Page 1

PRINT DATE: 06 March 2009

INSTRUCTION MANUAL

MODEL 360E

CARBON DIOXIDE ANALYZER

© TELEDYNE INSTRUMENTS

ADVANCED POLLUTION INSTRUMENTATION DIVISION

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone: 858-657-9800

Fax: 858-657-9816

Email: api-sales@teledyne.com

Website: http://www.teledyne-api.com/

Copyright 2008 Teledyne Advanced Pollution DCN 5341

Instrumentation 06 March 2009

04584 REV. C8

Page 2

THIS PAGE IS INTENTIONALLY LEFT BLANK

Page 3

Model 360E Instruction Manual M360E Documentation

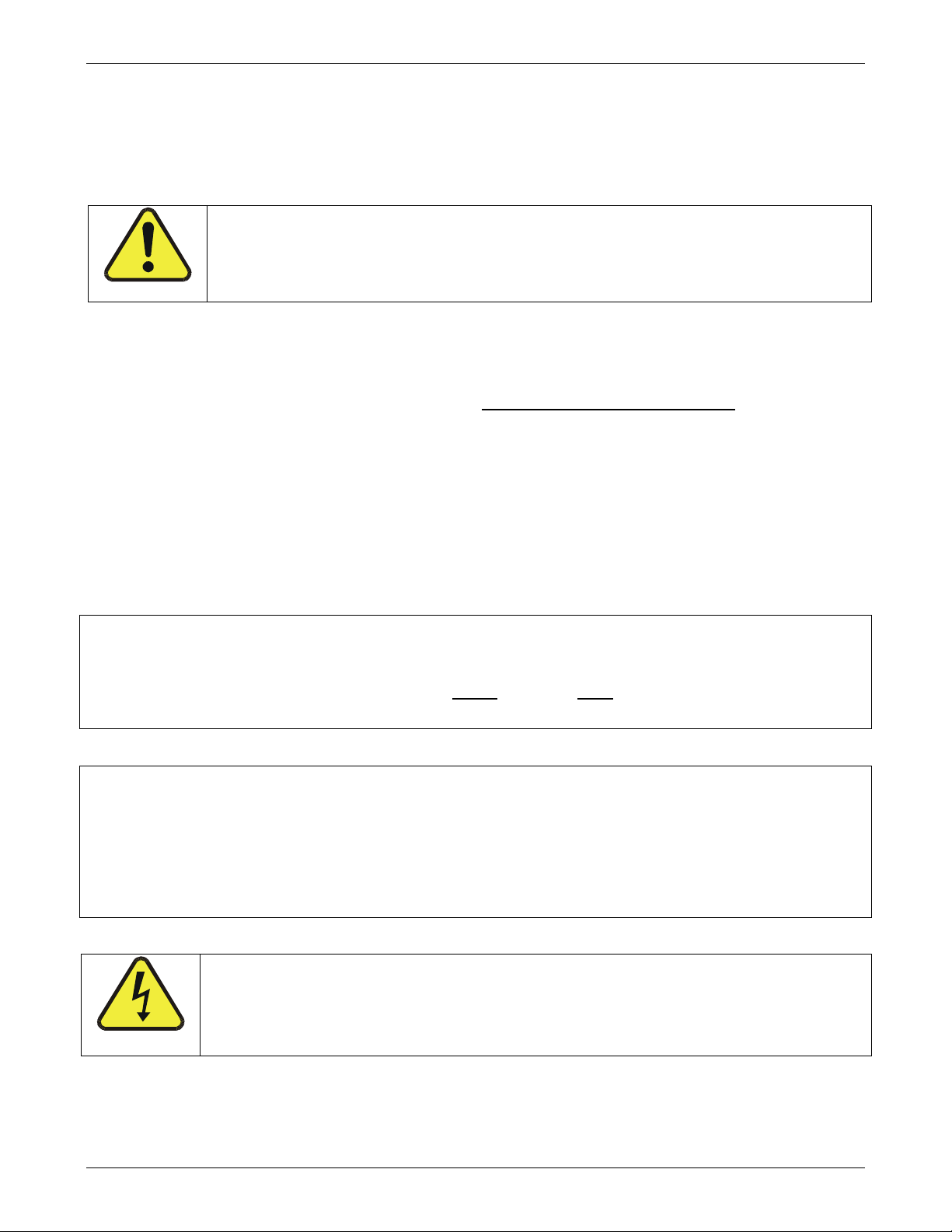

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety messages in

this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

associated with a safety alert symbol. These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL SAFETY HAZARD: Refer to the instructions for

details on the specific hazard.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

TECHNICIAN SYMBOL: All operations marked with this

symbol are to be performed by qualified maintenance

personnel only.

CAUTION

The analyzer should only be used for the purpose and in the manner described in this

manual. If you use the analyzer in a manner other than that for which it was intended,

unpredictable behavior could ensue with possible hazardous consequences.

0523

2 Rev B3 i

Page 4

Page 5

Model 360E Instruction Manual M360E Documentation

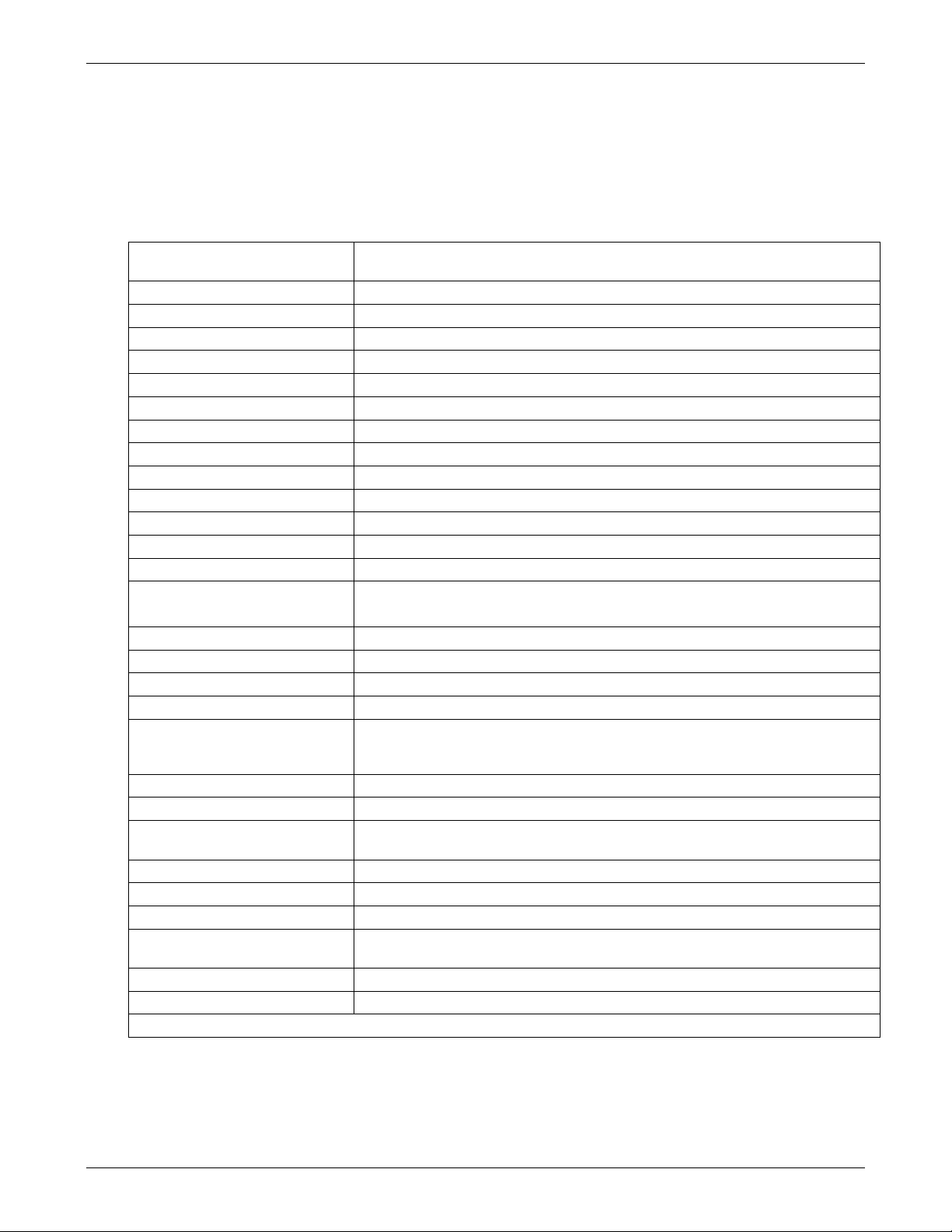

TABLE OF CONTENTS

1. M360E DOCUMENTATION.....................................................................................................................................................1

1.1. Using This Manual............................................................................................................................................................ 1

2. SPECIFICATIONS, APPROVALS AND WARRANTY ............................................................................................................3

2.1. Specifications ...................................................................................................................................................................3

2.2. CE Mark Compliance........................................................................................................................................................4

2.3. Warranty...........................................................................................................................................................................4

3. GETTING STARTED ...............................................................................................................................................................7

3.1. Unpacking and Initial Set Up ............................................................................................................................................7

3.1.1. M360 Layout.............................................................................................................................................................9

3.1.2. Electrical Connections ............................................................................................................................................ 12

3.1.2.1. Power Connection...........................................................................................................................................12

3.1.2.2. Output Connections ........................................................................................................................................13

3.1.2.3. Connecting the Status Outputs ....................................................................................................................... 14

3.1.2.4. Connecting the Control Inputs.........................................................................................................................15

3.1.2.5. Connecting the Serial Ports ............................................................................................................................16

3.1.2.6. Connecting to a LAN or the Internet................................................................................................................ 16

3.1.2.7. Connecting to a Multidrop Network .................................................................................................................16

3.1.3. Pneumatic Connections:.........................................................................................................................................16

3.1.3.1. Basic Pneumatic Connections ........................................................................................................................16

3.1.3.2. Connections with Internal Valve Options Installed .......................................................................................... 20

