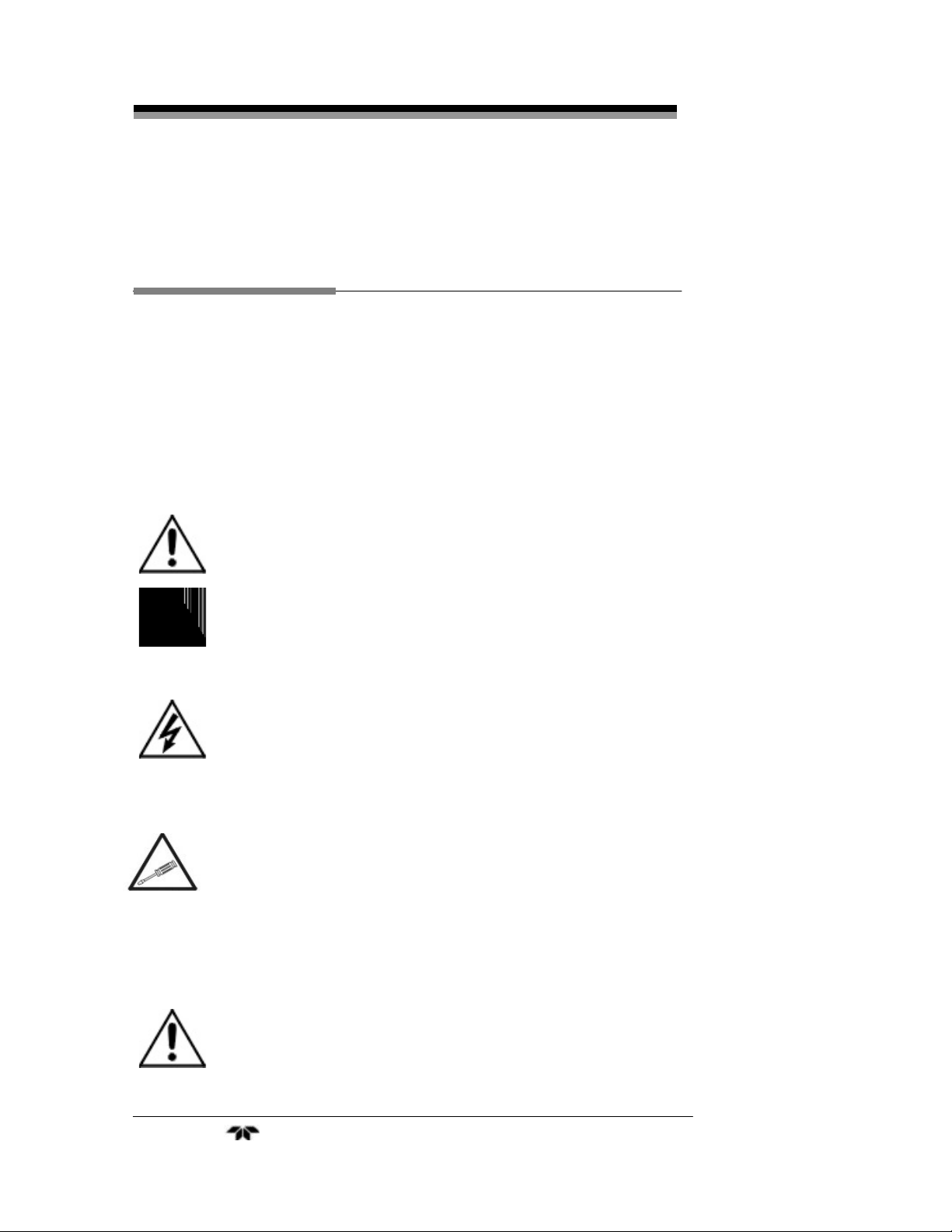

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These cautions

warn of specific procedures which if not followed could cause

bodily Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

No

Symbol

Page 5

Total Organic Carbon Analyzer

Teledyne Analytical Instruments v

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

TI/AI at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Page 6

Model 6750

Teledyne Analytical Instruments vi

Table of Contents

List of Figures.............................................................................. ix

List of Tables ............................................................................... xi

Introduction .................................................................................. 1

1.1 Main Features of the Analyzer 1

1.2 Options 2

1.3 Typical Applications 2

1.4 Intended Use of the Analyzer 2

1.5 Operator Interface 3

Theory of Operation ..................................................................... 5

2.1 Overview 5

2.2 Background 5

2.3 The UV/Heated Persulfate Method of Analysis 9

2.4 Subsystems Principles of Operation 11

2.4.1 Sample Handling 11

2.4.1.1 Liquid Phase Sample Handling 11

2.4.2.2 Gas Phase Sample Handling 13

2.4.2 Inorganic Carbon Removal/Analysis 14

2.4.3 Oxidation 15

2.4.4 NDIR CO2 Gas Detection 17

2.4.5 Electronic Signal Processing, Display and Control 18

2.4.5.1 Benchmark/Auto-Validation 19

2.4.5.2 Auto-Calibration 19

2.4.5.3 Auto-Cleaning 19

Installation .................................................................................. 21

3.1 Unpacking the Analyzer 21

3.2 Mounting the Analyzer 21

Page 7

Total Organic Carbon Analyzer

Teledyne Analytical Instruments vii

3.3 Electrical Connections 23

3.3.1 Power Connection 23

3.3.2 Analog Outputs 24

3.3.3 Alarm Connections 25

3.3.4 RS-232 Serial Connection 25

3.4 Gas/liquid Connections 25

3.4.1 Liquid Connections 25

3.4.2 Gas Connections 26

3.5 Checking the System 27

Setup and Operation...................................................................29

4.1 Analyzer Startup 29

4.2 Menus 31

4.2.1 Run Mode 31

4.2.2 Parameter Menu 32

4.2.3 Alarm Settings 33

4.2.4 Stream Sequencer 34

4.2.5 D/DBPR 35

4.3 Detailed Calibration Procedures 36

4.4 Operation 40

4.5 Shutdown 41

4.6 Historical Data 41

Maintenance ................................................................................43

5.1 Compupter-aided Testing 43

5.2 Troubleshooting 44

5.3 Module Service 45

5.3.1 NDIR (Gas Calibration) 45

5.3.2 NDIR Service 47

5.3.3 Master Interface Board (P/N ST13042-1). 53

5.3.4 D. C. Power Supply 54

5.3.5 CE Computer (P/N 13039) 55

5.3.6 UV Lamp (P/N ST20009) 56

5.3.7 UV Reactor Assembly (P/N ST20003-1) 57

Page 8

Model 6750

Teledyne Analytical Instruments viii

5.3.8 UV Power Supply 58

5.3.9 Mass Flow Controller (P/N ST18001A) 59

5.3.10 Metering Valve (P/N ST16050) 60

5.3.11 Sparger (P/N ST20025) 61

5.3.12 Pumps 63

5.3.12.1 Pump Motor Replacement 63

5.3.12.2 Pump Head Tubing Replacement 65

5.3.13 4-20 mA Adjustment Procedure 67

5.3.13.1 Setting 100 mV Control Voltage 68

5.3.13.2 Setting of 4-20 mA output 68

Appendix..................................................................................... 69

A.1Specifications 69

A.2 Parts Listing 71

A.3 Options 76

A.3.1 Option 200008 76

A.3.2 Option 200009 76

A.3.3 Option 200010 76

A.3.4 Option 200016 77

A.3.5 Option 200017 77

A.3.6 Option 200009 77

A.3.7 Option 400008 77

A.3.8 Option 200026 77

A.4 AS-BUILT Drawings 79

Index............................................................................................ 81

Page 9

Total Organic Carbon Analyzer

Teledyne Analytical Instruments ix

List of Figures

Figure 1-1: The Model 6750 TOC Analyzer (Front door removed) . 3

Figure 2-1: NPOC or TOC – Direct Method.................................... 6

Figure 2-2: TOC – True Method ..................................................... 6

Figure: 2-3: TOC Measurement Basics .......................................... 8

Figure 2-4: UV/Persulfate Method .................................................. 8

Figure 2-5: Comparison of TOC Measurement Technologies........10

Figure 2-6: Sample Handling for TOC -Direct................................12

Figure 2-7: Sample Handling TOC-True........................................13

Figure 2-8: Relationship Between TIC and pH ..............................15

Figure 2-9: Oxidation Reactions....................................................16

Figure 2-10: Model 6750 NDIR Unit ..............................................17

Figure 3-1: Analyzer Dimensions ..................................................22

Figure 3-2: Required Door Clearance ...........................................22

Figure 3-3: Internal Components of the Model 6750 Analyzer.......23

Figure 3-4: Electrical Connections to the Model 6750 ...................24

Figure 3-5: Gas and Liquid Connections to the Analyzer...............26

Figure4-1: Drain Connections ......................................................30

Figure 4-2: Gas Liquid Separator D. I. Filling ................................31

Figure 4-3: The RUN Screen.........................................................40

Figure 5-1: Disconnecting Tubing from Reactor ............................46

Figure 5-2: IR Calibration Adapter P/N ST20026...........................46

Figure 5-3: Installing Calibration Adapter ......................................47

Figure 5-4: Removing the NDIR Unit P/N ST 36000......................48

Figure 5-5: Removing the Master Interface Board.........................53

Page 10

Model 6750

Teledyne Analytical Instruments x

Figure 5-6: DC Power Supply Module........................................... 54

Figure 5-7: Replacing CE Computer............................................. 55

Figure 5-8: UV Lamp Replacement .............................................. 56

Figure 5-9: Removing the UV Reactor Assembly.......................... 57

Figure 5-10: Removing the UV Power Supply............................... 59

Figure 5-11: Mass Flow Controller................................................ 60

Figure 5-12: Metering Valve ......................................................... 61

Figure 5-13: Sparger .................................................................... 62

Figure 5-14: Removing the Pump ................................................ 65

Figure 5-15: Pump Head Tubing Replacement............................. 67

Page 11

Total Organic Carbon Analyzer

Teledyne Analytical Instruments xi

List of Tables

Table 4-1: Preparation of Standards (TOC/TIC) ............................37

Table 5-1: Troubleshooting ...........................................................44

Page 12

Model 6750

Teledyne Analytical Instruments xii

DANGER

COMBUSTIBLE GAS USAGE

WARNING

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne Instruments/ Analytical Instruments, referred as

TI/AI, no responsibility by TI/AI, its affiliates, and agents for

damage or injury from misuse or neglect of this equipment is

implied or assumed.

Page 13

Total Organic Carbon Analyzer Introduction

Teledyne Analytical Instruments 1

Introduction

Teledyne Model 6750 Total Organic Carbon Analyzer provides

accurate and reliable on-line TOC analysis with Windows™ CE

Operation, using the UV/Heated Persulfate Oxidation Method.

This manual includes all necessary information to help you install,

operate and service your Analyzer.

The Model 6750 TOC Analyzers have been designed for easy

operation and maintenance. Particular attention has been devoted to the

design, whereby any module can be replaced by the operator within 15

minutes. Components such as the NDIR unit have been specifically

designed with no moving parts and use a corrosion resistant design to

further reduce maintenance tasks.

Operating the analyzer is easy. It uses a standard, industrial

Windows CE computer programmed for complete automatic control

(there are no operator manual adjustments). Operators are advised to

study pertinent chapters in this manual to fully utilize the capabilities of

the analyzer and avoid problems that could be associated with any

instrument. The Model 6750 TOC is shown in Figure 1-1.

1.1 Main Features of the Analyzer

The Model 6750 TOC Analyzer is sophisticated, yet simple to use.

The main features of the analyzer include:

• TC (Total Carbon) analysis

• NPOC (Non-purgeable organic carbon) analysis

• TOC-True Analysis (including volatile organics)

• Microsoft Windows Touch Screen Computer with Paperless

Chart Recorder

• Two alarm levels

• One Master Fault Alarm

• 3 analog 4-20 mA outputs

Page 14

Introduction Model 6750

Teledyne Analytical Instruments 2

• RS-232C and RS-485 outputs

• Separate electronics and liquid compartments

1.2 Options

The following options are available for the Model 6750 TOC

Analyzer and are described in Appendix A.3:

• Correlated BOD/COD

• Dual NDIR Analyzers

• Benchmark/Auto Validation

• Auto-Cal/Auto-Clean

• Automatic Multi-Range

• Multi-Stream Analysis

• DBPR Drinking Water

1.3 Typical Applications

With excellent TOC accuracy from low parts-per-million to high

concentration levels of salt-free samples, the Model 6750 is used in a

variety of applications including:

Boiler Feedwater

Standard Method 5310 C/D Cooling Water

EPA 415.1 Drinking Water

EPA 9060 Wastewater (limited)

ASTM D 4839-88 River Water

ASTM D 4779-88 Oil in Water

1.4 Intended Use of the Analyzer

The Analyzer is exclusively designed for monitoring of Total

Organic Carbon (TOC) in water. This intended use involves carefully

following the instructions provided in this manual and observing all

indicated warnings, hints and instructions.

