D-Series Pumps

Installation and Operation Guide

Part #69-1243-969 of Assembly #60-1243-998

Copyright © 2013. All rights reserved, Teledyne Isco

Rev. F, July 2018

Foreword

This instruction manual is designed to help you gain a thorough understanding of the operation of

the equipment. Teledyne ISCO recommends that you read this manual completely before placing

the equipment in service.

Although Teledyne ISCO designs reliability into all equipment, there is always the possibility of a

malfunction. This manual may help in diagnosing and repairing the malfunction.

If a problem persists, call or e-mail Teledyne ISCO technical support for assistance. Simple

difficulties can often be diagnosed over the phone. For faster service, please have your serial

number ready.

If it is necessary to return the equipment to the factory for service, please follow the shipping

instructions provided by technical support, including the use of the Return Material

Authorization (RMA) specified. Be sure to include a note describing the malfunction. This will

aid in the prompt repair and return of the equipment.

Teledyne ISCO welcomes suggestions that would improve the information presented in this

manual or enhance the operation of the equipment itself.

Teledyne ISCO is continually improving its products and reserves the right to change

product specifications, replacement parts, schematics, and instructions without notice.

Contact Information

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: ISCO CSR@teledyne.com

Technical Support

Phone: Toll Free (800) 775-2965 (Syringe Pumps and Liquid Chromatography)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

(402) 464-0231 (Outside North America)

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Warnings and Cautions

The lightning flash and arrowhead within the triangle is a warning

sign alerting you to “dangerous voltage” inside the product.

The exclamation point within the triangle is a warning sign alerting

you to important instructions in this manual.

D Series Syringe Pumps

Warnings, Cautions, and Notices

Symboles de Sécurité

Ce symbole signale la présence d’un danger d’électrocution.

Ce symbole signale l’existence d’instructions importantes

relatives au produit dans ce manuel.

i

D Series Syringe Pumps

Warnings, Cautions, and Notices

Warnungen und Vorsichtshinweise

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sie vor

„gefährlichen Spannungen“ im Inneren des Produkts warnt.

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie

darauf aufmerksam macht, daß wichtige Anleitungen zu diesem

Handbuch gehören.

Advertencias y Precauciones

Esta señal alerta sobre la presencia de alto voltaje en el interior

del producto.

Esta señal le advierte sobre la importancia de las instrucciones

del manual que acompañan a este producto.

ii

D Series Syringe Pumps

Warnings, Cautions, and Notices

“To prevent damaging the instrument or injuring yourself, it is

absolutely necessary that you understand everything in English, above

all, technical terms, before operating the instrument. Otherwise, it is

necessary for you to receive complete instruction from someone

qualified who understands both the instrument and English very well.”

“Um eine Beschädigung des Gerätes oder eine Gefährdung des

Anwenders zu vermeiden ist es notwendig, daß dieser vollstandig die

englische Sprache und die technischen Bezeichnungen beherrscht.

Oder der Anwender muß von einer Person eingeübt werden, die bereits

vorher dieses Gerät bedienst hat.”

“Pour empêcher dommage à l’instrument ou blesser vous-même, il faut

absolument que vous compreniez tout en anglais, surtout les termes

techniques, avant d’actionner l’instrument. Autrement, il faut que vous

receviez l’instruction parfaite d’une personne très compétente qui

comprend bien les deux l’instrument et anglais.”

“Para prevenir cualquier daño en el instrumento o en el operador, es

necesario que el usuario comprenda perfectamente el lenguaje inglés y

las términos técnicos intrínsecos, o bien ser formado por una persona

que haya trabajado ya previamente con este instrumento.”

“For a forhindre skade på instrumentet eller operatøren er det

nødvendig at brukeren har full forståelse for det engelske sprak og

tekniske uttrykk Ellers må brukeren få opplæring av en person, som

kan engelsk, for instrumentet tas i bruk.”

“För att förhindra skade på instrumentet eller operatören, år det

nötvändigt att användaren har fullständiga kunskaper i det engelska

språket och dess tekniska termer, eller utbildas av en person, som

tidigare brukat instrumentet.”

“For at undgå skade på produktet eller på brugeren er det nødvendigt

at brugeren til fulde forstår det engelske sprog for at forstå den

tekniske formulering i den engelske manual. I modsat fald skal

brugeren modtage træning, inden apparatet tages I drift.”

iii

D Series Syringe Pumps

Warnings, Cautions, and Notices

Laitteelle tai käyttäjälle aiheutuvien vahinkojen välttämiseksi on

tärkeää, että käyttäjä hallitsee englannin kielen ja englantilaiset

tekniset termit tai on saanut käyttöopastuksen englantia osaavalta

henkilöltä.

“Per evitare danni allo struménto od incidenti all’operatore, é

necessario che l’utilizzatore abbia una completa conoscensza della

lingua inglese oppure che venga istruita da una persona che abbia

utilizzato precedentemente questo strumento.”

“Para impedir qualquer dano no aparelho ou ferimentos parao

operador, é necessario que o utilizador tenha um conhecimento

completo da lingua inglesa e dos respectivos termos técnicos, ou seja,

treinado por uma pessoa que tenha esse conhecimento, antes de

operar com este aparelho.”

“‘

”

С цел да избегне повреда на апаратурата или нараняване на

оператора е необходимо клиента добре да владее английски език и

техчническата терминолгия, която е използувана в описанието

или да бъде обучен от лице, което е вече работило с такъв апарат.

Figyelmeztetés! A készülék meghibásodásának valamint a kezelö

sérülésének megelözése érdekében a felhasználónak feltétlenül értenie

kell az angol nyelvet, ezen belül a müszaki kifejezéseket, vagy pedig a

használatba vételt megelözöen a készülék kezelésében már gyakarlott

személy által történö betanitás szükséges!

iv

D Series Syringe Pumps

Warnings, Cautions, and Notices

- EXPLOSION WARNING -

WARNING

Teledyne Isco D Series Pumps, SFX 2-10 and

SFX 220 Extractors are NOT EXPLOSION PROOF.

Teledyne Isco SFX System and D Series Syringe

Pump Safety Note when using a flammable fluid

The Teledyne Isco SFX system and syringe pumps must be placed within a properly operating vent hood (fume cupboard), when using ethane or any other flammable gas. Ensure that all SFE tubing connections are completely free of any gas

leaks by performing the leak test using CO

pump manual, Section 5 of the SFX 2-10 manual and Section 6 of the SFX 2-10,

220, and SFX 3560 manual). There must absolutely be NO gas leaks present before

introducing the flammable gas. In a temperature-stable, leak-free system, the flow

rate, as registered by the pump, should settle to a value below 0.01 ml/min after 15,

minutes during a static extraction.

(detailed in Section 2 of the D Series

2

Important: When using a Teledyne Isco extractor (either SFX 2-10, SFX

220, SFX 3560) be absolutely sure the built-in venting fan (a brushless

motor) is operating properly.

The Teledyne Isco D Series Syringe Pumps and the SFX units, use brush-type drive

motors. Minor modifications to the pumps may render them safer, especially in the

rare event of catastrophic piston seal failure. However, these modifications

will not make these pumps explosion proof.

•Remove the front and back cylinder covers located on the ball screw tower.

This will allow any escaped gas to quickly dissipate away from the pump cylinder area and to reduce the amount entering the motor compartment.

•Seal the syringe pump motor compartment with tape and purge it with a continuous flow of nitrogen (N

mulating an explosive mixture around the motor and relays.

•For further information, telephone Teledyne Isco at (800)775-2965, or fax

(402)465-3085 to consult the Teledyne Isco Service Department.

USE THE Teledyne Isco SFE SYSTEM AND SYRINGE PUMPS IN THESE

POTENTIALLY HAZARDOUS APPLICATIONS AT YOUR OWN RISK!

) gas. This will also reduce the possibility of accu-

2

5-97

v

D Series Syringe Pumps

Warnings, Cautions, and Notices

- AVERTISSEMENT D’EXPLOSION -

AVERTISSEMENT

Les pompes de Série ‘D’ Teledyne Isco et l’extracteur SFX 2-10,

SFX 220, et SFX 3560 ne sont pas à l’épreuve d’explosion!

Remarque de sûreté concernant l’usage d’un fluide inflammable avec les

pompes à seringue d’Isco Série ‘D’ et le système SFX.

