Page 1

INSTRUCTION MANUAL

MODEL 460H NEMA

OZONE MONITOR

© Teledyne Instruments

Advanced Pollution Instrumentation Division

(T-API)

6565 Nancy Ridge Drive

San Diego, CA 92121-2251

TOLL-FREE: 800-324-5190

TEL: 858-657-9800

FAX: 858-657-9816

EMAIL:

WEB SITE: www.teledyne-api.com

api-sales@teledyne.com

03662

Rev. D

1/8/04

Page 2

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many

important safety messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each

safety message is associated with a safety alert symbol. These symbols are found in the

manual and inside the instrument. The definition of these symbols is described below:

General Warning/Caution: Refer to the instructions for details on the specific

danger.

Caution: Hot Surface

Caution:

Technician Symbol

performed by qualified maintenance personnel only.

was intended, unpredictable behavior could ensue with possibly

Electrical Shock Hazard

: All operations marked with this symbol are to be

CAUTION

The monitor should only be used for the purpose and in the

manner described in this manual.

If you use the monitor in a manner other than that for which it

hazardous consequences.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page ii

Page 3

TABLE OF CONTENTS

SAFETY MESSAGES....................................................................................................................................II

TABLE

FIGURES........................................................................................................................................................

TABLES........................................................................................................................................................

I. 0 INTRODUCTION..................................................................................................................................7

1.

1.2

1.3

1.4

2.0 INSTALLATION.................................................................................................................................11

2.1

2.2

2.3

2.4 E

3.0 STARTUP..............................................................................................................................................18

4.0 OPERATION.........................................................................................................................................19

OF CONTENTS ...............................................................................................................................III

1 PREFACE....................................................................................................................................................7

WARRANTY POLICY............................................................................................................................8

PRINCIPLE OF OPERATION .........................................................................................................................9

SPECIFICATIONS ......................................................................................................................................10

MECHANICAL INSTALLATION...................................................................................................................11

PNEUMATIC CONNECTIONS ......................................................................................................................12

AC POWER CONNECTION .........................................................................................................................13

LECTRICAL I/O CONNECTIONS.......................................................................................................14

2.4.1 Analog Output.......................................................................................................................14

2.4.2 Digital Status Outputs ...........................................................................................................15

2.4.3 Control Inputs .......................................................................................................................16

2.4.4 RS232/RS485 Serial Communications Port ..........................................................................17

V

VI

FRONT PANEL DISPLAY............................................................................................................................19

4.1

4.1.1 O3 readout.......................................................................................................................................19

4.1.2 Pressure Display .............................................................................................................................19

4.1.3 Zero Calibration..............................................................................................................................19

4.1.4 Status LED’s....................................................................................................................................19

AUTO-ZERO OPERATION (OPTIONAL)......................................................................................................20

4.2

4.2.1 Auto-Zero Installation.....................................................................................................................20

4.2.2 Auto-Zero Function.........................................................................................................................20

4.2.3 Auto Zero Error...............................................................................................................................20

5.0 SERIAL COMMUNICATIONS..........................................................................................................21

SERIAL PORT CONFIGURATION.................................................................................................................21

5.1

COMMAND SYNTAX .................................................................................................................................21

5.2

COMMAND SUMMARY..............................................................................................................................22

5.3

COMMAND REFERENCE............................................................................................................................23

5.4

5.4.1 CAUTO............................................................................................................................................23

5.4.2 CZERO ............................................................................................................................................24

5.4.3 DACSTEP........................................................................................................................................25

5.4.4 O3....................................................................................................................................................26

5.4.5 SETADDR........................................................................................................................................27

5.4.6 TDUMP...........................................................................................................................................28

5.4.7 TLIST...............................................................................................................................................29

5.4.8 VGET...............................................................................................................................................30

5.4.9 VLIST...............................................................................................................................................31

5.4.10 VSET..............................................................................................................................................32

6.0 MAINTENANCE..................................................................................................................................33

REPLACING THE GAS FILTER ELEMENT (OPTIONAL)..................................................................................33

6.1

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page iii

Page 4

6.2

CLEANING EXTERIOR SURFACES OF THE M460H .....................................................................................33

DEGREE OF PROTECTION ..........................................................................................................................33

6.3

7.0 SENSOR AND SYSTEM TROUBLESHOOTING............................................................................34

7.1

STATUS OUTPUT SUMMARY .....................................................................................................................34

SENSOR OK..............................................................................................................................................34

7.2

INVALID READING ....................................................................................................................................35

7.3

LAMP LOW ...............................................................................................................................................35

7.4

CELL DIRTY..............................................................................................................................................35

7.5

STATUS OUTPUT SUMMARY TABLE..........................................................................................................36