Page 15

Total Organic Carbon Analyzer Introduction

Teledyne Analytical Instruments 3

All other types of usage beyond the intended use stated above, are

considered as misuse of the analyzer. The supplier assumes no

responsibility for damage incurred as the result of misuse of the product.

1.5 Operator Interface

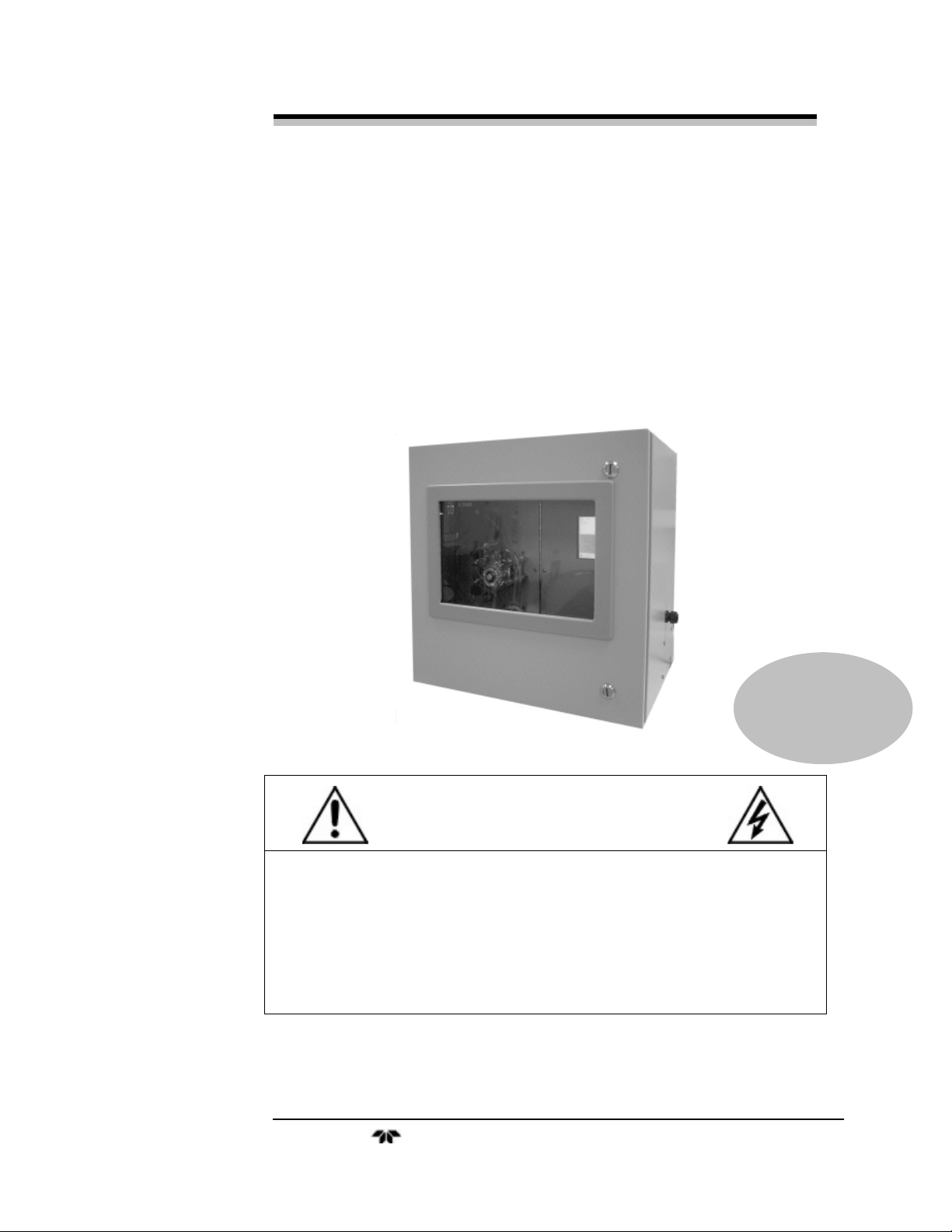

The Model 6750 Analyzer is housed in a rugged metal case and

may be wall or rack mounted for operator convenience.

The enclosure is equipped with a viewing window on the front

panel and all operator serviceable components may be viewed through

the cabinet window, including the display.

Figure 1-1: The Model 6750 TOC Analyzer (Front door removed)

All operations are automatic and are performed using the Windows

Touch Screen Computer.

Page 16

Introduction Model 6750

Teledyne Analytical Instruments 4

Page 17

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 5

Theory of Operation

2.1 Overview

The Model 6750 Analyzer uses the UV/Heated Persulfate method

of analysis and is well-suited for many applications involving accurate

TOC analysis. The basic analyzer is configured for maximum utility

using an advanced Microsoft™ Windows-based CE computer with touch

screen. The analyzer is suitable for both general purpose and/or

hazardous area classifications, if properly configured with required

safety equipment.

2.2 Background

TOC analysis is the primary screening tool and control parameter

for all water based applications but there are some discrepancies or

misunderstanding in just what TOC is comprised of.

Many manufacturers claim TOC analysis capability without

disclosing the limitations of their methods. Some treat all “TOC

analyzers” as a commodity, with no distinguishing characteristics among

them. Analytical results reported by the user can therefore be

questionable, unless the TOC method is matched to the analytical

requirement.

The following discussion is intended to provide the user adequate

information in order to allow intelligent cost/performance trade-offs and

select the appropriate TOC method for each application. The Model 6750

TOC Analyzer performs the following analyses on the SAME sample:

• TC: Total Carbon

• NPOC: Non-Purgeable Organic Carbon

• TIC: Total Inorganic Carbon

• POC (VOC): Purgeable Organic Carbon or Volatile Organic

Carbon

• TOC-True : Total Organic Carbon

Page 18

Theory of Operation Model 6750

Teledyne Analytical Instruments 6

To perform correct TOC analysis, the analysis system must be

capable of measuring all constituents of organic carbon present in the

sample: Non-Purgeable Organic Carbon (NPOC) and Purgeable

Organic Carbon (POC). Correct TOC analysis must also exclude the

Total Inorganic Carbon (TIC) interference.

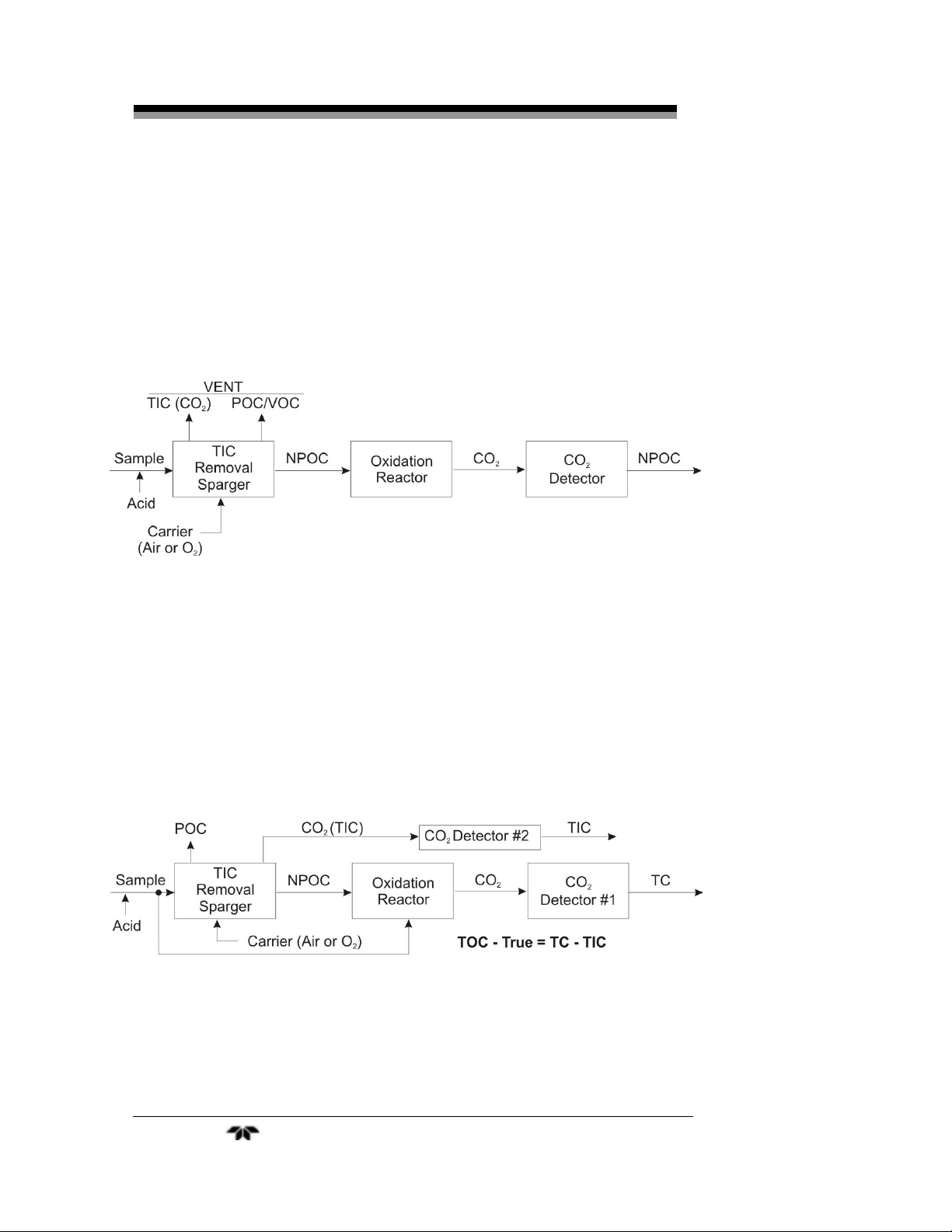

Figure 2-1 is a basic, commonly used technique to measure the

NPOC, sometimes referred to as “TOC-Direct”.

Figure 2-1: NPOC or TOC – Direct Method

In this method, acid is added to the sample, lowering its pH to

approximately 2.0, at which point the carbonates present in the sample are

converted to dissolved CO2. In the sparger, the carrier gas strips (sparges)

the CO2 converted from the TIC and vents it, along with any purgeable

(volatile) organics, leaving only NPOC in the sample. The resultant NPOC

is then oxidized to CO2 in the reactor and measured by the CO2 detector as

NPOC in the sample, often referred to and reported erroneously as “TOC”.

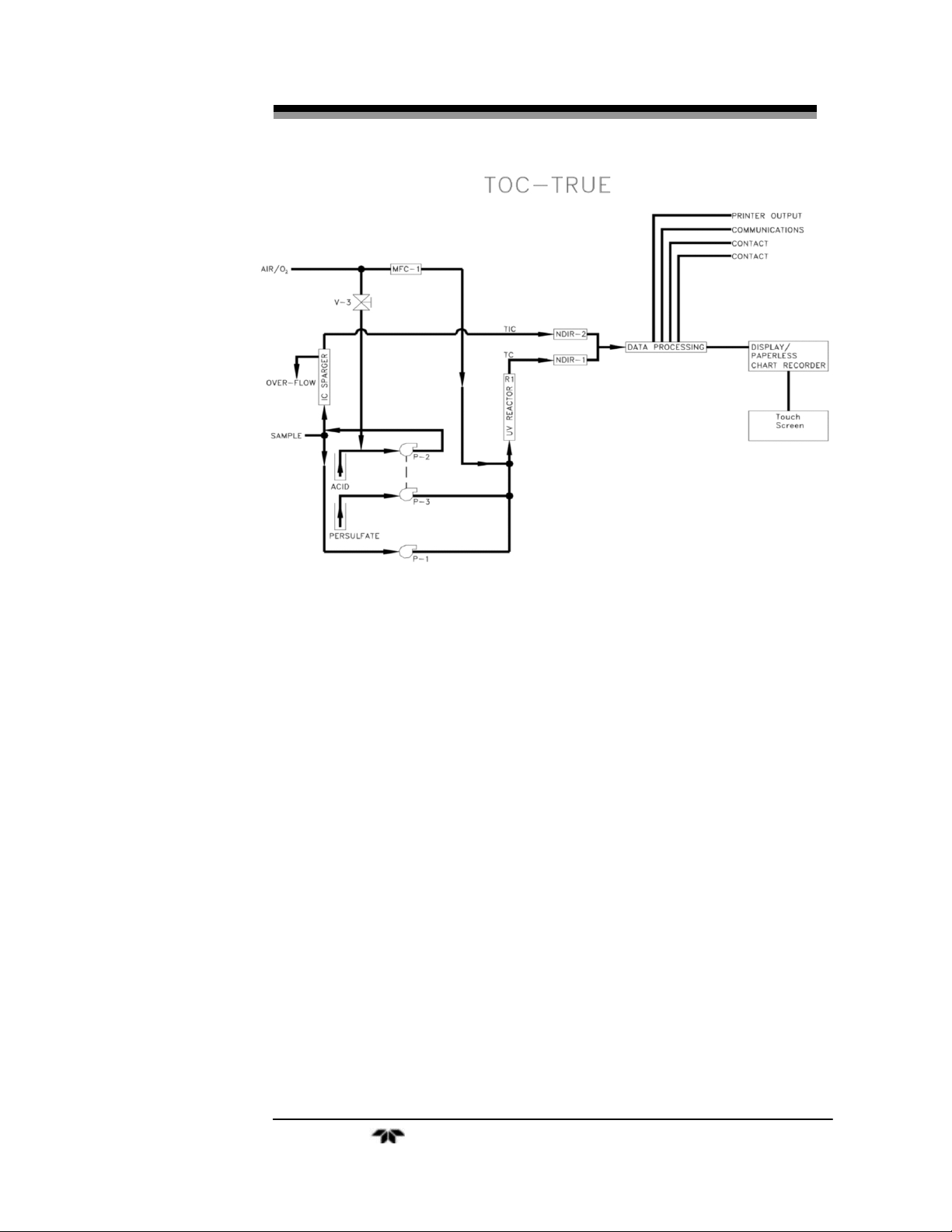

In Figure 2-2 a preferred method of performing a “TOC- True”

analysis is shown.

