Page 1

Ultra Trace Sensor Model 3060E

TELEDYNE BROWN ENGINEERING

Analytical Instruments

MODEL 3060E

Ultra Trace Oxygen Analyzer

MODEL 3060E

ULTRA TRACE OXYGEN ANALYZER

INSTRUCTION MANUAL

TELEDYNE BROWN ENGINEERING

Analytical Instruments

MODEL 3060E

Ultra Trace Oxygen Analyzer

Software Version 4.22

Edition: M59174-94-554

P/N M59174

ECO# 96-385

May 24, 1996

Teledyne Electronic Technologies

Analytical Instruments

i

Page 2

Model 3060E Ultra Trace Sensor

Copyright © 1994 Teledyne Electronic Technologies/Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any other language or computer language in whole or in part, in any form or by any means, whether it be electronic, mechanical, magnetic, optical, manual, or otherwise, without the prior written

consent of Teledyne Brown Engineering Analytical Instruments, 16830 Chestnut Street,

City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us

free from defects of material and of construction, and that our liability shall be limited

to replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others

bear the warranty of their manufacturer. This warranty does not cover defects caused by

wear, accident, misuse, neglect or repairs other than those performed by Teledyne or an

authorized service center. We assume no liability for direct or indirect damages of any

kind and the purchaser by the acceptance of the equipment will assume all liability for

any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts,

in so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control

process conditions. While this instrument may be able to provide early warning of

imminent danger, it has no control over process conditions, and it can be misused. In

particular, any alarm or control systems installed must be tested and understood, both as

to how they operate and as to how they can be defeated. Any safeguards required such

as locks, labels, or redundancy, must be provided by the user or specifically requested of

Teledyne at the time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions.

The purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Electronic Technologies/Analytical Instruments (TET/AI), the

manufacturer of this instrument, cannot accept responsibility for conditions beyond its

knowledge and control. No statement expressed or implied by this document or any

information disseminated by the manufacturer or its agents, is to be construed as a

warranty of adequate safety control under the user’s process conditions.

ii

Teledyne Electronic Technologies

Analytical Instruments

Page 3

Ultra Trace Sensor Model 3060E

Table of Contents

1 Introduction

Overview ............................................................................................................ 1-1

Components ........................................................................................................ 1-2

Main Features of the Analyzer ........................................................................... 1-2

Applications........................................................................................................ 1-4

2 Operational Theory

Overview .............................................................................................................2-1

Ultra Trace Sensor ..............................................................................................2-3

Ultra Trace Sensor Components ..................................................................2-3

Ultra Trace Sensor Operation ......................................................................2-4

Faradaic Calibrator .............................................................................................2-5

Faradaic Calibrator Components .................................................................2-5

Faradaic Calibrator Operation .....................................................................2-7

Sample System ....................................................................................................2-8

Electronics ...........................................................................................................2-11

Signal Processing Functions.........................................................................2-12

Analog Input Circuit Board .................................................................2-12

AnalogOutput Circuit Board................................................................2-12

Digital Circuit Board ...........................................................................2-14

Display Screens....................................................................................2-14

Temperature Controller ................................................................................2-15

Valve Control Circuit Board ........................................................................2-15

Power Supply Module..................................................................................2-15

3 Installation

Overview .............................................................................................................3-1

Unpacking the Analyzer ......................................................................................3-1

Cautions and Warnings .......................................................................................3-2

Ultra Trace Sensor Installation............................................................................3-3

Adding Electrolyte to the Ultra Trace Sensor ..............................................3-4

Ultra Trace Sensor Electrical Connections ..................................................3-8

Teledyne Electronic Technologies

Analytical Instruments

iii

Page 4

Model 3060E Ultra Trace Sensor

Faradaic Calibrator .............................................................................................3-9

Adding Electrolyte to the Calibrator ............................................................3-10

Adding Water to the Reservoir.....................................................................3-14

Level Detector and Solenoid Switch ............................................................3-15

Electrical Installation...........................................................................................3-16

Electrical Connections..................................................................................3-16

Voltage Selection and Fuse Changing ..........................................................3-17

Gas Line Connections..........................................................................................3-19

Installation Checklist ...........................................................................................3-22

4 Operations

Overview .............................................................................................................4-1

Front Panel Controls and Indicators ....................................................................4-2

Sample System Status Panel ........................................................................4-2

LED Display ................................................................................................4-3

Computer Control Module ...........................................................................4-3

Sensor Compartment Temperature Controller .............................................4-6

Ultra Trace Sensor Electrolyte Temperature................................................4-6

Rear Panel Connections.......................................................................................4-6

Operating the Analyzer........................................................................................4-7

Start-up Checklist ........................................................................................4-7

Modes of Operation......................................................................................4-8

Cold Start 4-8

Warm Start ..........................................................................................4-9

Full Start Versus Quick Start ..............................................................4-9

Forcing a COLD START by turning Power OFF/ON .......................4-9

Forcing a Cold Start Without First Shutting Down .............................4-10

Full Start Mode ............................................................................................4-11

Full Start Options.........................................................................................4-13

Setup for Internal Calibrator Use (Full Start)......................................4-13

Setup for Span Gas Use (Full Start) ....................................................4-15

Setup for Both Span Gas & Internal Calibrator (Full Start)................4-16

Quick Start Mode.........................................................................................4-20

Analyze Mode ..............................................................................................4-23

Conditioning the Ultra Trace Sensor....................................................4-23

Span Calibration Using an External Span Gas ............................................4-25

Span Calibration Using the Internal Calibrator ...................................4-29

iv

Teledyne Electronic Technologies

Analytical Instruments

Page 5

Ultra Trace Sensor Model 3060E

Zero Calibration...................................................................................4-33

Important Notes on Zero and Span Calibration ...................................4-37

Setup Mode: System Password ....................................................................4-38

Setup: Alarms ......................................................................................4-40

Setup: Auto Settling ............................................................................4-42

Setup: Clock/Scheduled Span or Scheduled Zero ................................4-47

Setup: More Options ............................................................................4-49

Setup: H2O Reservoir ..........................................................................4-52

Setup: Modem ......................................................................................4-54

Setup: Zero/Span Gas Source ..............................................................4-55

Setup: Negative O2 ..............................................................................4-56

Range Mode .................................................................................................4-57

AutoRange Function ............................................................................4-57

Manual Range Function.......................................................................4-58

Stand-by Mode.............................................................................................4-58

Normal Shutdown ................................................................................4-59

High Current Output Mode ..........................................................................4-60

5 Maintenance & T roubleshooting

Routine Maintenance Checklist ...........................................................................5-1

Ultra Trace Sensor Maintenance .........................................................................5-1

Adding Distilled Water to the Electrolyte ....................................................5-1

Purging Distilled Water................................................................................5-2

Replacing the Electrolyte in the Ultra Trace Sensor ....................................5-3

Scrubber Maintenance .........................................................................................5-4

Troubleshooting...................................................................................................5-4

Troubleshooting Tables................................................................................5-5

6 Quick Reference

Introduction .........................................................................................................6-1

Cold Start ............................................................................................................6-4

Full Start ............................................................................................................. 6-5

Quick Start ..........................................................................................................6-6

Span Calibration Using External Gas Source .....................................................6-7

Span Calibration Using Internal Calibrator.........................................................6-8

Zero Calibration ..................................................................................................6-9

Setting the Password ...........................................................................................6-10

Teledyne Electronic Technologies

Analytical Instruments

v

Page 6

Model 3060E Ultra Trace Sensor

Setting the Alarms ...............................................................................................6-11

Auto Settling........................................................................................................6-12

Scheduled Zero and Scheduled Span ...................................................................6-13

Filtering, Zero Display, Bypass and Reservoir....................................................6-14

Modem.................................................................................................................6-15

Setup: Zero and Span Gas Source .......................................................................6-16

Negative Oxygen Display ....................................................................................6-17

Auto and Fixed Range .........................................................................................6-18

Standby: Normal Shutdown.................................................................................6-19

Appendix

Specifications ......................................................................................................A-1

Spare Parts List ...................................................................................................A-2

Drawing List........................................................................................................A-3

Material Safety Data Sheets............................................... MSDS-1

vi

Teledyne Electronic Technologies

Analytical Instruments

Page 7

IntroductionIntroduction

Introduction

IntroductionIntroduction

Overview

The Teledyne Electronic Technologies/Analytical Instruments (TET/AI) Model

3060E Ultra Trace Oxygen Analyzer is a highly sophisticated microprocessorbased instrument designed to measure the oxygen concentration in a gas

mixture in a range as low as 0-50 parts per billion (PPB). The 3060E accurately

measures and analyzes the oxygen content in inert gases such as helium,

nitrogen and argon, and in flammable gases such as hydrogen and ethylene. The

analyzer is easy to use through LCD menu displays with five touch switches for

operator interface.

