Page 1

Trace Oxygen Analyzer

OPERATING INSTRUCTIONS FOR

MODEL 3000ZA2G

Trace Oxygen Analyzer

P/N M86303

11/14/2012

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only a trained service technician should open the front door of this instrument.

Only a trained service technician should conduct maintenance and/or

servicing. Before conducting any maintenance or servicing, consult with

authorized supervisor/manager.

Teledyne Analytical Instruments i

Page 2

3000ZA2G

Copyright © 2012 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91748.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations

or acknowledgements provide for a shorter period. Components manufactured by

others bear the warranty of their manufacturer. This warranty does not cover defects

caused by wear, accident, misuse, neglect or repairs other than those performed by

Teledyne Analytical Instruments or an authorized service center. We assume no

liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may

result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any

parts, in so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all

instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular,

any alarm or control systems installed must be tested and understood, both as to how

they operate and as to how they can be defeated. Any safeguards required such as

locks, labels, or redundancy, must be provided by the user or specifically requested of

Teledyne Analytical Instruments at the time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that

hazard warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control

under the user’s process conditions.

Teledyne Analytical Instruments ii

Page 3

Trace Oxygen Analyzer

Specific Model Information

The instrument for which this manual was supplied may

incorporate one or more options not supplied in the standard instrument.

Commonly available options are listed below, with check boxes. Any

that are incorporated in the instrument for which this manual is supplied

are indicated by a check mark in the box.

Instrument Serial Number: _______________________

Options Included in the Instrument with the Above Serial Number:

Auto Calibration: The Auto Cal option includes a manifold

with separate ports for sample in, zero and

span gases with solenoid control valves. The

internal valves are entirely under the control

of the 3000ZA2G electronics and can be

used to automatically switch between gases

in synchronization with the analyzer’s

operation.

4-20 mA Output: This option provides for additional analog

outputs for concentration and range

identification in the form of a 4-20 mA

current.

Teledyne Analytical Instruments iii

Page 4

3000ZA2G

Important Notice

Model 3000ZA2G complies with all of the requirements of the

Commonwealth of Europe (CE) for Radio Frequency Interference,

Electromagnetic Interference (RFI/EMI), and Low Voltage Directive

(LVD).

The following International Symbols are used throughout the

Instruction Manual. These symbols are visual indicators of important

and immediate warnings and when you must exercise CAUTION while

operating the instrument. See also the Safety Information on the next

page.

STAND-BY: Instrument is on Stand-by, but circuit is active

GROUND: Protective Earth

CAUTION: The operator needs to refer to the manual for

further information. Failure to do so may compromise the

safe operation of the equipment.

CAUTION: Risk of Electrical Shock

Teledyne Analytical Instruments iv

Page 5

Trace Oxygen Analyzer

Safety Messages

Your safety and the safety of others are very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These cautions

warn of specific procedures which if not followed could

cause bodily Injury and/or damage the instrument.

No

Symbol

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed

this warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this

symbol are to be performed by qualified maintenance

personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

Teledyne Analytical Instruments v

Page 6

3000ZA2G

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration and operation of your new analyzer. Please

read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne Analytical Instruments at the address given in the Appendix.

Some of our manuals are available in electronic form via the internet.

Please visit our website at: www.teledyne-ai.com.

Teledyne Analytical Instruments vi

Page 7

Trace Oxygen Analyzer

This is a general purpose instrument designed for use in a non-hazardous

area. It is the customer's responsibility to ensure safety especially when

combustible gases are being analyzed since the potential of gas leaks

always exist.

The customer should ensure that the principles of operation of this

equipment are well understood by the user. Misuse of this product in

any manner, tampering with its components, or unauthorized

substitution of any component may adversely affect the safety of this

instrument.

Since the use of this instrument is beyond the control of Teledyne

Analytical Instruments, no responsibility by Teledyne Analytical

Instruments, its affiliates, and agents for damage or injury from misuse

or neglect of this equipment is implied or assumed.

Teledyne Analytical Instruments vii

Page 8

3000ZA2G

Table of Contents

Safety Messages ............................................................. v

Introduction ..................................................................... 1

1.1 Overview 1

1.2 Typical Applications 1

1.3 Main Features of the Analyzer 1

1.4 Front Panel 2

1.5 Rear Panel (Equipment Interface) 5

Operational Theory ......................................................... 7

2.1 Introduction 7

2.2 ZrO2 Sensor 7

2.2.1 Principles of Operation 7

2.3 Sample System 10

2.4 Zirconium Oxide Sensor Application Notes 11

2.5 Electronics and Signal Processing 11

Installation ..................................................................... 15

3.1 Unpacking the Analyzer 15

3.2 Mounting the Analyzer 15

3.3 Rear Panel Connections 16

3.3.1 Gas Connections 17

3.3.2 Calibration Gas 18

3.3.3 Electrical Connections 18

3.3.3.1 Primary Input Power 18

3.3.3.2 50-Pin Equipment Interface Connector 19

3.3.3.3 RS-232 Port 25

3.4 Testing the System 26

Teledyne Analytical Instruments viii

Page 9

Trace Oxygen Analyzer

Operation....................................................................... 27

4.1 Introduction 27

4.2 Using the Data Entry and Function Buttons 28

4.3 The System Function 30

4.3.1 Tracking Oxygen Readings During Calibration and

Alarm Delay 31

4.3.2 Setting up an Auto-Cal 32

4.3.3 Password Protection 33

4.3.3.1 Entering the Password 34

4.3.3.2 Installing or Changing the Password 35

4.3.4 Logout 37

4.3.5 System Self-Diagnostic Test 38

4.3.6 Version Screen 39

4.3.7 Showing Negative Oxygen Readings 39

4.4 The Zero and Span Functions 40

4.4.1 Zero Cal 40

4.4.1.1 Auto Mode Zeroing 41

4.4.1.2 Manual Mode Zeroing 42

4.4.2 Span Cal 42

4.4.2.1 Auto Mode Spanning 42

4.4.2.2 Manual Mode Spanning 43

4.4.3 Span Failure 45

4.5 The Alarms Function 45

4.6 The Range Function 48

4.6.1 Setting the Analog Output Ranges 49

4.6.2 Fixed Range Analysis 49

4.7 The Analyze Function 50

4.8 Signal Output 50

Maintenance .................................................................. 53

5.1 Routine Maintenance 53

5.2 Sensor Replacement 53

5.3 Fuse Replacement 54

Teledyne Analytical Instruments ix

Page 10

3000ZA2G

5.4 System Self Diagnostic Test 55

5.5 Major Internal Components 55

5.6 Cleaning 56

5.7 Troubleshooting 56

Appendix ....................................................................... 57

A-1 Specifications 57

A-2 Recommended 2-Year Spare Parts List 59

A-3 Drawing List 60

Teledyne Analytical Instruments x

Page 11

Trace Oxygen Analyzer

List of Figures

Figure 1-1: Model 3000ZA2G Front Panel 3

Figure 1-2: Model 3000ZA2G Rear Panel 5

Figure 2-1: Sensor Offset Voltage 9

Figure 2-2: Zirconia Sensor Assembly 10

Figure 2-3: Flow Diagram 11

Figure 2-4: Component Locations 13

Figure 2-5: Electronic Block Diagram 14

Figure 3-1: Model 3000ZA2G 15

Figure 3-2: Required Front Door Clearance 16

Figure 3-3: Model 3000ZA2G Rear Panel 16

Figure 3-4: Equipment Interface Connector Pin Arrangement 19

Figure 3-5: Remote Probe Connections 24

Figure 3-6: FET Series Resistance 25

Figure 5-1: Removing Fuse Block from Housing 54

Figure 5-2: Installing Fuses 54

Teledyne Analytical Instruments xi

Page 12

3000ZA2G

List of Tables

Table 3-1: Analog Output Connections 20

Table 3-2: Alarm Relay Contact Pins 21

Table 3-3: Remote Calibration Connections 22

Table 3-4: Range ID Relay Connections 23

Table 3-5: Commands via RS-232 Input 26

Table 3-6: Required RS-232 Options 26

Table 5-1: Self-Test Result Display 55

Table 5-2: Troubleshooting 56

Teledyne Analytical Instruments xii

Page 13

Trace Oxygen Analyzer Introduction

Introduction

1.1 Overview

The Teledyne Analytical Instruments Model 3000ZA2G Trace

Oxygen Analyzer is a versatile microprocessor-based instrument for

detecting oxygen from parts-per-million (ppm) level to 25% oxygen in

background gases consistent with the zirconium oxide sensor. This

manual covers the Model 3000ZA2G 19” rack-mount units with CE

mark. These units are for indoor use in a non-hazardous environment.

1.2 Typical Applications

A few typical applications of the Model 3000ZA2G are:

Monitoring inert gas blanketing

Air separation and liquefaction

Chemical reaction monitoring

Semiconductor manufacturing

Petrochemical process control

Quality assurance

Gas analysis certification.

1.3 Main Features of the Analyzer

The Model 3000ZA2G Trace Oxygen Analyzer is sophisticated yet

simple to use. The main features of the analyzer include:

A 2-line alphanumeric display screen, driven by

microprocessor electronics that continuously prompts

and informs the operator.