3.1.3.3. Pneumatic Connections to M360E in Multipoint Calibration Applications .......................................................22

3.1.4. Setting the internal Purge Air Pressure...................................................................................................................22

3.2. Initial Operation ..............................................................................................................................................................23

3.2.1. Startup ....................................................................................................................................................................23

3.2.2. Warm Up ................................................................................................................................................................24

3.2.3. Warning Messages .................................................................................................................................................24

3.2.4. Functional Check ....................................................................................................................................................26

3.3. Initial Calibration Procedure ...........................................................................................................................................27

3.3.1. Initial O

3.3.1.1. O

3.3.1.2. O

4. FREQUENTLY ASKED QUESTIONS ...................................................................................................................................35

4.1. FAQ’s .............................................................................................................................................................................35

4.2. Glossary ......................................................................................................................................................................... 36

5. OPTIONAL HARDWARE AND SOFTWARE........................................................................................................................39

5.1. Rack Mount Kits (Options 20a, 20b & 21) ......................................................................................................................39

5.2. Current Loop Analog Outputs (Option 41) ......................................................................................................................39

5.2.1. Converting Current Loop Analog Outputs to Standard Voltage Outputs.................................................................40

5.3. Expendable Kits (Options 42C, 42D and 43)..................................................................................................................40

5.4. Calibration Valves Options ............................................................................................................................................. 41

5.4.1. Zero/Span/Shutoff Valve (Option 50)......................................................................................................................41

5.4.2. Zero/Span/Shutoff with External CO

5.4.3. Zero/Span Valve (Option 52) .................................................................................................................................. 42

5.4.4. Zero/Span Valve with External CO

5.5. Communication Options ................................................................................................................................................. 44

5.5.1. RS232 Modem Cable (Option 60)........................................................................................................................... 44

5.5.2. RS-232 Multidrop (Option 62) .................................................................................................................................44

5.5.3. Ethernet (Option 63) ...............................................................................................................................................45

5.6. Oxygen Sensor (OPT 65) ...............................................................................................................................................46

5.6.1. Theory of Operation................................................................................................................................................46

5.6.1.1. Paramagnetic measurement of O

5.6.1.2. Operation within the M360E Analyzer.............................................................................................................46

5.6.1.3. Pneumatic Operation of the O

5.7. Additional Manuals ......................................................................................................................................................... 48

5.7.1. Printed Manuals (Option 70) ...................................................................................................................................48

5.7.2. Manual on CD (Part number 045840200)...............................................................................................................48

5.8. Extended Warranty (Options 92 & 93)............................................................................................................................ 48

5.9. Special Software Features .............................................................................................................................................48

5.9.1. Dilution Ratio Option...............................................................................................................................................48

5.9.2. Maintenance Mode Switch...................................................................................................................................... 49

5.9.3. Second Language Switch .......................................................................................................................................49

Sensor Calibration Procedure ..................................................................................................................30

2

Calibration Setup .......................................................................................................................................30

2

Calibration Method..................................................................................................................................... 30

2

Scrubber (Option 51) .................................................................................. 42

2

Scrubber (Option 53)......................................................................................44

2

..................................................................................................................46

2

Sensor...........................................................................................................47

2

0523

2 Rev B3 iii

Page 6

M360E Documentation Model 360E Instruction Manual

6. OPERATING INSTRUCTIONS..............................................................................................................................................51

6.1. Overview of Operating modes ........................................................................................................................................ 51

6.2. Sample Mode .................................................................................................................................................................52

6.2.1. Test Functions ........................................................................................................................................................ 52

6.2.2. Warning Messages .................................................................................................................................................55

6.3. Calibration Mode ............................................................................................................................................................56

6.4. SETUP MODE................................................................................................................................................................ 57

6.5. SETUP CFG: Viewing the Analyzer’s Configuration Information ...............................................................................58

6.6. SETUP ACAL: Automatic Calibration.........................................................................................................................58

6.7. SETUP DAS: Using the Data Acquisition System (iDAS) ..........................................................................................59

6.7.1. iDAS Structure........................................................................................................................................................59

6.7.1.1. iDAS Channels................................................................................................................................................60

6.7.1.2. iDAS Parameters ............................................................................................................................................61

6.7.1.3. iDAS Triggering Events................................................................................................................................... 62

6.7.2. Default iDAS Channels ...........................................................................................................................................62

6.7.2.1. Viewing iDAS Data and Settings.....................................................................................................................65

6.7.2.2. Editing iDAS Data Channels ........................................................................................................................... 66

6.7.2.3. Trigger Events.................................................................................................................................................67

6.7.2.4. Editing iDAS Parameters ................................................................................................................................68

6.7.2.5. Sample Period and Report Period ..................................................................................................................70

6.7.2.6. Number of Records.........................................................................................................................................72

6.7.2.7. RS-232 Report Function .................................................................................................................................73

6.7.2.8. Compact Report..............................................................................................................................................73

6.7.2.9. Starting Date ...................................................................................................................................................73

6.7.2.10. Disabling/Enabling Data Channels................................................................................................................74

6.7.2.11. HOLDOFF Feature .......................................................................................................................................74

6.7.3. Remote iDAS Configuration.................................................................................................................................... 75

6.8. SETUP RNGE: Analog Output Reporting Range Configuration................................................................................. 77

6.8.1. Physical Range versus Analog Output Reporting Ranges...................................................................................... 77

6.8.2. Reporting Range Modes.........................................................................................................................................78

6.8.3. Single Range mode (SNGL) ................................................................................................................................... 79

6.8.4. Dual Range Mode (DUAL)......................................................................................................................................80

6.8.5. Auto Range Mode (AUTO) .....................................................................................................................................81

6.8.6. Range Units............................................................................................................................................................82

6.8.7. Dilution Ratio ..........................................................................................................................................................83

6.9. SETUP PASS: Password Feature .............................................................................................................................84

6.10. SETUP CLK: Setting the Internal Time-of-Day Clock ..............................................................................................85

6.11. SETUP MORE COMM: Using the Analyser’s Communication Ports.................................................................... 86

6.11.1. Analyzer ID ...........................................................................................................................................................86

6.11.2. COMM Port Default Settings.................................................................................................................................87

6.11.3. RS-485 Configuration of COM2 ............................................................................................................................89

6.11.4. DTE and DCE Communication ............................................................................................................................. 90

6.11.5. COMM Port Communication Modes ..................................................................................................................... 91

6.11.6. Ethernet Card Configuration .................................................................................................................................93

6.11.6.1. Ethernet Card COM2 Communication Modes and Baud Rate ......................................................................93

6.11.6.2. Configuring the Ethernet Interface Option using DHCP ................................................................................ 93

6.11.6.3. Manually Configuring the Network IP Addresses ..........................................................................................96

6.11.6.4. Changing the Analyzer’s HOSTNAME..........................................................................................................98

6.11.7. Multidrop RS-232 Set Up......................................................................................................................................99

6.11.8. COM Port Baud Rate..........................................................................................................................................101

6.11.9. COM Port Testing ...............................................................................................................................................102

6.12. SETUP MORE VARS: Internal Variables (VARS) ............................................................................................. 103

6.13. SETUP MORE DIAG: Using the Diagnostics Functions ...................................................................................105

6.13.1. Accessing the Diagnostic Features..................................................................................................................... 106

6.13.2. Signal I/O............................................................................................................................................................106

6.13.3. Analog Output Step Test ....................................................................................................................................107

6.13.4. Analog I/O Configuration ....................................................................................................................................108

6.13.4.1. Analog Output Signal Type and Range Span Selection.............................................................................. 110

6.13.4.2. Analog Output Calibration Mode .................................................................................................................110

6.13.4.3. Manual Analog Output Calibration and Voltage Adjustment .......................................................................112

6.13.4.4. Current Loop Output Adjustment ................................................................................................................114

6.13.4.5. AIN Calibration............................................................................................................................................116

6.13.5. Electric Test........................................................................................................................................................117

6.13.6. Dark Calibration Test ..........................................................................................................................................118

6.13.7. Pressure Calibration ........................................................................................................................................... 119

iv 05232 Rev B3

Page 7

Model 360E Instruction Manual M360E Documentation

6.13.8. Flow Calibration..................................................................................................................................................120

6.13.9. Test Channel Output...........................................................................................................................................121

6.14. SETUP MORE ALRM: Using the Gas Concentration Alarms.............................................................................122

6.14.1. Setting the Concentration Alarm Limits............................................................................................................... 122

6.15. Remote Operation of the Analyzer .............................................................................................................................123

6.15.1. Remote Operation Using the External Digital I/O................................................................................................123

6.15.1.1. Status Outputs ............................................................................................................................................ 123

6.15.1.2. Control Inputs..............................................................................................................................................125

6.15.2. Remote Operation Using the External Serial I/O ................................................................................................126

6.15.2.1. Terminal Operating Modes.......................................................................................................................... 126

6.15.2.2. Help Commands in Terminal Mode............................................................................................................. 126

6.15.2.3. Command Syntax .......................................................................................................................................127

6.15.2.4. Data Types..................................................................................................................................................127

6.15.2.5. Status Reporting .........................................................................................................................................128

6.15.2.6. Remote Access by Modem ......................................................................................................................... 129

6.15.2.7. COM Port Password Security .....................................................................................................................130

6.15.2.8. APICOM Remote Control Program .............................................................................................................131

6.15.3. Additional Communications Documentation .......................................................................................................131

6.15.4. Using the M360E with a Hessen Protocol Network.............................................................................................132

6.15.4.1. General Overview of Hessen Protocol ........................................................................................................ 132

6.15.4.2. Hessen COMM Port Configuration.............................................................................................................. 132

6.15.4.3. Activating Hessen Protocol ......................................................................................................................... 133

6.15.4.4. Selecting a Hessen Protocol Type ..............................................................................................................133

6.15.4.5. Setting The Hessen Protocol Response Mode ...........................................................................................134

6.15.4.6. Hessen Protocol Gas ID..............................................................................................................................134

