Page 1

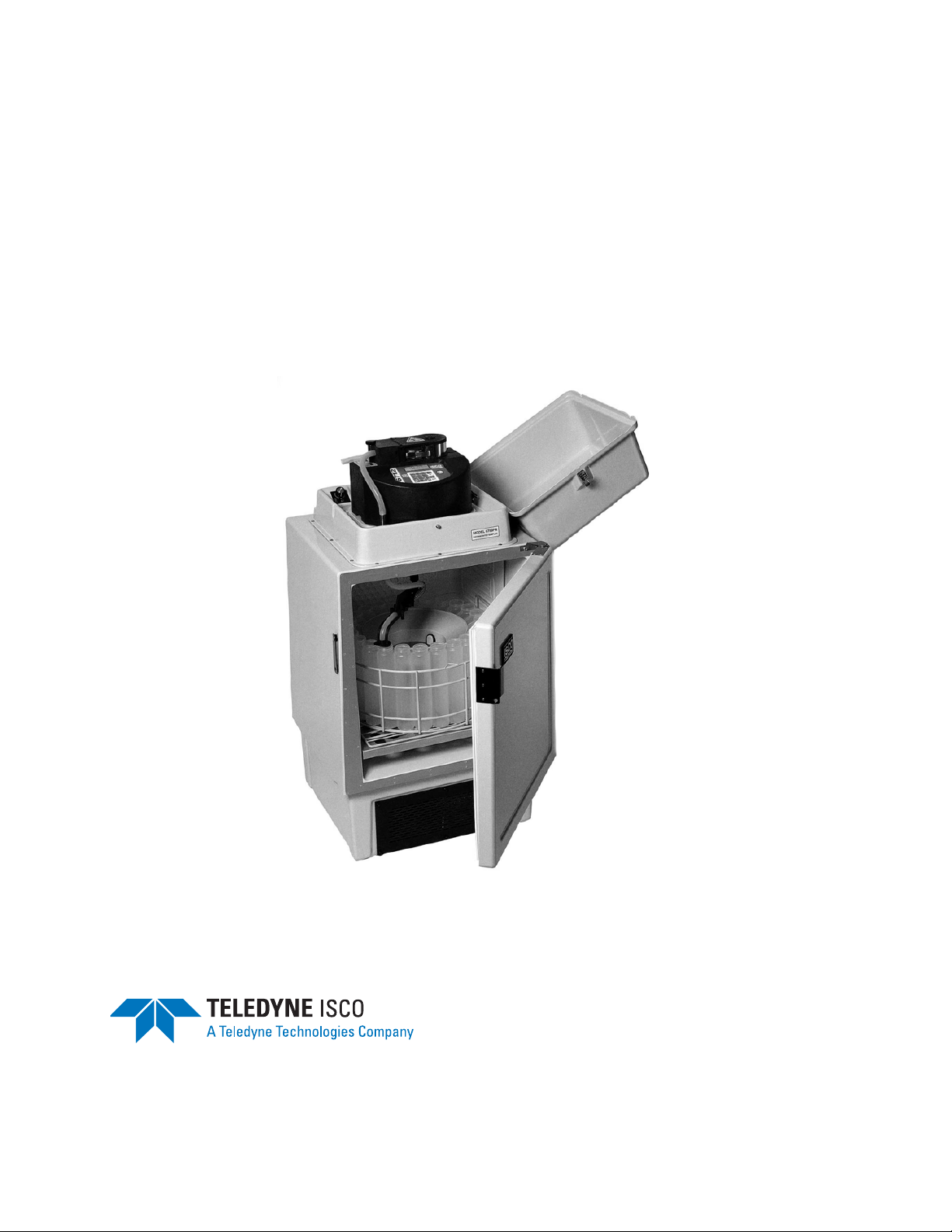

6712FR

Refrigerated Sampler

Installation and Operation Guide

Part #69-9003-590 of Assembly #60-9004-335

Copyright © 2001. All rights reserved, Teledyne Isco, Inc.

Revision

CC, September 1, 2009.

Page 2

Page 3

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Support

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(866) 298-6174 (Samplers and Flow Meters)

Revised March 17, 2009

Page 4

Page 5

6712FR Refrigerated Sampler

Safety

6712FR Refrigerated Sampler

Safety

The 6712FR Refrigerated Sampler is a “definite purpose” device,

intended for use only with compatible Isco equipment. Do not

use this product with any other manufacturers’ equipment, or for

any other purpose. Use for any purpose not described in this

manual could cause personal injury or property damage.

Electrical Requirements The refrigerator is available in both 120 V and 230 V config-

urations. The required operating voltage for the refrigerator is

listed on the Identification and Serial Number label, placed on

the inside of the sample compartment door.

Refrigerators configured for 120 V operation are equipped with

a North American NEMA 5-15P plug and is intended for use

only with 120 V , 60 Hz. The power source should be rated for

20 ampere service.

Refrigerators configured for 230 V operation are equipped with

a Continental European CEE 7/7 plug and is intended for use only

with 230 V , 50/60 Hz. The power source should be rated for 16

ampere service.

Refrigerators in either configuration provide 12.5 V at 5

amperes for the sampler controller. This output is from the

two-pin military-type connector on the cord on top of the refrigerator. This output is intended for 6700 Series Sampler controllers

only.

The refrigerator must be installed near a suitable

power outlet. Never use an extension cord.

The power outlet must be visible and easily accessible.

Unplugging the refrigerator is the only means of disconnecting power.

To minimize the risk of electrical shock, the refrigerator must be connected to an outlet with an electrical

ground contact.

The power source must be a dedicated circuit. The line

must not power any other devices.

Never operate the refrigerator with the lower front or

rear panels removed.

Never operate the refrigerator in an explosive atmosphere.

Do not locate the refrigerator where the lower compartment could become submerged.

Do not lift or carry the refrigerator. Use an appliance

carrying device.

Fuses must be replaced with the required size, current,

voltage, and blow-time specifications. Refer to the

Replacement Parts List for the correct part number.

iii

Page 6

6712FR Refrigerated Sampler

Safety

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed in the following general

warnings:

WARNING

This instrument has not been certified for use in

“hazardous locations” as defined by the National Electrical

Code.

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired; this will

increase your risk of injury.

AVERTISSEMENT

Éviter les usages périlleux! Si vous utilisez cet instrument

d’une manière autre que celles qui sont specifiées dans ce

manuel, la protection fournie de l’instrument peut être

affaiblie; cela augmentera votre risque de blessure.

iv

Page 7

6712FR Refrigerated Sampler

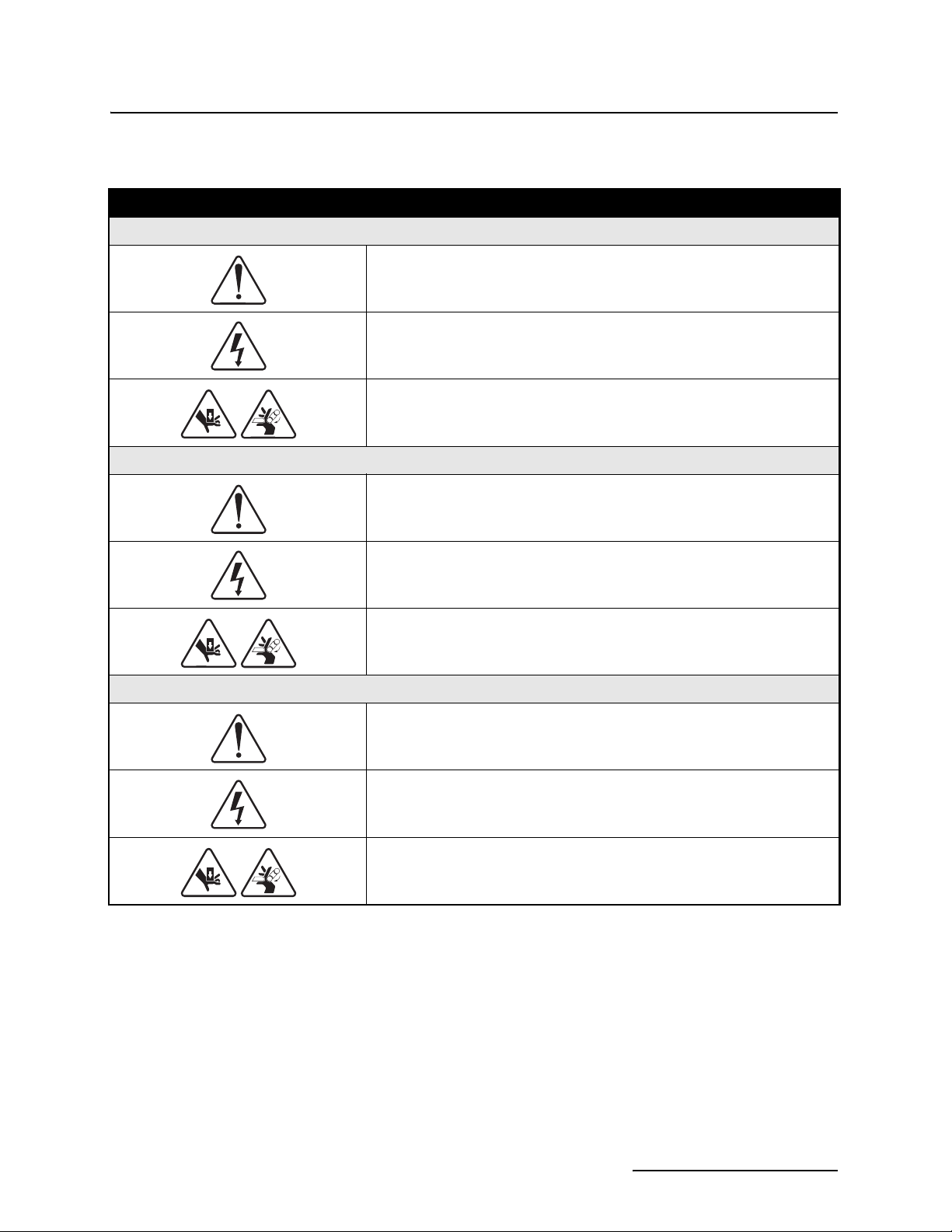

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Pinch point. These symbols warn you that your fingers or hands will be seriously injured if you place them between the moving parts of the mechanism

near these symbols.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au produit dans ce manuel.

Safety

Warnungen und Vorsichtshinweise

Ce symbole signale la présence d’un danger d’électocution.

