Page 1

Total Hydrocarbon Analyzer Table of Contents

INSTRUCTION MANUAL

MODEL 402R-EU

TOT AL HYDROCARBON ANALYZER

Teledyne

Analytic al Instruments

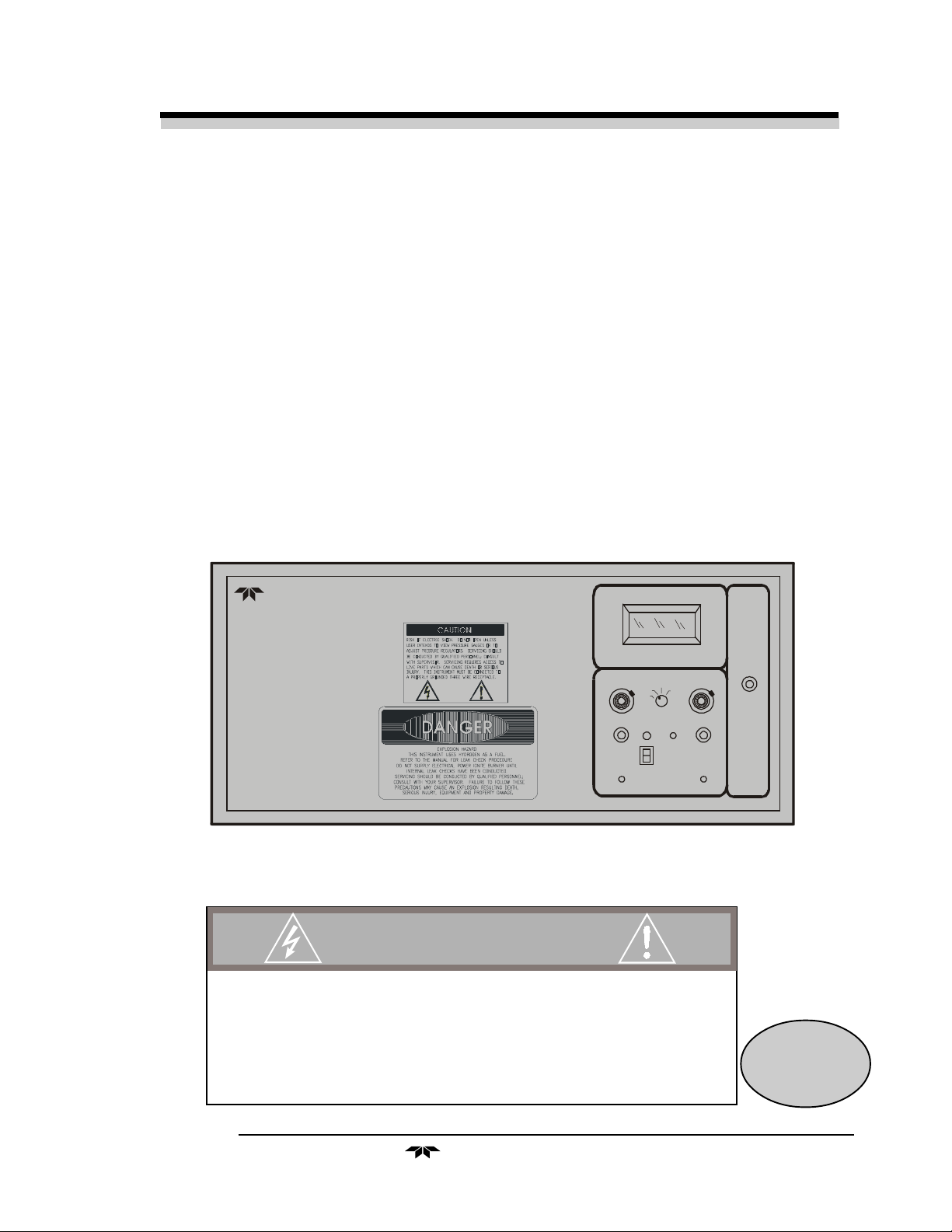

MODEL 402R

MED

LO

HI

IGNITE

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST FOR

A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

P/N M66893

ECO: #99-0323

08/06/1999

Teledyne Analytical Instruments

i

Page 2

Table of Contents Model 402R-EU

Copyright © 1999 Teledyne Electronic Technologies/Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any other language or computer language in whole or in part, in any form

or by any means, whether it be electronic, mechanical, magnetic, optical, manual, or otherwise, without the

prior written consent of Teledyne Electronic Technologies/Analytical Instruments, (TET/AI)

16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from defects of

material and of construction, and that our liability shall be limited to replacing or repairing at our factory

(without charge, except for transportation), or at customer plant at our option, any material or construction

in which defects become apparent within one year from the date of sale, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear the warranty of

their manufacturer. This warranty does not cover defects caused by wear, accident, misuse, or neglect. We

assume no liability for direct or indirect damages of any kind and the purchaser by the acceptance of the

equipment will assume all liability for any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus, and to make any

alterations in the dimensions, shape or weight of any parts, in so far as such alterations do not adversely

affect our warranty.

Important Notice

This instrument is intended to be used a tool to gather valuable data. The information provided by the

instrument may assist the user in eliminating potential hazards caused by the process that the instrument is

intended to monitor; however, it is essential that all personnel involved in the use of the instrument or its

interface with the process being measured be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process conditions. While this

instrument may be able to provide early warning of imminent danger, it has no control over process conditions, and can be misused. In particular, any alarm or control system installed must be tested and understood, both as to how they operate and as to how they can be defeated. Any safeguards required such as

locks, labels, or redundancy must be provided by the user or specifically requested of Teledyne.

The purchaser must be aware of the hazardous conditions inherent in the process(es) he uses. He is responsible for training his personnel, for providing hazard warning methods and instrumentation per the appropriate standards, and for ensuring that hazard warning devices and instrumentation are maintained and

operated properly.

TET/AI, the manufacturer of this instrument, cannot accept responsibility for conditions beyond its knowledge and control. No statement expressed or implied by this document or any information disseminated

by the manufacturer or his agents is to be construed as a warranty of adequate safety control under the

user's process conditions.

ii

Teledyne Analytical Instruments

Page 3

Total Hydrocarbon Analyzer Table of Contents

IN ORDER TO AVOID HAZARDOUS CONDITIONS, DAMAGE TO THE

INSTRUMENT, AND TO ASSURE PROPER OPERATION, THE USER SHOULD

READ THIS MANUAL BEFORE INSTALLING AND OPERATING THE 402R-EU

THIS INSTRUMENT SHOULD ONLY BE MAINTAINED BY SUITABLY

TRAINED AND QUALIFIED PERSONNEL.

IF USED OUTSIDE OF THE SPECIFICATIONS (SEE APPENDIX A), THE INSTRUMENT MAY BE DAMAGED AND HAZARDOUS CONDITIONS MAY BE

PRODUCED.

Model 402R-EU complies with all of the requirements of the Commonwealth of Europe (CE) for Radio Frequency Interference, Electromagnetic Interference (RFI/EMI), and Low Voltage Directive

(LVD).

The following International Symbols are used throughout the Instruction Manual for your visual and immediate warnings and when

you have to attend CAUTION while operating the instrument:

STAND-BY, Instrument is on Stand-by,

but circuit is active

GROUND

Protective Earth

CAUTION, The operator needs to refer to the manual

for further information. Failure to do so may

compromise the safe operation of the equipment.

CAUTION, Risk of Electric Shock

Teledyne Analytical Instruments

iii

Page 4

Table of Contents Model 402R-EU

T a ble of Contents

VI Safety Informations.............................................................VI

1 Introduction

1.1 Principle of Operation .................................................. 1-1

1.2 Analyzer Description ................................................... 1-1

1.3 Sampling System ........................................................ 1-2

1.3.1 Input Porting..................................................... 1-2

1.3.2 Sample Flow Control System ........................... 1-2

1.3.3 Fuel and Blanket Air Systems .......................... 1-3

1.3.4 Flame Ionization Detection Cell........................ 1-3

1.4 Applications................................................................. 1-3

2 Operational Theory

2.1 Electronics................................................................... 2-1

2.1.1 Detection Cell ................................................... 2-3

2.1.2 Electrometer-Amplifier...................................... 2-3

2.1.3 Differential Power Supply ................................. 2-4

2.1.4 Anode Power Supply........................................ 2-4

2.1.5 Flame Guard Circuit ......................................... 2-4

2.1.6 Flame Ignition Circuit........................................ 2 -4

2.1.7 Proportional Temperature Control Circuit ........ 2 -4

2.1.8 Output............................................................... 2 -5

iv

3 Installation

3.1 Electrical Requirements and Connections .................. 3-1

3.1.1 Primary Power.................................................. 3- 2

3.1.2 Voltage Output Signal ...................................... 3-3

3.2 Gas Connections ......................................................... 3-3

3.2.1 Supporting Gases............................................. 3-4

3.2.2 Sample Gas...................................................... 3-5

3.2.3 Effluent ............................................................. 3-5

3.2.4 Sample Bypass Vent ........................................ 3-5

3.2.5 Fuel and Air Connections ................................. 3-5

3.2.6 Fuses................................................................ 3-6

4 Operations

4.1 Equipment................................................................... 4-1

4.2 Preliminary Power-Off Check List ............................... 4-2

4.3 Preliminary Electronic Adjustment .............................. 4-3

4.3.1 Meter-Recorder Alignment ............................... 4-3

4.4 Placing the System in Operation................................. 4- 4

Teledyne Analytical Instruments

Page 5

Total Hydrocarbon Analyzer Table of Contents

4.5 Activating the Support Gases...................................... 4-4

4.5.1 Air..................................................................... 4- 4

4.5.2 Zero Gas .......................................................... 4-4

4.5.3 Span Gas ......................................................... 4-5

4.5.4 Fuel .................................................................. 4-6

4.6 Flame Ignition ............................................................. 4-6

4.6.1 Verification of the Flame Guard Circuit ............ 4-6

4.6.2 Ignition and/or Flame Guard Circuit Failure ..... 4-7

4.7 Calibration................................................................... 4-7

4.8 Stabilization Period ..................................................... 4-8

4.9 Sampling ..................................................................... 4-8

4.10 Routine Operation ....................................................... 4-9

4.10.1Verification of Calibration ................................. 4 -9

4.10.2Supporting Gases........................................... 4-10

5 Maintenance & Troubleshooting

5.1 Measuring Circuit Electrical Checks............................ 5 -2

5.1.1 Loss of Zero Control......................................... 5-3

5.1.2 Anode Voltage Check....................................... 5-3

5.1.3 Electronic Stability ............................................ 5-4

5.1.4 Printed Circuit Board Replacement .................. 5-4

5.1.5 Collector Cable................................................. 5-5

5.2 Temperature Control Electronic Check...................... 5-5

5.3 Ignition and/or Flame Guard Circuit Checks ............... 5-8

5.3.1 Flame Guard Circuit Calibration....................... 5-9

5.4 Sampling System ...................................................... 5-10

5.5 Printed Circuit Board Descriptions ............................ 5-10

5.5.1 Flame Guard and Anode Power Supply

Printed Circuit Board ...................................... 5-11

5.5.2 Regulated Differential Power Supply

Printed Circuit Board ...................................... 5-12

5.5.3 Proportional Temperature Controller

Printed Circuit Board ...................................... 5-13

5.5.4 Electrometer-Amplifier PC Board ................... 5-15

5.5.5 Comparator Alarm Printed Circuit Board........ 5-17

Appendix

Specifications ...................................................................... A-1

