Page 1

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

Power

Power Supply/Totalizer

Pod

400

ISO 9001

CERTIFIED

Page 2

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual.

The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda,

which are released between revisions, contain important change information that the user should incorporate

immediately into the manual. Addenda are numbered sequentially. When a new revision is created, all

addenda associated with the previous revision of the manual are incorporated into the new revision of the

manual. Each new revision includes a revised copy of this print history page.

Revision D (Document Number 164-082005) ................................................................ August 2005

Revision E (Document Number 164-102005) ............................................................... October 2005

Revision F (Document Number 164-012006) ................................................................ January 2006

Revision G (Document Number 164-092006) ........................................................... September 2006

Revision H (Document Number 164-112006) ........................................................... November 2006

Revision J (Document Number 164-022009) ............................................................... February 2009

Revision K (Document Number 164-062009) .................................................................... June 2009

Revision L (Document Number 164-082010) ................................................................. August 2010

Revision M (Document Number 164-102012) ............................................................. October 2012

Revision N (Document Number 164-122012) ........................................................... December 2012

Visit www.teledyne-hi.com for WEEE disposal guidance.

Hastings Instruments reserves the right to change or modify the design of its equipment

without any obligation to provide notification of change or intent to change.

164-122012 Power

POD

400 Page 2 of 42

Page 3

Table of Contents

1.0 QUICK START INSTRUCTIONS ..................................................................................................................................... 5

2.0 SAFETY ................................................................................................................................................................................ 6

3.0 FEATURES .......................................................................................................................................................................... 7

4.0 SPECIFICATIONS ............................................................................................................................................................... 9

5.0 FRONT PANEL ................................................................................................................................................................. 10

6.0 REAR PANEL..................................................................................................................................................................... 11

7.0 WIRING.............................................................................................................................................................................. 12

7.1. POWER ........................................................................................................................................................ 12

7.2. COMMUNICATIONS ............................................................................................................................... 12

7.3. TRANSDUCER CONNECTIONS ............................................................................................................ 13

7.4. ALARMS...................................................................................................................................................... 13

7.5. ANALOG SIGNAL FOLLOWERS ............................................................................................................ 14

8.0 MANUAL OPERATION ................................................................................................................................................... 15

8.1. POWER ON/OFF ........................................................................................................................................ 15

8.2. CHANGING THE COMMAND SET POINT .......................................................................................... 15

8.3. OVERRIDE OPEN ...................................................................................................................................... 15

8.4. OVERRIDE CLOSED ................................................................................................................................. 15

8.5. SETTING A CHANNEL TO AUTO CONTROL .................................................................................... 16

8.6. SETTING A CHANNEL TO DIRECTLY METER INCOMING SIGNALS ......................................... 16

8.7. SETTING A CHANNEL TO DISPLAY THE TOTALIZER FUNCTION ............................................ 16

9.0 EXTERNAL/REMOTE OPERATION .............................................................................................................................. 18

9.1. SELECTING EXTERNAL/REMOTE OPERATION (FRONT PANEL ONLY) ........................................ 18

9.2. CHOOSING RS-232 COMMUNICATION .............................................................................................. 18

9.3. CHOOSING RS-485 COMMUNICATION .............................................................................................. 18

10.0 SETUP/CAL MODE .......................................................................................................................................................... 19

10.1. ENTERING THE SETUP/CAL MODE .................................................................................................... 19

10.2. DISPLAY SETUP ........................................................................................................................................ 19

10.2.1. BLANKING A DISPLAY LINE/CHANNEL ........................................................................................................ 19

10.2.2. SELECTING DISPLAY BRIGHTNESS ............................................................................................................... 19

10.2.3. SELECTING UNIT-OF-MEASURE ................................................................................................................... 20

10.2.4. SELECTING GAS ID ...................................................................................................................................... 20

10.2.5. SETTING A/D CONVERSION RATE (FILTER) ................................................................................................ 20

10.2.6. FRONT PANEL LOCK OUT ............................................................................................................................ 21

10.3. TOTALIZER SETUP ................................................................................................................................. 21

10.3.1. COUNT UP TO A SET POINT ......................................................................................................................... 21

10.3.2. COUNT DOWN FROM A SET POINT .............................................................................................................. 22

10.3.3. COUNT CONTINUOUSLY .............................................................................................................................. 22

10.4. EXTERNAL COMMUNICATION SETUP ............................................................................................. 22

10.4.1. RS-232 SETTINGS ........................................................................................................................................ 22

10.4.2. RS-485 SETTINGS ........................................................................................................................................ 22

10.5. SELECTING THE ANALOG SIGNAL LEVEL ....................................................................................... 23

10.5.1. ZERO TO FIVE VOLT OPERATION ................................................................................................................. 23

10.5.2. ZERO TO TEN VOLT OPERATION ................................................................................................................. 23

164-122012 Power

POD

400 Page 3 of 42

Page 4

10.5.3. FOUR TO TWENTY MILLIAMP OPERATION .................................................................................................. 23

10.6. SETTING LIMIT ALARMS ...................................................................................................................... 24

10.6.1. SETTING A SINGLE CHANNEL’S HIGH LIMIT ............................................................................................... 24

10.6.2. SETTING A SINGLE CHANNEL’S LOW LIMIT ................................................................................................ 24

10.6.3. SETTING A SINGLE CHANNEL’S HYSTERESIS ............................................................................................... 24

10.7. SETTING RATIO CONTROL PARAMETERS ...................................................................................... 25

ENABLING RATIO CONTROL ..................................................................................................................................... 25

10.8. CALIBRATING A CHANNEL TO ITS INCOMING SIGNALS ............................................................ 26

10.8.1. RESETTING THE ZERO ONLY ....................................................................................................................... 26

10.8.2. RESETTING THE SPAN ONLY ........................................................................................................................ 26

10.8.3. RESETTING ZERO AND SPAN ........................................................................................................................ 27

10.8.4. SETTING A MULTIPLICATION FACTOR ........................................................................................................ 27

10.9. SERIAL COMMUNICATION ................................................................................................................... 28

10.9.1. COMMANDS .................................................................................................................................................. 28

10.9.2. SET POINT QUERIES ..................................................................................................................................... 28

10.9.3. ALARM/FLAG QUERIES ................................................................................................................................. 28

11.0 APPENDIX A ..................................................................................................................................................................... 30

12.0 APPENDIX B ..................................................................................................................................................................... 33

13.0 APPENDIX C ..................................................................................................................................................................... 33

14.0 APPENDIX D ..................................................................................................................................................................... 36

15.0 DRAWINGS ....................................................................................................................................................................... 41

16.0 WARRANTY ...................................................................................................................................................................... 42

16.1. WARRANTY REPAIR POLICY ......................................................................................................................... 42

16.2. NON-WARRANTY REPAIR POLICY ................................................................................................................ 42

164-122012 Power

POD

400 Page 4 of 42

Page 5

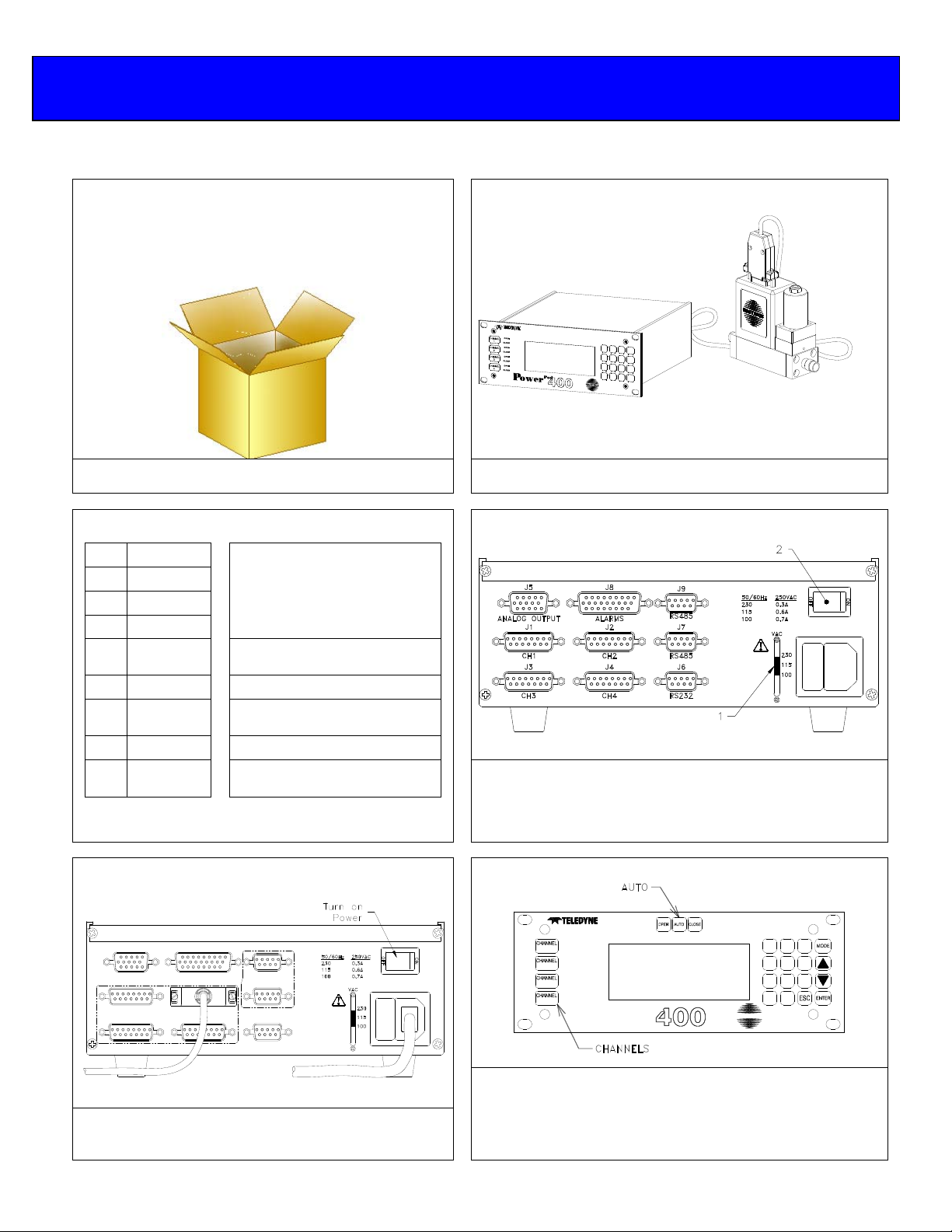

1.0 Quick Start Instructions

Important – The Power

Pod

-400 comes calibrated from the factory according to your specifications.

