Page 1

Rack Mount Installation Guide

The rack mount kit is for securing these systems in an

SierraNet

™ M408 and

SierraFC

™ M164

(for securing the

l

1U Height Systems

1

Introduction

This manual describes the procedure to retrofit protocol

analysis 1U-sized systems for rack mounting at your site.

EIA 310-D 19-inch equipment rack. The rack mount kit

is included with some systems, or may be purchased

as an accessory for existing systems.

Two brackets, which are attached (as shown in this

document) to the side of the chassis, connect the

chassis to the mounting posts of the rack.

Some racks provide a power strip along the length

of one of the rear posts. If your rack has this feature,

the systems and the rack mounting brackets are

designed so that power can be supplied to the rear of the unit while network cables

and user control is available at the front (exposed) portion of the system.

Rack Mount Kits covered by this document include kits for the Sierra™ M124,

.

2

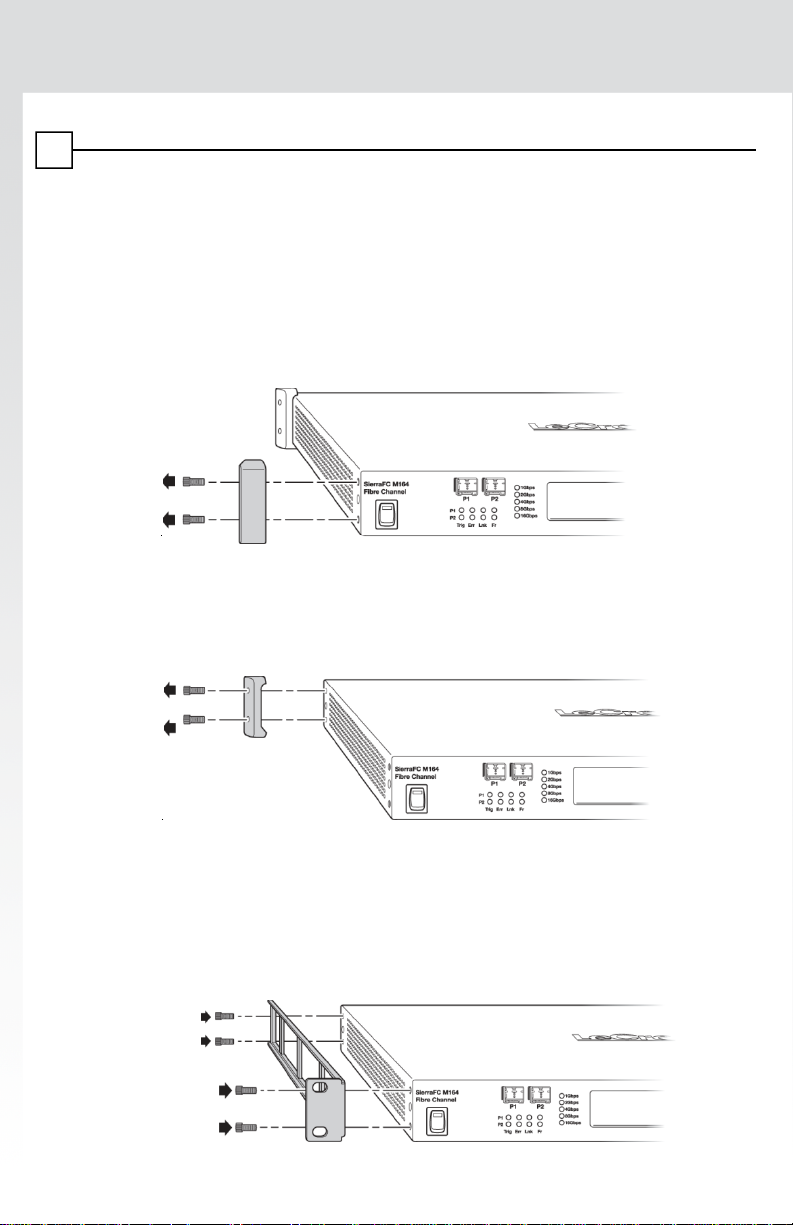

Rack Mount Kit Components

The kit includes the following components:

Quantity Part Description

2 Rack Mount Brackets

1 9/64” Allen Key

4 10-32 x 0.5 Screws

system chassis to the

rack)

You will also need the following

additional tools:

• Tape Measure

•Leve

• Phillips Screwdriver

2 Rack Mount Brackets

4 x Screws1 x Allen Key

Page 2

3

Planning

the

Installation

Most

rack

mounts

conformtothe

/

(

)ad

5/8(5

8

),

/( )ad5/8(58 ),

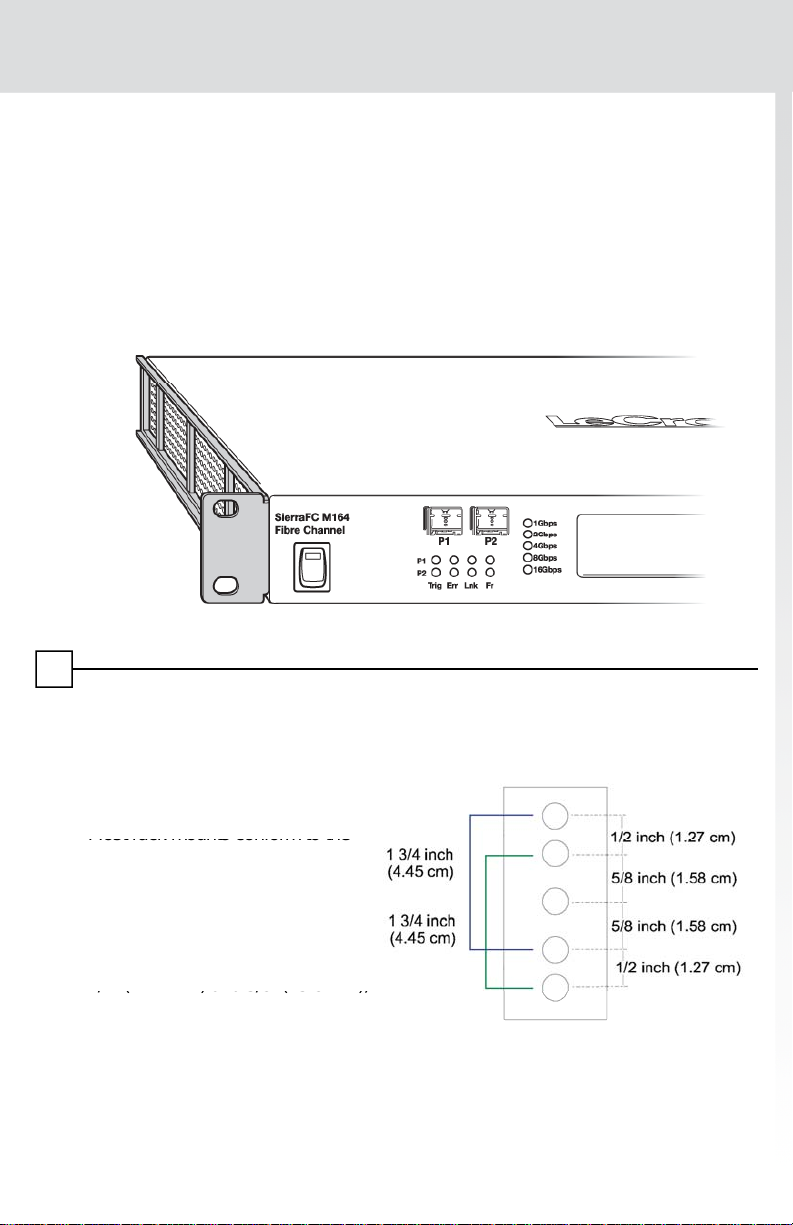

Installing the Rack Mount Brackets

Take the following steps to attach the two brackets to the system chassis:

Step 1: Place the system chassis on a sturdy surface.

Step 2: Using the 9/64” Allen Key provided, unscrew the two screws that

attach one of the front rubber bumpers to the system enclosure (see

illustration below). Keep these screws as they will be used to attach

the new rack mount brackets (see Steps 6-7).

Step 3: Repeat this procedure to remove the other front rubber bumper.

Step 4: Remove the two screws that attach one of the rear rubber bumpers to

the system enclosure (see illustration below):

Note: The SierraFC M164

is used as an example in

these illustrations. The steps

are identical for other 1U systems.

Step 5: Repeat this procedure to remove the other rear rubber bumper.

Step 6: Attach one of the brackets (shown below) to the left side of the system

chassis using the 9/64” Allen Key provided and four of the screws that

previously attached the rubber bumpers (these are the screws that

were removed in Steps 2-5). See illustration below.