6.15.4.7. Setting Hessen Protocol Status Flags......................................................................................................... 135

6.15.4.8. Instrument ID Code.....................................................................................................................................136

7. CALIBRATION PROCEDURES ..........................................................................................................................................137

7.1. Before Calibration......................................................................................................................................................... 137

7.1.1. Zero Air and Span Gas .........................................................................................................................................137

7.1.2. Calibration Gas Traceability..................................................................................................................................138

7.1.3. Data Recording Devices .......................................................................................................................................138

7.2. Manual Calibration without Zero/Span Valves.............................................................................................................. 138

7.3. Manual Calibration Checks...........................................................................................................................................141

7.4. Manual Calibration with Zero/Span Valves................................................................................................................... 141

7.5. Manual Calibration Checks with Zero/Span Valves......................................................................................................146

7.5.1. Zero/Span Calibration on Auto Range or Dual Ranges ........................................................................................ 147

7.5.2. Use of Zero/Span Valves with Remote Contact Closure ......................................................................................148

7.6. Automatic Zero/Span Cal/Check (AutoCal) ..................................................................................................................148

7.6.1. AutoCal with Auto or Dual Reporting Ranges Modes Selected ............................................................................151

7.7. Calibration Quality ........................................................................................................................................................ 151

8. EPA PROTOCOL CALIBRATION.......................................................................................................................................153

9. MAINTENANCE SCHEDULE & PROCEDURES ................................................................................................................155

9.1. Maintenance Schedule .................................................................................................................................................155

9.2. Predicting Failures Using the Test Functions ...............................................................................................................158

9.3. Maintenance Procedures.............................................................................................................................................. 159

9.3.1. Replacing the Sample Particulate Filter................................................................................................................159

9.3.2. Rebuilding the Sample Pump ...............................................................................................................................159

9.3.3. Performing Leak Checks ......................................................................................................................................160

9.3.3.1. Vacuum Leak Check and Pump Check ........................................................................................................160

9.3.3.2. Pressure Leak Check.................................................................................................................................... 160

9.3.4. Performing a Sample Flow Check ........................................................................................................................161

9.3.5. Cleaning the Optical Bench ..................................................................................................................................161

9.3.6. Cleaning Exterior Surfaces of the M360E............................................................................................................. 161

10. THEORY OF OPERATION................................................................................................................................................163

10.1. Measurement Method.................................................................................................................................................163

10.1.1. Beer’s Law..........................................................................................................................................................163

10.1.2. Measurement Fundamentals .............................................................................................................................. 163

10.1.3. Gas Filter Correlation..........................................................................................................................................164

10.1.3.1. The GFC Wheel ..........................................................................................................................................164

10.1.3.2. The Measure Reference Ratio .................................................................................................................... 165

10.1.4. Interference and Signal to Noise Rejection......................................................................................................... 166

10.1.4.1. Ambient CO

10.2. Pneumatic Operation..................................................................................................................................................168

Interference Rejection ........................................................................................................... 167

2

0523

2 Rev B3 v

Page 8

M360E Documentation Model 360E Instruction Manual

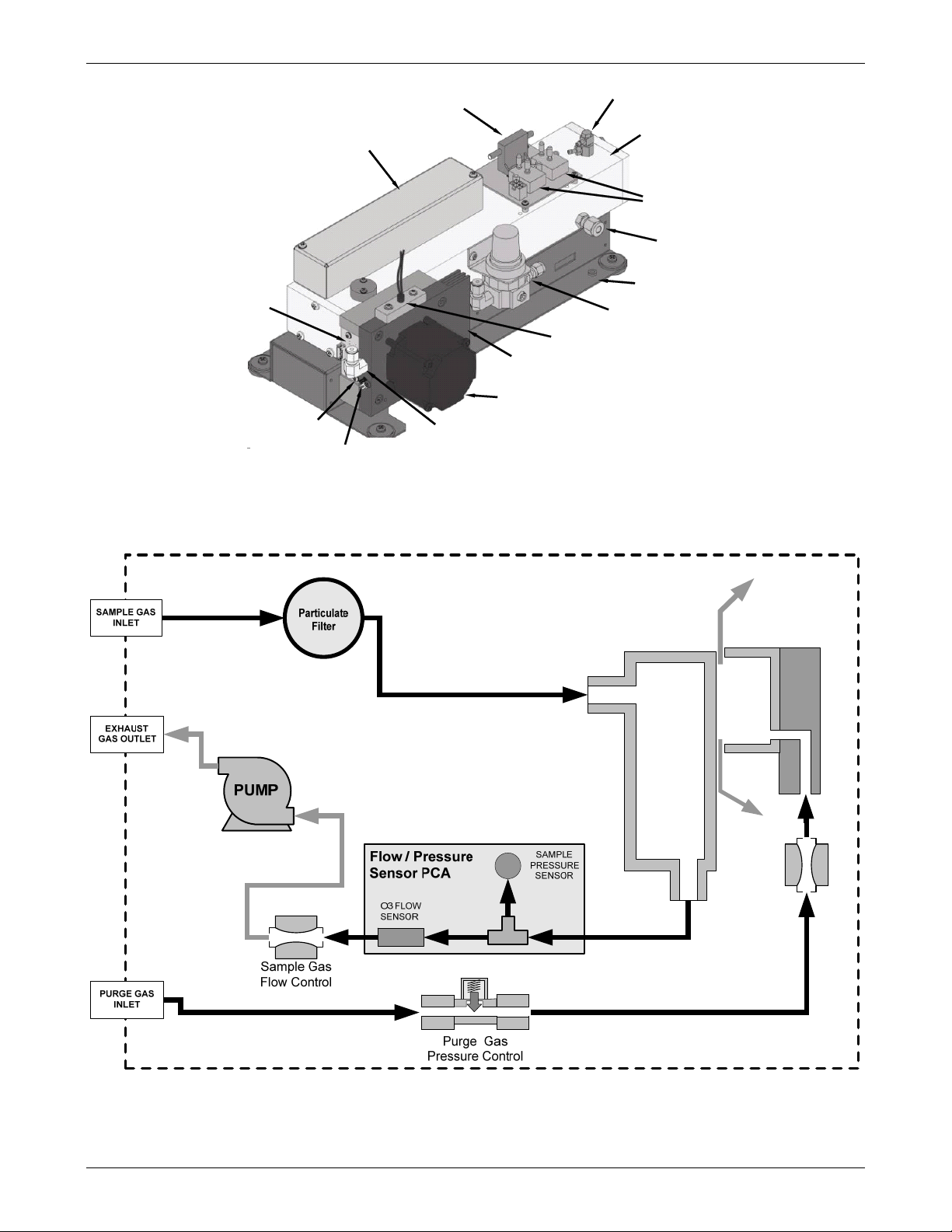

10.2.1. Sample Gas Flow ...............................................................................................................................................168

10.2.2. Flow Rate Control...............................................................................................................................................169

10.2.2.1. Critical Flow Orifice .....................................................................................................................................169

10.2.3. Purge Gas Pressure Control............................................................................................................................... 170

10.2.4. Particulate Filter..................................................................................................................................................170

10.2.5. Pneumatic Sensors.............................................................................................................................................170

10.2.5.1. Sample Pressure Sensor ............................................................................................................................ 170

10.2.5.2. Sample Flow Sensor...................................................................................................................................170

10.3. Electronic Operation...................................................................................................................................................171

10.3.1. Overview............................................................................................................................................................. 171

10.3.2. CPU ....................................................................................................................................................................173

10.3.3. Optical Bench & GFC Wheel ..............................................................................................................................173

10.3.3.1. Temperature Control...................................................................................................................................173

10.3.3.2. IR Source....................................................................................................................................................173

10.3.3.3. GFC Wheel ................................................................................................................................................. 174

10.3.3.4. IR Photo-Detector .......................................................................................................................................175

10.3.4. Synchronous Demodulator (Sync/Demod) Assembly.........................................................................................175

10.3.4.1. Overview.....................................................................................................................................................175

10.3.4.2. Signal Synchronization and Demodulation..................................................................................................176

10.3.4.3. Sync/Demod Status LED’s.......................................................................................................................... 177

10.3.4.4. Photo-Detector Temperature Control ..........................................................................................................178

10.3.4.5. Dark Calibration Switch............................................................................................................................... 178

10.3.4.6. Electric Test Switch.....................................................................................................................................178

10.3.5. Relay Board........................................................................................................................................................178

10.3.5.1. Status LED’s ............................................................................................................................................... 179

10.3.5.2. I

10.3.6. Mother Board......................................................................................................................................................180

10.3.6.1. A to D Conversion.......................................................................................................................................180

10.3.6.2. Sensor Inputs..............................................................................................................................................180

10.3.6.3. Thermistor Interface....................................................................................................................................181

10.3.6.4. Analog Outputs ........................................................................................................................................... 181

10.3.6.5. Internal Digital I/O .......................................................................................................................................182

10.3.6.6. External Digital I/O ......................................................................................................................................182

10.3.7. I

10.3.8. Power Supply/ Circuit Breaker............................................................................................................................183

10.4. Interface .....................................................................................................................................................................184

10.4.1. Front Panel Interface .......................................................................................................................................... 184

10.4.1.1. Analyzer Status LED’s ................................................................................................................................185

10.4.1.2. Keyboard.....................................................................................................................................................185

10.4.1.3. Display ........................................................................................................................................................185

10.4.1.4. Keyboard/Display Interface Electronics.......................................................................................................186

10.5. Software Operation.....................................................................................................................................................188

10.5.1. Adaptive Filter..................................................................................................................................................... 188

10.5.2. Calibration - Slope and Offset............................................................................................................................. 189

10.5.3. Measurement Algorithm...................................................................................................................................... 189

10.5.4. Temperature and Pressure Compensation .........................................................................................................189

10.5.5. Internal Data Acquisition System (iDAS) ............................................................................................................190

11. TROUBLESHOOTING & REPAIR PROCEDURES........................................................................................................... 191

11.1. General Troubleshooting Hints ...................................................................................................................................191

