Page 1

INSTRUCTION MANUAL

MODEL 401

O

CALIBRATOR

3

© TELEDYNE INSTRUMENTS

ADVANCED POLLUTION INSTRUMENTATION DIVISION

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

TOLL-FREE: 800-324-5190

E-MAIL: api-sales@teledyne.com

WEB SITE: www.teledyne-api.com

Copyright 2005 Teledyne Advanced Pollution

Instrumentation

(T-API)

FAX: 858-657-9816

TEL: 858-657-9800

01124

REV. J2

11 July, 2005

Page 2

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

GENERAL WARNING/CAUTION

specific danger.

CAUTION

CAUTION

Technician Symbol

by qualified maintenance personnel only.

The analyzer should only be used for the purpose

and in the manner described in this manual.

If you use the analyzer in a manner other than that for which

it was intended, unpredictable behavior could ensue with

: Hot Surface Warning

: Electrical Shock Hazard

: All operations marked with this symbol are to be performed

CAUTION

possible hazardous consequences.

: Refer to the instructions for details on the

ii

Page 3

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

TABLE OF CONTENTS

SAFETY MESSAGES .......................................................................................... II

TABLE OF CONTENTS...................................................................................... III

LIST OF FIGURES.............................................................................................VII

LIST OF TABLES..............................................................................................VIII

1 INTRODUCTION............................................................................................ 1-1

PREFACE .........................................................................................................................................1-1

1.1

1.2

WARRANTY.....................................................................................................................................1-1

1.3 PRINCIPLE OF OPERATION ..............................................................................................................1-2

1.3.1 Interferent Rejection...............................................................................................................1-4

1.4 SPECIFICATIONS ..............................................................................................................................1-5

1.4.1 Noise (PPB RMS)....................................................................................................................1-6

1.4.2 Lower Detectable Limit (LDL) PPB.......................................................................................1-6

1.4.3 Zero Drift (PPB).....................................................................................................................1-6

1.4.4 Span Drift................................................................................................................................1-6

1.4.5 Linearity..................................................................................................................................1-6

1.4.6 Lag Time .................................................................................................................................1-6

1.4.7 Rise And Fall Times................................................................................................................1-6

1.4.8 Temperature Range.................................................................................................................1-6

1.4.9 Humidity Range ......................................................................................................................1-6

1.4.10 Flow Rates ............................................................................................................................1-7

1.4.11 Power....................................................................................................................................1-7

1.4.12 Weight...................................................................................................................................1-7

1.5

INSTALLATION AND OVERVIEW......................................................................................................1-7

1.6 ELECTRICAL AND PNEUMATIC CONNECTIONS ..............................................................................1-14

1.6.1 Electrical Connections..........................................................................................................1-14

1.6.2 RS-232...................................................................................................................................1-14

1.6.3 Pneumatic System .................................................................................................................1-16

1.6.4 Exhaust Connections (See Figure 1-5).................................................................................1-16

1.6.5 Output Flow Adjustment.......................................................................................................1-16

OPERATION VERIFICATION............................................................................................................1-20

1.7

1.7.1 Final Test And Calibration Values.......................................................................................1-21

1.8 OPTIONS........................................................................................................................................1-22

1.8.1 Rack Mount With Slides........................................................................................................1-22

1.8.2 Status Outputs.......................................................................................................................1-22

2 OPERATION .................................................................................................. 2-1

KEY FEATURES ...............................................................................................................................2-1

2.1

2.1.1 O

Readout..............................................................................................................................2-1

3

iii

Page 4

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

2.1.2 O

Analog Output....................................................................................................................2-1

3

2.1.3 E2 ROM Backup Of Software Configuration..........................................................................2-1

2.1.4 Adaptive Filter........................................................................................................................2-1

2.1.5 Data Acquisition .....................................................................................................................2-2

2.1.6 RS-232 Interface .....................................................................................................................2-2

2.1.7 Password Protection...............................................................................................................2-2

FRONT PANEL .................................................................................................................................2-4

2.2

2.2.1 Front Panel Display................................................................................................................2-4

2.2.2 Programmable Pushbuttons ...................................................................................................2-7

2.2.3 Status LEDs.............................................................................................................................2-9

3 CALIBRATION............................................................................................... 3-1

MANUAL ZERO AIR SUPPLY............................................................................................................3-1

3.1

3.2

MANUAL O3 GENERATION ..............................................................................................................3-1

3.3

AUTOMATIC ZERO/SPAN (OR MULTIPOINT) CHECK ........................................................................3-2

3.4

MANUAL ZERO/SPAN (OR MULTI-POINT) CHECK ...........................................................................3-2

3.5

SUMMARY OF FRONT PANEL CALIBRATION CONTROLS..................................................................3-3

3.6

PHOTOMETER CALIBRATION ...........................................................................................................3-3

3.7

REMOTE ZERO/SPAN CHECK (CONTACT CLOSURE)........................................................................3-4

3.8

REMOTE ZERO/SPAN CHECK OR ADJUSTMENT (RS-232)...............................................................3-5

3.9

HOLD OFF .......................................................................................................................................3-5

4 SETUP MODE................................................................................................ 4-1

SETUP MODE OPERATION ...............................................................................................................4-1

4.1

4.2

SETTING AUTOMATIC MULTIPOINT (ASEQ) CHECK.......................................................................4-1

4.3

SETTING AUTOMATIC ZERO/SPAN DURATION.................................................................................4-1

4.4

EXAMINING THE OZONE FORMULA SLOPE AND OFFSET.................................................................4-2

4.5

SETTING THE O3 GENERATION MODE .............................................................................................4-3

4.5.1 BNCH Mode............................................................................................................................4-3

4.5.2 REF Mode...............................................................................................................................4-3

4.5.3 CNST Mode.............................................................................................................................4-3

SETTING THE TIME-OF-DAY...........................................................................................................4-3

4.6

4.7

SETTING THE DATE.........................................................................................................................4-3

4.8

ADJUSTING THE CLOCK SPEED .......................................................................................................4-4

SETTING THE O3 CONCENTRATION RANGE .....................................................................................4-4

4.9

4.10

SETTING THE ANALOG OUTPUT OFFSET .......................................................................................4-4

4.11

SETTING THE RS-232 BAUD RATE................................................................................................4-4

4.12

SETTING THE ANALYZER I.D........................................................................................................4-5

DISABLING THE CALIBRATION PASSWORD ...................................................................................4-5

4.13

4.14

SETTING THE FAULT LED TIMEOUT.............................................................................................4-5

4.15

SOFTWARE CONFIGURATION.........................................................................................................4-6

SUMMARY OF SETUP VARIABLES .................................................................................................4-6

4.16

5 DIAGNOSTICS............................................................................................... 5-1

TEST MEASUREMENTS ....................................................................................................................5-1

5.1

5.2 DIAGNOSTIC TESTS .........................................................................................................................5-1

iv

Page 5

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

5.2.1 D/A Output..............................................................................................................................5-2

6 HANDLING WARNINGS................................................................................ 6-1

7 RS-232 COMMUNICATIONS......................................................................... 7-1

7.1 DAS REPORTING.............................................................................................................................7-2

7.2

WARNINGS......................................................................................................................................7-3

7.3

STATUS/CONTROL...........................................................................................................................7-4

7.4

DIAGNOSTICS..................................................................................................................................7-6

7.5 TEST MEASUREMENTS ....................................................................................................................7-7

7.6

VIEWING AND MODIFYING VARIABLES ..........................................................................................7-8

8 ADJUSTMENTS............................................................................................. 8-1

8.1

POWER SUPPLY BOARD ADJUSTMENT.............................................................................................8-1