Page 3

Step 7: Attach the other bracket to the right side of the system chassis (using

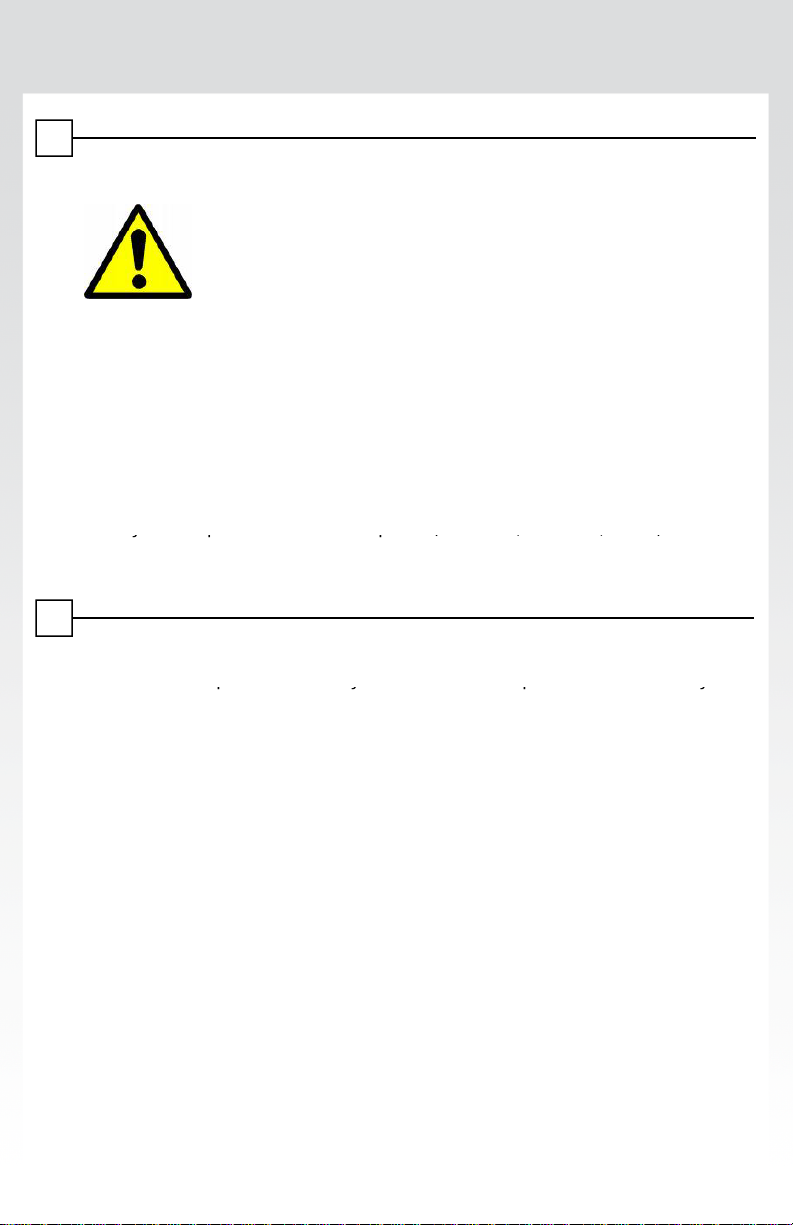

Planning the Installation

Most rack mounts conform to the

/

5/8” (15.8

/( )ad5/8(58 ),

the remaining four screws that were removed).

Note: Store the four rubber feet removed from the system in case you would

like to return the system to the original configuration at a later time.

4

Installing the system chassis in a rack mount enclosure requires some planning for

issues such as location, spacing, airflow and power supply. These issues are

reviewed below.

Location

EIA 310-D (RETMA) standard,

which provides mounting holes on

two vertical support rails which are

separated by 19” (480 mm). This

standard provides separation of the

spacing holes in increments of both

2” (12.7 mm) and

1

which allows for various multiples

of these spacing distances (such

as 1.75” [44.5 mm] which is

obtained by the separation of two 5/8” gaps and one 1/2” gap). See the diagram

on the right. The rack mount brackets supplied use 1.75” spacing.

mm),

Page 4

4

first be installed from the bottom, with the heaviest components

S

yq p(

,

,)

py p y

Step 3:

Make sure that your path to the rack is unobstructed

screws on each side of the unit

Use a Phillips screwdriver to tighten the

system

chassis

to

the

y

•

Phillips

Screwdriver

y

Planning the Installation (continued…)

WARNING: In order to provide stability to the rack, systems should

located in the bottom of the rack. If the rack is provided with

stabilizing devices, install the stabilizers before mounting or

servicing the unit in the rack.

A location for the system chassis should be planned taking these restrictions into

consideration.

pacing and Airflow

Allow, at a minimum, 1“ of air space around each side of the system, and 3-4” of

space in the rear of the system. This allows adequate airflow to cool the system.

The air temperature within the rack enclosure should not exceed 122°F (50°C).

Power Supply

The system requires a source of AC power (100-240V, 50-60 Hz, 230W) routed to

the rear of the system. All other controls and wiring connections are located on the

front panel of the system.

5

Installing the System Chassis into the Rack

Follow these steps to install the system chassis in an open rack that enables you

to slide the chassis in from the front.

Step 1: Position the chassis in the rack as follows:

Step 2: Use your tape measure and level to ensure that the supporting shelf and

the chassis are installed straight and level.

Step 4: Slide the unit into the rack and position using the attached L brackets so

that the slots in the brackets are positioned over the appropriate

mounting holes in the side rails of the rack.

Step 5: Securely fasten the unit into the rack by using the four 10-32 x 0.5

screws which are supplied with the rack mount kit, installing two of the

.

screws.

This concludes the rack mount installation.

.

PN: 920060-00 Rev B

v0812

Loading...

Loading...