Teledyne 6712 Pocket Manual

6712 Sampler

This pocket guide is not intended to replace

the instruction manual. Read the instruction

manual thoroughly before operating the

sampler.

COPYRIGHT © 2001-2003 by

Teledyne Isco, Inc., 4700 Superior St.,

Lincoln, Nebraska, U.S.A. 68504

Phone: (402) 464-0231

Toll Free: (800) 228-4373

FAX: (402) 465-3022

Part #69-9003-589

Issued: January, 2001

Revision C, December 2003

6712 Sampler

Table of Contents

1. Programming

1.1 Getting Started . . . . . . . . . . . . . . . . . 1-3

1.2 Using Menus and Entering Numbers 1-4

1.2.1 Selecting Menu Options . . . . . 1-4

1.2.2 Entering Numbers . . . . . . . . . 1-4

1.2.3 Clock and Calendar Entry Screens

1.3 Quick View Screens . . . . . . . . . . . . . 1-11

1.4 Help Notes . . . . . . . . . . . . . . . . . . . . 1-13

1.5 Warning Messages . . . . . . . . . . . . . . 1-13

1.6 Changing to and from Extended and

1.7 Storage For Extended Programs . . . 1-14

1.8 Programming the Modules . . . . . . . 1-16

1.9 Programming SDI-12 Sondes . . . . . 1-17

1.10 Programming Examples . . . . . . . . . 1-19

2. Operation

2.1 Installation and Operation Checklist 2-1

2.2 Installing Distributor Arm . . . . . . . . 2-2

2.3 Installing Bottle Kits . . . . . . . . . . . . . 2-6

2.4 Positioning a Sampler . . . . . . . . . . . . 2-7

2.5 Connecting An External Instrument 2-8

. . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.3.1 Paging Through the Quick View

Screens . . . . . . . . . . . . . . . . . 1-12

1.3.2 Changing Settings in a Quick

View Screen . . . . . . . . . . . . . 1-12

Standard Screens . . . . . . . . . . . . . . . 1-14

1.9.1 Stored Programs . . . . . . . . . . 1-17

2.5.1 Flow Meter Connector . . . . . . 2-8

2.5.2 Rain Gauge Connector . . . . . . 2-9

i

6712 Sampler

2.6 Running Programs . . . . . . . . . . . . . . . 2-9

2.7 Interrupting a Running Program . . . 2-9

2.8 Run Time Screens . . . . . . . . . . . . . . 2-10

2.8.1 Module and SDI-12 Sonde

2.9 Error Messages . . . . . . . . . . . . . . . . 2-11

2.10 Recovering the Sampler . . . . . . . . . . 2-12

2.11 Viewing the Data . . . . . . . . . . . . . . . 2-13

2.12 Configuring Reports . . . . . . . . . . . . . 2-14

2.13 Grab Samples . . . . . . . . . . . . . . . . . . 2-15

2.14 Calibrating . . . . . . . . . . . . . . . . . . . . 2-17

Readings . . . . . . . . . . . . . . . . 2-11

2.9.1 Fatal Error . . . . . . . . . . . . . . 2-12

2.14.1 Calibration Tips . . . . . . . . . . 2-18

3. Reference

3.1 Replacing the Pump Tube . . . . . . . . . 3-1

3.1.1 Pump Tube Warning . . . . . . . 3-1

3.1.2 Checklist For Replacing Pump

3.2 Rinses and Retries . . . . . . . . . . . . . . . 3-5

3.3 Pacing . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Distribution . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Sampler Enable . . . . . . . . . . . . . . . . 3-12

3.6 Start Times . . . . . . . . . . . . . . . . . . . . 3-13

3.7 Operating the Pump . . . . . . . . . . . . 3-17

3.8 Moving the Distributor Arm . . . . . . 3-18

Tube . . . . . . . . . . . . . . . . . . . . . 3-2

3.4.1 Sequential . . . . . . . . . . . . . . . . 3-6

3.4.2 Bottles Per Sample . . . . . . . . . 3-8

3.4.3 Samples Per Bottle . . . . . . . . 3-10

3.4.4 Composite . . . . . . . . . . . . . . . 3-12

3.4.5 Multiple Bottle Compositing 3-12

ii

6712 Sampler

Section 1 Programming

Before programming the 6712, you should

become familiar with its keys and how to use

the programming screens. A description of the

keys appears in Table 1-1.