8.1.1 Box Temperature Limits..........................................................................................................8-1

A/D - D/A CALIBRATION PROCEDURE ............................................................................................8-3

8.2

8.3

OUTPUT VOLTAGE RANGE CHANGES..............................................................................................8-4

8.4

FLOW READOUT ADJUSTMENT........................................................................................................8-4

8.5

DC POWER SUPPLY.........................................................................................................................8-6

8.6

CPU................................................................................................................................................8-6

8.7

STATUS LINES.................................................................................................................................8-7

8.8

UV LAMP POWER SUPPLY ADJUSTMENT ........................................................................................8-7

8.9

OZONE GENERATOR LAMP SETUP...................................................................................................8-8

8.10

OZONE GENERATOR CALIBRATION...............................................................................................8-9

8.11

DARK CURRENT SIGNAL ADJUST PROCEDURE..............................................................................8-9

8.12

BENCH FEEDBACK OPTION..........................................................................................................8-10

9 TROUBLESHOOTING ................................................................................... 9-1

OVERVIEW ......................................................................................................................................9-1

9.1

9.2

TROUBLESHOOTING FUNDAMENTAL CALIBRATOR OPERATION ......................................................9-1

9.2.1 Checking The Power Sub-Systems..........................................................................................9-2

9.2.2 Checking The CPU And Display.............................................................................................9-3

9.2.3 Checking The Keyboard..........................................................................................................9-3

TROUBLESHOOTING USING WARNING MESSAGES...........................................................................9-3

9.3

9.4

TROUBLESHOOTING USING TEST FUNCTION VALUES .....................................................................9-5

TROUBLESHOOTING DYNAMIC PROBLEMS ......................................................................................9-6

9.5

9.5.1 Noisy Or Unstable Readings At Zero .....................................................................................9-7

9.5.2 Noisy, Unstable, Or Non-Linear Span Readings....................................................................9-7

9.5.3 Slow Response To Changes In Concentration........................................................................9-7

9.5.4 Analog Outputs Do Not Agree With Front Panel Readings...................................................9-8

9.5.5 Cannot Zero............................................................................................................................9-8

9.5.6 Cannot Span............................................................................................................................9-8

TROUBLESHOOTING INDIVIDUAL SUB-ASSEMBLIES AND COMPONENTS.........................................9-9

9.6

9.6.1 Troubleshooting Flow Problems ............................................................................................9-9

9.6.2 Troubleshooting Temperature Problems..............................................................................9-10

9.6.3 Checking The V/F Card........................................................................................................9-11

v

Page 6

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

9.6.4 Checking The DC Power Supply Board................................................................................9-13

9.6.5 Checking The Pneumatic Sensor Board ...............................................................................9-14

9.6.6 Checking The Source Lamp And Detector............................................................................9-14

9.6.7 Checking Main Switching Valve...........................................................................................9-16

9.6.8 Checking The Lamp Power Supply.......................................................................................9-16

9.7

WARRANTY/REPAIR QUESTIONNAIRE.........................................................................................9-18

10 ROUTINE MAINTENANCE........................................................................ 10-1

MAINTENANCE SCHEDULE..........................................................................................................10-1

10.1

10.2

LEAK CHECKING .........................................................................................................................10-2

10.3

CLEANING OF SAMPLE CELL.......................................................................................................10-2

10.4 CHANGING THE PROM.................................................................................................................10-3

11 MODEL 401 SPARE PARTS AND EXPENDABLES KITS........................ 11-1

SPARE PARTS FOR CE MARK UNITS ...........................................................................................11-1

11.1

11.2

SPARE PARTS FOR NON-CE MARK UNITS ..................................................................................11-3

Appendix A LIST OF AVAILABLE MODEL 401 OPTIONS ................................................. A-1

Appendix B RECOMMENDED ZERO AIR SYSTEM............................................................. B-1

Appendix C REFERENCES....................................................................................................... C-1

Appendix D SOFTWARE MENU TREES ................................................................................ D-1

Appendix E ELECTRICAL SCHEMATIC INDEX ...................................................................E-1

vi

Page 7

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

LIST OF FIGURES

FIGURE 1-1: MODEL 401 OZONE CALIBRATOR BLOCK DIAGRAM..........................................................1-11

F

IGURE 1-2: M401 REAR PANEL ELECTRICAL CONNECTIONS................................................................1-12

F

IGURE 1-3: REAR PANEL ELECTRICAL AND PNEUMATIC CONNECTIONS (CE VERSION).......................1-13

F

IGURE 1-4: RS-232 PIN ASSIGNMENTS.................................................................................................1-15

F

IGURE 1-5: M401 CALIBRATOR PNEUMATIC CONNECTIONS ................................................................1-17

F

IGURE 1-6: M401 REAR PANEL (EXTERNAL DRY ZERO AIR)...............................................................1-18

F

IGURE 1-7: M401 CALIBRATOR CHASSIS LAYOUT...............................................................................1-19

F

IGURE 2-1: MODEL 401 FRONT PANEL...................................................................................................2-4

FIGURE 2-2: ILLUSTRATION OF NORMAL DISPLAY ..................................................................................2-8

F

IGURE 8-1: ELECTRICAL BLOCK DIAGRAM ............................................................................................8-2

F

IGURE 8-2: FLOW AND PRESSURE READOUT ADJUSTMENT....................................................................8-5

F

IGURE A-1: MODEL 401 SAMPLE SOFTWARE MENU TREE....................................................................D-1

F

IGURE A-2: MODEL 401 SETUP SOFTWARE MENU TREE.......................................................................D-2

vii

Page 8

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

LIST OF TABLES

TABLE 1-1: TEST VALUES.......................................................................................................................1-21

T

ABLE 2-1: PASSWORD LEVELS ...............................................................................................................2-3

T

ABLE 2-2: SYSTEM MODES ....................................................................................................................2-5

T

ABLE 2-3: TEST MEASUREMENTS ..........................................................................................................2-6

T

ABLE 2-4: WARNING MESSAGES............................................................................................................2-7

T

ABLE 2-5: STATUS LEDS........................................................................................................................2-9

T

ABLE 3-1: CALIBRATION CONTROLS......................................................................................................3-3

T

ABLE 4-1: SETUP VARIABLES.................................................................................................................4-7

TABLE 5-1: TEST CHANNEL OUTPUT........................................................................................................5-2

T

ABLE 5-2: DIAGNOSTIC TESTS ...............................................................................................................5-2

T

ABLE 7-1: RS-232 MESSAGE TYPES ......................................................................................................7-1

T

ABLE 7-2: WARNING MESSAGE CLEAR COMMANDS..............................................................................7-4

T

ABLE 7-3: STATUS REPORTS ..................................................................................................................7-4

T

ABLE 7-4: CONTROL COMMANDS...........................................................................................................7-5

T

ABLE 7-5: DIAGNOSTIC COMMANDS ......................................................................................................7-6

T

ABLE 7-6: SPECIAL DIAGNOSTIC COMMANDS........................................................................................7-7

T

ABLE 7-7: DIAGNOSTIC REPORTS...........................................................................................................7-7

T

ABLE 7-8: TEST MEASUREMENT REQUEST COMMANDS.........................................................................7-8

T

ABLE 7-9: RS-232 VARIABLE NAMES..................................................................................................7-10

T

ABLE 8-1: THE CALIBRATOR HAS THE FOLLOWING STATUS CONDITIONS.............................................8-7

T

ABLE 9-1: WARNING MESSAGES............................................................................................................9-4

T

ABLE 9-2: TEST FUNCTION VALUES.......................................................................................................9-5