No set up is necessary unless you need to change the specs

1ea Power

1ea AC power cord

1ea 15-pin, Hi Density, D-style connector

1ea 9-pin, D-style connector

1ea user’s manual

When unpacking the Power

contain everything you need.

Pod

-400

Pod

, the package will

J-1 Ch1

J-2 Ch2

J-3 Ch3

J-4 Ch4

J-5

Analog

out

J-6 RS-232 Serial Com Port

J-7 RS-485

J-8 Alarms Open-collector Alarms

J-9 RS-485

Transducer Power,

Command and Analog

Signals.

Transducer Signal, Volts

Only

Multi-drop com port

(Daisy Chained)

Multi-drop com port

(Daisy Chained)

Pin-outs (see section 7)

Connect a “known good” cable to the desired channel

(See next frame for pin-outs)

1) Check power setting switch on the back panel and make

sure it is set appropriately.

2) Ensure the power switch is off, and then connect the power

cord.

OPEN

1

CLOSE

OPEN

2

CLOSE

OPEN

3

CLOSE

OPEN

4

CLOSE

P

ower

1) Press the desired Channel # Key. Press the Auto key.

Turn power switch to on position. If you have just

turned on the mass flow instrument and the

power, some settling is necessary.

164-122012 Power

POD

400 Page 5 of 42

2) Press the desired Channel # Key. Enter desired flow.

Press the enter key.

Pod

(For Controllers)

HASTINGS

3

2

1

5

6

4

8

7

9

.

0

Page 6

2.0 Safety

Read this manual in its entirety before operating the POWER

POWER

and meters. Read all wiring and power hookup instructions and understand the requirements prior to

using another manufacturer’s products with the POWER

interfaced with the POWER

standards before operating.

POD

-400 is designed to operate with most Teledyne Hastings Instruments (THI) flow controllers

POD

-400 is wired according to prevailing local safety and operational

The following symbols and terms may be found on THI products and/or in THI manuals and indicate

important information.

When found on the device, this symbol indicates that the operator should refer to

the manual for important instructions on the proper use of this device. When found

in the manual, this symbol indicates that the reader should understand the

implications contained in the text before operating the device.

POD

-400 Power Supply/Totalizer. The

POD

-400. Insure that any product being

This symbol indicates that a shock hazard may be present. Read the instruction

manual carefully and insure that the device is wired properly and that all settings

have been checked prior to applying power to the device.

The WARNING label indicates important information that should be heeded for safe and proper

performance of the device.

The label, CAUTION, is used to indicate that damage to the power supply or equipment

connected to it could occur if directions are not followed. Warranty could be invalidated if the

instructions in this manual are not followed.

164-122012 Power

POD

400 Page 6 of 42

Page 7

3.0 Features

The POWER

rack hardware or can be used as a bench top unit. The POWER

character, vacuum fluorescent display (VFD). The display emulates a liquid crystal display in its

command structure but the VFD gives the unit a greater viewing angle and better visibility than available

with most conventional LED or LCD displays. The display can be set to four different brightness levels.

Use a lower brightness setting to extend the already long expected life time of the display. Use brighter

settings for viewing areas where ambient light may be too bright or cause glare, or where greater viewing

distances are required.

Most features are accessible via the membrane keys on the front panel. Consult the section on each

function to check its availability. Operators are guided through the many features and options by selecting

their choices from an intuitive menu structure.

FRONT PANEL LOCKOUT

ANALOG RANGE SELECTION

Analog signal and control ranges are operator selectable. The operator can choose between three different

DC ranges:

POD

-400 serves as a convenient control center that can be rack-mounted using standard half-

The Front Panel Lockout function is only available through serial communication. Manual

Overrides remain available during Lockout via a minimum number of keystrokes using

dedicated keys for this purpose and allow any command setting to be overridden in either the

high (open) or low (closed) state.

POD

-400 is equipped with a 4 X 20

A fifteen (15) pin, high density, sub-miniature, D-type connector is provided for separate monitoring of

each channel’s analog transducer signal.

CAUTION: Consult the appropriate section for limits to the loading of these signals.

SERIAL COMMUNICATION

The POWERPOD-400 comes equipped with standard RS-232 and RS-485, serial communication. Most

functions, features, signals and alarms are accessible and modifiable via any remote computer.

0 -5 VDC, 0-10 VDC or 4 -20 mA.

The following commands are manual commands only:

OPEN,

The status of these settings can be read via serial communication but they cannot be changed

except manually, from the front panel.

AUTO and CLOSE.

164-122012 Power

POD

400 Page 7 of 42

Page 8

POWER SELECTION

Power input is switchable between 100 VAC, 115 VAC and 230VAC (50 or 60 Hz) via

the rear panel. For the safety of the operator as well as the device, the correct power

level should be selected prior to connecting to the power mains. See the table

“POWERPOD-400 Specifications” in section 3.0 for the proper fusing when changing

power settings.

RATIO CONTROL

Ratio control is possible between channels using a familiar master/slave configuration. Channel one

(1) must be enabled as the master channel. Any combination of the remaining channels is possible

for slave channel assignment.

TOTALIZER

A Totalizer function is present for each channel with the capability of counting down from a set

point, counting up to a set point or continuous count up. The maximum count is ±999999 units.

When the set points are reached, a memory flag for each set point is set to a digital ‘1’ indicating a

Boolean ‘true’ value. The Totalizer set point flags must be polled via digital communication to be

read. Each flow channel has one low-limit and one high-limit set point available. These alarms are

available via open-collector, opto-isolated outputs on the rear panel as well as serial

communication.

POWER OUTAGES AND THE OVERRIDE CONDITION

In the event of a power outage, even one of short duration, the POWER

POD

-400 is

designed to conduct a software reset. During the period of time in which the reset is

occurring, it will not accept or respond to any commands either manually or digitally

until the reset process is completed. After said reset, the POWER

POD

-400 will have

remembered all previously entered set-points but all channels are designed to come up

in the “Override-CLOSEd” condition. For meters, this should have no affect on their

behavior. All analog-only, THI, flow controllers with normally-closed (NC) valves will

close and remain closed until operator intervention manually returns selected channels’

Override condition back to the AUTO mode.

For all other controllers, this means that the control signal (pins 5 to 14) of J1 through

J4 will return to the previously set level. For controllers not taking advantage of the

Override function (pin 8), these controllers will return to their normal, preset operating

condition unless other intermediary steps are undertaken. Controllers that are making

use of the override function (Pin 8) and have normally-open valves will be driven to the

fully open condition.

164-122012 Power

POD

400 Page 8 of 42

Page 9

y

y

4.0 Specifications

Power

Specification Value Units Notes

Power Inputs

V

P 68 VA

f 50 -60 Hz

Transducer

Number Channels 4

V

I

I/O

Display

Type

# Lines 4

# Characters 20

Brightness Levels 4

A/D Converter

Filtering Rate 4, 15, 30,

Alarms

3 per channel 1 High

1 Low

1 Total

Dimensions

Front Panel (h x w) 3.5 x 9.5 in

Case (h x w x d) 3 x 8 x 9.5 in

Hole Centers (h x

w)

Weight 5 1/4 lbs

Suppl

Suppl

Pod

-400 Specifications Table

100

115

VAC

230

±15

±250

0 - 5

0 - 10

VDC Bi-polar, per Channel

mA Bi-polar, per Channel

VDC

4 - 20 mADC

100

Hz

3 x 8.825 in

0.7 A, 250VAC, SB Fuse

0.6 A, 250VAC, SB Fuse

0.315 A, 250VAC, SB Fuse

Vacuum Fluorescent,

LCD Emulator

164-122012 Power

POD

400 Page 9 of 42

Page 10

(

A

A

(

(

p

A

e

5.0 Front Panel

1. CHANNEL NUMBER SELECT KEYS

Selects channel for editing. An asterisk (*) appears in the first column of the display to indicate that this is the channel to

be edited.

2. OVERRIDE INDICATORS

Indicates when a channel’s command signal is overridden high

3. OVERRIDE KEYS

Override the command signal on the

sets command to –15V. AUTO allows the user to set the command signal for normal operation. A channel must be

active before these keys can become operational.

