Page 1

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

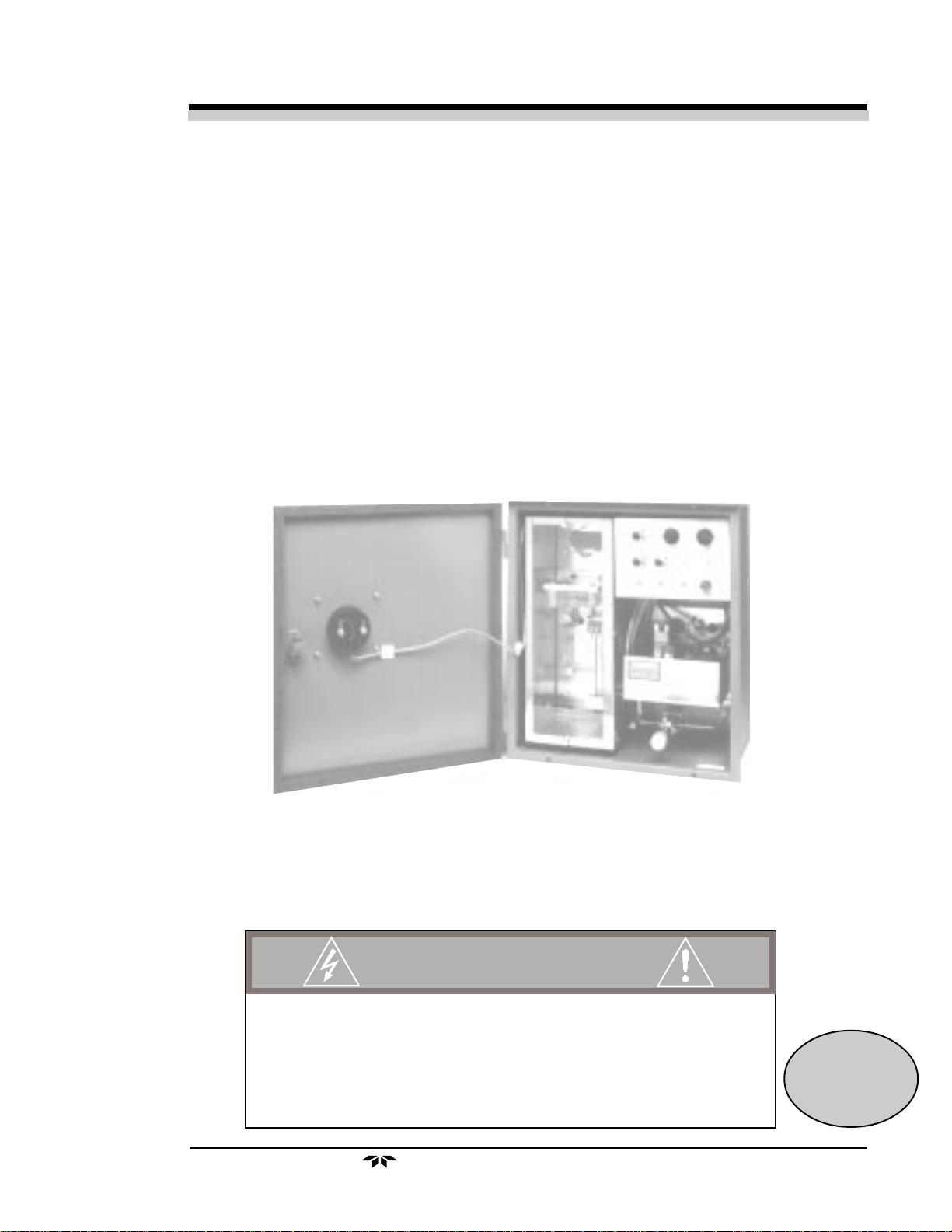

Model 356WA

Trace Oxygen Analyzer

Instruction Manual

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST FOR A

TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/MANAGER.

Teledyne Analytical Instruments

P/N M356WA

09/14/99

ECO # 99-0373

i

Page 2

Model 356WModel 356W

Model 356W

Model 356WModel 356W

Copyright © 1999 Teledyne Analytical InstrumentsCopyright © 1999 Teledyne Analytical Instruments

Copyright © 1999 Teledyne Analytical Instruments

Copyright © 1999 Teledyne Analytical InstrumentsCopyright © 1999 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

WarrantyWarranty

Warranty

WarrantyWarranty

This equipment is sold subject to the mutual agreement that it is warranted by us

free from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of sale, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, or neglect. We assume no liability for direct or indirect damages of any

kind and the purchaser by the acceptance of the equipment will assume all liability for

any damage which may result from its use or misuse.

AA

A

AA

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

Important NoticeImportant Notice

Important Notice

Important NoticeImportant Notice

This instrument is intended to be used a tool to gather valuable data. The information provided by the instrument may assist the user in eliminating potential hazards

caused by the process that the instrument is intended to monitor; however,

that all personnel involved in the use of the instrument or its interface with the processthat all personnel involved in the use of the instrument or its interface with the process

that all personnel involved in the use of the instrument or its interface with the process

that all personnel involved in the use of the instrument or its interface with the processthat all personnel involved in the use of the instrument or its interface with the process

being measured be properly trained in the process itself, as well as all instrumentationbeing measured be properly trained in the process itself, as well as all instrumentation

being measured be properly trained in the process itself, as well as all instrumentation

being measured be properly trained in the process itself, as well as all instrumentationbeing measured be properly trained in the process itself, as well as all instrumentation

related to it.related to it.

related to it.

related to it.related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and can be misused. In particular, any

alarm or control system installed must be tested and understood, both as they operate and

as they can be defeated. Any safeguards required such as locks, labels, or redundancy

must be provided by the user or specifically requested of Teledyne.

The purchaser must be aware of the hazardous conditions inherent in the process(es)

he uses. He is responsible for training his personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

it is essentialit is essential

it is essential

it is essentialit is essential

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control.

or implied by this document or any information disseminated by the manufacturer oror implied by this document or any information disseminated by the manufacturer or

or implied by this document or any information disseminated by the manufacturer or

or implied by this document or any information disseminated by the manufacturer oror implied by this document or any information disseminated by the manufacturer or

his agents is to be construed as a warranty of adequate safety control under the user'shis agents is to be construed as a warranty of adequate safety control under the user's

his agents is to be construed as a warranty of adequate safety control under the user's

his agents is to be construed as a warranty of adequate safety control under the user'shis agents is to be construed as a warranty of adequate safety control under the user's

process conditions.process conditions.

process conditions.

process conditions.process conditions.

ii

Teledyne Analytical Instruments

No statement expressedNo statement expressed

No statement expressed

No statement expressedNo statement expressed

Page 3

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

T ab le of Contents

1 Introduction

1.1 Method of Operation................................................. 1-1

1.2 Required Equipment................................................. 1-2

1.2.1 Sample Conditioning................................... 1-2

1.2.2 Recorder /Meter Readout ........................... 1-2

2 Operational Theory

2.1 Sensor ..................................................................... 2-1

2.2 Humidifier ................................................................ 2-1

2.3 Flow System............................................................ 2-2

3 Installation

3.1 Location.................................................................... 3-1

3.2 Electrical Connections............................................. 3-1

3.3 Sample Connections ............................................... 3-2

4 Operations

4.1 Filling the Reservoir.................................................. 4-1

4.2 Detector Cell............................................................. 4-1

4.2.1 Cell Packaging ............................................ 4-1

4.2.2 Electrolyte ................................................... 4- 1

4.2.3 Cell Installation............................................ 4-3

4.3 Throttle Valve ........................................................... 4 -5

4.4 Humidity Control....................................................... 4-5

4.5 Power ....................................................................... 4 -7

4.6 Warm-Up and Stabilization....................................... 4-7

4.7 Calibration ................................................................ 4-7

5 Maintenance & Troubleshooting

5.1 Flowmeter and Humidifier ....................................... 5- 1

5.2 Cell Electrolyte Level............................................... 5-1

5.3 Reservoir ................................................................. 5-1

5.4 Calibration ............................................................... 5-1

5.5 Cell .......................................................................... 5-2

5.5.1 Electrolyte Replacement.............................. 5 -2

5.5.2 Lead Electrode............................................. 5 -2

5.6 Screen Assembly..................................................... 5-4

Teledyne Analytical Instruments

iii

Page 4

5.7 Reservoir and Humidifier Column ........................... 5 -4

5.8 Leak Detection ........................................................ 5-6

5.8.1 Leak Detection Procedure ........................... 5-6

5.8.2 Cell Leak...................................................... 5 -7

Appendix

Specifications ................................................................. A-1

Spare Parts List.............................................................. A-2

Drawing List.................................................................... A-3

Calibration Data.............................................................. A-4

Material Safety Data Sheets........................................... A-9

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

iv

Teledyne Analytical Instruments

Page 5

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

The Teledyne Analytical Instruments Model 356WA Trace Oxygen

Analyzer is designed to detect oxygen concentrations in process streams. It

utilizes Teledyne’s patented electrochemical sensor which requires minimal

maintenance and exhibits a 90% response in less than one minute. Cell

output is insensitive to flow rate changes within the operating range of the

analyzer’s flowmeter.

The Model 356WA features a welded stainless sampling system for

long-term, leak-free operation.