11.1.1. Interpreting WARNING Messages ......................................................................................................................192

11.1.2. Fault Diagnosis with TEST Functions .................................................................................................................194

11.1.3. Using the Diagnostic Signal I/O Function ...........................................................................................................196

11.1.4. Internal Electronic Status LED’s .........................................................................................................................197

11.1.4.1. CPU Status Indicator ..................................................................................................................................197

11.1.4.2. Sync Demodulator Status LED’s.................................................................................................................197

11.1.4.3. Relay Board Status LED’s...........................................................................................................................198

11.2. Gas Flow Problems .................................................................................................................................................... 200

11.2.1. M360E Internal Gas Flow Diagrams ...................................................................................................................200

11.2.2. Typical Sample Gas Flow Problems ...................................................................................................................202

11.2.2.1. Flow is Zero ................................................................................................................................................202

11.2.2.2. Low Flow..................................................................................................................................................... 203

11.2.2.3. High Flow....................................................................................................................................................203

11.2.2.4. Displayed Flow = “XXXX”............................................................................................................................203

11.2.2.5. Actual Flow Does Not Match Displayed Flow..............................................................................................203

11.2.2.6. Sample Pump .............................................................................................................................................204

2

C Watch Dog Circuitry .............................................................................................................................. 180

2

C Data Bus .......................................................................................................................................................182

vi 05232 Rev B3

Page 9

Model 360E Instruction Manual M360E Documentation

11.2.3. Poor or Stopped Flow of Purge Gas...................................................................................................................204

11.3. Calibration Problems .................................................................................................................................................. 204

11.3.1. Miscalibrated.......................................................................................................................................................204

11.3.2. Non-Repeatable Zero and Span.........................................................................................................................205

11.3.3. Inability to Span – No SPAN Key........................................................................................................................205

11.3.4. Inability to Zero – No ZERO Key.........................................................................................................................205

11.4. Other Performance Problems.....................................................................................................................................206

11.4.1. Temperature Problems ....................................................................................................................................... 206

11.4.1.1. Box or Sample Temperature.......................................................................................................................206

11.4.1.2. Bench Temperature ....................................................................................................................................206

11.4.1.3. GFC Wheel Temperature............................................................................................................................207

11.4.1.4. IR Photo-Detector TEC Temperature.......................................................................................................... 207

11.4.2. Excessive Noise .................................................................................................................................................208

11.5. Subsystem Checkout..................................................................................................................................................209

11.5.1. AC Mains Configuration......................................................................................................................................209

11.5.2. DC Power Supply ...............................................................................................................................................209

11.5.3. I

11.5.4. Keyboard/Display Interface.................................................................................................................................210

11.5.5. Relay Board........................................................................................................................................................211

11.5.6. Sensor Assembly................................................................................................................................................211

11.5.7. Motherboard .......................................................................................................................................................213

11.5.8. CPU ....................................................................................................................................................................216

11.5.9. RS-232 Communications....................................................................................................................................216

11.6. Repair Procedures......................................................................................................................................................218

11.6.1. Repairing Sample Flow Control Assembly..........................................................................................................218

11.6.2. Removing/Replacing the GFC Wheel ................................................................................................................. 219

11.6.3. Disk-On-Chip Replacement Procedure............................................................................................................... 220

12. A PRIMER ON ELECTRO-STATIC DISCHARGE.............................................................................................................221

12.1. How Static Charges are Created................................................................................................................................221

12.2. How Electro-Static Charges Cause Damage.............................................................................................................. 222

12.3. Common Myths About ESD Damage ......................................................................................................................... 223

12.4. Basic Principles of Static Control................................................................................................................................ 223

12.4.1. General Rules.....................................................................................................................................................223

12.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance ....................................................................225

2

C Bus................................................................................................................................................................210

11.5.6.1. Sync/Demodulator Assembly......................................................................................................................211

11.5.6.2. Opto Pickup Assembly................................................................................................................................212

11.5.6.3. GFC Wheel Drive........................................................................................................................................212

11.5.6.4. IR Source....................................................................................................................................................212

11.5.6.5. Pressure/Flow Sensor Assembly ................................................................................................................ 212

11.5.7.1. A/D Functions .............................................................................................................................................213

11.5.7.2. Analog Outputs: Voltage ............................................................................................................................. 213

11.5.7.3. Analog Outputs: Current Loop ....................................................................................................................214

11.5.7.4. Status Outputs ............................................................................................................................................ 215

11.5.7.5. Control Inputs – Remote Zero, Span ..........................................................................................................215

11.5.9.1. General RS-232 Troubleshooting ...............................................................................................................216

11.5.9.2. Troubleshooting Analyzer/Modem or Terminal Operation...........................................................................217

12.4.2.1. Working at the Instrument Rack..................................................................................................................225

12.4.2.2. Working at an Anti-ESD Work Bench.......................................................................................................... 225

12.4.2.3. Transferring Components from Rack to Bench and Back ........................................................................... 226

12.4.2.4. Opening Shipments from Teledyne Instruments Customer Service............................................................ 226

12.4.2.5. Packing Components for Return to Teledyne Instruments Customer Service. ...........................................227

0523

2 Rev B3 vii

Page 10

M360E Documentation Model 360E Instruction Manual

LIST OF APPENDICES

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION

APPENDIX A-1: M360E Software Menu Trees, Revision G.4

APPENDIX A-2: Setup Variables For Serial I/O, Revision G.4

APPENDIX A-3: Warnings and Test Functions, Revision G.4

APPENDIX A-4: M360E Signal I/O Definitions, Revision G.4

APPENDIX A-5: M360E iDAS Functions, Revision G.4

APPENDIX A-6: Terminal Command Designators, Revision G.4

APPENDIX B - M360E SPARE PARTS LIST

APPENDIX C - REPAIR QUESTIONNAIRE - M360E

APPENDIX D - ELECTRONIC SCHEMATICS

LIST OF FIGURES

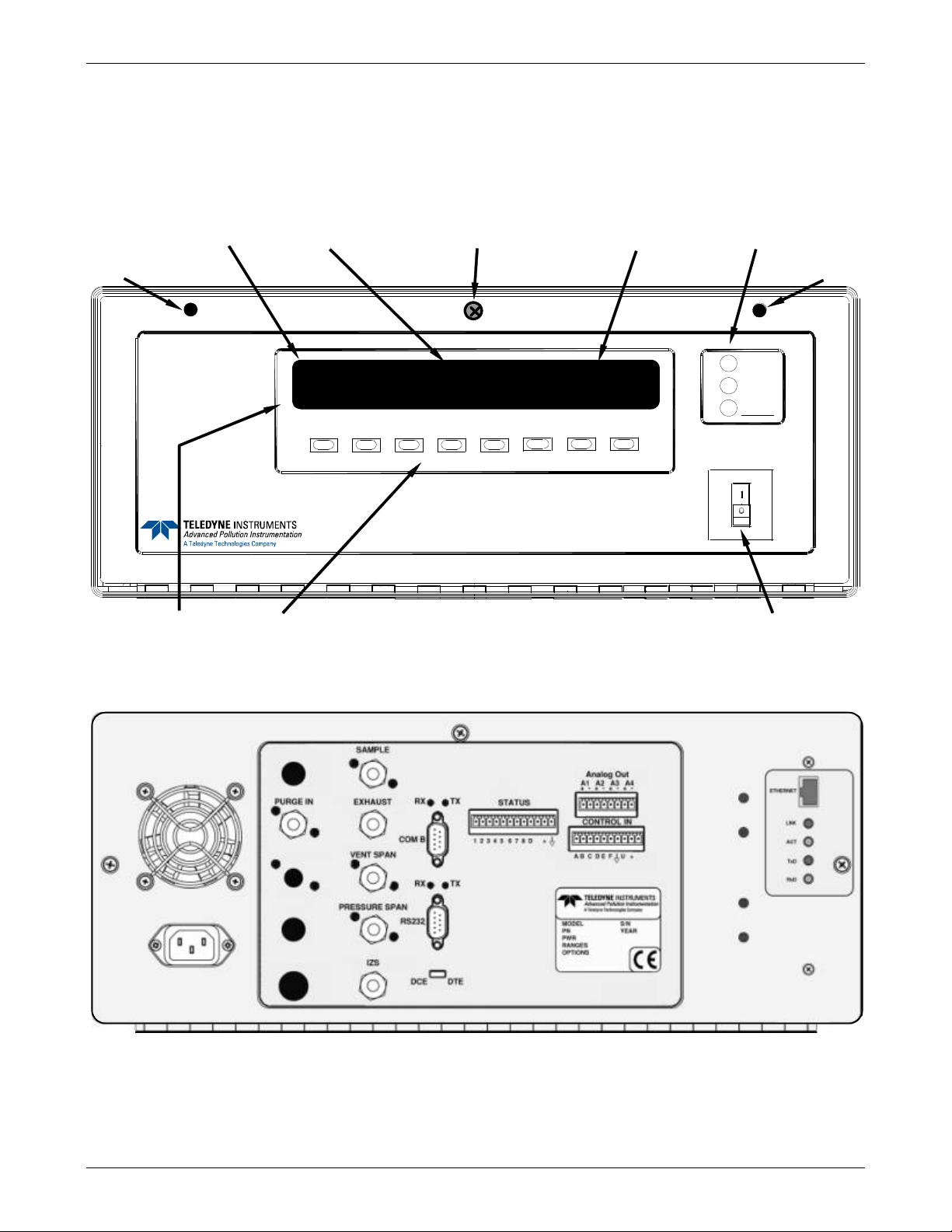

Figure 3-1: Front Panel Layout.............................................................................................................................. 9

Figure 3-2: Rear Panel Layout .............................................................................................................................. 9