4. DISPLAY AREA

Column 1: Reserved for displaying

Column 2: Reserved for

Col’s 3 – 8: Signal monitor. Displays current input signal while in METER mode,

Column 9: Spac

Col’s 10 – 14: UNITS OF MEASURE

Column 15: Space

Col’s 16 – 20: GAS

5. KEYPAD

Use to enter

OPEN

1

CLOSE

OPEN

2

CLOSE

OPEN

3

CLOSE

OPEN

4

CLOSE

Pod

P

ower

HASTINGS

400

OPEN) or low (CLOSED).

CTIVE CHANNEL. OPEN sets control override (pin 8) to +15V. CLOSED

CTIVE CHANNEL

TOTAL (T).

olarity indicator.

to average readings or TOTAL while in TOTALIZER mode.

display.

ID.

SET POINTS or to modify the SETUP or CALIBRATION of control unit.

*), MASTER channel (M), SLAVE

3

2

1

5

4

7

0

6

8

9

.

VERAGE while set

S) or

164-122012 Power

POD

400 Page 10 of 42

Page 11

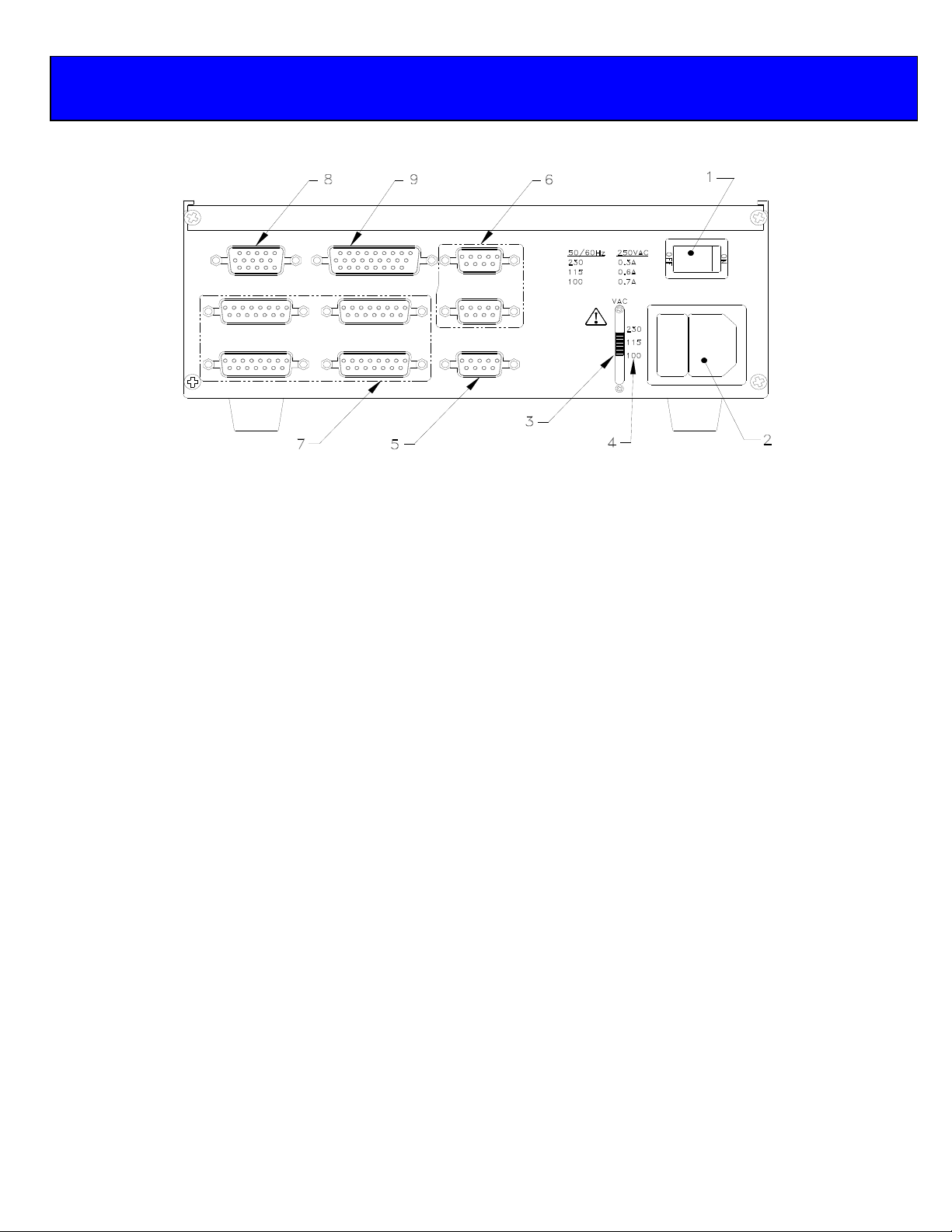

6.0 Rear Panel

1. POWER ON/OFF SWITCH

2. POWER INLET & FUSE

3. POWER SELECTOR SWITCH

4. FUSE Vs. POWER SETTING TABLE

5. RS-232 SERIAL PORT CONNECTOR (J6)

6. RS-485, DAISY CHAINED, SERIAL PORT CONNECTORS (J7, J9)

7. TRANSDUCER CONNECTORS (J1-J4)

8. ANALOG OUTPUT (J5)

9. ALARMS (J8)

164-122012 Power

POD

400 Page 11 of 42

Page 12

7.0 Wiring

7.1. POWER

Power is supplied through a fused, AC jack on the rear panel (item 2).Use the power cord

supplied with the unit (PN15-17-011 for 115 VAC, 60Hz). See the following table for

selecting the proper fuse rating. Use a metric, 5 x 20 mm sized, time-delayed fuse.

Power Setting (50 – 60 Hz) Fuse Rating THI P/N

100 VAC 0.315 Amp/250 VAC 23-05-038

115 VAC 0.60 Amp/250 VAC 23-05-039

230 VAC 0.70 Amp/250 VAC 23-05-040

Cords without plugs are supplied with units shipped outside of the U.S. Consult and comply with any

local laws and/or codes when connecting to any AC main. The AC input is user selectable between 100,

115 or 230 VAC, 50 or 60 Hz, via an AC selector switch next to the AC jack (Item 3).

WARNING: Be sure to set the power select switch prior to connecting to mains. Re-fuse the

connector according to the table above.

7.2. COMMUNICATIONS

Connectors J6 (Item 4), J7 (Item 6) and J9 (Item 6) are for RS-232, RS-485 connections respectively.

Settings for serial communication are accessible via the front panel.

J6 1 Unused

RS-232

(DB-9)

2 Tx

3 Rx

4 Unused

5 Gnd

6 Unused

7 RTS

8 CTS

9 Unused

J7, J9 1 Unused

RS-485

(DB-9)

2 Rx3 Tx+

4 Unused/Gnd (Gnd)

5 Unused

6 Gnd/VCC (VCC)

7 R+

8 T9 Unused

164-122012 Power

POD

400 Page 12 of 42

Page 13

7.3. TRANSDUCER CONNECTIONS

Connectors J1, 2, 3 and 4 (Item 7) are 15 pin D style connectors wired in the standard Hastings

Instruments pin-out (H pin-out).

J1, J2, J3, J4 1 NC

Transducer

Connectors

(DB-15)

(H-Pinout)

2 NC Valve Cntrl

3 NC mA Sig

4 NC mA Sig

5 Sig. Com.

6 Sig. In

7 Case Gnd.

8 Cntrl Over-ride 1.5mA

9 -15 VDC

10 NC

11 +15 VDC

12 Valve Return

13 NC Ext-In

14 Set Point Out

15 +5 VDC Ref. Not Used.

Voltage

7.4. ALARMS

Connector J8 (item 9) provides the user with open-collector, opto-isolated alarms for individual channels.

Each channel is provided with one user settable “High” and one “Low” alarm.

J8 1 Chnl 1, High Alarm

Open

Collector,

Opto-

Isolated, High

& Low

Alarms

(HD DB-26)

2 Chnl 1, Low Alarm

3 Chnl 1, Alarm Return

4 Chnl 2, High Alarm

5 Chnl 2, Low Alarm

6 Chnl 2, Alarm Return

7 NC

8 NC

9 NC

10 NC

11 NC

12 NC

13 NC

14 NC

15 NC

16 NC

17 NC

18 NC

19 Chnl 3, High Alarm

20 Chnl 3, Low Alarm

21 Chnl 3, Alarm Return

22 Chnl 4, High Alarm

23 Chnl 4, Low Alarm

24 Chnl 4, Alarm Return

25 NC

26 NC

164-122012 Power

POD

400 Page 13 of 42

Page 14

7.5. ANALOG SIGNAL FOLLOWERS

Analog signals from each channel’s transducers are available for reading or for sending to another power

supply for ratio (Master/Slave) operation. The signal can be sent to a channel on another power supply

and programmed as a Master for that power supply, allowing the remaining three channels to operate as

slaves. When operating 4 – 20 mA instruments, the followers supply a 0.5 -2.5 volt signal.

J5 1 Channel 1 Signal

2 Channel 1 Return

3 Channel 2 Signal

4 Channel 2 Return

5

6

Analog

Out

(HD DB-15)

7

8

9

10

11 Channel 3 Signal

12 Channel 3 Return

13 Channel 4 Signal

14 Channel 4 Return

15

164-122012 Power

POD

400 Page 14 of 42

Page 15

8.0 Manual Operation

8.1. POWER ON/OFF

The Power On switch, item 1 in rear panel drawing, is located in the upper right corner of the

rear panel. Insure that the proper power setting is selected prior to turning the power on. See

the Power section of WIRING THE POWER

8.2. CHANGING THE COMMAND SET POINT

Channel two (2), example shown.

