Page 1

Total Hydrocarbon Analyzer

INSTRUCTION, OPERATING, AND

MAINTENANCE MANUAL FOR

MODEL 4020

Standard Software Version

P/N M74661

4/05/2010 Rev 6

DANGER

Toxic and/or flammable gases or liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist for

a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing. Before

conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments i

Page 2

Model 4020

Copyright © 2010 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, an d serves as a to ol by whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface be properly trained in the

process being measured, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Total Hydrocarbon Analyzer

Specific Model Information

The instrument for which this manual was supplied may incorporate

one or more options not supplied in the standard instrument. Commonly

available options are listed below, with check boxes. Any that are

incorporated in the instrument for which this manual is supplied are

indicated by a check mark in the box.

Instrument Serial Number: _______________________

Options Included in the Instrument with the Above Serial Number:

Power Requirements: This instrument may be designed for

operation using a power source other than 115 VAC @ 60

Hz. If so, one of the boxes below will be checked indicating

the power requirements for your instrument.

110 VAC @ 50 Hz

115 VAC @ 50 Hz

220 VAC @ 50/60 Hz

Other: _______________

Using Hydrogen as Sample: For applications where the

sample gas is hydrogen, the sample gas doubles as the fuel

for combustion. The gas connections made at the back panel

are slightly different for this configuration. Connect the

hydrogen sample gas to the sample input as usual. Connect a

nitrogen source at 40 psig to the fuel input. This is discussed

in the manual in the Installation section.

Using Hydrogen as Fuel: For applications where the fuel is

hydrogen, the gas connections made at the back panel are

Teledyne Analytical Instruments iii

Page 4

Model 4020

slightly different. At the “FUEL” inlet, replace the “40%

H

/60% N2” with pure H2. This is discussed in the

2

Installation section.

Special Analysis Ranges: this model 4020 has special

analysis ranges:

Range 1: ___________

Range 2: ___________

Range 3: ___________

Auto-Calibration Module Option: This module consists of

solenoid for automatically selecting calibration or sample

flow to the analyzer and provides the user with the ability to

calibrate the analyzer on a user-programmed schedule.

AP Options: Vented Sample System Covers; Perforated

covers have been installed over the sample system

compartment and analyzer top cover for venting purposes.

Recommended warm-up period: hours

Other:

Teledyne Analytical Instruments iv

Page 5

Total Hydrocarbon Analyzer

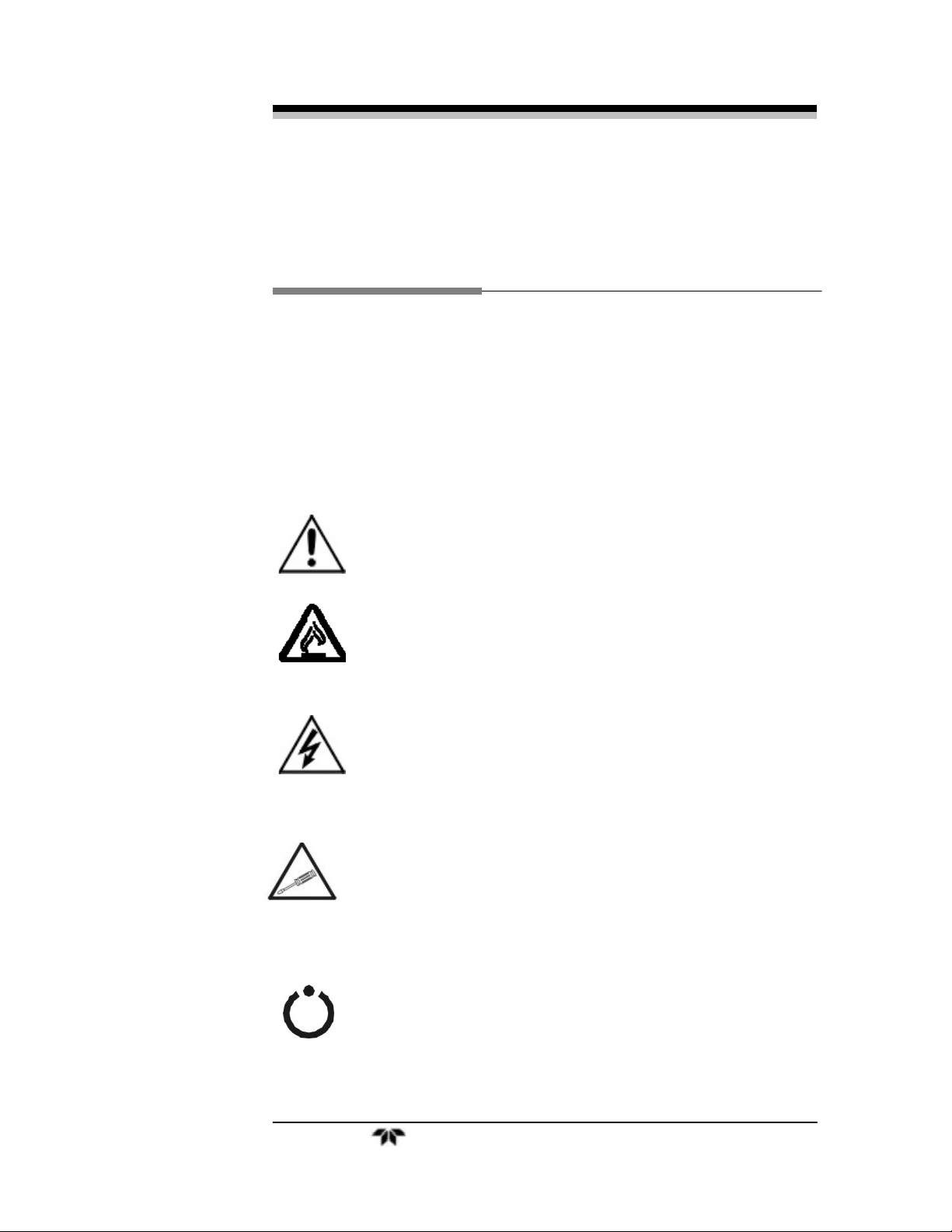

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These

cautions warn of specific procedures which if not

followed could cause bodily Injury and/or damage the

instrument.

No

Symbol

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument.

Failure to heed the warning could result in serious burns

to skin and underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed

this warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this

symbol are to be performed by qualified maintenance

personnel only.

NOTE: Additional information and comments regarding

a specific component or procedure are highlighted in the

form of a note.

STAND-BY: This symbol indicates that the instrument is

on Stand-by but circuits are active.

Teledyne Analytical Instruments v

Page 6

Model 4020

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through the

installation, calibration and operation of your new analyzer. Please read

this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be specific to your

instrument.

Manuals do get misplaced. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments vi

Page 7

Total Hydrocarbon Analyzer

Table of Contents

Safety Messages ........................................................................... v

List of Figures ............................................................................... xi

List of Tables ............................................................................... xii

Additional Safety Information .................................................. xiii

Procedure for Removal of Internal Inaccessible Shock Hazards xv

Introduction ................................................................................... 1

1.1 Main Features of the Analyzer 1

1.2 Principle of Operation 2

1.3 Analyzer Description 2

1.4 Applications 3

Operational Theory ....................................................................... 7

2.1 Introduction 7

2.2 Sample System 7

2.2.1 Input Porting 8

2.2.2 Sample Flow Control System 8

2.2.3 Fuel and Blanket Air Systems 8

2.2.4 Flame Ionization Detection Cell 9

2.3 Detection Cell 9

2.3.1 Electrometer-Amplifier 10

2.3.2 Anode Power Supply 11

2.3.3 Flame Guard Circuit 11

2.3.4 Flame Ignition Circuit 11

2.3.5 Proportional Temperature Control Circuit 11

Installation ................................................................................... 13

3.1 Unpacking the Analyzer 13

Teledyne Analytical Instruments vii

Page 8

Model 4020

3.2 Mounting the Analyzer 13

3.3 User Connections 14

3.3.1 Electrical Power Connections 14

3.3.2 Gas Connections 14

3.3.2.1 Vent Connections 16

3.3.3 Electrical Connections 16

3.3.3.1 Primary Input Power 17

3.3.3.2 Fuse Installation 17

3.3.3.3 50-Pin Equipment Interface Connector 17

3.3.3.4 Analog Output 18

3.3.3.5 Alarm Relays 20

3.3.3.6 Digital Remote Cal Inputs 21

3.3.3.7 Range ID Relays 23

3.3.3.8 Network I/O 23

3.3.3.9 Pin Out Table 23

3.3.4 RS-232 Port 25

3.3.5 Supporting Gases 26

3.3.5.1 Sample Gas 27

3.3.5.2 Effluent 27

3.3.5.3 Sample Bypass Vent 27

3.3.5.4 Fuel and Air Connections 27

Operation ..................................................................................... 29

4.1 Equipment 29

4.2 Preliminary Power-Off Check List 30

4.3 Placing the System in Operation 30

4.4 Activating the Support Gases 31

4.4.1 Air 31

4.4.2 Sample Gas 31

4.4.3 Span Gas 31

4.4.4 Fuel 31

Teledyne Analytical Instruments viii

Page 9

Total Hydrocarbon Analyzer

4.5 Flame Ignition 32

4.5.1 Verification of the Flame Guard Circuit 32

4.5.2 Ignition and/or Flame Guard Circuit Failure 33

4.6 Analyzer Operation 33

4.6.1 Default Parameters 34

4.6.2 Style Conventions 34

4.6.3 Using the Controls 35

4.6.4 Mode/Function Selection 35

4.6.4.1 Analysis Mode 36

4.6.4.2 Setup Mode 37

4.6.5 Data Entry 38

4.6.5.1 ENTER 38

4.6.5.2 ESCAPE 38

4.6.6 Setting up an AUTO-CAL 40

4.6.7 Password Protection 42

4.6.7.1 Entering the Password 43

4.6.7.2 Installing or Changing the Password 44

4.6.8 Logging Out 45

4.6.9 System Self-Diagnostic Test 45

4.6.10 The Model Screen 46

4.6.11 Zero and Span Functions 47

4.6.12 The Alarms Function 50

4.6.13 The Range Function 53

4.6.13.1 Manual (Select/Define Range) Screen 53

4.6.13.2 Auto Range 55

4.6.13.3 Digital Mode 56

4.6.14 Digital Filter Setup 57

4.6.15 Fuel Display 58

4.6.16 Valve Selections 58

4.6.16.1 Disabled 59

Teledyne Analytical Instruments ix

Page 10

Model 4020

4.6.16.2 User Select 59

4.6.16.3 Default (By Function) 61

4.6.16.4 Observing the gas Stream Concentrations 62

4.6.17 Standby 63

4.7 Advanced User Functions 63

4.7.1 Zero Offset Adjustment 64

4.7.2 Background Gas Selection 65

Maintenance & Troubleshooting ................................................ 67