While the analyzer is offered in several configurations, they are virtually

identical with the exception of housing or options such as special meters. For

purposes of clarity, this manual will discuss the unit in general. The differences between the configurations are minor and will be obvious to the user.

yzyz

erer

yz

er

yzyz

erer

IntroductionIntroduction

Introduction

IntroductionIntroduction

Introduction 1Introduction 1

Introduction 1

Introduction 1Introduction 1

1.11.1

1.1

1.11.1

Gas from the process stream is fed through a sample line to the sample

inlet port of the analyzer. The sample is directed through the analyzer’s

sample system, where oxygen concentration is detected by the sensor. The

sensor generates an output signal which is read out on a suitable recorder or

meter.

The analyzer components include:

• A throttle valve and flowmeter to control sample flow

• A humidifier to condition the sample

• The measuring cell where catalytic conversion occurs

• An electronic amplifier circuit for converting the output of the

cell to a DC signal.

• A thermostatic assembly for temperature control in the cell

compartment

• A reservoir for providing make-up water to the humidifier.

Method of OperationMethod of Operation

Method of Operation

Method of OperationMethod of Operation

Teledyne Analytical Instruments

1-1

Page 6

1 Introduction1 Introduction

1 Introduction

1 Introduction1 Introduction

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

1.21.2

1.2

1.21.2

For proper operation, the analyzer may require accessory equipment,

particularly in the area of sample conditioning. The need for additional

equipment is dictated by the conditions of each application.

1.2.11.2.1

1.2.1

1.2.11.2.1

The sample must be free of entrained solids and condensable vapors,

and be at a relatively constant pressure between

more efficient operation is obtained with pressures in the range of

psigpsig

psig. Pressure surges can carry fluid from the humidifier into the cell and

psigpsig

impair cell operation. Filters, scrubbers, or pressure regulators are often

necessary, depending on local conditions.

1.1.

Filters.Filters.

1.

Filters. If filters are necessary, they should be conveniently

1.1.

Filters.Filters.

located near the analyzer, and installed in a fashion which permits

easy removal for periodic cleaning or replacement.

2.2.

Scrubbers.Scrubbers.

2.

Scrubbers. If the sample contains small quantities of acidic

2.2.

Scrubbers.Scrubbers.

anhydrides (SO2, etc.) or mercaptans (H2S, etc.) they will react

with the electrolyte or the cathode, and must be removed. A

caustic scrubber is usually effective.

Required EquipmentRequired Equipment

Required Equipment

Required EquipmentRequired Equipment

Sample ConditioningSample Conditioning

Sample Conditioning

Sample ConditioningSample Conditioning

1 and 100 psig1 and 100 psig

1 and 100 psig. However,

1 and 100 psig1 and 100 psig

5 to 105 to 10

5 to 10

5 to 105 to 10

3.3.

Pressure regulators.Pressure regulators.

3.

Pressure regulators. While the analyzer will accept pressures to

3.3.

Pressure regulators.Pressure regulators.

100 psig, a range of

pressure surges can affect instrument operation. In either case, the

use of a pressure regulator is advisable. Install the regulator as

close to the sample point as possible to reduce sample travel time

to a minimium. The regulator should incorporate a metallic

diaphragm to prevent the diffusion of atmospheric oxygen into

the sample.

1.2.21.2.2

1.2.2

1.2.21.2.2

The meter installed on the 356WA is either analog or digital. The

recorder used for analyzer signal readout is usually of the self-balancing

potentiometric type. It should have an input inpedance of

Output is 0 to 1VDC or less (optional: 1 to 5, 4 to 20, or 10 to 50 mADC).

Recorder /Meter ReadoutRecorder /Meter Readout

Recorder /Meter Readout

Recorder /Meter ReadoutRecorder /Meter Readout

5 to 10 psig5 to 10 psig

5 to 10 psig is recommended. In addition,

5 to 10 psig5 to 10 psig

10 10

ΩΩ

10

Ω or higher.

10 10

ΩΩ

1-2

Teledyne Analytical Instruments

Page 7

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

The sensor is an open-cathode cell, an electrochemical transducer

specific to oxygen. The cathode of the cell is composed of silver screen

elements with a large surface area. The screen assembly is mounted in an

acrylic block, with the lower edges of the screens immersed in potassium

hydroxide electrolyte. A thin layer of electrolyte is maintained on the surfaces of the screens by capillary action. A lead disk is positioned under the

screens and serves as the anode. An exploded view of the cell is showm in

Figure 5-1.

yzyz

erer

yz

er

yzyz

erer

Operational TheoryOperational Theory

Operational Theory

Operational TheoryOperational Theory

2.1 Sensor2.1 Sensor

2.1 Sensor

2.1 Sensor2.1 Sensor

Operational Theory 2Operational Theory 2

Operational Theory 2

Operational Theory 2Operational Theory 2

The sample gas stream is passed directly over the cathode screens,

initiating an electrochemical reaction. Four electrons are generated by the

oxidation of the lead anode, and are then used to reduce oxygen at the

cathode. The flow of electrons between the anode and cathode creates an

electric current which is directly proportional to the oxygen concentration in

the sample stream. In the absence of oxygen, no oxidation or reduction

takes place, and no current is produced.

In simplified form, the reaction may be described as follows: oxygen is

reduced at the cathode by the mechanism

4e- +O2 + 2H2O → 4OH

This cathodic half-reaction occurs simultaneously with the anodic halfreaction

Pb + 2OH- → PbO + H2O + 2e

The overall reaction is

O2+ 2Pb → 2PbO

2.2 Humidifier2.2 Humidifier

2.2 Humidifier

2.2 Humidifier2.2 Humidifier

-

-

It is necessary to maintain a film of electrolyte on the screens of the

electrode assembly. This means that the humidity of the sample as it flows

through the cell must be such that the water vapor pressure of the electro-

Teledyne Analytical Instruments

2-1

Page 8

2 Operational Theory2 Operational Theory

2 Operational Theory

2 Operational Theory2 Operational Theory

lyte is equal to the water vapor pressure in the sample gas. If the humidity

of the sample is too low, water will evaporate from the electrolyte, drying

the cell. If the sample humidity is too high, water will condense out into the

electrolyte, flooding the cell.

The sample is humidified by bubbling it through water in the humidifier

column just before it enters the cell. The humidifier column is in the same

heated compartment as the cell and so is held at the same temperature. The

water in the column, however, is cooled by evaporation into the sample gas.

Thus, the sample gas will normally have a humidity that is too low for

equilibrium with the cell. It is assumed here, of course, that since the cell

component is heated above ambient temperature, the sample gas is less than

saturated at the compartment temperature when it enters the analyzer.

The humidity of the sample is increased to be in equilibrium with the

cell electrolyte by heating the water in the humidifier column. The humidifer

heater is in the base of the column, and the amount of heating is adjusted

with the humidity control that is located on the panel of the control unit.

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

The amount of heating required depends on the sample flow rate, the

sample humidity, and the specific heat of the sample. The correct adjustment for the operating conditions of any particular installation is obtained by

checking the cell electrolyte level periodically and replenished when necessary according to the instructions in Section 4.2.3:

The humidifier column also contains baffles to stop water from splashing up into the line to the sample cell at high flow rates.