Press the desired CHANNEL # key. An asterisk appears in the first space on the line representing the

selected channel. The meter display is immediately replaced with the current set point. Pressing a

number key begins the editing process. The cursor lands on the channel set point to be edited, and the

new command is entered with the most significant bit (MSB) first. The set point is filled in from left to

right on the display. When entering a new set point, you must use the decimal key when it has been

used in setting the SPAN. Pressing ENTER completes the editing process. The old command is not

changed until the ENTER key is actuated. Hitting the ESCape button at any time prior to the ENTER

key will return the display to its previous state without any changes being made. This command will not

be applied to the output until the channel is set for AUTO operation. See Setting a Channel to AUTO

Control.

POD

-400, above.

8.3. OVERRIDE OPEN

Press the desired CHANNEL # key. An asterisk appears in the first space on the line representing the

selected channel. The meter display is immediately replaced with the current set point. Pressing the

OPEN key results in the application of +15 VDC to pin number eight (8) of the corresponding 15 pin

Sub-D connector and returns the previously programmed metering function to the display.

8.4. OVERRIDE CLOSED

Press the desired CHANNEL # key. An asterisk appears in the first space on the line representing the

selected channel. The meter display is immediately replaced with the current set point. Pressing the

CLOSE key results in the application of -15 VDC to pin number eight (8) of the corresponding 15 pin

Sub-D connector and returns the previously programmed metering function to the display.

164-122012 Power

POD

400 Page 15 of 42

Page 16

8.5. SETTING A CHANNEL TO AUTO CONTROL

Press the desired CHANNEL # key. An asterisk appears in the first space on the line representing the

selected channel. The meter display is immediately replaced with the current set point. Pressing the

AUTO key causes pin number eight (8) of the 15 pin Sub-D connector to float and returns the previously

programmed metering function to the display. Pin 14 signal levels are now available for control.

8.6. SETTING A CHANNEL TO DIRECTLY METER INCOMING SIGNALS

Press the MODE key. The MODE menu appears in the display. To select METER, press 1, and then

ENTER. The METER menu allows the selection of the desired channel. Press the number key that

corresponds with the desired channel followed by ENTER. The previously programmed display returns

with the selected channel reading the signal between pins 5 and 6 of the corresponding channel’s 15 pin

D-connector (J1 – J4).

8.7. SETTING A CHANNEL TO DISPLAY THE TOTALIZER FUNCTION

The POWERPOD-400 provides an integrated (Riemann Sum) value of the incoming signal for each

channel.

=

)**(

fCfT∑= , where:

IS

Each channel samples the incoming signal at a rate

corresponding to the preset A/D conversion rate in Hz. At

each sampling interval, the TOTALIZER function multiplies

the average signal, as a fraction of the full-scale value (5v, 10v

or 20 mA), times the span, or cal, value. This results in a rate

for that interval. Next, a time element factor is determined

according to the flow rate programmed for that channel as

follows.

For a time element of seconds, the factor is 1/10.

For minutes, the factor is 1/600.

Hours use a factor of 1/36000.

Each calculation is summed and stored for a TOTAL value.

TotalT

⎧

⎪

=

⎪

S

⎨

=

⎪

⎪

=

I

⎩

FactorSignalFractionalf

ValueSpanorvalueCALC

IntervalTimeFractionalf

⎫

⎪

⎪

⎬

⎪

⎪

⎭

164-122012 Power

POD

400 Page 16 of 42

Page 17

Example (See Graph):

A linear flow transducer with a DC output of 0 to 5 volts is calibrated for a maximum flow of 25 SLH.

The transducer is connected to one channel of a POWER

volts input and has been programmed to display rate in SLH. The transducer is sending a constant 1.000volt signal to the POWERPOD-400. What is the total flow after 40 minutes?

During one sampling interval, the TOTALIZER reads the one-volt signal and calculates the fraction of the

possible full-scale value.

1 volt/5 volts or 0.20

The fractional signal value is multiplied times the CAL value

1/5 * 25 = 5

Then, because the channel’s programmed rate is in SLH (standard liters per hour), a factor of 1/3600 is

applied to the result.

5 * 1/36000 = 1.389 x 10^-4 standard liters per sampling interval.

A constant signal received over a 40 minute time period would amount to 40 minutes * 60 seconds * 10

samples per second = 24000 samples. The TOTAL would be

2.400 E03 * 1.389 E-04 = 3 1/3 Std Liters.

If no rate is programmed on that channel, The TOTALIZER function is disabled for that channel and the

display returns to its regular metering configuration.

POD

-400 which is CAL’d to read 25.000 at 5

To enable the TOTALIZER, press the MODE key. The MODE menu appears in the display. To select

TOTAL, press 2, and then ENTER. The TOTALIZER menu allows the operator to select the desired

channel. Press the number key that corresponds with the desired channel followed by ENTER. A

TOTALIZER menu is presented that allows the operator to go directly to displaying whatever the

Totalizer has currently stored as the total or to reset the counter. If DISPLAY is selected by pressing the

number 1 key followed by ENTER, the display will return to normal with the most recently stored total

being displayed on the appropriate line. If RESET is chosen by pressing the number 2 key followed by

ENTER, the display returns with the total value reset according to the pre-selected counting mode

presented in the table below with the Totalizer counting.

164-122012 Power

Mode Reset Value

Count Down Set Point

Count Up Zero

Continuous Zero

POD

400 Page 17 of 42

Page 18

9.0 External/Remote Operation

9.1. SELECTING EXTERNAL/REMOTE OPERATION (Front Panel Only)

The POWER

The following text describes how to choose and activate the desired method. Further information and

instructions on how conditions may be changed can be found in section 10, SETUP/CAL mode.

POD

-400 allows the user to select different methods of serial communication and control.

9.2. CHOOSING RS-232 COMMUNICATION

Press the MODE button. The MODE menu is displayed. Press the number “4” key for XTRNL

CNTRL. The XTRNL CNTRL menu is displayed. Choose RS-232 by pressing the number “1” key.

The normal display will return to its previously programmed state.

9.3. CHOOSING RS-485 COMMUNICATION

Press the MODE button. The MODE menu is displayed. Press the number “4” key for XTRNL

CNTRL. The XTRNL CNTRL menu is displayed. Choose RS-485 by pressing the number “2” key.

The normal display will return to its previously programmed state.

164-122012 Power

POD

400 Page 18 of 42

Page 19

10.0 Setup/Cal Mode

10.1. ENTERING THE SETUP/CAL MODE

Pressing the MODE key causes the MODE menu to be displayed. Choose the SETUP/CAL mode by

pressing the number “3” key then ENTER. A CHANNEL SELECT menu is presented on the display.

It should be noted that, although the user must select a specific channel number, some choices in the

following menus may affect the operation of all channels and/or the display (ex; Display Brightness, type of

communication). See the following menu options for more details.

10.2. DISPLAY SETUP

After entering the SETUP/CAL mode and selecting a channel number as described in the previous

section, several selections are available that will affect the display. Follow the steps below to gain the

desired customized display.

Note: Front panel lockout and display line (channel) blanking are only available

through serial communication.

10.2.1. Blanking a Display Line/Channel

Use the serial command “DndCr”, where

n = channel number,

d = 1 for Totalizer Mode,

2 for Meter Mode,

3 for a blanked line and

Cr = carriage return.

10.2.2. Selecting Display Brightness

While the SETUP/CAL menu is displayed, choose DISPLAY by pressing the keys “1” + ENTER.

Choose BRIGHTNESS by pressing the number “1” key + ENTER. The BRIGHTNESS menu will be

visible. One of four different brightness levels can be chosen by pressing a number key. The number “1”

key selects the dimmest setting while the number “4” key selects the brightest. Any change in brightness

will affect the entire display after pressing the ENTER key.

164-122012 Power

POD

400 Page 19 of 42

Page 20

10.2.3. Selecting Unit-of-Measure

After entering the SETUP/CAL mode and after selecting a channel number, the SETUP/CAL menu

is displayed. Choose DISPLAY (1) + ENTER and then select UNITS by pressing the number “2” key +

ENTER. The UNITS menu will be displayed allowing the selection of over 50 different units of measure

(UOM) simply by pressing the number key corresponding to the desired UOM. The number can be

found by scrolling up or down until the desired UOM is displayed or by consulting Appendix B, at the end

of this manual. Once selected, the UOM will be displayed in character spaces 10 to 14 on the appropriate

line. Selecting UOM = “0” results in the UOM characters being blanked.

10.2.4. Selecting Gas ID

While the SETUP/CAL menu is displayed, Select the DISPLAY menu by pressing 1 + ENTER. Then

choose GASID by pressing 3 + ENTER. The GASID menu will be displayed allowing the selection of

nearly one hundred different chemical symbols simply by pressing the number key corresponding to the

desired gas. The number can be found by scrolling up or down until the desired gas is displayed or by

consulting Appendix C at the end of this manual. Once selected, the formula will be displayed in

character spaces 16 through 20 on the appropriate line.

Note: Formulae too long to be completely displayed will display the Hastings

Instruments Gas ID number. Choosing “0” will blank the GASID elements on the

display.

10.2.5. Setting A/D Conversion Rate (Filter)

Press the MODE button. The MODE menu is displayed. Press the number “3” key followed by

ENTER. The CHANNEL SELECT menu is displayed. Choose the channel whose signal is to be

filtered using the number keys. For example, “1” + ENTER. The SETUP/CAL menu is displayed.

