Page 1

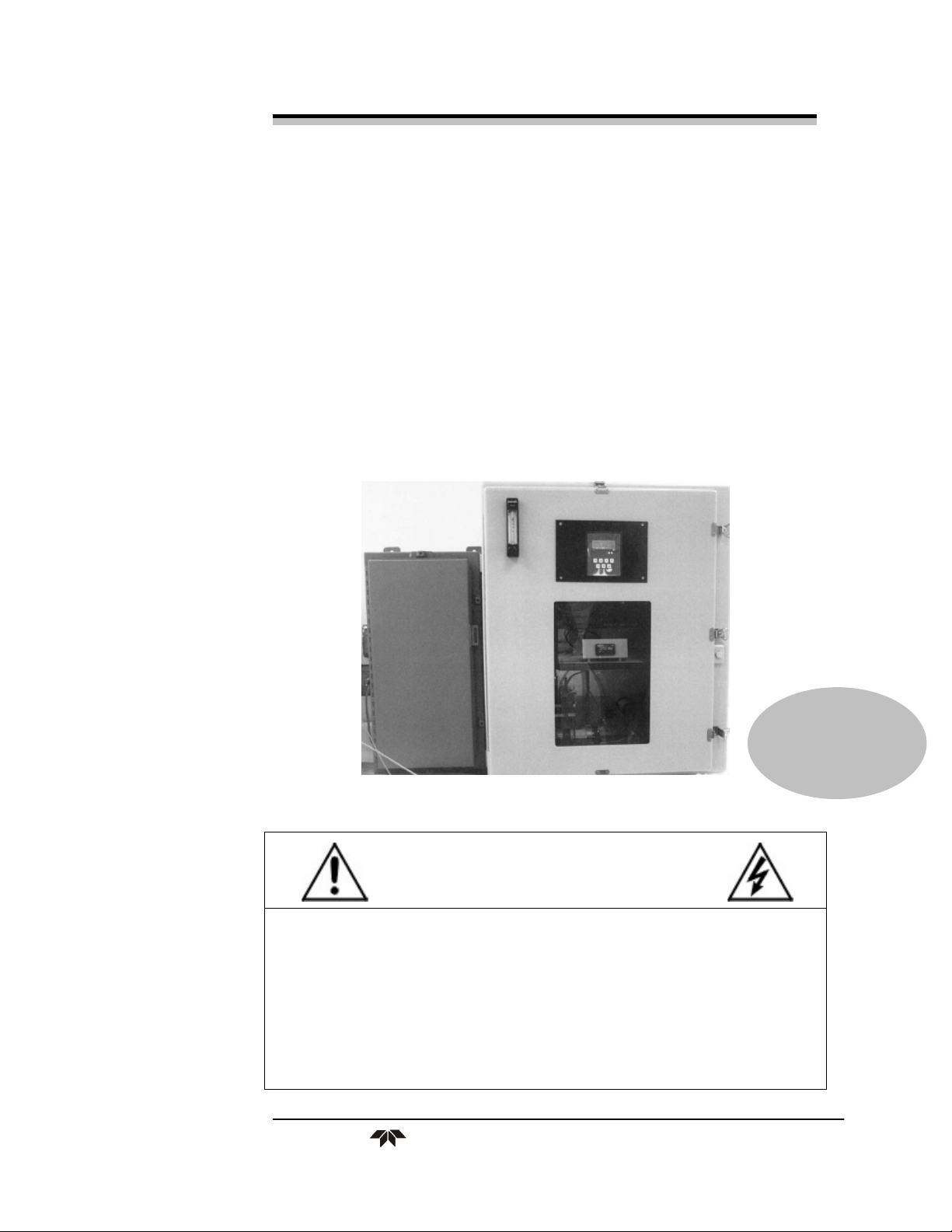

OPERATING INSTRUCTIONS FOR

Model 6700C

High Temperature Combustion

Online TOC Analyzer

P/N M6700C-C

DANGER

Depending upon your application, toxic gases may be present in this monitoring

system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

3/06/12

Page 2

Model 6700C TOC

Copyright © 2012 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/ Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, an d serves as a to ol by whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Teledyne Analytical Instruments ii

Page 3

High Temperature Combustion

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Page 4

Model 6700C TOC

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

WARNING: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

Teledyne Analytical Instruments iv

Page 5

High Temperature Combustion

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

TI/AI at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model 6700C TOC

Teledyne Analytical Instruments vi

Page 7

High Temperature Combustion

Additional Safety Information

All relevant precautions and safety remarks of the gas supplier must be

observed:

General Safety Rules

Legally Binding Safety Rules

In addition to safety rules outlined in this manual, all current

environmental, technical, legal, and governmental regulation must be

adhered to.

General Inspection Requirements

General inspection of the Analyzer must be performed by a trained

technician after each incidence of maintenance, repair, or service.

Power Connections

The Analyzer may only be installed and connected to a main power

supply according to the installation instructions provided in this manual.

All power lines to the Analyzer must have switches to cut off the

electricity.

Spare Parts

Only options and parts specified by TAI may be used in performing

maintenance or repair of the Analyzer.

Modifications and Alternations

Any modifications to the Analyzer or any of its options or parts must

first be authorized by TAI.

Responsibilities & Duties of the Supplier

The supplier is responsible for the safety of the product. However, such

safety can only be reasonably guaranteed if the end user of the product

adheres to the requirements and instructions stipulated in this manual.

