Page 1

Percent Oxygen Analyzer

OPERATING INSTRUCTIONS FOR

Model 3000PB

Percent Oxygen Analyzer

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST

FOR A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

Teledyne Analytical Instruments

P/N M66682

03/29/2006

ECO # 06-0059

i

Page 2

Model 3000PB

Copyright © 1999 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgments provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, neglect or repairs other than those performed by Teledyne or an authorized service center. We assume no liability for direct or indirect damages of any kind and

the purchaser by the acceptance of the equipment will assume all liability for any damage

which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the manufacturer or its agents, is to be construed as a warranty of adequate safety control under the user’s

process conditions.

ii

Teledyne Analytical Instruments

Page 3

Percent Oxygen Analyzer

Table of Contents

1 Introduction

1.1 Overview........................................................................ 1-1

1.2 Typical Applications ....................................................... 1-1

1.3 Main Features of the Analyzer....................................... 1-1

1.4 Model Designations ....................................................... 1-2

1.5 Operator Interface.......................................................... 1-3

1.5.1 Displays ................................................................. 1-6

1.5.2 Function Keys ........................................................ 1-6

1.5.3 Data Entry Keys..................................................... 1-6

1.5.4 I/O Power Button.................................................... 1-7

1.5.5 Access Door .......................................................... 1-7

1.6 Recognizing Difference Between LCD & VFD ............... 1-7

1.7 Equipment Interface....................................................... 1-7

1.7.1 Electrical Connector Panel..................................... 1-7

1.7.2 Gas Connector Panel............................................. 1-9

2 Operational Theory

2.1 Introduction .................................................................... 2-1

2.2 Micro-Fuel Cell Sensor .................................................. 2-1

2.2.1 Principles of Operation............................................ 2-1

2.2.2 Anatomy of a Micro-Fuel Cell.................................. 2-2

2.2.3 Electrochemical Reactions...................................... 2-3

2.2.4 The Effect of Pressure............................................. 2-4

2.2.5 Calibration Characteristics ...................................... 2-4

2.2.6 Micro-Fuel Cell “Class”............................................ 2-5

2.3 Sample System.............................................................. 2-6

2.4 Electronics and Signal Processing ................................ 2-7

3 Installation

3.1 Unpacking the Analyzer................................................. 3-1

3.2 Mounting the Analyzer ................................................... 3-1

3.3 Electrical Connections ................................................... 3-3

3.3.1 Primar y Input Power .............................................. 3-4

3.3.2 Fuse Installation..................................................... 3-4

3.3.3 Analog Outputs...................................................... 3-4

3.3.4 Alarm Relays ......................................................... 3-6

3.3.5 Digital Remote Cal Inputs ...................................... 3-7

3.3.6 Range ID Relays.................................................... 3-9

3.3.7 Network I/O............................................................ 3-9

3.3.8 RS-232 PorT.......................................................... 3-9

Teledyne Analytical Instruments

iii

Page 4

Model 3000PB

3.3.9 Remote Sensor and Solenoid Valves..................... 3-10

3.4 Installing the Micro-Fuel Cell.......................................... 3-12

3.5 Gas Connections ........................................................... 3-12

3.6 Testing the System ........................................................ 3-14

4 Operation

4.1 Introduction .................................................................... 4-1

4.2 Using the Data Entry and Function Buttons................... 4-2

4.3 The System Function..................................................... 4-3

4.3.1 Setting the Display................................................. 4-4

4.3.2 Setting up an Auto-Cal........................................... 4-5

4.3.3 Password Protection .............................................. 4-5

4.3.4 Logout.................................................................... 4-8

4.3.5 System Self-Diagnostic Test .................................. 4-9

4.3.6 Version Screen ...................................................... 4-9

4.4 The Span Functions....................................................... 4-10

4.4.1 Cell Failure............................................................. 4-10

4.4.2 Span Cal ................................................................ 4-11

4.5 The Alarms Function...................................................... 4-12

4.6 The Range Function ...................................................... 4-15

4.6.1 Setting the Analog Output Ranges ........................ 4-15

4.6.2 Autoranging Analysis ............................................. 4-16

4.6.3 Fixed Range Analysis ............................................ 4-16

4.7 The Analyze Function .................................................... 4-17

4.8 Signal Output ................................................................. 4-17

4.3.3.1 Entering the Password................................... 4-6

4.3.3.2 Installing or Changing the Password ............. 4-7

4.4.2.1 Auto Mode Spanning ..................................... 4-11

4.4.2.2 Manual Mode Spanning................................. 4-12

Maintenance

5.1 Routine Maintenance..................................................... 5-1

5.2 Major Internal Components ........................................... 5-1

5.3 Cell Replacement .......................................................... 5-2

5.4 Fuse Replacement......................................................... 5-7

5.5 System Self Diagnostic Test........................................... 5-7

5.6 LCD Display................................................................... 5-8

iv

5.3.1 Storing and Handling Replacement Cells ............... 5-3

5.3.2 When to Replace a Cell ........................................... 5-3

5.3.3 Removing the Micro-Fuel Cell ................................. 5-4

5.3.4 Installing a New Micro-Fuel Cell.............................. 5-6

5.3.5 Cell Warranty........................................................... 5-6

Teledyne Analytical Instruments

Page 5

Percent Oxygen Analyzer

5.7 Troubleshooting.............................................................. 5-9

Appendix

A-1 Specifications................................................................. A-1

A-2 Recommended 2-Year Spare Parts List......................... A-3

A-3 Drawing List ................................................................... A-4

A-5 Applicatiopn Notes on Restrictors, Pressures & Flow.... A-5

A-6 The Zero Functions........................................................ A-8

Teledyne Analytical Instruments

v

Page 6

Model 3000PB

DANGER

COMBUSTIBLE GAS USAGE WARNING

This is a general purpose instrument designed for usage in a

nonhazardous area. It is the customer's responsibility to ensure safety especially when combustible gases are being analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating of

this equipment is well understood by the user. Misuse of this

product in any manner, tampering with its components, or

unauthorized substitution of any component may adversely

affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

vi

Teledyne Analytical Instruments

Page 7

Percent Oxygen Analyzer Introduction 1

Introduction

1.1 Overview

The Teledyne Analytical Instruments Model 3000PB Percent Oxygen

Analyzer is a versatile microprocessor-based instrument for detecting oxygen

in a variety of gases. This manual covers the Model 3000PB, percent oxygen, general purpose, bulkhead-mount units only.

1.2 Typical Applications

A few typical applications of the Model 3000PB are:

• Monitoring inert gas blanketing

• Air separation and liquefaction

• Chemical reaction monitoring

• Semiconductor manufacturing

• Petrochemical process control

• Quality assurance

• Gas analysis certification.

1.3 Main Features of the Analyzer

The Model 3000PB Percent Oxygen Analyzer is sophisticated yet

simple to use. The main features of the analyzer include:

• A 2-line alphanumeric display screen, driven by microprocessor

electronics, that continuously prompts and informs the operator.

• High resolution, accurate readings of oxygen content from low %

levels through 100%. Large, bright, meter readout.

• Advanced Micro-Fuel Cell for percent analysis. Standard cell has

a six month warranty and an expected lifetime of eight months.

Teledyne Analytical Instruments

1-1

Page 8

1 Introduction Model 3000PB

• Versatile analysis over a wide range of applications.

• Microprocessor based electronics: 8-bit CMOS microprocessor

with 32 kB RAM and 128 kB ROM.

• Three user definable output ranges (from 0-1 % through

0-100 %) allow best match to users process and equipment.

• Air-calibration range for convenient spanning at 20.9 %.

• Auto Ranging allows analyzer to automatically select the proper

preset range for a given measurement. Manual override allows

the user to lock onto a specific range of interest.

• Two adjustable concentration alarms and a system failure alarm.

• Extensive self-diagnostic testing, at startup and on demand, with

continuous power-supply monitoring.

• RS-232 serial digital port for use with a computer or other digital

communication device.

• Analog outputs for concentration and range identification.

(0-1 V dc standard, and isolated 4–20 mA dc optional.)

1.4 Model Designations

3000PB: Standard model.

3000PB-C: In addition to all standard features, this model also has

separate ports for zero and span gases, and built-in control

valves. The internal valves are entirely under the control of

the 3000PB electronics, to automatically switch between

gases in synchronization with the analyzer’s operations

3000PB-S: Stainless steel cell block and sampling system.

3000PB-M: 4-20 mA dc Signal and Range ID outputs, in addition

to the standard voltage outputs.

All of the above options are available in combination. For example, the

-C and -V options are combined as Model 3000PB-C-V.