T

ABLE 9-2: TEST FUNCTION VALUES (CONTINUED) ................................................................................9-6

T

ABLE 9-3: V/F BOARD JUMPERS - FACTORY SETTINGS........................................................................9-12

T

ABLE 9-4: V/F BOARD DIP SWITCHES - RANGES FOR ANALOG OUTPUT..............................................9-12

T

ABLE 9-5: UV SOURCE LAMP AND DETECTOR DIAGNOSTICS..............................................................9-15

T

ABLE 10-1: MAINTENANCE SCHEDULE ................................................................................................10-1

ABLE 11-1: SPARE PARTS FOR CE MARK UNITS..................................................................................11-1

T

T

ABLE 11-1: SPARE PARTS FOR CE MARK UNITS (CONTINUED)...........................................................11-2

T

ABLE 11-2: SPARE PARTS FOR NON-CE MARK UNITS.........................................................................11-3

T

ABLE 11-2: SPARE PARTS FOR NON-CE MARK UNITS (CONTINUED) ..................................................11-4

ABLE A-1: AVAILABLE MODEL 401 OPTIONS.......................................................................................A-1

T

T

ABLE E-1: ELECTRICAL SCHEMATIC INDEX ...........................................................................................E-1

viii

Page 9

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1 INTRODUCTION

1.1 Preface

Teledyne API is pleased that you have purchased the Model 401. We offer a full one year

warranty (see Section 1.2) and we at Teledyne API will be pleased to provide you with any

support required so that you may utilize our equipment to the fullest extent.

The Teledyne API Model 401 keyboard/operator interface with its "talking keys" makes the

Teledyne API a very user-friendly system. We hope you will not experience any problems with

the Teledyne API Model 401 but if you do, the built-in tests and diagnostics should allow you to

quickly and easily find the problem. In addition, our full time customer service department is

always available to answer your questions.

1.2 Warranty

WARRANTY POLICY (02024c)

Prior to shipment, Teledyne API equipment is thoroughly inspected and tested. Should

equipment failure occur, Teledyne API assures its customers that prompt service and support

will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, Teledyne API stands ready to

provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in

the industry. All maintenance and the first level of field troubleshooting is to be performed by

the customer.

NON-TELEDYNE API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by Teledyne API is warranted and will be repaired to

the extent and according to the current terms and conditions of the respective equipment

manufacturers warranty.

GENERAL

Teledyne API warrants each Product manufactured by Teledyne API to be free from defects in

material and workmanship under normal use and service for a period of one year from the date of

delivery. All replacement parts and repairs are warranted for 90 days after the purchase.

If a Product fails to conform to its specifications within the warranty period, Teledyne API shall

correct such defect by, in Teledyne API's discretion, repairing or replacing such defective

Product or refunding the purchase price of such Product.

1-1

Page 10

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used

in any manner other than in accordance with the instruction provided by Teledyne API or (iii)

not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES

THEREFORE ARE EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. THE

REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONTAINED HEREIN. TELEDYNE API SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF OR RELATED TO THIS AGREEMENT OF TELEDYNE API'S

PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF WARRANTY OR

OTHERWISE.

TERMS AND CONDITIONS

All units or components returned to Teledyne API should be properly packed for handling and

returned freight prepaid to the nearest designated Service Center. After the repair, the equipment

will be returned, freight prepaid.

1.3 Principle Of Operation

M401 Ozone calibrator consist of two major parts; the ozone generating device and the

photometer. Ozone generating device itself also consist of a pump, an air scrubber to selfgenerate zero air, a pressure regulator to control flow rate, an ozone generator using UV lamp,

and a manifold. The pressure regulator provides very stable flow of zero air through the O

generator, while the light intensity of the UV lamp is controlled to generate accurate and stable

ozone output.

The photometer is used as part of a feedback lamp control to assure stable O

changing conditions. The photometer is compensated for both pressure and temperature

variations. This true photometer operation along with self-generated zero air results in a

completely self-contained O

The detection of ozone molecules of the photometer is based on absorption of 254 nm UV light

due to an internal electronic resonance of the O

mercury lamp constructed so that a large majority of the light emitted is at the 254nm

wavelength. Light from the lamp shines down a hollow glass tube that is alternately filled with

sample gas, then filled with zero air. The ratio of the intensity of light passing through the zero

air to that of the sample forms a ratio I/I

ozone concentration.

generating system.

3

output even during

3

molecule. The Model 401 Photometer uses a

3

. This ratio forms the basis for the calculation of the

o

3

1-2

Page 11

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

I

T

P

NOTE

Model 401 Photometric Calibrator is designed to be a dedicated

calibrator. The M401 Photometer should not be used as a monitor.

The Beer-Lambert equation, shown below, calculates the concentration of ozone from the ratio

of light intensities.

C

9

10

−=

O

3

a

×

T

0

K273

inHg92.29

P

I

n

ll×××

I

0

Where:

= Intensity of light passed through the sample

I = Intensity of light through sample free of ozone

0

a

= absorption coefficient

l

= path length

C

= concentration of ozone in ppm

= sample temperature in Kelvin

= pressure in inches of mercury

nl

= natural logarithm

As you can see the concentration of ozone depends on more than the intensity ratio. Temperature

and pressure influence the density of the sample. The density changes the number of ozone

molecules in the absorption tube which impacts the amount of light removed from the light

beam. These effects are addressed by directly measuring temperature and pressure and including

their actual values in the calculation. The absorption coefficient is a number that reflects the

inherent ability of ozone to absorb 254 nm light. Most current measurements place this value at

308 cm

-1

atm-1 at STP. The value of this number reflects the fact that ozone is a very efficient

absorber of UV radiation which is why stratospheric ozone protects the life forms lower in the

atmosphere from the harmful effects from solar UV radiation. Lastly, the absorption pathlength

determines how many molecules are present in the column of gas in the absorption tube.

1-3

Page 12

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

The intensity of light is converted into a voltage by the detector/preamp module. The voltage is

converted into a number by a voltage-to-frequency (V/F) converter capable of 80,000 count

resolution. The digitized intensities, along with the other variables, are used by the CPU to

compute the concentration using the above formula.

Every 8 seconds the M401 Photometer completes a measurement cycle consisting of a 2 second

wait period for the sample tube to flush, followed by 2 seconds of measuring the average light

intensity to determine I. The sample valve is switched to admit scrubbed sample gas for 2

seconds followed by 2 seconds measuring the average light intensity to obtain I

of the I

every 8 seconds minimizes instrument drift due to changing intensity of the lamp due to

o

. Measurement

o

aging and dirt. The 120 sec filter provides 32 averages.

1.3.1 Interferent Rejection

It should be noted that the UV absorption method for detecting ozone is subject to interference

from a number of sources. The Model 401 has been successfully tested for its ability to reject

interference from sulfur dioxide, nitrogen dioxide, nitric oxide, water, and meta-xylene.

While the instrument rejected interference from the aromatic hydrocarbon meta-xylene, it should

be noted that there are a very large number of volatile aromatic hydrocarbons that could

potentially interfere with ozone detection. If the Model 401 is installed in an environment where

high aromatic hydrocarbon concentrations are suspected, specific tests should be conducted to

reveal the amount of interference these compounds may be causing.