Teledyne Analytical Instruments vii

Page 8

Model 6700C TOC

Responsibilities & Duties of the End User

The end user is responsible to ensure that only trained, authorized

personnel operate and maintain the Analyzer. The end user is

responsible for self-training by reading and adhering to the instructions

in this manual.

Instruction of Dangers

The end user is responsible to ensure that all personnel who operate and

maintain the Analyzer are thoroughly instructed in its proper usage and

have received knowledge of all safety precautions.

Care & Maintenance

The end user is responsible to observe the recommended maintenance

schedule.

Observation & Information

The end user is responsible to immediately inform the supplier if any

additional risks, not addressed in this manual, are discovered.

Teledyne Analytical Instruments viii

Page 9

High Temperature Combustion

Table of Contents

Additional Safety Information .................................................... vii

List of Figures ............................................................................... xi

List of Tables ............................................................................... xii

Introduction ................................................................................. 15

1.1 Overview 15

Operational Theory ..................................................................... 17

2.1 Measurement Principle 17

Installation and Startup ............................................................... 19

3.1 Installation 19

3.2 Non – Catalytic Reactor Packing 20

3.2.1 Identify Parts 20

3.2.2 Preparation of Combustion Reactor 22

3.2.2.1 Install Quartz Sleeve (Insert) 23

3.2.2.2 Loading Ceramic Wool Slices 23

3.3 Catalytic Reactor Packing 24

3.4 Inserting Reactor into Furnace 25

3.5 Startup of the Analyzer 27

3.6 Shutdown 28

Operation ..................................................................................... 29

4.1 Menus 29

4.2 Run Mode 29

4.3 Edit 30

4.3.1 Edit/Parameters 31

4.3.2 Edit/Alarms 32

4.4 Cal 32

4.4.1 Organic and Inorganic Carbon Standards 32

Teledyne Analytical Instruments ix

Page 10

Model 6700C TOC

4.4.2 Reagents 34

4.4.2.1 Preparation Of Sulfuric Acid Solution 34

4.4.3 NDIR Calibration (Gas Calibration) 34

4.4.4.“End-to End” Calibration 36

4.5 Chart 37

4.5.1 Scale 38

4.5.2 Last 24 Hours 38

4.5.3 Historical Data 39

4.6 Test 39

Maintenance ................................................................................ 41

5.1 Factory Assistance 41

5.2 Troubleshooting Guide 41

5.3 Module Service 42

5.3.1 NDIR Calibration 42

5.3.2 NDIR Service 42

5.3.3 Master Interface Board 47

5.3.4 D.C. Power Supply 47

5.3.5 Computer 48

5.3.6 Reactor Assembly and Gas/Liquid Separator 49

5.3.7 Mass Flow Controller 51

5.3.8 Metering Valve 52

5.3.9 Sparger 53

5.3.10 Injector Assembly 54

Appendix ...................................................................................... 57

A.1 Specifications 57

A-2 Recommended Spare Parts 58

Teledyne Analytical Instruments x

Page 11

High Temperature Combustion

List of Figures

Figure 2-1 Typical Flow Diagram ................................................... 18

Figure 3-1: Combustion Module Interior ........................................ 20

Figure 3-2: Installing Quartz Insert into Reactor ............................ 23

Figure 3-4: Catalyst Packing ......................................................... 24

Figure 3-5: Gas/Liquid Separator .................................................. 25

Figure 3-6: Filling Separator with DI Water .................................... 26

Figure 3-7: Attaching Reactor Top ................................................ 26

Figure 3-8: Top Retainer Installation ............................................. 27

Figure 4-1: Connecting Calibration Adapter .................................. 35

Figure 5-1: Removing the NDIR .................................................... 43

Figure 5-2: Removing the Master Interface Board Assembly ........ 47

Figure 5-3: DC Power Supply ........................................................ 48

Figure 5-4: Removing Computer Module ...................................... 49

Figure 5-5: Reactor Assembly and GLS ........................................ 50

Figure 5-6: Typical Mass Flow Controller ..................................... 51

Figure 5-7: Metering Valve ............................................................ 52

Figure 5-8: Sparger ....................................................................... 53

Figure 5-9: Injector Assembly ........................................................ 55

Teledyne Analytical Instruments xi

Page 12

Model 6700C TOC

List of Tables

Table 3-1: Preparation of Standards (TOC) .................................. 33

Table 3-2: Preparation of Standards (TN) ..................................... 33

Table 3-3: Preparation of Standards (TIC) .................................... 33

Table 5-1 Troubleshooting ............................................................ 42

Teledyne Analytical Instruments xii

Page 13

High Temperature Combustion

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

WARNING

Since the use of this instrument is beyond the control of

Teledyne Analytical Instruments, referred as TAI, no

responsibility by TAI, its affiliates, and agents for damage or

injury from misuse or neglect of this equipment is implied or

assumed.

Teledyne Analytical Instruments xiii

Page 14

Page 15

High Temperature Combustion Operational Theory

Introduction

1.1 Overview

Teledyne Analytical Instruments (TAI) offers a variety of Total

Organic Carbon (TOC) analyzers to serve a wide range of applications.

