Page 1

INSTRUCTION MANUAL

MODEL 514

NDIR

A

NALYZER

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST FOR

A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

P/N M63700

08/06/99

ECO # 99-0323

Page 2

Copyright © 1999 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any other language or computer language in whole or in part, in any form or by any means, whether it be electronic, mechanical, magnetic, optical, manual, or otherwise, without the prior written

consent of Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA

91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us

free from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of sale, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others

bear the warranty of their manufacturer. This warranty does not cover defects caused by

wear, accident, misuse, or neglect. We assume no liability for direct or indirect damages

of any kind and the purchaser by the acceptance of the equipment will assume all

liability for any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts,

in so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument is intended to be used a tool to gather valuable data. The information provided by the instrument may assist the user in eliminating potential hazards

caused by the process that the instrument is intended to monitor; however, it is essential

that all personnel involved in the use of the instrument or its interface with the

process being measured be properly trained in the process itself, as well as all

instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control

process conditions. While this instrument may be able to provide early warning of

imminent danger, it has no control over process conditions, and can be misused. In

particular, any alarm or control system installed must be tested and understood, both as

they operate and as they can be defeated. Any safeguards required such as locks, labels,

or redundancy must be provided by the user or specifically requested of Teledyne.

The purchaser must be aware of the hazardous conditions inherent in the

process(es) he uses. He is responsible for training his personnel, for providing hazard

warning methods and instrumentation per the appropriate standards, and for ensuring

that hazard warning devices and instrumentation are maintained and operated properly.

TAI, the manufacturer of this instrument, cannot accept responsibility for conditions beyond its knowledge and control. No statement expressed or implied by this

document or any information disseminated by the manufacturer or his agents is to

be construed as a warranty of adequate safety control under the user's process

conditions.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 3

Table of Contents

1.0 Introduction

1.1 Method of Analysis............................................................1-1

1.2 Modules (Condulets) .........................................................1-2

1.2.1 Source Module .......................................................1-5

1.2.2 Sample Module ..................................................1-5

1.2.3 Power Module ..................................................1-5

1.2.4 Detector Module ..................................................1-5

1.2.5 Local Meter Readout ..............................................1-6

1.2.6 Control Module ..................................................1-6

1.3 Typical Applications ..........................................................1-6

2.0 Operational Theory

2.1 Circuit Description.............................................................2-2

2.1.1 Source Module .................................................... 2-2

2.1.2 Sample Module ..................................................2-3

2.1.3 Power Module ..................................................2-4

2.1.4 Detector Module ..................................................2-8

2.1.5 Control Module ..................................................2-10

3.0 Installation

3.1 Location ............................................................................3-1

3.2 Sample Saction Installation...............................................3-1

3.2.1 Filtering ..................................................................3-1

3.2.2 Effluent Return........................................................3-2

3.2.3 Flow Control ...........................................................3-2

3.2.4 Selector Manifold....................................................3-3

3.2.5 Automatic Zero Operation.......................................3-3

3.3 Electrical Installation .........................................................3-3

3.3.1 Power Check..........................................................3-3

3.4 Analysis Unit .....................................................................3-5

3.5 Optical Alignement............................................................3-6

4.0 Operations

4.1 Control Functions..............................................................4-1

4.1.1 General Purpose Version: Analysis Section...........4-1

4.1.2 General Purpose Version: Controle Module...........4-2

4.1.3 Explosion-Proof Version: Control Module ..............4-3

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 4

4.2 Start-up..............................................................................4-4

4.2.1 Preliminary Inspection............................................4-4

4.2.2 Pre-Start-up Electrical Checkout ............................4-5

4.2.3 Power On Observation ...........................................4-5

4.3 Calibration.........................................................................4-6

5.0 Maintenance & Troubleshooting

5.1 Replacement of Sample Cell Optics .................................5-2

5.2 Replacement of Filter Wheel Optics..................................5-2

5.3 Replacement of Source Lamp Assembly ..........................5-3

5.4 Replacement of Filter Position Sensor..............................5-4

5.5 Replacement of Preamplifier Circuitr Card........................5-4

5.6 Re-screening of Lens ..................................................5-5

5.7 Troubleshooting ..................................................5-5

Appendix

Specifications ....................................................................A.1

Application Data ................................................................A.2

Recommended Spare Parts List .......................................A.3

Drawing List ......................................................................A.4

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 5

Introduction 1.0

1.0 Introduction

The Model 514 Photometric Analyzer measures the concentration of

one component in a mixture of liquids or gases continuously by measuring

the radiation absorbed in selected bands in the near infrared (NIR) spectral

region. Most liquids or gases having a characteristic absorption spectrum in

this region can be measured with the analyzer. When we refer to the NIR

region we mean that portion of the electromagnetic energy spectrum from

1.0 to 2.8µ. This range can be extended to somewhat longer wavelengths

using special detectors. Most organic and some inorganic compounds can be

analyzed in the NIR region.

For example, the 514 is used to analyze parts per million (PPM) or the

percentage concentration of water in a variety of compounds (see Typical

Applications). The analyzer can also be used to measure the concentration of

one organic compound in the presence of another organic compound.

1.1 Method of Analysis

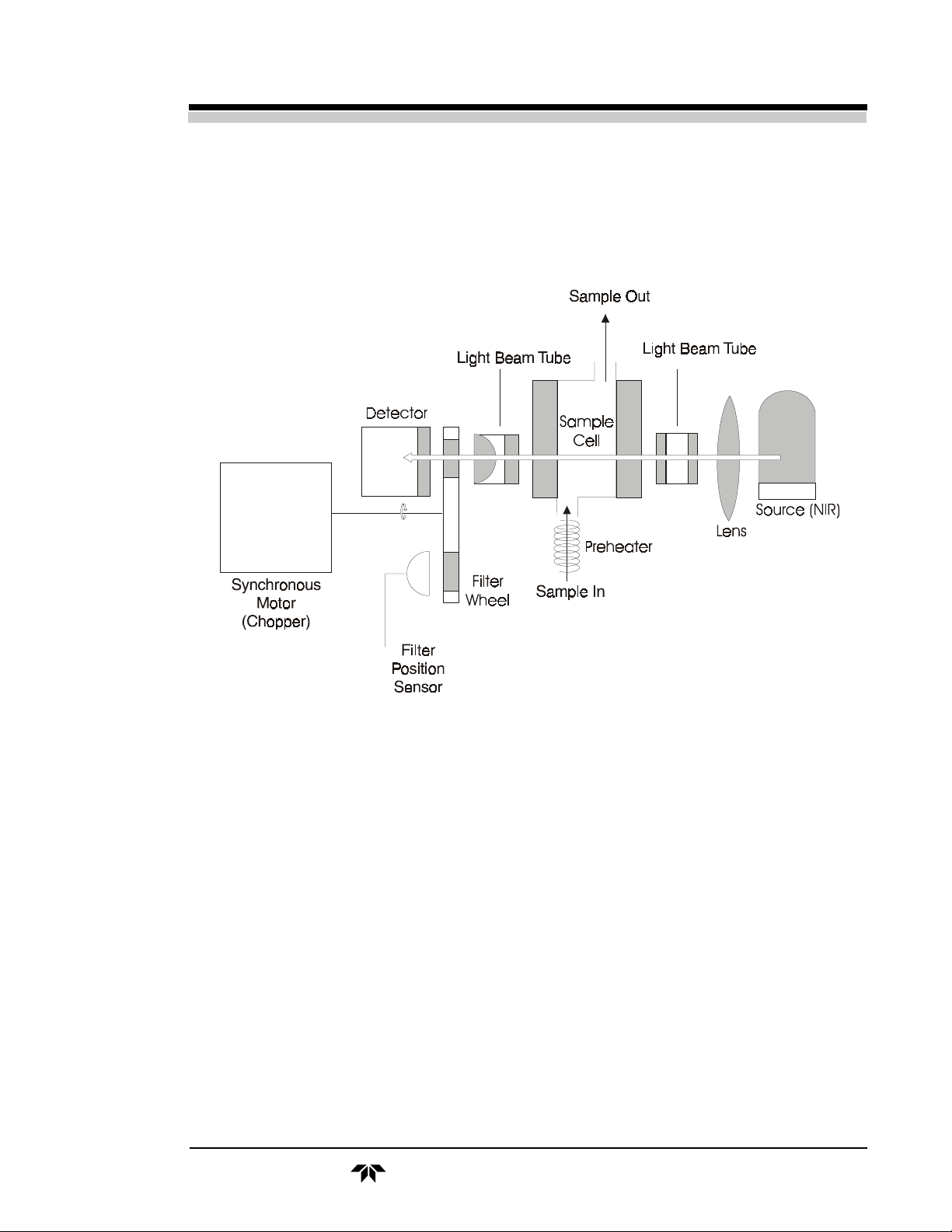

The 514 contains an optical system consisting of a quartz iodine source

lamp for NIR energy emission, collimating lens, sample cell and detector.

Isolator or light beam tubes filled with nitrogen gas interconnect the source

and sample, and sample and detector modules. In front of the detector is a

motor-driven filter wheel containing two optical interference-type filters,

located 180° from each other. These filters, designated the reference and

measuring filters, are alternately and continuously rotated in and out of the

optical path. The sample flows continuously through the sample cell absorbing energy at various wavelengths throughout the NIR spectrum. The wavelengths and intensities of absorption peaks throughout the spectrum are

characteristic of the specific compounds that are present in the sample.

In any photometric analysis, there is always the component that we are

interested in analyzing, and background components that we are not interested in measuring. Both the component of interest and the background

component may have complex NIR absorption spectra.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

1–1

Page 6

1.0 Introduction

The quantitative measurement of a compound using the 514 is based on

Beer’s Law, which states that the intensity of a beam of monochromatic

radiation transmitted through a sample decreases exponentially as the concentration of the absorbing sample increases.

To approximate monochromatic radiation, a specific wavelength is

isolated by the use of the interference-type filters. The filters allow transmission of NIR over a narrow band pass region of the NIR spectra and completely block all other wavelengths. Proper selection of the measuring and

reference filter wavelengths allows the accurate isolation and measurement

of the component of interest.

The use of two filters allows cancellation of energy changes due to

turbidity, dirty sample cell windows, and aging of the source and electronic

components.

