Teledyne 3000TA User Manual 2

Teledyne Analytical Instruments

QUICKSTART GUIDE

MODEL 3000 TA

Trace Oxygen Analyzer

Quickstart Guide Trace Oxygen Analyzer

Teledyne Analytical Instruments

Model 3000TA Quickstart Guide

Teledyne Analytical Instruments 3

GETTING STARTED

This Quickstart Guide is designed to get you set up and operating your Teledyne Analytical

Instruments Analyzer quickly. It shortcuts the details so you can install and use your new

analyzer with a minimum of fuss. This Quickstart Guide should be used in conjunction with the

Instruction Manual that shipped with your instrument. Only necessary features to get you

operational are discussed in this guide. Many of the advanced features of this analyzer are not

described here so you should refer to the Instruction Manual to get the most from your analyzer

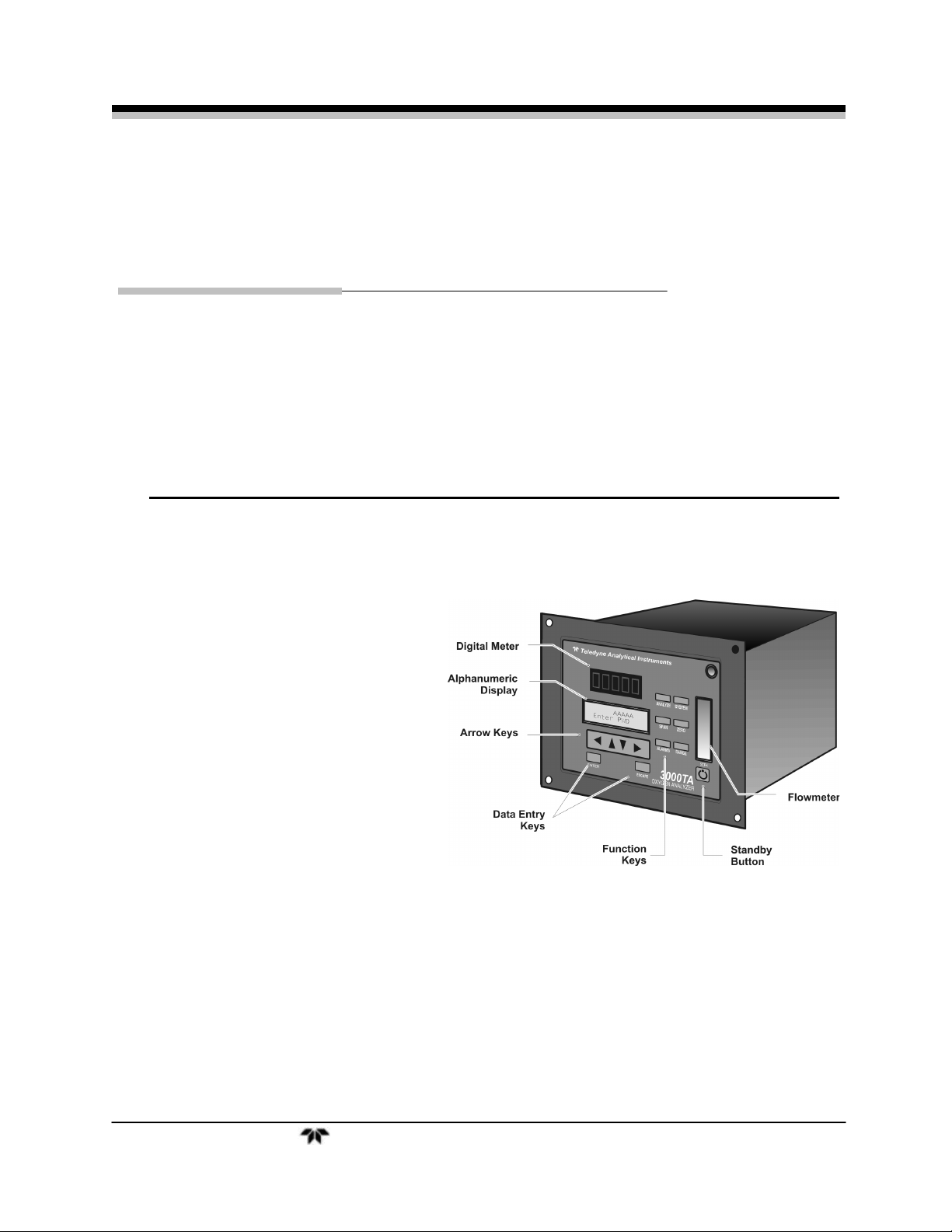

Front Panel (Operator Interface)

Take a minute to familiarize yourself with the analyzer’s interface. The standard 3000TA is

housed in a rugged metal case with all controls and displays accessible from the front panel. The

operator interface consists of thirteen buttons for operating the analyzer, a digital meter, an

alphanumeric display, and a window for viewing the sample flowmeter.