The Model 6700C High Temperature Combustion TOC Analyzer

provides accurate and reliable on-line TOC and TN analysis and is

configured to provide maximum utility using an advanced Micro s of t

Windows based CE computer with touch screen.

This manual includes all necessary information to help you install,

operate and service your Analyzer. The analyzer is designed for easy

Operator Maintenance and does not normally require field service.

The Windows-based CE operator interface provides easy, fast and

reliable analysis. This manual includes all necessary information to help

you install, operate and service your Analyzer.

The Model 6700C TOC-True Analyzer is designed for easy

operation and maintenance. Particular attention has been devoted to the

design, whereby any module can be replaced by the operator within 15

minutes. Components such as the NDIR units have been specifically

designed with no moving parts and use a corrosion resistant design to

further reduce maintenance tasks.

The analyzer is suitable for both General Purpose and/or Hazardous

Area classifications, if properly configured with required safety

equipment.

Operating the analyzer is easy. It uses a standard, industrial

Windows CE computer programmed for complete automatic control

(there are no operator manual adjustments). Operators are advised to

study pertinent chapters in this manual to fully utilize the capabilities of

the analyzer and avoid problems that could be associated with any

instrument.

Teledyne Analytical Instruments 15

Page 16

Operational Theory Model 6700C TOC

The Analyzer is designed for monitoring of Total Organic Carbon

(TOC) in water. This intended use involves carefully following the

instructions provided in this manual and observing all indicated

warnings, hints and instructions.

Teledyne Analytical Instruments 16

Page 17

High Temperature Combustion Operational Theory

Operational Theory

2.1 Measurement Principle

Refer to Figure 2-1.

The Injector is connected with all possible flow paths and separated

from sample and reagent liquids by a 10 ml volume loop. One end of the

volume loop is connected to the injector, the other is connected to the

center port of a 10 port Rotary Valve.

A typical sequence of events for the injection unit for measurement

of TOC is as follows:

The Rotary Valve will be engaged, opening a flow path to the drain

line of the analyzer. The Injector is then sent to the home or empty

position.

The DI Valve is turned on and a small amount of DI is then picked

up by the Injector. The DI Valve is then turned off and the Rotary Valve

is turned to the Acid Port where the Injector pulls a small amount of acid

into the loop. The Rotary Valve is then turned to the sample port and

sample is pulled into the loop. The Rotary Valve is turned to the Sparge

Port and the Injector then pushes the sample and acid to the sparger

through the Sparger Port, where the pH is lowered to approximately 2.0

and inorganic carbon is removed.

After the sparge time is completed, the Injector pulls the inorganic

free sample volume from the sparger. The Rotary Valve is then turned to

the Reactor Port. The Injector pumps the sample into the reactor at a

flow rate of one (1) drop in approximately seven (7) seconds.

The sample is oxidized in the High Temperature Furnace where

organic carbon is converted to CO2 and the gases are directed to a cooler

condenser where excess water is removed, and then on to the NDIR

where the CO2 is measured and TOC is determined. The gases are then

passed to vent.

Teledyne Analytical Instruments 17

Page 18

Operational Theory Model 6700C TOC

Figure 2-1 Typical Flow Diagram

Teledyne Analytical Instruments 18

Page 19

High Temperature Combustion Installation/Startup

Installation and Startup

The Model 6700C is often configured for a specific application as

requested by the customer. Optional equipment and any application

specific configuration of this instrument will be described in an

addendum to this manual. Please check the front of this manual for any

addenda that may be included.

3.1 Installation

Installation of the Total Organic Analyzer includes:

1. Unpacking

2. Mounting

3. Gas Connections

4. Electrical Connections

5. Testing the System

6. Unpacking the Analyzer

The analyzer is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the analyzer and

inspect it for damage and immediately report any damage to the

shipping agent.

Note: If the Reactor has been packed and shipped separately,

please follow the instructions below to properly prepare

and install the Reactor.

Open the door of the Combustion Module. Figure 3-1 shows the

reactor properly installed in the furnace.

See also Section 5.3.6.

Teledyne Analytical Instruments 19

Page 20

Installation/Startup Model 6700C TOC

Figure 3-1: Combustion Module Interior

3.2 Non – Catalytic Reactor Packing

The following pages describe the assembly of the Reactor using the

“Non-Catalytic” Oxidation Method at temperature up to 950°C.

Note: The Reactor life is directly related to temperature. It is

recommended that the operating temperature not exceed

900°C and preferably be at 850°C.

3.2.1 Identify Parts

Quartz Sleeve (P/N: S1795)

Teledyne Analytical Instruments 20

Page 21

High Temperature Combustion Installation/Startup

Quartz Combustion Reactor (P/N: R3332)

Ceramic Wool Disks (P/N: D685):

Teledyne Analytical Instruments 21

Page 22

Installation/Startup Model 6700C TOC

Glass Reactor Top (P/N: R3331)

Top Retainer (P/N: R3350)

3.2.2 Preparation of Combustion Reactor

Note: The React or may be operated with platinum catalyst at

680º to 750º C or non-catalytically at higher temperature

(850ºC recommended). The standard configuration is noncatalytic, although catalyst may be purchased and used, if

an unusually difficult to oxidize sample is encountered.

TAI recommends to first raise the temperature to 900º C (max.) to

determine if satisfactory performance is attained before packing the

Reactor with catalyst. The Reactor temperature profile is 100º C higher

than the temperature controller set point in certain areas of the Reactor.