164-122012 Power

POD

400 Page 20 of 42

Page 21

After SETUP/CAL is selected and a channel number has been chosen, the SETUP/CAL menu is

displayed. choose DISPLAY by pressing the number “1” key + ENTER. The FILTER option can

be reached by scrolling down once to view the selection number and then pressing the “4” key +

ENTER. A conversion rate of 4, 15, 30 or 100 Hertz may be selected by entering its menu number

+ ENTER. Enter the number of the desired A/D conversion rate and press ENTER. The normal

display will return. Changes may be noticed in the flickering of the LSB on the display. In most

situations, the flickering digits are an insignificant fraction of the display range and can be ignored.

Should the flickering become annoying or make reading the display difficult, choose a slower rate

of conversion.

NOTE: Slower rates of conversion may affect the accuracy of the TOTALIZER in

situations where flow is changing often. Steady flow rates will see little loss of

TOTALIZER accuracy.

10.2.6. Front Panel Lock Out

Front Panel Lockout is available only through serial communication. See the SERIAL

COMMUNICATIONS section of this manual and Appendix A.

CAUTION: While the front panel is locked out, all command functions, excluding

the override functions, are disabled. Commands can be overridden OPEN or

overridden CLOSED during front panel lockout. This was determined to be useful

both as a trouble shooting and as a safety tool. All other functions will be available

only through the use of serial communication.

10.3. TOTALIZER SETUP

The TOTALIZER can be set to count up to a set point, to count down from a set point or to count up

continuously to the maximum ability of the display (999999). In order for the TOTALIZER to work, a

unit of measure must be chosen that includes a time element. For example, standard liters per hour

(SLH) will totalize; percent (%) will not. Each mode is described in the following text and can be followed

in the diagram below.

10.3.1. Count Up to a Set Point

The TOTALIZER will be set to count from zero (0) to a set point. When the set point is reached, a

memory flag will be set to its logic high state. This flag is readable only through serial

communications. The TOTALIZER will continue to count up to the maximum ability of the display.

While the SETUP/CAL menu is displayed, choose TOTAL by pressing the number “2” key followed by

ENTER. A TOTALIZER menu is displayed. Press the number “1” key to choose the CNT UP option.

The COUNT UP/DN window is displayed for the selected channel. Enter the desired set point using the

numbered key pads and press ENTER. The unit returns the previously programmed display with the

selected channel now displaying the Riemann Sum of the received transducer signal.

164-122012 Power

POD

400 Page 21 of 42

Page 22

10.3.2. Count Down from a Set Point

The TOTALIZER will be set to count from a preset value to zero (0). When zero is reached, a

memory flag will be set to its logic high state. This flag is readable only through serial

communications. The TOTALIZER will continue to count in the negative direction from zero to the

maximum ability of the display (-999999).

While the SETUP/CAL menu is displayed, choose TOTAL by pressing the number “2” key + ENTER.

A TOTALIZER menu is displayed. Press the number “2” key to choose the CNT DN option. The

COUNT UP/DN window is displayed. Enter the desired set point using the numbered key pads and

press ENTER. The unit returns the previously programmed display with the selected channel now

displaying the set point minus the Riemann Sum of the received transducer signal.

10.3.3. Count Continuously

The TOTALIZER will be set to count from zero (0) to the maximum ability of the display. No flags or

alarms will be set.

While the SETUP/CAL menu is displayed, choose TOTAL by pressing the number “2” key and

ENTER. A TOTALIZER menu is displayed. Press the number “3” key to choose the CONT option

followed by the ENTER key. The previously programmed display returns with the selected channel now

displaying the Riemann Sum of the received transducer signal.

10.4. EXTERNAL COMMUNICATION SETUP

The following text describes how the POWER

communication. Instruction structure and syntax is covered in the section, Serial Protocol.

POD

-400 can be setup to respond to serial and network

10.4.1. RS-232 Settings

From

SETUP/CAL

Menu

After selecting SETUP/CAL, select any channel number and hit ENTER, choose option number 3 via

the numbered key pad. The first menu to be displayed is the BAUD menu. To select the desired baud

rate press the number key 1 or 2 respectively. Eight bit bytes, no parity, one stop bit and no handshaking

are automatically set. The preprogrammed display is returned upon completion.

10.4.2. RS-485 Settings

From

SETUP/CAL

Menu

After selecting SETUP/CAL, select any channel number and hit ENTER, choose option number 3 via

the numbered key pad. The BAUD menu will be displayed. To select the desired baud rate press the

corresponding number key.

164-122012 Power

POD

400 Page 22 of 42

Page 23

The default address as programmed at the factory is 01. If a different address is required, it may be

changed using either RS-232 or 485. After making the proper serial connections, use the command *00X

to read the default address. Use *00Xdd, where dd = the new address. If the old address is known, use

DDXdd, where DD is the old address and dd is the new address. See the section on "Serial

Communication: Commands" for more on command structure.

All commands listed in Appendix B are available for RS-485 use by inserting an asterisk and the unit's

address in front of the command.

Ex) Set the units of measure on channel two (2) to %.

*10UM203Cr

The command, *00XCr can be used to poll the unit for its current address setting using either RS-232 or

RS-485.

10.5. SELECTING THE ANALOG SIGNAL LEVEL

The POWER

selectable. The following diagram applies no matter which level of operation is chosen.

From

SETUP/CAL

Menu

POD

-400 is capable of 0 to 5 V, 0 to 10 V or 4 to 20 mA operation. Each level is user

10.5.1. Zero to Five Volt Operation

While in the SETUP/CAL menu, select ANALOG by pressing the number 4 key and the ENTER key.

From the ANALOG SIGNAL menu, choose 0V – 5V by pressing the number 1 key and pressing the

ENTER key. The normal display returns with 0 volts intended to correspond to 0% signal and 5 volts

intended to correspond to the 100% signal. Calibration may be required.

10.5.2. Zero to Ten Volt Operation

While in the SETUP/CAL menu, select ANALOG by pressing the number 4 key and the ENTER key.

From the ANALOG SIGNAL menu, choose 0V – 10V by pressing the number 2 key and pressing the

ENTER key. The normal display returns with 0 volts intended to correspond to 0% signal and 10 volts

intended to correspond to the 100% signal. Calibration may be required.

10.5.3. Four to Twenty Milliamp Operation

While in the SETUP/CAL menu, select ANLG by pressing the number 4 key and the ENTER key.

From the ANALOG SIGNAL menu, choose 4mA – 20 mA operation by pressing the number 3

key and pressing ENTER. The normal display returns with 4 milliamps intended to correspond to

0% signal and 20 milliamps intended to correspond to the 100% signal. Calibration may be

required.

164-122012 Power

POD

400 Page 23 of 42

Page 24

10.6. SETTING LIMIT ALARMS

POD

Each channel of the POWER

400 has one high limit alarm and

one low limit alarm. Each alarm is

provided by an open-collector,

opto-isolated signal at a

corresponding pin on the rear

panel, connector J8. Use the

provided diagram when referring

to the text below.

From

SETUP/CAL

Menu

-

10.6.1. Setting a Single Channel’s High Limit

After selecting a channel in the SETUP/CAL menu, choose ALARMS by pressing the number 5 key

followed by the ENTER key. The ALARMS menu will be displayed. Pressing the number “1” key

selects the HIGH LIMIT display. Using the number keys, enter the desired high limit level and then

press ENTER. EXIT the loop by pressing the number “4” + ENTER key while the ALARMS menu is

displayed.

10.6.2. Setting a Single Channel’s Low Limit

After selecting a channel in the SETUP/CAL menu, choose ALARMS by pressing the number 5 key.

The ALARMS menu will be displayed. Pressing the number 2 key selects the LOW LIMIT display.

Using the number keys, enter the desired high limit level and then press ENTER. EXIT the loop by

pressing the number 4 key while the ALARMS menu is displayed, followed by ENTER.

10.6.3. Setting a Single Channel’s Hysteresis

After selecting a channel in the SETUP/CAL menu, choose ALARMS by pressing the number 5 key. The

ALARMS menu will be displayed. Pressing the number 3 key selects the HYSTERESIS display. Using

the number keys, enter the desired degree of Hysteresis followed by the ENTER key. EXIT the loop by

pressing the number 4 key while the ALARMS menu is displayed, followed by ENTER.

164-122012 Power

POD

400 Page 24 of 42

Page 25

10.7. SETTING RATIO CONTROL PARAMETERS

Enabling Ratio Control

Ratio control is achieved through the SETUP/CAL menu. Ratio Control is activated by selecting channel

number one (1) and enabling it as master. After enabling channel one, the operator may assign the

channels that will follow its signal by some factor.

Press the MODE key and then 3 + ENTER. Select channel one by pressing 1 + ENTER. Choose

RATIO by pressing the 6 key + ENTER. Channel one (1) is enabled as the master when you press 2 +

ENTER.

After enabling RATIO control, a series of menus labeled SLAVE A, SLAVE B and SLAVE C will be

displayed. These menus correspond to channels 2, 3 and 4 respectively. Each of the channels, 2 through

4, can be enabled or disabled individually. For example, pressing the 1 key + ENTER while SLAVE A is

being displayed will eliminate channel two (2) from ratio control and allow channel two to work normally

as an independent channel. Pressing the number 2 key + ENTER will make channel 2 the first SLAVE

and an S will appear in the first column of line two on the display. Note that, if EXIT is selected at any

time, the previous settings remain unchanged and the display is returned to its previously programmed

configuration.

