Page 1

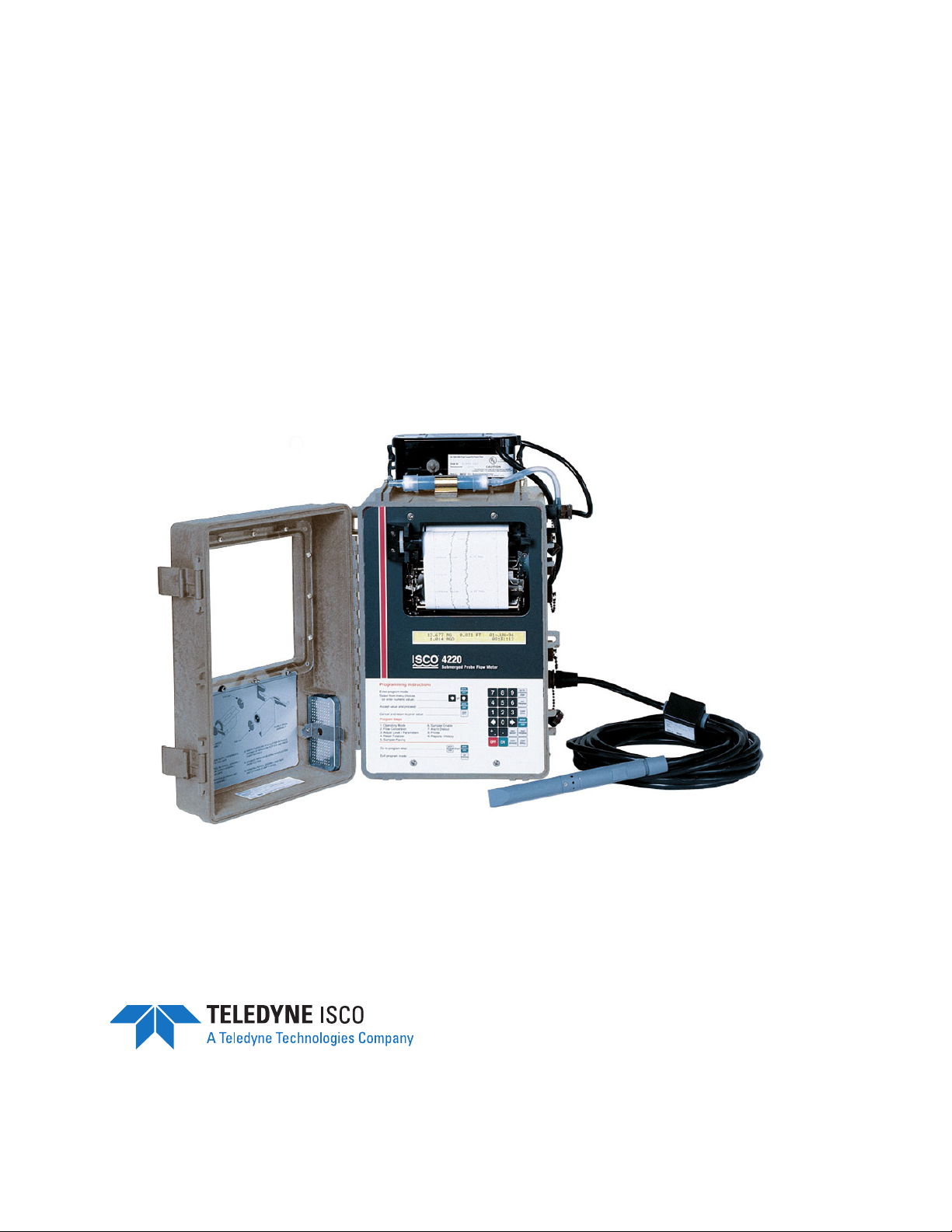

4220 Submerged Probe

Flow Meter

Installation and Operation Guide

Part #60-3223-130 of Assembly #60-3224-052

Copyright © 2001. All rights reserved, Teledyne Isco, Inc.

Revision T, March 6, 2006

Page 2

Page 3

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Service

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(800) 228-4373 (Samplers and Flow Meters)

Revised September 15, 2005

Page 4

Page 5

4220 Flow Meter

Safety

4220 Flow Meter

Safety

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed in the following general

warnings:

WARNING

Liquids associated with this instrument may be classified

as carcinogenic, biohazard, flammable, or radioactive.

Should these liquids be used, it is highly recommended that

this application be accomplished in an isolated

environment designed for these types of materials in

accordance with federal, state, and local regulatory laws,

and in compliance with your company’s chemical/hygiene

plan in the event of a spill.

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired.

WARNING

If this system uses flammable organic solvents, Isco

recommends that you place this system in a well-ventilated

environment, designed for these types of materials. This

environment should be constructed in accordance with

federal, state, and local regulations. It should also comply

with your organization’s plan concerning chemical and

hygiene mishaps. In all cases use good laboratory

practices and standard safety procedures.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

Page 6

4220 Flow Meter

Safety

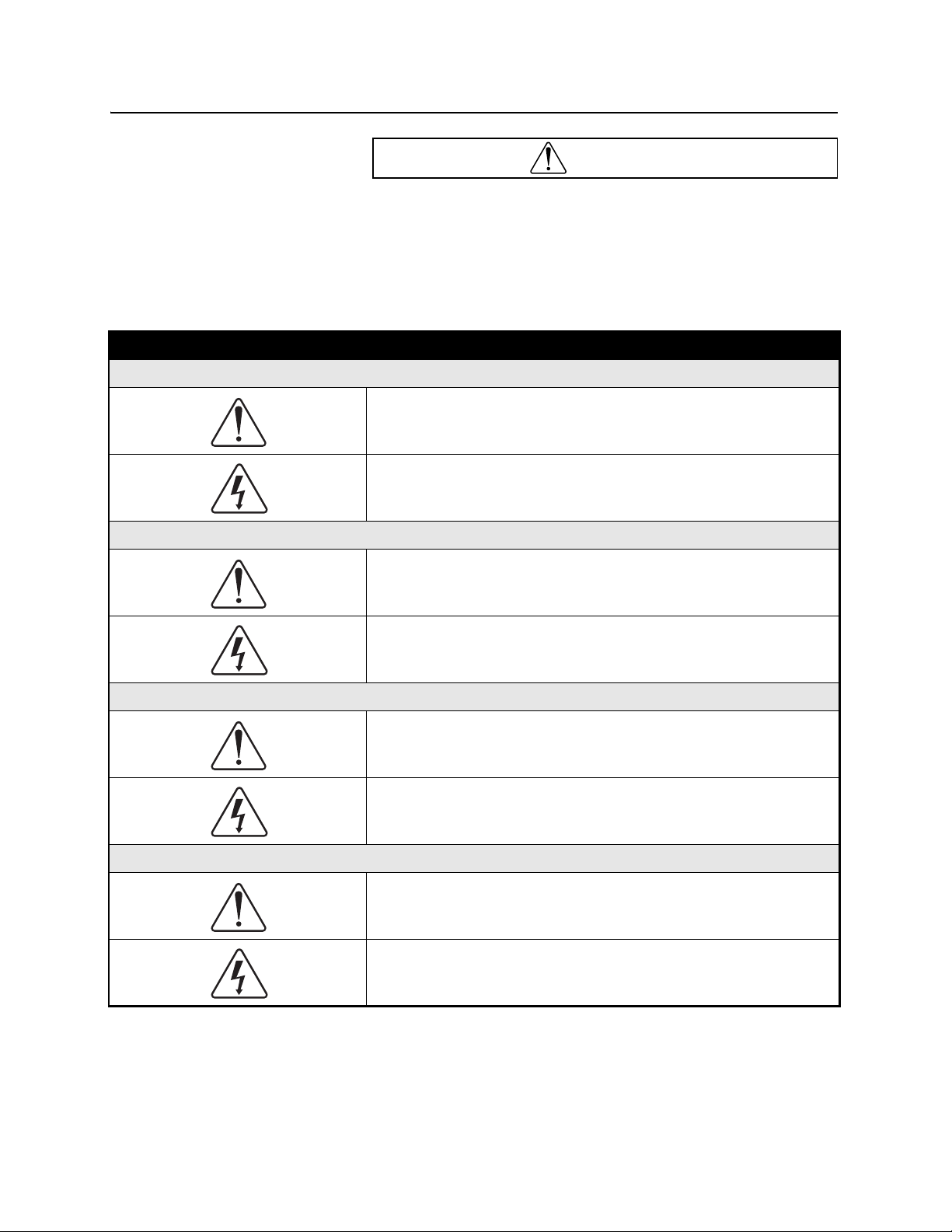

Hazard Symbols The equipment and this manual use symbols used to warn of

Warnings and Cautions

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

hazards. The symbols are explained below.

Hazard Symbols

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Symboles de sécurité

Warnungen und Vorsichtshinweise

Advertencias y Precauciones

Ce symbole signale l’existence d’instructions importantes relatives au produit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del

producto.

Page 7

4220 Flow Meter

Safety

IMPORTANT – PLEASE READ

WARNING

The installation and use of this product may require you to work in locations where

you could be seriously injured or even

killed.

sary to ensure your safety before entering the installation.

pervised. Install and operate this product in accordance with all applicable safety and

health regulations, as well as any appropriate local ordinances.

This product is often installed in confined spaces. Examples of confined spaces are manholes, pipelines,

digesters, and storage tanks. These places can be dangerous or fatal if you are not suitably prepared. The

primary hazards are the presence of poisoned air, the lack of ventilation, and the possibility of falls. Other

hazards may be present, as well. Work in such places is governed by OSHA 1910.146, and may require a

permit before entering.