Reactor life is highly dependent on operating temperature and the

operator is cautioned not to exceed these temperature set points in order

to prevent damage to the Reactor. The Reactor should be maintained at

temperature and not turned on and off in order to minimize stress failure

of the Reactor over a period of time.

Teledyne Analytical Instruments 22

Page 23

High Temperature Combustion Installation/Startup

3.2.2.1 INSTALL QUARTZ SLEEVE (INSERT)

Carefully place the Quartz Sleevet (P/N:S1795) into the Quartz

Reactor (P/N:R3332 as shown in Figure 3-2.

Figure 3-2: Installing Quartz Insert into Reactor

3.2.2.2 LOADING CERAMIC WOOL SLICES

Load the ceramic wool as shown in Figure 3-3.

Figure 3-3: Loading Ceramic Wool Slices

Teledyne Analytical Instruments 23

Page 24

Installation/Startup Model 6700C TOC

CAUTION: Be careful to slowly place the assembly in a

vertical position, AVOIDING A RAPID DROP of the

Ceramic Sleeve and Spacer to the bottom of the

Reactor.

If not carefully inverted, the Ceramic Sleeve and

Spacer will damage the bottom of the Reactor by

dropping too fast.

3.3 Catalytic Reactor Packing

The following figures represent the packing used for the catalytic

oxidation method.

The optimum furnace operating temperature is between 680°C and

750°C. The lower the temperature, the longer the life of the catalyst.

Figure 3-4: Catalyst Packing

1. Loosely pack Ceramic Wool at bottom of Reactor base.

2. Pour catalyst into Reactor.

3. Loosely pack Ceramic Wool on top of catalyst.

Teledyne Analytical Instruments 24

Page 25

High Temperature Combustion Installation/Startup

3.4 Inserting Reactor into Furnace

Carefully insert the Reactor Assembly into the Furnace and secure

the Assembly by following the procedure outlined in Figures 3-5

through 3-8.

Finger-tighten the Gas/Liquid Separator (P/N: G608) to Reactor,

as shown below in Figure 3-5.

Figure 3-5: Gas/Liquid Separator

Connect the Combustion Module Drain port to a facility gravity

drain with a 1 inch air break between the end of the drain line

and any liquids in the collection vessel (jar, facility drain) in

order to prevent a “vapor lock”. This drain line should be routed

in a straight fashion and free of kinks or restrictions thereby

allowing the liquids to drain freely.

Prepare the Gas/Liquid Separator by filling it with D.I. water

until it overflows to drain, as shown in Figure 3-6. This provides

proper sealing of the reacted sample gases.

Teledyne Analytical Instruments 25

Page 26

Installation/Startup Model 6700C TOC

Figure 3-6: Filling Separator with DI Water

Prepare to position Glass Reactor Top (PN: R3331) on Reactor,

per Figure 3-7.

Figure 3-7: Attaching Reactor Top

Using Top Retainer (P/N:R3350) position and fasten Glass

Reactor Top to Reactor, per Figure 3-8.

Teledyne Analytical Instruments 26

Page 27

High Temperature Combustion Installation/Startup

Figure 3-8: Top Retainer Installation

3.5 Startup of the Analyzer

Before starting the analyzer, please check the following:

Air/oxygen supply – This must provide a constant pressure of

15 ± 2 psi, ultra-pure oxygen or hydrocarbon and CO

a flow rate up to 300 cc/minute. Pre-purified air may be used

with optional Zero Air Generator which requires Instrument Air

or Oxygen Generator which requires electricity only.

Drain Line – Check to see if the Drain Line is sloped downward

and is free of kinks, loops and allows normal vented gravity flow

with an air break to an open receptacle (jar, pipe, etc.).

Vents – Vent lines must be properly installed and vented to

atmospheric conditions and not allowed to have either a

restriction or a pumping of exhaust flow, as either of these

conditions may result in improper analyzer operation.

–free air at

2

Teledyne Analytical Instruments 27

Page 28

Installation/Startup Model 6700C TOC

CAUTION: FAILURE TO OBSERVE THIS WILL RESULT IN

IMPROPER OPERATION OR A SAFETY HAZARD.

ELECTRICAL – Assure proper electrical installation.

SAFETY – All customer and TAI specified safety measures are

followed.

After all of the above checks, turn analyzer ON by activating the

facility power switch. Thereafter, follow the MENU on the display.

Ultimate stability of the analyzer will occur within a few hours,

although initial operation may proceed in one hour after the reactor

temperature reaches its set point.

Immerse the line from “sample” port of the Analyzer into a D.I.

water container. Immerse the acid line from the “ACID IN” port of the

Analyzer into an ACID container. (2N HCl)

Note: For “TC” only operation, No Acid is Requir ed.

3.6 Shutdown

Prior to shutdown of the analyzer or service on the Reactor, flush

D.I. water through all sample and reagent lines.

CAUTION: FAILURE TO OBSERVE ADEQUATE FLUSHING

COULD RESULT IN HARMFUL ACID BURNS AND/OR

A REACTOR CLOG.

Teledyne Analytical Instruments 28

Page 29

High Temperature Combustion Operation

Operation

After proper installation the instrument must be calibrated.

Following calibration, the instrument is ready to be placed “ON-LINE”.