High resolution, accurate readings of oxygen content for

low ppm levels. Large, bright, meter readout.

Teledyne Analytical Instruments 1

Page 14

Introduction 3000ZA2G

Zirconium oxide sensor to provide complete range of

analysis from 0-10 ppm to 0-25%.

Can be used without a flowing reference with only a

marginal performance impact.

Versatile analysis over a wide range of applications.

Microprocessor based electronics: 8-bit CMOS

microprocessor with 32 kB RAM and 128 kB ROM.

Three user definable output ranges (from 0-10 ppm

through 0-25%) allow best match to the end user’s

process and equipment.

Auto ranging allows analyzer to automatically select the

proper preset range for a given measurement. Manual

override allows the user to lock onto a specific range of

interest.

Two adjustable concentration alarms and a system

failure alarm.

Extensive self-diagnostic testing at startup and on

demand with continuous power-supply monitoring.

CE compliance

RS-232 serial digital port for use with a computer or

other digital communication device.

A 0-1 VDC analog output for concentration plus a 0-1

VDC output for range identification.

Convenient and versatile with standard 19” rack-mount

analyzer with slide-out electronics drawer.

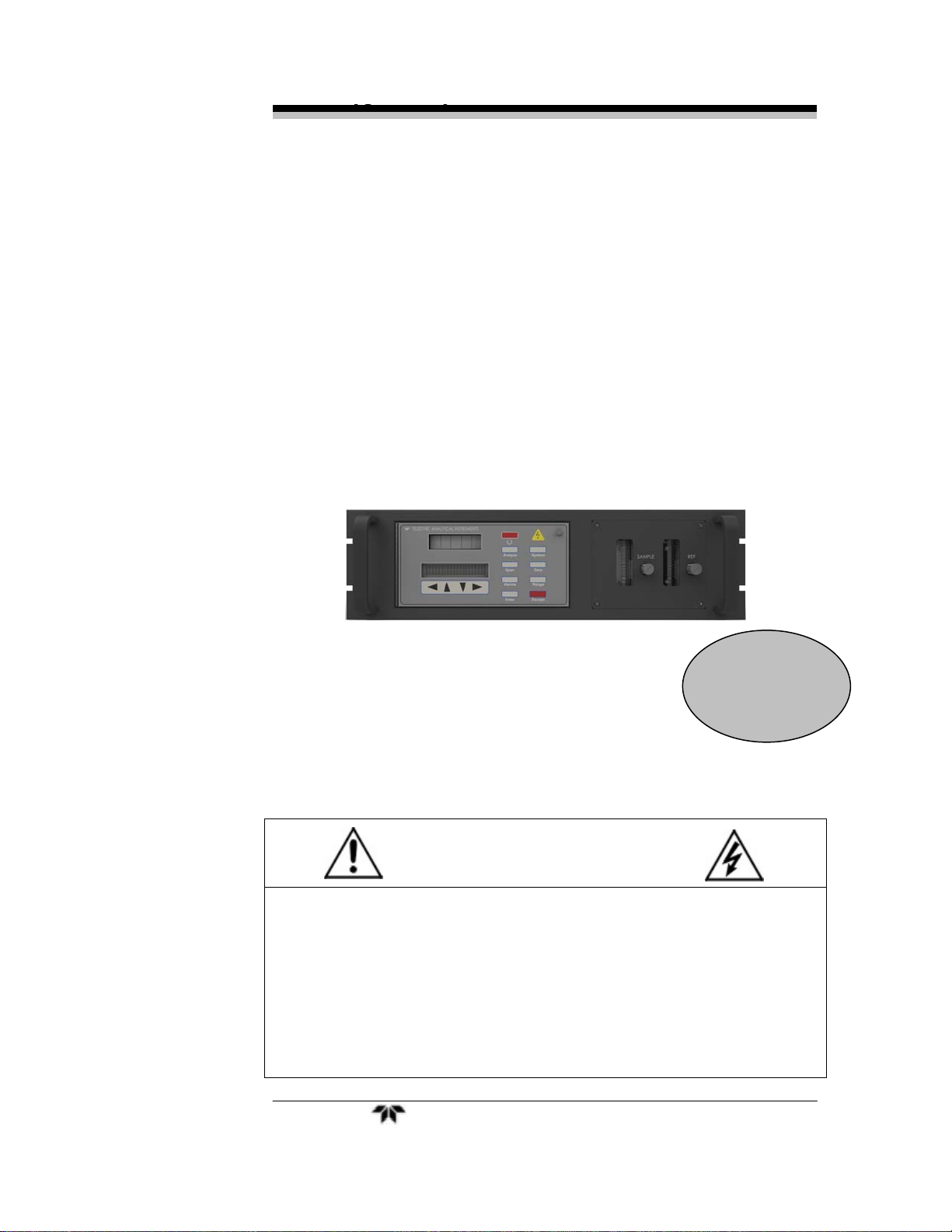

1.4 Front Panel

The standard 3000ZA2G is housed in a rugged metal case designed

for installation into a standard 19” equipment rack. All controls and

displays are accessible from the front panel. See Figure 1-1. The front

panel has thirteen buttons for operating the analyzer, a digital meter, an

alphanumeric display, a flowmeter, and sample flow control valve.

Teledyne Analytical Instruments 2

Page 15

Trace Oxygen Analyzer Introduction

Figure 1-1: Model 3000ZA2G Front Panel

Function Keys:

Six touch-sensitive membrane switches are used to change the specific

function performed by the analyzer:

Analyze Perform analysis for oxygen content of a sample

gas.

System Perform system-related tasks (described in detail

in chapter 4, Operation.).

Span Span calibrate the analyzer.

Zero Zero calibrate the analyzer.

Alarms Set the alarm setpoints and attributes.

Range Set up the 3 user definable ranges for the

instrument.

Data Entry Keys:

Six touch-sensitive membrane switches are used to input data to the

instrument via the alphanumeric VFD display:

Left & Right Arrows: Select between functions currently

displayed on the VFD screen.

Up & Down Arrows: Increment or decrement values of

functions currently displayed.

Teledyne Analytical Instruments 3

Page 16

Introduction 3000ZA2G

Enter: Advances VFD display to the next screen in a series

or returns to the Analyze screen if none remain.

Escape: Backs VFD display to the previous screen in a series

or returns to the Analyze screen if none remain.

Digital Meter Display:

The meter display is a Light Emitting Diode (LED) device that produces

large, bright, 7-segment numbers that are legible in any lighting. It produces

a continuous readout from 0-250 ppm. It is accurate across all analysis

ranges without the discontinuity inherent in analog range switching.

Alphanumeric Interface Screen:

The alphanumeric screen is a vacuum fluorescent display (VFD) screen

with an easy-to-use interface. It displays values, options, and messages

that give the operator immediate feedback.

Flowmeter:

Monitors the flow of gas past the sensor. Readout is 0.2 to 2.4 standard

liters per minute (SLPM).

Reference Flowmeter:

Monitors the flow of reference gas past the sensor. Readout is 0.2 to 2.4

standard liters per minute (SLPM).

Note: It is possible to use the analyzer without a flowing

reference but doing so will incur a marginal degradation in

performance. See Section 2.2.1. TAI recommends using a

flowing reference for best results.

Flow Control Valve:

The sample control valve allows precise adjustment over sample or

calibration gas flow to the analyzer.

Reference Flow Control Valve:

Control valve for the reference flow through the analyzer.

Standby Button

:

The Standby turns off the display and outputs but circuitry is still

operating.

CAUTION: THE POWER ENTRY SWITCH ON THE REAR OF THE

INSTRUMENT MUST BE TURNED OFF TO FULLY

DISCONNECT POWER FROM THE INSTRUMENT.

WHEN CHASSIS IS EXPOSED OR WHEN ACCESS

Teledyne Analytical Instruments 4

Page 17

Trace Oxygen Analyzer Introduction

V

(op

)

DOOR IS OPEN AND POWER CABLE IS CONNECTED ,

USE EXTRA CARE TO AVOID CONTACT WITH LIVE

ELECTRICAL CIRCUITS AND HOT SURFACES. ONLY

A TRAINED SERVICE TECHNICIAN SHOULD OPEN

THE FRONT DOOR.

Access Door:

For inspection of the instrument by a trained service technician , the

front panel swings open when the latch in the upper right corner of the

analyzer panel is pressed all the way in with a narrow gauge tool.

Accessing the main circuit board requires unfastening rear panel screws

and sliding the unit out of the case.