1-2

Teledyne Analytical Instruments

Page 9

Percent Oxygen Analyzer Introduction 1

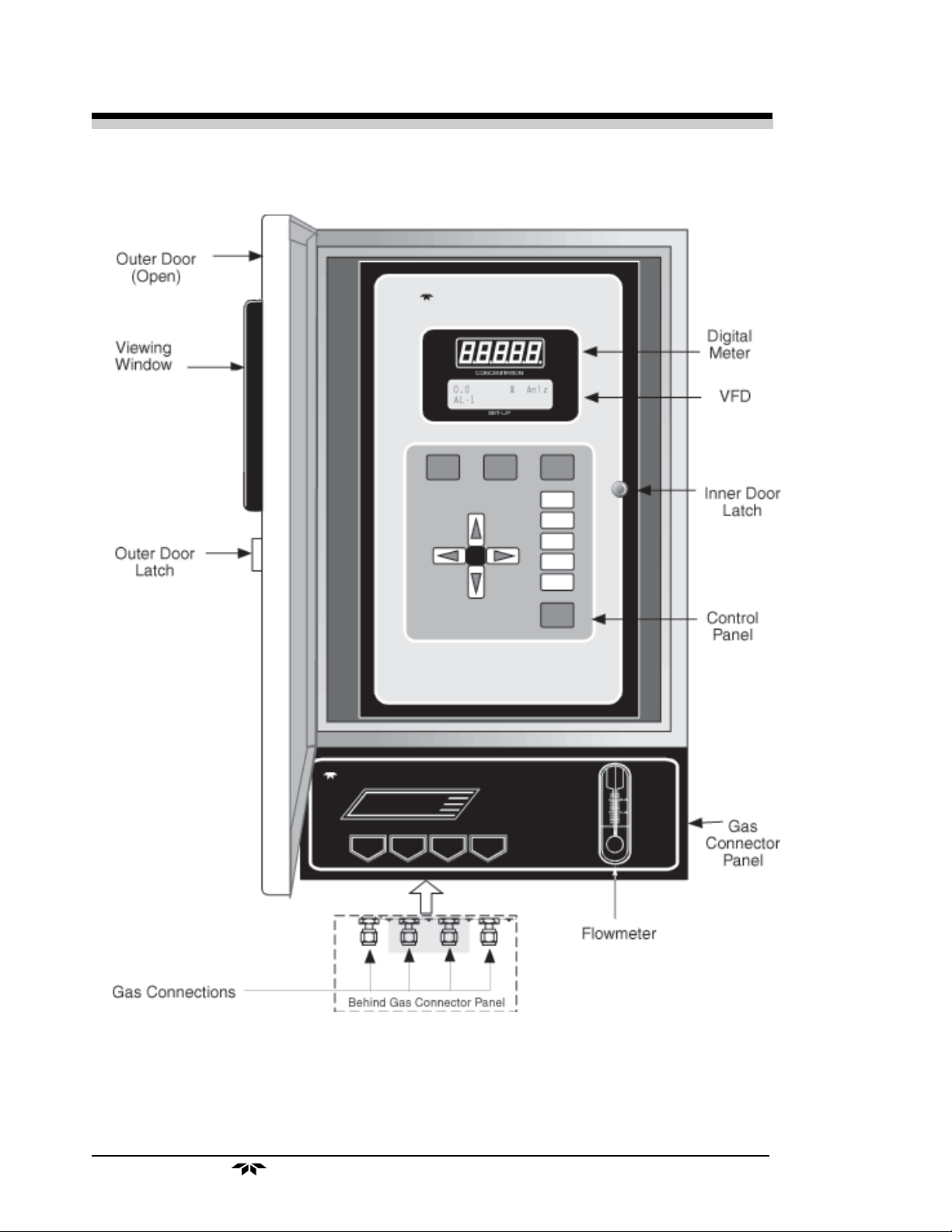

1.5 Operator Interface

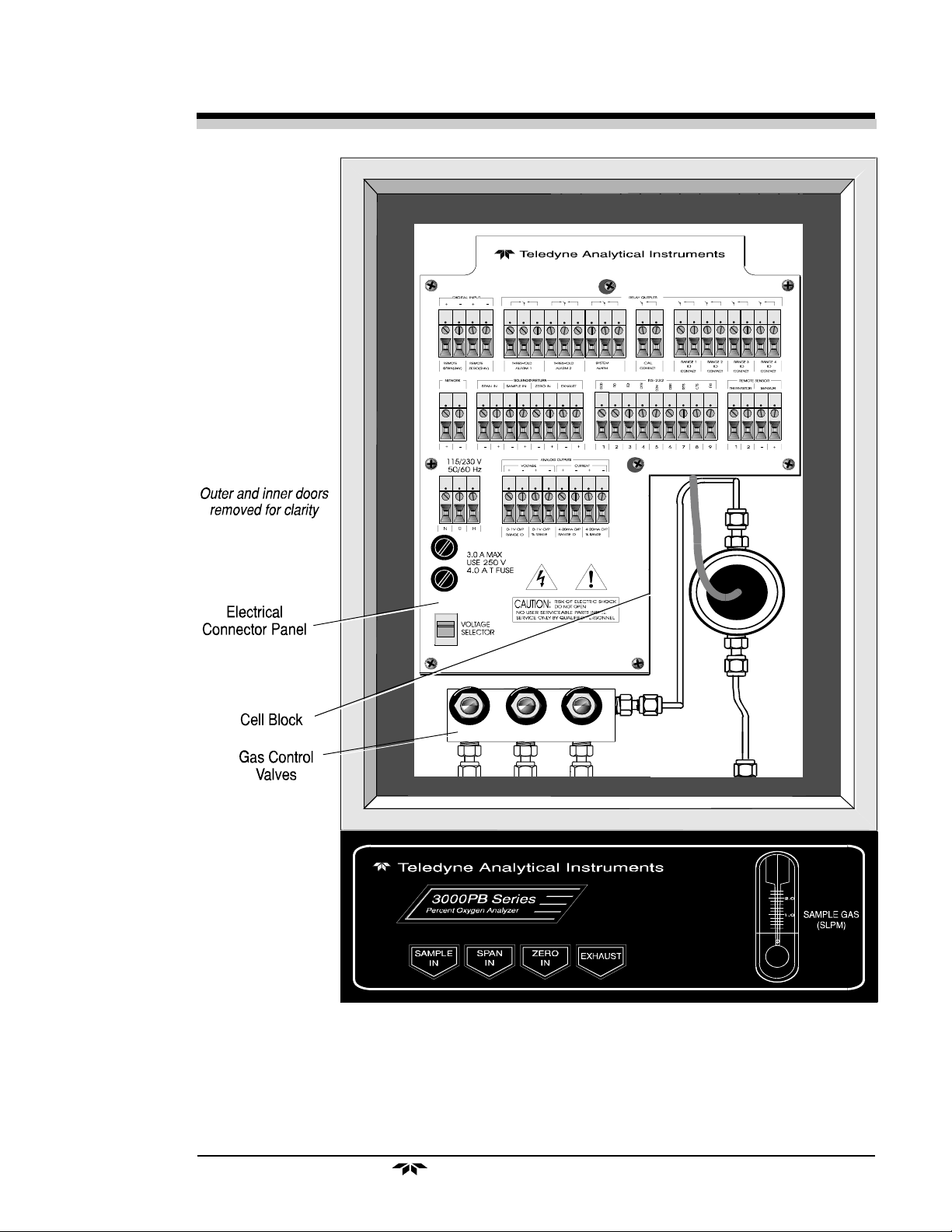

Figure 1-1 is an illustration of the front of the Model 3000PB Oxygen

Analyzer with the outer door open showing the control panel (which is also

the inner door).

All displays on the standard 3000PB are visible from outside the housing. The instrument has a digital meter and an alphanumeric display, which

are viewed through a glass viewing window in the outer door of the main

housing, and a sample flowmeter on the gas control panel attached to the

main housing. They give the operator constant feedback from the instrument.

The operator controls are pushbutton membrane switches located

behind the outer door of the housing. All of them are reached by unlatching

and swinging open the outer door of the enclosure. They are described

briefly here and in greater detail in chapter 4, Operation.

Figure 1-2 shows the 3000PB with the outer door and inner door both

open. The inner door is opened for access to the electrical connections and to

the cell block which houses the Micro-Fuel Cell. Door-mounted components

are shown in chapter 5, Maintenance.

Teledyne Analytical Instruments

1-3

Page 10

1 Introduction Model 3000PB

(Pressing the latch button

will open the Inner Door)

Figure 1-1: Model 3000PB—Outer Door Open—Showing Control Panel

1-4

Teledyne Analytical Instruments

Page 11

Percent Oxygen Analyzer Introduction 1

Figure 1-2: Model 3000PB—Inner Door Open—Showing Internal Components

Teledyne Analytical Instruments

1-5

Page 12

1 Introduction Model 3000PB

1.5.1 Displays

Digital Meter Display: The meter display is a LED device that

produces large, bright, 7-segment numbers that are legible in any lighting

environment. It produces a continuous readout from 0-100 %. It is accurate

across all ranges without the discontinuity of analog range switching.

Alphanumeric Interface Screen: The VFD screen is an easy-to-use

interface from operator to analyzer. It displays values, options, and messages

that give the operator immediate feedback.

Flowmeter: Monitors the flow of gas past the sensor. Readout is 0.2 to

2.4 standard liters per minute (SLPM).

1.5.2 Function Keys

Six touch-sensitive membrane switches are used to change the specific

function performed by the analyzer:

• Analyze Perform analysis for oxygen content of a sample gas.

• System Perform system-related tasks (described in detail in

chapter 4, Operation.).

• Span Span calibrate the analyzer.

• Zero Zero calibrate the analyzer.

• Alarms Set the alarm setpoints and attributes.

• Range Set up the 3 user definable ranges for the instrument.

1.5.3 Data Entry Keys

Six touch-sensitive membrane switches are used to input data and

commands to the instrument via the alphanumeric VFD display:

• Left & Right Arrows Select between functions currently

displayed on the VFD screen.

• Up & Down Arrows Increment or decrement values of

functions currently displayed.

• Enter Moves VFD display on to the next screen in a series. If

none remains, returns to the Analyze screen.

1-6

• Escape Moves VFD display back to the previous screen in a

series. If none remains, returns to the Analyze screen.

Teledyne Analytical Instruments

Page 13

Percent Oxygen Analyzer Introduction 1

1.5.4 I/O Power Button

The red I/O button switches the instrument power between I (ON) and

O (a Keep-Alive state). In the O state, the instrument’s circuitry is operating,

but there are no displays or outputs.

CAUTION: The power cable must be unplugged to fully

disconnect power from the instrument. When

chassis is exposed or when inner door is open and

power cable is connected, use extra care to avoid

contact with live electrical circuits.

1.5.5 Access Door

To access the electrical connector panel, or the cell block, the control

panel doubles as a door that can be unlatched and swung open (after unlatching and swinging open the outer access door). See Figure 1-2.

1.6 Recognizing Difference Between LCD &

VFD

LCD has GREEN background with BLACK characters. VFD has

DARK background with GREEN characters. In the case of VFD - NO

CONTRAST ADJUSTMENT IS NEEDED.

1.7 Equipment Interface

1.7.1 Electrical Connector Panel

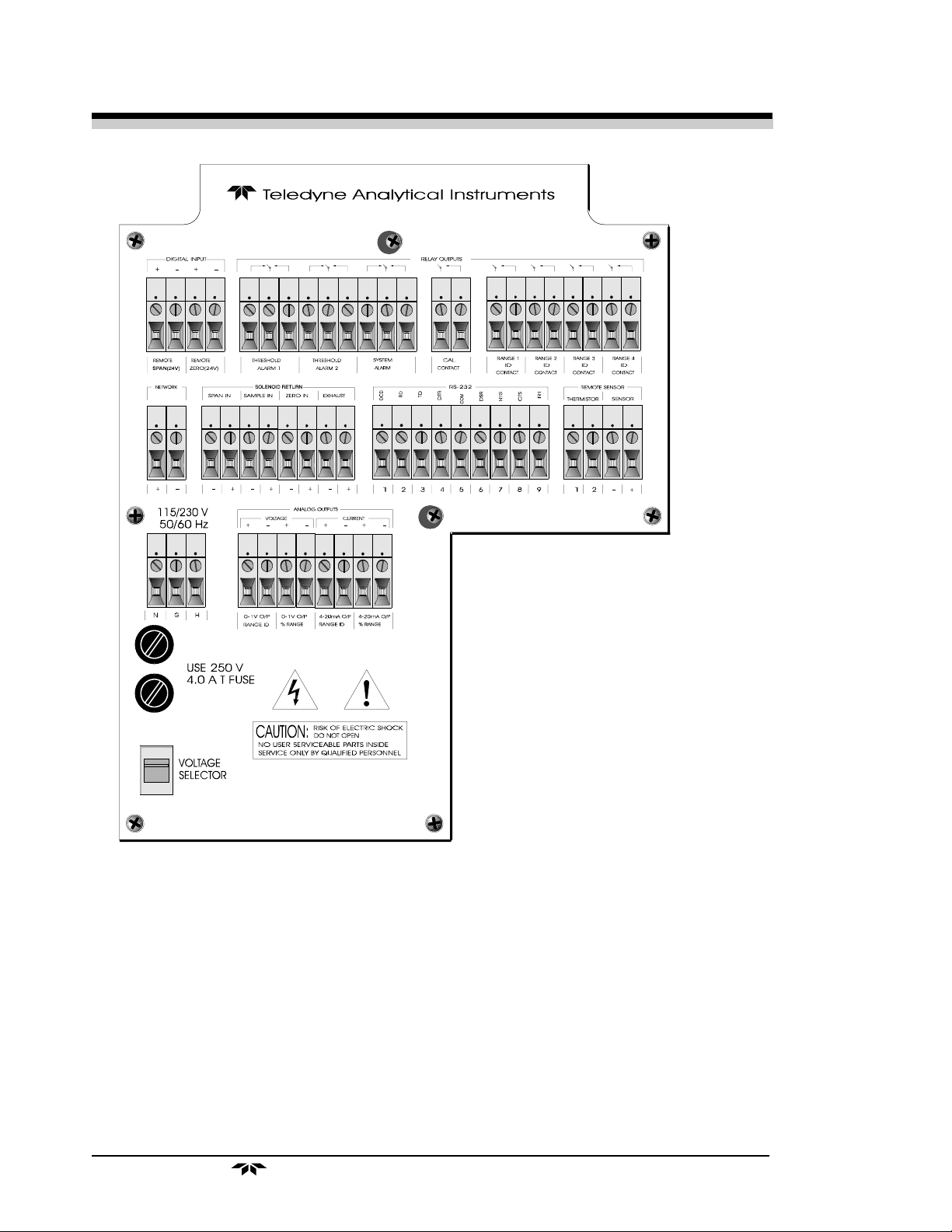

The electrical connector panel, shown in Figure 1-3, contains the

electrical connections for external inputs and outputs. The connectors are

described briefly here and in detail in the Installation chapter of this manual.