Ultra Ultra

Ultra

Ultra Ultra

Introduction

483 mm

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

SAMPLE

OXYGEN

SCRUBBER

13

CALIBRATOR

6

7

FLOWSET

SPARGER

BYPASS

1

10

2

MV1

3

CALIBRATOR

SAMPLE

SPAN

VENT1 VENT2

BYPASS

5

MV2

HO

2

8

N

2

AR

4

H

2

HE

SELECTOR

9

MV3

CELL

MFC

GAS

TELEDYNE BROWN ENGINEERING

Analytical Instruments

Model 3060E

ULTRA TRACE OXYGEN ANALYZER

SENSOR COMPARTMENT

35

83

51

310

82

35

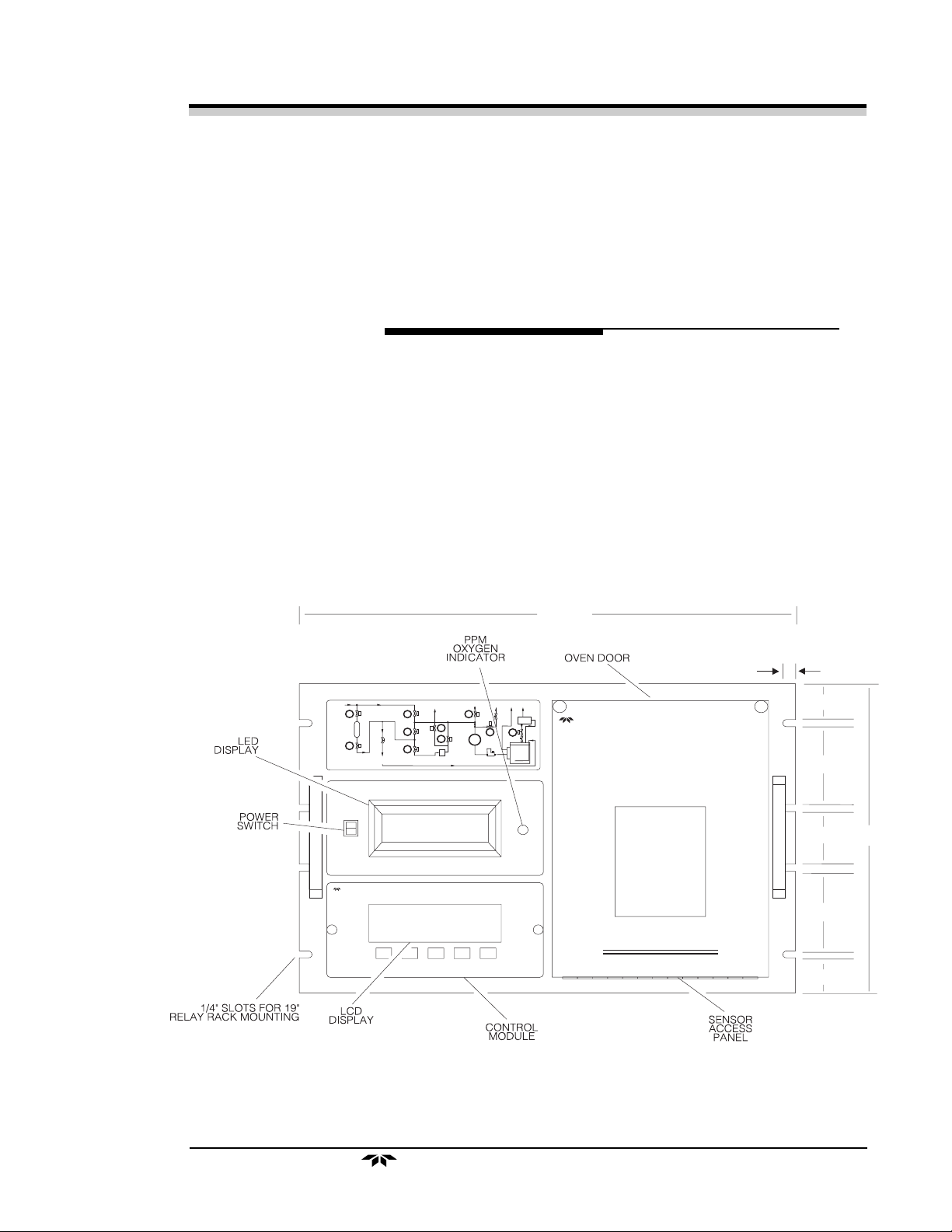

Figure 1-1: Model 3060E Front Panel

Teledyne Electronic Technologies

Analytical Instruments

1–1

Page 8

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Components

The 3060E is designed to mount in a standard 19-inch rack. All of the

operational controls are easily accessed through the well-marked front panel.

Each of the following components is contained within the analyzer:

• Analysis

Electrochemical Ultra Trace Sensor

Electrochemical Calibrator

Sample System

• Power Supply Module

• Control Module

• LED Display

• Valve Control Board

• Temperature Controller

Chapter 1Chapter 1

Chapter 1

Chapter 1Chapter 1

The external design consists of easily accessible controls and ports. The front

panel consists of:

• LED Display

• LCD Display

• Flow Schematic Display

• Ultra Trace Sensor Access Panel

The back panel ports are:

• Gas Inlet/Outlet Ports

• Electrical Connections

• Water Reservoir Inlet and Drain

Main Features of the Analyzer

The 3060E is highly sophisticated yet simple to use. Useful features help you

to operate the analyzer and also provide you with high quality analysis data.

Below is a list of the main features.

1. Low range (0–50 PPB): This range provides highest resolution and

accuracy for ultra-pure gases. Three other ranges (0–100 PPB, 0–1

PPM, and 0–10 PPM) are also provided to meet your analysis needs.

1–2

2. Linearity on all ranges: This feature allows the user to calibrate the

analyzer on any of the four ranges and then analyze the sample gases

for all ranges.

Teledyne Electronic Technologies

Analytical Instruments

Page 9

IntroductionIntroduction

Introduction

IntroductionIntroduction

3. AutoRanging with manual override: This feature allows the analyzer

4. Built-in oxygen scrubber: The built-in oxygen scrubber can be used

5. Faradaic calibrator: The built-in Faradaic calibrator generates oxy-

Ultra Ultra

Ultra

Ultra Ultra

to automatically select the appropriate range for a given measurement. A manual override allows the user to “lock in” a specific

range of interest.

to:

• Produce the zero gas needed to set the zero point.

• Feed the zero gas to sparge the electrolyte in the Ultra Trace

sensor.

• Feed the zero gas to the Faradaic calibrator to generate a

span gas for adjusting the span level.

Should very high oxygen levels be present in the sample gas, the

automatic scrubber inlet shut-off feature prolongs the life of the

scrubber.

gen from PPB levels up to 8 PPM, and allows the user to calibrate

the analyzer. A calibrator gauge logs the amount of time the calibrator is used and notifies you through the LCD display if the calibrator

electrolyte needs refilling.

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

6. Autozero and Autospan: The analyzer can be set to calibrate itself

(zero and span) at pre-programmed intervals.

7. Span gas port: The analyzer has separate sample and span gas ports,

which allow the installation of an external source of span gas for

calibration without interfering with the sample gas line.

8. A built-in water/electrolyte level detector in the Ultra Trace sensor

signals an automatic water feed to the sensor when the electrolyte

falls below a minimum level.

9. Insensitivity to minor flow changes and mechanical vibrations: The

analyzer output is not affected by minor changes in the flow rate.

10. Built-in correction factors for various gases: Built-in correction

factors for various gases allow you to select nitrogen, argon, helium

or hydrogen as background gases without the need to recalibrate the

mass flow controller.

11. Flow schematic display: This feature allows you to visually verify

the exact status of each of the pneumatic valves in the sampling

system.

Teledyne Electronic Technologies

Analytical Instruments

1–3

Page 10

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

12. Meter readouts (the analyzer includes two meter readouts):

13. Minimal maintenance: The electrochemical Ultra Trace sensor in the

analyzer requires virtually no maintenance. Water is automatically

replenished in the Ultra Trace sensor. Replacing the electrolyte is

easily done and does not require removing the Ultra Trace sensor

from the analyzer.

14. Remote capability: The 3060E can be remotely located and controlled from a microcomputer linked to the analyzer by a phone line.

Software provided with the analyzer allows you to control analyzer

functions through menus displayed on the computer.

15. Five direct-reading alarms: Five programmable setpoints and Form

C SPDT relays can be configured to practically any requirement.

Chapter 1Chapter 1

Chapter 1

Chapter 1Chapter 1

· A red LED readout with large, easy-to-read numerals

displaying oxygen concentration.

· An LCD graphic display which includes alphanumeric

information such as alarms, output, help menus, etc.

16. Isolated 4-20 mADC and 0-1 VDC (negative ground) outputs: Four

signal outputs provide for both oxygen measurement and range

identification.

Applications

The analyzer is an invaluable tool in the following applications and industries:

• Analysis of blanketing gases in semiconductor and electronics

industries.

• Measuring the purity of various gases in air separation plants.

• Controlling oxygen for cracking and heating furnaces in petrochemical industries.

• Prevention of oxidation by measuring the purity of blanketing gases

in fiber and glass industries.

• Monitoring and controlling gas atmospheres in the heat treatment of

metals in steel and other metal industries.

• Gas analysis and research in laboratories and research and development areas.

1–4

Teledyne Electronic Technologies

Analytical Instruments

Page 11

Operational Operational

Operational

Operational Operational

Overview

There are five main analyzer functional groups:

TheorTheor

Theor

TheorTheor

yy

y

yy

Operational Theory

1. Ultra Trace Sensor

2. Faradaic Calibrator

3. Sample System

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

4. Electronic Signal Processing

5. Temperature Controller.

The analyzer uses a sophisticated Ultra Trace oxygen (O2) sensor, which is an

electrochemical galvanic device with current output.

An electrochemical calibrator based on Faraday’s law is provided to facilitate

the calibration of the analyzer.

The sample system is designed to optimize the performance of the analyzer.

The components and the methods used for the fabrication of the sample system

assure leak-free transport of gases through the analyzer.

The electronic signal processing unit (control module) is designed to simplify

the operation of the analyzer and accurately process the signal from various

components. The control module incorporates a microprocessor which allows

the operation of the analyzer with a minimum of operator interaction.

A temperature controller regulates the temperature of the Ultra Trace sensor

to minimize the effects of ambient temperature variations during analysis.