The center band pass of the measuring filter is selected to transmit

energy in a narrow region where the component of interest absorbs strongly

in comparison with background absorbance. The center band pass of the

reference filter is selected to transmit energy in a band pass region where the

background absorption of NIR energy is equivalent to that seen by the

measuring filter. The reference filter is also selected to be in a region where

the component of interest has minimal absorption of energy.

The optical beam is converted from steady state to pulsed energy by the

rotation of the filters in the optical path. The measuring and reference pulses

of radiation strike a detector which converts the pulses of radiation into

electrical pulses which are then amplified. Signal processing involves

converting the electrical signals to logarithmic signals, and then comparing

the measuring to the reference logarithmic signals in order to give a readout

representing the concentration of the component of interest in the sample.

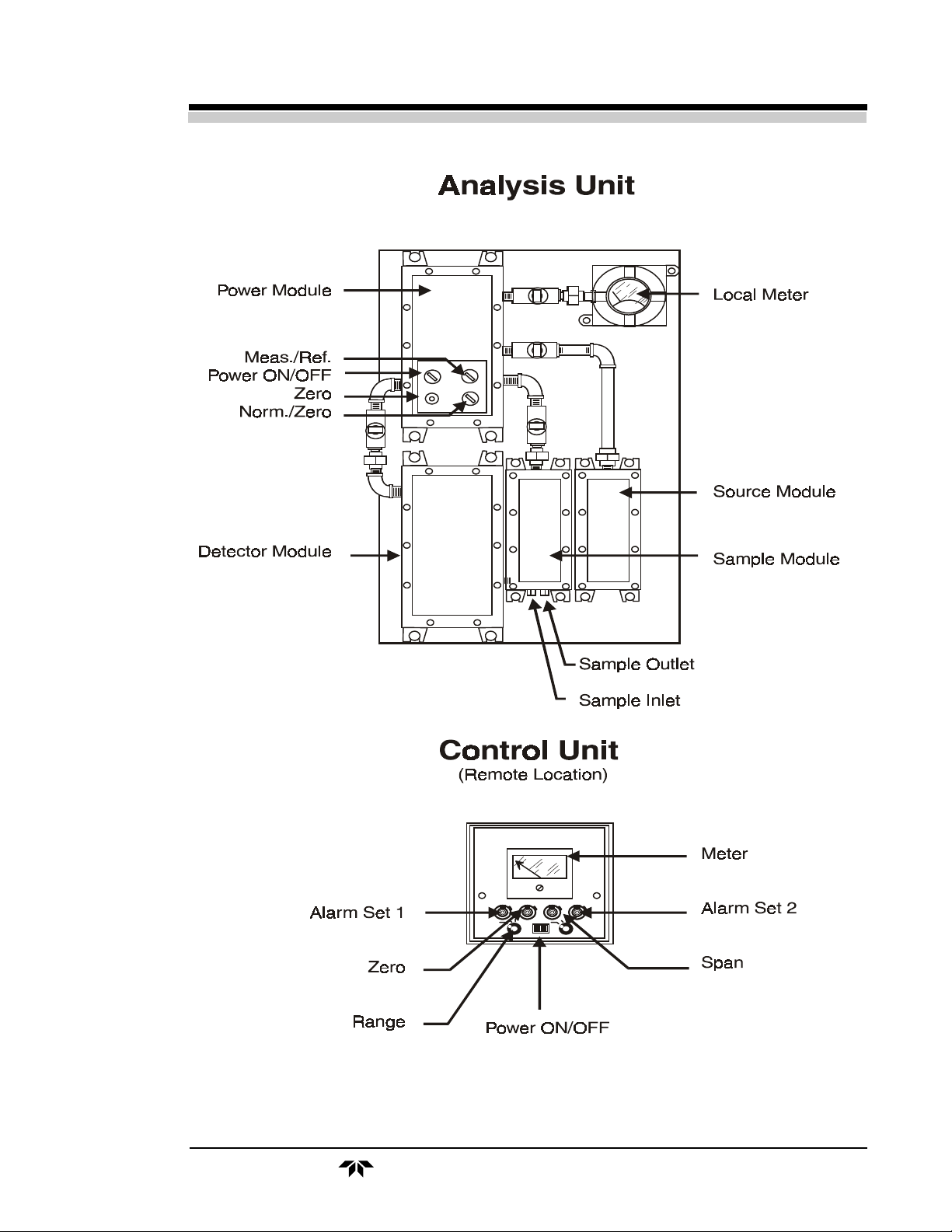

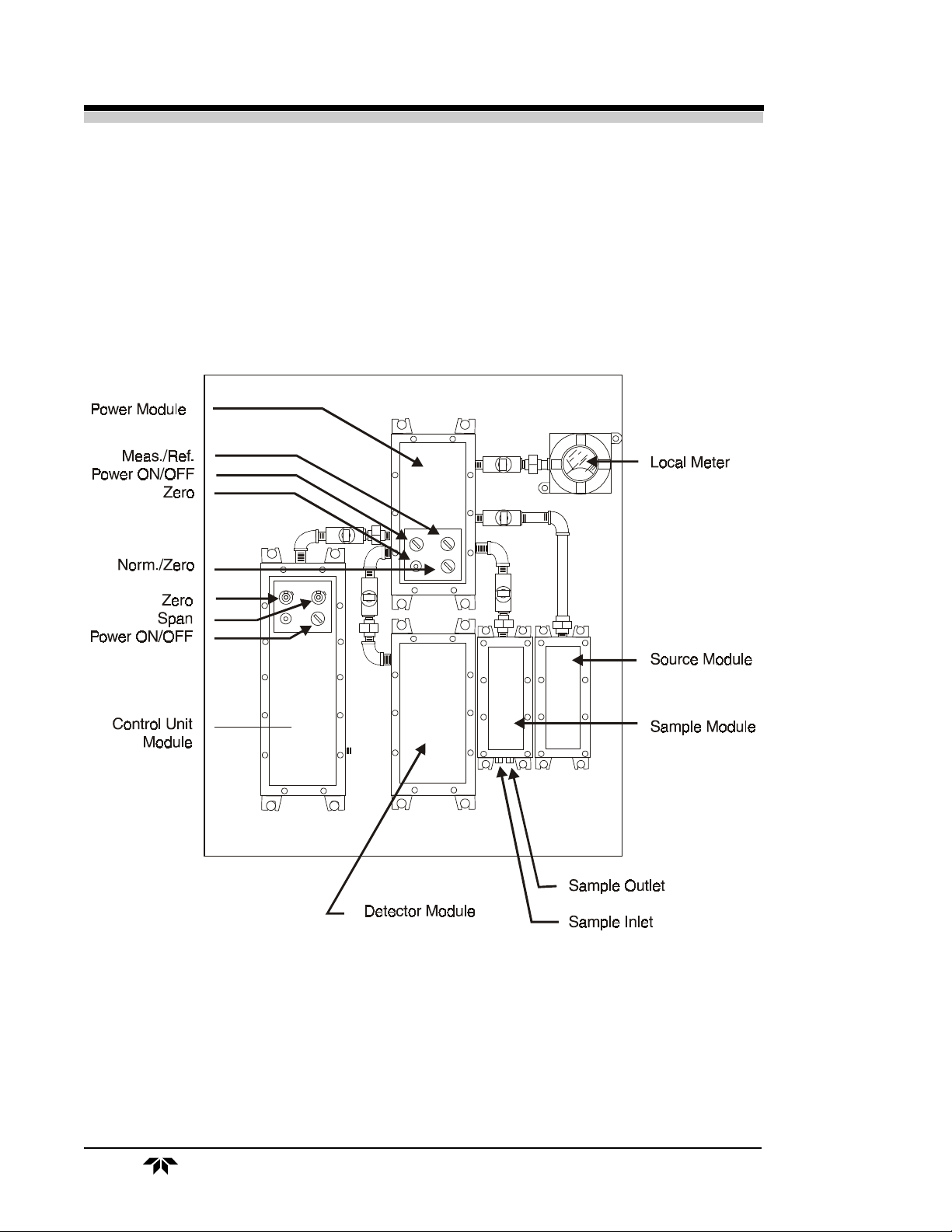

1.2 Modules (Condulets)

Physical layout of the analyzer is shown in Figures 1-1 and 1-2. The

control module is usually located apart from the analysis unit in a control

room. The explosion-proof version has the control and analysis units

mounted in one weather-resistant NEMA-12 enclosure suitable for outdoor

installation.

The analysis section is designed for hazardous area installation. Housings are rated for use in Class I, Div. I, Group D hazardous environments.

1–2

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 7

Introduction 1.0

Figure 1-1. Model 514 Photometric Analyzer (with General-Purpose Control Unit)

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

1–3

Page 8

1.0 Introduction

Figure 1-2. Model 514 Photometric Analyzer (with Explosion-Proof Control Unit)

1–4

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 9

Introduction 1.0

1.2.1 Source Module

The source module or condulet houses the quartz iodine source lamp,

collimating lens/lens holder, and transformer. The 115 VAC power to the

source transformer is derived directly from the line voltage regulating transformer installed in the power module.

1.2.2 Sample Module

The insulated sample module has sample inlet and outlet lines constructed of 1/8" O.D. 316SS tubing. The sample is routed through a

preheater, through the sample cell, then drained from the outlet port. A

thermistor-controlled preheater and compartment space heater are powered

from temperature controllers located in the power module. A thermal cutout

switch prevents temperature “runaway”.

The sample cell, which is configured for each particular application, is

provided with sapphire windows to admit NIR radiation.

1.2.3 Power Module

The power module contains a line voltage regulating transformer (with

capacitor) and three temperature controller circuit cards.

Each of the controllers incorporates a bridge circuit containing a thermistor located in the volume/compartment to be controlled. Bridge imbalance

produces an error signal, resulting in operation of the final control element

(heater) to restore bridge balance, and controlling the temperature to within a

fairly narrow proportional band.

Control functions for the analysis section are located on the power

module (see Figure 4-1).

1.2.4 Detector Module

As noted above, the detector is a part of the optical system (see Figure

2-1). The detector cell is mounted within a hermetically sealed block with a

quartz window through which the optical energy enters. The assembled cell

block, together with the preamplifier subassembly, filter wheel, and filter

position sensor, are contained within a temperature-controlled compartment

In addition to the heated optical compartment, the detector module

contains the chopper motor, power transformer, and six circuit cards whose

function is described in section 2. 2. 4, Detector Module.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

1–5

Page 10

1.0 Introduction

1.2.5 Local Meter Readout

For analyzer configurations having a remotely located control module,

the local meter is used to read the reference and measuring peak heights, or

the voltage output from the buffer amplifier before voltage-to-current conversion.