CAUTION: The power cable must be disconnected to fully

remove power from the instrument.

Teledyne Analytical Instruments

1-7

Page 14

1 Introduction Model 3000PB

3.0 AMAX

Figure 1-3: Electrical Connector Panel

Electrical Connections: The electrical connections on the electrical

connector panel are described briefly here, and in more detail in chapter 3

Installation.

• Power Connection 115 or 230 V ac, 50 or 60 Hz.

• Analog Outputs 0-1 V dc concentration plus 0-1 V dc

range ID, and isolated 4-20 mA dc plus

4-20 mA dc range ID.

• Alarm Connections 2 concentration alarms and 1 system

alarm.

1-8

Teledyne Analytical Instruments

Page 15

Percent Oxygen Analyzer Introduction 1

• RS-232 Port Serial digital concentration signal output

and control input.

• Remote Valves Used for controlling external solenoid

valves, if desired.

• Remote Sensor Used for external sensor and thermistor

• Remote Span/Zero Digital inputs allow external control of

analyzer calibration.

• Calibration Contact To notify external equipment that

instrument is being calibrated and

readings are not monitoring sample.

• Range ID Contacts Four separate, dedicated, range relay

contacts. Low, Medium, High, Cal.

• Network I/O Serial digital communications for local

network access. For future expansion.

Not implemented at this printing.

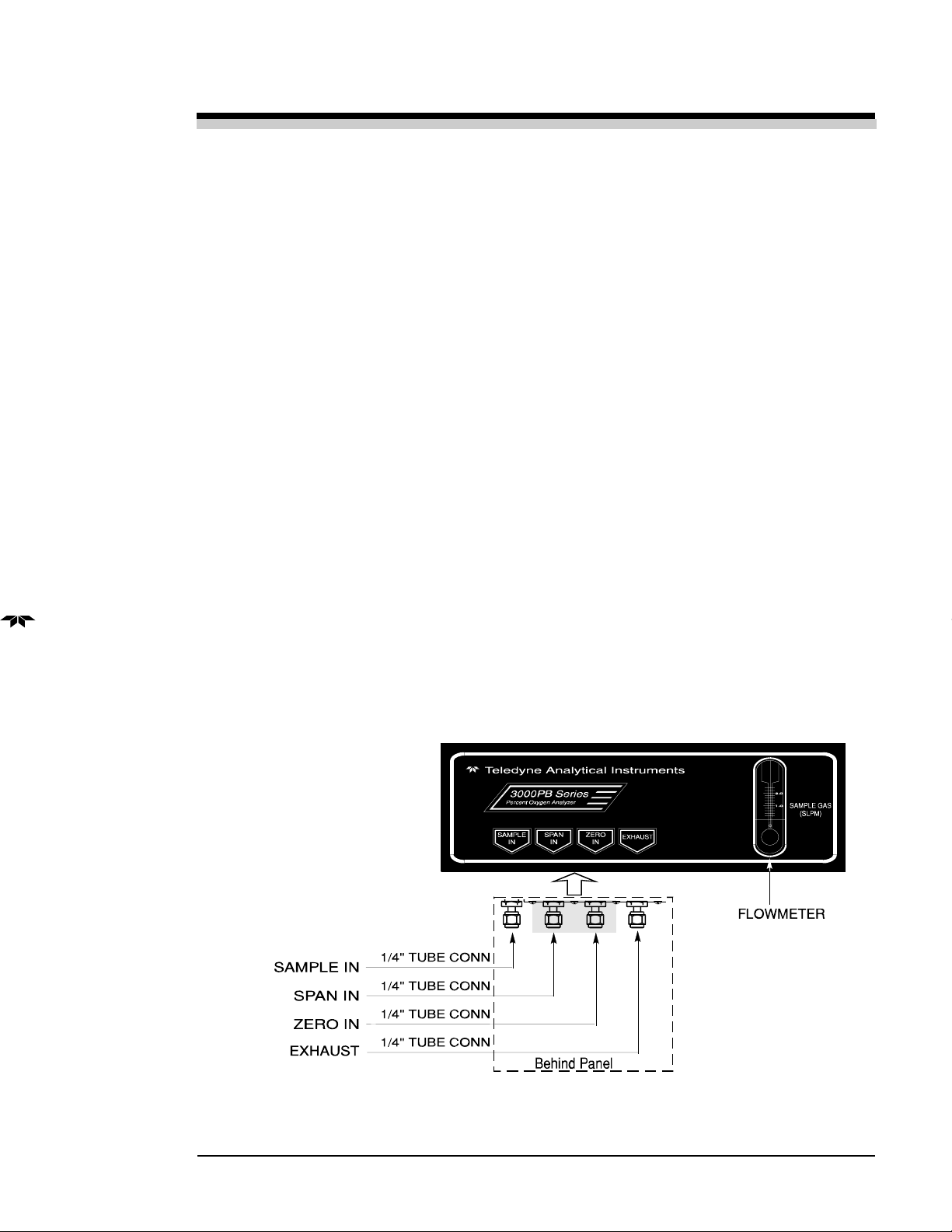

1.7.2 Gas Connector Panel

The gas connector panel, shown in Figure 1-4, contains the gas connections for external inlets and outlets. Those that are optional are shown

shaded in the figure. The connectors are described briefly here and in detail

in the Installation chapter of this manual.

Note:

For Additional information,

please, see page 1-4

Figure 1-4: Model 3000PB Gas Connector Panel

Teledyne Analytical Instruments

1-9

Page 16

1 Introduction Model 3000PB

• Gas Inlet and Outlet One inlet (must be externally valved)

and one exhaust out.

Optional:

• Calibration Gas Ports Separate fittings for zero, span and

sample gas input, plus internal valves for

automatically switching the gases in

sync with the 3000PB electronics.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model 3000PB is accurate to 2-3 %. Accordingly, internally

scheduled calibrations can vary 2-3 % per day.

1-10

Teledyne Analytical Instruments

Page 17

Percent Oxygen Analyzer Operational Theory 2

Operational Theory

2.1 Introduction

The analyzer is composed of three subsystems:

1. Micro-Fuel Cell Sensor

2. Sample System

3. Electronic Signal Processing, Display and Control

The sample system is designed to accept the sample gas and transport it

through the analyzer without contaminating or altering the sample prior to

analysis. The Micro-Fuel Cell is an electrochemical galvanic device that

translates the amount of oxygen present in the sample into an electrical

current. The electronic signal processing, display and control subsystem

simplifies operation of the analyzer and accurately processes the sampled

data. The microprocessor controls all signal processing, input/output and

display functions for the analyzer.

2.2 Micro-Fuel Cell Sensor

2.2.1 Principles of Operation

The oxygen sensor used in the Model 3000PB series is a Micro-Fuel

Cell designed and manufactured by Analytical Instruments. It is a sealed

plastic disposable electrochemical transducer.

The active components of the Micro-Fuel Cell are a cathode, an anode,

and the 15% aqueous KOH electrolyte in which they are immersed. The cell

converts the energy from a chemical reaction into an electrical current in an

external electrical circuit. Its action is similar to that of a battery.

There is, however, an important difference in the operation of a battery

as compared to the Micro-Fuel Cell: In the battery, all reactants are stored

within the cell, whereas in the Micro-Fuel Cell, one of the reactants (oxygen)

comes from outside the device as a constituent of the sample gas being

Teledyne Analytical Instruments

2-1

Page 18

2 Operational Theory Model 3000PB

analyzed. The Micro-Fuel Cell is therefore a hybrid between a battery and a

true fuel cell. (All of the reactants are stored externally in a true fuel cell.)

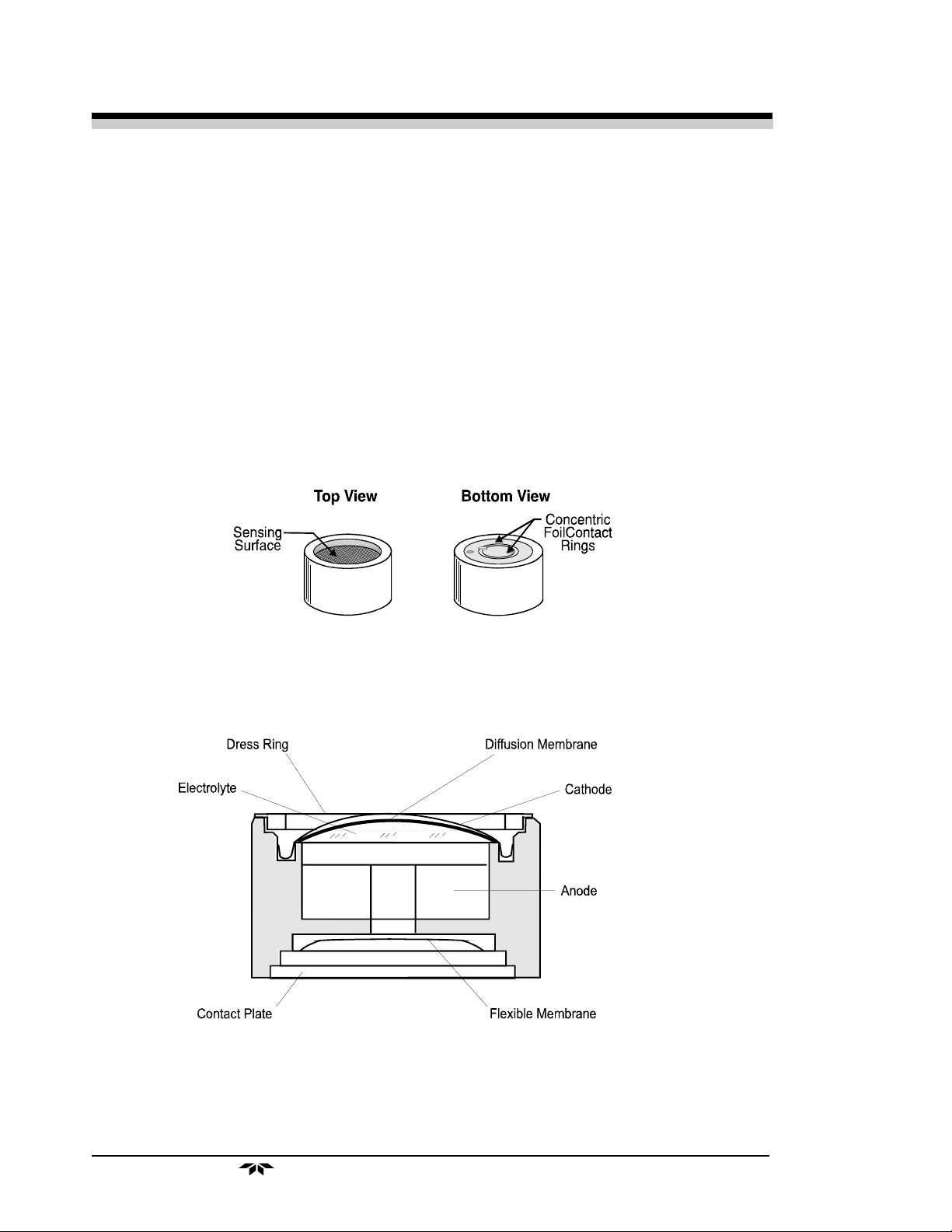

2.2.2 Anatomy of a Micro-Fuel Cell

The Micro-Fuel Cell is a cylinder only 1¼ inches in diameter and 1

inch thick. It is made of extremely inert plastic, which can be placed confidently in practically any environment or sample stream. It is effectively

sealed, although one end is permeable to oxygen in the sample gas. The

other end of the cell is a contact plate consisting of two concentric foil rings.