5.1 Measuring Circuit Electrical Checks 68

5.1.1 Loss of Zero Control 68

5.1.2 Anode Voltage Check 69

5.1.3 Electronic Stability 70

5.1.4 Printed Circuit Board Replacement 70

5.1.5 Collector Cable 70

5.2 Temperature Control Electronic Check 71

5.3 Ignition and/or Flame Guard Circuit Checks 72

5.4 Sampling System 73

5.5 Printed Circuit Board Descriptions 73

5.5.1 Flame Guard and Anode Power Supply PCB 73

5.5.3 Proportional Temperature Controller PCB 74

5.5.4 Electrometer-Amplifier PCB 76

Appendix ...................................................................................... 79

Specifications 79

Application Data 80

Recommended Spare Parts List 81

Drawing List 82

Teledyne Analytical Instruments x

Page 11

Total Hydrocarbon Analyzer

List of Figures

Figure 1-1: Gas Sample System with Optional AutoCal Valves ...... 4

Figure 1-2: Gas Sample System Without Optional AutoCal Valves . 5

Figure 1-3: Flame Ionization Cell ..................................................... 6

Figure 2-1: View Inside Cabinet .................................................... 10

Figure 3-1: Gas Connections ......................................................... 15

Figure 3-2: Equipment Interface Connector Pin Arrangement ....... 18

Figure 4-1: Front Panel View of Regulator and Gages .................. 32

Figure 4-2: Typical VFD Screen Layout ........................................ 35

Figure 4-3: Setup Mode Functions ................................................ 39

Figure 4-4: AUTOCAL Screens ..................................................... 42

Teledyne Analytical Instruments xi

Page 12

Model 4020

List of Tables

Table 3-1: Analog Output Connections ......................................... 18

Table 3-2: Analog Concentration Output—Example ...................... 19

Table 3-3: Analog Range ID Output—Example ............................. 20

Table 3-4: Alarm Relay Contact Pins ............................................ 21

Table 3-5: Remote Calibration Connections .................................. 22

Table 3-6: Range ID Relay Connections ....................................... 23

Table 3-7: Pin out of 50 pin D-Sub Connector ............................... 24

Table 3-8: Commands via RS-232 Input ....................................... 26

Table 3-9: Required RS-232 Options ............................................ 26

Table 4-1: Digital Range Selection Signals ................................... 56

Teledyne Analytical Instruments xii

Page 13

Total Hydrocarbon Analyzer

Additional Safety Information

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for usage in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

WARNING

The customer should ensure that the principles of operating

of this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

WARNING: HYDROGEN GAS IS USED IN THIS INSTRUMENT AS

A FUEL. HYDROGEN IS EXTREMELY FLAMMABLE.

EXTREME CARE MUST BE USED WHEN WORKING

AROUND GAS MIXTURES CONTAINING

FLAMMABLE GASES.

A Successful leak check was performed at TI/AI on

the sample system of this instrument prior to

calibration, testing and shipping. Ensure that there

are no leaks in the fuel supply lines before applying

power to the system.

Teledyne Analytical Instruments xiii

Page 14

Model 4020

Always purge the entire system before performing

any maintenance and always leak check the system

after removing any tubing or fittings on the sample

system. See the procedures for purging and leak

checking this instrument on the following pages.

If toxic gases or other hazardous materials are

introduced into the sample system, the same

precautions regarding leak checking and purging

apply to the sample lines and sample supply or

delivery lines.

WARNING: ELECTRICAL SHOCK HAZARD. WITH THE

EXCEPTION OF OPENING THE DOOR AND

ADJUSTING THE PRESSURE REGULATORS, FLOW

CONTROLLER, OR OBSERVING THE PRESSURE

GAUGES AND THE FLOWMETER, ONLY

AUTHORIZED AND SUITABLY TRAINED

PERSONNEL SHOULD PERFORM WORK INSIDE OF

THE INSTRUMENT. COMPONENTS WITHIN THE

COVER ON THE INSIDE OF THE DOOR, INSIDE THE

ISOTHERMAL CHAMBER (SAMPLE SYSTEM), AND

ON THE ELECTROMETER-AMPLIFIER PC BOARD

CONTAIN DANGEROUSLY HIGH VOLTAGE

SUFFICIENT TO CAUSE SERIOUS INJURY OR

DEATH.

There are the following three types of inaccessible

shock hazards within the 4020:

1. Line voltages and line related voltages such as

115 VAC which exists within the 230 VAC version

as well. These voltages stop when the 4020 is

turned off and the mains (line) cord is removed

from the instrument.

2. The sensor anode supply voltage (approximately

250 VDC). This voltage exists on the Flame

Guard, anode power supply, PCB, the

motherboard, and the anode/igniter terminals on

the sensor. THIS VOLTAGE WILL REMAIN

HAZARDOUS FOR MANY MINUTES AFTER THE

MODEL 4020 HAS BEEN TURNED OFF!

Teledyne Analytical Instruments xiv

Page 15

Total Hydrocarbon Analyzer

3. External hazardous voltages which may be

connected to the Model 4020 alarm relay

connections.

Procedure for Removal of Internal Inaccessible

Shock Hazards

CAUTION: SERVICING OR MAINTENANCE OF THE 4020

SHOULD ONLY BE DONE BY SUITABLE TRAINED

PERSONNEL. TO AVOID THESE INACCESSIBLE

HAZARDOUS VOLTAGES WHEN SERVICING THE

4020, PERFORM EACH OF THE FOLLOWING STEPS,

IN THE ORDER GIVEN, BEFORE SERVICING

BEGINS:

1. Switch off the power to the 4020 and remove the mains (line)

power cord from the 4020.

2. Remove all external voltages from the connections to the

alarm contacts.

3. Wait one minute.

4. Discharge the anode supply voltage.

a. Connect one end of an insulated (to 1000 VDC or more)

clip lead to 4020 chassis ground (the standoff for the

upper right corner of the mother PCB).

b. Put one end of a 500V rated 1000 ohm resistor in the

other end of the clip lead.

c. Check the voltage between chassis ground (the standoff

for the upper right corner of the mother PCB) and the top

side of R2 at PCB number B74671. It should be between

-5VDC and +5VDC. If is in that range, the inaccessible

hazardous voltage removal procedure is completed, if not

repeat steps 4.a and 4.b.

If it is absolutely necessary to work inside the instrument with power

on, use the ONE HAND RULE:

Work with one hand only.

Keep the other hand free without contacting any other object. This

reduces the possibility of a ground path through the body in case of

accidental contact with hazardous voltages.

Teledyne Analytical Instruments xv

Page 16

Model 4020

WARNING: THIS INSTRUMENT IS DESIGNED TO BE OPERATED

IN A NONHAZARDOUS AREA. THE ANALYZER USES

HYDROGEN GAS AND/OR OTHER COMBUSTIBLE

GASES IN ITS OPERATION. THIS EQUIPMENT, IF

NOT USED AND MAINTAINED PROPERLY CAN BE

AN EXPLOSION HAZARD. THE ANALYZER,

DEPENDING ON THE APPLICATION, MAY ALSO USE

TOXIC GASES. IT IS THEREFORE, THE

CUSTOMER'S RESPONSIBILITY TO ENSURE THAT

PROPER TRAINING AND UNDERSTANDING OF THE

PRINCIPLES OF OPERATION OF THIS EQUIPMENT

ARE UNDERSTOOD BY THE USER. SINCE THE USE

OF THIS INSTRUMENT IS BEYOND THE CONTROL

OF TELEDYNE, NO RESPONSIBILITY BY TELEDYNE,

ITS AFFILIATES AND AGENTS FOR DAMAGE OR

INJURY RESULTING FROM MISUSE OR NEGLECT

OF THIS INSTRUMENT IS IMPLIED OR ASSUMED.

MISUSE OF THIS PRODUCT IN ANY MANNER,

TAMPERING WITH ITS COMPONENTS OR

UNAUTHORIZED SUBSTITUTION OF ANY

COMPONENT MAY ADVERSELY AFFECT THE

SAFETY OF THIS INSTRUMENT.

CAUTION: WHEN OPERATING THIS INSTRUMENT, THE DOORS

MUST BE CLOSED AND ALL COVERS SECURELY

FASTENED. THE GAUGES MUST BE IN PROPER

WORKING ORDER. DO NOT OVERPRESSURIZE THE

SYSTEM.

READ THIS MANUAL BEFORE OPERATING THE

INSTRUMENT AND ADHERE TO ALL WARNINGS

INCLUDED IN THIS MANUAL.

Teledyne Analytical Instruments xvi

Page 17

Total Hydrocarbon Analyzer Introduction

Introduction

Teledyne Analytical Instruments Model 4020 Total Hydrocarbon

Analyzer is a versatile instrument designed to measure the quantity of

hydrocarbons present in a positive pressure sample as equivalent

methane. The Model 4020 is a microprocessor controlled digital

instrument based on Teledyne’s highly successful Model 402R series

analog Total Hydrocarbon Analyzer.

1.1 Main Features of the Analyzer

The Model 4020 Total Hydrocarbon Analyzer is sophisticated yet

simple to use. A dual display on the front panel prompts and informs the

operator during all phases of operation. The main features of the

analyzer include:

Easy-to-use front panel interface that includes a red 5-digit

LED display and a vacuum fluorescent display (VFD), driven

by microprocessor electronics.