7.6

APPENDIX A – SERIAL PORT CONFIGURATION............................................................................37

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page iv

Page 5

FIGURES

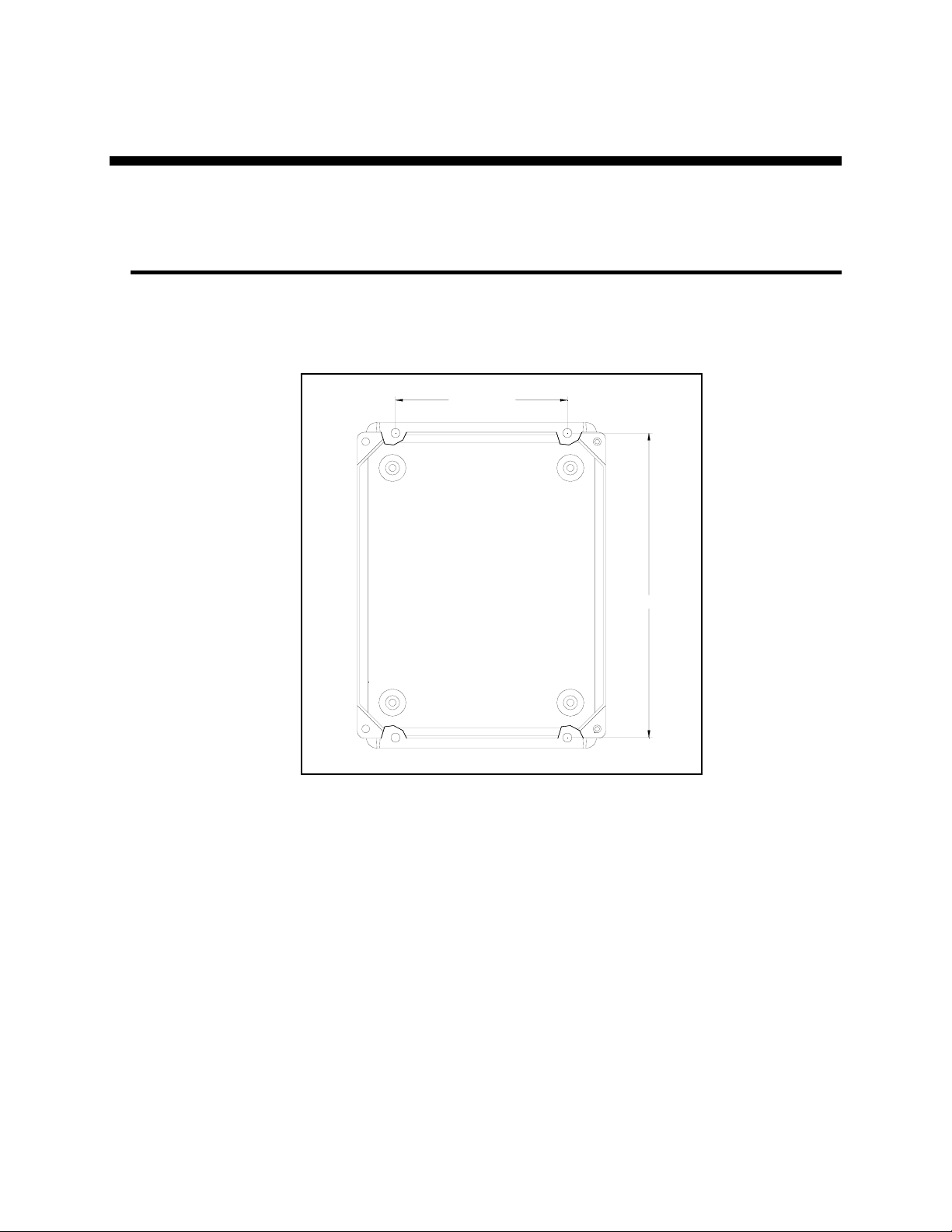

Figure 2-1 Mounting Hole Locations........................................................................................................11

Figure 2-2 Pneumatic Connections...........................................................................................................12

Figure 2-3 Electrical Connections.............................................................................................................14

Figure 2-4 Digital Output Connections....................................................................................................15

Figure 2-5 Typical RS232 and RS485 Connections.................................................................................17

Figure A-1 RS232/RS485 Jumpers (Controller PCA#03492) ................................................................37

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page v

Page 6

TABLES

Table 2-1 Digital Status Output Pins........................................................................................................15

Table 2-2 Control Inputs.............................................................................................................................16

Table 2-3 Serial Port Pins...........................................................................................................................17

Table 4-1 Auto-Zero Function....................................................................................................................20

Table 5-1 Serial Port Configuration ..........................................................................................................21

Table 5-2 Serial Port Command Summary...............................................................................................22

Table 7-1 Digital Status Outputs...............................................................................................................34

Table 7-2 Status Output Truth Table.......................................................................................................36

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page vi

Page 7

I.0 INTRODUCTION

1.1 Preface

Teledyne API is pleased that you have purchased the Model 460H NEMA. Included is a

full one-year warranty (see Section 1.2) and we at Teledyne API will be pleased to

provide you with any support required so that you may utilize our equipment to the

fullest extent.

The Model 460H is a microprocessor based high concentration ozone monitor for

monitoring process streams in water treatment, food processing, and research

applications. The Model 460H has been designed to give accurate and stable readings

over long time periods with little or no maintenance or calibration.

The flexibility of the software as well as the analog and digital I/O allow the Model 460H

to interface with a broad range of devices for process control and data logging.

We hope you will not experience any problems with the Teledyne API Model 460H but if

you do, our full time customer service department is always available to answer your

questions.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 7

Page 8

1.2 WARRANTY POLICY

ADVANCED POLLUTION INSTRUMENTATION DIVISION

02024c

Prior to shipment, Teled yne API equipment is thoroughly inspected and tested. Should equipment

failure occur, Teledyne API assures its customers that prompt service and support will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, Teledyne API stands ready to

provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in the

industry. All maintenance and the first level of field troubleshooting are to be performed by the

customer.

NON- TELEDYNE API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by Teled yn e API is warranted and will be repaired to the

extent and according to the current terms and conditions of the respective equipment manufacturers

warranty.

GENERAL

Teledyne API warrants each Product manufactured by Teledyne API to be free from defects in

material and workmanship under normal use and service for a period of one year from the date of

delivery. All replacement parts and repairs are warranted for 90 days after the purchase.

If a Product fails to conform to its specifications within the warranty period, Teledyne API shall

correct such defect by, in Tele d y n e API's discretion, repairing or replacing such defective Product or

refunding the purchase price of such Product.

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used in

any manner other than in accordance with the instruction provided by Teledyne API or (iii) not

properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES

THEREFORE ARE EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. THE

REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES

FOR BREACH OF ANY WARRANTY CONTAINED HEREIN.

SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF OR RELATED TO THIS AGREEMENT OF

TELEDYNE API'S PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF

WARRANTY OR OTHERWISE.

TERMS AND CONDITIONS

All units or components returned to API should be properly packed for handling and

returned freight prepaid to the nearest designated Service Center. After the repair, the

equipment will be return e d , frei g h t p r e p a i d .

TELEDYNE API

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 8

Page 9

1.3 Principle of Operation

α

C

T

P

The detection of ozone molecules is based on absorption of 254 nm UV light due to an

internal electronic resonance of the O3 molecule. The Model 460H uses a mercury lamp

constructed so that a large majority of the light emitted is at the 254nm wavelength. Light

from the lamp shines through an absorption cell through which the sample gas being

measured is passed. The ratio of the intensity of light passing through the gas to a

reference measurement which does not pass through the gas forms the ratio I/Io. This

ratio forms the basis for the calculation of the ozone concentration.

The Beer-Lambert equation, shown below, calculates the concentration of ozone from the

ratio of light intensities.

6

C

O

3

=−

α

10

l

×

Where:

I = Intensity of light passed through the sample

I

= Intensity of light through sample free of ozone

o

= absorption coefficient

l = path length

= concentration of ozone in parts per million

O

3

= sample temperature in degrees Kelvin

= pressure in pounds per square inch (absolute)

As can be seen the concentration of ozone depends on more than the intensity ratio.

Temperature and pressure influence the density of the sample. The density of the gas

changes the number of ozone molecules in the absorption cell which impacts the amount

of light removed from the light beam. These effects are addressed by directly measuring

temperature and pressure and including their actual values in the calculation. The

absorption coefficient is a number that reflects the inherent ability of ozone to absorb 254

nm light. Most current measurements place this value at 308 cm-1 atm-1 at STP. The

value of this number reflects the fact that ozone is a very efficient absorber of UV

radiation which is why stratospheric ozone protects the life forms lower in the

atmosphere from the harmful effects from solar UV radiation. Lastly, the absorption path

length determines how many molecules are present in the column of gas in the absorption

cell.

The intensity of light is converted into a voltage by the detector/preamp module. The

voltage is converted into a number by a voltage-to-frequency (V/F) converter capable of

80,000 count resolution. The digitized signal, along with the other variables, are used by

the CPU to compute the concentration using the above formula.

Τ

×× ×

o

Κ

273

.

14 695

Ρ

psi

Ι

l

n

Ι

o

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 9

Page 10

1.4 Specifications

Measurement Principle UV Absorption (Beer Lambert Law)

Ranges 0-5%, 0-10%, 0-15% w/w, 0-20% w/w

Measurement Units wt%, g/Nm

Accuracy

Precision/Repeatability

Resolution 0.1 % w/w or .01 g/Nm

Response Time (95%) <5 sec to 95%

Compensation Pressure, Temperature (NTP = 273.15K,

Gas Inlet Pressure Range 3.0 – 30.0 psig

Gas Flow Rate 0.2 – 2.0 LPM

Temperature Range 5-45oC

Dimensions (H x W x D) 12.64" x 11.19" x 6.08"

Weight 9.40lb (4.27kg)

Power 110-240V~, 50/60Hz, 2.5A

Environmental Conditions Installation Category (Overvoltage Category) II

Maximum Operating Altitude 2000 meters

Analog Output Voltage 0-5V, 4-20mA (Optional)

Isolated Analog Output 4-20mA

Mode*

Degree of Protection (IP Code) IPX65

*Optional

0-100 g/Nm

400g/ Nm

3

, 0-200 g/Nm3, 0-300 g/Nm3, 0-

3

3

± 1% of Full Scale

±0.5% of Full Scale Range

3

760mmHg)

(321mm x 284mm x 154mm)

Pollution Degree 2

Maximum voltage between outputs and ground

60V peak

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 10

Page 11

2.0 Installation

Upon receiving the Model 460H please verify that there is no apparent shipping damage.

(If damage has occurred please advise shipper first, then Teledyne API.)

2.1 Mechanical Installation

1. Mount the enclosure securely to a vertical surface. Figure 2-1 below shows the

locations of the four mounting holes. All four mounting holes should be used to

secure the monitor.

6.050 [153.67]

10.700 [271.78]

Figure 2-1 Mounting Hole Locations

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 11

Page 12

2.2 Pneumatic Connections

1. Connect a ¼” exhaust line to the fitting labeled ‘Exhaust.’ This line should be vented

to an outside area, since the exhaust gas may still contain trace levels of ozone that may

not be completely removed by the built-in the ozone scrubber.

CAUTION

Exhaust gas from the M460H may contain dangerous levels of

2. Connect the ozone delivery line to the ¼” inlet fitting labeled “Ozone Inlet” on the

bottom face of the enclosure (See Figure 2-2.) The ozone delivery should be

regulated to no more than 30psig. All tubing used should be made of ozone resistant

material such as PTFE(Teflon™) or FEP. API can supply appropriate tubing for

connecting the ozone supply line.

3. Connect the oxygen or other zero gas source to the ¼” tube fitting labeled ‘Zero Gas

Inlet.’ Zero Gas supply pressure should be regulated between 5 and 30 psig.

4. The gas flow rate through the monitor should be established between 0.5 and 2.0

L/min.

ozone!