The rings mate with spring-loaded contacts in the sensor block assembly and

provide the electrical connection to the rest of the analyzer. Figure 2-1

illustrates the external features.

Figure 2-1: Micro-Fuel Cell

Refer to Figure 2-2, Cross Section of a Micro-Fuel Cell, which illustrates the following internal description.

Figure 2-2. Cross Section of a Micro-Fuel Cell (not to scale)

At the top end of the cell is a diffusion membrane of Teflon, whose

thickness is very accurately controlled. Beneath the diffusion membrane lies

2-2

Teledyne Analytical Instruments

Page 19

Percent Oxygen Analyzer Operational Theory 2

the oxygen sensing element—the cathode—with a surface area almost 4 cm2.

The cathode has many perforations to ensure sufficient wetting of the upper

surface with electrolyte, and it is plated with an inert metal.

The anode structure is below the cathode. It is made of lead and has a

proprietary design which is meant to maximize the amount of metal available

for chemical reaction.

At the rear of the cell, just below the anode structure, is a flexible

membrane designed to accommodate the internal volume changes that occur

throughout the life of the cell. This flexibility assures that the sensing membrane remains in its proper position, keeping the electrical output constant.

The entire space between the diffusion membrane, above the cathode,

and the flexible rear membrane, beneath the anode, is filled with electrolyte.

Cathode and anode are submerged in this common pool. They each have a

conductor connecting them to one of the external contact rings on the contact

plate, which is on the bottom of the cell.

2.2.3 Electrochemical Reactions

The sample gas diffuses through the Teflon membrane. Any oxygen in

the sample gas is reduced on the surface of the cathode by the following

HALF REACTION:

O2 + 2H2O + 4e– → 4OH

–

(cathode)

(Four electrons combine with one oxygen molecule—in the presence of

water from the electrolyte—to produce four hydroxyl ions.)

When the oxygen is reduced at the cathode, lead is simultaneously

oxidized at the anode by the following HALF REACTION:

Pb + 2OH

–

→ Pb+2 + H2O + 2e

–

(anode)

(Two electrons are transferred for each atom of lead that is oxidized.

Therefore it takes two of the above anode reactions to balance one cathode

reaction and transfer four electrons.)

The electrons released at the surface of the anode flow to the cathode

surface when an external electrical path is provided. The current is proportional to the amount of oxygen reaching the cathode. It is measured and used

to determine the oxygen concentration in the gas mixture.

The overall reaction for the fuel cell is the SUM of the half reactions

above, or:

2Pb + O2 → 2PbO

Teledyne Analytical Instruments

2-3

Page 20

2 Operational Theory Model 3000PB

(These reactions will hold as long as no gaseous components capable of

oxidizing lead—such as iodine, bromine, chlorine and fluorine—are present

in the sample.)

The output of the fuel cell is limited by (1) the amount of oxygen in the

cell at the time and (2) the amount of stored anode material.

In the absence of oxygen, no current is generated.

2.2.4 The Effect of Pressure

In order to state the amount of oxygen present in the sample as a percentage of the gas mixture, it is necessary that the sample diffuse into the cell

under constant pressure.

If the total pressure increases, the rate that oxygen reaches the cathode

through the diffusing membrane will also increase. The electron transfer, and

therefore the external current, will increase, even though the oxygen concentration of the sample has not changed. It is therefore important that the

sample pressure at the fuel cell (usually vent pressure) remain constant

between calibrations.

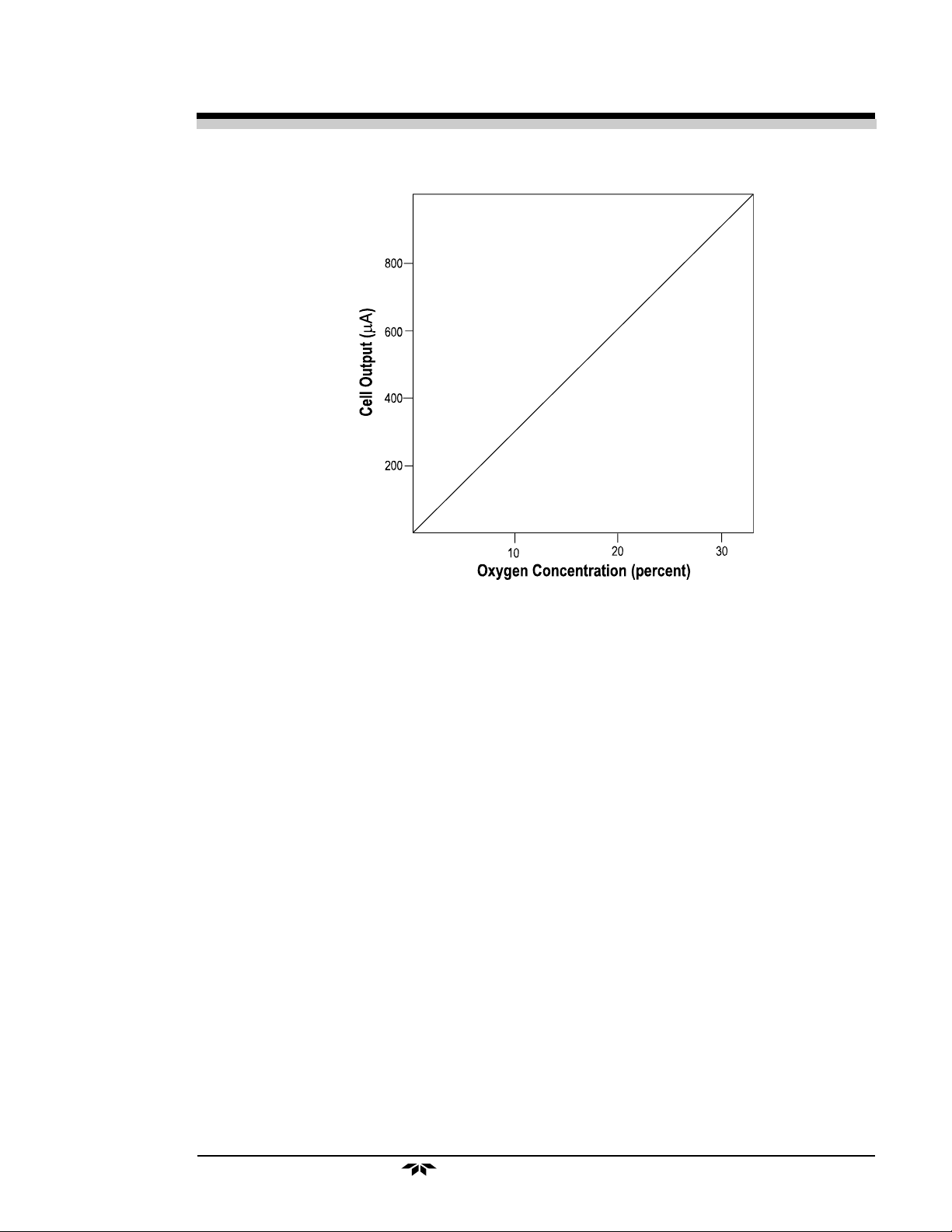

2.2.5 Calibration Characteristics

Given that the total pressure of the sample gas at the surface of the

Micro-Fuel Cell input is constant, a convenient characteristic of the cell is

that the current produced in an external circuit is directly proportional to the

rate at which oxygen molecules reach the cathode, and this rate is directly

proportional to the concentration of oxygen in the gaseous mixture. In other

words it has a linear characteristic curve, as shown in Figure 2-3. Measuring

circuits do not have to compensate for nonlinearities.

In addition, since there is zero output in the absence oxygen, the characteristic curve has close to an absolute zero. In the percent ranges, the cell

itself does not need to be zeroed. In practical application zeroing is still used

to compensate for zero offsets in the electronics. (The electronics is zeroed

automatically when the instrument power is turned on.)

2-4

Teledyne Analytical Instruments

Page 21

Percent Oxygen Analyzer Operational Theory 2

Figure 2-3. Characteristic Input/Output Curve for a Micro-Fuel Cell

2.2.6 Micro-Fuel Cell “Class”

TBE manufactures Micro-Fuel Cells with a variety of characteristics to

give the best possible performance for any given sample conditions. A few

typical Micro-Fuel Cells are listed below with their typical use and electrical

specifications.

2.2.6.1 Class A-3 Cell

The class A-3 cell is for use in applications where it is exposed continuously to carbon dioxide concentrations between 1 % and 100 % in the

sample gas.

Nominal output in air is 0.20 mA, and 90 % response time is 45 s.

Expected life in flue gas is 8 months.

2.2.6.2 Class A-5 Cell

The class A-5 cell is for use in applications where it is exposed intermittently to carbon dioxide concentrations up to 100 % in the sample gas.

Teledyne Analytical Instruments

2-5

Page 22

2 Operational Theory Model 3000PB

Nominal output in air is 0.19 mA, and 90 % response time is 45 s.

Expected life in flue gas is 8 months.

2.2.6.3 Class B-1 Cell

The class B-1 cell is for use in applications where it is exposed to less

than 0.1 % of carbon dioxide, and where fast response is important.

Nominal output in air is 0.50 mA, and 90 % response time is 7 s.

Expected life in air is 8 months.

2.2.6.4 Class B-3 Cell

The class B-3 cell is for use in applications where a slightly longer

response time is acceptable in order to have a longer cell life.

Nominal output in air is 0.30 mA, and 90 % response time is 13 s.

Expected life in air is 12 months.

2.2.6.5 Class C-3 Cell

The class B-1 cell is for use in applications where it is exposed to less

than 0.1 % of carbon dioxide, and where a longer response time is acceptable in order to have a longer cell life.

Nominal output in air is 0.20 mA, and 90 % response time is 30 s.

Expected life in air is 18 months.

2.2.6.6 Hydrogen and/or Helium Service

If the sample gas contains 10 % or more hydrogen and/or helium,

“clamp” cells are used. These Micro-Fuel cells are identified by the suffix -C

added to the cell class number.