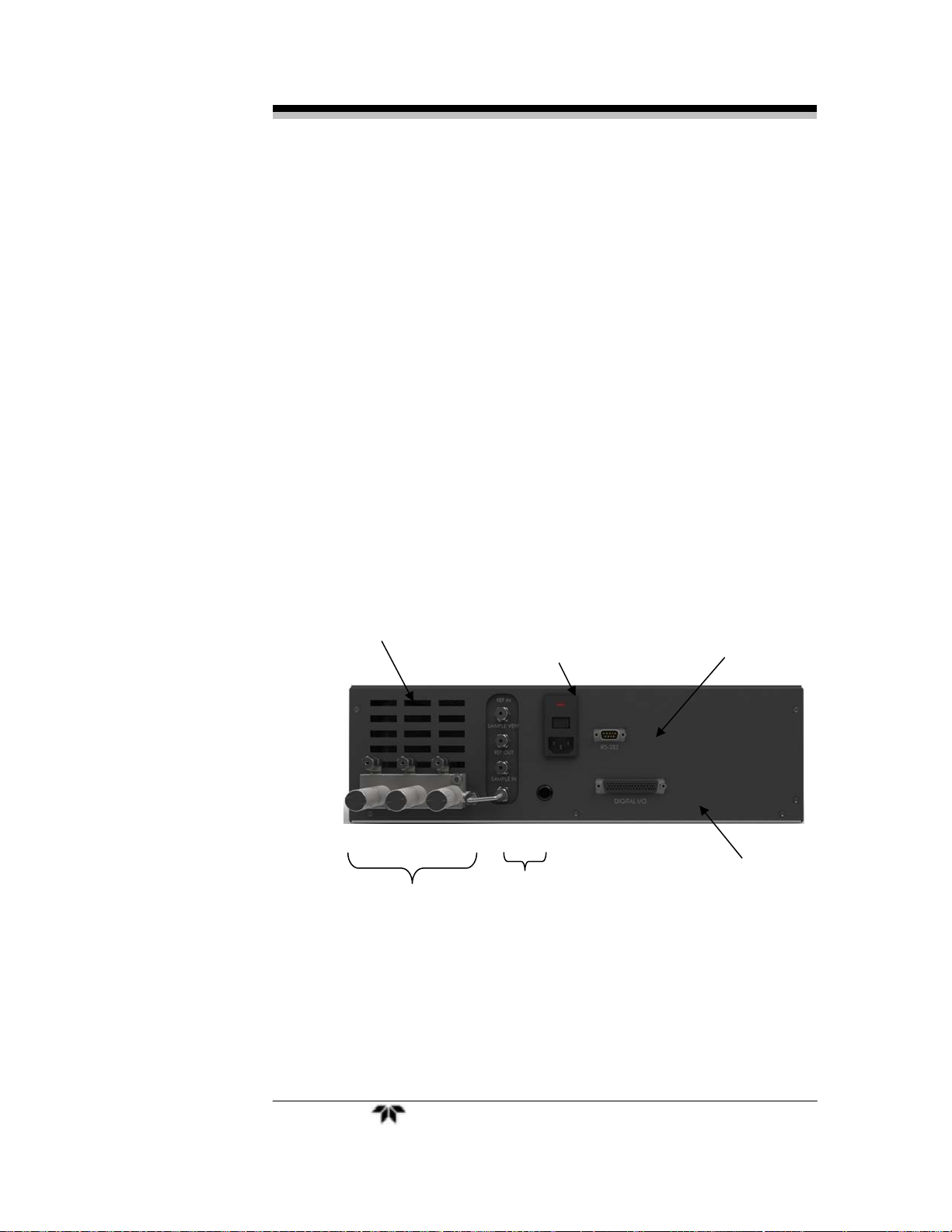

1.5 Rear Panel (Equipment Interface)

The rear panel, shown in Figure 1-2, contains the gas and electrical

connectors for external inlets and outlets. Some of those depicted are

optional and may not appear on your instrument. The connectors are

described briefly here and in detail in Chapter 3 Installation.

entilation

Auto Cal Valves

tional

Power Entry

Module w/ Fuse

Housing

Gas

Connections

RS-232 Port

50-Pin Equipment

Figure 1-2: Model 3000ZA2G Rear Panel

Power Connection Factory configured for either 115

VAC or 230 VAC operation , 50/60 Hz.

Connector

Teledyne Analytical Instruments 5

Page 18

Introduction 3000ZA2G

Sample Inlet and Outlet: One inlet (must be externally

valved) and one exhaust. Three inlets when auto calibration

option is present.

Reference Inlet and Outlet: Flowing air reference inlet and

exhaust.

9-Pin RS-232 Port: Serial digital concentration signal

output and control input.

50-Pin Equipment Interface Port:

Analog Outputs: 0–1 VDC oxygen concentration plus

0-1 VDC range ID

Alarm Connections: 2 concentration alarms and 1

system alarm.

Remote Valve: Used in the 3000ZA2G for controlling

external solenoid valves only.

Remote Span/Zero: Digital inputs allow external

control of analyzer calibration.

Calibration Contact: To notify external equipment that

instrument is being calibrated and readings are not

monitoring sample.

Range ID Contacts: Four separate, dedicated, range

relay contacts. Low, Medium, High, Cal.

Network I/O: Serial digital communications for local

network access. For future expansion. Not currently

implemented.

Optional

Calibration Gas Ports: Separate fittings for zero, span, and

sample gas input, internal valves for automatic gas switching.

Current Signal Output: Additional isolated 4–20 mA DC

plus 4–20 mA DC range ID.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model 3000ZA2G is accurate to 2-3 %. Accordingly,

internally scheduled calibrations can vary 30-45 minutes

per day.

Teledyne Analytical Instruments 6

Page 19

Trace Oxygen Analyzer Operational Theory

Operational Theory

2.1 Introduction

The analyzer is composed of three subsystems:

1. The zirconium oxide (ZrO

) sensor with a 0-25%

2

analysis range

2. Sample System

3. Electronic Signal Processing, Display and Control

The sample system is designed to accept the sample gas and

transport it through the analyzer without contaminating or altering the

sample prior to analysis. The ZrO

sensor is a device that translates the

2

amount of oxygen present in the sample into a voltage output. The

electronic signal processing, display and control subsystem simplifies

operation of the analyzer and accurately processes the sampled data. The

microprocessor controls all signal processing, input/output and display

functions for the analyzer.

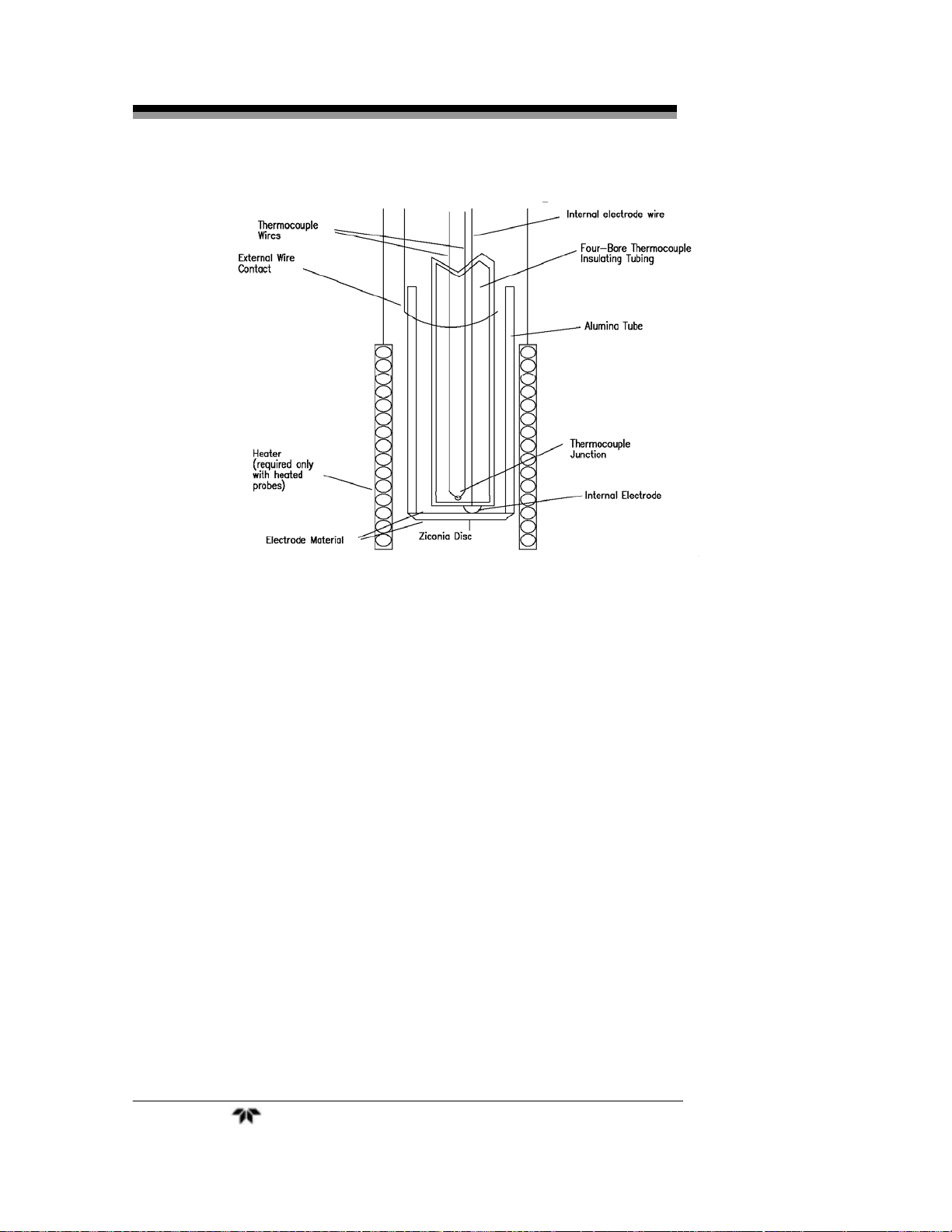

2.2 ZrO2 Sensor

2.2.1 Principles of Operation

The zirconium oxide (ZrO2) sensor is a solid state sensor. It is a

voltage device with a logarithmic response. The sensor uses a stabilized

zirconia disc as an electrolyte with a sensing electrode (the cathode) and

a counter electrode (the anode) on each side of the disc and contains a

thermocouple. The sensor is designed to have a small sample of the

unknown gas passed inside the sensor tube. Air (20.95% oxygen)

surrounds the outside of the tube. A heater is mounted around the sensor

to keep the sensor hot. The sensor construction is shown in Figure 2.1.