When the control module is integral with the analysis section, i. e., the

explosion-proof configuration, the meter is connected to the output of the

control module in order to display the concentration of the component of

interest as well as the previously mentioned information.

1.2.6 Control Module

In the explosion-proof version, the calibration meter is used as an all

purpose readout; in this case, there is some modification in the switching at

both the control module and power module.

In addition to control switching, adjustment (zero and span), and readout components, the control module has provisions for five circuit cards: an

automatic zero/extended voltage amplifier, E-to-I converter, I-to-E converter,

power supply, and alarm comparator. The alarm comparator circuit card

incorporates two circuits with jumpers that permit setting the alarm(s) for

high, low, high/low, high/high, and low/low settings. Setpoint adjustments

are performed with potentiometers on the module front panel.

1.3 Typical Applications

WATER MONITORING

Background Typical Range

Acids, including: 0–4000 PPM

Acetic

Formic

Sulfuric

Acetaldehyde 0–1000 PPM

Air 0–2%

Alcohols, including: 0–400 ppm

Butanol

Ethanol

Isopropanol

Methanol

Alkanes, including: 0–500 ppm

Heptane

Hexane

1–6

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 11

Ammonia 0–1000 ppm

Aromatics, including: 0–500 ppm

Benzene

Cumene

Toluene

Xylene

Chlorinated Hydrocarbons including: 0–200 ppm

Carbon Tetrachloride

Ethyl Chloride

Ethylene Dichloride

Methyl Chloride

Perchloroethylene

Propylene Dichloride

Trichloroethylene

Vinyl Chloride

Chloroprene 0–200 ppm

Chloropicrin 0–200 ppm

Deuterium Oxide 0–200 ppm

Epichlorohydrin 0–2000 ppm

Ethylene Glycol 0–500 ppm

Freons 0–500 ppm

Gasoline 0–500 ppm

Hydrogen Fluoride 0–10%

Hydroperoxides 0–5%

Kerosene 0–500 ppm

Ketones 0–1000 ppm

Methyl Acetate 0–1000 ppm

Methyl Methacrylate 0–1000 ppm

Oils 0–1%

Olefins 0–500 ppm

Pentane 0–300 ppm

α-Picolene 0–300 ppm

Phenol 0–1000 ppm

Polyols 0–500 ppm

Propylene Glycol 0–500 ppm

Propylene Oxide 0–200 ppm

Sulfinol 0–15%

Sulfur Dioxide 0–1000 ppm

Vinyl Acetate 0–2%

NOTE: Range may be higher or lower per application.

Introduction 1.0

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

1–7

Page 12

1.0 Introduction

OTHER NIR ABSORBERS

Acetic Acid

Alcohols

Amines

Aromatics

Butadiene

Carbonyls

Chloroprene

Esters

Hydrocarbons

Hydrogen Chloride

Hydrogen Fluoride

Hydroxyl Value

Ketones

Olefins

Oximes

Epoxides

Methylene

1–8

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 13

Operational Theory 2.0

2.0 Operational Theory

The energy source for the analyzer is provided by a high intensity

quartz iodine lamp located in the source module. Quartz iodine was chosen

because it produces sufficient NIR to operate the system and maintains a

nearly constant brightness over its lifetime. (See Figures 2-1 and 2-2).

This energy is then fed through the sample, which is temperature

controlled, and into the detector module where it passes through a rotating

filter wheel before reaching the lead sulfide (PbS) detector.

The filter wheel, driven at 30 RPS or 1800 RPM by a synchronous

AC motor, contains two optical filters with bandpasses selected for each

application, thus providing reference and measuring pulses from which the

required information may be obtained.

The detector receives pulses at the rate of 60 PPS, or two pulses per

revolution of the filter wheel. Every other pulse is from the measuring

filter, while the alternate pulse is from the reference filter, so that pulses

through the measuring filter alternate with pulses through the reference

filter. A filter position sensor, which is an optical device having an integral

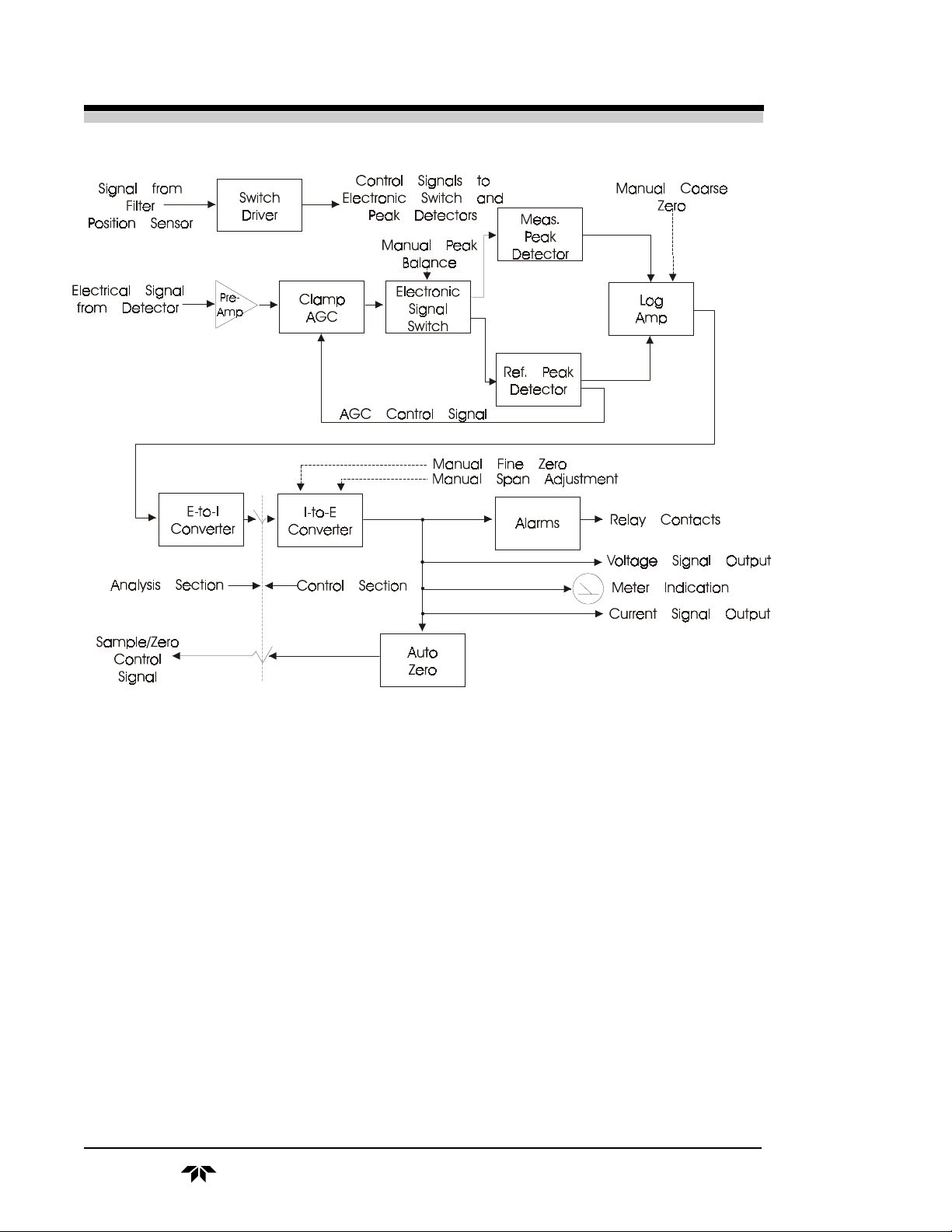

light source and light detector, differentiates between the two.

The two entrained pulses received by the detector each revolution are

amplified through a preamplifier which is physically located inside the

sealed compartment with the filter wheel and detector. This signal is then

sent to a clamping circuit where an exact zero reference is established.

This clamped video signal is then fed through a gain control network,

which is controlled by the automatic gain control loop, through another

amplifier, to the electronic switch. This switch is controlled by the switch

driver network which derives its information from the filter position sensor

in order to separate the entrained video signal into its component parts of a

measuring peak and a reference peak. These peaks are then fed through a

balancing network and channeled into separate peak height detectors which

produce DC voltage levels which are exactly equal to the peak height or

absolute magnitude of the voltage from the base to the peak of each of the

pulses.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

2–1

Page 14

2.0 Operational Theory

At this point the reference signal is fed back to the automatic gain

control loop to maintain the desired system gain. In addition, both the

measuring and reference levels are fed to selector switches in order to

enable direct meter indication, which greatly eases the task of balancing

the system during initial system installation and periods of calibration.

The DC voltage levels are fed to a logarithmic ratio amplifier which

produces a voltage output that is proportional to the logarithm of the ratio

of the two DC input voltages. This output voltage, directly proportional to

the concentration of sample, is, within certain limits, a linear function of

the concentration. For purposes of transmission, the voltage signal is

converted by an E-to-I converter; thus, the output signal from the analysis

unit is a current signal that is proportional to the concentration of sample in

the sample module.

Upon arrival at the control module, which is normally located in a

remote location away from the analyzer unit, the signal is processed

through an I-to-E converter which incorporates fine zero and span controls

for calibration. Following the span control, a buffer amplifier provides

isolation between the calibrated signal and any of the selected output

devices. This signal is then sent to the meter driver circuit and readout

meter, to the alarm comparator circuits, voltage output circuits, current

output circuits, etc., depending upon the particular application requirement.

There is also an option of providing an automatic zero circuit (see

drawing B-14729) in the control unit. This circuit provides electrical

signals for switching a fluid which contains none of the material to be

measured into the sample module, electrically adjusting the zeros and

switching back to sample.

2.1 Circuit Descriptions

2.1.1 Source Module

The source module is the source of infrared energy. This is provided

through the use of a high-intensity quartz iodine lamp operating directly

from a 6.3 V transformer. To ensure a stable source of radiation in the face

of line-voltage variations, the lamp transformer derives its input directly

from a line voltage-regulating transformer, selected for its ability to maintain a constant output voltage level regardless of fluctuations in the input

line voltage within the control range of 105 to 130 VAC.

In some applications where we have an abundance of energy due to

low sample absorption, the focusing lens is removed to avoid excess

energy reaching the detector. However, other systems have high energy

2–2

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 15

Operational Theory 2.0

losses in the sample module due to strong sample absorbance or exceptionally long sample path-lengths. These systems require a focusing lens to

gather and collimate the radiation for maximum utilization of source

energy. The collimating lens is quartz.