Figure 2-2: TOC – True Method

In this case, acid is added to the sample, lowering its pH to

approximately 2.0, at which point the carbonates present in the sample

are converted to dissolved CO2. In the sparger, the carrier gas strips

Page 19

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 7

(sparges) the CO2 converted from the TIC and it is measured by an

independent CO2 detector as “TIC”. POC is also stripped from the

sample in the sparger as HC, but the HC is undetected by the CO2

detector and does not interfere with the TIC measurement.

A portion of the same sample is also directed to the oxidation

reactor, where inorganic and all organic carbon is converted to CO2 and

detected by a second CO2 detector as “Total Carbon”.

A mathematical subtraction of the TIC from the TC measurement

yields a complete, Total Organic Carbon analysis performed as a “TOCTrue” method.

TOC - True = TC - TIC

The difference between the Model 6750’s TOC-True Method

and other simple (TC-TIC) subtraction methods is that most other

simple TC-TIC subtraction methods only deal with a TC measurement,

then a separate TIC measurement and a simple mathematical difference

to derive a “TOC” analysis.

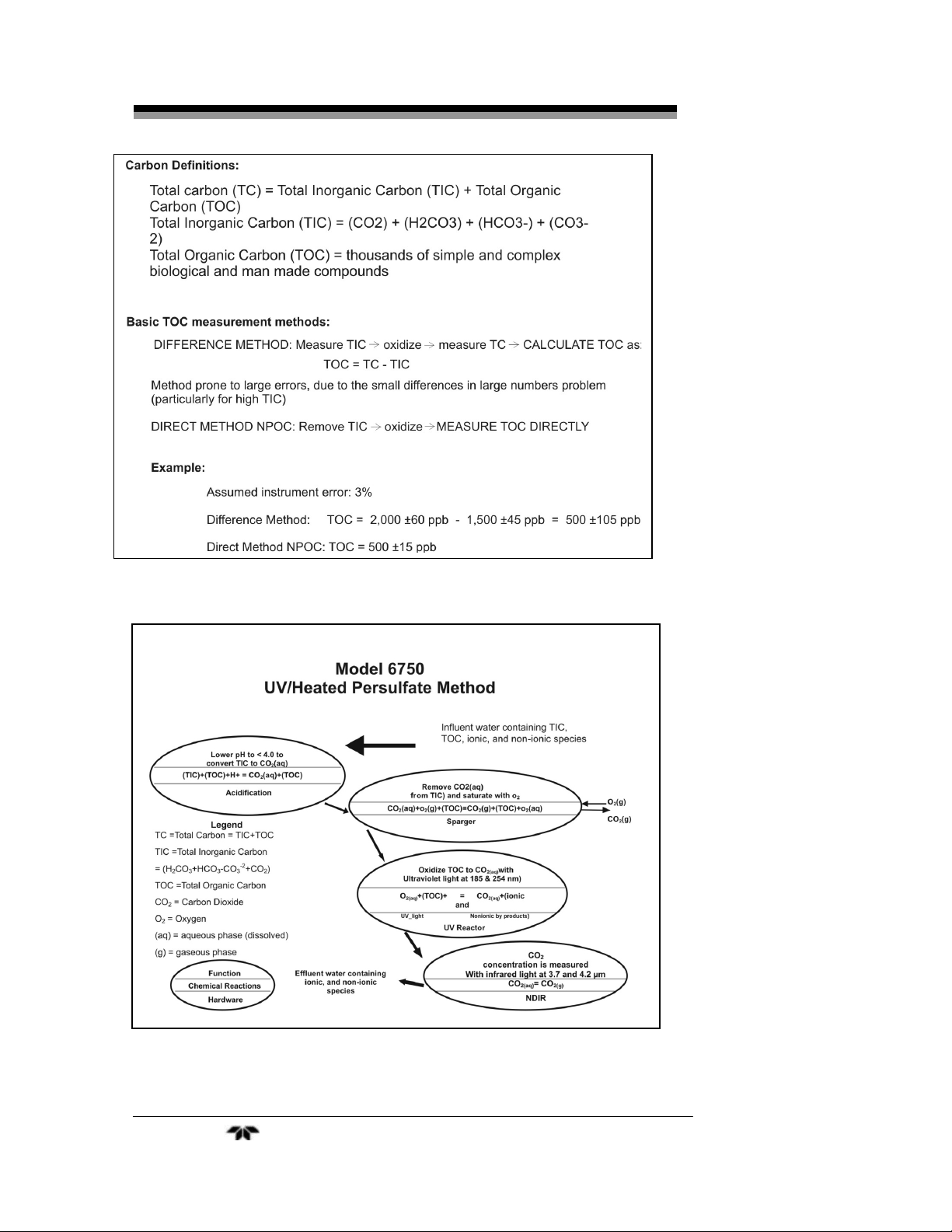

In the TOC-True method used by the Model 6750, the analyzer

actually performs both TC and TIC measurements simultaneously and

continuously on the same sample. The TOC Measurement Basics and

Methods are illustrated in Figures 2-3 and 2-4.

In conclusion:

1. NPOC is the preferred method if no POC/VOC is present

in the sample.

2. TOC-True is the preferred method if POC/VOC exists in

the sample and a TOC analysis is desired which includes

all organic carbon species, for a TOTAL Organic Carbon

measurement.

Page 20

Theory of Operation Model 6750

Teledyne Analytical Instruments 8

Figure: 2-3: TOC Measurement Basics

Figure 2-4: UV/Persulfate Method

Page 21

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 9

2.3 The UV/Heated Persulfate Method of Analysis

In the UV/Heated Persulfate Method as used by the Model 6750,

the sample is initially mixed with acid and directed to the sparger. For

TOC-Direct (NPOC) analysis, the CO2 converted from the inorganic

carbon is sparged out of solution by the carrier gas and vented to

atmosphere. Any volatile organic loss would occur at this point, exiting

the sparger as HC gas. For TOC-True, the TIC-related CO2 is measured

by the NDIR CO2 detector, which is blind to the HC. For NPOC

analysis, the liquid, carbonate-free sample is then directed to the UV

reactor, where the remaining organic carbon is oxidized to CO2 and

measured by the NDIR as a "TOC-Direct" (or NPOC) analysis.

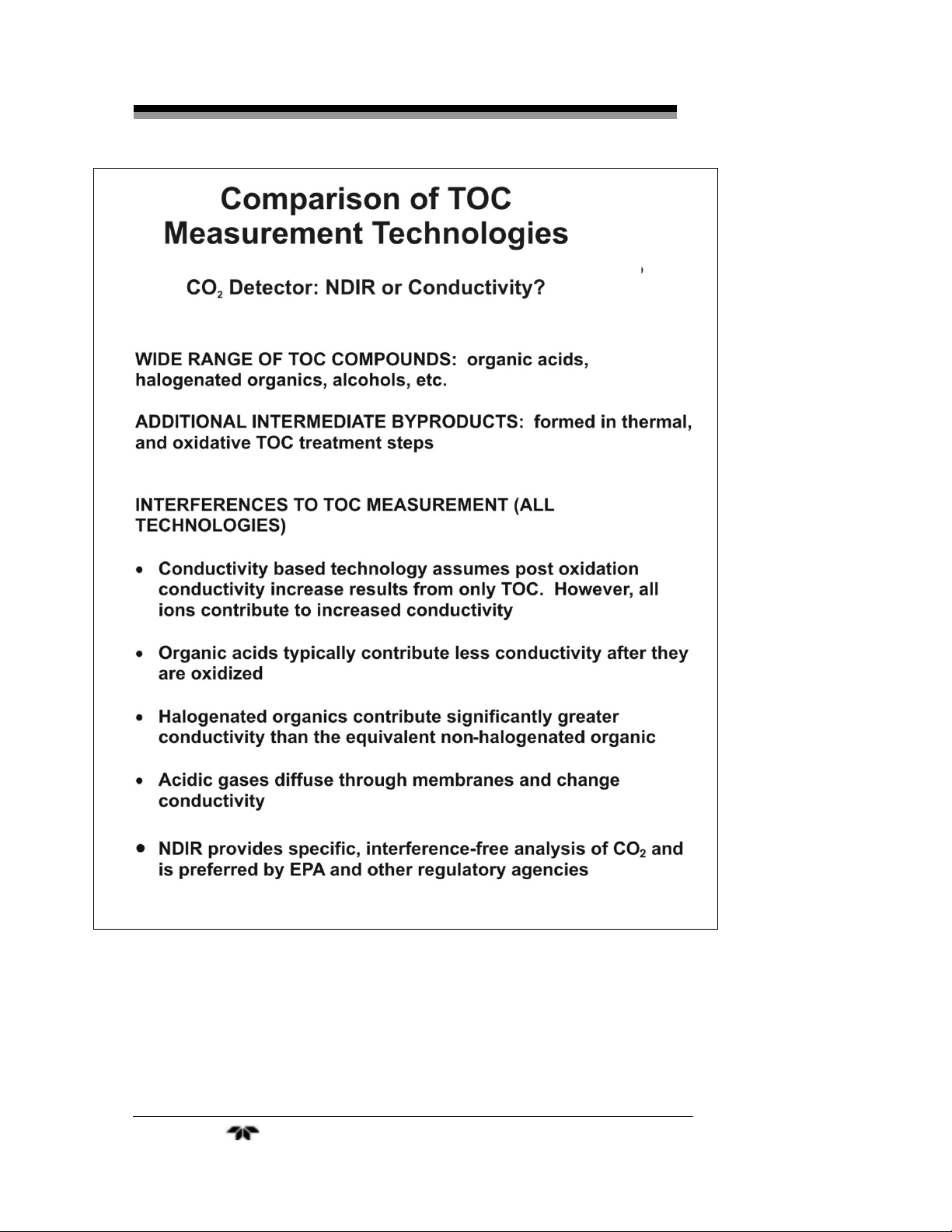

NDIR analysis of CO2 is specific and interference-free and is used

in all critical and regulatory applications. The TOC-Direct method is the

most accurate TOC analytical method, as determined by the EPA and

other governmental agencies. Teledyne also offers conductivity

detection but it is of limited use in these applications and is not proposed

as a primary detection method for TOC analysis, especially in critical

industrial applications where multiple or unknown analytes are present.

Figure 2-5 compares both CO2 detection methods.

For the TC analysis, the combined liquid/gas sample is sent directly

to the reactor, where all carbon (including the volatile HC) is converted

to CO2. The NDIR thus measures the TOTAL CO2 (including that

generated from the TIC, volatile HC and NPOC) and reports it as "TC."

The important thing is that all measurements are made on the same

sample, eliminating potential sample introduction errors and multiple

sampling inaccuracies.