High resolution, accurate readings of concentration from low

ppm levels to 6%.

Microprocessor based electronics: 8-bit CMOS

microprocessor with 32 kB RAM and 128 kB ROM.

Versatile analysis with three user-definable analysis ranges

from 1 ppm through 6%.

Autoranging allows analyzer to automatically select the

proper preset range for a given measurement. Manual

override allows the user to lock onto a specific range of

interest.

A digital mode for range selection allows the user to perform

range switching using the remote calibration contacts.

O2/N2 background gas selection allows the use of two

different sample background gases with separate calibration

parameters stored in memory.

Teledyne Analytical Instruments 1

Page 18

Introduction Model 4020

Two adjustable concentration alarms and a system failure

alarm.

Extensive self-diagnostic testing at startup and on demand

with continuous power supply monitoring.

RS-232 serial digital port for use with a computer or other

digital communication device.

Analog outputs for concentration and range identification (0-

1 VDC standard and isolated 4-20 mA dc).

Superior Accuracy

1.2 Principle of Operation

The sample gas is mixed with a fuel (normally a composition of

hydrogen and nitrogen) and burned in an atmosphere of “blanket air”.

The ions formed in the burning process cause an electrical conduction

between two electrodes in the combustion chamber (or detector cell) that

is amplified by a highly sensitive electrometer-amplifier circuit. The

electrical output of the electrometer-amplifier is directly proportional to

the quantity of flame ionizable hydrocarbons present, and is linear over

the range of 0-60,000 PPM methane.

1.3 Analyzer Description

The information contained in this manual describes individual analyzers

of the Model 4020 standard series. The versatility of this analyzer is inherited

through the long heritage of the earlier analog unit. Very often, special

customer driven design features are incorporated and will require additional

or supplementary information in addition to the information described in this

manual. These special considerations, if applicable, will be described in detail

on specific application pages as Addenda to this manual. When the Model

4020 is a part of a larger system, it is subordinate to that system, and specific

installation and operation conditions of that system will apply. Consult

system sections of the manuals for those applications, where conditions

specific to those systems will be detailed.

To best suit the needs of the purchaser, specialized designs may have

been adopted. Details of the design differences may be found in the

various drawings (outline, assembly, schematic, wiring, and piping

diagrams) in the drawings section at the rear of the manual.

Teledyne Analytical Instruments 2

Page 19

Total Hydrocarbon Analyzer Introduction

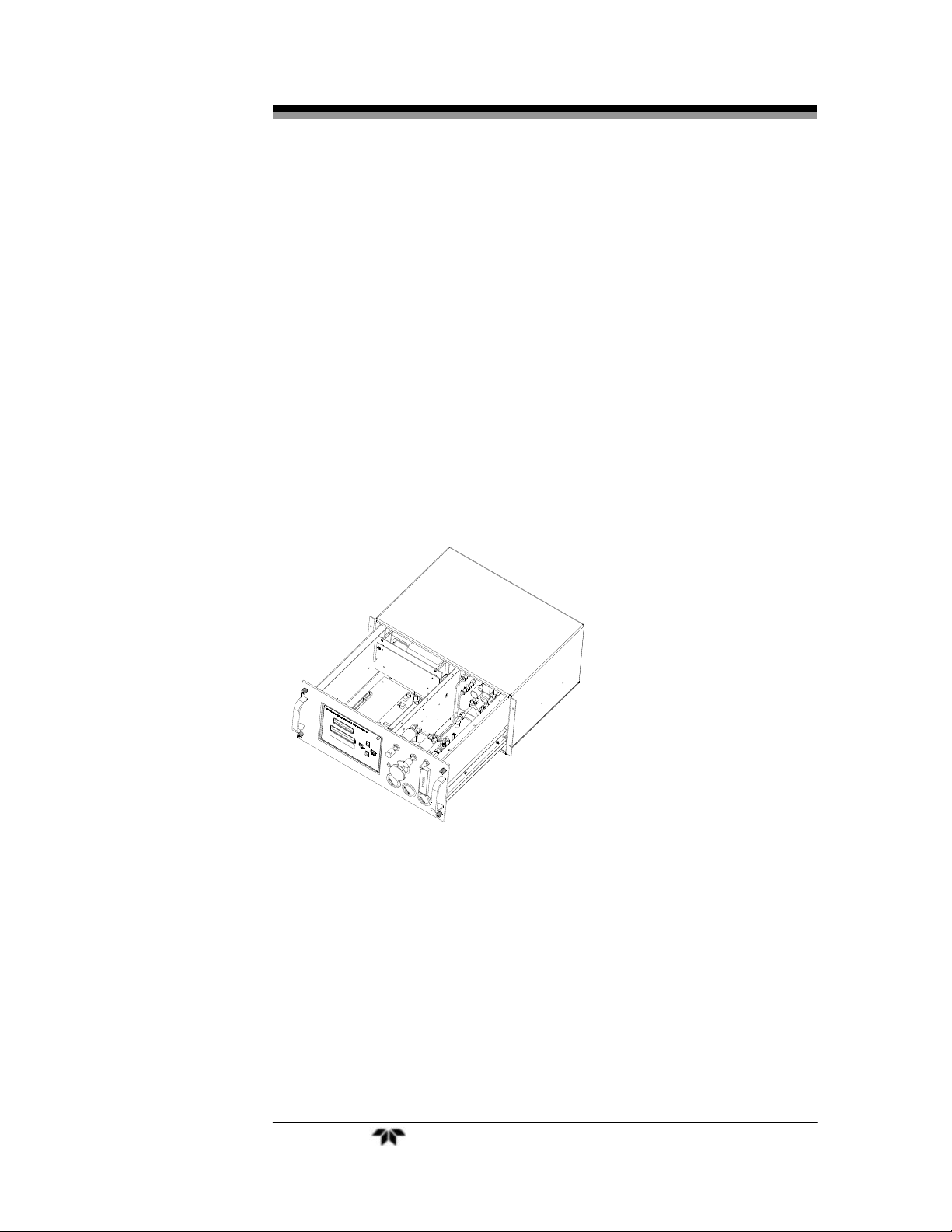

The standard analyzer is housed in a sheet steel equipment case

flush-mounted in a 19" rack. The front interface panel is mounted on a

door which, when opened, allows convenient access to the 4020

electronics. The entire front panel can slide out of the chassis to provide

greater access to the electronics and to the sample system. Gas pressure

and flow controls are mounted on the front panel adjacent to the LED

and VFD displays and user interface.

At the rear of the instrument are ports for the introduction of air,

fuel, zero, span, and sample gas. A single 50-pin user-interface cable

connector contains input/output and alarm signals available to the user.

An RS-232 port is also available at the rear panel for connection to a

remote computer or other digital communication device. The Model

4020 is set up for either 120 VAC 60 Hz or 230 50/60 Hz operation

depending on the customer’s requirements. The appropriate power cord

for your unit has been shipped with this instrument.

1.4 Applications

Monitoring the purity of oxygen, argon, nitrogen and other

gases in the manufacture of semiconductors and related

equipment.

Monitoring hydrocarbon contamination in air liquefaction

and other gas production processes.

Gas purity certification.

Detecting trace hydrocarbons in ambient air.

Detecting atmospheric pollutants.

Cryogenics.

Monitoring for fuel leakage or toxic solvents.

Monitoring hydrocarbons in a wide range of process streams.