164-122012 Power

POD

400 Page 25 of 42

Page 26

10.8. CALIBRATING A CHANNEL TO ITS INCOMING SIGNALS

The POWER

POD

-400 is designed to accept the input from almost any transducer that operates in the

ranges of zero to five volts, zero to ten volts or four to twenty milliamps. In most cases, transducers are

capable of having their minimum signal and maximum signal adjusted to correspond with the minimum

(ZERO) and maximum (SPAN) unit-of-measure that they are designed to reflect.

For example:

A transducer designed to output 0 volts while reading a temperature of 0 degrees centigrade and output 5

POD

volts while reading 100 degrees centigrade is connected to channel one of the POWER

-400.

In actuality, the transducer is sending -0.23 volts at 0 degrees and 5.11 volts at 100 degrees. By zeroing

POD

channel one of the POWER

-400 while reading the low signal from the transducer, the display will be

000.0 when the temperature is 0°C. Like wise, by setting the CAL value to 100.0 while reading the 5.11

volt signal causes the POWER

POD

-400 to display 100.0 when the temperature is actually 100°C.

This procedure will not account for any non-linearity in any transducer’s output. That is, the

accuracy/calibration of any transducer must be independently set, checked and verified before

connecting to the POWER

POD

-400, or, the transducer/ POWER

POD

-400 combination must be

calibrated together as a system, if the accuracy of the whole system is to be known.

10.8.1. Resetting the Zero Only

While the SETUP/CAL menu is being displayed and after making a selection from the CHANNEL

SELECT menu, select CALIBRATE by pressing the number 7 key followed by ENTER, then choose

ZERO ONLY by pressing the number 1 key and ENTER. The ZERO menu will be displayed which also

displays the selected channel number and the signal being received. If this signal is an acceptable signal

for zero, press the ENTER key to accept it. If the indicated signal is not an acceptable level for reading

zero, the operator has an opportunity at this stage to correct any problems while reading the incoming

signal before pressing the ENTER key and accepting it. Alternatively, the operator can press ESC to exit

the SETUP/CAL mode and return to it later. After accepting the displayed signal level as the zero point,

the display returns to its previously programmed settings. See Appendix D.

10.8.2. Resetting the Span Only

After selecting a channel in the CHANNEL SELECT portion of the SETUP/CAL menu, press 7 +

ENTER to select CALIBRATE. SPAN ONLY is selected by pressing number 3 + ENTER. The

SPAN window is displayed which contains the chosen channel and the incoming signal on that channel.

If the displayed signal is an acceptable full range value, press ENTER to accept it. The previously

programmed display returns with the selected channel now displaying the CAL’d value. If the incoming

164-122012 Power

POD

400 Page 26 of 42

Page 27

signal is not an acceptable full range value, the operator has an opportunity to correct any problems at this

stage prior to pressing ENTER. Alternatively, the operator can press ESC to exit SETUP/CAL and

return later. See Appendix D.

10.8.3. Resetting Zero and Span

Should it be required to zero and set a new span value for a given channel, The menu option is provided

that will present the programmer with the zero menu first, followed by the span, or cal, menu. After

selecting a channel in the CHANNEL SELECT portion of the SETUP/CAL menu, press the number 7

key to select CALIBRATE. ZERO & SPAN is selected by pressing the number 2 key. The ZERO

window is displayed first. It contains the chosen channel and the incoming signal on that channel. If the

signal displayed is within an acceptable range for zero, Press the ENTER key to accept this signal as

representing a display of zero while monitoring the transducer. If this signal is not appropriate, the user

may correct the problem while the window is displayed or press the ESC key and come back at a later

time to zero and span.

After setting the zero of the power supply, the SPAN menu window is displayed. If the displayed signal is

an acceptable full range value, press ENTER to accept it. The previously programmed display returns

with the selected channel now displaying the CAL’d value. If the incoming signal is not an acceptable full

range value, the operator try to correct any problems at this stage prior to pressing ENTER or, by pressing

the ESC key, they can exit SETUP/CAL and return to perform this procedure at a later date. See

Appendix D.

10.8.4. Setting a Multiplication Factor

For convenience, it is possible to leave a channel setup one way and merely multiply the display value by

some factor and replace the display with the new value. An example might be to set up a channel to read

from zero to one hundred percent and use a multiplication factor to make the display read from zero to

500 SCCM. An infinite number of possibilities are possible.

Once a channel in the CHANNEL SELECT portion of the SETUP/CAL menu has been selected, press

the number 7 key to select CALIBRATE. From the CALIBRATE menu, choose MULTIPLIER by

pressing the number 4 key. While the MULTIPLIER window is in the display, enter the multiplication

factor and press ENTER. The display returns to normal with the selected channel now displaying the

product of the normally displayed value and the entered factor.

164-122012 Power

POD

400 Page 27 of 42

Page 28

10.9. SERIAL COMMUNICATION

Follow the instructions in the section, WIRING THE POWER

serial communication with the unit. After insuring that the POWER

POD

-400 for cabling and proper pin out for

POD

-400 is wired properly, the unit

must be set up following the instructions in the section entitled, External Communications Setup.

POD

The instruction set for the POWER

-400 can be divided into two different types. They differ only in

that they

1. Write a command only or

2. Write a command and read a response.

Taking liberty with this vernacular, they may be differentiated using the terms COMMAND or QUERY.

The entire set of instructions can be found in Appendix B.

10.9.1. Commands

Typical RS-232 command structure is as follows: CMNDn<value>Cr

For example: To change channel three’s high alarm value to 75.00, send A3H075.00Cr.

RS-485 commands require only that an asterisk and the unit’s address precede the RS-232 Command.

Using the same example as above with a unit whose address is 10 (default), send *10A3H075.00Cr.

POD

When the POWER

shorted to add the required terminating resistors. Remove two machine screws from the rear of the top

cover. Slide the cover off. The two jumpers are near the serial communication connectors.

-400 is the terminating unit on a 485 bus, two jumpers, CJ1 and CJ2 can be

10.9.2. Set Point Queries

Queries are used when information from the unit is required. Each query is followed by a response from

the POWERPOD-400.

In this case, the query is asking for a programmed value. Specifically, the set point of channel three, which

happens to be set at 50.00 of 100.00.

Sent SP3Cr

Response SP3 050.00

10.9.3. Alarm/Flag Queries

The state of the high and low flow alarms for each channel can be monitored via the DB-15 connecter (J8)

on the rear panel for immediate action from an alarm situation but the Totalizer set points can only be

monitored by reading a memory location’s Boolean setting via serial communication.

As shown in the section, Setting Limit Alarms, to simply QUERY channel three’s high alarm set point,

send A3HCr. Expect a response similar to A3H 075.00. The actual state of the alarm can be polled using

the STATUS query.

STCr

Which results in a response similar to

STATUS

OCA : CH1 AUTO CH2 CLOSED CH3 OPEN CH4 AUTO

HI/LO: 0/0 0/1 1/0 0/0

OCA is short for OPEN/CLOSED/AUTO.

HI/LO stands for the high flow limit alarm or the low flow limit alarm. One must parse the states if digital

tests are to be conducted.

164-122012 Power

POD

400 Page 28 of 42

Page 29

To query the status of the totalizer flag on channel four (4), use the following command.

TF4Cr

The response will be either TF4 0 corresponding to a Boolean ‘FALSE’ indication that the totalizer flag

has not been set, or TF4 1, a Boolean ‘TRUE’, indicating that the total is equal to or beyond the totalizer

set point..

D41Cr command tells channel four (4) to display the TOTAL. It is not necessary that the front panel

read the total for the TOTALIZER to work. The Totalizer works in the background no matter what mode

the display is in.

NOTE: It must be emphasized that, if the total reaches the maximum of the

display (±999999), the unit effectively stops counting.