Figure 2-1 shows the locations of the major components of the analyzer.

Teledyne Electronic Technologies

Analytical Instruments

2-1

Page 12

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

Figure 2-1. Main Components

Temperature

Controller

2-2

Teledyne Electronic Technologies

Analytical Instruments

Page 13

Operational Operational

Operational

Operational Operational

Ultra Trace Sensor

The analyzer incorporates an electrochemical ultra trace O2 sensor exclusively

designed by TET/AI (U.S. Patent #5,085,760). The sensor shows exceptionally high sensitivity for O2 and remarkable long-term stability. The highly

accurate sensing element of the sensor enables it to detect as low as 0.5 PPB

of O

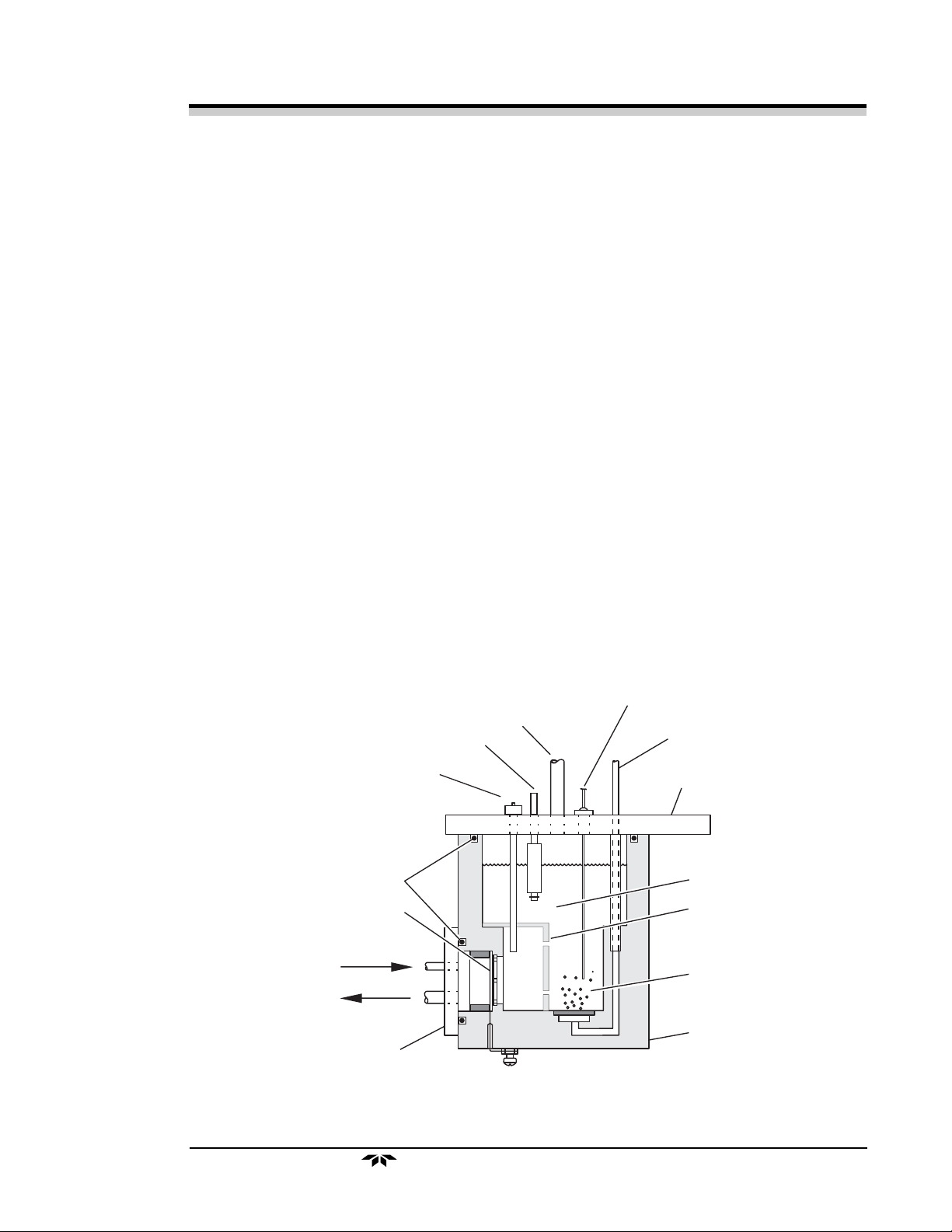

The components of the sensor are shown in Figure 2-2. The main body of the

sensor is made of clear acrylic. The sensor has a U-shaped profile with an open

top end. The left-hand wall of the sensor has a circular aperture for mounting

the O2-sensing cathode. A high surface area cadmium anode is inserted through

the top stainless steel plate. A fine porous frit disc is mounted at the bottom of

the sensor in order to remove any dissolved O2 by continuously sparging the

electrolyte with O2 free gas. A baffle plate is inserted between the sparger and

the sensing electrode to minimize the noise level caused by the sparger.

TheorTheor

Theor

TheorTheor

in a gas mixture.

2

yy

y

yy

Ultra Ultra

Ultra

Ultra Ultra

Ultra Trace Sensor Components

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

The main body of the sensor contains 15% aqueous KOH electrolyte. A

thermistor is inserted into the sensor’s main body through an opening on the top

stainless steel mounting plate. The opening serves as a port for adding water/

electrolyte to the sensor. An electrolyte level detector is also mounted through

the top stainless steel plate.

WATER LEVEL

DETECTOR

CADMIUM ANODE

O-RING

CATHODE

SAMPLE IN

SAMPLE OUT

PURGE GAS OUT

(-)

THERMISTOR

PURGE GAS IN

TOP STAINLESS

STEEL PLATE

ELECTROLYTE

BAFFLE PLATE

ZERO GAS BUBBLES

(OXYGEN-FREE)

CELL BODY

SIDE STAINLESS

STEEL PLATE

Figure 2-2. Ultra Trace Sensor Components

(+)

CATHODE

Teledyne Electronic Technologies

Analytical Instruments

2-3

Page 14

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

The sensing cathode used in the sensor is a high surface-area metal-catalyzed

gas diffusion electrode, with a surface area of 150–180 m2/g. A 0.4 mg/cm

catalyst load provides an effective cathode surface area of up to 600 times the

geometric area of the cathode. This produces a very high signal output per unit

concentration of O2; hence, an excellent signal-to-noise ratio is achieved even

at the highest sensitivity.

The metal-catalyzed gas-diffusion electrode consists of a hydrophobic Tefloncarbon gas diffusion backing layer and a Teflon-carbon metal catalyst layer

bonded together. The thickness of the catalyst layer is approximately one-tenth

of the gas diffusion layer. The overall thickness of the cathode is approximately

0.5 mm.

The cathode is held against the sensor body by a polyethylene ring. The catalyst

layer of the cathode is exposed to the electrolyte phase; the hydrophobic

backing layer is exposed to the gas to be analyzed. The cathode assembly is

sealed by placing a polypropylene O-ring between the stainless steel plate,

containing stainless steel gas inlet and outlet tubes, and the sensor body.

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

2

The electrolyte in the sensor is continuously purged by bubbling the zero gas

(generated by passing the sample gas through the built-in scrubber) through the

fine porous frit mounted in the inner floor of the sensor. Sparging of the

electrolyte removes most of the dissolved O

from the electrolyte, reducing the

2

background signal.

Ultra Trace Sensor Operation

The gas to be analyzed enters the cavity through an inlet tube between the

cathode and the stainless steel plate, and exits through the outlet tube. During

this process, the gas diffuses through the gas wicks of the hydrophobic backing

layer, and reaches the catalyst surface where O2 present in the gas mixture reacts

by the following mechanism:

O2 + 2H2O + 4e- → 4OH

Due to the high surface area of the catalyst, most of the O2 reacts at the cathode

surface and a very small amount of O2 dissolves in the bulk electrolyte. The

continuous sparging of the electrolyte with zero gas does not allow the O

concentration to build up in the bulk electrolyte. The amount of O2 that reaches

the catalyst surface is proportional to the partial pressure of O2 in the gas

mixture.

-

(cathode)

2

2-4

Teledyne Electronic Technologies

Analytical Instruments

Page 15

Operational Operational

Operational

Operational Operational

When the O2 is reduced at the cathode, cadmium is simultaneously oxidized by

the following mechanism:

TheorTheor

Theor

TheorTheor

yy

y

yy

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Cd → Cd+2 + 2e

The electrons released at the anode surface flow to the cathode surface via an

external circuit. This current is measured and used to determine the O

concentration in the gas mixture. The resulting current is directly proportional

to the O2 level in the gas mixture.

The current output of the sensor changes with temperature therefore, in order

to minimize the effects of ambient temperature variation on the current output,

the sensor is housed in a temperature-controlled oven maintained at 28°C

±2°C. Variations in temperature affecting the sensor are detected by a resistive

thermal device (RTD) attached to the sensor, which signals the temperature

controller to adjust the oven temperature accordingly.

A thermistor installed in the sensor monitors electrolyte temperature. Changes

in electrolyte temperature above 30°C are relayed to the microprocessor, which

adjusts the current output through a compensation algorithm.

NOTE: Since the gas to be analyzed does not flow through the bulk

electrolyte of the sensor, the probability of contaminating the

electrolyte by the particulates (if any) in the sample gas is very low.

This eliminates the requirements for frequent replacement of

sensor electrolyte. This is in contrast to Hercsh type galvanic cells

where gas is bubbled through the electrolyte and frequent replacement of electrolyte (3-6 month intervals) is essential to maintain

sensor performance.