CAUTION: THE SENSOR IS HOT. DO NOT TOUCH THE SENSOR

OR ALLOW FLAMMABLE MATERIAL TO COME IN

CONTACT WITH THE ASSEMBLY.

Teledyne Analytical Instruments 7

Page 20

Operational Theory 3000ZA2G

THE SENSOR ASSEMBLY REMAINS HOT EVEN IN

STANDBY MODE. REMOVE POWER FROM THE

INSTRUMENT AND ALLOW SENSOR TO COOL FOR

TWO HOURS BEFORE PERFORMING ANY

MAINTENANCE ON THE SENSOR.

The heater control is a time proportioning temperature controller

that maintains the thermocouple junction at the sensor operating

temperature of 575°C (1070°F).

When exposed to different oxygen partial pressures at the outside

and inside of the sensor, an EMF (E) is developed which obeys the

Nernst equation:

E

(mV)

RT

F

4

log

e

Inside P

O2

Ouside P

O2

Where T is the temperature (K) at the zirconia disc, R is the gas

constant, F is the Faraday constant and (PO2) Inside and (PO2) Outside

are the oxygen partial pressures at the inner and outer electrodes,

respectively, with the higher oxygen partial pressure electrode being

positive.

When dry air at atmospheric pressure, (21% oxygen) is used as a

reference gas at the inner electrode, the following equations are

obtained:

2

TxE

log10154.2(mV)

e

0.21

Ouside P

O2

Transposing this equation:

2

exp21.0(Atm) Outside %O

E421.46

T

The analyzer solves this equation, which is valid above the

minimum operating temperature.

The oxygen sensor assembly provides a means of exposing the

zirconia sensor to the atmosphere to be measured on the inside of the

sensor while maintaining air as a reference gas at atmospheric pressure

on the outside of the sensor.

Teledyne Analytical Instruments 8

Page 21

Trace Oxygen Analyzer Operational Theory

The sensor offset voltage changes with sample flowrate as shown in

Figure 2-1. Assuming that the environment remains constant and within

the specifications of the sensor, the difference in offset voltage between

a flowing reference gas at 200 ml/min and at 0 ml/min is nearly constant

over the operating range of sample flowrates (100-300 ml/min). This

offset is removed during calibration assuming that the sample flowrate

used in calibration is the same as the process flow. Hence the analyzer

can be used without a flowing reference gas during operation with only a

marginal degradation in performance. For best performance, a flowing

reference should be used.

Figure 2-1: Sensor Offset Voltage

The sensor assembly also provides the means of maintaining the

sensor operating temperature by surrounding the sensor tube with a

heater element, and measuring the temperature of the zirconia disc with

a thermocouple inside the sensor. (See Figure 2.2).

The logarithmic output of the sensor depends therefore on the

partial pressure of the oxygen in the sample gas.

The non-linear output is linearized by the system software and a

linear output signal is generated and used by the DAC circuit to produce

the requisite output signals.

Teledyne Analytical Instruments 9

Page 22

Operational Theory 3000ZA2G

Figure 2-2: Zirconia Sensor Assembly

2.3 Sample System

The sample system delivers gases to the ZrO2 sensor from the

analyzer rear panel inlet. Depending on the mode of operation either

sample or calibration gas is delivered.

The Model 3000ZA2G sample system is designed and fabricated to

ensure that the oxygen concentration of the gas is not altered as it travels

through the sample system.

The sample system for the standard instrument incorporates 1/8”

tube fittings for sample inlet and outlet at the rear panel. The sample or

calibration gas that flows through the system is monitored by a

flowmeter downstream from the cell.

Figure 2-3 shows the flow diagram. Shaded portions of the diagram

pertain to instruments with other options as listed. In the standard

instrument, calibration gases can be connected directly to the Sample In

port by teeing to the port with appropriate valves.

Teledyne Analytical Instruments 10

Page 23

Trace Oxygen Analyzer Operational Theory

Figure 2-3: Flow Diagram

2.4 Zirconium Oxide Sensor Application Notes

The following sample gases require conditioning prior to entering

the sensors:

Flammable gases such as methane, alcohol and carbon

monoxide may cause a measurement error. They must be

filtered from the sample gas before entering the cell.

Gases containing halogen atoms (F, Cl, Br, etc.) such as

Freon, must be filtered before entering the cell. The sensor

will be damaged by the decomposition of Freon.

Gases containing SOx, H

S, silicone vapor and adhesives

2

must not enter the sensor. These components adversely affect

the performance of the sensor.

Dust and oil should be filtered from the sample gas.

Water vapor in contact with the sensor will damage the

sensor. Use a moisture trap or filter to remove any water

vapor in the sample.

2.5 Electronics and Signal Processing

The Model 3000ZA2G Trace Oxygen Analyzer uses an 8031

microcontroller with 32 kB of RAM and 128 kB of ROM to control all

signal processing, input/output, and display functions for the analyzer.

System power (110/230 VAC) is user selectable from an internal switch.

It is set at the factory for your specific requirement. Figure 2-4 shows the

location of the power supply and the main electronic PC boards.

The signal processing electronics including the microprocessor,

analog to digital (ADC), and digital to analog (DAC) converters are

located on the motherboard at the bottom of the case. The preamplifier

board is mounted on top of the motherboard as shown in the figure.

Teledyne Analytical Instruments 11

Page 24

Operational Theory 3000ZA2G

These boards are accessible after removing the enclosure cover. Figure

2-5 is a block diagram of the analyzer electronics.

In the presence of oxygen the zirconia sensor generates a

logarithmic response in the mV range and is passed to an amplifier. The

output from the amplifier is sent to an 18 bit analog to digital converter

controlled by the microprocessor.

The high operating temperature of the ZrO

sensor is required for

2

proper operation of the sensor. The amplifier PCB contains a circuit that

drives the heater embedded in the sensor. The voltage across the heater

rises slowly to avoid damaging the heater/sensor assembly. After a few

minutes, the sensor will be at the proper operating temperature.

The digital concentration signal along with input from the control

panel is processed by the microprocessor, and appropriate control

signals are directed to the display, alarms and communications port. The

digital information representing the output from the sensor is linearized

by the Model 3000ZA2G software and passed to a 12 bit digital to

analog converter that produces the 4-20 mADC and the 0-1 VDC analog

concentration signal outputs, and the analog range ID outputs.

Signals from the power supply are also monitored, and through the

microprocessor, the system failure alarm is activated if a malfunction is

detected.

Teledyne Analytical Instruments 12

Page 25

Trace Oxygen Analyzer Operational Theory

Figure 2-4: Component Locations

Teledyne Analytical Instruments 13

Page 26

Operational Theory 3000ZA2G

Figure 2-5: Electronic Block Diagram

Teledyne Analytical Instruments 14

Page 27

Trace Oxygen Analyzer Installation

Installation

Installation of the Model 3000ZA2G Analyzer includes:

1.

Unpacking

2.

Mounting

3.

Gas connections

4.

Electrical connections

5.

Installing the sensor

6.

Testing the system.

3.1 Unpacking the Analyzer

The analyzer is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the analyzer and

inspect it for damage. Immediately report any damage to the shipping

agent.

3.2 Mounting the Analyzer

The Model 3000ZA2G is for indoor use in a general purpose area.

It is NOT for hazardous environments of any type.

The standard model is designed for 19” rack mounting. Figure 3-1 is

an illustration of the 3000ZA2G.

Figure 3-1: Model 3000ZA2G

All operator controls, except the flow control needle valve, are

mounted on the control panel, which is hinged on the left edge and

doubles as the door that provides access to the sensor and connections

Teledyne Analytical Instruments 15

Page 28

Installation 3000ZA2G

V

(op

inside the instrument. The door latch is spring loaded and will swing

open when the button in the center of the latch (upper right corner) is

pressed all the way in with a narrow gauge tool (less than 0.18 inch

wide). Allow clearance for the door to open in a 90-degree arc of radius

7.125 inches. See Figure 3-2.