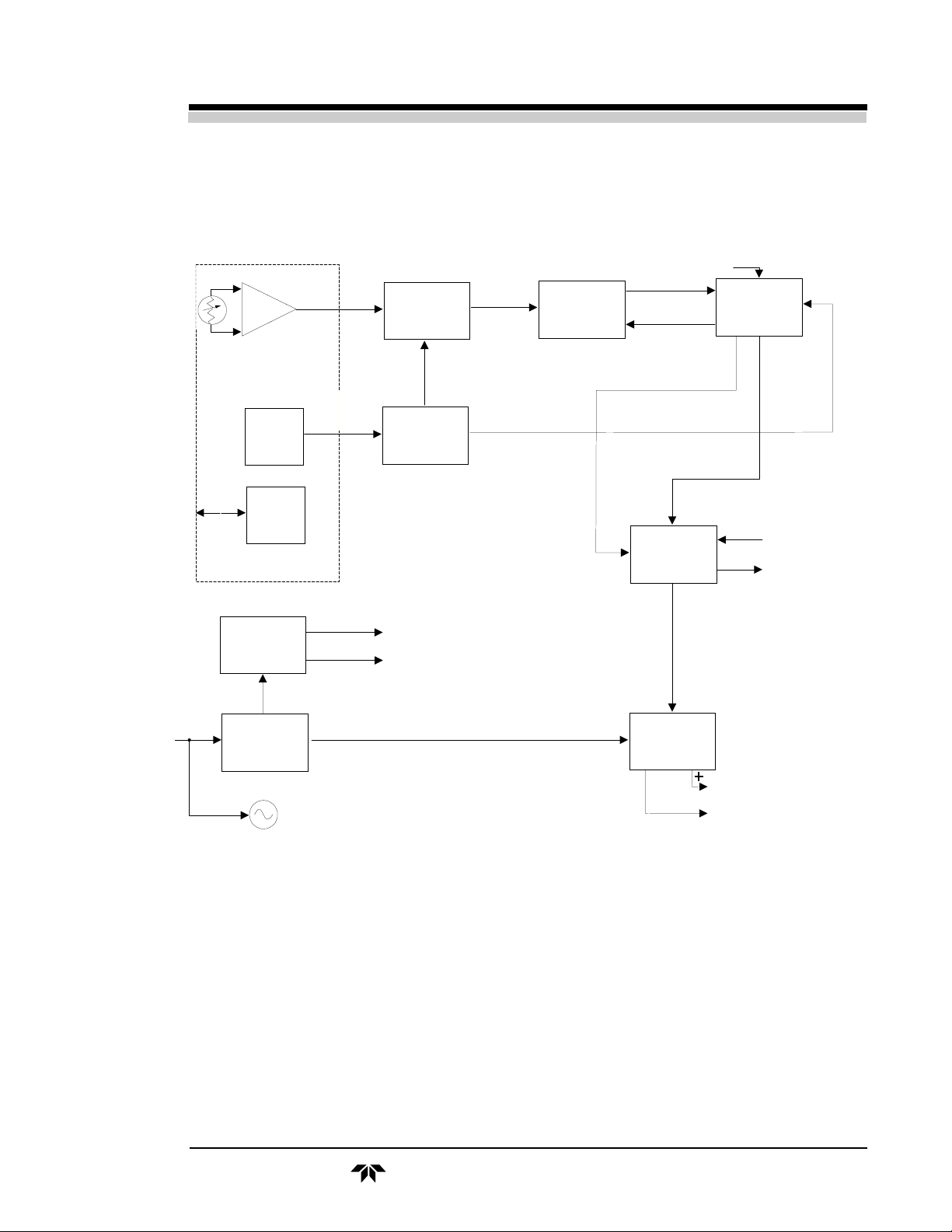

Figure 2-1. Optical System

2.1.2 Sample Module

The sample cell, generally constructed of 316SS, is located in the path

of the NIR radiation, between the source and the detector modules. Each

compound in the sample path exhibits its own characteristic absorption

spectrum. Cell spacer thicknesses will vary depending upon the absorbance

of the component of interest at the measuring wavelength. Due to the

possible variation of absorption with temperature, it is necessary to maintain the sample at a constant temperature during analysis. To achieve this,

two separate methods of temperature control are employed

1. A preheater is used on the incoming sample stream to raise it to

the desired level.

2. The entire sample module is separately controlled to maintain

the sample temperature during analysis.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

2–3

Page 16

2.0 Operational Theory

Figure 2-2 Analyzer System - Block Diagram

2.1.3 Power Module

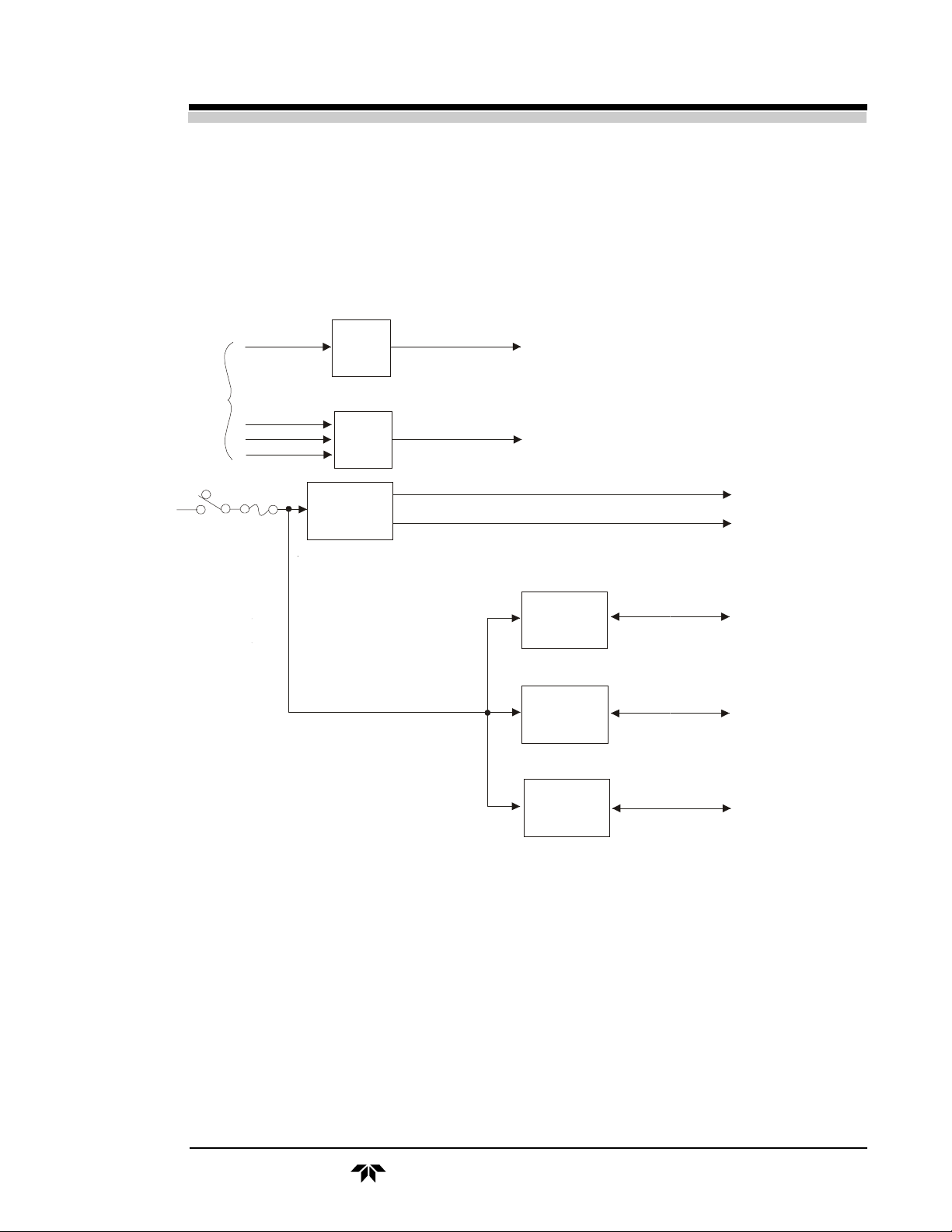

See Figure 2-3. The power module controls power to the analyzer unit,

providing the switching function for the local meter, and providing temperature control for the sample and detector modules. In the case of the explosion-proof configuration, where the control unit is mounted locally, the

power module simply routes the AC input power to its destination and

allows the control unit to provide the ON/OFF function.

When power is applied to the system, it is directed to the constant

voltage transformer and to the three temperature controllers which are

insensitive to line voltage fluctuations.

In order to facilitate easier calibration and to provide a quick visual

indication of the instrument’s status, a local meter is provided. With the

2–4

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 17

Operational Theory 2.0

NORM/ZERO switch on the power module set to the NORM position, the

meter will provide a constant readout of either the reference level or the

measuring level. During calibration periods, the ZERO switch control may

be used to monitor the signal into the E-to-I converter, and if a known zero

sample is applied, then the ZERO potentiometer may be varied to ensure

zero output to the control unit.

115 VAC

60 Hz

Input

S1

From Detector Module

Power

15 VDC

MEAS

REF

ZERO

5A

Coarse

Zero

Control

Selector

Switch

Line Voltage

Regulator

Transformer

To Log Amplifier

To Meter Driver

Preheater

Temp.

Control

Sample

Module

Temp.

Control

115 VAC to

Source Module

115 VAC to

Detector Module

Thermistor

and Heater

Thermistor

and Heater

Detector

Module

Temp.

Control

Thermistor

and Heater

Figure 2-3. Power Module - Block Diagram

All of the temperature controller circuit cards for the analyzer are

located in the power module. The schematic diagram for these circuits is

shown in dwg. B-15016.

The purpose of the time-proportional temperature controllers is to sense

the temperature in the compartment or volume to be controlled and, at a rate

of approximately twice per second, turn on the heater(s) for a specified

portion of the time cycle, depending upon how much heat is needed. When

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

2–5

Page 18

2.0 Operational Theory

ON, the heater is fully turned on; only the duration of the ON interval will

vary.

As the compartment heats up, the heater-on time interval is shortened.

The less heat needed, the shorter the heater-on interval during each cycle.