2.3 Flow System2.3 Flow System

2.3 Flow System

2.3 Flow System2.3 Flow System

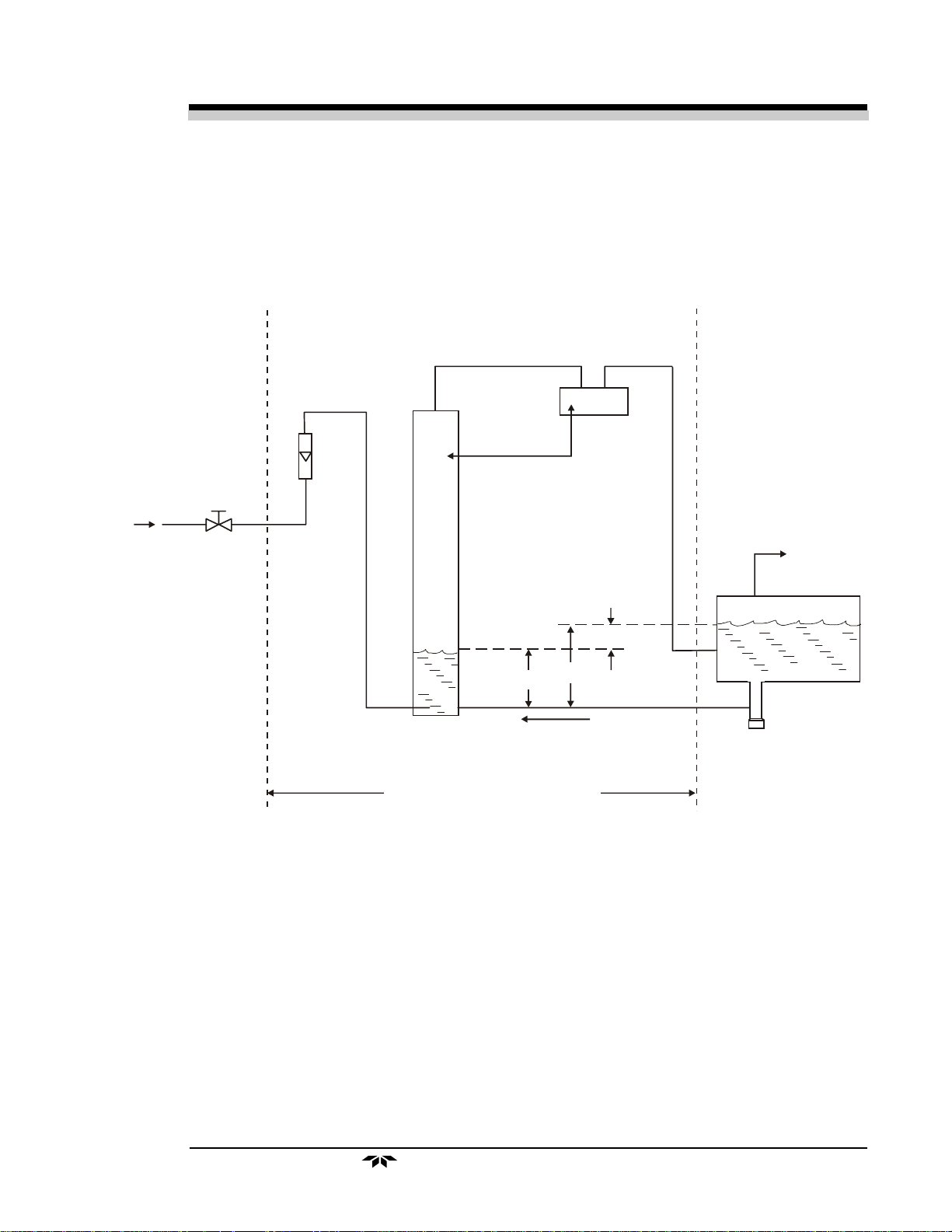

The analyzer flow system is shown schematically in Figure 2-1. It

includes a needle valve for adjusting the sample flow rate, a flowmeter to

indicate the sample flow required for calibration, the humidifier, the measuring cell, and an automatic level control system for the water in the humidifier.

As can be seen from Figure 2-1, the sample enters the humidifier

column against the pressure of a water column from the base of the humidifier to the water level in the reservoir, which is approximately 4 inches.

This determines the minimum sample pressure at which any sample can flow

through the analyzer. In practice, the sample pressure must be somewhat

greater than this in order to have an adequate flow rate.

Cell Installation

.

The automatic level control in the humidifier column is accomplished

by connecting the sample outflow from the cell to the bottom of the reser-

2-2

Teledyne Analytical Instruments

Page 9

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Cell

Operational Theory 2Operational Theory 2

Operational Theory 2

Operational Theory 2Operational Theory 2

Flowmeter

Sample In

Throttle

Valve

Humidifier

Column

Cell Comp a rtment

Pressure

ATM + (b - a)

Vent

b - a

b

a

Water

Reservoir

Drain

Figure 2-1: Flow System Schematic

Teledyne Analytical Instruments

2-3

Page 10

2 Operational Theory2 Operational Theory

2 Operational Theory

2 Operational Theory2 Operational Theory

voir. This places a back pressure on the sample in the cell and upper portion

of the humidifier column equal to the water column from the bottom of the

reservoir to the water level in the reservoir. Thus, the water level in the

humidifier column is held even with the sample connection at the bottom of

the reservoir. There will be a slight additional pressure in the top of the

humidifier column depending on the flow rate (the pressure needed to push

the sample through the cell and associated tubing), but at normal flow rates

this merely slightly lowers the level in the humidifier column.

The sample bubbles through the water in the reservoir on its way to the

outlet port. Some of the water vapor will re-condense, so that the sample

flows out of the outlet port saturated at the reservoir temperature, which is

slightly above ambient. The sample bubbling through the make-up water

will scrub out any oxygen which may be dissolved in it. This assures that the

sample will not pick up any oxygen as it passes through the humidifier

column.

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

2-4

Teledyne Analytical Instruments

Page 11

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

erer

yz

er

yzyz

erer

InstallationInstallation

Installation

InstallationInstallation

3.1 Location3.1 Location

3.1 Location

3.1 Location3.1 Location

Installation 3Installation 3

Installation 3

Installation 3Installation 3

With proper shielding of the leads, the analyzer and the readout device

can be separated by as much as 1,000 feet. However, they should be placed

as close together as possible. For the most convenient operation, the readout recorder or meter should be within view of the controls, particularly

when the unit is being calibrated. Figure 2-1 depicts a typical system layout.

Other location considerations:

1) The analyzer should be sheltered from the elements.

2) Ambient temperature must be within

30 to 120 °F.30 to 120 °F.

30 to 120 °F.

30 to 120 °F.30 to 120 °F.

3) The unit should not be subject to excessive shock or vibration.

4) It should be as close as possible to the sample point.

5) There must be access to the back and side of the unit for

connection or maintenance of sample lines and power.

NOTE:NOTE:

NOTE:

NOTE:NOTE:

Since the level of the electrolyte in the measuring cell is critical andSince the level of the electrolyte in the measuring cell is critical and

Since the level of the electrolyte in the measuring cell is critical and

Since the level of the electrolyte in the measuring cell is critical andSince the level of the electrolyte in the measuring cell is critical and

the water level control system for the humidifier is gravity sensitive,the water level control system for the humidifier is gravity sensitive,

the water level control system for the humidifier is gravity sensitive,

the water level control system for the humidifier is gravity sensitive,the water level control system for the humidifier is gravity sensitive,

THE ANALYZER MUST BE MOUNTED SO THAT THE BOTTOM OFTHE ANALYZER MUST BE MOUNTED SO THAT THE BOTTOM OF

THE ANALYZER MUST BE MOUNTED SO THAT THE BOTTOM OF

THE ANALYZER MUST BE MOUNTED SO THAT THE BOTTOM OFTHE ANALYZER MUST BE MOUNTED SO THAT THE BOTTOM OF

THE CASE IS LEVEL.THE CASE IS LEVEL.

THE CASE IS LEVEL.

THE CASE IS LEVEL.THE CASE IS LEVEL.