Application Data .................................................................. A-2

Recommended Spare Parts List ......................................... A-3

Drawing List ........................................................................ A-4

Teledyne Analytical Instruments

v

Page 6

Table of Contents Model 402R-EU

vi

Teledyne Analytical Instruments

Page 7

Total Hydrocarbon Analyzer Introduction

Introduction

The Teledyne Electronic Technologies/Analytical Instruments

(TET/AI) Model 402R-EU Total Hydrocarbon Analyzer meets or exceeds

all of the requirements of the Commonwealth of Europe (CE) for Radio

Frequency Interference and Electromagnetic Interference (RFI/EMI)

protection and Low Voltage Directive (LVD). The analyzer is designed to

measure the quantity of hydrocarbons present in a positive pressure sample

as equivalent methane.

1.1 Principle of Operation

The sample gas is mixed with a fuel (normally a composition of

hydrogen and nitrogen) and burned in an atmosphere of “blanket air”. The

ions formed in the burning process cause an electrical conduction between

two electrodes in the combustion chamber (or detector cell) that is amplified by a highly sensitive electrometer-amplifier circuit. The electrical

output of the electrometer-amplifier is directly proportional to the quantity

of flame ionizable hydrocarbons present, and is linear over the range of

0-10,000 PPM methane.

1.2 Analyzer Description

The information contained in this manual describes individual analyzers of the Model 402R-EU standard series. In cases of special design, other

factors may apply requiring additional or supplementary information.

These special considerations will be described in detail on specific application pages labelled Addenda, in each manual. When the Model 402R-EU is

a part of a larger system, it is subordinate to that system, and specific

installation and operation conditions of that system will apply. Consult

system sections of the manuals for those applications, where conditions

specific to those systems will be detailed.

Teledyne Analytical Instruments

1-1

Page 8

Chapter 1 Model 402R-EU

To best suit the needs of the purchaser, specialized designs are available. Details of the design differences may be found in the various drawings (outline, assembly, schematic, wiring, and piping diagrams) in the

drawings section at the rear of the manual. The standard analyzer is

housed in a sheet steel equipment case that has been designed for flushmounting in a 19" rack.

CAUTION: Since the measured component for the 402R-EU is hydrocarbon

content, and since hydrocarbon lubricants and conditioners as

well as synthetic plastics are common to instrumentation

supply processes, utmost precaution must be taken at all times

to specify hydrocarbon-free gases, regulator diaphragms and

supplies.

1.3 Sampling System

All components used to control the sample and supporting gases, as

well as the combustion portion of the detector cell, are located inside,

behind the electronics control panel. The basic analyzer consists of an

isothermal chamber containing the pressure regulators, pressure gauges and

flow restrictors. The temperature within the chamber is maintained at

125°F by a heating element. The regulated temperature of the chamber

insures stable gas flow. An optional sample selector module is an integral

gas selector panel inside the instrument enclosure for conveniently switching between sample and calibration gases. When installed, it is part of the

isothermal chamber. The bypass flow is also controlled from this optional

panel.

1.3.1 Input Porting

The analyzer is equipped with ports for the introduction of air, fuel,

zero, span, and sample gas.

1.3.2 Sample Flow Control System

Stable sample flow is achieved by maintaining a constant pressure

across a restrictor through the use of a back-pressure regulation system,

which includes an adjustable regulator, pressure gauge, throttle valve, and

flowmeter. The throttle valve and flowmeter are included so that the

bypass flow required by the back-pressure regulator can be limited. Without these controls, a high sample point pressure would result in unnecessary sample waste through the back-pressure regulator.

The components of the system are arranged so that no dead volume is

present in the sample path to the detector cell. This guarantees rapid response to changes in hydrocarbon concentration—a fact that can be dem-

Teledyne Analytical Instruments1-2

Page 9

Total Hydrocarbon Analyzer Introduction

onstrated when zero and span gas are exchanged during the standardization

procedure.

The restrictors used in the system look alike; however, they are not

interchangeable.

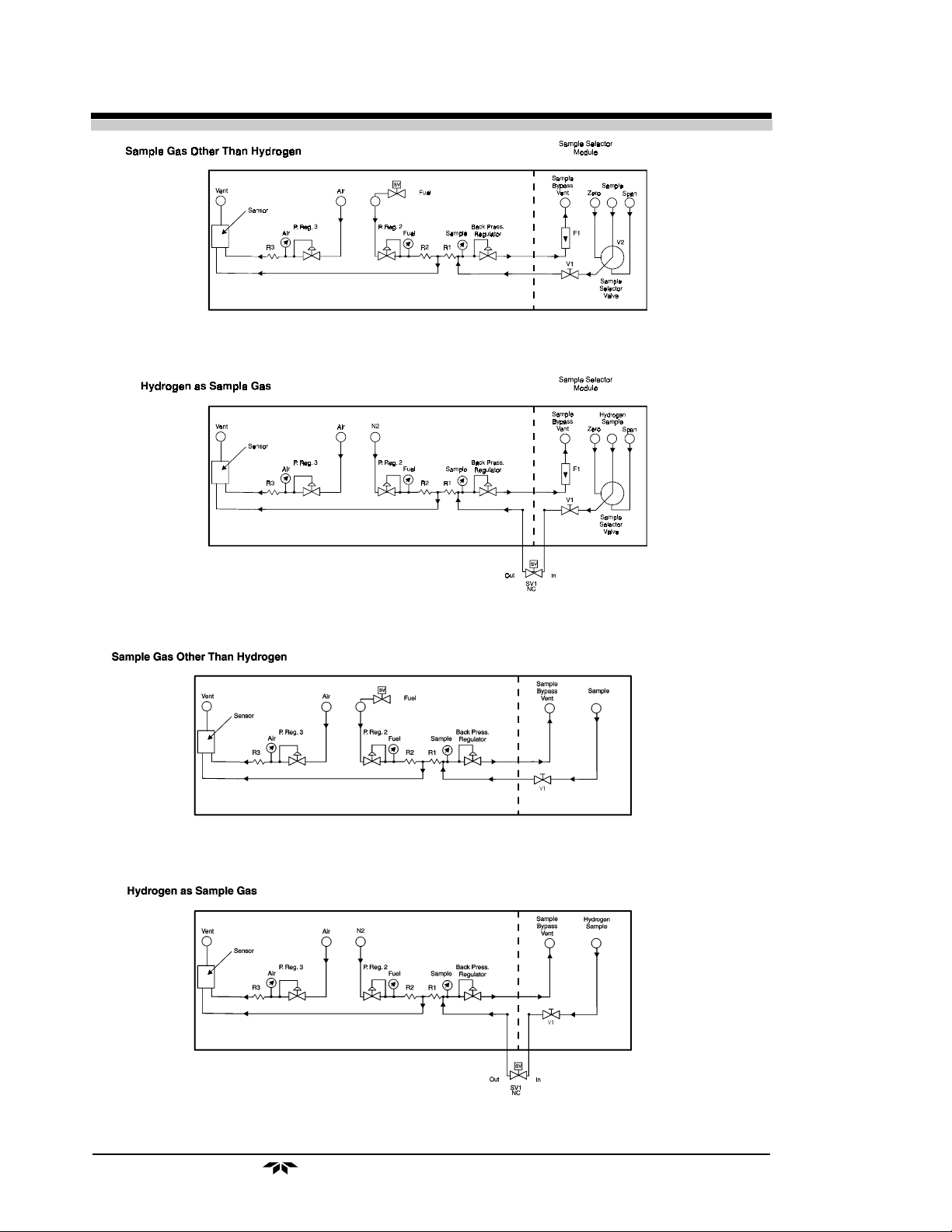

1.3.3 Fuel and Blanket Air Systems

The fuel and blanket air systems use similar components. Stable flow

is achieved by maintaining a constant pressure across restrictors upstream

from the cell. Each system incorporates an adjustable pressure regulator,

pressure gauge, and restrictor. A flame out light is included to indicate

when the flame fails. A fuel shut-off solenoid valve, mounted on the line

that supplies hydrogen, stops the fuel flow in case of flame failure. This

valve is located in line with the fuel port; except for instruments using

hydrogen as the sample gas. In this case, the sample is used as fuel and the

valve is located in line with the sample port. See Figure 1-1A for a flow

schematic for instruments equipped with a sample selector module. Figure

1-1B shows the flow schematic for instruments without the optional gas

selector module.