2.3 Sample System

The sample system delivers gases to the Micro-Fuel Cell sensor from

the analyzer rear panel inlet. Depending on the mode of operation either

sample or calibration gas is delivered.

The Model 3000PB sample system is designed and fabricated to ensure

that the oxygen concentration of the gas is not altered as it travels through the

sample system. The sample encounters almost no dead space. This mini-

2-6

Teledyne Analytical Instruments

Page 23

Percent Oxygen Analyzer Operational Theory 2

mizes residual gas pockets that can interfere with very low level oxygen

analysis.

The sample system for the standard instrument incorporates ¼ inch tube

fittings for sample inlet and outlet connections at the rear panel. For metric

system installations, 6 mm adapters are supplied with each instrument. The

sample or calibration gas flow through the system is monitored by a flowmeter downstream from the cell.

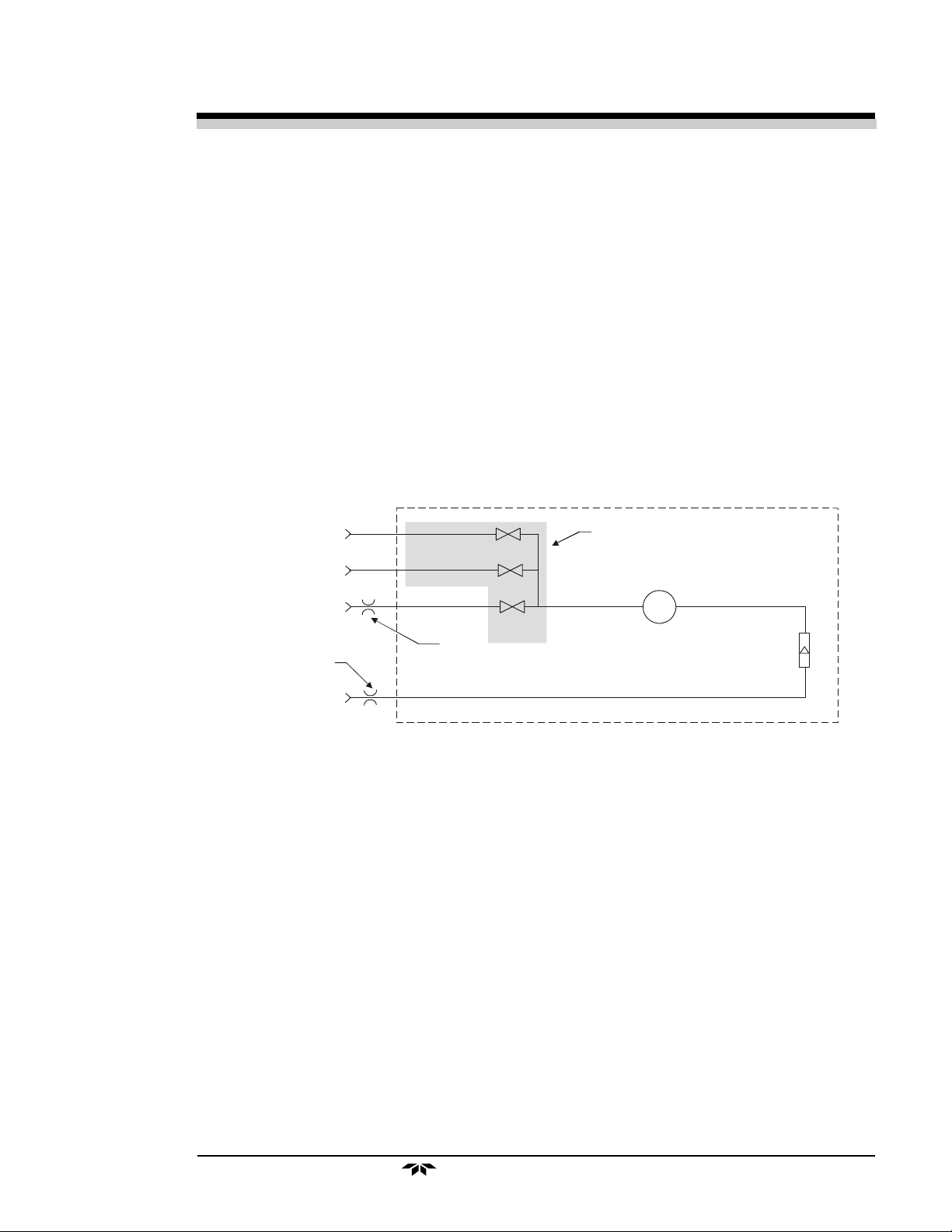

Figure 2-4 is the flow diagram for the sampling system. In the standard

instrument, calibration gases (zero and span) can be connected directly to the

Sample In port by teeing to the port with appropriate valves. The shaded

portion of the diagram shows the components added when the –C option is

ordered. The valves, when supplied, are installed inside the NEMA enclosure and are regulated by the instrument's internal electronics.

Span In

Zero In

Sample In

In va c u u m service th e

restrictor should be

placed here.

Exhaust Out

Restrictor

In normal service the

restricto r s h o u ld b e

placed here.

Solenoid

Valves

Components in the shaded area are in

the -C option (internal control valves)

only and are not shown in the piping

diagram above.

Cell

Flowmeter

Figure 2-4: Flow Diagram

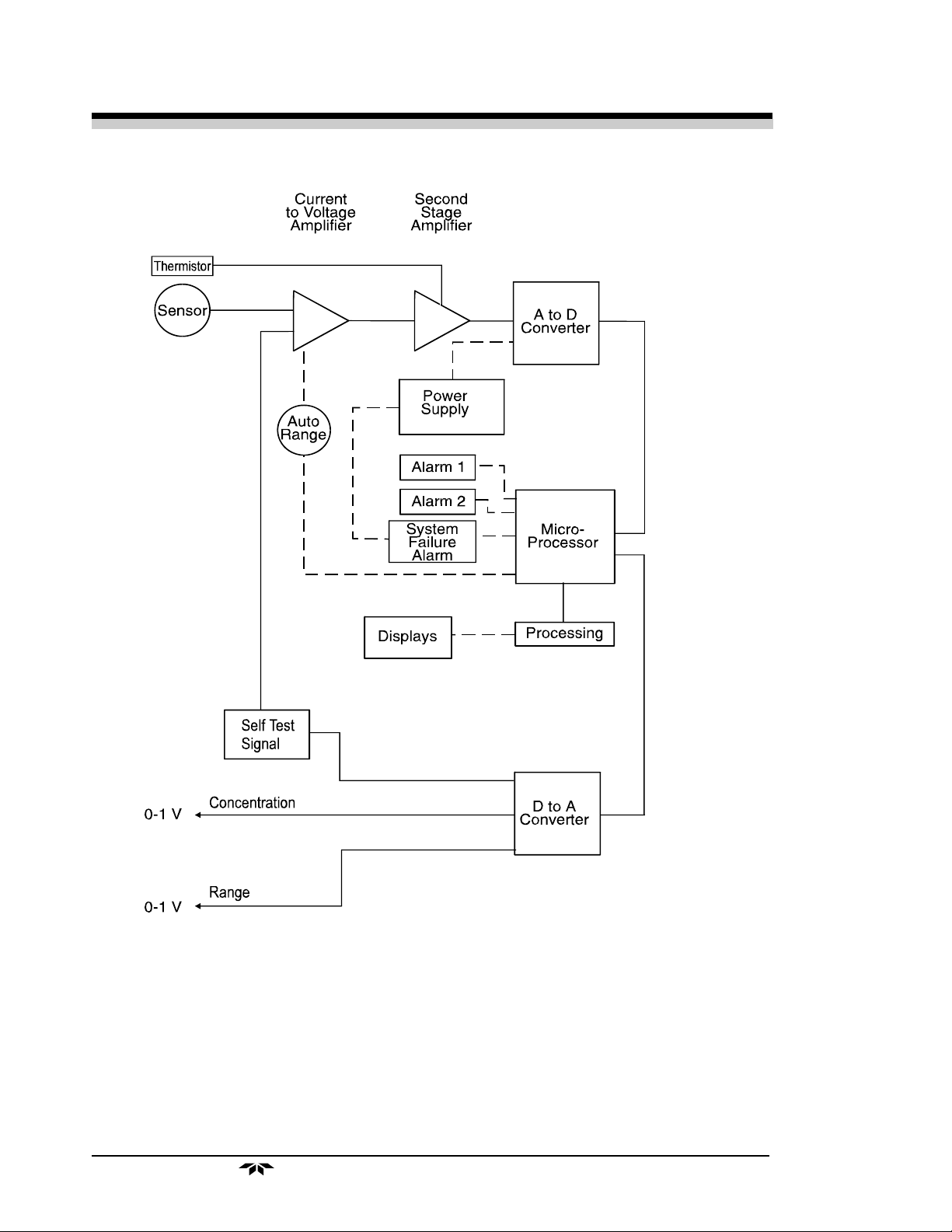

2.4 Electronics and Signal Processing

The signal processing and display electronics PCBs are mounted on the

back of the inner door. See Major Internal Components in chapter 5, for

illustration. The power supply module is mounted underneath the bottom end

of the Electrical Connector Panel.

The Model 3000PB Percent Oxygen Analyzer uses an 8031 microcontroller with 32 kB of RAM and 128 kB of ROM to control all signal processing, input/output, and display functions for the analyzer. System power

is supplied from a universal power supply module designed to be compatible

with most international power sources. CE approved units for the European

market also contain an EMI filter. Figure 2-5 is a simplified block diagram of

the Analyzer electronics.

Teledyne Analytical Instruments

2-7

Page 24

2 Operational Theory Model 3000PB

Figure 2-5: Block Diagram of the Model 3000PB Electronics

In the presence of oxygen the cell generates a current. A current to

voltage amplifier converts this current to a voltage, and then the voltage is

amplified in the second stage amplifier.

The second stage amplifier also supplies temperature compensation for

the oxygen sensor output. This amplifier circuit incorporates a thermistor,

which is physically located in the cell block. The thermistor is a temperature

2-8

Teledyne Analytical Instruments

Page 25

Percent Oxygen Analyzer Operational Theory 2

dependent resistance that changes the gain of the amplifier in proportion to

the temperature changes in the block. This change is inversely proportional

to the change in the cell output due to the same temperature changes. The

result is a signal that is temperature independent. The output from the second

stage amplifier is sent to an 18 bit analog to digital converter controlled by

the microprocessor.

The digital concentration signal along with input from the control panel

is processed by the microprocessor, and appropriate control signals are

directed to the display, alarms and communications port. The same digital

information is also sent to a 12 bit digital to analog converter that produces

the 0-1 V dc analog percent-of-range signal output and the analog range ID

output. Models with the –M option also have a 4-20 mA dc percent-of-range

signal output and analog range ID output.

Signals from the power supply are also monitored by the microprocessor, and the system failure alarm is activated if a malfunction is detected.

Teledyne Analytical Instruments

2-9

Page 26

2 Operational Theory Model 3000PB

2-10

Teledyne Analytical Instruments

Page 27

Percent Oxygen Analyzer Installation 3

Installation

Installation of the Model 3000PB Analyzer includes:

1. Unpacking

2. Mounting

3. Gas connections

4. Electrical connections

5. Installing the Micro-Fuel Cell

6. Testing the system.

3.1 Unpacking the Analyzer

The analyzer is shipped with all the materials you need to install and

prepare the system for operation. Carefully unpack the analyzer and inspect

it for damage. Immediately report any damage to the shipping agent.