Risque de pincement. Ces symboles vous avertit que les mains ou les

doigts seront blessés sérieusement si vous les mettez entre les éléments

en mouvement du mécanisme près de ces symboles

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Vorsicht Quetschgefahr! Dieses Symbol warnt vor einer unmittelbar drohenden Verletzungsgefahr für Finger und Hände, wenn diese zwischen die

beweglichen Teile des gekennzeichneten Gerätes geraten.

v

Page 8

6712FR Refrigerated Sampler

Safety

vi

Page 9

6712FR Refrigerated Sampler

Table of Contents

Section 1 Introduction

1.1 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 About 700 Series Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 SDI-12 Sondes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Memory to Store Monitoring Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Pump Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Section 2 Installation/Preparation

2.1 Preparing the Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Installing the Distributor Shaft Extension . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.3 Installing the Distributor Arm and Discharge Tube . . . . . . . . . . . . . . . . . . 2-2

2.2 Installing Bottle Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Installing Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Removing Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.3 Installing Composite Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 Suction Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Guidelines for Measuring and Cutting the Suction Line . . . . . . . . . . . . . . 2-7

2.3.2 Attaching Suction Line to Pump Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.1 Alternative to Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.5 How Does the Sampler Work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5.1 Measuring Sample Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.6 Installing the Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.6.1 Tips for Routing Suction Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.6.2 Intake Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.6.3 Positioning a Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.7 Connecting External Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.7.1 Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.7.2 Rain Gauge Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.8 Locking the Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9 Servicing the Sampler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Section 3 Programming Introduction

3.1 Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Selecting a Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Using Menus and Entering Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1 Selecting Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.2 Entering Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Quick View Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 Paging Through Quick View Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.2 Changing Settings in a Quick View Screen . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Clock and Calendar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.2 Menu Screens: Clock Start Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Menu Screens: Site Descriptions and Program Names . . . . . . . . . . . . . . . . . . . . . 3-7

3.6 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6.1 Information Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

i

Page 10

6712FR Refrigerated Sampler

Table of Contents

3.6.2 Help Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6.3 Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6.4 Operation Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.7 Menu Trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Section 4 Standard Programming

4.1 Switching Between Standard and Extended Modes . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Language Selection, Units of Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Pacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4.1 Trigger Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5 Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.1 Sequential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.2 Bottles Per Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.3 Samples Per Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.4 Composite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.5 Continuous Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.6 Start Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.6.1 How Do Start Times Work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.6.2 Sampler Enable/Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.7 Running Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.7.1 Run Time Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.7.2 Module Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.8 Interrupting a Running Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.8.1 Stop Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.8.2 Resume Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.8.3 View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.4 Grab Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.5 Pump Tube Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.6 Calibrate Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.7 Cal/Adj Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.8 Adjust Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.8.9 Adjust Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.8.10 Power Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.9 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.10 Manual Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.11 Grab Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.12 Calibrate Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.12.1 Calibration Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.13 Operating the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.14 Moving the Distributor Arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.15 Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.15.1 Collecting Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.15.2 Viewing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.15.3 Configuring Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.15.4 Sampling Results Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.15.5 Combined Results Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.15.6 Summary Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.16 System IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.17 Programming for 700 Series Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Section 5 Extended Programming

5.1 Extended and Standard Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 One-Part and Two-Part Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Storage for Extended Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Selecting a Stored Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

ii

Page 11

6712FR Refrigerated Sampler

Table of Contents

5.4 Programming for 700 Series Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5 Programming SDI-12 Sondes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.6 Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.6.1 Storm Water Runoff Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.7 Suction Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.8 Rinses and Retries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.9 Pacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.9.1 Event Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.9.2 Event Paced Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.9.3 Nonuniform Time Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.9.4 Nonuniform Clock Time Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.9.5 Nonuniform Interval Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.9.6 Random Interval Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.10 Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.1 Sequential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.2 Bottles Per Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.3 Samples Per Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.4 Composite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.5 Multiple Bottle Compositing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.6 Time Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.10.7 Continuous Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.11 Flow Proportional Sample Volumes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.11.1 Calculating Variable Sample Volume Settings . . . . . . . . . . . . . . . . . . . . 5-20

5.11.2 Calculations when Using an External Flow Meter . . . . . . . . . . . . . . . . . 5-21

5.11.3 Calculations when Using a 700 Series Flow Module . . . . . . . . . . . . . . . . 5-22

5.12 Sampler Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.12.1 Sampler Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.13 Sampler Enable Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.13.1 Once Enabled Stay Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.13.2 Repeatable Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.13.3 Sample at Enable or Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.13.4 Delay To Start Of Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.13.5 “Dry Period” Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.13.6 Resetting the Sample Interval at Enable . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.14 Pauses/Resumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.15 Running Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.15.1 Run Time Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.15.2 Interrupting a Running Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.16 Sampling Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.17 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.18 Software Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.18.1 Liquid Detector Enable/Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.18.2 Programming Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.18.3 Measurement Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.18.4 Dual Sampler Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.18.5 Pre-sample and Post-sample Purge Counts . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.18.6 Serial Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.18.7 Program Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5.19 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.19.1 SDI-12 Sonde Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.19.2 Rain Gauge Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.19.3 I/O Pin Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.19.4 Dialout Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.19.5 Pager Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

5.19.6 Digital Modem Text Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

5.19.7 Refrigerator Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

5.19.8 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

5.20 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

5.21 Pressurized Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

iii

Page 12

6712FR Refrigerated Sampler

Table of Contents

5.22 Command Driven Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

5.23 Command Driven Sampler Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

Section 6 SDI-12 Sondes

6.1 SDI-12 Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Scanning For Sondes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Isco Ready Sondes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Other SDI-12 Sondes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.5 Sonde Setup - Storing Parameter Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.6 Sonde Calibration and Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.6.1 The Calibration Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.6.2 The Validation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.7 Disconnecting Sondes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Section 7 Remote Operation

7.1 Computer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 Menu Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.2 External Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.1.3 Remote Control of Sampler Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.2 Telephone Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Section 8 Maintenance

8.1 Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Cleaning Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2.1 Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2.2 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.3 Sample Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.4 Suction Line, Pump Tube, and Discharge Tube . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.5 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.6 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.7 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Cleaning Protocols for Priority Pollutants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3.1 Isco Glass Sample Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3.2 Vinyl Suction Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3.3 PTFE Suction Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3.4 Isco Pump Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.4 Maintenance Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.4.1 Set Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.4.2 Pump Tube Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.4.3 Internal Battery Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.4.4 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.5 Replacing the Pump Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.5.1 Checklist For Replacing Pump Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.6 Opening the Controller Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.7 Replacing the Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.8 Replacing the Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.9 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.10 Pump Tube Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.11 Servicing the Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.11.1 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.11.2 Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Appendix A Menu Flowcharts

iv

Page 13

6712FR Refrigerated Sampler

Table of Contents

Appendix B Material Safety Data Sheets

Appendix C General Safety Procedures

C.1 Practical Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.1.1 Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.1.2 Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.1.3 Adverse Atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.1.4 Entering Manholes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.1.5 Traffic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.1.6 Falling Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.1.7 Removing the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.1.8 Other Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.1.9 Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.1.10 Field Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.2 Lethal Atmospheres in Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.3 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Appendix D Replacement Parts List

D.1 Replacement Parts Diagrams and Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Appendix E Accessories List

E.1 Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E.2 Samplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E.3 Bottle Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E.4 Bottle Racks, Retaining Rings, Discharge Tubes, Distributor Arm . . . . . . . . . . . E-2

E.5 Bulk Sets of Bottles with Lids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

E.6 Pump Tubes, Suction Line, Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

E.7 Data Collection Devices and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

E.8 12-Volt Power Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

E.9 Modules, Rain Gauges, & Interfacing Instruments . . . . . . . . . . . . . . . . . . . . . . . . E-4

E.10 SDI-12 Data Acquisition Connect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

List of Illustrations

2-1 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Installing the Bottle Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3 Installing the 24-bottle, 12-bottle, and 8-bottle Kits . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-4 Installing the 2-bottle Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-5 Attaching the suction line to the pump tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-6 Identifying the Sampler Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3-1 Menu Tree for Standard Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4-1 Sample Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-2 Start Time Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4-3 Running a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-4 Taking a Grab Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-5 Report: Program Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4-6 Report: Sampling Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4-7 Report: Combined Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4-8 Report: Combined Results (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-9 Report: Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

5-1 Sample Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-2 Factors Affecting Flow-Weighted Variable-Volume Samples . . . . . . . . . . . . . . . 5-20

5-3 Variable-Volume Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

v

Page 14

6712FR Refrigerated Sampler

Table of Contents

5-4 Start Time Diagram for Sampler Enable Settings . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5-5 Event Mark Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5-6 Password Protected Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

6-1 SDI-12 Sonde Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7-1 Press and hold ?? to connect to the sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7-2 Example list of remote menu commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8-1 Removing and Replacing the Pump Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8-2 Placing the Pump Tube in the Liquid Detector . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8-3 Opening the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8-4 Main Circuit Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8-5 Rear View of the 6712FR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-6 Thermostat Logic Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-7 Control Box Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-8 Control Box Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-9 Refrigeration System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

A-1 6712 Menu Tree for Standard Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A-2 Standard Programming: Programming Screens . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A-3 Standard and Extended Programming: Start Times . . . . . . . . . . . . . . . . . . . . . . . A-3

A-4 Standard Programming: Quick View; Programming Screens . . . . . . . . . . . . . . . . A-4

A-5 Standard Programming: Quick View; Start Times . . . . . . . . . . . . . . . . . . . . . . . . A-5

A-6 View Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A-7 Maintenance Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A-8 Manual Functions Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A-9 Extended Programming: Programming Screens . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A-10 Extended Programming: Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A-11 Extended Programming: Pacing and Distribution . . . . . . . . . . . . . . . . . . . . . . A-11

A-12 Extended Programming: Event Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

A-13 Extended Programming: Programmed Sampler Enable . . . . . . . . . . . . . . . . . A-13

A-14 Extended Programming: Quick View; Programming Screens . . . . . . . . . . . . . A-14

A-15 Extended Programming: Quick View; Equipment Set-Up . . . . . . . . . . . . . . . . A-15

A-16 Extended Programming: Quick View; Pacing and Distribution . . . . . . . . . . . A-16

A-17 Extended Programming: Quick View; Programmed Sampler Enable . . . . . . . A-17

A-18 Extended Programming: Normal View; Software Options . . . . . . . . . . . . . . . . A-18

A-19 Extended Programming: Quick View; Software Options . . . . . . . . . . . . . . . . . A-19

A-20 Extended Programming: Normal View; Hardware . . . . . . . . . . . . . . . . . . . . . . A-20

A-21 Extended Programming: Quick View; Hardware . . . . . . . . . . . . . . . . . . . . . . . A-21

A-22 Analog and Dialout Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

A-23 Analog Output and Dialout Quick View Screens . . . . . . . . . . . . . . . . . . . . . . . A-22