Figure 3-2: Required Front Door Clearance

3.3 Rear Panel Connections

Figure 3-3 shows the Model 3000ZA2G rear panel. There are ports

for gas, power, and equipment interface. The Zero In and Span In ports

are not included on the standard model but are available as options.

entilation

Auto Cal Valves

tional)

Power Entry

Module w/ Fuse

Housing

Gas

Connections

RS-232 Port

50-Pin Equipment

Connector

Figure 3-3: Model 3000ZA2G Rear Panel

Teledyne Analytical Instruments 16

Page 29

Trace Oxygen Analyzer Installation

3.3.1 Gas Connections

All gas and exhaust connections are made to the labeled 1/4” tube

fittings (6 mm adapters for metric system installations are available) on

the rear panel. The rear panel connections are different between the

standard unit and one which includes the auto calibration option. For

safe connections:

Insert the tube into the fitting and finger-tighten the nut until

1.

the tubing cannot be rotated freely by hand in the fitting. This

may require an additional 1/8 turn beyond finger tight.

Hold the fitting body steady with a backup wrench. Using

2.

another wrench, rotate the nut another 1-1/4 turns.

SAMPLE IN:

In the standard model, gas connections are made at the

EXHAUST OUT connections. Calibration gases must tee into the sample

SAMPLE IN and

inlet with appropriate valves (not supplied).

The inlet gas pressure should be reasonably regulated. Pressures

between 2 and 50 psig are acceptable as long as the pressure, once

established, will keep the front panel flowmeter reading in the

acceptable range.

Use the sample flow control valve on the front panel to adjust the

flow rate to within the acceptable range of 0.1-0.3 SLPM.

If greater sample flow is required for improved response time,

install a bypass in the sampling system upstream of the analyzer input.

SAMPLE VENT:

Exhaust connections must be consistent with the hazard level of the

constituent gases. Check local, state, and federal laws, and ensure that

the exhaust stream vents to an appropriately controlled area, if required.

REF IN/OUT:

Flowing air reference. Air must be clean, dry, and free of hydrocarbons.

Use the reference flow control valve on the front panel to adjust the flow

rate to within the acceptable range of 0.1-0.2 SLPM.

Note: It is possible to use the instrument without a flowing

reference however doing so will result in a marginal

reduction in performance and is not recommended for best

performance.

Teledyne Analytical Instruments 17

Page 30

Installation 3000ZA2G

ZERO IN and SPAN IN (Auto Calibration Option):

With the auto calibration option there are additional ports for span and

zero gas connections. The auto calibration module uses electrically

operated valves for automatic switching between calibration and sample

gases. These valves are completely under control of the 3000ZA2G

electronics. They can also be externally controlled indirectly through the

remote cal inputs as described below.

Pressure, flow, and safety considerations are the same as prescribed for

the SAMPLE IN inlet above.

3.3.2 Calibration Gas

The Model 3000ZA2G will require periodic calibration on known

gases for maintaining the specified accuracy. Both zero and span

calibrations are required. Air (20.9% O

) must be used for the zero gas.

2

For span gas requirements, see Section 4.4. These gases must be

supplied to the instrument at the same pressure and flow as the sample

gas.

3.3.3 Electrical Connections

For safe connections, no uninsulated wiring should be able to come

in contact with fingers, tools or clothing during normal operation.

CAUTION: USE SHIELDED CABLES. ALSO, USE PLUGS THAT

PROVIDE EXCELLENT EMI/RFI PROTECTION. THE

PLUG CASE MUST BE CONNECTED TO THE CABLE

SHIELD, AND IT MUST BE TIGHTLY FASTENED TO

THE ANALYZER WITH ITS FASTENING SCREWS.

ULTIMATELY, IT IS THE INSTALLER WHO ENSURES

THAT THE CONNECTIONS PROVIDE ADEQUATE

EMI/RFI SIELDING.

3.3.3.1 PRIMARY INPUT POWER

The power cord receptacle and fuse block are located in the same

assembly. Insert the power cord into the power cord receptacle.

CAUTION: POWER IS APPLIED TO THE INSTRUMENT'S

CIRCUITRY AS LONG AS THE SWITCH ON THE

REAR PANEL IS IN THE ON POSITION. THE RED

SWITCH ON THE FRONT PANEL IS FOR SWITCHING

POWER ON OR OFF TO THE DISPLAYS AND

OUTPUTS ONLY.

Teledyne Analytical Instruments 18

Page 31

Trace Oxygen Analyzer Installation

Fuse Installation: The fuse block, at the right of the power cord

receptacle, accepts US or European size fuses. A jumper replaces the

fuse in whichever fuse receptacle is not used. Fuses are not installed at

the factory. Be sure to install the proper fuse as part of installation. (See

Fuse Replacement in Chapter 5, Maintenance.)

3.3.3.2 50-PIN EQUIPMENT INTERFACE CONNECTOR

Figure 3-4 shows the pin layout of the Equipment Interface

Connector. The arrangement is shown as seen when the viewer faces the

rear panel of the analyzer. The pin numbers for each input/output function

are given where each function is described in the paragraphs below.

Figure 3-4: Equipment Interface Connector Pin Arrangement

Analog Outputs: There are four DC output signal pins—two pins per

output. For polarity, see Table 3-1. The outputs are:

0–1 VDC % of Range: Voltage rises linearly with

increasing oxygen, from 0 V at 0

ppm to 1 V at full scale ppm. (Full

scale = 100% of programmable

range.)

0–1 VDC Range ID: 0.20 V = Low Range, 0.5 V =

Medium Range, 0.80 V = High

Range.

4–20 mA DC % Range: Current increases linearly with

increasing oxygen, from 4 mA at 0

ppm to 20 mA at full scale ppm.

(Full scale = 100% of

programmable range)

4–20 mA DC Range ID: 7.2 mA = Low Range

12 mA = Medium Range

16.8 mA = High Range

Teledyne Analytical Instruments 19

Page 32

Installation 3000ZA2G

Table 3-1: Analog Output Connections

Pin Function

3 + Range ID, 4-20 mA, floating

4 – Range ID, 4-20 mA, floating

5 + ppm Range, 4-20 mA, floating

6 – ppm Range, 4-20 mA, floating

8 + Range ID, 0-1 VDC

23 – Range ID, 0-1 V dc, negative ground

24 + ppm Range, 0-1 VDC

7 – ppm Range, 0-1 VDC, negative ground

Alarm Relays: The nine alarm-circuit connector pins connect to the

internal alarm relay contacts. Each set of three pins provides one set of

Form C relay contacts. Each relay has both normally open and normally

closed contact connections. The contact connections are shown in Table

3-2. They are capable of switching up to 3 amperes at 250 VAC into a

resistive load. The possible alarm configurations are as follows:

Threshold Alarm 1:

Can be configured as high (actuates when concentration is

above threshold), or low (actuates when concentration is

below threshold).

Can be configured as failsafe or non-failsafe.

Can be configured as latching or non-latching.

Can be configured out (defeated).

Threshold Alarm 2:

Can be configured as high (actuates when concentration is

above threshold), or low (actuates when concentration is

below threshold).

Can be configured as failsafe or non-failsafe.

Can be configured as latching or non-latching.

Can be configured out (defeated).

Teledyne Analytical Instruments 20

Page 33

Trace Oxygen Analyzer Installation

System Alarm:

Actuates when DC power supplied to circuits is unacceptable

in one or more parameters. Permanently configured as

failsafe and latching. Cannot be defeated. Actuates if self test

fails.

(Reset by pressing button to remove power to relay. Then

press

again and any other button Up and Down

simultaneously to resume.

Further detail can be found in Chapter 4, Section 4.6.

Table 3-2: Alarm Relay Contact Pins

Pin Contact

45 Threshold Alarm 1, normally closed contact

28 Threshold Alarm 1, moving contact

46 Threshold Alarm 1, normally open contact

42 Threshold Alarm 2, normally closed contact

44 Threshold Alarm 2, moving contact

43 Threshold Alarm 2, normally open contact

36 System Alarm, normally closed contact

20 System Alarm, moving contact

37 System Alarm, normally open contact

Digital Remote Cal Inputs: Accept 0 V (off) or 24 VDC (on) inputs for

remote control of calibration. (See Remote Calibration Protocol below).

See Table 3-3 for pin connections.

Zero: Floating input. 5 to 24 V input across the + and – pins puts the

analyzer into the

Zero mode. Either side may be grounded at

the source of the signal. 0 to 1 volt across the terminals allows

Zero mode to terminate when done. A synchronous signal must

open and close the external zero valve appropriately. See

Remote Probe Connector. (The –C option internal valves

operate automatically.)

Teledyne Analytical Instruments 21

Page 34

Installation 3000ZA2G

Span: Floating input. 5 to 24 V input across the + and – pins puts the

analyzer into the

the source of the signal. 0 to 1 volt across the terminals allows

Span mode. Either side may be grounded at

Span mode to terminate when done. A synchronous signal

must open and close external span valve appropriately. See

Figure 3-5 Remote Probe Connector. (The –C option internal

valves operate automatically.)

Cal Contact: This relay contact is closed while analyzer is spanning

and/or zeroing. (See Remote Calibration Protocol below).