Teledyne Analytical Instruments 3

Page 20

Introduction Model 4020

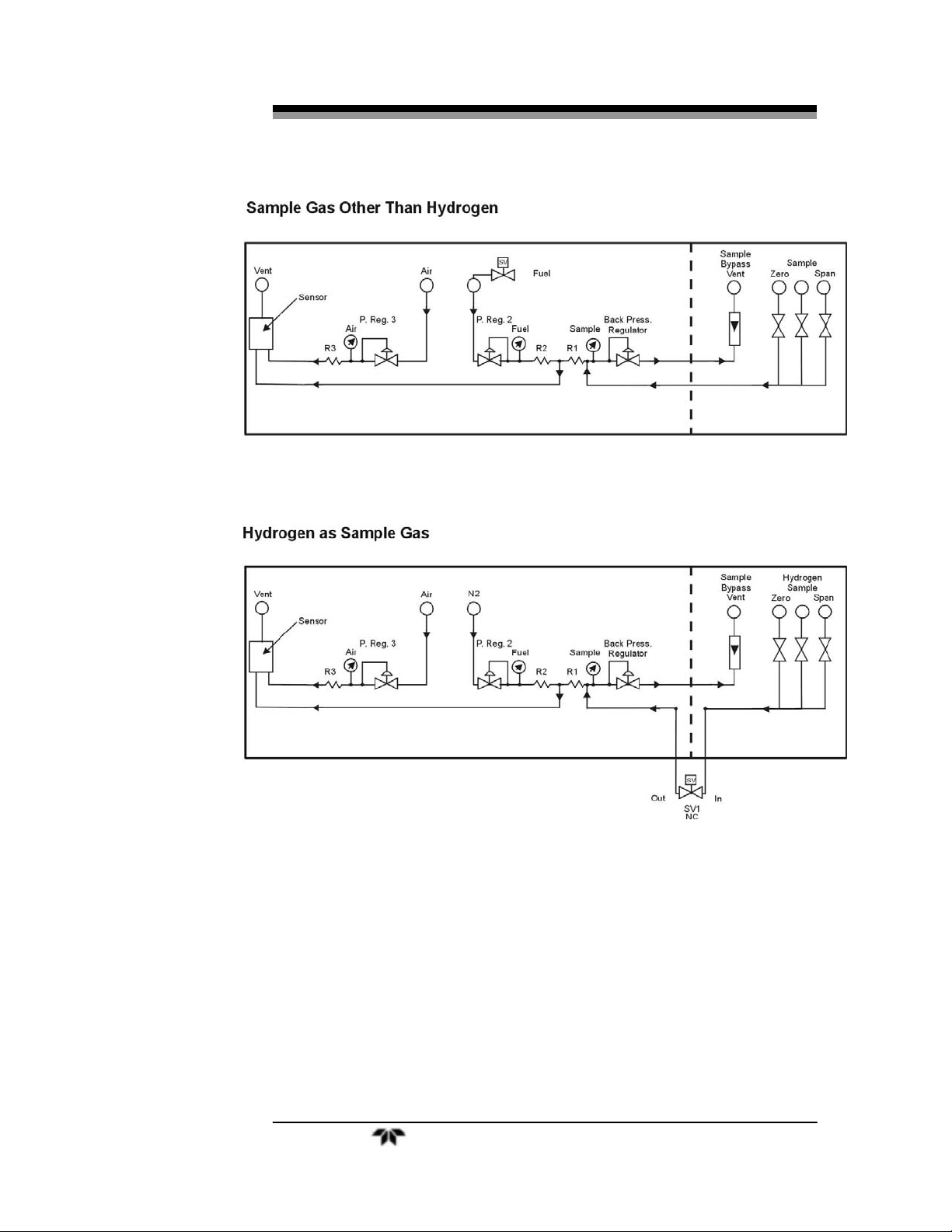

Figure 1-1: Gas Sample System with Optional AutoCal Valves

Teledyne Analytical Instruments 4

Page 21

Total Hydrocarbon Analyzer Introduction

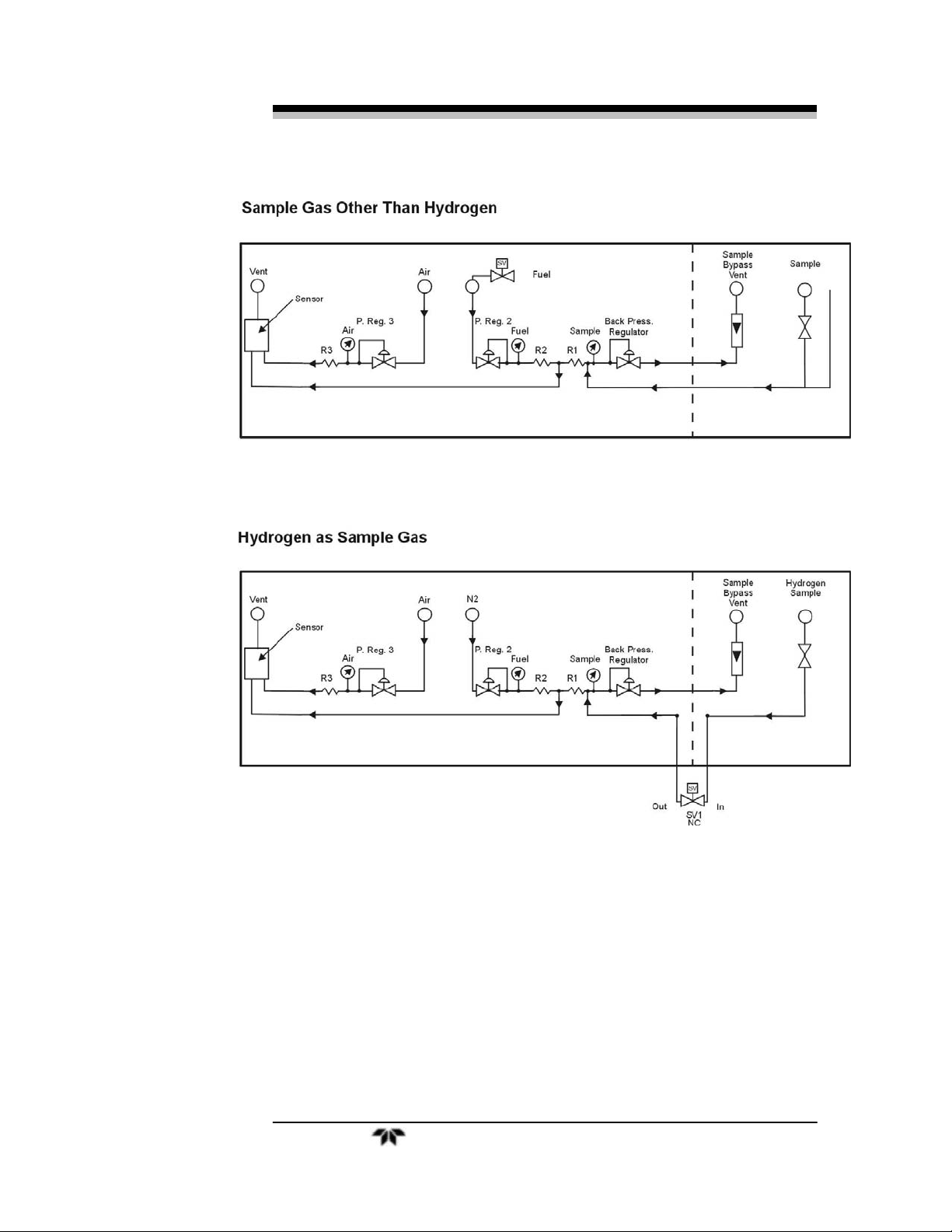

Figure 1-2: Gas Sample System Without Optional AutoCal Valves

Teledyne Analytical Instruments 5

Page 22

Introduction Model 4020

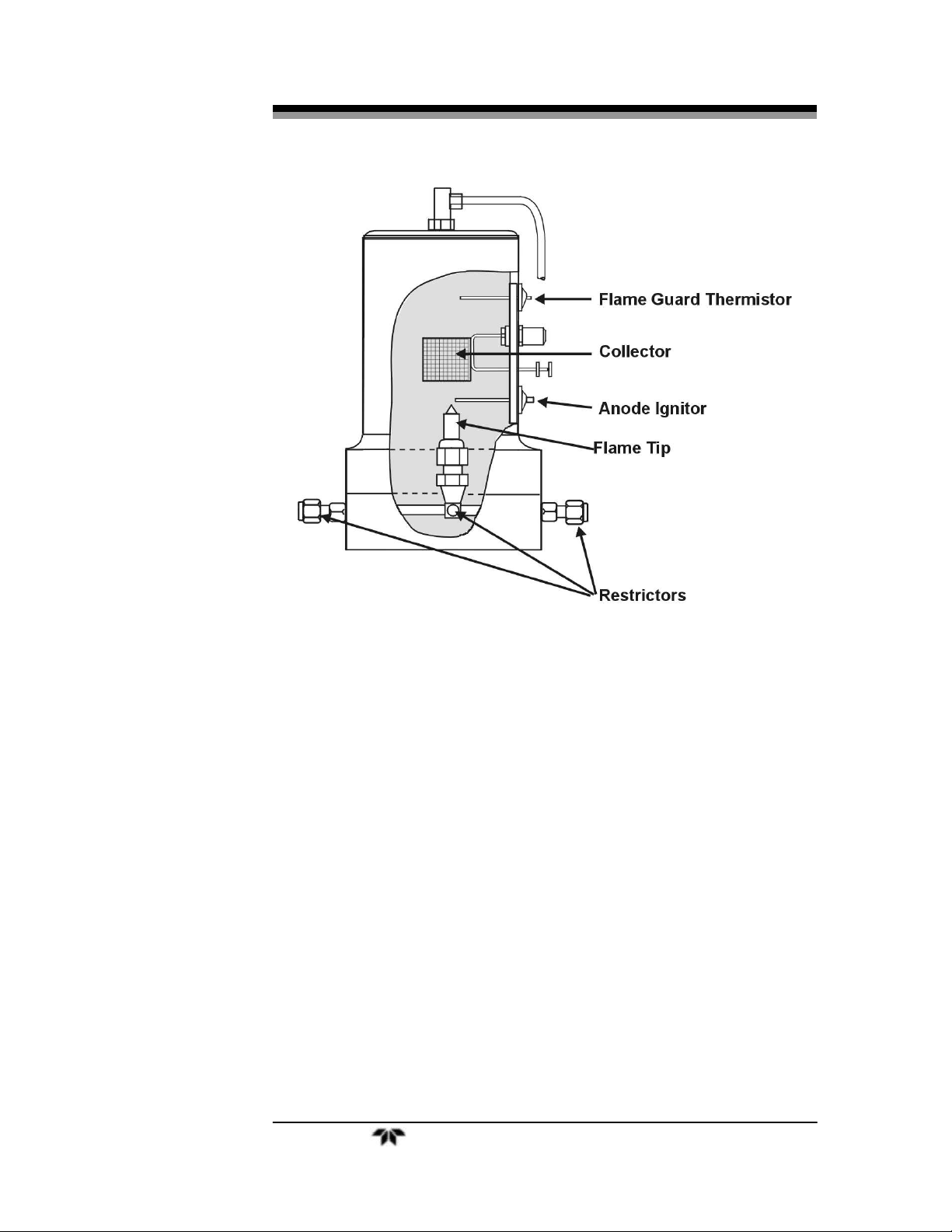

Figure 1-3: Flame Ionization Cell

Teledyne Analytical Instruments 6

Page 23

Total Hydrocarbon Analyzer Operational Theory

Operational Theory

2.1 Introduction

The Model 4020 Total Hydrocarbon Analyzer is composed of three

subsystems:

1. Sample System

2. Detector Cell

3. Electronic Signal Processing, Display and Control

2.2 Sample System

Note: The measured component for the Model 4020 is

hydrocarbon content. Hydrocarbon lubricants and

conditioners, as well as synthetic plastics are common to

instrumentation supply processes. Utmost precaution must

be taken at all times to specify hydrocarbon-free gases,

regulator diaphragms, and supplies.

All components used to control the sample and supporting gases, as

well as the combustion portion of the detector cell, are located inside the

enclosure, behind the electronics control panel and are accessible by

sliding the front of the unit out from the rack enclosure. Adjustments are

made using the appropriate control on the front panel.

The software in the Model 4020 allows the system to be used for

analyzing a sample gas in two different backgrounds, O

separate calibration must be performed on each sample/background

combination. The calibration parameters are stored internally and are

appropriately applied when the user selects the specific background gas

in use. See Section 4.7.2 Background Gas Selection.

