Page 1

PRINT DATE: 19 February 2009

INSTRUCTION MANUAL

MODEL 460L

Nema Ozone Monitor

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone:

Phone:

Fax:

Email:

Website:

800-324-5190

858-657-9800

858-657-9816

api-sales@teledyne.com

http://www.teledyne-api.com/

05012 REV. D

DCN 5164

© 2008 T-API 22 January 2009

Page 2

TELEDYNE INSTRUMENTS

HIGHLIGHTS Model 460L – NEMA Ozone Monitor Instruction Manual

THIS PAGE IS INTENTIONALLY LEFT BLANK

H-ii 05012 Rev D

22 January 2009 PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 3

TELEDYNE INSTRUMENTS

460L Instruction Manual Safety Messages

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols may be found in the manual and

inside the monitor. The definition of these symbols is described below:

GENERAL SAFETY HAZARD: Refer to the instructions for details on the

specific hazard.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

TECHNICIAN SYMBOL: All operations marked with this symbol are to

be performed by qualified maintenance personnel only.

CAUTION

The monitor should only be used for the purpose and in the manner described in this

manual. If you use the monitor in a manner other than that for which it was intended,

unpredictable behavior could ensue with possible hazardous consequences.

NOTE

Technical Assistance regarding the use and maintenance of the Model 460L Nema Ozone

Monitor or any other Teledyne Instruments product can be obtained by:

Contacting Teledyne Instruments’ Customer Service Department at 800-324-5190

or

Via the internet at http://www.teledyne-api.com/inquiries.asp

05228 Rev B i

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 4

TELEDYNE INSTRUMENTS

Safety Messages 460L Instruction Manual

THIS PAGE IS INTENTIONALLY LEFT BLANK

ii 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 5

TELEDYNE INSTRUMENTS

460L Instruction Manual Table of Contents

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................... 1

1.1. Preface ..................................................................................................................................1

1.2. 460L Documentation................................................................................................................1

1.3. Using This Manual ...................................................................................................................2

2. SPECIFICATIONS AND WARRANTY .............................................................................................. 5

2.1. Specifications .........................................................................................................................5

2.2. Warranty................................................................................................................................6

3. GETTING STARTED....................................................................................................................... 7

3.1. Unpacking ..............................................................................................................................7

3.2. Mechanical Installation .............................................................................................................9

3.3. Pneumatic Connections ..........................................................................................................10

3.4. Electrical Connections ............................................................................................................ 12

3.4.1. AC Power Connection.......................................................................................................12

3.5. Signal I/O Connections........................................................................................................... 13

3.5.1. Analog Output ................................................................................................................13

3.5.2. Digital Status Outputs......................................................................................................14

3.5.3. Control Inputs ................................................................................................................ 15

3.5.4. Relay Outputs.................................................................................................................15

3.6. Initial Startup .......................................................................................................................17

3.7. Setting up the Serial Communications Port................................................................................ 17

3.7.1. Physical Serial Port Configuration ......................................................................................18

3.7.2. Software Setup for Serial Port Communications ...................................................................19

4. FREQUENTLY ASKED QUESTIONS................................................................................................21

5. OPTIONAL HARDWARE AND SOFTWARE .....................................................................................23

5.1. Sample Conditioning System................................................................................................... 23

5.2. Current Loop Analog Output.................................................................................................... 23

5.3. Ozone Destruct Option ...........................................................................................................23

6. OPERATING INSTRUCTIONS .......................................................................................................25

6.1. Front Panel Display................................................................................................................ 25

6.1.1. O

6.1.2. Zero Point Calibration ...................................................................................................... 25

6.1.3. Status LED’s...................................................................................................................25

6.2. Concentration Alarms............................................................................................................. 26

6.2.1.1. Concentration Alarm Configuration.............................................................................. 26

6.2.1.2. Remotely Sensing the Status of the Alarm.................................................................... 26

6.2.1.3. Clearing Alarms........................................................................................................ 26

7. SERIAL COMMUNICATIONS.........................................................................................................27

7.1. Serial Port Command Syntax...................................................................................................27

7.2. Serial Port Command Summary............................................................................................... 28

7.3. Serial Port Command Reference .............................................................................................. 29

7.3.1. ALMACK.........................................................................................................................29

7.3.2. ALMSTAT .......................................................................................................................30

7.3.3. CZERO ..........................................................................................................................31

7.3.4. DACSTEP .......................................................................................................................32

7.3.5. O

7.3.6. SETADDR.......................................................................................................................34

7.3.7. TDUMP ..........................................................................................................................35

7.3.8. TLIST ............................................................................................................................ 36

7.3.9. VGET ............................................................................................................................37

7.3.10. VLIST ..........................................................................................................................38

7.3.11. VSET ........................................................................................................................... 39

8. CALIBRATION .............................................................................................................................41

8.1. Zero Point calibration............................................................................................................. 41

8.2. Span Point Calibration............................................................................................................ 41

8.3. Adjusting the Optional Current Loop Output .............................................................................. 43

9. MAINTENANCE:...........................................................................................................................45

9.1. Replacing the Particulate Filter Element .................................................................................... 45

readout ....................................................................................................................25

3

.................................................................................................................................33

3

05228 Rev B iii

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 6

TELEDYNE INSTRUMENTS

Table of Contents 460L Instruction Manual

9.1.1. Filter Replacement Procedure............................................................................................45

9.1.2. Mounting the Particulate Filter Externally............................................................................ 46

9.2. Maintaining the Optional H

9.2.1. Draining the Optional Coalescing Filter ...............................................................................47

9.2.2. Replacing the Coalescing Membrane ..................................................................................48

9.3. UV Lamp Replacement ........................................................................................................... 49

9.4. Cleaning Exterior Surfaces of the 460L ..................................................................................... 50

9.5. Degree of Protection ..............................................................................................................50

10. THEORY OF OPERATION............................................................................................................51

10.1. Basic O

Measurement Principle .............................................................................................51

3

10.1.1. (Beer’s Law)................................................................................................................. 51

10.1.2. The Absorption Path ...................................................................................................... 52

10.1.3. The Reference / Measurement Cycle ................................................................................53

10.1.4. Digital Noise Filter ......................................................................................................... 54

10.2. Pneumatic Theory of Operation.............................................................................................. 55

10.2.1. Basic Pneumatic Flow And Flow Control ............................................................................55

10.2.2. Internal Pump and Flow Control.......................................................................................55

10.2.3. Optional Sample Conditioning .........................................................................................56

10.2.3.1. H

10.2.3.2. H

O Coalescing Filter ............................................................................................... 56

2

O Vapor Dryer..................................................................................................... 56

2

10.2.3.3. Ozone Destruct Scrubber ......................................................................................... 57

10.3. Electronic Theory of Operation............................................................................................... 58

10.3.1. Main Board................................................................................................................... 58

10.3.2. O

10.3.2.1. O

Sensor Module.......................................................................................................... 59

3

Sensor Components ............................................................................................ 59

3

10.3.2.2. Sensor Module PCA .................................................................................................60

10.3.3. CPU Board....................................................................................................................61

10.3.3.1. I/O Functions ......................................................................................................... 61

10.3.3.2. Status and Alarm Functions...................................................................................... 61

10.3.4. Display Driver and Keyboard Assembly............................................................................. 62

10.3.4.1. Keyboard............................................................................................................... 62

10.3.4.2. Display.................................................................................................................. 62

10.3.4.3. Display Driver ........................................................................................................62

10.3.5. Power Distribution ......................................................................................................... 63

11. TROUBLESHOOTING..................................................................................................................65

11.1. Status Output Summary .......................................................................................................65

11.2. Troubleshooting Using Status Outputs .................................................................................... 65

11.2.1. Sensor OK.................................................................................................................... 65

11.2.2. Invalid Reading............................................................................................................. 66

11.2.3. Lamp Low .................................................................................................................... 66

11.2.4. Status LED / Status Output Troubleshooting Summary .......................................................66

11.3. Concentration Alarm Outputs.................................................................................................67

11.4. Technical Assistance ............................................................................................................68

12. A PRIMER ON ELECTRO-STATIC DISCHARGE.............................................................................69

12.1. How Static Charges are Created.............................................................................................69

12.2. How Electro-Static Charges Cause Damage .............................................................................70

12.3. Common Myths About ESD Damage ....................................................................................... 71

12.4. Basic Principles of Static Control ............................................................................................ 72

12.4.1. General Rules ...............................................................................................................72

12.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance ..........................................73

12.4.2.1. Working at the Instrument Rack................................................................................73

12.4.2.2. Working at an Anti-ESD Work Bench.......................................................................... 73

12.4.2.3. Transferring Components from Rack to Bench and Back................................................74

12.4.2.4. Opening Shipments from Teledyne Instruments’ Customer Service.................................75

12.4.2.5. Packing Components for Return to Teledyne Instruments Customer Service ...................76

O Coalescing Filter ........................................................................... 47

2

iv 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 7

TELEDYNE INSTRUMENTS

460L Instruction Manual Table of Contents

List of Figures

Figure 3-1 M460L Front Cover Layout .............................................................................7

Figure 3-2 460L Layout ................................................................................................8

Figure 3-3 460L Sensor Module Layout ........................................................................... 9

Figure 3-4 460L Mounting Hole Locations and Dimensions ............................................... 10

Figure 3-5 460L Pneumatic Connections........................................................................ 11

Figure 3-6 Location of Electrical Connectors................................................................... 12

Figure 3-7 Signal I/O Connector Pin Assignments........................................................... 13

Figure 3-8 Digital Status Output Connections................................................................. 14

Figure 3-9 Control Input Connections ........................................................................... 15

Figure 3-10 Alarm Output Relays................................................................................... 16

Figure 3-11 RS-232/RS-485 Jumper Location and Settings................................................ 18

Figure 3-12 Typical RS-232 and RS-485 Connections........................................................ 19

Figure 8-1 Setup for Measuring Current Output Signal Level ............................................ 43

Figure 8-2 Location Current Output Adjustment Potentiometers ....................................... 44

Figure 9-1 Changing the Particulate Filter...................................................................... 45

Figure 9-2 Changing the Particulate Filter...................................................................... 46

Figure 9-3 Draining the Optional H2O Coalescing filter..................................................... 47

Figure 9-4 Replacing the Membrane of the Optional H2O Coalescing filter........................... 48

Figure 9-5 UV Lamp Set Screws and Calibration Test Points............................................. 49

Figure 10-1 O3 Absorption Path ..................................................................................... 53

Figure 10-2 Reference / Measurement Gas Cycle ............................................................. 53

Figure 10-3 460L Internal Pneumatic Diagram – Basic Configuration................................... 55

Figure 10-4 460L Internal Pneumatic Diagram with Optional Sample Conditioning ................ 56

Figure 10-5 460L Electronic Block Diagram ..................................................................... 58

Figure 10-6 460L Power Distribution Block Diagram ......................................................... 63

Figure 12-1 Triboelectric Charging ................................................................................. 69

Figure 12-2 Basic anti-ESD Workbench........................................................................... 72

LIST OF TABLES

Table 2-1 460L Specifications....................................................................................... 5

Table 3-1 460L Ventilation Clearances ......................................................................... 10

Table 3-2 Digital Status Output Descriptions................................................................. 14

Table 3-3 Control Inputs............................................................................................ 15

Table 3-4 Relay Output Operation............................................................................... 16

Table 3-5 Serial I/O Port Connection ........................................................................... 17

Table 3-6 Serial Port Configuration.............................................................................. 20

Table 6-1 Status LED’s .............................................................................................. 25

Table 6-2 Concentration Alarm Default Settings ............................................................ 26

Table 7-1 Serial Port Command Summary.................................................................... 28

Table 7-2 VAR_INDEX List for VGET Command ............................................................. 37

Table 7-3 VAR_INDEX List for VSET Command.............................................................. 39

Table 10-1 Measurement / Reference Cycle.................................................................... 54

Table 11-1 Digital Status Outputs Definitions ................................................................. 65

Table 11-2 Status LED / Output Trouble shooting Truth Table........................................... 67

Table 11-3 Alarm Output Troubleshooting...................................................................... 67

Table 12-1 Static Generation Voltages for Typical Activities .............................................. 70

Table 12-2 Sensitivity of Electronic Devices to Damage by ESD......................................... 70

05228 Rev B v

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 8

TELEDYNE INSTRUMENTS

Table of Contents 460L Instruction Manual

LIST OF APPENDICES

Appendix A – Spare Parts List

Appendix B – List of Schematics

vi 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 9

TELEDYNE INSTRUMENTS

460L Instruction Manual Introduction

1. INTRODUCTION

1.1. Preface

Teledyne Instruments is pleased that you have purchased the Model 460L NEMA Ozone Monitor.

Included is a full one-year warranty (see Section 2.2) and we at Teledyne Instruments will be

pleased to provide you with any support required so that you may utilize our equipment to the

fullest extent.

The Model 460L is a microprocessor based low range ozone monitor for safety monitoring of ozone

levels in a variety of applications such as water treatment, food processing, and research. The

design has been specifically optimized for applications requiring the measurement of ozone at the

typically low concentration levels encountered when tracking ambient conditions. The Model 460L

has been designed to give accurate and stable readings over long time periods with little or no

maintenance or calibration.