OZONE INLET

WARNING - DO NOT EXCEED

30 PSIG GAS DELIVERY

PRESSURE

ZERO GAS INLET

WARNING - DO NOT EXCEED

30 PSIG GAS DELIVERY

PRESSURE

OF OZONE

EXHAUST

WARNING - THIS GAS MAY

CONTAIN HARMFUL LEVELS

Figure 2-2 Pneumatic Connections

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 12

Page 13

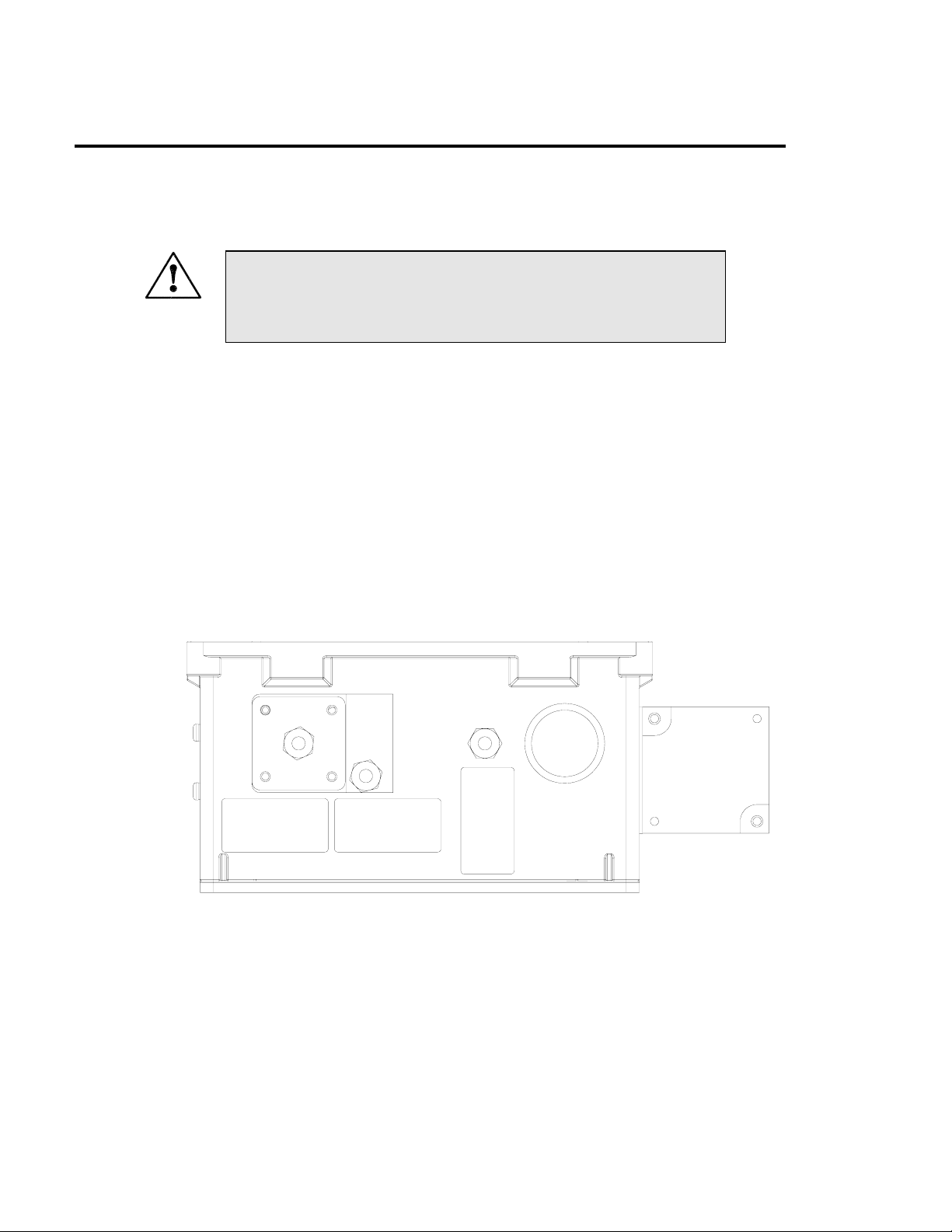

2.3AC Power Connection

Connect AC power to the instrument. A hole is provided on the bottom face of the

enclosure for installing a ½” conduit fitting for routing the electrical wiring into the

instrument. In order to maintain the IP (NEMA4X) rating of the enclosure, an

appropriate sealed conduit connector should be used. Figure 2-3 below shows the

location of the three terminal connector for the AC power. It is recommended that if

multi-strand wires are used to make the AC connections, the wire ends should first be

“tinned” with solder to ensure that the screw terminals can make a reliable connection to

the wires.

CAUTION!

Disconnect power to the AC mains before making any electrical

connections to the Model 460H.

IMPORTANT!

A proper earth ground connection must be made to the receptacle

labeled “Earth Ground” on the 3 pin AC connector. Failure to do

so may result in a shock hazard and malfunction of the

instrument.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 13

Page 14

EARTH GROUND

AC LINE

AC NEUTRAL

I/O CONNECTOR

AC POWER CONNECTOR

Figure 2-3 Electrical Connections

2.4 Electrical I/O Connections

All user I/O connections are available on the 16 pin connector on the mainboard (See

Figure 2-3 for location.) This connector can be unplugged from the header on the

mainboard for easier access when wiring. To disconnect from mainboard, loosen the two

retaining screws at either end of the connector.

When connecting multi-strand wire to this connector, the wire ends should be “tinned”

with solder to ensure a reliable connection. This is not necessary if solid-core wire is

used.

2.4.1 Analog Output

The analog output is located on the two pins labeled ‘Analog Out +’ and ‘Analog Out –‘

The analog output can be configured for voltage or current output. The standard output is

a 0-5 volt output. The analog output can also be optionally configured for a 4-20mA

Current output. Check the serial number tag on the instrument to determine Analog

Output configuration.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 14

Page 15

2.4.2 Digital Status Outputs

The M460H has four digital status outputs for indicating error and operational status

conditions. These outputs are in the form of opto-isolated open-collector transistors.

They can be used to drive status LED’s on a display panel or interface to a digital device

such as a Programmable Logic Controller (PLC).