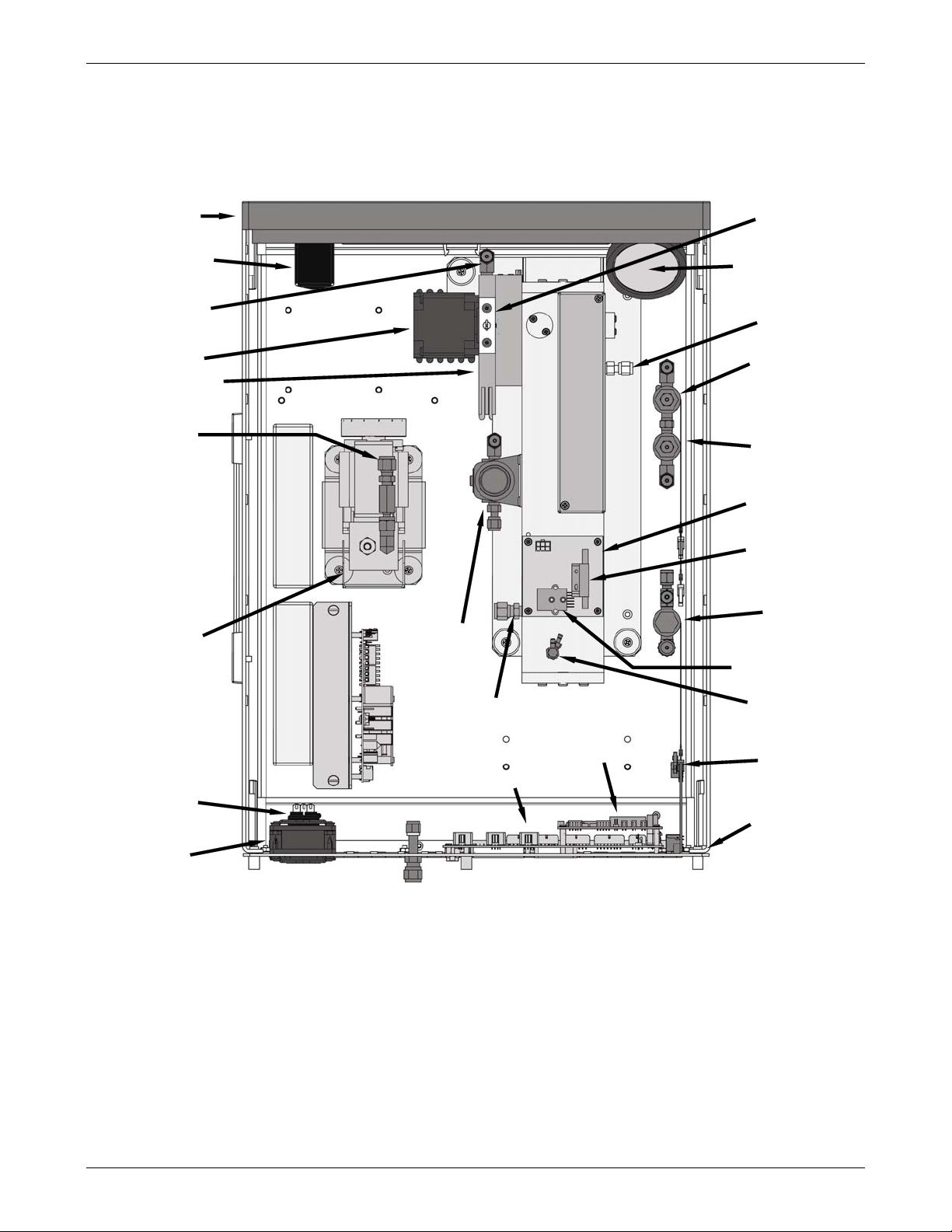

Figure 3-3: Assembly Layout............................................................................................................................... 10

Figure 3-4: Optical Bench Layout ........................................................................................................................ 11

Figure 3-5: M360E Internal Gas Flow.................................................................................................................. 11

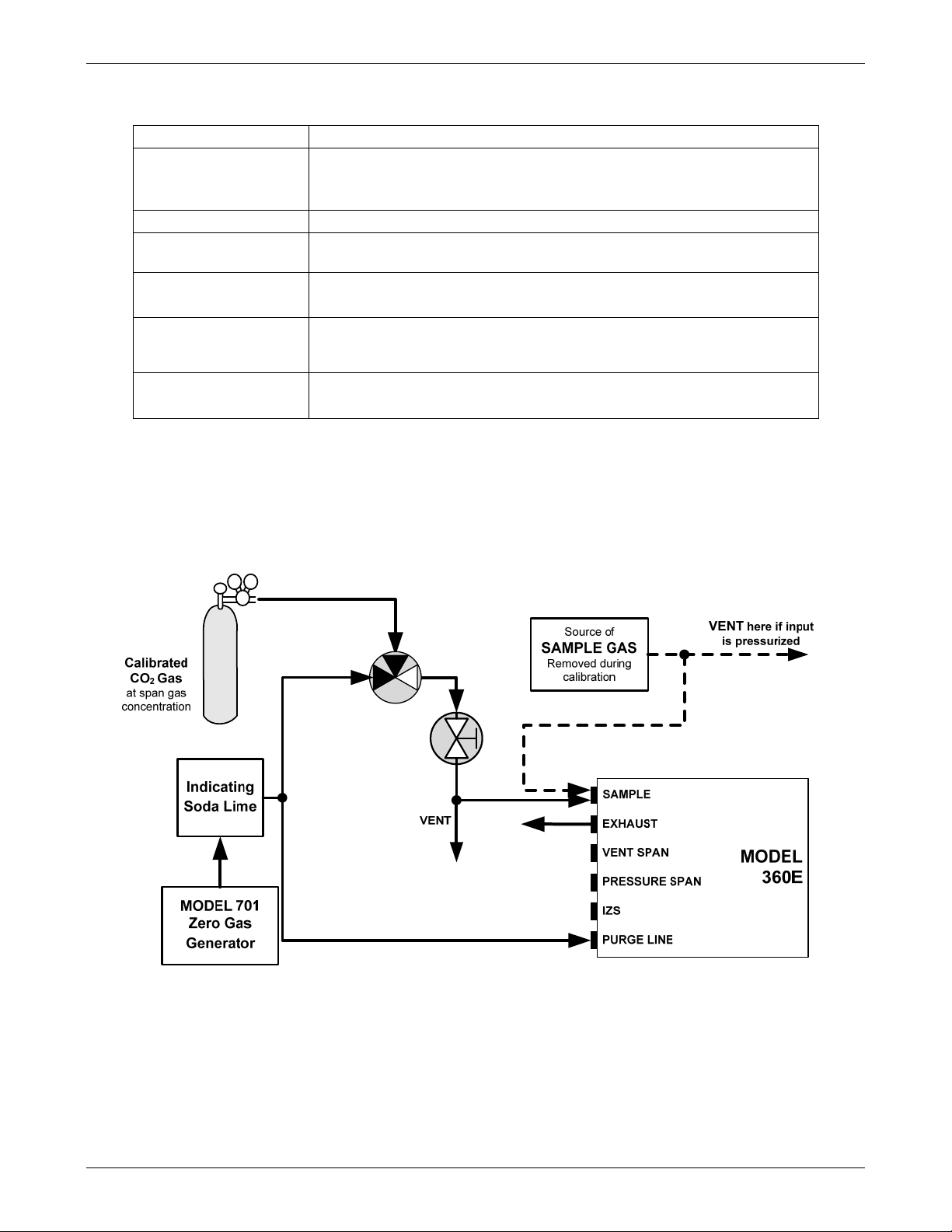

Figure 3-6: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas .......................................... 17

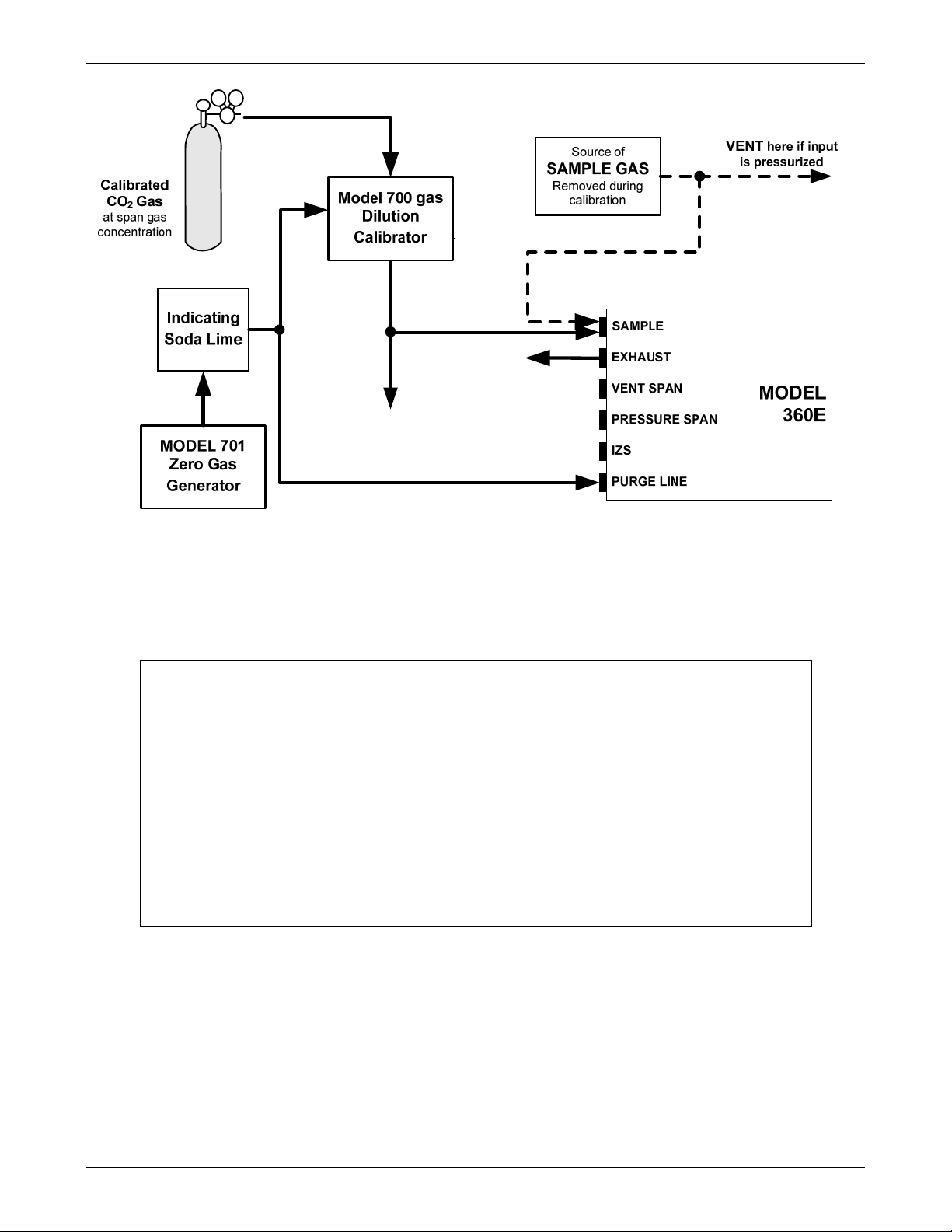

Figure 3-7: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator.................................. 18

