Page 1

TELEDYNE HASTINGS

INSTRUCTION MANUAL

INSTRUMENTS

MODEL 2002MODEL 2002

MODEL 2002

MODEL 2002MODEL 2002

VV

AA

V

VV

CUUM GCUUM G

A

CUUM G

AA

CUUM GCUUM G

AA

UGEUGE

A

UGE

AA

UGEUGE

Model 2002 page 1

Page 2

Manual Print HistoryManual Print History

Manual Print History

Manual Print HistoryManual Print History

The print history shown below lists the printing dates of all revisions and addenda created for

this manual. The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between revisions, contain important change

information that the user should incorporate immediately into the manual. Addenda are numbered sequentially . When a new revision is created, all addenda associated with the previous

revision of the manual are incorporated into the new revision of the manual. Each new revision

includes a revised copy of this print history page.

Revision A (Document Number 149-0798) .......................................................September 1998

Revision B (Document Number 149-032000) ......................................................... March 2000

Revision C (Document Number 149-052002) .............................................................May 2002

Revision D (Document Number 149-102002)....................................................... October 2002

Revision E (Document Number 149-062004).............................................................. June 2004

Revision F (Document Number 149-082005)..........................................................August 2005

Revision F (Document Number 149-102005)........................................................ October 2005

Visit www.teledyne-hi.com for WEEE disposal guidance.

CAUTION

!

Refer to accompanying documents

CAUTION

!

If equipment is not used in the manner specified by this manual,

protection provided by the equipment may be impaired

page 2 Model 2002

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

Page 3

TT

able of Contentsable of Contents

T

able of Contents

TT

able of Contentsable of Contents

1.01.0

GENERAL INFORMAGENERAL INFORMA

1.0

GENERAL INFORMA

1.01.0

GENERAL INFORMAGENERAL INFORMA

1.1 Features................................................................................................................................5

1.2 Model 2002 Sensors ............................................................................................................5

1.3 Model 2002 Control Unit ....................................................................................................6

1.4 Specifications ....................................................................................................................... 6

2.02.0

INSTINST

2.0

INST

2.02.0

INSTINST

2.1 Receiving Inspection............................................................................................................ 7

2.2 Quick Start ...........................................................................................................................7

2.3 Transducer Installation ........................................................................................................8

2.4 Control Unit Installation......................................................................................................8

2.5 Initial Operation...................................................................................................................8

3.03.0

FRFR

3.0

3.03.0

3.1 Overall Functional Description............................................................................................9

ONT PONT P

FR

ONT P

FRFR

ONT PONT P

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

ANEL OPERAANEL OPERA

ANEL OPERA

ANEL OPERAANEL OPERA

TIONTION

TION

TIONTION

..............................................................................................................................................................................

.......................................................................................

..............................................................................................................................................................................

......................................................................................................................................

...................................................................

......................................................................................................................................

TIONTION

TION

TIONTION

................................................................................................................................

................................................................

................................................................................................................................

55

5

55

77

7

77

99

9

99

3.2 RUN Mode ........................................................................................................................10

3.3 HI and LOW Set Point Modes ..........................................................................................11

3.4 CAL Mode.........................................................................................................................11

3.5 GAS Mode.........................................................................................................................14

3.6 UNITS Mode ....................................................................................................................15

4.04.0

REAR PREAR P

4.0

REAR P

4.04.0

REAR PREAR P

4.1 Remote Zero Input ...........................................................................................................17

4.2 Analog Output ...................................................................................................................17

4.3 TTL Outputs.....................................................................................................................19

4.4 Power Entry Module..........................................................................................................20

5.05.0

THEORTHEOR

5.0

THEOR

5.05.0

THEORTHEOR

5.1 Piezoresistive Sensor..........................................................................................................22

5.2 Pirani Sensor......................................................................................................................24

5.3 Dual Sensor Operation ......................................................................................................26

ANEL DESCRIPTIONANEL DESCRIPTION

ANEL DESCRIPTION

ANEL DESCRIPTIONANEL DESCRIPTION

Y OF OPERAY OF OPERA

Y OF OPERA

Y OF OPERAY OF OPERA

TIONTION

TION

TIONTION

......................................................................................................................................

...................................................................

......................................................................................................................................

............................................................................................................................

..............................................................

............................................................................................................................

1717

17

1717

2121

21

2121

6.06.0

COMMUNICACOMMUNICA

6.0

COMMUNICA

6.06.0

COMMUNICACOMMUNICA

6.1 RS-232-E Interface Specifications.....................................................................................29

6.2 RS-232 Interface Connector Pin Assignments ..................................................................29

6.2.1 RS-485 Interface Connector Pin Assignments .........................................................30

6.3 Operation of the Serial Interface........................................................................................30

TIONS OPTION BOTIONS OPTION BO

TIONS OPTION BO

TIONS OPTION BOTIONS OPTION BO

ARDARD

ARD

ARDARD

........................................................................................

............................................

........................................................................................

Model 2002 page 3

2929

29

2929

Page 4

7.07.0

RELARELA

7.0

RELA

7.07.0

RELARELA

7.1 Relay Board Specifications .............................................................................................. 35

7.2 Relay Connector Pin Assignment .................................................................................... 35

7.3 Operation ......................................................................................................................... 36

8.08.0

4-20mA INTERF4-20mA INTERF

8.0

4-20mA INTERF

8.08.0

4-20mA INTERF4-20mA INTERF

8.1 4-20 mA Interface Connector Pin Assignments .............................................................. 37

8.2 Operation ......................................................................................................................... 38

9.09.0

0-10 0-10

9.0

0-10

9.09.0

0-10 0-10

9.1 0-10 Volt Interface Connector Pin Assignments .............................................................. 39

10.010.0

10.0

10.010.0

11.011.0

11.0

W

11.011.0

11.1 Warranty Repair Policy .................................................................................................... 43

Y INTERFY INTERF

Y INTERF

Y INTERFY INTERF

VV

olt INTERFolt INTERF

V

olt INTERF

VV

olt INTERFolt INTERF

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

WW

ARRANTY ARRANTY

ARRANTY

WW

ARRANTY ARRANTY

AA

CE OPTION BOCE OPTION BO

A

CE OPTION BO

AA

CE OPTION BOCE OPTION BO

AA

CE OPTION BOCE OPTION BO

A

CE OPTION BO

AA

CE OPTION BOCE OPTION BO

AA

CECE

......................................................................................................................................................

A

CE

...........................................................................

AA

CECE

......................................................................................................................................................

TING GUIDETING GUIDE

TING GUIDE

TING GUIDETING GUIDE

AND REPAND REP

AND REP

AND REPAND REP

AIRAIR

AIR

AIRAIR

ARDARD

............................................................................................

ARD

..............................................

ARDARD

............................................................................................

ARDARD

..........................................................................................

ARD

.............................................

ARDARD

..........................................................................................

....................................................................................................................

..........................................................

....................................................................................................................

..................................................................................................................................

.................................................................

..................................................................................................................................

3535

35

3535

3737

37

3737

3939

39

3939

4141

41

4141

4343

43

4343

11.2 Non-Warranty Repair Policy ........................................................................................... 43

11

2.02.0

DIA DIA

1

11

2.0

2.02.0

DIA

DIA DIA

GRAMS GRAMS

GRAMS

GRAMS GRAMS

AND DRAAND DRA

AND DRA

AND DRAAND DRA

WINGSWINGS

WINGS

WINGSWINGS

....................................................................................................................

..........................................................

....................................................................................................................

4545

45

4545

page 4 Model 2002

Page 5

The Model 2002 is a wide range vacuum measuring instrument consisting of a digital microprocessor-based display unit, a miniature, rugged, thin film based sensing element that measures from

below 1x10

EEPROM (Electrically Erasable/Programmable Read Only Memory), and an interconnecting

cable. Together, these components provide accurate vacuum measurement over 7 decades of

vacuum from 1x10-4 to 1000 Torr. This instrument is a new design approach based on over 50

years of experience by Hastings Instruments with well-known and widely used thermal conduction vacuum measurement techniques. The Model 2002 is designed for quick, easy installation

and will provide the user with long lasting, trouble free, accura te vacuum measurement.

1.1 Features

SECTION 1

General Information

-4

up to 100 Torr, a piezoresistiv e sensor that measures from 1 to 1000 Torr,

• Wide dynamic range: 1x10

• Compact rugged design

• Attitude insensitive

• Fast dynamic response

• Withstands 150 psig positive pressure

• Linear per decade

• Bakeable to 250

• TTL output process control

• Interchangeable transducer

• Corrosion resistant

1.2 Model 2002 Sensors

The Model 2002 transducer is comprised of an ion implanted, piezoresistive, direct force sensor

and a thin film Pirani type sensor. The Pirani sensing element is a Pt thin film serpentine element

(see Figure 5.3a) deposited on a 1 micron thick Si3N4 membrane. The membrane is peripherally

supported by a Si box shaped die and is covered by a thick Si lid parallel to the membrane and

open on two ends (see Figure 5.3b). The piezoresistive unit is an ion implanted Wheatstone

bridge in a 50 micron thick Si membrane peripherally supported by a Si box shaped die which

has been anodically bonded to a Pyrex substrate.