Since TRIAC Q1 is used as the control element for the heater, it is supplied

with the full AC line power. The output TRIAC is mounted on a heat sink

and can handle the full heater wattage.

A4 is a zero crossing switch and TRIAC driver, providing a gating

signal output pulse to turn on the TRIAC. Turn-on pulses are only applied

to TRIAC Q1 when commanded by a control signal, i.e., at the time the

line voltage crosses zero.

A1B is a comparator that compares the output of the temperature

amplifier (voltage representing temperature) A1A (at pin 5) with a reference ramp voltage from A2B (at pin 6), causing TRIAC Q1 to be turned on

for a time interval proportional to the required heat.

A2B and A3 comprise a ramp generator that produces a sawtooth

voltage ranging from 6 to 12 VDC with a period of approximately one-half

second.

The output voltage from the temperature amplifier A1A will range

from less than 6 volts to something more than 12 volts. When the output

voltage is greater than 12 volts, the TRIAC will be turned on a full time

interval each cycle. When the output is less than 6 volts, the TRIAC will be

turned off all the time. When the output is in the middle of the range

(approximately 9 volts), the TRIAC will be turned on for about one-half of

the time interval.

The thermistor, which is a negative temperature coefficient device, is

set up in a bridge circuit. Resistor R2, the setpoint resistor, is selected to be

approximately equal to the resistance of the thermistor at the desired

operating temperature. The other half of the bridge, the voltage divider

network comprised of resistors R4 and R5, is balanced. When the resistance of the thermistor is equal to the resistance of R2 at the desired operating temperature, the bridge is balanced and the voltage at pins 2 and 3 of

A1A is the same.

When the temperature in the compartment rises, the thermistor resistance will decrease and the inverting input of A1A will fall below the

reference point. This input will be amplified by A1B to broaden the proportional band and preclude the possibility of the device overshooting and

operating as an on/off temperature controller.

2–6

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 19

To

Power

Module

PbS

Detector

Circuit components C1, D3, and D4 provide stable internal power to

the rest of the controller circuitry.

Video

Signal

Preamplifier

Filter

Position

Sensor

Heater

&

Therm.

Detector

Compartment

Power

Supply

Filter Pos.

Signal

(Gate Pulse)

15 VDC

24 VDC

Clamp

Signal

Switch

Driver

Timing

Clamped

Video

Clamping

Switch

Operational Theory 2.0

Manual Peak Balance

Video

AGC

(+9VDC)

Ref.Level

Ref. Level

Switching Signals

(S, S', P, P')

Log

Amplifier

0to0.4VDC

FullScale

Elec.S ig.

Sw. & Peak

Level Detect.

Meas.Level

(+9VDC)

Coarse

Zero

Control

From

Power

Module

To Meter

115 VAC

60 Hz

Input

Power

Transformer

Chopper

Motor

E-to-I

Converter

Com.

10 to 18 mA (Nominal Value)

To ControlModule

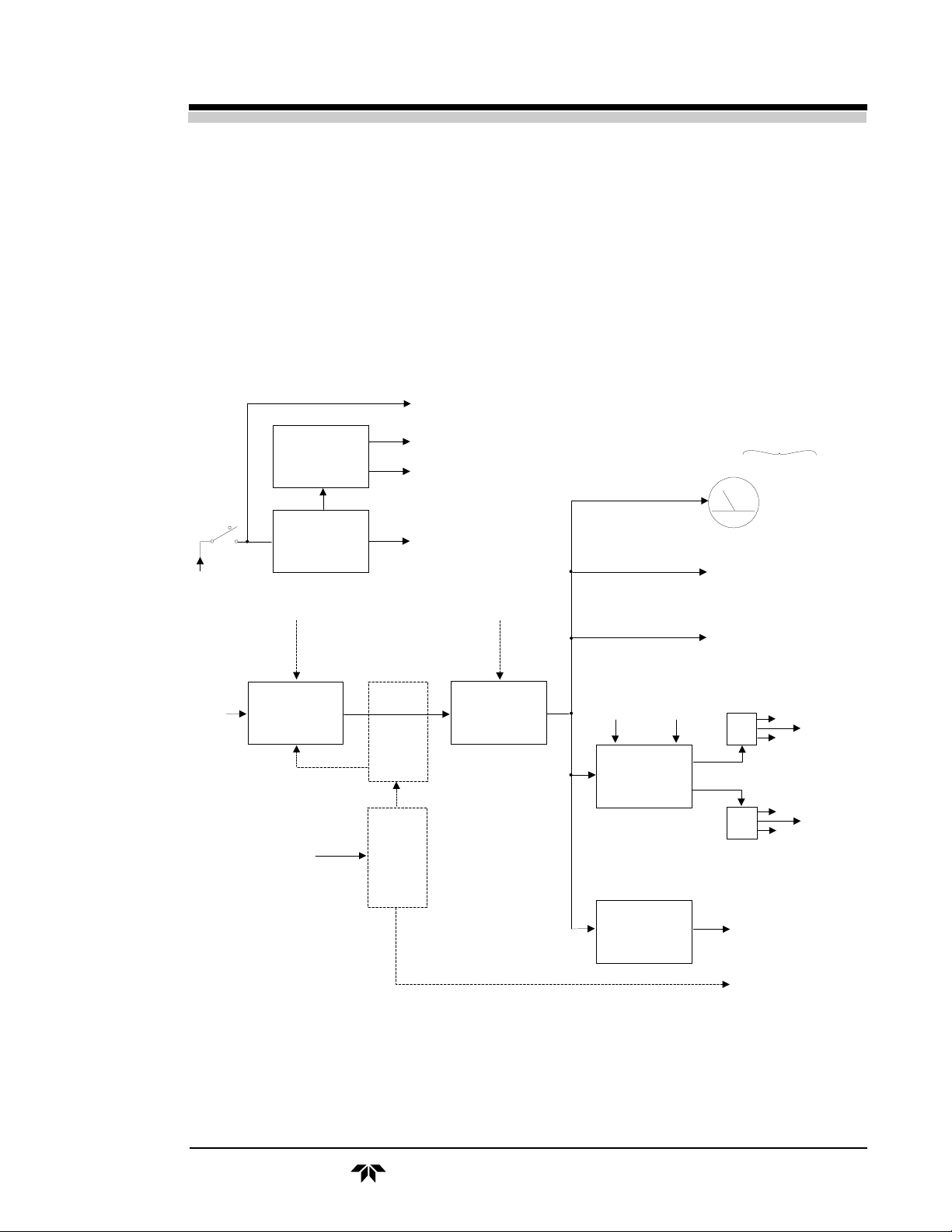

Figure 2-4. Detector Module - Block Diagram

Operating controls for the analysis section are located on the door

casting of the power module enclosure. In the general purpose configuration, these controls include the POWER ON/OFF switch, the MEAS/REF

switch to select the measuring or reference peak voltage to be fed to the

local meter driver, ZERO control, and the NORM/ZERO switch, which

operates in conjunction with the MEAS/REF and ZERO controls.

When used with the explosion-proof control module, the NORM/REF

and NORM/MEAS switches are used on the module instead of the MEAS/

REF switch. A NORM/ZERO switch is also included.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

2–7

Page 20

2.0 Operational Theory

2.1.4 Detector Module

See Figure 2-4. After energy has passed through the sample, it arrives at

the filter wheel where it is fed alternately through two filters (measuring and

reference) before reaching the detector.

These filters are specially selected for each application according to the

absorption characteristics of the compounds under analysis. The reference

and measuring filter waveforms occur along a baseline at approximately 16

milliseconds intervals; each reference or measuring waveform reoccurs at a

time interval of 33 mS, or one per revolution of the filter wheel.

At the detector, infrared energy is transformed into electrical pulses and

fed through an impedance-matched preamplifier (see dwg. A-14619). Depending upon the application, length of the cell spacer, etc., the gain of the

preamplifier may vary from 1 to 10, depending upon the energy intensity at

the detector, to achieve an AC signal output of approximately 0.1 to 1.0 volt

peak-to-peak.

Additionally, the detector, filters, and preamplifier are housed in an

electrically and thermally isolated box to provide maximum stability and

minimum noise. This box, or compartment, is normally temperature controlled at 46 °C.

The negative-going video from the preamplifier is fed to the clamp

circuit (see dwg. B-14561) to establish a precise zero reference to the

baseline of the pulses. This is accomplished by applying a gate to Ql at a

time when neither filter is in the energy path. This gated signal is fed

through A2 where it subtracts itself from the composite signal at the noninverting input. The signal output of A3 is clamped to ground and has an

amplitude of approximately two times the input.

The gating pulse for the clamp circuit is derived from the filter position sensor which is located in the detector compartment. The sensor emits

radiation which is reflected from the white pattern on the rear side of the

rotating filter wheel and sensed by a photo transistor. This creates a square

wave of 5 volts amplitude at TP4 which is then further processed by Q2,

A4 and A5 to generate the gating pulse for the clamp circuit as well as the

switching signals S, S', P and P', which are later used to demodulate the

composite video.

The clamped-to-ground, negative-going video is then sent to the

automatic gain control circuit (see dwg. B-14564). This circuit receives a

reference signal from the peak level detector and uses it to adjust the

current through LEDs B1 and B2. The current through LED B1 controls its

2–8

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 21

Operational Theory 2.0

light output and, therefore, the resistance of its shunt resistors. This enables

the signal at TP2 to be continually adjusted up or down to hold the reference

signal at a constant level (nominally 9 volts) and thus eliminate the effects of

turbidity or other foreign substances in the sample, within design limits.

After the automatic gain control circuit, the signal proceeds to the peak

level detector, where it is demodulated by A1 and A2, using the timing

signals previously generated (see dwg. B-14554). Potentiometer R3 can be

used to precisely balance the signal levels by adjusting the feedback loop

gain resistance of the two respective peaks. The separate peaks are then sent

through peak detector networks where they are transformed into stable DC

voltage levels. In the case of the reference peak level, it is from here that a +9

VDC signal is fed back to the automatic gain control network. The signal

levels are then fed to either one of two logarithmic ratio amplifiers (see dwgs.

C-14586 and C-14907).

For applications of high sensitivity, a chopper-stabilized log amplifier is

used (see dwgs. C-14586 and C-17706). A3 generates an approximate 200

Hz square wave which alternately allows the signals to be fed into the log

amplifier (A1) itself, and then blocks the measuring level and feeds the

reference level into both log amplifier inputs, allowing it to zero itself. The

log signal is then applied through amplifier A4 and A6 to A7 where a

coarse zero offset voltage may be applied through the ZERO potentiometer

on the power module

For less sensitive applications, a simpler log ratio circuit is used (dwg.

