Page 1

OPERATING INSTRUCTIONS FOR

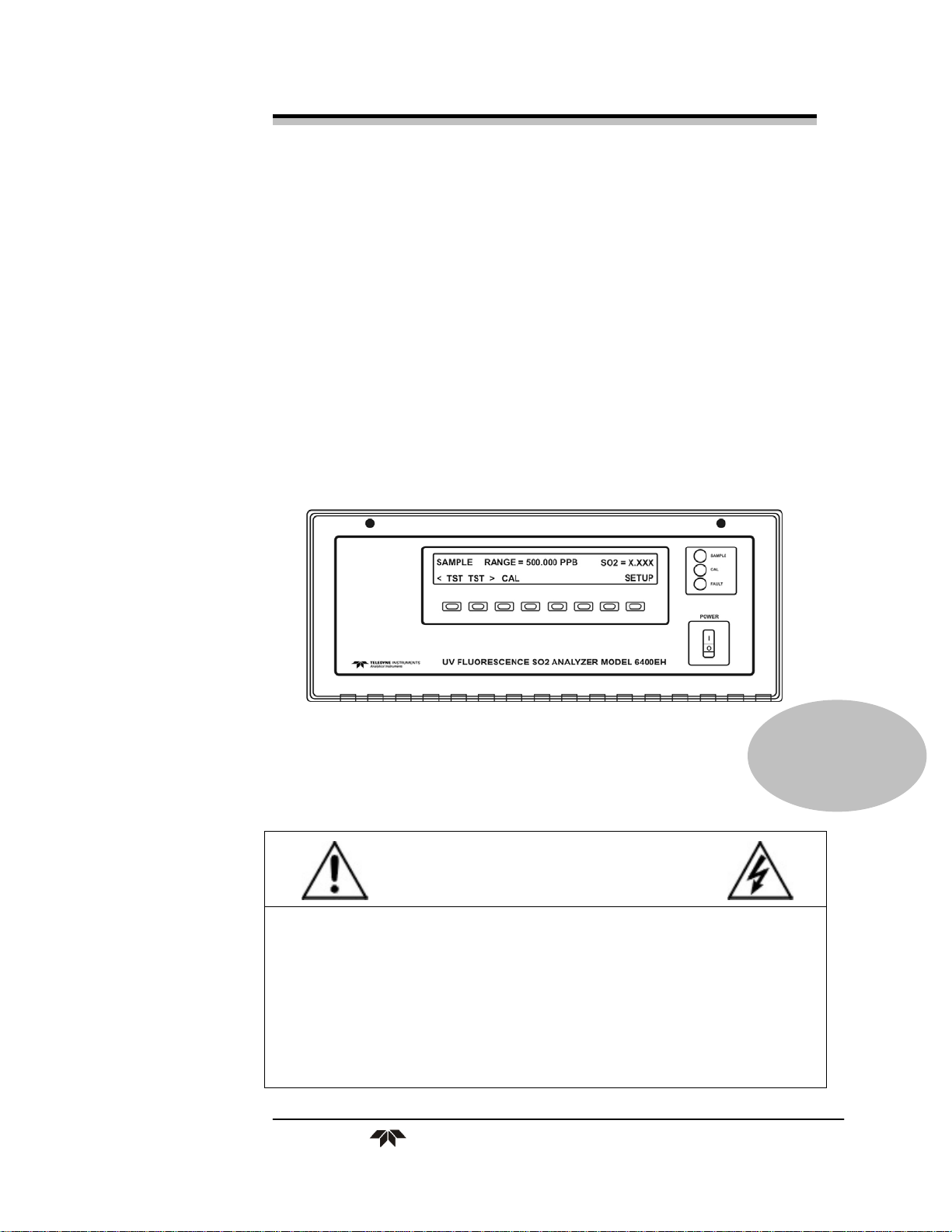

Model 6400EH

UV Fluorescence SO2 Analyzer

P/N M77713

DANGER

Dependingon your application, toxic gases may be present in this monitoring

system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Page 2

Model 6400EH

Copyright © 2008 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/ Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/ Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Teledyne Analytical Instruments ii

Page 3

UV Fluorescence SO2 Analyzer

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Page 4

Model 6400EH

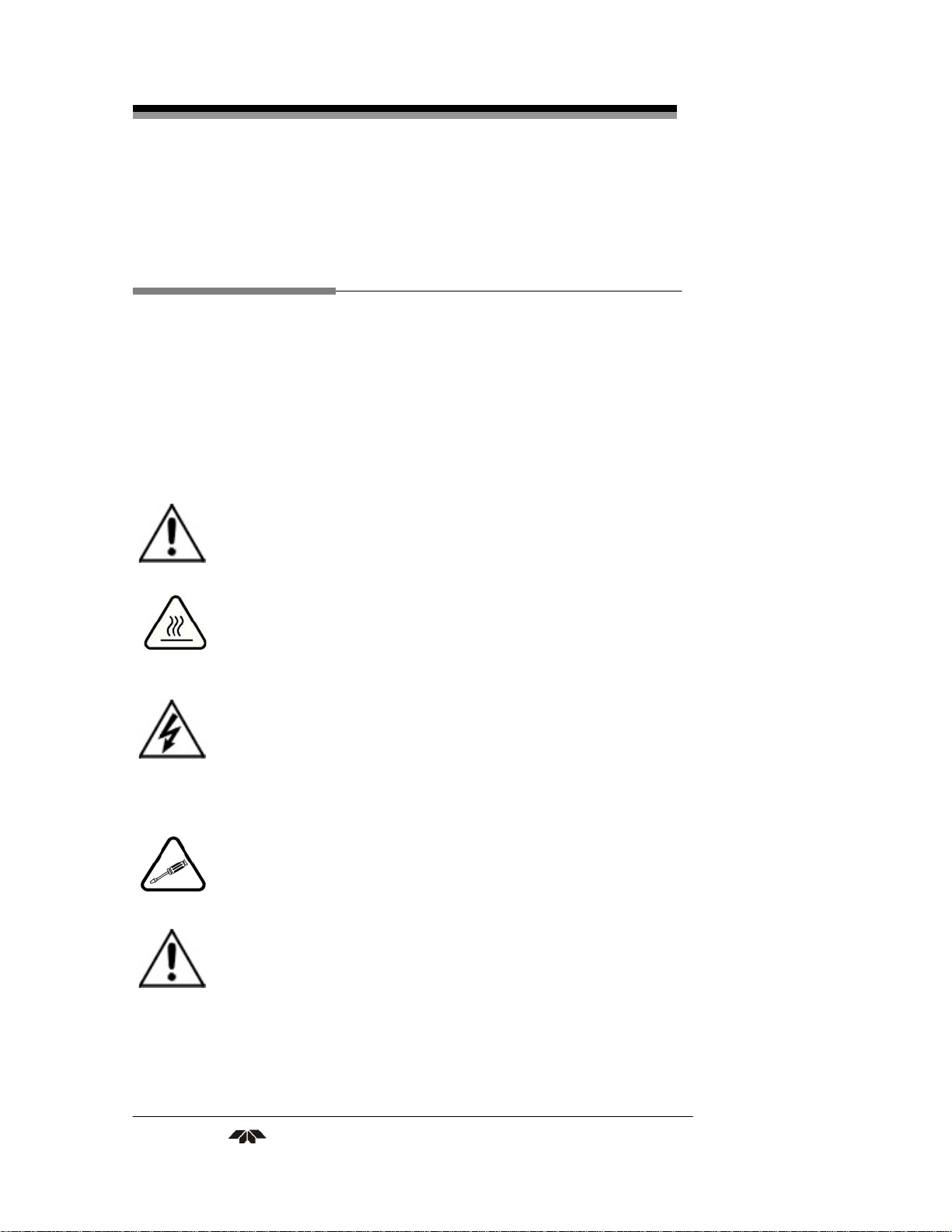

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

Teledyne Analytical Instruments iv

Page 5

UV Fluorescence SO2 Analyzer

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

TI/AI at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model 6400EH

Table of Contents

List of Figures .............................................................................. ix

List of Tables ................................................................................ xi

Documentation .............................................................................. 1

1.1. Using This Manual Addendum 2

Specifications, Approvals & Warranty ........................................ 5

2.1. Specifications 5

2.2. CE Mark Compliance 6

2.3. Warranty 7

Getting Started .............................................................................. 9

3.1. Unpacking and Initial Setup 9

3.1.1. Electrical Connections: 10

3.1.1.1. External Pump 10

3.2 Pneumatic Connections 11

3.2.2 Pneumatic Connections to the 6400EH 11

3.2.2.1 Pneumatic Connections to 6400EH Basic

Configuration 11

3.2.2.2 Connections with Internal Valve Options Installed 12

3.2.3 6400EH Layout 13

3.3 Initial Operation 15

3.3.1 Warning Messages 15

3.3.2 Test Functions 15

3.3.3 Interferents for SO2 Measurements 15

Frequently Asked Questions ...................................................... 17

Optional Hardware and Software ............................................... 19

5.1 Zero/Span Valves (Option 50) 19

5.2 Internal Zero/Span Gas Generator (Option 51) 20

Teledyne Analytical Instruments vi

Page 7

UV Fluorescence SO2 Analyzer

5.3 Zero and Two Span Point Valve Option (OPT 52) 20

5.4 Hydrocarbon Kicker Option (OPT 65) 22

Operating Instructions ................................................................ 25

6.1 Warning Messages 25

6.2 Test Functions 25

6.2.1 Test Channel Output 26

6.2.2 Range Units 26

6.2.3 Using the 6400EH with a Hessen Protocol Network 26

6.2.4 Default iDAS Channels 28

6.2.5 Remote Operation Using the External Digital I/O 28

6.2.5.1 Status Outputs 28

6.2.5.2 Control Inputs 29

Calibration and Calibration Check Procedures ........................ 31

7.1 Manual Calibration with the Zero and Two Span Point

Valve Option (OPT 52) installed 31

7.2 Manual Calibration Check with the Zero and Two Span

Point Valve Option (OPT 52) installed 33

Instrument Maintenance ............................................................. 35

8.1 Maintenance Schedule 35

8.2 Predictive Diagnostics 35

Theory of Operation .................................................................... 37

9.1 The UV Light Path 37

9.1.1 The Reference Detector 38

9.1.2 Direct Measurement Interferences 38

9.2 Pneumatic Operation 39

9.2.1 Sample Gas Flow 39

9.2.2 Pneumatic Sensors 40

9.2.2.1 Sample Pressure Sensor 40

9.2.2.2 Vacuum Pressure Sensor 40

9.2.2.3 Sample Flow Calculation 40

9.3 Electronic Operation 41

Troubleshooting & Repair .......................................................... 43

Teledyne Analytical Instruments vii

Page 8

Model 6400EH

10.1.1 Fault Diagnosis with Warning Messages 43

10.1.2 Fault Diagnosis with Test Functions 43

10.2 Subsystem Checkout 43

10.2.1 Pneumatic Sensor Assembly 43

10.3 Repair Procedures 44

10.3.1 Repairing the Sample Gas Flow Control Assembly 44

10.3.2 Sensor Module Repair & Cleaning 46

10.3.2.1 Adjusting the UV Lamp (Peaking the Lamp) 47

10.3.2.2 PMT Hardware Calibration (FACTORY CAL) 49

10.4 Technical Assistance 52

Appendix A — Version Specific Software Documentation ...... 53

Appendix A-1: 6400EH Software Menu Trees, Revision C.0 54

Appendix A-2: Setup Variables For Serial I/O, Revision C.0 62

Appendix A-3: Warnings and Test Functions, Revision C.0 69

Appendix A-4: 6400EH Signal I/O Definitions, Revision C.0 72

Appendix A-5: 6400EH iDAS Functions, Revision C.0 77

Appendix A-6: Terminal Command Designators, Revision C.0 79

Appendix B - 6400EH Spare Parts List ...................................... 81

B-1: 6400EH Spare Parts List 81

B-2: Recommended Spare Parts Stocking Levels Model

6400EH 83

B-3: 6400E/EH Expendables Kit 84

Appendix C Warranty Questionnaire ......................................... 85

Appendix D - Electronic Schematics ......................................... 89

Teledyne Analytical Instruments viii

Page 9

UV Fluorescence SO2 Analyzer

List of Figures

Figure 3-1: Example of Pneumatic Connections to 6400EH

External Pump ............................................................ 12

Figure 3-2: Pneumatic Connections to 6400EH with Zero and Two

Span Point Valve Option ............................................. 12

Figure 3-3: Internal Pneumatic flow for 6400EH in Basic

Configuration .............................................................. 13

Figure 3-4: 6400EH Layout (Basic Unit – No Valve Options) ........ 14

Figure 3-5: Available Functions in the Model 6400EH ................... 16

Figure 5-1: Pneumatic Diagram of the 6400EH With Z/S Option

Installed. ..................................................................... 19