-4

to 1000 Torr

0

C

The dual sensor assembly is encased in a corrosion resistant 316 stainless steel tube shell. The

durable tube design withstands high pressure (150 psig/10.2 bar) and high pressure surges. Since

the Pirani sensor is miniaturized and employs a Pt thin film on a Si3N4 membrane (instead of a

conventional long fragile wire), the transducer can withstand high lev els of mechanical shock.

The Model 2002 is designed for fast response. The micromachined sensing elements have a very

small mass and operate in a constant temperature (Pirani) and a constant current (piezo) feedback mode. This makes response time very fast as compared to other commercially available

sensors which have to change the temperature of a significant mass to reflect pressure changes

and have a large internal volume which must equalize in pressure with the system before the

sensor can reach its final value. The transducer’s small internal volume (<1.5cc) permits rapid

pneumatic response to system pressure changes. Further, the small geometry of the transducer

prevents thermal convection currents which allows the sensor to be mounted in any orientation

without calibration shifts.

Model 2002 page 5

Page 6

1.3 Model 2002 Control Unit

The Model 2002 control unit consists of the power supply, Pirani resistance bridge control, signal

processing and display circuitry. The user interface consists of a flat panel display with smooth operating tactile switches and large green LED digits (0.56"/14.2mm). The pressure is displayed in scientific

format using a 3 digit mantissa and a 1 digit (plus the sign) exponent. The pressure can be displayed in

Torr, mbar or Pascal. The instrument comes standard with 2 alarm setpoints that have TTL level

digital outputs. An optional dual relay board can be internally mounted to trip on the alarm setpoints

to turn on/off various equipment such as pumps, valves, heaters, bakeout ovens and safety equipment.

An optional 4-20 mA or 0-10V analog output board is also available. The Model 2002 instrument

accepts an external TTL level "Remote Zero" to zero the instrument when another instrument (e.g. an

-5

ion gauge) indicates that the pressure is less than 1x10

Torr. The standard analog output is linear per

decade directly corresponding to the control unit’s display. The Model 2002 comes calibrated for

nitrogen. Conversion factors for other gases are selectable by the user (see section 3.5). This direct

readout display allows for flexibility in user system configurations which operate with various gases.

An optional serial interface board can be installed to provide RS232 or RS485 support. The Model

2002 control unit fits a standard DIN 43700 insert (1/4 DIN) and mounts into a 3.62 in. (92 mm)

square hole. The case is constructed of NORYL rated UL-94-V1 (self-extinguishing plastic) and is

equipped with mounting brackets that are adjustable up to 3/16” (4.8mm).

1.4 Specifications

Measuring range................................................................................................ 1x10-4 to 10+3 Torr

1.3x10-4 to 1.3x10+3 mbar

Accuracy (N2, T=230C) ..................................................+ 15% of reading (5x10-4 to 3x10

+ 1.5% of reading (3x10+1 to 1x10

Ambient temperature operating range............................................................................. 00 to 500C

Bakeout temperature (with transducer electronics removed)................................................ 2500C

Analog output................................................................ 1.0-4.5 Volts (0.5 VDC linear per decade)

Process control ................................................................ 2 TTL outputs (1 TTL auto zero input)

Digital readout................................................................ Four green LED - resolution is three digit

!

(plus exponent)

Equipment operating range............................................................... 120/240 V~, 0.25A, 50/60 Hz

A 6 ft., 3-wire power cord is provided with each unit.

Fuse ..............................................................................................................................250 V , 1/4 A.

Transducer mounting................................................................ Any position without recalibration.

T ransducer internal volume .................................................................................................. <1.5cc

Wetted material ........................................................................................Au, Si3N4, Si, Pt, PyrexTM,

KovarTM and 316 stainless steel

Stability with voltage ....................................................................Variation in reading undetectable

as power fluctuates within power specification.

+1

+3

Tor r)

Tor r)

page 6 Model 2002

Weight (display, cable, and sensor) ............................................... Net: 2.5 lbs., Shipping: 3.4 lbs.

T ransducer response time .................................................. Typically, less than 150 msec for a step

change from 10-3 Torr to 10+3 Tor r.

Positive pressure................................................................150 psig, Recalibration may be required

if unit is exposed to pressures greatly exceeding measuring range.

Page 7

This section is designed to assist in getting a new pressure gauge into operation as quickly and

easily as possible. Please read the following instructions thoroughly before installing the instrument.

2.1 Receiving Inspection

Carefully unpack the Hastings Model 2002 Instrument (part # HPM-2002), transducer (part

#HPM-2002s) and cable (part # CB 2002). Inspect all items for any obvious signs of damage

due to shipment. Immediately advise the carrier who delivered the shipment if any damage is

suspected.

Compare each component shipped against the packing list. Ensure that all parts are present (i.e.

transducer, power supply, cables, etc.). In addition to the components listed on the packing list,

the shipment includes: AC power cord, panel mounting hardware, 9-pin female D connector.

Optional equipment or accessories will be listed separately on the packing list.

2.2 Quick Start

SECTION 2

Installation

FF

olloollo

w this procedure to get yw this procedure to get y

F

ollo

w this procedure to get y

FF

olloollo

w this procedure to get yw this procedure to get y

1.1.

RemoRemo

vv

1.

Remo

1.1.

RemoRemo

2.2.

TT

2.

T

2.2.

TT

likely to occur,likely to occur,

likely to occur,

likely to occur,likely to occur,

3.3.

When installing 1/8”When installing 1/8”

3.

When installing 1/8”

3.3.

When installing 1/8”When installing 1/8”

the tube stem.the tube stem.

the tube stem.

the tube stem.the tube stem.

4.4.

Connect transducer cable (orange) to controller .Connect transducer cable (orange) to controller .

4.

Connect transducer cable (orange) to controller .

4.4.

Connect transducer cable (orange) to controller .Connect transducer cable (orange) to controller .

5.5.

Connect other end of transducer cable to transducerConnect other end of transducer cable to transducer

5.

Connect other end of transducer cable to transducer

5.5.

Connect other end of transducer cable to transducerConnect other end of transducer cable to transducer

is adequais adequa

is adequa

is adequais adequa

6.6.

If yIf y

6.

If y

6.6.

If yIf y

be abe a

ttached.ttached.

be a

ttached.

be abe a

ttached.ttached.

7.7.

I/O porI/O por

7.

I/O por

7.7.

I/O porI/O por

8.8.

Connect the Connect the

8.

Connect the

8.8.

Connect the Connect the

120/240120/240

120/240

120/240120/240

9.9.

TT

9.

T

9.9.

TT

“T“T

oror

r”r”

“T

or

r”

“T“T

oror

r”r”

10.10.

FF

10.

F

10.10.

FF

dodo

wn to lown to lo

do

wn to lo

dodo

wn to lown to lo

tion for one hourtion for one hour

tion for one hour

tion for one hourtion for one hour

e sensor from protective sensor from protectiv

v

e sensor from protectiv

vv

e sensor from protective sensor from protectiv

ransducer tube maransducer tube ma

ransducer tube ma

ransducer tube maransducer tube ma

then the por then the por

then the por

then the por then the por

te for proper operate for proper opera

te for proper opera

te for proper operate for proper opera

ou haou ha

vv

e computer interface or process control options,e computer interface or process control options,

ou ha

v

e computer interface or process control options,

ou haou ha

vv

e computer interface or process control options,e computer interface or process control options,

t diagt diag

ram is gram is g

t diag

ram is g

t diagt diag

ram is gram is g

AA

C poC po

A

C po

AA

C poC po

VV

AA

C 50/60 HzC 50/60 Hz

V

A

C 50/60 Hz

VV

AA

C 50/60 HzC 50/60 Hz

urur

n on pon on po

ur

n on po

urur

n on pon on po

(default).(default).

(default).

(default).(default).

or best accuracor best accurac

or best accurac

or best accuracor best accurac

w 10w 10

w 10

w 10w 10

-6-6

-6

-6-6

..

.

..

ww

er ser s

witch.witch.

w

er s

witch.

ww

er ser s

witch.witch.

yy

,,

y

,

yy

,,

TT

oror

r (if possible).r (if possible).

T

or

r (if possible).

TT

oror

r (if possible).r (if possible).

..

.

..

our newour new

our new

our newour new

y be installed in any be installed in an

y be installed in an

y be installed in any be installed in an

t should be ort should be or

t should be or

t should be ort should be or

NPT style transducer tube, NPT style transducer tube,

NPT style transducer tube,

NPT style transducer tube, NPT style transducer tube,

tion.tion.

tion.

tion.tion.

iviv

en in the manual.en in the manual.

iv

en in the manual.

iviv

en in the manual.en in the manual.

ww

er cord.er cord.

w

er cord.

ww

er cord.er cord.