Page 22

Theory of Operation Model 6750

Teledyne Analytical Instruments 10

Figure 2-5: Comparison of TOC Measurement Technologies

Page 23

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 11

2.4 Subsystems Principles of Operation

The Model 6750 TOC Analyzer is comprised of five subsystems:

1. Sample Handling

2. Inorganic Carbon Removal

– OR –

Inorganic Carbon Analysis/TOC-True Method

3. Oxidation

4. NDIR CO2 Gas Detection

5. Electronic Signal Processing, Display and Control

The sample system is designed to accept the liquid sample and any

required reagents, transporting them through the analyzer to the

appropriate components. For TOC (actually, NPOC) analysis, the

sample is pumped initially to the sparger, where it is mixed with acid to

lower the pH between 2.0 and 3.0. At that pH, all inorganic

carbon/carbonates are converted to dissolved CO2 gas, which is sparged

out of the liquid solution by the air/O2 carrier gas. At this point, any

volatile organic carbon is also sparged out and lost for inclusion in the

“TOC” analysis, unless a TOC-True analysis is performed, as described

below.

2.4.1 Sample Handling

The sample is processed through the analyzer in two phases: liquid

and gaseous

2.4.1.1 LIQUID PHASE SAMPLE HANDLING

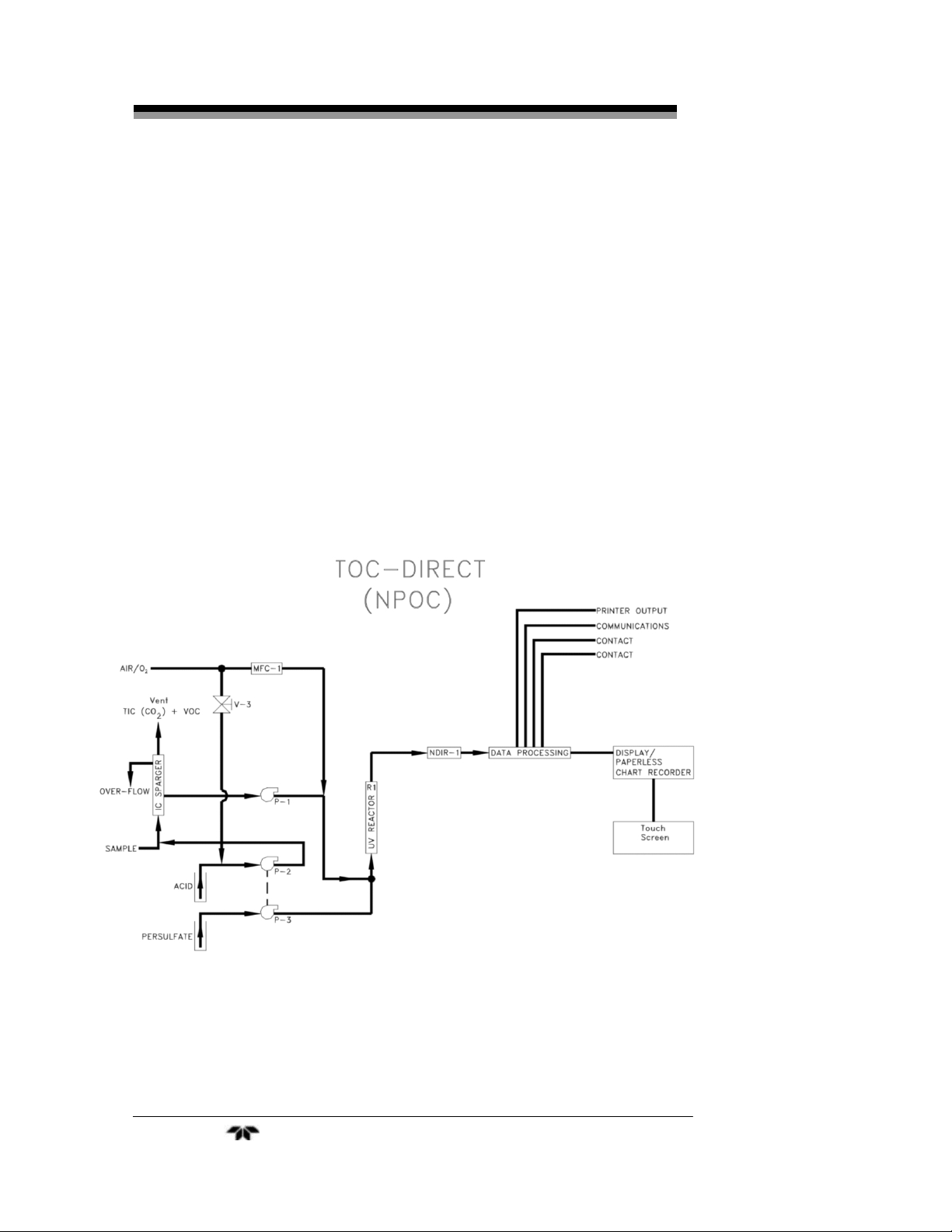

Referencing Figures 2-6 and 2-7, the sample is introduced to the

analyzer with a self-priming peristaltic pump (P-4). It is then initially

directed to the Inorganic Carbon (IC) Sparger, where it is mixed with

acid delivered by pump (P-2). The pH of the solution is lowered to

approximately 2, converting the inorganic carbon to CO2, which is

sparged out by the carrier gas and measured as Total Inorganic Carbon

(TIC) by an infrared analyzer (NDIR-2) in the “TOC-True” mode.

The “TOC-True” mode is the preferred method of use if volatile

hydrocarbons are present, which would otherwise be lost in the sparging

process. Thus, through subsequent analysis of Total Carbon (TC) and

Page 24

Theory of Operation Model 6750

Teledyne Analytical Instruments 12

actual measurement of the TIC, a more accurate TOC is achieved since

(TOC = TC - TIC).

“TOC-Direct” mode is preferred for accuracy when no or little

volatiles are present. In this mode, the carbonate-free sample is

extracted from the organic carbon reactor and measured directly as

TOC. Pump (P –1) continuously introduces the carbonate-free sample

to the reactor. No valves or complicated injection mechanisms are

required. The remaining organic carbon is oxidized to CO2 in the

reactor. The resultant gaseous stream is directed to a gas/liquid

separator and then to the NDIR. The CO2 gas is analyzed by the

infrared analyzer (NDIR) as a direct correlation of Total Organic Carbon

(TOC).

A computer controls all functions and outputs. A “Touch Screen”

provides operator interface and a paperless chart recorder utility.

Figure 2-6: Sample Handling for TOC -Direct

Page 25

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 13

Figure 2-7: Sample Handling TOC-True

2.4.2.2 GAS PHASE SAMPLE HANDLING

Referencing Figure 3-5 and “As Built” drawings in the Appendix, a

carrier gas of (99.8%) pure oxygen or CO2 and hydrocarbon-free air is

required. Erroneous TOC analysis will occur if the carrier gas has these

impurities, since both CO2 and Hydrocarbon gases will contribute a

higher TOC value to the analysis than is actually present in the sample.

An Oxygen Generator (P/N ST200025) is available from Teledyne

that separates oxygen from the ambient air. It is a pressure swing

absorption PSA device requiring only electricity only to operate. Also

available from Teledyne is an Instrument Air Purifier (P/N ST200019).

This device can supply the oxygen demands of the instrument using

facility instrument air.

Facility carrier gas is introduced to the analyzer, regulated at 15± 2

psi, and then controlled by an internal mass flow controller (MFC-1) to

precisely control the flow rate of the carrier.

Note: Precise carrier gas flow control is mandatory for accurate

Page 26

Theory of Operation Model 6750

Teledyne Analytical Instruments 14

TOC analysis in a continuous, on-line TOC analyzer.

The CO2 generated by the oxidation of carbon in the reactor is read

by the NDIR as a percentage concentration of the CO2 in the carrier gas.

CO2 (TOC)

CO2 (TOC) + Carrier

Any increase or decrease of the carrier flow rate will have a

corresponding inverse effect on TOC reported value, (eg. double the

carrier flow rate, reported TOC will approximate ½ of actual sample

TOC concentration).

The Model 6750 uses a computer-controlled mass flow controller

rather than a less accurate system consisting of pressure regulation with

a flow meter in a capillary system.

The inorganic carbon removal system (sparger) flow rate is

controlled by needle valves (V1 & V2) set at the factory. The operator

will note bubbles through the liquids in the sparger, which is stripping

the CO2 converted from the carbonates to eliminate the potential

interference from inorganic carbon in TOC analysis.

The carrier gas directs the CO2 and other products of oxidation

from the reactor to the Gas/Liquid Separator (GLS), where liquid waste

is directed to drain and gases containing CO2 and other gaseous products

of oxidation are directed to the CO2 specific NDIR. The CO2

concentration is directly related to sample TOC concentration and is

reported accordingly.

2.4.2 Inorganic Carbon Removal/Analysis

The choice of either TOC –Direct (NPOC) or TOC-True analysis

involves a method of either measuring the TIC (for a TOC-True

analysis) or not (for a Non-Purgeable TOC analysis only). The Model

6750 Analyzer can perform either method. The TOC-True method

measures the inorganic carbon and is able to detect volatile organic loss

in the sparger. The NPOC analysis ignores the volatile organics for a

less precise NPOC analysis if organic volatiles are present.

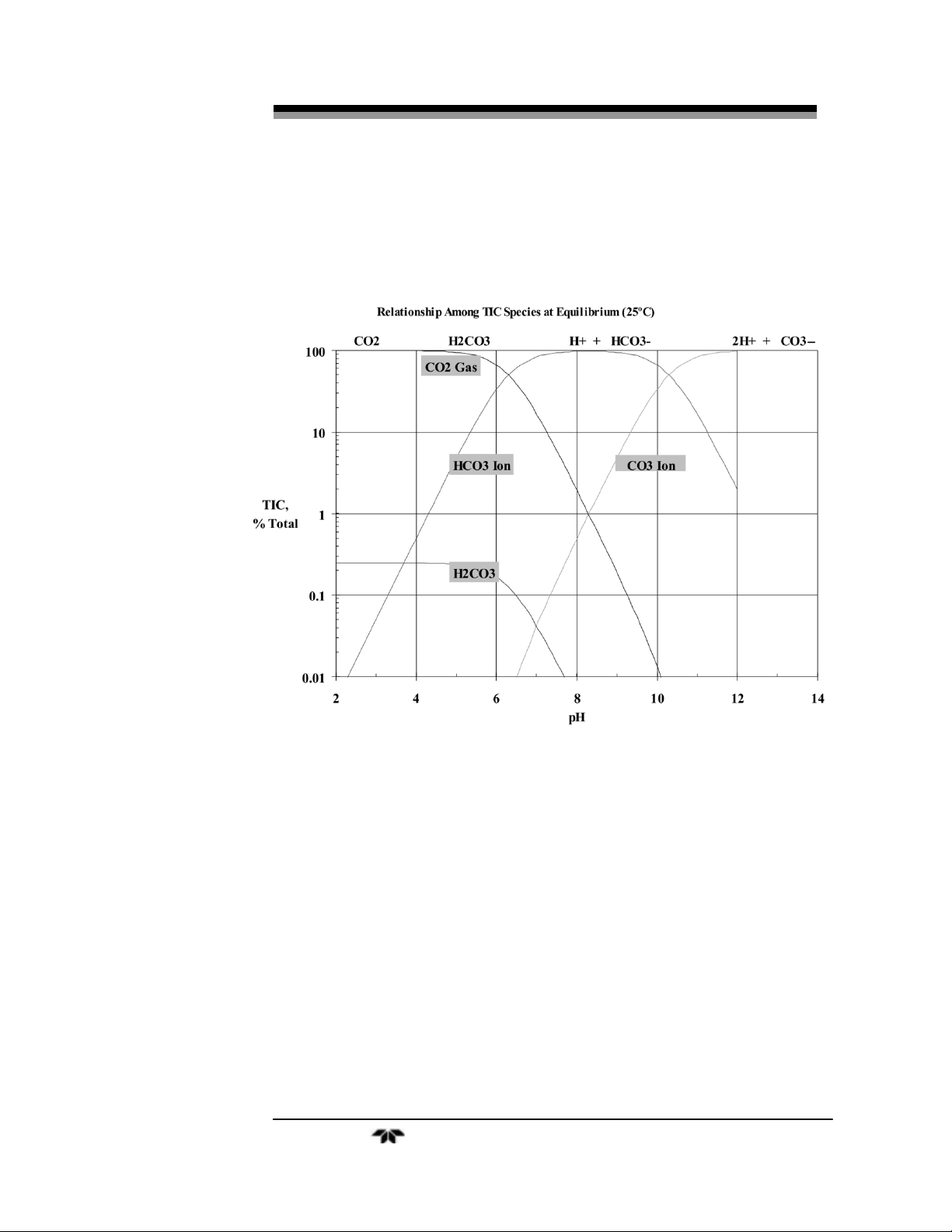

The sparger used in the Model 6750 is a gas/liquid counter-flow

stripper. Actual acid addition depends on the amount of sample

buffering and pH. Factory set-up is for a nominal sample pH of 7.0, to

Page 27

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 15

be reduced to approximately 2.0 to 3.0. If the sample pH is not properly

reduced as described in Figure 2-8, increase the normalcy of the acid

reagent until the water exiting the sparger drain is between 2.0 and 3.0.