1-4

Page 13

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.4 Specifications

Photometer

Ranges User selectable to any full scale range from 100 ppb to 20,000 ppb

Zero Noise < 0.3 ppb (rms)

Span Noise < 0.5% of reading (rms)

Lower Detectable Limit < 0.6 ppb (rms)

Zero Drift (24 hours) < 1.0 ppb*

Zero Drift (7 days) < 1.0 ppb*

Span Drift (24 hours) 1% of reading *

Span Drift (7 days) 2% of reading *

Linearity Better than 1% FS

Precision 1.0 ppb

Lag Time 10 sec

Rise/Fall Time (95%) <20 sec

Sample Flow Rate

Temperature Range

Humidity Range 0-95% RH, Non-Condensing

Temp Coefficient

Voltage Coefficient < 0.05 % per V

Dimensions HxWxD 7" x 17" x 27" (178 mm x 432 mm x 686 mm)

Weight, Analyzer 60 lb. (27 kg)

Power, Analyzer 110v/60Hz, 220v/50Hz 250 watts

Environmental Conditions Installation Category (Overvoltage Category) II

Recorder Instantaneous

(Bi-Polar)

Status 12 Status Outputs from Opto-Isolators

Calibration Ozone Generator

Flow rate 2 to 5 LPM adjustable

800 cc/min ± 10%

5-40° C

< 0.05 % per °C

Pollution Degree 2

± 100 mV, ± 1 v

± 5 v, ± 10 v

Maximum concentration 1.0 ppm @ 5 LPM

Minimum concentration 0.050 ppm @ 2 LPM

Stability

* at constant temperature and voltage

± 0.002 ppm (bench feedback)

1-5

Page 14

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.4.1 Noise (PPB RMS)

The standard deviation of reported concentration calculated over 25 samples times 7 runs

minimum, N-1 weighted.

1.4.2 Lower Detectable Limit (LDL) PPB

LDL is defined as twice the (RMS) noise at the lower end of the most sensitive operating range.

1.4.3 Zero Drift (PPB)

Zero drift is defined as unadjusted (automatic) operation maximum shift over the given period at

constant temperature and pressure.

1.4.4 Span Drift

Span drift is defined similarly to zero drift, requiring unadjusted operation at constant

temperature and pressure.

1.4.5 Linearity

< 1.0% of URL, best-straight-line deviation over range of LDL to URL.

1.4.6 Lag Time

Lag time is defined as the time interval between a step change, at the sample inlet port, of input

concentration and the first observable corresponding change in analyzer output.

1.4.7 Rise And Fall Times

Rise/fall times are defined as the time interval between a step change in input concentration and

95% of final response unless otherwise noted.

1.4.8 Temperature Range

5-40° C.

1.4.9 Humidity Range

0 to 95% relative humidity, non-condensing.

1-6

Page 15

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.4.10 Flow Rates

800 scc/min ± 10% (standard cubic centimeters/minute) sample flow rate.

2-5 l/min ± 10% (standard cubic liter/minute) O

1.4.11 Power

Standard input power: 120VAC rms, 60 Hz, 250 watts maximum and 220, 240 V, 50 Hz.

5A resettable circuit breaker.

1.4.12 Weight

27 Kg (60 lb.) maximum.

1.5 Installation And Overview

The Model 401 is shipped with the following standard equipment:

1. Power cord.

2. Instruction manual.

CAUTION

generator flow rate.

3

To avoid personal injury, always use two persons to lift and carry

the Model 401.

Upon receiving the Model 401 please do the following:

1. Verify no apparent shipping damage. (If damage has occurred please advise shipper first,

then Teledyne API.)

2. Remove all red colored shipping screws from the underside of the instrument. Note: Save

these shipping screws and re-install them whenever the unit is shipped to another location.

3. When installing the Model 401, allow a minimum of 4 inches (100mm) of clearance at the

back of the instrument and 1 inch (25mm) of clearance on each side for proper ventilation.

4. Check that all options ordered are enclosed.

5. Connect analyzer' sample inlet line to the M401 sample port of manifold on rear panel.

1-7

Page 16

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

NOTE

See Figure 1-4 for rear panel pneumatic connections. Span gas

should only come into contact with PTFE or glass. Leak check

all fittings with soap solution.

Maximum pressure for leak check is 15 PSIG.

6. Connect the pump exhaust to a suitable vent outside the analyzer area.

CAUTION

Connect the exhaust fitting on the rear panel (see Figure 1-5) to a

suitable vent outside the analyzer area.

7. For internal pressurized zero air using an external dry air supply connect AIR IN port to a

clean, dry air supply (see Figure 1-6).

NOTE

For best O3 generator stability and to avoid moisture condensation,

it is recommended that zero air be dried to approximately -20°C dew

point.

For external pressurized dry zero air using an external dry pressurized source (see Figure 1-

6) proceed as follows:

a. Remove cap plug from the tee of zero air scrubber assembly and connect external dry

zero air line instead (air pressure should be about 30-40 psi).

b. Install the cap plug to dry air inlet port.

c. Verify the power is off and unplug O

GENERATOR pump's power cable connector.

3

8. Connect a recording device to the terminal strip connections on the rear panel (see

Figure 1-2). See Table 9-4 for setting proper analog output voltage jumpers.

9. Connect the power cord to an appropriate power outlet (see the serial number tag for correct

voltage and frequency).

NOTE

Power plug must have ground lug.

1-8

Page 17

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

10. Turn on the M401 by switching the switch on the lower right corner of the front panel (See

Figure 2-1). The front panel display should light with a sequence of messages,-API - M401 software version number, then a normal display as shown in Figure 2-2.

11. Allow about 60 minutes for the temperatures to come up to their respective setpoints then

press the leftmost button on the front keyboard to scroll through the TEST values. Compare

these values to those noted during the final factory checkout listed in Table 1-1. The values

observed should closely match the Table 1-1 values.

NOTE

Words in all caps are messages on the analyzer front panel.

12. Select the range the analyzer will be calibrated on.

a. From the MAIN menu press SETUP to enter the SETUP menu. (See Figure 2-2 for

appearance of front panel.)

b. Press MISC.

c. Press D/A.

d. Enter the PASSWORD (818).

e. Press RNGE (RANGE).

f. Enter the derived full scale range for analog outputs and press ENTR. (Example: if full

scale range is 500 ppb, then press corresponding digit's button until desired range is

selected and press ENTR.)

g. Press EXIT 3 times to return to the MAIN menu.

13. O

generator flow adjustment. The O3 generator flow is controlled by a precision pressure

3

regulator and flow restrictor. Increasing upstream pressure of flow restrictor will increase

flowrate and vice versa. In order to increase pressure, adjust knob clockwise as needed while

monitoring the O

flow test measurement display. In general, the O3 generator flow should be

3

at least 1 L/MIN in addition of total flow demands for the Model 401 (800 cc/min) and

remote analyzers.

NOTE

Adjustment of the O3 generator flow is to be performed by qualified

maintenance personnel only.

1-9

Page 18

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

14. Generate the Zero Air.

a. Press ZERO from the main menu and enter the password (512).

b. Press STBY to terminate or press O

15. Generate the O

a. Press O

b. Enter the O

Span Gas.

3

GN from the main menu and enter the password (512).

3

concentration value desired (0.05 - 1 ppm range).

3

c. Press CONC in order to change O

d. Press STBY to terminate O

GN to continue to generate O3 span gas.

3

gas concentration while generating specified O3 gas.

3

gas generation or press zero to continue to generate zero air.