Gauge is no Gauge is no

Gauge is no

Gauge is no Gauge is no

the gauge should no the gauge should no

the gauge should no

the gauge should no the gauge should no

Model 2000 vModel 2000 v

Model 2000 v

Model 2000 vModel 2000 v

e package packag

e packag

e package packag

ientaienta

ienta

ientaienta

The Model 2002 automaThe Model 2002 automa

The Model 2002 automa

The Model 2002 automaThe Model 2002 automa

w reading pressure in units ofw reading pressure in units of

w reading pressure in units of

w reading pressure in units ofw reading pressure in units of

w be zeroed.w be zeroed.

w be zeroed.

w be zeroed.w be zeroed.

Ideally the gauge should be operaIdeally the gauge should be opera

Ideally the gauge should be opera

Ideally the gauge should be operaIdeally the gauge should be opera

ing.ing.

ing.

ing.ing.

y ory or

y or

y ory or

ted doted do

ted do

ted doted do

acuum gauge up and racuum gauge up and r

acuum gauge up and r

acuum gauge up and racuum gauge up and r

ientaienta

tion.tion.

Ho Ho

ww

ienta

tion.

ientaienta

tion.tion.

wnwwnw

wnw

wnwwnw

use the 7/16” use the 7/16”

use the 7/16”

use the 7/16” use the 7/16”

evev

Ho

w

ev

Ho Ho

ww

evev

ard.ard.

ard.

ard.ard.

..

A finger tight connectionA finger tight connection

.

A finger tight connection

..

A finger tight connectionA finger tight connection

these cables can no these cables can no

these cables can no

these cables can no these cables can no

tically adjusts fortically adjusts for

tically adjusts for

tically adjusts fortically adjusts for

Pump the vPump the v

Pump the v

Pump the vPump the v

unning.unning.

unning.

unning.unning.

er if condensaer if condensa

er if condensa

er if condensaer if condensa

wrench fla wrench fla

wrench fla

wrench fla wrench fla

acuum systemacuum system

acuum system

acuum systemacuum system

ted in thisted in this

ted in this

ted in thisted in this

tion istion is

tion is

tion istion is

ts onts on

ts on

ts onts on

ww

w

ww

condi-condi-

condi-

condi-condi-

11.11.

Place the Model 2002 in the Place the Model 2002 in the

11.

Place the Model 2002 in the

11.11.

Place the Model 2002 in the Place the Model 2002 in the

up and doup and do

up and do

up and doup and do

12.12.

12.

12.12.

mode smode s

mode s

mode smode s

The gauge is now ready for normal operation and the display is a true indication of the system

pressure (P < 8 Torr is N2 equivalent).

wn arwn ar

wn ar

wn arwn ar

Press the Press the

Press the

Press the Press the

witch.witch.

witch.

witch.witch.

roro

ws simultaneously (“CALws simultaneously (“CAL

ro

ws simultaneously (“CAL

roro

ws simultaneously (“CALws simultaneously (“CAL

“ZER“ZER

O”O”

s s

“ZER

“ZER“ZER

witch once and returwitch once and retur

O”

s

witch once and retur

O”O”

s s

witch once and returwitch once and retur

“CAL“CAL

“CAL

“CAL“CAL

””

mode b mode b

”

mode b

””

mode b mode b

””

light is no light is no

”

light is no

””

light is no light is no

y using the mode sy using the mode s

y using the mode s

y using the mode sy using the mode s

w flashing).w flashing).

w flashing).

w flashing).w flashing).

n to the n to the

n to the

n to the n to the

“R“R

“R

“R“R

UN”UN”

UN”

UN”UN”

witch.witch.

Press the Press the

witch.

Press the

witch.witch.

Press the Press the

mode using the mode using the

mode using the

mode using the mode using the

Model 2002 page 7

Page 8

2.3 Transducer Installation

The transducer may be installed in any orientation. Although the transducer is rugged and will

perform well in many harsh environments, the tube should be installed in a clean and careful

manner. The tube is configured with the vacuum fitting requested. If your vacuum environment

is highly contaminated or has unique fitting requirements, a Hastings filter or special adapter may

be needed. Please contact the Hastings Instruments Sales Department for assistance in your

system configuration.

2.4 Control Unit Installation

EnEn

vironment:vironment:

En

vironment:

EnEn

vironment:vironment:

Indoor use

Altitude up to 2000 meters

Operating temperature range from 50 to 400C

Maximum relative humidity: 80% for tempera tures up to 310C decreasing linearly to 50%

relative humidity at 400C

Installation category II

PP

anel Mount Instranel Mount Instr

P

anel Mount Instr

PP

anel Mount Instranel Mount Instr

The control unit can be panel mounted. See detail on page 43. The hole dimensions on the panel

are 3.62" x 3.62"(92.8mm x 92.8 mm). Slide the neoprene gasket that was shipped with the

control unit onto the case from the back. Slide the controller through the panel cutout. Hold the

hardware against the side and tighten the two screws.

uctions:uctions:

uctions:

uctions:uctions:

TT

ransducer Cable ransducer Cable

T

ransducer Cable

TT

ransducer Cable ransducer Cable

The threaded connector attaches to the transducer. A finger tight connection is adequate for

proper operation. The 9-pin male “D” connector attaches to the back panel (See Figure 4.2).

The transducer cable connects to the left hand connector when looking at the back.

I/O Cable I/O Cable

I/O Cable

I/O Cable I/O Cable

The mating male plug to the I/O connector is supplied with the unit. An I/O cable can be wired

with the 9-pin female “D” connector to use the analog output, digital alarms or the remote zero

functions. The connector will accept 20 gauge or smaller wire. The pinout is shown in Figure 4.2

(back panel figure). A detailed description of these pins is given in Section 4.

Attachment:Attachment:

Attachment:

Attachment:Attachment:

2.5 Initial Operation

Upon applying power to the control unit a pressure measurement will be given in Torr for nitrogen.

However, it is recommended that the user follow the instructions for zeroing and adjusting the

output at atmospheric pressure in Section 3.4 ("Cal Mode").

Attachment:Attachment:

Attachment:

Attachment:Attachment:

page 8 Model 2002

Page 9

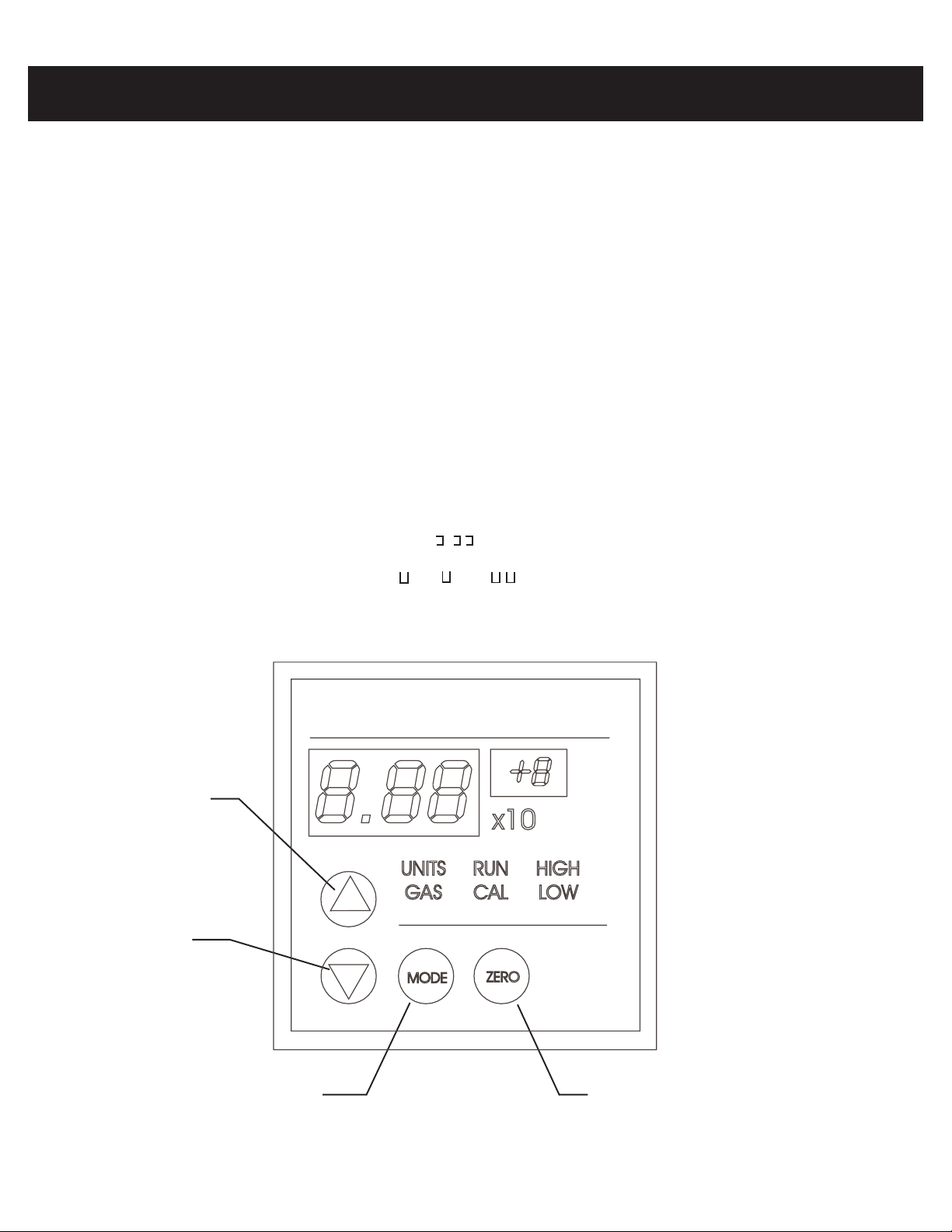

3.1 Overall Functional Description

The front panel of the control unit is shown in Figure 3.1. The four circular blue buttons are

used for the selection of display readout and the input of data. The green data field displays the

data as determined by mode selection. The MODE switch toggles the control unit in a clockwise

fashion among the six modes of operation:

RR

UNUN

R

UN Normal operation, pressure is displayed in scientific notation. The analog to digital

RR

UNUN

converter speed can be adjusted and the factory calibration can also be restored in

this mode. See Section 3.2 for further information.