Figure 5-2: Pneumatic Diagram of the 6400EH With 2-Span Point

Option Installed ........................................................... 21

Figure 5-3: Hydrocarbon Scrubber (Kicker) – OPT 65 .................. 23

Figure 5-4: 6400EH Internal Pneumatic Diagram with

Hydrocarbon Scrubber Installed ................................. 23

Figure 9-1: UV Light Path .............................................................. 37

Figure 9-2: Pneumatic Diagram of the6400EH – Base

Configuration .............................................................. 39

Figure 9-3: 6400EH Electronic Block Diagram .............................. 41

Figure 9-4: Model 6400EH Power Distribution Block Diagram ...... 42

Figure 10-1: Flow Control Assembly ............................................. 45

Figure 10-2: Sensor Module Wiring and Pneumatic Fittings .......... 46

Figure 10-3: Shutter Assembly - Exploded View ........................... 47

Figure 10-4: Location of UV Reference Detector Potentiomete

r .... 49

Figure 10-5: Pre-Amplifier Board Layout ....................................... 50

Figure A-1: Basic Sample Display Menu ....................................... 54

Teledyne Analytical Instruments ix

Page 10

Model 6400EH

Figure A-2: Sample Display Menu - Z/S Valve Option installed .... 55

Figure A-3: Primary Setup Menu (Except iDAS) ........................... 56

Figure A-4: Primary Setup Menu (iDAS) ....................................... 57

Figure A-5: Secondary Setup Menu (COMM & VARS) ................. 58

Figure A-6: Secondary Setup Menu (COMM Menu with Ethernet

Card) .......................................................................... 59

Figure A-7: Secondary Setup Menu - HESSEN Submenu ............ 60

Figure A-8: Secondary Setup Menu (DIAG) .................................. 61

Teledyne Analytical Instruments x

Page 11

UV Fluorescence SO2 Analyzer

List of Tables

Table 2-1: Model 6400EH Basic Unit Specifications ....................... 5

Table 3-1: Inlet / Outlet Connector Nomenclature ......................... 11

Table 3-2: Possible Warning Messages at Start-Up ...................... 15

Table 5-1: Two-Point Span Valve Operating States ...................... 22

Table 6-1: Additional 6400EH Warning Messages ........................ 25

Table 6-2: Additional 6400EH Test Functions ............................... 25

Table 6-3: Additional 6400 EH Test Parameters Available for

Analog Output A3 ......................................................... 26

Table 6-4: 6400EH Default Hessen Status Bit Assignments ......... 27

Table 6-5: Status Output Signals ................................................... 28

Table 6-6: Control Input Signals .................................................... 30

Table 8-1: Predictive Uses for Test Functions ............................... 35

Table 10-1: Warning Messages - Indicated Failures ..................... 43

Table 10-2: Test Functions - Possible Causes for Out-Of-Range

Values ......................................................................... 43

Table 10-3: Example of HVPS Power Supply Outputs .................. 48

Table A-1: 6400EH Setup Variables, Revision C.0 ....................... 62

Table A-2: 6400EH Warning Messages, Revision C.0 .................. 69

Table A-3: 6400EH Test Functions, Revision C.0 ......................... 70

Table A-4: 6400EH Signal I/O Definitions, Revision C.0 ............... 72

Table A-5: 6400EH DAS Trigger Events, Revision C.0 ................. 77

Table A-6: 6400EH iDAS Functions, Revision C.0 ........................ 77

Table A-7: Terminal Command Designators, Revision C.0 ........... 79

Table B-1: Model 6400EH Spare Parts List ................................... 81

Table D-1: List of Included Electronic Schematics ........................ 89

Teledyne Analytical Instruments xi

Page 12

Model 6400EH

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

WARNING

Since the use of this instrument is beyond the control of

Teledyne Analytical Instruments, referred as TAI, no

responsibility by TAI, its affiliates, and agents for damage or

injury from misuse or neglect of this equipment is implied or

assumed.

Teledyne Analytical Instruments xii

Page 13

UV Fluorescence SO2 Analyzer Documentation

Documentation

Note: Throughout this manual, words printed in capital, bold letters,

such as SETUP or ENTR represent messages as they appear

on the analyzer’s front panel display

Note: The flowcharts in this manual contain typical

representations of the analyzer’s display during the

various operations being described. These representations

are not intended to be exact and may differ

slightly from the actual display of your instrument.

Thank you for purchasing the Model 6400EH UV Fluorescence

SO2 Analyzer.

The electronic manual is in Adobe® Systems Inc. “Portable

Document Format”. The Adobe® Acrobat Reader® software, which is

necessary to view these files, can be downloaded for free from the

internet at http://www.adobe.com/.

The electronic version of the manual has many advantages:

Keyword and phrase search feature

Figures, tables and internet addresses are linked so that clicking on

the item will display the associated feature or open the website.

A list of chapters and sections as well as thumbnails of each page

are displayed to the left of the text.

Entries in the table of contents are linked to the corresponding

locations in the manual.

Ability to print sections (or all) of the manual

Additional documentation for the Model 6400EH UV Fluorescence

SO2 Analyzer is available from Teledyne Instruments’ website at

http://www.teledyne-ai.com/manuals/

Teledyne Analytical Instruments 1

Page 14

Documentation Model 6400EH

APICOM software manual

Multi-drop manual

DAS Manual

1.1. Using This Manual Addendum

This manual addendum has the same overall structure as that of the

6400E operator’s manual, to simplify referring between the two. The

manual has the following sections:

Table of Contents:

Outlines the contents of the addendum in the order the information

is presented. This is a good overview of the topics covered in the

manual. There is also a list of tables, a list of figures and a list of

appendices.

Specifications and Warranty

This section contains a list of the analyzer’s performance

specifications, a description of the conditions and configuration under

which EPA equivalency was approved and Teledyne Instrument’s

warranty statement.

Getting Started:

A concise set of instructions for setting up, installing and running

your analyzer for the first time.

FAQ:

Answers to the most frequently asked questions about operating the

analyzer.

Optional Hardware & Software:

A description of optional equipment to add functionality to your

analyzer.

Operation Instructions:

This section includes step by step instructions for operating the

analyzer and using its various features and functions.

Calibration Procedures:

Teledyne Analytical Instruments 2

Page 15

UV Fluorescence SO2 Analyzer Documentation

General information and step by step instructions for calibrating

your analyzer.

Instrument Maintenance:

Description of preventative maintenance procedures that should be

regularly performed on you instrument to assure good operating

condition.

Theory of Operation:

This section describes the aspects of 6400EH operation that differ

from the 6400E manual.

Maintenance & Troubleshooting Section:

This section includes pointers and instructions for diagnosing

problems that are specific to the 6400EH. The 6400E manual has a more

complete troubleshooting section, most of which also applies to the

6400EH.

Appendices:

For easier access and better updating, some information has been

separated out of the manual and placed in a series of appendices at the

end of this addendum. These include: software menu trees, warning

messages, definitions of iDAS & serial I/O variables, spare parts list,

repair questionnaire, interconnect listing and drawings, and electronic

schematics.