C-14907). The reference and measuring levels are processed through a

filter network before being compared by A1. This comparison results in

the log ratio output which is fed to A2 for application to a zero offset

voltage from the zero adjust potentiometer on the power module.

From the log amplifier the signal is finally sent to the voltage-tocurrent (E-to-I) converter for transmission to the control unit. Conversion

of the voltage signal to a current signal allows for signal transmission over

greater distances without noise pickup.

The E-to-I converter (see dwg. B-14075) is set with a nominal offset

so that with 0 VDC input, 10 mA output is obtained. This baseline setting

is adjustable through R7, the zero adjustment.

The converter is scaled so that with a 0.5 VDC input, the output will

be 20 mA (set with balance potentiometer R12). Output nominally ranges

from 10 mA to 18 mA with a 0 to 0.4 VDC input. When required, zero

drift can be accommodated; i.e., inputs ranging from -0.5 to +0.5 VDC will

produce 0 to 20 mA outputs.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

2–9

Page 22

2.0 Operational Theory

Power for the detector module is provided by a center-tapped transformer which takes 115 VAC input, reduces it to 40 VAC, then feeds the

voltage to the DC power supply. An additional winding on the transformer

provides output power to the E-to-I card.

The power supply utilizes a fullwave rectifier in order to provide +24

VDC unregulated. The 24 VDC is further filtered, then fed through a

voltage regulator to obtain +15 VDC regulated.

As noted previously, the filter wheel is driven by a synchronous AC

chopper motor which operates at 1800 RPM. The filter wheel performs

two functions: (1) switching filters, and (2) chopping the optical signal to

give pulses which can be amplified for high quality processing.

2.1.5 Control Module

The control module provides voltage and current output signals which

are properly scaled for the application, alarm signals in the form of relay

contacts, and a meter output. Optional provisions are also included for an

automatic zero and dual-range capability.

Upon arrival at the control module, the milliampere signal is converted to a 0 to +2 volt full scale output for connection to the span

potentiometer (see dwg. A-14620). An optional millivolt output can also be

provided by the I-to-E converter circuit card. At this point, fine zero

control is also applied by means of a potentiometer located on the front of

the module.

The voltage is then scaled so that 1 VDC full scale output is obtained

at the center of the span potentiometer. This signal is coupled through an

extended voltage amplifier circuit and used to drive the 0 to 100 µA meter

on the control module.

The standard 0 to 1 VDC output is also generated by the extended

voltage amplifier circuit (see dwg. B-16221).

The 0 to 1 VDC full scale from the span potentiometer is connected to

the alarm comparator circuit (see dwg. B-14718) where it is used to drive a

pair of amplifier circuits which couple the alarm setpoints to relays K1 and

K2.

A current output (normally 4 to 20 mA) is optional. If desired, an

optically isolated current transmitter can be installed in the explosion-proof

control module.

2–10

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 23

Operational Theory 2.0

Power for the control module is provided by a center-tapped transformer which takes the 115 VAC input, reduces it to 40 VAC, and feeds the

voltage to a DC power supply identical to the one installed in the detector

module. Power supply outputs are +24 VDC unregulated, and +15 VDC

regulated.

To Timer

Power

115 VAC

60 Hz

Input

Current

Signal

Input

From

Analysis

Unit

Power

Supply

Power

Transformer

Manual

Fine Zero

I-to-E

Converter

115 VAC

60 Hz

±

15 VDC

24 VDC

±

To I-to-E Converter

Span

Adjust.

Ext. Volt.

Auto

Zero

Timer

Amplifier

Meter

Indication

(0 to 1 V f.s.)

(0 to 5 mV f.s.)

Manual Setpoint Adjust.

Voltage

Millivolts

#1

Comparator

#2

Alarm

Relays

Output

N.O.

N.C.

N.O.

N.C.

Com.

Com.

E-to-I

Converter

(4 to 20 mA)

Figure 2-5. Control Module - Block Diagram

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Current

Standard

Valve

Control

Signal

2–11

Page 24

2.0 Operational Theory

2–12

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 25

Installation 3.0

3.0 Installation

Before power is supplied to the analyzer, all modules should be opened

and inspected for damage or loose components. Also check unit for proper

wiring and connections. All plug in circuit cards should be removed and

checked individually for correct assembly.

3.1 Location

The analysis section should be installed in an area where the ambient

temperature does not fall below 32 °F or rise above 110 °F. Steam or

electrical enclosure heating may be provided as an option. Do not install

the assembly in the path of an air conditioner or in an extremely drafty

area. The analysis section, as well as the explosion-proof version of the

analyzer, is suitable for installation in Class I, Group D, Division I areas.

Since the analysis section of the general purpose version of the analyzer is

enclosed in a weather-resistant enclosure, it is suitable for outdoor location.

The control module of the general purpose version of the analyzer is

generally intended for flush panel mounting indoors in general purpose

areas.

3.2 Sample Section: Installation

Recommendations

See Figure 3-1. The sample is introduced and drained (or vented) from

two 1/8 " Swagelok bulkhead fittings located on the bottom side of the

sample module. The following guidelines are recommended:

3.2.1 Filtering

Suspended particulate matter must be eliminated from the process

sample prior to introduction into the analyzer sampling system. Aside from

clogging the lines, accessories, integral sample paths of the analyzer and

coating sample cell windows, solid particles may interfere with the analy-

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

3–1

Page 26

3.0 Installation

sis. TAI recommends that a bypass filter assembly in the sample loop be

installed.

Sample

Zero Fluid

Span Fluid

Cell Drain

Calibration

Fluid Return

Sample Return

Filter installed only

when required

Bypass

Flowmeter

Ring Manifold

Diff. Regulator

Sample Outlet

Analyzer Flow Cell

Samp le Inlet

Sample

Flowmeter

Regulator

Bypass Valve

Figuire 3-1. Sampling Considerations

3.2.2 Effluent Return

Returning the sample effluent to the process may require a separate

calibration fluid return so that the calibration fluids can be kept out of the

process during standardization periods.

3.2.3 Flow Control

A differential pressure regulator is often used in TAI systems across the

sample flowmeter and needle valve control to give a constant flow, regardless of upstream or downstream pressure fluctuations. Constant flow may or

may not be important, depending upon the application.

It is necessary to insure sufficient contact of the sample with the

preheater in order to bring the sample up to the control temperature. Do not

allow flow in excess of 50 ml/minute.

For liquid applications, TAI recommends that the throttle valve and

flowmeter always be downstream from the analyzer. Such an installation

will pressurize the sample cell and eliminate bubbles in the sample.

Bubbles suspended in the sample fluid will produce erratic, ambiguous

analysis of the sample.

3–2

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 27

Installation 3.0

The cell with sapphire windows will withstand up to 600 psi pressure.

TAI does not recommend high pressure sample handling, but don’t hesitate

to slightly pressurize the analyzer for optimum results.

3.2.4 Selector Manifold

TAI recommends a three valve selection system that reports into a

“ring” manifold for sample and calibration fluid control. Such a system

will permit you to conserve calibration fluid. Calibration fluids can be

introduced by a simple gravity system. A bypass valve around the differential pressure regulator is recommended for calibrating with gravity feed.

Calibration fluid flow need only be long enough to insure adequate flushing of the system, and then the calibration fluid drain valve can be closed.

A ring manifold will insure a good flush with a minimum expenditure of

fluid.

3.2.5 Automatic Zero Operation

Analyzers equipped with automatic zero control will require a threeway electrically or pneumatically actuated valve in the sample system. In

addition, if it is undesirable for zero fluid to return to the process, a similar

three-way valve must be used for the calibration fluid return. In addition, a

time delay on the operation of the second three-way valve is desirable to

allow sample fluid purging of the zero fluid in the analyzer returning to the

process stream. This time delay must be built into the analyzer at the time

of purchase.

With automatic zeroing, zero fluid can be actuated manually by

setting the SAMPLE-ZERO switch to the ZERO position. Span fluid is

introduced by setting the switch to SPAN.

3.3 Electrical Installation

3.3.1 Power Check

1. Plug in the +15 volt power supply PC card (see dwg. B-14708)

but leave all other PC boards out.

2. Turn power ON.

3. With a digital multimeter (DMM), check for +15 volts on the

+15 volt power supply.

4. Check for proper starting of the chopper motor and source lamp.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

3–3

Page 28

3.0 Installation

WARNING: The light intensity from the quartz iodine lamp is intense and

should not be looked at directly without special protective

eyewear. Protective goggles with shaded lenses (Fed. Spec. #5)

should be worn if it is necessary to look directly at the source.

Explosion-Proof Version

See dwg. B-16571.

Control module power in:

TS2-14: Hot

TS2-13: Neutral

TS2-12: Ground

Control module output:

TS2-1 (Com)

TS2-2 (+)

TS2-3 (Com)

TS2-4 (+)

TS2-10 (Com)

TS2-9 (+)

TS1-1 (-)

TS1-2 (+)

TS1-6 (Com)

TS1-7 (N.O.)}alarm relay K1

TS1-8 (N.C.)

TS1-9 (Com)

TS1-10 (N.O.)}alarm relay K2

TS1-11 (N.C.)

NOTE: In order to maintain the explosion-proof integrity of the system,

See dwg. C-15245.

Control Module Power In:

}0-1 V output

}mA output

}mV output

}mA output (isolated)

interconnecting wiring between the power and control modules is

performed by TAI.

General Purpose (Control Module Remote)

TS2-14: Hot

TS2-15: Neutral

TS2-16: Ground

Power Module Power In:

TS1-1: Hot

TS1-2: Neutral

TS1-3: Ground

3–4

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 29

Control Module (mA Input):

+ - TS2-7 from TS2-7

mA output

Control Module Output:

TS2-1 (Com)

TS2-2 (+)

TS2-3 (Com)

TS2-4 (+)

TS2-10 (Com)

TS2-9 (+)

TS2-12 (Com)

TS2-11 (N.O.)}alarm relay K1

TS2-13 (N.C.)

TS1-12 (Com)

TS1-11 (N.O.)}alarm relay K2

TS1-13 (N.C.)