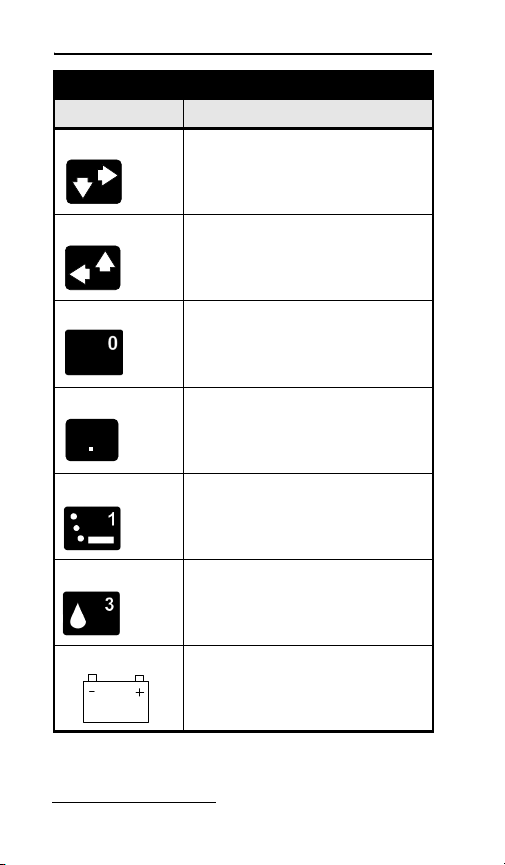

Table 1-1 Keypad and Connector Icons

Icon Function

On-Off Turns sampler on or off.

Stop Stops the pump, distributor, or a

running program.

In programming screens, returns

to a previous screen.

Enter Accepts a menu choice or

number entry and goes to next

screen.

Help In programming screens,

displays a brief help message.

1-1

6712 Sampler

Table 1-1 Keypad and Connector Icons

Icon Function

Down-Right Selects the menu option right or

below the current choice.

Up-Left Selects the menu option left or

Nu mbers Types a numbe r.

Decimal Point Types a decimal point.

Pump Reverse Press when at main menu to run

Pump Forward Press when at main menu to run

Power 12 volt power source

above the current choice.

pump.

pump.

1-2

Section 1 Programming

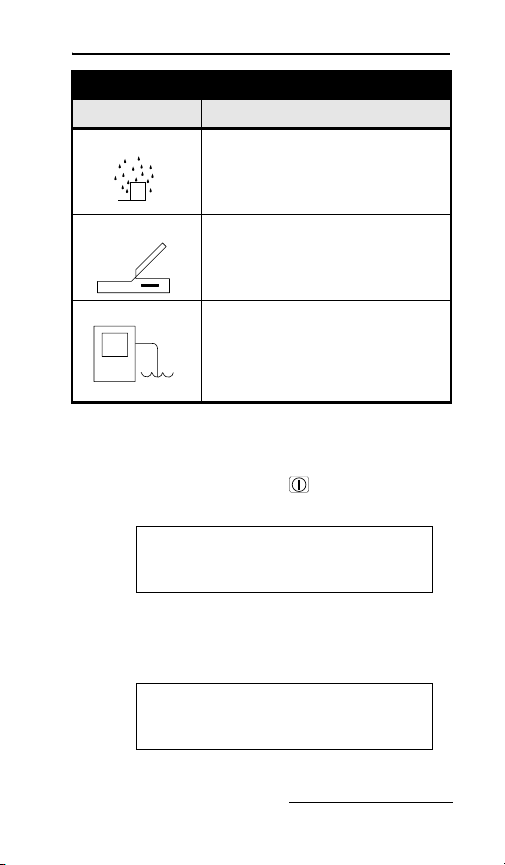

Table 1-1 Keypad and Connector Icons

Icon Function

Rain Gauge 674 Rain Gauge

Interrogator 581 RTD

Flow Meter 4200 Series Flow Meters

SDI-12 Sondes

Programmable Pins

(Pins C, H, and I)