HIGHHIGH

HIGH High set point is displayed in scientific notation, above this pressure the HIGH

HIGHHIGH

TTL output will be +5V.

LOLO

WW

LO

W Low set point is displayed in scientific notation, below this pressure the LO W TTL

LOLO

WW

output will be +5V.

CALCAL

CAL Pressure is displayed and can be adjusted.

CALCAL

GASGAS

GAS Gas number is displayed and selection may be changed.

GASGAS

UNITSUNITS

UNITS Units used to display pressure are selected.

UNITSUNITS

SECTION 3

Front Panel Operation

In the RUN, HIGH, and LOW modes, it is possible to see the display indicate that the data is out

of range. Overrange is indicated by . x10- . Underrange is indicated by 0.0 x10-. A measured pressure below 1x10

sensor(s), it is possible to see “ .“, “. “ or “ . “. See trouble shooting section (section 8) for

more detail.

UP SWITCH

DOWN

SWITCH

-4

Torr is indicated by 0.0 x10+. In the case of an unconnected or faulty

HASTINGS INSTRUMENTS

DUAL SENSOR V ACUUM GAUGE

MODEL 2002

mbar

Torr

Pa

Model 2002

Control Unit

Front Panel

MODE SWITCH ZERO SWITCH

Model 2002 Control Unit Front Panel

Figure 3.1

Model 2002 page 9

Page 10

All six modes of the Model 2002 have features which can be accessed and modified after bypassing

the front panel interlock. The interlock is in place to prevent the accidental corruption of the

instrument’s configuration and calibration. The interlock is bypassed using the following steps:

1. Place the instrument in one of the six modes.

2. Simultaneously press the up and down switches.

The mode light will now flash indicating that the interlock has been bypassed.

Scientific NotaScientific Nota

Scientific Nota

Scientific NotaScientific Nota

The Model 2002 measures pressure that spans more than seven decades. In order to easily display

these readings, Hastings Instruments has employed scientific notation. In scientific notation, the

mantissa (the fixed point part) is multiplied by some power of 10 (given by the exponent).

103 = 1000 10-1 = 0.1

2

10

101 = 10 10-3 = 0.001

100 = 1 10-4 = 0.0001

As an example: 7.60 x 10

"7.60 multiplied by 100" = 760 Torr which is one atmosphere of pressure.

3.2 RUN Mode

NorNor

mal Operamal Opera

Nor

mal Opera

NorNor

mal Operamal Opera

tiontion

tion

tiontion

Powers of 10

= 100 10-2 = 0.01

+2

Tor r

{

mantissa exponent

tiontion

tion

tiontion

The Model 2002 will automatically enter RUN mode upon start-up. This is the mode for normal

operation and the mode in which the instrument will typically spend most of its time. In the run

mode, the Model 2002 unit will continuously monitor the pressure and update the alarm conditions

at the speed of the A/D con verter and will update the display about four times per second.

A/D Speed A/D Speed

A/D Speed

A/D Speed A/D Speed

The Model 2002 utilizes a 24 bit sigma-delta analog to digital converter. This type of converter

averages the input over time to reject interference. Longer averaging times result in more accurate

readings. Increasing the A/D speed will respond to sudden pressure changes faster.

While in the RUN mode, the user can adjust the A/D speed of operation. At start-up, the instrument

will be operating with an A/D frequency of about 60 Hz. The speed can be adjusted one step faster

or slower. Each step will increase or decrease the A/D frequency by a factor of two.

To adjust the A/D speed, press the MODE switch until the RUN light is illuminated. Then simultaneously press the UP and DOWN switches. The RUN light will now flash indicating tha t the

interlock has been bypassed and the A/D speed can be adjusted. Push the UP switch to speed up

the A/D conv erter one step and decrease the response time . This will result in a faster triggering of

alarms or relays if a sudden catastrophic failure occurs. Pressing the switch after the limit is reached

has no effect.

Pushing the down switch will slow down the A/D converter and increase its accuracy. This will

improve the ability to resolve low pressure readings. If a certain speed is desired, press the UP or

DO WN switch three times and then press the other switch to select the other speed.

On older units. There will be no indication of the operating speed other than the least significant

digits of the display will tend to run at higher speeds. On units with software version 1.60 and

AdjustAdjust

Adjust

AdjustAdjust

page 10 Model 2002

Page 11

above, press the ZERO switch to display the decimation ratio (filtering). The larger the ratio, the

longer the response time.

EEPREEPR

EEPR

EEPREEPR

There are interlocks built into the CAL mode to minimize the chance of accidental alteration of the

calibration coefficients, but if calibration alteration does occur, the EEPROM calibration data can be

restored in the RUN mode by pressing the UP and DOWN switches simultaneously (RUN light will

flash), then press the “ZERO” switch, UP and DOWN switches (all three) simultaneously.

This will not correct the calibration if the tube has become contaminated or damaged. This reset will

not affect the gas selection, units or setpoints.

Also see units mode for default calibration restoration.

OM CalibraOM Calibra

OM Calibra

OM CalibraOM Calibra

tion Restoration Restora

tion Restora

tion Restoration Restora

tiontion

tion

tiontion

3.3 HIGH and LOW Set Point Modes

The Model 2002 provides TTL outputs for process control. The I/O cable is attached via a 9-pin

sub-D connector to the rear panel of the control unit. The pinout is shown in Figure 4.2.

To view the high set point, place the Model 2002 in the HIGH mode by pressing the MODE switch

to illuminate the HIGH light and no other mode light. The display will show the set point selected.

During normal operation the alarm light will illuminate and the TTL output (pin # 3) will go high

(+5 V) if the pressure

Similarly, to view the low set point access LOW mode by pressing the mode switch until the LOW

light is lit and no other mode light is illuminated. During normal operation, the LOW light will

illuminate and the LOW alarm TTL output (pin # 4) will go high (+5 V) if the pressure becomes

less less

less than the set point.

less less

exceedsexceeds

exceeds the set point.

exceedsexceeds

The alarm lights cannot indicate an alarm condition while in the set point modes. Therefore, it is

advisable not to leave the instrument in these modes for extended periods.

To adjust a set point, press the mode switch until the set point is viewed. Then simultaneously press

the UP and DOWN switches. The active mode light will now flash indicating that the interlock has

been bypassed and the set point can be adjusted. The display shows the present set point.

Enter the new set point by using the UP and DOWN switches. Press and hold the UP switch to

increase the set point and the DOWN switch to decrease the setpoint. Allow a few seconds for the

circuitry to respond. If the button is held down for and extended period of time the adjustment rate

will start to increase. Release the button and press again to get finer control of the exact trigger

point.

At this point, the new set point is in temporary memory. If the instrument were unplugged now,

the Model 2002 would revert back to the original set point upon restarting. Return the 2002 to the

RUN mode to store the set point in permanent memory.

Once the interlock has been bypassed in the HIGH mode, it will stay active until the CAL mode is

entered. This will allow the user to set both setpoints without repeating the interlock bypass.