A-24 SDI-12 Sonde Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-23

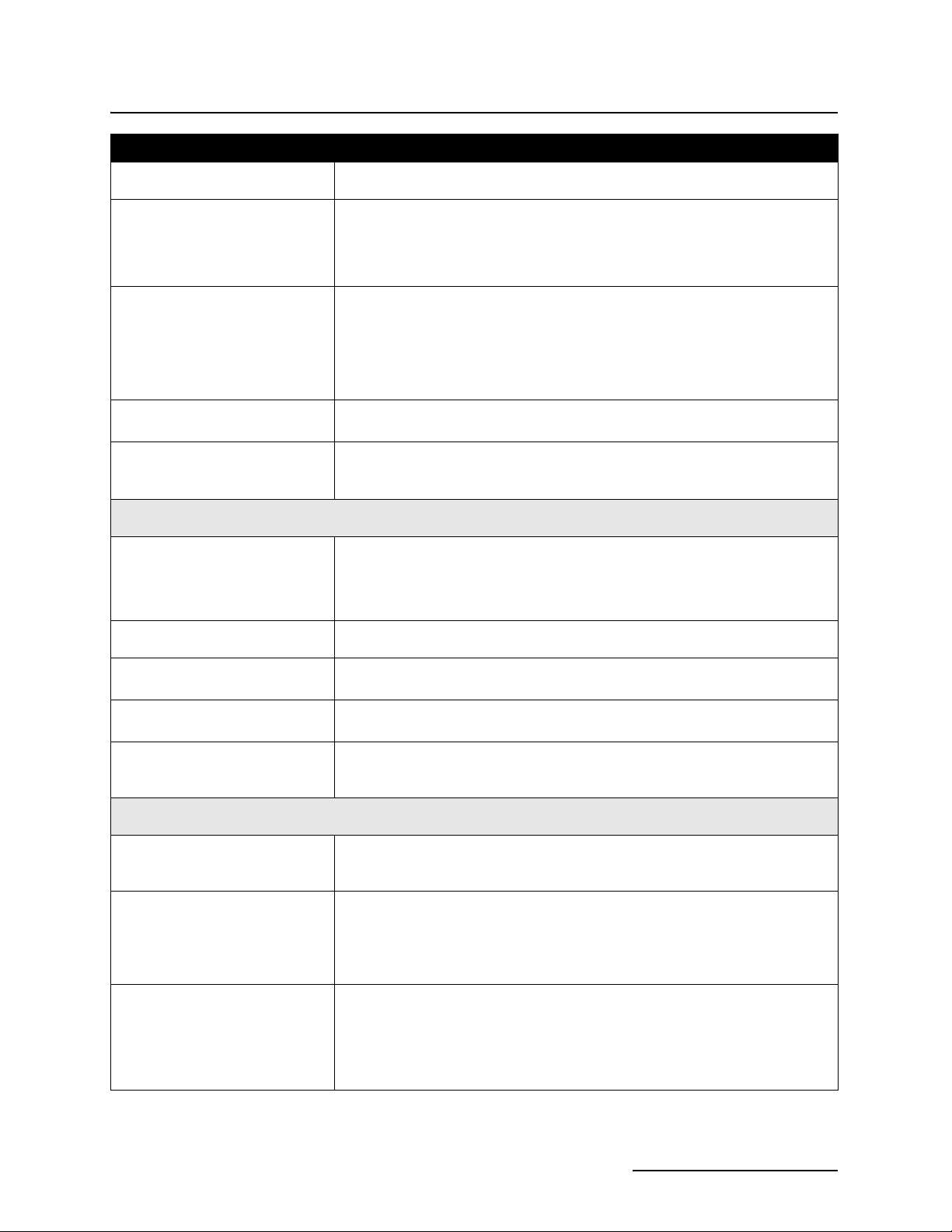

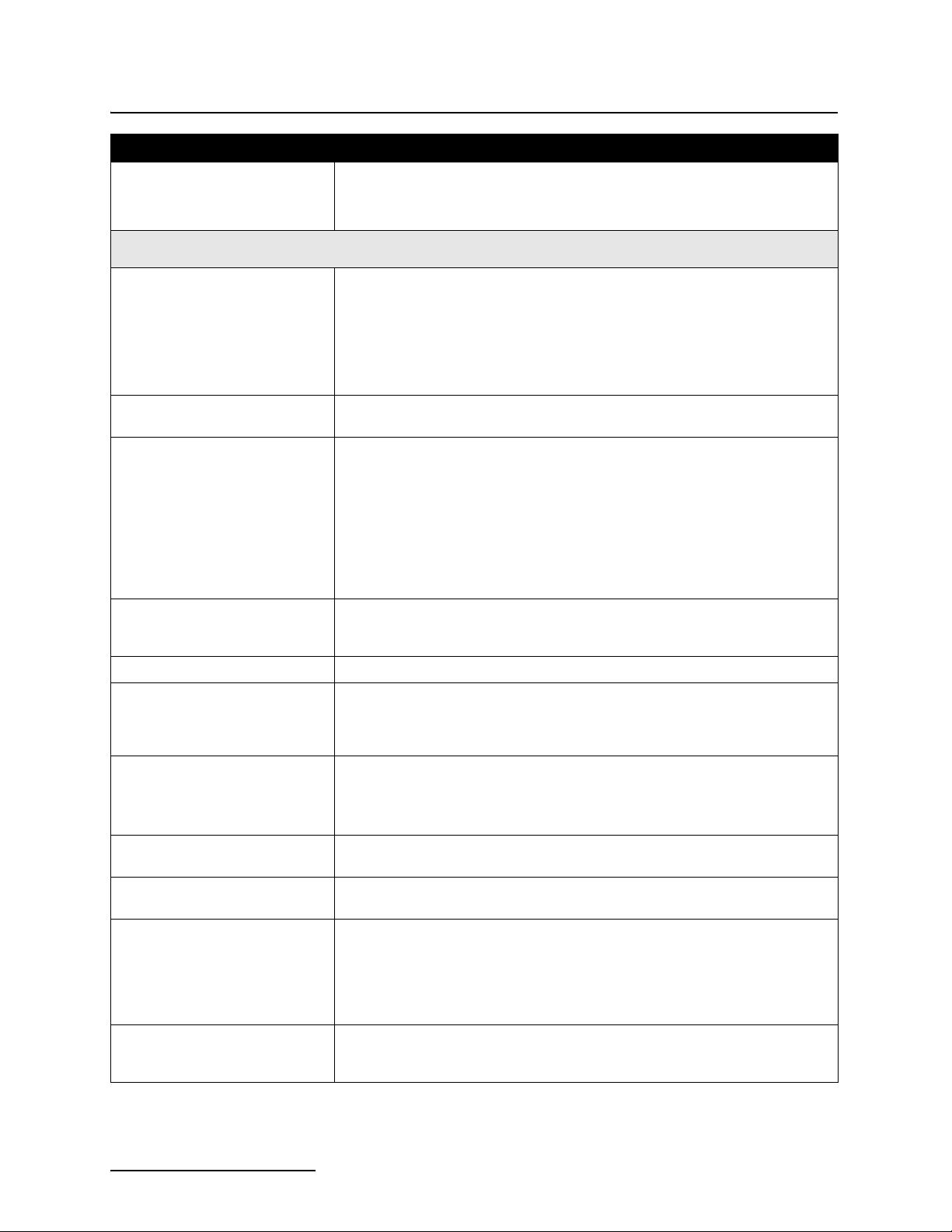

List of Tables

1-1 6712FR Sampler Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 6712FR Sampler Construction Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3 Technical Specifications for the 6712FR Refrigerated Sampler . . . . . . . . . . . . . . 1-7

1-4 Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

2-1 Distributor Arm Positions and Discharge Tube Lengths for Bottle Kits . . . . . . . 2-3

2-2 Selecting the Right Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3 Connecting Isco Instruments to the Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

3-1 About the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4-1 Standard Program: Sample Every 15 Minutes, One Sample Per Bottle . . . . . . . 4-2

4-2 Standard Program: Flow-Paced Sampling, Two Bottles Per Sample . . . . . . . . . . 4-3

4-3 Reports: Program Events, Source Codes, and Error Codes . . . . . . . . . . . . . . . . . 4-21

4-4 Programming Example With 730 Module Installed . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-5 Programming Example With 750 Module Installed . . . . . . . . . . . . . . . . . . . . . . . 4-31

5-1 Selecting a Stored Extended Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2 Storm Water Runoff Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

vi

Page 15

6712FR Refrigerated Sampler

Table of Contents

5-3 Event Paced Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5-4 Sampler Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5-5 Serial Data Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

7-1 6712 Remote Menu Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-2 Serial Data Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7-3 Remote Control of Sampler Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7-4 6712 Remote Phone Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

8-1 Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8-2 Resetting the Pump Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8-3 Checking and Replacing the Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

C-1 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

vii

Page 16

6712FR Refrigerated Sampler

Table of Contents

viii

Page 17

6712FR Refrigerated Sampler

Section 1 Introduction

The 6712FR Refrigerated Sampler is an integral part of Teledyne

Isco’s comprehensive sampling system. The system includes the

6712FR and 6712SR Refrigerated Samplers, the 6712 Compact

Sampler, and the 6712 Standard Sampler.

The 6712FR is ideally suited for permanent installation in a wide

variety of indoor and outdoor environments. Constructed from

durable, corrosion resistant materials, the 6712FR withstands

the hostile environments of industrial and municipal monitoring

sites. However, do not install in locations where the refrigerator’s

lower compartment could become submerged.

The 6712FR accepts a variety of sequential and composite bottle

kits. Like all samplers in the 6712 series, it is compatible with a

variety of Isco instruments.

6712 Controller

1.1 About This Manual This manual contains the information you will need to install,

program, operate, and maintain a 6712FR refrigerated sampler.

There are eight sections and five appendices:

• Section 1, Introduction lists the features and specifica-

tions of the 6712FR refrigerated sampler.

• Section 2, Installation/Preparation steps you through

installing the sampler and preparing it for use.

• Section 3, Getting Started describes features that are

common to both standard and extended programming

modes.

• Section 4, Standard Programming shows how to

program your sampler using standard programming

mode.

• Section 5, Extended Programming shows how to

program your sampler using extended programming

mode.

• Section 6, SDI-12 Sondes provides information on

setting up sondes to work with the 6712FR.

• Section 7, Remote Operation explains how the 6712

controller can be operated remotely from external

devices.

• Section 8, Maintenance covers the basic maintenance

required to keep your sampler in top operating

condition.

1-1

Page 18

6712FR Refrigerated Sampler

Section 1 Introduction

The appendices are:

• Appendix A, Menu Flowcharts

• Appendix B, Material Safety Data Sheets

• Appendix C, General Safety Procedures

• Appendix D, Replacement Parts

• Appendix E, Accessories List

1.2 About 700 Series Modules

The bay on the controller’s side accepts any of Teledyne Isco’s 700

Series Modules. The 700 Series includes:

• 701 pH Parameter Module for monitoring pH and

temperature.

• 710 Ultrasonic Module for monitoring a flow stream’s

level and flow rate with an ultrasonic level sensor.

• 720 Submerged Probe Module for monitoring a flow

stream’s level and flow rate with a submerged probe.

• 730 Bubbler Flow Module for monitoring a flow stream’s

level and flow rate with a bubbler system.

• 750 Area Velocity Module for monitoring a flow stream’s

level, velocity, and flow rate.

• 780 4-20mA Input Module for interfacing to non-Isco

devices with 4 to 20 milliampere output signals.

The modules are optional accessories, and are not required for

operation. However, the modules offer a number of advantages:

they are an economical way to combine flow rate or parameter

monitoring with sampling, and you can program the samplers

and modules as a single unit. Finally, the samplers store the

readings in memory.

1.3 SDI-12 Sondes As an option, the sampler accepts up to 16 parameters from up to

ten sensors with SDI-12 addresses from 0 - 9 (refer to SDI-12

Sonde Readings, page 1-10, for specific parameters).

The data parameters used by the sensing device (sonde) and

recording device (sampler) must match. Certain vendors’ sondes

have enhanced commands that facilitate “plug and play” setup.

These Isco Ready sondes can tell the 6712FR what values they

have, their order, and units of measure. Other sondes can be

used, but require manual setup to identify proper data types for

each data value reported.

1.4 Memory to Store Monitoring Data

1-2

The samplers contain enough memory to store five sampling programs, sampling data, Isco 700 Series Module readings, and

SDI-12 parameter readings. You can view the readings on your

sampler’s display.

You can also retrieve the readings and reports so the information

can be processed on a personal computer. Readings and reports

may be collected with a computer running Teledyne Isco’s

Flowlink™ software. Flowlink can download the information

through a direct connection, a modem connection (when the

sampler is equipped with the optional dial-out modem or con-

Page 19

6712FR Refrigerated Sampler

Section 1 Introduction

nected to the optional digital cellular modem), or from a 581

Rapid Transfer Device (RTD). The RTD is a quick and simple

way to transfer the data from the field to your computer. Reports

are easily collected with Teledyne Isco’s Samplink software.

1.5 Pump Requirements The pump also requires a pump tube made specifically for the

6712 and 6700 Series samplers. These pump tubes are easily recognized by their blue alignment collars. The 6712 pump tubing is

the same as that for Teledyne Isco’s 6700 Series samplers, but

different from Teledyne Isco’s earlier model samplers, such as the

3700 Series. Other types of pump tubing will not work in

the 6712FR. Refer to Replacing the Pump Tube on page 8-9.

CAUTION

This sampler has a high performance pump. As with all such

pumps, it relies upon liquid to cool working components. If the

sampler is programmed to pump in the absence of liquid in

excess of 5 minutes, excessive heat buildup may damage the

paddles, rollers, and housing. Ensure that the liquid inlet is

completely immersed.