Le système SFX et pompes à seringue Teledyne Isco doivent être placées à l'intérieur d’une hotte

chimique fonctionnelle, quand vous utilisez éthane C2H6, ou tout autre gaz inflammable.

Assurez-vous que toute la tuyauterie SFE est complètement scellée avec aucune fuite de gaz en exécutant une épreuve de fuite en utilisant du CO2. (Cette méthode est détaillée à la partie 2 du manuel de la pompe Série ‘D’et à la partie 2 du manuel SFX 2-10, SFX 220, et 3560.) Il faut absolument

qu'il n'y ait aucune fuite de gaz avant d'introduire le gaz inflammable au système. À partir d’un système à température stable et sans aucune fuite de gaz, la valeur du flot qui est indiqué par la

pompe, devrait se stabiliser à une valeur moins de 0,01 ml/min après 15 minutes, pendant une

extraction statique.

Important: Quand vous utilisez un extracteur Teledyne Isco SFX 2-10, SFX 220, et 3560,

soyez absolument certain que le ventilateur (du moteur sans brosses) fonctionne

correctement. Quand vous installez l'extracteur, assurez-vous qu'ilyaunespace vide de

15 centimètres au moins entre le mur et l'arrière de l'extracteur pour assurer ventilation

adéquate.

Le système SFE et les pompes de série 'D' utilisent les moteurs de courant continu. Ils possédent

des collecteurs et brosses qui produisent des décharges électriques (étincelles) entre eux quand les

moteurs fonctionnent normalement. Ces décharges, aussi bien que celles qui sont produites aux

contacts des relais pourraient faire exploser un mixture d'air et de gaz inflammable. De petites

modifications aux pompes peuvent les rendre moins dangereuses, surtout dans le cas rare d’une

panne catastrophique du joint d’étanchéité du piston. Cependant, il n’y a aucune modification

qui fera ces pompes à l’épreuve d’explosion!

• Enlevez les couvercles de devant et d'arrière du cylindre qui sont situés sur la tour de la

pompe. Cela permettra au gaz qui s'échappe de dissiper plus rapidement loin de la pompe et

réduira aussi la quantité de gaz qui entre dans le compartiment du moteur.

• Scellez le compartiment du moteur de la pompe avec un ruban adhésif et circulez un flot continu d'azote (N2) à l’intérieur du compartiment. Cela réduira aussi la possibilité d'accumuler

une mixture explosive autour du moteur et relais, où se trouvent la première possibilité des

étincelles électriques.

• Pour l'information supplémentaire, téléphonez gratuitement (800) 775-2965, ou télécopiez

(402) 465-3085 pour consulter le département de service technique.

UTILISEZ LE SYSTÈME SFE ET LES POMPES À SERINGUE TELEDYNE ISCO DANS TELLES

APPLICATIONS POTENTIELLEMENT HASARDEUSES Á VOS RISQUES ET PÉRILS!

vi

D Series Syringe Pumps

Warnings, Cautions, and Notices

WARNING:

PLEASE READ

At the request of our Supercritical Fluid Extraction laboratory staff, we want our customers

to be aware of the potential hazards involved with supercritical fluid extraction. Oxidizing

gases, such as nitrous oxide, in contact with organic matrices or flammable modifiers, can

detonate under certain conditions. Likewise, flammable fluids, such as methane, under high

pressure conditions can present a hazard.

With concern for the safety of our customers, we have designed our extractors to be as safe as

possible. However, we do not recommend the use of our instrument with potentially explosive

reactions.

The letter below, which appeared in the July 22, 1991 edition of Chemical and Engineering

News, is reprinted with permission from Professor Robert E. Sievers and his colleagues at

the University of Colorado at Boulder. Even though they were not performing supercritical

fluid extraction, it details the problems their lab experienced using nitrous oxide under similar conditions. We add our support for their suggestion to use only carbon dioxide or other

less hazardous fluids for supercritical fluid extraction.

vii

D Series Syringe Pumps

Warnings, Cautions, and Notices

CAUTION:

Avoid spills! Liquids associated with this instrument may be classified

as carcinogenic, biohazardous, flammable, or radioactive. Should

these liquids be used, it is highly recommended that this application be

accomplished in an isolated environment designed for these types of

materials in accordance with federal state and local regulatory laws

and in compliance with your organization’s chemical/hygiene plan in

the event of a spill.

In all cases, when using Teledyne Isco instrumentation, prudence and

common sense must be used.

WARNING:

Pinch point. This symbol warns you that your fingers or hands will

sustain serious injury if you place them between the moving parts of

the mechanism near this symbol.

WARNING:

Avoid hazardous practices! If you use this instrument in any way not

specified in this manual, the protection provided by the instrument may

be impaired; this will increase your risk of injury.

CAUTION:

Liquids associated with this instrument may be classified as

carcinogenic, biohazardous, flammable, or radioactive. Should these

liquids be used, it is highly recommended that this application be

accomplished in an isolated environment designed for these types of

materials, in accordance with federal, state, and local regulatory laws,

and in compliance with your company’s chemical/hygiene plan in the

event of a spill.

In all cases, when using Teledyne Isco instrumentation, prudence and

common sense must be used.

WARNING:

Team lift.To reduce the risk of injury do not attempt to lift this

instrument independently. It is highly recommended that a team be

used when lifting this instrument.

viii

D Series Syringe Pumps

Warnings, Cautions, and Notices

AVIS: Éviter de répandre! Les liquides qui sont pompés dans cet

instrument peuvent être cancérigènes, hasards biologiques,

inflammables, ou radioactifs. Si vous devez utiliser ces liquides

hasardeux, il est très recommandé que vous le faites à l'intérieur

d'un environnement isolé conçu pour tels liquides. Cet

environnement isolé devrait être construit selon les règlements

fédéraux, provinciaux, et locaux, aussi que le plan de votre

organisation qui concerne l'évènement d'un accident avec les

matières hasardeuses. En tout cas, utilisez toujours

l'instrumentation d'Isco avec prudence et sens commun

ATTENTION:

Risque de pincement. Ce symbole vous avertit que les mains ou les

doigts recevront une blessure sérieuse si vous les mettez entre les

éléments en mouvement du mécanisme près de ce symbole.

ATTENTION:

Éviter les usages hasardeux! Si vous utilisez cet instrument d’une

manière autre que celles qui sont specifiées dans ce manuel, la

protection fournie par l’instrument peut être affaiblie; cela augmentera

votre risque de blessure.

.

AVIS:

Les liquides qui sont analysés dans cet instrument peuvent être

cancérigènes, hasards biologiques, inflammables, ou radioactifs.

Si vous devez utiliser ces liquides hasardeux, il est très recommandé

que vous le faites à l'intérieur d'un environnement isolé conçu pour tels

liquides.

Cet environnement isolé devrait être construit selon les règlements

fédéraux, provinciaux, et locaux, aussi que le plan de votre

organisation qui concerne l'évènement d'un accident avec les matières

hasardeuses.

En tout cas, utilisez toujours l'instrumentation d'Isco avec prudence et

sens commun.

ix

D Series Syringe Pumps

Warnings, Cautions, and Notices

Commonly Ordered Replacement Parts for the

Description Part Number

Cylinder Seals General:

30D Seal Assembly 0-2068 bar 60-1249-128

30D Piston Assembly 0-2068 bar 60-1249-129

65D 0-1379 bar 202-9096-08

65DM 0-689.5 bar 202-9096-08

100DX/DM 0-689.5 bar 202-9090-75

260D 0-517.1 bar 202-9091-06

500D 0-258.6 bar 202-9091-56

500HPx 0-344.7 bar 202-9091-56

1000D 0-137.8 bar upper seal 202-9990-25

1000D 0-137.8 bar lower seal 202-9990-23

(For more information on seals, refer to Table 2-7.)