Figure 2-8: Relationship Between TIC and pH

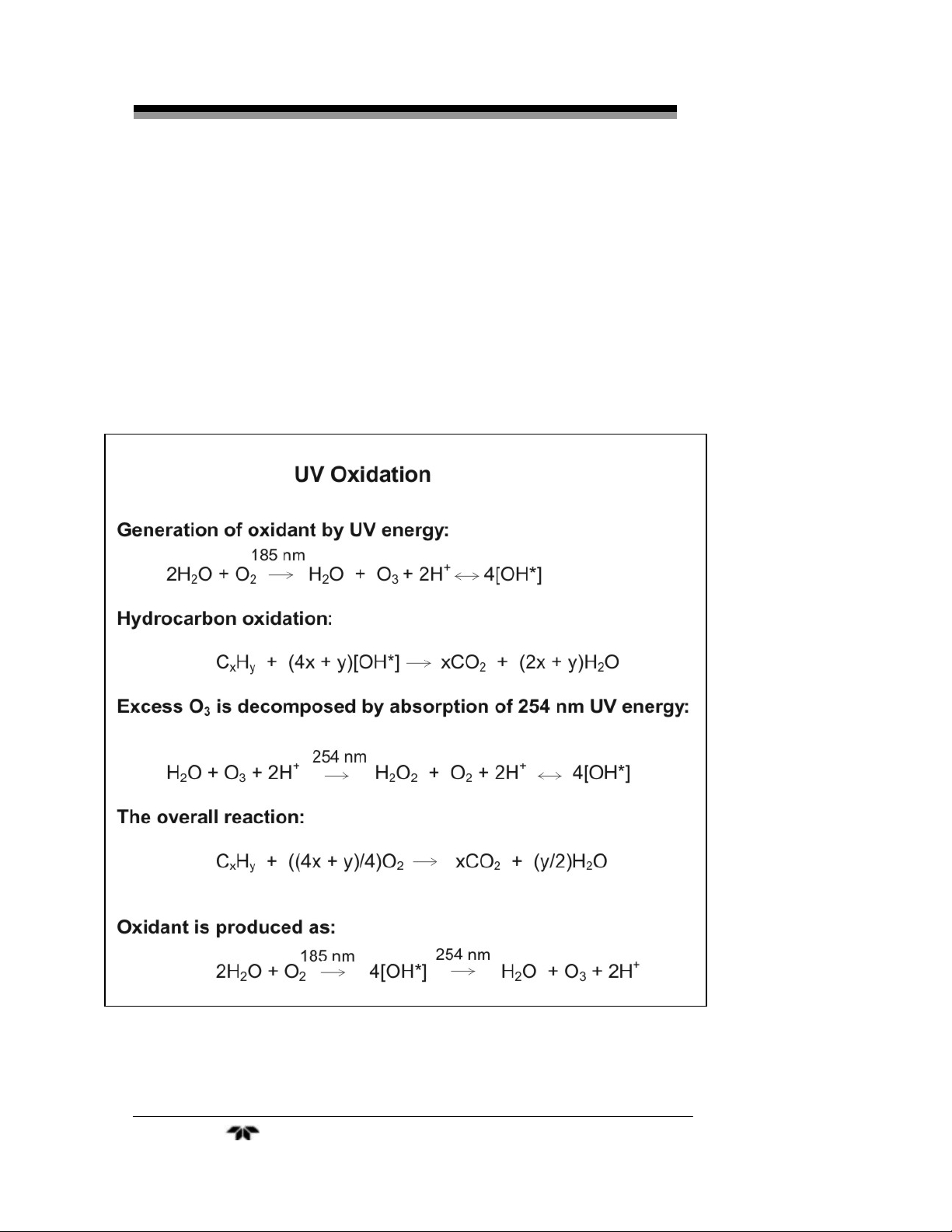

2.4.3 Oxidation

The UV reactor and persulfate reagent provide oxidation of the

carbon to CO2. The UV reactor consists of the following:

• Mounting enclosure with viewing window

• Borosilicate reactor body

• Heater/Temperature sensor

• UV Lamp

• Miscellaneous fittings and clamps

Page 28

Theory of Operation Model 6750

Teledyne Analytical Instruments 16

The construction of the patented UV reactor in the Model 6750

affords superior oxidation by precisely controlling the sample

temperature, adding a precise amount of ultra-pure persulfate reagent

(P/N ST40000) and precisely controlling the carrier gas flow rate.

Pump (P-1) continuously meters a precise amount of carbonate-free

sample from the sparger to the UV reactor. Pump (P-3) continuously

meters a precise amount of persulfate reagent to the reactor. Mass Flow

Controller (MFC-1) precisely controls the carrier flow rate. Refer to

Figures 2-6 and 2-7.

Figure 5-10 shows UV oxidation methodology.

Figure 2-9: Oxidation Reactions

Page 29

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 17

2.4.4 NDIR CO2 Gas Detection

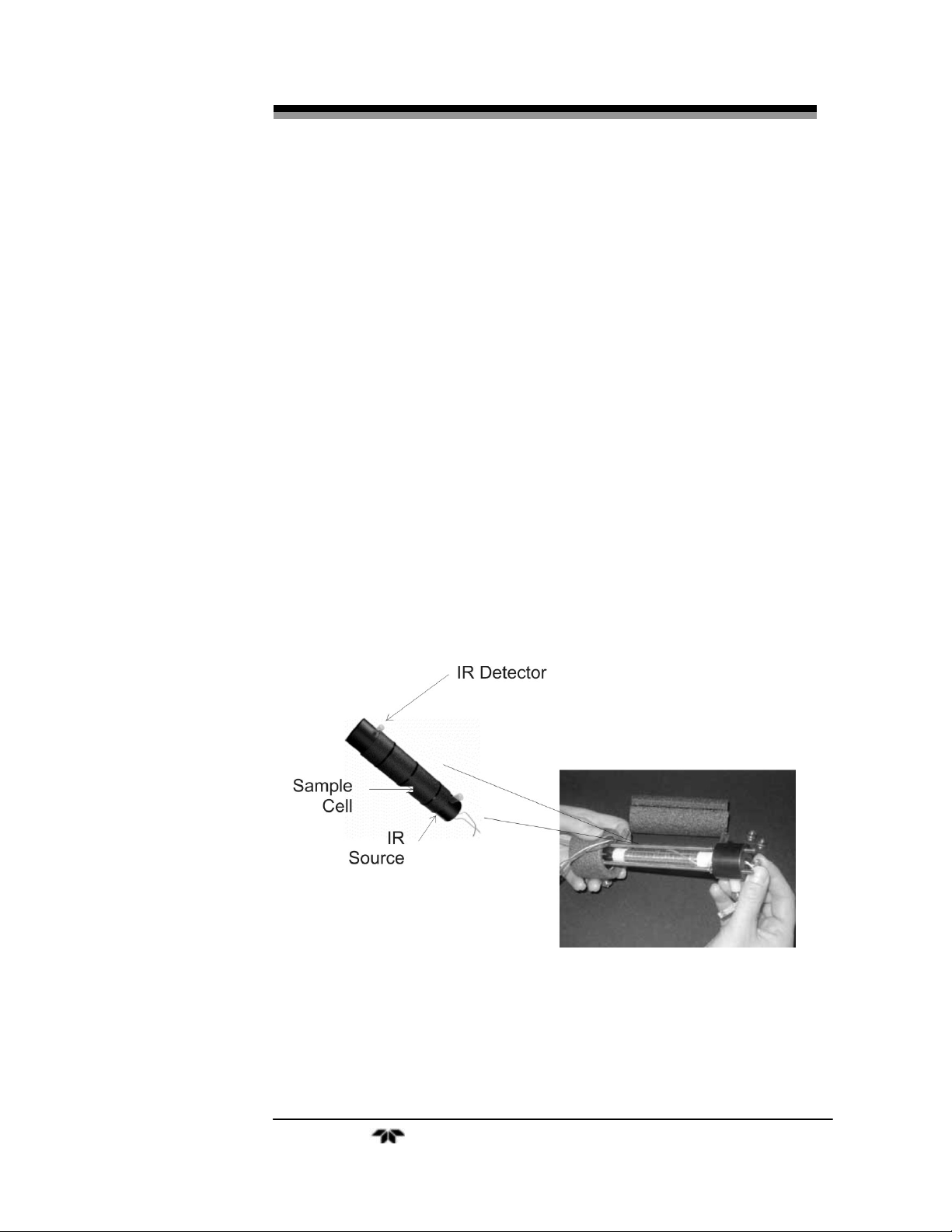

The key component for reliable TOC analysis is the precise and

interference-free detection of CO2. The Model 6750 NDIR unit requires

very little maintenance because of its ability to handle the corrosive

gases generated in TOC analysis. This is due in part to its non-reflective

borosilicate sample cell. It has no moving parts which further reduces

the maintenance load and it uses an internal self-calibrating technique.

The NDIR unit is shown in Figure 2-10. Some of the features of the

NDIR unit are as follows:

• Specific, interference-free CO2 detection

• Dual-wavelength rationing compensates for drift

• Computer-controlled for accuracy

• Sapphire protected optics

• Non-corrosive, non-reflective sample cell (borosilicate)

• No moving parts or tools required for easy maintenance and

service

• No critical realignment required

Figure 2-10: Model 6750 NDIR Unit

The NDIR CO2 detector uses a completely solid state, dual

wavelength ratioing technique with a single borosilicate sample cell that

Page 30

Theory of Operation Model 6750

Teledyne Analytical Instruments 18

requires no wall reflectivity and is completely resistant to corrosive

gases. The NDIR unit requires no optical chopper motor or mechanical

devices but utilizes a single flashing infrared source to optically “chop”

the infrared (IR) beam, which equally irradiates CO2/reference detectors.

Using a reference eliminates water vapor interference. The nonreflective, corrosive resistant sample cell removes the requirement for

chemically removing acid gases prior to detection.

Automatic gain control (AGC) is employed during the

reference/sample cycle to compensate for such factors as IR source

deterioration, dirty optical windows, etc. When the AGC level reaches a

predetermined threshold, an optics alarm is activated. Malfunctions of

major NDIR components are detected and indicated as an alarm,

providing “fail-safe” operation. Signal detection is completely

synchronous and because of the differential ratioing technique, drift is

virtually eliminated.

All critical optics are protected by sapphire windows. The NDIR

optical bench can be easily disassembled and windows cleaned (rarely

ever required) and reassembled within fifteen (15) minutes, without

realignment or the use of any tools.

The benefit of this absolute measuring, dual line spectral

differential analytical technique, is that it provides simple, direct

measurement of all CO2 contributing factors (including background) for

a true and accurate calibration, and precisely offsets these effects for

very accurate TOC determinations.

2.4.5 Electronic Signal Processing, Display and Control

A true, industrialized Microsoft Windows™-CE Computer offers

complete automatic control of the analyzer, including the following:

• Benchmark/Auto-Validation

• Auto-Calibration

• Auto-Cleaning

• On-Board Historical Data for up to one (1) year

• Paperless Chart Recorder

• Diagnostics

• Networking (RS-232C/485)

Page 31

Total Organic Carbon Analyzer Theory of Operation

Teledyne Analytical Instruments 19

2.4.5.1 BENCHMARK/AUTO-VALIDATION

Benchmark is the European NAMUR* specified validation

technique, whereby on command a chemical calibration standard is

automatically introduced to the analyzer and the response is compared to

the previous analyzer calibration. If the response falls within a certain

specified limit, the computer/output indicates “Benchmark Passed”. If

the response falls outside specified performance limits, either a

“Maintenance Request” or a “Fault” alarm is activated, depending on

preset tolerances.

Thus, in cases of process spills, when the analyzer performance is

questioned, Benchmark can rapidly and automatically validate analyzer

performance. It eliminates time consuming and unnecessary

recalibration cycles, which take the analyzer out of service just when it

is most critically needed. Benchmark may be on-demand, or operator

programmed for designated day and time activation on a repetitive basis.

On command (manual or automatic by selection of day/time), the

combination of valves V3 and V4 divert the sample and introduce a

liquid calibration solution to the analyzer. This is the same calibration

solution used to previously calibrate the analyzer, “end-to-end”. If the

TOC value from the calibration solution falls within a limit (generally

set at 5% of the previous calibration), then “Benchmark Passed” will be

displayed and remotely reported. If the TOC “Benchmark” solution

falls outside the set tolerance, then a “Benchmark Failed” message and a

“Maintenance Request” are reported.