Top Cover

Controller Only

(does not include refrigerator)

Refrigerator

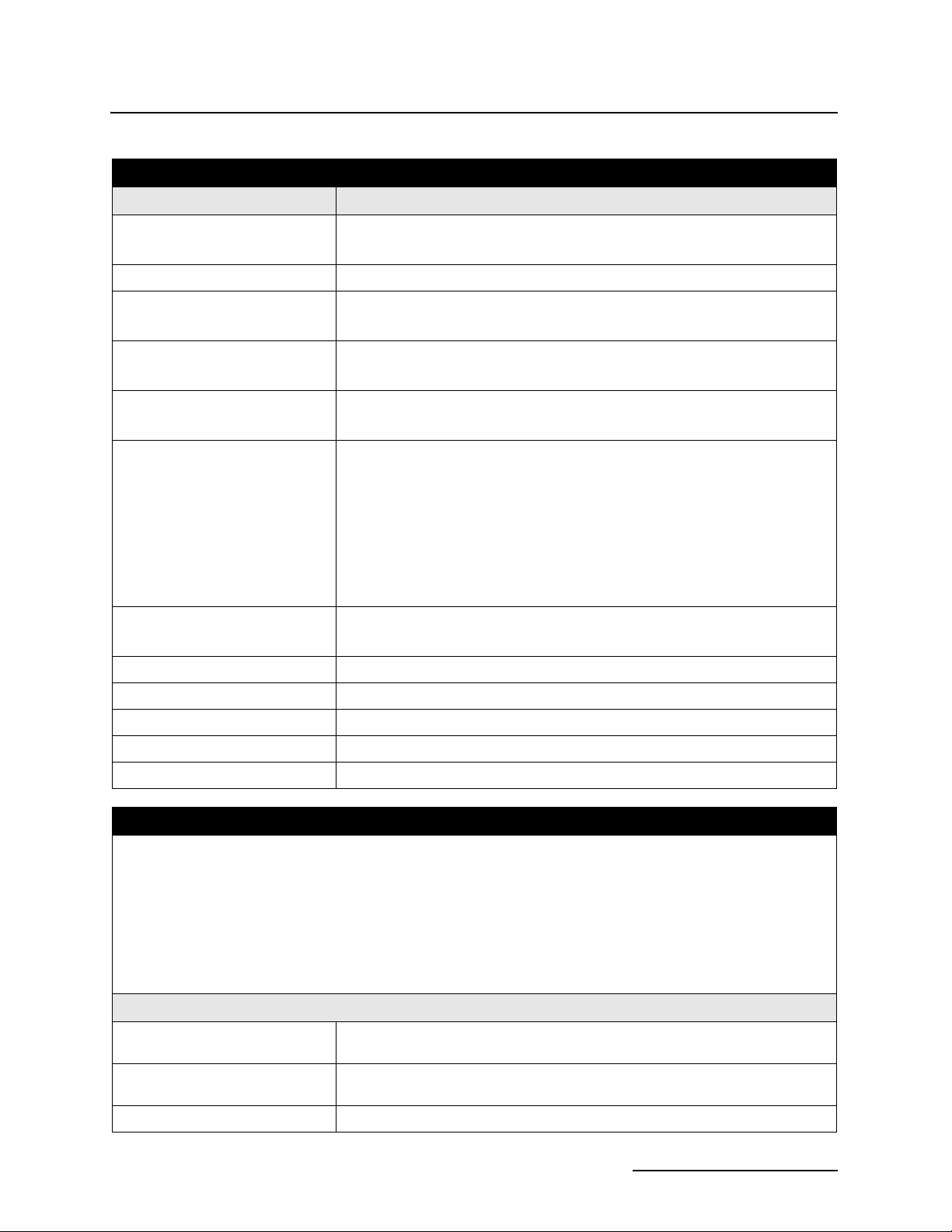

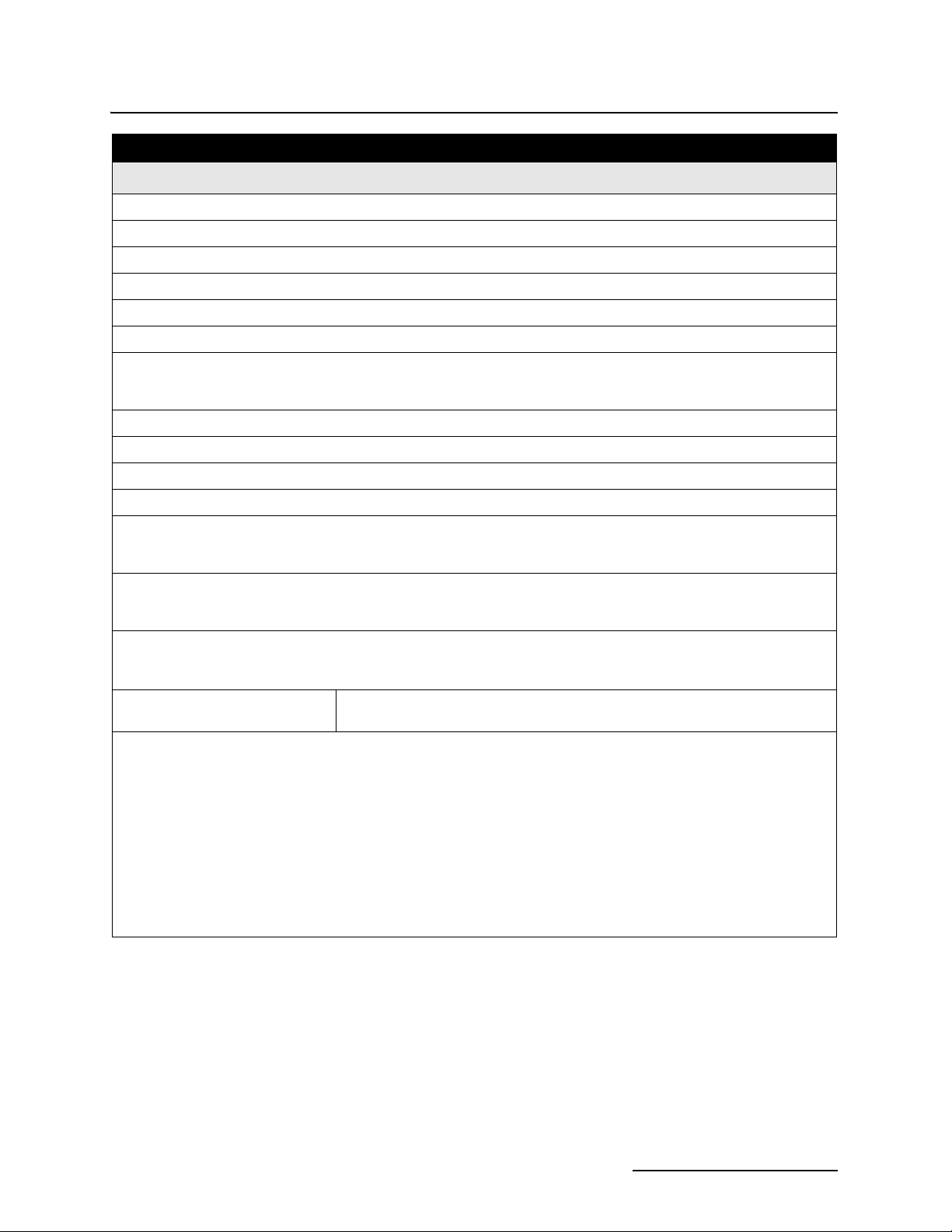

Table 1-1 6712FR Sampler Features

General Features

• Protects pump, power source, and controller.

• Lockable latches.

• Contains a rechargeable desiccant to prevent moisture damage to the

electronics, pump, and distributor systems.

• Control panel sloped 15 degrees for easy reading.

• Keys labeled with large, vivid icons.

• 80-character display (4 lines by 20 columns).

• Display has selectable backlight:

Always on or always off.

Timed, switching off when keypad is inactive for 60 seconds.

• Memory for program and data storage.

• Flash memory for easy software upgrades.

• NEMA 4X and 6 (IP67) ratings.

• The 6712FR requires 120 volts AC, 60 Hz, or optional 230 volts Ac, 50 Hz. A

built-in 12 volt DC power converter powers the controller.

• The power supply and solid state thermostat are sealed inside the refrigerator’s

base. However, electrical connections for the fan and compressor are not

sealed.

• A forced air condensing coil and front ventilation let you place the unit close to a

wall or in a corner.

• The oversized wrap-around evaporator plate cools the sampling compartment

quickly and efficiently. Heaters on the plate let the sampler continue to operate

in cold temperatures. The evaporator plate is self-defrosting.

• Food-grade ABS plastic interior will not support bacterial growth or leach

plasticizers into the sample.

1-3

Page 20

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-1 6712FR Sampler Features (Continued)

Adjustable

Distributor Arm

Discharge Tube and Support

Spring

Composite Tube Guide for Composite Sampling

Compatible

Isco Products

Real-Time Displays As the sampler runs a sampling program, it displays the program’s status. The

Programming for Modules Program the modules from the sampler’s control panel. The module’s program

• A single distributor arm adjusts quickly to fit all bottle kits. Easily removed for

composite sampling.

• Routes sample liquid from pump tube, through distributor arm to sample bottle.

• Keeps discharge tube in place over composite bottles.

• 581 Rapid Transfer Device

• 1640 Liquid Level Actuator

• 2100 Series Flow Modules

• 674 Rain Gauge

• 700 Series Modules

• 4100 Series Flow Loggers

• SDI-12 Sondes

• 4200 Series Flow Meters

• Refrigerator Temperature Sensor

• Flowlink, Samplink

status display may include such information as the time of the next sample, the

number of the next bottle, or whether the sampler is disabled or stopped. If the

sampler encounters an error while running the program, it displays a message

alerting you to the problem.

settings become part of the sampling program.

Setup for SDI-12 Sondes Calibrate and program SDI-12 sondes from the sampler’s control panel. The pro-

Memory for Stored Programs

and Readings

Five Reports Available

Serial Data Output

Units of Measure A variety of metric and English units of measure for length, flow rate, flow vol-

External Sampler Enable Isco flow meters and flow loggers have a programmable sampler enable feature

gram settings become part of the sampling program. See Section 6.

512 kilobytes of battery-backed RAM (Random Access Memory), to store:

• Five sampling programs.

• A sampling report from the most recently run program. It records as many as

1000 sampling events; events can be the program start time, enable time,

sample event information, etc.

• 700 Series module readings. The readings can be: level, flow rate, velocity, pH,

temperature, or the data collected by the 4-20 mA module.

• Rain gauge and refrigerator temperature readings.

• SDI-12 sonde readings.

• The Program Settings report, listing current program settings.

• The Sampling Results report, listing the events occurring during the program.

• The Combined Results report, combining sampling events with readings from a

rain gauge, module, or SDI -12 sonde.

• The Module Summary report, summarizing flow rate or parameter readings.

• The Rainfall Summary report, listing a summary of rainfall readings.

• ASCII data output from the interrogator port.

ume, and temperature.

that lets them send an electronic signal to a 6712FR that enables (starts) or disables (stops) a running sampling program.

Dual Sampler Mode Dual Sampler Mode operates two samplers.