The flexibility of the software as well as the analog and digital I/O allow the Model 460L to

interface with a broad range of devices for process control and data logging.

We hope you will not experience any problems with the Teledyne Instruments Model 460L but if

you do, our full time customer service department is always available to answer your questions.

1.2. 460L Documentation

The documentation for this monitor is available in several different formats:

Printed format, part number 050120100

Electronic format on a CD-ROM, part number 050120200

The electronic manual is in Adobe

Acrobat Reader

the Internet at http://www.adobe.com/.

The electronic version of the manual has many

Keyword and phrase search feature

Figures, tables and internet addresses are linked so that clicking on the item will display

the associated feature or open the website.

®

software, which is necessary to view these files, can be downloaded for free from

®

Systems Inc. “Portable Document Format”. The Adobe®

advantages:

A list of chapters and sections as well as thumbnails of each page are displayed to the left

of the text.

Entries in the table of contents are linked to the corresponding locations in the manual.

Ability to print sections (or all) of the manual

05228 Rev B 1

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 10

TELEDYNE INSTRUMENTS

Introduction 460L Instruction Manual

1.3. Using This Manual

This manual has the following data structures:

1.0 Table of Contents:

Outlines the contents of the manual in the order the information is presented. This is a good

overview of the topics covered in the manual. There is also a list of tables, a list of figures and a

list of appendices. In the electronic version of the manual, clicking on any of these table entries

automatically views that section.

2.0 Specifications and Warranty

This section contains a list of the monitor’s performance specifications, a description of the

conditions and configuration under which Teledyne Instruments Incorporated warranty statement

applies.

3.0 Getting Started:

A concise set of instructions for setting up, installing and starting your monitor for the first time.

This includes unpacking; mechanical installation; attaching all pneumatic lines; attaching all

electrical and electronic connections and the physical configuration the RS-232/RS-485 port.

4.0 FAQ:

Answers to the most frequently asked questions about operating the monitor.

5.0 Optional Hardware & Software

A description of optional equipment to add functionality to your monitor.

6.0 Operation Instructions

Instructions for operating the monitor and using its basic features and functions.

7.0 Serial Communications

Information regarding the syntax and command definitions for the monitor’s serial I/O interface.

8.0 Calibration Procedures

General information and step-by-step instructions for manually calibrating your monitor.

9.0 Monitor Maintenance

Description of certain preventative maintenance procedures that should be regularly performed on

your monitor to keep it in good operating condition.

10.0 Theory of Operation

An in-depth look at the various principals by which your monitor operates as well as a description

of how the various electronic, mechanical and pneumatic components of the monitor work and

2 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 11

TELEDYNE INSTRUMENTS

460L Instruction Manual Introduction

interact with each other. A close reading of this section is invaluable for understanding the

monitor’s operation.

11.0 Troubleshooting Section:

This section includes pointers and instructions for diagnosing problems with the monitor, such as

excessive noise or drift, as well as instructions on performing repairs of the monitor’s major

subsystems.

12.0 Electro-Static Discharge (ESD) Primer:

This section describes how static electricity occurs; why it is a significant concern and how to

avoid it and; how to avoid allowing ESD to affect the reliable and accurate operation of your

monitor.

USER NOTES:

05228 Rev B 3

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 12

TELEDYNE INSTRUMENTS

Introduction 460L Instruction Manual

USER NOTES:

4 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 13

TELEDYNE INSTRUMENTS

460L Instruction Manual Specifications and Warranty

2. SPECIFICATIONS AND WARRANTY

2.1. Specifications

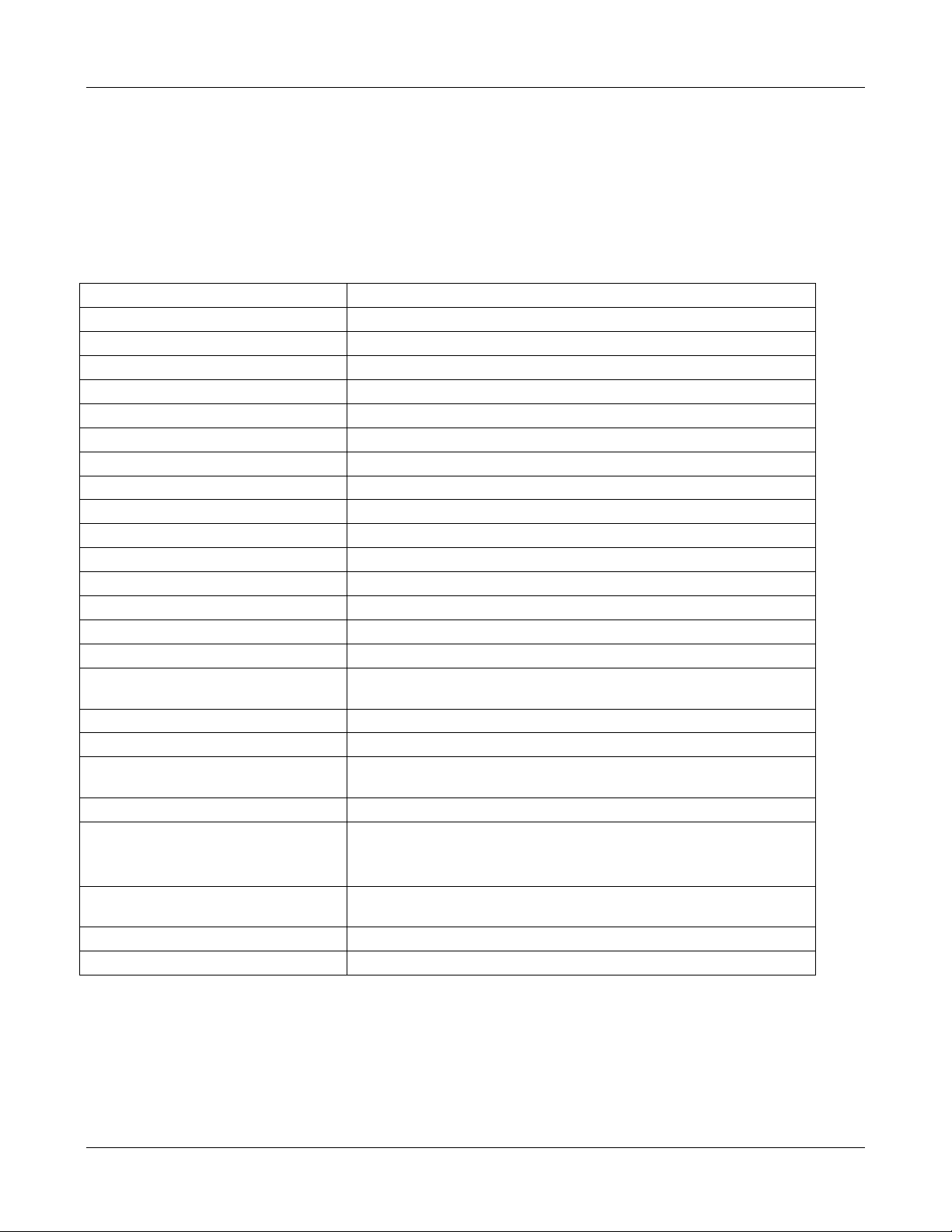

Table 2-1 460L Specifications

Measurement Principle UV Absorption (Beer Lambert Law)

Ranges 1ppm to 500 ppm: User selectable

Measurement Units ppm; ppb

Accuracy 1% of Full Scale

Zero Noise < 0.0015 ppm (rms)

Span Noise < 0.5% of reading (rms) (above 0.1 ppm)

Lower Detectable Limit < 0.003 ppm (rms)

Linearity Better than 1% of selected range

Response Time (95%) <30 sec

Repeatability 0.5% of selected range

Display Resolution 0001 ppm, 1 ppb

Gas Flow Rate 1.0-2.0 LPM

Compensation Pressure, Temperature (NTP = 273.15K, 760mmHg)

Gas Inlet Pressure Range 11.0 – 16.0 psia

Temperature Range 5-45 ˚C

Humidity Range 10-90% RH, Non-Condensing

Dimensions (H x W x D) 12.64" x 11.19" x 6.08"

(321mm x 284mm x 154mm)

Weight 9.40lb (4.27kg)

Power 110-240V~, 50/60Hz, 200 VA

Environmental Conditions Installation Category (Over Voltage Category) II

Pollution Degree 2

Maximum Operating Altitude 2000 meters

Analog Voltage Output Single output: 0-5V,

Option available converting voltage output to 4-20mA output

with maximum voltage between outputs and ground 60V peak

Relay Outputs 3 relay outputs: Sensor OK and two concentration alarms (HI &

Hi-Hi)

Relay type & Output Rating SPDT: 250V AC, 3A

Degree of Protection (IP Code) IP65 (NEMA 4X)

05228 Rev B 5

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 14

TELEDYNE INSTRUMENTS

Specifications and Warranty 460L Instruction Manual

2.2. Warranty

WARRANTY POLICY (02024D)

Prior to shipment, T-API equipment is thoroughly inspected and tested. Should equipment failure

occur, T-API assures its customers that prompt service and support will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, T-API stands ready to provide

on-site or in-plant service at reasonable rates similar to those of other manufacturers in the

industry. All maintenance and the first level of field troubleshooting is to be performed by the

customer.

NON-API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by T-API is warranted and will be repaired to the

extent and according to the current terms and conditions of the respective equipment

manufacturers warranty.

GENERAL

During the warranty period, T-API warrants each Product manufactured by T-API to be free from

defects in material and workmanship under normal use and service. Expendable parts are

excluded.

If a Product fails to conform to its specifications within the warranty period, API shall correct such

defect by, in API's discretion, repairing or replacing such defective Product or refunding the

purchase price of such Product.

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used

in any manner other than in accordance with the instruction provided by T-API, or (iii) not

properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES THEREFORE ARE

EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR

PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED.

THE REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES FOR BREACH OF

ANY WARRANTY CONTAINED HEREIN. API SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF OR RELATED TO THIS AGREEMENT OF T-API'S

PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF WARRANTY OR OTHERWISE

6 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 15

TELEDYNE INSTRUMENTS

460L Instruction Manual Getting Started

3. GETTING STARTED

3.1. Unpacking

1. Inspect the received packages for external shipping damage. If damaged, please advise

the shipper first, then Teledyne Instruments.

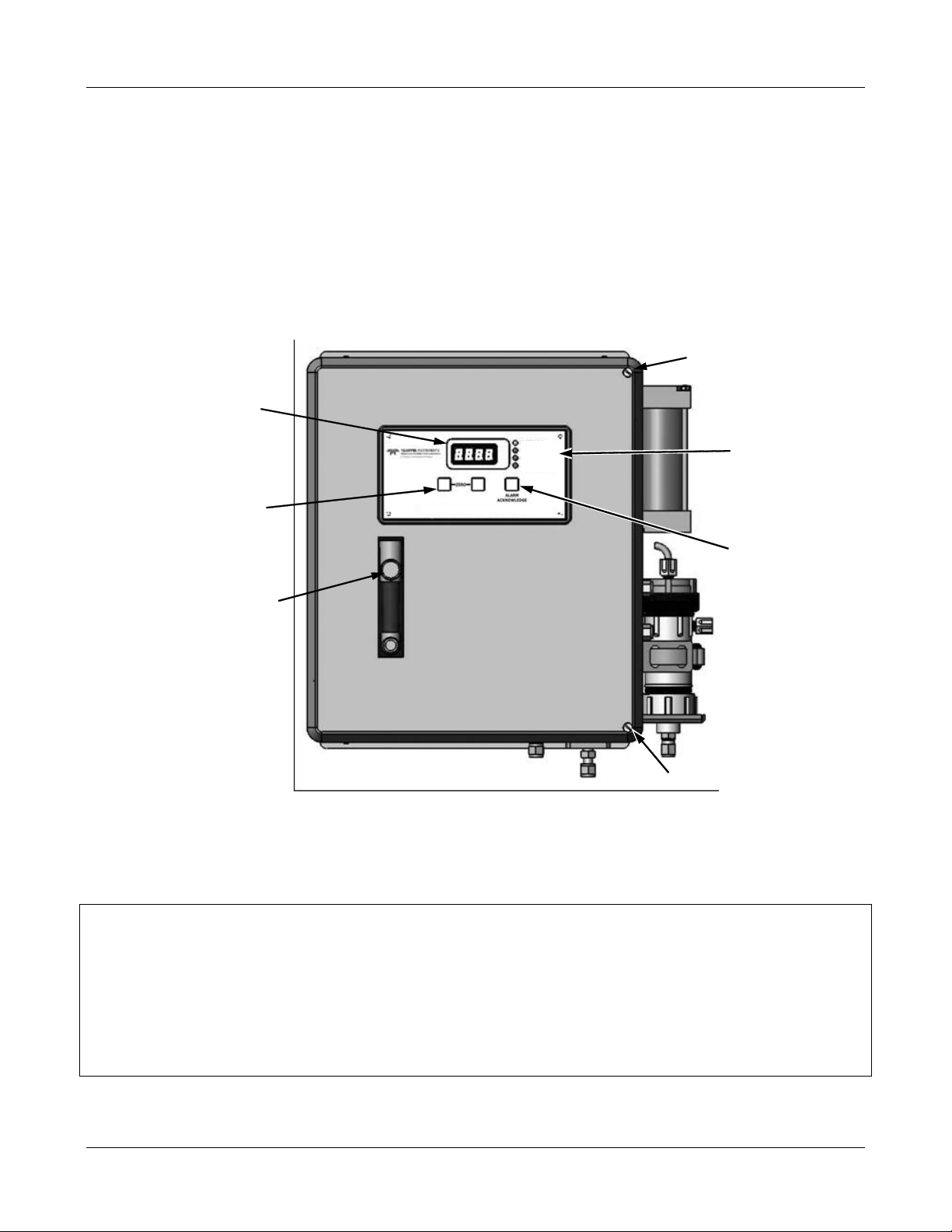

2. Loosen the 2 setscrews located in the top and bottom left corners of the front and swing

open the cover.

