Page 1

ADDENDUM TO

MODEL 101E

OPERATORS MANUAL

(P/N 04740 REV. A)

FOR

MODEL 102E

TOTAL REDUCED SULFUR ANALYZER

with

MODEL 501 TRS

THERMAL CONVERTER

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone: 858-657-9800

Fax: 858-657-9816

Email: Api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

04988

REV. A1

© 2005 T-API 18 October 2005

Page 2

Page 3

M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

TABLE OF CONTENTS

1. PREFACE ...................................................................................................................................... 1

1.1. Reference Numbering convention...............................................................................................2

2. SPECIFICATIONS, APPROVALS AND WARRANTY.......................................................................... 3

2.1. Specifications..........................................................................................................................3

2.1.1. M501-TRS Specifications ....................................................................................................3

2.2. EPA Equivalency Designation.....................................................................................................3

2.3. CE Mark Compliance ................................................................................................................4

3. GETTING STARTED....................................................................................................................... 5

3.1. Unpacking the M102E ..............................................................................................................5

3.2. Unpacking the M501-TRS .........................................................................................................5

3.2.1. M501-TRS Ventilation Clearance: ........................................................................................6

3.3. Internal Layouts......................................................................................................................7

3.4. Internal Pneumatic Flow of the M102E & the M501-TRS ................................................................8

3.5. Rear Panel Layout for the M102E & M501-TRS .............................................................................9

3.6. Initial Setup .........................................................................................................................10

3.6.1. Electrical Connections:..................................................................................................... 10

3.6.1.1. M102E Analog Output Connections.............................................................................. 10

3.6.1.2. M501-TRS Alarm Output Connections .......................................................................... 11

3.6.2. Pneumatic Connections:...................................................................................................11

3.6.2.1. Connections with Internal Valve Options Installed..........................................................14

3.7. Initial Operation ....................................................................................................................17

3.7.1. Startup / Warm Up of the M102E.......................................................................................17

3.7.2. Functional Check of the M102E..........................................................................................17

3.7.3. Startup / Warm Up of the M501-TRS..................................................................................18

3.8. Initial Calibration...................................................................................................................19

4. OPTIONAL HARDWARE AND SOFTWARE .................................................................................... 21

4.1. Rack Mount Kits (Options 20a, 20b, 21, 22 & 81)....................................................................... 21

4.2. Calibration Valves Options ......................................................................................................21

4.2.1. Zero/Span Valves (Option 50) & Internal Zero/Span Gas Generator (Option 51)....................... 21

4.3. Additional Manuals.................................................................................................................24

4.3.1. Printed Manuals (P/N 049880000) ..................................................................................... 24

4.3.2. Addendum on CD (Part number 049880200) ....................................................................... 24

5. M102E OPERATING INSTRUCTIONS........................................................................................... 25

5.1.1. M102E Analog Output Signals ........................................................................................... 25

5.1.2. Setting the M102E Gas Measurement Mode......................................................................... 26

5.2. SETUP – DIAG: Using the Diagnostics Functions......................................................................... 26

5.2.1. M102E Analog I/O Configuration........................................................................................26

5.2.2. M102E Test Channel Output .............................................................................................27

5.3. SETUP – COMM: Setting Up the M102E’s Communication Ports ....................................................27

5.3.1. M102E ID Code............................................................................................................... 27

5.3.2. M102E Ethernet Host Name .............................................................................................. 27

5.4. Remote Operation of the Analyzer............................................................................................28

5.4.1. Control Inputs ................................................................................................................28

5.4.2. Using the M102E with a Hessen Protocol Network ................................................................29

5.4.2.1. M102E Hessen Protocol Gas ID List. ............................................................................29

5.4.2.2. Setting Hessen Protocol Status Flags ...........................................................................30

6. M501-TRS OPERATING INSTRUCTIONS ..................................................................................... 31

6.1. Basic M501-TRS Controls........................................................................................................ 31

6.2. To Display The Current Temperature:....................................................................................... 32

6.3. To Manually Adjust the Converter Oven Temperature: ................................................................ 33

6.4. Autotune the Temperature Controller: ......................................................................................34

6.4.1. Initiating the Autotune Process: ........................................................................................34

6.4.2. Aborting the Autotune Process:.........................................................................................35

6.5. M501TRS Alarm Relay Adjustment ...........................................................................................35

7. CALIBRATION PROCEDURES...................................................................................................... 37

7.1. M102E Calibration .................................................................................................................37

7.2. M501-TRS Calibration ............................................................................................................37

05514 Rev A1 i

Page 4

M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

8. INSTRUMENT MAINTENANCE..................................................................................................... 39

8.1. Additional and Updated Maintenance Procedures........................................................................40