1-4

Page 21

6712FR Refrigerated Sampler

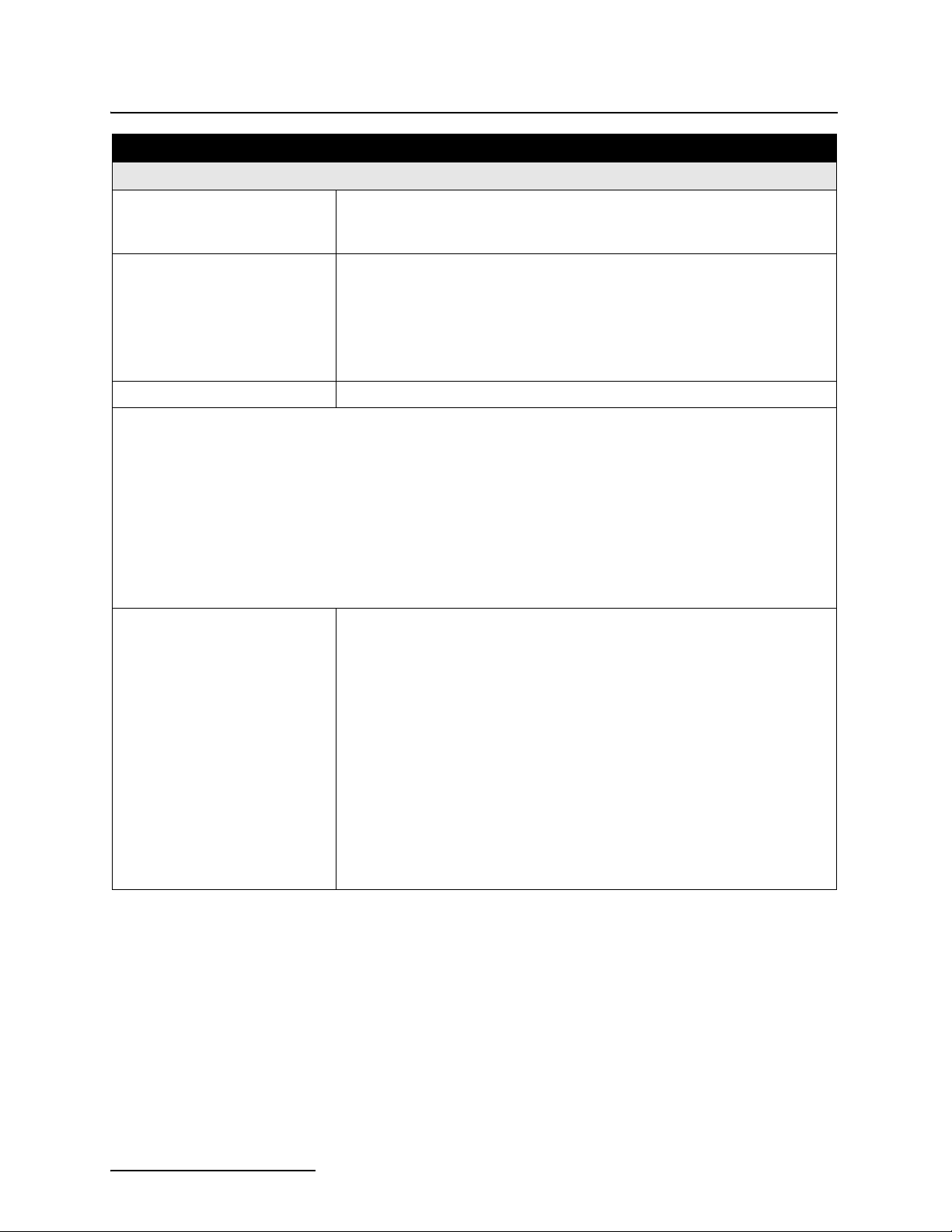

Table 1-1 6712FR Sampler Features (Continued)

Section 1 Introduction

Command Driven Operation

Warning Messages

Optional Dialout Modem The 6712 controller can be ordered with a factory-installed 2400 baud dialout

On-Line Help Notes When programming the sampler, press the [?] (Help) key for a brief help note. All

Two Programming Levels Standard programming lets you set up typical sampling programs quickly.

• Operate sampler functions using RS-232 communications.

• Pump Tube Warning. The 6712FR displays a warning to inspect the tube.

• Internal Battery Warning. From the Maintenance screen, the 6712FR displays a

warning when it is time to replace the internal battery. The internal battery

preserves stored data when the 6712FR is without external power.

modem. With the modem you can:

• connect to the sampler and download data using Flowlink software.

• program the sampler to call a contact list when an “alarm” condition exists.

• use the Remote Commands to control the sampler’s operation from a remote

location.

help topics appear in the index.

Extended programming includes all features available in standard programming

plus additional features.

Sample Delivery System Features

Peristaltic Pump

• Benefits: Liquid moves continuously under pumped flow. The pump has no

metering chambers or gravity fed internal tubing to trap sediment or residual

liquid. Sample liquid contacts only the strainer, suction line, tube coupling,

pump tube, bulkhead fitting, and sample bottles.

LD90 Liquid Detector

Two Line Purges in Sampling

Cycle

Easy Grab Samples Simply disconnect the pump tube from the bulkhead fitting on the center section,

Vinyl and PTFE

Suction Lines

• Non wetted Detection: Sample liquid never touches the detector.

The sampling cycle always includes a pre-sample purge and post-sample purge

that clears the suction line of residual liquid.

and place the pump tube over your sample container.

3

•

/8-inch ID (Inside Diameter) vinyl line.

3

•

/8-inch ID PTFE lined with polyethylene jacket.

Standard Programming Features

Pacing

Distribution Methods

Three Flexible

Start-Time Settings

• Uniform Time Pacing: Sampling at regular time intervals.

• Flow Pacing: Sampling at regular flow-volume intervals.

• Composite: Samples deposited in a single large bottle.

• Sequential: Only one sample placed in each bottle.

• Samples Per Bottle: Multiple samples placed in each bottle.

• Bottles Per Sample: One sample deposited in multiple bottles.

• Start Immediately: Starts the sampling program immediately.

• Delayed Start: Starts the sampling program after a user-definable delay of 1 to

999 minutes.

• Clock Time: Starts the sampling program at a user-definable time on one or

more days of the week.

1-5

Page 22

6712FR Refrigerated Sampler

Section 1 Introduction

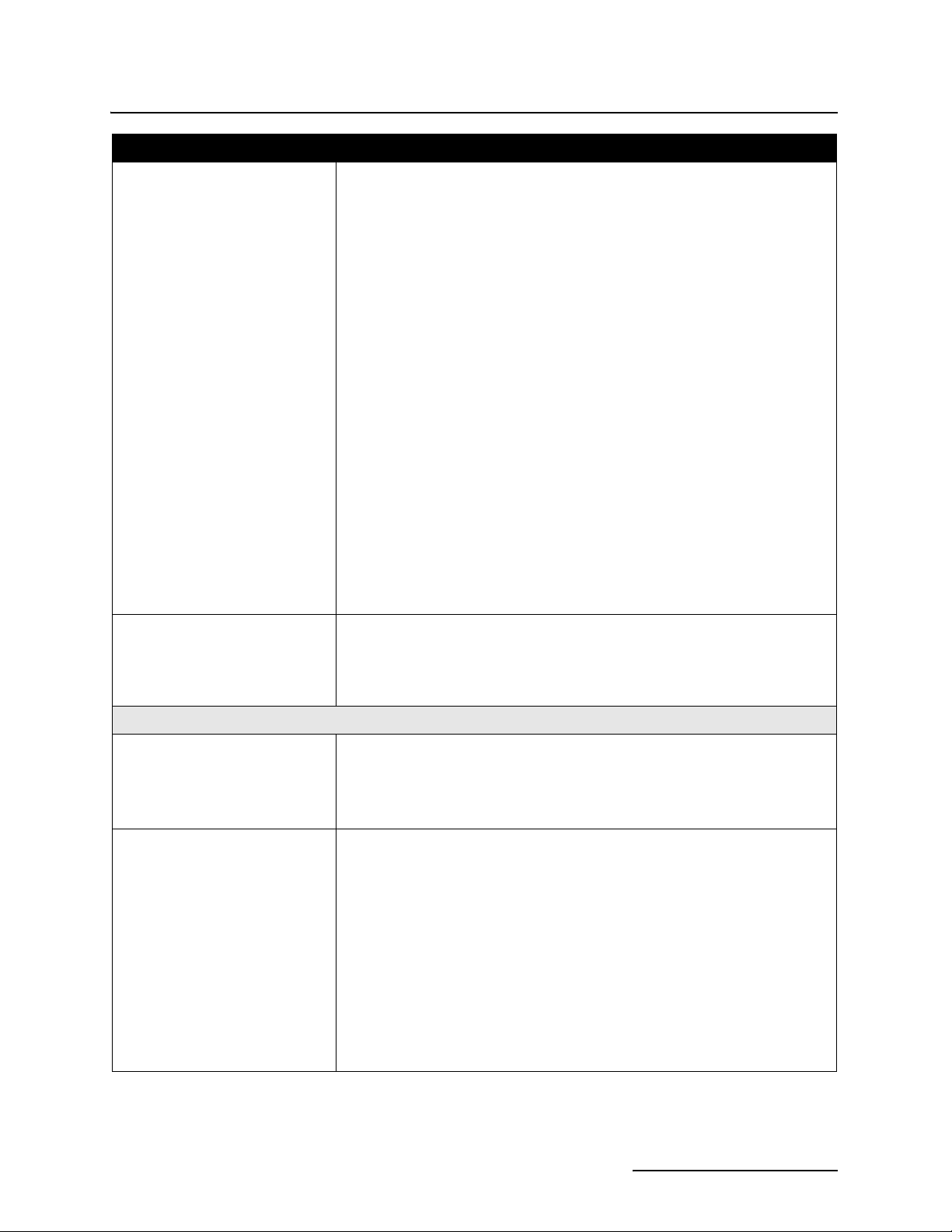

Table 1-1 6712FR Sampler Features (Continued)

Option for a Continuous Running Program

• Continuous Sampling: When sample bottles are regularly replaced, the

sample distribution can restart with the first bottle set after the last bottle set is

filled, without interrupting the running program.

Extended Programming Features

Pacing

Flow Proportional

Sample Volumes

Distribution Methods

Programmable Sampler Enable A 6712FR sampler can be programmed to enable or disable a running sampling

Pauses and Resumes Create intermittent sampling schedules.

Two-Part Programming Two-part programming lets you set up a sampling program that divides the bot-

• Uniform Time Pacing: Sampling at regular time intervals.

• Nonuniform Time Pacing: Sampling at irregular time intervals.

• Random Interval Pacing: Sampling at unique random time intervals generated

by the controller.

• Flow Pacing: Sampling at regular flow-volume intervals.

• Event Pacing: Sampling each time a user-definable event occurs.

Allows for sample sizes to be based on flow. (This option is available only with

uniform time pacing.)

• Composite: Samples deposited in a single large bottle.

• Sequential: Only one sample placed in each bottle.

• Samples Per Bottle: Multiple samples placed in each bottle

• Bottles Per Sample: One sample deposited in multiple bottles

• Multiple Bottle Compositing: A combination of samples per bottle and bottles

per sample distribution methods.

• Time Switched Bottles or Bottle sets: Control the sample distribution using

clock times.

program when readings received from a connected rain gauge, module, or

SDI-12 Sonde meet certain conditions.

tles into two groups, filling each group according to separate pacing, distribution,

sampler enable, and pause and resume settings. This is ideal for storm-water

run-off sampling.

Auto Suction Head or Fixed Suction Head

Suction Line Rinses Program setting for the number of times (0 to 3) that the 6712 rinses the suction

Sampling Retries Program setting for the number of times (0 to 3) that the 6712 attempts to sample

Three Flexible

Start Time Settings

Option for a Continuous Running Program

The suction head, is the vertical distance from the flow stream to the liquid detector. Extended programming has two settings.

• Auto-Suction Head: The head is automatically determined.