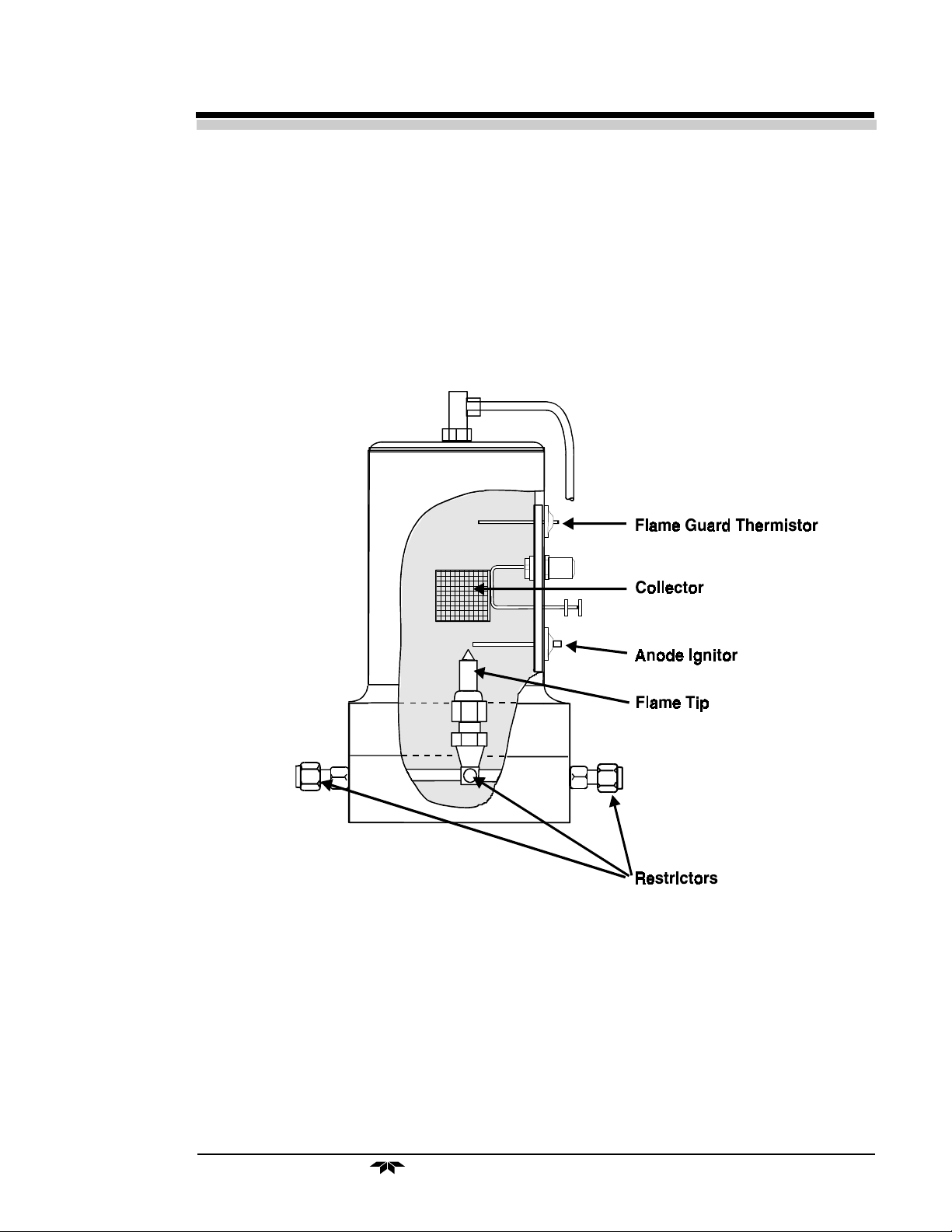

1.3.4 Flame Ionization Detection Cell

The sample and fuel are combined within a tee fitting located in the

isothermal chamber. The mixed gas is emitted from a burner within the

sensor assembly. Blanket air is introduced into the sensor (or cell) by

means of a separate fitting that is located in the base section of the assembly. The upper half of the assembly houses the anode-igniter, collector, and

flame guard thermistor. The cell is located at the left hand front area inside

the enclosure for easy access. See Figure 1-2.

1.4 Applications

• Monitoring the purity of oxygen, argon, nitrogen and other

gases in the manufacture of microcircuits.

• Monitoring hydrocarbon contamination in air liquefaction and

other gas production processes.

• Gas purity certification.

• Detecting trace hydrocarbons in ambient air.

• Detecting atmospheric pollutants.

• Cryogenics.

• Monitoring for fuel leakage or toxic solvents.

• Monitoring hydrocarbons in a wide range of process streams.

Teledyne Analytical Instruments

1-3

Page 10

Chapter 1 Model 402R-EU

Figure 1-1A: Schematic Flow Diagram With Gas Selector Panel

Figure 1-1B: Schematic Flow Diagram Without Gas Selector Panel

Teledyne Analytical Instruments1-4

Page 11

Total Hydrocarbon Analyzer Introduction

Figure 1-2: Flame Ionization Cell

Teledyne Analytical Instruments

1-5

Page 12

Chapter 1 Model 402R-EU

Teledyne Analytical Instruments1-6

Page 13

Total Hydrocarbon Analyzer Operational Theory

Operational Theory

2.1 Electronics

The analyzer features semiconductor circuitry throughout. Integrated

(IC) circuits are employed in the highly sensitive electronic circuits of the

instrument to reduce circuit component requirements and increase reliability. Aside from the necessary power transformers, three fuses, and electrical controls, all circuitry is mounted on plug-in type printed circuit cards.

The circuitry has been sectionalized so that spare circuit cards can be

employed without the use of expensive test equipment or the services of a

highly-trained technician. With spare circuit cards available for replacement, you will only need a multimeter to isolate and remedy an electronic

malfunction.

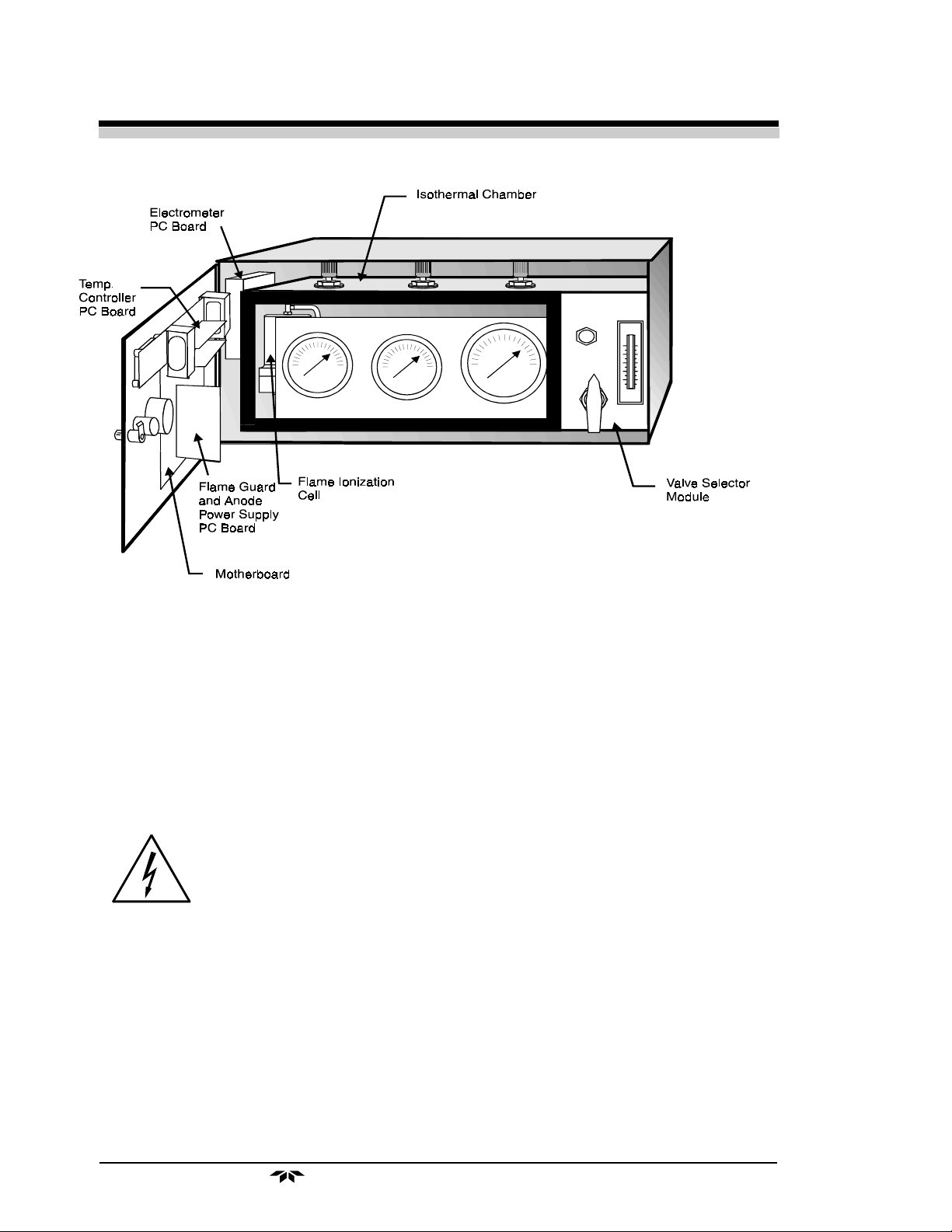

All the electronic PC board units (except the electrometer-amplifier)

plug into an interconnecting unit called the motherboard. See Figure 2-1

for motherboard location.

WARNING: The PCBs in the 402R-EU contain dangerously high

voltages. Ensure that all power to the instrument has been

removed before disconnecting or handling any of the

PCBs.

MOVAL OF INTERNAL INACCESSIBLE SHOCK HAZARDS").

The only electromechanical devices used are the control and fuel shutoff relays in the flame guard circuit.

The isothermal chamber components including the detector cell are

interconnected with the electronics chassis by means of plug-in cables.

The bulk of the electronic circuitry is located behind the hinged door

of the analyzer. Access to the interior of the analyzer is gained by rotating

(See Section 1 Page VII: "PROCEDURE FOR RE-

Teledyne Analytical Instruments

2-1

Page 14

Chapter 2 Model 402R-EU

Figure 2-1: View Inside 402R-EU Cabinet

(with internal door cover removed)

the doorknob located on the upper right-hand side of the hinged door, and

swinging it out.