3

1-10

Page 19

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-1: Model 401 Ozone Calibrator Block Diagram

1-11

Page 20

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

8.7

Figure 1-2: M401 Rear Panel Electrical Connections

1-12

Page 21

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-3: Rear Panel Electrical and Pneumatic Connections (CE Version)

1-13

Page 22

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

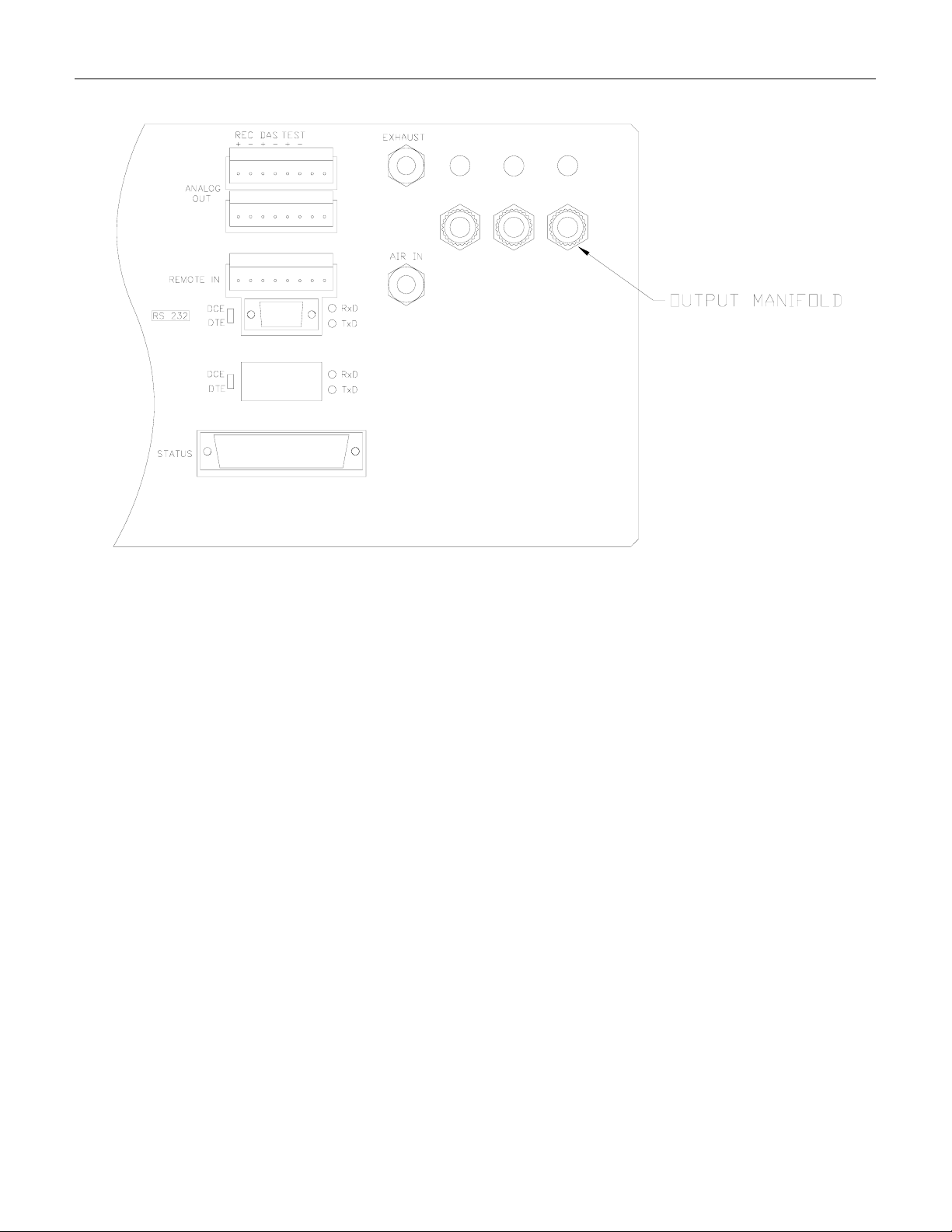

1.6 Electrical And Pneumatic Connections

1.6.1 Electrical Connections

Output #1 Ozone concentration - chart recorder

Output #2 Ozone concentration - DAS

Output #3 Test function analog output

Input #4 Zero valve request

Input #5 Span valve request

Input #6 N/C

There are 2 six-pin connector strips on the rear panel shown in Figure 1-2. The pins are divided

into 3-plus/minus pairs and have the functions shown above.

Outputs 1 and 2 have identical signals and electrical characteristics. Output 3 is the same as 1

and 2 electrically, but has analog TEST function signals routed to it. See Diagnostics in Section

5 for details.

1.6.2 RS-232

See Figure 1-4.

The RS-232 connection is a male 9-pin D-sub connector.

1-14

Page 23

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-4: RS-232 Pin Assignments

1-15

Page 24

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.6.3 Pneumatic System

The Model 401 Photometric Calibrator is equipped with a compression pump to deliver up to 5

L/MIN for ozone generator system. It is also equipped with a second pump capable of pulling

800 cc/min across a critical flow orifice. This allows a smooth, stable flow of sample through the

Photometer.

Compressed air is delivered through a charcoal scrubber. While one path is used as zero air

reference, the other path of same zero air is used to generate the stable ozone output. This will

ensure reliable ozone output as well as proper Photometer operation. Please see Figure 1-1 for

flow diagram and Figure 1-5 for pneumatic connections.

NOTE

The photometer output varies linearly with pressure and

temperature. Temperature and pressure compensation is

done automatically.

A critical flow orifice is used to control the sample flow. The orifice is a precision-drilled

sapphire jewel protected by a 20 micron sintered filter. The critical flow orifice never needs

adjustment and maintains precise flow control as long as the ratio of the up-stream to downstream pressures is greater than 0.53 (sonic flow conditions).

1.6.4 Exhaust Connections (See Figure 1-5)

A single 1/4" O.D. tube should be connected from the Analyzer sample exhaust to an area

outside of the room the analyzer occupies. The maximum length of the exhaust line should not

exceed 30 feet.

1.6.5 Output Flow Adjustment

The flow rate of gas supplied to the output manifold can be changed by adjusting the internal

pressure regulator located on the top of the optical bench (see Figure 1-7). The output flow, O

FLOW, can be read on the front panel test functions. Adjust this flow rate to provide a minimum

of 1 LPM for each analyzer being calibrated plus 1 LPM for the internal photometer in the

M401. For example, when calibrating one analyzer the O

LPM.

flow rate should be set to at least 2

3

3

1-16

Page 25

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-5: M401 Calibrator Pneumatic Connections

1-17

Page 26

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-6: M401 Rear Panel (External Dry Zero Air)

1-18

Page 27

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 1-7: M401 Calibrator Chassis Layout

1-19

Page 28

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.7 Operation Verification

The Model 401 Calibrator is now ready for operation.

1. Read Section 1.3 and all of Section 4 of the manual to understand the Calibrator operation.

2. Turn on the power by pressing the on/off switch on the front panel (see Figure 2-1). The

display should turn on and green (sample) status LED should be energized. The green LED

should blink indicating the instrument has entered the HOLD-OFF mode. The standby mode

can be entered immediately by pressing the EXIT button on the front panel. The red "fault"

light will also be on until the flows, temperatures and voltages are within operating limits.

Clear the fault messages.

3. After a 60 minute warm-up, review the TEST function values in the front panel display by

pushing the leftmost keyboard button labeled TEST. Not every TEST function is a diagnostic

of correct analyzer operation, therefore TEST functions not covered below can be ignored for

now.

4. O3 REF, O3 MEAS: TEST function values should be between 4200 mv and 4700 mv.

5. Pressure: 29 to 30 Inches-Mercury-Absolute at sea level. Other values will be displayed

depending on altitude of analyzer.

6. Sample Flow: 800 cc/min ± 10 %.

7. Sample Temp: Ambient temperature +10°

C.

8. Analytical Lamp Temp: 52° C ± 0.1 The computer drives the temp to this setpoint -it should

be this value and not vary.

9. O

GEN Lamp Temp: 48° C ± 1° C.