Material Safety Data Sheets (MSDS) for chemical agents supplied or recommended for use with this

product are in the MSDS Appendix. These sheets provide information about possible hazards from the

chemicals. Additional MSDS, covering various proprietary agents (name-branded or trademarked mix-

tures) that can also be used with this product, are available from the manufacturers of those agents.

Take whatever precautions are neces-

Never

work alone or unsu-

NOTE

FLOWLINK is a registered trademarks of Isco Inc. All other brand or product names used in this manual are trademarks

or registered trademarks of their respective companies and/or organizations.

This manual uses the following notations to set

apart hazard warnings and notes:

DANGER

DANGER describes situations which if not

will

avoided,

result in loss of life or serious

personal injury. The emphasis is on a clear

and immediate threat to your life or safety.

WARNING

WARNING describes situations which if not

result in loss of life or serious per-

avoided,

sonal injury. The emphasis here is on the

tial

could

poten-

for a serious accident.

CAUTION describes situations which if not avoided,

may result in moderate personal injuries, property

damage, or damage to the equipment.

NOTES draw your attention to specific features, practices, or other information useful in setting up or

installing the product.

CAUTION

NOTE

Page 8

4220 Flow Meter

Safety

Page 9

4220 Flow Meter

Table of Contents

Section 1 Introduction

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Compatible Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.1 Submerged Probe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Transducer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.3 Two Probes Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Software Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Controls, Indicators, and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.7 How to Make Battery Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7.1 Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Section 2 Programming

2.1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Operation of the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Keypad Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Description of Program Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.1 Step 1, Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.2 Step 2, Flow Conversion Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.3 Step 3 - Adjust Level, Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.4 Step 4 - Reset Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.5 Step 5 - Sampler Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.6 Step 6 - Sampler Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.7 Step 7 - Alarm Dialout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.8 Step 8 - Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.9 Step 9 - Reports/History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4 Interpreting the Program Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.1 Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.2 Optional Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.4.3 Step 1 - Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.4.4 Step 2 - Flow Conversion (Level-to-Flow Rate . . . . . . . . . . . . . . . . . . . . . . 2-29

2.4.5 Step 3 - Parameter to Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.4.6 Step 4 - Reset Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.4.7 Step 5 - Sampler Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.4.8 Step 6 - Sampler Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.4.9 Step 7 - Alarm Dialout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

2.4.10 Step 8 - Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

2.4.11 Step 9 - Reports/History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Section 3 Installation

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Installing the Desiccant Canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.3 Installing the External Desiccant Cartridge . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.4 Opening the Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Connection to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

i

Page 10

3.2.1 Low Power Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.2 Isco Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3 Isco Nickel-Cadmium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.4 Attaching the Nickel-Cadmium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.5 Isco Lead-Acid Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.6 Attaching the Isco Lead-Acid Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.7 AC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.8 Attaching the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.9 External 12 Volt DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3 Flow Meter Mounting and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1 Carrying Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.2 Location of the Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.3 Mounting the 4220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.4 Suspension Above the Flow Stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4 Quick-Disconnect Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5 Extension Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6 Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.7 Isco Sampler Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Section 4 Submerged Probe Installation

4.1 General Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Functionality Under Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Minimum Reliable Detection Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Submerged Probe Nose Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Mounting Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1 Spring Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.2 Universal Mounting Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

U-Channel or Invert Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.3

4.3.4 Power-Actuated Stud Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.5 Completing the Probe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4 Other Mounting Techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.1 Rectangular Pipes and Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.2 Stilling Wells or Streams with Very Low Velocity . . . . . . . . . . . . . . . . . . . 4-10

4.4.3 Weirs and Flumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.4 Securing Probe with a Weighted Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.4.5 Completing the Probe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Section 5 Options and Accessories

5.1 4200T Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Modems and Flowlink Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3 Connection to a Telephone Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.4 Types of Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Connection to External Serial Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 4-20 mA Analog Outputs: External and Internal . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.1 External Analog Output Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.2 Internal Multiple Analog Output Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4 Tipping Bucket Rain Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5 Isco Flowlink Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.6 High-Low Alarm Relay Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.6.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.2 Wiring to a 4200 Series Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.7 Parameter Sensing with Isco 4200 Series Flow Meters . . . . . . . . . . . . . . . . . . . . 5-10

5.7.1 Installation of Parameter Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.8 The Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.9 The pH Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

ii

Page 11

5.9.1 pH Probe Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.9.2 pH Probe Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.9.3 Storage and Maintenance of pH Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.10 The Dissolved Oxygen (D.O.) Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.10.1 How the D.O. Probe Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.10.2 Probe Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.10.3 Membrane Thicknesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.10.4 Probe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.10.5 Probe Operation and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.10.6 Calibrating the D.O. Probe with a Flow Meter . . . . . . . . . . . . . . . . . . . . 5-22

5.11 Installation of Parameter Probes in Mounting Rings . . . . . . . . . . . . . . . . . . . . . 5-23

5.12 The YSI 600 Multiple Parameter Sonde . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.13 Mechanical Totalizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Section 6 Maintenance and Service

6.1 Routine Maintenance and Minor Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Care of the Flow Meter Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.2 Care of the Case Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.3 Preventing Moisture Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Reactivation of the Desiccators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.1 Regenerating the Internal Case Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.2 Regenerating the External Desiccant Cartridge . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Care of the Submerged Probe and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.1 Low Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.2 Cleaning the Submerged Probe Without Disassembly . . . . . . . . . . . . . . . . 6-5

6.3.3 Disassembling the Probe for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.4 Cable Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.4 Maintenance of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4.1 Changing the Roll of Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4.2 Ink Ribbon Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.4.3 Do Not Disassemble or Lubricate the Printer . . . . . . . . . . . . . . . . . . . . . . 6-10

6.5 Servicing And Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.5.1 Disassembling the Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.5.2 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.5.3 Display Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.5.4 System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.6 Preliminary Troubleshooting Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.6.1 If Serious Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.6.2 Inspection Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.7 Precautions for Servicing CMOS Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.7.1 Hazard of Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.8 Using FLASH UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.8.1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.8.2 Before Running FLASH UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.8.3 Running FLASH UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.8.4 About Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Appendix A Replacement Parts

Appendix B Accessories List

Appendix C Programming Worksheets

C.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C.2 Flow Conversion: Level-to-Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

iii

Page 12

C.3 Parameter to Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.4 Reset Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.5 Sampler Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.6 Sampler Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.7 Alarm Dialout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

C.8 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

C.9 Reports/History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Appendix D General Safety Procedures

D.1 Practical Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

D.2 Lethal Atmospheres in Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D.3 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Appendix E Material Safety Data Sheets

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

List of Illustrations

1-1 Submerged Probe Level Sensor with Standard Tip . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 4220 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 4220 Side View Showing Connectors and Pin Functions . . . . . . . . . . . . . . . . . . . . 1-6

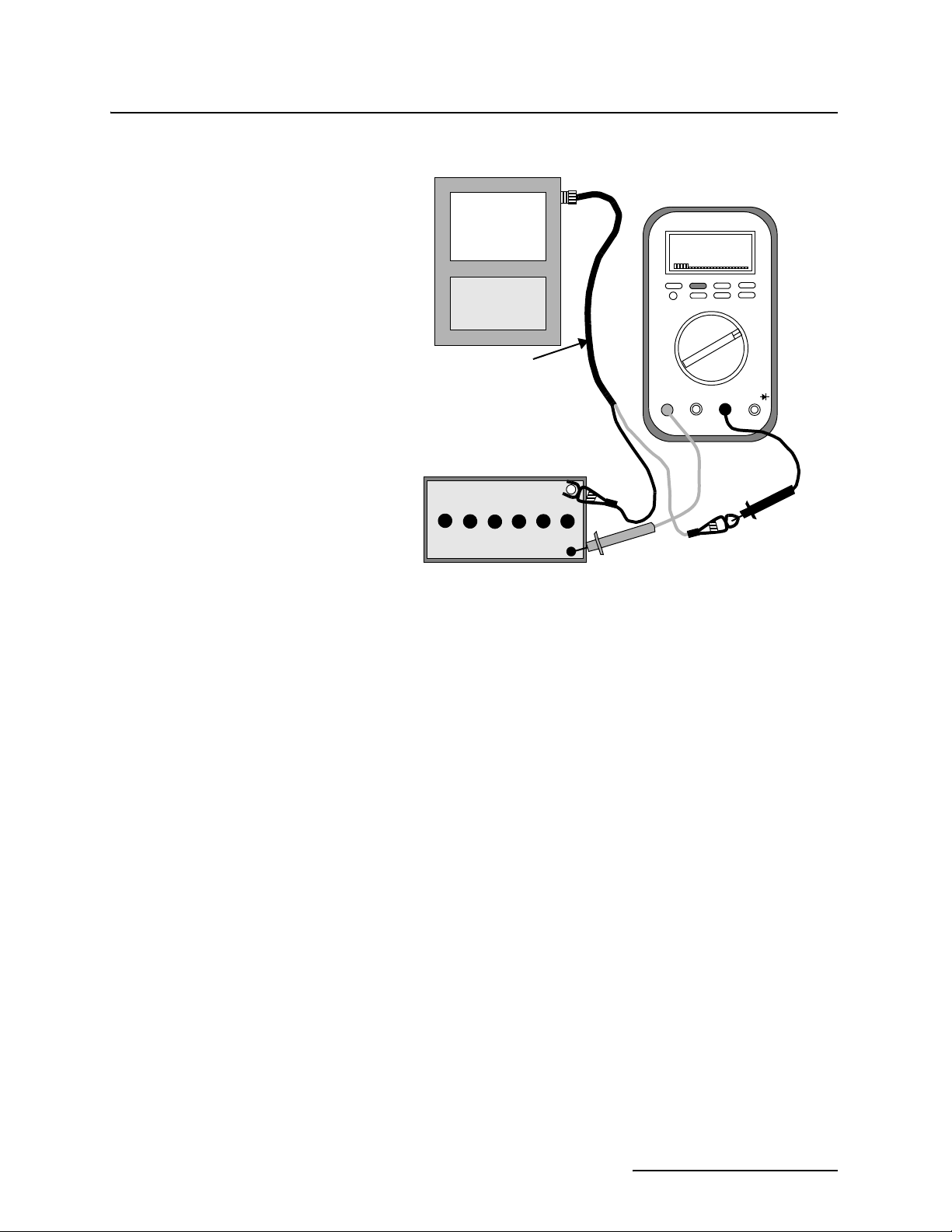

1-4 Measuring the Flow Meter Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