Note: For any non–standard or specific operational procedures,

please refer to the “INSTALLATION” and any addenda

that accompanies this manual for details on your specific

application. Items such as valving, stream sequencing,

automatic calibration, etc. are non-standard items and will

be described in an attached addendum.

4.1 Menus

The advanced design of the Model 6700C Analyzer eliminates

complicated, routine, and sometimes confusing Menus. The operator/

software interface is as simple as the analyzer’s construction, operation,

and most importantly, maintenance.

The analyzer has no manual adjustments. Complete calibration and

operation are computer controlled by the operator, following menu

prompting and selection of the operation of choice.

The following menu and operation descriptions are intended to

guide the Operator through all the functions of the Model 6700C TOC

High Temperature Combustion Analyzer.

After primary power (110/220VAC) has been applied to the

Analyzer and self-diagnostic procedure has been completed, the system

automatically boots up to the following Run Screen. If not, turn main

power OFF, then ON to reboot.

4.2 Run Mode

Run is the normal analysis mode. The display indicates the current

TOC or both TOC and TN (optional) values, [IR] IR response, and

[Flow] carrier gas flow rate.

Teledyne Analytical Instruments 29

Page 30

Operation Model 6700C TOC

Although your analyzer has been configured for optimum

performance in your application, on initial startup the setup parameters

should be verified (Consult Factory Settings for Your Application).

4.3 Edit

The Edit menu contains functions that allow you to configure the

instrument to your application. Within the EDIT menu you can:

Set instrument parameters

Set Alarms and setpoints

Benchmark scheduling

Autocal scheduling

Set volumes

Define species

From the Run Screen, select [EDIT]. The following menu will

appear:

Teledyne Analytical Instruments 30

Page 31

High Temperature Combustion Operation

4.3.1 Edit/Parameters

From the EDIT Menu, select: [Parameters]. The following Screen

Appears:

The Model 6700C TOC High Temperature Combustion Analyzer

may be configured to suit the requirements of the operator by the use of

[Parameters] Menus.

Carrier Flow Rate

Liquid Range

Note: The “Liquid Range” setting is that value to which the full-

scale output is to be set (not the value of the Liquid Span).

Teledyne Analytical Instruments 31

Page 32

Operation Model 6700C TOC

4.3.2 Edit/Alarms

The next recommended settings to be verified or set are the Alarm

Settings.

From the [Edit] Menu, select [Alarms]. The following Menu

appears:

From this menu you can verify or select the desired Alarm points.

4.4 Cal

Although the instrument has been calibrated to your specifications

at the factory, it should be rechecked after satisfactory installation and

periodically calibrated as suggested for your application.

The analyzer calibration is performed by an “end-to-end” method,

whereby a known chemical standard solution is introduced to the

analyzer and the analyzer is “spanned” to that value.

4.4.1 Organic and Inorganic Carbon Standards

KHP (Potassium Hydrogen Phthalate) is recommended for the

organic carbon standard solution. Sodium Carbonate is recommended

for the inorganic carbon standard. Table 3-1 provides the concentration

to be used for two ranges of different chemical compounds (organic &

inorganic carbon). Using a ratio of these concentrations will provide

other ranges for the span solution.

Teledyne Analytical Instruments 32

Page 33

High Temperature Combustion Operation

Table 3-1: Preparation of Standards (TOC)

ORGANIC COMPOUNDS

Ethylene Glycol

Methanol

Ethanol

Acetone

Carbon Tetrachloride

Sucrose

Urea

Acetic Acid

KHP (Potassium acid phthalate)

Glycine

Sodium Stearate

Succinic Acid

Sodium Oxalate

Table 3-2: Preparation of Standards (TN)

100 mg/Liter

TOC (AS CARBON)

.233 ml/L H

.337 ml/L H

.242 ml/L H

.204 ml/L H

.807 ml/L H

.238 gm/L H

.500 gm/L H

.250 gm/L H

.212 gm/L H

.313 gm/L H

.141 gm/L H

.246 gm/L H

.555 gm/L H

20 2.33 ml/L H20

20 3.37 ml/L H20

20 2.42 ml/L H20

20 2.04 ml/L H20

20 8.07 ml/L H20

20 2.38 gm/L H20

20 5.00 gm/L H20

20 2.50 gm/L H20

20 2.12 gm/L H20

20 3.13 gm/L H20

20 1.41 gm/L H20

20 2.46 gm/L H20

20 5.55 gm/L H20

1000 mg/Liter

TOC (AS CARBON)

Total Nitrogen 100 mg/Kiter 1000 mg/Liter

Ammonium Sulfate

Table 3-3: Preparation of Standards (TIC)

Inorganic Compounds

Sodium Carbonate

Potassium Carbonate

Ammonium Carbonate

Teledyne Analytical Instruments 33

0.4728 gm/L 4.728 gm/L

50 mg/Liter

TIC (As Carbon)

.442 gm/L H

.575 gm/L H

.475 gm/L H

2

2

2

O.

O.

O.

Page 34

Operation Model 6700C TOC

4.4.2 Reagents

The following provides reagent preparation guides for acid reagent.

Sulfuric Acid is the acid of choice. Phosphoric Acid may NOT be

used in the Model 6700C TOC High Temperature Combustion

Analyzer.

4.4.2.1 PREPARATION OF SULFURIC ACID SOLUTION

TAI recommends the use of Ethylene Glycol and Ammonium

Sulfate, but the user may choose another standard from the above tables.