2.4.5.2 AUTO-CALIBRATION

On command (manual or automatic by selection of day/time), the

combination of valves V3 and V4 alternately introduce D. I. water for a

“Zero” calibration and the “Span” solution. The computer then resets

the analyzer to the new calibration values.

2.4.5.3 AUTO-CLEANING

On command (manual or automatic by selection of day/time), the

combination of valves V3 and V4 operate to introduce a “cleaning”

solution, depending on the chemical constituents of the sample. Acid or

persulfate is generally used.

Page 32

Theory of Operation Model 6750

Teledyne Analytical Instruments 20

Page 33

Total Organic Carbon Analyzer Installation

Teledyne Analytical Instruments 21

Installation

This manual contains “AS BUILT” drawings and a parts list to aid

in the installation and operation of the analyzer. These drawings should

be referred to when ordering spare parts, operating or servicing the

equipment. See the Appendix for the AS BUILT drawing package.

Installation of the Model 6750 On-line UV/Heated Persulfate TOC

Analyzer includes:

1. Unpacking

2. Mounting

3. Electrical Connections

4. Gas Connections

5. Testing the System

3.1 Unpacking the Analyzer

The analyzer is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the analyzer and

inspect it for damage. Immediately report any damage to the shipping

agent.

3.2 Mounting the Analyzer

The analyzer is for indoor use in a general purpose area. The

Hazardous Area Option should be used for applications involving

hazardous areas.

The standard model is designed for wall or rack mounting. Figure

3-1 is an illustration of the mounting and Figure 3-2 shows the required

front door clearance. There are four mounting holes – one in each corner

of the enclosure. Refer to “As Built” drawings in the Appendix.

Page 34

Installation Model 6750

Teledyne Analytical Instruments 22

Figure 3-1: Analyzer Dimensions

Figure 3-2: Required Door Clearance

Page 35

Total Organic Carbon Analyzer Installation

Teledyne Analytical Instruments 23

All operator controls and serviceable components are mounted on

the control panel, which is hinged and doubles as the door that provides

access to those components not normally requiring maintenance.

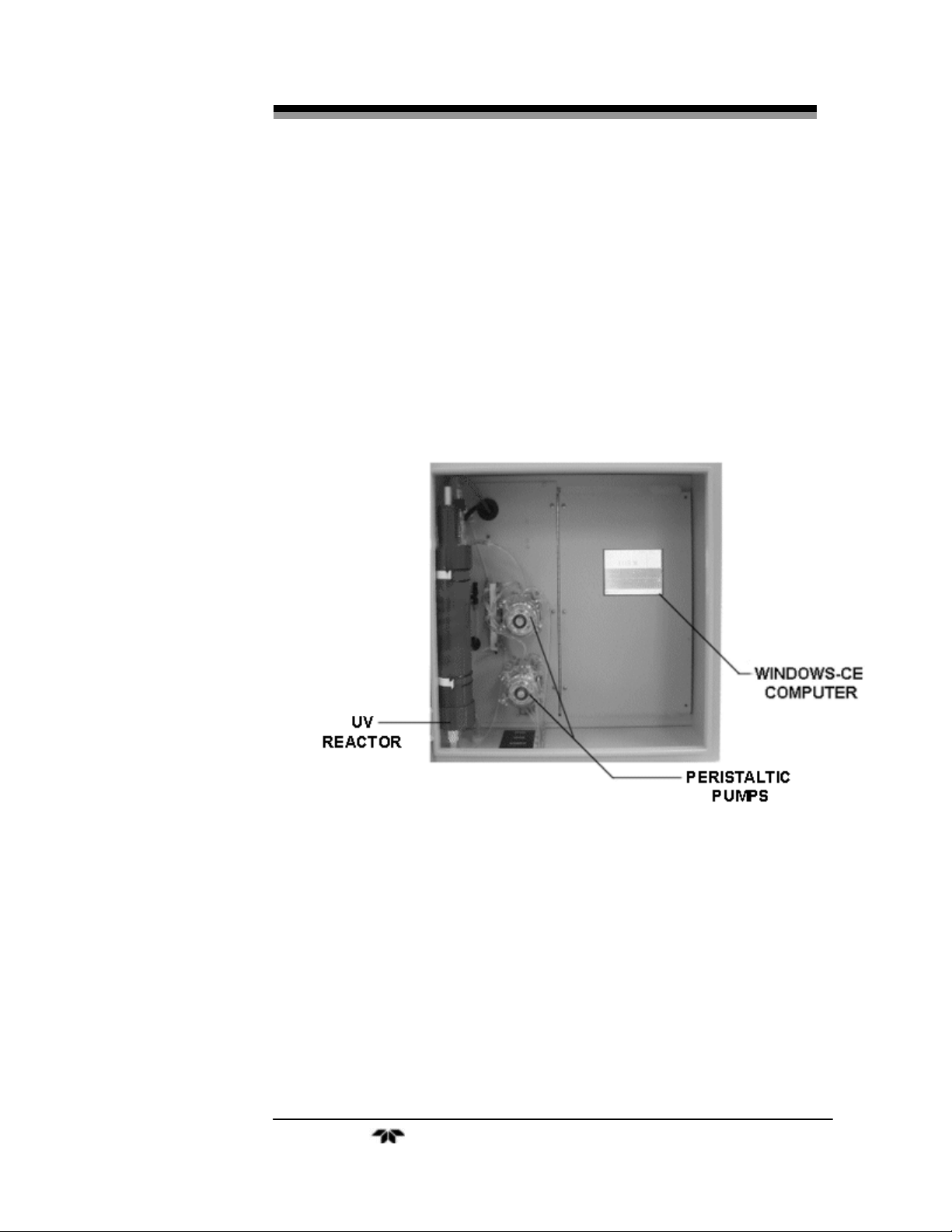

Internal components of the Model 6750 TOC Analyzer are shown

in Figure 3-3.

Figure 3-3: Internal Components of the Model 6750 Analyzer

3.3 Electrical Connections

Figure 3-4 shows the analyzer electrical/electronics connections for

power, communication, and both digital and analog concentration

outputs. See also the AS-BUILT drawing package included in the

Appendix.

3.3.1 Power Connection

The universal power supply requires an 85-250 VAC, 47-63 Hz

power source.

For safe connections, ensure that no uninsulated wire extends

outside the connectors they are attached to. Stripped wire ends must

insert completely into terminal blocks. No uninsulated wiring should be

able to come in contact with fingers, tools or clothing during normal

operation. Electrical/Electronics hookups include the following:

Page 36

Installation Model 6750

Teledyne Analytical Instruments 24

• Power Connection Universal AC Power Source

• Primary Input Power

CAUTION: POWER IS APPLIED TO THE INSTRUMENT’S

CIRCUITRY AS LONG AS THE INSTRUMENT IS

CONNECTED TO THE FACILITY POWER SOURCE.

THE FACILITY MUST HAVE AN EXTERNAL POWER

SWITCH TO REMOVE PRIMARY POWER FROM THE

ANALYZER.

• Analog Output Connections

• Alarm Connections

Figure 3-4 shows where the electrical connections are made to the

instrument.

3.3.2 Analog Outputs

There are two analog output signal connections. There are two

wires per output with the polarity noted. See “As Built Drawings” in the

Appendix. The outputs are non isolated 4-20 mA.

Figure 3-4: Electrical Connections to the Model 6750

Page 37

Total Organic Carbon Analyzer Installation

Teledyne Analytical Instruments 25

3.3.3 Alarm Connections

The Model 6750 is equipped with two concentration alarms and

one analyzer malfunction alarm. The three alarm-circuit connectors use

spring terminals for making connections to internal alarm relay

connects. Each alarm provides a set of Form C contact with both

normally open and normally closed contact connections. The contact

connections are indicated by diagrams on the rear panel. They are

capable of switching up to 3 amperes at 250 VAC into a resistive load.

See “As Built Drawings” in the Appendix. The connections are:

• Threshold Alarms:

• Can be configured as high (actuates when concentration

is above setpoint), or low (actuates when concentration is

below threshold).

• Can be configured as failsafe or non-failsafe.

• Can be configured as latching or non-latching

• Malfunction Alarm

3.3.4 RS-232 Serial Connection

An RS-232 port is provided for serial communication (MODBUS).

Connect a standard RS-232 cable from the computer to the RS-232 port

on the main board.

3.4 Gas/liquid Connections

Refer to the “As Built Drawings” in the Appendix for details and

Figure 3-5.

The Model 6750 Analyzer provides easy access for liquid, gas, vent

and drain connections.

3.4.1 Liquid Connections

Liquid phase sample connections include the following: (See

Figure 3-5):

• Sample (On-Line)

• D. I./Dilution Water

• Calibration Standard

Page 38

Installation Model 6750

Teledyne Analytical Instruments 26

• Reagents

• Drain (s)

Connect these lines as per Figure 3-4 and the AS-BUILT drawings

in the Appendix. Make sure there are no restrictions or kinks in the

sample lines.

Figure 3-5: Gas and Liquid Connections to the Analyzer

3.4.2 Gas Connections

The gas connections include:

• Sample Gas

• Carrier Gas

• Vent

• Calibration Gases (zero and span)

Page 39

Total Organic Carbon Analyzer Installation

Teledyne Analytical Instruments 27

With the exception of the vent and carrier gas inlet, all other gas

connections are made on the same bottom panel as the liquid connections

and are shown in Figure 3-5. The NDIR vent and carrier gas connections

are made on the left side of the unit.

Gas Carrier Connections:

The facility carrier gas must be free of CO2 and hydrocarbons and

be regulated to 15±2 psi and connected as shown in “As Built”

Drawings in the Appendix).

NDIR Vent (gas exhaust):

Exhaust connections must be consistent with the hazard level of the

constituent gases. Check Local, State, and Federal laws, and ensure that

the exhaust stream vents to an appropriately controlled area if required.

CAUTION: OPERATING THE UNIT WITHOUT CARRIER GAS

CAN DAMAGE THE ANALYZER.

3.5 Checking the System

Before applying power to the instrument, check:

• All gas and liquid lines as well as vent and drains are

properly connected and there are no leaks in the lines or at

fittings.

• Power and signal wiring are correct and that there are no

frayed or loose wires that could cause a short.

Prior to powering up the system and using the instrument for

analysis, the system must be configured for your application and

calibrated. This is described in Section 4.

Page 40

Installation Model 6750

Teledyne Analytical Instruments 28

Page 41

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 29

Setup and Operation

Once the analyzer has been installed, it can be configured to your

application. To do this you will:

• Set system parameters

• Calibrate the instrument

• Define the analysis range. Then choose auto-ranging or

select a fixed range of analysis, as required.

• Set alarm setpoints, and modes of alarm operation (latching,

failsafe, etc.)

4.1 Analyzer Startup

Referring to the Installation section and “AS-BUILT” Drawings in

the Appendix, check the following:

1. Air/oxygen supply – This must provide a constant

pressure of 15 +/- 2.0 psi, ultra-pure oxygen or CO2–free

air at a flow rate up to 500 cc/minute. (Pre-purified air

may be used with optional Air Purifier P/N ST910003).

2. Drain Line – Check to see if the drain line is free of kinks

and loops and allows normal vented gravity flow to an

open receptacle (jar, pipe, etc.). AN AIR GAP AS

DEFINED IS MANDATORY.

CAUTION: FAILURE TO OBSERVE THIS WILL RESULT IN

IMPROPER OPERATION.

3. ELECTRICAL – Assure proper electrical installation.

Refer to facility requirements.

4. SAFETY – All customer and Teledyne specified safety

measures are followed.

Page 42

Setup and Operation Model 6750

Teledyne Analytical Instruments 30

Figure4-1: Drain Connections

5. On initial start–up or after UV Reactor or Glass Liquid

Separator (GLS) servicing, fill the U-Tube with D. I.

water as indicated in Figure 4-2.

6. After all of the above checks, turn analyzer ON by

activating the facility power switch. The system starts up

in Run Mode.

7. Immerse line from “sample” port of the analyzer into D.

I. water container.

8. Immerse persulfate line from the “persulfate” port of the

analyzer into persulfate container.

9. Immerse acid line from the “ACID IN” port of the

analyzer into ACID container.

Page 43

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 31

Figure 4-2: Gas Liquid Separator D. I. Filling

After reagents and DI have filled all tubing lines, it is

recommended to proceed with IR Calibration followed by cal (liquid

calibration) of the system. Then the analyzer may be placed in service.

4.2 Menus

The advanced design of the Model 6750 TOC Analyzer eliminates

complicated, routine, and sometimes confusing menus. The

operator/software interface is simple and easy to use. Menus prompt the

user for required actions or input.