Table 3-3: Remote Calibration Connections

Pin Function

9 + Remote Zero

11 – Remote Zero

10 + Remote Span

12 – Remote Span

40 Cal Contact

41 Cal Contact

Remote Calibration Protocol: To properly time the Digital Remote Cal

Inputs to the Model 3000ZA2G Analyzer, the customer's controller must

monitor the Cal Relay Contact.

When the contact is OPEN, the analyzer is analyzing, the Remote

Cal Inputs are being polled, and a zero or span command can be sent.

When the contact is CLOSED, the analyzer is already calibrating. It

will ignore your request to calibrate, and it will not remember that

request.

Once a zero or span command is sent, and acknowledged (contact

closes), release it. If the command is continued until after the zero or

span is complete, the calibration will repeat and the Cal Relay Contact

(CRC) will close again.

For example:

Test the CRC. When the CRC is open, send a zero command

1.

until the CRC closes (The CRC will quickly close.)

2.

When the CRC closes, remove the zero command.

Teledyne Analytical Instruments 22

Page 35

Trace Oxygen Analyzer Installation

3. When CRC opens again, send a span command until the

CRC closes. (The CRC will quickly close.)

4.

When the CRC closes, remove the span command.

When CRC opens again, zero and span are done, and the sample is

being analyzed.

Note: The Remote Valve connections (described below) provides

signals to ensure that the zero and span gas valves will be

controlled synchronously. If you have the –C Internal valve

option—which includes additional zero and span gas

inputs—the 3000ZA2G automatically regulates the zero,

span and sample gas flow.

Range ID Relays: There are four dedicated Range ID relay contacts. The

first three ranges are assigned to relays in ascending order—Low range is

assigned to Range 1 ID, Medium range is assigned to Range 2 ID, and

High range is assigned to Range 3 ID. Table 3-4 lists the pin connections.

Table 3-4: Range ID Relay Connections

Pin Function

21 Range 1 ID Contact

38 Range 1 ID Contact

22 Range 2 ID Contact

39 Range 2 ID Contact

19 Range 3 ID Contact

18 Range 3 ID Contact

34 Spare Contact

35 Spare Contact

Network I/O: Pins 13 (+) and 29 (–) are for serial digital input/output

for local network protocol. At this printing, this port is not yet

functional. It is to be used for future options to the instrument.

Remote Valve Connections: The 3000ZA2G is a single-chassis

instrument, which has no Remote Valve Unit. Instead, the Remote Valve

connections are used as a method for directly controlling external

sample/zero/span gas valves. See Figure 3-5.

Teledyne Analytical Instruments 23

Page 36

Installation 3000ZA2G

Figure 3-5: Remote Probe Connections

The voltage from these outputs is nominally 0 V for the OFF and

15 VDC for the ON conditions. The maximum combined current that

can be pulled from these output lines is 100 mA. (If two lines are ON at

the same time, each must be limited to 50 mA, etc.) If more current

and/or a different voltage is required, use a relay, power amplifier, or

other matching circuitry to provide the actual driving current.

In addition, each individual line has a series FET with a nominal

ON resistance of 5 ohms (9 ohms worst case). This can limit the

obtainable voltage, depending on the load impedance applied. See

Figure 3-6.

Teledyne Analytical Instruments 24

Page 37

Trace Oxygen Analyzer Installation

Figure 3-6: FET Series Resistance

3.3.3.3 RS-232 PORT

The digital signal output is a standard, full duplex RS-232 serial

communications port used to connect the analyzer to a computer,

terminal, or other digital device. It requires a standard 9-pin D

connector.

The output data is status information, in digital form, updated every

two seconds. Status is reported in the following order:

The concentration in ppm or percent

The range in use (HI, MED, LO)

The span of the range (0-100 ppm, etc)

Which alarms—if any—are disabled (AL–x DISABLED)

Which alarms—if any—are tripped (AL–x ON).

Each status output is followed by a carriage return and line feed.

Three input functions using RS-232 have been implemented to

date. They are described in Table 3-5.

Teledyne Analytical Instruments 25

Page 38

Installation 3000ZA2G

Table 3-5: Commands via RS-232 Input

Command Description

as<enter> Immediately starts an auto span.

az<enter> Immediately starts an auto zero.

st<enter> Toggling input. Stops/Starts any

status message output from the

RS-232, until st<enter> is sent

again.

The RS-232 protocol allows some flexibility in its implementation.

Table 3-6 lists certain RS-232 values that are required by the 3000ZA2G

implementation.

Table 3-6: Required RS-232 Options

Parameter Setting

Baud 2400

Byte 8 bits

Parity none

Stop Bits 1

Message Interval 2 seconds.

3.4 Testing the System

Before applying power to the instrument:

Check the integrity and accuracy of the gas connections.

Make sure there are no leaks.

Check the integrity and accuracy of the electrical

connections. Make sure there are no exposed conductors.

Check that inlet sample pressure is within the accepted range

(see Section 3.3.1).

Power up the system, and test it by repeating the Self-

Diagnostic Test as described in Chapter 4, Section 4.3.5.

Teledyne Analytical Instruments 26

Page 39

Trace Oxygen Analyzer Operation

Operation

4.1 Introduction

Once the analyzer has been installed, it can be configured for your

application. To do this you will:

Set system parameters.

Establish a security password, if desired, requiring the

operator to log in.

Establish and start an automatic calibration cycle, if desired.

Calibrate the instrument.

Define the three user selectable analysis ranges, then choose

auto ranging or select a fixed range of analysis, as required.

Set alarm setpoints, and modes of alarm operation (latching,

failsafe, etc).

Before you configure your 3000ZA2G, these default values are in

effect:

Ranges: LO = 10 ppm, MED = 1000 ppm, HI = 250,000

ppm. Auto Ranging: ON

Alarm Relays: Defeated, 1000 ppm, HI, Not failsafe, Not

latching.

Zero: Auto, every 0 days at 0 hours.

Span: Auto, at 000008.00 ppm, every 0 days at 0 hours.

Password: TAI

If you choose not to use password protection, the default password

is automatically displayed on the password screen when you start up and

you have access to all functions of the analyzer.

Teledyne Analytical Instruments 27

Page 40

Operation 3000ZA2G

4.2 Using the Data Entry and Function Buttons

Data Entry Buttons: The ◄►arrow buttons select options from

the menu currently being displayed on the VFD screen. The selected

option blinks.

When the selected option includes a modifiable item, the ▲/▼

arrow buttons can be used to increment or decrement that modifiable

item.

Enter button is used to accept any new entries on the VFD

The

screen. The

screen that are not yet accepted by use of the

Figure 4-1 shows the hierarchy of functions available to the

operator via the function buttons. The six function buttons on the

analyzer are:

Escape button is used to abort any new entries on the VFD

Enter button.

Analyze. This is the normal operating mode. The analyzer

monitors the oxygen content of the sample, displays

the percent of oxygen, and warns of any alarm

conditions.

System. The system function consists of six sub functions that

regulate the internal operations of the analyzer:

Auto-Cal setup

Password assignment

Self-Test initiation

Checking software version

Logging out

Display negative oxygen readings

Zero. Used to set up a zero calibration. Zero calibration must

use air as the zero gas.

Span. Used to set up a span calibration.

Alarms. Used to set the alarm setpoints and determine whether

each alarm will be active or defeated, HI or LO acting,

latching, and/or failsafe.

Range. Used to set up three analysis ranges that can be

switched automatically with auto-ranging or used as

individual fixed ranges.

Teledyne Analytical Instruments 28

Page 41

Trace Oxygen Analyzer Operation

Any function can be selected at any time by pressing the

appropriate button (unless password restrictions apply). The order as

presented in this manual is appropriate for an initial setup.

Each of these functions is described in greater detail in the

following procedures. The VFD screen text that accompanies each

operation is reproduced, at the appropriate point in the procedure, in a

Monospaced type style. Pushbutton names are printed in Italic type.

Figure 4-1: Hierarchy of Functions and Sub functions

Teledyne Analytical Instruments 29

Page 42

Operation 3000ZA2G

4.3 The System Function

The sub functions of the System function are described below.

Specific procedures for their use follow the descriptions:

Auto-Cal: Used to define an automatic calibration sequence

and/or start an Auto-Cal.

Note: This function will have no effect if the auto calibration

option is not present.

PSWD: Security can be established by choosing a 5 digit

password (PSWD) from the standard ASCII character set.

(See Installing or Changing a Password, below, for a table of

ASCII characters available.) Once a unique password is

assigned and activated, the operator MUST enter the

UNIQUE password to gain access to set-up functions which

alter the instrument's operation, such as setting the instrument

span or zero setting, adjusting the alarm setpoints, or defining

analysis ranges.

After a password is assigned, the operator must log out to

activate it. Until then, anyone can continue to operate the

instrument without entering the new password.

Only one password can be defined. Before a unique

password is assigned, the system assigns

allows access to anyone. After a unique password is

assigned, to defeat the security, the password must be

changed back to

TAI.

TAI by default. This

Logout: Logging out prevents an unauthorized tampering

with analyzer settings.

More: Select and enter More to get a new screen with

additional sub functions listed.

Self–Test: The instrument performs a self-diagnostic test to

check the integrity of the power supply, output boards and

amplifiers.