2-1 The YSI 600 Sonde . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-2 Measuring Level in Round Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2-3 YSI 600 Sonde Calibration Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

3-1 Nickel-Cadmium Battery Installed on a Flow Meter . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2 Power Pack Installed on a Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-3 4220 Flow Meter Suspended by the Handle (handles may vary) . . . . . . . . . . . . . 3-7

3-4 Quick-Disconnect Box for the Submerged Probe (Cover Removed) . . . . . . . . . . . . 3-9

4-1 Sensor Installed on a Spring Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-2 Spring Ring Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3 Mounting Ring in a Round Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-4 Universal Mounting Ring Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-5 Universal Mounting Ring Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-6 Submerged Probe Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-7 Typical Primary Device Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5-1 674 Tipping Bucket Rain Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-2 Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-3 pH Probe (with protective cap) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5-4 pH Parameter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5-5 The D.O. Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-6 D.O. Parameter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5-7 Mounting of Four Foot Probe Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5-8 The YSI 600 Multiple Sensor Sonde . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

6-1 Location of the Desiccant Canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Warning Disk Inside Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-3 Alignment of Grounding Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4 Changing the Chart Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-5 Changing the Ink Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-6 Lifting the Flow Meter from the Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-7 Location of the Three Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-8 Update File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-9 Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6-10 Preferences Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

iv

Page 13

List of Tables

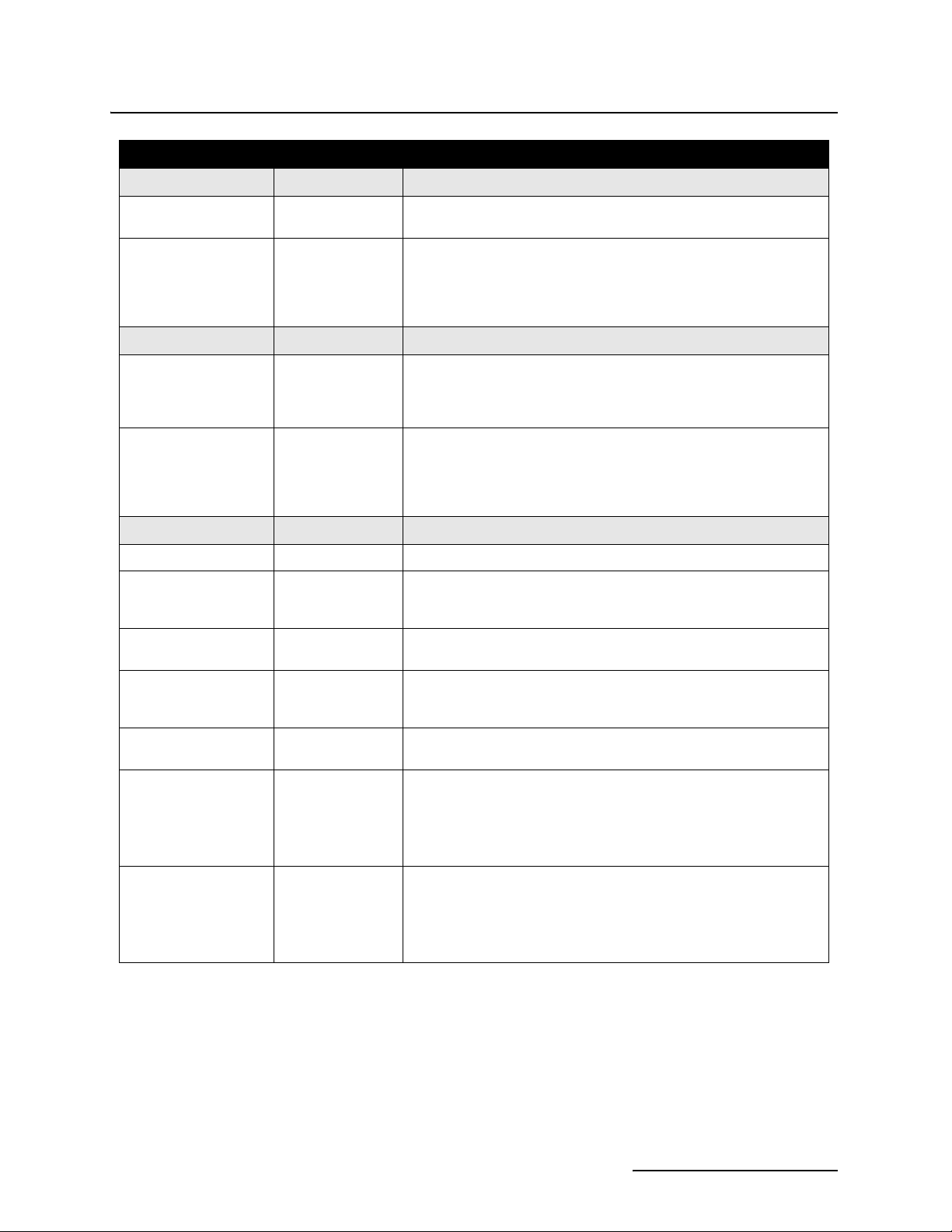

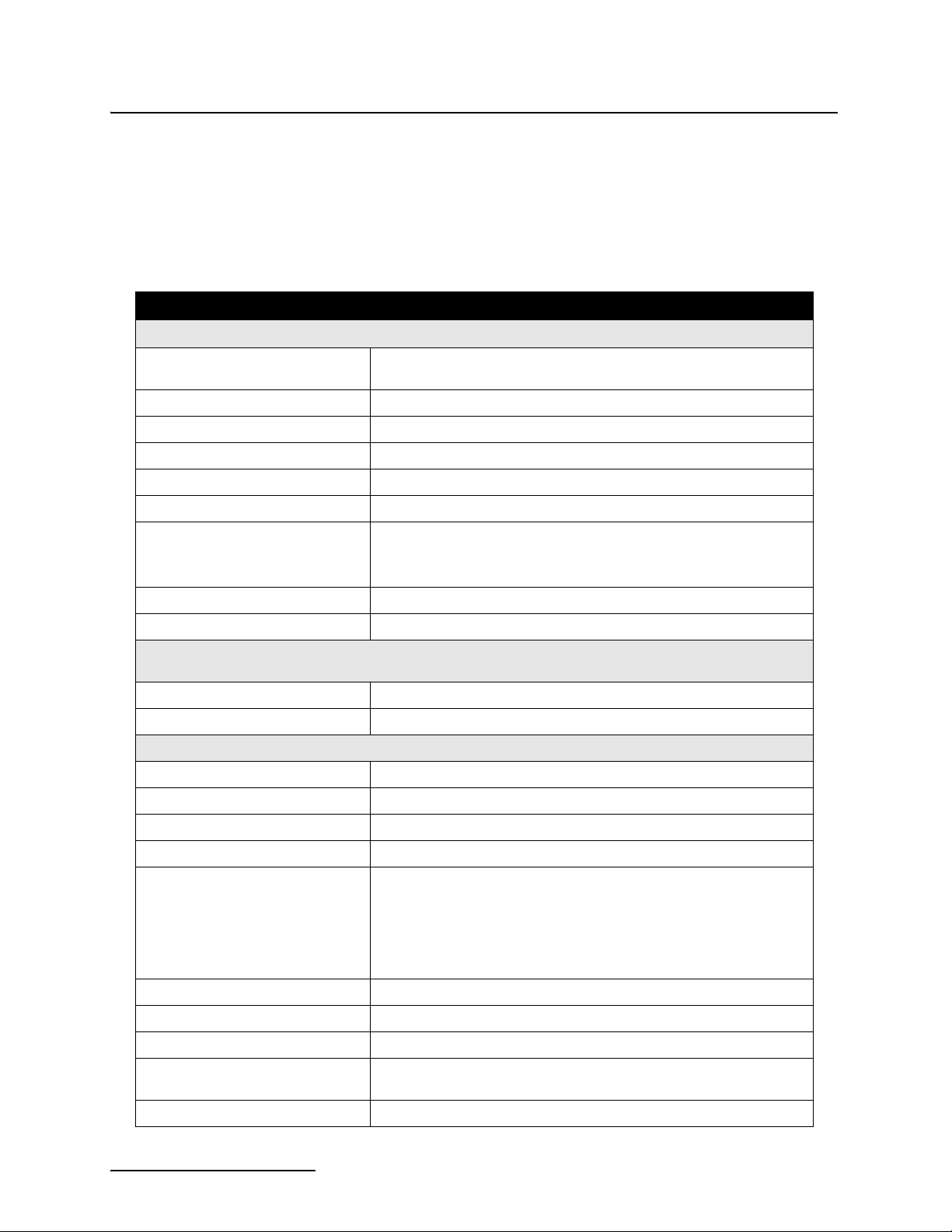

1-1 Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-2 Technical Specifications for the 4220 Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3 Technical Specifications for the 3222 Submerged Probe . . . . . . . . . . . . . . . . . . . . 1-9