3

10. Box Temp: Ambient ± 10° C.

11. DC Power Supply: 2500 mV ± 100 mv. This is a composite of all of the DC voltages in the

instrument. The value is not important but it should be within the range indicated, and should

be constant.

12. If the TEST functions are within the limits given above the instrument should function

correctly. If there is a problem please read the manual and check your set-up. The Model 401

is now ready for calibration, see Section 3.

1-20

Page 29

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.7.1 Final Test And Calibration Values

Table 1-1: Test Values

Test Parameter Displayed Value Units

TIME HH:MM:SS

DCPS MV

BOX TEMP DEG C

O3 OFFSET PPB

O3 SLOPE REG PRESSURE IN-HG-A

O3 GEN TMP DEG C

O3 GEN FLOW L/MIN

ANA LAMP TMP DEG C

SAMPLE TEMP DEG C

SAMPLE FLOW SCC/MIN

SAMPLE PRESS IN-HG-A

O3 DRIVE MV

O3 GEN REF MV

O3 REF MV

O3 MEAS MV

O3 SET PPB/PPM

Options

RACK MOUNTS/SLIDES

POWER VOLTS/Hz

STATUS OUTPUT

RS-232 OUTPUT

Calibration Settings

O3 SPAN SETTING PPB

O3 ZERO SETTING PPB

O3 SLOPE

O3 OFFSET

PROM # Serial #

Date Technician

1-21

Page 30

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

1.8 Options

1.8.1 Rack Mount With Slides

This option, including slides and rack mounting ears, permits the Analyzer to be mounted in a

standard 19" wide x 30" deep RETMA rack.

1.8.2 Status Outputs

The status output is an option that reports Analyzer conditions to a 50 pin connector from the

mother board. The contacts are NPN transistors which can pass 50 ma of direct current. See

Section 8.6 for status output pin assignments.

1-22

Page 31

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

2 OPERATION

2.1 Key Features

The important features of the Teledyne API Model 401 Photometric Calibrator are listed below.

2.1.1 O3 Readout

The Teledyne API Model 401 Photometric Calibrator constantly displays the current ozone

reading

(in PPB) in the upper right hand corner of the alphanumeric display.

2.1.2 O3 Analog Output

The Teledyne API Photometric Calibrator provides a buffered analog output of the current O3

readings on each of two pairs of outputs on the rear panel (see Figure 1-2) for DAS and recorder

reporting. The analog outputs provide for 20% overrange. For example, on the 500ppb range the

M401 will correctly report concentrations up to 600 ppb and output up to 6.00 volts to the DAS

and recorder outputs. (See Table 9-4 for setting proper analog output voltage jumpers.)

In addition TEST function values can be routed to a third analog output.

2.1.3 E2 ROM Backup Of Software Configuration

The Teledyne API Photometric Calibrator has few DIP switches or jumpers that need to be set

by the operator. Configuration of the calibrator is done under software control and the

configuration options are stored in electrically erasable (E

are saved even when the Analyzer is powered off.

There is one exception to this. The analog output voltage ranges are set by DIP switches on the

A/D-I/O board as shown in Section 9.6.3.

2.1.4 Adaptive Filter

The Teledyne API Photometric Calibrator is able to provide a smooth, stable output by means of

an adaptive filter. During conditions of constant or nearly constant concentration the filter is

allowed to grow to 32 samples (2 minutes) in length, providing a smooth, stable reading. If a

rapid change in concentration is detected, the filter is cut to 6 samples to allow the Analyzer to

quickly respond to rapidly varying signals.

2

) ROM. Thus, configuration options

2-1

Page 32

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

2.1.5 Data Acquisition

The Teledyne API Photometric Calibrator contains a built-in data acquisition system which

keeps track of the average O

readings and the last 100 averages. This data is made available to

3

other systems via the RS-232 interface. The Photometric Calibrator can be programmed to

automatically output a 1 minute to 60 minute average. The last 100 averages can be called up

through the remote

RS-232 I/O or viewed on the display through keyboard call-up.

2.1.6 RS-232 Interface

The Teledyne API Photometric Calibrator features an optional RS-232 interface which can

output the instantaneous and/or average O

data to another computer. It can also be used as a

3

command and status channel to allow another computer to control the Analyzer. Refer to Figure

1-4 for details on using the RS-232 interface.

2.1.7 Password Protection

The Teledyne API Photometric Calibrator provides password protection of the calibration and

setup functions to prevent incorrect adjustments to the Calibrator. There are three levels of

passwords which correspond to operator, supervisor/maintenance, and dynamic span level

functions. When prompted for a password, any of the valid passwords can be entered, but the

CPU will limit access to the functions allowed for that password level. Each level allows access

to the functions of all the levels below plus some additional functions. The table on the following

page lists the password levels and the functions allowed for each level.

2-2

Page 33

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Table 2-1: Password Levels

Password Level Functions Allowed

No password required

Operator (512) 1 ZERO, 03GN, ASEQ

Setup (818) 2 SETUP-EVNT,

Setup (717) 3 SETUP-MISC-O3-SLPE,

0

TEST, MSG, CLR,

SETUP-DAS-VIEW

SETUP-BCAL,

SETUP-COMM,

SETUP-MISC-O3 GEN,

SETUP-MISC-DARK,

SETUP-MISC-CLK,

SETUP-MISC-D/A,

SETUP-MISC-MORE,

SETUP-PASS,

SETUP-DIAG

SETUP-MISC-03-OFFS

NOTE

All passwords can be disabled. To do this, enter setup-password,

enter 818 and turn "enable" off. If the wrong password is entered, the

analyzer will beep when enter is pressed.

2-3

Page 34

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

2.2 Front Panel

This section describes the operator interface from the point of view of the front panel. The front

panel consists of a 2-line by 40-character alphanumeric display, 8 pushbuttons, and 3 status

LEDs. Each of these features are described in Section 2.2.1.

2.2.1 Front Panel Display

The display is divided into 4 main "fields": the mode field in the upper left, the message field in

the top center, the sample concentration field consisting of the most recent instantaneous ozone

value field in the upper right, and the MENU field which occupies the entire bottom line of the

display. A typical display is shown in Figure 2-1.

Figure 2-1: Model 401 Front Panel

The mode field indicates the current mode of the Analyzer. Usually, it shows "STBY ZS ",

indicating that the instrument is in the standby mode and that automatic zero/span checking is

enabled. Manual span checking or calibration can only be performed by pressing the buttons on

the front panel labeled "ZERO", "O

calibration which is displayed only if automatic multipoint sequence is selected (see Section 3.3

for detailed information). Automatic span check only occurs at the preset time. Calibration and

span adjustments are discussed in greater detail in Section 3.6. Table 2-2 lists all the possible

modes in the Analyzer and their meanings.

GN" or “ASEQ.” ASEQ is a sequence of multipoint

3

2-4

Page 35

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Table 2-2: System Modes

Mode Meaning

STBY xxxx (1) Standby mode (Photometer is operating normally)

ZERO CAL x (2) Zero check in progress

O3GN CAL x (2) Span check in progress

ASEQ xxx (5) x (2) Multi-point calibration in progress

HOLD OFF Hold off delay after power reset

D/A OUTPUT (3) Test analog output channels

BCAL ZERO Bench zero calibration

BCAL SPAN Bench span calibration

SETUP xxx (4) Configuring analyzer (operation continues)

(1) xxxx = AZS ( Auto Zero & Span programmed), AZ2S (Auto Zero & 2 span points; 25% &

100% of O

(Zero & 5 span points; 20%, 40%, 60%, 80% & 100% of O

(2) x = M (manual), A (auto), R (remote)

set concentration) programmed AZ5S

3

set concentration) programmed.