65D/30D

Inlet/Outlet fittings:

1

4" F250C Gland 209-0164-02

1

4" F250C Collar 209-0164-03

1

4" F250C Plug 209-0164-05

65DM

Inlet/Outlet fittings:

Valco -18" Nut 209-0169-27

1

8" Ferrule 209-0169-41

1

8" Plug 209-0166-80

1

8 –116" Tubing Reducer 209-0169-42

100DX/DM and 260D

Inlet/Outlet fittings:

Valco -18" Nut 209-0169-27

1

16" Nut 209-0094-07

1

8" Plug 209-0166-80

1

8 –116" Tubing Reducer 209-0169-42

500D

Inlet/Outlet fittings:

1

8" Tubing Connector to18" NPT 209-0161-01

1

8" NPT Plug 209-0168-00

1

8 –116" Tubing Reducer 209-0162-00

500 HPx

Inlet/outlet fittings:

3/

8" Tubing Connector to

3/

8" NPT Plug 209-016-813

D Series Syringe Pumps

3

8" NPT 209-016-100

x

D Series Syringe Pumps

Warnings, Cautions, and Notices

Commonly Ordered Replacement Parts for the

D Series Syringe Pumps

Description Part Number

1000D

Inlet/Outlet fittings:

1

4" NPT Plug 209-0168-09

1

4" NPT Connector to14" tubing 209-1063-36

Stainless Steel Tubing:

1

16"OD0.020" ID 004-7300-21

1

8"OD0.069" ID 004-7302-22

xi

D Series Syringe Pumps

Warnings, Cautions, and Notices

-NOTICE-

If you have ordered one of the following custom pumps from Teledyne

Isco, technical specifications for tubing and fittings listed in this manual

do not apply to your system.

Contact the factory for details about your custom pump.

Models:

65HP

260HP

500HP

500HV

500SP

xii

D Series Syringe Pumps

Table of Contents

Section 1 Introduction

1.1 About This Manual ..................................................1-1

1.2 Specifications .......................................................1-1

1.3 Unpacking ........................................................1-13

1.4 Controls and Indicators..............................................1-14

1.5 Electrical Connections...............................................1-18

1.5.1 Cabling .....................................................1-19

1.6 Preliminary Checkout...............................................1-21

Section 2 Fluid System Connections and Accessories

2.1 Introduction ........................................................2-1

2.2 Fluid System Connections ............................................2-1

2.2.1 Ports ........................................................ 2-1

2.2.2 Installation Tips ...............................................2-2

2.2.3 Tubing Requirements ..........................................2-2

2.2.4 Accessory Packages ............................................2-3

2.2.5 Installing the

2.2.6 Draining Overflow .............................................2-5

2.2.7 Cylinder Washing: Wash Gland ..................................2-5

2.2.8 Cylinder Washing: Nitrogen Purge ................................2-7

2.2.9 Flushing Pumps with External Transducers ........................2-8

2.3 Fluid Connection Accessories ..........................................2-8

2.3.1 Manual Refill Kit ..............................................2-8

2.3.2 Manual Outlet Valve Kit ........................................2-9

2.3.3 CO

2.3.4 In-Line Filter Package .........................................2-11

2.4 Temperature and Pressure Controls ...................................2-12

2.4.1 Cylinder Insulating Cover ......................................2-12

2.4.2 Temperature Control Jacket ....................................2-13

2.4.3 Back Pressure Regulation ......................................2-18

2.5 Seal Options.......................................................2-19

Cylinder Connection Package ...............................2-10

2

1

/16" Fittings (260D, 65DM, and 100DM/DX only) ........2-4

Section 3 Basic Programming and Operation

3.1 Introduction ........................................................3-1

3.2 General Controller Information ........................................3-1

3.2.1 Rates, Units, and Limits ........................................3-1

3.2.2 Programming Screens ..........................................3-1

3.2.3 Run Screens ..................................................3-2

3.2.4 Selecting Operating Parameters ..................................3-3

3.3 Main Menus........................................................ 3-3

3.4 Menu One..........................................................3-3

3.4.1 Flow and/or Pressure Units of Measure ............................3-3

3.4.2 Pump Selection

(if multiple pumps) ............................................3-4

3.4.3 Refill ........................................................3-4

3.4.4 Power Failure [STOP] ..........................................3-5

xiii

D Series Syringe Pumps

Table of Contents

3.5 Menu Two .........................................................3-5

3.6 Menu Three ........................................................3-8

3.7 Menu Four .........................................................3-9

3.8 Front Panel Keys...................................................3-10

3.9 Control of Multiple Pumps ...........................................3-13

3.10 Operating Modes ..................................................3-15

3.11 External Control ..................................................3-18

3.12 External Control: Analog ...........................................3-18

3.13 Remote RUN/STOP................................................3-21

3.14 Analog Flow Rate and Volume Output Options .........................3-22

3.4.5 System Reset (Restore Default Settings) ...........................3-5

3.4.6 Display Contrast ..............................................3-5

3.5.1 Serial Option .................................................3-6

3.5.2 Pump Status ..................................................3-6

3.5.3 External Control ..............................................3-6

3.5.4 Multiple Pumps ...............................................3-6

3.5.5 Total Volume Reset ............................................3-6

3.5.6 Valve ........................................................3-7

3.6.1 Poor Fill Alarm ................................................3-8

3.6.2 Diagnostic Menu ..............................................3-8

3.6.3 Pressure Calibration ...........................................3-8

3.6.4 Diff. Modes ...................................................3-9

3.6.5 Press. Integral ................................................3-9

3.6.6 Pressure Deadband ............................................3-9

3.7.1 Modbus Options ...............................................3-9

3.8.1 CONST PRESS and CONST FLOW .............................. 3-10

3.8.2 PRGM GRAD ................................................3-10

3.8.3 HOLD ......................................................3-10

3.8.4 RECALL ....................................................3-10

3.8.5 STORE .....................................................3-10

3.8.6 REFILL .....................................................3-10

3.8.7 LIMITS .....................................................3-10

3.8.8 RAPID PRESS ...............................................3-12

3.8.9 DISP .......................................................3-13

3.8.10 ACC CTRL .................................................3-13

3.8.11 ZERO PRESS ...............................................3-13

3.9.1 Multi-Pump Operation ........................................ 3-14

3.9.2 Independent Control of up to Four Separate Pumps .................3-14

3.10.1 Constant Flow ..............................................3-16

3.10.2 Constant Pressure ...........................................3-16

3.10.3 Dispense Mode ..............................................3-17

3.12.1 Wire connections ............................................

3.12.2 Preparation ................................................3-19

3.12.3 External Control for Refill .....................................3-19

3.12.4 Calculation Examples ........................................3-20

3.12.5 Setup ......................................................3-20

3.13.1 Wire Connections ............................................3-21

3.14.1 Voltage Analog Output .......................................3-22

3.14.2 Current Loop Output .........................................3-23

3-18

xiv

Section 4 Gradient Pumping for Pressure, Flow, and Concentration

Modes

4.1 Introduction ........................................................4-1

4.2 Connecting the System ...............................................4-2

4.2.1 Inlet Connections ..............................................4-4

4.2.2 Outlet Connections ............................................ 4-5

4.2.3 Dual Gradient System Connections ...............................4-6

D Series Syringe Pumps

Table of Contents

4.3 Single-Pump Gradient Programming ...................................4-8

4.4 Dual Pump Concentration Gradient Programming .......................4-10

4.5 Review, Revise, & Hold Options .......................................4-12

4.6 Program Conclusion ................................................4-12

Section 5 Continuous Flow Introduction, Installation, & Operation

5.1 Introduction ........................................................5-1

5.2 Continuous Flow Check Valves ........................................5-1

5.2.1 Check Valve Technical Specifications ..............................5-2

5.2.2 Dual Check Valve Installation ...................................5-2

5.2.3 Inlet Tubing ..................................................5-3

5.3 Continuous Flow Air Valves ...........................................5-7

5.3.1 Dual Air Valve Installation ......................................5-7

5.4 Continuous Flow Electric Valves ......................................5-13

5.4.1 Technical Specifications .......................................5-13

5.4.2 Dual Electric Valve Installation .................................5-14

5.5 User Supplied Valves ...............................................5-16

5.6 Continuous Flow Mode ..............................................5-17

5.6.1 Defining Operation ...........................................5-17

5.6.2 Constant Flow Mode ..........................................5-18

5.6.3 Constant Pressure Mode .......................................5-19

5.6.4 No Check Valve ..............................................5-20

5.6.5 To Run or Stop ...............................................5-21

5.6.6 Tips for Running Continuous Flow ...............................5-21

Section 6 Modifier Addition

6.1 Overview ..........................................................6-1

6.1.1 Installing the Kit ..............................................6-1

6.1.2 Modifier Mode Setup ...........................................6-4

6.1.3 Two Pump Operation ...........................................6-5

6.2 Programming .......................................................6-6

6.2.1 Mininum Modifier Pressure Setting ...............................6-7

6.2.2 Modifier Concentration .........................................6-7

6.3 Refilling ...........................................................6-8

Section 7 Modbus Configuration

7.1 Overview ..........................................................7-1

7.1.1 Modbus RTU .................................................7-1

7.1.2 Modbus TCP/IP ...............................................7-2

7.1.3 Modbus Configuration Options ...................................7-2

Section 8 Serial Interface

8.1 Overview ..........................................................8-1

8.2 Network Control and Communication ...................................8-2

8.3 USB Interface ......................................................8-3

8.4 Cabling for Serial Control .............................................8-3

8.4.1 One Controller ................................................8-3

8.4.2 Two Controllers (Compiler required) ..............................8-4

8.4.3 Three or More Controllers (Compiler required) ......................8-4

8.5 Serial Control Check List ............................................. 8-5

8.6 Controller Setup ....................................................8-5

8.6.1 Restore Defaults (if desired) .....................................8-5

8.6.2 Change Defaults ...............................................8-5

8.6.3 Verify Operation ..............................................8-6

xv

D Series Syringe Pumps

Table of Contents

8.7 User-written Software................................................8-6

8.8 Serial Commands for the D Series Pump ...............................8-20

Section 9 Pump Maintenance, Troubleshooting, and Servicing

9.1 Introduction ........................................................9-1

9.2 Maintenance Kits ...................................................9-3

9.3 General Cleaning....................................................9-4

9.4 Resetting the System ................................................9-4

9.5 Diagnostic Menu ....................................................9-6

9.6 Removing the Case Top...............................................9-9

9.7 Test Points........................................................9-11

9.8 Lubrication .......................................................9-12

9.9 Seal Cleaning and Replacement .......................................9-13

9.10 Wear Ring Cleaning and Replacement ................................9-17

9.11 Flushing the Cylinder ..............................................9-17

9.12 Overpressure Conditions ...........................................9-18

9.13 Motor Brushes ....................................................9-23

9.14 Calibrations ......................................................9-35

8.7.1 DASNET .....................................................8-6

8.7.2 Universal Driver from Teledyne Isco ..............................8-7

8.8.1 Get Status Command .........................................8-25

8.8.2 Gradient Download Command ..................................8-29

8.8.3 Gradient Upload Commands ....................................8-29

8.8.4 Range Command .............................................8-33

8.8.5 Error Messages .............................................. 8-34

9.1.1 Service Department ............................................9-2

9.1.2 How to Ship Returns ...........................................9-2

9.4.1 Basic Reset ...................................................9-4

9.4.2 Hard Reset ...................................................9-4

9.5.1 LCD TEST ................................................... 9-6

9.5.2 ANALOG INPUTS .............................................9-6

9.5.3 KEYPAD TEST ...............................................9-7

9.5.4 MOTOR CONTROL/LIMITS .....................................9-7

9.5.5 SERIAL TEST ................................................9-8

9.6.1 Controller Case Top Removal ....................................9-9

9.6.2 Pump Case Top Removal .......................................9-10

9.7.1 Power Supply (A1) ............................................9-11

9.7.2 Controller ...................................................9-11

9.8.1 Ball Nut ....................................................9-12

9.9.1 Piston Seal

(Excludes 30D) ...............................................9-14

9.9.2 Piston Seal Break-In (Aqueous seals only) .........................9-14

9.9.3 All other piston seals ..........................................9-15

9.9.4 Wiper Seal

(Excludes 30D) ...............................................9-15

9.11.1 Gas Solvent Changeover ......................................9-17

9.11.2 Liquid Solvent Changeover and Flushing ........................9-18

9.12.1 Shear Key ..................................................9-19

9.12.2 Replacement Using Installation Tool ............................ 9-20

9.12.3 Replacement Without Installation Tool ..........................9-21

9.12.4 Pump Bearings

(30D and 65DM Only) .........................................9-21

9.12.5 Completion of Shear Key Replacement ..........................9-22

9.13.1 Motor Brush Disassembly .....................................9-25

9.13.2 HPx Motor Brush Replacement ................................ 9-26

9.14.1 Pressure Transducer Calibration ...............................9-35

9.14.2 A/D Circuit Adjustment .......................................9-35

xvi

D Series Syringe Pumps

Table of Contents

9.14.3 Limit Sensor Adjustment .....................................9-35

9.14.4 Limit Sensor Calibration

(Excludes 30D) ...............................................9-39

9.14.5 30D Limit Sensor Calibration ..................................9-40

9.14.6 Electric Valve Motor Calibration ...............................9-41

Appendix A Replacement Parts

A.1 Replacement Parts ..................................................A-1

A.1.1 D Series Controller ............................................A-2

A.1.2 1000D Pump .................................................A-5

A.1.3 500D/DX Pump ...............................................A-9

A.1.4 500HPx Pump ...............................................A-13

A.1.5 100DM/DX and 260D Pumps ...................................A-16

A.1.6 65D Pump ..................................................A-20

A.1.7 65DM ......................................................A-33

A.1.8 Power Circuit Board ..........................................A-47

A.1.9 Analog Output Circuit Board ...................................A-51

A.1.10 Interface Circuit Board .......................................A-53

A.1.11 Dual Electric Valve Package ...................................A-55

A.1.12 Single Electric Valve Package .................................A-57

A.1.13 SST Dual Air Valve Package for 100/260D/500D ..................A-59

A.1.14 SST Dual Air Valve Package for 1000D ..........................A-61

A.1.15 Single Air Valve Package .....................................A-63

A.1.16 Dual Air Valve Package for 500HPx ............................A-65

A.1.17 Dual Check Valve Package for 100/260/500D .....................A-67

A.1.18 Dual Check Valve Package for 1000D ...........................A-69

A.1.19 Single Check Valve Package ...................................A-71

Appendix B Continuous Flow Introduction, Installation, and Operation for 30D

B.1 Introduction .......................................................B-1

B.2 Continuous Flow Air Valves...........................................B-1

B.2.1 Dual Air Valve Installation .....................................B-2

B.3 Continuous Flow Electric Valves .......................................B-4

B.3.1 Technical Specifications ........................................B-4

B.3.2 Dual Electric Valve Installation ..................................B-5

B.4 User Supplied Valves ................................................B-7

B.5 Continuous Flow Mode ...............................................B-8

B.5.1 Defining Operation ............................................B-9

B.5.2 Constant Flow Mode ..........................................B-10

B.5.3 Constant Pressure Mode .......................................B-10

B.5.4 No Check Valve ..............................................B-11

B.5.5 To Run or Stop ...............................................B-12

B.5.6 Tips for Running Continuous Flow ..............................B-12

B.6 Replacement Parts List .............................................B-14

B.6.1 30D Pump ..................................................B-14

B.6.2 30D Air Valve ...............................................B-17

B.6.3 30D Electric Air Valve ........................................B-19

List of Figures

1-1 260D flow rate range ...............................................1-11

1-2 500D flow rate range ...............................................1-11

1-3 500 HPx flow rate range ............................................1-12

1-4 1000D flow rate range ..............................................1-12

xvii

D Series Syringe Pumps

Table of Contents

1-5 Pump controller key functions ........................................1-14

1-6 Pump controller rear panel connectors .................................1-16

1-7 Pump rear panel connectors .........................................1-17

1-8 Pump front panel controls ...........................................1-18

1-9 Syringe pump cylinder cap: Attach to pressure transducer connector on back of

1-10 Connecting the pump and controller ..................................1-21

1-11 Status Screen ....................................................1-21

1-12 Menu 1 .........................................................1-22

1-13 Three pump stop menu ............................................1-23

1-14 Four pump stop menu .............................................1-23

2-1 Liquid system plumbing connections (30D on Left) ........................2-2

2-2

2-3 30D/65DFitting .....................................................2-4

2-4 Drain tube installation ...............................................2-5

2-5 Drain tube installation and wash gland connection ........................2-6

2-6 Purge connector installation ..........................................2-7

2-7 Refill kit installation ................................................2-9

2-8 Outlet valve package connection ......................................2-10

2-9 CO

2-10 In-line filter package ..............................................2-11

2-11 Cylinder insulation cover ...........................................2-12

2-12 System with temperature control jacket installed .......................2-13