Version: Displays Manufacturer, Model, and Software

Version of the instrument.

Teledyne Analytical Instruments 30

Page 43

Trace Oxygen Analyzer Operation

Show Negative: The operator selects whether display can

show negative oxygen readings or not.

TRAK/HLD: The operator sets whether the instrument

analog outputs track the concentration change during

calibration and sets a time delay for the concentration alarms

after calibration

4.3.1 Tracking Oxygen Readings During Calibration and

Alarm Delay

The user has the option of setting the preference as to whether the

analog outputs track the display readings during calibration or not. To

set the preference, press the

System key once and the first System menu

will appear in the VFD display:

TRAK/HLD Auto-Cal

PSWD Logout More

TRAK/HLD should be blinking. To enter this system menu press

Enter key once:

the

Output Sttng: TRACK

Alarm Dly: 10 min

or

Output Sttng: HOLD

Alarm Dly: 10 min

In the first line, TRACK or HOLD should be blinking. The

operator can toggle between TRACK and HOLD with the ▲/▼ keys.

When TRACK is selected, the analog outputs (0-1 VDC and 4-20 mA)

and the range ID contacts will track the instrument readings during

calibration (either zero or span). TRACK is the factory default.

When HOLD is selected, the analog outputs (0-1 VDC and 4-20

mA) and the range ID contacts will freeze on their last state before

entering one of the calibration modes. When the instrument returns to

the Analyze mode, either by a successful or an aborted calibration, there

Teledyne Analytical Instruments 31

Page 44

Operation 3000ZA2G

will be a three-minute delay before the analog outputs and the range ID

contacts start tracking again.

The concentration alarms freeze on their last state before entering

calibration regardless of selecting HOLD or TRACK. But, when HOLD

is selected the concentration alarms will remain frozen for the time

displayed in the second line of the TRAK/HLD menu after the analyzer

returns to the Analyze mode.

The factory default is three minutes, but the delay time is programmable. To adjust to delay time use the

◄► arrow keys. When the time

displayed on the second line blinks, it can be adjusted by pressing the

▲/▼ keys to increase or decrease its value. The minimum delay is 1

minute, the maximum is 30.

This preference is stored in non-volatile memory so that it is

recovered if power is removed from the instrument.

4.3.2 Setting up an Auto-Cal

When proper automatic valving is connected (see Chapter 3,

Installation), the analyzer can cycle itself through a sequence of steps

that automatically zero and span the instrument.

Note: If you require highly ac curate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model 3000ZA2G is accurate to 2-3 %. Accordingly,

internally scheduled calibrations can vary 2-3 % per day.

To setup an Auto–Cal cycle:

Choose

System from the Function buttons. The LCD will display

five sub functions.

TRAK/HLD Auto—Cal

PSWD Logout More

Use ◄►arrows to blink Auto—Cal, and press Enter. A new screen

Span/Zero set appears.

for

Span OFF Nxt: 0d 0h

Zero OFF Nxt: 0d 0h

Teledyne Analytical Instruments 32

Page 45

Trace Oxygen Analyzer Operation

Press

◄►arrows to blink Span (or Zero), then press Enter again.

(You won’t be able to set

OFF to ON if a zero interval is entered.) A

Span Every ... (or Zero Every ...) screen appears.

Span Every 0 d

Start 0 h from now

Use ▲/▼ arrows to set an interval value, and then use ◄

► arrows

to move to the start-time value. Use ▲/▼ arrows to set a start-time

value.

To turn

System again, choose Auto—Cal, and press Enter again. When

Press

Span/ Zero values screen appears, use the ◄► arrows to blink the

the

ON the Span and/or Zero cycles (to activate Auto-Cal):

Span (or Zero) OFF/ON field. Use ▲/▼ arrows to set the OFF/ON

field to

ON. You can now turn these fields ON because there is a

nonzero span interval defined.

4.3.3 Password Protection

If a password is assigned, then setting the following system

parameters can be done only after the password is entered:

Span and zero settings

Alarm setpoints

Analysis range definitions

Switching between auto ranging and manual override

Setting up an auto-cal

Assigning a new password

However, the instrument can still be used for analysis or for

initiating a self- test without entering the password.

If you have decided not to employ password security, use the

default password

TAI. This password will be displayed automatically by

the microprocessor. The operator just presses the Enter key to be

allowed total access to the instrument’s features.

Teledyne Analytical Instruments 33

Page 46

Operation 3000ZA2G

Note: If you use password security, it is advisable to keep a copy

of the password in a separate, safe location.

4.3.3.1 ENTERING THE PASSWORD

To install a new password or change a previously installed

password, you must key in and

default password is in effect, pressing the

default

TAI password for you.

Enter the old password first. If the

Enter button will enter the

Press System to enter the System mode.

TRAK/HLD Auto—Cal

PSWD Logout More

Use the

Enter to select the password function. Either the default TAI

press

password or

◄►arrow keys to scroll the blinking over to PSWD, and

AAAAA place holders for an existing password will appear

on screen depending on whether or not a password has been previously

installed.

T A I

Enter PWD

or

A A A A A

Enter PWD

The screen prompts you to enter the current password. If you are

not using password protection, press

Enter to accept TAI as the default

password. If a password has been previously installed, enter the

password using the

◄►arrow keys to scroll back and forth between

letters, and the ▲/▼ arrow keys to change the letters to the proper

password. Press

Enter to enter the password.

Teledyne Analytical Instruments 34

Page 47

Trace Oxygen Analyzer Operation

If the password is accepted, the screen will indicate that the

password restrictions have been removed and you have clearance to

proceed.

PSWD Restrictions

Removed

In a few seconds, you will be given the opportunity to change this

password or keep it and go on.

Change Password?

<ENT>=Yes <ESC>=No

Press Escape to move on, or proceed as in Changing the

Password, below.

4.3.3.2 INSTALLING OR CHANGING THE PASSWORD

If you want to install a password, or change an existing password,

proceed as above in Entering the Password. When you are given the

opportunity to change the password:

Change Password?

<ENT>=Yes <ESC>=No

Press Enter to change the password (either the default TAI or the

previously assigned password), or press

Escape to keep the existing

password and move on.

If you chose

Enter to change the password, the password

assignment screen appears.

T A I

<ENT> To Proceed

or

A A A A A

<ENT> To Proceed

Teledyne Analytical Instruments 35

Page 48

Operation 3000ZA2G

}

$

Enter the password using the ◄►arrow keys to move back and

forth between the existing password letters, and the ▲/▼ arrow keys to

change the letters to the new password. The full set of 94 characters

available for password use is shown in the table below.

Characters Available for Password Definition:

A B C D E F G H I J

K L M N O P Q R S T

U V W X Y Z [ ¥ ] ^

i j k l m n o p q r

s t u v w x y z { |

) * + ' - . / 0 1 2

3 4 5 6 7 8 9 : ; <

= > ? @

` a b c d e f g h

→

! " #

%& '(

When you have finished typing the new password, press

Enter. A

verification screen appears. The screen will prompt you to retype your

password for verification.

A A A A A

Retype PWD To Verify

Wait a moment for the entry screen. You will be given clearance to

proceed.

A A A A A

<ENT> TO Proceed

Use the arrow keys to retype your password and press

Enter when

finished. Your password will be stored in the microprocessor and the

system will immediately switch to the

Analyze screen, and you now

have access to all instrument functions.

If all alarms are defeated, the

Analyze screen appears as:

Teledyne Analytical Instruments 36

Page 49

Trace Oxygen Analyzer Operation

0.0 ppm Anlz

Range: 0 — 100

If an alarm is tripped, the second line will change to show which

alarm it is:

0.0 ppm Anlz

AL—1

Note: If you log off the system using the logout function in the

system menu, you will now be required to re-enter the

password to gain access to Span, Zero, Alarm, and Range

functions.

4.3.4 Logout

The Logout function provides a convenient means of leaving the

analyzer in a password protected mode without having to shut the

instrument off. By entering

Logout, you effectively log off the

instrument leaving the system protected against use until the password is

reentered. To log out, press the

System button to enter the System

function.

TRAK/HLD Auto—Cal

PSWD Logout More

Use the ◄►arrow keys to position the blinking over the Logout

function, and press

Enter to Log out. The screen will display the

message:

Protected Until

Password Reentered

Teledyne Analytical Instruments 37

Page 50

Operation 3000ZA2G

4.3.5 System Self-Diagnostic Test

The Model 3000ZA2G has a built-in self-diagnostic testing routine.

Pre-programmed signals are sent through the power supply, output board

and sensor circuit. The return signal is analyzed, and at the end of the

test the status of each function is displayed on the screen, either as

OK

or as a number between 1 and 3. (See System Self Diagnostic Test in

Chapter 5 for number code).

The self diagnostics are run automatically by the analyzer

whenever the instrument is turned on, but the test can also be run by the

operator at will. To initiate a self diagnostic test during operation:

Press the

System button to start the System function.

TRAK/HLD Auto—Cal

PSWD Logout More

Use the ◄►arrow keys to blink

More, and then press Enter.

Version Self—Test

Use the ◄►arrow keys again to move the blinking to the Self–

Test function. The screen will follow the running of the diagnostic.