O3 Concentration

Display

SYSTEM OK

INVALID READING

LAMP LOW

ALARM ACTIVE

Set Screw

Status

LED’s

ZERO

Buttons

Gas

Ozone Monitor – Model 460L

Alarm

Acknowledge

Key

Flowmeter

&

Control

Set Screw

Figure 3-1 M460L Front Cover Layout

3. Inspect the interior of the monitor to make sure all circuit boards and other components

are in good shape and properly seated.

NOTE

Printed circuit assemblies (PCAs) are static sensitive. Electro-static discharges (ESD),

too small to be felt by the human nervous system, are large enough to destroy sensitive

circuits.

Before touching PCAs, read Chapter 12 of this manual and follow the procedure

described there for avoiding damage to your monitor due to ESD.

05228 Rev B 7

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 16

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

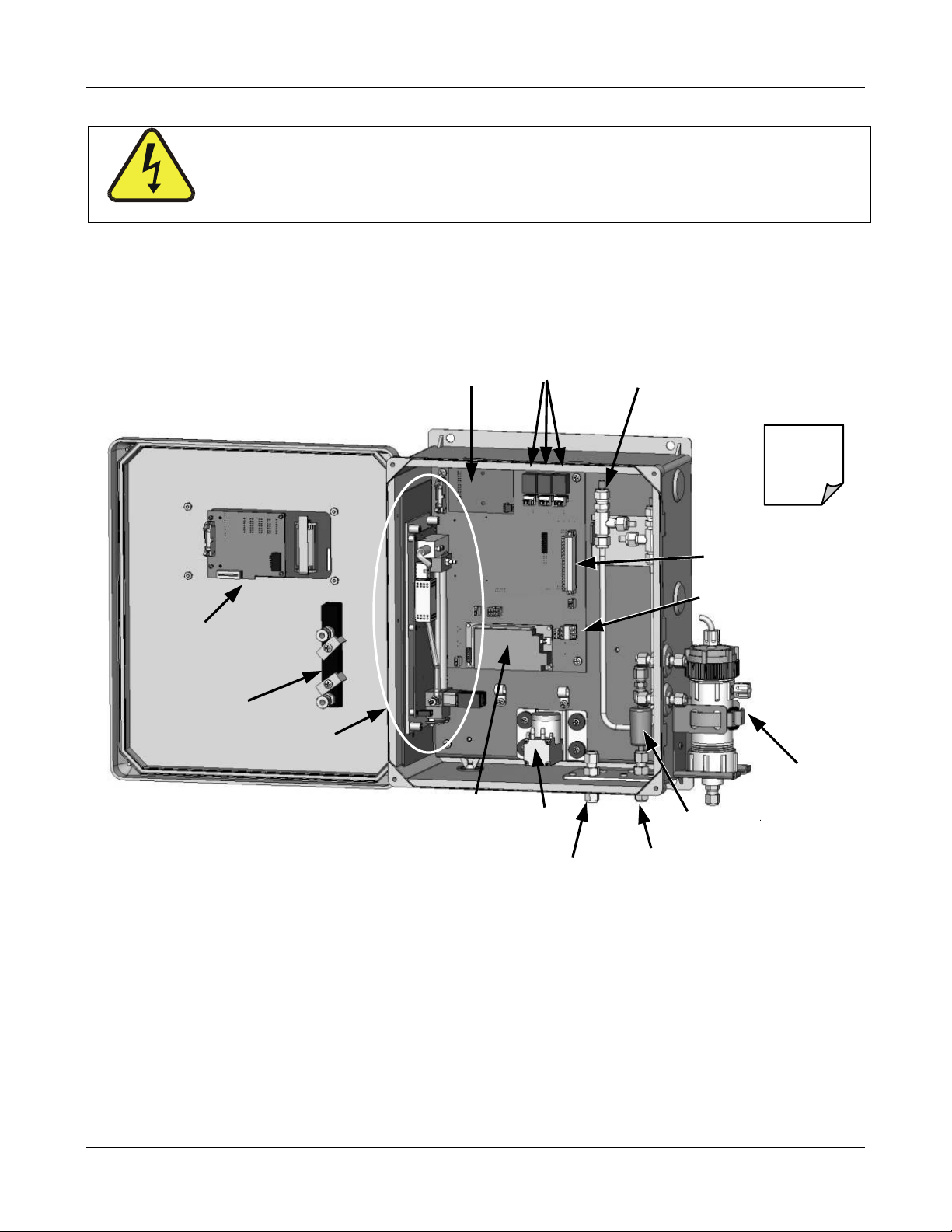

CAUTION

Never disconnect electronic circuit boards, wiring harnesses or

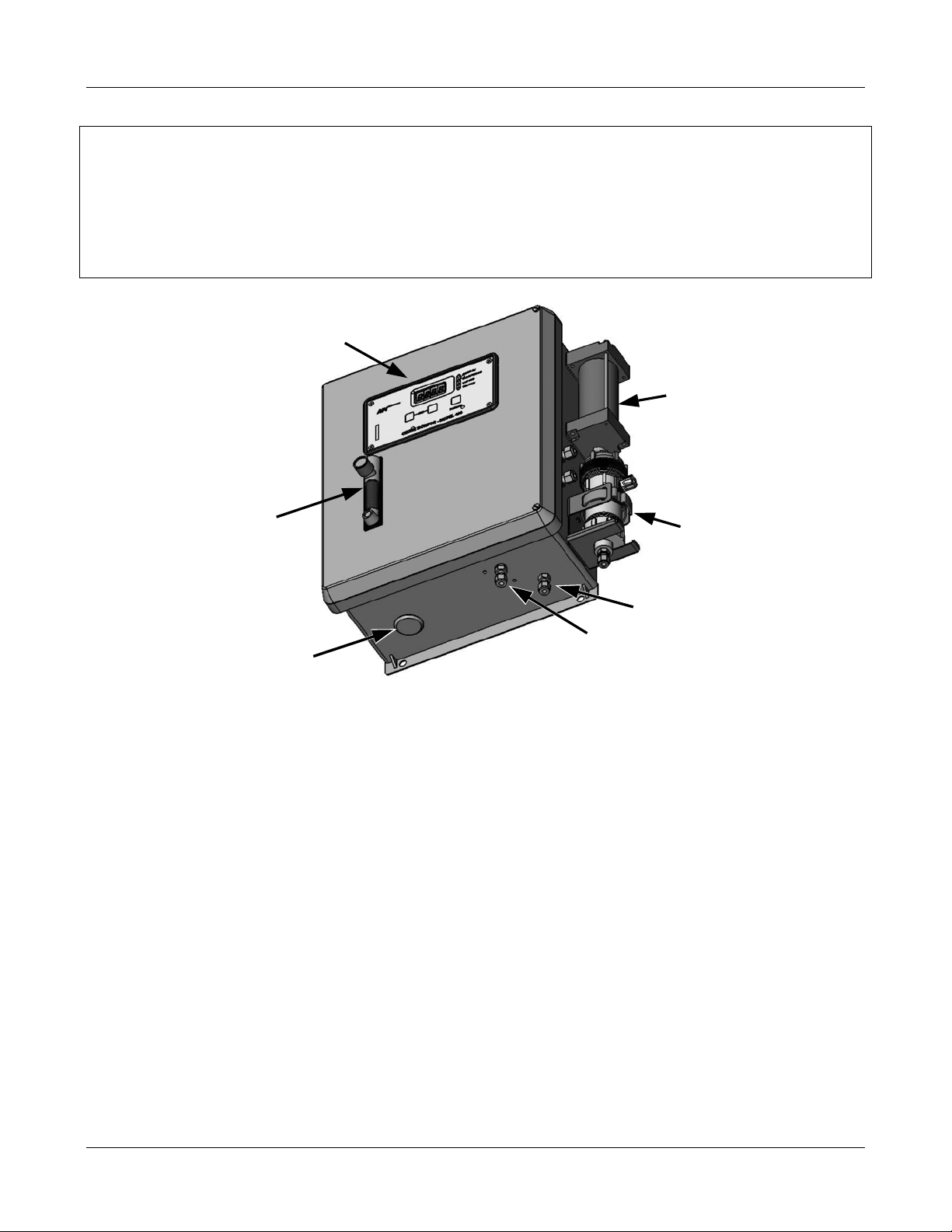

4. Check the connectors of the various internal wiring harnesses and pneumatic hoses to

make sure they are firmly and properly seated (see Figure 3-2).

5. Verify that all of the optional hardware ordered with the unit has been installed. These are

listed on the paperwork accompanying the monitor.

electronic subassemblies while the unit is under power.

Analog Relay

CPU

Board

Outputs

O Vapor Dryer

H

2

(optional)

Scrubber

Not Shown

Optional

Ozone

Display

Board

Flow Meter

Sensor Module

Main

Board

Main

Power

Supply

Pump

Exhaust

Outlet

Figure 3-2 460L Layout

Particulate

Filter

Ozone

Inlet

Signal I/O

Connector

AC Power

Input

Connector

H2O

Coalescing

Filter

(optional)

8 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 17

TELEDYNE INSTRUMENTS

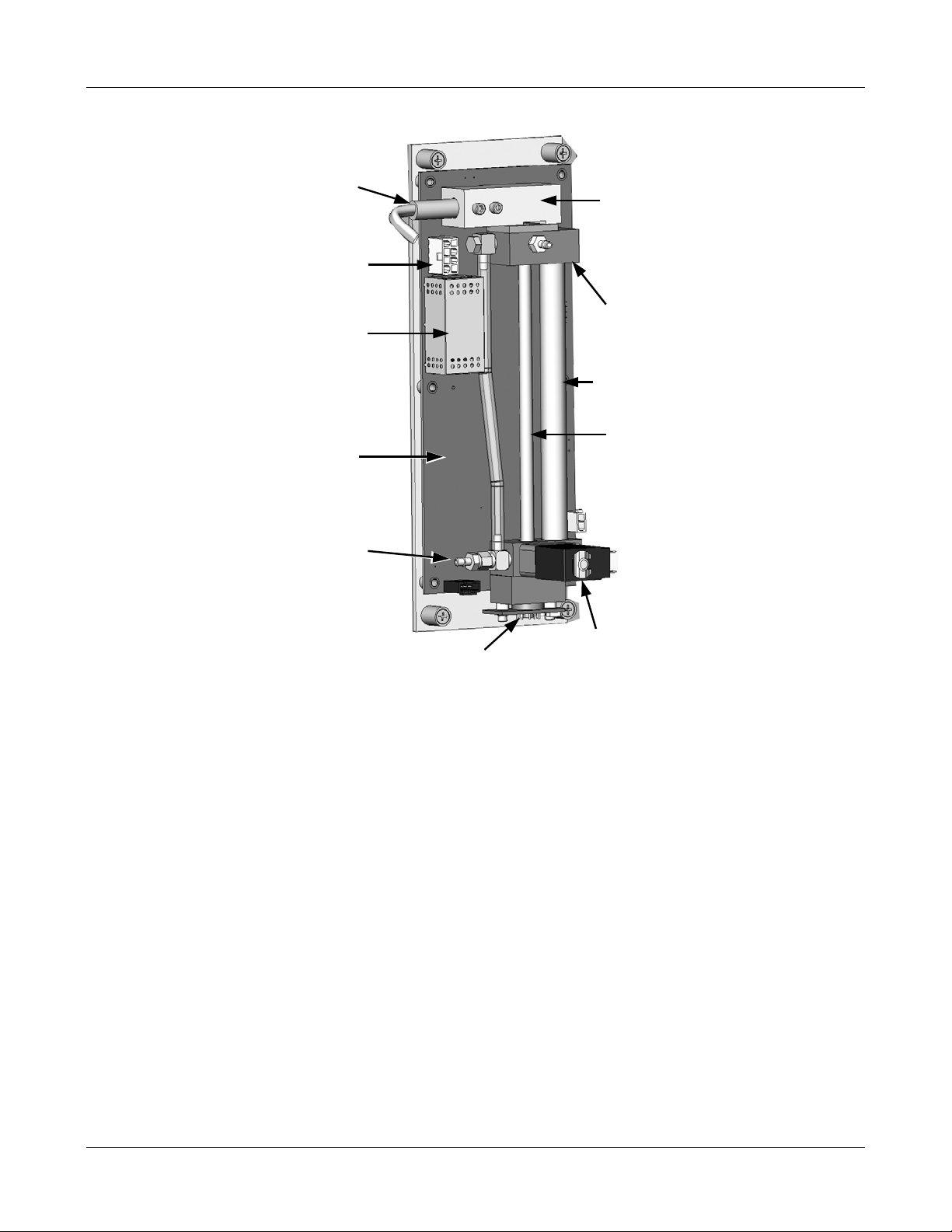

A

460L Instruction Manual Getting Started

UV

Lamp

UV Lamp

Power Connector

UV Lamp

Power Supply

Sensor

Module PCA

UV Lamp

Housing

Ozone Outlet

Manifold

Reference

Scrubber

bsorption

Tube

Ozone Intlet

Manifold

UV

Detector

Measure / Reference

Valve

Figure 3-3 460L Sensor Module Layout

3.2. Mechanical Installation

Mount the enclosure securely to a vertical surface.