Teledyne Analytical Instruments 3

Page 16

Documentation Model 6400EH

Teledyne Analytical Instruments 4

Page 17

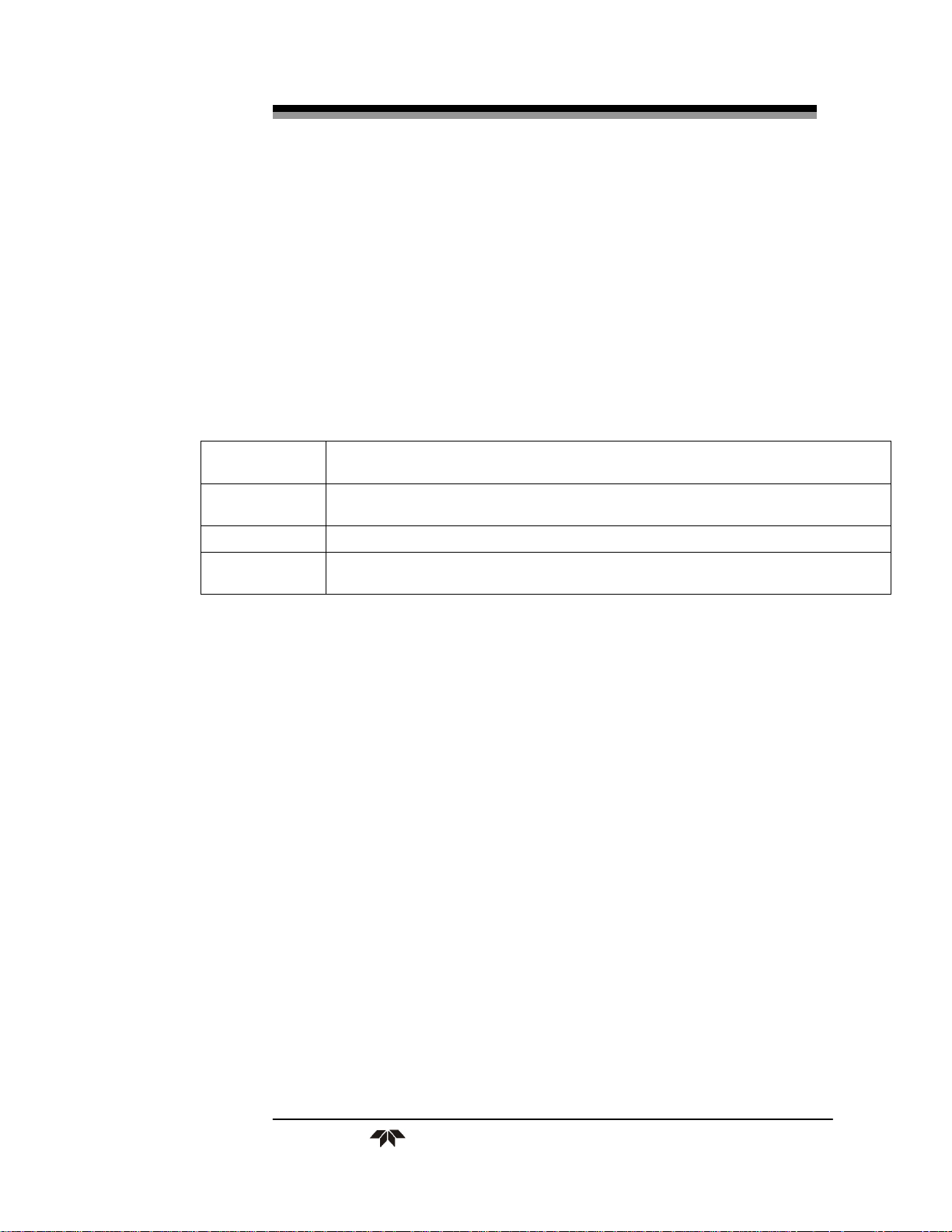

UV Fluorescence SO2 Analyzer Specifications/Warranty

Specifications, Approvals & Warranty

2.1. Specifications

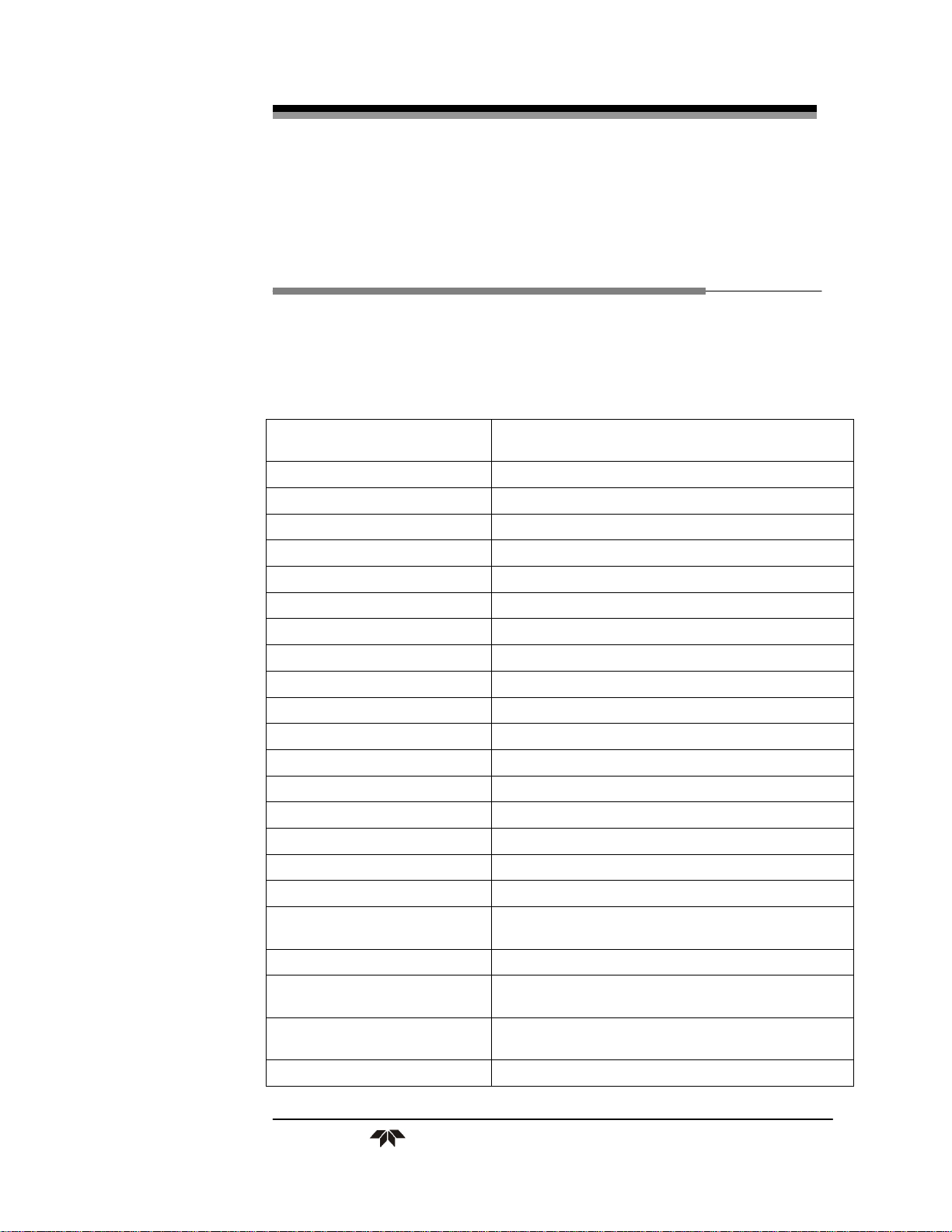

Table 2-1: Model 6400EH Basic Unit Specifications

Min/Max Range

(Physical Analog Output)

Measurement Units ppm, mg/m3 (user selectable)

Zero Noise1 0.05 ppm rms

Span Noise1 < 0.5% of reading (above 50 ppm)

Lower Detectable Limit2 0.1 ppm rms

Zero Drift (24 hours) < 1 ppm

Zero Drift (7 days) < 2 ppm

Span Drift (7 Days) < 0.5% FS

Linearity 1 % of full scale

Precision 0.5% of reading1

Temperature Coefficient < 0.1% per oC

Voltage Coefficient < 0.05% per V

Lag Time1 5 sec

Rise/Fall Time1 95% in < 30 sec

Sample Flow Rate 700 cm3/min. ±10%

Temperature Range 5-40oC

Humidity Range 0 - 95% RH, non-condensing

Dimensions H x W x D 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight, Analyzer

(Basic Configuration)

Weight, Pump Pack 16 lbs (7 kg)

AC Power Rating

Environmental

Analog Outputs Three (3) Outputs

In 1 ppb increments from 10ppm to 5,000 ppm, dual

ranges or auto ranging

45 lbs (20.5 kg) w/internal pump

100 V, 50/60 Hz (3.25A); 115 V, 60 Hz (3.0 A);

220 – 240 V, 50/60 Hz (2.5 A)

Installation category (over-voltage category) II; Pollution

degree 2

Teledyne Analytical Instruments 5

Page 18

Specifications/Warranty Model 6400EH

100 mV, 1 V, 5 V, 10 V, 2-20 or 4-20 mA isolated

Analog Output Ranges

Analog Output Resolution 1 part in 4096 of selected full-scale voltage

Status Outputs 8 Status outputs from opto-isolators

Control Inputs 6 Control Inputs, 3 defined, 3 spare

Serial I/O

Certifications

1 As defined by the USEPA.

2 Defined as twice the zero noise level by the USEPA.

current loop.

All Ranges with 5% Under/Over Range

One (1) RS-232; One (1) RS-485 (2 connecters in

parallel)

Baud Rate : 300 – 115200: Optional Ethernet Interface

EN61326 (1997 w/A1: 98) Class A,

FCC Part 15 Subpart B Section 15.107 Class A,

ICES-003 Class A (ANSI C63.4 1992) & AS/NZS 3548

(w/A1 & A2; 97) Class A.

IEC 61010-1:90 + A1:92 + A2:95,

2.2. CE Mark Compliance

Emissions Compliance

The TAI UV Fluorescence SO2 Analyzer 6400EH was tested and

found to be fully compliant with:

EN61326 (1997 w/A1: 98) Class A, FCC Part 15 Subpart B Section

15.107 Class A, ICES-003 Class A (ANSI C63.4 1992) & AS/NZS

3548 (w/A1 & A2; 97) Class A.

Tested on 21 February 2003 - 08 March 2003 at CKC Laboratories,

Inc., Report Number CE03-021 A.

Safety Compliance

The TAI UV Fluorescence SO

found to be fully compliant with:

I EC 61010-1:90 + A1:92 + A2:95,

Issued by CKC Laboratories on 4 April 2003, Report Number WO-

80146.

Analyzer 6400EH was tested and

2

Teledyne Analytical Instruments 6

Page 19

UV Fluorescence SO2 Analyzer Specifications/Warranty

2.3. Warranty

Warranty Policy (02024d)

Prior to shipment, TAI equipment is thoroughly inspected and

tested. Should equipment failure occur, TAI assures its customers that

prompt service and support will be available.

Coverage

After the warranty period and throughout the equipment lifetime,

TAI stands ready to provide on-site or in-plant service at reasonable

rates similar to those of other manufacturers in the industry. All

maintenance and the first level of field troubleshooting is to be

performed by the customer.

NON-TAI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAI is warranted and

will be repaired to the extent and according to the current terms and

conditions of the respective equipment manufacturers warranty.

GENERAL

During the warranty period, TAI warrants each Product

manufactured by TAI to be free from defects in material and

workmanship under normal use and service. Expendable parts are

excluded.

If a Product fails to conform to its specifications within the

warranty period, TAI shall correct such defect by, in TA's discretion,

repairing or replacing such defective Product or refunding the purchase

price of such Product.

The warranties set forth in this section shall be of no force or effect

with respect to any Product: (i) that has been altered or subjected to

misuse, negligence or accident, or (ii) that has been used in any manner

other than in accordance with the instruction provided by TAI, or (iii)

not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES

THEREFORE ARE EXCLUSIVE AND IN LIEU OF ANY IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED

OR IMPLIED. THE REMEDIES SET FORTH IN THIS SECTION ARE THE

EXCLUSIVE REMEDIES FOR BREACH OF ANY WARRANTY CONTAINED

HEREIN. TAI SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

Teledyne Analytical Instruments 7

Page 20

Specifications/Warranty Model 6400EH

CONSEQUENTIAL DAMAGES ARISING OUT OF OR RELATED TO THIS

AGREEMENT OF TAI'S PERFORMANCE HEREUNDER, WHETHER FOR

BREACH OF WARRANTY OR OTHERWISE

Terms and Conditions

All units or components returned to TAI should be properly packed

for handling and returned freight prepaid to the nearest designated

Service Center. After the repair, the equipment will be returned, freight

prepaid.

Teledyne Analytical Instruments 8

Page 21

UV Fluorescence SO2 Analyzer Getting Started

Getting St arted

3.1. Unpacking and Initial Setup

CAUTION: TO AVOID PERSONAL INJURY, ALWAYS USE TWO

PERSONS TO LIFT AND CARRY THE MODEL

6400EH.

1. Inspect the received packages for external shipping damage. If

damaged, please advise the shipper first, then TAI.

2. Included with your analyzer is a printed record of the final

performance characterization performed on your instrument at

the factory. This record is an important quality assurance and

calibration record for this instrument. It should be placed in the

quality records file for this instrument.

3. Carefully remove the top cover of the analyzer and check for

internal shipping damage.

Remove the set screw located in the top, center of the rear

panel

Remove the screws fastening the top cover to the unit (four

per side).

Lift the cover straight up.

Note: Printed circuit assemblies (PCAs) are sensitive to electro-

static discharges too small to be felt by the human nervous

system. Failure to use ESD protection when working with

electronic assemblies will void the instrument warranty.

See Chapter 12 of the 6400E Manual (P/N 04515) for more

information on preventing ESD damage.

Teledyne Analytical Instruments 9

Page 22

Getting Started Model 6400EH

CAUTION: NEVER DISCONNECT ELECTRONIC CIRCUIT

BOARDS, WIRING HARNESSES OR ELECTRONIC

SUBASSEMBLIES WHILE THE UNIT IS UNDER

POWER.

4. Inspect the interior of the instrument to make sure all circuit

boards and other components are in good shape and properly

seated.

5. Check the connectors of the various internal wiring harnesses

and pneumatic hoses to make sure they are firmly and properly

seated.

6. Verify that all of the optional hardware ordered with the unit has

been installed. These are checked on the paperwork

accompanying the analyzer.

3.1.1. Electrical Connections:

For full details on the electrical connections of the 6400EH, please

refer to Chapter 3 in the 6400E user’s manual.

3.1.1.1. External Pump

The 6400EH is equipped with an external pneumatic pump. This

pump is powered separately from the instrument via it’s own power

cord. The pump has no ON/OFF switch and should begin operating as

soon as it is plugged into a live power supply.

CAUTION: CHECK THE VOLTAGE / FREQUENCY LABEL ON

THE REAR PANEL OF THE INSTRUMENT AND ON

THE EXTERNAL PUMP FOR COMPATIBILITY WITH

THE LOCAL POWER. DO NOT PLUG IN EITHER THE

ANALYZER OR THE PUMP UNLESS THE VOLTAGES

OR FREQUENCIES ARE CORRECT.