2-13 Fluid fittings .....................................................2-14

2-14 Secure screws with the

2-15 Removing the cylinder cap with wrenches .............................2-16

2-16 Temperature control jacket installation ...............................2-17

2-17 Back pressure regulator ............................................2-18

2-18 Inside the pump cylinder: wetted materials ............................2-19

3-1 Menu 1 program selections ...........................................3-3

3-2 Units menu ........................................................3-3

3-3 Menu 2 program selections ...........................................3-5

3-4 Serial option menu ..................................................3-6

3-5 Total volume reset ..................................................3-6

3-6 Types of valves .....................................................3-7

3-7 Menu 3 program selections ...........................................3-8

3-8 Location of transducer midpoint value ..................................3-8

3-9 Limits menu ......................................................3-11

3-10 Limits setpoint (Max Press) menu ...................................3-11

3-11 Depiction of dispense mode sequence .................................3-17

3-12 External control for refill menu ......................................3-20

3-13 Button sequence for external control setup ............................3-21

3-14 Analog voltage output connection, rear panel ..........................3-22

3-15 Output range selection jumpers ..................................... 3-23

4-1 Pump inlet connections ..............................................4-4

4-2 Pump outlet connections .............................................4-5

4-3 Dual gradient system connections

4-4 Dual gradient connections: Detail ......................................4-7

5-1 Check valve package installation: 65DM/100D/265D/500D pumps ...........5-4

5-2 Check valve package installation: 1000D pump ...........................5-6

5-3 Air valve installation for 65DM, 100DM/DX, 260D, and 500D pumps ......... 5-9

5-4 Air valve installation for 500HPx pumps ...............................5-10

5-5 Air valve installation for 1000D pump .................................5-11

5-6 Air valve installation for 65D pump ...................................5-12

5-7 Electric valve installation ...........................................5-15

5-8 Keystrokes to specify valve type ......................................5-18

5-9 Keystrokes to reset volume totalizer ...................................5-18

5-10 Keystrokes to set up constant flow ...................................5-19

pump. ...........................................................1-20

1

/16" Tubing adapter for 30D/65D pumps ................................ 2-4

package installation ............................................2-11

2

1

/4” hex wrench ...............................2-15

(Inlet valves (A & C) are from refill valve kits) ...........................4-7

xviii

D Series Syringe Pumps

Table of Contents

5-11 Keystrokes to set up constant pressure ...............................5-19

5-12 Keystrokes to set up No Check Valve .................................5-20

5-13 Keystrokes to Run or Stop the pumps .................................5-21

6-1 Modifier addition kit installation (Two-pump configuration) ................ 6-2

6-2 Modifier addition kit installation (continuous flow) ........................6-3

6-3 Minimum modifier pressure screen .....................................6-7

7-1 RS-485 Connection ..................................................7-1

8-1 Serial network connection example - Single connection .................... 8-4

8-2 Serial network connection example - Dual connection ......................8-4

8-3 Get Status String “G” Command ......................................8-26

8-4 Get Status String “GG” Command ....................................8-26

8-5 Get All Status String “G&” Command .................................8-27

8-6 Get all status strings from four pump operation “G&2” Command ..........8-28

8-7 Gradient Download Commands - Single pump flow gradient ...............8-29

8-8 Gradient Download Commands - Two pump flow gradient .................8-30

8-9 Gradient Upload Commands - Single pump flow gradient .................8-31

8-10 Gradient Upload Commands - Two pump flow gradient ..................8-32

8-11 Upload Commands - Single pump pressure programming ................8-33

8-12 Range Serial Commands ...........................................8-33

9-1 500HPx fan filter ...................................................9-4

9-2 Accessing the diagnostic menu ........................................9-6

9-3 Analog Input diagnostic screen ........................................9-6

9-4 Optical sensor, interrupted by flag (bottom sensor shown, rear tower cover plate re-

moved) ........................................................... 9-7

9-5 Serial connection to a computer .......................................9-8

9-6 Controller case top screws (2 of 4 shown) ...............................9-10

9-7 Pump case top screws (2 of 4 shown) ...................................9-10

9-8 Gear train lubrication and motor drive service ..........................9-12

9-9 Break-in procedure for aqueous seals (Drawing does not apply to the 30D) . . . 9-15

9-10 Accessing the shear key ............................................9-20

9-11 Shear key replacement .............................................9-20

9-12 30D and 65DM Bearing set ......................................... 9-22

9-13 30D and 65DM Shear key replacement ...............................9-22

9-14 D Series motor brush replacement ...................................9-24

9-15 Location of motor brushes ..........................................9-24

9-16 Length of a new motor brush (1.1 cm) .................................9-24

9-17 Inserting new motor brush .........................................9-25

9-18 For 30D a cable tie holds the wires together ...........................9-25

9-19 Remove screws and washers, then the plate ...........................9-26

9-20 Remove the five screws from the bottom of the pump .................... 9-26

9-21 two pin connector .................................................9-27

9-22 Encoder .........................................................9-27

9-23 Location of screws and washers holding the motor in place ...............9-28

9-24 Motor assembly ...................................................9-28

9-25 Support plate ....................................................9-29

9-26 Position of wires connected to the motors ..............................9-29

9-27 Wire connections ..................................................9-29

9-28 Set screws holding the two negative brushes ...........................9-30

9-29 Wires disconnected from brush contact ...............................9-30

9-30 Connector connected to the brush ....................................9-31

9-31 Removing the set screws ...........................................9-31

9-32 Loosen the connector ..............................................9-32

9-33 New brush reinstalled; set screw replaced .............................9-32

9-34 Location of locating pins ...........................................9-33

9-35 Motor plate and bearing plate .......................................9-34

9-36 Installing the deflector shield .......................................9-34

9-37 Capacitor and motor shaft ..........................................9-35

9-38 Limit sensor replacement ..........................................9-37

9-39 Installing the plastic mounts ........................................9-37

xix

D Series Syringe Pumps

Table of Contents

9-40 Electric valve motor voltage ......................................... 9-42

9-41 Electric valve motor adjustment .....................................9-43

B-1 Air valve installation for 30D pump ....................................B-3

B-2 Electric valve installation ............................................B-6

B-3 Keystrokes to specify valve type .......................................B-9

B-4 Keystrokes to reset volume totalizer ...................................B-9

B-5 Keystrokes to set up constant flow ....................................B-10

B-6 Keystrokes to set up constant pressure ................................B-10

B-7 Keystrokes to set up No Check Valve ..................................B-11

B-8 Keystrokes to Run or Stop the pumps .................................B-12

List of Tables

1-1 30D Technical Specifications ..........................................1-2

1-2 65D Technical Specifications ..........................................1-3

1-3 65DM Technical Specifications ........................................1-4

1-4 100DM Technical Specifications .......................................1-5

1-5 100DX Technical Specifications ........................................1-6

1-6 260D Technical Specifications .........................................1-7

1-7 500D Technical Specifications .........................................1-8

1-8 500HPx Technical Specifications .......................................1-9

1-9 1000D Technical Specifications .......................................1-10

1-10 Pump Controller Front Panel Label ..................................1-14

1-11 Pump Controller Key Functions .....................................1-15

1-12 Pump Controller Rear Panel Connectors ..............................1-16

1-13 Pump Rear Panel Connectors .......................................1-17

1-14 Pump Front Panel ................................................1-18

2-1 D Series Syringe Pump Accessory Packages .............................2-3

2-2 Manual Refill Kits ..................................................2-9

2-3 Manual Outlet Valve Kits ...........................................2-10

2-4 CO

2-5 Optional in-line Filter Package 68-1247-011 ............................ 2-11

2-6 Packages and Parts ................................................2-14

2-7 Seal Selection Chart ................................................2-20

3-1 Key functions in the Multi-pump Mode ................................3-14

3-2 Analog Output Options (connections to female 25 pin Sub-D) ..............3-23

3-3 Analog Output Signal/Sub-D Pins for 4-20mA ...........................3-24

3-4 Analog Output Signal/Sub-D Pins for 0-10 VDC .........................3-25

4-1 Manual Refill Valve Kits .............................................4-1

4-2 Manual Outlet Valve Kits ............................................4-2

4-3 Swaging Detail .....................................................4-2

5-1 Continuous Flow Technical Specifications-Check Valves: ...................5-2