Figure 3-4 below shows the locations of the four mounting holes.

All four mounting holes should be used to secure the monitor.

Use stainless steel, 5/16” diameter bolts.

VENTILATION CLEARANCE:

When installing the monitor be sure to leave sufficient ventilation clearance.

05228 Rev B 9

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 18

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

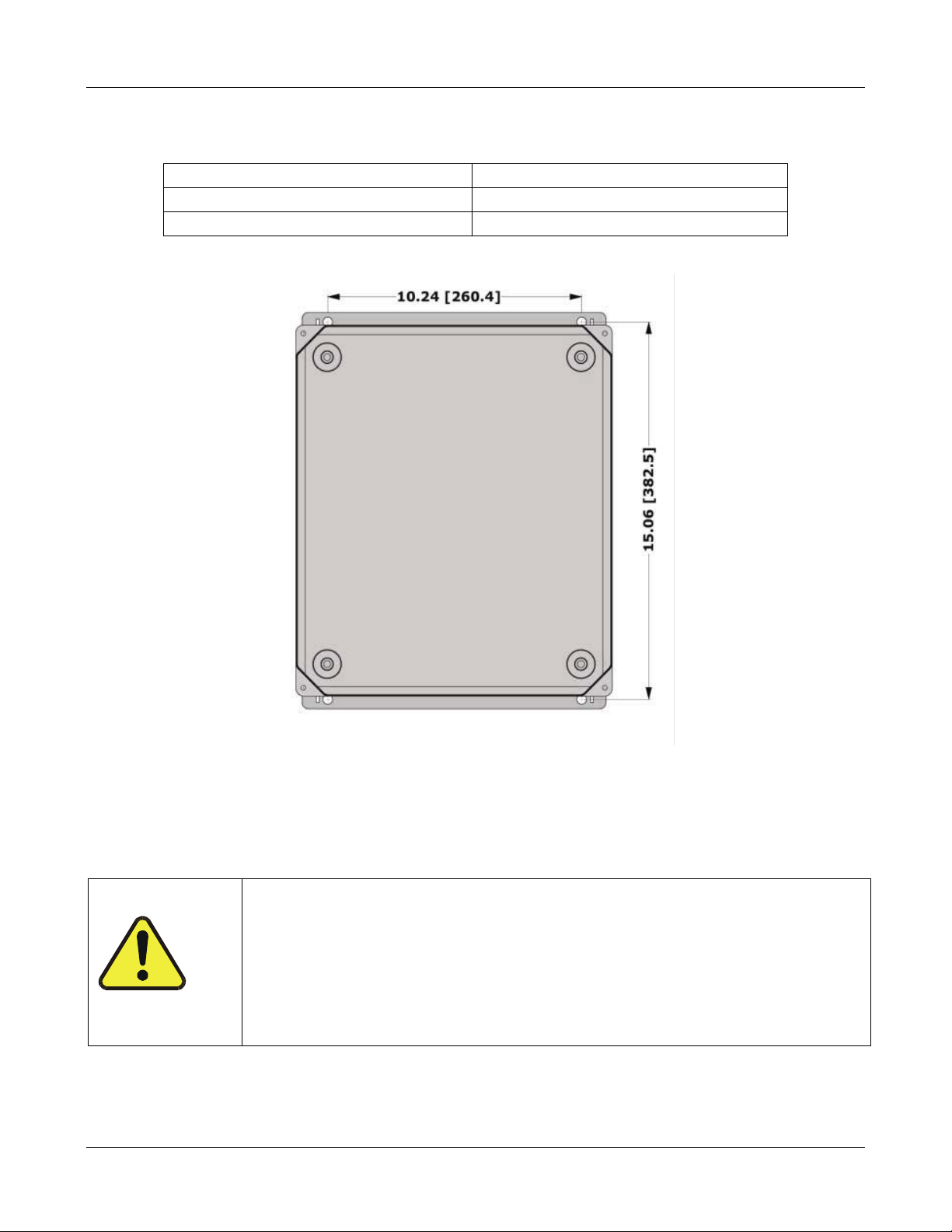

Table 3-1 460L Ventilation Clearances

AREA MINIMUM REQUIRED CLEARANCE

Sides of the monitor 1 inch

Above and below the monitor. 1 inch

Figure 3-4 460L Mounting Hole Locations and Dimensions

3.3. Pneumatic Connections

1. Connect a ¼” exhaust line to the fitting labeled ‘Exhaust.’

CAUTION

If using the 460L to measure O3 levels that are ≥100 ppb exhaust gas

from the MODEL 460L may contain dangerous levels of ozone!

2. Connect the ozone delivery line to the ¼” inlet fitting labeled “Ozone Inlet” on the bottom

face of the enclosure (See Figure 3-5.)

10 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

The optional ozone destruct (see Section 5.3) should be installed

and

Make sure that the exhaust line is vented to an outside area.

Page 19

TELEDYNE INSTRUMENTS

460L Instruction Manual Getting Started

NOTE

The ozone delivery pressure should be at ambient pressure +/- 5 PSIG.

All tubing used should be made of ozone resistant material such as Stainless Steel, PTFE

(Teflon) or FEP. API can supply appropriate tubing for connecting the ozone supply

line.

Display

Ozone

Scrubber

(optional)

Gas

Flowmeter

&

Control

Coalescence

Filter

(optional)

OZONE INLET

Install AC

Power Cord

Through Here

EXHAUST

OUTLET

Figure 3-5 460L Pneumatic Connections

The gas flow rate through the monitor should be established between 1.0 and 2.0 L/min.

05228 Rev B 11

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 20

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

3.4. Electrical Connections

NOTE

It is recommended that if multi-strand wires are used for the following electrical

connections. To ensure a reliable connection the wires should be:

“Tinned” with solder or;

Terminated with insulated crimped ferrules, such as Entrelec

(18 gauge) or 304.558.10 (22 gauge)

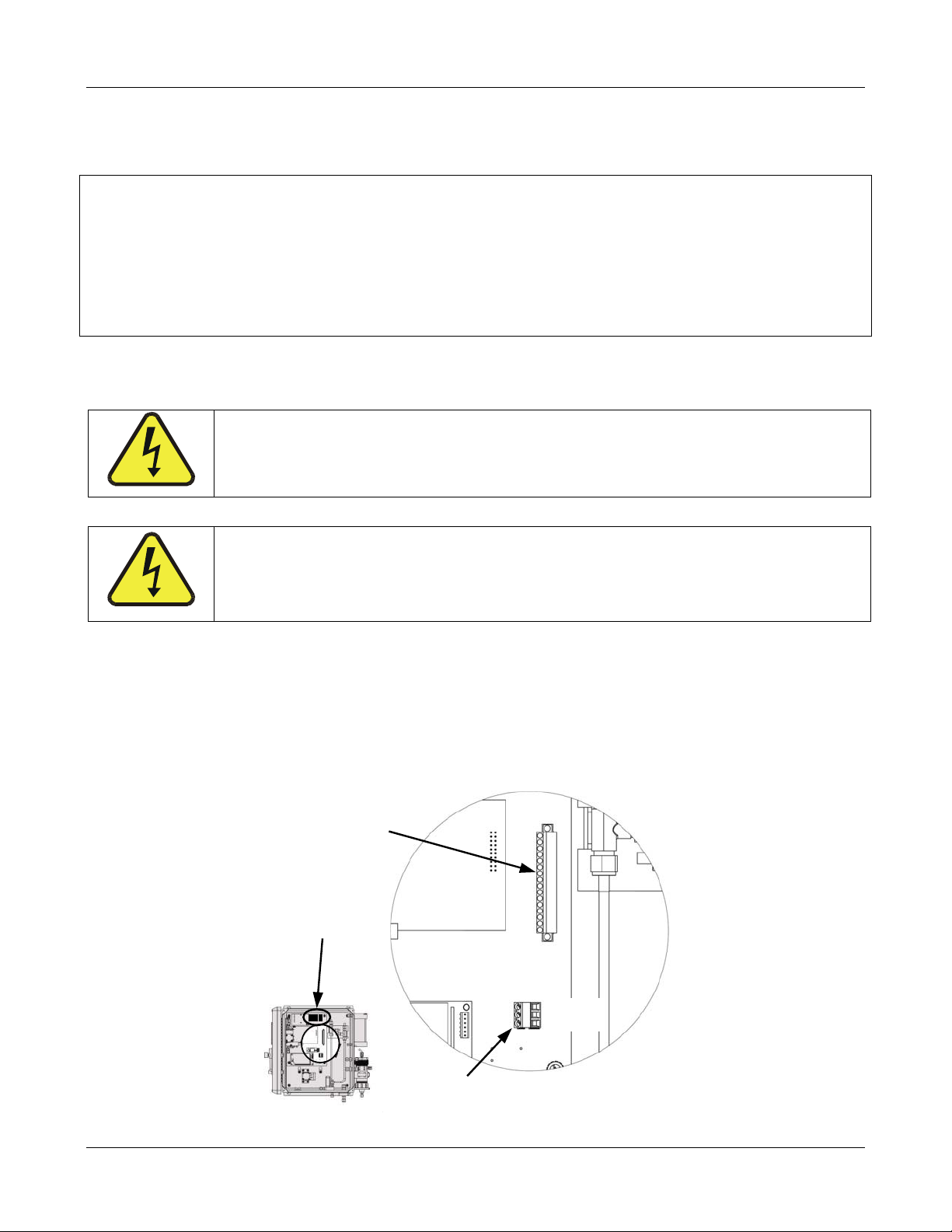

3.4.1. AC Power Connection

CAUTION

Disconnect power to the AC mains before making or removing any

electrical connections to the 460L.

®

P/N 304.456.02

CAUTION

A proper earth ground connection must be made to the receptacle

labeled “Earth Ground” on the 3-pin AC connector. Failure to do so may

result in a shock hazard and malfunction of the monitor

Connect AC power to the monitor.

3. Install a ½” conduit fitting for routing the electrical wiring into the monitor through the

hole provided (see Figure 3-5). In order to maintain the IP (NEMA4X) rating of the

enclosure, an appropriate sealed conduit connector should be used.