To gain access to the electronics mounted on the inside of the door,

the cover must be removed.

WARNING: No user serviceable parts are located in this area

and hazardouz voltage exist in this area. There

fore this cover should only be removed by suitably trained service personnel. (

Page VII: "PROCEDURE FOR REMOVAL OF INTERNAL

INACCESSIBLE SHOCK HAZARDS").

See Section 1

While reading the following descriptive subsections, refer to Figure

2-1 and the schematics, electronics chassis component layout and wiring

diagrams in the drawings section at the rear of the manual. In addition,

detailed descriptions of the various plug-in printed circuit boards are

provided in the printed circuit board description section of the manual. Any

specialized information unique to your instrument will be detailed in an

Addendum and included at the front of this manual.

Teledyne Analytical Instruments2-2

Page 15

Total Hydrocarbon Analyzer Operational Theory

2.1.1 Detection Cell

The upper section of the stainless steel flame ionization cell houses

the cylindrical collector electrode, the high voltage (+260 VDC) anodeigniter coil, and the sensing thermistor of the flame guard circuit (see cell

wiring diagram and Figure 2-1).

WARNING: Dangerous high voltage exists at the anode igniter

coil (+260 VDC). Do not attempt to disconnect the

igniter coil cable or disassemble any of the flame

ionization cell components without first applying

the following procedure in

DURE FOR REMOVAL OF INTERNAL INACCESSIBLE

SHOCK HAZARDS"

, then disconnect plug P3 from

Section 1 Page VII: "PROCE-

receptacle J3.

The collector is interconnected with the electrometer-amplifier PC

board by a coaxial cable. Although the cable and fittings are intended for

coaxial service, the cable is actually being used as a shielded single-conductor connection.

The anode-igniter, as its name implies, serves two functions. When

the selector switch is held in the ignite position, the coil becomes an electrical heating element that glows red hot and ignites the hydrogen fuel.

When the switch is released, the heater circuit is broken, and the coil is

connected to the +272 volt DC terminal of the anode-flame guard power

supply PC board. In this configuration, the necessary potential difference is

established between the coil (anode) and collector to promote ionization of

the burned hydrocarbons. The coil functions as the high voltage anode in

all three range positions of the selector switch.

The thermistor acts as the sensor in the flame guard circuit. Its ambient temperature resistance is in the 100 KΩ region. When the flame is

ignited, its resistance is reduced by a factor of 100. The thermistor is

coupled to a semiconductor control circuit on the anode-flame guard power

supply PC board, which will be described in a following section.

The cell electrodes of both the anode-igniter and flame guard thermistor are connected to the electronics chassis by means of a plug-in cable.

The electrode section of the cell may be removed for inspection by

turning off the power, disconnecting the electrode lead plug, and removing

the screws which retain the electrode assembly in the sensor body.

2.1.2 Electrometer-Amplifier

The collector cable is coupled directly to a coaxial fitting located on

the electrometer-amplifier PC board. The plug-in PC board is located on

Teledyne Analytical Instruments

2-3

Page 16

Chapter 2 Model 402R-EU

the side panel next to but outside of the isothermal chamber. See Figure

2-1. and consists of an electrometer amplifier and an operational amplifier.

This circuit is a very high-gain, current-to-voltage converter circuit, having

an input impedance measuring in the billions of ohms. It is static sensitive

and highly susceptible to contamination. Special care must be taken in

handling this PC board.

Refer to Section 5-4: Electrometer-Amplifier PC Board for more

information concerning the electrometer-amplifier and the other printed

circuits that follow.

2.1.3 Differential Power Supply

The positive and negative operating voltage required by the electrometer-amplifier is furnished by a regulated, differential power supply circuit.

The output of the power supply as referenced to chassis ground is positive

15 (±1) VDC, and negative 15 (±1) VDC. Regulation is better than 1% of

the rated voltage.

2.1.4 Anode Power Supply

The high voltage anode power supply components are mounted on the

anode power supply printed circuit board. High voltage regulation is

achieved through the use of series-connected zener diodes. The simplicity

of this circuit’s design can be attributed to the extremely low current

demand of the anode circuit. The positive output voltage is nominally 250

volts. Output tolerance is ±22 volts from the specified 250 volts.

2.1.5 Flame Guard Circuit

A thermistor-controlled, transistorized switching circuit is employed

to operate a relay in the event of a flameout condition. A panel indicator

light and fuel shut-off solenoid valve are operated by the relay to alarm

personnel that a flameout condition has occurred. The fuel shut-off solenoid valve stops the hydrogen flow.

2.1.6 Flame Ignition Circuit

The flame ignition circuit includes the anode-igniter electrode (in the

detector cell), a transformer, and the momentary IGNITE position of the

selector switch.

2.1.7 Proportional Temperature Control Circuit

The temperature of the isothermal chamber containing the sampling

components is regulated by a thermistor-directed electronic circuit. The

thermistor and heating element are located in the chamber, and the balance

of the circuit components are mounted on the temperature controller

printed circuit board. A temperature limit switch protects the isothermal

Teledyne Analytical Instruments2-4

Page 17

Total Hydrocarbon Analyzer Operational Theory

chamber against excessive temperature, which may occur if the temperature controlling system fails.

2.1.8 Output

The electrometer-amplifier output is connected to a span potentiometer, whose slider is connected to a 3½ digit digital panel meter (DPM) a

voltage-to-current (E-to-I) converter, as well as optional output circuits

which may be utilized, such as alarm comparators. Description of optional

circuits employed can be found in the Printed Circuit Board Description

section of Chapter 5.

Teledyne Analytical Instruments

2-5

Page 18

Chapter 2 Model 402R-EU

Teledyne Analytical Instruments2-6

Page 19

Total Hydrocarbon Analyzer Installation

Installation

The analyzer should be panel mounted (unless otherwise designed) in

an upright position in a sheltered area that is not exposed to the following

conditions:

1. Direct sunlight.

2. Drafts of air.

3. Temperatures below 55 °F or above 110 °F.

Subject to the specified conditions, the analyzer should be installed as

close to the sample point as is possible.

An outline diagram of the analyzer can be found in the drawings at

the rear of the manual. After the cutout has been made in the equipment

panel, TET/AI recommends that the case be used as a template to lay out

the mounting holes. Such a procedure will compensate for sheet metal

tolerance errors.

Special statistical information will be covered on the Specifications

page in the Appendix. All pertinent dimensions, connecting points, and

piping details can be found in the drawings section as part of the outline,

input-output, and piping diagrams. These drawings are specific to the

instrument or system to which the manual applies.

3.1 Electrical Requirements and Connections

WARNING: Follow the procedure in

DURE FOR REMOVAL OF INTERNAL INACCESSIBLE

SHOCK HAZARDS"

before performing any mainte

nance, except for adjusting the pressure regulator.

Section 1 Page VII: "PROCE

All electrical connections are made at the terminal block located on

the rear panel of the 402R-EU, except primary power, (see the "InputOutput Diagram"). Before making any electrical connections, you must

Teledyne Analytical Instruments

3-1

Page 20

Chapter 3 Model 402R-EU

detach the EMI/RFI Block Cover by removing four screws. Then, after

making the connections, ensure that the Block Cover is securely remounted

over the terminal block to insure EMI/RFI protection of the 402R-EU.

NOTE: Some features displayed on the terminal strip may not be present in your

system, i.e., no alarms.

3.1.13.1.1

3.1.1

3.1.13.1.1

Primary PowerPrimary Power

Primary Power

Primary PowerPrimary Power

The standard version of the 402R-EU is designed and specified to

function properly for mains (line) voltage in the range 115VAC ±10% at

50Hz or 60Hz. For the 230V version this range of voltages is 230VAC

±10% at 50Hz or 60Hz.

Subjecting the 402R-EU to mains (line) voltages which are either

higher than or lower than these ranges can cause permanent demage to

the 402R-EU.

If the unconditioned mains (line) voltages are expected to exceed

these ranges, the use of some form of voltage conditioner (such as an

uninterruptible power supply) should be used to protect the 402R-EU.

A source of single phase, 115V± 10% (or 230V±10%), 50 or 60 Hz

power will be required to operate the analyzer electronics. The nominal

valt-amp consumption of the analyzer is 150VA..

The primary power is connected to an IEC connector in the power

entry module at the rear of the 402R-EU. This power entry module also

contains the EMI/RFI line filters and holds the two 5mm x 20mm main

(line) fuses. These fuses may be replaced by using a small bladed screwdriver to pry out the cover plate ( marked “USE ONLY 250V FUSES”).

This cover plate is the outside surface of the fuse carrier. The line fuses

used are manifactured by LITTELFUSE INC., their part number: 21501.6.

Only this manafacturer, and manufacturer’s part number fuse may be

used for replacement. This is a 250V, 1.6A fuse with a current

interupting rating of 1500A and a nominal melting I2t rating of 3.9 A2 Sec.

The main (line) cord used to power the 402R-EU must contain a

safety ground wire and this must be connected to a safety earth ground

such as a proper cold water pipe ground. In addition to this safety ground

connection the 402R-EU, a safety ground wire (green - yellow, AWG #16)

must be connected to the proctective earth ground 8-32 screw marked with:

This ground wire must be connected to this screw by a ring-lug with

external star lock washers on both sides of the lug. After the lug and

Teledyne Analytical Instruments3-2

Page 21

Total Hydrocarbon Analyzer Installation

lockwasher are put on the screw, the screw must be screwed into the 402REU case firmly to assure that the lockwasher next to the case cuts throught

the paint on the case to the metal of the case. The other end of this wire

must be connected to an approved safety ground (protective ground).

After connecting this wire to the 402R-EU and before connecting this

wire to the safety ground, check that the resistance from this wire to the

case of the 402R-EU is less than 1.0 ohms. If the resistance is greater than

or equal to 1.0 ohm:

1. Remove the screw, lug and star washers,

2. Scrape away the paint on the case in that area,

3. Reconnect the screw, lug and star washers,

4. And recheck the resistance.

The ground pin on the IEC power connector and the protective earth

ground screw are both protective conductor terminals and functional earth

terminals. Both must be grounded for personel safety and for proper

functioning of the equipment. A lack of grounding will result in erratic

instrument performance.