3

(3) diagnostic test modes

(4) xxx = software revision

(5) 0%, 20%, 25%, 40%, 60%, 80%, 100%

The message field shows test measurements or warning messages. Table 2-3 and Table 2-4

summarize the test measurements and warning messages and their meanings. Refer to Sections 4

and 5 for detailed information on viewing test measurements and warning messages and clearing

warnings.

2-5

Page 36

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Table 2-3: Test Measurements

Test Message Meaning

TIME=xx:xx:xx Current time-of-day (HH:MM:SS)

O3 SET =xxxx PPB Ozone generator set concentration

O3 MEAS=xxxx MV Current measure channel in mV

O3 REF =xxxx MV Current reference channel in mV

O3 GEN =xxxx MV O3 GEN ref channel feedback voltage

PRES=xxx IN-HG-A Absolute pressure : inches Hg

SMP FLW=xxx CC/M Sample flow through Photometer (cc/min)

SAMPLE TEMP=xxx C Temperature in the absorption tube

ANA LAMP TMP=xxx C Analytical Lamp Housing Temperature

O3 FLOW=x.x L/M Gas flow through O3 generator

O3 LAMP TMP=xx C O3 GEN Lamp Housing temp. (deg. C)

REG = xx.x IN-HG-A Regulator pressure - Inches Hg.

BOX TEMP=xxx C Internal box temperature (deg. C)

DCPS=xxxxxx MV DC power supply (mV)

2-6

Page 37

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Table 2-4: Warning Messages

Warning Message Meaning

SYSTEM RESET Issued whenever Analyzer is powered on

RAM INITIALIZED RAM was erased (including DAS reports)

ANA LAMP WARNING Analyzer lamp < 40000 OR >= 80000 counts

O3 LAMP SHUTDOWN O3 lamp temperature control not working

O3 FLOW WARNING O3 GEN flow < 1.8 L/M or > 5.5 L/M

O3 REF DET WARN O3 reference detector < 50 mV

SAMPLE FLOW WARNING Sample flow < 500 cc/m or > 1000 cc/m

SAMPLE PRESSURE WARN Sample pressure < 15 or > 35 In-Hg-A

SAMPLE TEMP WARNING Sample temperature < 12 or > 48 deg. C

BOX TEMP WARNING Box temp. < 12 deg. C or > 48 deg. C

O3 GEN LAMP TEMP WARN O3 lamp < 43 or > 53 deg. C

ANA LAMP TEMP WARN Analyzer lamp < 51 or > 61 deg. C

V/F NOT INSTALLED A/D - I/O card not installed, bad, or no handshake.

The menu field changes depending on the mode of the Analyzer and the buttons that have been

pressed. It indicates the current function of each of the 8 pushbuttons below the display. See

Section 2.2.2 for information on using the pushbuttons.

2.2.2 Programmable Pushbuttons

The 8 pushbuttons below the display are programmable by the CPU in that their functions

change depending on the mode of the Analyzer or the operations being performed. The legend

above a button identifies its current function. If there is no legend above a button, it has no

function and will be ignored if pressed.

2-7

Page 38

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

Figure 2-2: Illustration Of Normal Display

If TEST is pushed, the upper center display cycles through the menu of test parameters, e.g.

Sample flow (see Table 2-3).

If STBY is pushed, the calibrator is in stand-by mode.

If ZERO is pushed, the sequence of operations for generating ZERO gas is initiated.

O

GN is used to initiate span setting using sample gas, such as during a formal calibration.

3

Pushing ASEQ will initiate multi-point calibration if it is preset. (see Section 3.4)

Pushing MSG will cause a message to appear on the upper center display if warning exits (also

red status led will be blinking).

Pushing CLR will erase a message, provided the condition causing the message has ceased.

Pushing SETUP changes the function of the pushbuttons and is used for setting basic parameters

as described in Section 4.

2-8

Page 39

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

2.2.3 Status LEDs

The three status LEDs to the right of the display indicate the general status of the Model 401

Photometric Calibrator. The green SAMPLE LED indicates the sampling status. The yellow

CAL LED indicates the calibration status. The red FAULT LED indicates the fault status. Table

2-5 summarizes the meanings of the status LEDs.

Table 2-5: Status LEDs

LED State Meaning

Green Off

On

Yellow Off

On

Blinking

Red Off

Blinking

Not monitoring (should never be off)

Monitoring normally

(STBY/ZERO/O

Auto cal. disabled

Auto cal. enabled

Calibrating

No warnings exist

Warnings exist

GN/ASEQ MODE)

3

2-9

Page 40

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

INTENTIONALLY BLANK

2-10

Page 41

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

3 CALIBRATION

The M401 is designed to be used as a dedicated ozone calibrator with built-in photometer.

Zero/Span gas generation and calibration of Model 401 are discussed in Section 3. The emphasis

in Section 3 is on the operation of the buttons and the internal adjustments they make in the

instrument.

3.1 Manual Zero Air Supply

The Model 401 calibrator can generate zero air using the internal scrubbing module. Press zero

and enter password (512) to generate zero air. The IZS pump will start to run and flow control

system will maintain stable flowrate of zero air to both the photometer and the analyzer being

calibrated. Supply flowrate should exceed demand flowrate to ensure good zero measurement.

Dry air should be provided into the inlet of rear panel for internal zero air supply.

3.2 Manual O3 Generation

Press O3GN, then enter the password (512), to generate the O3 span gas. Specify O3 gas

concentration up to 1000 ppb and minimum of 50 ppb and press enter to select. Again, the O

generator pump will start to run and the flow control system will maintain stable flowrate

through the O

measurement. Pressing CONC allows a change of O

generation.

The M401 software has a "Learning" feature that will remember the

parameters from the last several concentrations that were generated

by the instrument. The first time a specific concentration is

requested, the response time may be somewhat slow. Any subsequent

requests for that same concentration will be much faster since the

instrument will remember the previous settings. This information

remains in memory even when the instrument is turned off.

generator. Supply flowrate should exceed demand flowrate to ensure good span

3

gas concentration during specified O3 gas

3

NOTE

3

3-1

Page 42

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

3.3 Automatic Zero/Span (or Multipoint) Check

Automatic zero/span gas supply must be enabled in the setup mode. There are five parameters

that affect zero/span checking: the zero and span duration, the time of day for calibration, the

time shift, the zero and multipoint calibration switch, and the feedback mode. These are

described individually below.

To set the duration of the zero/span check, press the following sequence of buttons from the

STBY mode: SETUP-EVNT-WAIT. Enter the duration for the zero check and then press

ENTR. Similarly enter the duration for the span check and then press enter. To shift the Z/S

check time backwards each day, select "-" and enter a number from 1 to 60. To disable shifting

of the check time (i.e. to Z/S check at the same time each day), enter a time shift of 0.

To enable automatic zero/span checking, press following sequence of SETUP-EVNT-ASEQ.

The CPU will display the current setting in the menu field above the first button. Press "OFF" in

order to disable automatic sequence, then press "ENTR". Likewise, select AZS for zero and span

(See Section 3.2 or 3.4 How To preset O

main menu.), AZ2S for zero and two span points, (25% AND 100% of preset O

and AZ5S for zero and five span multipoint (20%, 40%, 60%, 80%, and 100% of preset O

concentration) sequence.

concentration which is specified in O3 GN or ASEQ of

3

concentration)

3

3

O

generator has three different modes of lamp feedback control. Press sequence of SETUP-

3

MISC-O3-GEN-MODE to select constant (CNST) lamp current control, reference (REF)

detector feedback control, or bench (BNCH) feedback lamp control. Bench feedback is

recommended to generate fast response, stable, and accurate O

optical bench is used as a feedback detector to control O

generating lamp.