4. Attach the leads of the power line to the AC power connector (see Figure 3-6)

Analog and

Digital I/O

Connector

Relay

Outputs &

Connectors

Ground

AC Line

AC Neutral

AC POWER

Connector

Figure 3-6 Location of Electrical Connectors

12 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 21

TELEDYNE INSTRUMENTS

460L Instruction Manual Getting Started

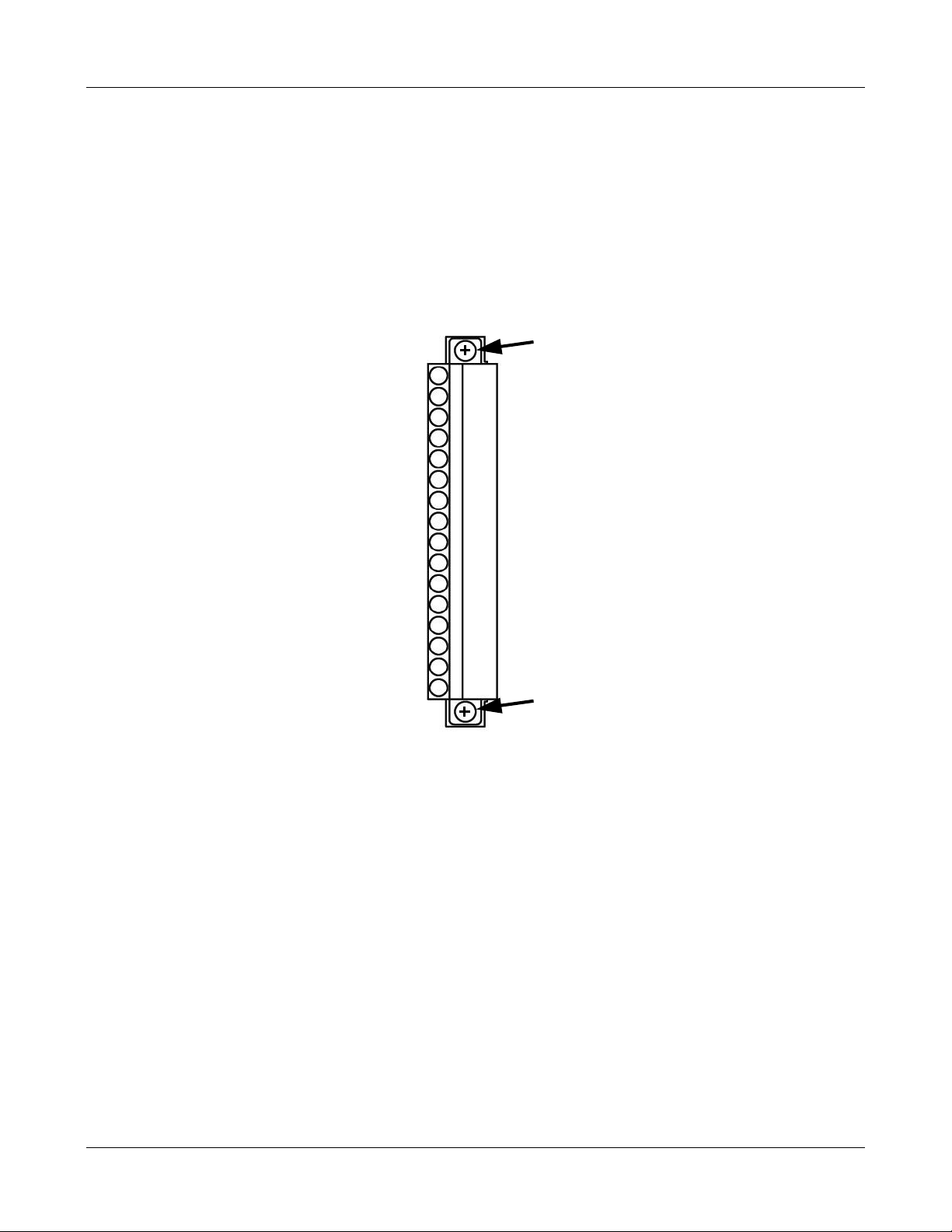

3.5. Signal I/O Connections

All digital and analog signal I/O connections are made via a 16-pin connector on the main board

(See Figure 3-6 for the location of the connector.)

This connector can be unplugged from the header on the main board for easier access when

wiring. To disconnect from main board, loosen the two retaining screws at either end of the

connector.

Retaining Screw

Analog Out +

Analog Out -

Zero Input

Aux Input

Gnd

Status Out 1

Status Out 2

Status Out 3

Status Out 4

Status Com

Serial TX

Serial RX

Serial GND

Status Out 5

Status Out 6

Retaining Screw

Figure 3-7 Signal I/O Connector Pin Assignments

3.5.1. Analog Output

The 460L is equipped with one analog output that is factory configurable as either a 0-5 VDC

signal or a 4-20 mA signal. You may verify how your 460L is set up by checking the information

on the

The analog output requires two connections: ANALOG +, the signal line, and ANALOG–, the

ground connection. See Figure 3-7 for the locations of the ANALOG OUT + and ANALOG OUT–

pins.

monitor’s serial number tag.

05228 Rev B 13

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 22

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

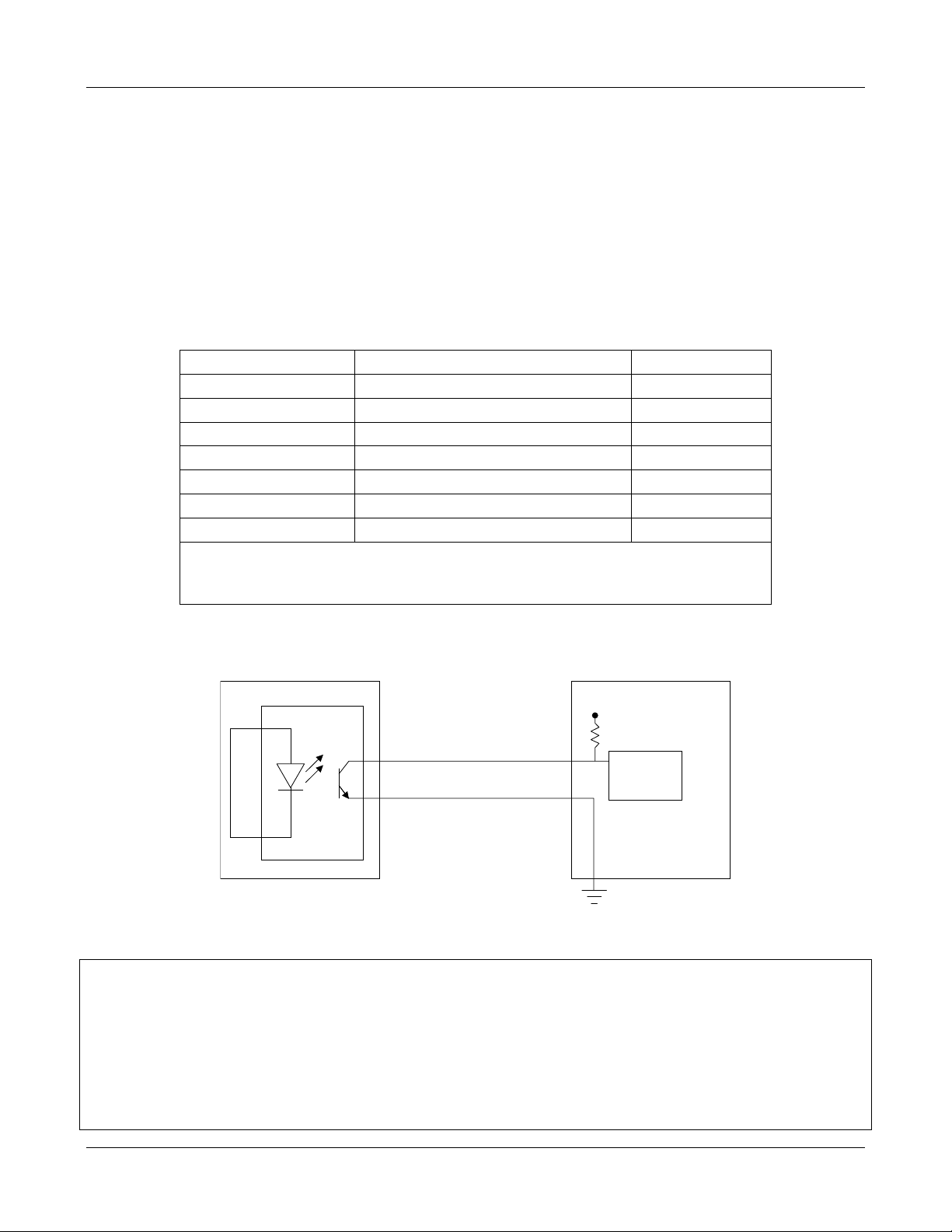

3.5.2. Digital Status Outputs

The 460L has six assigned digital status outputs for indicating error and operational status

conditions of the monitor as well as the status of its O

These outputs are in the form of opto-isolated open-collector transistors. They can be used to

drive status LED’s on a display panel or interface to a digital device such as a Programmable Logic

Controller (PLC). Several of the status outputs are useful tools for diagnosing sensor and system

level malfunctions (see Section 11.2 for more information).

Table 3-2 Digital Status Output Descriptions

concentration alarms (see Table 3-2).

3

LABEL

STATUS OUT 1

STATUS OUT 2

STATUS OUT 3

1

2

2

2

NAME OPERATION

Sensor O.K. Normally On

Invalid Reading Normally Off

Lamp Low Normally Off

STATUS OUT 4 Alarm Active Normally Off

STATUS OUT 5 HI Alarm Status Normally Off

STATUS OUT 6 HI-HI Alarm Status Normally Off

STATUS COM Common Pin for all Status Outputs N/A

1

See Figure 3-7 for pin locations of the these output lines on the monitor’s 16-pin I/O

connector

2

See Section 11-2 for definitions and interpretations of these output.

Figure 3-8 shows the most common way of connecting the digital outputs to an external device

such as PLC.

460M

Status Outputs 1-6 (C ollector)

STATUS COM (Emitter)

PLC OR OTHER DEVICE

+5V

Digital Input

Opto-Isolator

Ground

Connection

Provided by PLC

Figure 3-8 Digital Status Output Connections

Note

Most devices, such as PLC’s, have internal provision for limiting the current that the

input will draw from an external device.

When connecting to a unit that does not have this feature, external dropping-resistors

must be used to limit the current through the transistor output to 50mA or less.

At 50 mA, the transistor will drop approximately 0.2V from its collector to emitter.

14 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 23

TELEDYNE INSTRUMENTS

g

460L Instruction Manual Getting Started

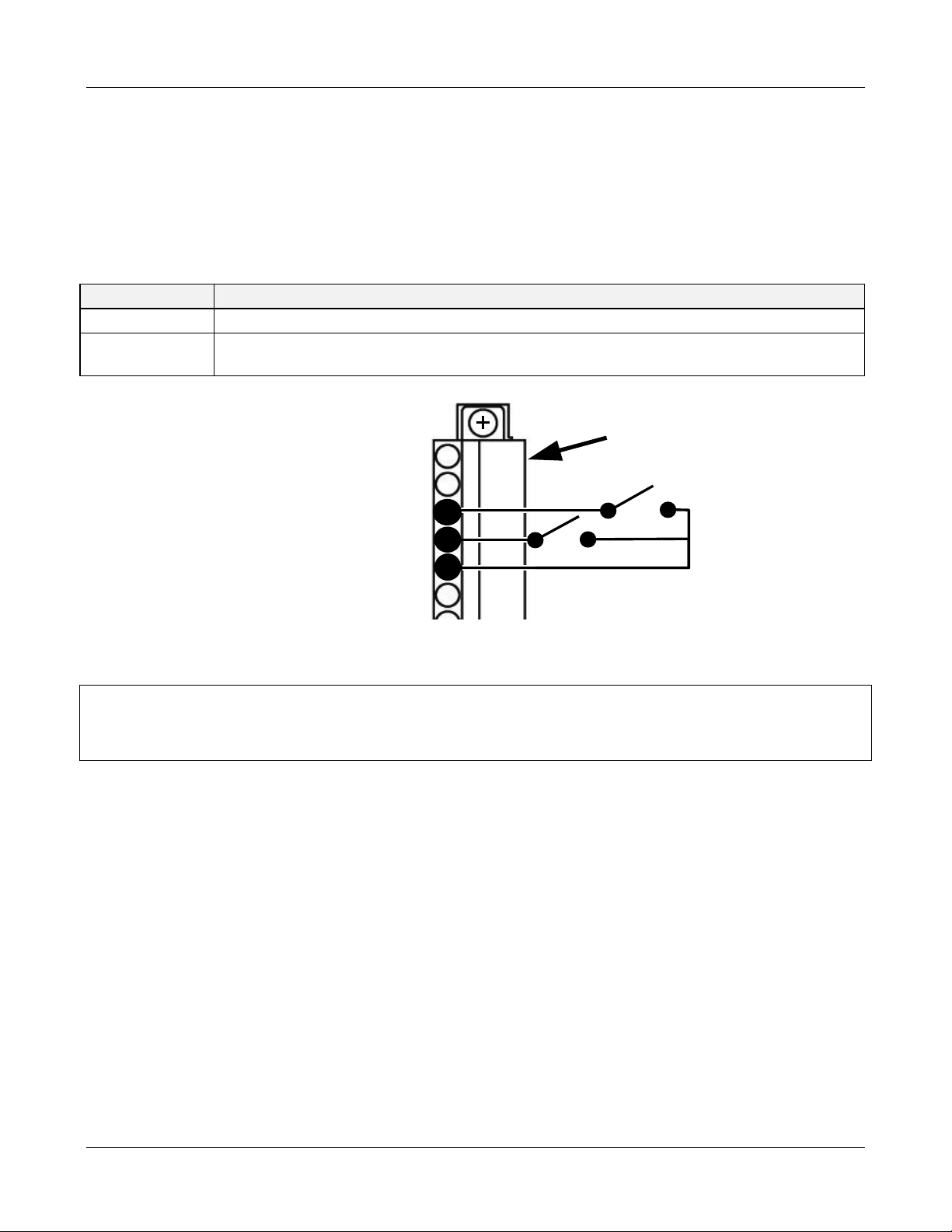

3.5.3. Control Inputs

Two digital control inputs are also available for use on the 460L. The control inputs are used for

remote control of the 460L by a device such as a PLC. They are labeled ZERO INPUT and AUX

INPUT (see Figure 3-9).

Table 3-

INPUT DESCRIPTION

ZERO INPUT This input performs exactly the same function as the ‘Zero’ buttons on the front panel.

AUX INPUT This input can be used to clear active concentration alarms in similar fashion as the serial

communications ALMACK.

3 Contro

l Inputs

Signal I/O

Connector

Analog Out +

Analo

Out -

Zero Input

Aux Input (AlmAck)

Gnd

Figure 3-9 Control Input Connections

NOTE:

Never connect a voltage level output from another device to these contacts.