Function Keys:

Six touch-sensitive membrane switches

are used to change the specific function

performed by the analyzer:

• Analyze Perform analysis for

oxygen content of a

sample gas.

• System Perform system-

related tasks

(described in detail

in chapter 4,

Operation.).

• Span Span calibrate the analyzer.

• Zero Zero calibrate the analyzer.

• Alarms Set the alarm setpoints and attributes.

• Range Set up the 3 user definable ranges for the instrument.

Data Entry Keys:

Six touch-sensitive membrane switches are used to input data to the instrument via the

alphanumeric VFD display:

Quickstart Guide Trace Oxygen Analyzer

Teledyne Analytical Instruments 4

• Left & Right Arrows Select between functions currently displayed on the VFD

screen.

• Up & Down Arrows Increment or decrement values of functions currently displayed.

• Enter Advances VFD display to the next screen in a series or returns to the Analyze

screen if none remain.

• Escape Backs VFD display to the previous screen in a series or returns to the Analyze

screen if none remain.

Digital Meter Display:

The meter display is a Light Emitting Diode (LED) device that produces large, bright, 7-segment

numbers that are legible in any lighting. It produces a continuous readout from 0-10,000 ppm and

then switches to a continuous percent readout from 1-25%.

Alphanumeric Interface Screen

The VFD screen displays values, options, and messages for immediate feedback.

Set Flow:

Needle valve used to adjust flow of gas sample

Flowmeter:

Monitors the flow of gas past the sensor. Readout is 0.2 to 2.4 SLPM of nitrogen.

Standby Button:

The Standby turns off the display and outputs, but circuitry is still operating.

Access Door:

For access to the Micro-fuel Cell,the front panel swings open when the latch in the upper right

corner of the panel is pressed all the way in.

Rear Panel (Equipment Interface)

At the rear panel you make the gas and electrical connections to the instrument.

• Power Connection:

Universal AC power

source.

• Gas Inlet and Outlet:

Inlet, exhaust, zero and

span.

• Remote Probe

Connection: Used for

controlling external solenoid valves only.

• RS-232 Port: Serial digital concentration signal output and control input.

Model 3000TA Quickstart Guide

Teledyne Analytical Instruments 5

• Analog Output Connection: Terminals for current and voltage analog output

signals.

• Digital Input Terminals: Terminals for connecting digital input signals.

• Alarm Connections: 2 concentration alarms and 1 system alarm.

• Calibration Contact : To notify external equipment that instrument is being

calibrated and readings are not monitoring sample.

• Range ID Contacts: Four separate, dedicated, range relay contacts. Low, Medium,

High, Cal.

• Remote Span/Zero: Digital inputs for externally controlling calibration.

• Network I/O: Serial digital communications for local network access.

Quickstart Guide Trace Oxygen Analyzer

Teledyne Analytical Instruments 6

SETUP AND INSTALL

Mount the Analyzer

The Model 3000TA is for indoor use in a general purpose area. It is NOT for hazardous

environments of any type. It is designed for flush panel mounting. Use the four mounting holes—

one in each corner of the rigid frame to panel mount the instrument.

Gas Connections

Note: Do not remove plastic caps on VCR fittings, unless you are ready to make

connections.

The analyzer is equipped with 1/4 inch tube fittings, and 6 mm adapters are supplied for

metric system installations.

You will need:

• Zero gas — regulated supply of oxygen free gas.

• Span gas — regulated supply of a standard gas typically containing oxygen at 70-

90% of the full scale value on the range of interest.

• Purge gas — oxygen free inert gas for purging if applicable.

• Sample gas — regulated supply of sample gas available to the analyzer.

Make your gas connections to the analyzer as follows:

1. Install the flow restrictor that shipped with your instrument:

• For positive pressure applications, install the restrictor with the blue dot to the

SAMPLE IN port. The small circular orifice should face away from the back of

the unit. Remove the sticker after installing.

• For low pressure applications (less than 5 psig), connect the restrictor without the

blue dot to the SAMPLE IN port.

• For vacuum service (5-10 in Hg), install the restrictor without the blue dot to the

EXHAUST port.

2. Connect your sample gas to the SAMPLE IN port.

3. Connect a vent line to EXHAUST OUT port.

Loading...

Loading...