164-122012 Power

POD

400 Page 29 of 42

Page 30

Pod

11.0 Appendix A

Power

Command Name Query Response

Channel 1 Display C1 CH1 ddd.dd U of M GasID

Channel 2 Display C2 CH2 ddd.dd U of M GasID

Channel 3 Display C3 CH3 ddd.dd U of M GasID

Channel 4 Display C4 CH4 ddd.dd U of M GasID

All Channels’ Display C5

SP1<dd.ddd> Set Point - Channel 1 SP1 SP1 ddd.dd notes 1, 2

SP2<dd.ddd> Set Point - Channel 2 SP2 SP2 ddd.dd

SP3<dd.ddd > Set Point - Channel 3 SP3 SP3 ddd.dd

SP4<dd.ddd > Set Point - Channel 4 SP4 SP4 ddd.dd

A1H<dd.ddd > Alarm Set Point, Ch1, High A1H A1H ddd.dd notes 1, 2

A1L<dd.ddd > Alarm Set Point , Ch1, Low A1L A1L ddd.dd

A2H<dd.ddd > Alarm Set Point , Ch2, High A2H A2H ddd.dd

A2L<dd.ddd > Alarm Set Point , Ch2, Low A2L A2L ddd.dd

A3H<dd.ddd > Alarm Set Point , Ch3, High A3H A3H ddd.dd

A3L<dd.ddd > Alarm Set Point , Ch3, Low A3L A3L ddd.dd

A4H<dd.ddd > Alarm Set Point , Ch4, High A4H A4H ddd.dd

A4L<dd.ddd > Alarm Set Point , Ch4, Low A4L A4L ddd.dd

HY1<ddd> Hysteresis, Ch1 HY1 HY1 ddd

HY2<ddd> Hysteresis, Ch2 HY2 HY2 ddd

HY3<ddd> Hysteresis, Ch3 HY3 HY3 ddd

HY4<ddd> Hysteresis, Ch4 HY4 HY4 ddd

UM1<dd> Unit of Meas, Ch1 UM1 UM1 dd

UM2<dd> Unit of Meas, Ch2 UM2 UM2 dd

UM3<dd> Unit of Meas, Ch3 UM3 UM3 dd

UM4<dd> Unit of Meas, Ch4 UM4 UM4 dd

GS1<ddd > Gas ID, CH1 GS1 GS1 ddd

GS2<ddd > Gas ID, CH2 GS2 GS2 ddd

GS3<ddd > Gas ID, CH3 GS3 GS3 ddd

GS4<ddd > Gas ID, CH4 GS4 GS4 ddd

IN1<d> I/O Select, Ch1 IN1

IN2<d> I/O Select, Ch2 IN2

IN3<d> I/O Select, Ch3 IN3

IN4<d> I/O Select, Ch4 IN4

FL1<d> Filter Setting, Ch1 FL1 FL1 d

FL2<d> Filter Setting, Ch2 FL2 FL2 d

FL3<d> Filter Setting, Ch3 FL3 FL3 d

FL4<d> Filter Setting, Ch4 FL4 FL4 d

ML1<d.dddd> Multiplier, CH1 ML 1 ML 1 dddd.d notes 1, 2

ML2<dd.ddd> Multiplier , CH2 ML 2 ML 2 ddd.dd

ML 3<ddd.dd> Multiplier , CH3 ML 3 ML 3 dd.ddd

ML 4<dddd.d> Multiplier , CH4 ML 4 ML 4 d.dddd

-400 Serial Commands

CH1 ddd.dd U of M GasID

CH2 ddd.dd U of M GasID

CH3 ddd.dd U of M GasID

CH4 ddd.dd U of M GasID

IN1 d

rz - r

IN2 d

rz - r

IN3 d

rz - r

rz - r

IN4 d

fs

fs

fs

fs

notes 6, 7

164-122012 Power

POD

400 Page 30 of 42

Page 31

APPENDIX A (Cont.)

Pod

Power

Command Name Query Response

D1<d > Ch1 Disp Mode D1 d note 5

D2<d> Ch2 Disp Mode D2 d

D3<d > Ch3 Disp Mode D3 d

D4<d > Ch4 Disp Mode D4 d

T1S<dddddd> Totalizer Set Point, Ch1 T1S T1S dddddd

T2S<dddddd> Totalizer Set Point, Ch2 T2S T2S dddddd

T3S<dddddd> Totalizer Set Point, Ch3 T3S T3S dddddd

T4S<dddddd> Totalizer Set Point, Ch4 T4S T4S dddddd

T1M<d> Totalizer Mode, Ch1 T1M T1M d note 8

T2M<d> Totalizer Mode, Ch2 T2M T2M d

T3M<d> Totalizer Mode, Ch3 T3M T3M d

T4M<d> Totalizer Mode, Ch4 T4M T4M d

T1R Totalizer Reset, Ch1 note 8

T2R Totalizer Reset, Ch2

T3R Totalizer Reset, Ch3

T4R Totalizer Reset, Ch4

Totalizer Flag, Ch1 TF1 TF1 d note 9

Totalizer Flag, Ch2 TF2 TF2 d

Totalizer Flag, Ch3 TF3 TF3 d

Totalizer Flag, Ch4 TF4 TF4 d

SN1<d.dddd> Cal Value, CH1 SN1 SN1 d.dddd notes 1, 2

SN2<dd.ddd> Cal Value, CH2 SN2 SN2 d.dddd

SN3<ddd.dd> Cal Value, CH3 SN3 SN3 d.dddd

SN4<dddd.d> Cal Value, CH4 SN4 SN4 d.dddd

Z1 Zero Ch1

Z2 Zero Ch2

Z3 Zero Ch3

Z4 Zero Ch4

F1 Set Full Scale Value, Ch1

F2 Set Full Scale Value, Ch2

F3 Set Full Scale Value, Ch3

F4 Set Full Scale Value, Ch4

Status, All Channels ST

R1<d> Ratio Mode, Ch1 R1 R1 d note 11

R2<d> Ratio Mode, Ch2 R2 R2 d

R3<d> Ratio Mode, Ch3 R3 R3 d

R4<d> Ratio Mode, Ch4 R4 R4 d

BR<d> Baud Rate BR BR d note 12

RE<d> Front Panel Lock Out RE REn: REMOTE/LOCAL note 13

*00X<dd> Multi-drop Address *00X MULTIDROP ADDRESS: dd

-400 Serial Commands (Cont'd)

OCA: CH1 text CH2 text Note 10

CH3 text CH4 text

HI/LO: CH1 d/d CH2 d/d

CH3 d/d CH4 d/d

164-122012 Power

POD

400 Page 31 of 42

Page 32

APPENDIX A (Notes:)

1. All returned values will include decimal points wherever unit has been programmed to display them.

2. All Commands needing decimal points must include them wherever they are intended to be displayed.

3. d = decimal digit (ASCII)

4. n = Channel Number

⎧

5.

⎪

⎪

⎨

⎪

⎪

⎩

=

=

=

,3

6. rz = range, zero; . r

#:

channelselectedBlanksd

= range, full scale

fs

MassUnitsTotalDisplaysd

RateUnitsFlowDisplaysd

⎫

⎪

)(,1

⎪

⎬

)(,2

⎪

⎪

⎭

=

ChnlnDnd

=

ChnlnINnd

7.

8.

9.

⎧

⎪

⎪

⎨

⎪

⎪

⎩

⎧

⎪

⎪

⎨

⎪

⎪

⎩

⎧

=

⎪

⎨

⎪

⎩

#:

−=

VDCd

50,1

−=

VDCd

100,2

−=

mADCd

204,3

=

ChnlnTnMd

#:

=

=

=

ChnlnTFnd

#:

<=

≥=

⎫

⎪

⎪

⎬

⎪

⎪

⎭

⎫

Re,,1

ZerotosetsUpCountsTotalizerd

PoSettosetsDownCountsTotalizerd

Re,,3

⎪

⎪

⎬

intRe,,2

⎪

⎪

ZerotosetslyContinuousCountsTotalizerd

⎭

⎫

⎪

PoSetTotald

PoSetTotald

int,0

⎬

⎪

int,1

⎭

10. text = “OPEN” or “CLOSE”

d = 0 or 1

#:

ChnlnRnd

=

=

==19200,2

==REMOTEd

⎫

⎪

1

Enabledd

==

,2

Disabledd

9600,1:ddBRd

⎬

⎪

⎭

⎫

⎬

⎭

LOCALdREd

,1:

,2

⎫

⎬

⎭

11.

12.

13.

⎧

⎪

⎨

⎪

⎩

⎧

⎨

⎩

⎧

⎨

⎩

164-122012 Power

POD

400 Page 32 of 42

Page 33

12.0 Appendix B 13.0 Appendix C

# Name Rate Total # Name Rate Total

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Units-of-Measure for Meter Reading & Corresponding Totalizer Units

Standard Cubic Centimeters per Minute SCCM SCC

Standard Liters per Minute SLM SL

Percent %

Volts V

Millivolts MV

Counts CNT

Normal Liters per Minute NLM NL

Standard Liters per Second SLS SL

Normal Liters per Second NLS NL

Standard Liters per Hour SLH S L

Normal liters per Hour NLH NL

Standard Mililiters per Minute SMLM SML

Normal Mililiters per Minute NMLM NML

Standard Mililiters per Second SMLS SML

Normal Mililters per Second NMLS NML

Standard Mililiters per Hour SMLH SML

Normal Mililiters per Hour NMLH NML

Normal Cubic Centimet ers per Minute NCCM NCC

Standard Cubic Centimeters per Second SCCS SCC

Normal Cubic Centimeters per Second NCCS NCC

Standard Cubic Centimeters per Hour SCCH SCC

Normal Cubic Centimet ers per Hour NCCH NCC

Standard Cubic Feet per Minute SCFM SCF

Normal Cubic Feet per Minute NCFM NCF

Standard Cubic Feet per Second SCFS SCF

Normal Cubic Feet per Second NCFS NCF

Standard Cubic Feet per Hour SCFH SCF

Normal Cubic Feet per Hour NCFH NCF

Standard Cubic Meters per Minute SCMM SCM

Normal Cubic Meters per Minute NCMM NCM

Standard Cubic Meters per Second SCMS SCM

Normal Cubic Meters per Second NCMS NCM

Standard Cubic Meters per Hour SCMH SCM

Normal Cubic Meters per Hour NCMH NCM

Standard Cubic Inches per Minute SCIM SCI

35

Normal Cubic Inches per Minute NCIM NCI

36

Standard Cubic Inches per Second SCIS SCI

37

Normal Cubic Inches per Second NCIS NCI

38

Standard Cubic Inches per Hour S CI H SCI

39

Normal Cubic Inches per Hour NCIH NCI

40

Pounds per Minute LBM LB

41

Pounds per Second LBS LB

42

Pounds per Hour LBH LB

43

Kilograms per Minute KgM Kg

44

Kilograms per Second KgS Kg

45

Kilograms per Hour KgH Kg

46

Grams per Minute GRM GR

47

Grams per Second GMS GR

48

Grams per Hour GRH GR

49

Moles per Minute MolM Mol

50

Moles per Second MolS Mol

51

Moles per Hou r MolH Mol

52

Kilomoles per Minute KMolM KMol

53

Kilomoles per Second KMolS KMol

54

Kilomoles per Hour KMolH KMol

55

Watts W

56

Bits per Second BPS Bits

57

Seconds Sec

58

Minutes Min

59

Hours Hrs

60

Watt * Hours WH W

61

Torr Torr

62

Bar Bar

63

Pascals Pa

64

Inches of Water inH2O

65

Pounds per Square Inch, Absolute PSIA

66

Pounds per Square Inch, Gage PSIG

67

164-122012 Power

POD

400 Page 33 of 42

Page 34

Gas ID Table (Page 1 of 2)