8.1.1. Maintaining the SO

8.1.1.1. Predicting When the SO

8.1.1.2. Checking the Function of the SO

8.1.1.3. Changing the SO

9. THEORY OF OPERATION............................................................................................................. 43

9.1. Measurement Principle ...........................................................................................................43

9.1.1. TRS Conversion ..............................................................................................................43

9.1.2. SO

Ultraviolet Fluorescence ............................................................................................. 43

2

9.2. The UV Light Path..................................................................................................................46

9.2.1. UV Lamp Shutter & PMT Offset.......................................................................................... 46

9.3. Pneumatic Operation..............................................................................................................46

9.3.1. Sample gas Flow.............................................................................................................46

9.3.2. M501 SO

Scrubber ......................................................................................................... 46

2

9.4. Electronic Operation...............................................................................................................47

9.4.1. Sensor Module................................................................................................................ 47

9.4.1.1. Sample Chamber......................................................................................................48

9.4.1.2. Sample Chamber Heating Circuit.................................................................................48

9.4.2. M501-TRS electronics ......................................................................................................49

9.4.2.1. Thermal Switch ........................................................................................................49

9.4.2.2. Temperature Alarms and Alarm Output ........................................................................ 50

10. TROUBLESHOOTING & REPAIR ................................................................................................ 51

10.1.1. Fault Diagnosis with Warning Messages ............................................................................ 51

10.1.1.1. M102E Warning Messages ........................................................................................ 51

10.1.1.2. M501-TRS Error Codes.............................................................................................51

10.1.2. Fault Diagnosis with Test Functions.................................................................................. 52

10.2. M501-TRS Trouble shooting ..................................................................................................53

10.2.1. TRS Converter Not Heating:............................................................................................ 53

10.3. Other Performance Problems ................................................................................................. 53

10.3.1. Excessive noise.............................................................................................................53

10.4. Subsystem Checkout............................................................................................................ 54

10.4.1. Checking the Efficiency of the M501-TRS SO

10.4.2. Checking the Efficiency of the M501-TRS TRS Æ SO

10.5. Additional Repair Procedures ................................................................................................. 55

10.5.1. UV Lamp Adjustment and/or Replacement ........................................................................55

10.5.1.1. Adjusting the UV Lamp (Peaking the Lamp) ................................................................56

10.5.1.2. Replacing the UV Lamp............................................................................................57

10.5.2. Replacing the UV filter/lens .............................................................................................. 58

10.5.3. Replacing the PMT, HVPS or TEC......................................................................................59

10.5.4. M102E PMT Hardware Calibration (FACTORY CAL) .............................................................. 61

10.5.5. Replacing the TRS Converter Heating Tube .......................................................................63

10.6. Manually Programming the M501-TRS Temperature Controller ...................................................64

10.6.1. Temperature Controller Primary Menu Parameters..............................................................65

10.7. Technical Assistance ............................................................................................................67

Scrubber ...........................................................................................40

2

Scrubber Material ............................................................................ 41

2

Scrubber Should Be Replaced. ................................................. 40

2

Scrubber................................................................... 41

2

Scrubber....................................................... 54

2

Converter............................................ 54

2

LIST OF APPENDICES

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION

APPENDIX A-1: M102E Software Menu Trees, Revision A.2

APPENDIX A-2: Setup Variables For Serial I/O, Revision A.2

APPENDIX A-3: Warnings and Test Functions, Revision A.2

APPENDIX A-4: M102E Signal I/O Definitions, Revision A.2

APPENDIX A-5: M102E iDAS Functions, Revision A.2

APPENDIX B - M102E SPARE PARTS LIST

APPENDIX D - ELECTRONIC SCHEMATICS

ii 05514 Rev A1

Page 5

M102E/M501 TRS PREFACE

(Addendum to M101E Manual - P/N 04740 Rev A)

LIST OF FIGURES

Figure 3-1: M102E Internal Layout ...................................................................................7

Figure 3-2: M501-TRS Internal Layout...............................................................................7

Figure 3-3: Internal Pneumatic Diagram of the M102E Standard Configuration........................ 8

Figure 3-4: M102E Rear Panel Layout................................................................................9

Figure 3-5: M501-TRS Rear Panel Layout...........................................................................9

Figure 3-6: Analog Output Connector .............................................................................. 10

Figure 3-7: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator ........... 12

Figure 3-8: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas .................. 12

Figure 3-9: Basic Pneumatic Connections for Units with Zero/Span Valve Option ................... 15

Figure 3-10: Pneumatic Connections for Formal Calibration of Units with an IZS Valve Option ... 16

Figure 3-11: Pneumatic Connections for Informal Calibration Checks of Units with IZS Valve

Option ...................................................................................................... 16

Figure 3-12: M501-TRS Temperature Controller Startup ..................................................... 18