Note: The user must supply the necessary valves and any

associated switching equipment for delivering the correct

sample/background gas combination to the analyzer.

and N2. A

2

Teledyne Analytical Instruments 7

Page 24

Operational Theory Model 4020

The basic analyzer consists of an isothermal chamber containing the

pressure regulators, pressure gauges and flow restrictors. The

temperature within the chamber is maintained at 125°F by a heating

element. The regulated temperature of the chamber insures stable gas

flow. An optional AutoCal module is available which when fitted,

mounts inside the instrument enclosure and integrates with the sample

system. It allows convenient switching between sample and calibration

gases. When installed, it is part of the isothermal chamber. The bypass

flow is also controlled from this optional panel.

2.2.1 Input Porting

The analyzer is equipped with ports for the introduction of air, fuel,

zero, span, and sample gas.

2.2.2 Sample Flow Control System

Stable sample flow is achieved by maintaining a constant pressure

across a restrictor through the use of a back-pressure regulation system,

which includes an adjustable regulator, pressure gauge, throttle valve,

and flowmeter. The throttle valve and flowmeter are included so that the

bypass flow required by the back-pressure regulator can be limited.

Without these controls, a high sample point pressure would result in

unnecessary sample waste through the back-pressure regulator.

The components of the system are arranged so that no dead volume

is present in the sample path to the detector cell. This guarantees rapid

response to changes in hydrocarbon concentration—a fact that can be

demonstrated when zero and span gas are exchanged during the

standardization procedure.

The restrictors used in the system look alike; however, they are not

interchangeable.

2.2.3 Fuel and Blanket Air Systems

The fuel and blanket air systems use similar components. Stable flow

is achieved by maintaining a constant pressure across restrictors upstream

from the cell. Each system incorporates an adjustable pressure regulator,

pressure gauge, and restrictor. A flame out light is included to indicate

when the flame fails. A fuel shut-off solenoid valve, mounted on the line

that supplies fuel, stops the fuel flow in case of flame failure. This valve is

located in line with the fuel port; except for instruments using hydrogen as

the sample gas. In this case, the sample is used as fuel and the valve is

Teledyne Analytical Instruments 8

Page 25

Total Hydrocarbon Analyzer Operational Theory

located in line with the sample port. See Figure 1-1 for a flow schematic

for instruments equipped with AutoCal valves and Figure 1-2 for

instruments without the AutoCal option.

2.2.4 Flame Ionization Detection Cell

The sample and fuel are combined within a tee fitting located in the

isothermal chamber. The mixed gas is emitted from a burner within the

sensor assembly. Blanket air is introduced into the sensor (or cell) by

means of a separate fitting that is located in the base section of the

assembly. The upper half of the assembly houses the anode-igniter,

collector, and flame guard thermistor. The cell is located at the left hand

front area inside the enclosure for easy access. See Figure 2.1.

2.3 Detection Cell

The upper section of the stainless steel flame ionization cell houses

the cylindrical collector electrode, the high voltage (+260 VDC) anodeigniter coil, and the sensing thermistor of the flame guard circuit (see

cell cross-section Figure 1-3).

WARNING: DANGEROUS HIGH VOLTAGE EXISTS AT THE

ANODE IGNITER COIL (+260 VDC). DO NOT

ATTEMPT TO DISCONNECT THE IGNITER COIL

CABLE OR DISASSEMBLE ANY OF THE FLAME

IONIZATION CELL COMPONENTS WITHOUT

TURNING OFF THE POWER AND DISCONNECTING

THE POWER CORD.

The collector is interconnected with the electrometer-amplifier PC

board by a coaxial cable. Although the cable and fittings are intended for

coaxial service, the cable is actually being used as a shielded singleconductor connection.

The anode-igniter, as its name implies, serves two functions. When

relay K2 at PCB part number B74671 is energized, the coil becomes an

electrical heating element that glows red-hot and ignites the hydrogen

fuel. When relay K2 at B74671 is de-energized, the coil is connected to

the +260 volt DC terminal of the anode-flame guard power supply PC

board. In this configuration, the necessary potential difference is

established between the coil (anode) and collector to promote ionization

of the burned hydrocarbons. The coil functions as the high voltage anode

in all three range positions of the selector switch.

Teledyne Analytical Instruments 9

Page 26

Operational Theory Model 4020

The thermistor acts as the sensor in the flame guard circuit. Its

ambient temperature resistance is in the 100 K ohms region. When the

flame is ignited, its resistance is reduced by a factor of 100. The

thermistor is coupled to a semiconductor control circuit on the anodeflame guard power supply PC board, which will be described in a

following section.

The cell electrodes of both the anode-igniter and flame guard

thermistor are connected to the electronics chassis by means of a plug-in

cable.

The electrode section of the cell may be removed for inspection by

turning off the power, disconnecting the electrode lead plug, and

removing the screws which retain the electrode assembly in the sensor

body.

Figure 2-1: View Inside Cabinet

2.3.1 Electrometer-Amplifier

The collector cable is coupled directly to a coaxial fitting located on

the electrometer-amplifier PC board. The PC board is located on the side

panel next to but outside of the isothermal chamber. See Figure 2-1. and

consists of an electrometer amplifier and an operational amplifier. This

circuit is a very high-gain, current-to-voltage converter circuit, having

Teledyne Analytical Instruments 10

Page 27

Total Hydrocarbon Analyzer Operational Theory

an input impedance measuring in the billions of ohms. It is static

sensitive and highly susceptible to contamination. Special care must be

taken in handling this PC board.

Refer to Section 5.5.4: Electrometer-Amplifier PC Board for more

information concerning the electrometer-amplifier and the other printed

circuits that follow.

2.3.2 Anode Power Supply

The high voltage anode power supply components are mounted on

the anode power supply printed circuit board. High voltage regulation is

achieved through the use of series-connected zener diodes. The

simplicity of this circuit’s design can be attributed to the extremely low

current demand of the anode circuit. The positive output voltage is

nominally 125 volts. Output tolerance is ±10 volts from the specified

125 volts.

2.3.3 Flame Guard Circuit

A thermistor-controlled, transistorized switching circuit is employed

to operate a relay in the event of a flame-out condition. A panel indicator

light and fuel shut-off solenoid valve are operated by the relay to alarm

personnel that a flame-out condition has occurred. The fuel shut-off

solenoid valve stops the hydrogen flow.

2.3.4 Flame Ignition Circuit

The flame ignition circuit includes the anode-igniter electrode (in the

detector cell), a transformer, and processor controlled relay. The circuit

is automatically energized after the warm up count down timer expires.

If automatic ignition fails, there will be a message that reports this,

and the flame can be manually ignited by pressing simultaneously the

Up and Down key.

2.3.5 Proportional Temperature Control Circuit

The temperature of the isothermal chamber containing the sampling

components is regulated by a thermistor-directed electronic circuit. The

thermistor and heating element are located in the chamber, and the

balance of the circuit components are mounted on the temperature

controller printed circuit board. A temperature limit switch protects the

Teledyne Analytical Instruments 11

Page 28

Operational Theory Model 4020

isothermal chamber against excessive temperature, which may occur if

the temperature controlling system fails.

Teledyne Analytical Instruments 12

Page 29

Total Hydrocarbon Analyzer Installation

Installation

Installation of the Model 4020 Total Hydrocarbon Analyzer

includes:

1. Unpacking

2. Mounting

3. Gas connections

4. Electrical connections

5. Testing the system.

3.1 Unpacking the Analyzer

Although the analyzer is shipped with all the materials you need to

install and prepare the system for operation. Carefully unpack the

analyzer and inspect it for damage. Immediately report any damage or

shortages to the shipping agent.

3.2 Mounting the Analyzer

The Model 4020 is a general-purpose analyzer and as such is

designed with (non-sealed) enclosures. It must be installed in an area

where the ambient temperature is not permitted to drop below 32ºF nor

rise above 100ºF. In areas outside these temperatures, auxiliary

heating/cooling must be supplied. The 4020 enclosure is oil and dust

resistant and although it is designed to resist moisture, it should NOT be

considered completely watertight. Mounting to walls or racks must be

made securely. Avoid locations that are subject to extreme vibration and

sway.

Sufficient space must be provided around the analyzer to

accommodate the necessary electrical conduit and plumbing connections.

The front panel must be allowed to be pulled out for possible service

access to all components of the enclosure. Refer to the system/analyzer

outline drawings for dimensions.

Teledyne Analytical Instruments 13

Page 30

Installation Model 4020

Note: To completely slide the analyzer out of the enclosure, pull

analyzer out until it stops, then push down on the release levers found

almost at the end of the sliders, both sides at the same time.

Regardless of configuration, the analyzer/system must be installed

on a level surface with sufficient space allocated on either side for

personnel and test equipment access. Subject to the foregoing, the

analyzer/system should be placed as close to the sample point as is

possible.

All pertinent dimensions, connecting points, and piping details can

be found in the drawings section as part of the outline, input-output, and

piping diagrams. These drawings are specific to the instrument or

system to which the manual applies.

3.3 User Connections

All user connections are made on the rear panel. Consult the inputoutput and outline diagrams in the drawing section of the manual. Not

all the features displayed may be present in your system. Refer to any

Addenda for additional information that may apply to your instrument.

3.3.1 Electrical Power Connections

The standard analyzer requires a supply of 100-125VAC, singlephase power. Power connections are made at the rear panel of the unit.

Refer to the input-output diagram for more information. The electrical

power service must include a high-quality ground wire. A high-quality

ground wire is a wire that has zero potential difference when measured

to the power line neutral. If you have the 220 VAC option, you will

require 220 or 240 VAC, 50/60 Hz power. Check the analyzer inputoutput diagram, power schematic, outline, and wiring diagrams for

incoming power specifications and connecting points.

CAUTION: PRIMARY POWER TO THE SYSTEM SHOULD NOT

BE SUPPLIED UNTIL ALL CUSTOMER WIRING IS

INSPECTED PROPERLY BY START-UP PERSONNEL.

3.3.2 Gas Connections

The analyzer gas connection diagram identifies the various gas

connection points as to function and location. Figure 3-1 shows the gas

connection points for instruments with the optional AutoCal module.

Teledyne Analytical Instruments 14

Page 31

Total Hydrocarbon Analyzer Installation

Figure 3-1: Gas Connections

Gas connections to the instrument are made at the 1/8”or 1/4”

stainless steel tube fittings provided on the rear panel. Note that the

Purge and Sensor Vent fittings are 1/4” while all other gas connections

are 1/8”.