3.1.23.1.2

3.1.2

3.1.23.1.2

The output signal is available at the terminal block on the rear of the

analyzer case (see the "Input-Output Diagram"). A 2-conductor shielded

cable must be used to interconnect the analyzer with an auxiliary indicating

and/or recording instrument. Connect the shield at the analyzer end only.

Connecting both ends of the shield can produce a ground loop and erratic

performance. Polarize the signal connections as shown on the "InputOutput Diagram".

Auxiliary indicating and/or recording equipment must have an input

impedance of no less than 10KΩ. A self-balancing potentiometer is ideally

suited as an auxiliary indicator.

An isolated 4-20mA current output is also privided.

Voltage Output SignalVoltage Output Signal

Voltage Output Signal

Voltage Output SignalVoltage Output Signal

3.2 Gas Connections

The analyzer gas connection diagram identifies the various gas connection points as to function and location. Figure 3-1 shows the gas connection points for instruments with or without the optional gas selector

Teledyne Analytical Instruments

3-3

Page 22

Chapter 3 Model 402R-EU

module. Gas connections to the instrument are made at the 1/8" or 1/4"

stainless steel tube fittings provided on the rear panel. Note that the Purge

and Sensor Vent fittings are 1/4" while all other gas connections are 1/8".

Before tubing is connected to the system, it must be decontaminated

to rid it of hydrocarbon deposits. Using a small torch, heat each length of

tubing, while passing nitrogen through it, until it glows red. Begin at the

nitrogen source end and proceed down the length of the tube, “chasing” the

red glow (and hydrocarbon deposits) down to the open end of the tube. Cap

tubing while not in use with suitable non-contaminating caps.

All sample, calibration, and supporting gas lines which deliver into

the analyzer must be decontaminated before connection; vent lines do not.

When connecting the various gas lines to the system, be absolutely

certain that no “dead ends” are left; that is, no unused branch lines should

be left capped off, where pockets might form of material that is not representative of the current contents of the line, or which might keep contaminants from being purged out of the system.

3.2.13.2.1

3.2.1

3.2.13.2.1

Supporting GasesSupporting Gases

Supporting Gases

Supporting GasesSupporting Gases

Normally, four supporting gases of different composition (see Chapter 4:

Equipment) will be required to operate the analyzer. The recommended

composition of these gases is specified in the Application Data section of

the Appendix. The gases should be supplied from cylinders that are

equipped with the type of regulator specified in the aforementioned sections.

CAUTION: Under no circumstances should you employ a regulator that is

not equipped with a metallic diaphragm anywhere in the system.

The regulators should be inspected prior to installation to be

sure that they are oil-free. Failure to comply with these directives will result in a constant drift in analyzer output, as organic

compounds will outgas into the plumbing system at a rate that

is related to the ambient temperature. Use 316 stainless steel,

dual-stage regulators only in fuel, sample, and blanket air lines;

shutoff valves should be used downstream from each regulator.

Place the supply cylinders as close to the analyzer as possible, and

interconnect them to the analyzer with new tubing. Be sure that all plumbing connections are free of leaks.

NOTE: Use only stainless steel tubing within the analyzer and throughout

the system. Consult the assembly, piping, outline drawings, and

any Addenda included with this manual to determine if special

conditions apply.

Teledyne Analytical Instruments3-4

Page 23

Total Hydrocarbon Analyzer Installation

3.2.23.2.2

3.2.2

3.2.23.2.2

Sample GasSample Gas

Sample Gas

Sample GasSample Gas

An oil-free, metallic diaphragm regulator must be installed as close

to the sample point as possible. Use new tubing in the installation. The

output pressure of the regulator should be 30 psig, whenever possible, to

match the settings of other regulators on the support gas tanks; sample inlet

pressure must exceed the operating sample pressure by at least 10 psig and

provide at least 1 SCFH bypass flow. In any case, the zero and span gas

regulators should be set to match the sample pressure regulator—as the

back-pressure regulator within the analyzer ultimately determines the

sample flow to the detection cell. Refer to Chapter 4: Sampling.

3.2.33.2.3

3.2.3

3.2.33.2.3

EffluentEffluent

Effluent

EffluentEffluent

All the gases introduced into the detection cell vent from one fitting at

the rear of the analyzer. TBE/AI recommends that the cell be permitted to

vent directly to the atmosphere wherever possible.

If a vent line is required, the installation must include a drop-out pot

to collect the water that is formed by the burning of the hydrogen fuel. The

vent line must be constructed so that water and dirt cannot collect in it.

3.2.43.2.4

3.2.4

3.2.43.2.4

Sample Bypass VentSample Bypass Vent

Sample Bypass Vent

Sample Bypass VentSample Bypass Vent

The sample bypassed by the back-pressure regulation system vents

from a separate port at the rear of the analyzer. If a vent line is required, it

must be installed so that water and dirt cannot accumulate in it.

3.2.53.2.5

3.2.5

3.2.53.2.5

Fuel and Air ConnectionsFuel and Air Connections

Fuel and Air Connections

Fuel and Air ConnectionsFuel and Air Connections

The fuel used to provide combustion should be a gas mixture comprised of 40% H2 and 60% N2. The fuel is mixed with air to provide a

combustion source for the analyzer. Connect the fuel and air sources to the

instrument according to the gas connection diagram included at the back of

this manual.

NOTE: For applications where the sample gas is hydrogen, the sample gas

is doubles as the fuel for combustion and is diluted with nitrogen.

Connect a nitrogen source (40 psig) to the fuel inlet port. See Figure

3-1.

Teledyne Analytical Instruments

3-5

Page 24

Chapter 3 Model 402R-EU

Figure 3-1: Rear Panel of Model 402R-EU With Gas Connections

3.2.63.2.6

3.2.6

3.2.63.2.6

FusesFuses

Fuses

FusesFuses

The fuses used in Table 1, should be used in the instrument to avoid

hazardous conditions and avoid damage to the instrument.

Table 1 - Fuses in 402R-EU

Teledyne Analytical Instruments3-6

Page 25

Total Hydrocarbon Analyzer Operations

Operations

4.1 Equipment

The following supporting gases and hardware will be required to

operate the (standard) analyzer:

1. Fuel: A cylinder containing a 40% hydrogen, 60% nitrogen

composition will be required to supply the fuel for the flame

ionization burner. The cylinder is to be equipped with an oil-

free metallic diaphragm regulator (dual stage).

NOTE: When hydrogen is the parent gas in the application, an auxiliary

source of fuel may not be required. See the Appendix: Specifications for specific recommendations.

2. Blanket Air: A cylinder of water-pumped (low hydrocarbon)

compressed air will be required to maintain the proper

atmosphere within the cell. The cylinder is to be equipped with

an oil-free, dual stage, metallic diaphragm regulator. Less than

1% of the full scale reading (in the selected measurement range)

of hydrocarbon contamination is advisable, if the instrument’s

accuracy is to be realized.

3. Zero Gas: A cylinder of the parent (or background) gas,

containing less than 10% full scale (of the narrowest range)

hydrocarbon impurity, will be required to zero standardize the

analyzer. For example, if 10 PPM is the narrowest range of the

instrument, then the zero gas impurities are to be less than 1

PPM. The cylinder is to be equipped with an oil-free, dual

stage, metallic diaphragm regulator.

Teledyne Analytical Instruments

4-1

Page 26

Chapter 4 Model 402R-EU

4. Span Gas:A cylinder containing a composition consisting of

the parent gas and a specified (see Appendix: Specifications)

amount of methane will be required to standardize the

sensitivity setting of the analyzer. The cylinder is to be

equipped with an oil-free, dual stage metallic diaphragm

regulator.

5. Sample Pressure Regulation: An oil-free, metallic

diaphragm regulator must be installed at the sample point when

possible; see Section 4-9: Sampling.

4.2 Preliminary Power-Off Check List

Make the following checks of the installation before proceeding

further into the start-up procedure:

1. Check to see that the sample and supporting gas installation is

in accordance with the specifications called for in the

installation and application sections of the manual. Be sure that

the supporting gases are of the proper composition and are

connected to the correct fittings at the rear of the analyzer.

2. Check to see that the electrical connections conform to the

instructions contained in the installation section and on the

input-output diagram.

NOTE:Ensure that the Terminal Block Coverplate is securely in place to

maintain RFI/EMI protection.

3. The digital meter requires no adjustments. If you feel that your

digital readout needs adjustment and you are not familiar with

the procedures required, consult TET/AI before making any

adjustments.

4. Open the door and check to see that the printed circuit boards

and cables are firmly seated in their respective sockets.

NOTE:The boards and cable plugs are keyed so that they cannot be

inserted incorrectly in either the wrong position or the wrong

connector.

5. Confirm that recorder and alarm connections are properly

made.

Teledyne Analytical Instruments4-2

Page 27

Total Hydrocarbon Analyzer Operations

Figure 4-1: Front Panel of Model 402R-EU Total Hydrocarbon Analyzer

4.3 Preliminary Electronic Adjustment

After the foregoing preliminary checks and adjustments have been

made, turn the analyzer and recorder (if applicable) switches on (see Figure

4-1) and make the following checks and adjustments:

4.3.1 Meter-Recorder Alignment

If the application involves the use of an auxiliary recording and/or

indicating device, the following procedure should be used to check and

adjust the output circuit so that the meter and recorder are in close agreement:

1. Set the analyzer span control so that the dial indicates the

number recorded in the Application Data sheet in the Appendix

under “Start-up Span Setting”.

2. Place the selector switch in the "LO" position.

3. Adjust the door-mounted zero control until the meter stabilizes

at a full scale indication.

4. Check the recorder reading. If the recorder’s input sensitivity

coincides with the analyzer’s output specification (see

Appendix: Specifications), the recorder should be at a balance

at its full scale marker.

Teledyne Analytical Instruments

4-3

Page 28

Chapter 4 Model 402R-EU

5. If the meter and recorder do not agree, open the electrical

control panel, and locate the span potentiometer’s slider

terminal. Under full scale conditions 1000 millivolts ±1mv

should be present. Using a digital multimeter set for about 2

volts, measure between the slider and ground. If necessary,

adjust the span potentiometer until 1000 mv (±1mv) is obtained,

and verify that all output devices agree; adjustment of devices

which read incorrectly may be required. If a remote indicator

panel or device is used, check that as well.