5-2 Continuous Flow Check Valve Package for

5-3 Continuous Flow Check Valve Package for 1000D, part #68-1247-128 ........5-6

5-4 Continuous Flow Technical Specifications-Air Valves: .....................5-7

5-5 Continuous Flow Technical Specifications-Electric Valves: ................5-13

5-6 Accessory Control Digital Outputs ....................................5-16

5-7 Key functions in the Multi-pump Mode ................................5-17

6-1 Modifier Addition Kit for Two Pumps (part #68-1247-079) ..................6-3

6-2 Modifier Addition Components for Continuous Flow System ................6-4

7-1 Modbus TCP/IP Configuration Options .................................7-2

7-2 Modbus RTU Configuration Options ....................................7-2

7-3 Supported Modbus Function Codes .....................................7-3

7-4 Exception Responses ................................................7-3

7-5 Coils ..............................................................7-4

Cylinder Connection Package 68-1247-043 ..........................2-10

2

100D/260D /500D, part #68-1247-059 ................................... 5-5

xx

D Series Syringe Pumps

Table of Contents

7-6 Holding Registers ...................................................7-7

8-1 External control connector

serial pin connections ...............................................8-2

8-2 USB Interface Pin Connections ........................................8-3

8-3 Example of BASIC program to demonstrate

conversion of pump commands to DASNET frames .......................8-8

8-4 Example of C program to demonstrate

conversion of pump commands to DASNET frames .......................8-9

8-5 Example of a Visual C++ program to demonstrate conversion

of pump commands to DASNET frames ................................ 8-10

8-6 Serial Commands ..................................................8-20

8-7 Error Messages ....................................................8-34

9-1 Maintenance Kit Contents ............................................9-3

9-2 Maintenance Kit Part Numbers .......................................9-4

9-3 Piston Wrench Tools ................................................9-16

9-4 Replacement Shear Keys ............................................9-19

B-1 Continuous Flow Technical Specifications-Air Valves: .....................B-2

B-2 Continuous Flow Technical Specifications-Electric Valves: .................B-4

B-3 Accessory Control Digital Outputs .....................................B-7

B-4 Key functions in the Multi-pump Mode .................................B-8

xxi

D Series Syringe Pumps

Table of Contents

xxii

D Series Syringe Pumps

Section 1 Introduction

1.1 About This Manual The 65DM, 100DM, 100DX, 260D, and 500D pumps have

standard Valco ports. Pipe thread fittings of14" diameter are

used for the 1000D,38" diameter for the 500HPx, and18"

diameter for the 500D. The 65D and 30D use AE F250C high

pressure fittings. Because of these differences, the packages,

tubing, and options for different models have different part

numbers. Additionally, these pumps are typically used for different applications; therefore, optional kits and accessories may

differ.

The installation procedures for the different D Series pump

models have been combined where applicable, and separated

where necessary, for your convenience.

Optional system configurations may require additional kits

and/or software. These additional options are described in their

respective sections.

This manual contains the following sections:

Section 1 Introduction

Section 2 Fluid System Connections and Accessories

Section 3 Basic Programming and Operation

Section 4 Gradient Pumping for Pressure, Flow, and Concen-

tration Modes

Section 5 Continuous Flow Introduction, Installation, & Oper-

ation

Section 6 Modifier Addition

Section 7 Modbus Configuration

Section 8 Serial Interface

Section 9 Pump Maintenance, Troubleshooting, and Servicing

Appendix A Replacement Parts

1

8"

1.2 Specifications The technical specifications for the D Series Syringe Pumps are

detailed in Tables 1-2 through 1-9.

Note

Underwriters Laboratories (UL) has certified all Series D

Pumps with the exception of the 100 VAC versions.

1-1

D Series Syringe Pumps

Section 1 Introduction

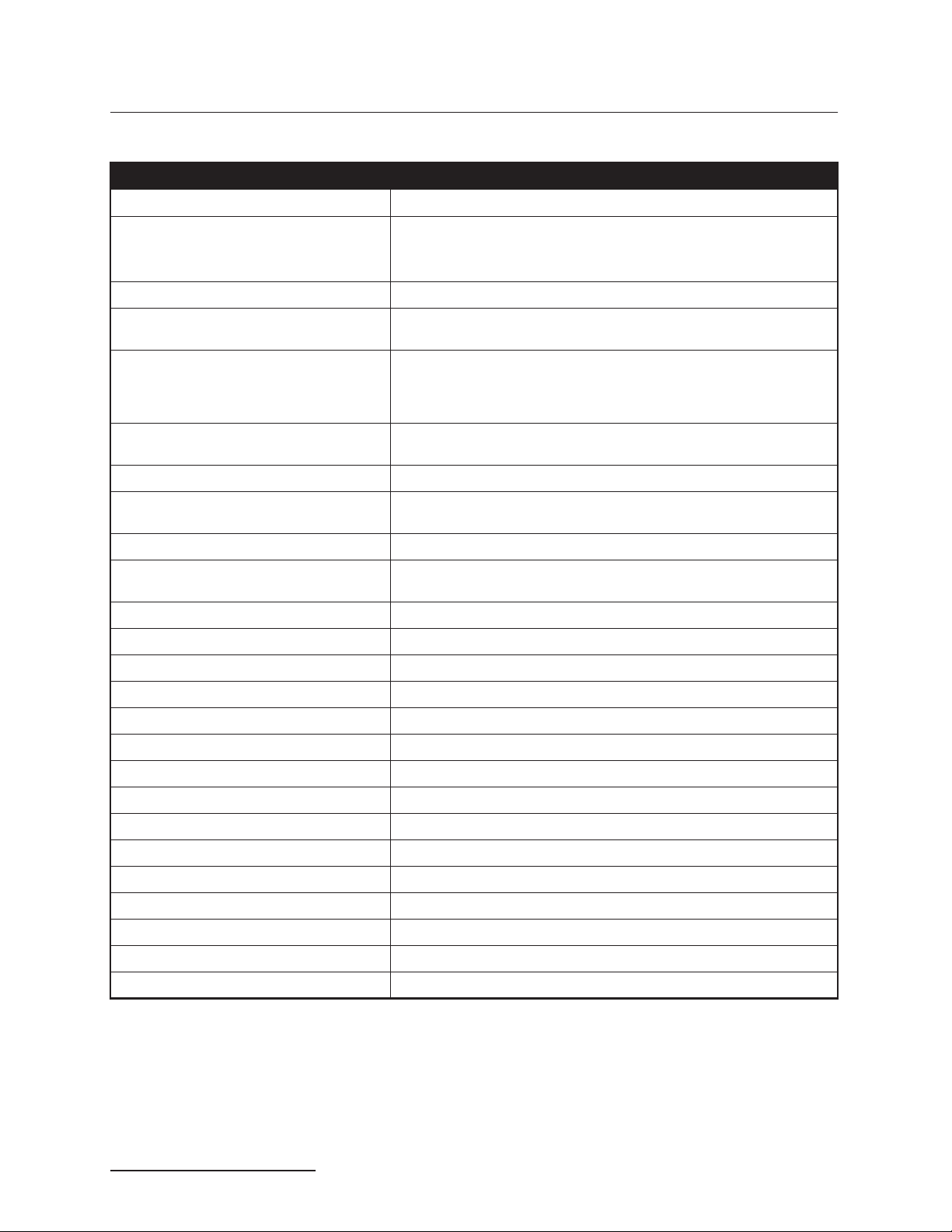

Table 1-1 30D Technical Specifications

CYLINDER CAPACITY 30.42 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE 0.01 µl/min to 22 ml/min (for any pressure up to 2068 bar)

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 0.01 µl/min (1.0 µl/min in Constant Pressure Mode)

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 1.825 nl /step

REFILL TIME 1.05 minutes

REFILL OR DEPRESSURIZATION RATE 0.01 µl/min to 29 ml/min at any pressure from 0 to 2068 bar

a

b

100 ± 10 VAC, 2.8 A maximum

117 ± 12 VAC, 2.4 A maximum

234 ± 23 VAC, 1.2 A maximum

Factory Set

}

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 100 cm 13.59 cm

36.4 kg 2.96 kg

± 0.5% above 69 bar and above 0.25 ml/min

(maximum 1.0 µl/min seal leakage)