IBM PC or compatible computer

running FLOWLINK or

SAMPLINK.

4100 Series Flow Logger

1640 Liquid Level Actuator

2100 Series Flow Modules

Non-Isco flow meters

1.1 Getting Started

Turn the sampler on by pressing the On/Off key.

It is labeled with this icon: . The start up

screen appears first.

6712 SAMPLER

STANDARD PROGRAMMING

For HELP at any

SCREEN PRESS ? KEY.

It remains on the display for about 8 seconds or

until you press a key. The main menu screen

appears next.

RUN

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

1-3

6712 Sampler

1.2 Using Menus and Entering Numbers

A menu is a list of options. The main menu has

four options:

•Run

•View Report

•Program

• Other Functions

1.2.1 Selecting Menu Options

In menu screens, one menu option always

blinks.

•Press (Enter) when the blinking

option is the one you want; it will accept

your choice and go to the next screen.

The Enter key always accepts the blinking

option.

• Select a different option by pressing an

arrow key until the option you want

blinks. Then press Enter.

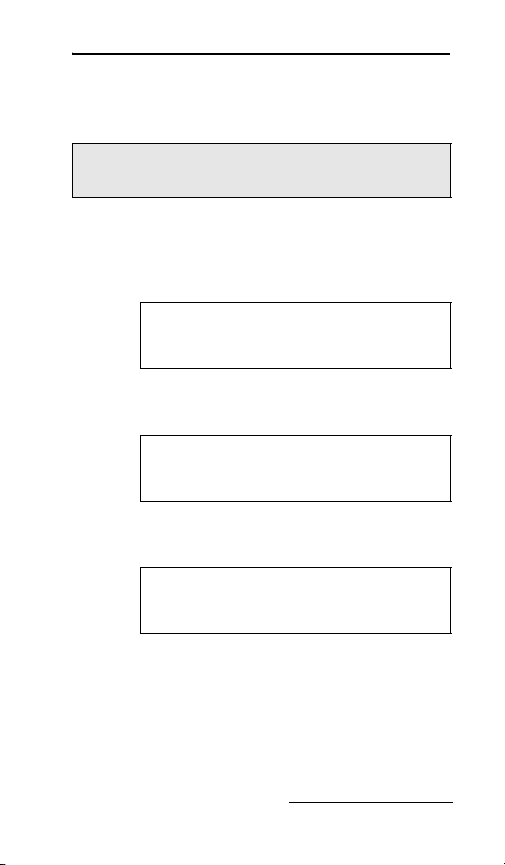

1.2.2 Entering Numbers

Press the number keys to type the number.

Then, press Enter. As soon as you press Enter,

the sampler saves your number and moves to

the next screen. In some screens, you can use

the (Decimal Point) key in a number.

Some screens display the range of acceptable

numbers between parentheses. If you enter a

number that is too low or high, the controller

1-4

Section 1 Programming

beeps and erases the entry. Type a new number

and continue.

Example 1-1 Programming

One Sample every 15 Minutes, One Sample

in Each Bottle Using Normal Programming

Style, no module attached.

6712 SAMPLER

1.

This screen disappears on its own after 8

seconds.

2.

The option PROGRAM will be blinking.

Press Enter.

3.

The option NO will be blinking. Press

Enter.

STANDARD PROGRAMMING

For HELP at any

SCREEN PRESS ? KEY.