3.2 Electrical Connections3.2 Electrical Connections

3.2 Electrical Connections

3.2 Electrical Connections3.2 Electrical Connections

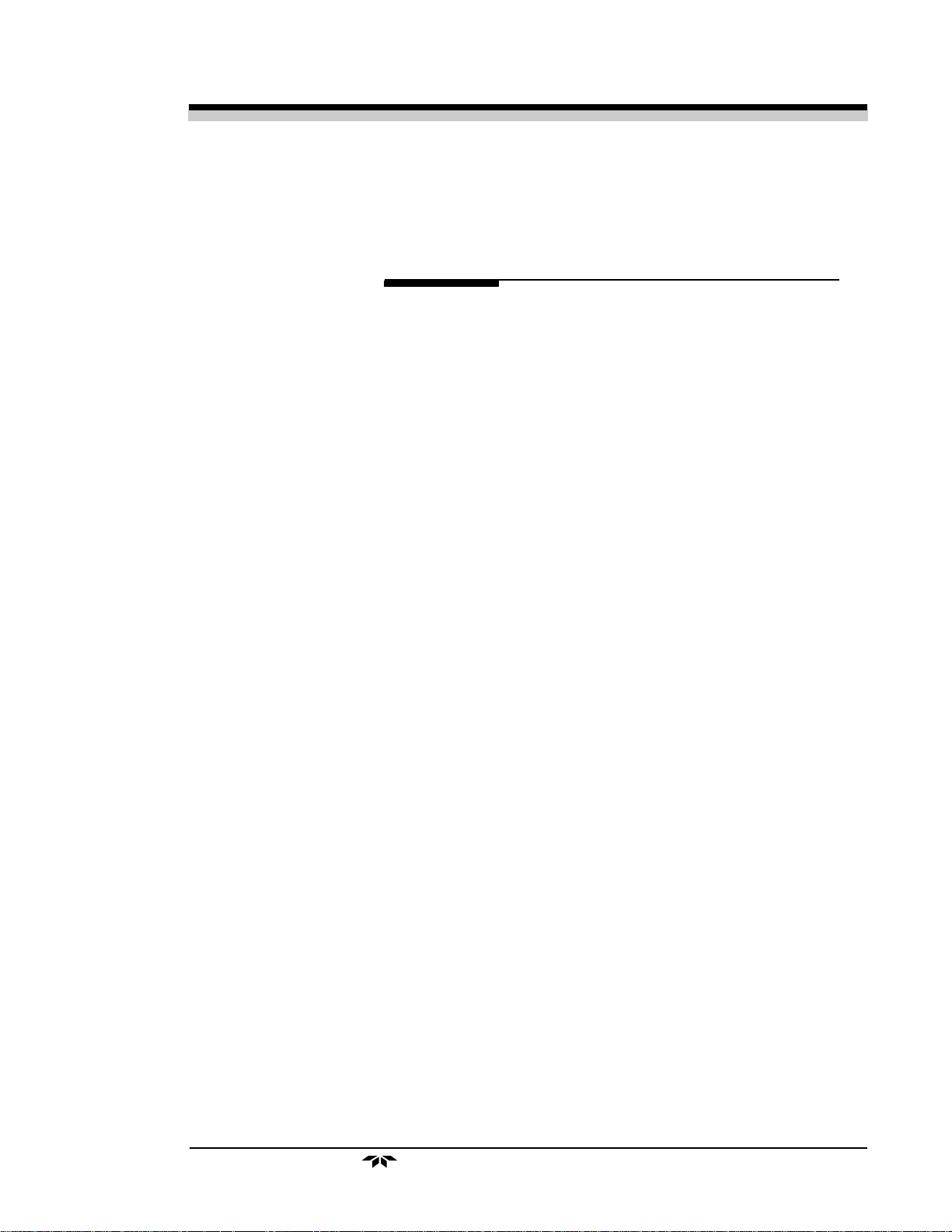

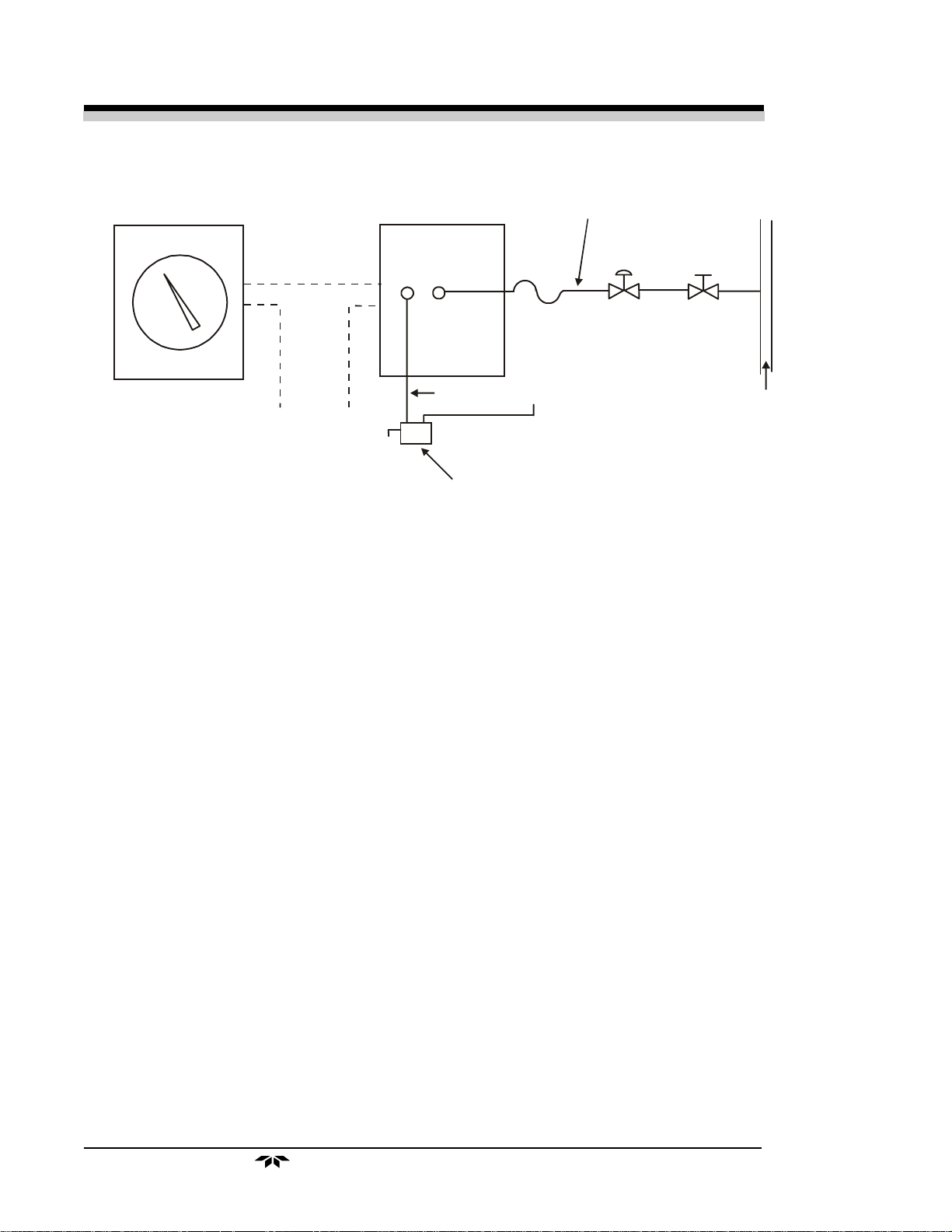

A diagram of the necessary electrical connections is shown in Figure 2-2.

Note: Note:

Note:

Note: Note:

See the Interconnection Diagram (drawing A-37526) included in theSee the Interconnection Diagram (drawing A-37526) included in the

See the Interconnection Diagram (drawing A-37526) included in the

See the Interconnection Diagram (drawing A-37526) included in theSee the Interconnection Diagram (drawing A-37526) included in the

back of this manual, as well as any Addenda that may be includedback of this manual, as well as any Addenda that may be included

back of this manual, as well as any Addenda that may be included

back of this manual, as well as any Addenda that may be includedback of this manual, as well as any Addenda that may be included

with this manual for information specific to your instrument.with this manual for information specific to your instrument.

with this manual for information specific to your instrument.

with this manual for information specific to your instrument.with this manual for information specific to your instrument.

Teledyne Analytical Instruments

3-1

Page 12

3 Installation3 Installation

3 Installation

3 Installation3 Installation

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

Recorder

115 VAC Power and Ground

2 Power Leads

1 Ground Wire

(16 ga. Insulated)

Signal Leads

(22 ga. Twisted

Pair Shielded

Cable)

Figure 2-1 Typical System Layout

Perc ent Oxygen

Analyzer

Vent

Sample

In

1/4"

Tubing

Condensat e Trap

Vent

Sample Line

(1/4" or 1/8" Metal Tubing)

Pressure

Regulator

(5-10 psig Output)

The connections include a terminal for grounding the analyzer case and

chassis in accordance with accepted industrial practices. The maximum

power requirement is less than

1½ amperes at 115 VAC1½ amperes at 115 VAC

1½ amperes at 115 VAC.

1½ amperes at 115 VAC1½ amperes at 115 VAC

Shut Off

Valve

Sample

Line

3.3 Sample Connections3.3 Sample Connections

3.3 Sample Connections

3.3 Sample Connections3.3 Sample Connections

The sample line is connected at the back of the analyzer case as depicted in Figure 2-3. Use care in assembling any part of the sampling system

to avoid leaks. Oxygen can diffuse into the system through small leaks even

when sample pressure is much greater than atmospheric pressure. A 1/8"

female NPT fitting is installed on the back of the instrument for making

sample and vent line connections. Thepurge line is fitted with a 1/4" tube

fitting.

ConnectorsConnectors

1.

Connectors. Use straight tube connectors where possible.

ConnectorsConnectors

This facilitates removal of the analyzer section from the case

during maintenance or service.

LinesLines

2.

Lines. Lines should consist of metallic tubing, since oxygen can

LinesLines

diffuse through plastic. Use continuous tubing where possible.

VentVent

3.

Vent. The analyzed sample is vented through the back of the

VentVent

unit as shown in Figure 2-3.

3-2

Teledyne Analytical Instruments

Page 13

mV

Output

GND

Current

Output

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

erer

yz

er

yzyz

erer

TS 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Installation 3Installation 3

Installation 3

Installation 3Installation 3

HOT

NEUT

GND

NO

C

NC

NO

C

NC

AC Power In

150 Watt Max

Load

Alarm 2

Alarm 1

Figure 2-2: General Connection Diagram

See the specific Interconnection Diagram for your instrument in the drawing

package located at the back of the manual. See also any Addenda that may be

included with this manual.

The analyzer should have a vent line of ¼" diameter tubing at least two

feet long, running

downwarddownward

downward from the vent connection. This is to prevent

downwarddownward

air from diffusing into the reservoir and dissolving into the humidifier makeup water.

If it is not desirable to vent the sample into the atmosphere, a vent line

to carry the sample to a suitable venting area will be required. The sample

leaves the vent connection of the analyzer saturated with water vapor at a

temperature somewhat above ambient, so a suitable trap to remove condensate without plugging the vent line will be required. The vent line should

also be arranged so that it cannot become plugged by dirt or dust.

Teledyne Analytical Instruments

3-3

Page 14

3 Installation3 Installation

3 Installation

3 Installation3 Installation

15"

Model 356WModel 356W

Model 356W

Model 356WModel 356W

9"

AA

A

AA

18-1/4"

7/8" dia. holes

for 1/2" conduit

5/16"

17-9/16"

115 V 50/60 Hz

Pow er I n

Signal Out

2"

17"

7-15/16"

Sample

Purge

Vent

1/4" Female NPT

3-4

FIGURE 5 ANALYZER OUTLINE DIA GRAM

Figure 5: Gas Connections to Back of Analyzer

Teledyne Analytical Instruments

Page 15

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

erer

yz

er

yzyz

erer

OperationsOperations

Operations

OperationsOperations

Operations 4Operations 4

Operations 4

Operations 4Operations 4

4.14.1

4.1

4.14.1

The reservoir is located on the right side of the analyzer case.

1) Insure that the cap on the drain spout is securely tightened.

2) Remove cap from fill port on top of reservoir.

3) Pour distilled water into reservoir until it is half full (about one

quart). The water will automatically flow into the humidifier

column.

4) Replace cap on fill port and securely tighten. A missing or loose

cap will permit the sample to vent into the analyzer case.