Figure 2-4 shows the most common way of connecting the digital outputs to an external

device such as PLC. Note: Most devices, such as PLC’s, have internal provision for

limiting the current that the input will draw from an external device. When connecting to

a unit that does not have this feature, external dropping resistors must be used to limit the

current through the transistor output to 50mA or less.

See Chapter 7 for details on using the Status Outputs for diagnosing sensor and systemlevel malfunctions.

Table 2-1 below describes the function of the status outputs.

Table 2-1 Digital Status Output Pins

Label Name Operation

STATUS OUT 1 Sensor O.K. Normally On

STATUS OUT 2 Invalid Reading Normally Off

STATUS OUT 3 Lamp Low Normally Off

STATUS OUT 4 Cell Dirty Normally Off

STATUS OUT 5 Auto-Zero Error Normally Off

STATUS OUT 6 Spare Undefined

STATUS COM Common Pin for

all Status Outputs

N/A

Programmable Logic

Controller or other devi ce

+5V

Digital

Input

Opto-Isolator

M454

Digital Output #1-4 (Collector)

Digital Output Common (Emmiter)

Ground Provided

by PLC

Figure 2-4 Digital Output Connections

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 15

Page 16

2.4.3 Control Inputs

There are 2 digital control inputs on the I/O connector; they are labeled ‘Zero Input’ and

‘Aux Input.’ The control inputs are used for remote control of the M460H by a device

such as a PLC. These inputs are triggered by providing a contact closure or low

impedance current path between the Input and the Gnd pin. This can be done by using a

mechanical switch or isolated transistor type output from another device, such as a PLC.

Never connect a voltage level output from another device to these contacts. The

functions of the control inputs is summarized below in Table 2-2:

Table 2-2 Control Inputs

Input Description

Zero Input Zero Calibration

Aux Input Pressure Display

Zero Calibration Input:

The zero calibration input is used to initiate zero calibration from an external device.

This input performs exactly the same function as the ‘Zero’ buttons on the front panel.

Pressure Display Input:

The pressure display input is used to display the pressure on the front panel. This input

performs exactly the same function as the ‘Pressure’ buttons on the front panel.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 16

Page 17

2.4.4 RS232/RS485 Serial Communications Port

A bi-directional RS232/485 Serial Port Interface is provided that can be used for data

acquisition and instrument control. All that is required to use this interface is a computer

with a serial communications port (COM port) and terminal software. Three pins are

provided on the I/O connector for serial communications as shown in Table 2-3.

Table 2-3 Serial Port Pins

Label Description

SERIAL TX Serial Transmit (RS485 – A)

SERIAL RX Serial Receive (RS485 – B)

SERIAL GND Serial Ground (RS232 Only)

The Serial Port can be configured for either RS232 or RS485. The standard factory

configuration is RS232. For direct connection to a PC or Laptop, RS232 should be used.

For a permanent connection into a data acquisition system, RS485 is recommended

because it has better noise immunity and is more reliable when communicating over

longer distances. See Appendix A for details on changing the Serial Port configuration.

Figure 2-5 below shows typical connections using RS232 and RS485. Note that the

RS485 connection does not use the SERIAL GND pin.

DB9-FEMALE

SERIAL GND

SERIAL RX

SERIAL TX

RS232

SERIAL TX

SERIAL RX

RS485-A

RS485-B

RS485

Figure 2-5 Typical RS232 and RS485 Connections

See Chapter 5 for information on the Serial Communications protocol used by the

M460H.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 17

Page 18

3.0 Startup

Perform the following steps when fist installing the M460H ozone monitor or when

bringing the monitor back into service.

1. Turn on power to the monitor. The display will briefly display the “API” logo

followed by the software version. The display will then begin showing ozone

concentration.

2. Establish a flow of zero gas to the monitor. Zero gas can be oxygen or clean, dry air.

If monitor cannot be disconnected from an ozone generator, then establish flow

through the generator and monitor with the generator turned off. Flow rate through

monitor should be between 0.5 – 2.0 LPM (Liters per minute.)

3. Let monitor warm up and purge for a minimum of 5 minutes. Zero the monitor by

simultaneously pressing the Zero buttons on the front panel. The display should

momentarily show dashes (‘----‘) after which the display should go quickly to zero.

4. Check Status LED’s on front panel; Sensor OK led should be ON, all other LED’s

should be OFF. If the Status LED’s are not in this state, refer to Chapter 7 for

troubleshooting information.

5. Observe the monitor for several more minutes at zero to ensure that it is stable.

6. The monitor is now ready to measure ozone.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 18

Page 19

4.0 Operation

The M460H has been designed for simple and trouble-free operation. The Sections

below detail the operational features of the M460H.

4.1 Front Panel Display

4.1.1 O3 readout

The current ozone concentration is displayed in the 4 digit readout in the center of the

display. The concentration is displayed in the currently selected units, either wt% or

g/Nm3.

4.1.2 Pressure Display

The pressure inside the measurement cell can be displayed on the readout by pressing and

holding the ‘Pressure’ key on the front panel. The pressure is displayed in units of psia

(pounds per square inch absolute.) The normal ambient pressure at sea level is about

14.7psia. Ambient pressure at higher elevations will be somewhat less.

The M460H can accurately measure ozone at cell pressures of 12 - 20psia. Care should

be taken in setting up the monitor to avoid over-pressurizing the cell, as this will result in

erroneous readings.

4.1.3 Zero Calibration

A Zero Calibration can be performed on the monitor at any time by simultaneously

pressing the two ‘Zero’ buttons on the front panel. The monitor will briefly display

dashes (‘----‘) after which the concentration should quickly go to zero.

The Zero Calibration is calculated based on the current measurement in the cell; so care

must be taken to ensure that all ozone is purged from the cell before pressing the ‘Zero’

buttons.