3.2 Mounting the Analyzer

The Model 3000PB is designed for bulkhead mounting in nonhazardous environments. There are four mounting lugs—one in each corner of the

enclosure. The outline drawing, at the back of this manual, gives the mounting hole size and spacing. The drawing also contains the overall dimensions.

Do not forget to allow an extra 13/8" for the hinges.

Be sure to allow enough space in front of the enclosure to swing the

outer door open—a 11 3/4" radius, as shown in Figure 3-2.

All electrical connections are made via cables which enter the NEMA-4

housing through ports in its side. No conduit fittings are supplied. The

installer must provide two 3/4" NPT and two 1" NPT adapters and the

appropriate sealing conduit.

For gas connections, the unit is supplied with 1/4" tube fittings, and 6

millimeter adapters are supplied for metric system installations.

Teledyne Analytical Instruments

3-1

Page 28

3 Installation Model 3000PB

3-2

Figure 3-1: Front View of the Model 3000PB (Simplified)

Teledyne Analytical Instruments

Page 29

Percent Oxygen Analyzer Installation 3

Figure 3-2: Required Front Door Clearance

3.3 Electrical Connections

Figure 3-3 shows the Model 3000PB Electrical Connector Panel. There

are terminal blocks for connecting power, communications, and both digital

and analog concentration outputs.

Figure 3-3: Electrical Connector Panel

Teledyne Analytical Instruments

3-3

Page 30

3 Installation Model 3000PB

For safe connections, ensure that no uninsulated wire extends outside of

the connectors they are attached to. Stripped wire ends must insert completely into terminal blocks. No uninsulated wiring should be able to come in

contact with fingers, tools or clothing during normal operation. Terminal

block can accept ware guage 20 to 10.

3.3.1 Primary Input Power

The universal power supply requires a 115 or 230 V ac, 50 or 60 Hz,

power source. The actual input voltage used must show in the window of the

VOLTAGE SELECTOR switch before the power source is connected. See

Figure 3-4 for detailed connections.

DANGER: Power is applied to the instrument's circuitry as

long as the instrument is connected to the power

source. The Standby function switches power on or

off to the displays and outputs only.

Figure 3-4: Primary Input Power Connections

3.3.2 Fuse Installation

The fuse holders accept 5 x 20 mm, 4.0 A, T type (slow blow) fuses.

Fuses are not installed at the factory. Be sure to install the proper fuse as part

of installation. (See Fuse Replacement in chapter 5, maintenance.)

3.3.3 Analog Outputs

There are eight DC output signal connectors on the ANALOG OUTPUTS connector block. There are two connectors per output with the polarity noted. See Figure 3-5.

3-4

Teledyne Analytical Instruments

Page 31

Percent Oxygen Analyzer Installation 3

Figure 3-5: Analog Output Connections

The outputs are:

0–1 V dc % of Range: Voltage rises linearly with increasing oxygen, from

0 V at 0 % to 1 V at 100 %. (Full scale = 100% of

programmable range.)

0–1 V dc Range ID: 0.25 V = Low Range, 0.5 V = Medium Range,

0.75 V = High Range, 1 V = Air Cal Range.

4–20 mA dc % Range: (-M Option) Current increases linearly with increas-

ing oxygen, from 4 mA at 0 % to 20 mA at full

scale 100 %. (Full scale = 100% of programmable

range.)

4–20 mA dc Range ID: (-M Option) 8 mA = Low Range, 12 mA = Me-

dium Range, 16 mA = High Range, 20 mA = Air

Cal Range.

Examples:

The analog output signal has a voltage which depends on the oxygen

concentration AND the currently activated analysis range. To relate the

signal output to the actual concentration, it is necessary to know what range

the instrument is currently on, especially when the analyzer is in the

autoranging mode.

The signal output for concentration is linear over the currently selected

analysis range. For example, if the analyzer is set on a range that was defined

as 0–10 % O

, then the output would be as shown in Table 3-1.

2

Teledyne Analytical Instruments

3-5

Page 32

3 Installation Model 3000PB

Table 3-1: Analog Concentration Output—Example

Voltage Signal Current Signal

% O

2

Output (V dc) Output (mA dc)

0 0.0 4.0

1 0.1 5.6

2 0.2 7.2

3 0.3 8.8

4 0.4 10.4

5 0.5 12.0

6 0.6 13.6

7 0.7 15.2

8 0.8 16.8

9 0.9 18.4

10 1.0 20.0

To provide an indication of the range, a second pair of analog output

terminals are used. They generate a steady preset voltage (or current when

using the current outputs) to represent a particular range. Table 3-2 gives the

range ID output for each analysis range.

Table 3-2: Analog Range ID Output—Example

Range Voltage (V) Current (mA)

LO 0.25 8

MED 0.50 12

HI 0.75 16

CAL (0-25%) 1.00 20

3.3.4 Alarm Relays

There are three alarm-circuit connectors on the alarm relays block

(under RELAY OUTPUTS) for making connections to internal alarm relay

contacts. Each provides a set of Form C contacts for each type of alarm.

Each has both normally open and normally closed contact connections. The

contact connections are indicated by diagrams on the rear panel. They are

capable of switching up to 3 amperes at 250 V ac into a resistive load. See

Figure 3-6.

3-6

Teledyne Analytical Instruments

Page 33

Percent Oxygen Analyzer Installation 3

Figure 3-6: Types of Relay Contacts

The connectors are:

Threshold Alarm 1: • Can be configured as high (actuates when concen-

tration is above threshold), or low (actuates when

concentration is below threshold).

• Can be configured as failsafe or nonfailsafe.

• Can be configured as latching or nonlatching.

• Can be configured out (defeated).

Threshold Alarm 2: • Can be configured as high (actuates when concen-

tration is above threshold), or low (actuates when

concentration is below threshold).

• Can be configured as failsafe or nonfailsafe.

• Can be configured as latching or nonlatching.

• Can be configured out (defeated).

System Alarm: Actuates when DC power supplied to circuits is

unacceptable in one or more parameters. Permanently

configured as failsafe and latching. Cannot be defeated. Actuates if self test fails.

To reset a System Alarm during installation, discon-

nect power to the instrument and then reconnect it.

Further detail can be found in chapter 4, section 4-5.

3.3.5 Digital Remote Cal Inputs

Remote Zero and Span Inputs: The REMOTE SPAN and RE-

MOTE ZERO inputs are on the DIGITAL INPUT terminal block. They

accept 0 V (OFF) or 24 V dc (ON) for remote control of calibration. (See

Remote Calibration Protocol below.)

Teledyne Analytical Instruments

3-7

Page 34

3 Installation Model 3000PB

ZERO: Floating input. 5 to 24 V input across the + and – terminals

puts the analyzer into the Zero mode. Either side may be

grounded at the source of the signal. 0 to 1 volt across the

terminals allows Zero mode to terminate when done. A

synchronous signal must open and close the external zero

valve appropriately. See 3.3.9 Remote Sensor and Solenoid

Valves. (With the –C option, the internal valves automatically

operate synchronously.)

SPAN: Floating input. 5 to 24 V input across the + and – terminals

puts the analyzer into the Span mode. Either side may be

grounded at the source of the signal. 0 to 1 volt across the

terminals allows Span mode to terminate when done. A

synchronous signal must open and close the external span

valve appropriately. See 3.3.9 Remote Sensor and Solenoid

Valves. (With the –C option, the internal valves automatically

operate synchronously.)

Cal Contact: This relay contact is closed while analyzer is spanning

and/or zeroing. (See Remote Calibration Protocol below.)

Remote Calibration Protocol: To properly time the Digital Remote

Cal Inputs to the Model 3000PB Analyzer, the customer's controller must

monitor the CAL CONTACT relay.

When the contact is OPEN, the analyzer is analyzing, the Remote Cal

Inputs are being polled, and a zero or span command can be sent.

When the contact is CLOSED, the analyzer is already calibrating. It

will ignore your request to calibrate, and it will not remember that request.

Once a zero or span command is sent, and acknowledged (contact

closes), release it. If the command is continued until after the zero or span is

complete, the calibration will repeat and the Cal Relay Contact (CRC) will

close again.

For example:

1) Test the CRC. When the CRC is open, Send a zero command

until the CRC closes (The CRC will quickly close.)

2) When the CRC closes, remove the zero command.

3) When CRC opens again, send a span command until the CRC

closes. (The CRC will quickly close.)

4) When the CRC closes, remove the span command.

When CRC opens again, zero and span are done, and the sample is

being analyzed.

3-8

Teledyne Analytical Instruments

Page 35

Percent Oxygen Analyzer Installation 3

Note: The remote probe connections (paragraph 3.3.9) provides

signals to ensure that the zero and span gas valves will be

controlled synchronously. If you have the –C Internal valve

option—which includes additional zero and span gas inputs—

the 3000PB automatically regulates the zero, span and sample

gas flow.

3.3.6 Range ID Relays

There are four dedicated RANGE ID CONTACT relays. The first

three ranges are assigned to relays in ascending order—Low range is assigned to RANGE 1 ID, Medium range is assigned to RANGE 2 ID, and

High range is assigned to RANGE 3 ID. RANGE 4 ID is reserved for the

Air Cal Range (25%).

3.3.7 Network I/O

A serial digital input/output for local network protocol. At this printing,

this port is not yet functional. It is to be used in future versions of the instrument.

3.3.8 RS-232 Port

The digital signal output is a standard RS-232 serial communications

port used to connect the analyzer to a computer, terminal, or other digital

device. The pinouts are listed in Table 3-3.

Table 3-3: RS-232 Signals

RS-232 Sig RS-232 Pin Purpose

DCD 1 Data Carrier Detect

RD 2 Received Data

TD 3 Transmitted Data

DTR 4 Data Terminal Ready

COM 5 Common

DSR 6 Data Set Ready

RTS 7 Request to Send

CTS 8 Clear to Send

RI 9 Ring Indicator

The data sent is status information, in digital form, updated every two

seconds. Status is reported in the following order:

• The concentration in percent

Teledyne Analytical Instruments

3-9

Page 36

3 Installation Model 3000PB

• The range in use (HI, MED, LO)

• The span of the range (0-100 %, etc)

• Which alarms—if any—are disabled (AL–x DISABLED)

• Which alarms—if any—are tripped (AL–x ON).

Each status output is followed by a carriage return and line feed.

Three input functions using RS-232 have been implemented to date.

They are described in Table 3-4.

Table 3-4: Commands via RS-232 Input

Command Description

as<enter> Immediately starts an autospan.

az<enter> Immediately starts an autozero.

co<enter> Reports “Raw Cell Output” (current output of the sensor

itself) in μA. For example—

Raw Cell Output: 99

μμ

μA

μμ

st<enter> Toggling input. Stops/Starts any status message output from

the RS-232, until st<enter> is sent again.

The RS-232 protocol allows some flexibility in its implementation.

Table 3-5 lists certain RS-232 values that are required by the 3000PB implementation.

Table 3-5: Required RS-232 Options

Parameter Setting

Baud 2400

Byte 8 bits

Parity none

Stop Bits 1

Message Interval 2 seconds

3.3.9 Remote Sensor and Solenoid Valves

The 3000PB is a single-chassis instrument, which has its own sensor

and, in the –C option, its own gas-control solenoid valves. However, The

REMOTE SENSOR and SOLENOID RETURN connectors are provided

for use with a remote sensor and/or sampling system, if desired. See Figures

3-7 and 3-8.