4.4 Placing the System in Operation

1. Turn the power switch to the ON position.

2. Place the range switch in the "HI" (widest) range

position.

3. Allow at least 2 hour warm-up (heat up sensor & sample

system) after making the air adjustment described below.

4. DO NOT attempt to ignite the flame yet. Condensation

will occur.

4.5 Activating the Support Gases

4.5.1 Air

1. Set the air tank regulator to 30 psig.

2. Adjust the instrument air regulator until the air pressure

gauge reads the recommended air pressure. See Figure 4-2.

3. Air should thus be flowing through the sensor during the

warm-up (see step 3 above).

After the air is flowing through the sensor and a 1 hour warm-up

has been completed, activate the following gases:

4.5.2 Zero Gas

1. Set the gas selector valve to the ZERO position.

Teledyne Analytical Instruments4-4

Page 29

Total Hydrocarbon Analyzer Operations

Figure 4-2: Setting the Air, Fuel and Sample Pressure

2. Set the zero gas tank regulator to 30 psig (or a pressure

which matches the sample pressure) and adjust the instrument

sample regulator until its (sample) pressure gauge reads the

recommended sample pressure (except that zero gas is

flowing rather than sample). See Figure 4-2.

3. Adjust the bypass flow to 0.3-1.0 SCFH.

4.5.3 Span Gas

1. Set the gas selector valve to the SPAN position.

2. Set the span gas tank regulator to 30 psig or to match the

sample pressure.

3. Observe that the instrument sample pressure gauge still

reads the recommended sample pressure and that the bypass

flowmeter reads from 0.5 to 1.0 SCFH.

Teledyne Analytical Instruments

4-5

Page 30

Chapter 4 Model 402R-EU

4.5.4 Fuel

1. Make sure that the valve on the regulated side of the fuel

tank is closed.

2. Open the main valve on the tank and set the fuel tank

pressure regulator to 30 psig (or to match sample pressure).

3. To avoid pressure shock to the instrument fuel regulator,

slowly open the secondary valve until it is wide open.

4. Set the instrument fuel regulator to the recommended pressure.

See Figure 4-2.

NOTE: When adjusting fuel settings, the front panel switch must be held in

the IGNITE position.

4.6 Flame Ignition

Observe that after 1 hour preheating of the sensor, the amber heater

lamp is blinking (indicating that the temperature controller is maintaining

the temperature setpoint) and the red flame failure lamp is on. See Figure

4-1.

With the gas selector valve in the SPAN position and the range switch

in the highest range, turn the range switch to the IGNITE position and

release as soon as the meter is upscale (or off scale) and the red flame

failure light turns off, indicating flame on (no flame failure).

Limit the time that the switch is held in the IGNITE position to

intervals of about 5 seconds, with similar intervals of time between ignite

cycles, until the flame stays lit (and the light stays off). Such a procedure

will prevent damage to the anode-igniter electrode through overheating.

4.6.1 Verification of the Flame Guard Circuit

The operation of the flame guard circuit has been checked at the

factory, but should be re-verified during start-up. Employ the following

procedure, once ignition of the flame has been achieved:

1. Turn off the fuel at the supply cylinder.

2. Observe the fuel pressure gauge on the analyzer control panel.

The gauge indication will decay as the fuel in the line is

exhausted. When the gauge reading reaches the vicinity of 5

lbs, the flame will be extinguish as the fuel solenoid shuts off

Teledyne Analytical Instruments4-6

Page 31

Total Hydrocarbon Analyzer Operations

the fuel supply. Within 5–30 seconds the flame out indicator

light will come on.

3. Open the cylinder supply valve and re-ignite the flame.

4.6.2 Ignition and/or Flame Guard Circuit Failure

If the flame ignition or guard circuits do not operate as described in

the above two sections, proceed as directed in Chapter 5: Maintenance &

Troubleshooting.

4.7 Calibration

Switch the gas selector valve to ZERO and observe that the meter

drives downscale. Switch the range switch to the LOW range and adjust

the zero control such that an on scale indication is observed. A recording

should be made so that the stabilization progress of the instrument can be

observed. After a stable reading is obtained:

1. “Zero” the analyzer by adjusting the zero control until the

meter reads the methane concentration indicated on the zero gas

tank, if other than 0 PPM; otherwise set the meter to zero.

2. After a stable zero reading is obtained, “span” the analyzer.

a. Switch the range switch to the range which gives the highest

resolution of the span gas used (usually the high range), and

observe that the meter reads zero.

b. Switch the gas selector valve to SPAN and observe that the

meter drives upscale. Wait until stable ready is obtained.

c. Adjust the span control until the meter reads the methane

concentration indicated on the span gas tank.

d. Repeat this procedure to confirm proper calibration.

Teledyne Analytical Instruments

4-7

Page 32

Chapter 4 Model 402R-EU

3. After completion of calibration, shut off the main valves on

the zero and span gas tanks to avoid losing gas to minute leaks,

etc.

4.8 Stabilization Period

After the proper gas flow rates have been established and the flame

ignited, the analyzer should be permitted to operate on zero gas until the

isothermal chamber temperature comes to equilibrium, and, more importantly, until the user is satisfied that the analyzer is operating in a stable

fashion in the absence (or near absence) of hydrocarbons.

Run the analyzer at the span setting found after calibration (and the

selector switch in the low position) on zero gas until a stable recording is

obtained. If time permits, allow the instrument to run for 24 hours. If all

lines are free of hydrocarbons, the recorder should chart a closed circle

from the point where temperature equilibrium was reached. The recording

should have no more than 1% noise, and there should be no more than 2%

diurnal indicated.

4.9 Sampling

After a satisfactory recording is obtained on zero gas (see Calibration,

above), make sure that the process gas sample is in a condition acceptable

to the analyzer, or contamination of the sample system may occur.

The gas must be dry, free of particulates, and at a temperature not to

exceed 120 °F.

Incoming sample pressure should be regulated to 30 psig. In case the

sample pressure is lower than 30 psig, make sure that the incoming sample

pressure exceeds the recommended sample pressure as read on the instrument sample pressure gauge by at least 10 psig and is capable of maintaining a stable bypass flowrate of 0.5-1.0 SCFH. The use of a sample pump is

otherwise indicated.

NOTE: Your analyzer may be designed with a low pressure input option for

sample pressures as low as 5 psig.

If a sample pump is required, one must be selected which does not

emit chemicals visible to the analysis, and should have, if at all possible,

metal bellows and valves. Rubber diaphragms and valves are not ac-

ceptable.

Teledyne Analytical Instruments4-8

Page 33

Total Hydrocarbon Analyzer Operations

Set the process sample regulator to 30 psig.

Switch the gas selector switch to SAMPLE and set range switch to a

range which comfortably accommodates the process fluctuations in sample

hydrocarbon concentration. Sample flow should now be established.

NOTE: On standard instruments, the hydrocarbon concentration of a

mixture of different species of hydrocarbons will be indicated as if it

were only methane, unless the instrument is specifically calibrated

to read a different species.

4.10 Routine Operation

The pressure gauges and bypass flow rate should be checked on a

daily basis to insure continuous flow. The large cross-sectional area of the

sintered disc restrictors should eliminate the possibility of particulate

matter stopping or restricting flow. Nevertheless, even with the design

safeguards, the condition of the system should be checked daily. Any

change in fuel or sample flow rate will result in a change in signal output.

Since the only moving parts in the system are the fuel shut-off solenoid valve and the flame guard relay, no routine maintenance is required to

keep the electrical portion of the analyzer operative. The relay is designed

to operate continuously in an energized condition. In the event of failure,

the relay is a plug-in device.

4.10.1 Verification of Calibration

Repeat the zero and span standardization until no further adjustment

of either control is necessary to produce repeatable readings when switching from zero to span conditions.

Whenever a change is made in the pressure settings of either the air, fuel,

or sample regulators of the instrument,

IMPORTANT: The accuracy of the analysis can be no better than the

user’s knowledge of the hydrocarbon content of the standardization gases.

the instrument must be recalibrated.the instrument must be recalibrated.

the instrument must be recalibrated.

the instrument must be recalibrated.the instrument must be recalibrated.

These gases should be procured from a supplier who will certify their

composition. If a wide discrepancy exists between the span setting recorded in the manual and that finally reached through the use of span gas,

you should investigate either the zero or span gas composition, or both. If

Teledyne Analytical Instruments

4-9

Page 34

Chapter 4 Model 402R-EU

such is the case, have the compositions of these gases laboratory-analyzed

before relying on the information obtained from the analyzer.

4.10.2 Supporting Gases

The supporting gases (particularly the fuel and air) should be procured

well in advance of their need. TET/AI suggests that the gases be replaced

when their pressure gauges indicate that the supply is down to 100 psi.

Most cylinder regulators operate marginally in very low pressure ranges.

IMPORTANT: Whenever the fuel or air supply is replaced, the analyzer

must be restandardized. Any hydrocarbons present in these

gases will alter the instrument’s calibration and must be

compensated for through restandardization (see Section 48: Stabilization Period.)

Teledyne Analytical Instruments4-10

Page 35

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

Maintenance & Troubleshootin

WARNING: There are dnagerous high voltages within the in-

strument.

There are no user serviceable parts within the cover

on the inside of the door, inside the isothermal

chamber (sample system), and on the ElectrometerAmplifier PC Board. Work in these areas shall only

be performed by authorized suitably trained personnel.

Before starting any of these maintenance and

troubleshooting procedure, whenever possible apply

procedures provided in

FOR REMOVAL OF INTERNAL INACCESSIBLE SHOCK HAZARDS"

. When the 402R-EU must be turned on during

Section 1 Page VII: "PROCEDURE

any of these maintenance and troubleshooting procedures, be carefull and work with the ONE HAND

RULE (SECTION 1, PAGE viII). After the need to have

the instrument turned on passes, apply procedure in

section , page VI and then proceed.