± 0.2% 4-20 mA output, ± 0.5% voltage output using the 12 channel

output option

PRESSURE RANGE 0.6895 to 2068.4 bar

PRESSURE ACCURACY ± 0.2% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.05% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.015% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Using water at constant pressure and constant temperature above 69 bar and above 0.25 ml/min.

b. The analog output is an optional accessory.

c. Pressure repeatability specification is based on zeroing the pressure transducer before measurement. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

d. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

c

d

± 0.05% of full scale within 48 hours at constant temperature

0.88 ± 0.02 ml

1-2

Table 1-2 65D Technical Specifications

CYLINDER CAPACITY 67.97 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

D Series Syringe Pumps

Section 1 Introduction

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE 0.01 µl/min to 25 ml/min (for any pressure up to 1379 bar)

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 0.01 µl/min (1.0 µl/min in Constant Pressure Mode)

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 2.55 nl /step

REFILL TIME 1.7 minutes

REFILL OR DEPRESSURIZATION RATE 0.01 µl/min to 40 ml/min at any pressure from 0 to 1379 bar

PRESSURE RANGE 0.6895 to 1379 bar

PRESSURE ACCURACY ± 0.1% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 101.09 cm 13.59 cm

32.8 kg 2.96 kg

± 0.3% (maximum 0.25 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.015% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

1.30 ± 0.020 ml

1-3

D Series Syringe Pumps

Section 1 Introduction

Table 1-3 65DM Technical Specifications

CYLINDER CAPACITY 67.97 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

LINE VOLTAGE NOISE TOLERANCE 1.7

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Factory Set

}

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE 0.01 µl/min to 30 ml/min (for any pressure up to 689 bar)

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 0.01 µl/min (1.0 µl/min in Constant Pressure Mode)

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 2.55 nl /step

REFILL TIME 1.7 minutes

REFILL OR DEPRESSURIZATION RATE 0.01 µl/min to 40 ml/min at any pressure from 0 to 689 bar

PRESSURE RANGE 0.6895 to 689 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

AMBIENT TEMPERATURE RANGE 5 to 40°C

b

c

d

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 103.0 cm 13.59 cm

33.2 kg 2.96 kg

± 0.3% of setpoint, (maximum 0.25 µl/min seal leakage)

± 1% of selected range

(± 0.1% FS optional)

± 0.5% of full scale within 48 hours at constant temperature

TEMPERATURE DRIFT ± 0.12% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

1.30 ± 0.020 ml

1-4

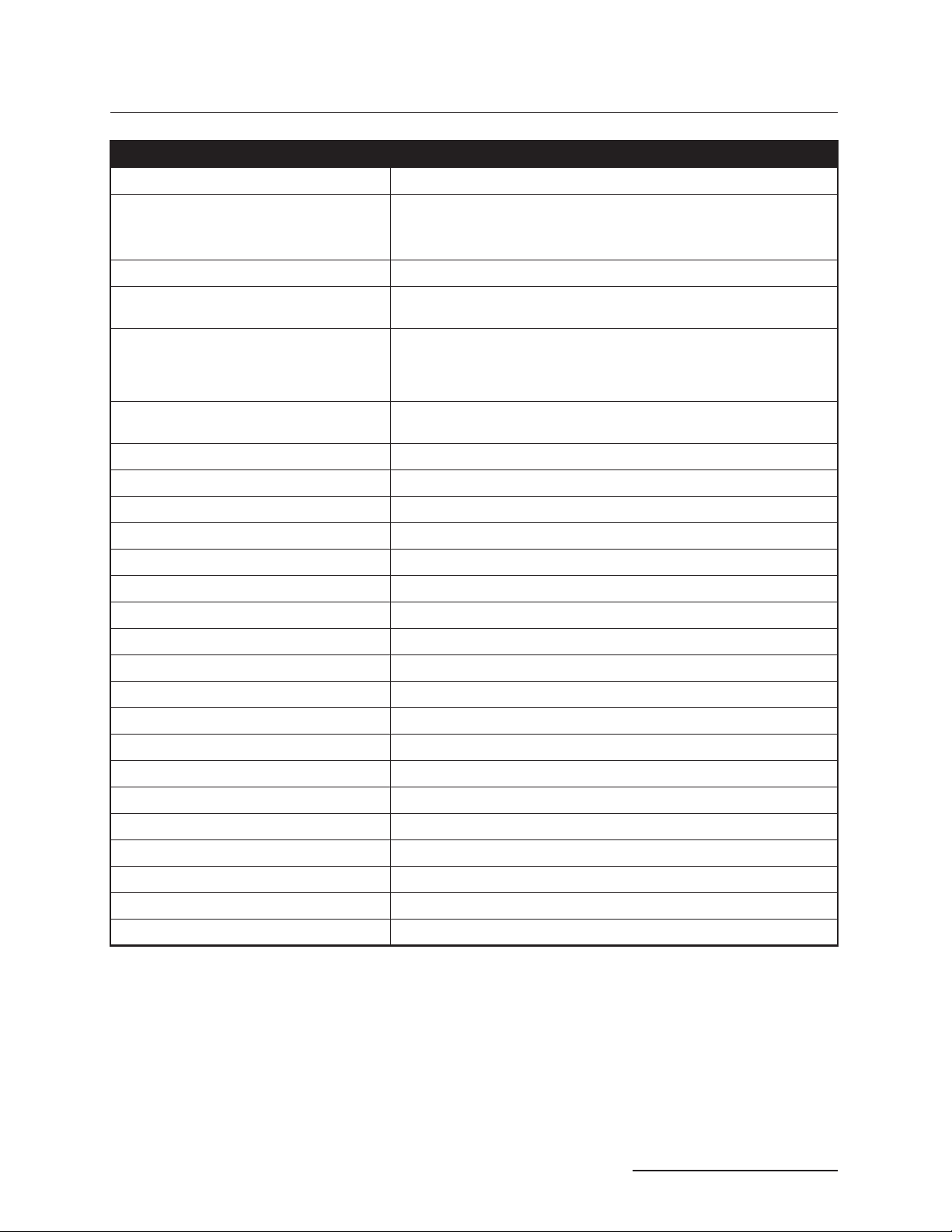

Table 1-4 100DM Technical Specifications

CYLINDER CAPACITY 102.93 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

D Series Syringe Pumps

Section 1 Introduction

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE 0.01 µl/min to 25 ml/min (for any pressure up to 689.5 bar)

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 0.01 µl/min (1.0 µl/min in Constant Pressure Mode)

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 4.825 nl /step

REFILL TIME 3.5 minutes

REFILL OR DEPRESSURIZATION RATE 0.01 µl/min to 30 ml/min at any pressure from 0 to 689.5 bar

PRESSURE RANGE 0.6895 to 689.5 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 101.09 cm 13.59 cm

32.8 kg 2.96 kg

± 0.3% (maximum 0.25 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.0.12% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

NOTES:

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

1.30 ± 0.020 ml

1-5

D Series Syringe Pumps

Section 1 Introduction

Table 1-5 100DX Technical Specifications

CYLINDER CAPACITY 102.93 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE 0.01 µl/min to 50 ml/min (for any pressure up to 689.5 bar)

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 0.01 µl/min (1.0 µl/min in Constant Pressure Mode)

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 9.65 nl /step

REFILL TIME 1.72 minutes

REFILL OR DEPRESSURIZATION RATE 0.01 µl/min to 60 ml/min at any pressure from 0 to 689.5 bar

PRESSURE RANGE 0.6895 to 689.5 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 101.09 cm 13.59 cm

32.8 kg 2.96 kg

± 0.3% (maximum 0.25 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.0.12% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

1.30 ± 0.020 ml

1-6

Table 1-6 260D Technical Specifications

CYLINDER CAPACITY 266.05 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

D Series Syringe Pumps

Section 1 Introduction

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE See Figure 1-1.

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 1.0 µl/min

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 16.63 nl /step

REFILL TIME 2.5 minutes

REFILL OR DEPRESSURIZATION RATE 1.0 µl/min to 107 ml/min at any pressure from 0 to 517.1 bar

PRESSURE RANGE 0.6895 to 517.1 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 101.09 cm 13.59 cm

32.8 kg 2.96 kg

± 0.5% (maximum 0.50 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.15% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

2.10 ± 0.020 ml

1-7

D Series Syringe Pumps

Section 1 Introduction

Table 1-7 500D Technical Specifications

CYLINDER CAPACITY 507.38 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT PUMP CONTROLLER

FLOW RATE RANGE See Figure 1-2.