3-10

Teledyne Analytical Instruments

Page 37

Percent Oxygen Analyzer Installation 3

Figure 3-7: Remote Sensor Connector Pinouts

Figure 3-8: Remote Solenoid Return Connector Pinouts

The voltage from these outputs is nominally 0 V for the OFF and

15 V dc for the ON conditions. The maximum combined current that can be

pulled from these output lines is 100 mA. (If two lines are ON at the same

time, each must be limited to 50 mA, etc.) If more current and/or a different

voltage is required, use a relay, power amplifier, or other matching circuitry

to provide the actual driving current.

In addition, each individual line has a series FET with a nominal ON

resistance of 5 ohms (9 ohms worst case). This could limit the obtainable

voltage, depending on the load impedance applied. See Figure 3-9.

Figure 3-9: FET Series Resistance

Teledyne Analytical Instruments

3-11

Page 38

3 Installation Model 3000PB

3.4 Installing the Micro-Fuel Cell

The Micro-Fuel Cell is not installed in the cell block when the

instrument is shipped. It must be installed before the analyzer is placed in

service.

Once it is expended, or if the cell is exposed to air for too long, the

Micro-Fuel Cell will need to be replaced. The cell could also require replacement if the instrument has been idle for too long.

When the micro-Fuel Cell needs to be installed or replaced, follow the

procedures in chapter 5, Maintenance, for removing and installing cells.

3.5 Gas Connections

Before using this instrument, it should be determined if the unit will be

used for pressurized service or vacuum service and low pressure applications. Inspect the restrictor kit that came with the unit. The kit consist of two

restrictors and a union for 1/4” diameter tubing. Notice that the two 1 3/4”

long, 1/4” diameter tubing are restrictors. It has an open end and a closed

end with a small circular orifice. The restrictor without the blue sticker is for

low pressure and vacuum service. For high pressure (5 to 50 psig) applications, use the restrictor that has a blue sticker on the body.

For pressurized service, use the restrictor without the blue dot and union

from the restrictor kit and attach it to the Sample In port. The small circular

orifice should face away from the back of the unit (against the direction of

gas flow). Use the restrictor without the blue dot sticker in the same manner

for low pressure applications (less than 5 psig).

For vacuum service (5-10 in Hg), use the restrictor without the blue dot

sticker and union but attach it to the Exhaust Out port. The small circular

orifice should face toward the back of the unit (against the direction of gas

flow).

Remove the blue sticker from the restrictor before using.

WARNING: Operating the unit without restrictors can cause damage to t

the micro-fuel cell.

Figure 3-10 is an illustration of the Gas Connector Panel. Optional gas

connections are shown in shaded blocks.

The unit is manufactured with 1/4 inch tube fittings, and 6 mm adapters

are supplied for metric system installations.

For a safe connection:

3-12

Teledyne Analytical Instruments

Page 39

Percent Oxygen Analyzer Installation 3

1. Insert the tube into the tube fitting, and finger-tighten the nut until

the tubing cannot be rotated freely, by hand, in the fitting. (This

may require an additional 1/8 turn beyond finger-tight.)

2. Hold the fitting body steady with a backup wrench, and with

another wrench rotate the nut another 11/4 turns.

Behind Panel

Figure 3-10: Gas Connector Panel

SAMPLE IN: In the standard model, gas connections are made at the

SAMPLE IN and EXHAUST OUT connections. Calibration gases must be

Tee'd into the Sample inlet with appropriate valves.

The gas pressure in should be reasonably regulated. Pressures between

3 and 40 psig are acceptable as long as the pressure, once established, will

keep the front panel flowmeter reading in an acceptable range (0.1 to 2.4

SLPM). Exact figures will depend on your process.

If greater flow is required for improved response time, install a bypass

in the sampling system upstream of the analyzer input.

Note: If you have the –V option, The above numbers apply instead to

the vacuum at the EXHAUST OUT connector, described below, with minus signs before the pressure readings.

ZERO IN and SPAN IN: These are additional ports, included on

models with the -C option, for inputting span gas and zero gas. There are

electrically operated valves inside for automatic switching between sample

Teledyne Analytical Instruments

3-13

Page 40

3 Installation Model 3000PB

and calibration gases. These valves are completely under control of the

3000PB Electronics. They can be externally controlled only indirectly

through the Remote Cal Inputs, described below.

Pressure, flow, and safety considerations are the same as prescribed for

the SAMPLE IN inlet, above.

EXHAUST OUT: Exhaust connections must be consistent with the

hazard level of the constituent gases. Check Local, State, and Federal laws,

and ensure that the exhaust stream vents to an appropriately controlled area if

required.

Note: If your 3000PB has the –V option, see Sample In, above, for

gas pressure/flow considerations.

3.6 Testing the System

Before plugging the instrument into the power source:

• Check the integrity and accuracy of the gas connections. Make

sure there are no leaks.

• Check the integrity and accuracy of the electrical connections.

Make sure there are no exposed conductors

• Check that sample pressure is between 3 and 40 psig, according

to the requirements of your process.

• Check that the voltage selector switch on the Electrical

Connector Panel is in the appropriate position for your power

source.

Power up the system, and test it by performing the following

operations:

1. Repeat the Self-Diagnostic Test as described in chapter 4, section

4.3.5.

3-14

Teledyne Analytical Instruments

Page 41

Percent Oxygen Analyzer Operation 4

Operation

4.1 Introduction

Once the analyzer has been installed, it can be configured for your

application. To do this you will:

• Set system parameters:

• Establish a security password, if desired, requiring operator to

log in.

• Establish and start an automatic calibration cycle, if desired.

• Calibrate the instrument.

• Define the three user selectable analysis ranges. Then choose

autoranging or select a fixed range of analysis, as required.

• Set alarm setpoints, and modes of alarm operation (latching,

failsafe, etc).

Before you configure your 3000PB these default values are in effect:

Ranges: LO = 1 %, MED = 5 %, HI = 10 %

Auto Ranging: ON

Alarm Relays: Defeated, 10 %, HI, Not failsafe, Not latching

Zero: Auto, every 0 days at 0 hours

Span: Auto, at 20.9 %, every 0 days at 0 hours

If you choose not to use password protection, the default password is

automatically displayed on the password screen when you start up, and you

simply press Enter for access to all functions of the analyzer.

Teledyne Analytical Instruments

4-1

Page 42

4 Operation Model 3000PB

4.2 Using the Data Entry and Function

Buttons

Data Entry Buttons: The < > arrow buttons select options from the

menu currently displayed on the VFD screen. The selected option blinks.

When the selected option includes a modifiable item, the

buttons can be used to increment or decrement that modifiable item.

The Enter button is used to accept any new entries on the VFD screen.

The Escape button is used to abort any new entries on the VFD screen that

are not yet accepted by use of the Enter button.

Figure 4-1 shows the hierarchy of functions available to the operator via

the function buttons. The six function buttons on the analyzer are:

• Analyze. This is the normal operating mode. The analyzer

monitors the oxygen content of the sample, displays the percent

of oxygen, and warns of any alarm conditions.

• System. The system function consists of six subfunctions that

regulate the internal operations of the analyzer:

• Set LCD screen contrast

• Setup Auto-Cal

• Assign Password

• Initiate Self -Test

• Check software version

• View sensor output

Contrast Function is DISABLED

(Refer to Section 1.6)

ΔΔ

Δ∇ arrow

ΔΔ

• Log out.

• Zero. Used to set up a zero calibration.

• Span. Used to set up a span calibration.

• Alarms. Used to set the alarm setpoints and determine whether

each alarm will be active or defeated, HI or LO acting, latching,

and/or failsafe.

• Range. Used to set up three analysis ranges that can be switched

automatically with auto-ranging or used as individual fixed

ranges.

Any function can be selected at any time by pressing the appropriate

button (unless password restrictions apply). The order as presented in this

manual is appropriate for an initial setup.

Each of these functions is described in greater detail in the following

procedures. The VFD screen text that accompanies each operation is repro-

4-2

Teledyne Analytical Instruments

Page 43

Percent Oxygen Analyzer Operation 4

Contrast Function is DISABLED

(Refer to Section 1.6)

Figure 4-1: Hierarchy of Functions and Subfunctions

duced, at the appropriate point in the procedure, in a Monospaced type

style. Pushbutton names are printed in Oblique type.

4.3 The System Function

The subfuctions of the System function are described below. Specific

procedures for their use follow the descriptions:

• Auto-Cal: Used to define an automatic calibration sequence

and/or start an Auto-Cal.

• PSWD: Security can be established by choosing a 5 digit

password (PSWD) from the standard ASCII character set. (See

Installing or Changing a Password, below, for a table of ASCII

characters available.) Once a unique password is assigned and

activated, the operator MUST enter the UNIQUE password to

gain access to set-up functions which alter the instrument's

Teledyne Analytical Instruments

4-3

Page 44

4 Operation Model 3000PB

operation, such as setting the instrument span or zero setting,

adjusting the alarm setpoints, or defining analysis ranges.

After a password is assigned, the operator must log out to

activate it. Until then, anyone can continue to operate the

instrument without entering the new password.

Only one password can be defined. Before a unique password

is assigned, the system assigns TBEAI by default. This allows

access to anyone. After a unique password is assigned, to defeat

the security, the password must be changed back to TBEAI.

• Logout: Logging out prevents unauthorized tampering with

analyzer settings.

• More: Select and enter More to get a new screen with additional

subfunctions listed.

• Self–Test: The instrument performs a self-diagnostic test to

check the integrity of the power supply, output boards and

amplifiers.

• Version: Displays Manufacturer, Model, and Software Version

of instrument.

4.3.1 Setting the Display

Contrast Function is DISABLED

(Refer to Section 1.6)

If you cannot read anything on the display after first powering up:

1. Observe LED readout.

a. If LED meter reads all eights and periods, go to step 3.

b. If LED meter displays anything else, go to step 2.

2. Press I/O button twice to turn Analyzer OFF and ON again. LED

meter should now read all eights and periods.

4-4

Teledyne Analytical Instruments

Page 45

Percent Oxygen Analyzer Operation 4

4.3.2 Setting up an Auto-Cal

When proper automatic valving is connected (see chapter 3, installa-

tion), the Analyzer can cycle itself through a sequence of steps that automati-

cally zero and span the instrument.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model 3000PB is accurate to 2-3 %. Accordingly, internally

scheduled calibrations can vary 2-3 % per day.

To setup an Auto–Cal cycle:

Choose System from the Function buttons. The VFD will display five

subfunctions.

Contrast Function is DISABLED

(Refer to Section 1.6)

Contrast Auto—Cal

PSWD Logout More

Use < > arrows to blink Auto—Cal, and press Enter. A new screen for

Span/Zero set appears.

Span OFF Nxt: 0d 0h

Zero OFF Nxt: 0d 0h

Press < > arrows to blink Span (or Zero), then press Enter again. (You

won’t be able to set OFF to ON if a zero interval is entered.) A Span

Every ... (or Zero Every ...) screen appears.

Span Every 0 d

Start 0 h from now

ΔΔ

Use

Δ∇ arrows to set an interval value, then use < > arrows to move to

ΔΔ

the start-time value. Use

ΔΔ

Δ∇ arrows to set a start-time value.