POWER CONNECTION MUST HAVE A FUNCTIONING

GROUND CONNECTION. DO NOT DEFEAT THE

GROUND WIRE ON POWER PLUG.

TURN OFF ANALYZER POWER BEFORE

DISCONNECTING OR CONNECTING ELECTRICAL

SUBASSEMBLIES.

DO NOT OPERATE WITH COVER OFF.

Teledyne Analytical Instruments 10

Page 23

UV Fluorescence SO2 Analyzer Getting Started

3.2 Pneumatic Connections

3.2.2 Pneumatic Connections to the 6400EH

Note: To prevent dust from getting into the analyzer, it was

shipped with small plugs inserted into each of the

pneumatic fittings on the rear panel. Make sure that all dust

plugs are removed before attaching exhaust

and supply gas lines.

Table 3-1: Inlet / Outlet Connector Nomenclature

REAR PANEL

LABEL

Sample Connects the sample gas to the analyzer. When operating the analyzer without

zero/span option, this is also the inlet for any calibration gases.

Exhaust Connect an exhaust gas line to this port to the inlet of the external pump.

Zero Air

On Units with zero/span valve option installed, this port connects the zero air gas or the

zero air cartridge to the analyzer.

FUNCTION

Figure 3-5 of the 6400E Manual shows the internal pneumatic flow

of the 6400E in its standard configuration. For a diagram of the internal

pneumatic flow of the 6400EH, see Figure 3-2 of this manual.

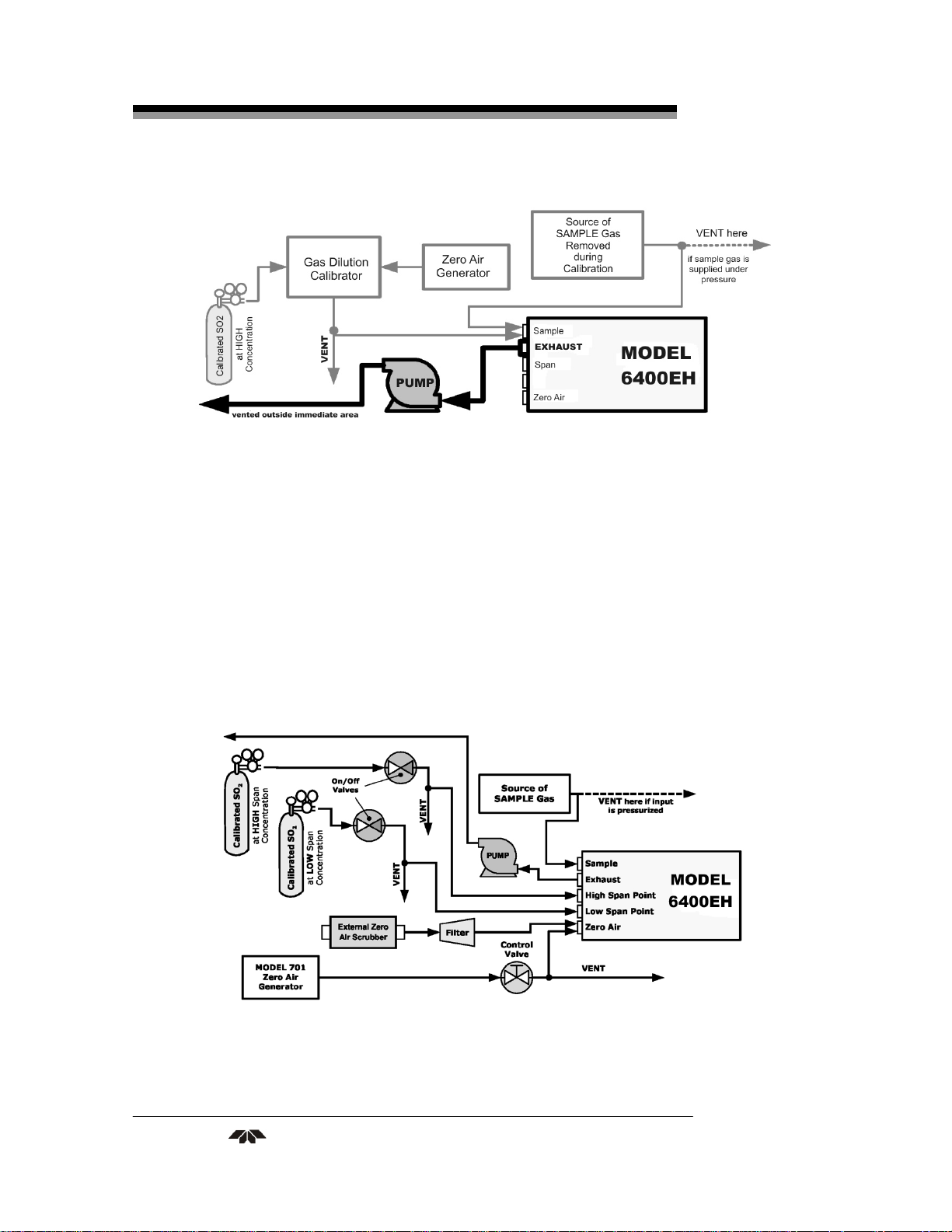

3.2.2.1 PNEUMATIC CONNECTIONS TO 6400EH BASIC CONFIGURATION

The pneumatic connections for the 6400EH analyzer in its basic

configuration are nearly identical to those described the 6400E Manual

in Section 3.1.2.2 except that the 6400EH has an external pump.

Therefore:

A pneumatic line of ¼” PTEF must be attached between the

analyzer’s exhaust port and the inlet port of the pump.

The exhaust from must be vented outside the shelter or immediate

area surrounding the instrument using a maximum of 10 meters of

1/4” PTFE tubing.

Teledyne Analytical Instruments 11

Page 24

Getting Started Model 6400EH

Figure 3-1: Example of Pneumatic Connections to 6400EH

External Pump

This change is true for all configurations and variations of the

6400EH.

3.2.2.2 CONNECTIONS WITH INTERNAL VALVE OPTIONS INSTALLED

There is no IZS option available for the 6400EH .

An additional valve option (Option 52 - Zero & Two Span Points)

is available on the 6400EH. The pneumatic set up for this option

is:

Figure 3-2: Pneumatic Connections to 6400EH with Zero and Two

Span Point Valve Option

Teledyne Analytical Instruments 12

Page 25

UV Fluorescence SO2 Analyzer Getting Started

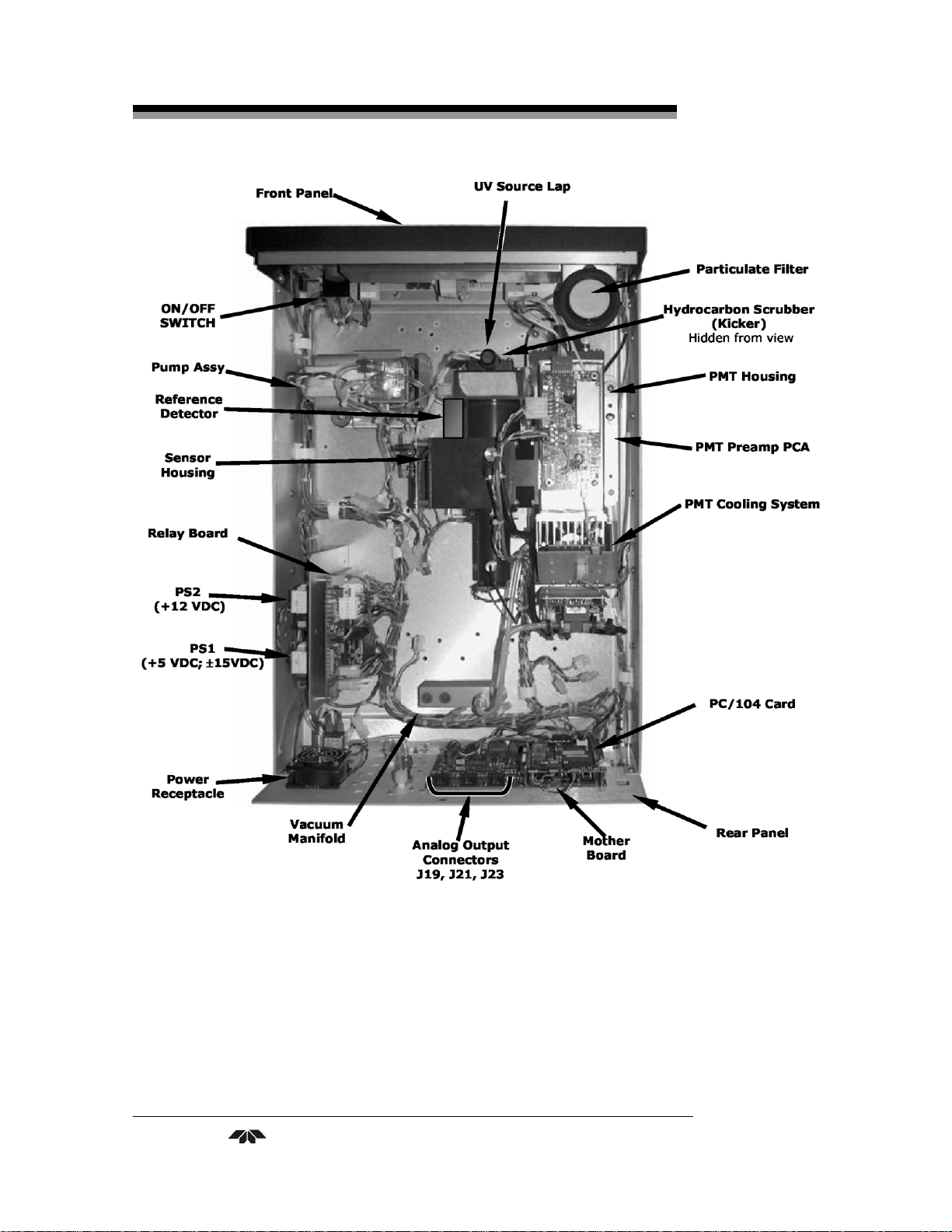

3.2.3 6400EH Layout

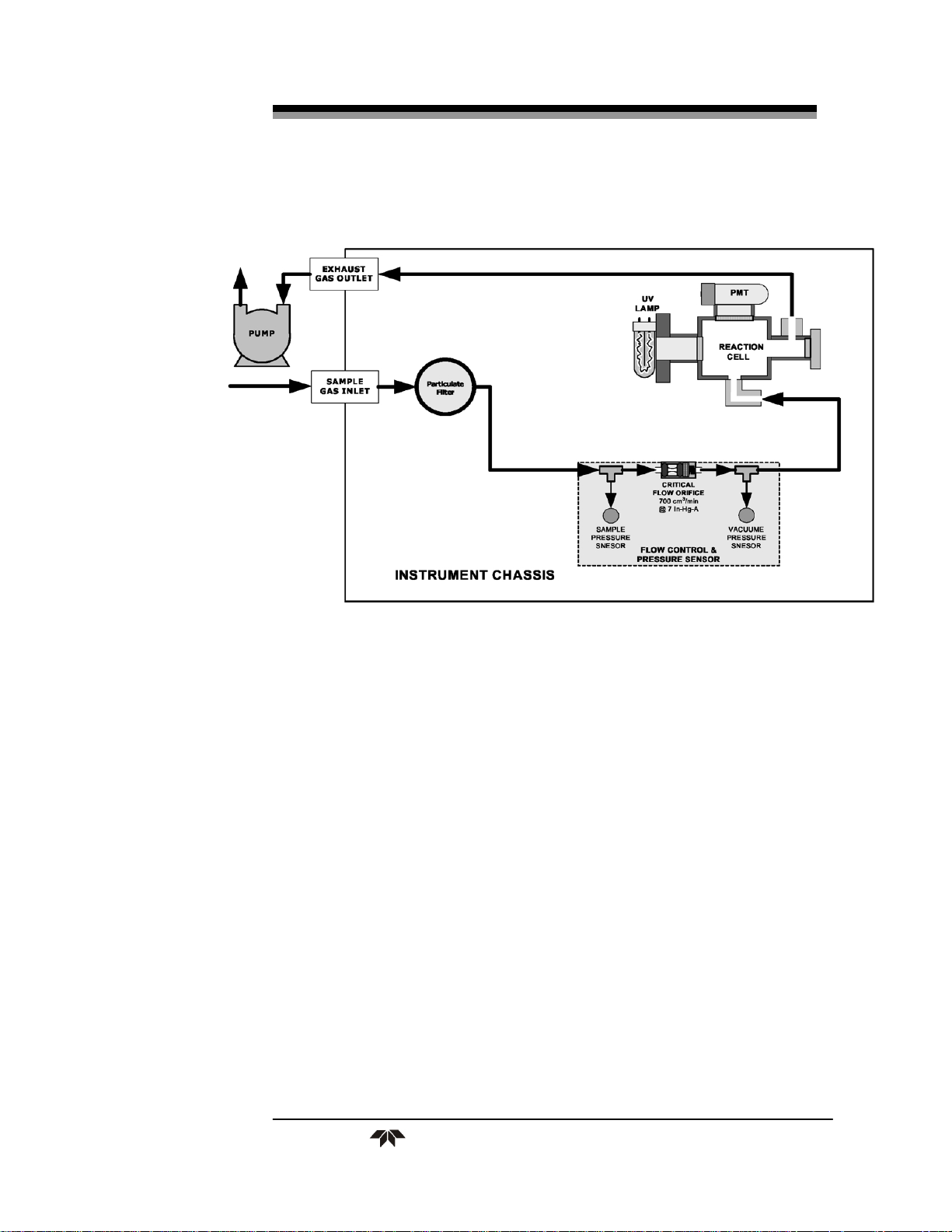

Figure 3-3: Internal Pneumatic flow for 6400EH in Basic

Configuration

Teledyne Analytical Instruments 13

Page 26

Getting Started Model 6400EH

Figure 3-4: 6400EH Layout (Basic Unit – No Valve Options)

Teledyne Analytical Instruments 14

Page 27

UV Fluorescence SO2 Analyzer Getting Started

3.3 Initial Operation

With the following exceptions, the operation of the 6400EH is

nearly identical to that of the 6400E. Please refer to the 6400E User’s

Manual, Chapter 3, for details on initial operation, including common

warning messages, functional checkout of the instrument, initial

calibration and common interferents for the 6400EH.

3.3.1 Warning Messages

Please refer to the 6400E User’s Manual, Chapter 3, for a complete

listing of warnings for the 6400EH. The following table lists warnings

that differ in the 6400EH from those described in the 6400E manual.

Table 3-2: Possible Warning Messages at Start-Up

MESSAGE MEANING

Vacuum Pressure Warning

The vacuum pressure reading is out of it’s allowed range. The pump

may have failed, or the instrument may have a leak or obstruction in

the flow path.

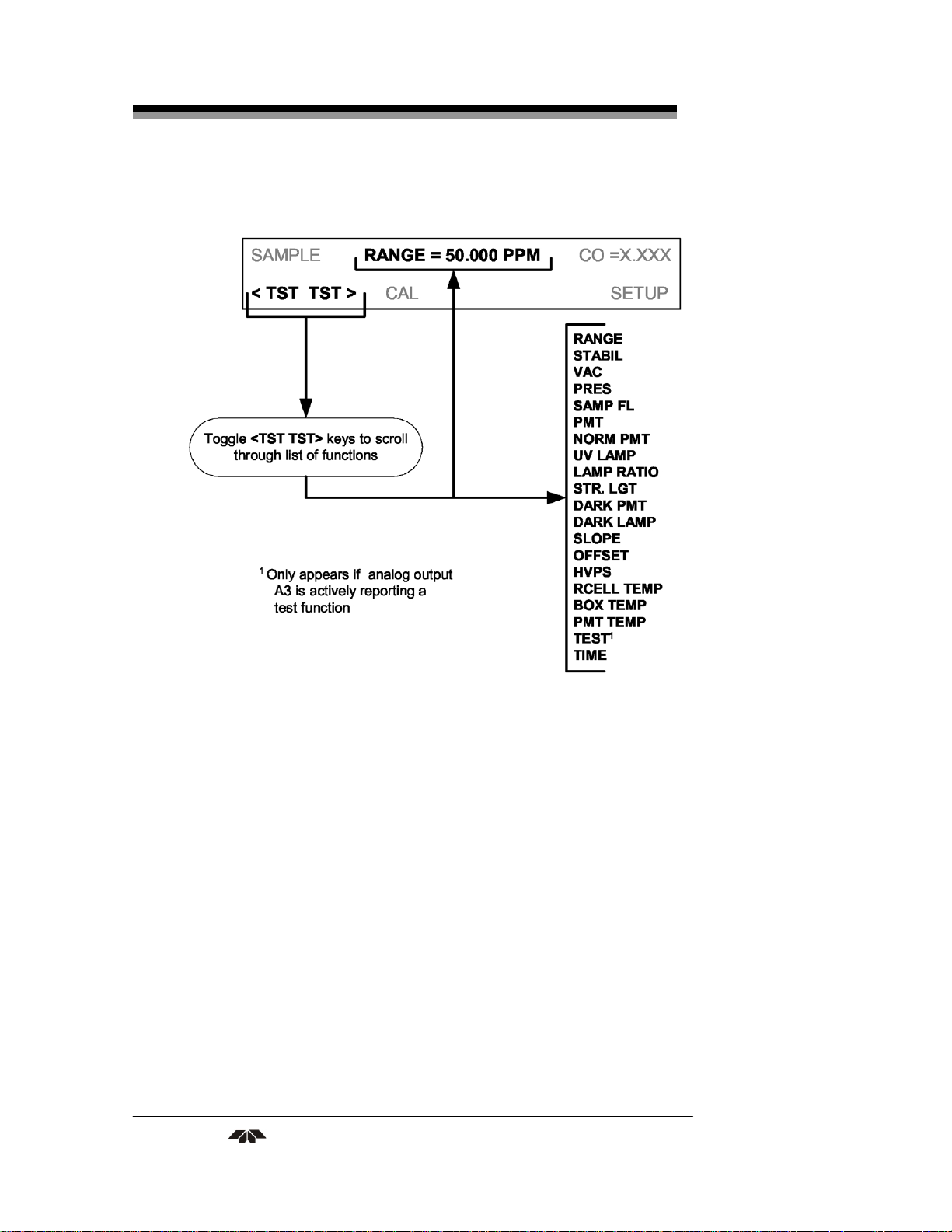

3.3.2 Test Functions

Check to make sure that the analyzer is functioning within

allowable operating parameters As described in Section 3.2.4 of the

6400E Manual (P/N 04515). The available test functions for the 6400EH

is shown in Figure 3-5.

3.3.3 Interferents for SO

2 Measurements

Hydrocarbons are a significant interferent for UV fluorescent SO2

measurements, however, the typical 6400EH application does not have

hydrocarbons in the sample stream. Therefore, in order to reduce cost to

the customer, the 6400EH in its standard configuration does not include

a hydrocarbon kicker/scrubber.

If your application includes hydrocarbons in the sample gas stream,

it is very important that they be removed from the sample gas prior to

them entering the analyzer’s sample chamber. A hydrocarbon Kicker

Option (OPT 65) package (see Section 5 below) is available for this

purpose.

Teledyne Analytical Instruments 15

Page 28

Getting Started Model 6400EH

Figure 3-5: Available Functions in the Model 6400EH

Teledyne Analytical Instruments 16

Page 29

UV Fluorescence SO2 Analyzer FAQ

Frequently Asked Questions

Q: How long does the sample pump last?

A: The sample pump should last about one year and the pump

diaphragms should to be replaced annually or when

necessary.

To determine if the diaphragm on a 6400EH needs replacing check

the VAC test function (instead of the PRES function as described in the

6400E Manual). If the VAC value is > 10 in-Hg-A, the diaphragm should

be replaced.

Teledyne Analytical Instruments 17

Page 30

FAQ Model 6400EH

Teledyne Analytical Instruments 18

Page 31

UV Fluorescence SO2 Analyzer Optional Hardware/Software

Optional Hardware and Software

With the following additions, changes and exceptions, the options

listed in Chapter 5 of the 6400E Manual are also available for the

6400EH.

5.1 Zero/Span Valves (Option 50)

The 6400EH zero/span valve option is identical to that of the

6400E in respect to operation and valve states (see Table 5-1 of the

6400E Manual). The internal pneumatic connections are slightly

different.

Figure 5-1: Pneumatic Diagram of the 6400EH With Z/S Option

Installed.

Teledyne Analytical Instruments 19

Page 32

Optional Hardware/Software Model 6400EH

5.2 Internal Zero/Span Gas Generator (Option 51)

The IZS valve option (OPT 51) is not available for the 6400EH.

5.3 Zero and Two Span Point Valve Option (OPT 52)

This option includes a special set of valves that allows two separate

SO

mixtures to enter the analyzer from two independent sources.

2

Typically these two gas mixtures will come from two, separate,

pressurized bottles of certified calibration gas: one mixed to produce a

SO2 concentration equal to the expected span calibration value for the

application and the other mixed to produce a concentration at or near the

midpoint of the intended measurement range. Individual gas inlets,

labeled HIGH SPAN and LOW SPAN are provided at the back on the

analyzer.

The valves allow the user to switch between the two sources via

keys on the front panel or from a remote location by way of either the

analyzer’s digital control inputs or by sending commands over it’s serial

I/O port(s). The pneumatic diagram for instruments with the zero and

two span point valve option (OPT 52) is shown in Figure 5-2.

Note: The analyzer’s software only allows the SLOPE and

OFFSET to be calculated when sample is being

routed through the HIGH SPAN inlet.

The LOW SPAN gas is for midpoint reference checks only.

Teledyne Analytical Instruments 20

Page 33

UV Fluorescence SO2 Analyzer Optional Hardware/Software

Figure 5-2: Pneumatic Diagram of the 6400EH With 2-Span Point

Option Installed

Table 5-1 describes the state of each valve during the analyzer’s

various operational modes.

Teledyne Analytical Instruments 21

Page 34

Optional Hardware/Software Model 6400EH

Table 5-1: Two-Point Span Valve Operating States

MODE VALVE CONDITION

SAMPLE

ZERO

CAL

HIGH

SPAN

CAL

LOW

SPAN

CHECK

Sample/Cal

Zero Gas Valve Closed to ZERO AIR inlet

High Span Valve Closed to HIGH SPAN inlet

Low Span Valve Closed to LOW SPAN inlet

Sample/Cal Closed to SAMPLE inlet

Zero Gas Valve

High Span Valve Closed to HIGH SPAN inlet

Low Span Valve Closed to LOW SPAN inlet

Sample/Cal Closed to SAMPLE inlet

Zero Gas Valve Closed to ZERO AIR inlet

High Span Valve

Low Span Valve Closed to LOW SPAN inlet

Sample/Cal Closed to SAMPLE inlet

Zero Gas Valve Closed to ZERO AIR inlet

High Span Valve Closed to HIGH SPAN inlet

Low Span Valve

Open to SAMPLE inlet

Open to ZERO AIR inlet

Open to HIGH SPAN inlet

Open to LOW SPAN inlet

5.4 Hydrocarbon Kicker Option (OPT 65)

This option is specifically designed for those applications where

hydrocarbons are present in the sample gas stream. It includes an

internal, scrubber consisting of a tube of a specialized plastic that

absorbs hydrocarbons very well located within an outer flexible plastic

tube shell.