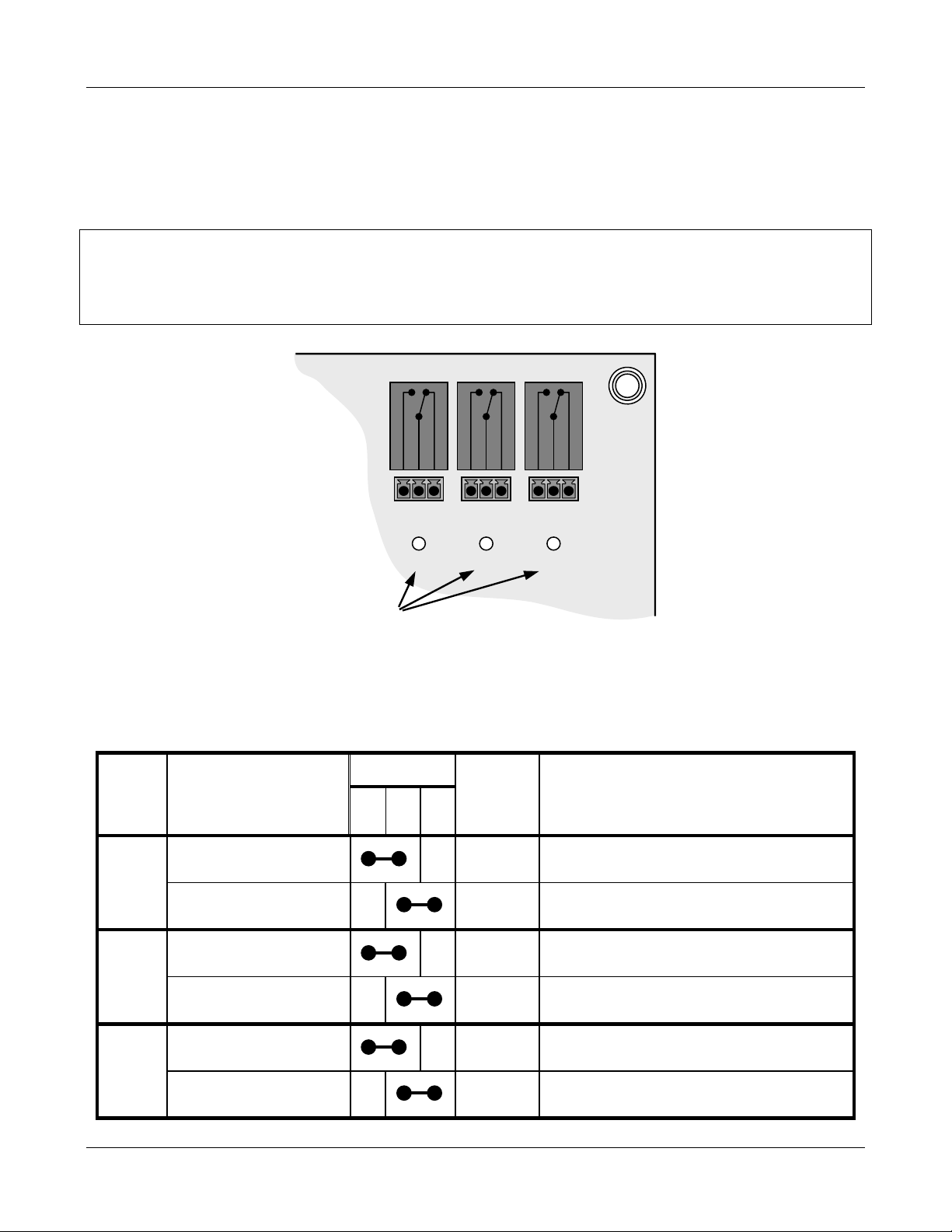

3.5.4. Relay Outputs

The 460L is equipped with three SPDT relays. They are located at the top right hand side of the

main board and are labeled RELAY 1, RELAY 2 & RELAY 3.

RELAY 1 corresponds to the Sensor OK status output and LED;

RELAY 2 corresponds to the HI concentration alarm, and;

RELAY 3 corresponds to the HI-HI concentration alarm

See Section 11.2.1 for more information on the Sensor OK status output.

See Section 6.2 for more information on these alarms.

05228 Rev B 15

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 24

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

Below each relay is a 3-pin connector that allows the relay to be connected for either

normally open or normally closed operation.

Table 3-4 describes how to connect the alarm relays.

NOTE

The relay contacts are rated to 3A at 240VAC. Do not exceed these ratings when

connecting equipment to the instrument.

RELAY FUNCTION

STATUS LEDS

RELAY 1

N.O.

COM

D6

RELAY 2

N.C.

N.O.

D7

RELAY 3

N.C.

COM

N.O.

Figure 3-10 Alarm Output Relays

Table 3-4 Relay Output Operation

RELAY PIN

N.

O.

STATE

C

O

M

2

N.

C.

STATUS

1

LED

N.C.

COM

D8

COMMENTS

SENSOR OK ON

D6 ON 460L is operating normally

1

SENSOR OK OFF

HI Alarm ON

D6 OFF

D7 ON O3 concentration > HI alarm limit

Problem with the O

See Section 11.2.

sensor module.

3

2

HI Alarm OFF

HI-HI Alarm ON

D7 OFF O3 concentration < HI alarm limit

D8 ON O3 concentration > HI-HI alarm limit

3

HI-HI Alarm OFF

16 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

D8 OFF O3 concentration < HI-HI alarm limit

Page 25

TELEDYNE INSTRUMENTS

460L Instruction Manual Getting Started

1

Located just below each relay connector (see Figure 3-10)

2

N.O. = Normally Open operation.

N.C. = Normally Closed operation.

3.6. Initial Startup

Perform the following steps when initially starting up the 460L or when bringing the monitor back

into service it has been shut down for repair or maintenance.

1. Turn on power to the monitor.

The display will briefly display the “API” logo followed by the software version.

The display will then begin showing ozone concentration.

2. Establish a flow of ozone to the monitor.

Flow rate through the monitor should be between 0.5 – 2.0 LPM (Liters per minute.)

Adjust as needed using the needle valve of the flow meter on the front panel

(see Figure 3-1).

3. Let the monitor warm up for a minimum of 5 minutes.

4. Check Status LED’s on front panel;

Sensor OK LED should be ON.

All other LED’s should be OFF.

If the Status LED’s are not in this state, refer to Chapter 11 for troubleshooting

information.

5. Observe the monitor for several more minutes at zero to ensure that it is stable.

THE MONITOR IS NOW READY TO MEASURE OZONE.

3.7. Setting up the Serial Communications Port

The 460L’s bi-directional RS-232/485 Serial Port Interface allows the user to communicate with

the monitor via a computer over that computer’s serial communications port (COM port). A

terminal emulation program such as HyperTerminal is required to be installed and running on the

host computer.

The following three pins are provided on the I/O connector for serial communications (see Figure

3-12).

Table 3-

LABEL DESCRIPTION

SERIAL TX Serial Transmit (RS-485 – A)

SERIAL RX Serial Receive (RS-485 – B)

SERIAL GND Serial Ground (RS-232 Only)

5 Serial I/O Port C

onnection

05228 Rev B 17

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 26

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

While the standard factory configuration is for RS-232, the monitor’s serial port can be configured

for either RS-232 or RS-485 (see Section 3.7.1 for the procedure).

Use RS-232 for direct connection to a nearby (no more than 6-8 feet cable length) PC or

Laptop, RS-232 should be used.

Use RS-485 for permanent connection to continuously operating data acquisition systems

or connections over greater distances.

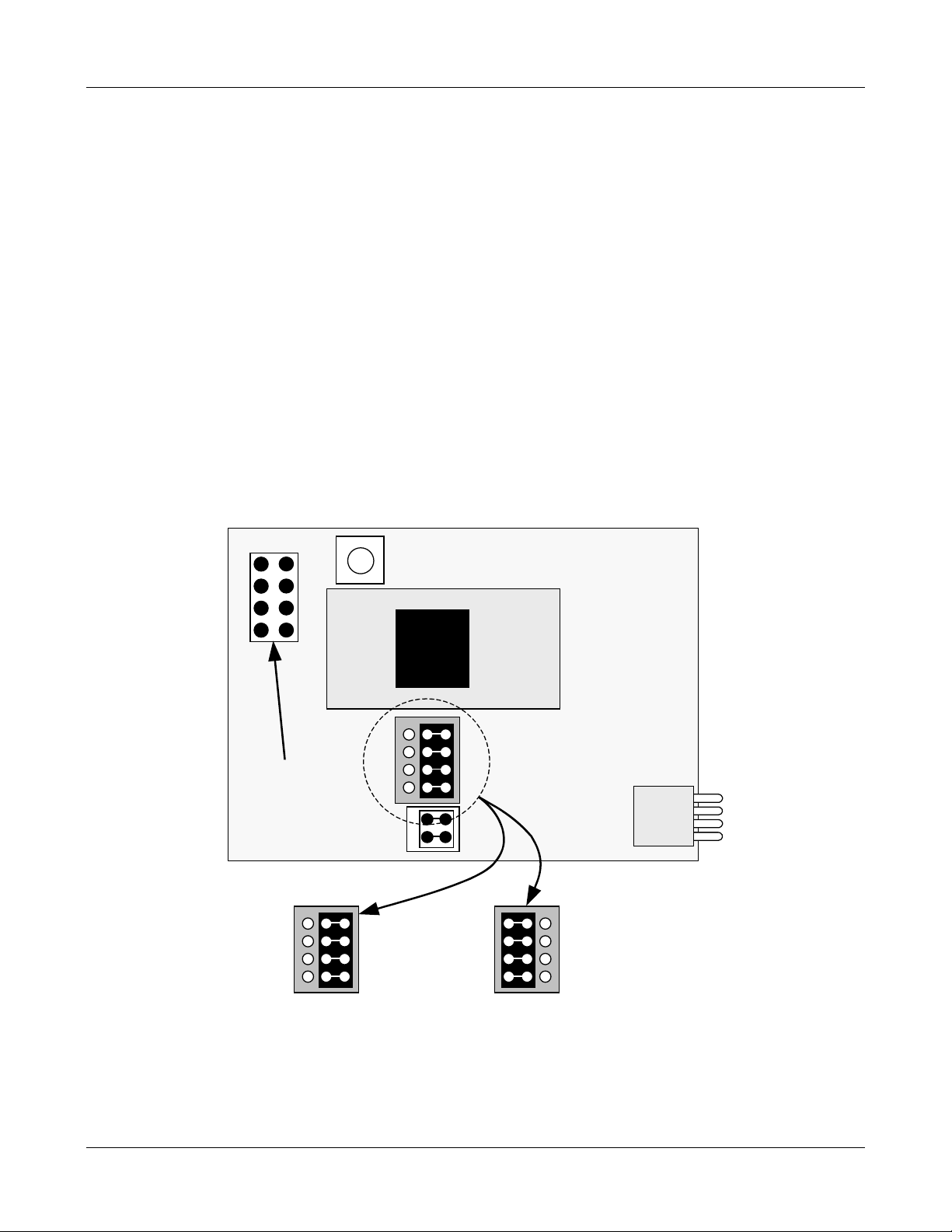

3.7.1. Physical Serial Port Configuration

6. To configure the com port for RS-232 or RS-485, move the 4 shunts on JP3 of the CPU PCA

(P/N #03492) to the proper position as shown in below.

The jumpers may already be in this position but this still needs to be verified.

Also make sure that JP1 is jumpered. It may be hanging off of one pin, make sure it is

jumpered together as in Figure 3-11.

JP2 can either be jumpered or not as it is already shorted on the board.