3

concentration in which the

3

3.4 Manual Zero/Span (or Multi-Point) Check

Manual zero/span (or multi-point) is activated by pressing "ASEQ" button from the main menu

display. Then enter the password, specify full scale concentration between 50ppb - 1000ppb

which would be 100% of span concentration, and press ENTER to select. This feature is

identical to the automatic zero/span check sequence except it is activated manually. This ASEQ

entry is not shown on display unless it is programmed. In order to enable this feature, automatic

zero/span check parameters must be preset (See Section 3.3 or 4.2). While multipoint calibration

is in progress pressing "STBY" will terminate "ASEQ".

3-2

Page 43

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

3.5 Summary Of Front Panel Calibration Controls

The calibration controls are summarized below in terms of the button sequences used to access

them.

Table 3-1: Calibration Controls

Button Sequence Function Default Limits

STBY Select stand by mode - ZERO-ENTR Begin zero calibration - O3GN-ENTR Begin span calibration - ASEQ-ENTR Begin multi-point calibration - SETUP-WAIT Zero/span/duration 15 min 1-20 min

SETUP-EVNT-TIME Auto check time-of-day 23:30 00:00-23:59

SETUP-EVNT-ASEQ En/disable auto multi-point check OFF OFF/ZS/Z2S/Z5S

SETUP-EVNT-SHFT Auto check time shift 0 min

SETUP-MISC-O3-

GEN-MODE

Select lamp control mode Bench

3.6 Photometer Calibration

Model 401 is capable of accurately reproducing O3 span gas. However, it should be

quantitatively verified by relating to a master standard such as certified Model 400 O

photometric analyzer. The calibration of Model 401 photometer can be verified by periodic

(recommended every 3 months) intercomparison between Model 401 photometer and a master

standard.

Photometer Zero Calibration

1. Turn the power on for both Model 401 and Model 400 (as master standard) and allow them

to stabilize for minimum of one hour.

2. Start to generate the zero gas by pressing "zero" button from the main menu and enter the

password (512). In case of using external dry zero air, verify proper IZS flow and pressure of

external air source. (See Figure 1-5 for pneumatic connections.)

± 60 min

CNST/REF/BNCH

3

3-3

Page 44

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

3. Allow to sample zero gas for approximately 10 minutes.

4. Follow sequence of SETUP, BCAL, and ZERO. Then select "yes" to adjust zero.

NOTE: in case of using external dry zero air, check if dry zero air is supplied into the rear

panel port (see Figure 1-5 for pneumatic connections) at about 30 - 40 PSI pressure. O

3

generator flow should be exceeding at least 1 l/min in addition of total flow demands. (See

Section 1.6.5 for O3 generator flow adjustment.)

Photometer Span Calibration

1. Turn the power on for both Model M401 and Model M400 (master standard). Let them

stabilize for minimum of one hour.

2. Start to generate the span (O

) gas by pressing O3GN from the main menu and enter the

3

password (512). (In case of using external dry zero air, verify proper pressure of external air

source.)

3. Allow to sample span gas for approximately 10 minutes.

4. Follow the sequence of SETUP, BCAL, and enter correct span concentration related to the

Model M400 (master standard). Then select "yes" to set span.

3.7 Remote Zero/Span Check (Contact Closure)

In addition to calibration check via the front panel buttons, the calibrator can be activated by

means of two contact closures called EXT-ZERO-CAL and EXT-SPAN-CAL. (See Figure 1-2

for the location of the terminals for connection of the contacts on the rear panel.) The CPU

monitors these two contact closures every 1 second and looks for a positive transition (i.e. 0 ->

1) on either signal. If a positive transition occurs on EXT-ZERO-CAL, the M401 will perform a

zero check. If a positive transition occurs on EXT-SPAN-CAL, the M401 will perform a span

check. If a positive transition occurs on both EXT-ZERO-CAL and EXT-SPAN-CAL

simultaneously and ASEQ is preset, then the M401 will perform a multi-point sequence as

selected in SETUP-EVNT-ASEQ menu (see Section 4.2.). When a negative transition (i.e. 1 ->

0) is detected, the CPU will go into standby mode.

Also, if a positive transition occurs on either signal while the M401 is in zero, span check or

ASEQ mode, it will immediately switch to the specified mode. For example, if the analyzer is in

zero check and a positive transition is detected on EXT_SPAN_CAL, then the instrument will

immediately go into span check. To perform a zero check followed by a span check, first

generate a positive transition on EXT-ZERO-CAL, and then when you want to do the span

check, generate a positive transition on EXT-SPAN-CAL.

The remote calibration signals may be activated in any sequence, providing a virtually unlimited

number of calibration types.

3-4

Page 45

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

NOTE

Teledyne API recommends that contact closures remain closed at

least

10 minutes to allow for an accurate average zero or span value

to be established.

3.8 Remote Zero/Span Check Or Adjustment (RS-232)

Besides Z/S checking from the front panel, automatic Z/S checking, and remote Z/S checking via

the contact closure inputs, the Analyzer can also be checked via the RS-232 interface. Remote

checking via the RS-232 interface supports zero, span, and zero followed by span check, and is

identical to remote check via the contact closure inputs.

This RS-232 control feature is provided mainly so that a host computer at another location can

control the Analyzer. See Section 7 for detailed information on using the RS-232 interface to do

a remote Z/S check.

3.9 Hold Off

Every type or check or adjustment (zero, span, manual, remote, etc.) is followed by a hold-off

period of 30 seconds during which the internal data acquisition system (DAS) does not

accumulate ozone readings into the DAS average.

3-5

Page 46

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

INTENTIONALLY BLANK

3-6

Page 47

Teledyne API Model 401 O3 Photometric Calibrator Instruction Manual, 01124, Rev. J2

4 SETUP MODE

This section describes the setup variables which are used to configure the analyzer.

4.1 Setup Mode Operation

All the setup variables are stored in the analyzer's EEPROM and are retained during power off

and even when new software revisions are installed.

NOTE

If a variable is modified, but ENTR is not pressed, the variable will

not be changed and the analyzer will beep when EXIT is pressed.

4.2 Setting Automatic Multipoint (ASEQ) Check

Automatic sequence of multipoint calibration can be programmed to select one zero and five

span points 20%, 40%, 60%, 80%, and 100% of selected (see Section 3.4 How to set

concentration) O

Likewise, select AZS for zero and one span point (selected O

zero and two span points 25% and 100% of selected O

pre-programmed automatic sequence. If ASEQ is selected, then front panel's yellow status LED

will be turned on.

concentration by pressing sequence of SETUP-EVNT-ASEQ-AZ5S.

3

concentration), select AS2S for

3

concentration, or press OFF to disable

3

4.3 Setting Automatic Zero/Span Duration

Duration of each zero/span calibration step can be programmed by selecting SETUP-EVNTWAIT. Enter the duration between 1 - 20 minutes for the zero check and then press ENTR.

similarly enter the duration for span check and press ENTR.

NOTE

Teledyne API recommends that the durations are set at least 10

minutes to allow for an accurate and reliable ZERO or SPAN value

to be established.

Automatic zero/span calibration will be initiated once per day on a timed basis. Set starting time

of the automatic calibration by selecting SETUP-EVNT-TIME. Time should be between 00:00

- 23:59.

Starting time of the automatic cal. can be shifted ± 60 min to avoid missing data of remote

analyzer during same time of the day. Set desired shift time by selecting SETUP-ENVT-SHFT.

4-1

Page 48