-

(anode)

2

Faradaic Calibrator

The analyzer may be calibrated by using either the internal Faradaic calibrator

or an external span gas. The calibration using an external span gas is simple and

self-explanatory. The internal calibrator generates O2 at a precisely controlled

rate. The unique design of the calibrator allows repeated and reliable calibration

of the analyzer.

Faradaic Calibrator Components

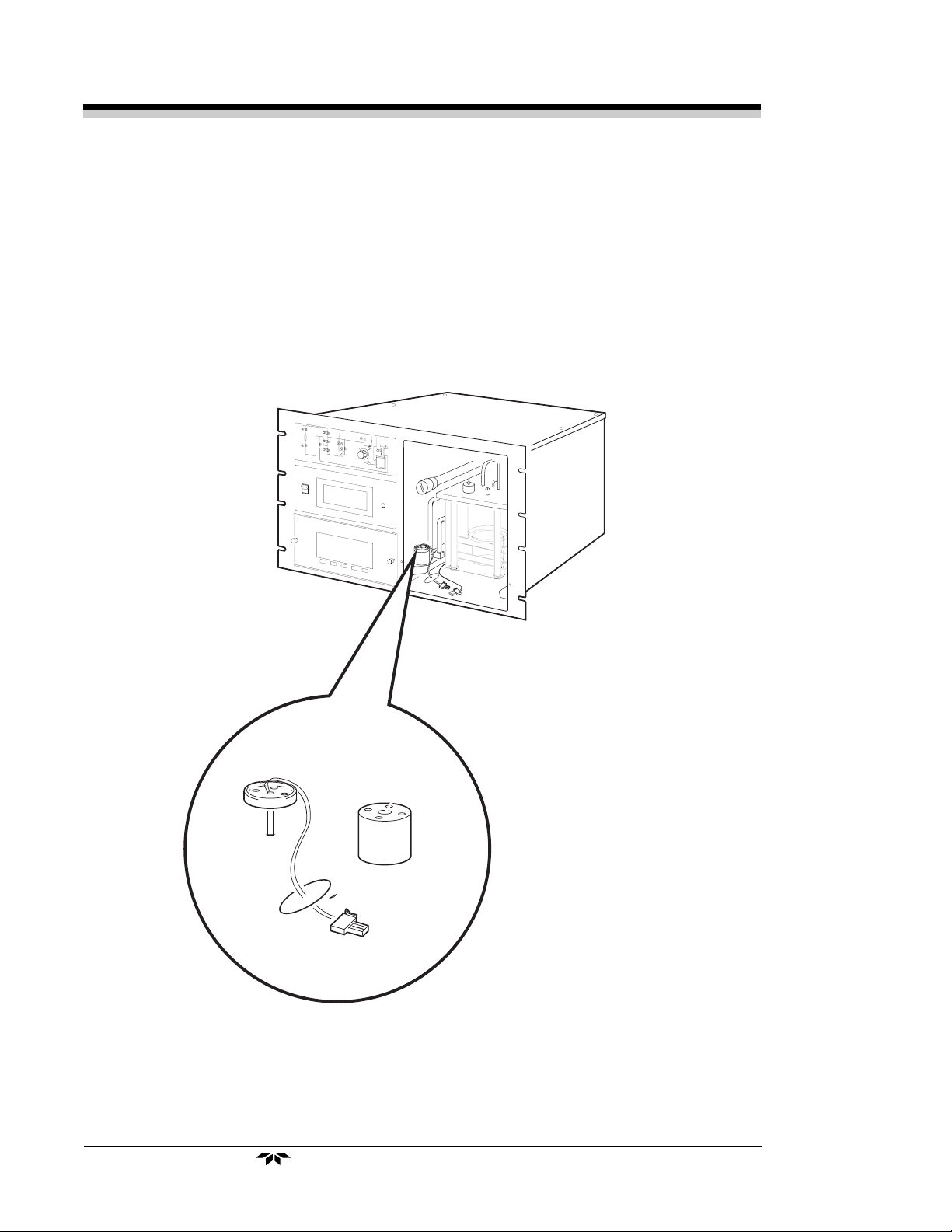

Figure 2-3 illustrates major calibrator components. The calibrator is comprised

of a top electrode assembly and a bottom mounting block containing a cup for

electrolyte. An O-ring is used to make a leak-free seal between these two

components.

Teledyne Electronic Technologies

Analytical Instruments

2-5

Page 16

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

The two platinum/gold wire electrodes are attached to a feed-through header,

which is sealed to the stainless steel plate. The two electrodes are wrapped

around a porous polyethylene rod. The bottom end of the porous polyethylene

rod is submerged into the pool of electrolyte. Capillary action causes the

electrolyte to fill the pores, keeping the electrodes wet, which helps to maintain

the ionic conductivity between the two electrodes.

O

N

P

O

W

E

R

TE

LE

DYN

A

NA

E

LYTIC

AL

INS

TR

UM

EN

TS

PPBO XYGEN

P

P

M

O

X

Y

G

E

N

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

C

O

N

T

R

O

L

M

O

D

U

L

E

2-6

Figure 2-3. Major Calibrator Components

Teledyne Electronic Technologies

Analytical Instruments

Page 17

Operational Operational

Operational

Operational Operational

The calibrator is based on Faraday’s Law of Electrolysis. When applied to the

electrolysis of water, it states that the rate at which oxygen is generated is

directly proportional to the quantity of electric current flowing through the

electrodes. Based on this, the following formula is derived to determine the

current required to generate a mixture with the desired oxygen concentration

(PPM) and flow rate (SCCM).

The desired O2 concentration is entered through the calibration menu, and the

mass flow controller provides the flow rate of O2-free zero gas through the

calibrator. The required current for the electrolysis of water is calculated by the

microprocessor and then supplied to the calibrator electrodes.

A calibrator bypass uses zero gas to flush out any O2 that has seeped into the

calibration cavity path, eliminating excess O2 that might otherwise enter the

sampling system.

TheorTheor

Theor

TheorTheor

yy

y

yy

Ultra Ultra

Ultra

Ultra Ultra

Faradaic Calibrator Operation

µµ

I (

µA) = 40/150 X O2 (PPM) X Flow Rate (SCCM)

µµ

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

The accuracy of the calibration gas formed using the calibrator is best in the

0-10 PPM range. Since the sensor has linear output through all ranges, the

analyzer may be calibrated at one or two ranges above the normal range of

operation.

NOTE: For example, if the analyzer is to be used for analysis in the 0–50

PPB range, calibrate the analyzer in the 0–100 PPB or 0–1 PPM

range to minimize calibration error. At this level, errors due to

mass flow controller calibration, measurement of current from a

current source and current leakage are minimized.

To see why, assume the absolute error during calibration on any range is 2 PPB.

If the analyzer is calibrated at 25 PPB, 2 PPB error constitutes an 8% error in

calibration. However, if the analyzer is calibrated at 80 PPB the calibration

error will be only 2.5%.

Teledyne Electronic Technologies

Analytical Instruments

2-7

Page 18

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Sample System

The sample system delivers gases to the O2 sensor from the analyzer rear panel

inlet. Depending on the mode of operation (determined by which valves are

open or closed), either a sample, span or zero gas is delivered.

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

The 3060E sample system is designed and fabricated to insure that the O

concentration of the gas is not altered (except in the O2 scrubber) as it travels

through the sample system.

• Electropolished 316L Stainless Steel Components

To eliminate O2 absorption and desorption from the internal wetted

surfaces of the sample system components, the sample system is

fabricated from electropolished 316L stainless steel.

• Welding/Metal Gasket-Type Fittings

All of the joints upstream of the O2 sensor are orbitally welded,

except for the metal gasket-type compression connections at the O

scrubber and mass flow controller. Orbital welding is used in the

sample system wherever feasible. Orbital welding fuses the electropolished 316L stainless steel components together, forming a

smooth, clean internal (wetted) weld junction and eliminating small

spaces around the weld junction where gases can get trapped or

absorbed. All of the weld junctions in the entire assembly are

purged using an inert gas during welding to ensure that there is no

O2 contamination.

Orbital welding is used where practical; otherwise, conventional

precision welding is used. For example, conventional precision

welding is used to fuse the tubes to the mounting plates. Metal

gasket-type compression connections are used at the O2 scrubber

and at the mass flow controller to facilitate replacement. The metal

gasket-type connection creates an airtight, metal-to-metal seal,

eliminating inboard and outboard gas leakage.

2

2

2-8

Teledyne Electronic Technologies

Analytical Instruments

Page 19

Operational Operational

Operational

Operational Operational

TheorTheor

Theor

TheorTheor

• Valves

yy

y

yy

The analyzer sampling system utilizes three different types of valves.

Each valve is selected to prevent O2 contamination of the sample

depending on its position and purpose in the circuit.

Air-Actuated Bellows Valves

These valves are normally closed in the sample system. They are

used to control the delivery through the sample system of the

sample, span or zero gas. The valve bodies are orbitally welded

in the system and the valve bonnets make a metal-to-metal seal

to the body. This valve system eliminates inboard and outboard

gas leakage. The valves are activated (open/closed) by computer-controlled solenoid valves.

The valves have the following basic functions:

PV1: Sample gas to the Ultra Trace sensor.

PV2: Zero gas to the Ultra Trace sensor.

PV3: Zero gas to the calibrator.

PV4: Span gas out of the calibrator.

PV5: External span gas to the Ultra Trace sensor.

PV6: Sample gas into the scrubber.

PV7: Zero gas out of the scrubber.

PV8: Sample bypass vent.

PV9: Water to the Ultra Trace sensor.