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 1.0 µl/min

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 31.71 nl /step

REFILL TIME 2.5 minutes

REFILL OR DEPRESSURIZATION RATE 1.0 µl/min to 204 ml/min at any pressure from 0 to 258.6 bar

PRESSURE RANGE 0.6895 to 258.6 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 102.36 cm 13.59 cm

33.25 kg 2.96 kg

± 0.5% (maximum 1.0 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.15% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. Using water at 137.9 bar and a temperature controlled environment at 30°C.

c. The analog output is an optional accessory.

d. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

e. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

e

4.00 ± 0.020 ml

1-8

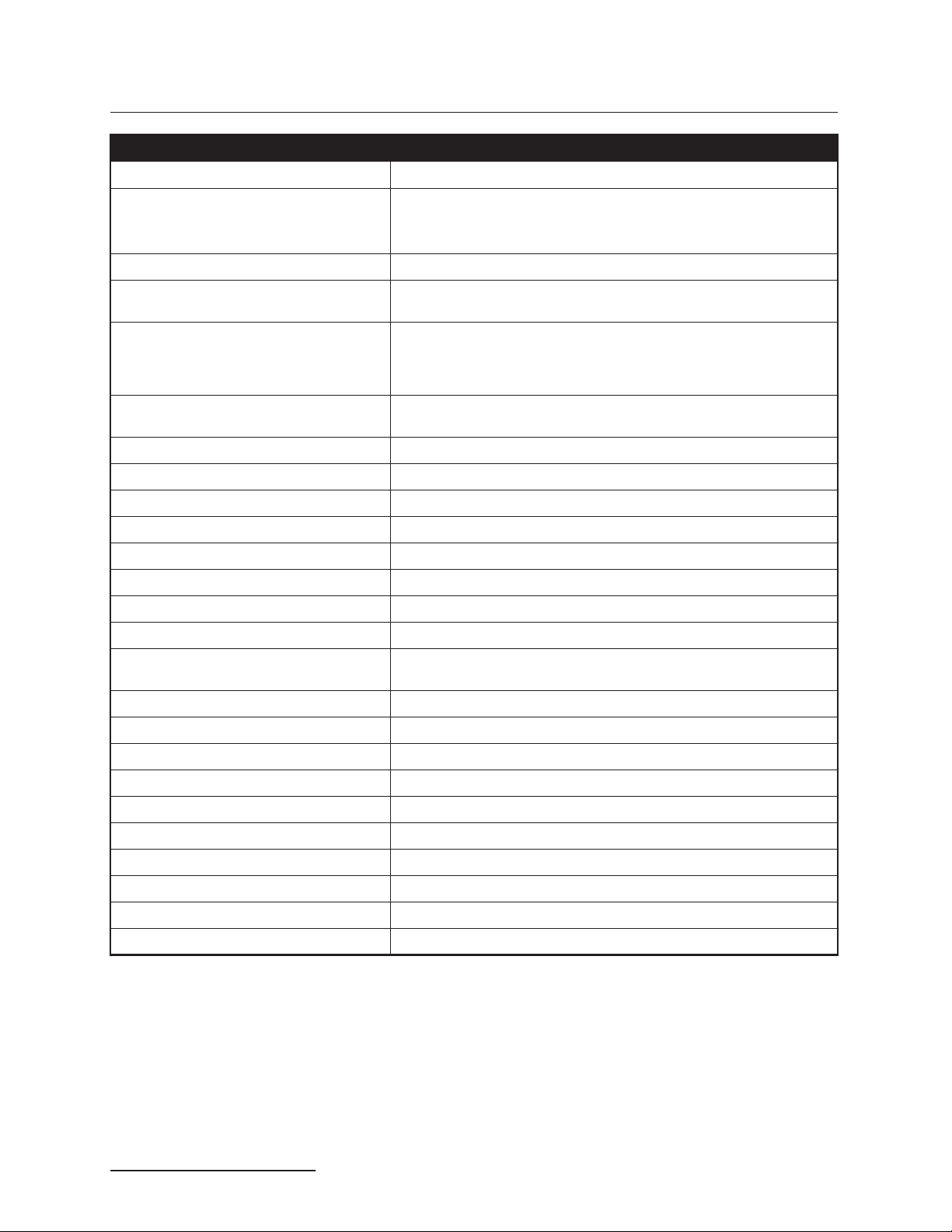

Table 1-8 500HPx Technical Specifications

CYLINDER CAPACITY 507.38 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 5A maximum

117 ± 12 VAC, 5A maximum

234 ± 23 VAC, 2.5A maximum

Factory Set

}

D Series Syringe Pumps

Section 1 Introduction

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT

FLOW RATE RANGE See Figure 1-3.

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 1.0 µl/min

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 25.36 nl /step

REFILL TIME 1.25 minutes

REFILL OR DEPRESSURIZATION RATE 1.0 µl/min to 408 ml/min at any pressure from 0 to 344.7 bar

PRESSURE RANGE 0.6895 to 344.7 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

e

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 102.36 cm 13.59 cm

PUMP CONTROLLER

42.64 kg 2.96 kg

± 0.5% (maximum 1.0 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.15% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. A team lift is recommended when moving this instrument.

c. Using water at 137.9 bar and a temperature controlled environment at 30°C.

d. The analog output is an optional accessory.

e. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section

ZERO PRESS in Section 3 of the manual for re-zeroing procedure.

f. Volume in and above the piston seal, head clearance at automatic shutoff, and inlet and outlet ports to the fittings.

f

10.45 ± 0.65 ml

1-9

D Series Syringe Pumps

Section 1 Introduction

Table 1-9 1000D Technical Specifications

CYLINDER CAPACITY 1015.0 ml

POWER REQUIREMENTS

(Mains voltage line cord is a

“Disconnect Device”)

LINE FREQUENCY 50 or 60 Hz

a

100 ± 10 VAC, 1.5 A maximum

117 ± 12 VAC, 1.5 A maximum

234 ± 23 VAC, 0.75 A maximum

Factory Set

}

LINE VOLTAGE NOISE TOLERANCE 1.7

DIMENSIONS PUMP CONTROLLER

WEIGHT

FLOW RATE RANGE See Figure 1-4.

FLOW RATE ACCURACY

FLOW RATE DISPLAY RESOLUTION 1.0 µl/min

ANALOG OUTPUT ACCURACY

DISPLACEMENT RESOLUTION 25.38 nl /step

REFILL TIME 2.5 minutes

REFILL OR DEPRESSURIZATION RATE 1.0 µl/min to 408 ml/min at any pressure from 0 to 137.9 bar

PRESSURE RANGE 0.6895 to 137.9 bar

PRESSURE ACCURACY ± 0.5% of full scale at constant temperature

PRESSURE REPEATABILITY

ZERO PRESSURE DRIFT ± 0.25% of full scale within 48 hours at constant temperature

PRESSURE DISPLAY RESOLUTION 6.895 kPa

b

c

d

e

nominal rms line voltage, 10 µsecond pulses, any phase

angle, random or repetitive

Width: 27.18 cm 27.18 cm

Depth: 46.74 cm 30.48 cm

Height: 102.36 cm 13.59 cm

PUMP CONTROLLER

38.5 kg 2.96 kg

± 0.5% (maximum 1.5 µl/min seal leakage)

± 1% of selected range

± 0.5% of full scale within 48 hours at constant temperature

AMBIENT TEMPERATURE RANGE 5 to 40°C

TEMPERATURE DRIFT ± 0.12% of full scale/°C

HUMIDITY 95% maximum

DEAD (HEADSPACE) VOLUME

POLLUTION DEGREE 2

INSTALLATION CATEGORY II

MAXIMUM ALTITUDE 2000 m

a. Underwriters Laboratories (UL) has certified all D Series Pumps with the exception of the 100 VAC versions.

b. A team lift is recommended when moving this instrument.

c. Using water at 137.9 bar and a temperature controlled environment at 30°C.

d. The analog output is an optional accessory.

e. Pressure repeatability specification is based upon re-zeroing pressure transducer every 48 hours. Refer to sub-section