CAUTION: Many of the electrical parts within the 402R-EU are

susceptable to damage from the electrostatic

discharge. Therefore, ESD safe procedures shall

be followed during servicing of the 402R-EU.

If the analyzer is suspected of incorrect operation, always evaluate

performance with zero or span gas flowing in the sample path. Never

attempt to evaluate performance on sample gas. If analyzer sensitivity is

questionable, use the span gas. For all other evaluations, use the zero gas

and low range for maximum sensitivity. The important consideration is to

control as many variables as possible. Using cylinder-supplied gases of

known hydrocarbon content eliminates the possibility of introducing an

unknown variable.

Teledyne Analytical Instruments

5-1

Page 36

Chapter 5 Model 402R-EU

Do not overlook the seemingly obvious. Check to see that power is

available for the instrument (and of the proper voltage, etc.), and that

connections are correct. Also verify that support/calibration gases are not

depleted.

5.1 Measuring Circuit Electrical Checks

If the analyzer performs erratically on zero gas, the trouble can be

related to either the integral gas control systems, or the electronics. To

isolate the problem, the two systems must be separated. To isolate the

electronics, employ the following procedure:

1. Open the door and disconnect the collector cable from the

electrometer-amplifier, leaving it attached to the cell. (Consult

schematic and assembly drawings for circuitry and location,

also see Figure 2-1. ) Do not use a twisting motion—instead,

pull the cable straight up through the hole in the cover. With

this cable disconnected, the electronic circuitry is completely

isolated from the gas control system and cell.

2. Select the lowest measurement range (for maximum sensitivity)

and adjust the zero control until the readout device indicates

above midscale. (The span control should already be set; see

Section 4.8: Stabilization Period.)

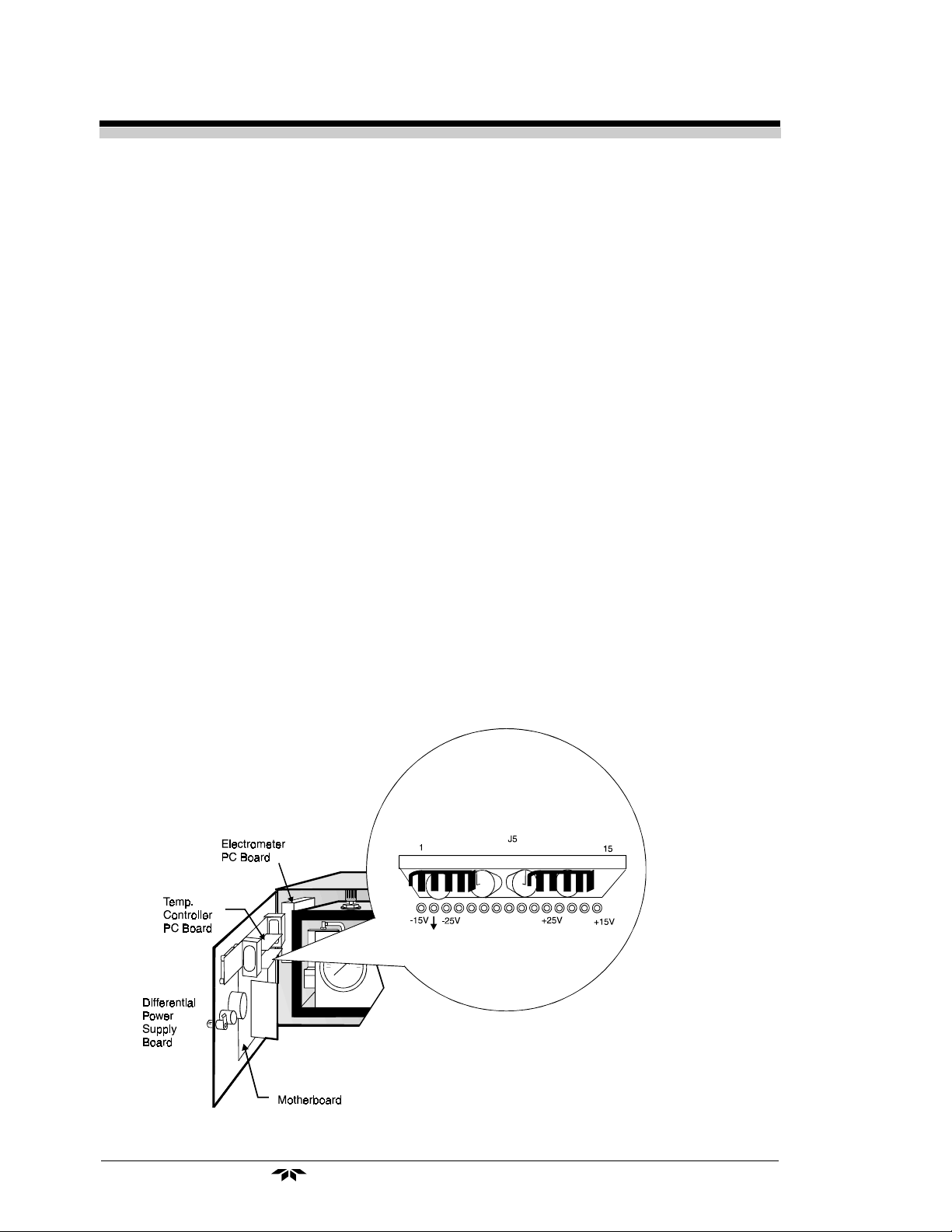

Figure 5-1: Checking the Differential Power Supply

Teledyne Analytical Instruments5-2

Page 37

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

5.1.1 Loss of Zero Control

If the zero cannot be controlled as directed above, a failure has occurred in either the differential power supply or the electrometer-amplifier.

Use the following procedure to isolate the fault:

With a digital voltmeter (DVM) set to read 15 VDC, check the positive and negative 15 V output of the power supply as follows:

(See schematic and assembly drawings for the differential power

supply PC board. Additional information can be found in the printed

circuit board description section at the end of this chapter.)

1. Connect the negative voltmeter lead to the common (pin 2) and

the positive lead to pin 15 of connector J5. The measured

voltage should be 15±1 volt. See Figure 5-1.

2. Then connect the positive DVM lead to pin 1 of connector J5.

Measured voltage should be -15±1 volt.

If correct readings are not obtained at both points, the differential

power supply has failed, and the printed circuit card must be replaced. If

correct readings are noted, the electrometer-amplifier has failed, and that

printed circuit card must be replaced.

NOTE: TET/AI recommends that spares for each of the printed circuits be

kept on hand so that service can be restored immediately. The

faulty circuit card should be returned to the factory for repair.

Unless personnel knowledgeable in electronics are available, do not

tamper with the circuits.

5.1.2 Anode Voltage Check

If the output can be adjusted by the zero control (the above section,

step 2), the cell anode voltage should be verified as follows:

WARNING These procedures should be caried out only by suitably

trained personnel familiar with high voltage circuit

boards. The anode-igniter unit and associate circuitry

involve dangerously high voltages.

Refer to the cell wiring diagram. Using a voltmeter set to measure 299

VDC, check the voltage on terminal four on the terminal strip TS6 on the

(mother) PCB, as follows:

1. Connect the negative voltmeter lead to ground and the positive

lead to TS6 terminal 4. Be careful not to short the circuit by

touching both an electrode and the cell body simultaneously.

The reading obtained should be 250±22 VDC.

Teledyne Analytical Instruments

5-3

Page 38

Chapter 5 Model 402R-EU

2. Apply procedure given in Section 1, Page VI of this manual,

then unplug P3 from J3 of the anode-igniter cable.

3. Reconnect the mains (line) cord to the 402R-EU and turn it ON.

4. Measure the voltage between socket "3" of J3 and ground and

then reapply the same procedure as provided in section 1, page

VI of this manua.

5. If the voltage was 250±22VDC, then check the anode-ignitor

cable and the sensor for low electrical resistance to ground or

other problems. Else, if the voltage was not 250±22VDC, then

replace the flame guard and anode power supply Pc Board.

WARNING:Do not touch capacitor C1 or C2, resistor R1 or R2, di-

odes D1, ZD2 or ZD3 or their related circuit foils. A shock

hazard may exist. Note and follow the turn off procedure

given in

INTERNAL INACCESSIBLE SHOCK HAZARDS"

Section 1 Page VII: "PROCEDURE FOR REMOVAL OF

.

Carefully remove the circuit board without touching any connections

which might lead to C1 or C2. After removal, discharge the two capacitors

by placing a jumper wire across each.

3. The anode voltage may also disappear or be greatly diminished

when condensation inside the sensor has occurred, shorting the

ignitor to the sensor body across the wet insulator. This usually

occurs when the flame is turned on, if the sensor has not been

preheated for at least 1 hour.

5.1.3 Electronic Stability

If the checks outlined above indicate that conditions are normal, allow

the analyzer to run electronically with the collector cable disconnected for

several hours in the lowest range, and with the zero control adjusted so that

the recorder is reading midscale. If all is normal electronically, a noise-free

(pen width) recording, showing absolutely no instability, should be obtained for as long as the analyzer is allowed to run in this configuration. If

the recording obtained is noisy or erratic, replace the electrometer-amplifier PC board.

5.1.4 Printed Circuit Board Replacement

Whenever the differential power supply temperature controller or

electrometer-amplifier printed circuit boards are replaced (or repaired),

instrument performance should be rechecked. The replacement circuit

boards are tested and adjusted at the factory before they are sent, and in

most cases, no recalibration will be required.

Teledyne Analytical Instruments5-4

Page 39

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

If performance is not adequate, then the analyzer must be

restandardized as described in Section 4-7: Calibration before being placed

back in service.

Whenever the flame guard and anode power supply printed circuit

board has been replaced, the flame guard circuit must be recalibrated (see

Section 5.3.1: Flame Guard Circuit Calibration) and the analyzer must be

restandardized.

If the instrument performs as outlined in this section, the problem is

not related to the measuring circuit electronics.

5.1.5 Collector Cable

Before reconnecting the collector cable, check the continuity of the

center wire of the cable with an ohmmeter by measuring between the

center pins at each plug on the lowest resistance scale of the meter. Flex

the cable while making this measurement to be sure that there is not an

intermittent open circuit. If there is, replace the cable. Do not attempt to

repair the cable, as special tooling is required to disassemble and reassemble the cable plugs.