If the Auto-Zero option is not used, API recommends performing a manual Zero

Calibration on the monitor once a week.

4.1.4 Status LED’s

The four status LED’s to the right of the display indicate the general status of the Model

460H Monitor. During normal operation, after the monitor has warmed up, the green

‘Sensor OK’ LED should be on and all other Status LED’s should be off. For

information on troubleshooting using the Status LED’s, see Chapter 7.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 19

Page 20

4.2 Auto-Zero Operation

The Auto-Zero feature allows the monitor to operate unattended for extended periods of

time. This feature automatically performs a Zero Calibration at specific intervals (default

interval is 12hrs.) The monitor does this by opening a solenoid valve to allow externally

supplied Zero Gas to purge the monitor and then automatically performs a Zero

Calibration.

4.2.1 Auto-Zero Installation

In order for this feature to function properly, external, pressurized zero gas must be

supplied to the monitor as detailed in Section 2.2.

4.2.2 Auto-Zero Function

When the Auto-Zero function is triggered, the monitor performs the steps outlined in

Table 4-1 below.

Table 4-1 Auto-Zero Function

Step Function Display Reads

1 Switch Auto-Zero valve on N/A

2 Purge cell for 20 seconds Holds and Flashes Concentration Value

3 Perform Zero Calibration Dashes: ‘----‘

4 Switch Auto-Zero valve off Dashes: ‘----‘

5 Hold-Off for 3 sec to return

Measurement Gas to cell

6 Return to Measurement Mode Normal Concentration Display

4.2.3 Auto Zero Error

Dashes: ‘----‘

When performing an Auto-Zero Calibration, the monitor checks to make sure the ozone

concentration is near zero before calibration. If the ozone concentration is above 0.5wt%

or 5.0 g/Nm3, the monitor will not perform the calibration and will display a “ZERO

ERR” message on the display. The monitor will also turn on the Auto-Zero Error status

signal (See Section 2.4.2 Digital Status Outputs.) This Status Signal will remain on until

another Auto-Zero Calibration is successfully performed or a Manual Zero Calibration is

performed.

If an Auto-Zero error is detected, a manual Zero Calibration should be performed (See

Section 4.1.3 Zero Calibration.)

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 20

Page 21

5.0 Serial Communications

The M460H comes equipped with a powerful digital Serial Communications Port that

can be used for Data Acquisition and for changing instrument configuration. This port

can be configured for either RS232 or RS485(half-duplex) operation. See Section 2.4.4

for details on connecting the port to a computer or Data Acquisition system.

5.1 Serial Port Configuration

The Serial Port of the device being used to communicate with the M460H should be

configured as follows:

Table 5-1 Serial Port Configuration

Parameter Value

Baud Rate 9600 bps

Data Bits 8

Stop Bits 1

Parity None

5.2 Command Syntax

All characters sent and received are standard Ascii characters and all numbers are

decimal numbers converted to Ascii text.

All commands are sent using the following syntax:

<address><command>:<data1>,<data2>#<checksum><CR>

Where:

address is the instrument address(default =1)

command is the command string being sent

: (colon) is the data separator and is only included if data is being sent as part of the

command (See Command Details below to see if a command requires data or

not)

data1 is the first data parameter, if required.

data2 is the second data parameter, if required.

# is the Checksum separator, sent only if optional checksum is included

checksum is an Ascii checksum of all characters up to the # character. The checksum is

optional, commands sent without the checksum(and checksum separator,) are

also valid.

CR is a carriage return, Ascii 13.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 21

Page 22

Examples of valid Commands with no data:

Checksum Included:

1O3#179<CR>

No Checksum:

1O3<CR>

Examples of valid Commands with data:

Checksum Included:

1VSET:1,20#620<CR>

No Checksum:

1VSET:1,20<CR>

5.3 Command Summary

Table 5-2 below lists the commands available and a summary of their function.

Table 5-2 Serial Port Command Summary

Command Description

CAUTO Perform an Auto-Zero Calibration (if option is installed)

CZERO Perform a manual zero calibration (zero calibration is

computed based on current O3 reading in cell)

DACSTEP Analog Output Test Mode, Step Function

O3 Returns current O3 concentration

SETADDR Set communications address

TDUMP Returns a compact list of current measurement parameters

TLIST Returns all current measurement parameters

VGET Get Single VAR value

VLIST Lists all internal VARS

VSET Sets value of internal VAR

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 22

Page 23

5.4 Command Reference

5.4.1 CAUTO

Syntax

<address>CAUTO<CR>

Description

Perform an Auto-Zero Calibration. Valid only if Auto-Zero option is installed in

monitor.

Data Parameters Sent

None

Response <address>:<success_flag>#<checksum><CR>

Example

Command:

1CAUTO<CR>

Response:

1:OK#261<CR> - Calibration Successful

1:FAIL#391<CR> - Calibration Failed

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 23

Page 24

5.4.2 CZERO

Syntax

<address>CZERO<CR>

Description

Perform a Zero Calibration. Note that calibration is performed based on concentration

currently in measurement cell. Instrument should be sufficiently purged with zero gas

before issuing this command.

Data Parameters Sent

None

Response <address>:<success_flag>#<checksum><CR>

Example

Command:

1CZERO<CR>

Response:

1:OK#261<CR> - Calibration Successful

1:FAIL#391<CR> - Calibration Failed

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 24

Page 25

5.4.3 DACSTEP

Syntax

<address>DACSTEP<CR>

Description

Puts instrument in the Analog Output setup mode. The Analog Output steps from zero to

full-scale in 20% increments, pausing for 4 seconds at each level. This repeats 5 times,

after which the instrument returns to normal operation. This mode is useful for testing

the Analog Output and the operation of any equipment measuring the Analog Output.