• Fixed Suction Head: A user-definable measurement for the head.

line before drawing a sample.

if it fails to deliver the entire sample volume.

• Run Immediately: Starts the sampling program immediately.

• Delayed Start: Starts the sampling program after a user-definable delay of 1 to

999 minutes.

• Clock Time: Starts the sampling program at a user-definable time on one or

more days of the week.

Continuous Sampling: When sample bottles are regularly replaced, the sample

distribution can restart with the first bottle set after the last bottle set is filled,

without interrupting the running program.

1-6

Page 23

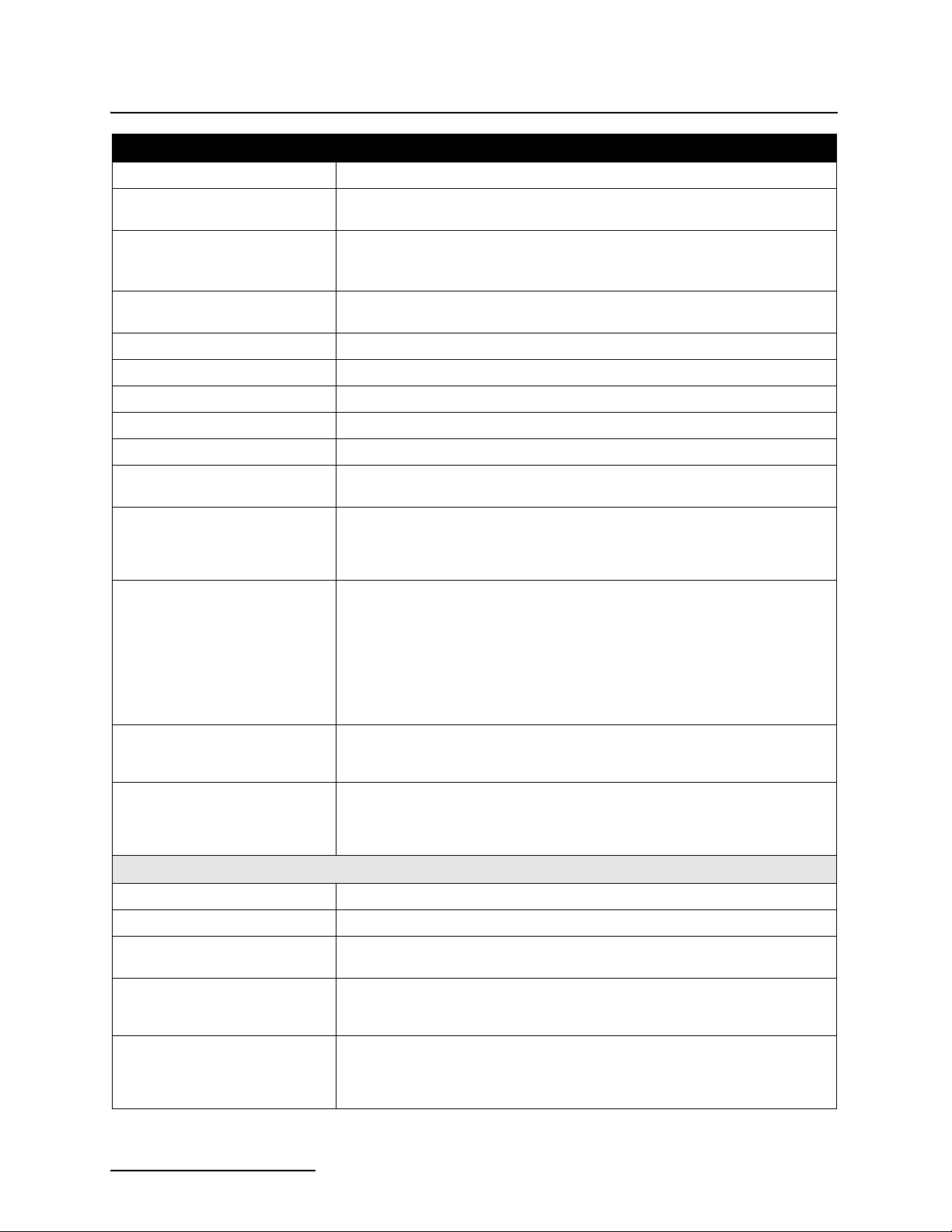

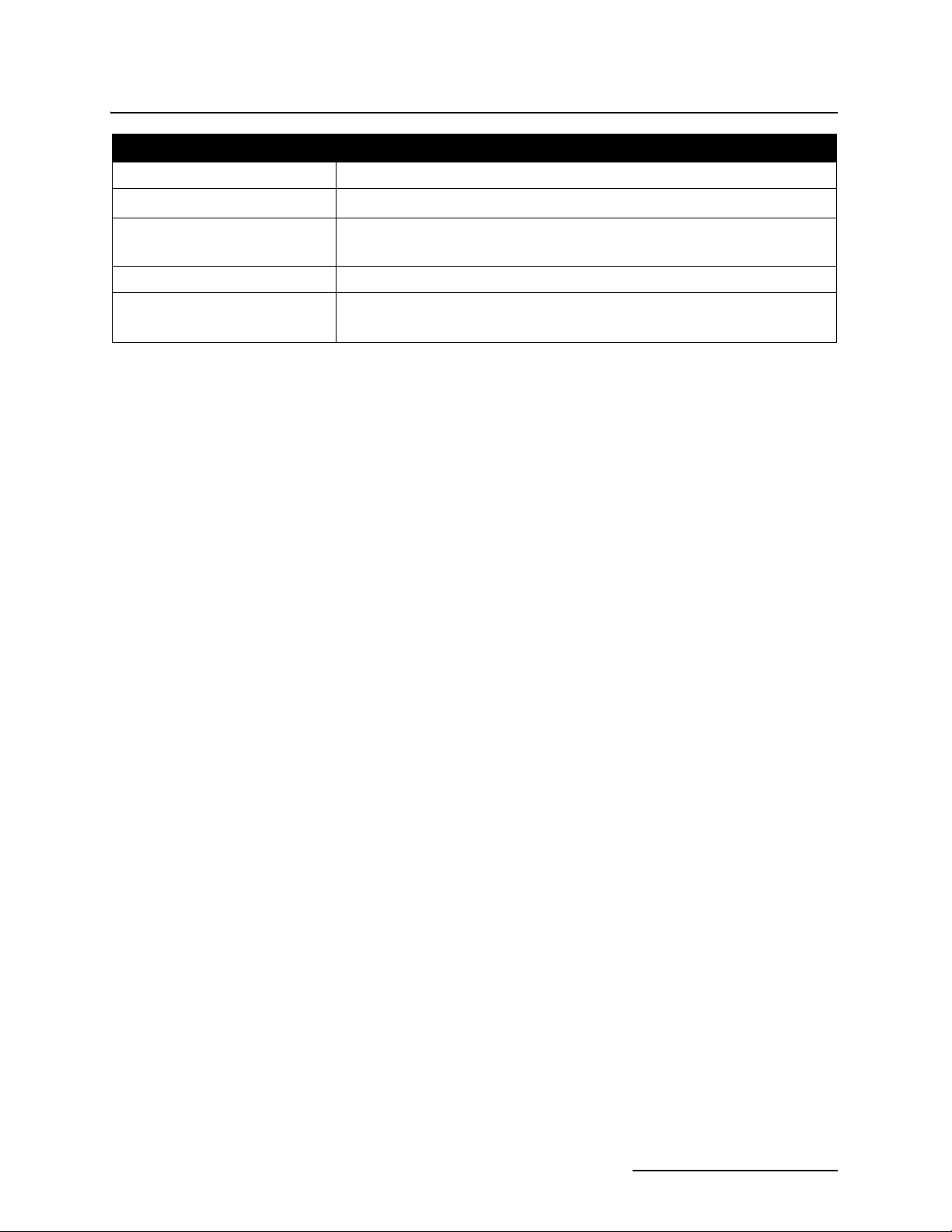

Table 1-2 6712FR Sampler Construction Materials

Item Material

6712FR Refrigerated Sampler

Section 1 Introduction

Top Cover and

Refrigerator Body

Plastic Retaining Rings ABS (Acrylonitrile Butadiene Styrene) plastic

Controller Case

Distributor Arm

Distributor Arm Nut

Pump Rollers

Control Panel

Connector Labels

Distributor Shaft

Pump Shaft

Pump Paddles

Pump Band

Bulkhead Fitting

Latches

Metal Retaining Rings

Refrigeration Tubing

Protection

Condenser Protection Powder coated with polyester.

Evaporator Protection Powder coated with food-grade epoxy.

Fiberglass reinforced plastic with ultraviolet-resistant gel coat.

®

Noryl

®

Delrin

Polyester

Stainless steel

Protected with polyester tubing or phenolic resin.

Refrigerant R134a (1,1,1,2-tetrafluoroethane CH

Insulation Polyurethane

Amphenol Connectors Cadmium Plated Aluminum

FCF3)

2

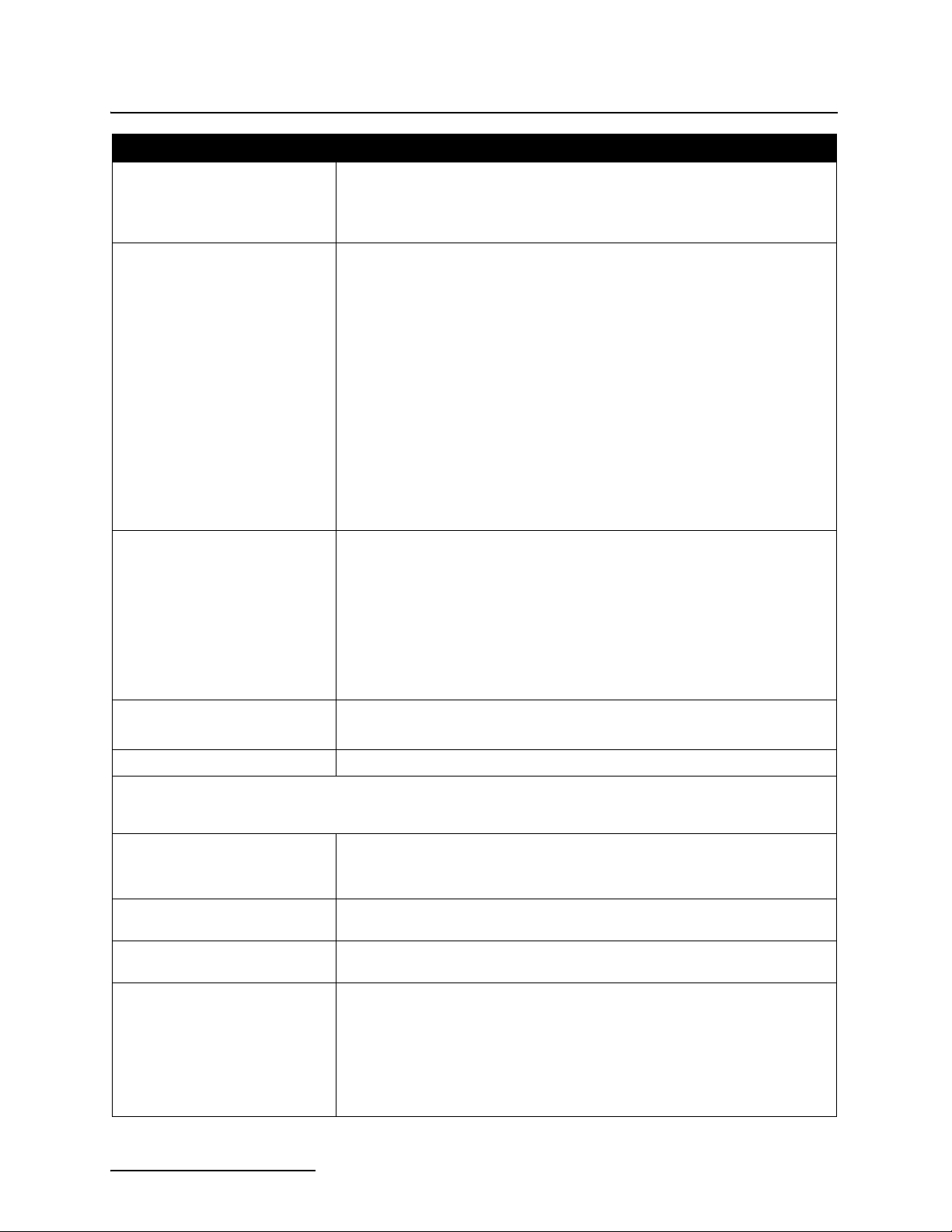

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler

General Notes:

1

1. All weights may vary ±1 lb (±

2. All dimensions may vary ±

3. Sample delivery specifications valid for the following conditions and ranges, unless otherwise stated: 75°F (24°C)

ambient, sample liquid–tap water at 50 to 80°F (10 to 27°C), sample volumes from 50 ml to 1000 ml, suction line

lengths of 25 ft (7.6 m) or less, suction heads from 1 to 20 ft (0.3 to 6.1 m), atmospheric pressure between 29.92 and

31.89 inHg (760 and 810 mmHg), and a power source of an Isco High Capacity Power Pack at 12.5 volts DC no load

output.