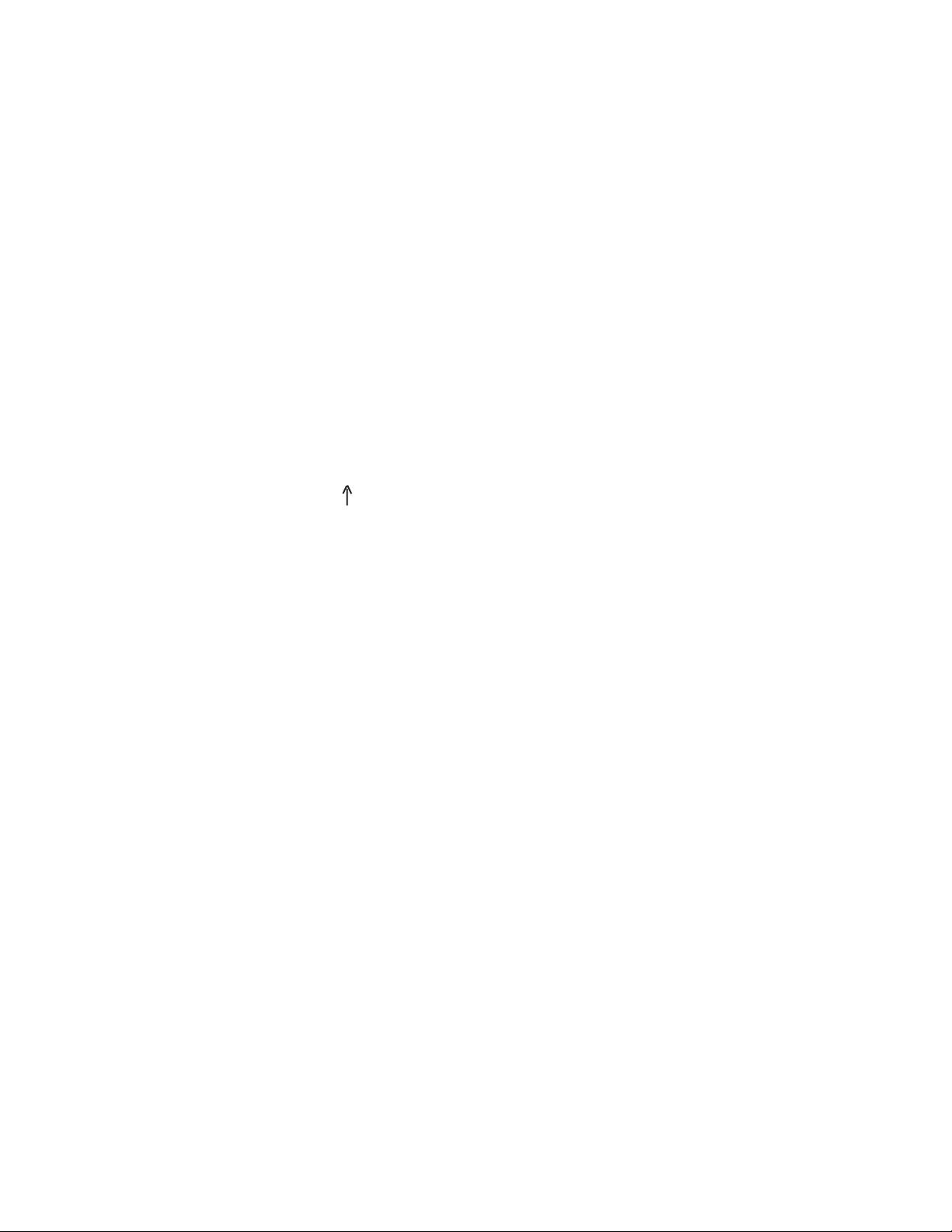

3.4 CAL Mode

Optimal performance of the Model 2002 is achieved by performing in situ adjustments to the

calibration coefficient in the CAL mode. There are three calibration coefficients. These are the zero

coefficient, the midrange coefficient and the atmosphere coefficient. Once a tube has been fully

calibrated the midrange coefficient should never need further adjustment, but it may be helpful to

adjust the zero coefficient or the atmosphere coefficient under certain situations. Even though the

operator inputs may be identical for adjustment of all three coefficients, microprocessor will detect

Model 2002 page 11

Page 12

Maintainance and Repair 4-3

the power level of the tube and adjust the proper coefficient for pressure level of the adjustment.

The CAL MODE presupposes that the operator is applying a known pressure of the correct gas

composition (see GAS MODE). The factory calibration points are 800 Torr, 7 Torr, and <1e-6

Torr. The users calibration points are not required to be exactly those values, but should be

somewhat close, and must be within the ranges shown in the following figure. The HPM-2002

detects the voltage signal within the sensor tube, which is converted and displayed as a pressure

reading. The resulting pressure reading determines which of the three coefficients will be adjusted.

page 12 Model 2002

To adjust a calibration coefficient press the MODE switch until the CAL light is illuminated.

Then simultaneously press the UP and DOWN switch. The CAL light will now flash indicating

that the interlock has been bypassed and the calibration can be adjusted. Press and hold the UP

switch to increase the displayed v alue or the DOWN switch to decrease the displayed value. If

the switch is held down for an extended period of time the adjustment rate will start to increase.

Release the switch and then press and hold again to regain finer control of the displayed number.

An important point to be noted is the fact that after the adjustment, the new calibration coefficient is only in temporary memory. If the instrument were unplugged at this point, it would rev ert

Page 13

back to the original displayed value upon restarting. Place the Model 2002 back in the RUN

mode to store all of the current calibration coefficients in permanent memory.

To perform a full calibration on the Model 2002 system, first use the Zero Coefficient Adjustment Procedure. Followed by the Midrange Coefficient Adjustment Procedure, and finally

perform the Atmosphere Coefficient Adjustment Procedure.

Zero Coefficient Zero Coefficient

Zero Coefficient

Zero Coefficient Zero Coefficient

The zero coefficient corrects for the constant power level which is present ov er the entire pressure

range. Typically, this adjustment corrects for low pressure errors. The instrument will need to be

re-zeroed often if measurements are being made in the 10-4 Torr range, especially if the ambient

temperature changes. The transducer may have a temperature coefficient of up to 2x10-4 Tor r/oC.

The instrument remote zero input will allow an external gauge such as an ion gauge to automatically re-zero the Model 2002 whenever the pressure drops below the desired pressure level (if it

has a TTL output).

NOTE: Do not attempt to zero the Model 2002 in pressures abov e 10-2 Torr; the microprocessor will not accept a zero abov e this pressure.

To manually adjust the zero use the following procedure:

1. If possible, evacuate the vacuum system into the low 10-6 T orr (1.33x10-6 mbar) range or as

low as possible below 10

2. Allow the sensor to operate in this condition for a minimum of 15 minutes.

3. Place the instrument in the CAL mode, then simultaneously press the UP and DOWN

switches to bypass the interlock. The CAL light will start to flash indicating

that the calibration mode has been activated.

4. Press the ZERO switch once if below 6x10-5 Torr otherwise use the UP and DOWN switch

to adjust the display of the Model 2002 to match the pressure indicated by

the reference. If using the UP and DOWN switch to adjust the display , wait 20

seconds between presses at very low pressure to allow the adjustment to take

affect the data to settle.

AdjustmentAdjustment

Adjustment

AdjustmentAdjustment

-4

Torr.

5. The unit is now fully zeroed. Place the Model 2002 back in the RUN mode to store the zero

in permanent memory.

Midrange Coefficient Midrange Coefficient

Midrange Coefficient

Midrange Coefficient Midrange Coefficient

The midrange coefficient corrects for errors in the slope of the power curve of the thin film

Pirani. Typically, this is due to the geometry of a particular sensor and will only need to be

performed once in the lifetime of the sensor. This adjustment might be needed if a full calibration

is being performed in a gas other than nitrogen.

before making this adjustmentbefore making this adjustment

before making this adjustment.

before making this adjustmentbefore making this adjustment

To adjust the midrange coefficient use the following procedure:

1. Evacuate the vacuum chamber and refill with the desired gas to a pressure of 7 Torr, as

indicated by a reference vacuum gauge.

2. Press the MODE switch repeatedly until the CAL mode is illuminated.

3. Simultaneously, press both the UP and DOWN switches. The CAL light will start to flash,

signalling that the calibration can now be conducted.

4. Press, hold and release the UP and DOWN switches as necessary to adjust the display to

match the pressure indicated by the reference. Note: It may be necessary to hold the

desired switch down for a few seconds before any movement is seen.

AdjustmentAdjustment

Adjustment

AdjustmentAdjustment

The zero adjustment will need to be perforThe zero adjustment will need to be perfor

The zero adjustment will need to be perfor

The zero adjustment will need to be perforThe zero adjustment will need to be perfor

medmed

med

medmed

Model 2002 page 13

Page 14

5. Press and release the MODE switch as necessary to return the 2002 to the RUN mode and

store the coefficients to permanent memory.

Atmosphere Coefficient Atmosphere Coefficient

Atmosphere Coefficient

Atmosphere Coefficient Atmosphere Coefficient

If a reference high pressure gauge is not available, the ambient barometric pressure acquired from

the weather channel or other weather service can be used to adjust the proper reading.

To adjust the atmosphere coefficient, use the following procedure:

1. Press the MODE switch a sufficient number of times to enter the CAL mode.

2. Simultaneously, press both the UP and DOWN switches to bypass the interlock. The CAL

light will start to flash, signaling that the calibration can now be conducted.

3. Press, hold and release either of the UP and DOWN switches as necessary to adjust the

display to match the pressure indicated by the reference. Note: It may be necessary to hold the desired switch down for a few seconds before any movement is

seen.

4. Press and release the MODE switch as necessary to return the Model 2002 to the RUN

mode and store the coefficients to permanent memory.