Figure 3-8: Pneumatic Connections–M360E with Zero/Span/Shutoff Valves (OPT 50) ..................................... 20

Figure 3-9: Pneumatic Connections–M360E with Zero/Span/Shutoff Valves and External Zero Air Scrubber

(OPT 51) ..................................................................................................................................... 20

Figure 3-10: Pneumatic Connections–M360E with Zero/Span Valves (OPT 52) ................................................. 21

Figure 3-11: Pneumatic Connections–M360E with Zero/Span Valves with External Zero air Scrubber (OPT 53)21

Figure 3-12: Example of Pneumatic Set up for Multipoint Calibration of M360..................................................... 22

Figure 3-13: O

Figure 5-1: Current Loop Option Installed on the Motherboard .......................................................................... 39

Figure 5-2: Internal Pneumatic Flow – Zero/Span/Shutoff Valves OPT 50 & 51 ................................................ 42

Figure 5-3: Internal Pneumatic Flow – Zero/Span OPT 52 & 53......................................................................... 43

Figure 5-4: M360E Multidrop Card ...................................................................................................................... 44

Figure 5-5: M360E Ethernet Card ....................................................................................................................... 45

Figure 5-6: M360E Rear Panel with Ethernet Installed ....................................................................................... 45

Figure 5-2: Oxygen Sensor - Principle of Operation ........................................................................................... 46

Figure 5-3: M360E – Internal Pneumatics with O

Figure 6-1: Front Panel Display........................................................................................................................... 51

Figure 6-3: Viewing M360E TEST Functions ...................................................................................................... 54

Figure 6-3 Viewing and Clearing M360E WARNING Messages........................................................................ 56

Figure 6-4: Default iDAS Channels Setup........................................................................................................... 63

Figure 6-5: APICOM user interface for configuring the iDAS.............................................................................. 75

Figure 6-6: iDAS Configuration Through a Terminal Emulation Program. .......................................................... 76

Figure 6-7: Analog Output Connector Pin Out .................................................................................................... 77

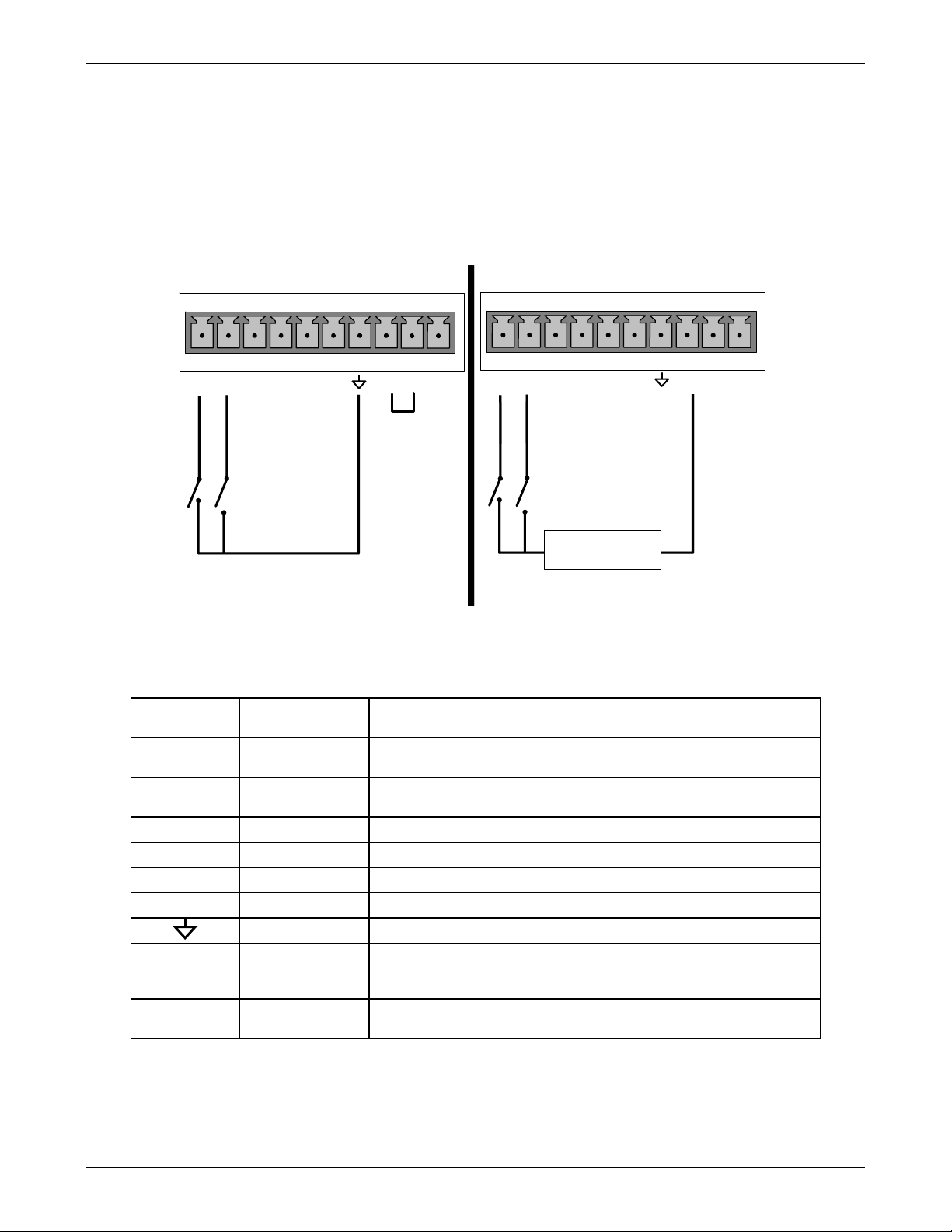

Figure 6-8: Back Panel connector Pin-Outs for COM1 & COM2 in RS-232 mode. ............................................ 87

Figure 6-9: CPU connector Pin-Outs for COM1 & COM2 in RS-232 mode........................................................ 88

Figure 6-10: CPU card Locations of RS-232/486 Switches, Connectors and Jumpers...................................... 89

Figure 6-11: Back Panel connector Pin-Outs for COM2 in RS-485 mode. .........................................................90

Figure 6-12: CPU connector Pin-Outs for COM2 in RS-485 mode....................................................................... 90

Figure 6-13: Location of JP2 on RS232-Multidrop PCA (option 62) .................................................................... 99

Figure 6-14: RS232-Multidrop PCA Host/Analyzer Interconnect Diagram.......................................................... 100

Figure 6-15: Setup for Calibrating Analog Voltage Outputs ............................................................................... 113

Figure 6-16: Setup for Calibrating Current Outputs............................................................................................ 114

Figure 6-17: Status Output Connector................................................................................................................. 123

Figure 6-18: Control Inputs.................................................................................................................................. 125

Sensor Calibration Set Up ........................................................................................................... 30

2

Sensor Option 65 ................................................................. 47

2

viii 05232 Rev B3

Page 11

Model 360E Instruction Manual M360E Documentation

Figure 6-19: APICOM Remote Control Program Interface.................................................................................. 131

Figure 7-1: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas ........................................ 138

Figure 7-2: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator................................ 139

Figure 7-3: Pneumatic Connections–M360E with Zero/Span/Shutoff Valves (OPT 50) ................................... 142

Figure 7-4 Pneumatic Connections–M360E with Zero/Span/Shutoff Valves and External Zero Air Scrubber

(OPT 51) ................................................................................................................................... 142

Figure 7-5: Pneumatic Connections–M360E with Zero/Span Valves (OPT 52) ............................................... 143

Figure 7-6: Pneumatic Connections–M360E with Zero/Span Valves with External Zero air Scrubber (OPT 53)143

Figure 9-1: Sample Particulate Filter Assembly ................................................................................................ 159

Figure 10-1: Measurement Fundamentals .......................................................................................................... 164

Figure 10-2: GFC Wheel ..................................................................................................................................... 164

Figure 10-3: Measurement Fundamentals with GFC Wheel............................................................................... 165

Figure 10-4: Affect of CO

Figure 10-5: Effects of Interfering Gas on CO2 MEAS & CO2 REF ................................................................... 166

Figure 10-6: Chopped IR Signal .......................................................................................................................... 167

Figure 10-7: Internal Pneumatic Flow – Basic Configuration .............................................................................. 168

Figure 10-8: Flow Control Assembly & Critical Flow Orifice................................................................................ 169

Figure 10-9: 360E Electronic Block Diagram ...................................................................................................... 172

Figure 10-10: GFC Light Mask .............................................................................................................................. 174

Figure 10-11: Segment Sensor and M/R Sensor Output ...................................................................................... 175

Figure 10-12: 360E Sync / Demod Block Diagram................................................................................................ 176

Figure 10-13: Sample & Hold Timing .................................................................................................................... 177

Figure 10-14: Location of relay board Status LED’s.............................................................................................. 180

Figure 10-15: Power Distribution Block Diagram .................................................................................................. 183

Figure 10-16: Interface Block Diagram.................................................................................................................. 184