It is recommended that all gas tubing leading to the connections on

the back of the analyzer be of the coiled type. This will facilitate sliding

the unit out of the case without disconnecting the gas supply to the

analyzer.

Before tubing is connected to the system, it must be decontaminated

to rid it of hydrocarbon deposits. Using a small torch, heat each length

of tubing, while passing nitrogen through it, until it glows red. Begin at

the nitrogen source end and proceed down the length of the tube,

“chasing” the red glow (and hydrocarbon deposits) down to the open

end of the tube. Cap tubing while not in use with suitable noncontaminating caps.

All sample, calibration, and supporting gas lines which deliver gas to

the analyzer must be decontaminated before connection; vent lines do not.

When connecting the various gas lines to the system, be absolutely

certain that no “dead ends” are left; that is, no unused branch lines

should be left capped off, where pockets might form of material that is

not representative of the current contents of the line, or which might

keep contaminants from being purged out of the system.

Note: If different background gases are being used, the user

must supply the necessary valves and any associated

switching equipment for delivering the correct

sample/background gas combination to the analyzer.

Teledyne Analytical Instruments 15

Page 32

Installation Model 4020

3.3.2.1 VENT CONNECTIONS

Two separate vent connections may be required on your instrument:

Sensor Vent

Bypass Vent

Sensor vent and sample bypass vent must run separately.

The sample and bypass vent lines should not be tied together outside

of the system enclosure and the lines need to be installed at a downward

sloping angle to prevent a potential build-up of condensing water vapor

in the vent lines. Follow the installation guidelines below.

Sensor Vent:

All the gases introduced into the detection cell are vented from a

single fitting labeled SENSOR VENT at the rear of the analyzer.

1. TAI recommends that the cell be permitted to vent directly to

atmosphere wherever possible.

2. If the vent line is required, the installation must include a

drop-out pot to collect any water that is formed by the

burning of the hydrogen fuel.

3. The vent line must be constructed so that the water and dirt

cannot collect in it.

4. Sensor vent line must slope downward so condensed water

will freely drain.

SAMPLE BYPASS VENT:

The sample bypassed by the back-pressure regulation system vents

from a separate port labeled

BYPASS VENT at the rear of the analyzer.

If this vent is required, it must be installed so that water and dirt

cannot accumulate in it.

3.3.3 Electrical Connections

Figure 3-1 shows the Model 4020 rear panel. There are connections

for power, digital communications, and both digital and analog

concentration output.

Teledyne Analytical Instruments 16

Page 33

Total Hydrocarbon Analyzer Installation

For safe connections, no uninsulated wiring should be able to come

in contact with fingers, tools or clothing during normal operation.

CAUTION: USE SHIELDED CABLES. ALSO, USE PLUGS THAT

PROVIDE EXCELLENT EMI/RFI PROTECTION. THE

PLUG CASE MUST BE CONNECTED TO THE CABLE

SHIELD, AND IT MUST BE TIGHTLY FASTENED TO

THE ANALYZER WITH ITS FASTENING SCREWS.

ULTIMATELY, IT IS THE INSTALLER WHO ENSURES

THAT THE CONNECTIONS PROVIDE ADEQUATE

EMI/RFI SIELDING.

3.3.3.1 PRIMARY INPUT POWER

The power cord receptacle and fuse block are located in the same

assembly. Insert the power cord into the power cord receptacle.

CAUTION: POWER IS APPLIED TO THE INSTRUMENT'S

CIRCUITRY AS LONG AS THE INSTRUMENT IS

CONNECTED TO THE POWER SOURCE.

The standard power supply requires 110 VAC, 50/60 Hz or 220

VAC, 50/60 Hz (optional) power.

3.3.3.2 FUSE INSTALLATION

The fuse block, at the right of the power cord receptacle, accepts US

or European size fuses. A jumper replaces the fuse in whichever fuse

receptacle is not used.

3.3.3.3

50-PIN EQUIPMENT INTERFACE CONNECTOR

Figure 3-2 shows the pin layout of the Equipment Interface

connector. The arrangement is shown as seen when the viewer faces the

rear panel of the analyzer. The pin numbers for each input/output

function are given where each function is described in the paragraphs

below.

Teledyne Analytical Instruments 17

Page 34

Installation Model 4020

Figure 3-2: Equipment Interface Connector Pin Arrangement

3.3.3.4 ANALOG OUTPUT

There are four DC output signal pins—two pins per output. For

polarity, see Table 3-1. The outputs are:

0–1 VDC % of Range: Voltage rises linearly with increasing

concentration, from 0 V at 0

concentration to 1 V at full scale. (Full

scale = 100% of programmable range.)

0–1 VDC Range ID: 0.20 V = Low Range

0.5 V = Medium Range

0.80 V = High Range

4–20 mA DC % Range: Current increases linearly with

concentration , from 4 mA at 0

concentration to 20 mA at full scale.

(Full scale = 100% of programmable

range.)

4–20 mA dc Range ID: 6.8 mA = Range 1

12.0 mA = Range 2

16.8 mA = Range 3

Table 3-1: Analog Output Connections

Pin Function

3 + Range ID, 4-20 mA, floating

4 – Range ID, 4-20 mA, floating

5 + % Range, 4-20 mA, floating

6 – % Range, 4-20 mA, floating

8 + Range ID, 0-1 VDC

Teledyne Analytical Instruments 18

Page 35

Total Hydrocarbon Analyzer Installation

23 – Range ID, 0-1 VDC, negative ground

24 + % Range, 0-1 VDC

7 – % Range, 0-1 VDC, negative ground

Examples:

The analog output signal has a voltage which depends on gas

concentration relative to the full scale of the range. To relate the signal

output to the actual concentration, it is necessary to know what range the

instrument is currently on, especially when the analyzer is in the

autoranging mode.

The signal output for concentration is linear over the currently

selected analysis range. For example, if the analyzer is set on a range

that was defined as 0-10 ppm CH

, then the output would be as shown in

4

Table 3-2.

To provide an indication of the range, the Range ID analog outputs

are used. They generate a steady preset voltage (or current when using

the current outputs) to represent a particular range. Table 3-3 gives the

range ID output for each analysis range.

Table 3-2: Analog Concentration Output—Example

ppm Voltage Signal Current Signal

CH4 Output (VDC) Output (mA DC)

0 0.0 4.0

1 0.1 5.6

2 0.2 7.2

3 0.3 8.8

4 0.4 10.4

5 0.5 12.0

6 0.6 13.6

7 0.7 15.2

8 0.8 16.8

9 0.9 18.4

10 1.0 20.0

Teledyne Analytical Instruments 19

Page 36

Installation Model 4020

Table 3-3: Analog Range ID Output—Example

Range Voltage Signal Current Signal Application

Output (VDC) Output (mA DC)

Range 1 0.20 6.8 0–1 ppm CH

Range 2 0.50 12 0–10 ppm CH

Range 3 0.80 16.8 0–100 ppm CH

4

4

4

3.3.3.5 ALARM RELAYS

The nine alarm-circuit connector pins connect to the internal alarm

relay contacts. Each set of three pins provides one set of Form C relay

contacts. Each relay has both normally open and normally closed contact

connections. The contact connections are shown in Table 3-4. They are

capable of switching up to 3 amperes at 250 VAC into a resistive load.

The connectors are:

Threshold Alarm 1:

Can be configured as high (actuates when

concentration is above threshold), or low (actuates

when concentration is below threshold).

Can be Configured as failsafe or non-failsafe

Can be configured out (defeated).

Threshold Alarm 2:

Can be configured as high (actuates when

concentration is above threshold), or low (actuates

when concentration is below threshold).

Configured as failsafe or non-failsafe

Can be configured out (defeated).

System Alarm:

Actuates when DC power supplied to circuits is

unacceptable in one or more parameters. Permanently

configured as failsafe and latching. Cannot be defeated.

Teledyne Analytical Instruments 20

Page 37

Total Hydrocarbon Analyzer Installation

(Reset by pressing the STANDBY button to remove

power. Then press STANDBY again and any other

button except SYSTEM to resume

Further detail can be found in Chapter 4, Section 4.5.15.

Table 3-4: Alarm Relay Contact Pins

Pin Contact

45 Threshold Alarm 1, normally closed contact

28 Threshold Alarm 1, moving contact

46 Threshold Alarm 1, normally open contact

42 Threshold Alarm 2, normally closed contact

44 Threshold Alarm 2, moving contact

43 Threshold Alarm 2, normally open contact

36 System Alarm, normally closed contact

20 System Alarm, moving contact

37 System Alarm, normally open contact

3.3.3.6

DIGITAL REMOTE CAL INPUTS

The digital remote calibration input accepts 0 V (off) or 24 VDC

(on) for remote control of calibration. (See Remote Calibration

Protocol below.) See Table 3-5 for pin connections.

The remote cal inputs are shared by the digital range selection mode.

When the user selects the digital range selection mode, the input is used

by the analyzer for range selection. See Section 4.6.13.3 Digital Mode.

Zero: Floating input. A 5–24 V input across the + and –

pins puts the analyzer into the Zero mode. Either side

may be grounded at the source of the signal. A 0–1

volt across the terminals allows Zero mode to

terminate when done. A synchronous signal must

open and close the external zero valve appropriately.

Span: Floating input. A 5–24 V input across the + and –

pins puts the analyzer into the Span mode. Either

side may be grounded at the source of the signal. A

Teledyne Analytical Instruments 21

Page 38

Installation Model 4020

0–1 volt across the terminals allows Span mode to

terminate when done. A synchronous signal must

open and close external span valve appropriately.

Cal Contact: This relay contact is closed while analyzer is spanning

and/or zeroing. (See Remote Calibration Protocol below.)

Table 3-5: Remote Calibration Connections

Pin Function

9 + Remote Zero

11 – Remote Zero

10 + Remote Span

12 – Remote Span

40 Cal Contact

41 Cal Contact

Remote Calibration Protocol: To properly time the Digital Remote Cal

Inputs to the Model 4020 Analyzer, the customer's controller must

monitor the Cal Relay Contact.