ΔΔ

To turn ON the Span and/or Zero cycles (to activate Auto-Cal): Press

System again, choose Auto—Cal, and press Enter again. When the Span/

Zero screen appears, use the < > arrows to blink the Span (or Zero) OFF/

ON field. Use

ΔΔ

Δ∇ arrows to set the OFF/ON field to ON. You can now turn

ΔΔ

these fields ON because there is a nonzero span interval defined.

4.3.3 Password Protection

If a password is assigned, then setting the following system parameters

can be done only after the password is entered: span and zero settings,

alarm setpoints, analysis range definitions, switching between autoranging

and manual override, setting up an auto-cal, and assigning a new password.

However, the instrument can still be used for analysis or for initiating a selftest without entering the password.

Teledyne Analytical Instruments

4-5

Page 46

4 Operation Model 3000PB

If you have decided not to employ password security, use the default

password TBEAI. This password will be displayed automatically by the

microprocessor. The operator just presses the Enter key to be allowed total

access to the instrument’s features.

NOTE: If you use password security, it is advisable to keep a copy of

the password in a separate, safe location.

4.3.3.1 Entering the Password

To install a new password or change a previously installed password,

you must key in and ENTER the old password first. If the default password

is in effect, pressing the ENTER button will enter the default TBEAI

password for you.

Press System to enter the System mode.

Contrast Auto—Cal

PSWD Logout More

Contrast Function is DISABLED

(Refer to Section 1.6)

Use the < > arrow keys to scroll the blinking over to PSWD, and press

Enter to select the password function. Either the default TBEAI password or

AAAAA place holders for an existing password will appear on screen

depending on whether or not a password has been previously installed.

T B E A I

Enter PWD

or

A A A A A

Enter PWD

The screen prompts you to enter the current password. If you are not

using password protection, press Enter to accept TBEAI as the default

password. If a password has been previously installed, enter the password

using the < > arrow keys to scroll back and forth between letters, and the

ΔΔ

Δ∇

ΔΔ

arrow keys to change the letters to the proper password. Press Enter to enter

the password.

If the password is accepted, the screen will indicate that the password

restrictions have been removed and you have clearance to proceed.

In a few seconds, you will be given the opportunity to change this

password or keep it and go on.

4-6

Teledyne Analytical Instruments

PSWD Restrictions

Removed

Page 47

Percent Oxygen Analyzer Operation 4

Change Password?

<ENT>=Yes <ESC>=No

Press Escape to move on, or proceed as in Changing the Password,

below.

4.3.3.2 Installing or Changing the Password

If you want to install a password, or change an existing password,

proceed as above in Entering the Password. When you are given the opportunity to change the password:

Change Password?

<ENT>=Yes <ESC>=No

Press Enter to change the password (either the default TBEAI or the

previously assigned password), or press Escape to keep the existing password and move on.

If you chose Enter to change the password, the password assignment

screen appears.

T B E A I

<ENT> To Proceed

or

A A A A A

<ENT> To Proceed

Enter the password using the < > arrow keys to move back and forth

between the existing password letters, and the

ΔΔ

Δ∇ arrow keys to change the

ΔΔ

letters to the new password. The full set of 94 characters available for password use are shown in the table below.

Characters Available for Password Definition:

ABCDEFGHI J

KL MNOPQRST

UVWXYZ[¥]^

_` abcdef gh

i j kl mnopqr

st uvwxyz{ |

} → ! " #$%&' (

)*+'-./012

3456789: ; <

=>?@

Teledyne Analytical Instruments

4-7

Page 48

4 Operation Model 3000PB

When you have finished typing the new password, press Enter. A

verification screen appears. The screen will prompt you to retype your

password for verification.

A A A A A

Retype PWD To Verify

Wait a moment for the entry screen. You will be given clearance to

proceed.

A A A A A

<ENT> TO Proceed

Use the arrow keys to retype your password and press Enter when

finished. Your password will be stored in the microprocessor and the system

will immediately switch to the Analyze screen, and you now have access to

all instrument functions.

If all alarms are defeated, the Analyze screen appears as:

0.0 % Anlz

Range: 0 — 10

If an alarm is tripped, the second line will change to show which alarm

it is:

0.0 % Anlz

AL—1

Note: If you log off the system using the logout function in the

system menu, you will now be required to re-enter the

password to gain access to Span, Zero, Alarm, and Range

functions.

4.3.4 Logout

The Logout function provides a convenient means of leaving the

analyzer in a password protected mode without having to shut the instrument

off. By entering Logout, you effectively log off the instrument leaving the

system protected against use until the password is reentered. To log out,

press the System button to enter the System function.

Contrast Auto—Cal

PSWD Logout More

Contrast Function is DISABLED

(Refer to Section 1.6)

Use the < > arrow keys to position the blinking over the Logout func-

tion, and press Enter to Log out. The screen will display the message:

Protected Until

Password Reentered

4-8

Teledyne Analytical Instruments

Page 49

Percent Oxygen Analyzer Operation 4

4.3.5 System Self-Diagnostic Test

The Model 3000PB has a built-in self-diagnostic testing routine. Preprogrammed signals are sent through the power supply, output board and

sensor circuit. The return signal is analyzed, and at the end of the test the

status of each function is displayed on the screen, either as OK or as a

number between 1 and 3. (See System Self Diagnostic Test in chapter 5 for

number code.)

The self diagnostics are run automatically by the analyzer whenever the

instrument is turned on, but the test can also be run by the operator at will.

To initiate a self diagnostic test during operation:

Press the System button to start the System function.

Contrast Function is DISABLED

(Refer to Section 1.6)

Contrast Auto—Cal

PSWD Logout More

Use the < > arrow keys to blink More, then press Enter.

Version Self—Test

Cell Output: ### μA

Use the < > arrow keys again to move the blinking to the Self–Test

function. The screen will follow the running of the diagnostic.

RUNNING DIAGNOSTIC

Testing Preamp — 83

During preamp testing there is a countdown in the lower right corner of

the screen. When the testing is complete, the results are displayed.

Power: OK Analog: OK

Preamp: 3

The module is functioning properly if it is followed by OK. A number

indicates a problem in a specific area of the instrument. Refer to Chapter 5

Maintenance and Troubleshooting for number-code information. The results

screen alternates for a time with:

Press Any Key

To Continue...

Then the analyzer returns to the initial System screen.

4.3.6 Version Screen

Move the < > arrow key to More and press Enter. With Version

blinking, press Enter. The screen displays the manufacturer, model, and

software version information.

Teledyne Analytical Instruments

4-9

Page 50

4 Operation Model 3000PB

4.4 The Span Functions

The analyzer is calibrated using span gas.

NOTE: Zero is not necessary for Percent (%) level measurements.

Additional information on Zero functions is provided in the

Appendix A-6 of this manual.

Although the instrument can be spanned using air, a span gas with a

known oxygen concentration in the range of 70–90% of full scale of the

range of interest is recommended. Since the oxygen concentration in air is

20.9 %, therefore 20.9% is ideal calibration.

Connect the calibration gases to the analyzer according to the instructions given in Section 3.4.1, Gas Connections, observing all the prescribed

precautions.

Shut off the gas pressure before connecting it to the analyzer, and

be sure to limit the pressure to 40 psig or less when turning it back on.

Readjust the gas pressure into the analyzer until the flowrate (as read on

the analyzer’s SLPM flowmeter) settles between 0.5 and 2.4 SLPM (approximately 1-5 scfh).

If you are using password protection, you will need to enter your

password to gain access to either of these functions. Follow the instructions

in section 4.3.3 to enter your password. Once you have gained clearance to

proceed, you can enter the Zero or Span function.

4.4.1. Cell Failure

When the sensor in the 3000PB begins to fail, the analyzer will usually

require more and more frequent calibration. If the 3000PB analysis readings

drift downward uncharacteristically, try recalibration. If recalibration raises

the readings temporarily only, the cell may be failing.

You can check the output of the cell itself by going to the System

function, selecting More, and pressing Enter. The cell output reading will be

on the second line of the display.

Version Self—Test

Cell Output: ### μA

The “good” reading depends on the class of cell your analyzer is using.

Although the B-1 cell is standard in the 3000PB, check Specific Model

Information in the Front Matter in this manual for the class of cell you

purchased. Then check Cell Replacement in chapter 5 Maintenance, and do

4-10

Teledyne Analytical Instruments

Page 51

Percent Oxygen Analyzer Operation 4

the prescribed calculations. If a weak cell is indicated, replace the cell as

described.

4.4.2 Span Cal

The Span button on the control panel is used to span calibrate the

analyzer. Span calibration can be performed using the automatic mode,

where an internal algorithm compares consecutive readings from the sensor

to determine when the output matches the span gas concentration. Span

calibration can also be performed manual mode, where the operator determines when the span concentration reading is acceptable and then manually

exits the function.

4.4.2.1 Auto Mode Spanning

Press Span to enter the span function. The screen that appears allows

you to select whether the span calibration is to be performed automatically or

manually. Use the

ΔΔ

Δ∇ arrow keys to toggle between AUTO and MAN span

ΔΔ

settling. Stop when AUTO appears, blinking, on the display.

Span: Settling: AUTO

<ENT> For Next

Press Enter to move to the next screen.

Span Val: 20.90

<ENT>Span <UP>Mod #

Use the

the < > arrow keys to blink the digit you are going to modify. Use the

ΔΔ

Δ∇ arrow keys to enter the oxygen-concentration mode. Use

ΔΔ

ΔΔ

Δ∇

ΔΔ

arrow keys again to change the value of the selected digit. When you have

finished typing in the concentration of the span gas you are using (20.90 if

you are using air), press Enter to begin the Span calibration.

#### % Span

Slope=#### ppm/s

The beginning span value is shown in the upper left corner of the

display. As the span reading settles, the screen displays and updates information on Slope. Spanning automatically ends when the span concentration

corresponds, within tolerance, to the value of the span gas concentration.

Then the instrument automatically returns to the analyze mode.

Teledyne Analytical Instruments

4-11

Page 52

4 Operation Model 3000PB

4.4.2.2 Manual Mode Spanning

Press Span to start the Span function. The screen that appears allows

you to select whether the span calibration is to be performed automatically or

manually.

Span: Settling:MAN

<ENT> For Next

Use the Δ∇ keys to toggle between AUTO and MAN span settling.

Stop when MAN appears, blinking, on the display. Press Enter to move to

the next screen.

Span Val: 20.90

<ENT>Span <UP>Mod #

Press Δ (<UP>) to permit modification (Mod #) of span value.

Use the arrow keys to enter the oxygen concentration of the span gas

you are using (20.90 if you are using air). The < > arrows chose the digit,

and the Δ∇ arrows choose the value of the digit.

Press Enter to enter the span value into the system and begin the span

calibration.

Once the span has begun, the microprocessor samples the output at a

predetermined rate. It calculates the difference between successive samplings

and displays this difference as Slope on the screen. It takes several seconds

for the first Slope value to display. Slope indicates rate of change of the

Span reading. It is a sensitive indicator of stability.

#### % Span

Slope=#### ppm/s

When the Span value displayed on the screen is sufficiently stable,

press Enter. (Generally, when the Span reading changes by 1 % or less of

the full scale of the range being calibrated for a period of five minutes it is