3.5 GAS Mode

The Model 2002 can provide true pressure measurements in many gas environments. At pressure

levels above 32 Torr where the direct force piezoresistive sensor is operative, the instrument is gas

composition insensitive and measures the true pressure regardless of gas composition. The Pirani

is gas composition sensitive so below 32 Torr, the actual composition must be known and the

Pirani calibrated in that gas. When the vacuum system’s gas composition is dominated by a single

gas species (for example, during system venting with an inert gas), the user can enter a gas

selection into the Model 2002. To view the gas selection, place the instrument in the GAS mode

AdjustmentAdjustment

Adjustment

AdjustmentAdjustment

page 14 Model 2002

TABLE 1

Gas Mode

Displayed Number

0.0............................... nitrogen

0.1................................... argon

0.2................................. helium

0.3..........................water vapor

0.4.................................custom

and reference Table 1. The Model 2002 is factory set to display N2 pressure readings. To select a

different gas, refer to Table 1 to find the number code of the gas to be entered. Press the UP and

DOWN switches simultaneously, the GAS light will now flash. Use the UP and DOWN switches

to individually select the desired code. Return the Model 2002 to the RUN mode.

Gas

Page 15

Note: Factory calibration is performed using nitrogen only. Displayed pressure measurements using other gases are based on established g as thermal conductivity data.

3.6 UNITS Mode

The Model 2002 can display the measured pressure in different pressure units, Torr, mbar or

Pascal. To switch between these units press the MODE switch until the UNITS field is lit. Press

the UP and DOWN switches simultaneously. The UNITS light will now flash. Use the UP and

DO WN switches individually to select the desired unit.

The units mode is also used to display the RS-485 address, (see section 6.3).

A commonly used unit is mTorr which is also known as the micron (short for micron of Hg).

One Torr is equal to 1000 mTorr. The table below illustrates how to interpret the display in

mTorr.

Table 2 gives conversion factors for the most often used pressure units.

mTorr Conversions

1 mTorr = 1.00 x 10-3 Tor r

10 mTorr = 1.00 x 10-2 Tor r

100 mT orr = 1.00 x 10

-1

Tor r

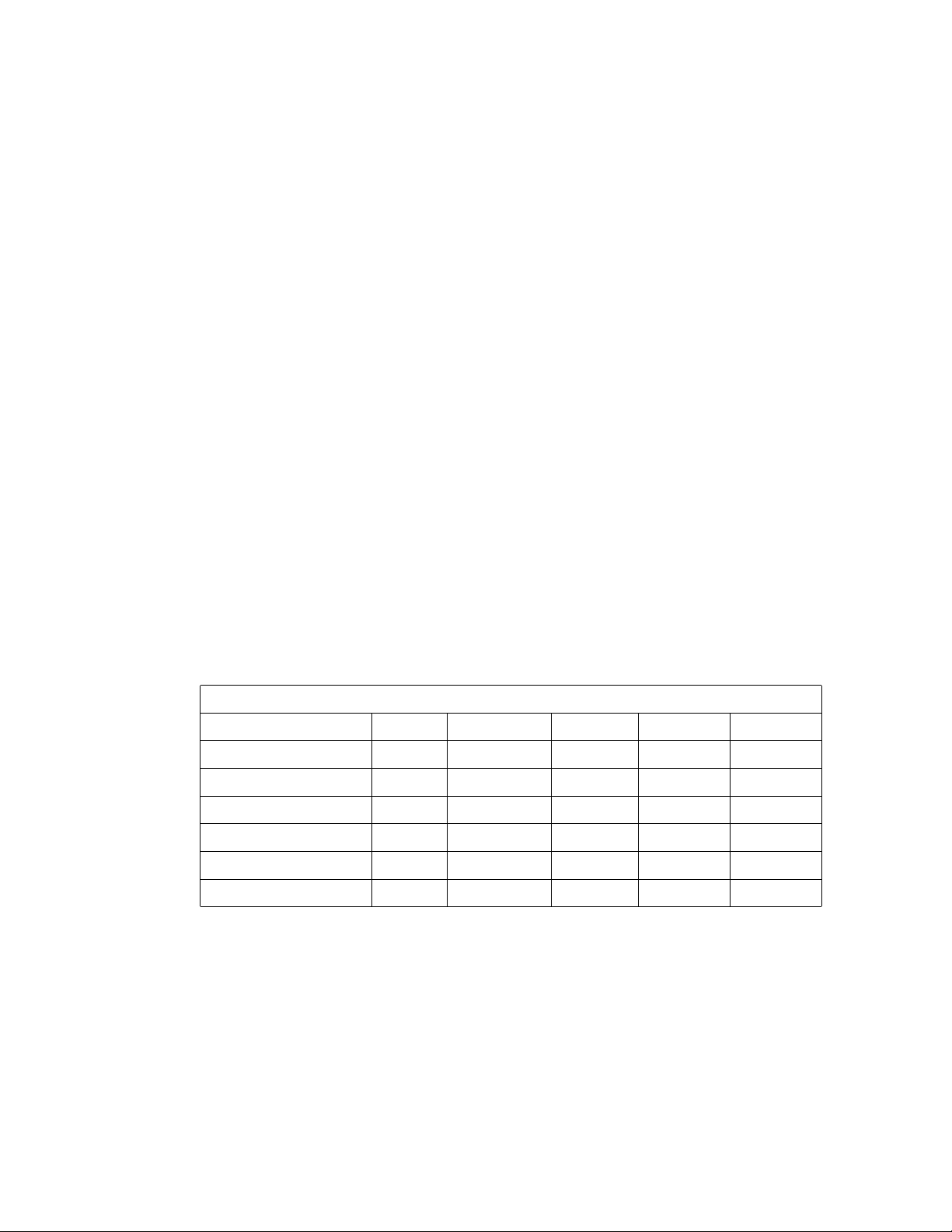

TABLE 2

Torr

Torr (mm Hg)

mTorr (micron Hg)

atm (athmosphere)

mbar (millibar)

Pa

1 1.32x10

-3

10

760

0.75

7.5x10

-3

psi (lb/in ) 51.72

Default CalibraDefault Calibra

Default Calibra

Default CalibraDefault Calibra

The UNITS mode is also used to load default calibration data in rare cases where the transducer

EEPROM has become corrupted. The default calibration data should be considered an approximate calibration because the values entered in the controller’s software are based on averaged data

collected over a large number of transducers. While this type of calibration download is not a true

calibration, it does allow the user to return the unit to a reasonable status from which a full

calibration can be easily performed.

tion Restoration Restora

tion Restora

tion Restoration Restora

tiontion

tion

tiontion

atm

-3

1.3332 133 .32

1.32x10

9.869x10

9.869x10

6.805x10 68.953

-6

0.00133

1

1013.23

-4 -2

-6

-2

1

0.01

.13332

1.013x10

100

1

6895.3

psiPambar

1.934x10

1.934x10

14.7

1.45x10

1.45x10

1

-2

-5

-4

Model 2002 page 15

Page 16

This page was intentionally left blank

page 16 Model 2002

Page 17

A schematic of the rear panel of the Model 2002 control unit is shown in Figure 4.2 ( Rear Panel Figure).

The transducer is connected to the control unit via an female 9-pin “D” connector on the rear panel. An

I/O cable can be connected via a male 9-pin “D” connector on the rear panel. The I/O cable provides an

analog output signal, a remote zero input capability, high and low alarm TTL outputs, and a + 5 VDC

Power Supply Output. The I/O cable also provides an analog ground and a digital common.

4.1 Remote Zero Input

The Model 2002 can be zeroed remotely via the I/O cable using the remote zero input line. Upon setting

this line to TTL low level, the instrument will set its current pressure reading to zero. A common application of this feature is to utilize a process control output from a high vacuum gauge (for example an ion

gauge controller) to automatically zero the Model 2002 whenever the pressure is below the low 10-5 Torr

range. A Digital Common is provided on pin # 5 which can be used with relay contacts or switch

contacts to remotely zero the instrument.

4.2 Analog Output

The Model 2002 provides an analog voltage output signal (0.5 VDC linear per decade) for process

control and for pressure monitoring. A plot of the analog output signal as a function of pressure is

shown in Figure 4.1 . Note that the output voltage is directly proportional to the pressure over each

complete decade (see detailed region in Figure 4.1) and that each decade has a different linear slope.

SECTION 4

Rear Panel Description

Above an indicated pressure of 103 Torr, the analog output signal will be +5 VDC. Below the minimal

displayable pressure of 1 x 10-4 Torr, the analog output will be 1.0 VDC.

(EXP + 6) (MANT - 1)

V =

The analog output voltage is given by the following equation:

Where EXP is equal to the exponent of the displayed pressure.

218

+

EXP = -2

MANT = 1.53

(1.53 - 1)

+

18

example: p = 1.53 x 10

(-2 + 6)

V =

-2

2

2 + 0.0294

=

2.0294 VDC

=

EXP = +2

MANT = 9.87

(+2 + 6)

V =

4 + 0.4928

=

4.4928 VDC

=

2

(9.87 - 1)

+

18

Model 2002 page 17

Page 18

If the analog output voltage is being used in a data aquisition system, the following formulas can

be used to calculate pressure.