The container used should be flushed with distilled or deionized (DI)

water. Add 56ml of 66 Baume sulfuric acid to 1 liter of D. I.

Recommended Reagent Container size is 4 Liter.

CAUTION: ALWAYS ADD ACID TO WATER TO KEEP FROM

SPLASHING OR SPRAYING REACTION

COMPONENTS.

4.4.3 NDIR Calibration (Gas Calibration)

Note: On the initial Startup or after a prolonged storage, the gas

calibration should be checked and, if necessary, performed

prior to liquid calibration (see Section 3.5).

From Menu, select [CAL]. The following screen will appear:

Select [Sensor].

Teledyne Analytical Instruments 34

Page 35

High Temperature Combustion Operation

The following screen appears:

Disconnect the tubing from the GLS and connect the “IR”

calibration adapter (P/N A1000) to the calibration gas cylinder tubing as

shown in Figure 4-1. TAI recommends using the Cal. Gas Kit P/N

K258 (1.0% CO2) or K259 (0.1% CO2).

Figure 4-1: Connecting Calibration Adapter

Teledyne Analytical Instruments 35

Page 36

Operation Model 6700C TOC

To set IR “Zero”:

Flow 200cc/minute oxygen (or CO

free air) for 5 minutes.

2

Allow the NDIR reading to stabilize. Select [ZERO]. The

NDIR Reading will be set to 0.

To set IR “Span”, a gas calibration standard mixture of 1% CO2 in

pure nitrogen is required for the 6 inch (shorter) IR bench. A gas

mixture of 0.1% CO2 in pure nitrogen is required for the longer (15 inch)

bench.

Flow 200 cc/minute of this cal gas.

Allow the NDIR reading to stabilize and then select [SPAN].

The NDIR reading will be set to 10,000.

Select [OK] to save or [CANCEL] to reject the calibration

setting.

The NDIR has now been properly calibrated. Re-connect tubing as

before.

4.4.4.“End-to End” Calibration

Note: On the initial Startup, the gas calibration should be

checked and, if necessary, performed prior to liquid

calibration.

From Menu, select [CAL]. The following screen will appear:

Teledyne Analytical Instruments 36

Page 37

High Temperature Combustion Operation

Select [Liquid]. The following screen appears:

Select “ZERO”. D. I. water is automatically introduced to the

analyzer. The user will be notified upon completion.

Select the span solution value, and press [Span] to introduce the

solution and then select [SPAN]. If the calibration is acceptable, select

[OK] or [CANCEL] if not acceptable.

The analyzer is now calibrated and ready to run samples.

4.5 Chart

Historical Data may be obtained from the Chart menu. The

following data can be edited or recalled:

Scale – set the scale for the screen

Last 24 hours – Review of data taken within the last 24 hours

Historical Data – Recall archived data

To enter the menu, select [Chart] from the screen. The following

menu will appear.

Teledyne Analytical Instruments 37

Page 38

Operation Model 6700C TOC

4.5.1 Scale

Select [Scale] to edit the scale displayed. The following screen will

appear.

Edit Scale as desired.

4.5.2 Last 24 Hours

Select [Last 24 Hours] to view the data produced in the last 24

hours. The following screen will appear:

Teledyne Analytical Instruments 38

Page 39

High Temperature Combustion Operation

Using the Scroll Bar, select the data to be viewed.

4.5.3 Historical Data

Select [Historical Data] to view any archived data. The following

screen appears:

Select time period desired.

4.6 Test

From the screen, select [Test]. The following menu appears:

Teledyne Analytical Instruments 39

Page 40

Operation Model 6700C TOC

Select [System Diagnostics]. The following menu appears:

From this screen the operator may perform individual testing of

components related to functionality and settings.

See Section 5 for information on troubleshooting and maintenance.

Teledyne Analytical Instruments 40

Page 41

High Temperature Combustion Maintenance

Maintenance

Aside from normal cleaning and checking for leaks at the

connections, the Model 6700C should not require any maintenance

beyond recalibration, as described in Chapter 4, Operation.

5.1 Factory Assistance

For factory assistance, contact TAI Customer Assistance via phone,

fax, or email:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, California 91748-1020, USA

Tel: 626-961-9221 or 626-934-1500

Fax: 626-961-2538 or 626-934-1651

Toll free: 888-789-8168

Email: ask_tai@teledyne.com

Note: Please provide the analyzer model and serial number

when contacting Customer Service.

5.2 Troubleshooting Guide

Prior to performing detailed troubleshooting procedures detailed

below, it is suggested that the operator first perform computer-aided

testing of the analyzer using built-in test routine as described in Section

4.6.

If you are experiencing trouble with your instrument, please refer to

the following checklist:

Teledyne Analytical Instruments 41

Page 42

Maintenance Model 6700C TOC

Table 5-1 Troubleshooting

PROBLEMS SOLUTION

Analyzer will not turn on Check fuse & power connections.

Look for loose or damaged wiring.

Check for 12V DC from power supply.

Check power supply fuse.

Analyzer will not calibrate, is

sluggish

Analyzer is excessively noisy Check for leaks at tubing connection

Display not functioning Check cable connections

Injector not operating (Syringe

plunger not moving back and

forth)

Injector operating but not

pumping fluid

Look for & correct any liquid or gas line

leaks.