Data Parameters Sent

None

Response <address>:<success_flag>#<checksum><CR>

Example

Command:

1DACSTEP<CR>

Response:

1:OK#261<CR> - Calibration Successful

1:FAIL#391<CR> - Calibration Failed

Notes

Note that the DACSTEP function takes some time to complete. When the command is

sent to the monitor, it will immediately respond with the <address> and colon ‘:’ as an

acknowledgement that the message was received. After the function is complete the rest

of the response will be sent. No additional commands should be issued to the monitor

until the function completes.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 25

Page 26

5.4.4 O3

Syntax

<address>O3<CR>

Description

Returns the current ozone concentration measured by the monitor.

Data Parameters Sent

None

Response <address>:<o3_conc>#<checksum><CR>

Example

Command:

1O3<CR>

Response:

1:12.01898#518<CR> - Current O3 Concentration (reading 12.02 wt%)

Notes

Note that the concentration value returned shows more digits after the decimal than the

front panel display. Concentration values should only be considered valid to 4 significant

digits.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 26

Page 27

5.4.5 SETADDR

Syntax <address>SETADDR:<new_address><CR>

Description

Changes the communications address to a new value.

Data Parameters Sent

new_address is the new address for the monitor; Range for new_address is 1-9.

Response <address>:<success_flag>#<checksum><CR>

Example

Command:

1SETADDR:2<CR> - Change address from 1 to 2

Response:

1:OK#261<CR> - Change Address Successful

1:FAIL#391<CR> - Change Address Failed

Notes

Note that monitor response is from previous address, but any further commands must be

at new address. In the example above, after sending back the OK response, the monitor

will no longer respond to commands with address 1.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 27

Page 28

5.4.6 TDUMP

Syntax

<address>TDUMP<CR>

Description

Returns the current measured parameters: O3 Concentration, Cell Pressure(psia,) Cell

Temperature (K,) Lamp Temperature (K,) Measure Detector (mV,) Calibrated

Refererence Detector (mV,) Reference Detector (mV)

Data Parameters Sent

None

Response

<address>:<o3_conc>,<pressure>,<cell_temp>,<lamp_temp>,<measure>,<cal_ref>,<ref

erence>#<checksum><CR>

Example

Command:

1TDUMP<CR>

Response:

1:0.0282144,14.77461,300.7179,324.7713,2881.437,2940.903,4412.52#3228

<CR>

Notes

Note that the concentration value returned shows more digits after the decimal than the

front panel display. Concentration values should only be considered valid to 4 significant

digits.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 28

Page 29

5.4.7 TLIST

Syntax

<address>TLIST<CR>

Description

Returns a verbose list of the current measured parameters with labels for each parameter:

O3 Concentration, Cell Pressure(psia,) Cell Temperature (K,) Lamp Temperature (K,)

Measure Detector (mV,) Calibrated Reference Detector (mV,) Reference Detector (mV)

Data Parameters Sent

None

Response

Test Parameter List (See Below)

Example

Command:

1TLIST<CR>

Response:

O3 = 0.0226168

Press = 14.7753

Cell Temp = 300.7116

Lamp Temp = 324.7965

Ref = 2881.52

Meas = 2941.092

Raw Ref = 4412.646

Notes

Note that the concentration value returned shows more digits after the decimal than the

front panel display. Concentration values should only be considered valid to 4 significant

digits.

Also, note that no checksum is sent in the response to the TLIST command.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 29

Page 30

5.4.8 VGET

Syntax <address>VGET:<var_index><CR>

Description

Returns value of an internal configuration variable (VAR.)

Data Parameters Sent

var_index is index number for internal VAR as follows:

Var

Index

0 analog_range Full-Scale concentration

1 azero_enable Auto-Zero Enable VAR.

2 azero_period Period for Auto-Zero

3 carrier_weight Mol weight of carrier gas

4 comm_mode Not Used N/A

5 iir_filt Digital Concentration

Name Description Allowable Range

5.0 – 400.0 (Units are

range for Analog Output

scaling

current unit of measure,

wt% or g/Nm3)

0 = Off

(only valid if Auto-Zero

1 = On

hardware is installed)

5.0 - 86400.0 Seconds

Calibration timer

27.0 – 32.0 mol weight

for wt% calculations (32.0

= O2)

0.05 – 1.0

filter

(1.0 = No Filtering, lower

values increases filtering)

6 conc_units O3 Concentration

measurement units

0 = wt%

1 = g/Nm3

Response <address>:<var_value>#<checksum><CR>

Example

Command:

1VGET:0<CR> - Request analog_range value

Response:

1:15.0#303 - analog_range returned as 15.0 (wt%)

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 30

Page 31

5.4.9 VLIST

Syntax

<address>VLIST<CR>

Description

Returns a verbose list of an internal configuration variables (VARs.)

Data Parameters Sent

None

Response

Var List (See Below)

Example

Command:

1VLIST<CR>

Response:

#0 analog_range = 15.0

#1 azero_enable = 0.0

#2 azero_period = 720.0

#3 carrier_weight =32.0

#4 comm_mode = 0.0

#5 iir_filt = 0.4

#6 conc_units = 0.0

Notes

Note that no checksum is sent in the response to the VLIST command.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 31

Page 32

5.4.10 VSET

Syntax <address>VSET:<var_index>,<new_value><CR>

Description

Sets value of an internal configuration variable (VAR.)

Data Parameters Sent

var_index is index number for internal VAR (See VGET for index list)

new_value new value for VAR.