When the contact is OPEN, the analyzer is analyzing, the

Remote Cal Inputs are being polled, and a zero or span command

can be sent.

When the contact is CLOSED, the analyzer is already calibrating. It

will ignore your request to calibrate, and it will not remember that

request.

Once a zero or span command is sent, and acknowledged (contact

closes), release it. If the command is continued until after the zero or

span is complete, the calibration will repeat and the Cal Relay Contact

(CRC) will close again.

For example:

1. Test the CRC. When the CRC is open, Send a zero command

until the CRC closes (The CRC will quickly close.)

2. When the CRC closes, remove the zero command.

3. When CRC opens again, send a span command until the

CRC closes. (The CRC will quickly close.)

4. When the CRC closes, remove the span command.

Teledyne Analytical Instruments 22

Page 39

Total Hydrocarbon Analyzer Installation

When CRC opens again, zero and span are done, and the sample is

being analyzed.

Note: The remote valve connections (described below) provides

signals to ensure that the zero and span gas valves will be

controlled synchronously.

3.3.3.7

RANGE ID RELAYS

There are three dedicated Range ID relay contacts. They are

assigned to relays in ascending order—Low range is assigned to Range

1 ID, Medium range is assigned to Range 2 ID, and High range is

assigned to Range 3 ID. Table 3-6 lists the pin connections.

Table 3-6: Range ID Relay Connections

Pin Function

21 Range 1 ID Contact

38 Range 1 ID Contact

22 Range 2 ID Contact

39 Range 2 ID Contact

19 Range 3 ID Contact

18 Range 3 ID Contact

34 Not Used

35 Not Used

3.3.3.8

NETWORK I/O

A serial digital input/output for local network protocol. At this

printing, this port is not yet functional. It is to be used in future options

to the instrument. Pins 13 (+) and 29 (–).

3.3.3.9

PIN OUT TABLE

The following table summarizes all the outputs/inputs available in

the 50 pin D-Sub connector on the backpanel of the analyzer.

Teledyne Analytical Instruments 23

Page 40

Installation Model 4020

Table 3-7: Pin out of 50 pin D-Sub Connector

pin # Description

1

2

3 + Range ID 4-20 ma

4 - Range ID 4-20 ma

5 + Output 4-20 ma

6 - Output 4-20 ma

7 - Output 0-1 v

8 + Range ID 0-1 v

9 Remote Zero +

10 Remote Span +

11 Remote Zero 12 Remote Span 13 Network +

14 Remote Thermistor

15 Zero Solenoid Return

16 Span Solenoid Return

17 Span Solenoid Hot

18 Range 3 Contact

19 Range 3 Contact

20 Alarm 3 C Contact

21 Range 1 Contact

22 Range 2 Contact

23 - Range ID 0-1 v

24 + Output 0-1 v

25

26

27

28 Alarm 1 C Contact

29 Network 30 Remote Sensor +

31 Remote Thermistor

32 Exhaust Solenoid Hot

33 Sample Solenoid Hot

34 Range 4 Contact/ not used

35 Range 4 Contact/not used

36 Alarm 3 NC Contact

37 Alarm 3 NO Contact

38 Range 1 Contact

39 Range 2 Contact

40 Calibration Contact

Teledyne Analytical Instruments 24

Page 41

Total Hydrocarbon Analyzer Installation

pin # Description

41 Calibration Contact

42 Alarm 2 NC Contact

43 Alarm 2 NO Contact

44 Alarm 2 C Contact

45 Alarm 1 NC Contact

46 Alarm 1 NO Contact

47 Remote Sensor 48 Exhaust Solenoid Return

49 Zero Solenoid Hot

50 Sample Solenoid Return

3.3.4 RS-232 Port

The digital signal output is a standard RS-232 serial communications

port used to connect the analyzer to a computer, terminal, or other digital

device. It requires a standard 9-pin D connector.

Output: The data output is status information, in digital form, updated

every two seconds. Status is reported in the following order:

1. The concentration in ppm

2. The range in use (R-1 = Range 1, R-2 = Range 2, R-3 =

Range 3, R-4 = Range 4)

3. The span of the range (0- 10.00 ppm, etc)

4. Mode the analyzer is in: ANLZ, ZERO, or SPAN

5. Which alarms—if any—are tripped (AL–1 and/or AL-2).

Each status output is followed by a carriage return and line feed. For

example:

5.88 ppm R-1 (0- 10.00 ppm) ANLZ AL-1 <CR>

Input: The input functions using RS-232 that have been implemented

to date are described in Table 3-8.

Teledyne Analytical Instruments 25

Page 42

Installation Model 4020

Table 3-8: Commands via RS-232 Input

Command Description

as<enter> Immediately starts an autospan.

az<enter> Immediately starts an autozero.

Implementation: The RS-232 protocol allows some flexibility in its

implementation. Table 3-8 lists certain RS-232 values that are required

by the Model 4020 implementation.

Table 3-9: Required RS-232 Options

Parameter Setting

Baud 2400

Byte 8 bits

Parity none

Stop Bits 1

Message Interval 2 seconds

3.3.5 Supporting Gases

Normally, four supporting gases of different composition (see

Section 4.1: Equipment) will be required to operate the analyzer. The

recommended composition of these gases is specified in the Application

Data section of the Appendix. The gases should be supplied from

cylinders that are equipped with the type of regulator specified in the

aforementioned sections.

CAUTION: UNDER NO CIRCUMSTANCES SHOULD YOU

EMPLOY A REGULATOR THAT IS NOT EQUIPPED

WITH A METALLIC DIAPHRAGM ANYWHERE IN THE

SYSTEM.

The regulators should be inspected prior to installation to be sure

that they are oil-free. Failure to comply with these directives will result

in a constant drift in analyzer output, as organic compounds will outgas

into the plumbing system at a rate that is related to the ambient

temperature. Use 316 stainless steel, dual-stage regulators only in fuel,

sample, and blanket air lines; shutoff valves should be used downstream

from each regulator.

Teledyne Analytical Instruments 26

Page 43

Total Hydrocarbon Analyzer Installation

Place the supply cylinders as close to the analyzer as possible, and

interconnect them to the analyzer with new tubing. Be sure that all

plumbing connections are free of leaks.

Note: Use only stainless steel tubing throughout the system.

Consult the assembly, piping, outline drawings, and any

Addenda included with this manual to determine if special

conditions apply.

3.3.5.1 SAMPLE GAS

An oil-free, metallic diaphragm regulator must be installed as close

to the sample point as possible. Use new tubing in the installation. The

output pressure of the regulator should be 30 psig, whenever possible, to

match the settings of other regulators on the support gas tanks; sample

inlet pressure must exceed the operating sample pressure by at least 10

psig and provide at least 1 SCFH bypass flow. In any case, the zero and

span gas regulators should be set to match the sample pressure

regulator—as the back-pressure regulator within the analyzer ultimately

determines the sample flow to the detection cell. Refer to Chapter 4:

Sampling.

3.3.5.2

EFFLUENT

All the gases introduced into the detection cell vent from one fitting

at the rear of the analyzer. TAI recommends that the cell be permitted to

vent directly to the atmosphere wherever possible.

If a vent line is required, the installation must include a drop-out pot

to collect the water that is formed by the burning of the hydrogen fuel.

The vent line must be constructed so that water and dirt cannot collect in

it.

3.3.5.3 SAMPLE BYPASS VENT

The sample bypassed by the back-pressure regulation system vents

from a separate port at the rear of the analyzer. If a vent line is required,

it must be installed so that water and dirt cannot accumulate in it.

3.3.5.4 FUEL AND AIR CONNECTIONS

The fuel used to provide combustion should be a gas mixture

comprised of 40% H2 and 60% N2. The fuel is mixed with air to provide

a combustion source for the analyzer. Connect the fuel and air sources to

Teledyne Analytical Instruments 27

Page 44

Installation Model 4020

the instrument according to the gas connection diagram included at the

back of this manual.

Note: For applications where the sample gas is hydrogen, the

sample gas doubles as the fuel for combustion and is

diluted with nitrogen. Connect a nitrogen source (40 psig)

to the fuel inlet port. See Figure 3-1.

Note: A gas mixture of 40% H2 and 60% He can be used as fuel

as well.

Teledyne Analytical Instruments 28

Page 45

Total Hydrocarbon Analyzer Operation

Operation

This section of the manual describes how to setup and operate the

Model 4020 Analyzer. Sections 4.1 through 4.5 describe preliminary

steps and equipment needed to operate the analyzer. Beginning with

Section 4.6, the actual operation of the analyzer is described along with

descriptions of the display prompts, messages and options available to

the user within a menu or sub menu.

4.1 Equipment

The following supporting gases and hardware will be required to

operate the (standard) analyzer:

1. Fuel: A cylinder containing a 40% hydrogen, 60% nitrogen

composition will be required to supply the fuel for the flame

ionization burner. The cylinder is to be equipped with an oil-free

metallic diaphragm regulator (dual stage).

Note: When hydrogen is the parent gas in the application, an

auxiliary source of fuel may not be required. See the

Appendix: Specifications for specific recommendations.

2. Blanket Air: A cylinder of water-pumped (low hydrocarbon)

compressed air will be required to maintain the proper

atmosphere within the cell. The cylinder is to be equipped with

an oil-free, dual stage, metallic diaphragm regulator. Less than

1% of the full scale reading (in the selected measurement range)

of hydrocarbon contamination is advisable, if the instrument’s

accuracy is to be realized.

3. Zero Gas: A cylinder of the parent (or background) gas,

containing less than 10% full scale (of the narrowest range)

hydrocarbon impurity, will be required to zero standardize the

analyzer. For example, if 10 PPM is the narrowest range of the

instrument, then the zero gas impurities are to be less than 1

PPM. The cylinder is to be equipped with an oil-free, dual stage,

metallic diaphragm regulator.

Teledyne Analytical Instruments 29

Page 46

Operation Model 4020

4. Span Gas: A cylinder containing a composition consisting of the

parent gas and a specified (see Appendix: Specifications) amount

of methane will be required to standardize the sensitivity setting

of the analyzer. The cylinder is to be equipped with an oil-free,

dual stage metallic diaphragm regulator.