4.24.2

4.2

4.24.2

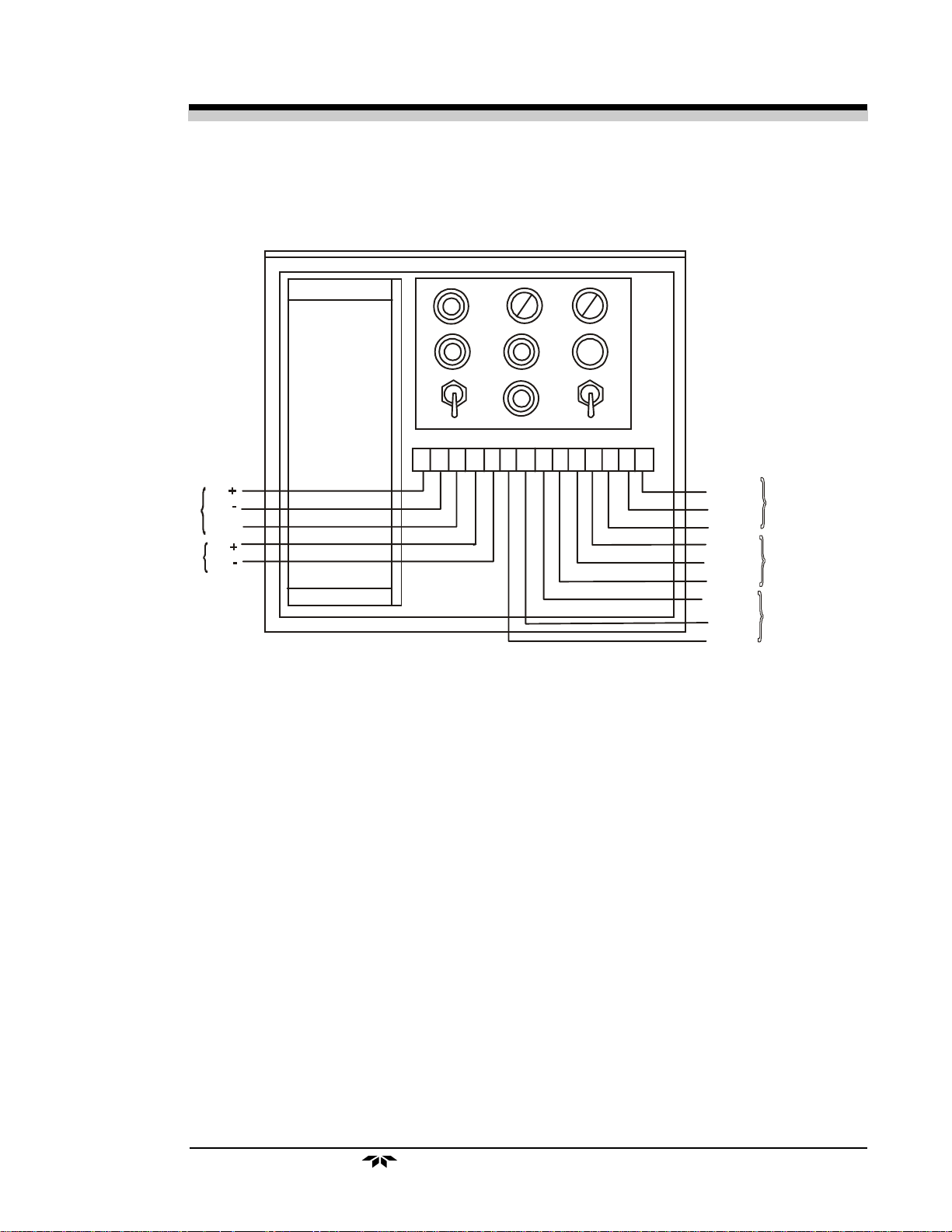

The cell is located in the heated compartment on the left side of the

analyzer case, as shown in Figure 4-1. To open the compartment, unscrew

the captive knurled knobs at the top and bottom of the compartment and

remove the plastic window.

4.2.14.2.1

4.2.1

4.2.14.2.1

The cell is packaged separately from the analyzer. It is filled with

distilled water to prevent oxidation of the electrodes from exposure to the

atmosphere. The cell should be left filled with the distilled water until the

analyzer is installed and ready for operation. The cell should not be exposed

to the atmosphere for any prolonged duration.

Filling the ReservoirFilling the Reservoir

Filling the Reservoir

Filling the ReservoirFilling the Reservoir

Detector CellDetector Cell

Detector Cell

Detector CellDetector Cell

Cell PackagingCell Packaging

Cell Packaging

Cell PackagingCell Packaging

4.2.24.2.2

4.2.2

4.2.24.2.2

The cell electrolyte is Teledyne Type A, used in applications where

there is a complete absence of acidic anhydrides (CO2, SO2) in the sample

gas. Type A electrolyte is a 10% solution (w/v) of reagent-grade potassium

hydroxide (KOH) in distilled water.

ElectrolyteElectrolyte

Electrolyte

ElectrolyteElectrolyte

Teledyne Analytical Instruments

4-1

Page 16

4 Operations4 Operations

4 Operations

4 Operations4 Operations

Cell Compartment Terminal Strip

Heater

Control Assembly

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

Cell

Assembly

Heate r

Flowmeter

Humidifier

Column

Assembly

Sample

System

Assembly

1 2 3 4 5

Span

Current Adj

2

1

Range

Alarm 1

Alarm 2

3

20

10

Humidifier

Control

2 Amp

30

Interconnect

Terminal Strip

Throttle

Valve

Sample

System

Assembly

with

Reservoir

Figure 4-1: Typical Model 306WA With 2 Alarm Option

WARNING:

Type A electrolyte is caustic. Use extreme care in

handling. Protective equipment including but not

limited to gloves and safety glasses should be worn

while handling electrolyte. Refer to the Material Safety

Data Sheet in the Appendix regarding potential hazards

and corrective action in case of accident.

Type B electrolyte is a 20 % solution (w/v) of potassium carbonate and

should be used when the CO2 level in the background gas is between 500

ppm and 1 %. This narrow range is rarely encountered. It is, however

available from the factory. Safety related information for this electrolyte can

be found in the Appendix.

Type C electrolyte is a 20 % solution (w/v) of potassium bicarbonate

and should be used when the CO2 level in the background gas is between 1

and 100 %. Safety related information for this electrolyte can be found in

the Appendix.

4-2

Teledyne Analytical Instruments

Page 17

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

Sufficient electrolyte is provided for initial servicing of the cell. Electrolyte for future service should be ordered from Teledyne. When ordering,

specify type and quantity.

yzyz

yz

yzyz

erer

er

erer

Operations 4Operations 4

Operations 4

Operations 4Operations 4

4.2.34.2.3

4.2.3

4.2.34.2.3

Prior to servicing and installing the cell, inspect the lead electrode in

the acrylic base for signs of oxidation, indicated by a reddish-brown or

yellow discoloration. If discoloration is noted, clean the cell as directed in

section 5.5.2 before placing it in service.

WARNING: Type A electrolyte is caustic. Use extreme care in

handling. Protective equipment including but not

limited to gloves and safety glasses should be worn

while handling electrolyte. Refer to the Material Safety

Data Sheet in the Appendix regarding potential hazards

and corrective action in case of accident.

1) Remove the four cell mounting bolts which secure the plastic

cover. Pour out the distilled water.

2) Pour about half the furnished electrolyte into the cell and slosh

until all components within the cell are wetted by the solution.

Drain and dispose of the solution.

3) Wipe the top of the cell and the O-ring with a clean, disposable

tissue to remove solution from the exterior.

interior of the cell.

4) Carefully pour in electrolyte until it just touches the bottom edge

of the silver screen assembly at all points. This is indicated by a

definite wicking of electrolyte onto the screen assembly at every

point along ithe bottom edge. It is essential at this point that the

bottom edge of the screen assembly be wetted at all points (as

seen by the wicking action), but not over-immersed (as large a

surface area as possible of the screen assembly must remain

above the electrolyte, while every point of the bottom edge must

be wetted). The level is correct when the bottom edge of the

sensor screen is wetted but not immersed; approximately 3/32 "of

the silver electrode extends into the pool of eelectrolyte.

Cell InstallationCell Installation

Cell Installation

Cell InstallationCell Installation

DO NOTDO NOT

DO NOT touch the

DO NOTDO NOT

NOTE:The electrolyte level in the cell is critically related to its sensitivity

due to the change in the cathode surface area exposed to the

eledctrolyte.

5) Carefully place the cell under the cell mounting plate with the

outer terminal toward the front. Secure in place with four bolts

supplied with the cell. Refer to Figure 4-2.

Teledyne Analytical Instruments

4-3

Page 18

4 Operations4 Operations

4 Operations

4 Operations4 Operations

O-Ring

Cell Mounting

Bolts

Flowmeter

Model 356WModel 356W

Model 356W

Model 356WModel 356W

Terminal Strip

No. 4

AA

A

AA

4-4

Cell Block

Sample Flow

Control Valve

Humidifier Column Heater

Humidifier Column

Figure 4-2: Cell Compartment Components

Teledyne Analytical Instruments

Page 19

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

6) Connect the red lead to the center terminal and the black lead to

NOTE:The silver screens in the cell have been specially treated to pro-

vide proper detection characteristics. They must be kept clean and

MUST NOT be touched. Even clean fingers secrete natural oils

which contaminate the screens. If the screens need straightening,

wash a small pair of tweezers thoroughly to remove any grease,

rinse them in distilled water, and use them to carefully bend the

screens back into place.

yzyz

erer

yz

er

yzyz

erer

the outer terminal.

Operations 4Operations 4

Operations 4

Operations 4Operations 4

4.34.3

4.3

4.34.3

The throttle valve is located at the top of the reservoir tank. Refer to

Figure 4-1.

1) Gently turn the valve counterclockwise. A stream of bubbles

should appear at the base of the humidifier column, and the float

of the flowmeter should rise in its tube.

2) Adjust the valve so that the flowmeter float is centered in the

flow rate reference indicator.