{

Com - TS2-8 from TS2-6

}0-1 V output

}mA output

}mV output

Installation 3.0

}Power module

3.4 Analysis Unit

Explosion-Proof Version, Control Unit: Input power connections for

this unit are at TS2 pins: 12 (ground), 13 (neutral), 14 (line) (see dwg. B-

16571). The input resistance between line and neutral with the ON/OFF

switch in the ON position should be 4 ohms +10%. The resistance between

ground-hot and ground-neutral should be infinite resistance.

General Purpose Version, Control Unit: Control unit input

power connections are to be found at TS2 pins: 14 (line), 15 (neutral), 16

(ground) (see dwg. C-15245). The input resistance between line and

neutral with the ON/OFF switch in the ON position should be infinite

resistance.

General Purpose Version, Power Module: Power Module input

power connections are at TS1 pins: -1 (line), -2 (neutral), -3 (ground) (see

dwg. C-15245). The input resistance between line and neutral with the ON/

OFF switch in the ON position should be 5 ohms +10%. The resistance

between ground-line and ground-neutral should be infinite resistance. At

this point all interconnections between the control unit and power module

should be made. The interconnections are as follows: Connect the input AC

power to TS2: -14 (line), -15 (neutral), -16 (ground).

Next, a power line connection should be installed between the control

unit switch AC power in TS1: -14 (line), -15 (neutral), -16 (ground), and

the power module AC power in TS1: -1 (line), -2 (neutral), -3 (ground).

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

3–5

Page 30

3.0 Installation

Signal connections should now be installed from the control unit TS2: -7

(plus), 6 (common) (see dwg. C-15245).

3.5 Optical Alignment

The object of optical alignment is to bring the optimum source energy

to the detector. Generally the optimum energy will be the maximum

amount of energy which can be focused on to the detector. This can be done

by adjusting the various elements in the source module (see dwg. C-14628).

WARNING: The light intensity from the quartz iodine lamp is intense and

should not be looked at directly without special protective

eyewear. Protective goggles with shaded lenses (Fed. Spec.

#5) should be worn if it is necessary to look directly at the

source.

Use a Variac on the input AC line to reduce the voltage and the lamp

intensity to a tolerable level.

1. Vertical lamp position is achieved by loosening the screws of

the base lamp bracket and moving the assembly up or down.

2. Horizontal position is achieved by loosening the Allen screw at

the base of the lamp holder which allows side to side movement

of the lamp.

3. Beam focusing is then achieved by loosening the lens holding

bracket and moving the lens back and forth until the best

focusing is obtained.

4. First visually optimize the lamp energy using a white piece of

paper at various locations in the light path. Make adjustments as

in steps 1, 2, and 3 above.

5. Then electronically optimize the energy as follows (the preamp

must be installed in the detector compartment):

a. Insert an extender card in the switch driver and clamp

position (remove keys as necessary).

b. Connect an oscilloscope to pin 6 (video from pre-amp),

and pin 3 (ground).

c. Remove the lens assembly from the light path.

d. Optimize lamp energy by adjusting the lamp position as

described in steps 1 and 2 above.

e. Replace the lens assembly.

f. Focus the lamp as described in step 3 to give the

maximum peak heights displayed on the oscilloscope.

g. If a Variac was used to alter the light intensity,

disconnect it and reconnect source to power supply.

3–6

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 31

Operations 4.0

4.0 Operations

Before shipment, TAI calibrates the analyzer for your application when

feasible. Calibration data is listed in the Appendix. Prior to calibration, TAI

checks the electronics of the analyzer and makes all of the necessary internal

printed circuit board adjustments. Calibration is performed to determine the

proper zero and span settings, and also to verify that the analyzer response is

linear.

After calibration, TAI makes a lengthy stability check to insure that the

analyzer performs within all specifications. We advise that you recalibrate

your equipment as part of start-up for the following reasons:

1. During shipment, it is possible that components have been jarred

out of position or damaged.

2. Your process may be of a proprietary nature. Beyond checking

electrical stability, TAI is unable to make a meaningful calibration of the system, requiring these adjustments to be made by

you.

3. In other cases precise calibration can only be made with the

analyzer connected to your process stream.

In any case, it is important that you calibrate the analyzer when it is

first installed. Zero checks should be made routinely once or twice a week

and span calibration should be performed weekly, at first, and monthly

after reproducibility is assured.

4.1 Control Functions

4.1.1 General Purpose Version, Analysis Section

The control functions for the analysis section are located on the power

module:

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

4–1

Page 32

4.0 Operations

1. POWER ON/OFF: This switch controls power to the analysis

section.

2. NORM/ZERO: NORM setting gives a local meter reading of

the peak-to-peak (P-P) voltage of the measuring or reference

signal, depending upon the mode setting of the MEAS/REF

switch.

ZERO setting allows the meter to display the voltage output of

the analysis section after comparing the logarithm of the

measuring and reference signals. This output is fed to meter

driver prior to conversion to a current signal for transmission to

the control module.

With zero fluid in the cell, the analysis section local meter

should read zero when the NORM/ZERO control is set to

ZERO. The setting of the MEAS/REF switch has no effect on

meter readout in the ZERO position of this switch.

3. MEAS/REF: selects either the measuring or reference peak

voltage to be fed to the local meter driver. The NORM/ZERO

switch must be in the NORM position; the reference peak

voltage should read 9±0.1 volts. With zero fluid in the sample

cell, the measuring peak voltage should be the same as the

reference peak voltage.

4. ZERO: potentiometer control allows an adjustment of the

analysis section output voltage to the E-to-I converter. The

ZERO control should be adjusted to give a zero reading when

zero fluid is in the sample cell.

5. Local Meter Readout: reads reference or measuring peak

heights, or voltage output from buffer amplifier before E-to-I

conversion.

4.1.2 General Purpose Version, Control Module

l. ZERO:control to adjust the control module to read zero output

when zero fluid is in the sample cell, i.e., fine zero.

4–2

2. SPAN:control to adjust the span calibration to make the control

module meter read the correct concentration of the span fluid.

3. POWER ON/OFF: This switch controls power to the control

module.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 33

Operations 4.0

4. ALARM SET (#l and #2): optional controls; position of dial

setting determines alarm setpoints. If dual alarms are used,

these may be set for high/low, high/high or low/low. Single

alarms can be either high or low. Dial settings can be determined

from the following formula:

X = Unknown dial setting to achieve desired alarm setpoint.

A = Analysis scale unit for low end of range.

B = Analysis scale unit for high end of range.

C = Analysis scale unit desired for alarm setpoint.

X =

(C-A)(1000)

(B-A)

For example, if the range of analysis is 20-80%, and a desirable alarm

setpoint is 30%, then A = 20, B = 80, and C = 30

X =

(30-20)(1000)

= 167

(80-20)

5. RANGE: optional switch; allows changing the range by some

predetermined amount, such as 4X or 5X; i.e., dual range: low

range of 0-100 ppm and a high range of 0-500 ppm.

6. Mode: selector for units incorporating an automatic zero.

SAMPLE position is the automatic zero; ZERO position is the

manual zero; SPAN position is the manual span adjustment.

7. Meter Readout: indicates the concentration of the component

of interest.

4.1.3 Explosion-Proof Version: Control Module

When the control module is integral with the analysis section (explosion-proof), it has all of the same control functions as the remote control

module. However, the meter readout function will be performed by the

analysis section.

Since the meter readout must handle functions for both the analysis

section and the control module, some of the controls on the power module

are different from those on the general purpose unit.

The NORM/REF and NORM/MEAS switches are on the power

module in place of the MEAS/REF switch. In addition, the NORM/ZERO

switch is located on the power module.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

4–3

Page 34

4.0 Operations

To read output from the control module, the NORM/ZERO, NORM/

REF and NORM/MEAS switches all must be in the NORM position.

4.2 Start-up

Information contained in this paragraph is based on the premise that the

analyzer has been properly installed as outlined in Chapter 3.0, and that it is

in operable condition. If difficulties arise during start-up, it is probable that

some form of damage has incurred during shipment or some installation error

has inadvertently been made.

Accessory test equipment is not necessary for start-up of the 514.

However, if the analyzer malfunctions at start-up, an oscilloscope and a

multimeter will be required for troubleshooting (see Chapter 5.0). TAI

recommends that a dual trace oscilloscope be used. A dual trace oscilloscope will permit the operator to see two different waveforms simultaneously.

4.2.1 Preliminary Inspection

Before power is supplied to the analyzer, all modules should be opened

and inspected for damage or loose components. Plug-in circuit cards should

be firmly seated in their sockets. All barrier strip wiring connections must be

inspected, and user-installed wiring between units verified as being in agreement with the system interconnection diagram.

Control Settings

Prior to turning on the power, the controls on and within the control

module should be positioned as follows:

Analyzers not equipped with Auto Zero

1. ON/OFF switches on OFF.

2. SPAN control preset to the setting noted in Specific Application

Data in the Appendix.

Analyzers equipped with Auto Zero

1. ON/OFF switches on OFF.

4–4

2. SAMPLE/ZERO switch on ZERO.

3. RUN/TEST switch (on timer unit within control module) in

TEST position.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 35

Operations 4.0

4. SPAN control preset to the setting noted in Specific Application

Data in the Appendix.

4.2.2 Pre-Start-up Electrical Checkout

After the preliminary procedures have been accomplished (refer to

Preliminary Inspection and Control Settings, above), the integrity of the

system interconnection and the power sources must be verified before

attempting the analytical start-up procedures.

The observations and measurements described in the following paragraphs are vital to the operation of the analyzer. If the analyzer does not

respond as described, the equipment has been damaged in shipment or

installation, or the user-installed wiring is in error. If a problem arises,

correct it before proceeding further.

The following procedures should be employed in the same sequence

in which they appear.

4.2.3 Power On Observations

Turn both the analysis section and control module ON/OFF switches to

ON and make the following observations:

1. Open the analysis section detector module and verify that the

chopper motor is operating. The motor should start turning the

instant power is established. If it does not, check the integrity of

the main fuse on the control module door. If the fuse is blown,

re-check the power service connections on TS2 in the control

module, and the control module to analysis section

interconnection wiring (refer to Electrical Installation in

Chapter 3.0: Installation, and dwg. C-15245).

2. The lamp source should light the instant power is established.

Open the cover on the source module to verify illumination.

WARNING: 1. The light intensity from the quartz iodine lamp is intense

and should not be looked at directly without special protective

eyewear. Protective goggles with shaded lenses (Fed. Spec.

#5) should be worn if it is necessary to look directly at the

source.