1-4 Chart Longevity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-5 Battery Life Expectancy1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2-1 ASCII Output Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

4-1 Locating the Head-Measuring Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

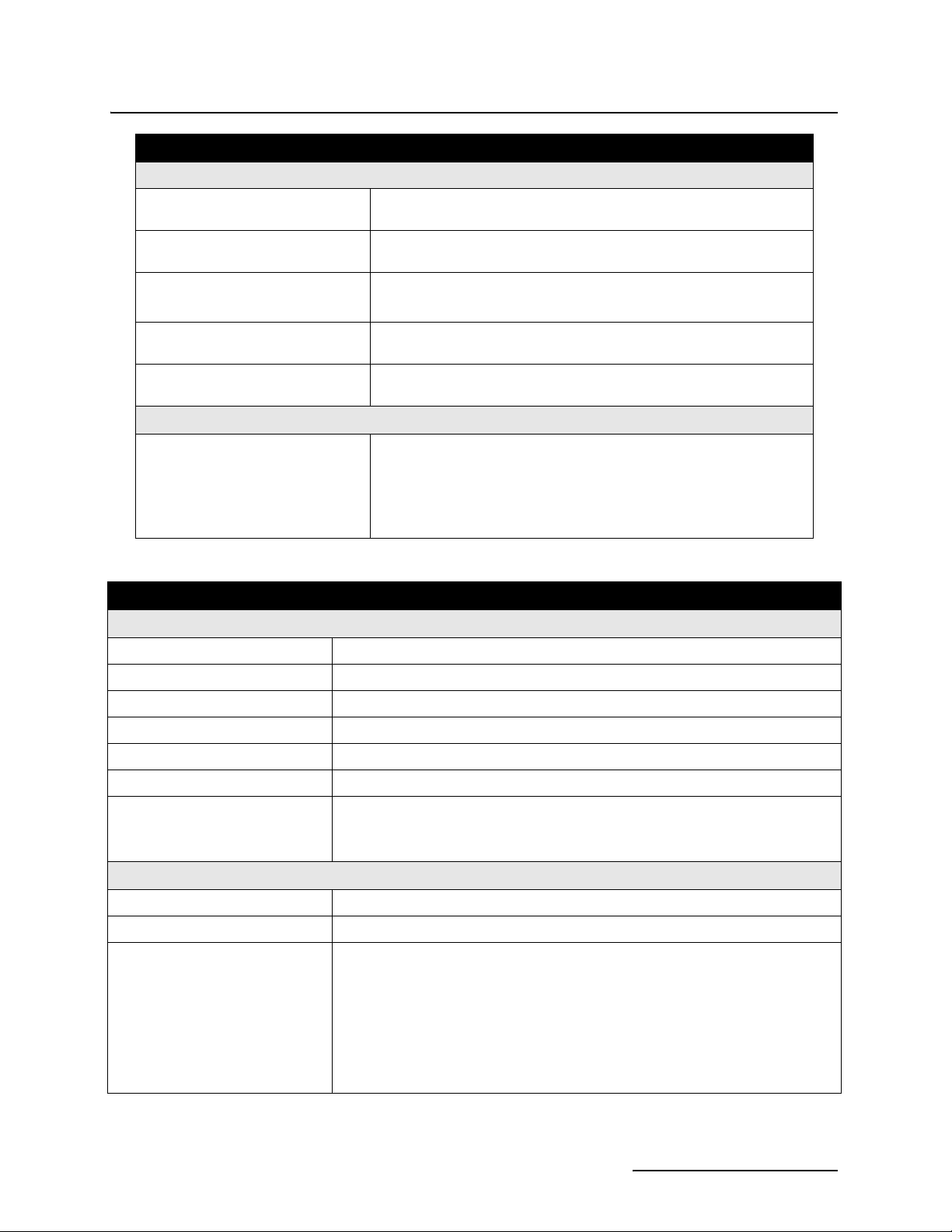

5-1 4-20 mA Output Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-2 Multiple Analog Output Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-3 pH Probe Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-4 D.O. Probe Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

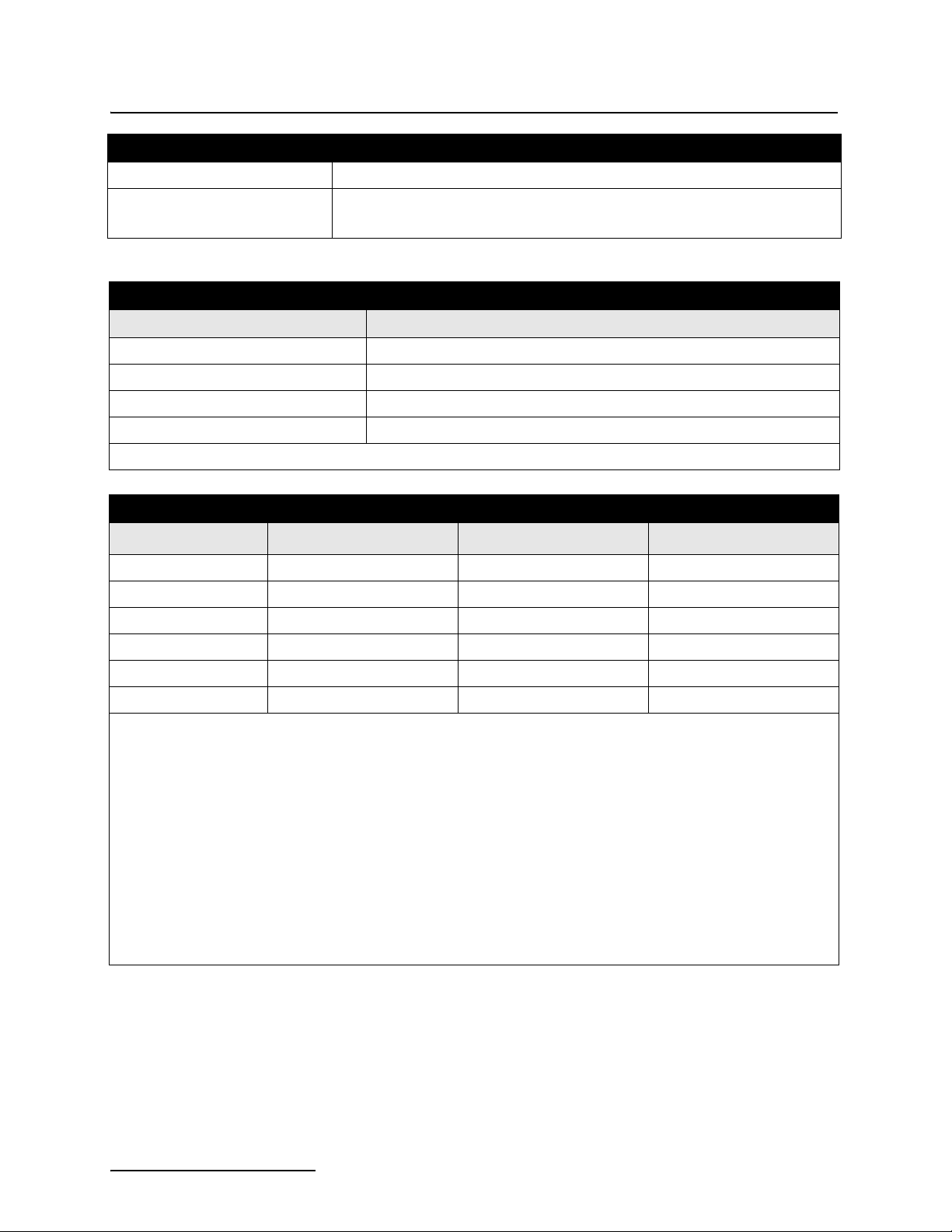

5-5 YSI 600 Probe Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

6-1 Minimum DOS and Computer Hardware Requirements . . . . . . . . . . . . . . . . . . 6-20

A-1 Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

D-1 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

v

Page 14

vi

Page 15

4220 Flow Meter

Section 1 Introduction

This section provides a general introduction to the 4220 Submerged Probe Flow Meter. It includes a description, an explanation of how the unit operates, and technical specifications.

Manual Organization

This manual provides the information necessary to operate,

maintain, and perform minor service on the 4220. The manual is

organized into five sections:

• Section 1: Introduction, operation, and specifications

• Section 2: Keypad operation and programming for all

4200 series flow meters

• Section 3: Installation and options application-specific to

this flow meter

• Section 4: Installation of the Submerged Probe

• Section 5: Options and Accessories

• Section 6: Maintenance, Service, Troubleshooting, and

Upgrades

Following Section 6 are appendices covering replacement parts,

accessory parts, worksheets, and safety information.

1.1 Description The 4220 uses a submerged probe level sensor to measure level.

The flow meter is normally used with some type of primary measuring device for measuring flow in an open channel. The 4220

has built-in standard level-to-flow conversions that cover the

vast majority of open channel flow measurement situations. You

can also enter a non-standard equation, or sets of data points

that effectively plot a user-derived flow profile for a flow stream.

The 4220 supports the Isco data acquisition, storage, and

retrieval system with optional Flowlink software. Using

Flowlink, the 4220 has enough memory to store 40,000 level

readings. An optional 4200T Modem with speech capability is

available to transmit stored data over standard dial-up telephone lines.