The analyzer has no manual adjustments. All calibrations and

operations are computer controlled by the operator following menu

prompting and selection of the operation of choice.

The following menu and operation descriptions are intended to

guide the operator through all the functions of the analyzer.

After primary power (110/220VAC) has been applied to the

analyzer and self-diagnostic procedure has been completed, the system

automatically boots up to the following RUN Screen. If not, turn main

power OFF, then ON to reboot.

4.2.1 Run Mode

RUN – This is the normal analysis mode. In this mode, the display

indicates:

Page 44

Setup and Operation Model 6750

Teledyne Analytical Instruments 32

• The current TOC value,

• [IR] IR response

• [Flow] Carrier Gas Flow rate

• [m] Available Memory (kb).

4.2.2 Parameter Menu

Although your analyzer has been optimally configured for your

application, on initial startup the setup parameters should be verified

Consult Factory Settings for Your Application – “As Built Drawings” in

the Appendix.

To get to the Parameters menu:

1. From the Run Screen, select [EDIT]. The following

menu will appear.

Note: Options not included in your analyzer will have no

response, if selected.

Page 45

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 33

2. From this menu, select:[Parameters]

The following screen appears:

This is the Parameters menu from which the analyzer may be

configured to suit the requirements of the operator

Verify the following settings are correct or select the desired

settings: (Consult “As Built Drawings’ in the Appendix and Factory

Settings Chart – Page V”)

• Carrier Flow Rate

• Liquid Range

Note: The “Liquid Range” setting is that value to which the full-

scale output range is to be set (not the value of the Liquid

Span).

4.2.3 Alarm Settings

The next settings to verify or set are the Alarm Settings.

To adjust the alarm settings:

From the [Edit] Menu, select [Alarms].

The following Menu appears:

Page 46

Setup and Operation Model 6750

Teledyne Analytical Instruments 34

From this menu verify or change the concentration alarm setpoints

using the onscreen scroll arrows.

4.2.4 Stream Sequencer

If your analyzer has been configured for a multi-stream sequencer

(P/N ST200009), from the [Edit] Menu, select [Sequencer]. The

following menu appears:

From this menu, you can:

• Configure the duration of analysis for each stream (how long

it will analyze that stream before selecting the next stream)

• Configure the changeover time (to allow the prior stream to

pass through sampling systems and clear the analyzer before

analysis of the next steam begins),

• Enable and disable each stream analysis (for example, to

concentrate on only one stream).

The following window is illustrative of a dual stream [Run] screen.

Page 47

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 35

4.2.5 D/DBPR

This optional utility allows convenient external pH calibration and

input of alkalinity data consistent with the D/DBPR requirements

If your analyzer has been configured for the D/DBPR option, from

the following [Edit] Menu, select [D/DBPR].

The following screen appears:

Page 48

Setup and Operation Model 6750

Teledyne Analytical Instruments 36

The following window is illustrative of the D/DBPR [Run] screen.

4.3 Detailed Calibration Procedures

1. Although the instrument has been calibrated to your

specifications at the factory, it should be rechecked after

satisfactory installation and periodically calibrated as

suggested for your application.

2. Instrument calibration is performed by an “end-to-end”

method, whereby a known organic carbon chemical

standard solution is introduced to the analyzer and the

analyzer is “spanned” to that value.

3. Organic and Inorganic Carbon Standards:

a. (Potassium Hydrogen Phthalate) is recommended for

the organic carbon standard solution.

b. Sodium Carbonate is recommended for the inorganic

carbon standard.

c. Table 4-1 provides the concentration to be used for

two ranges of different chemical compounds (organic

& inorganic carbon).

d. Ratioing of these concentrations will provide other

ranges for the span solution.

Page 49

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 37

Table 4-1: Preparation of Standards (TOC/TIC)

ORGANIC COMPOUNDS

100 mg/Liter

TOC (AS CARBON)

1000 mg/Liter

TOC (AS CARBON)

Ethylene Glycol

.233 ml/L H20

2.33 ml/L H20

Methanol

.337 ml/L H20

3.37 ml/L H20

Ethanol

.242 ml/L H20

2.42 ml/L H20

Acetone

.204 ml/L H20

2.04 ml/L H20

Carbon Tetrachloride

.807 ml/L H20

8.07 ml/L H20

Sucrose

.238 gm/L H20

2.38 gm/L H20

Urea

.500 gm/L H20

5.00 gm/L H20

Acetic Acid

.250 gm/L H20

2.50 gm/L H20

KHP (Potassium acid

phthalate)

.212 gm/L H20

2.12 gm/L H20

Glycine

.313 gm/L H20

3.13 gm/L H20

Sodium Stearate

.141 gm/L H20

1.41 gm/L H20

Succinic Acid

.246 gm/L H20

2.46 gm/L H20

Sodium Oxalate

.555 gm/L H20

5.55 gm/L H20

INORGANIC COMPOUNDS

50 mg/Liter

TIC (AS CARBON)

Sodium Carbonate

.442 gm/L H20

Potassium Carbonate

.575 gm/L H20

Ammonium Carbonate

.475 gm/L H20

Add amounts shown (in milliliters or grams) to clean dry, one liter

volumetric flask and dilute to one (1) liter with distilled, deionized

water.

4. Reagent Preparation:

PREPARATION OF ONE MOLAR SODIUM

PERSULFATE SOLUTION (OXIDIZING REAGENT)

Page 50

Setup and Operation Model 6750

Teledyne Analytical Instruments 38

CAUTION: SODIUM PERSULFATE IS A STRONG OXIDIZING

AGENT. TAKE ALL NECESSARY PRECAUTIONS AS

WITH HANDLING ANY CORROSIVE MATERIAL.

ALL CHEMICALS, INCLUDING WATER, SHOULD BE

REAGENT GRADE OR BETTER AND FREE OF

CARBON-CONTAINING COMPOUNDS.

THE CONTAINER USED SHOULD BE FLUSHED WITH

DISTILLED OR DEIONIZED (DI) WATER.

a. Dissolve 238 grams of ultra-pure reagent grade

sodium persulfate (P/N ST40000) into one (1) liter of

distilled water.

b. Do not heat reagent to dissolve, as this is not

necessary and can reduce the effectiveness of the

solution. It should be noted that some reagent grade

sodium persulfate is not really “pure”. All persulfate

supplied by Teledyne is guaranteed to have sufficient

purity for proper operation.

5. Acid Preparation:

Phosphoric Acid is the acid of choice.

PREPARATION OF PHOSPHORIC ACID SOLUTION

a. The container used should be flushed with distilled or

deionized (DI) water.

b. Add 117ml of 85% phosphoric acid to one (1) liter of

DI Water.

CAUTION: CONTACT WITH PHOSPHORIC ACID LIQUID OR

VAPOR CAN DAMAGE TISSUE, CAUSE EYE

DAMAGE, RESULT IN SEVERE BURNS AND CAUSE

LUNG AND RESPIRATORY DAMAGE. WEAR

PROPER PROTECTIVE CLOTHING AND SAFETY

GLASSES WITH SPLASH SHIELDS. TREAT ALL

ACIDS WITH CAUTION AND HANDLE WITH CARE.

ALWAYS WORK IN AN APPROVED FUME HOOD

WHEN HANDLING OPEN CONTAINERS OF ACIDS.

6. “End-to End” Calibration:

Page 51

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 39

Note: On the initial Startup, IR gas calibration should be

performed prior to liquid calibration

a. Select [CALIBRATE] from the main menu. The

following screen will appear:

b. Select [TOC].

The following screen appears:

c. Flow “ZERO” (D. I. Water) and allow NDIR reading

to stabilize. For maximum accuracy, especially at

lower ranges, this process may take 20 minutes.

When reading is stable, select [ZERO].

d. Flow Liquid Span Standard Solution. Allow NDIR

reading to stabilize, (approximately 15 minutes).

e. Select [SPAN]. It is recommended that the operator

continue to observe the reading and if not stabilized at

the desired span setting ± 2%, repeat the span

selection until stable.

Page 52

Setup and Operation Model 6750

Teledyne Analytical Instruments 40

f. If the calibration is acceptable, select [OK] or

[CANCEL] if not acceptable.

The analyzer is now calibrated and ready for analysis.

4.4 Operation

After proper installation and calibration, the instrument is ready to

be placed “ON-LINE” for continuous operation.

Note: For any non–standard or specific operational procedures,

please refer to the “INSTALLATION” and “AS–BUILT”

drawings in the Appendix or any Addenda that

accompanies this manual. If applicable, the Appendix or

Addenda will include details on your specific application,

which may involve valving, stream sequencing, automatic

calibration, etc.

The RUN screen will automatically appear on the screen. It will

also appear whenever the computer is rebooted or the power is turned

off and back on again. Figure 4-3 shows the RUN screen and identifies

the data fields.

Figure 4-3: The RUN Screen

Page 53

Total Organic Carbon Analyzer Setup and Operation

Teledyne Analytical Instruments 41

4.5 Shutdown

Prior to shutdown of the analyzer or performing service on the

reactor, flush D. I. water through all sample and reagent lines for at least

30 minutes to clean all tubing.

CAUTION: FAILURE TO OBSERVE ADEQUATE FLUSHING

COULD RESULT IN HARMFUL ACID BURNS AND/OR

A REACTOR CLOG.

4.6 Historical Data

Previous data may be obtained by selecting [CHART] from the

screen. The following menu will appear.

The display scale can be adjusted using the Select [TOC SCALE]

item from the [CHART] menu. The following screen will appear.

Edit Scale as desired.

Page 54

Setup and Operation Model 6750

Teledyne Analytical Instruments 42

To view the data produced in the last 24 hours, select [LAST 24

HOURS]. The following screen will appear:

Using the Scroll Bar, select the data to be viewed.

Selecting [HISTORICAL DATA] allows you to view any archived

data within the memory limits of the computer. A screen appears

which will allow you to select the archived time period desired. How

far back you can go depends on the available memory.

Page 55

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 43

Maintenance

5.1 Compupter-aided Testing

Prior to performing detailed troubleshooting procedures listed

below, first perform computer-aided testing of the analyzer, as follows:

1. From the screen, select [TEST]. The following menu

appears:

2. Select [SYSTEM DIAGNOSTICS]. The following

menu appears:

Page 56

Maintenance Model 6750

Teledyne Analytical Instruments 44

From this screen the operator may perform individual

testing of components related to functionality and

settings.

5.2 Troubleshooting

If you are experiencing trouble with your instrument, refer to Table

5-1: Troubleshooting.

Table 5-1: Troubleshooting

PROBLEMS

SOLUTION

Analyzer will not turn on

• Check fuse & power connections.

• Look for loose or damaged wiring.

• Check for 12V DC from power supply.

• Check power supply fuse.

Analyzer does not Calibrate, is

sluggish

• Look for & correct any liquid or gas line

leaks.

Analyzer is excessively noisy

• Check for leaks at tubing connections

Display not functioning

• Check cable connections

• Check power supply voltage

• Suspect:

• Malfunctioning Computer (P/N ST13039).

• Master Control Panel Assembly (P/N

ST13042-1)

Pump head not rotating

• Refer to section “Pumps” 12.3.12

• Verify that carrier loss did not cause the

pumps to be turned off.

• Check for AC voltage at terminal strip on

inside of application panel.

•

Pump head rotating but not

pumping fluid

• Refer to section “PUMPS”

• Change tubing

• Verify sample line is in liquid.

Page 57

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 45

5.3 Module Service

5.3.1 NDIR (Gas Calibration)

1. From the Menu, select [CALIBRATE].

The following screen will appear:

2. Select [INFRARED ANALYZER]. The following

Screen will appear:

3. Disconnect tubing from reactor output and connect IR

calibration adapter (P/N ST20026) as shown in Figures 51, 5-2, and 5-3.

4. Connect facility tubing to “Zero” and “Span” Gas Bottles

Page 58

Maintenance Model 6750

Teledyne Analytical Instruments 46

Figure 5-1: Disconnecting Tubing from Reactor

Figure 5-2: IR Calibration Adapter P/N ST20026

Page 59

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 47

Figure 5-3: Installing Calibration Adapter

5. To set IR “Zero”, flow 200cc/minute oxygen (or CO2-

free air) for 5 minutes. Allow NDIR reading to stabilize.

Select [ZERO]. NDIR reading is reset to 0.

6. To set IR “Span” for the 6 inch (shorter) IR bench, use a

gas calibration standard mixture of 1% CO2 in pure

nitrogen. For the longer (15 inch) bench, a gas mixture

of 0.1% CO2 in pure nitrogen is required for. Flow 200

cc/minute of this cal gas for at least three minutes. Allow

NDIR reading to stabilize and then select [SPAN]. NDIR

reading is set to 10,000. Select [OK] to save or

[CANCEL] to reject the calibration setting.