Check power supply voltage

Suspect: Malfunctioning display — replace.

Refer to section “Injection System”

Verify that carrier loss did not cause the

injector to be turned off.

Verify ribbon cable connection to injector.

Exchange injector (P/N )

Refer to section “Injector”

Change tubing

Verify DI line is in full DI container.

5.3 Module Service

5.3.1 NDIR Calibration

(Refer to Section 4.4.3).

5.3.2 NDIR Service

(P/N CP2805 or CP2802 determined by measurement range)

Teledyne Analytical Instruments 42

Page 43

High Temperature Combustion Maintenance

To remove and service the NDIR, follow the illustrated sequence as

described in the following NDIR Module Exchange Directions. See

Figure 5-1.

Figure 5-1: Removing the NDIR

Replacement:

1. Turn off power.

2. Remove inlet tube from NDIR Assembly.

3. Remove vent tube from NDIR Assembly.

4. Unplug interface cable from NDIR Assembly.

5. 5. Remove NDIR Assembly from cabinet.

Note: Appearance may differ depending on range of machine.

Teledyne Analytical Instruments 43

Page 44

Maintenance Model 6700C TOC

Remove insulation from IR

Cell.

Remove lock-tight from three

thumbnuts and remove.

Slide out and remove Source

Assembly.

Teledyne Analytical Instruments 44

Page 45

High Temperature Combustion Maintenance

Remove IR Cell

Assembly

Note:

a. ‘O’-Rings in each of

Detector Assembly (left)

and Source Assembly

(right).

b. Sapphire windows

located under ‘O’-Rings

Teledyne Analytical Instruments 45

Page 46

Maintenance Model 6700C TOC

*Remove ‘O’-Ring and

Sapphire window taking care

to avoid scratching sapphire

window.

*Recommend using toothpick.

Clean sapphire windows with

a soft, lintless tissue (use DI

water, if necessary).

To Reassemble:

Install IR Cell.

Install Source Assembly end

piece.

Note: Large outlet port goes

into Detector Assembly (left)

Insert lock-tight on three thumbnuts to prevent back off.

Install insulation. Replace assembly as before.

Recalibrate NDIR (Section 4.4.4).

Teledyne Analytical Instruments 46

Page 47

High Temperature Combustion Maintenance

5.3.3 Master Interface Board

(P/N B718 & P/N B717)

The Master Control Panel has no field adjustment. If

malfunctioning, exchange modules by using the following instructions.

See Figure 5-2.

Figure 5-2: Removing the Master Interface Board Assembly

Procedure:

1. Turn off power.

2. Remove plastic cover.

3. Disconnect connectors.

4. Remove panel.

5.3.4 D.C. Power Supply

(P/N P1506)

The power supply has no field adjustment. If malfunctioning,

replace the module (P/N P1506) using the directions below. Refer to

Figure 5-3.

Procedure:

1. Turn off power.

2. Remove plastic cover.

Teledyne Analytical Instruments 47

Page 48

Maintenance Model 6700C TOC

3. Disconnect connectors.

4. Slide Power Supply off the Din Rail.

5. Remove Power Supply Module.

6. Replace Power Supply Module.

7. Reverse steps for installation.

8. Recalibrate liquid and span values.

Figure 5-3: DC Power Supply

5.3.5 Computer

If malfunctioning, exchange Computer Module using the

directions below. See Figure 5-4.

Procedure:

1. Turn off power

2. Disconnect electrical connectors.

3. Remove screws holding Module in place.

4. Remove module.

5. 5. Install new CE Computer in reverse disassembly instruction

procedure steps. Recalibrate liquid zero and span values.

Teledyne Analytical Instruments 48

Page 49

High Temperature Combustion Maintenance

6. 6. Recalibrate liquid Zero and Span.

Figure 5-4: Removing Computer Module

5.3.6 Reactor Assembly and Gas/Liquid Separator

(P/N R3332) Reactor

(P/N G608) GLS

If Reactor is malfunctioning or GLS is broken, use the following

procedure for removal. Also, see Section 3.2.2 for information on

repacking the Reactor. See Figure 5-5.

Procedure:

Replacement

1. Turn off power to Reactor.

2. Verify ambient temperature. The Reactor temperature is

displayed at the top center of the display.

CAUTION: HOT SURFACES! WEAR GLOVES TO AVOID

SEVERE BURNS.

Teledyne Analytical Instruments 49

Page 50

Maintenance Model 6700C TOC

Figure 5-5: Reactor Assembly and GLS

3. Remove GLS.

Loosen fitting.

Raise Reactor until the Reactor bottom clears the GLS.

Remove GLS.

4. Remove Reactor top piece.

5. Remove back plate nuts.

Teledyne Analytical Instruments 50

Page 51

High Temperature Combustion Maintenance

6. Tilt black plate forward.

7. Remove Reactor after complete cool-down.

5.3.7 Mass Flow Controller

If proper flow is not detected by the computer, an alarm will be

activated and displayed. The fault may be in the O2/Air supply (check

for 20 psi and flow of the supply by disconnecting the input). If supply

flow exists, fault may be in the tubing. Disconnect output side of Mass

Flow Controller and check for flow. If no flow exists, exchange Mass

Flow Controller according to the procedures given below. Refer to

Figure 5-6. If flow still does not exist, check all tubing for restrictions,

leaks, etc.