1.2 Compatible Equipment

The 4220 Flow Meter may be used with the following equipment:

Manufactured by Teledyne Isco

• 3700 Series Sequential, Composite and Refrigerated

Samplers

• 6700 Series Portable and Refrigerated Samplers

• 4-20 mA Output Interface

• 581 Rapid Transfer Device

1-1

Page 16

4220 Flow Meter

Section 1 Introduction

• 674 Tipping Bucket Rain Gauge

• High Low Alarm Relay Box

Non-Isco Products

• IBM Personal Computer or compatible clone with Isco

Flowlink software

• Laptop Computer with Isco software

• YSI 600 Multi-Parameter Sonde

Optional Accessories

• 4200T Modem - Speech-capable, with connector and

cable

• D.O. (dissolved oxygen) and pH parameter probes

• Submerged probe Extension Cables (Vented), in lengths

of 25 and 50 feet. (Maximum distance between probe

and flow meter with extension cables is 75 feet.)

• Quick-Disconnect Box for Submerged Probe (Allows

installation of probe as far as 1000 feet from flow meter.)

• Isco Flowlink Software for data acquisition, storage, and

management

• Mounting rings and extensions for the submerged probe.

1.3 Operating Principles When measuring flow rate, the 4220 is normally used with a

primary measuring device (weir or flume) or other open channel

flow arrangement where a known relationship exists between

level and flow rate. You can also use the 4220 to measure flow

using the Manning equation. The level measuring device is a

submerged probe. The flow meter electronically converts the

level reading into a properly-scaled flow rate value. The flow

meter also provides standard or optional flow-related output

signals to be used for:

• Flow-proportional sampler pacing and enabling

• Transmitting level and flow data to an external device

on a serial communications loop

• Data transfer to a remote location through a modem

• Control of an external 4-20 mA device

• Data transfer by a laptop computer

The flow meter contains microprocessor-controlled circuitry to

calculate level and flow rates from the output produced by the

submerged probe, store user programming instructions, operate

the display and internal printer. An alphanumeric liquid crystal

display (LCD) shows current total flow, level, and flow rate information. It also prompts you while you program the flow meter

during initial setup or subsequent program changes. An internal

printer provides a hard copy printout of the information computed by the flow meter, plots level or flow rate, and generates

reports. Connectors for other equipment you can use with the

4220 Flow Meter are on the right side of the flow meter's case.

1-2

Page 17

4220 Flow Meter

Section 1 Introduction

1.3.1 Submerged Probe Operation

1.3.2 Transducer Operation The transducer in the submerged probe detects pressure with a

The submerged probe is mounted beneath the surface of the flow

stream and measures liquid level by responding to changes in

hydrostatic pressure against the probe's sensing element. The

probe contains an IC (integrated circuit) differential pressure

transducer. This transducer provides an output signal that

changes proportionally to the pressure placed against it by the

flow stream. The 4220 converts this signal to the flow rate with

level-to-flow rate conversion formulas or tables characteristic of

the primary device at the site.

small stainless steel diaphragm that transfers pressure to a

silicon diaphragm containing a resistance bridge. Pressure

against one side of this diaphragm causes it to flex slightly. This

flexing causes the resistors on one side of the bridge to stretch,

while the resistors on the other side of the bridge compress. The

result is an unbalance in the current across the bridge, that is

proportional to the increase of hydrostatic pressure caused by an

increasing level in the flow stream. This bridge is fed from a constant-voltage source, so any change in its output is a result of

hydrostatic pressure against the transducer.

CAUTION

You may need to disassemble the submerged probe for cleaning. If you do, do not touch the metal diaphragm inside the

probe with either your fingers or tools. Deforming the diaphragm even slightly may ruin the transducer. Flush the diaphragm with gently running water only.

The inner face of the transducer disk is referenced to the atmosphere through the internal vent tube that runs the full length of

the probe’s cable. The outer face is subjected to the pressure

exerted by both the flow stream and the atmosphere. The difference between the two pressures exerted on the diaphragm is

the hydrostatic pressure.

CAUTION

Any obstruction in the reference port of the cable could cause

faulty level readings. Moisture in the reference port can lead to

permanent internal damage to the probe. Keep the reference

port free of debris and moisture.

The output from the transducer is low and the impedance is high,

so an in-line amplifier boosts the signal to make sure the flow

meter can still detect it even when the submerged probe and the

flow meter are separated by some distance. The amplifier is

encapsulated in the box mounted on the submerged probe cable

near the connector.

1-3

Page 18

4220 Flow Meter

Section 1 Introduction

Figure 1-1 Submerged Probe Level Sensor with Standard Tip

1.3.3 Two Probes Available Teledyne Isco offers two different submerged probe level sensors

for use with the 4220. The standard unit is intended for operation in depths from 1 inch to 10 feet maximum. The other unit is

capable of operation to depths as great as 30 feet. The difference

in the probes is in the pressure transducer used inside. The two

are not interchangeable. You must select the appropriate unit

based on the maximum anticipated depth in your flow situation.

1.4 Software Upgrades Software for the 4200 Series Flow Meters can be upgraded

without the unit being returned to the factory. With Flash

Memory, software updates can easily be installed in the field

with a disk, a computer, and a cable. For more information about

installing software upgrades in the 4220 Flow Meter, see Section

6.

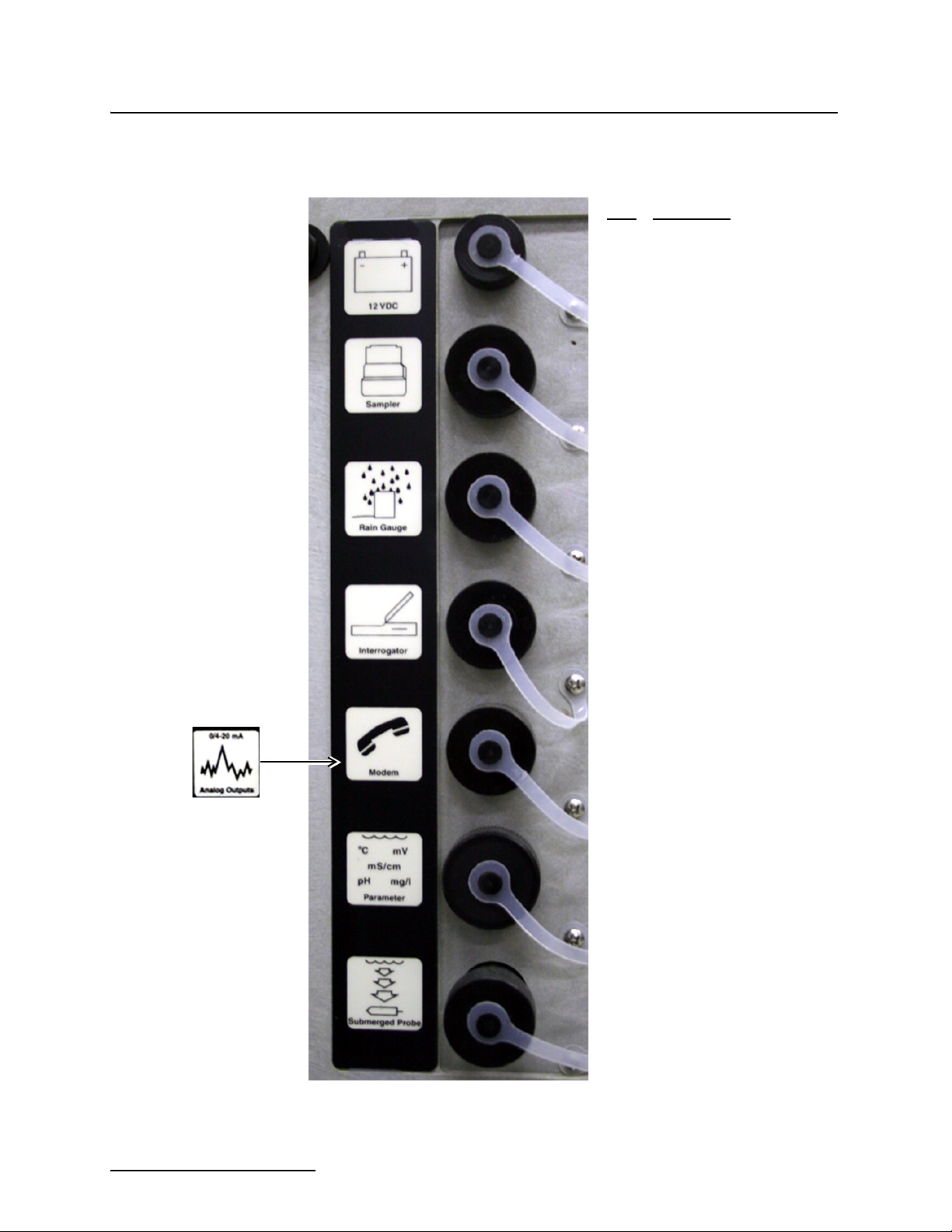

1.5 Controls, Indicators, and Connectors

The controls, indicators and connectors of the 4220 Flow Meter

are listed in Table 1-1, and their functions are briefly described.

Refer to Figure 1-2 for a view of the controls and indicators, and

Figure 1-3 for a view of the connectors and their pin functions.

1-4

Page 19

4220 Flow Meter

Section 1 Introduction

Figure 1-2 4220 Controls and Indicators

1-5

Page 20

4220 Flow Meter

Section 1 Introduction

Pin Function

Power

Sampler

Rain Gauge

Interrogator

A Ground

B 12V

A 12V

B Ground

C Flow Pulse Output

D Bottle Number Input

E Event Mark Input

F Inhibit/Enable Output

A 12V

B Ground

C SDO

D Rain Gauge Input

A 12V

B Ground

C Sense Line

D SDO

E SDI

F Analog Output Pulse

Modem

(or Analog

Output)

A = Channel 1 (-) Red

B = Channel 3 (+) Green

C = Channel 1 (+) White

D = Channel 2 (-) Brown

E = Channel 3 (-) Black

F = Channel 2 (+) Blue

Parameter

Submerged

Probe

Figure 1-3 4220 Side View Showing Connectors and Pin

Functions

1-6

B Tip

C Ring

A 12V

B Ground

C Input Signal (+)

D Temp (-)

E Temp (+)

F Switched 12V

G Input Signal (-)

A 12V

B Ground

C Level (+)

D Level (-)

E Ground

Page 21

4220 Flow Meter

Section 1 Introduction

Table 1-1 Controls, Indicators, and Connectors

Controls Settings Function

ON/OFF On - Off Turns the flow meter on and off. Internal memory is protected with a

standby battery. See Section 2.