5.2 Temperature Control Electronic Check

If the heating circuit fails, the output of the analyzer will tend to drift

with changes in ambient temperature. Such a failure will be more evident

in the low range. If the temperature environment surrounding the analyzer

is closely regulated, failure in this circuit might go unnoticed after the

initial failure. If the environment follows day and night temperature

changes, the analyzer will show a diurnal, bi-directional drift when operated on zero gas. The magnitude of the drift will be a function of the

temperature differential experienced by the analyzer. To check the circuit,

employ the following procedure:

Consult the 402R-EU schematic and assembly drawings, as well as

the temperature control PC board schematic and assembly drawings at the

rear of the manual for circuit details and component placement. See also

Figures 5-2 and 5-3 for the location of the Temperature Controller PC

Board.

1. An indicator light on the control panel cycles on and off with

the heating element; the light is on when the heater is on, and

vice versa. Failure of the light to come on at all when the cell

compartment is cold indicates a problem in the temperature

sensing or control circuitry or the wiring that interconnects the

Teledyne Analytical Instruments

5-5

Page 40

Chapter 5 Model 402R-EU

thermistor to the circuit. If the light stays on constantly, but the

compartment does not heat up, then a problem with the heating

element or connecting wiring is indicated.

2. Apply procedure for removal of internal inacessible shock

hazards, mentioned in section 1, page VI of this manual

3. Check the sensing thermistor by measuring the resistance

between its connecting wires. See Figure 5-2. Disconnect one of

the thermistor wires from terminal strip TS-2 (terminals 1 and

2) on the mother board and measure resistance between that

Figure 5-2: Identification and Location of Thermistor and Wires

Teledyne Analytical Instruments5-6

Page 41

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

Figure 5-3: Motherboard

wire and the remaining undisturbed terminal. See Figure 5-3.

Resistance of the thermistor varies with its surrounding

temperature. A reading of between 10KΩ and 20KΩ at around

25 °C may be measured. (Under very cold conditions, the

resistance could be as high as 50KΩ; under hot conditions, just

a few thousand ohms.) If the thermistor measures anywhere in

this range, it is most likely OK. Otherwise, if the circuit is open,

check the wires leading to the thermistor.

4. Check the heating element by measuring its resistance.

Disconnect one of the heater wires from either terminal 3 or

terminal 4 of TS-2 on the motherboard which is shown in

Figure 5-3, and check the resistance between that wire and the

remaining undisturbed terminal. If a reading of 288Ω ±10% is

found, then the heating element is most likely OK. If an open

circuit is found, check the heater wires and a possible connector

between the heater and TS-2. If no problems are found, and the

heater circuit is open, then replace the heater element.

Teledyne Analytical Instruments

5-7

Page 42

Chapter 5 Model 402R-EU

NOTE: If any of the components located inside the isothermal chamber has

failed, the instrument must be removed for service. The sample

selector module can be unplugged for service. All other components can be reached without instrument removal.

5. If no problems are found with either the thermistor or the heater

circuits, then replace the temperature control board.

5.3 Ignition and/or Flame Guard Circuit Checks

If the flame guard circuit will not hold the flame-out lamp off when

the ignition procedure is employed (see Chapter 3: Flame Ignition), perform the following procedure to isolate the problem (consult the system

schematic for details of the circuit):

1. Disconnect connector J3 (4 sockets) from connector P3 (4

pins). These are one of the large pairs of connectors just outside of

and to the left of the isothermal chamber. See Figure 5-2.

2. Check the flame guard sensing thermistor by measuring the resis-

tance between pins 1 and 2 of P3. The nominal resistance at

25°C is 100K, resistance readings at about 25°C of greater than

250K or less than 40K indicate that the thermistor is defective and

should be replaced.

3. Check the anode-igniter coil for continuity by measuring

between pins 3 and 4 of the disconnected cable plug P3. The

ohmmeter should indicate a maximum resistance of 1Ω.

4. If either step 2 or 3 does not check as indicated, remove the

electrode assembly of the detection cell and return it to the

factory for repair. If the quartz flame tip is damaged, the top

section of the cell may be removed by disconnecting the vent

line, and removing the screws around its flange. Return the unit

complete with attached electrode cable. If steps 2 and 3 both

check out properly, reconnect the anode-igniter cable (connect

J3 to P3).

Teledyne Analytical Instruments5-8

Page 43

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

5. Observe the K3 relay operation as the selector switch is moved

in and out of the IGNITE position (see Figure 5-3). If the relay

does not energize in the IGNITE position, remove it and check

it for an open coil (pins 13 and 14). The nominal resistance is

650Ω. If the coil checks OK, remove the flame guard power

supply board and check the forward and backward resistance of

its transient suppression diode by measuring pins 13 and 14 of

the relay socket. A multimeter should be set to the “diode test”

setting. The positive lead from the multimeter shall be

connected to socket number 13 on the relay socket and the

negative lead to socket 14. In this direction the multimeter

should indicate approx. 0.6 V and it should indicate an

overload when the lead connections are reversed. If these

readings are not obtained, then the diode (“D1” on the mother

PCB) must be replaced.

NOTE: If, after replacing a defective diode, the circuit still does not work

properly, the flame guard circuit components have been damaged,

and the flame guard PC board must be replaced.

6. If the preceding steps check out correctly, the flame guard

portion of the circuitry on the flame guard/anode power supply

PC board is either defective or needs recalibrating. Use the

following procedure to determine which problem exists:

IMPORTANT: If the circuit proves defective, the analyzer will have to be

restandardized (see Chapter 3: Stabilization Period) after the

board is replaced. (See section 5.1.4: Printed Circuit Board

Replacement.)

5.3.1 Flame Guard Circuit Calibration

1. With the selector switch in the high position, introduce span gas

into the sample path of the analyzer. Verify that all control

panel pressure readings are correct, and that the bypass flowrate

is 0.5 SCFH or greater.

2. Operate the selector switch in and out of the IGNITE position

until the presence of fuel is assured.

3. Observe the panel meter. If the meter reads up scale when the

selector switch is returned to the high position, ignition of the

Teledyne Analytical Instruments

5-9

Page 44

Chapter 5 Model 402R-EU

flame has occurred. If ignition failure is indicated (the meter

will read zero when the switch is in the high range), then refer

to Section 5.3: Ignition and/or Flame Guard Circuit Checks to

check the ignition circuit.

4. If ignition is verified, adjust the miniature potentiometer on the

flame guard anode power supply board until it is over 75% of

its travel clockwise (but not fully clockwise or counterclockwise), and repeat the ignition procedure. If the sensing

thermistor is intact (see step 2 under Section 5.3), and a fault

does not exist on the PC board, the flame guard circuit should

hold the flame-out indicator light in the off condition. If it does

not, replace the circuit board. If it does (or after a new board is

installed and the preceding steps completed), proceed with the

remaining steps of this section.

5. Turn the potentiometer slowly counter-clockwise until the

flame-out indicator light just comes on. Turn the potentiometer

gradually clockwise again (while repeating the ignition

procedure) until the light remains off. This adjusts the

sensitivity of the flame guard circuit. If properly adjusted, the

flame guard circuit should illuminate the flame-out indicator

light within 10-20 seconds after flame failure. This can be

easily tested by turning off the fuel and checking the light.

5.4 Sampling System

If the procedures outlined above do not correct the problem, the fault

must be related to the gas control systems. Plugged or faulty regulators,

plugged restrictors, or leaks within the system can cause erratic performance. TET/AI recommends that the factory or an authorized representative be contacted before attempting any repairs to the sample or supporting

gas systems within the analyzer.

5.5 Printed Circuit Board Descriptions

The electronics circuitry of the analyzer is designed with the latest

integrated circuit technology. The individual circuits which are required to

process the incoming signal and condition it to provide the various outputs,

alarms, indicators, etc., are built upon separate plug-in printed circuit

Teledyne Analytical Instruments5-10

Page 45

Total Hydrocarbon Analyzer Maintenance and Troubleshooting

boards and interconnected via a motherboard, which contains the connectors into which the circuit boards are inserted.

The layout of the motherboard changes very little, in spite of the fact

that it is used in a wide variety of instruments. This allows a universal

approach to its use, and the circuit boards which are used can thus remain

the same in varied applications.

The circuit board connectors on the Mother Board are labeled J1

through J6 and are used in totally standard instruments to connect and hold

plug-in printed circuit boards in the following configuration:

J1: Flame guard-anode power supply

J2: Not used for the standard Model 402R

J3: E-to-I converter (isolated)

J4: Alarm comparator (dual)

J5: Differential power supply

J6: Temperature control

In addition, connector J1 is used with the Model 402R-EU; J1 plugs

onto the electrometer amplifier PC board. These are shown in Figures 5-2

and 5-3.

The alarm comparator is an optional circuit; it has two (dual) adjustable setpoints at which an alarm or indicator is activated. Alarm circuits

normally employ relays to provide contacts which may be connected, via

terminal strip, to auxiliary signal devices.

Consult the following pages for detailed descriptions of the plug-in

circuits used with the Model 402R.

5.5.1 Flame Guard and Anode Power Supply Printed

Circuit Board

Schematic No. B-67810

Assembly Dwg. No. B-67797

Anode Power Supply: The high voltage anode power supply com-

ponents (except for transformer) are mounted on the flame guard and

anode power supply printed circuit board. High voltage regulation is

Teledyne Analytical Instruments

5-11

Page 46

Chapter 5 Model 402R-EU

achieved through the use of series-connected zener diodes. The simplicity

of this circuit’s design can be attributed to the extremely low current

demand of the anode circuit. The positive output voltage is nominally 250

volts. Output tolerance is ±22 volts from the specified 250 volts, due to

variation in components from unit to unit.

Flame Guard Circuit: A thermistor-controlled, transistorized

switching circuit is employed to operate a relay in the event of a flame-out

condition. A panel indicator light is turned on by the relay to alarm personnel that a flame-out condition has occurred.

The controlling thermistor is located within the upper section of the