PV10: Calibration bypass.

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Metering Valve

The metering valve (labeled MV1 on the flow schematic) is used

to manually control the sparge rate to the sensor. The body of

the metering valve is orbitally welded and the bonnet is sealed to

the body with metal O-rings. The manual control knob is located in the sensor compartment.

Solenoid Valves

The solenoid valves control the air flow to the air-activated

bellows valves. The solenoid valves are controlled by the microprocessor. When de-energized, the valve outlet is open to

ambient air, allowing the air-activated bellows valve to close.

Teledyne Electronic Technologies

Analytical Instruments

2-9

Page 20

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

• Oxygen Scrubber

The O2 scrubber is used to remove O2 (down to less than 1 PPB,

typically 0.5 PPB) from the sample gas. The scrubbed gas is used

for:

Sparging

Electrolyte in the Ultra Trace oxygen sensor is sparged with

oxygen-free gas to reduce dissolved oxygen from the electrolyte.

Zero Calibration

The oxygen-free gas is used to electronically offset the background signal of the Ultra Trace sensor. This provides a zero

point for the system to measure the oxygen content of the

sample gas during analysis.

Span Calibration Using Internal Calibrator

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

The oxygen-free gas is mixed with oxygen generated in the

electrochemical calibrator to produce a span gas with a known

oxygen concentration. This provides a span point for the system

to measure the oxygen content of the sample during analysis.

NOTE: The standard O2 scrubber has a capacity of 80 cc of pure O2 .

Under normal operating conditions, the scrubber is expected to

last several years. The scrubber is installed in the system using

metal gasket and VCR type fittings.

The life of the scrubber is approximately 10 years when subjected

to an O2 concentration of 10 PPM at a flow rate of 150 cc/min.

• Mass Flow Controller

A mass flow controller is used to control the rate of gas flowing by

the sensing electrode of the sensor. The flow controller is located

upstream of the sensor. It provides signal input to the electronics in

the control module. The flow rate is displayed on the LCD screen

and is typically set at 150 cc/min.

• Fittings

The electropolished 316L stainless steel tees, elbows and crosses

used in the sampling system are orbitally welded for system integrity.

Small size fittings are used to make the sample system compact and

to minimize total system internal volume.

2-10

Teledyne Electronic Technologies

Analytical Instruments

Page 21

Operational Operational

Operational

Operational Operational

TheorTheor

Theor

TheorTheor

yy

y

yy

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

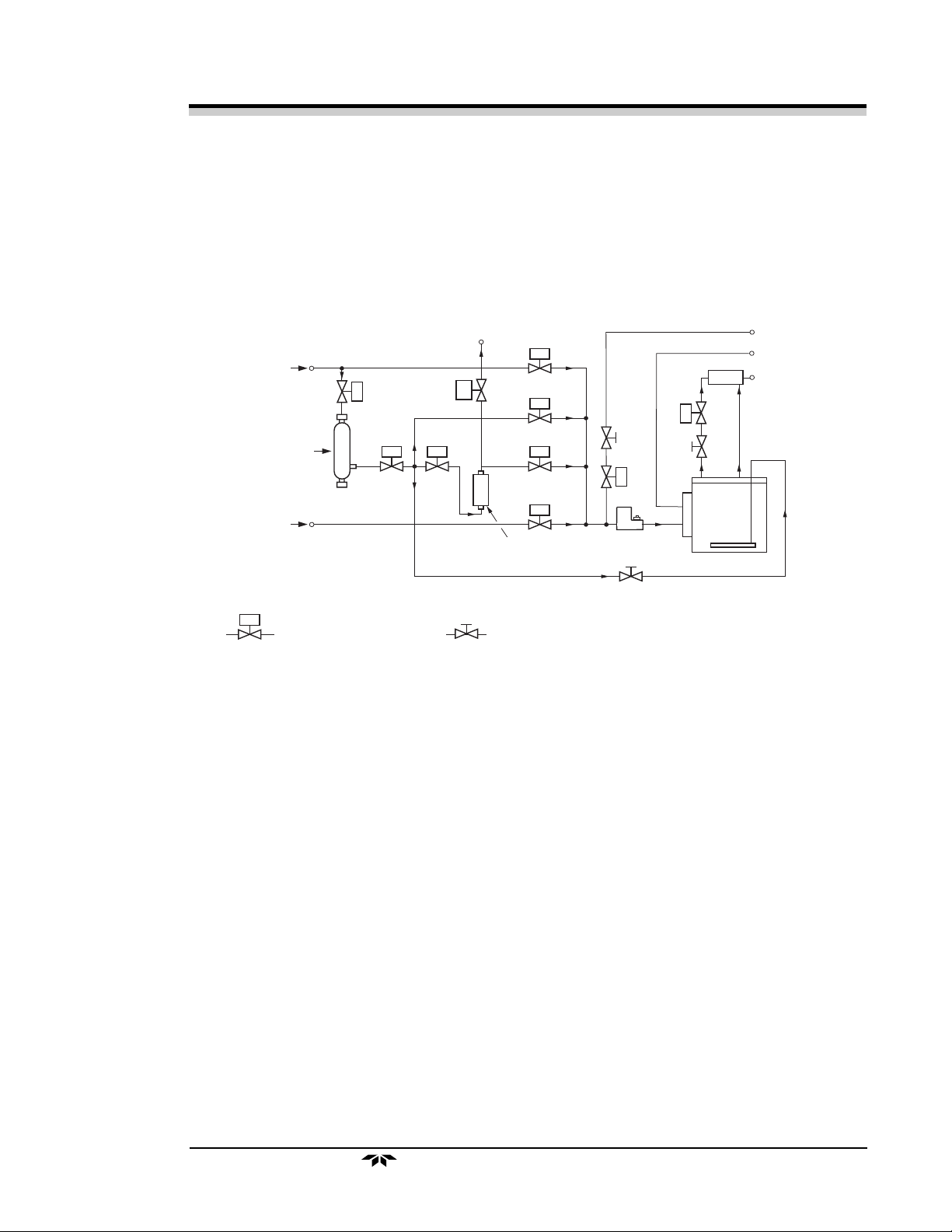

• Overall Sample System Design

The design of the sample system minimizes the volume of dead

space, which can retain residual gas from another route or previous

mode of analysis. Dead space contamination is minimized by the

structure of the gas flow routes (Figure 2-4).

yzyz

yz

yzyz

erer

er

erer

SAMPLE IN

OXYGEN SCRUBBER

SPAN GAS IN

PV

1

SHUT-OFF VALVE METERING

Electronics

The analyzer has an embedded microcomputer, that controls all signal processing, input/output and display functions of the analyzer. System power is

supplied from a power supply module designed to be compatible with any

international power source.

PV

CALIBRATOR

BYPASS

6

PV

7

10

PV

3

CALIBRATOR

MV1

Figure 2-4. Flow Schematic

PV

PV

PV

PV

1

2

4

5

VALVE

MV2

8

MV1

PV

9

ULTRATRACE

SENSOR

H2O

MV3

BYPASSVENT (SAMPLE)

VENT #1 (SAMPLE/SPAN)

VENT #2 (SPARGER)

The microcomputer, a liquid crystal display (LCD) and all analog signal

processing electronics are located inside a replaceable control module. A light

emitting diode (LED) display and circuitry to actuate the valves in the sample

are located outside the control module.

Functional groups of analyzer electronics are:

1. Signal Processing

2. Temperature Control

3. Valve Control

4. Power Supply

Teledyne Electronic Technologies

Analytical Instruments

2-11

Page 22

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Signal Processing Functions

Analog signal processing is accomplished in two plug-in circuit cards operating

under control of the microcomputer. One card processes analog input signals

and the other processes analog output signals. Digital signal processing is

accomplished directly by the microcomputer. All analog signals are converted

to digital early in the processing cycle to minimize analog processing and assure

maximum system accuracy, since digital processing is much more accurate than

analog and immune to many parameters such as drift and aging.

Analog Input Circuit Board

The analog input printed circuit board (PCB) is actually a plug-in module

consisting of a main board and a daughter board. Two analog signals are

connected to the inputs of this module for processing. They are:

• Ultra Trace Sensor Current Output

• Mass Flow Controller Output

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

The circuitry on the daughter board converts the Ultra Trace sensor current to

a corresponding voltage, provides range control, isolates system grounds, and

filters high frequencies from the signal.

The circuitry on the main board processes the filtered output signal from the

daughter board and the signal outputs from the flow controller. All signals are

eventually connected through an analog multiplexer (electronic switch) to the

input of an analog-to-digital converter, where they are converted to digital

signals for use by the microcomputer.

This circuit board also contains a voltage measuring circuit to monitor the

voltage outputs of the system power supply, and a gas selector switch circuit

to adjust the mass flow controller for the background gas selected.