As gas flows through the inner tube, hydrocarbons are absorbed

into the membrane walls and transported through the membrane wall and

into the hydrocarbon free, purge gas flowing through the outer tube (see

Figure 5-3). This process is driven by the hydrocarbon concentration

gradient between the inner and outer of the tubes.

Teledyne Analytical Instruments 22

Page 35

UV Fluorescence SO2 Analyzer Optional Hardware/Software

Figure 5-3: Hydrocarbon Scrubber (Kicker) – OPT 65

The scrubbed air from the inner tube is returned to be used as the

purge gas in the outer tube after it passes through the analyzers reaction

cell. This means that when the analyzer is first started, the concentration

gradient between the inner and outer tubes is small and the scrubber’s

efficiency is relatively low. When the instrument is turned on after

having been off for more than 30 minutes, it takes a certain amount of

time for the gradient to become large enough for the scrubber to

adequately remove hydrocarbons from the sample air.

Figure 5-4: 6400EH Internal Pneumatic Diagram with

Hydrocarbon Scrubber Installed

Teledyne Analytical Instruments 23

Page 36

Optional Hardware/Software Model 6400EH

Teledyne Analytical Instruments 24

Page 37

UV Fluorescence SO2 Analyzer Operating Instructions

Operating Instructions

6.1 Warning Messages

Please refer to the 6400E User’s Manual, Chapter 3, for a complete

listing of warnings for the 6400EH. The following table lists warnings

that differ in the 6400EH from those described in the 6400E manual.

Table 6-1: Additional 6400EH Warning Messages

MESSAGE MEANING

The vacuum pressure reading is out of its allowed

Vacuum Pressure Warning

range. The pump may have failed, or the instrument

may have a leak or obstruction in the flow path.

6.2 Test Functions

Please refer to the 6400E Manual, Chapter 6, for a complete list of

test functions for the 6400EH. The following table lists test functions

that are in addition to or differ from those listed there.

Table 6-2: Additional 6400EH Test Functions

DISPLAY PARAMETER UNITS DESCRIPTION

The actual pressure measured on the vacuum side

VAC

PRES

Vacuum

Pressure

Sample GAS

Pressure

In-Hg-A

in-Hg-A

of the 6400EH’s critical flow orifice. This is the

pressure of the gas in the instrument’s sample

chamber.

The current pressure of the sample gas as it enters

the sample inlet at the back of the analyzer, but

upstream of the critical flow orifice and before the

gas enters the reaction cell.

Teledyne Analytical Instruments 25

Page 38

Operating Instructions Model 6400EH

6.2.1 Test Channel Output

When activated, output channel A3 can be used to report one of the

test functions viewable from the SAMPLE mode display. To activate the

A3 channel and select a test function, follow instructions in Section

6.9.10 of the 6400E Manual.

The following table lists test functions that are in addition to or

differ from those listed in Table 6-14 of the 6400E Manual.

Table 6-3: Additional 6400 EH Test Parameters Available for Analog

Output A3

TEST CHANNEL TEST PARAMETER RANGE

VACUUM PRESSURE

0-40 in-Hg-A

6.2.2 Range Units

The 6400EH only displays concentrations in parts per million (106

mols per mol, PPM) or milligrams per cubic meter (mg/m3, MGM).

NOT AVAILABLE: Parts per billion (10

9

mols per mol, PPB)

and micrograms per cubic meter (µg/m3, UGM).

To change the concentration units of the 6400EH follow the

instructions found in Section 6.7.7 of the 6400E Manual.

6.2.3 Using the 6400EH with a Hessen Protocol Network

The set up and use of the 6400EH in Hessen protocol networks is

the sane as described in Section 6.12.4 of the M1 00E Manual (P/N

04515) except that there are minor differences in the status flags. The

following table supercedes Table 6-27 of the 6400E Manual.

Teledyne Analytical Instruments 26

Page 39

UV Fluorescence SO2 Analyzer Operating Instructions

Table 6-4: 6400EH Default Hessen Status Bit Assignments

STATUS FLAG NAME DEFAULT BIT ASSIGNMENT

WARNING FLAGS

SAMPLE FLOW WARNING 0001

PMT DET WARNING 0002

UV LAMP WARNING 0002

HVPS WARNING 0004

DARK CAL WARNING 0008

RCELL TEMP WARNING 0010

PMT TEMP WARNING 0040

INVALID CONC 0080

OPERATIONAL FLAGS

In Manual Calibration Mode 0200

In Zero Calibration Mode 0400

In Low Span Calibration Mode 0800

In Span Calibration Mode 0800

UNITS OF MEASURE FLAGS

UGM1 0000

MGM 2000

PPB1 4000

PPM 6000

SPARE/UNUSED BITS 0020, 0100, 8000

UNASSIGNED FLAGS

Box Temp Warning System Reset

Sample Press Warning Front Panel Warning

Vacuum Press Warning Analog Cal Warning

Rear Board Not Detected Cannot Dyn Zero

Relay Board Warning Cannot Dyn Span

1

Although assigned flags, these units are not available on the 6400EH

Teledyne Analytical Instruments 27

Page 40

Operating Instructions Model 6400EH

6.2.4 Default iDAS Channels

The default Data Channels included in the 6400EH analyzer’s

software include the CONC, PNUMT & CALDAT channels. The FAST &

DETAIL preset channels are not included.

6.2.5 Remote Operation Using the External Digital I/O

6.2.5.1 STATUS OUTPUTS

The function and pin assignment5s for the 6400EH digital status

outputs are:.

Table 6-5: Status Output Signals

STATUS

CONNECTOR

PIN NUMBER

1

2

3

4

5

6

7

8

D

+

1

SYSTEM OK

CONC VALID

HIGH RANGE

ZERO CAL

HIGH SPAN CAL

DIAG MODE

LOW SPAN CAL

SPARE

EMITTER BUS

SPARE

DC POWER

STATUS

DEFINITION

CONDITION

ON if no faults are present.

OFF any time the

as during calibration or when other faults exist

possibly invalidating the current concentration

measurement (example: sample flow rate is outside

of acceptable limits).

ON if concentration measurement is valid.

ON if unit is in high range of the AUTO Range Mode

ON whenever the instrument’s ZERO point is being

calibrated.

ON whenever the instrument is set for DUAL or

AUTO reporting range

mode an it’s high range span point is being calibrated

.

ON whenever the instrument is in DIAGNOSTIC

mode

ON whenever the instrument is set for DUAL or

AUTO reporting range mode an it’s lows range span

point is being calibrated .

The emitters of the transistors on pins 1-8 are bussed

together.

+ 5 VDC, 300 mA source (combined rating with

Control Output, if used).

HOLD OFF feature is active, such

Teledyne Analytical Instruments 28

Page 41

UV Fluorescence SO2 Analyzer Operating Instructions

STATUS

CONNECTOR

PIN NUMBER1

1

Located on Rear Panel

6.2.5.2 CONTROL INPUTS

STATUS

DEFINITION

Digital Ground

CONDITION

The ground level from the analyzer’s internal DC

power supplies

Figure 6-1: Control Input Connector

Teledyne Analytical Instruments 29

Page 42

Operating Instructions Model 6400EH

Table 6-6: Control Input Signals

INPUT # STATUS DEFINITION ON CONDITION

A

B

C

D, E & F

REMOTE ZERO CAL

REMOTE

HIGH SPAN CAL

REMOTE

LO SPAN CAL

SPARE

The analyzer is placed in Zero Calibration mode. The mode field of the

display will read ZERO CAL R.

If the instrument is set for DUAL or AUTO reporting rang mode,

activating this input causes the analyzer to enter high range span

calibration mode. The mode field of the display will read SPAN CAL R.

The analyzer is placed in low span calibration mode as part of

performing a low span (midpoint) calibration. The mode field of the

display will read LO CAL R.

U

+

Digital Ground

External Power input

5 VDC output

The ground level from the analyzer’s internal DC power supplies

(same as chassis ground)

Input pin for +5 VDC required to activate pins A – F.

Internally generated 5V DC power. To activate inputs A – F, place a

jumper between this pin and the “U” pin. The maximum amperage

through this port is 300 mA (combined with the analog output supply, if

used).

Teledyne Analytical Instruments 30

Page 43

UV Fluorescence SO2 Analyzer Calibration and Check

Calibration and Calibration Check Procedures

Calibration procedures for the 6400EH are the same as those for the

6400E. One exception to this statement is that the 6400EH has a special

valve option, Zero and Two Span Point Valve Option - OPT 52 (See

Section 5.1), that allows a mid-span point be checked.

7.1 Manual Calibration with the Zero and Two Span

Point Valve Option (OPT 52) installed

Note: It is only possible to calibrate to the high span gas. The low

span gas is only used for calibration checks.

Zero and Span calibrations using the Zero and two Span Valve

option are similar to that described in Section 7.2, except that:

Zero air and both span gas is supplied to the analyzer through the

zero gas and span gas inlets rather than through the sample inlet.

The zero and cal operations are initiated directly and

independently with dedicated keys (CALZ & CALS)

STEP ONE: Connect the sources of zero air and span gas to the

respective ports on the rear panel (see Figure 3-2 of this manual).

STEP TWO: Set the expected SO

high span gas value:

2

Teledyne Analytical Instruments 31

Page 44

Calibration and Check Model 6400EH

STEP THREE: Perform the calibration according to the following flow

chart:

Teledyne Analytical Instruments 32

Page 45

UV Fluorescence SO2 Analyzer Calibration and Check

7.2 Manual Calibration Check with the Zero and Two

Span Point Valve Option (OPT 52) installed

Set up is identical to that shown in STEP ONE of the preceding

section. To perform the zero/span check:

Teledyne Analytical Instruments 33

Page 46

Calibration and Check Model 6400EH

Teledyne Analytical Instruments 34

Page 47

UV Fluorescence SO2 Analyzer Maintenance

Instrument Maintenance

8.1 Maintenance Schedule

There is no Internal IZS offered for the 6400EH.

8.2 Predictive Diagnostics

Because the 6400EH’s internal pneumatics are monitored in a

different manner than those of the 6400E there are some differences in

how the instruments test functions are used as predictive diagnostics.

Table 8-1 of this addendum supersedes Table 9-2 of the 6400E Manual

Table 8-1: Predictive Uses for Test Functions

TEST

FUNCTION

PRES SMPPRS

PRES SMPPRS

VAC VACUUM

IDAS

FUNCTION

CONDITION

Sample gas

pressure

upstream of the

critical flow

orifice.

Sample gas

pressure

upstream of the

critical flow

orifice.

Gas pressure

downstream of

the critical flow

orifice (e.g.

inside reaction

cell.

EXPECTED ACTUAL

Constant within

atmospheric

changes

Constant within

atmospheric

changes

Constant within

atmospheric

changes

BEHAVIOR

Slowly

increasing

Slowly

decreasing

Slowly

increasing

Slowly

decreasing

Fluctuating

INTERPRETATION

• Flow path is clogging up.

- Check critical flow

orifice & sintered filter.

- Replace particulate

filter

• Developing leak in

pneumatic system to

vacuum (developing

valve failure)

• Flow path is clogging up.

- Check critical flow

orifice & sintered filter.

- Replace particulate

filter

• Developing leak in

pneumatic system to

vacuum (developing

valve failure)

• Developing leak in

pneumatic system

Teledyne Analytical Instruments 35

Page 48

Maintenance Model 6400EH

TEST

FUNCTION

SAMP FL SMPFLW

DRK PMT DRKPMT

SO2

Concentration

LAMP RATIO LAMPR

FUNCTION

CONC1

IDAS

CONDITION

Standard

Operation

PMT output

when UV Lamp

shutter closed

Standard

configuration at

span

Standard

Operation

EXPECTED ACTUAL

Stable

Constant within

±20 of checkout value

stable for

constant

concentration

Stable and near

100%

BEHAVIOR

Slowly

Decreasing

Significantly

increasing

Decreasing

over time

Fluctuating • Leak in gas flow path.