CAUTION: Open the throttle valve carefully. Excessive flow rate

may cause water in the humidifier column to be carried

into the detector cell. This can cause erratic readings

and may require disassembly, cleaning, and refilling of

the sensor

3) The flowmeter indicator has been factory set to a flow rate of

150 cc/min150 cc/min

150 cc/min. for the specified sample gas.

150 cc/min150 cc/min

CAUTION: Excessive flow rate may cause water in the humidifier

to be carried to the flowmeter causing moisture to

accumulate. This can cause the ball to stick in the

flowmeter. To remove moisture, remove the flowmeter

and allow to air or blow dry. Refer to the detailed instructions in Figure 5-2 for removal and installation of

the column.

Throttle ValveThrottle Valve

Throttle Valve

Throttle ValveThrottle Valve

.

4.44.4

4.4

4.44.4

The humidity control is located on the front panel of the control unit,

and is adjusted to maintain a constant electrolyte level in the detector cell.

In effect, the control governs the humidity of the sample which is directed

to the cell.

Humidity ControlHumidity Control

Humidity Control

Humidity ControlHumidity Control

Teledyne Analytical Instruments

4-5

Page 20

4 Operations4 Operations

4 Operations

4 Operations4 Operations

Wick Saturated With KOH

Electrolyte Solution

Outside Electrode Connected to

"Y" Terminal Post (+)

Oxygen Generated Here

Model 356WModel 356W

Model 356W

Model 356WModel 356W

Electrical Terminal Board

Sub-Assembly

AA

A

AA

4-6

O-Ring

Inside Electrode Connected

to "B" Terminal Po st (-)

Hydrogen Generated Here

Figure 8: Calibrator Assembly

Teledyne Analytical Instruments

Page 21

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Operations 4Operations 4

Operations 4

Operations 4Operations 4

1) At start-up, the humidity control knob should be set to

the cell electrolyte level as a reference. Approximately 3/32" of

the bottom edge of the screen assembly should be immersed in

the electrolyte.

2) Operate the analyzer for 24 hours and compare the electrolyte

level with the “reference” established in Step 1. If the level is

lower than the reference, adjust the knob a few divisions

clockwise; if higher, adjust a few divisions counterclockwise.

3) Operate another 24 hours and repeat Step 2.

4) Continue adjustments at ever-increasing intervals until a constant

electrolyte level is attained in the cell.

Once the analyzer is suitably located, all components serviced and

installed, and sample and electrical connections made, the instrument is

ready for operation.

4.54.5

4.5

4.54.5

When power is turned on, power is applied to the cell compartment

heater. The cell operates without applied power, but its output will vary

with changes in ambient temperature.

PowerPower

Power

PowerPower

30 30

30. Note

30 30

4.64.6

4.6

4.64.6

When the analyzer is initially put into operation, the air in the lines and

sample passages will drive the output indication to the top of the scale. The

time required to sweep out this residual air may be several hours before an

on-scale indication is reached. During this time the cell compartment is

heating and reaching its controlled temperature.

4.74.7

4.7

4.74.7

The analyzer is calibrated by adding a known amount of oxygen into

the analyzer by means of a calibrated span gas. The sensitivity of the analyzer is adjusted until the change indicated by the analyzer is equal to the

amount of oxygen known to be present in the span gas. The span gas must

be composed of the same elements as the specified sample gas if the

analyzer's calibrated flowmeter is to be used. TBE/AI recommends that the

oxygen content of the span gas be between 70–90% of full scale on the

range of interest.

Warm-Up and StabilizationWarm-Up and Stabilization

Warm-Up and Stabilization

Warm-Up and StabilizationWarm-Up and Stabilization

CalibrationCalibration

Calibration

CalibrationCalibration

Teledyne Analytical Instruments

4-7

Page 22

4 Operations4 Operations

4 Operations

4 Operations4 Operations

To calibrate the analyzer:

1. Shut the sample gas off, disconnect the sample in line and

connect the the span gas to the sample inlet. Allow the span gas

to flow through the system. Adjust the span gas flow rate until

the flowmeter float is centered in the flowmeter reference

indicator. Note the reading of the external recorder or meter.

2. Turn the range selector switch to the range which encompases

the oxygen concentration of the span gas. The meter or recorder

should move upscale and indicate the exact concentration of

oxygen in the span gas.

3. If the external recorder/meter does not indicate the proper

amount of oxygen, adjust the span dial until it does.

4. After the recorder or meter has stabilized on the proper readout,

turn off the span gas flow, disconnect the span gas, reconnect

the sample gas and establish the proper flow.

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

4-8

Teledyne Analytical Instruments

Page 23

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

After the analyzer has been put into operation and calibration has been

accomplished, routine inspection will be required for normal operation.

5.1 Flowmeter and Humidifier5.1 Flowmeter and Humidifier

5.1 Flowmeter and Humidifier

5.1 Flowmeter and Humidifier5.1 Flowmeter and Humidifier

The flowmeter and humidifier column must be checked daily to insure

proper flow, and corrected as necessary. Refer to Section 2.2:

and 4.4:

as necessary. Refer to Section 4.2.3:

the electrolyte is when the bottom edge of the sensor screen is wetted but not

immersed. Approximately 3/32 " of the silver electrode should extend into the

pool of electrolyte.

Throttle Valve

5.2 Cell Electrolyte Level5.2 Cell Electrolyte Level

5.2 Cell Electrolyte Level

5.2 Cell Electrolyte Level5.2 Cell Electrolyte Level

The level of electrolyte in the cell must be checked daily and adjusted

.

TT

rr

ouboub

T

r

TT

rr

Cell Installation

leshootingleshooting

oub

leshooting

ouboub

leshootingleshooting

Humidifier

. The proper level for

5.3 Reservoir5.3 Reservoir

5.3 Reservoir

5.3 Reservoir5.3 Reservoir

The water level in the reservoir should be checked at least every two

weeks. Follow this procedure:

a) Remove the cap from the filler spout.

b) Obtain a clean glass tube about 4 to 5 inches long and about ¼ "

outer diameter.

c) Lower the tube into the tank through the filler spout until it

touches bottom.

d) Place a finger over the end of the tube, and withdraw the tube

from the tank. The height of water in the tube is the height

of the water level in the tank.

e) If the water level in the reservoir is below

distilled water.

f) Replace the filler spout cap securely after verifying that the O-

ring seal is in good condition.

Teledyne Analytical Instruments

1 "1 "

1 ", add a quart of

1 "1 "

5-1

Page 24

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

5.4 Calibration5.4 Calibration

5.4 Calibration

5.4 Calibration5.4 Calibration

The sensitivity of the unit should be checked at two to four week

intervals. Calibration procedures are described in Section 4.7:

5.5 Cell5.5 Cell

5.5 Cell

5.5 Cell5.5 Cell

The electrochemical reaction in the analytical process results in the

accumulation of lead ions in the electrolyte, making the replacement of the

lead electrode or the electrolyte necessary.

5.5.1 Electrolyte Replacement5.5.1 Electrolyte Replacement

5.5.1 Electrolyte Replacement

5.5.1 Electrolyte Replacement5.5.1 Electrolyte Replacement

Replace the electrolyte at least every two months, or even more frequently if foreign matter is accumulating in the cell. Remove the cell from is

compartment, and drain, clean, rinse, and refill as described in Section 4.2.3:

Cell Installation

as outlined in Section 4.7:

TT

rr

ouboub

T

TT

r

rr

leshootingleshooting

oub

leshooting

ouboub

leshootingleshooting

Calibration

. After the cell is serviced or replaced, calibrate the analyzer

Calibration

.

Model 356WModel 356W

Model 356W

Model 356WModel 356W

.

AA

A

AA

5.5.2 Lead Electrode5.5.2 Lead Electrode

5.5.2 Lead Electrode

5.5.2 Lead Electrode5.5.2 Lead Electrode

If electrode is discolored when new, or has obviously deteriorated from

use, it may be necessary to clean or replace the electrode. Use the following

procedure while referring to Figure 5-1.

If the lead electrode is simply discolored, clean the entire cell according

to the following procedure:

a) Heat a quart of Teledyne cleaning solution to slightly below the

boiling point, and completely fill the cell cavity with the heated

solution.

b) Let the solution stand for approximately five minutes. Drain and

dispose of solution in an approved manner.

c) Repeat steps a) and b).

d) Rinse the cell with distilled water and then fill with electrolyte.

Let stand for approximately two minutes and then drain and

dispose of electrolyte in an approved manner.

e) Refill the cell with electrolyte, immersing the lower edge of the

33

3

33

//

" "

silver screens to about a

If the lead electrode is obviously beyond repair, it must be replaced.

3232

/

32

" depth.

3232

//

" "

a) Remove the terminal nuts by removing them from the mounting

screws.

b) Carefully remove the screw which holds the screen assembly in

place. Remove the screen assembly. Use clean tweezers and

Teledyne Analytical Instruments5-2

dodo

do

dodo

Page 25

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

Mounting Bolts (4)

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Cell Block

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

Cell Mounting

Nuts (4)

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

Terminal seal

O-rings (2)

Cover

Lead Electrode

Cathode Screen

Assembly

O-Ring

Figure 5-1: Cell Assembly

Teledyne Analytical Instruments

5-3

Page 26

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

not touch it with your fingersnot touch it with your fingers

not touch it with your fingers. Avoid any possible

not touch it with your fingersnot touch it with your fingers

contamination of the screen.

c) Cleanse the cell thoroughly in electrolyte solution.

d) Insert the new lead electrode in place in the cell body and secure

with lock washers and screws.

e) Carefully install screen assembly and secure with mounting

screw.

f) Immerse the cell assembly in hot cleaning solution and then rinse

in distilled water.