Reset Button

Micro-Controller

Connector for

Optional 4-20 mA

output

JP2

JP1

JP3

JP3 set for RS-232 JP3 set for RS-485

Figure 3-11 RS-232/RS-485 Jumper Location and Settings

18 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 27

TELEDYNE INSTRUMENTS

A

460L Instruction Manual Getting Started

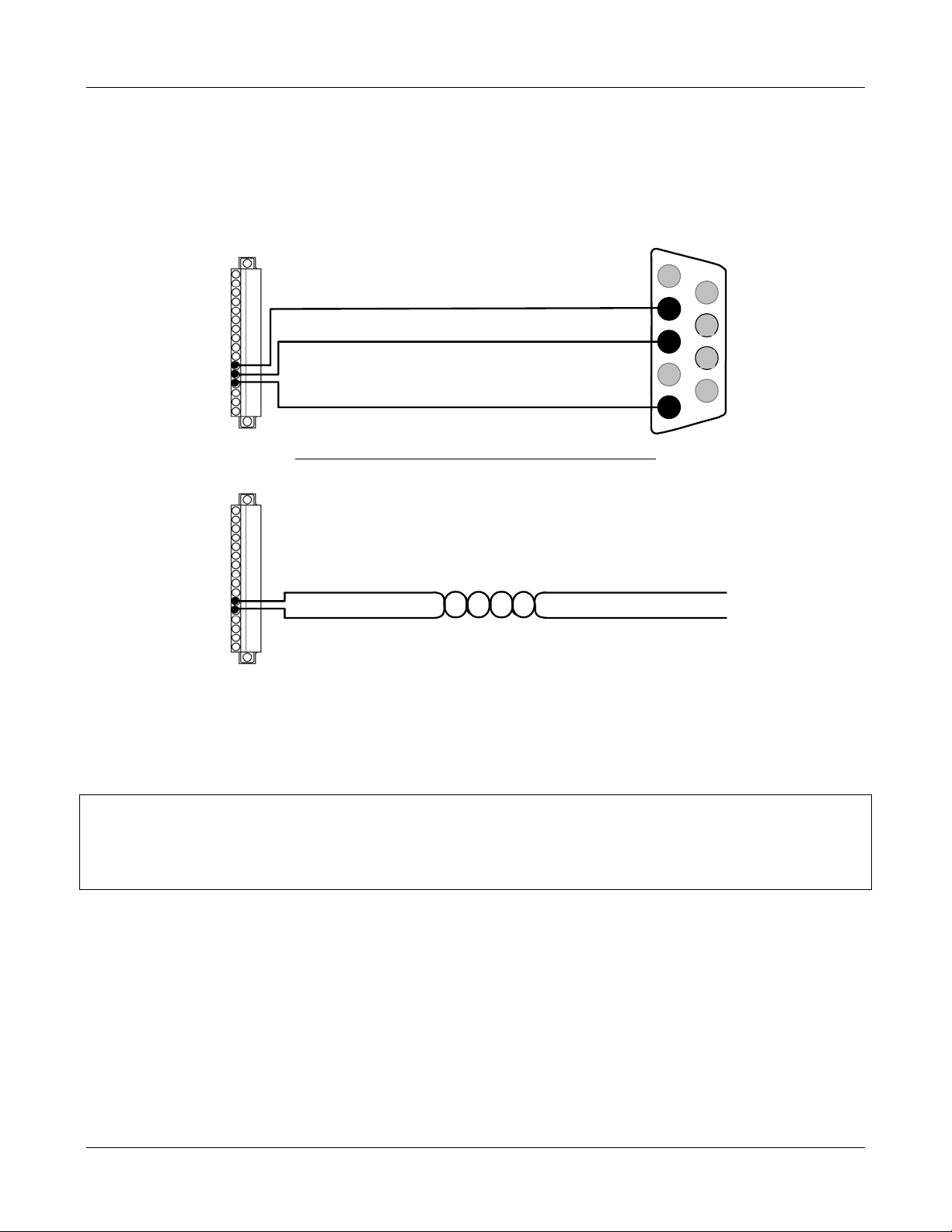

7. Connect the appropriate type of cable to the 16 pin Signal I/O connector inside the

analyzer.

8. A cable may be included with you instrument. If not, Figure 3-12 below illustrates how to

construct wiring for both RS-232 and RS-485

RS-232

Serial TXD

Serial RXD

Serial GND

connections.

DB9 Female

1

6

2

7

3

8

4

9

5

RS-485

Serial TXD

Serial RXD

Twisted Pair

RS-485-

RS-485-B

Figure 3-12 Typical RS-232 and RS-485 Connections

3.7.2. Software Setup for Serial Port Communications

NOTE

This section refers to various serial communication commands for the M460M. For

detailed information regarding these commands see Chapter 7.

1. Connect the other end of the cable to your serial Com port on your computer

2. Open up Hyper-terminal or another terminal program and set up a connection with the

settings below. Your com port is most likely COM1.

05228 Rev B 19

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 28

TELEDYNE INSTRUMENTS

Getting Started 460L Instruction Manual

The Serial Port of the device being used to communicate with the 460L should be

configured as follows:

Table 3-6 Serial Port Configuration

PARAMETER VALUE

Baud Rate 9600 bps

Data Bits 8

Stop Bits 1

Parity None

3. Find the address of the 460L.

This can be accomplished by repeating the O3 command (see Section 7.3.5) for each

possible ad

EXAMPLE: 0O3<CR>

dress (0-9) until the M4

1O3<CR>

2O3<CR>

…

9O3<<CR>

60M responds:

When the instrument responds record the first number in the response line

This is the address of the analyzer.

4. To determine if the M460L is operating correctly type:

1TLIST<CR>

This analyzer will respond with a list of the current values of its test functions. See Section

7.3.8 for a list of the nominal values for these functions

5. C

heck the analyzer’s operation variables (VARS). These describe certain application

ic conditions such as units of measure, measurement ranges, etc.

specif

To check the current state of the VARS, type:

1VLIST<CR>

This analyzer will respond with a list of the current values of its VARS. See Section 7.3.10

for a l

ist of the nomi

6. If you need to change one of the VARS settings, see the VSET command (see Table 7-3 of

Section 7.3.11)

7. After viewing the data

After changing the value of any of the VARS return the analyzer to normal operation.

The simplest way to do this is to turn the analyzer off and back on. User Notes:

nal values for these functions

you can return the analyzer to normal operation.

USER NOTES:

20 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 29

TELEDYNE INSTRUMENTS

460L Instruction Manual Frequently Asked Questions

4. FREQUENTLY ASKED QUESTIONS

Q: What do I do if I smell Ozone and suspect a leak?

A: Ensure that all the fittings are tight. If the fittings are tight and ozone is still detected send

the monitor back for repair to Teledyne Instruments’ customer service for repair.

Q: What do I do if my CPU status light stops flashing?

A: The CPU has stopped working. This is a major malfunction of the monitor. Return it to

Teledyne Instruments’ customer service for repair.

Q: What do I do if the Status OK light turns off or doesn't turn on after 30 min.?

A: If the status ok light is off and the Lamp low light is on then the monitor’s UV lamp needs to

be adjusted.

If the status ok light is off and the Lamp Low light is off then most likely the UV lamp output

has drifted to >5000mv and needs to be adjusted.

Q: What does it mean if the Invalid Reading light turns on?

A: This will happen if the:

Ozone supply pressure exceeds 14.9 psia.

Ozone concentration exceeds the Range of the monitor then this light will turn on.

Ozone concentration goes excessively negative.

Q: What do I do if my Lamp Low light turns on?

A: If the Lamp Low light turns on and the Status OK light is ON, the UV reference value has

dropped to < 1000mv. The monitor will continue to run with no problems until the UV

reference drops below 500mv.

If the Lamp low light turns on and the Status OK light is OFF, the UV reference has dropped

below acceptable limits and will have to be adjusted.

Q: When should I change the Particulate Filter and how do I change it?

A: The Particulate filter should be changed monthly. See Section 9.1 for instructions on

performing this replacement.

05228 Rev B 21

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 30

TELEDYNE INSTRUMENTS

Frequently Asked Questions 460L Instruction Manual

USER NOTES:

22 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 31

TELEDYNE INSTRUMENTS

460L Instruction Manual Optional Hardware and Software

5. OPTIONAL HARDWARE AND SOFTWARE

This section includes descriptions of the hardware and software options available for the 460L

monitor. For assistance with ordering these options please contact the sales department of

Teledyne Instruments at:

TOLL-FREE: 800-324-5190

TEL: +1 858-657-9800

FAX: +1 858-657-9816

E-MAIL: apisales@teledyne.com

WEB SITE: http://www.teledyne-api.com/

5.1. Sample Conditioning System

This option is required for 460L’s that will be used in applications where the sample gas includes

liquid or vaporous water. This option includes two major components:

A coalescing water drop-out filter, and;

A permeation tube dryer.

5.2. Current Loop Analog Output

This option adds isolated, voltage-to-current conversion circuitry to the monitor’s CPU card. This

option be installed at the factory or added later. Call Teledyne Instruments sales for pricing and

availability.

The standard configuration of the current loop option is 4 – 20 mA. 0-20 mA is also available.

5.3. Ozone Destruct Option

An externally mounted scrubber (see Figure 3-5) is available for the 460L monitor for use when

measuring O

components of the monitor downstream of the sensor module such as the flow meter and the

pump. High levels of O

levels that are ≥100 ppb. Ozone levels this high will damage several of the

3

are hazardous and should be removed from the gas stream exhaust.

3

CAUTION

05228 Rev B 23

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Make sure that the exhaust line is vented to an outside area.

Page 32

TELEDYNE INSTRUMENTS

Optional Hardware and Software 460L Instruction Manual

USER NOTES:

24 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 33

TELEDYNE INSTRUMENTS

460L Instruction Manual Operating Instructions

6. OPERATING INSTRUCTIONS

The 460L has been designed for simple and trouble-free operation. The sections below detail the

operational features of the 460L.

6.1. Front Panel Display

6.1.1. O

The current ozone concentration is displayed in the 4-digit readout in the center of the display.

The concentration is displayed in the currently selected units either: wt%, g/Nm3 or ppm, ppb.

readout

3

6.1.2. Zero Point Calibration

The 460L needs little or no calibration in the field; however sometimes minor measurement

offsets can occur. To compensate for this a zero point calibration can be initiated by using the

two ZERO buttons. See Section 8.1 for more information.

6.1.3. Status LED’s

The four status LED’s to the right of the display indicate the general status of the 460L Monitor.

During normal operation, after the monitor has warmed up, the green ‘Sensor OK’ LED should be

on and all other Status LED’s should be off. For information on troubleshooting using the Status

LED’s, see Sections 11.2.4.

Table 6-1 Status LED’s

NAME ON STATE OFF STATE

OFF when

SENSOR O.K. Normal State is STEADY GLOW

Reference or Measure > 4995mV;

Reference < 1000mV

STEADY GLOW if:

INVALID

READING

LAMP LOW

ALARM

ACTIVE

Definitions for these four LED’s correspond to the definitions of the monitor’s four digital status

outputs with identical names. See Sections 11.2 and 11.3 for more detailed information.

05228 Rev B 25

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Ozone Pressure > 14.9 psia,

Negative Ozone Concentration,

Concentration Over-Range

STEADY GLOW if Reference

Detector<2500mV

BLINKS whenever the measured O3

concentration exceeds either the alarm

limits.

Normal State

Normal State

Normal State

Page 34

TELEDYNE INSTRUMENTS

Operating Instructions 460L Instruction Manual

6.2. Concentration Alarms

There are two O3 concentration alarms, HI and HI-HI. Both alarms are triggered when the

measured O

HI alarm must always be a lower value than that of the HI-HI alarm. If the O

between the HI limit and the HI-HI limit, the HI alarm will be active, but the HI-HI alarm will be

inactive.

When either the HI or the HI-HI alarms are active the ALARM ACTIVE status LED on the front

panel (see Figure 3-1) will blink. In addition when the HI alarm is active alarm trigger LED D7 (on

the main PCA, see Figure 3-12) will glow and when the HI-HI alarm is active alarm trigger LED

D8 will glow.

6.2.1.1. Concentration Alarm Configuration

Either of the concentration alarms can be independently configured via the 460L’s serial

communication port (see Section 7.3.11).

The user can set the alarms to operate in either the latching or non-latching as well as

independently adjust the trigger levels of the alarm limits.

concentration equals or rises above the set limit for that alarm. The set limit for

3

concentration is

3

In non-latching mode, the alarms will be triggered when O

associated limit is reached and will automatically return to an inactive state if the O

concentration equals or exceeds the

3

concentration

3

falls below the limit level. In latching mode once an alarm is triggered it will stay active until

cleared by the user regardless of how the O

concentration measurement changes.

3

6.2.1.2. Remotely Sensing the Status of the Alarm

Besides the LEDs located on the front panel and on the monitor’s main PCA, the status of each

alarm can be sensed externally via a single-pull, double-throw relay (see Section 3.5.4) or

determined from a remote locati

on via the monitor’s serial communication port (See Chapter 7).

6.2.1.3. Clearing Alarms

When set for non-latching mode the alarms will only clear when the alarm condition disappears

and will do so automatically. When in latching mode, the concentration alarms may be cleared in

several ways:

FRONT PANEL: Pressing the ALARM ACKNOWLEDGE key on the monitor’s front panel

will clear all active alarms.

SERIAL COMMUNICATION PORT: The ALMACK command to clear all active alarms (see

Section 7.3.1)

Table 6-2 Concentration Alarm Default Settings

ALARM CONDITION MODE TRIGGER LIMIT

HI 100 ppb

HI-HI

Enabled Latching

300 ppb

26 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 35

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7. SERIAL COMMUNICATIONS

The 460L comes equipped with a powerful digital Serial Communications Port that can be used for

Data Acquisition and for changing the monitor’s configuration. This port can be configured for

either RS-232 or RS-485 (half-duplex) operation. See Section 3.7.1 for details on configuring the

and connect

port

7.1. Serial Port Command Syntax

All characters sent and received are standard ASCII characters and all numbers are decimal

numbers converted to ASCII text.

All commands are sent using the following syntax:

<address><command>:<data1>,<data2>#<checksum (optional)><CR>

Where:

ing it to a computer or data acquisition system.

address is the monitor address (default =1)

command is the command string being sent

: (colon) is the data separator and is only included if data is being sent as part of the

command (See Command Details below to see if a command requires data or

not)

data1 is the first data parameter, if required.

data2 is the second data parameter, if required.