Keypad Momentary

Switches

24-key, four column matrix. Programs flow meter through a series of

keystrokes prompted by messages on the display. Certain keys perform specific functions (printing reports or entering program choices

into memory). Arrow keys move through menus. Number keys enter

numeric values. See Section 2.

Indicators Reading Function

Display Multi-function 2-line, 40 characters per line, liquid crystal display (LCD). Prompts

Internal Plotter Various Provides hard copy of total flow, level or flow rate variation over

you through program procedure; displays total flow, present flow

rate, and level. May also display parameter readings, if sensors

present.

time; provides sampling information and a printout of the program.

Prints reports. Generates three different linear data plots. Chart

characters and plots are generated on plain paper roll with an ink

ribbon.

Connector Type Function

12 VDC 2-pin male M/S Connects 12 VDC power to flow meter.

Sampler 6-pin male M/S Connects flow meter to sampler; provides flow pulses to sampler;

receives sampler bottle number, composite sample, and event mark

signal.

Submerged Probe 5-pin, female M/S Connects submerged probe level sensor to flow meter. Also pro-

vides connection for reference port vent tube.

Rain Gauge/YSI 600

Sonde

9-pin Male M/S

(Custom)

Connects flow meter to an Isco 674 Rain Gauge or YSI 600

Multi-Parameter Sonde. Also provides output to High Low Alarm

Relay Box.

Interrogator 6-pin female M/S Provides serial data in/out and power. Can also be used with the

Modem (optional)

Analog Output

(optional)

Parameter 7-pin female M/S Connects flow meter to parameter sensor: temperature, pH, or D.O.

5-pin male M/S

6-pin male M/S

4-20 mA Output Interface and the 581 Rapid Transfer Device.

Connects flow meter to telephone line for remote data transmission.

This connector will only be present on units that have the optional

modem installed.

Provides analog data output from the flow meter to external,

non-Isco control and recording devices.

Note that you can only have temperature and one parameter (pH or

D.O.) at the same time.

NOTE: The 270 D.O. module is no longer available from Teledyne

Isco.

1-7

Page 22

4220 Flow Meter

Section 1 Introduction

1.6 Technical Specifications

The technical specifications for the 4220 Flow Meter are found in

Table 1-2. The anticipated longevity for a roll of paper used in the

internal plotter is shown for various chart speeds in Table 1-4.

Battery life expectancy is found in Table 1-5.

Table 1-2 Technical Specifications for the 4220 Flow Meter

Physical Specifications

1

Size 16" high × 11 1⁄2" wide × 10

power source attached).

Weight 17 lb. 4 oz. (7.7 kg)

Material High-impact molded polystyrene structural foam.

Type Self-certified NEMA 4X Enclosure.

Display Type 2-line, 40 character/line alphanumeric dot matrix liquid crystal.

Power 12 -14 VDC, 16 mA average at 12.5 VDC (Plotter set at 1" per hour).

Typical Battery Life 7-10 days with plotter at 1" per hour and 4 Ampere-hour Ni-Cad bat-

tery.

14 days with plotter turned off.

⁄2" deep (40.6 × 29.2 × 26.7 cm) (without

Operating Temperature 0° to 140°F (–18° to 60°C).

Storage Temperature –40° to 158°F (–40° to 70°C).

Additional Power Required

for Optional Equipment

Modem 60 mA maximum during operation; 0.1 mA maximum standby.

High-Low Alarm Relay Box 10 mA standby, typical; 190 mA - both relays operated.

Internal Printer

1

Chart Speeds Off,

Ribbon 19.7 ft. (6 m) black nylon - replaceable.

Operating Speed 1.5 lines per second at 68° F. (20° C).

Character Size 0.09" high × 0.07" wide (2.4mm × 1.7 mm), 12 pitch.

Printer Recording Span

Chart Resolution

Display Resolution

Paper 4.5" wide × 65 ft. (11.4 cm × 19.8 m) plain white paper, replaceable.

Printer Reliability 2.5 million lines MCBF (mean cycles before failure).

Reports Printed Program selections, interval activity reports, flow meter history.

⁄2, 1, 2, or 4 inches per hour.

User-selected from 1⁄4 ft. (3.6 cm) to over 30 ft. (9.1 m) with multiple

over-ranges.

1

⁄240 of selected recording span

0.001 ft. (0.3 mm)

Printer Recording Modes Level, flow rate; includes totalized flow, sampler events, rainfall, tem-

Plotted Linear Data 3 different linear plots can be printed at the same time.

perature, velocity, pH (or) D. O. (dissolved oxygen).

1-8

Page 23

4220 Flow Meter

Section 1 Introduction

Table 1-2 Technical Specifications for the 4220 Flow Meter (Continued)

Flowlink Data Storage and Retrieval System

Memory Partitions Maximum of 6 user-defined memory partitions for level or event stor-

age.

Data Storage Rate of data storage user-selected in 1, 2, 5, 10, 15, 30, 60, or 120

minute intervals.

Baud Rates Serial connection - 300, 1200, 2400, 4800, or 9600 baud.

Serial connection with the optional internal modem - 2400 baud.

Storage 80,000 bytes, apportioned per reading as follows: flow = 4 bytes,

Level Data Level readings are stored as a 16-bit number representing .1mm

level = 2 bytes, sample = 4 bytes, pH or D. O. = 1 byte)

(0.0394 inch); effective range is 0–65279 meters.

Flow Conversion

Flow Rate Calculations The flow meter creates a table of level-versus-flow rate from program

selections; this table divides the level span into 256 equally-spaced

level increments. Each level increment corresponds to a specific flow

rate. During data collection, if the measured level falls between two

table values, the flow meter will perform a linear interpolation to calculate the flow rate value.

Table 1-3 Technical Specifications for the 3222 Submerged Probe

Physical Specifications

Dimensions

Weight 3 lb, (including amplifier box and cable) (1.4 kg).

Body Material CPVC (chlorinated polyvinyl chloride) housing, stainless steel.

Cable Length 25 ft. (7.6 m).

Operating Temperature 32° to 160°F (0° to 71°C).

Storage Temperature –40° to 160°F (–40° to 71°C).

Maximum Distances

(between flow meter and level sensor)

7

⁄8” diameter × 91⁄2" long (2.2 × 24.1 cm).

75 feet (22.7 m) with optional extension cables.

1,000 feet (305 m) with optional Quick-Disconnect Box.

Level Measurement Specifications

Measurement Range 0.1 to 10.0 ft. (0.03 to 3.05 meters).

Maximum Level 20.0 ft. (6.1 m).

Measurement Accuracy Standard Sensor:

0.033 to 5.0 ft: ±0.008 ft/ft (0.01 to 1.52 m: ±0.008 m/m)

>5.0 ft: ±0.012 ft/ft (>1.52 m: ±0.012 m/m)

@ 77° F (25° C). Includes non-linearity, repeatability, and hysteresis, but does not

include temperature coefficient.

Specifications include nonlinearity, repeatability, and hysteresis, but do not

include a temperature coefficient.

1-9

Page 24

4220 Flow Meter

Section 1 Introduction

Table 1-3 Technical Specifications for the 3222 Submerged Probe (Continued)

Compensated Temperature Range 32° to 122°F (0° to 50° C).

Temperature Error (over compensated temperature range)

0.1 to 4.0 ft. (0.03 to 1.2 m) ±0.005 ft. per degree F

4.0 to 10.0 ft. (1.2 to 3.1 m) ±0.007 ft. per degree F

Table 1-4 Chart Longevity

Chart Speed, Inches/Hour Time to Empty Roll

1

/4 Days

1

/2 Days

1

/2 Days)

4 195 Hours (8

216

132

0.5 65 Days

Note: Times assume Report Generator is turned off.

Table 1-5 Battery Life Expectancy

Flow Meter Settings Minimum

Reading Interval 5 Minutes Continuous Continuous

Printer Off Off 4” per Hour

Report Generator Off Off Every Hour

Average Current 14 mA 9 mA 23 mA

Nickel-Cadmium

Lead-Acid

Notes:

1. These figures are approximations based on calculations; actual times for your flow meter may vary due to

factors of battery age, charge condition, operating temperatures, and component differences. “Minimum” settings are those providing the lowest average current draw. “Maximum” settings are those requiring the highest current

draw. Your program should draw somewhere between the two.

2. The default settings are the program entered at the factory. You can reset the flow meter to the default program at

any time by holding down the 1 and Clear Entry keys at the same time.

3. The nickel-cadmium battery has a capacity of 4.0 ampere-hours at 20° C.

4. The lead-acid battery has a capacity of 6.5 ampere-hours at 20° C.

Both batteries are assumed to be fully charged with at least 95% of rated capacity and in good condition. These calculations also assume a 5% safety factor at the end of discharge. Lead-acid batteries should never be completely

discharged.

5. All fractional times are rounded down, rather than up.

3

4

10.7 Days

17.4 Days 27 Days 10.5 days

5

Default

16.6 Days 6.5 Days

2

1

Maximum

1.7 How to Make Battery Calculations

1-10

To calculate battery life expectancy for an installation, you must

know two things:

•The capacity of the battery you are using

•The average current draw of the flow meter or (other

device) powered.