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

g) Install prepared cell assembly as described in Section 4.2.3:

Installation

5.6 Screen Assembly5.6 Screen Assembly

5.6 Screen Assembly

5.6 Screen Assembly5.6 Screen Assembly

The screen assembly will become discolored after prolonged use due to

contamination. When this occurs, and if the cell no longer displays adequate

sensitivity, the entire cell assembly must be replaced. Refer to Section 4.2.3:

Cell Installation

Approximately once each year the reservoir and humidifier column

should be drained and cleaned. Use the following procedure:

a) Reduce sample flow to approximately

b) Refer to Figure 4-1. Place a small funnel with attached tubing

c) Replace the drain spout cap, turn the sample flow off, and

for cell installation instructions.

5.7 Reservoir and Humidifier Column5.7 Reservoir and Humidifier Column

5.7 Reservoir and Humidifier Column

5.7 Reservoir and Humidifier Column5.7 Reservoir and Humidifier Column

beneath the drain spout which is located on the underside of the

reservoir. Remove the drain spout cap and allow the reservoir

and humidifier column to drain thoroughly.

remove the fill cap on the top of the reservoir.

..

.

..

50 cc/min50 cc/min

50 cc/min.

50 cc/min50 cc/min

Cell

d) Add a small amount of electrolyte to a pint of warm distilled

water. Pour the solution into the reservoir and replace the fill cap.

e) Gently open the throttle valve and permit the sample to flow for

five to ten minutes.

f) Reduce the sample flow to

from the reservoir. When drained, replace the drain cap and turn

off the sample flow.

g) Rinse by filling with distilled water and draining several times.

h) If the humidifier column still retains deposits on its walls, it should

be removed and cleaned with a brush and suitable cleaner. See

Teledyne Analytical Instruments5-4

50 cc/min50 cc/min

50 cc/min. and drain the solution

50 cc/min50 cc/min

Page 27

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

NOTE: If electrolyte has severely etched the

column, it should be replaced.

i) After the reservoir and column

1) Grasp the tube, and with a

yzyz

erer

yz

er

yzyz

erer

Figure 5-2. After cleaning,

thoroughly rinse the column in

distilled water before

reinstalling.

have been cleaned, refill the

reservoir as outlined in Section

4.1:

Filling the Reservoir

Removing the HumidifierRemoving the Humidifier

Removing the Humidifier

Removing the HumidifierRemoving the Humidifier

Column:Column:

Column:

Column:Column:

twisting motion, work it up into

the top humidifier block until it

clears the bottom block

completely.

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

.

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

2) Angle the bottom of the tube

towards you and twist it free of

the top block.

3) The top and bottom O-rings will

remain captive in their blocks.

To Reinstall:To Reinstall:

To Reinstall:

To Reinstall:To Reinstall:

1) Engage the top of the tube in the

top block at an angle and twist

up into the cavity of the top

block unit the bottom of the tube

clears the bottom block.

2) Swing the tube into line, and

twist down into the bottom

block until the tube seats.

NOTE:NOTE:

NOTE:

NOTE:NOTE:

Refer to the Spare Parts List in the Appendix for replacement part numbers for the

The flowmeter is similarly constructed

and can be removed and reinstalled

following the same procedure outlined

above.

Figure 5-2: Removing/Replacing the

Humidifier

Teledyne Analytical Instruments

5-5

Page 28

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

flowmeter column or humidifier column.

5.9 Leak Detection5.9 Leak Detection

5.9 Leak Detection

5.9 Leak Detection5.9 Leak Detection

The most frequent cause of trouble in trace measurement is leakage.

Tiny leaks which may be unnoticeable can cause serious errors in trace

measurements. One of the principal problems is that air can diffuse into a gas

line through a small leak, even though the gas pressure in the line may

greatly exceed atmospheric pressure.

When a leak occurs in a system where the mass flow velocity is less

than the molecular velocity, gas molecules move in both directions through

the leak. The net flow of a particular gas, e.g. oxygen, will depend on the

relative partial pressure of that gas on each side of the leak. In a sample

having only a few parts-per-million oxygen, there will be a net flow of

oxygen inward unless the sample pressure is many thousands of pounds.

5.9.1 Leak Detection Procedure5.9.1 Leak Detection Procedure

5.9.1 Leak Detection Procedure

5.9.1 Leak Detection Procedure5.9.1 Leak Detection Procedure

The procedure outlined here is based on the premise that the leak rate is

independent of sample flow rate.

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

a) Stop the sample flow to permit oxygen to accumulate at the point

of the leak.

b) After approximately one minute, restart the sample flow. It is

advisable to practice establishing the flow rate to

reference flow indication on the flowmeter, with one quick turn

of the throttle valve.

c) Simultaneous to restarting the flow, start a stopwatch to measure

the time required for the recorder/meter to respond to the

accumulated oxygen.

d) The following are approximate times for the accumulated oxygen

to reach the cell from various points in the sample path through

the analyzer at

1.5 to 2 seconds Calibrator

3.5 to 3.75 seconds Base of humidifier column*

5.5 seconds Flowmeter

6.5 seconds Metering valve

7.5 seconds Gas connection at rear of analyzer

> than 7.5 seconds Sample connection lines leading to

* A leak at this location may indicate a leak in the column or in the

reservoir system.

150 cc/min150 cc/min

150 cc/min.

150 cc/min150 cc/min

analyzer

150 cc/min150 cc/min

150 cc/min., the

150 cc/min150 cc/min

5.9.2 Cell Leak5.9.2 Cell Leak

5.9.2 Cell Leak

5.9.2 Cell Leak5.9.2 Cell Leak

Teledyne Analytical Instruments5-6

Page 29

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

If there is no rise in oxygen reading when the sample flow is restarted in

step 5.9.1.b, the measuring cell should be checked for leaks. The two most

likely leaks locations are at the two terminal seal O-rings, or at the large Oring in the cell block mounting base.

Check that the terminals are screwed tightly into place. Frequently,

when a leak occurs at a terminal connection, a greenish crystalline deposit

will be found inside the cell around the terminal mounting screw. This is lead

carbonate, which is formed by carbon dioxide in the air reacting with lead

ions in the electrolyte.

If the large O-ring at the mounting plate is leaking, the oxygen indication will begin rising almost immediately after the sample flow is stopped. It

will continue to rise until sample flow is restarted, at which time it will begin

to gradually decrease.

yzyz

yz

yzyz

erer

er

erer

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

Teledyne Analytical Instruments

5-7

Page 30

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

SymptomSymptom

Symptom

SymptomSymptom

No analyzer response to

oxygen.

CauseCause

Cause

CauseCause

a) Poor electrical connection,

or F1 fuse (a standard 2

amp Slo-Blo fuse) has

blown.

b) Cell electrolyte level too

low.

c) Dirty cell.

d) Short between cell cathode

and anode (the screen to

lead [the base material] is

shorted.)

e) If d) above corrects the

problem, the cell has

probably been poisoned,

probably by fluid flowing into

the cell humidifier column.

f) Cell has been poisoned by a

component in the sample.

What What

What

What What

a) Verify proper connection

from the cell through the

control unit to the external

recorder or meter; check for

blown fuse. Replace as

necessary.

b) Inspect electrolyte level and

add as necessary. See

Section 4.2.3, item 4.

c) Remove cell and clean

thoroughly. See Section

4.2.3.

d) Correct short. Refill with

fresh electrolyte as needed.

e) Check for excessive flow-

rate.

Check for excessive foaming in the humidifier column.

Drain and clean reservoir as

necessary. Refer to Section

5.8.

f) If there has been no change

in the normal sample

composition, a scrubber

may be required to remove

the offending component.

TT

o Doo Do

T

o Do

TT

o Doo Do

Cell lacks sensitivity.

a) Cell electrolyte level too low

due to misadjusted or faulty

humidity control.

b) Cell electrolyte too high,

due to misadjusted or faulty

humidity control.

c) Faulty humidity control.

Teledyne Analytical Instruments5-8

a) Add electrolyte as neces-

sary. Adjust humidity

control. See Section 4.5.

b) Drain electrolyte and refill.

Adjust humidity control. See

Section 4.5.

c) • Shut off main power.

• Disconnect orange wire

from TS1 terminal 5,

place a voltmeter (set to

AC current, range 0–100

mA) in series with TS1-5

and the disconnected

orange wire.

CAUTION: High voltage AC

present.

Page 31

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

SymptomSymptom

Symptom

SymptomSymptom

Cell lacks sensitivity (continued.)

CauseCause

Cause

CauseCause

Faulty humidity control (contin-

ued.)

What What

What

What What

• Turn humidifier control

completely counterclockwise.

• Turn on main power.

• While watching the

voltmeter, turn the

humidifier control clockwise; the meter reading

should go from 0–50

milliamps. If not, replace

the humidifier heater

element or the humidifier

heater control. To determine which should be

replaced, see paragraph

below.

If there is no current, either

the humidifier element or

control is defective. To

determine which it is:

• Turn the humidifier control

knob fully ccw.

• Disconnect the voltmeter

from TS1-5 and orange

wire. Reconnect the

orange wire.

• Change the voltmeter

function to 200V AC.

• Place the voltmeter

across TS1-5 and terminal TS1-4.

• Watching the meter, turn

the humidifier control

knob cw and watch the

voltmeter read 0–110 to

120V AC.