6712 Controller, Pump, and Tubing: Mechanical Specifications

Weight of Controller: Controller only: 13.0 lbs (5.9 kg)

Weight of Nickel Cadmium Battery:

Weight of Lead Acid Battery: 5.7 lbs (2.6 kg)

/2 kg).

1

/4 inch (±0.64 cm).

With pump tube: 13.2 lbs (6.0 kg)

4.3 lbs (2.0 kg)

1-7

Page 24

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

Weight of Power Pack: 6.0 lbs (2.7 kg)

Weight of Battery Backed Power

Pack:

Controller Dimensions: Length: 10.3 in (26.0 cm)

Temperature Ranges: Operational: 32 to 120 °F (0 to 49 °C)

Maximum Altitude: 2,000 Meters

Installation Category: II

Pollution Degree: 2

Humidity: 95% RH Maximum

Enclosure: NEMA 4X and 6 Pump: IP17 Enclosure: IP67

Typical Delivered

Volume Accuracy:

Typical Repeatability: (The ability to repeat the delivered volume for a set of samples collected under

Typical Pump Flow Rate and

Line Transport Velocity:

6.6 lbs (3.0 kg)

Width: 12.5 in (31.7 cm)

Height: 10 in (25.4 cm)

Storage: 0 to 140 °F (–18 to 60 °C)

(The ability to deliver the programmed sample volume.)

±10 ml or ±10% of programmed value, whichever is greater.

the same conditions.)

±5 ml or ±5% of the average of the maximum and minimum sample volume in a

sample set, whichever is greater, at lifts up to 25 feet.

Suction Head Flow Rate Line Transport Velocity

3 feet 3.9 liters per minute 3.0 ft/s (0.91 m/s)

5 feet 3.9 liters per minute 3.0 ft/s (0.90 m/s)

10 feet 3.7 liters per minute 2.9 ft/s (0.87 m/s)

15 feet 3.6 liters per minute 2.7 ft/s (0.83 m/s)

20 feet 3.3 liters per minute 2.5 ft/s (0.77 m/s)

23 feet 3.1 liters per minute 2.3 ft/s (0.71 m/s)

25 feet 2.8 liters per minute 2.2 ft/s (0.66 m/s)

Maximum Suction Head: (The maximum suction head is the vertical height at which a sample can be

taken.)

28 ft (8.5 m) at 30 inHg (762 mmHg)

Pump Tube Life: Tube life may vary depending on the abrasiveness of the sample liquid.

Recommended maximum 1,000,000 pump counts. This equates to 912 standard samples. A standard sample is 200 ml at 5 ft (1.5 m) suction head using a

10 ft (3 m) vinyl suction line.

6712 Controller: Electrical Specifications

Controller Internal Battery: 5 years minimum (maintains internal logic, program settings & stored data)

Real Time Clock Accuracy: 1 minute per month

Program Memory: Nonvolatile programmable Flash.

Can be field updated via interrogator connector.

Sampler Power Requirements: Nominal: 12 volts DC supplied by the refrigerator

Operational: 11 to 13 Volts DC

Absolute Maximum: 14.4 Volts DC

Power Pack Requirements:

Use only Isco-made power

packs certified by UL.

(P/N 60-1684-088)

120VAC ±12VAC, 60 Hz., 1.0 Amp.

Note: This is the only version certified by UL. The line cord (mains

connect cable) is the “Disconnect Device.”

1-8

Page 25

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

Power Consumption

a

6712 Controller in Standby 10 mA

Average Current of Accessories

Controller Display Backlight 228 mA

701 pH Module

710 Ultrasonic Module

b

b

720 Submerged Probe Module

730 Bubbler Module

b

b

11 mA

11 mA

11 mA

— at 2 ft of liquid level 24 mA

— at 10 ft of liquid level 31 mA

750 Area Velocity Module

780 4-20 mA Module

YSI 600 with pH, DO, Conductivity, and Temperature

Programmable Analog 4-20 mA Output Option

b

b

b

c

12 mA

10 mA

11 mA

124 mA

CDMA cellular telephone modem

— standby current 35 mA

— current while communicating 150 mA

GSM cellular telephone modem

— standby current 62 mA

— current while communicating 230 mA

a. Current ratings when input power is 12.5 VDC and ambient temperature is 77 °F (25 °C)

b. Average current when programmed to take readings at 15 minute intervals.

c. Rating for three outputs.

Sampler Only

Operating Current:

Approximately 30 mA based on 200 ml sample every hour, 10 ft (3 m) suction

line, and 5 ft (1.5 m) suction head.

Isco External Battery Capacity: Number of Complete Standard Sampling Routines

Nickel-Cadmium Battery Lead-Acid Battery

Sampler Only: 6 9

Sampler with pH Module: 6 9

Sampler with Ultrasonic Module: 6 9

Sampler with Submerged Probe Module: 6 9

Sampler with Bubbler Module (1-2 ft head): 3 5

Sampler with Area Velocity Module: 4 6

Sampler with 4-20 mA Module: 6 9

A Standard Sampling Routine is a 200 ml sample taken every hour in 24 bottle mode, with a 10 foot (3 m) vinyl suction line at 5 feet (1.5 m) of head. The module is set to take a reading every 15 minutes.

1-9

Page 26

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

6712 Controller: Software Specifications

Suction Line: Programmable 3 to 99 ft (1 to 30 m) lengths of:

Sample Frequency:

Rainfall Reading Units: Inches or millimeters

Module Readings: pH 8 bits representing pH 0.1 pH storage resolution

Ultrasonic 16 bits representing level 0.0001 m storage resolution

Submerged Probe 16 bits representing level 0.0001 m storage resolution

Bubbler 16 bits representing level 0.0001 m storage resolution

Area Velocity 16 bits representing level 0.0001 m storage resolution

4–20 mA 16 bits representing percent 0.1% storage resolution

SDI-12 Sonde Readings: Parameter Range Resolution Storage Bytes

3

•

/8" (0.95 cm) I.D. Vinyl

3

•

/8" (0.95 cm) I.D. PTFE-lined with polyethylene jacket

• From 1 minute to 99 hours and 59 minutes in 1 minute increments between

consecutive samples.

• Nonuniform times in minute intervals or clock time

• Random time intervals between consecutive samples

• From 1 to 9,999 flow pulses in single-pulse intervals

• Flow paced in volume with attachable flow module

16 bits representing temp. 0.1 °C storage resolution

16 bits representing velocity 0.001 ft/s storage resolution

16 bits representing level

32 bits representing flow

Temperature -40 - 100 °C 0.1 °C 2

Conductivity 0 - 100 mS/cm 0.01 mS/cm 2

Specific Conductance 0 - 100 mS/cm 0.01 mS/cm 2

Total Dissolved Solids 0 - 90 g/l 0.01 g/l 2

Salinity 0 - 70 ppt 0.1 ppt 2

Dissolved Oxygen 0 - 20 mg/l 0.1 mg/l 1

pH 0 - 14 0.1 1

ORP -999 - 999 mv 0.1 mv 2

Level 0 - 6.5279 m 0.0001 m 2

Ammonium-Nitrogen 0 - 200 mgN/l 0.1 mgN/l 2

Ammonia-Nitrogen 0 - 200 mgN/l 0.1 mgN/l 2

Nitrate-Nitrogen 0 - 200mgN/l 0.1 mgN/l 2

Turbidity 0 - 5000 NTU 0.1 NTU 2

Chloride 0 - 1000 mg/l 0.1 mg/l 2

Chlorophyll 0-400 ug/l 0.1 ug/l 2

Other -99999.0-99999.0 0.0001 4

1-10

Page 27

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

Module Reading Conversions: • Level and 4–20 mA readings converted to flow rate units:

• Velocity units:

• Totalized flow units:

• Devices supported in flow conversion:

Weirs: V-notch; 22.5, 30, 45, 60, 90, and 120 degrees

Flumes:Parshall; 1", 2", 3", 6", 9", 1.5', 2', 3', 4', 5', 6', 8', 10', 12'

Equation: Q = a x H

where:

Q = flow

H = head

a,b,c, and d = entered values

Manning Formula: Round, U-channel, Rectangular, Trapezoidal

Area Velocity: Round, U-channel, Rectangular, Trapezoidal

Data Points: 50 level-flow rate points, 50 level-area points

gallons per second gallons per minute

million gallons per day cubic feet per second

cubic meters per second cubic meters per hour

cubic meters per day liters per second

feet per second meters per second

gallons million gallons

cubic feet cubic meters

liters

Rectangular; with and without end contractions

Cipoletti.

Palmer-Bowlus; 4", 6", 8", 12", 15", 18", 21", 24", 27", 30", 48"

Trapezoidal; LG 60 V, 2" 45 WSC, 12" 45 SRCRC

H; 0.5', 0.75', 1', 1.5', 2', 2.5', 3', 4.5'

b+c

x H

d

Refrigerator Temperature Sensor

6712FR Refrigerated Sampler: Physical Specifications

Dimensions:

Bottle Configurations:

Optional sensor and 5 ft (1.55 m) cable to record temperature readings.

Intended for use with fiberglass refrigerated (FR) samplers.

Range: -40.0 °C to 100 °C

Accuracy specification: ±0.3 °C over a range of 0.0 to 10.0 °C.

Reading data is 2 bytes, with a storage resolution of 0.1 °C.

Height: Top cover closed: 49.25 in (125 cm)

Top cover open: 59.25 in (150.5 cm)

Width: 26 in (66 cm)

Depth: 26 in (66 cm)

• 24 wedge polypropylene bottles, 1,000 ml

• 24 round glass bottles, 350 ml

• 12 wedge polyethylene bottles, 2.5 liters

• 8 round polyethylene bottles, 2.0 liters

• 8 round glass bottles, 1.8 liters

• 2 rectangular polyethylene bottles, 7.5 liters (2 gal)

• 2 round glass bottles, 9.4 liters (2.5 gal)

• 1 round polyethylene bottle, 9.4 liters (2.5 gal)

• 1 round glass bottle, 9.4 liters (2.5 gal)

• 1 round polyethylene bottle, 15 liters (4 gal)

• 1 round polyethylene bottle, 20.5 liters (5.5 gal)

• 1 round glass bottle, 18.5 liters (5.0 gal)

1-11

Page 28

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

Dry Weight: 145 lbs (66 kg) Refrigerator only, no controller or bottle configuration

160 lbs (73 kg) Includes refrigerator, controller, top cover, center section, tub,

pump tube, distributor shaft extension, distributor arm and nut, and discharge

tube for the 24 plastic bottle configuration.