Analog Output Circuit Board

The analog output printed circuit board (PCB) generates the two 0-1 volt and

the two 4-20 mA analog signal outputs available on the rear panel of the

analyzer. These signals, generated in digital format by the microcomputer, are

converted into analog signals by the circuitry on this PCB. The output signals

represent the following:

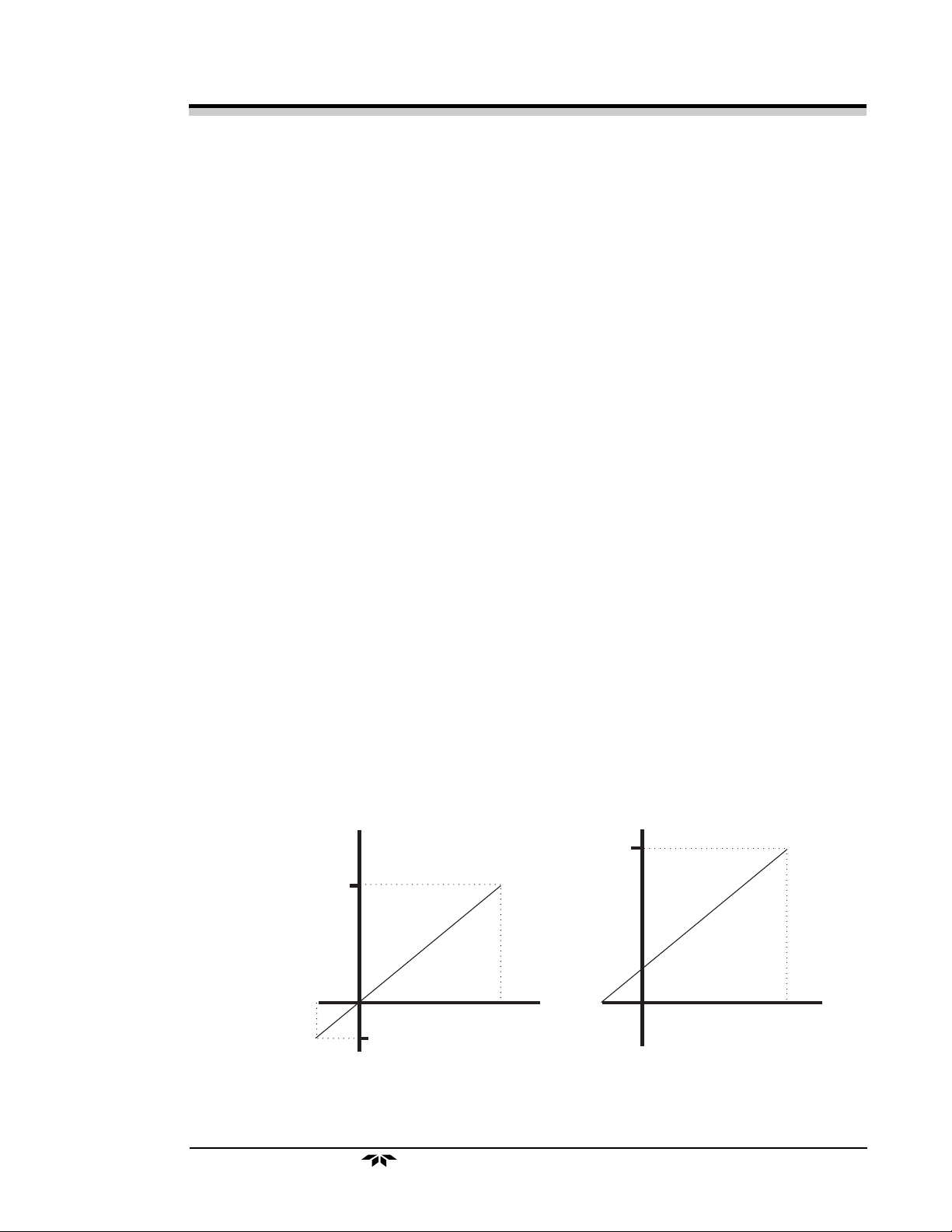

• 0-1V Signal (Oxygen Measurement)

2-12

This output goes from 0 to 1, representing 0 to 100% of the scale

that has been set; i.e., 0.6 volt is equal to 60% of the full scale, or 30

PPB when on the 50 PPB scale. It is possible that the signal may go

past zero into the negative range up to -0.25, especially if the ana-

Teledyne Electronic Technologies

Analytical Instruments

Page 23

Operational Operational

Operational

Operational Operational

TheorTheor

Theor

TheorTheor

yy

y

yy

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

lyzer has been zeroed with a gas that contains a significant concentration of O2 (Figure 2-3).

• 0-1V Range Identifier

This 0 to 1 volt output represents each range with a particular

voltage as shown in Table 2-1.

• Isolated 4-20 mA Signal (Oxygen Measurement)

This is a 4 to 20 mA output representing 0 to 100% of the scale,

with 4 mA equal to 0%, and 20 mA equal to 100% of that range.

This output may also range lower than 4 mA, especially if the

analyzer has been zeroed with a gas that contains a significant

concentration of O2 (Figure 2-5).

• Isolated 4-20 mA Range Identifier

This 4 to 20 mA output identifies individual ranges with discrete

current output as shown in Table 2-1.

yzyz

yz

yzyz

erer

er

erer

1 V

- 1/4

Full Scale

Value

Identifier Identifier

Range Voltage (V) Current (mA)

50 PPB 0.0 4.0

100 PPB 0.2 7.2

1 PPM 0.4 10.4

10 PPM 0.6 13.6

30 PPM 0.8 16.8

Table 2-1. Range Identifier

Voltage (V)

20 mA

O2

(0,0)

-0.25

Full

Scale

- 1/4

Full

Scale

Value

Current (I)

O2

(0,0)

Full

Scale

Figure 2-5. Analog Signal Output Offset

Teledyne Electronic Technologies

Analytical Instruments

2-13

Page 24

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Digital Circuit Board

The digital PCB is a general purpose microcomputer used to control all

functions of the analyzer. The analog input PCB and the analog output PCB

plug directly into connectors located on the digital PCB. In addition to

controlling these analog PCBs, the digital board performs the following

functions:

1. Provides valve control commands for the sampling system.

2. Processes input from the control panel pushbuttons.

3. Provides signals for the selectable alarms.

4. Processes serial I/O functions (RS-232 data). The following serial

interface default parameters are used:

Defaults

1200 Baud Fixed

8 Bits

No Parity

1 Stop Bit

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

5. Controls the LCD and the LED displays.

Display Screens

There are two display screens on the front panel of the analyzer:

LCD

This screen is a dot-matrix display located on the control module of the

analyzer. It displays all of the menus and commands for the user to

control the system and is the user interface for system operations.

LED

This screen is a 7-segment display located on the front panel of the

analyzer, above the control module. This screen displays only oxygen

concentration, but it is large and bright to allow the operator to read it

at a greater distance. A dimmer switch for this display is located on the

display PCB behind the front panel.

2-14

Teledyne Electronic Technologies

Analytical Instruments

Page 25

Operational Operational

Operational

Operational Operational

Temperature control in the oven, which houses the sensor and Faradaic

calibrator, is processed by a stand-alone proportional integrative derivative

(PID) controller. Input from the resistive thermal device (RTD) sensor located

in the oven is used to regulate two 25-watt heaters. Oven temperature is set at

28 ±2°C and should be kept at this temperature during analyzer operation.

The valve control PCB is external to the control module, across the top of the

front panel of the analyzer. This PCB contains driver circuitry to activate the

solenoid valves. It also contains and controls dual-color LEDs that indicate the

actual status of the pneumatic valves (green for OPEN and red for CLOSED).

The valve control PCB operates under the control of the system microcomputer.

TheorTheor

Theor

TheorTheor

yy

y

yy

T emperature Controller

Valve Control Circuit Board

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Power Supply Module

NOTE: This power supply contains an International Power Entry Module.

This feature allows operation on any of four international voltage

ranges: 100V, 120V, 220V or 240V (50Hz or 60Hz). It also

facilitates both North American and European fusing arrangements. Instructions for programming this module are described in

Chapter 3, Voltage Selection.

The analyzer power supply module is a replaceable assembly containing four

power supplies and five alarm relays. Electronic circuitry used to drive and

interface the alarm relays to the output of the microcomputer is also located

inside this module.

Teledyne Electronic Technologies

Analytical Instruments

2-15

Page 26

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Chapter 2Chapter 2

Chapter 2

Chapter 2Chapter 2

2-16

Teledyne Electronic Technologies

Analytical Instruments

Page 27

InstallationInstallation

Installation

InstallationInstallation

Overview

Installation of the analyzer includes:

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

Installation

1. Unpacking the system.

2. Recognizing the necessary precautions when installing the system.

3. Adding electrolyte to the Ultra Trace sensor.

4. Adding electrolyte to the calibrator.

5. Hooking up electrical connections.

6. Hooking up the sample/span gas and instrument air supply to the

appropriate connections.

7. Testing the system.

yzyz

yz

yzyz

erer

er

erer

Unpacking the Analyzer

Carefully unpack the analyzer and inspect it for damage. Immediately report

any damage to the shipping agent. Remove the packing slip and verify that you

have received all of the correct materials.

Packing list:

1. Model 3060E Ultra Trace Oxygen Analyzer

2. 3060E Accessory Kit (P/N A59582)

The analyzer is shipped with all the materials and special items you need to

install and prepare the system for operation. The shipping carton contains the

following components:

1. Analyzer assembly

• Ultra Trace sensor

• Calibrator

• Two cadmium anodes (in holders)

• Electronics

Teledyne Electronic Technologies

Analytical Instruments

3-1

Page 28

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

2. Standard accessory kit for the 3060E (P/N A59582):

Qty P/N Description

12 G284 Gaskets, VCR-type

6 G352 Weld glands, male, VCR-type

6 N284 Nuts, female

5

7

/64 "

/16 "

1 W66 Wrench, open end, ¼ " 1 S915 Screwdriver, #0 Phillips drive

1 S916 Screwdriver, slotted drive

1 S914 Socket, 7/16 " for ¼ " drive

1 R1549 Rachet, quick release, ¼ " drive

1 W68 Allen wrench, with handle, 7/64 "

1 W69 Allen wrench, long arm,

1 A51934 KOH electrolyte

1 A64239 Calibration electrolyte

1 B51752 Syringe 50 cc (Assembled)

1 A51886 Syringe 2 cc (Assembled)

1 T1052 Fritted glass tube

1 Safety glasses

1 pr. Gloves, rubber

1 MP-A56133 Procedure for Preparation of Electrolyte

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

3. Instruction Manual

4. Quick Reference: Start Up

Cautions and Warnings

1. Always use extreme care when handling the electrolyte bottles.

Electrolyte can cause skin irritation. If the electrolyte comes into

contact with skin, immediately wash the affected area with cold

water.