Page 25

4220 Flow Meter

Section 1 Introduction

Battery capacity is expressed in ampere-hours. The battery

manufacturer provides this information for each battery. This

value is the product of a load current times an arbitrary time

period, ten hours for nickel-cadmium batteries, and twenty hours

for lead-acid types. The terminal voltage of the battery at the end

of this time period is the discharged cell voltage, 10 volts for

nickel-cadmium and 10.5 volts for lead-acid types. Note that batteries are fully discharged well before the terminal voltage drops

to zero volts.

Isco batteries are rated at 4 ampere-hours for the

nickel-cadmium and 6.5 ampere-hours for lead-acid types.

Convert the battery current capacity into milliamperes and then

divide this figure by the average current drawn by the unit. This

will give you a number in hours. Divide that figure by 24, and

you will have the number of days.

Note that the published ampere-hour figures do not mean that

you can expect to draw 4 amperes from the nickel-cadmium

battery (or 6.5 amperes from the lead-acid battery) for one hour.

At the one-hour rate, discharges are typically less than half the

ten- or twenty-hour rate.

To convert ampere-hours to milliamperes, multiply by 1,000.

Examples:

4 ampere-hours × 1,000 = 4,000 mAh.

6.5 ampere-hours × 1,000 = 6,500 mAh.

If you divide this figure by the average current of the flow meter,

say 15 mA, you will have:

4,000 ÷ 15 = 266.67 hours.

Divide this number by twenty-four to get days:

266.67 hours ÷ 24 = 11.1 days.

As a margin of safety, we suggest you subtract 10% from this

number (100% – 5% for 95% capacity and 5% for a reserve at the

end of discharge).

11.1 – 1.1 = 10 days

This is the battery expectancy for a nickel-cadmium battery with

a 15 mA continuous average drain, with a 10% derating factor.

You can use the same method to calculate for lead-acid batteries,

except the current will be 6,500 mA, and the period correspondingly longer, in this case a little over 16 days. You can run the full

number of days calculated without derating if your batteries are

new and at 100% capacity, but you will leave yourself no safety

factor if you are in error on either of these assumptions.

Remember, if the battery fails, there will be a period of time

during which no measurements will be taken, (and no data

stored, if you are also using Flowlink® software).

Batteries lose capacity as they age. Capacity also drops off as

temperature falls. Low temperatures make less capacity

available due to the slowing of the chemical reactions, while high

temperatures accelerate the deterioration of battery plate separators, particularly if they are aged. Note also that

1-11

Page 26

4220 Flow Meter

Section 1 Introduction

nickel-cadmium batteries show fairly rapid rates of self-discharge. A battery that is fully charged and then placed in storage

will lose some capacity each day. In a week, this could easily be

5% or more.

When using lead-acid batteries, you must be careful to avoid

complete discharge, as this may cause cell reversal, which will

ruin the battery. Also, complete discharge in low temperature

ambients may cause the battery to freeze, which can deform the

plates or even crack the case. Always operate these batteries

with a reserve factor!

1.7.1 Current Draw Calculating current draw for a 4220 Flow Meter is somewhat more difficult than calculating the battery capacity. You cannot simply measure the idle current of the unit unless the printer and report generator are turned off in the program. These functions require power periodically, but not all the time. If the figures given in the previous table are not satisfactory for your application, you can use the following procedure (shown in Figure 1-4) to measure the actual current draw.

Note

Do not attempt this procedure unless you have the proper

equipment available and know how to make electrical measurements.

To measure current for a varying load requires a more-sophisticated type of multimeter, one that is capable of averaging high

and low readings over a period of time. You should set the meter

on MIN/MAX and let it run with your program for several hours

or more. Other manufacturers’ meters are also acceptable, but

only if they are capable of averaging current draw. For a more

representative test, the area-velocity sensor should be attached

and submerged in water. You should run the test for at least

eight hours, longer if necessary, or until the flow meter has

exercised the entire program. The longer you run the test, the

more accurate the average will be.

1-12

Page 27

4220 Flow Meter

Section 1 Introduction

Fluke® 87

(or other current-

averaging meter)

FLUKE 87 TRUE RMS MULTIMETER

00I5

Flow

Meter

Connect Cable

60-1394-023,

or you can make

your own.

Battery, 12 Volt

A

mA μA

–

Com

+ lead

mA

V Ω

A

Figure 1-4 Measuring the Flow Meter Current

Additional information about batteries used to power Isco

equipment is available from the Isco Power Products Guide,

which is shipped with this manual and any flow meter order.

+

+ clip

A good quality, adjustable, regulated DC power supply

can be substituted for the 12-volt battery. The power

supply should have at least 3 Amperes output, preferably more, and capable of overcurrent surges.

1-13

Page 28

4220 Flow Meter

Section 1 Introduction

1-14

Page 29

4220 Flow Meter

Section 2 Programming

2.1 Getting Started You must program the 4220 Flow Meter to accurately monitor a

flow stream. You must also install the submerged probe level

sensor. The 4220 will usually also need a primary measuring

device, a structure placed across a stream that regulates flow.

This section describes programming the flow meter with the aid

of the keypad and display. There are nine program steps that

control all aspects of the flow meter's operation.

Teledyne Isco ships the flow meter with a program already

installed that is called the default program. You can use this

program as an example to see the flow meter's capabilities. Note

that the default program is just to test the unit at the factory.

The flow meter's internal computer must always have something

programmed into the unit, so that becomes the default program.

Your flow situation will usually require other programming

choices. The text provided with each screen explains the reasons

for the various menu options.

2.1.1 Operation of the

Display

The display is a two-line, forty character-per-line liquid crystal

(LCD). It has a backlight feature for easy viewing in low light situations. The display has three different operating modes:

normal, programming, and messages. In the normal mode,

the display shows such things as level, flow rate, total flow,

parameter measurement, etc. In the programming mode, the

top line of the display shows each step as you work through the

program while the bottom line shows the choices available for

that step. In the message mode, the display provides instructional information, such as how to leave programming, or what to

do if you have entered a number that is out-of-range.

Following is a “normal” display on the flow meter. This is typical

of what the flow meter will display when it is in the normal operating mode and you are not programming it.

0000004.78 CF 1.13 FT 16-NOV-02

1.03 CFS (X X) 8:25:37

An interpretation of the numbers on this display would be as

follows: Time and date will be replaced by pH/D.O. and temperature if you are using parameter sensing. The (X X) to the right

of the time indicates letters that may appear from time to time

on the 4220 Flow Meter.

The letter C will appear when the flow meter is communicating

with a remote computer (Flowlink applications only). The letters

E or D will appear (Enable or Disable) when the sampler enable

function (step 6) is programmed by condition. (Programmed by

2-1

Page 30

4220 Flow Meter

Section 2 Programming

condition means that the flow meter will enable the sampler only

when a certain condition or set of conditions, sensed by the flow

meter, are met.)

Total Flow Current Level Date (or pH/D.O.)

Flow Rate Time (temperature)

Following is a typical programming display on the flow meter.

One of the items in the second line will be flashing. The item

flashing is the selection currently held in memory.

TOTALIZED VOLUME UNITS

• CF • • GAL • • M3 • • AF • • L • • MGAL •

Following is a typical display providing instructional information:

CHANGES HAVE BEEN MADE IN STEP

PRESS '0' TO CONTINUE, PRESS '1' TO DISCARD

If you stop programming for more than two minutes, the flow

meter will time out, and whatever is on the display (message or

program step) will revert to the “normal” display, shown previously.

The program consists of steps and substeps. The steps are listed

on the flow meter front panel. Most steps contain several substeps. Generally, you need to complete all the substeps before

stopping, or the flow meter will reject the changes you made for

that step after it times out. There are some exceptions.

The flow meter keeps in memory any changes that you made for

the finished steps (all substeps completed before stopping). Most

steps not finished when you stop will return to the previous

selection.

2.1.2 Keypad Functions Programming is done on the flow meter's keypad with prompts from the display. The following sections describe the function of each key.

OFF and ON - These two keys turn the flow meter off and on.

Go To Program Step - Pressing this key lets you go directly to a

particular program step without passing through all the steps of

the entire program. The display will ask you to enter the number

of the step you want to program. Enter the number by pressing

one of the number keys. There are nine program steps, so

numbers from one to nine are valid.

Exit Program - Press this key when you want to leave the programming mode and return to the normal operating mode.

Clear Entry - This key lets you return to the previous entry for

a program step if you have changed the entry, but not yet pressed

Enter.

Enter/Program Step - This key has two functions. One is to

enter a program selection into the flow meter's memory (Enter).

The other is to step through the program (Program Step).

2-2

Page 31

4220 Flow Meter

Section 2 Programming

Print Program - Pressing this key will make the flow meter

print out a complete list of the current program choices retained

in memory.

Print Report - One function of the flow meter is to print reports

of all recorded activity at regular intervals. The contents of these

reports are defined in step 1. If you set up the report generator,

you can have a report printed anytime by pressing this key. The

report will cover the time from the last scheduled report up to

when you press this key.

The flow meter will print its next report at the next scheduled

time. Note that if power fails for five minutes or more, the flow

meter will print a report when power is restored that will cover

the interval between the last report and the time that the power

failed. The next report will cover the time from the power failure

to next scheduled report time.

Chart Advance - Pressing this key causes the paper chart to

advance through the printer at the fastest possible speed.

Nothing will be printed while you are holding this key.