Fluctuating

or Slowly

increasing

Slowly

deceasing

INTERPRETATION

• Flow path is clogging up.

- Check critical flow

orifice & sintered filter.

- Replace particulate

filter

• PMT cooler failure

• Shutter Failure

• Drift of instrument

response; UV Lamp

output is excessively

low.

• UV detector wearing out

• UV source Filter

developing pin holes

• UV detector wearing out

• Opaque oxides building

up on UV source Filter

• UV lamp aging

Teledyne Analytical Instruments 36

Page 49

UV Fluorescence SO2 Analyzer Theory of Operation

Theory of Operation

9.1 The UV Light Path

The UV light path of the 6400EH is similar to that of the 6400E

(see Section 10.2 of the 6400E Manual). The main differences between

the 6400EH and the 6400E are:

The location of the reference detector (See Section 9.1.1 of this

addendum).

The methods used to reject for certain measurement interferents is

different (see Section 9.1.2 of this manual).

Figure 9-1: UV Light Path

Teledyne Analytical Instruments 37

Page 50

Theory of Operation Model 6400EH

9.1.1 The Reference Detector

A vacuum diode UV detector that converts UV light to a DC

current is used to measure the intensity of the excitation UV source

lamp. The location of the 6400EH reference detector differs from that of

the 6400E.

On the 6400E this detector is located directly across the reaction cell

from the lamp where it can measure the output of the lamp

directly. Because the 6400E is designed to measure relatively

low concentrations of SO

, enough of the lamp’s 214 nm source

2

light makes it through the reaction cell to get a reliable reading.

On the 6400EH the detector is located between the UV lamp and the

reaction cell and to the side. A beam splitter reflects a portion of

the lamp output 90 degrees, through a window and onto the

detector. This arrangement is required because nearly all of 214

nm UV source light entering the reaction cell is absorbed by the

higher concentrations of SO2 typically measured by the 6400EH.

A window transparent to UV light provides an air-proof seal that

prevents ambient gas from contaminating the sample chamber.

9.1.2 Direct Measurement Interferences

The most common source of interference when measuring SO2 is

from other gases that fluoresce in a similar fashion to SO2 when exposed

to UV Light. The most significant of these are:

A class of hydrocarbons called poly-nuclear aromatics (PNA) of

which xylene and naphthalene are two prominent examples.

Nitric oxide (NO), which fluoresces in a spectral range near to SO

.

2

For critical applications where high levels of NO are expected an

optional 360 nm optical filter is available that improves the rejection

of NO (contact customer service for more information).

The methods by which the Model 6400EH rejects interference for

these substances differs from the M1 00E as follows.

Since the typical application for which the 6400EH rarely includes

the presences of hydrocarbons or PNA’s, no hydrocarbon scrubber

(kicker) is included in the 6400EH’s base configuration. An

optional scrubber (see Section 5.4 of this manual is available).

Teledyne Analytical Instruments 38

Page 51

UV Fluorescence SO2 Analyzer Theory of Operation

On the other hand the typical 6400EH application often includes

much higher concentrations of Nitric Oxide (NO), which

fluoresces in a spectral range near that of SO

. Therefore a 360

2

nm filter replaces the 330nm UV filter located between the PMT

and the reaction cell in order to more efficiently reject for

interference due to the higher concentrations of NO.

9.2 Pneumatic Operation

9.2.1 Sample Gas Flow

The flow of gas through the 6400EH UV Fluorescence SO

2

Analyzer is created by a small external pump that pulls air through the

instrument. The 6400EH has no kicker to scrub hydrocarbons from the

sample stream. Typical applications for the 6400EH do not have

hydrocarbons in the sample stream.

Figure 9-2: Pneumatic Diagram of the6400EH – Base

Configuration

Teledyne Analytical Instruments 39

Page 52

Theory of Operation Model 6400EH

9.2.2 Pneumatic Sensors

The 6400EH uses two pneumatic sensors to verify gas flow. These

sensors are located on a printed circuit assembly, called the pneumatic

pressure/flow sensor board. This PCA is attached to a manifold

containing the critical flow orifice that sets the instrument flow rate.

9.2.2.1 SAMPLE PRESSURE SENSOR

An absolute pressure transducer plumbed to the input of the

analyzer’s sample chamber is used to measure the pressure of the sample

gas before it passes through the critical flow orifice. This is used to

validate the critical flow condition (2:1 pressure ratio) through the

instrument’s critical flow orifice.

The actual sample gas pressure measurement is viewable through

the analyzer’s front panel display as the test function PRES.

9.2.2.2 VACUUM PRESSURE SENSOR

An absolute pressure transducer measures the pressure on the

vacuum side of the critical flow orifice and is used to measure the

sample gas pressure in the reaction cell. If the vacuum pressure is not in

the correct range, a warning will be displayed by the software. Also, if

the temperature/pressure compensation (TPC) feature is turned on, the

output of this sensor is also used to supply pressure data for that

calculation.

The actual pressure of the gas downstream from the critical flow

orifice (including the gas inside the reaction cell) viewable through the

analyzer’s front panel display as the test function

9.2.2.3 SAMPLE FLOW CALCULATION

VAC.

Unlike the 6400E, which uses a thermal-mass flow sensor to

directly measure the gas flow though the instrument, the 6400EH

calculates the gas as follows.

The ratio of the two pressures is measured and used to validate

critical flow. If the ratio is not correct (< 2:1) the

FLOW WARN

SAMP FL test function is set to XXXX.

message is activated. Also, the value of the

SAMPLE

If the pressure ratio between the two sensors is valid (≥ 2:1), the

instrument calculates the flow based on sample gas pressure level

(PRES) and is viewable via the front panel as the SAMP FL test function.

Teledyne Analytical Instruments 40

Page 53

UV Fluorescence SO2 Analyzer Theory of Operation

9.3 Electronic Operation

There following figures replace Figures 10-10 & 10-19 of the

6400E Manual. There is no IZS option, a vacuum pressure sensor

replaces the 6400E’s thermal-mass flow sensor and provision is made

for the two span point valve option

Figure 9-3: 6400EH Electronic Block Diagram

Teledyne Analytical Instruments 41

Page 54

Theory of Operation Model 6400EH

Figure 9-4: Model 6400EH Power Distribution Block Diagram

Teledyne Analytical Instruments 42

Page 55

UV Fluorescence SO2 Analyzer Troubleshooting

Troubleshooting & Repair

For the most part the information contained in Chapter 11 of the

6400E Manual is also applicable to the 6400EH. There are a few

exceptions however.

10.1.1 Fault Diagnosis with Warning Messages

Table 10-1: Warning Messages - Indicated Failures

WARNING

MESSAGE

VACUUM

PRESS

WARN

10.1.2 Fault Diagnosis with Test Functions

Table 10-2: Test Functions - Possible Causes for Out-Of-Range Values

TEST

FUNCTION

VAC

10.2 Subsystem Checkout

10.2.1 Pneumatic Sensor Assembly

the 6400E in that there is no flow sensor. Instead the assembly includes

two pressure sensors located on either side of a critical flow orifice. The

6400EH software infers the gas flow rate by mathematically comparing

the two pressure readings.

FAULT CONDITION POSSIBLE CAUSES

Gas pressure inside the

reaction cell outside of

warning limits.

NOMINAL

VALUE(S)

<9.1 IN-HG-A

If sample pressure is > 10 in-Hg:

o Pneumatic Leak

o Bad Pump→Rebuild Pump

o Failed pressure sensor/circuitry

POSSIBLE CAUSE(S)

Incorrect sample gas pressure could be due to: pneumatic leak;

malfunctioning valve; malfunctioning pump; clogged flow orifices;

sample inlet overpressure; faulty pressure sensor

The pneumatic sensor assembly of the 6400EH differs from that of

Teledyne Analytical Instruments 43

Page 56

Troubleshooting Model 6400EH

If you suspect that one of the two pressure sensors is failing:

1. Cap the sample inlet.

2. After a few seconds, check the

VAC and PRES test functions and

verify that:

The VAC value matches the PRES value to within 1 In-Hg-A,

and;

Both are less than 10 in-Hg-A (i.e. under vacuum).

3. Uncap the sample inlet and unplug the pump.

4. After a few minutes, the value VAC and PRES should match

within 1 In-Hg-A, and read atmospheric pressure.

If the two sensors do not match or are significantly different from

ambient atmospheric pressure, call Teledyne Analytical Instruments

customer service.

10.3 Repair Procedures

10.3.1 Repairing the Sample Gas Flow Control Assembly

The Critical Flow Orifice is part of the pressure sensor and flow

control assembly. The jewel orifice is protected by a sintered filter, so it

is unusual for the orifice to need replacing, but it is possible for the

sintered filter and o-rings to need replacing. See the Spare Parts list in

Appendix B for part numbers and kits.

To replace the filter and/or orifice

1. Turn off Power to the analyzer.

2. Locate the pressure sensor / flow control assembly.

3. Disconnect the signal cable and pneumatic fittings.

4. Remove the assembly from the optical bench by removing the 2

screws at each end of the assembly.

5. The inlet end of the assembly is located at the end with the

straight pneumatic fitting. Remove the fitting and the

components as shown in the exploded view.

6. Replace the o-rings (p/n:OR01) and the sintered filter (p/n:

FL01).

Teledyne Analytical Instruments 44

Page 57

UV Fluorescence SO2 Analyzer Troubleshooting

7. if you are replacing the Critical Flow Orifice itself

(p/n:00094100), make sure that the side with the colored window

(usually RED) is facing upstream to the flow gas flow.

8. Re-assemble in reverse order. See the Spares List in Appendix B

for part numbers.

9. After re-connecting the power and pneumatic lines, flow check

the instrument as described in the Section 11.5.2 of the 6400E

Operator’s Manual.

Figure 10-1: Flow Control Assembly

Teledyne Analytical Instruments 45

Page 58

Troubleshooting Model 6400EH

10.3.2 Sensor Module Repair & Cleaning

Note: After any repair or service has been performed on the

sensor module, the 6400EH should be allowed to warm up

for 60 minutes.

Always perform a leak check (See Section 11.5.1) and

calibrate the analyzer (see Chapter 7)

before placing it back in service.

The most significant difference between the 6400E sensor module

and the 6400EH sensor module is the location of the reference detector.

Therefore most of the procedures described in Section 11.6.3 apply to

the 6400EH as well.

Exceptions are noted below:

Figure 10-2: Sensor Module Wiring and Pneumatic Fittings

Teledyne Analytical Instruments 46

Page 59

UV Fluorescence SO2 Analyzer Troubleshooting

10.3.2.1 ADJUSTING THE UV LAMP (PEAKING THE LAMP)

There are three ways in which ambient conditions can effect the

UV Lamp output and therefore the accuracy of the SO2 concentration

measurement. These are:

Line Voltage Change: UV lamp energy is directly proportional to the

line voltage. This can be avoided by installing adequate AC Line

conditioning equipment such as a UPS/surge suppressor.

Lamp Aging - Over a period of months, the UV energy will show a

downward trend, usually 30% in the first 90 days, and then a slower rate,

until the end of useful life of the lamp. Periodically running the UV

lamp calibration routine (see Section 6.9.7) will compensate for this

until the lamp output becomes too low to function at all.

Lamp Positioning – The UV output level of the lamp is not even across

the entire length of the lamp. Some portions of the lamp shine slightly

more brightly than others. At the factory the position of the UV lamp is

adjusted to optimize the amount of UV light shining through the UV

filter/lens and into the reaction cell. Changes to the physical alignment

of the lamp can affect the analyzers ability to accurately measure SO2.