RUN

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

SITE DESCRIPTION:

“FACTORY “

CHANGE?

YES NO

1-5

6712 Sampler

Example 1-1 Programming

(Continued)

4.

NUMBER OF BOTTLES:

12481224

Select 24. Press Enter.

5.

BOTTLE VOLUME IS

1000 ml (300-30000)

Type the volume for the bottles in your kit.

For this example, 1000 is correct, so

simply press Enter.

6.

SUCTION LINE LENGTH

IS 10 ft

(3-99)

Type the length of the suction line, then

press Enter.

7.

TIME PACED

FLOW PACED

Select TIME PACED by pressing an

arrow until the option TIME PACED

blinks. Then, press Enter.

1-6

Section 1 Programming

Example 1-1 Programming

(Continued)

TIME BETWEEN

8.

Type 0 for hours and press ↵ (Enter).

Type 15 for minutes and press Enter.

9.

Select SEQUENTIAL by pressing an

arrow until the option SEQUENTIAL

blinks. Then, press Enter.

SAMPLE EVENTS

0 HOURS, 15 MINUTES

SEQUENTIAL

BOTTLES/SAMPLE

SAMPLES/BOTTLE

10.

RUN CONTINUOUSLY?

YES NO

Select NO. Press Enter after making your

choice.

11.

SAMPLE VOLUME:

200 ml (10-1000)

Type the volume of the sample you want

deposited in each bottle. Then, press

Enter.

1-7

6712 Sampler

Example 1-1 Programming

12.

13.

14.

15.

(Continued)

NO DELAY TO START

DELAYED START

CLOCK TIME

Select DELAYED START by pressing an

arrow until the option blinks. Then, press

Enter.

FIRST SAMPLE

AFTER A

5 MINUTE DELAY

(1-999)

Type the delay period you want between

the time you run the program and the

time the sampler takes the first sample.

Then, press Enter.

PROGRAMMING COMPLETE

RUN THIS PROGRAM

NOW?

YES NO

Select NO. Press Enter after making your

choice.

RUN

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

Run the program by selecting RUN and

pressing Enter.

1-8

Section 1 Programming

1.2.3 Clock and Calendar Entry Screens

When setting the clock and calendar, use a 24

hour clock for times and the day-month-year

format for dates.

• To move without changing the setting,

press the arrow keys.

• Change the setting by typing a new

number. Press Enter to accept the new

setting.

For example, to enter 2:00 p.m. (2:00 p.m. is

14:00 on a 24-hour clock), type 14. Press Enter.

Type 0 (zero) for the minutes, and press ↵

(Enter). To enter a date, such as January 22,

2001, type: 22 ↵ 01 ↵ 01 ↵ .

1-9

6712 Sampler

Example 1-2 Setting the Clock and

Calendar

RUN

1.

Select OTHER FUNCTIONS.

2.

Select MAINTENANCE.

3.

Select SET CLOCK.

4.

Enter the time and date.

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

MAINTENANCE

MANUAL FUNCTIONS

MODULE

SET CLOCK

PUMP TUBE ALARM

INTERNAL BATTERY

DIAGNOSTICS

ENTER TIME AND DATE:

HH:MM DD-MON-YY

14:00 22-JAN-01

1-10

SET CLOCK

5.

PUMP TUBE A.LARM

INTERNAL BATTERY

DIAGNOSTICS

Press Stop to return to the main menu.

Section 1 Programming

1.3 Quick View Screens

Quick view screens are a special type of menu

screen. They show the current program settings

and let you move quickly through the program.

You must change the programming style to

QUICK VIEW/CHANGE to see the quick view

screens.

Example 1-3 Changing the

Programming Style

RUN

1.

Select OTHER FUNCTIONS.

2.

Select PROGRAMMING STYLE.

3.

Select QUICK VIEW/CHANGE.