# is the Checksum separator, sent only if optional checksum is included

The checksum is an ASCII checksum of all characters up to the # character.

The checksum is optional. Commands sent without the checksum (and

checksum separator,) are also valid.

CR is a carriage return, ASCII 13.

Examples

Valid Commands with no data:

Checksum Included: 1ALMACK#474<CR>

No Checksum: 1ALMACK<CR>

Valid Commands with data:

Checksum Included: 1VSET:1,20#620<CR>

No Checksum: 1VSET:1,20<CR>

05228 Rev B 27

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 36

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.2. Serial Port Command Summary

Table 7-1 below lists the commands available and a summary of their function.

Table 7-1 Serial Port Command Summary

COMMAND DESCRIPTION

ALMACK Acknowledges and clears any active concentration

alarms

ALMSTAT Returns the current state of the concentration

alarms

CZERO Perform a manual zero calibration. The CZERO

does not

therefore the calibration is calculated based on the

current ozone content of the measurement cell.

DACSTEP Analog Output Test Mode, Step Function

O3 Returns O3 concentration currently being

measured

activate the zero-gas solenoid valve,

SETADDR Sets communication address for this 460L to a

specific value

TDUMP Returns the current values of a set of

measurement parameters as a single data string

TLIST Returns list of measurement parameters and their

current values as a formatted list.

VGET Returns the current value of a single VAR

VLIST Lists all VARS and their current values

VSET Sets value of internal VAR

28 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 37

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3. Serial Port Command Reference

7.3.1. ALMACK

SYNTAX

<address>ALMACK<CR>

DESCRIPTION

Acknowledges any active concentration alarm and clears them if possible For more information

see Section 6.2.

DATA PARAMETERS SENT

None

RESPONSE

<address>:<success_flag>#<checksum><CR>

EXAMPLE

Command:

1ALMACK<CR>

Response:

1:OK#261<CR> - Command successfully received. All alarms capable of being cleared

have been.

NOTE

The alarm(s) will only clear if the condition causing the alarm no longer exists,

EXAMPLE

If the current O

both alarms will activate. If the O

is still above the HI limit, the ALMACK command will only clear the HI-HI alarm.

concentration rises above the trigger levels for both the HI and HI-HI alarms,

3

level falls below the HI-HI alarm limit, but is still above the

3

05228 Rev B 29

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 38

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.3.2. ALMSTAT

SYNTAX

<address>ALSTAT<CR>

DESCRIPTION

Returns the current status of both of the concentration alarms.

0= Inactive

1= Active

DATA PARAMETERS SENT

None

RESPONSE

<address>:<HI alarm state>,<HI-HI alarm state>#<checksum><CR>

EXAMPLE

Command:

1ALMSTAT<CR>

Response:

1:0,0#247<CR> - Both concentration alarms are INACTIVE

1:1,0#248<CR> - The HI alarm is ACTIVE and the HI-HI alarm is INACTIVE

1:1,1#249<CR> - Both concentration alarms are ACTIVE

30 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 39

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3.3. CZERO

SYNTAX

<address>CZERO<CR>

DESCRIPTION

Performs a zero calibration using gas sourced from the ozone gas inlet.

DATA PARAMETERS SENT

None

RESPONSE

<address>:<success_flag>#<checksum><CR>

EXAMPLE

Command:

1CZERO<CR>

Response:

1:OK#261<CR> - Calibration Successful

1:FAIL#391<CR> - Calibration Failed

NOTE

Once the CZERO function is activated the monitor will briefly display dashes

(‘----‘) after which

the concentration should quickly go to zero.

The CZERO does not activate the zero-gas solenoid valve, therefore the gas flowing through the

monitor is sourced from the ozone inlet and the zero calibration is calculated based on the current

ozone content of that gas source.

Care must be taken to ensure that all ozone is purged from the monitor before activating the

CZERO function. Before activating the CZERO function, disconnect the O

monitor and allow room air to flow through the

monitor for several minutes.

supply line from the

3

Use a shutoff valve to make sure that the O

source does not continue to feed O3 into the supply

3

line while it is disconnected

05228 Rev B 31

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 40

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.3.4. DACSTEP

SYNTAX

<address>DACSTEP<CR>

DESCRIPTION

Puts the monitor into Analog Output setup mode. The Analog Output steps from zero to full-scale

in 25% increments, pausing for 10 seconds at each level. This repeats 5 times, after which the

monitor returns to normal operation. This mode is useful for testing the Analog Output and the

operation of any equipment measuring the Analog Output.

DATA PARAMETERS SENT

None

RESPONSE

<address>:<success_flag>#<checksum><CR>

EXAMPLE

Command:

1DACSTEP<CR>

Response:

1:OK#261<CR> - DACSTEP command acknowledged and initiated

NOTES

The DACSTEP function takes some time to complete.

When the command is sent to the monitor, it will immediately respond with the <address> and

colon ‘:’ as an acknowledgement that the message was received. After the function is complete

the rest of the response will be sent.

No additional commands should be issued to the monitor until the function completes.

32 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 41

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3.5. O

SYNTAX

<address>O3<CR>

DESCRIPTION

Returns the current ozone concentration measured by the monitor.

DATA PARAMETERS SENT

None

RESPONSE

<address>:<o3_conc>#<checksum><CR>

EXAMPLE

Command:

1O3<CR>

3

Response:

1:250.1898#522<CR> - Current O3 Concentration (reading 250.2 ppb)

NOTES

While the concentration value returned shows more digits after the decimal than the front panel

(in the example above, 250.1898) display it is only valid to 4 significant digits (in the example

above, 250.2).

The returned value will be in whichever units of measure for which the monitor is set.

05228 Rev B 33

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 42

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.3.6. SETADDR

SYNTAX

<address>SETADDR:<new_address><CR>

DESCRIPTION

Changes the communications address to a new value.

DATA PARAMETERS SENT

new_address is the new address for the monitor; Range for new_address is 1-9.

RESPONSE

<address>:<success_flag>#<checksum><CR>

EXAMPLE

Command:

1SETADDR:2<CR> - Change address from 1 to 2

Response:

1:OK#261<CR> - Change Address Successful

1:FAIL#391<CR> - Change Address Failed

NOTES

The monitor response is from the previous address (1 in the example shown above), but any

further commands must be at new address (2 in the example shown above).

If the address change was successful, after sending back the OK response, the monitor will no

longer respond to commands with address 1.

34 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 43

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3.7. TDUMP

SYNTAX

<address>TDUMP<CR>

DESCRIPTION

This command is best used if the response is intended as input for a database program or data

acquisition system

It returns a string made up of the current values of the following parameters in the following

order: O3 Concentration, Cell Pressure (psia), Cell Temperature (K,) Lamp Temperature (K,)

Measure Detector (mV,) Calibrated Reference Detector (mV,) Reference Detector (mV).

DATA PARAMETERS SENT

None

RESPONSE

<address>:<o3_conc>,<pressure>,<cell_temp>,<lamp_temp>,<measure>,<cal_ref>,<referenc

e>,<al-hi-stat>,<al-hi-hi-stat>#<checksum><CR>

EXAMPLE

Command:

1TDUMP<CR>

Response:

1:0.0282144,14.77461,300.7179,324.7713,2881.437,2940.903,4412.52,1,0#3413

<CR>

NOTES

While the concentration value returned shows more digits after the decimal than the front panel

display (in the example above, 0.0282144), it is only valid to 4 significant digits (in the example

above, 0.028).

05228 Rev B 35

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 44

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.3.8. TLIST

SYNTAX

<address>TLIST<CR>

DESCRIPTION

Returns a formatted, easy to read list of the parameters by name with the current values for

each.

DATA PARAMETERS SENT

None

RESPONSE

Test Parameter List (See Below)

EXAMPLE

Command:

1TLIST<CR>

Response:

O3 = 0.0226168

Press = 14.7753

Cell Temp = 300.7116

Lamp Temp = 324.7965

Ref = 2881.52

Meas = 2941.092

Raw Ref = 4412.646

HI Alarm = ON

HI-HI Alarm = OFF

NOTES

The set of parameters is not the same as those returned by the TDUMP command.

While the concentration value returned shows more digits after the decimal than the front panel

display (in the example above, 0.0226168), it is only valid to 4 significant digits (in the example

above, 0.022).

No checksum is sent in the response to the TLIST command.

36 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 45

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3.9. VGET

SYNTAX

<address>VGET:<var_index><CR>

DESCRIPTION

Returns value of an internal configuration variable (VAR.)

DATA PARAMETERS SENT

var_index is index number for internal VAR as follows:

Table 7-2 VAR_INDEX List for VGET Command

var_index Name Description

0

1

2

3

4

5

6

7

8

NOTE: Only one yar_index is allowed per iteration of the VGET command

RESPONSE

ANALOG_RANGE Full-Scale concentration range for Analog Output scaling

ALARM_ENABLE

ALARM_MODE

CARRIER_WEIGHT

COMM_MODE Not Used

IIR_FILT

CONC_UNITS

HI_ALARM_LEVEL Sets the trigger limit of the HI alarm

HI-HI_ALARM_LEVEL Sets the trigger limit of the HI-HI alarm

0 = disabled

1 = enabled

0 = latching

1 =non-latching

Molecular weight of carrier gas(e.g. 32.0 = O2). Only used by

460L’s with ppmw capability

The sensitivity of the software filter used by the monitor to reduce

noise and hysteresis in the reported O

2 =ppb

3 = ppm

concentration reading.

3

<address>:<var_value>#<checksum><CR>

EXAMPLE

Command:

1VGET:8<CR> - Request limit value for HI concentration Alarm

Response:

1:300.0#348<CR> - HI alarm limit is 300.0 ppb

NOTE

Response is in units of measure for which the monitor is set.

05228 Rev B 37

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 46

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

7.3.10. VLIST

SYNTAX

<address>VLIST<CR>

DESCRIPTION

Returns a formatted, easy to read list of an internal configuration variables (VAR’s) and their

current values.

DATA PARAMETERS SENT

None

RESPONSE

VAR List (See Below)

EXAMPLE

Command:

1VLIST<CR>

Response:

#0 analog_range = 1000.0

#1 alarm_enable = 1.0

#2 alarm_mode = 0.0

#3 carrier_weight =32.0

#4 comm_mode = 0.0

#5 iir_filt = 0.25

#6 conc_units = 2.0

#7 hi_al_level = 100.0

#8 hihi_al_level = 300.0

NOTES

No checksum is sent in the response to the VLIST command.

The 460L does not use the comm_mode VAR, so its value will always be 0.

hi_al_level and hihi_al_level are returned in the units of measure for which the monitor is set.

38 05228 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5164

Page 47

TELEDYNE INSTRUMENTS

460L Instruction Manual Serial Communications

7.3.11. VSET

SYNTAX

<address>VSET:<var_index>,<new_value><CR>

DESCRIPTION

Sets value of an internal configuration variable (VAR.)

DATA PARAMETERS SENT

var_index index number for internal VAR (See VGET for index list)

new_value new value for VAR.

RESPONSE

<address>:<var_value>#<checksum><CR>

Table 7-3 VAR_INDEX List for VSET Command

var_index Name Description Allowable Range

0

1

2

3

4

5

6

7

8

NOTE: Only one yar_index is allowed per iteration of the VSET command

ANALOG_RANGE

ALARM_ENABLE Enables or disables the Concentration alarms

ALARM_MODE

CARRIER_WEIGHT

COMM_MODE Not Used N/A

IIR_FILT

CONC_UNITS O3 concentration measurement units

HI_AL_LEVEL Sets the trigger limit of the HI alarm

HIHI_AL_LEVEL Sets the trigger limit of the HI-HI alarm

Sets the full-scale concentration range for

Analog Output scaling

Selects latching mode or non-latching mode for

both alarms.

Sets the molecular weight of carrier gas for

wt% calculations (e.g. 32.0 = O2)

Sets the sensitivity of the software filter used

by the monitor to reduce noise and hysteresis

in the reported O

concentration reading.

3

EXAMPLE1

Command:

1VSET:8,275.0<CR> - Set HI-HI concentration alarm to 275.0 ppb

Response:

1:OK#261<CR> - VSET Successful

1:FAIL#391<CR> - VSET Failed

1 ppb – 1000 ppb

0.001 ppm – 1.000 ppm

0 = disabled

1 = enabled

0 = latching

1 =non-latching

27.0 – 32.0

0.05 – 1.0

2 =ppb

3 = ppm

10 ppb < x < 1000 ppb

0.010 ppm < x < 1.000 ppm

10 ppb < x < 1000 ppb

0.010 ppm < x < 1.000 ppm

05228 Rev B 39

DCN 5164 PRINTED DOCUMENTS ARE UNCONTROLLED

Page 48

TELEDYNE INSTRUMENTS

Serial Communications 460L Instruction Manual

EXAMPLE2

Command:

1VSET:6,1<CR> - Set CONC_UNITS VAR to ppm

Response:

1:OK#261<CR> - VSET Successful

1:FAIL#391<CR> - VSET Failed

NOTES