Dry Weight With:

24 plastic bottles, rack, hold down, no caps 175 lbs(79 kg)

24 glass bottles, rack, expander ring, no caps 195 lbs(88 kg)

12 plastic bottles, rack, hold down, no caps 175 lbs(79 kg)

8 plastic bottles, rack, adaptor, no caps 170 lbs(77 kg)

8 glass bottles, rack, adaptor, no caps 180 lbs(82 kg)

2 plastic bottles, rack, no caps 175 lbs(79 kg)

2 glass bottles, rack, no caps 165 lbs(75 kg)

1-9.4 l plastic bottle and cap, no distributor arm or nut165 lbs(75 kg)

1-9.4 l glass bottle and cap, no distributor arm or nut 170 lbs(77 kg)

1-15.0 l plastic bottle and cap, no distributor arm or nut165 lbs(75

kg)

1-20.5 l plastic bottle and cap, no distributor arm or nut165 lbs(75

kg)

1-18.5 l glass bottle and cap, no distributor arm or nut170 lbs(77 kg)

Filled Bottle Weight: 24 plastic bottles 101 lbs(46 kg)

24 glass bottles 104 lbs(48 kg)

12 plastic bottles 89 lbs (41 kg)

12 glass bottles 95 lbs (43 kg)

8 plastic bottles 84 lbs (38 kg)

8 glass bottles 90 lbs (41 kg)

4 plastic bottles 98 lbs (45 kg)

4 glass bottles 104 lbs(48 kg)

1 plastic bottle 90 lbs (41 kg)

1 glass bottle 94 lbs (43 kg)

Average Thermal

Resistance Factor:

Recovery time 5 minutes

Recovery time is the time for the internal air temperature to return to 39°F (4°C) after the door has been opened for

one minute. The empty refrigerator is running and set at 39°F (4°C). The door is opened at least 4 minutes after the

compressor has turned on. Ambient air temperature is 75°F (24°C).

Thermostat Set point range: 32° to 46°F (0° to 8°C)

Temperature Ranges Operational: -20° to 120°F (-29° to 49°C)

Environment Rain and spray resistant, but not watertight. Do not install in locations where the

Electrical

R-16

The average R-value for a complete FR refrigerator not running

Set point accuracy: ±1.8°F (±1°C) at 39°F (4°C)

[With an ambient air temperature of 75°F (24°C)]

Storage: 0° to 140°F (-18° to 60°C)

refrigerator’s lower compartment could become submerged.

Power Requirements: 120 Volts, 60 Hz 230 Volts, 50 Hz

(optional)

Running current: 3.5 amp 1.75 amp

Starting current: 17 amp 8.5 amp

Stalled Compressor current:21 amp 10.5 amp

(maximum)

1-12

Page 29

6712FR Refrigerated Sampler

Section 1 Introduction

Table 1-3 Technical Specifications for the 6712FR Refrigerated Sampler (Continued)

Heater Capacity 60 watts

Compressor 1/5 HP (150W) Tecumseh compressor

Compressor Protection

Temperature safety cutout that will disengage the compressor if the

compressor reaches 221°F (105°C)

Refrigerant R134a, 8 ounce (0.21 kg) charge

Pressure High side: 165 to 215 psig (1.14 to 1.48 MPa)

Low side: 2 to 10 psig (13.8 to 69 kPa)

1-13

Page 30

6712FR Refrigerated Sampler

Section 1 Introduction

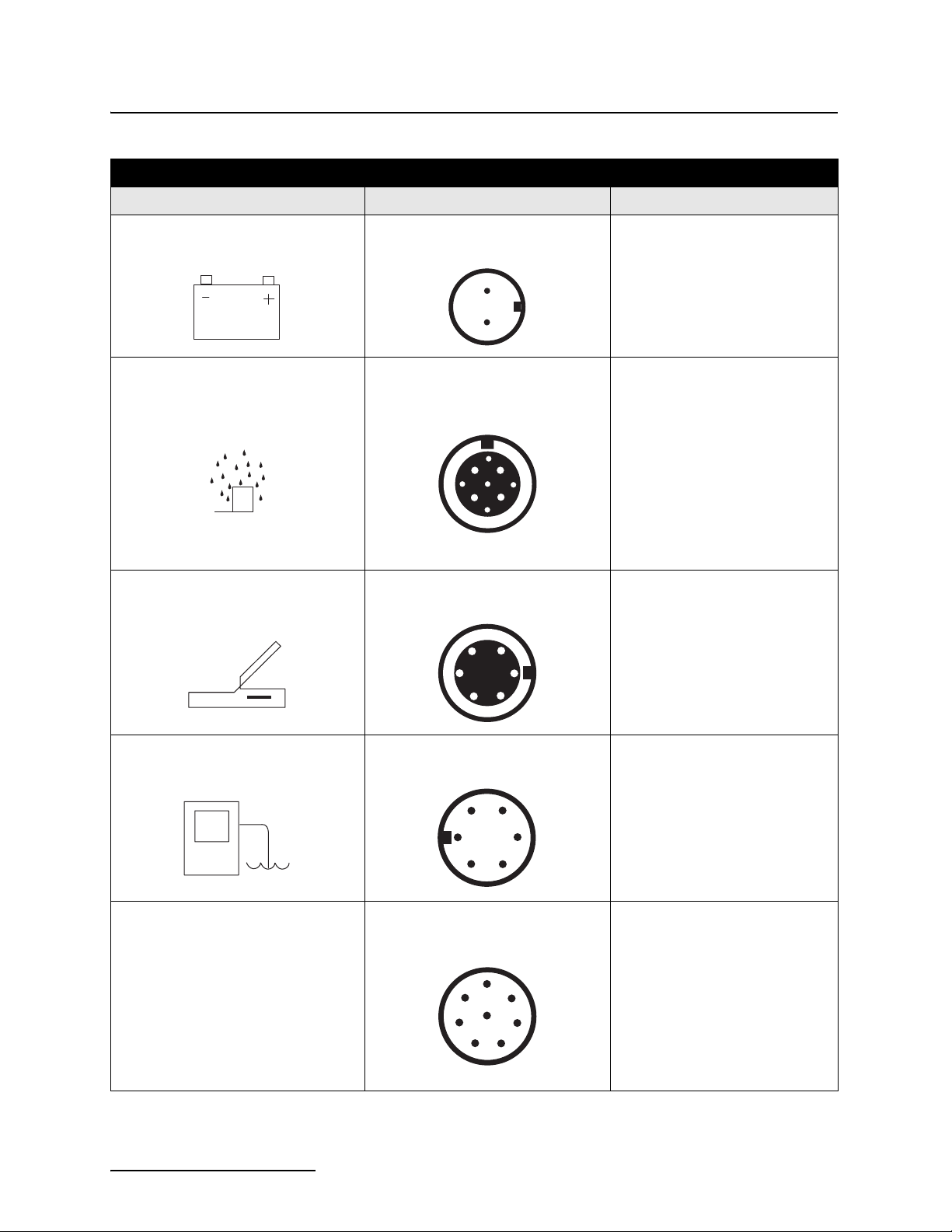

Connector Icon Pin Location Diagram Pin Function

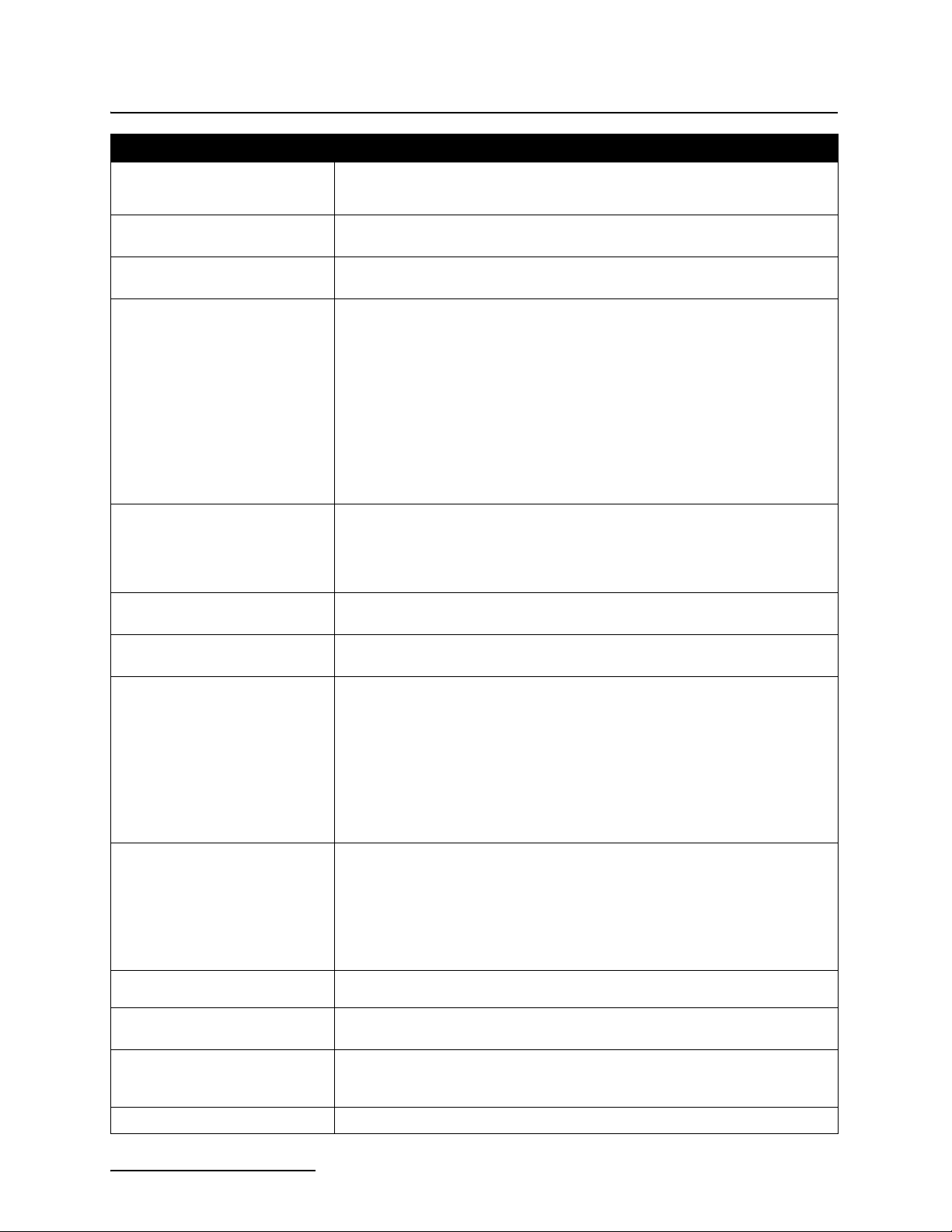

Table 1-4 Connector Specifications

POWER SOURCE

2-PIN MALE, SEALED

A

B

RAIN GAUGE 9-PIN FEMALE, SEALED

E

A

D

F

I

H

B

C

G

INTERROGATOR 6-PIN FEMALE, SEALED

B

C

D

E

A

F

A Ground

B +12 volts DC

A +12 volts DC

B Ground

C Programmable I/O1 pin