• If not, replace R2 (behind

the control knob); see

paragraph below.

• If there is voltage, replace

the heater element; see

paragraph below.

TT

o Doo Do

T

o Do

TT

o Doo Do

Teledyne Analytical Instruments

5-9

Page 32

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

SymptomSymptom

Symptom

SymptomSymptom

Cell lacks sensitivity (continued.)

CauseCause

Cause

CauseCause

Faulty humidity control (contin-

ued.)

What What

What

What What

To replace humidifierTo replace humidifier

To replace humidifier

To replace humidifierTo replace humidifier

controlcontrol

control:

controlcontrol

• Shut off all power and

remove the AC power

cord from the power

source.

• Refer to wiring diagram D18633 (upper right-hand

corner of the control unit.)

Remove the wiring and

controls. Replace R2 with

appropriate part, P/N P31.

To replace humidifierTo replace humidifier

To replace humidifier

To replace humidifierTo replace humidifier

heater elementheater element

heater element:

heater elementheater element

• Shut off all power and

remove the AC power

cord from the power

source.

• Refer to wiring diagram C18593 (left-hand side,

bottom of the cell compartment.)

• Pull out the block assembly from the bottom of the

humidifier column; pull out

the heater element, and

unsolder the wires.

• Replace with new heater

element (P/N R139.)

Solder wires, turn the

terminals down into the

holder, and replace the

holder.

TT

o Doo Do

T

o Do

TT

o Doo Do

d) Cell compartment not at

proper temperature

(120 °F).

e) Faulty triac (Q6) in heater

control or faulty triac driver

(A4).

Teledyne Analytical Instruments5-10

d) Verify that the power switch

is ON.

Check condition of 2A fuse.

e) • Remove the cell compart-

ment cover. Refer to

Interconnection diagram

A-18594 (upper left-hand

corner.)

• Connect voltmeter (set to

high AC) to terminals 1

and 2 of terminal strip

TS4 (Schematic diagram

D-18632, lower right-hand

corner; Wiring diagram C18593, upper left-hand

corner.)

Page 33

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Maintenance & Maintenance &

Maintenance &

Maintenance & Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshooting 5leshooting 5

leshooting 5

leshooting 5leshooting 5

SymptomSymptom

Symptom

SymptomSymptom

Cell lacks sensitivity (continued.)

CauseCause

Cause

CauseCause

Faulty triac (Q6) in heater

control or faulty triac driver (A4)

(continued.)

What What

What

What What

• Disconnect the thermoswitch by removing one of

the wires from TS4

terminal 3. Meter should

show voltage.

• If voltage shows, short

terminals 3 and 4 with a

test jumper. Meter reading

should drop to about zero

(less than 10 VAC.)

• If power fails to go on and

off as jumper is alternately installed and

removed between terminals 3 and 4, the triac or

triac driver is probably at

fault and should be

replaced.

• If power does go on and

off, the thermoswitch (P/N

T22) is faulty and should

be replaced.

• If none of the above

improve the sensitivity,

replace the cell.

TT

o Doo Do

T

o Do

TT

o Doo Do

Teledyne Analytical Instruments

5-11

Page 34

5 Maintenance & 5 Maintenance &

5 Maintenance &

5 Maintenance & 5 Maintenance &

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

Teledyne Analytical Instruments5-12

Page 35

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

Response and Recovery Time:Response and Recovery Time:

Response and Recovery Time: 90% in less than 1 minute (for lowest

Response and Recovery Time:Response and Recovery Time:

Operating Temperature Range:Operating Temperature Range:

Operating Temperature Range: +40 °F to +120 °F (+5 °C to +49 °C).

Operating Temperature Range:Operating Temperature Range:

Recorder Signal Output:Recorder Signal Output:

Recorder Signal Output: Voltage: 0-1 VDC or less.

Recorder Signal Output:Recorder Signal Output:

yzyz

erer

yz

er

yzyz

erer

AppendixAppendix

Appendix

AppendixAppendix

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

Standard Ranges:Standard Ranges:

Standard Ranges: Three ranges between 0-10 PPM and

Standard Ranges:Standard Ranges:

0-5000 PPM O2 (0-2 PPM O2 available as an option).

Sampling System:Sampling System:

Sampling System: Wetted parts: 304 welded stainless

Sampling System:Sampling System:

steel.

Sensitivity:Sensitivity:

Sensitivity: 1% of low range.

Sensitivity:Sensitivity:

Accuracy:Accuracy:

Accuracy: +2% of low range.

Accuracy:Accuracy:

range).

Sample Requirement:Sample Requirement:

Sample Requirement: Flow: 150 cc/min.*

Sample Requirement:Sample Requirement:

Pressure: 1 to 150 psig.

Temperature: +60 °F to +100 °F

(+15 °C to +38 °C)

Power Requirement:Power Requirement:

Power Requirement: 115 VAC, 50/60 Hz, 150 W (other

Power Requirement:Power Requirement:

voltages available.)

Alarms:Alarms:

Alarms: Adjustable single or dual alarm (op-

Alarms:Alarms:

tional) setpoints.

Current: 1-5, 4-20, 10-50 mADC

(optional.)

Local Readout:Local Readout:

Local Readout: Digital or analog meter.

Local Readout:Local Readout:

AppendixAppendix

Appendix

AppendixAppendix

* Specified flow rate required only during calibration. Measuring

cell is not sensitive to changes in flow rate.

Teledyne Analytical Instruments

A-1

Page 36

AppendixAppendix

Appendix

AppendixAppendix

QTY. PART NO. DESCRIPTION

1 B1473 Lead electrode

1 C1372 Cell assembly

NOTE:NOTE:

NOTE:

NOTE:NOTE:

Specify cell class and range of analyzer when ordering.Specify cell class and range of analyzer when ordering.

Specify cell class and range of analyzer when ordering.

Specify cell class and range of analyzer when ordering.Specify cell class and range of analyzer when ordering.

2 O5 O-ring, cell terminal

1 O25 O-ring, cell seal

1 O26 O-ring, calibrator cover plate

2 O9 O-ring, humidifier column

2 O8 O-ring, reservoir cap

2 O204 O-ring, flowmeter

1 A33748 Thermistor assembly

1 A3042 Humidifier column assembly

1 R2454 Humidifier column heater (110V)

1* R2453 Humidifier column heater (220V)

1 A5267 Reservoir cap

5 F10 Fuse, 3AG-2A

5 F6 Fuse, 3AG-1/4A, Slo-Blo

2 H2 Heater

1 B6274 Flowmeter asm. (specify background gas)

1 B30868 PC Board, Proportional temp. control

1* B36026 PC Board, Proportional temp. control (220V)

1 C14449 PC Board, Proportional temp. control

1* C41274 PC Board, Proportional temp. control (220V)

1* B29600 PC Board, E/I converter, isolated (O option)

1* A9309 PC Board, Alarm comparator, dual (-2 opt.)

Spare Parts ListSpare Parts List

Spare Parts List

Spare Parts ListSpare Parts List

(For applications 10 PPM or higher)

(For applications less than 10 PPM)

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

* optional

A minimum charge is applicable to spare parts orders.

IMPORTANT: Orders for replacement parts should include the model num-IMPORTANT: Orders for replacement parts should include the model num-

IMPORTANT: Orders for replacement parts should include the model num-

IMPORTANT: Orders for replacement parts should include the model num-IMPORTANT: Orders for replacement parts should include the model num-

ber, serial number, and range of the analyzer for which theber, serial number, and range of the analyzer for which the

ber, serial number, and range of the analyzer for which the

ber, serial number, and range of the analyzer for which theber, serial number, and range of the analyzer for which the

parts are intended.parts are intended.

parts are intended.

parts are intended.parts are intended.

A-2

Teledyne Analytical Instruments

Page 37

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

Orders should be sent to:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500

FAX (626) 961-2538

TWX (910) 584-1887 TDYANLY COID

Web: www.teledyne-ai.com

or your local representative

yzyz

erer

yz

er

yzyz

erer

Drawing ListDrawing List

Drawing List

Drawing ListDrawing List

AppendixAppendix

Appendix

AppendixAppendix

A-5855 Outline

A-47143 Piping

D-47142 Schematic

B-30364 Schematic

B-14718 Schematic

B-15016 Schematic

D-22297 Wiring

D-47139 Wiring

B-21916 Interconnection

Teledyne Analytical Instruments

A-3

Page 38

AppendixAppendix

Appendix

AppendixAppendix

The ranges of this analyzer are:

Calibration DataCalibration Data

Calibration Data

Calibration DataCalibration Data

RangeRange

Range

RangeRange

Model 356WModel 356W

Model 356W

Model 356WModel 356W

AA

A

AA

Range Switch Position No. 1 PPM O

Range Switch Position No. 2 PPM O

Range Switch Position No. 3 PPM O

Output SignalOutput Signal

Output Signal

Output SignalOutput Signal

The output signal is D.C.

Background GasBackground Gas

Background Gas

Background GasBackground Gas

This analyzer is intended to measure oxygen in a background of:

The flowmeter has been set to indicate a flow of 150 cc/min. of this gas.

If any other type of gas is to be analyzed, the flowmeter must be reset for that

gas, using a displacement type flowmeter, when the flow is set to 150 cc/

min.

Cell ClassCell Class

Cell Class:

Cell ClassCell Class

Electrolyte TypeElectrolyte Type

Electrolyte Type

Electrolyte TypeElectrolyte Type