EXP = INT (2*V)-6

MANT = 1 + 18 *V-9*(EXP + 9)

Pres su re (T o rr ) = Mant x 1 0

Therefore,

Note that the INT function simply returns to the first digit in a number.

examples:

INT (2.56) = 2

INT (9.87) = 9

Voltage to pressure conversion example:

Given V = 2.35 Volt

First calculate the exponent;

EXP = INT (2*2.35) - 6

= INT (4.7 - 6

EXP

Next calculate the mantissa;

MANT = 1 + 18 * V - 9 (EXP +6)

Finally the pressure is given by;

Pressure (torr) = MANT x 10

= INT 4-6

= - 2

= 1 + 18 * (2.35) - 9 * (2+6)

= 1 + 42.3 - 36

= 7.3

EXPEXP

EXP

EXPEXP

-2 -2

-2

= 7.3 x 10

-2 -2

Torr

page 18 Model 2002

Page 19

2.5

2.4

2.3

2.2

4.5

4.0

3.5

3.0

2.5

2.0

VDC

1.5

1.0

0.5

0.0

1.0E-5 1.0E-4 1.0E-3 1.0E-2 1.0E-1 1.0E+0 1.0E+1 1.0E+2 1.0E+3

VDC

2.1

2.0

12345678910

X 10-2 Torr

0.5 VDC Linear per Decade

Pressure (Torr)

4.3 4.3

TTL OutputsTTL Outputs

4.3

TTL Outputs

4.3 4.3

TTL OutputsTTL Outputs

MODEL 2002 MODEL 2002

MODEL 2002

MODEL 2002 MODEL 2002

Analog OutputAnalog Output

Analog Output

Analog OutputAnalog Output

Figure 4.1

VDC (volts) -vs- Pressure (Torr)

TTL outputs are provided for process control. High and Low set points are entered on the front panel

(see Section 3.4) and TTL signals are generated on the I/O cable in the following manner:

1) When the pressure as indicated by the Model 2002 is abov e the High set point, the High

signal line (pin #3) will be set to a TTL high level (+5 VDC). When the indicated pressure

is below the High set point, the High signal line (pin#3) will be set to a TTL low level (+0 VDC).

2) When the pressure as indicated by the Model 2002 is below the Low set point, the Low signal

line (pin #4) will be set to a TTL high level (+5 VDC). When the indicated pressure is above

the Low set point, the Low signal line (pin #4) will be set to a TTL low level (+0 VDC).

These TTL signals are used for a variety of applications. With these signals, the user has the capability

to turn off/on various equipment such as valves, flo w controllers, pumps, heaters, and safety equipment.

Model 2002 page 19

Page 20

4.4 Power Entry Module

The AC power for the Model 2002 enters the instrument through a power entry module that

contains a fuse, on/off switch and an IEC 320 power inlet.

The fuse is rated for 250 V, 1/4 A. It can be accessed by unplugging the AC cord and prying the

fuse compartment open with the tab and slot in the power inlet chamber. There is a spare fuse in

the compartment within the fuse holder.

LOW SETPOINT OPTION BOARD HIGH SETPOINT

RELAY CONNECTOR (MALE) RELAY

Model 2002

Rear Panel Detail

TRANSDUCER CONN. STANDARD

(FEMALE) I/O CONNECTOR

Analog 0-10V OPTION

BOARD CONNECTOR

Pin# Connection

1 Analog Out 1 (1024 Torr) High

2 Analog Out 1 (1024 Torr) Shield

3 Analog Out 1 (1024 Torr) Low

4

5

6

7 Analog Out 2 (1000 mTorr) Low

8 Analog Out 2 (1000 mTorr) High

9 Analog Out 2 (1000 mTorr) Shield

4-20mA OPTION

BOARD CONNECTOR

Pin# Connection

1 I-Loop Out (+) 1024 Torr

3 I-Loop In (-) 1024 Torr

8 I-Loop Out (+) 1000 mTorr

7 I-Loop In (-) 1000 mTorr

Figure 4.2

SENSOR CONNECTOR

Pin# Connection

1 Sensor

2 Bridge (sense)

3 Bridge-Power

4 Reference

5 Common

6 Common (sense)

7 N/C

8 N/C

I/O CONNECTOR

Pin# Connection

1 Analog Output

2 Analog Common

3 High Setpoint

4 Low Setpoint

5 Digital Common

6 Remote Zero

7 +5V

page 20 Model 2002

Page 21

The Model 2002 transducer is comprised of two very different sensors which provide a span of

measurement extending from 1000 Torr down to less than 1x10-4 Torr. The piezoresistive device is

a direct force sensor which provides pressure indication from 1000 Torr down to less than 1 Torr.

The thin film Pirani device is a thermal conductivity sensor that provides pressure indication

from 100 Torr down to less than 1x10

convenient for smooth transition either descending or ascending in pressure. Both sensors are

small micromachined die that are bonded to a Au coated Al2O3 preform (stress isolation) which in

turn is bonded to a TO-8 header. The header is resistance welded into a 316 stainless steel

envelope as shown in Figure 5.1.

5.1 Piezoresistive Sensor

Cable connector

SECTION 5

Theory of Operation

-4

Torr. The two decade overlap in measurement range is

Electronics board

(contains EEPROM)

Top cap

TO-8

HEADER

Piezoresistive

sensor

Tube shell

Dual Sensor Embodiment

Preform

Pirani sensor

Figure 5.1

Model 2002 page 21

Page 22

V

T

Figure 5.2 shows a typical schematic of a B implanted Wheatstone bridge network in a Si diaphragm inverted box type geometry. The inside of the box is evacuated during anodic bonding to

a Pyrex substrate. The membrane has maximum deflection at atmosphere (or higher pressure)

and the membrane resistances change value as the differential pressure is decreased during

pumpdown. The resulting differential output is

VdS

dT

1

)

Vo = SPV+V

where

S is the sensitivity

P is the pressure

V is the applied bridge voltage

1

is the no load output voltage

V

Since the sensitivity changes so dramatically with temperature, some correction is required for

compensation. The change in output voltage

To insure temperature invariance,

dV

dT

0

SdV

P

(

d

dV

dV

0

dT

which requires for any change in sensitivity to be countered by an equal but opposite change in

applied voltage. The temperature compensation is a network of tempera ture dependent resistive

components and fixed temperature compensation current source compensation, TCR = -TCS.

Sensitivity of the sensor is proportional to the sensor factor (K), the strain gauge positioning of

the diaphragm (φ) and the diaphragm geometry (θ) thus S

the resistive film and piezo membrane have been established, the sensor factor is dependent on

the crystal orientation of the membrane material, the doping level and diffusion parameters and

the strain gauge geometry. The sensor factor is essentially the change in resistance for a change in

strain or,

Boron ion implanted doped Si matrix resistance elements are employed as shown in Figure 5.2.

0

therefore

1

dT

dS

1

dT

S

∝Kφθ. Once the defining geometry of

R

K

R

L

L

page 22 Model 2002

The die is electrostatically bonded on to a Pyrex substrate in a good vacuum so that the die cavity

is evacuated, this provides maximum deflection at atmospheric pressure. When the sensor is

exposed to vacuum the deflection becomes less and less as the die cavity pressure and the

vacuum system pressure equalizes. Eventually the strain in the membrane due to ∆P becomes

zero and only the residual strain in the lattice remains. The bridge resistive elements are oriented

to give maximum change in bridge resistance which in turn gives maximum voltage out for a

given strain.

Page 23

Diaphragm

Backing surface or

restrainer

Pressure

Diffused bridge resistors

View A-A

Diffused bridge resistors

E

e

S

1

e

2

Ground

A-A

Ground

Figure 5.2

Model 2002 page 23

Page 24

5.2 Pirani Sensor

Figure 5.3a shows a thin film Pt resistive element on a one micron thick Si3N4 continuous membrane surrounded by a thin film Pt reference resistor on a Si substrate. The membrane is heated

to a constant 80C above ambient temperature that is monitored by the substrate resistor. The

membrane resistor is approximately 60 Ω and a constant substrate to membrane resistance ratio

is maintained at 3.86. Figure 5.3b shows the Pirani die in cross section. A parallel Si lid is

eutectically bonded to the Au pads and sits 5 microns above the membrane. As shown, this

dimension gives a Knudsen number of greater than 0.01 up to atmospheric pressure, which

insures a molecular flow component. At 10 Torr the region above the membrane is totally in the

molecular flow regime and thus provides a relatively linear output verses pressure ov erlapping the

linear output versus pressure of the piezo.

The measurement technique is to produce an output signal that is proportional to the power

supplied to the heated resistor by using the product of the current and voltage. This rejects errors

introduced by resistance changes since the sensor resistance is no longer part of the power

equation.