Figure 5-6: Typical Mass Flow Controller Used in the Model

6700C

Teledyne Analytical Instruments 51

Page 52

Maintenance Model 6700C TOC

Procedure:

1. Shut off Power to Instruments.

2. Shut off all gas to analyzer and bleed system for “0” pressure.

3. Disconnect fittings/tubing.

4. Loosen screws holding Module in-place.

5. Remove Module.

6. Recalibrate analyzer after re-installation of exchange Module.

Note: Mass Flow Controllers of different manufacture may be

used. Include the manufacturer, make and model

information when communicating with TAI Customer

Service.

5.3.8 Metering Valve

If no O2/air flow to the Sparger is observed (no bubbles), check for

tubing and fitting leaks or restrictions. Adjust the Metering Valve being

careful to return to previous indicated bubble rate. If flow cannot be

restored, replace the Metering Valve according to the procedure given

below. Refer to Figure 5-7.

Figure 5-7: Metering Valve

Teledyne Analytical Instruments 52

Page 53

High Temperature Combustion Maintenance

Procedure:

1. Turn carrier gas (Air/O2) OFF.

2. Turn Pumps OFF.

3. Remove fittings and tubing.

4. Remove Metering Valve.

5. Recalibrate TIC if TIC and/or TOC–TRUE analysis is

required. Only NPOC analysis does not require recalibration.

6. Reinstall Metering Valve in reverse order.

5.3.9 Sparger

The Sparger may be removed for cleaning with detergent and

subsequent flushing with DI water. If the Sparger inner glass body is

leaking (cracked glass, etc.), or is clogged beyond cleaning, replace the

Sparger according to the procedure given below. Refer to Figure 5-8.

Figure 5-8: Sparger

Teledyne Analytical Instruments 53

Page 54

Maintenance Model 6700C TOC

Procedure:

CAUTION: OBSERVE NORMAL PRECAUTIONS WHEN

HANDLING ACIDS.

Replacement

1. Turn machine OFF.

2. Turn carrier gas (Air/O

) OFF.

2

3. Remove and drain tubing and Sparger.

4. Remove Sparger from spring clips.

Cleaning

1. Run warm water through tubing to flush out any solid

contamination.

2. Reinstall Sparger in reverse order.

5.3.10 Injector Assembly

To remove the Injector Assembly (See Figure 5-9):

1. Turn off power

2. Disconnect all tubing

3. Remove Injector

4. Reinstall new injector in reverse order

Teledyne Analytical Instruments 54

Page 55

High Temperature Combustion Maintenance

Figure 5-9: Injector Assembly

Teledyne Analytical Instruments 55

Page 56

Maintenance Model 6700C TOC

Teledyne Analytical Instruments 56

Page 57

Percent Oxygen Analyzer Appendix

Appendix

A.1 Specifications

(The following specifications are nominal and depend on the actual

application).

Measuring Method: TC (Total Carbon) – High Temperature

Combustion.

TOC (Total Organic Carbon) acidification

and sparging to eliminate inorganic carbon

interference.

Range: 0-100 through 0-10,000 ppm, full scale.

(Range changes often require carrier gas

adjustments. This analyzer uses the

precision of computer controlled mass

flow controllers to eliminate operator error

and the use of inaccurate mechanical flow

meters.)

Display: Windows with Paperless Chart Recorder

Data Handling: RS-232C, RS-485

Output: 4-20 mA

Alarms: Two alarm levels

One master fault alarm

Response Time: Application dependent

Repeatability: ±3% FS (std. dev. 1 sigma)

Zero/Span Stability: ±3% FS

Linearity: ±3% FS

Inlet Pressure: Atmospheric to 3 psig ±0.5 psi

Carrier Gas Flow Rate: 300 ccm (max.)

Teledyne Analytical Instruments 57

Page 58

Appendix Model 3290

Drain: Gravity drain, vented to atmosphere.

Suspended Solids: 400 microns (max.)

Reagents: 2N HCl (TOC only)

Calibration: Zero TOC (DI water) and one point span

(TOC standard). Computer stored multiple

calibration curves.

Power: 115 ±10% VAC, 50/60 Hz (10 amp)

220 ±10% VAC, 50/60 Hz

Air/Oxygen: 300 ccm (max.) at 15 ±2 psi

Drain: Gravity drain

A-2 Recommended Spare Parts

PART

QTY.

1 F2487 Furnace

1 CP3178 Temp Controller

1 T1722 Thermocouple

2 D685 Ceramic wool disk

1 S1795 Quartz sleeve

1 R3331 Reactor top w/ needle

1 R3332 Quartz combustion reactor

1 G608 GLS

1 T1516 1/8” PFA Tubing (25 ft roll)

1 CP2618 1/8” Peek Flangeless Nuts (10/pkg)

1 CP2617 1/8” Flangeless Ferrules

1 CP2619 White Cable Ties

1 U262 Peek Union

NO.

DESCRIPTION

1 T1517 Peek Tee

Teledyne Analytical Instruments 58

Page 59

Percent Oxygen Analyzer Appendix

Send orders to:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91748

Telephone: (626) 934-1500

Fax: (626) 961-2538

Web: www.teledyne-ai.com

or your local representative.

Teledyne Analytical Instruments 59

Loading...

Loading...