Figure 10-17: M360E Front Panel Layout ............................................................................................................. 184

Figure 10-18: Keyboard and Display Interface Block Diagram ............................................................................. 186

Figure 10-19: Basic Software Operation ............................................................................................................... 188

Figure 11-1: Viewing and Clearing Warning Messages ...................................................................................... 192

Figure 11-2: Example of Signal I/O Function ...................................................................................................... 196

Figure 11-3: CPU Status Indicator....................................................................................................................... 197

Figure 11-4: Sync/Demod Board Status LED Locations ..................................................................................... 198

Figure 11-5: Relay Board Status LEDs ............................................................................................................... 198

Figure 11-7: M360E – Basic Internal Gas Flow................................................................................................... 200

Figure 11-6: Internal Pneumatic Flow OPT 50– Zero/Span/Shutoff Valves........................................................ 201

Figure 11-8: Internal Pneumatic Flow – Zero/Span OPT 52 & 53....................................................................... 201

Figure 11.9: M360E – Internal Pneumatics with O

Figure 11-10: Critical Flow Restrictor Assembly Disassembly .............................................................................. 218

Figure 11-11: Opening the GFC Wheel Housing .................................................................................................. 219

Figure 11-12: Removing the GFC Wheel .............................................................................................................. 220

Figure 12-1: Triboelectric Charging ....................................................................................................................... 221

Figure 12-2: Basic anti-ESD Work Station ............................................................................................................ 223

in the Sample on CO2 MEAS & CO2 REF ............................................................... 166

2

Sensor Option 65 ............................................................... 202

2

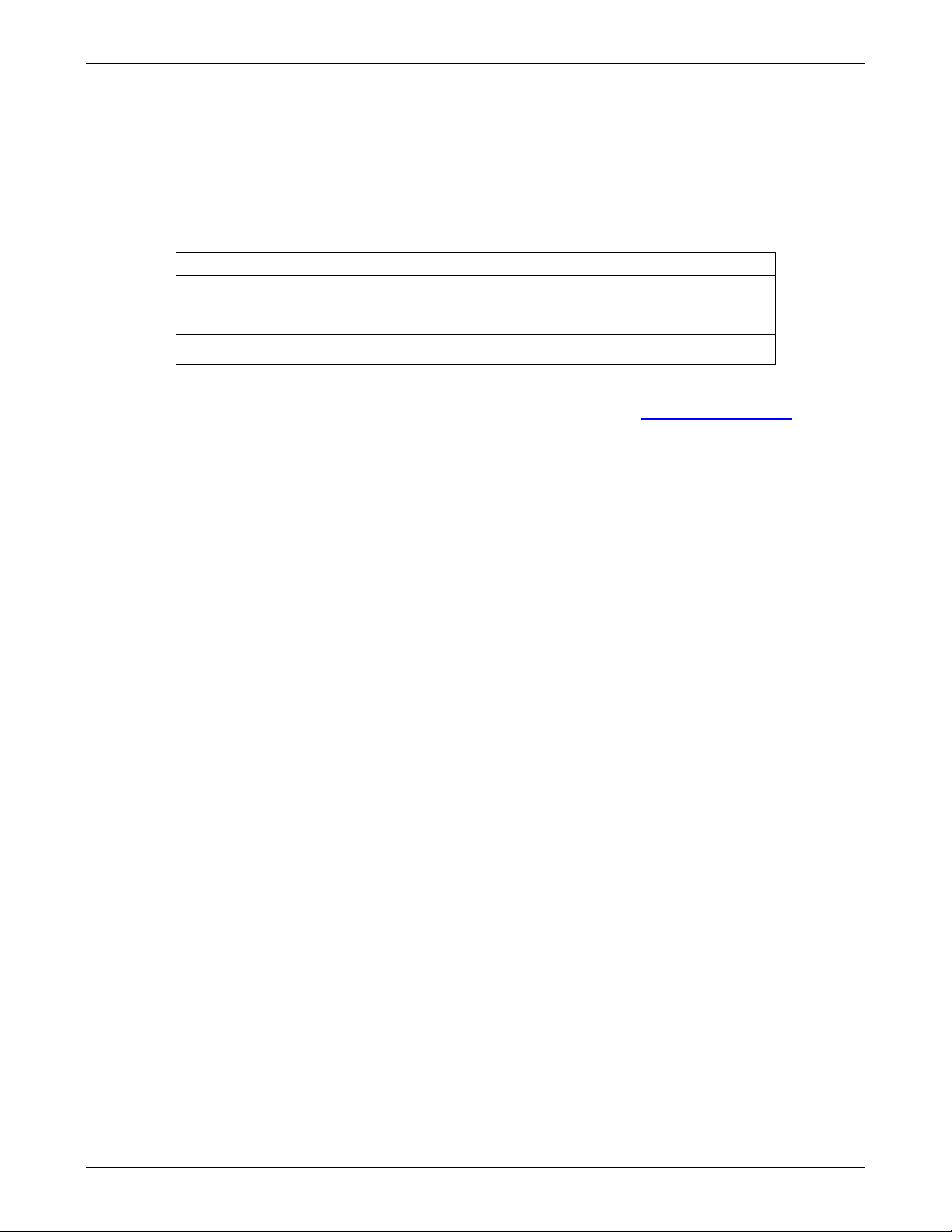

LIST OF TABLES

Table 2-1: Model 360E Basic Unit Specifications.................................................................................................. 3

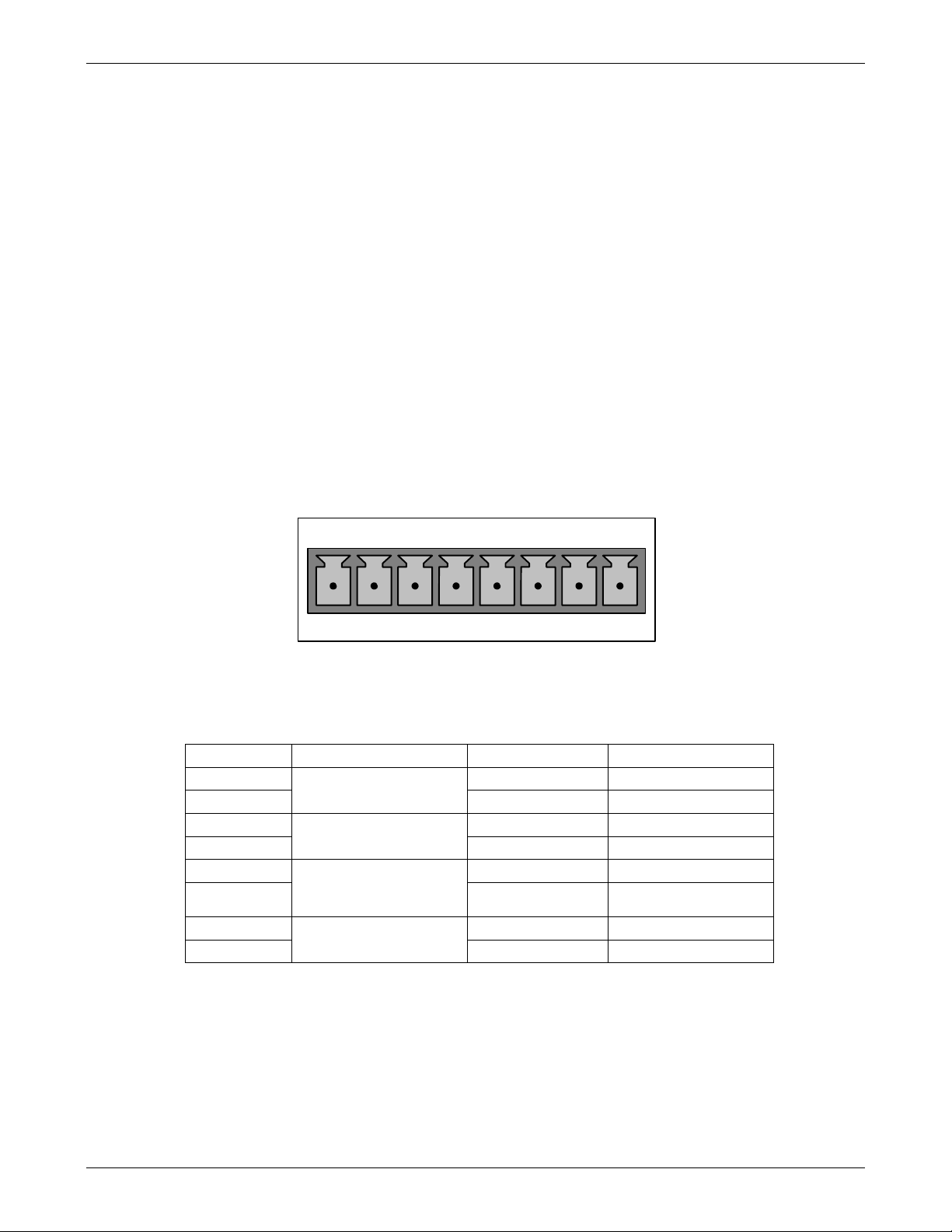

Table 3-1: M360E Analog Output Pin Outs ......................................................................................................... 13