A signal proportional to the power is obtained by multiplying the voltage across the heated sensor

and the voltage impressed by the direct current across a constant series resistance. The power

supplied to the sensor resistor must equal the heat dissipated (E

routes from the heated sensor are thermal conduction through the silicon nitride membrane to the

silicon substrate (Es) radiation losses (Er) and thermal conduction through the gas to the silicon

substrate (Eg); thus, as shown in Figure 5.3c,

EE

= E = E

E

= E

EE

= E = E

tt

t

tt

+ E + E

+ E

+ E + E

ss

s

ss

+ E + E

+ E

+ E + E

rr

r

rr

). The three main heat loss

t

gg

g

gg

The first term, Es, is dependent on the thermal conductivity of the silicon nitride (K), the temperature difference (∆T) between the heater and silicon substrate and geometric factors (AM &

L). ES is given by

EE

= (K = (K

E

= (K

EE

= (K = (K

ss

s

ss

∆∆

∆

∆∆

T T

T

T T

AA

A

AA

mm

m

mm

)/L)/L

)/L

)/L)/L

Am is the membrane cross sectional area through which the heat transfer occurs. This is, approximately, the outer circumference of the membrane multiplied by the membrane thickness. L is the

distance from the edge of (Rs) the heated sensor resistor to the silicon substrate.

For any particular sensor, all of the factors, except ∆T, are constants dependent on its construction. The ∆T is held constant by the control circuit. The thermal loss through the silicon nitride

will be a constant value independent of the thermal conductivity and pressure of the gas.

Radiation is another source of thermal losses. It can be determined from

44

44

4

4

44

EE

= =

σεσε

=

= =

rr

r

rr

σε

σεσε

(T(T

(T

(T(T

E

EE

44

-T-T

)A)A

-T

)A

-T-T

)A)A

hh

aa

h

hh

ss

a

s

aa

ss

where

σ = Stefan-Boltzmann radiation constant

ε = thermal emissivity of the silicon nitride membrane

AS= surface area of the heated portion of the membrane

Th= temperature of R

s

Ta= ambient temperature

page 24 Model 2002

Page 25

Temperature compensation

resistor (Pt)

Silicon nitride membrane

Heated sensor

resistor (Pt)

Silicon substrate

Silicon lid

x

Membrane

Silicon lid

Figure 5.3a

Au

Silicon base

TO-8 header

Figure 5.3b

Es

Er

Membrane

Eg

Er

Silicon base

Es

Figure 5.3c

Model 2002 page 25

Page 26

This radiation loss is also independent of the thermal conductivity of the gas. It is somewhat

dependent upon the absolute temperature of R

and the ambient temperature, but since ∆T is

s

kept to less than 20°C, this loss is only approximately 10% of Es. If ambient changes are small

compared to the absolute values of the temperature this loss can approximated as a constant with

temperature.

Since the first two losses are essentially constant at high vacuum for a given sensor, we can

measure these losses and subtract them from the input power which leaves only the ra te of heat

transmission through the gas (E

In the viscous flow regime, the E

).

g

loss is directly dependent on the thermal conductivity of the gas

g

(Kg), the surface area of the membrane, the differential temperature and is inversely proportional

to distance between the membrane and the lid. It can be written as

EE

E

EE

gg

g

gg

= (K = (K

= (K

= (K = (K

∆∆

T T

AA

)/)/

∆∆

A

AA

xx

)/

∆

x

)/)/

∆∆

xx

ss

s

ss

∆

T

∆∆

T T

gg

g

gg

The thermal conductivity of the gas is essentially constant when in viscous flow where the

Knudsen number (Kn) is less than 0.01. In the viscous flow regime there is no change in sensor

output with pressure since all of the losses are constants with pressure.

In the molecular flow regime where (Kn > 1) the thermal conductivity of the gas becomes

directly proportional to the gas pressure as shown below. We can expect then that Eg will be

constant at high pressures and directly proportional to the pressure at low pressures. The energy

loss Eg, changes between these two controlling equations as the system passes through the

transition region (0.01 < Kn < 1).

1/21/2

1/2

EE

= =

aa

LL

a

L

aa

LL

rr

r

rr

(273/T(273/T

(273/T

(273/T(273/T

tt

t

tt

E

=

EE

= =

gg

g

gg

1/21/2

))

(T(T

-T-T

)A)A

)

(T

(T(T

hh

h

hh

-T

-T-T

))

hh

h

hh

aa

a

aa

)A

)A)A

PP

P

PP

gg

g

gg

Where

ar= accomodation coefficient

Lt= free molecule thermal conductivity

Th= temperature of heated membrane

Ta= ambient temperature

P = pressure

Ag= surface area of the heated portion of the membrane

For nitrogen at a pressure of 760 Torr and a temperature of 20°C the mean free path (λ) is less

than 1 x 10-7 meters and is inversely proportional to pressure. Since the thermal transfer distance

(∆x) is a few micrometers, this sensor will remain in the molecular flow regime at a much higher

pressure (10 Torr) than is typical for a thermal vacuum gauge. This extends the linear response

part of the output curve up into the 1 Torr range. The nonlinear transition region will extend up

to 1000 Torr.

5.3 Dual Sensor Operation

The microprocessor in the control unit continuously monitors the outputs of both the piezoresistive

sensor and the Pirani sensor. Figure 5.4 shows representa tions of the sensors output ov er the

pressure range from 10

sensor at high pressures (>32 Torr) and uses the output of the Pirani sensor at low pressures (<8

Torr). In the crossover region, a software a v eraging algorithm ensures a smooth transition between

the two sensors.

-5

Torr to 10

+3

Torr. The microprocessor uses the output of the piezoresistive

page 26 Model 2002

Page 27

1.0E+03

1.0E+02

1.0E+01

1.0E+00

1.0E-01

1.0E-02

Model 2002

Dual Sensor Vacuum Ga uge

1.0E-03

Pirani

Piezo

Zeroed Sensor Output (Arbitrary Units)

1.0E-04

1.0E-05

1.0E-05 1.0E-04 1.0E-03 1.0E-02 1.0E-01 1.0E+00 1.0E+01 1.0E+02 1.0E+03

Pre ssu re (Torr)

Figure 5.4

Model 2002 page 27

Page 28

This page was intentionally left blank

page 28 Model 2002

Page 29

Both RS-232 and RS-485 communication interface boards are available as an option for the

Model 2002. The communication option boards allow data to be output to a host computer with

the appropiate interface. Connection to the RS-232 or RS-485 communication interface boards

are via a 9 pin D-subminiature female connector.

6.1 RS-232-E Interface Specifications

Format ................................. EIA standard RS-232-E, full-duplex, no handshaking, asynchronous

Data Rate......................................................................................................................... 9600 baud

Character Length ...................................................................................................... Eight data bits

Parity ................................................................................................................................. No parity

Stop bits.........................................................................................................................One stop bit

A common application of the RS232 version of the HPM-2002, is to connect the pressure gauge

directly to the serial port of a PC. This is done by first wiring a communication cable in the

SECTION 6

Communications Option Board

Figure 6.1

manner shown below.

PIN MNEMONIC SIGNAL DESCRIPTION

2 TX Transmit Data Transmits data within RS-232-E voltage levels

3 RX Receive Data Accepts data within RS-232-E voltage levels.

5 SG Signal Ground Establishes the common ground reference

potential for all interchange circuits

when communicating via RS232-E.

4 CTS Clear to send Host computer ready to accept data. (Reserved

for future use, not implemented by present

software.

8 RDY Ready Ready to receive data (always high, not

implemented by present software.

Model 2002 page 29

Page 30

6.2.1 Interface Connector Pin Assignments for RS-485

(full duplex-4 wire)(jumper position 2-3).

PIN MNEMONIC SIGNAL DESCRIPTION

2 TX+ Transmit + Differential data

signal levels to

8 TX - Transmit - the RS-485 bus

3 RX+ Receive + Differential data

4 RX- Receive - the RS-485 bus

6.2.2 For RS-485 (Half Duplex - 2 wire)

(jumper position 1-2).

}

signal levels from

}

PIN MNEMONIC SIGNAL DESCRIPTION

2 TX+/RX+ Transmit +/Receive + Differential data

signal levels to and from

8 TX-/RX- Transmit -/Receive - the RS-485 bus

6.2 Interface Connector Pin Assignments for RS-232

Note: an alternate method of connecting to a 2 wire bus is to leave the interface configured for

full duplex and externally connect pins 2 and 3 to the(+) bus and pins 4 and 8 to the (-) bus.

6.3 Operation of the Serial Interface

Communication with the serial interface of the Model 2002 is via an ASCII data string. In the RS-232

mode the command message consist only of a command string and the terminator. The attention

character and address string are not required, but if they are used they MUST be valid. If all components of the ASCII data string are valid the command will be accepted and executed. The RS-232

mode is sometimes referred to as point-to-point mode since only one device may be connected to the

controller at any given time.

}

page 30 Model 2002

A message to the Model 2002 in the RS-485 mode consist of an attention character followed by

the address string , the command string, and the terminator. If all components of the ASCII data

string are valid the command will be accepted and executed. The RS-485 mode is also referred to

as multipoint mode since up to 31 devices may be connected to the same controller in a network

scheme.