Chart Reroll - It is possible to unroll the chart from the take-up

roll on the flow meter by pulling it out with your hands. Pressing

this key lets you rewind the chart onto the take-up roll.

Number keys - These keys let you enter numeric values into the

flow meter when programming.

Decimal Point - This key lets you enter a decimal point into a

numeric value when programming. On flow meters equipped

with the optional modem only, you can use this character as a

comma (delay) when entering dialout numbers.

Arrow keys - These keys, referred to as the left and right

arrow keys let you select a programming option by moving

across the menus shown on the second line of the display.

+/– key - This key lets you enter a plus or minus to a quantity

entered. Its most common use is in entering values for the

equation, a method of flow conversion. On flow meters equipped

with the optional modem only, you can use this character as a

dash when entering dialout numbers.

2.2 Programming Procedure

To start programming, turn on the flow meter and wait for the

display to settle. Then either press the Enter/Program Step

key (generally referred to as Enter) or the Go To Program

Step key.

The display will change to two lines of text; the first line

describes the step you are programming and the second line

shows the choices available. One choice shown will be flashing.

The flashing indicates that this is the current one held in the

memory. If you are satisfied with this choice, just press Enter,

and the flow meter will advance to the next step.

2-3

Page 32

4220 Flow Meter

Section 2 Programming

If you want a different choice from the one that is flashing, you

can move across the display by using the left and right arrow

keys. Each time you press the right arrow key, the flashing

selection will move one position to the right. This will continue

until the flashing cursor is over the last display.

You may notice an arrow pointing to the edge of the display. This

indicates additional choices are available beyond what you can

see. By continuing to press the right arrow key you can view

these unseen menu options. After reaching the furthest option,

the arrow will move to the left side of the display, indicating that

there are options unseen to the left. These will be the options you

started with. If you want to go back to one of them, use the left

arrow key until the option you need reappears. When the

desired selection is flashing, just press Enter. The display will

then automatically advance to the next step of the program.

All of the program steps contain “substeps” that must be completed before you advance to the next step. Some steps, like

Reset Totalizer contain only a few substeps. Some steps require

the entry of a numeric value. Program these steps by using the

number and decimal keys to enter the value.

Note that it is possible to program the flow meter in the shop,

rather than at the job site, with the exception of step 3, Adjust

Level/Parameters. To set level you must make an accurate measurement of the level in the flow stream and then enter that

value. This can only be done at the job site.

If you are programming the flow meter for the first time, generally you will press Enter, start with step 1, and go on from

there. If the flow meter has been in use and you need to change

only certain aspects of the program, you would more likely use

the Go To Program Step key. With this key you can go directly

to the program step you need to change, which saves time.

If you change an entry and do not like it you can make the

display revert to the original entry by pressing Clear Entry. If

you have already pressed Enter, however, the new value will be

in memory. To change it, press Exit Program. If you are in the

middle of a program step with multiple substeps, the flow meter

will display, “Changes have been made in step; press 0 to continue or 1 to discard.” If you press 1, the display will return to

normal and the last step you were working on will revert to its

previous selection. (Any program step you completely change

before exiting will remain changed.)

You can re-enter the program with either Enter or the Go To

Program Step keys. If you become confused while programming, the best suggestion is to press Exit Program and

start over. Also remember that you can have the flow meter print

a complete list of your program choices by exiting the program

and by pressing the Print Program key as soon as the display

returns to the normal operating condition, displaying level and

total flow, etc.

2-4

Page 33

4220 Flow Meter

Section 2 Programming

2.3 Description of Program Steps

2.3.1 Step 1, Operating Mode

The Program Steps for the 4220 are:

1. Operating Mode

2. Flow Conversion

3. Adjust Level/Parameters

4. Reset Totalizer

5. Sampler Pacing

6. Sampler Enable

7. Alarm Dialout

8. Printer

9. Reports/History

Note

If you choose NOT MEASURED for any selection, the flow

meter will make no further reference to that value or function

for the rest of the program, and you will not be able to activate

that process or function later on unless you reprogram step 1.

If there is a feature or option you need that does not appear on

your display when the manual says it should, return to step 1

and make sure you have not inadvertently left it turned off in

either the Program or Setup menus.

Note that selecting some features automatically excludes others. For example, selection of pH or D. O. excludes the other

parameter, unless you use the YSI 600 Multi-Parameter

Sonde, which measures pH, D.O., and conductivity at the

same time.

Step 1, Operating Mode, determines how you set up the flow

meter. In this step there are two choices, Program and Setup.

Program advances you to step 2, and from there on you correlate the flow meter to the flow stream. Setup selects various

basic “housekeeping” features for the flow meter. Here you

determine the internal clock, site identification, measurement

setup, hysteresis, report contents, operation of the display backlight, and program lock. In Program you select the units of

measure the flow meter will use for the display, calculations, and

reports.

This method keeps program size manageable and makes programming more efficient. By turning off unneeded features of the

program early, you do not have to keep de-selecting those features over and over as you work through the program.

Consequently, you should choose carefully from the first step. We

suggest you study the program first, then fill out the Pro-

gramming Worksheets (in the back of this manual), and program

the flow meter last, if you are unfamiliar with the unit.

2-5

Page 34

4220 Flow Meter

Section 2 Programming

2.3.2 Step 2, Flow Conversion Type

Step 2, Flow Conversion Type, determines how the flow meter

calculates flow rate and total flow. For the 4220 Flow Meter, flow

rate is calculated by knowing the measured level and (usually)

the characteristics of a structure called a primary measuring

device.

A primary measuring device is a structure placed across a flow

stream through which the entire stream must flow. These devices

are made in a number of styles and sizes, but they all have one

thing in common: For any type of primary measuring device

there is a known relationship between the level in the flow

stream ahead of the device and flow rate through the device.

Consequently, after you measure level with the flow meter, it can

calculate flow rate and total flow from the measured level, by

consulting built-in look-up tables.

Detailed information about many commonly-used primary measuring devices is provided in the Isco Open Channel Flow Mea-

surement Handbook. This useful book provides formulas, flow

rates at various levels, and values for maximum head, as well as

much interesting descriptive material, and is available from

Teledyne Isco. If your installation uses a nonstandard primary

device, you should consult the manufacturer of the device for flow

rates at given levels. The flow meter will then calculate a flow

conversion for such a device on the basis of the manufacturers'

data you enter as data points or an equation. In some

instances, a nonstandard primary device could be supplied with a

flow equation; you can enter that equation into the flow meter

and the flow meter will calculate the flow rate from that

equation.

Note however, that it is not always necessary to have a primary

measuring device. The 4220 Flow Meters can measure level and

calculate flow without having any primary device installed in the

flow stream. Sometimes the shape of the flow stream itself forms

the primary device.

The Manning formula uses the shape of a pipe or channel and

its slope to calculate flow in open (non-pressurized) pipe situations.

The conversion types available are WEIR/FLUME, MANNING,

DATA POINTS, and EQUATION.

You us e Weir/Flume flow conversion when your primary measuring device is a weir or a flume. A weir is a wall or dam across

the flow stream. Water must rise to the point where it flows over

the top of the wall. The measured level upstream behind the wall

is used to calculate the flow rate. Flumes differ from weirs in

that there is no wall or barrier, but instead a restriction, typically

a sharp narrowing or change in the slope of the channel that

restricts the flow. Again, the measured level of the stream at

some point ahead of the restriction is used by the flow meter to

calculate flow. In this flow conversion mode, the flow meter uses

internal look-up tables for many common primary measuring

devices.

2-6

Page 35

4220 Flow Meter

Section 2 Programming

An Equation is used when you have a non-standard primary

device, or want to use different values from those programmed

into the look-up tables of the flow meter. Equation uses the

standard flow equation:

Q = k1H

Where Q equals flow rate; k1 and k2 are constants; H is level (or

head), and P1 and P2 are the powers to which the two H terms

are raised. (Your equation may not have the second term, in

which case you would enter 0 for the second constant, k2.) Most

common primary devices are supported in the flow meter's

software, so generally you will not need this option. But it is

available for those needing to enter their own values, or for those

who have a nonstandard primary device for which an equation

can correlate level and flow.

MANNING Flow Conversion uses the Manning formula to calculate flow in open or closed (non pressurized) gravity-flow situations based on slope, diameter, and roughness of the pipe. The

Manning formula is named for its developer, Robert Manning, a

19th-century Irish civil engineer. There is no primary measuring

device as such. Instead the pipe, with considerations for its slope

and internal roughness, serves as the primary device. The 4220

Flow Meter can calculate flow in round pipes, rectangular,

U-shaped, or trapezoidal channels based on this formula.

Data Point Flow Conversion (DATA POINTS) calculates flow

based on a set of user-entered data points for a flow stream. Data

consist of correlated level and flow measurements for the stream.

Like the Equation method of flow conversion, this flow conversion is most commonly used where the primary measuring

device is nonstandard, but where tables of level and flow rate

data are available from the device manufacturer. The 4220 Flow

Meter has space for four sets of data with as many as fifty points

per set. The flow meter then calculates flow from these data

tables using a three-point interpolation.

P1

+ k2H

P2

2.3.3 Step 3 - Adjust Level, Parameters

Adjust Level, Parameters calibrates the measuring sensors

that provide the flow meter with level and other information. In

this step you set the level that the flow meter measures. First

you measure, as accurately as possible, the level in the flow

stream. Then you enter this value with the numeric keys.

Accuracy is important. Remember that measured level provides

the basis for calculated flow in the flow meter.

The flow meter also has an input port for measurements other

than level. This is the Parameter Port. Here you can sense

such variables in the flow stream as temperature, pH (the acidity

or alkalinity of a solution) and D.O. (dissolved oxygen) in the flow