The NDIR unit has now been properly calibrated. Reconnect the

fitting to reactor output tube.

5.3.2 NDIR Service

To remove and service the NDIR, simply follow the illustrated

sequence as described in this section following Figure 5-4.

Page 60

Maintenance Model 6750

Teledyne Analytical Instruments 48

Figure 5-4: Removing the NDIR Unit P/N ST36000

To Replace the NDIR Unit:

1. Turn off power.

2. Remove inlet tube from NDIR Assembly.

3. Remove vent tube from NDIR Assembly.

4. Unplug interface cable from NDIR Assembly.

5. Remove NDIR Assembly from cabinet.

Page 61

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 49

• Remove insulation from IR

Cell.

• Remove lock-tight from three

thumbnuts and remove.

• Slide out and remove Source

Assembly.

Page 62

Maintenance Model 6750

Teledyne Analytical Instruments 50

• Remove IR Cell Assembly

Note:

a. ‘O’-Rings in each of Detector

Assembly (left) and Source

Assembly (right).

b. Sapphire windows located under

‘O’-Rings

Page 63

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 51

• *Remove ‘O’-Ring and Sapphire

window taking care to avoid

scratching Sapphire window.

*Recommend using toothpick.

• Clean sapphire windows with a

soft, lintless tissue (use DI water,

if necessary).

To Reassemble

• Install IR Cell.

• Install Source Assembly end

piece.

Note: Large outlet port goes into

Detector Assembly (left)

Page 64

Maintenance Model 6750

Teledyne Analytical Instruments 52

• Tighten three thumbnuts until

Source Assembly bottoms out on

squeeze nuts.

•

Recommend:

Use alternate tightening sequence

• Insert lock-tight on three thumbnuts to prevent backoff.

• Install insulation. Replace assembly as before.

• Recalibrate NDIR (Section 4.3).

Note: IR Cell installed

incorrectly. Large outlet

port MUST go into

Detector Assembly (left)

Page 65

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 53

5.3.3 Master Interface Board (P/N ST13042-1).

The Master Interface Board has no field adjustment. If

malfunctioning, replace the module P/N ST13042-1 using the

instructions below. See Figure 5-5.

Figure 5-5: Removing the Master Interface Board

To Remove the PC Board:

1. Turn off power.

2. Remove plastic cover.

3. Disconnect connectors.

4. Remove panel.

Note: Depending on the configuration, there may be one or two

master interface boards.

Page 66

Maintenance Model 6750

Teledyne Analytical Instruments 54

5.3.4 D. C. Power Supply

The power supply has no field adjustment. If malfunctioning,

replace the module (P/N ST15083) using the directions below. See

Figure 5-6.

Figure 5-6: DC Power Supply Module

To replace the module:

1. Turn off power.

2. Remove plastic cover.

3. Disconnect connectors.

4. Remove nuts holding Power Supply.

5. Remove Power Supply Module.

6. Replace Power Supply Module.

7. Reverse steps for installation.

8. (Refer to Installation Drawings for proper connector

assembly.)

9. Recalibrate liquid and span values.

Page 67

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 55

5.3.5 CE Computer (P/N 13039)

If malfunctioning, replace the Computer Module using the

directions below. See Figure 5-7.

Figure 5-7: Replacing CE Computer

To Replace the CE Computer:

1. Turn off power

2. Disconnect electrical connectors.

3. Remove screws holding Module in place.

4. Remove module.

5. Install new CE Computer in reverse disassembly

instruction procedure steps. (Install electrical connectors

per supplied drawing).

6. Verify proper software install per directions shipped with

new CE Computer.

7. Recalibrate liquid zero and span values.

Page 68

Maintenance Model 6750

Teledyne Analytical Instruments 56

5.3.6 UV Lamp (P/N ST20009)

Normal lamp replacement frequency is suggested at least every 12

months, however, if a lamp is “burned-out” (weak or no blue glow),

replace with UV Lamp (P/N ST20009), per directions in Figure 8.

Figure 5-8: UV Lamp Replacement

To replace the UV lamp:

1. Turn off the UV lamp at the UV power supply. Remove

persulfate and acid reagent lines from containers, as well

as the sample inlet line and submerse all three (3) lines

into D. I. water to completely flush system.

CAUTION: FAILURE TO DO SO MAY RESULT IN ACID BURNS,

CLOGGED REACTOR. FLUSH FOR 30 MINUTES.

CAUTION: USE ONLY P/N ST20009 UV LAMP TO ASSURE

PROPER 185 MM AND 254 MM POWER SPECTRAL

DENSITY AND PROPER OXIDATION EFFICIENCY.

Page 69

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 57

CAUTION: THE UV LIGHTED LENGTH MUST BE AT LEAST 12 ½

INCHES FOR PROPER OPERATION. DO NOT USE

STANDARD 12 INCH LIGHTED LENGTH UV LAMPS.

2. Turn off power allow 10 minutes for cool down.

3. Disconnect electrical connectors.

4. Loosen fittings as illustrated.

5. Remove UV Lamp.

6. Recalibrate analyzer.

5.3.7 UV Reactor Assembly (P/N ST20003-1)

If malfunctioning, clean the assembly. If still malfunctioning,

replace the assembly (P/N ST20003-1). See Figure 5-9.

Figure 5-9: Removing the UV Reactor Assembly

To Replace the UV Reactor Assembly:

1. Turn off UV Lamp at the UV Power Supply. Remove

Persulfate and Acid Reagent lines from containers, as

Page 70

Maintenance Model 6750

Teledyne Analytical Instruments 58

well as the sample inlet line and submerse all three (3)

lines into D. I. water to completely flush system.

CAUTION: FAILURE TO DO SO MAY RESULT IN ACID BURNS,

CLOGGED REACTOR, ETC. FLUSH FOR 30

MINUTES.

2. Turn off power.

3. Disconnect electrical connectors.

4. Disconnect tubing.

5. Remove thumbnuts holding UV Reactor in—place.

6. Remove UV Lamp (See Figure 5-9).

To clean the UV Reactor Assembly:

1. Run warm water through all tubing until clean.

2. Replace assembly as before.

3. Charge reactor with D. I. water.

4. Recalibrate analyzer.

5.3.8 UV Power Supply

The UV Power Supply (P/N ST15002 for 110 VAC or P/N

ST15000 for 220VAC) is normally checked with another good UV

lamp. If it activates the UV lamp, the UV Power Supply is good. If the

Power Supply is not good, replace the Module (P/N ST15002 for 110

VAC or P/N ST15000 for 220 VAC). See Figure 5-10.

To replace the UV Power Supply:

1. Turn power off.

2. Disconnect UV and main power connectors.

3. Remove power supply mounting screws.

4. Replace power supply.

5. Reverse steps for installation.

6. Recalibrate liquid and span value.

Page 71

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 59

Figure 5-10: Removing the UV Power Supply

5.3.9 Mass Flow Controller (P/N ST18001A)

If proper flow is not detected by the computer, an alarm will be

activated and displayed. The fault may be in the O2/Air supply (check

for 20 psi and flow of the supply by disconnecting the input). If supply

flow exists, fault may be in the tubing. Disconnect output side of mass

flow controller and check for flow. If no flow exists, exchange mass

flow controller as described below. See Figure 5-11. If flow still does

not exist, check rest of tubing for restrictions, leaks, etc.

To remove the mass flow controller:

1. Shut off Power to Instruments.

2. Shut off all gas to analyzer and bleed system for “O”

pressure.

3. Disconnect fittings/tubing.

4. Loosen screws holding Module in-place.

5. Remove Module

6. Recalibrate analyzer after re-installation of exchange

Module.

Page 72

Maintenance Model 6750

Teledyne Analytical Instruments 60

Figure 5-11: Mass Flow Controller

5.3.10 Metering Valve (P/N ST16050)

If no O2/air flow to the sparger (P/N ST20025) is observed (no

bubbles), check for tubing and fitting leaks, restrictions and adjust

metering valve (be careful to return to previous indicated bubble rate).

If flow cannot be restored, replace the metering valve (P/N ST16050)

according to the directions below. See Figure 5-12.

To replace the metering valve:

1. Turn carrier gas (Air/O2) OFF.

2. Turn pumps OFF.

3. Remove fittings and tubing.

4. Remove metering valve.

5. Recalibrate TIC if TIC and/or TOC–TRUE analysis is

required. NPOC analysis only does not require

recalibration.

6. Reinstall metering valve in reverse order.

Page 73

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 61

Figure 5-12: Metering Valve

5.3.11 Sparger (P/N ST20025)

The sparger may be removed for cleaning with detergent and

subsequent flushing with DI water. If the sparger inner glass body is

observed to be leaking (cracked glass, etc.), or is clogged beyond

cleaning, replace sparger (P/N ST20025) according to the directions

below. See Figure5-13.

To replace the sparger:

CAUTION: CONTACT WITH ACID LIQUID OR VAPOR CAN

DAMAGE TISSUE, CAUSE EYE DAMAGE, RESULT IN

SEVERE BURNS AND CAUSE LUNG AND

RESPIRATORY DAMAGE. WEAR PROPER

PROTECTIVE CLOTHING AND SAFETY GLASSES

WITH SPLASH SHIELDS. TREAT ALL ACIDS WITH

CAUTION AND HANDLE WITH CARE. ALWAYS

WORK IN AN APPROVED FUME HOOD WHEN

HANDLING OPEN CONTAINERS OF ACIDS.

Page 74

Maintenance Model 6750

Teledyne Analytical Instruments 62

1. Turn machine OFF.

2. Turn carrier gas (Air/O2) OFF.

3. Remove and drain tubing and sparger.

4. Remove sparger from spring clips.

To clean the sparger:

1. Run warm water through tubing to flush out any solid

contamination.

2. Reinstall sparger in reverse order.

Figure 5-13: Sparger

Page 75

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 63

5.3.12 Pumps

If any of the pumps are not pumping (liquid flow is not observed

moving up the tubing), check to see if the motor is turning the pump

heads and the motor is not binding. Check for proper power and

connections to the pump motor. If the motor has failed (e.g., open

windings, etc.), replace motor. For 110 V 2 RPM motor , use P/N

ST18002; for 220 V 2 RPM motor use P/N ST18003. For pump motor

replacement, refer to Section 5.3.12.1 and Figure 5-14.

If the motor is operating properly, worn tubing is the probable

cause for poor or non–existent pumping. Retube pump heads as

described in Section 5.3.12.2 and Figure 5-15.

5.3.12.1 PUMP MOTOR REPLACEMENT

Note: Masterflex pump heads must be removed for access to

Pump Motor Mounting Screws.

1. Turn main power OFF.

2. Remove 4 wing nuts from pump

head mounting hardware.

Page 76

Maintenance Model 6750

Teledyne Analytical Instruments 64

3. Remove pump as illustrated to

gain access to pump mounting

screws.

4. Remove two thumbscrews for

pump panel removal.

5. Disconnect Pump Motor

Connector.

Page 77

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 65

6. Remove 4 pump mounting screws

for pump removal.

7. Replace motor and reassemble in

reverse step sequence.

Figure 5-14: Removing the Pump

Note: Actual mounting panel may appear somewhat different but

mounting hardware is the same.

5.3.12.2 PUMP HEAD TUBING REPLACEMENT

1. Separate the end bells (the pump head

halves).

2. Hold the end bell containing the rotor as

shown with the tubing retainer grooves

pointing down.

Page 78

Maintenance Model 6750

Teledyne Analytical Instruments 66

3. Place tubing in the right groove and against

the first two rollers.

4. Hold tubing with thumb.

5. Near groove, insert smaller prong of

loading key between the top of the rotor

and tubing.

6. Push key in as far as possible.

7. Push down and turn key counterclockwise

(ccw) completely around the rotor.

8. The key will push the tubing uniformly into

the end bell assembly.

9. Hold the second end of tubing.

10. Remove the key.

Page 79

Total Organic Carbon Analyzer Maintenance

Teledyne Analytical Instruments 67

11. Position the other end bell on top and press

the end bells together.

12. Be careful not to pinch the tubing.

13. If end bells do not snap tightly together,

reload tubing.

14. If necessary, turn key in slot on rotor shaft to

adjust tubing (as in next step - E).

15. With key in slot on rotor shaft, turn key to

align tang on rotor shaft with slot in motor

drive shaft.

16. Point tubing retainer grooves up.

17. Shift the pump head slightly until it snaps on

the alignment pins (if present).

18. Secure with four provided screws.

19. Tighten with fingers only.

Figure 5-15: Pump Head Tubing Replacement

5.3.13 4-20 mA Adjustment Procedure