When the testing is complete, the results are displayed.

Power: OK Analog: OK

The module is functioning properly if it is followed by

OK. A

number indicates a problem in a specific area of the instrument. Refer to

Chapter 5 Maintenance and Troubleshooting for number-code

information. The results screen alternates for a time with:

Press Any Key

To Continue...

Teledyne Analytical Instruments 38

Page 51

Trace Oxygen Analyzer Operation

Then the analyzer returns to the initial System screen.

4.3.6 Version Screen

Move the ◄►arrow key to More and press Enter. With Version

blinking, press

Enter. The screen displays the manufacturer, model, and

software version information.

4.3.7 Showing Negative Oxygen Readings

For software version 1.4.4 or later, the instrument only displays

oxygen readings that are positive or zero. The instrument can be

reconfigured to show negative readings if sensor output drifts below

zero. This situation may arise after the instrument has been zeroed, as

time progresses the sensor may drift below the zero calibration setpoint.

To show negative oxygen readings on the display:

Press the System key.

TRAK/HLD Auto-Cal

PSWD Logout More

Use the Right or Left arrow keys and select More. Press

Version Self-Test

Show_Negative=NO

Enter.

Use the ◄► arrow keys and select “

Use the ▲/▼ keys to toggle from

Press the

Escape key twice to return to the analyze mode.

Show_Negative=NO”.

NO to YES.

This preference is stored in non-volatile memory, so this

configuration is remembered after a power shutdown. If the instrument

is cold started, it will go back to default (not showing negative oxygen

readings).

Teledyne Analytical Instruments 39

Page 52

Operation 3000ZA2G

4.4 The Zero and Span Functions

Note: A zero calibration is required for the zirconia sensor

installed in this instrument. Air must be used for the zero

gas. The Zero calibration will eliminate offset error

contributed by sensor, electronics, and internal and

external sampling system and maintain performance at the

published specification for this instrument.

The analyzer is calibrated using air for zero calibration and a

known concentration of oxygen in a suitable background gas for span

calibration.

The software in the Model 3000ZA2G assumes that air is used as

the zero gas and automatically sets the zero point of the instrument

based on the 20.9% oxygen concentration in air. Do not substitute

another gas for zero gas.

A known oxygen concentration in the range of 70–90% of full scale

of the range of interest is recommended for use as a span gas. The span

gas used must have a concentration greater than 7.0 ppm oxygen. When

70-90% of full scale is close to air concentration (e.g. 0-25% range), 0.1-

1.0% O

span gas is recommended.

2

Connect the calibration gases according to the instructions given in

Section 3.4.1, Gas Connections, observing all the prescribed

precautions.

Shut off the gas pressure before connecting it to the analyzer,

and be sure to limit the pressure to 40 psig or less when turning it

back on.

Adjust the needle valve on the front panel of the analyzer until the

flow rate (as read on the analyzer’s flowmeter) is 0.1-0.3 SLPM.

If you are using password protection, you will need to enter your

password to gain access to either of these functions. Follow the

instructions in Sections 4.3.3 to enter your password. Once you have

gained clearance to proceed, you can enter the

Zero or Span function.

4.4.1 Zero Cal

The Zero button on the front panel is used to enter the zero

calibration function. Zero calibration can be performed in either the

automatic or manual mode. In the

Teledyne Analytical Instruments 40

automatic mode, an internal

Page 53

Trace Oxygen Analyzer Operation

algorithm compares consecutive readings from the sensor to determine

when the output is within the acceptable range for zero. In the

manual

mode, the operator determines when the reading is within the acceptable

range for zero. Make sure air is connected to the instrument. If you get a

CELL FAILURE message skip to Section 4.4.1.3.

4.4.1.1 AUTO MODE ZEROING

Press Zero to enter the zero function mode. The screen allows you

to select whether the zero calibration is to be performed automatically or

manually. Use the ▲/▼ arrow keys to toggle between

zero settling. Stop when

AUTO appears, blinking, on the display.

AUTO and MAN

Zero: Settling: AUTO

<ENT> To Begin

Press Enter to begin zeroing.

#### PPM Zero

Slope=#### ppm/s

The beginning zero level is shown in the upper left corner of the

display. As the zero reading settles, the screen displays and updates

information on

Slope (unless the Slope starts within the acceptable zero

range and does not need to settle further).

Then, and whenever Slope is less than 0.08 for at least 3 minutes,

instead of Slope you will see a countdown:

5 Left, 4 Left, and so forth.

These are five steps in the zeroing process that the system must

complete, AFTER settling, before it can go back to

#### PPM Zero

4 Left=### ppm/s

Analyze.

The zeroing process will automatically conclude when the output is

within the acceptable range for a good zero. Then the analyzer

automatically returns to the

Analyze mode.

Teledyne Analytical Instruments 41

Page 54

Operation 3000ZA2G

4.4.1.2 MANUAL MODE ZEROING

Press Zero to enter the Zero function. The screen that appears

allows you to select between automatic and manual zero calibration. Use

the ▲/▼ keys to toggle between

MAN appears, blinking, on the display.

when

AUTO and MAN zero settling. Stop

Zero: Settling: Man

<ENT> To Begin

Press Enter to begin the zero calibration.

After the zero calibration completes its cycle, the information is

stored in the microprocessor, and the instrument automatically returns to

Analyze mode.

the

4.4.2 Span Cal

The Span button on the front panel is used to span calibrate the

analyzer. Span calibration can be performed using the

automatic mode,

where an internal algorithm compares consecutive readings from the

sensor to determine when the output matches the span gas concentration.

Span calibration can also be performed in

manual mode, where the

operator determines when the span concentration reading is acceptable

and manually exits the function.

4.4.2.1 AUTO MODE SPANNING

Press Span to enter the span function. The screen that appears

allows you to select whether the span calibration is to be performed

automatically or manually. Use the ▲/▼ arrow keys to toggle between

AUTO and MAN span settling. Stop when AUTO appears, blinking, on

the display.

Span: Settling: AUTO

<ENT> For Next

Press

Enter to move to the next screen.

Teledyne Analytical Instruments 42

Page 55

Trace Oxygen Analyzer Operation

Calib. Holding time

Cal hold: 5 min

This menu allows the operator to set the time the analyzer should

be held in the span mode, after the readings of the analyzer settle. Five

minutes is the default, but it could be adjusted anywhere from 1 to 60

minutes by using the UP or DOWN keys.

Enter to move to the next screen.

Press

Span Val: 000008.00

<ENT>Span <UP>Mod #

Use the ▲/▼ arrow keys to enter the oxygen-concentration mode.

Use the ◄►arrow keys to blink the digit you are going to modify. Use

the ▲/▼ arrow keys again to change the value of the selected digit.

When you have finished typing in the concentration of the span gas you

are using, press

Enter to begin the Span calibration.

#### ppm Span

Slope=#### ppm/s

The beginning span value is shown in the upper left corner of the

display. As the span reading settles, the screen displays and updates

information on

Slope. Spanning automatically ends when the span

output corresponds, within tolerance, to the value of the span gas

concentration. Then the instrument automatically returns to the analyze

mode.

4.4.2.2 MANUAL MODE SPANNING

Press Span to start the Span function. The screen that appears

allows you to select whether the span calibration is to be performed

automatically or manually.

Teledyne Analytical Instruments 43

Page 56

Operation 3000ZA2G

Span: Settling:MAN

<ENT> For Next

Use the ▲/▼ keys to toggle between AUTO and MAN span

settling. Stop when MAN appears, blinking, on the display. Press

Enter

to move to the next screen.

Press

Enter to move to the next screen.

Calib. Holding time

Cal hold: 5 min

This menu allows the operator to set the time the analyzer should

be held in the auto span mode. It does not affect anything in Manual

Mode. Just press

Enter to continue.

Span Val: 000008.00

<ENT>Span <UP>Mod #

Press ▲ (<UP>) to permit modification (Mod #) of span value.

Use the arrow keys to enter the oxygen concentration of the span

gas you are using (209000.00 if you are using air). The ◄►arrows

choose the digit, and the ▲/▼ arrows choose the value of the digit.

Press

Enter to enter the span value into the system and begin the

span calibration.

Once the span has begun, the microprocessor samples the output at

a predetermined rate. It calculates the difference between successive

samplings and displays this difference as Slope on the screen. It takes

several seconds for the first Slope value to display. Slope indicates rate

of change of the Span reading. It is a sensitive indicator of stability.

Teledyne Analytical Instruments 44

Page 57

Trace Oxygen Analyzer Operation

#### % Span

Slope=#### ppm/s

When the Span value displayed on the screen is sufficiently stable,

press

Enter. (Generally, when the Span reading changes by 1% or less

of the full scale of the range being calibrated for a period of ten minutes

it is sufficiently stable.) Once

Enter is pressed, the Span reading

changes to the correct value. The instrument then automatically enters

the Analyze function.

4.4.3 Span Failure

The analyzer checks the output of the sensor at the end of the span.

The output signal decreases approximately 50 mV per decade increase in

the oxygen concentration. The software analyzes the change in output

and will trigger a span failure message if it is found differ significantly