2. Before opening any of the enclosure covers with the power on,

make certain that the area has been classified as safe to do so.

3. If the analyzer section has been equipped with the automatic zero

option, the zero solenoid device in the accessory sampling system

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

4–5

Page 36

4.0 Operations

should have energized the instant power was established. The

device (or devices) should be energized because the mode switch

has been preset to the ZERO position.

4. If the test procedure was normal, the devices should have been

seen or heard to operate as described by personnel located at the

analysis section installation site, and no further check need be

made at this time. If operation is not as described, refer to

Troubleshooting in Chapter 5.0.

5. Check analyzer operation by completing the calibration

procedure described below in Calibration after allowing the

instrument to warm up. The electrical circuits take from 30 to

40 minutes to stabilize.

NOTE: It will take at least four hours for the analyzer to completely stabilize

with respect to temperature.

4.3 Calibration

Standardization Fluids

Two standardization fluids are necessary to calibrate the analyzer:

1. Zero Fluid:The zero standard fluid must have a composition

similar to the sample, and ideally, contains none of the

components of interest. The zero fluid should be laboratory

analyzed to determine its composition. The exact composition

must be known, as the accuracy of the analysis can be no better

than the your knowledge of the standardization fluid.

2. Span Fluid: The span fluid must be representative of the

sample fluid in composition (like the zero fluid), and contain a

measured quantity of the component of interest. The component

of interest content of the fluid should be in the region of 75% to

100% of the range of measurement. As with the zero fluid, the

accuracy of the system is dependent upon the your knowledge

of the span fluid composition. Ideally, the span sample should

contain 100% of whatever the instrument is set up to analyze.

Procedure

1. Introduce zero fluid (see above) into the sample cell. Flow liquid

samples into the cell at a flow rate of less than 50 ml/minute to

allow the sample preheater time to heat the sample up to the

4–6

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 37

Operations 4.0

control temperature. Make certain that bubbles are not introduced

or formed in the cell. (Some back-pressure may help avoid this.)

Gas samples can be introduced at about 200 ml/minute.

2. Turn the power module NORM/ZERO switch to NORM.

3. Turn the power module MEAS/REF switch to REF. Verify that

the analysis section meter reads 9±0.1 volts.

4. Make adjustment of the measuring peak voltage as follows

(zero fluid must be in the sample cell during this adjustment):

a. Switch the MEAS/REF switch to the MEAS position.

The meter should read almost the same as in the REF

mode. If the reading is somewhat different, the

measuring peak may be re-adjusted with R3 on the peak

level detector circuit card (see dwg. B-14554 and “Peak

Level Detector” in Chapter 5) inside the detector

module.

b. If the measuring peak is so far out of balance with the

reference peak that it can no longer be adjusted with

potentiometer R3, the optical filters require rescreening. If the analyzer has been in use for some time,

it is possible that the sample cell windows need cleaning

or that a filter has deteriorated.

Another cause of peak imbalance might be that the

sample chemical background has changed. In some

cases, TAI is not able to duplicate the background your

sample for purposes of optically balancing the analyzer

before shipment. In these cases, it is necessary for you to

screen for an approximate balance, and to then

electronically adjust R3 for precise balance. To do so:

1. Reset R3 to its midpoint.

2. Re-screen the filter wheel, as necessary, to obtain a

measuring voltage within 10% of the reference voltage.

Every time a screen is added or removed from a filter, the

analyzer must be turned off, and the filter wheel removed

from the analyzer. When the filter wheel is replaced in the

analyzer, its rotational position is not critical, but the

white backing must face in the direction of the position

sensor. The filter wheel must also be securely tightened,

so that no slippage or vibration can occur. See Figure 5-1.

NOTE: Refer to Figure 5-1 when installing filter screens. Screens should be

installed in the filter disk cup, under the filter holder. Also, if a

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

4–7

Page 38

4.0 Operations

balance ring is used, it should be placed over the screen.

5. Turn the NORM/ZERO switch to ZERO. The analysis section

meter should be made to read zero by adjusting the coarse

ZERO control on the analysis section power module.

6. Check the control module SPAN setting to make sure it agrees

with the calibration results obtained by TAI (see Specific

Application Data in the Appendix).

7. Adjust the ZERO control on the control module to give a zero

reading on the control module meter.

8. Add span fluid (see Span Fluid, above) to the sample cell. Make

certain that all of the zero fluid is displaced.

c. After screening to bring the measuring voltage to within

10% of the reference voltage, adjust R3 as in step a

above to make the measuring peak voltage read the

same as the reference peak voltage.

9. Adjust the control module SPAN control to obtain the correct

meter reading with reference to the concentration of span fluid.

For example, if the sample contains 100% of whatever the

instrument is set up to analyze, then the SPAN control must be

adjusted for a full scale reading, i. e., 200 ppm water in EDC.

10. Re-check the ZERO setting with zero fluid.

11. If desired, the linearity of the analyzer can be checked with a

fluid intermediate in concentration between the zero and the

span fluid.

12. The analyzer is now calibrated. It is often desirable to check

calibration (fine tune) on a dynamic sample from your process,

double checking the 514 analyzer response with laboratory

analyzed grab samples. This is desirable where there is a

possibility that your sample stream may have some background

materials not in the makeup of the calibration fluid.

13. From time to time, re-check the zero setting. If it is found that

there is no zero drift, re-checking the zero setting may become

unnecessary or may be performed only on an occasional basis.

4–8

14. Some optical filters used in some applications will be so

temperature sensitive that screening must be performed with the

filters near the operating temperature.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 39

Maintenance & Troubleshooting 5.0

5.0 Maintenance & Troubleshooting

Under normal operating conditions, little or no maintenance is required.

When, after prolonged use, the sample cell builds up an accumulation of dirt

or particulate deposits that take the instrument out of range of the ZERO

controls, then the sample cell must be removed (see Figure 5-2) and the

optics cleaned.

The filters should also be checked to see if any deposits have accumulated on their surfaces, requiring cleaning. Also, carefully inspect the filters

for any signs of deterioration. If necessary, remove and replace filter(s) (see

Figure 5-1). If optics/filters require cleaning, proceed as follows:

1. Windows are synthetic sapphire and lenses are quartz. They can

be cleaned, if necessary, with mild detergent and water, or with a

solvent such as ethanol.

2. The filters are sensitive to moisture and can be damaged by

water. They are held in place with epoxy cement which may be

attacked by solvents. Therefore, if filters must be cleaned beyond

the removal of dust with a brush, they may be cleaned by

application of ethanol with a cotton-tipped swab, being careful

not to wet the epoxy cement.

CAUTION: Extreme care must be observed when cleaning the optics of the

analyzer, particularly the reference and measuring filter elements,

which are critical, coated interference-type filters. Do not use

abrasive cleaners of any type. Dust or dirt can be removed with a

camel’s hair brush.

Periodic lamp replacement may be necessary. This is performed by

disconnecting the old lamp, removing it, and reconnecting the leads of a

replacement lamp.

With the exception of the items noted above, the analyzer system is

virtually maintenance-free and should perform satisfactorily almost indefinitely.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

5–1

Page 40

5.0 Maintenance & Troubleshooting

5.1 Replacement of Sample Cell Optics

If it becomes necessary to remove the sample cell optics for cleaning,

proceed as follows (see dwg. C-14631):

1. Loosen the bulkhead nuts on the two Swagelok fittings located

on the bottom of the condulet.

2. Remove the four mounting screws that secure the backplate to

the condulet interior.

3. Remove the two top mounting screws for sample preheater.

4. Unclip heater assembly from top of the compartment.

5. Remove two bulkhead fittings for clearance, then remove entire,

wired backplate assembly. There is no need to remove the wire

connections to the terminal strips. However, observe caution

when removing backplate from condulet; make sure that wire is

not twisted or pulled from connections.

6. Disassemble sample cell (see Figure 5-2).

7. To reinstall the sample cell, reverse the removal/disassembly

procedure.

5.2 Replacement of Filter Wheel Optics

If it becomes necessary to replace filter wheel optics, or re-screen

filter(s), proceed as follows:

1. Remove four screws securing detector compartment cover;

remove cover from compartment.

2. Use long-handled Allen-head wrench (7/64") to remove filter

wheel from chopper motor shaft. Hold filter wheel steady, insert

wrench in sockethead screw, then rotate shaft to remove the

screw and washers.

3. Carefully remove the filter wheel. Make certain that filter is not

touched with fingers, scratched, or marred in any way. Oil from

the fingers, or merely a fingerprint on the filters, can seriously

degrade performance of the analyzer.

5–2

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

Page 41

Maintenance & Troubleshooting 5.0

4. A total of six spare screens are furnished with the analyzer

system. As shown in Figure 5-1, the screens are placed under the

filters. Re-screen, as required, then reassemble filter wheel and

install by reversing the removal/disassembly procedure. Make

sure to reassemble any balance weights or, if balancing facilities

are available, re-balance filter wheel if re-screening has resulted

in a weight shift.

5. It is extremely important that the filters are not

interchanged. The measuring filter is located adjacent to the

white arc on the filter wheel. If the filters are interchanged, meter

readings will be reversed, i. e., the meter will indicate downscale

values instead of upscale.

5.3 Replacement of Source Lamp Assembly

The replacement source lamp assembly is installed in place with the

evacuation seal oriented toward the right side of the module, i. e., away from

the lens. Make lamp electrical connections to terminals TS1-3 and TS1-4

(green leads).

After replacement, it may be necessary to adjust the lens associated with

the source lamp. Two screws secure the lens mount by means of slotted

mounting holes, permitting horizontal and vertical adjustment of the lens.

Likewise, the screw securing the source lamp mount can be loosened,

allowing movement of the lamp for adjustment purposes. After adjustment,

re-tighten all mounting screws. Make adjustments as follows:

1. Disconnect power originating in the power module (line voltage

regulating transformer) by removing the leads from TS1-1 and

TS1-2 in the source module.

2. Connect lamp transformer primary terminals (black, black-red

leads) to a source of adjustable AC (Variac, Powerstat, etc.).

3. Energize the source lamp sufficiently to make the optical

adjustment; however, do not make source lamp illumination so

excessive that brightness can harm the eyes or make the mount

too hot to handle.

4. Move the lamp until the light can be seen centered in the optical

tube separating the source and sample modules.

Teledyne Analytical Instruments

A Business Unit of Teledyne Electronic Technologies

5–3

Page 42

5.0 Maintenance & Troubleshooting