CAUTION: The sensor electrolyte is caustic. Protective equipment

including, but not limited to, gloves and safety glasses should

be worn while handling electrolyte. See the Material Safety

Data Sheets for potential hazards and corrective action in

case of accident.

2. Use the correct syringe for each type of electrolyte. The 50 cc

syringe is used with the sensor electrolyte. The 2 cc syringe is used

with the calibrator electrolyte.

3. Before adding electrolyte to the sensor, examine the electrical

connections on the sensor body to make sure that they are firmly

secured to the proper terminals.

3-2

Teledyne Electronic Technologies

Analytical Instruments

Page 29

InstallationInstallation

Installation

InstallationInstallation

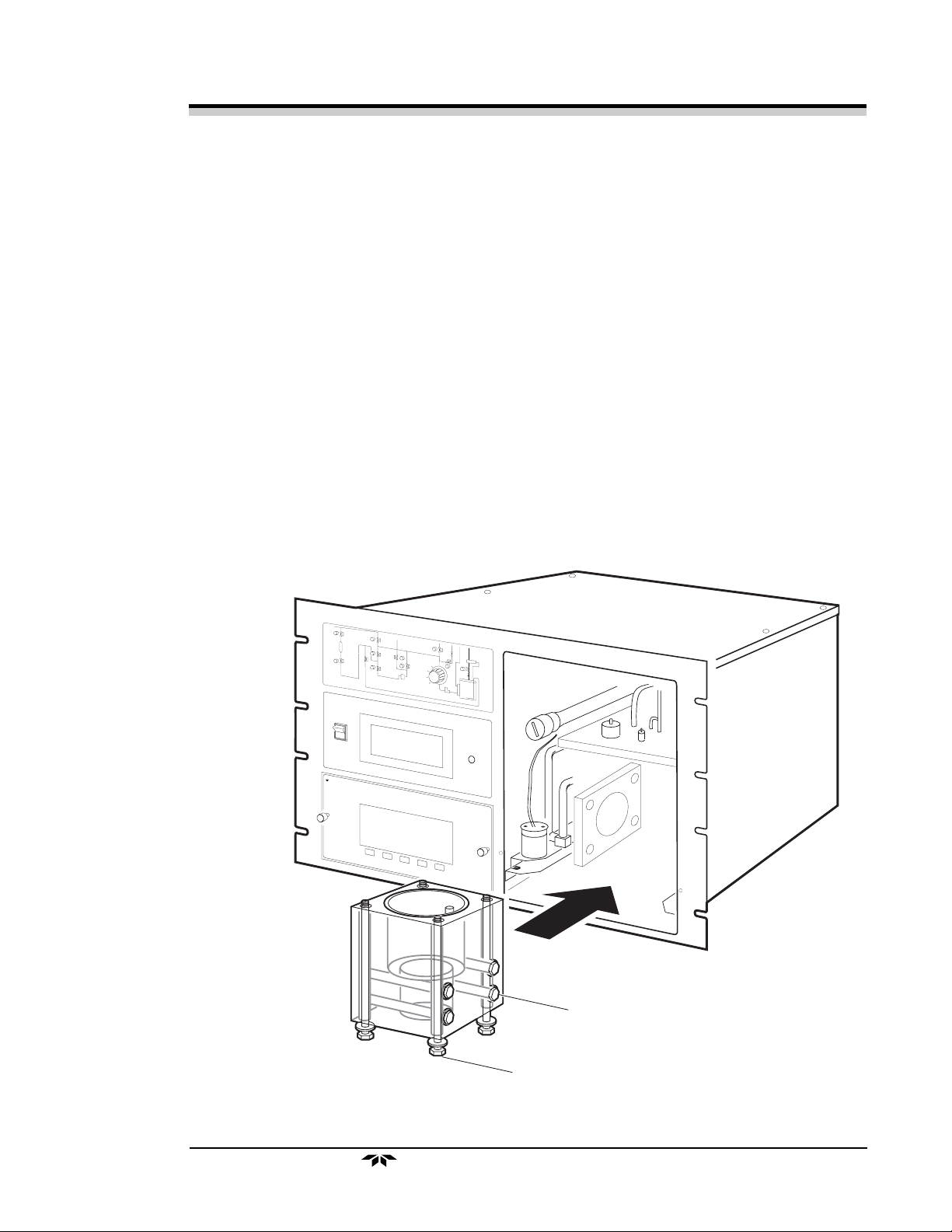

Ultra Trace Sensor Installation

The analyzer is usually shipped with the sensor installed. If you need to install

or replace the sensor assembly before using the analyzer, use the procedure

below.

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

4. When adding electrolyte to the calibrator, do not overfill.

5. When hooking up electrical connections, do not connect the output

to the chassis.

6. Do not begin operating the analyzer until you have completed all of

the installation procedures.

1. Prepare the analyzer casing for the sensor. Place four of the short

bolts in the holes on the side of the sensor and four of the long bolts

in the holes at the bottom of the sensor and bring the sensor between

the top and side stainless steel plates (see Figure 3-1). Leave all

eight bolts loose until Step 3.

yzyz

yz

yzyz

erer

er

erer

O

N

P

O

W

E

R

PPM O

X

YG

PPB O

T

E

L

E

D

Y

N

E

A

N

A

L

Y

T

I

C

A

L

I

N

S

T

R

U

M

E

XYG

N

T

S

EN

C

O

N

T

R

O

L

M

O

D

U

L

E

EN

SIDE BOLTS

BASE BOLTS

Figure 3-1. Ultra Trace Sensor Bolt Installation

Teledyne Electronic Technologies

3-3

Analytical Instruments

Page 30

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

2. Slip the Teflon tubing (mounted inside the sensor) onto the 1/8 "

stainless steel tube at the bottom of the stainless steel top plate (see

Figure 3-2).

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

Figure 3-2. Tube Alignment

3. Push the sensor all the way up against the top stainless steel plate.

4. Finger-tighten the side and then the bottom bolts with your hand.

5. Using the rachet (RL547) supplied, tighten each of the four bolts to

secure the sensor to the top plate.

6. Using the rachet (RL547) supplied, tighten each of the four bolts on

the side plate.

NOTE: Make sure that the O-rings are in their grooves on the top and side

of the sensor before tightening the bolts.

Adding Electrolyte to the Ultra Trace Sensor

CAUTION: Protective equipment including but not limited to gloves,

safety glasses, face shield and rubber apron must be worn

while handling electrolyte. The safety of the people in the

vicinity of the area in which the electrolyte is being handled

must be given similar consideration. Please refer to Material

Safety Data Sheets to learn about potential hazards and

corrective action in case of accident.

3-4

Teledyne Electronic Technologies

Analytical Instruments

Page 31

InstallationInstallation

Nitrogen

Teflon/Nylon

tube

Fritted tube

P/N T1052

Electrolyte

bo ttle

P/N BT L-P-32OZ

KOH

electrolyte

Nitrogen

bubbles

Installation

InstallationInstallation

Prior to adding electrolyte to the Ultra Trace sensor, the electrolyte must be

purged with nitrogen (N2) to remove most of the dissolved oxygen (O2). This

will reduce the time required to remove the dissolved O

by sparging it with N

purge the electrolyte:

Ultra Ultra

Ultra

Ultra Ultra

inside the sensor and hence, shorten the start-up time. To

2

1. Prepare the sensor electrolyte by following procedure MP-A56133

included in the Accessory Kit.

2. Open the cap of the electrolyte bottle.

3. Insert the fritted glass tube (P/N T1052) through the opening in the

bottle and bubble O

of the N

can be seen dispersing through the electrolyte.

should be adjusted so that a large number of small bubbles

2

-free N2 through the electrolyte. The flow rate

2

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

from the electrolyte

2

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Figure 3-3. Electrolyte Bottle with Fritted Tube

4. Purge the electrolyte for about one hour.

NOTE: TET/AI recommends that the sensor be purged before adding

electrolyte. This is done by lowering a plastic/Teflon tube (clean

and free of any oil/grease and/or particulates) into the sensor

through the opening on the top of the stainless steel mounting plate

and flushing the sensor with O2-free gas. Add electrolyte into the

sensor while flushing the sensor with O2-free gas. This will

eliminate the O2 from the sensor before the addition of prepurged

electrolyte. This procedure will substantially reduce the downtime

associated with clean-up at the first startup of the analyzer.

Teledyne Electronic Technologies

Analytical Instruments

3-5

Page 32

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

After the electrolyte has been purged, it can be added to the sensor using the

following procedure:

1. Remove the plastic screw cap from the anode port on the stainless

steel plate on the top of the sensor body (Figure 3-4.1) and flush out

the sensor by using oxygen-free gas.

Gas Out

Oxygen-Free

Gas In

Plastic/Teflon

Tube

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

3-6

Figure 3-4.1. Flushing Out the Ultra Trace Sensor by O2-Free Gas

2. Insert the tube attached to the 50 cc syringe into the electrolyte

bottle and slowly fill the syringe with electrolyte.

3. Insert the tube attached to the syringe into the sensor through the

opening on the top stainless steel plate. Slowly pour electrolyte into

the sensor (Figure 3-4.2).