Note: The analyzer is capable of analyzing a sample in two

different background gases, O

and N2. To use this feature

2

you must calibrate the instrument with each background

gas. Therefore separate zero and span gases will be

required for each background gas.

5. Sample Pressure Regulation: An oil-free, metallic diaphragm

regulator must be installed at the sample point when possible; see

Section 3.3.5.1 Sample Gas.

6. Background Gas Selector: If using different sample

background gases, a suitable manifold for switching the gas to

the analyzer will be required. It can be either manual or

automatically operated valves.

4.2 Preliminary Power-Off Check List

Make the following checks of the installation before proceeding

further into the start-up procedure:

1. Check to see that the sample and supporting gas installation is in

accordance with the specifications called for in the installation

and application sections of the manual (Chapter 3). Be sure that

the supporting gases are of the proper composition and are

connected to the correct fittings at the rear of the analyzer.

2. Check to see that the electrical installation conforms to the

instructions contained in the installation section (Chapter 3) and

on the input-output diagram.

3. Open the door and check to see that the printed circuit boards

and cables are firmly seated in their respective sockets.

4. Confirm that recorder and alarm connections are properly made.

4.3 Placing the System in Operation

1. Turn the power switch to the ON position.

Teledyne Analytical Instruments 30

Page 47

Total Hydrocarbon Analyzer Operation

2. Allow at least 2 hours warm-up (heat up sensor & sample

system) after making the air adjustment described below. Warm

up time is set by the software at the factory.

DO NOT attempt to ignite the flame during warm up

countdown. Condensation will occur.

4.4 Activating the Support Gases

4.4.1 Air

1. Set the air tank regulator to 30 psig.

2. Adjust the instrument air regulator until the air pressure

gauge reads the recommended air pressure.

After the air is flowing through the sensor and warm-up time has

been completed, activate the following gases:

4.4.2 Sample Gas

Set the sample gas tank regulator to 30 psig (or a pressure which

matches the sample pressure) and adjust the instrument sample

regulator until its (sample) pressure gauge reads the recommended

sample pressure.

4.4.3 Span Gas

1. Feed span gas to the analyzer. This instrument has an automatic

valve selection feature for directing sample or calibration gas to

the analyzer. See Section 4.6.16 for setup and operation of the

valve selection feature..

2. Set the span gas regulator to 30 psig or to match the sample

pressure.

3. Observe that the instrument sample pressure gauge still reads the

recommended sample pressure and that the bypass flowmeter

reads from 0.5 to 1.0 SCFH.

4.4.4 Fuel

1. Open the main valve on the tank and set the fuel tank pressure

regulator to 30 psig (or to match sample pressure).

Teledyne Analytical Instruments 31

Page 48

Operation Model 4020

2. To avoid pressure shock to the instrument fuel regulator, slowly

open the secondary valve until it is wide open.

Note: adjust fuel settings only when the red LED (flame failure

light) is off.

Figure 4-1: Front Panel View of Regulator and Gages

4.5 Flame Ignition

Observe that after warm up count down timer reaches zero (timer to

preheat the sensor), the amber heater lamp is blinking (indicating that

the temperature controller is maintaining the temperature setpoint) and

the red flame failure lamp is on. See Figure 4-1.

The Model 4020 will automatically attempt a flame ignition

sequence following the warm-up period which has been preset at the

factory. If the ignition process fails, the instrument will attempt to ignite

the flame a second time. If it continues to fail after the fifth attempt, a

flame failure message will appear on the display. If this occurs refer to

Section 5.

4.5.1 Verification of the Flame Guard Circuit

The operation of the flame guard circuit has been checked at the

factory, but should be re-verified during start-up. Use the following

procedure after ignition of the flame has been achieved:

Teledyne Analytical Instruments 32

Page 49

Total Hydrocarbon Analyzer Operation

1. Turn off the fuel at the supply cylinder.

2. Observe the fuel pressure gauge on the analyzer control panel. The

gauge indication will decay as the fuel in the line is exhausted.

When the gauge reading reaches the vicinity zero, the flame will

be extinguish as the fuel solenoid shuts off the fuel supply. The

analyzer will automatically try to re-ignite. After 5 attempts, it will

display: flame failure, check air, fuel and the flame failure LED

will be on.

3. Open the cylinder supply valve and re-ignite the flame.

4.5.2 Ignition and/or Flame Guard Circuit Failure

If the flame ignition or guard circuits do not operate as described in

the above two sections, set the instrument fuel regulator to the

recommended pressure. If still fails to ignite, proceed as directed in

Chapter 5: Maintenance & Troubleshooting.

4.6 Analyzer Operation

Although the Model 4020 has been programmed for your application

at the factory, it can be further configured at the operator level, or even

(cautiously) reprogrammed. Depending on the specifics of the

application, this might include all or a set of the following procedures:

Setting system parameters

Establish a security password, if desired, requiring

operator to log in

Establish and start an automatic calibration cycle

Routine operation

Calibrate the instrument

Choose autoranging or select a fixed range of analysis

Set alarm setpoints and modes of alarm operation

(high, low, failsafe, etc.)

Program/reprogram the analyzer

Linearize the ranges

Teledyne Analytical Instruments 33

Page 50

Operation Model 4020

Special functions setup

Calibrate analog output

Procedures for accessing and/or changing parameters as well as

analyzer operation are detailed in the sections to follow. In general, the

sequence of menus available on screen follow a logical course for setup

and operation. It is not required, however to follow this sequential path.

The user could, for instance, go directly to set an analysis range and then

program an offset to the current output for matching a range on the

user’s recording device. The only exception to this is when the

instrument is powered up. It will go through a diagnostic self-test

routine and, if programmed to do so, request a password to be entered

before allowing access to any function.

4.6.1 Default Parameters

The versatility of this analyzer usually results in significant changes

being made to parameters over the course of time to better suit a

particular application. Occasionally processes change requiring

alteration to alarms, filter settings etc. At some time, it may be

beneficial to reset the analyzer to the default conditions as it was when

shipped from the factory. Below is a listing of the default parameters

used in configuring your instrument:

Range/Application: Refer to the data sheet on the application

page found in the appendix of this manual

Range: Manual

Alarm Relays: Active, HI, 80 ppm (alarm 1),

90 ppm (alarm 2), non-failsafe

Zero: Auto disabled, every 7 days, at 12 hours

Span: Auto disabled, every 7 days, at 12 hours

Password: TAI

4.6.2 Style Conventions

The following typeface conventions are used when referring to

screen names, key presses and screen readout:

Screens: Arial 12 pt. type in capital letters. Example:

ANALYZE or MAIN screen or menu.

Teledyne Analytical Instruments 34

Page 51

Total Hydrocarbon Analyzer Operation

Key presses: <key> The particular keystroke to enter is

placed between < and >. Example:

<enter> or <escape> or <▲> (UP key) or

<▼> (DOWN key.

Only when the keystroke is to be entered

will it be placed between the brackets. If

discussing a particular key it will be typed

as text using all caps. Example: this is the

ENTER key.

Screen Modes: Times New Roman 12 pt. italic. Example:

Analysis Mode or Setup Mode.

Screen Readout: Arial Narrow, 12 pt bold. Example:

AUTOCAL or Zero in 12 days.

4.6.3 Using the Controls

To get the proper response from these controls, press the desired key

(<Escape> or <Enter> or <▲▼>. To enter the screen menu, press any

key.

The item that is adjacent to the arrow on the screen as shown in Figure

4-2,

is the item that is currently selectable by pressing the <Enter> key.

Figure 4-2: Typical VFD Screen Layout

In these instructions, to <Enter> means to press the ENTER KEY,

and to <Escape> means to press the ESCAPE KEY. To scroll <▲> (or

scroll <▼>) means to press UP or DOWN keys as many times as

necessary to reach the required menu item.

4.6.4 Mode/Function Selection

When the analyzer is first powered up, a warm-up for a period

ranging from 1 to 16 hours will occur depending on the exact factory

configuration.

Note: The warm-up period may be bypassed by pressing

Teledyne Analytical Instruments 35

Page 52

Operation Model 4020

<Enter> at the initialization screen.

The warm-up period is a crucial factor affecting the overall accuracy

for this instrument and should not be bypassed .unless the instrument

has only been off for a short period or for maintenance purposes. Check

Specific Model Information on page iii of this manual as well as any

accompanying Addenda for the specific warm up time required for your

configuration.

After warm-up, the instrument will undergo an initialization and self

diagnostic routine. Once this has been completed, the ANALYZE screen

(Analysis Mode) will appear. The ANALYZE screen is the only screen

of the Analysis Mode. It is also the default screen appearing whenever

the instrument is on and not in the warm-up phase, self testing routines

or purposely put into another mode of operation such as Setup Mode .

The analyzer will automatically return to the ANALYZE screen from

any other input screen whenever the instrument is idle with no buttons

pressed for approximately 20 seconds.

The MAIN MENU screen is the top level in a series of screens used

in the Setup Mode to configure the analyzer for the specific application.

The DOWN/ UP commands scroll through the options displayed on the

VFD screen. The selectable option appears between arrows. When you

reach the desired option by scrolling, <Enter> the selection as described

below.

ESCAPE takes you back up the hierarchy of screens until you reach

the Analyze Mode. ESCAPING any further just toggles between the

MAIN MENU and the ANALYZE screen.

Note: The m ai n m enu or any sub m enu will time out after

approximately 20 seconds, and return to the analyze

screen.

4.6.4.1

ANALYSIS MODE

This is the normal operating mode. The analyzer monitors the

concentration of the sample, displays the percent of the concentration in

the sample stream, and warns of any alarm conditions. Pressing any key

switches you into Setup Mode and brings up its main menu. Setup Mode

switches back to Analyze Mode if no controls are used for more than

twenty seconds.

Teledyne Analytical Instruments 36

Page 53

Total Hydrocarbon Analyzer Operation

4.6.4.2 SETUP MODE

The MAIN MENU consists of functions you can use to customize

and check the operation of the analyzer. Figure 4-3 shows the functions