#

1 Acetic Acid 1 46 Diethyl Ether 46 91 Hydrogen Cyanide CHN

Acetic Acid, Anhydride 2

2

3 Acetone C

Acetonitryl C2H3N

4

5 Acetylene C

Air Air

6

7 Allene C

Ammonia NH3

8

9 Argon Ar 54 Ethane, 1-chloro-1,1,2,2-tetrafluoro- 54 99 Isopentane C

Arsine AsH3

10

11 Benzene C

Boron Trichloride BCl3

12

13 Boron Triflouride BF

Bromine Br2

14

15 Bromochlorodifluoromethane 15 60 Ethyl Bromide 60 105 Methanol CH

Bromodifluoromethane 16

16

17 Bromotrifluormethane CBrF

Butane C4H10

18

19 Butanol 19 64 Ethylene Dibromide 64 109 Methyl Bromide CH

Butene C4H8

20

21 Carbon Di oxide CO

Carbon Disulfide CS2

22

23 Carbon Monoxide CO 68 Ethylidene Dichloride 68 113 Methyl Ethyl Ether C

Carbon Tetrachloride CCl4

24

25 Carbonyl Sulfide COS 70 Fluorine F

Chlorine Cl2

26

27 Chlorine Trifluoride ClF

Chlorobenzene 28

28

29 Chlorodifluoroethane 29 74 Freon 13 CClF

Chloroform CHCl3

30

31 Chloropentafluoroethane 31 76 Freon 22 76 121 Neon Ne

Chloropropane 32

32

33 Cisbutene C

Cyanogen C2N2

34

35 Cyanogen Chloride ClCN 80 Helium He 125 Nitrogen Tetroxide N

Cyclobutane C4H8

36

37 Cyclopropane C

Deuterium H22

38

39 Diborane B2H6 84 Hexane C

Dibromodifluoromethane 40

40

41 R21 R21 86 Hexene C

Dichloromethane 42

42

43 Dichloropropane 43 88 Hydrogen H

Dichlorosilane 44

44

45 Diethyl Amine 45 90 Hydrogen Chloride HCl 135 Pentaborane B

GAS NAME Symbol # GAS NA ME Symbol # GAS NAME Symbol

Diethyl Sulfide 47

47

O 48 Difluoroethylene 48 93 Hydrogen Iodide HI

3H6

Dimethylamine C2H7N

49

50 Dimethyl Ether C2H6O 95 Hydrogen Sulfide H2S

2H2

Dimethyl Sulfide C2H6S

51

52 Divinyl C4H6 97 Isobutanol 97

3H4

Ethane C2H6

53

Ethane, 1-chloro-1,2,2,2-tetrafluoro- 55

55

56 Ethanol C2H6O 101 Isoxazole 101

6H6

Ethylacetylene C4H6

57

58 Ethyl Amine C2H7N 103 Krypton Kr

3

Ethylbenzene C8H10

59

Ethyl Chloride 61

61

62 Ethyl Fluoride C2H5F 107 Methyl Acetylene C3H4

3

Ethylene C2H4

63

Ethylene Dichloride 65

65

66 Ethylene Oxide C2H4O 111 Methylcyclohexane C7H14

2

Ethyleneimine C2H4N

67

Ethyl Mercaptan C2H6S

69

115 Methyl Fluoride CH3F

2

Formaldehyde CH2O

71

72 Freon 11 CCl3F 117 Methyl Iodide CH3I

3

Freon 12 73

73

119 Methylpentene C6H12

3

Freon 14 CF4

75

Freon 23 CHF3

77

78 Freon 114 78 123 Nitrogen N2

4H8

Furan C4H4O

79

Heptafluoropropane C3HF7

81

82 HMDS HMDS 127 Nitromethane 127

3H6

Hexamethyldisiloxane 83

83

129 Nitrous Oxide N2O

6H14

Hexafluorobenzene C6F6

85

131 Octane C8H18

6H12

Hydrazine N2H4

87

133 Oxygen Difluoride F2O

2

Hydrogen Bromide HBr

89

Hydrogen Fluoride HF

92

Hydrogen Selenide H2Se

94

Isobutane C4H10

96

Isobutene C4H8

98

Isopropyl Alcohol C3H8O

100

Ketene C2H2O

102

Methane CH4

104

Methyl Acetate 106

106

Methylamine CH5N

108

Methyl Chloride CH3Cl

110

Methyl Ethyl Amine C3H9N

112

Methyl Ethyl Sulfide C3H8S

114

Methyl Formate 116

116

Methyl Mercaptan CH4S

118

Methyl Vinyl Ether C3H6O

120

Nitric Oxide NO

122

Nitrogen Dioxide NO2

124

Nitrogen Trifluoride NF3

126

Nitrosyl Chloride NOCl

128

n-Pentane C5H12

130

Oxygen O2

132

Ozone O3

134

5H12

3H8

2O4

5H9

3

4

Br

O

O

164-122012 Power

POD

400 Page 34 of 42

Page 35

Gas ID Table (Page 2 of 2)

136 Pentane C

137

138 Perfluorocyclobutane C

139

140 Perfluoropropane C

141

142 Phosgene COCl

143

144 Phosphorus Trifluoride PF

145

146 Propyl Alcohol C

147

148 Propylene C

149

150 R32 CH

151

152 R123A R123A 172 Tetrahydrofuran C

153

154 R134 R134 174 Thiophene C

155

GAS NAME Symbol GAS NAME Symbol GAS NAME Symbol

156 R143 R143 175 Toluene C7H8

5H12

Perchloryl Fluoride ClFO3

158 R152A R152A 177 Trichloroethane 177

4F8

R116 C2F6

160 R1416 R1416 179 R113 R113

3F8

Phenol C6H6O

162 Sec-butanol 162 181 Trimethyl Amine C3H9N

2

Phosphine PH3

164 Silicone Tetrafluoride SiF4 183 Uranium Hexafluoride UF6

3

Propane C3H8

O 166 Sulfur Hexafluoride SF6 185 Vinyl Chloride 185

3H8

Propyl Amine C3H9N

168 Sulfur Trifluoride SF3 187 Water Vapor H2O

3H6

Pyradine C5H5N

170 Tetrachloroethylene 170 189 Xylene, m- C8H10

2F2

R123 R123

R125 C2HF5

R134A R134A

R143A R143A

157

R218 C3F8

159

Radon Rn

161

Silane SiH4

163

Sulfur Dioxide SO2

165

Sulfur Tetrafluoride SF4

167

Sulfur Trioxide SO3

169

Tetrafluoroethylene C2F4

171

Tert-butanol 173

173

Transbutene C4H8

176

Trichloroethylene 178

178

Triethylamine 180

180

Tungsten Hexafluoride WF6

182

Vinyl Bromide 184

184

Vinyl Flouride C2H3F

186

Xenon Xe

188

Xylene, o- C8H10

190

O 191 Xylene, p- C8H10

4H8

Mixtures MIXT

191

S 193 Other ????

4H4

194

164-122012 Power

POD

400 Page 35 of 42

Page 36

14.0 Appendix D

Setting the Zero & Span

on the

Power

All procedures outlined in this document must be performed with the power supply turned on and

warmed up for at least one hour.

All procedures outlined in this document must be performed with NO transducers connected to the

channel being adjusted*.

You CANNOT successfully zero a channel without, first, supplying zero volts or four milliamps to

the meter input for that channel.

You CANNOT successfully span a channel without, first, supplying the meter input for that channel

with its appropriate span voltage or span current.

14.1 Zeroing Unit (Voltage Range).

The following instructions explain how to short a given channel’s input signal to ground (0 volts DC)

and set the display to read zero at this voltage.

Locate the 15-pin, ‘D’ type connector that corresponds to the channel to be zeroed.

Short pin 5 (signal common) to pin 6 (signal in).

Press MODE

Press 3

Press ENTER

Press 1, 2, 3 or 4, depending on which channel is to be zeroed.

Press ENTER

Press 7

Press ENTER

Press 1

Press ENTER

Press ENTER again

You have just told a channel to display zero when the input signal is zero volts

Pod

-400 Power Supply/Totalizer

J1 = Channel 1

J2 = Channel 2

J3 = Channel 3

J4 = Channel 4

!

.

164-122012 Power

POD

400 Page 36 of 42

Page 37

14.2 Zeroing Unit (4 to 20 mA Range)

The following instructions explain how to use the POWER

POD

-400 command signal to supply

4mAmp signal to a channel’s input and set the display to read zero at this current level.

Disconnect all connectors from the channel to be calibrated.

Insure that the channel is set to read 4 to 20 mA signals by performing the following steps.

Press MODE

Press 3

Press ENTER

Press 1, 2, 3 or 4, depending on which channel is to be zeroed.

Press ENTER

Press 4

Press ENTER

Press 3