Response <address>:<var_value>#<checksum><CR>

Example

Command:

1VSET:0,15.0<CR> - Set analog_range VAR to 15.0 (wt%)

Response:

1:OK#261<CR> - VSET Successful

1:FAIL#391<CR> - VSET Failed

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 32

Page 33

6.0 Maintenance

6.1 Replacing the gas filter element

The Model 460H is equipped with a gas filter on the ozone inlet. These filters accept

25mm diameter glass fiber elements. Only filter elements of borosilicate glass or quartz

fibers should be used. When the instrument is first installed, the sample filters should be

checked at least once a week for particulate loading and replaced if necessary. Once the

replacement frequency is determined, a regular schedule for filter replacement should be

instituted.

For replacement 25mm filter elements, please contact API’s sales department and request

part number 02851.

Filter Replacement Procedure:

1. First ensure that the gas delivery line is not under pressure and has been purged of

ozone.

2. Remove the four screws securing the gas filter assembly.

3. Remove the bottom half of the filter housing

4. Examine the internal sealing o-ring and replace if necessary.

5. Pull out the stainless steel screen securing the filter element.

6. The element can now be removed and replaced. When re-assembling filter, make

sure that the top stainless steel screen is pushed into the filter cavity, securing the

element in place.

7. After re-assembly, the gas line should be pressurized with oxygen or dry air and

checked for leaks using a bubble solution.

6.2 Cleaning Exterior Surfaces of the M460H

If necessary, the exterior surfaces of M454H can be cleaned with a damp cloth. Do not

attempt to clean any of the other surfaces of the instrument. Do not submerge any part of

the instrument in water or cleaning solution.

6.3 Degree of Protection

The Model 460NEMA has a water ingress rating of IPX65 which indicates that it can

withstand strong jets of water and is totally protected against dust.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 33

Page 34

7.0 Sensor and System Troubleshooting

This chapter gives guidelines for diagnosing system and sensor malfunctions using the

five digital Status Outputs provided by the M460H. All troubleshooting should be done

after the M460H has been turned on and allowed to warm up for at least 15 minutes.

7.1 Status Output Summary

Table 7-1 below gives a summary of the operation of the five Status Outputs on the

M454H. See 2.4.2 Digital Status Outputs for information on connecting these outputs.

Table 7-1: Digital Status Outputs

Output

#

1 Sensor O.K. Normal State Reference or

2 Invalid Reading Pressure > 45 psia,

3 Lamp Low Reference

4 Cell Dirty Measure/Reference

5 Auto-Zero Error Auto-Zero Failed Normal State

Name On State Off state

Measure > 4995mV;

Reference < 1000mV

Normal State

Negative Ozone

Concentration,

Concentration Over-

Range

Normal State

Detector<2500mV

Normal State

ratio < 0.5 (zero gas)

7.2 Sensor OK

The normal state for the Sensor OK output in ON. During the warm-up period on startup this output will stay off until the UV lamp reaches a minimum intensity. If this output

remains off after the 15 minute warm-up period, or goes off during normal operation,

then the M460H is in need of servicing.

If the Sensor O.K. output turns off AND the Lamp Low output is on, this indicates that

the lamp intensity has below the minimum level required for proper operation.

If the Sensor O.K. output turns off and the Lamp Low output is also off, then one of the

analog voltages in the sensor has exceeded the range of the internal A/D converter.

Adjustment by qualified service personnel is required.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 34

Page 35

7.3 Invalid Reading

The normal state for the Invalid Reading output is OFF. If this output turns on, this

indicates that the M460H is still operational, but a system fault or calibration fault exists

that may make the current ozone reading invalid.

The Invalid Reading output is turned on for any of the following conditions:

1. When the measured pressure in the measurement cell exceeds 45 psia.

2. When the measured concentration has exceeded the full-scale concentration

range of the sensor. Check the serial number tag for the full-scale concentration

range.

3. The sensor is indicating an excessive negative reading.

7.4 Lamp Low

The normal state for the Lamp Low output is OFF. If this output turns on, this indicates

that the UV lamp intensity as measured by the reference detector has dropped below

2500mV.

If the Lamp Low output turns ON and the Sensor O.K. output is ON, this indicates that

the lamp intensity is still adequate for measurement, but adjustment should be made

when possible.

If the Lamp Low output turns ON and the Sensor O.K. output is OFF, this indicates a

failure condition and measurement is no longer possible.

7.5 Cell Dirty

The normal state for the Cell Dirty output is OFF. If this output turns on, then the ratio

of the measure detector to the reference detector (at zero) is < 0.5. This value is

calculated when the zero calibration is performed.

When this output is on, it indicates a loss of optical transmission through the windows in

the absorption cell or a calibration fault.

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 35

Page 36

7.6 Status Output Summary Table

Table 7-2 below is a logic truth table summarizing the recommended actions based on the

states of the four status outputs. A ‘1’ indicates the output is ON, a ‘0’ indicates the

output is OFF, and ‘X’ indicates the output is in either state.

Table 7-2: Status Output Truth Table

Sensor

OK

1 0 0 0 Normal operation, no action

0 X X X Service required

1 1 X X Check Pressure > 45 psia

1 X 1 X Lamp adjustment useful,

1 X X 1 Calibrate at zero

Invalid

Reading

Lamp

Low

Cell

Dirty

Actions

required

Verify that concentration has

not exceeded full scale range

of sensor.

Calibrate at Zero.

though not required

Clean Cell

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 36

Page 37

Appendix A – Serial Port Configuration

To configure the com port for RS232 or RS485, move the 4 shunts on JP3 of the

Controller PCA (#03492) to the proper position as shown in Figure A-1.

RS232 RS485

Figure A-1 RS232/RS485 Jumpers (Controller PCA#03492)

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 37

Page 38

Appendix B – Pneumatic Diagram

O3 Gas In

Zero Gas In

Exhaust Out

Filter

Azero Valve

Flow Control

Orifice

O3

Measurement

Cell

Flow-Meter

O3 Destruct

P/N 03662D Teledyne API Model 460H O3 Monitor Operator Manual - Page 38

Loading...

Loading...