Teledyne Electronic Technologies

Analytical Instruments

Page 33

InstallationInstallation

Installation

InstallationInstallation

ELECTROLYTE

ANODE

PORT

TOP

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

CELL BODY

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Figure 3-4.2. Adding Electrolyte to the Ultra Trace Sensor

NOTE: Review the cautions and warnings on the use of electrolyte at

the beginning of this chapter and in the Material Safety Data

Sheets.

Avoid spilling electrolyte on the stainless steel plate. If you spill

any electrolyte on the stainless steel plate, wipe it up with damp

tissue paper. If electrolyte is not completely wiped, a white

residue (potassium carbonate, a reaction product of potassium

hydroxide and carbon dioxide in air) will appear with time.

As you pour, ensure that no large air bubbles remain trapped

inside the sensor. If large bubbles appear, use the syringe to

withdraw electrolyte from the sensor until the bubbles disappear. Return the withdrawn electrolyte to the sensor slowly.

4. Add electrolyte until the level reaches about 1 inch above the yellow

level marker on the front of the Ultra Trace sensor body. DO NOT

add electrolyte above the green level marker.

5. Remove the cadmium anode from the holder and immediately insert

it into the sensor through the opening in the top mounting plate

(Figure 3-5). Ensure that the O-ring is attached to the anode assembly.

Teledyne Electronic Technologies

Analytical Instruments

3-7

Page 34

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

ELECTROLYTE

ANODE

PORT

TOP

CELL BODY

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

Figure 3-5. Inserting the Anode

Ultra Trace Sensor Electrical Connections

There are two wires to be connected so that the sensor can send signals to the

central processor to generate the O2 content data, and two wires to send

temperature data to the processor.

The cathode terminal is located at the bottom of the sensor body and connected

to the red wire. The anode connection is on top of the sensor and is connected

to the black wire. The thermistor terminal is mounted on the stainless steel plate

on the top of the sensor body. With the exception of the anode, each of these

terminals is already connected to the signal processing unit when the analyzer

is shipped.

The positive and negative current source leads for the calibrator are located on

the top of the calibrator assembly (Figure 3-6).

After installing the analyzer, examine all of the connectors to ensure that they

are firmly secured to their respective terminals.

3-8

Teledyne Electronic Technologies

Analytical Instruments

Page 35

InstallationInstallation

Installation

InstallationInstallation

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

*

Some instruments have

a switch mounted here for

toggling solenoid valve 9

(see Status Panel) on and

off. See Section 3.4.3

The two wires from the switch

*

are connected so as to short

between the white/red wires

of the level detector

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

erer

er

erer

Figure 3-6. Sensor Cell Components and Connections

Faradaic Calibrator

The Faradaic calibrator is located inside the Ultra Trace sensor compartment.

The calibrator consists of a stainless steel block with a Teflon liner inside the

block and an electrode assembly. In order to use the Faradaic calibrator, you

must add electrolyte to the Teflon calibrator liner.

Adding the recommended amount of calibration electrolyte (about 1/2 c c) to the

calibrator generally enables you to use the calibrator for about 10 hours. A

countdown timer in the upper right-hand corner of the LCD keeps track of the

amount of time the calibrator has been used in a hh:mm format. A flashing

“C=0:00” on the display indicates that the calibrator needs refilling.

Teledyne Electronic Technologies

Analytical Instruments

3-9

Page 36

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

NOTE: If you try to use the calibrator with insufficient electrolyte or

without the current source leads connected, the LCD will display CURRENT FAILURE MODE. If this occurs, refill the

calibrator with calibrator electrolyte, connect the current source

leads, and turn the analyzer OFF and then ON. Proceed with

the Quick Reference: Start Up and perform the calibration

again (see Chapter 4 for details).

O

N

P

O

W

E

R

P

P

M

O

X

Y

G

E

TELEDYNE

ANALYTICALINSTRUMENTS

P

P

B

O

X

Y

G

E

N

N

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

CONTROLMODULE

Calibrator current

source connector

Figure 3-7. Removing the Calibrator Assembly.

Adding Electrolyte to the Calibrator

CAUTION: Calibration electrolyte is not the same as the Ultra Trace

sensor electrolyte. Calibration electrolyte is a combination of

an aqueous 0.5% CF3SO3H and an ionic surfactant. Do not

use the aqueous 15% KOH electrolyte (Ultra Trace sensor

electrolyte) in the calibrator. Using the Ultra Trace sensor

electrolyte in the calibrator will seriously damage the calibrator and the sampling system valves.

3-10

Teledyne Electronic Technologies

Analytical Instruments

Page 37

InstallationInstallation

Installation

InstallationInstallation

WARNING: Protective equipment including but not limited to gloves,

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

yzyz

yz

yzyz

safety glasses, face shield and rubber apron must be worn

while handling electrolyte. The safety of the people in the

vicinity of the area in which the electrolyte is being handled

must be given similar consideration. Please refer to Material

Safety Data Sheets to learn about potential hazards and

corrective action in case of accident.

ON

P

O

W

E

R

T

E

L

E

D

A

Y

N

N

A

E

L

Y

T

I

C

A

L

I

N

S

T

R

U

M

PPMOXYGEN

PPBOXYGEN

E

N

T

S

C

O

N

T

R

O

L

M

O

D

U

L

E

erer

er

erer

Figure 3-8. Adding Electrolyte to the Calibrator.

Teledyne Electronic Technologies

Analytical Instruments

3-11

Page 38

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

The analyzer is shipped with the calibrator electrode assembly installed. In

order to add electrolyte to the calibrator, the electrode assembly must be

removed from the calibrator block. To remove the calibrator electrode

assembly, use the following procedures:

1. Disconnect the current source connector from the calibrator assembly.

2. Using the wrenches (W68 and W69) provided, unscrew the four

bolts from the top of the calibrator assembly (see Figure 3-7).

3. Lift up and remove the calibrator electrode holder. To avoid contaminating the electrodes, do not touch the calibrator wick and

avoid contact between the wick and the calibrator block. Place the

calibrator electrode holder on a flat surface with the calibrator wick

facing upward.

4. Using the 2 cc micro-syringe supplied, add 1/2 cc of the calibration

electrolyte to the calibrator housing by lowering the micro-syringe

needle into the center of the Teflon liner in the stainless steel block

(see Figure 3-8).

Chapter 3Chapter 3

Chapter 3

Chapter 3Chapter 3

CAUTION: Avoid spilling electrolyte on the stainless steel block. If you

spill any electrolyte on the stainless steel block, wipe it up with

a damp tissue paper.

If the electrolyte has entered between the Teflon liner and the

stainless steel block, remove the electrolyte from the Teflon

liner and then remove the Teflon liner by using a clean screw

driver pushing against the liner and pulling it up. Clean the

inside of the stainless steel block and the outside of the Teflon

liner with tissue paper. Insert the Teflon liner in the stainless

steel block and carefully refill it with calibration electrolyte.

Do not add more than 1/2 cc electrolyte to the calibrator. If you

overfill the calibrator and electrolyte enters the gas manifold,

it can damage the Ultra Trace oxygen sensor, the flow

controller, and the valves.

5. After adding electrolyte to the calibrator housing, rinse the calibrator

wick with distilled water.

6. With the syringe, carefully put a few drops of electrolyte onto the

entire wick including the portion under the electrodes and wait until

the wick absorbs some of the electrolyte (see Figure 3-9).

3-12

7. Gently shake the electrode assembly to remove any excess electrolyte on the calibrator wick.

Teledyne Electronic Technologies

Analytical Instruments

Page 39

InstallationInstallation

Installation

InstallationInstallation

NOTE: DO NOT wipe the wick with a tissue paper.

Ultra Ultra

Ultra

Ultra Ultra

TT

race Oxygrace Oxyg

T

race Oxyg

TT

race Oxygrace Oxyg

en Analen Anal

en Anal

en Analen Anal

8. Place the calibrator electrode assembly back on the stainless steel

block.

9. Using the wrench (P/N W68) provided, secure the calibrator electrode assembly on the stainless steel block by tightening the four

bolts and then tighten the bolts with the wrench (P/N W69) provided. See Figure 3-10.

10. Reconnect the current source connector to the calibrator.

O

N

P

O

W

E

R

P

P

M

O

X

Y

G

E

N

P

P

B

O

X

Y

G

E

T

N

E

L

E

D

A

Y

N

N

A

E

L

Y

T

I

C

A

L

I

N

S

T

R

U

M

E

N

T

S

CO

N

TR

O

L

M

O

D

U

L

E

yzyz

yz

yzyz

erer

er

erer

Figure 3-9. Soaking the Calibrator Wick with the Electrolyte.

O

N

POWER

P

P

M

O

X

Y

G

E

PPBOXYGEN

T

E

L

A

E

N

D

A

Y

L

N

Y

E

T

IC

A

L

IN

S

T

R

U

M

E

N

T

S

C

O

N

T

R

O

L

M

O

D

U

N

L

E

Ca librator

current source

connector

Figure 3-10. Installing the Calibrator.

Teledyne Electronic Technologies

Analytical Instruments

3-13

Page 40

Model 3060EModel 3060E

Model 3060E

Model 3060EModel 3060E

Adding Water to the Reservoir

If the analyzer is to be used continuously for on-line gas analysis, then add

approximately 800 cc of distilled water to the reservoir. The rate of water

addition to the sensor is controlled by the metering valve MV3 located adjacent

to the reservoir, below the top cover plate. The valve MV3 is also accessible

from the rear of the analyzer.

The water drip rate is set at the factory at 1 drop every 2–4 minutes. This drip