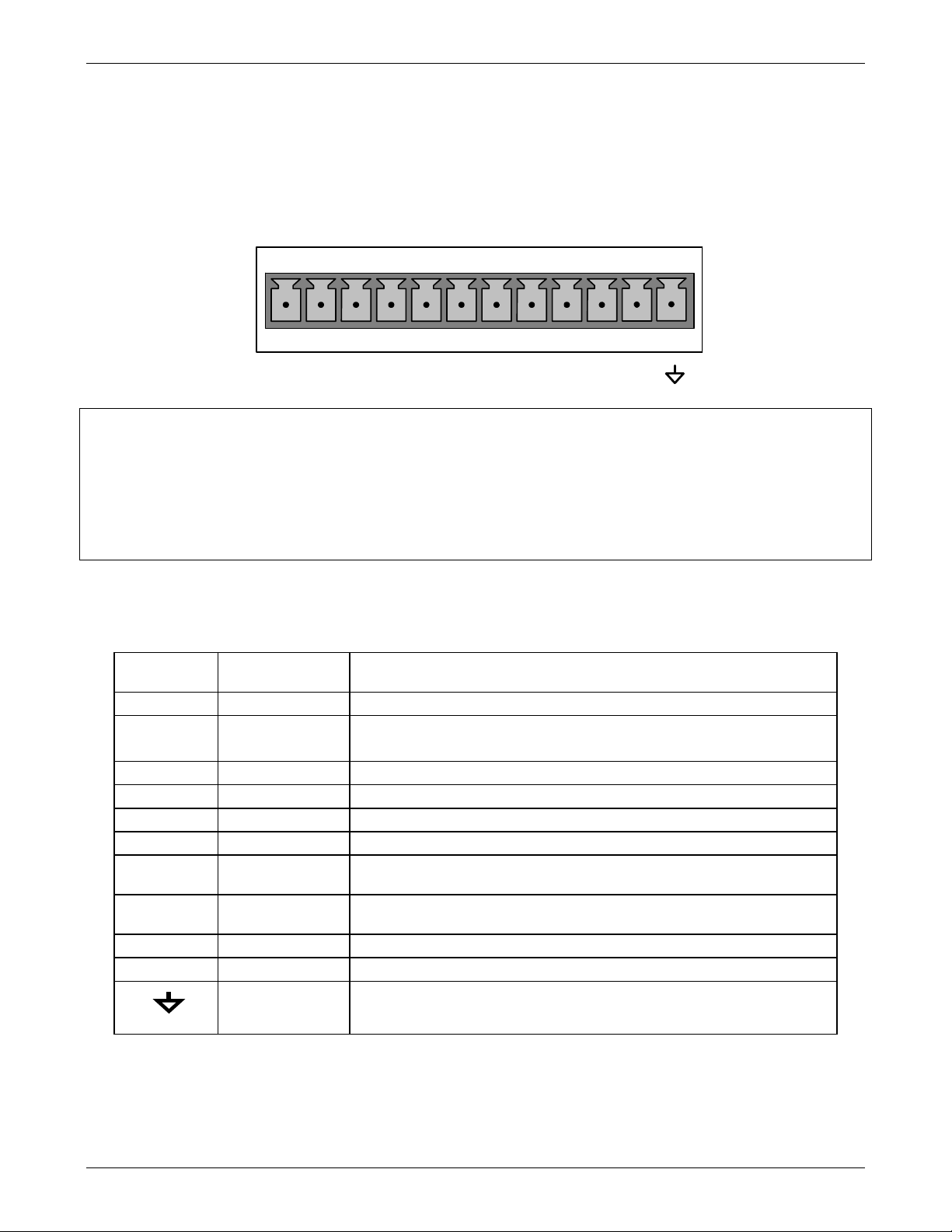

Table 3-2: M360E Status Output Pin Outs .......................................................................................................... 14

Table 3-3: M360E Control Input Pin Outs ........................................................................................................... 15

Table 3-4: Model 360E Rear Panel Pneumatic Connections.............................................................................. 17

Table 3-5: Front Panel Display During System Warm-Up................................................................................... 24

Table 3-6: Possible Warning Messages at Start-Up ........................................................................................... 25

Table 5-1: Zero/Span Valve Operating States for Options 50 & 51 .................................................................... 41

Table 5-2: Zero/Span Valve Operating States for Options 52 & 53 .................................................................... 43

Table 6-1: Analyzer Operating modes................................................................................................................. 52

Table 6-2: Test Functions Defined ...................................................................................................................... 53

0523

2 Rev B3 ix

Page 12

M360E Documentation Model 360E Instruction Manual

Table 6-3: List of Warning Messages .................................................................................................................. 55

Table 6-4: Primary Setup Mode Features and Functions.................................................................................... 57

Table 6-5: Secondary Setup Mode Features and Functions............................................................................... 57

Table 6-6: Front Panel LED Status Indicators for iDAS ........................................................................................ 59

Table 6-7: iDAS Data Channel Properties........................................................................................................... 60

Table 6-8: iDAS Data Parameter Functions ........................................................................................................ 61

Table 6-9: Password Levels ................................................................................................................................ 84

Table 6-10: COMM Port Communication modes......................................................................................... 91

Table 6-11: Ethernet Status Indicators .................................................................................................................. 93

Table 6-12: LAN/Internet Configuration Properties ............................................................................................... 94

Table 6-13: Internet Configuration Keypad Functions........................................................................................... 98

Table 6-14: Variable Names (VARS) Revision B.3 ............................................................................................. 103

Table 6-15: M360E Diagnostic (DIAG) Functions ............................................................................................... 105

Table 6-16: DIAG - Analog I/O Functions............................................................................................................ 108

Table 6-17: Analog Output Voltage Ranges....................................................................................................... 108

Table 6-18: Analog Output Current Loop Range................................................................................................. 109

Table 6-19: Analog Output Pin Assignments ...................................................................................................... 109

Table 6-20: Voltage Tolerances for Analog Output Calibration........................................................................... 112

Table 6-21: Current Loop Output Calibration with Resistor................................................................................. 115

Table 6-22: Test Parameters Available for Analog Output A4 ............................................................................ 121

Table 6-23: CO

Table 6-24: Status Output Pin Assignments ....................................................................................................... 124

Table 6-25: Control Input Pin Assignments......................................................................................................... 125

Table 6-26: Terminal Mode Software Commands............................................................................................... 126

Table 6-27: Command Types .............................................................................................................................. 127

Table 6-28: Serial Interface Documents .............................................................................................................. 131

Table 6-29: RS-232 Communication Parameters for Hessen Protocol............................................................... 132

Table 6-30: Teledyne Instruments Hessen Protocol Response Modes .............................................................. 134

Table 6-31: Default Hessen Status Bit Assignments........................................................................................... 135

Table 7-1: AUTOCAL Modes............................................................................................................................. 148

Table 7-2: AutoCal ATTRIBUTE Setup Parameters ......................................................................................... 148

Table 7-3: Calibration Data Quality Evaluation ................................................................................................. 151

Table 9-1: M360E Maintenance Schedule ........................................................................................................ 156

Table 9-2: M360E Test Function Record .......................................................................................................... 157

Table 9-3: Predictive uses for Test Functions ................................................................................................... 158

Table 10-1: Sync/Demod Status LED Activity ..................................................................................................... 177

Table 10-2: Relay Board Status LED’s................................................................................................................ 179

Table 10-3: Front Panel Status LED’s................................................................................................................. 185

Table 11-1: Warning Messages - Indicated Failures........................................................................................... 193

Table 11-2: Test Functions - Indicated Failures .................................................................................................. 195

Table 11-3: Sync/Demod Board Status Failure Indications................................................................................. 197

Table 11-4: I

Table 11-5: Relay Board Status LED Failure Indications .................................................................................... 199

Table 11-6: DC Power Test Point and Wiring Color Codes ................................................................................ 209

Table 11-7: DC Power Supply Acceptable Levels............................................................................................... 210

Table 11-8: Relay Board Control Devices ........................................................................................................... 211

Table 11-9: Opto Pickup Board Nominal Output Frequencies ............................................................................ 212

Table 11-10: Analog Output Test Function - Nominal Values Voltage Outputs .................................................... 214

Table 11-11: Analog Output Test Function - Nominal Values Current Outputs .................................................... 214

Table 11-12: Status Outputs Check ...................................................................................................................... 215

Table 12-1: Static Generation Voltages for Typical Activities................................................................................ 221

Table 12-2: Sensitivity of Electronic Devices to Damage by ESD ........................................................................ 222

Concentration Alarm Default Settings ...................................................................................... 122

2

2

C Status LED Failure Indications................................................................................................... 198

User Notes

x 05232 Rev B3

Page 13

Model 360E Instruction Manual M360E Documentation

1. M360E DOCUMENTATION

Thank you for purchasing the Model 300E Gas Filter Correlation Carbon monoxide Analyzer!

The documentation (part number 04584) for this instrument is available in several different formats:

Printed format, or;

Electronic format on a CD-ROM.

The electronic manual is in Adobe

software, which is necessary to view these files, can be downloaded for free from the internet at

www.adobe.com/.

http://

The electronic version of the manual has many advantages:

Keyword and phrase search feature

Figures, tables and internet addresses are linked so that clicking on the item will display the associated

feature or open the website.

A list of chapters as well as thumbnails of each page is displayed to the left of the text.

Entries in the table of contents are linked to the corresponding locations in the manual.

Ability to print s (or all) of the manual

Additional documentation for the Model 360E CO

http://www.teledyne-api.com/manuals/

APICOM software manual, part number 03945

Multi-drop manual, part number 01842

DAS Manual, part number 02837.

®

Systems Inc. “Portable Document Format”. The Adobe® Acrobat Reader®

Analyzer is available from Teledyne Instruments’ website at

2

1.1. Using This Manual

This manual has the following data structures:

1.0 TABLE OF CONTENTS:

Outlines the contents of the manual in the order the information is presented. This is a good overview of the

topics covered in the manual. There is also a list of tables, a list of figures and a list of appendices. In the

electronic version of the manual, clicking on any of these table entries automatically views that section.

2.0 SPECIFICATIONS AND WARRANTY

This section contains a list of the analyzer’s performance specifications, a description of the conditions and

configuration under which EPA equivalency was approved and Teledyne Instruments Incorporated’s warranty

statement.

3.0 GETTING STARTED:

A concise set of instructions for setting up, installing and running your analyzer for the first time.

4.0 FAQ:

Answers to the most frequently asked questions about operating the analyzer.

05232 Rev B3 1

Page 14

M360E Documentation Model 360E Instruction Manual

5.0 OPTIONAL HARDWARE & SOFTWARE

A description of optional equipment to add functionality to your analyzer.

6.0 OPERATION INSTRUCTIONS

This section includes step-by-step instructions for operating the analyzer and using its various features and

functions.

7.0 CALIBRATION PROCEDURES