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

MAINTENANCE

MANUAL FUNCTIONS

PROGRAMMING STYLE

PROGRAMMING STYLE

NORMAL

QUICK VIEW/CHANGE

1-11

6712 Sampler

1.3.1 Paging Through the Quick View Screens

The arrows in the corners of each quick view

screen are menu options that let you move from

one quick view screen to another.

• Select the reverse arrow to go to the

previous screen.

• Select the forward arrow to go to the next

screen.

• Press Stop to return to the main menu.

1.3.2 Changing Settings in a Quick View Screen

Although the quick view screens offer you a

quick way to see the program settings, they also

provide you with a way to change settings.

Using quick view screens to change settings is

sometimes a faster way to change a program

because you can go quickly to the setting or

settings that needs updating.

To chan ge the pr ogr am se ttings in a quick view

screen, press an arrow until the setting blinks.

Press Enter. The 6712 then displays the screen

used to change the setting.

When you change a setting, the sampler stores

the new settings and returns to the updated

quick view screen.

1-12

Section 1 Programming

1.4 Help Notes

To s ee a help not e:

1. Press the Help key.

2. When the note requires several screens, the

word “more” appears in the lower right

corner. Press Enter for the next note.

3. Move back and forth between screens by

pressing the arrow keys.

4. Press Stop at any time to return to the

programming screen.

Screens that are self explanatory or that

require extensive explanation have notes that

contain only references to the manual.

1.5 Warning Messages

Warning messages appear when the sampler

determines something is out of the ordinary.

For example, screen b appears when you type a

number in screen a that is larger than the

standard bottle volume.

a

b

BOTTLE VOLUME IS

3500 ml (300-30000)

WARNING!

STANDARD BOTTLE

VOLUME EXCEEDED!

The 6712 does accept nonstandard volumes. For

a list of recommended volumes, press the Help

key at screen b or refer to the manual.

1-13

6712 Sampler

The 6712 uses the bottle and sample volume

settings to determine the maximum number of

samples that can be deposited without

overfilling the bottles. Entering a volume that

exceeds the standard volume may cause the

sampler to overfill the bottle.

1.6 Changing to and from Extended and Standard Screens

At the main menu, type “6712.2” to show the

Extended Programming screens.

At the main menu type 6712.1 to show the

Standard Programming screens.

1.7 Storage For Extended Programs

The sampler stores five sampling programs:

one standard and four extended. Program

storage eliminates the need to reprogram the

sampler with frequently used settings.

1-14

Section 1 Programming

Example 1-4 Selecting a Stored

Extended Program

6712 SAMPLER,

1.

If “STANDARD PROGRAMMING”

appears on the second line of the start

up message, type 6712.2

menu.

2.

Select PROGRAM from the main menu.

3.

Select PROGRAM NAME: “EXTENDED

1" from the quick view menu.

EXTENDED PROGRAMMING

For HELP at any

SCREEN, PRESS ? KEY.

at the main

RUN “EXTENDED 1”

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

PROGRAM NAME:

"EXTENDED 1"

SITE DESCRIPTION:

"______"

4.

SELECT NEW PROGRAM

CHANGE PROGRAM NAME

Select SELECT NEW PROGRAM to

change the program.

1-15

6712 Sampler

Example 1-4 Selecting a Stored

Extended Program (Continued)

“EXTENDED 1”

5.

Select the name of the extended program

you want to use.

6.

Select NO.

“EXTENDED 2”

“EXTENDED 3”

“EXTENDED 4”

•

•

•

PROGRAMMING COMPLETE

RUN THIS PROGRAM

NOW?

YES NO

RUN “EXTENDED 2”

PROGRAM

VIEW REPORT

OTHER FUNCTIONS

1.8 Programming the Modules

The module programming screens contain a

branch of setup screens that let you specify the

units of measure and the data storage interval.

Some module setup screens are available to you

even when no module or rain gauge is attached

to the sampler. When you attach a 700 Series

Module to the sampler, the sampler adds an

additional set of screens needed to program the

1-16

Loading...

Loading...