Figure 10-3: Shutter Assembly - Exploded View

Teledyne Analytical Instruments 47

Page 60

Troubleshooting Model 6400EH

CAUTION: ALWAYS WEAR UV-PROTECTIVE, SAFETY

GLASSES WHEN WORKING WITH THE UV LAMP

ASSEMBLY.

1. Set the analyzer display to show the signal I/O function,

UVLAMP_SIGNAL (see Section 11.1.3). UVLAMP_SIGNAL is

function 33.

2. Slightly loosen the large brass thumbscrew located on the shutter

housing (see Figure 10-3) so that the lamp can be moved.

3. While watching the UVLAMP_SIGNAL reading, slowly rotate the

lamp or move it back and forth vertically until the

UVLAMP_SIGNAL reading is at its maximum.

DO NOT grasp the UV lamp by its cap when changing its

position (see Figure 10-3). Always grasp the main body of

the lamp.

4. Compare the UVLAMP_SIGNAL reading to the information in

Table 10-3 and follow the instructions there.

Table 10-3: Example of HVPS Power Supply Outputs

UVLAMP_SIGNAL ACTION TO BE TAKEN

3500mV±200mV. No Action Required

Adjust the UV reference detector potentiometer (see Figure 10-4) until

> 4900mV at any time.

>4500mV or < 1000mV

.< 600mV Replace the lamp.

UVLAMP_SIGNAL reads approximately 3600mV before continuing to adjust the lamp

position.

Adjust the UV reference detector potentiometer (see Figure 10-4) until

UVLAMP_SIGNAL reads as close to 3500mV as possible.

5. Finger tighten the thumbscrew.

Note: DO NOT over-tighten the thumbscrew.

Teledyne Analytical Instruments 48

Page 61

UV Fluorescence SO2 Analyzer Troubleshooting

Figure 10-4: Location of UV Reference Detector Potentiometer

10.3.2.2 PMT HARDWARE CALIBRATION (FACTORY CAL)

The sensor module hardware calibration adjusts the slope of the

PMT output when the instrument’s slope and offset values are outside of

the acceptable range and all other more obvious causes for this problem

have been eliminated.

Teledyne Analytical Instruments 49

Page 62

Troubleshooting Model 6400EH

Figure 10-5: Pre-Amplifier Board Layout

1. Set the instrument reporting range type to SNGL (see Section

6.7.4 of the 6400E Manual)

2. Perform a zero–point calibration using zero air (see Chapter 7 of

the 6400E Manual).

3. Let the instrument stabilize by allowing it to run for one hour.

4. Adjust the UV Lamp. (See Section 10.3.2.1 of this manual)

5. Perform a LAMP CALIBRATION procedure (see Section 6.9.7 of

the 6400E Manual).

6. Locate the Preamp board (see Figure 3-4 of this manual).

7. Locate the Following Components On the Preamp board (see

Figure 10-5 of this manual):

HVPS coarse adjustment switch (Range 0-9, then A-F)

HVPS fine adjustment switch (Range 0-9, then A-F)

Gain adjustment potentiometer (Full scale is 10 to 12 turns).

8. Set the

Teledyne Analytical Instruments 50

HVPS coarse adjustment to its minimum setting (0).

Page 63

UV Fluorescence SO2 Analyzer Troubleshooting

9. Set the HVPS fine adjustment switch to its maximum setting (F).

10. Turn the gain adjustment potentiometer clockwise to its

maximum setting.

11. Set the front panel display to show STABIL (see Section 6.2.1 of

the 6400E Manual)

12. Feed span gas into the analyzer.

13. Wait until the

STABIL value is below 0.5 ppm,

Note: Use a span gas equal to 80% of the reporting range.

Example: for a reporting range of 200 ppm, use a span gas

of 160 ppm.

14. Scroll to the OFFSET function and record the value.

15. Scroll to the NORM PMT value.

Note: Do not overload the PMT by accidentally setting both

adjustment switches to their maximum setting.

This can cause permanent damage to the PMT.

16. Determine the target NO RM PMT value according to the

following formulas.

If the reporting range is set for ≤ 500 ppm (the instrument

will be using the 500 ppm physical range):

Target NORM PMT = (8 x span gas concentration) + OFFSET

If the reporting range is set for ≥ 2,001 ppb (the instrument

will be using the 5,000 ppm physical range):

Target

NORM PMT = (0.8 x span gas concentration) + OFFSET

EXAMPLE

: If the OFFSET is 33 mV, the Reporting Range is

1000 ppm, the span gas should be 800 PPM SO2 and the

calculation would be:

Target

NORM PMT = (0.8 x 800) + 33 mV

Target NORM PMT = 640 + 33 mV

Target

NORM PMT = 673 mV

17. Set the HVPS coarse adjustment switch to the lowest setting that

will give you more than the target

NORM PMT signal from Step

16.

Teledyne Analytical Instruments 51

Page 64

Troubleshooting Model 6400EH

18. The coarse adjustment typically increments the NORM PMT

signal in 100-300 mV steps.

19. Adjust the HVPS fine adjustment such that the NORM PMT value

is at or just above the target NORM PMT signal from Step 16.

20. Continue adjusting the both the coarse and fine switches until

NORM PMT is as close to (but not below) the target NORM PMT

value from Step 16.

21. Adjust gain adjustment potentiometer until the NORM PMT value

is ±10 mV of the target level from Step 16.

22. Perform span calibration (see Chapter 7 of the 6400E Manual)

23. Scroll to the SLOPE function and record the value.

24. If the value of the SLOPE is between 0.900 and 1.100 the PMT

Hardware calibration is complete.

25. If the value of the SLOPE is less than 0.900 or greater than 1.100:

a. Multiply the slope value from step 22 by the norm PMT

value from step 19.

b. Repeat steps 17 through 24 using this new value for NORM

PMT

.

10.4 T echnical Assist ance

If this manual and its trouble-shooting / repair sections do not solve

your problems, technical assistance may be obtained from:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Telephone: (626) 961-9221

TWX: (910) 584-1887 TDYANYL COID

Fax: (626) 961-2538

or from our website at: www.teledyne-ai.com.

Before you contact customer service, fill out the problem report

form in Appendix C.

Teledyne Analytical Instruments 52

Page 65

UV Fluorescence SO2 Analyzer Appendix A

Appendix A — Version Specific Software

Documentation

APPENDIX A-1: Model 6400EH Software Menu Trees

APPENDIX A-2: Model 6400EH Setup Variables Available Via Serial

I/O

APPENDIX A-3: Model 6400EH Warnings and Test Measurements

Via Serial I/O

APPENDIX A-4: Model 6400EH Signal I/O Definitions

APPENDIX A-5: Model 6400EH IDAS Functions

APPENDIX A-6: Model 6400EH Terminal Command Designators

Teledyne Analytical Instruments 53

Page 66

Appendix A Model 6400EH

Appendix A-1: 6400EH Software Menu Trees,

Revision C.0

Figure A-1: Basic Sample Display Menu

Teledyne Analytical Instruments 54

Page 67

UV Fluorescence SO2 Analyzer Appendix A

Figure A-2: Sample Display Menu - Z/S Valve Option installed

Teledyne Analytical Instruments 55

Page 68

Appendix A Model 6400EH

Figure A-3: Primary Setup Menu (Except iDAS)

Teledyne Analytical Instruments 56

Page 69

UV Fluorescence SO2 Analyzer Appendix A

Figure A-4: Primary Setup Menu (iDAS)

Teledyne Analytical Instruments 57

Page 70

Appendix A Model 6400EH

Figure A-5: Secondary Setup Menu (COMM & VARS)

Teledyne Analytical Instruments 58

Page 71

UV Fluorescence SO2 Analyzer Appendix A

Figure A-6: Secondary Setup Menu (COMM Menu with Ethernet

Card)

Teledyne Analytical Instruments 59

Page 72

Appendix A Model 6400EH

Figure A-7: Secondary Setup Menu - HESSEN Submenu

Teledyne Analytical Instruments 60

Page 73

UV Fluorescence SO2 Analyzer Appendix A

Figure A-8: Secondary Setup Menu (DIAG)

Teledyne Analytical Instruments 61

Page 74

Appendix A Model 6400EH

Appendix A-2: Setup Variables For Serial I/O,

Revision C.0

Table A-1: 6400EH Setup Variables, Revision C.0

SETUP VARIABLE

DAS_HOLD_OFF Minutes 15 0.5–20 Duration of DAS hold off period.

TPC_ENABLE — ON OFF, ON

RCELL_SET ºC

DYN_ZERO — OFF OFF, ON

DYN_SPAN — OFF OFF, ON

CONC_PRECISION — 1

CLOCK_ADJ Sec./Day 0 -60–60 Time-of-day clock speed adjustment.

LANGUAGE_SELECT — ENGL

MAINT_TIMEOUT Hours 2 0.1–100

CONV_TIME — 33 MS

DWELL TIME

_

FILT_SIZE Samples 30 1–480 Moving average filter size.

FILT_ASIZE Samples 6 1–100

FILT_DELTA

FILT_PCT % 5 1–100

NUMERIC

UNITS

Seconds 1 0.1–10

PPM 10 1–100

DEFAULT

VALUE

50

Warnings

45–55

VALUE RANGE DESCRIPTION

ON enables temperature and

pressure compensation; OFF

disables it.

30-70

AUTO, 0, 1, 2,

3, 4

ENGL, SECD,

EXTN

33 MS, 66 MS,

133 MS 266 MS

533 MS, 1 SEC,

2 SEC

Reaction cell temperature set point

and warning limits.

ON enables contact closure dynamic

zero; OFF disables it.

ON enables contact closure dynamic

span; OFF disables it.

Number of digits to display to the

right of the decimal point for

concentrations on the display.

Enclose value in double quotes (“)

when setting from the RS-232

interface.

Selects the language to use for the

user interface. Enclose value in

double quotes (“) when setting from

the RS-232 interface.

Time until automatically switching

out of software-controlled

maintenance mode.

Conversion time for PMT and UV

detector channels. Enclose value in

double quotes (“) when setting from

the RS-232 interface.

Dwell time before taking each

sample.

Moving average filter size in

adaptive mode.

Absolute change to trigger adaptive

filter.

Percent change to trigger adaptive

Teledyne Analytical Instruments 62

Page 75

UV Fluorescence SO2 Analyzer Appendix A

SETUP VARIABLE

FILT_DELAY Seconds 180 0–300

FILT_ADAPT — ON OFF, ON

DIL_FACTOR

USER_UNITS — PPM PPM, UGM

LAMP CAL

_

LAMP GAIN — 0.9 0.5–1.5

TEMPCO_GAIN — 0 0–2

SLOPE CONST — 6.25 0.1–10

DARK_ENABLE — ON OFF, ON

DARK_FREQ Minutes 30, 0.1–1440 Dark calibration period.

DARK LAMP OFF Seconds 1 0.01–10 Dark calibration lamp off period.

DARK_PRE_DWELL Seconds 10 1–60

DARK POST DWELL Seconds 30 1–180

DARK_SAMPLES Samples 5 1–10 Number of dark samples to average.

DARK_FSIZE Samples 2 1–100

DARK_LIMIT mV 400 0–1000 Maximum dark offset allowed.

SO2 SPAN1

_

SO2_SLOPE1 PPM/mV 1 0.25–4 SO2 slope for range 1.

SO2_OFFSET1 mV 0 -1500–1500 SO2 offset for range 1.

SO2 SPAN2 Conc 4000 0.1–50000

SO2_SLOPE2 PPM/mV 1 0.25–4 SO2 slope for range 2.

SO2_OFFSET2 mV 0 -1500–1500 SO2 offset for range 2.

RANGE MODE — SNGL SNGL, DUAL,

NUMERIC

UNITS

— 1 0.1–1000

mV 3500 1000–5000 Last calibrated UV lamp reading.

Conc 4000 0.1–50000

DEFAULT