Figure 4-1: Internal Pneumatic Diagram of the M102E With Z/S Option Installed................... 22

Figure 4-2: Internal Pneumatic Diagram of the M102E with IZS Options Installed.................. 23

Figure 5-1: Analog Output Connector Key ........................................................................ 25

Figure 5-2: Control Inputs with local 5 V power supply ...................................................... 28

Figure 5-3: Control Inputs with external 5 V power supply ................................................. 29

Figure 6–1: M501-TRS Temperature Controls ................................................................... 31

Figure 9-1: UV Absorption in the M102E Reaction Cell ....................................................... 44

Figure 9-2: M102E Sensor Module .................................................................................. 47

Figure 9-3: M102E Sample Chamber............................................................................... 48

Figure 9-4: M501-TRS Electronic Block Diagram ............................................................... 49

Figure 10-1: Shutter Assembly - Exploded View.................................................................. 57

Figure 10-2: Disassembling the Shutter Assembly............................................................... 58

Figure 10-3: PMT Assembly - Exploded View ...................................................................... 59

Figure 10-4: Pre-Amplifier Board Layout............................................................................ 62

LIST OF TABLES

Table 2-1: Model 102E Basic Unit Specifications..................................................................3

Table 3-1: TRS – SO

Table 3–2: Analog output Pin Outs................................................................................... 10

Table 3-3: Inlet / Outlet Connector Nomenclature............................................................. 11

Table 3-4: NIST-SRM's Available for Traceability of H2S & SO

Table 4-1: Zero/Span Valve Operating States.................................................................. 22

Table 4-2: IZS Valve Operating States ........................................................................... 23

Table 5-1 M102E gas Measurement Modes...................................................................... 26

Table 5-2: Analog Output Pin Assignments ....................................................................... 26

Table 5-3: Test Parameters Available for Analog Output A4 ................................................ 27

Table 5-4: M102E Control Input Pin Assignments .............................................................. 28

Table 5-5: M102E Default Hessen Gas ID’s....................................................................... 29

Table 5-6: Default Hessen Status Bit Assignments ............................................................ 30

Table 6-1: M501-TRS Temperature Controls and Definitions ............................................... 32

Table 8-1: M102E Preventive Maintenance Schedule.......................................................... 39

Table 10-1: Test Functions - Possible Causes for Out-Of-Range Values ................................... 51

Table 10-2: Test Functions - Possible Causes for Out-Of-Range Values ................................... 52

Table 10-3 – Temperature Controller – Primary Parameter Settings......................................... 66

Table 10-4 – Temperature Controller – Primary Parameter Settings......................................... 67

Switching Valve Operating Modes....................................................... 8

2

Calibration Gases .................... 14

2

05514 Rev A1 iii

Page 6

Page 7

M102E/M501 TRS PREFACE

(Addendum to M101E Manual - P/N 04740 Rev A)

1. PREFACE

NOTE

The information contained in this addendum is pertinent to M102E analyzers running

software revision A.2. Some or all of the information may not be applicable to previous

revision of that software.

The software revision your analyzer is running is displayed in the upper left-hand

corner of the display any time the instrument is in SETUP mode.

This addendum is based on the Model 101E Operators Manual (P/N 04740, REV. A). In most ways

the M102E is identical to the M102E in design and operation, therefore most of the basic set up

information, operating instructions as well as calibration, maintenance, troubleshooting and repair

methods are found in that manual.

This addendum documents only those areas where the M102E is different in design or operating

method from the M102E.

Specifically:

• Areas where updates and improvements to the M10XE software have been implemented

since the publication date of the M101E Manual - P/N 04740 Rev A.

• Corrections of errors and omissions discovered in the M101E Manual - P/N 04740 Rev A.

• EXTERNAL TRS CONVERSION: Like the M101E, which converts H

measures the amount of SO

converts total reduced sulfur (TRS) gases into SO

present using a UV fluorescence technique, the M102E

2

before measuring the SO2 using the

2

S to SO2, then

2

same UV fluorescence method.

Unlike the M102E, which performs the H

S Æ SO2 conversion internally, the M102E

2

requires an external TRS converter, in this case a Teledyne Instruments M501-TRS.

Therefore this addendum includes instructions and information regarding:

• Areas of operation and setup of the M102 that depart from the method described by

the M101E operator’s manual because the TRS Æ SO

conversion is performed

2

externally.

• The proper set up and operation on the M501-TRS.

05514 Rev A1 1

Page 8

PREFACE M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

1.1. Reference Numbering convention

Unless otherwise specified, chapter, section, figure and table reference numbers referred to within

this text are relative to this document.

EXAMPLE: “Figure 2-1” refers to the figure, within this document, labeled as 2-1.

References to chapters, sections, figures and tables in the original document will be labeled as

such.

EXAMPLE: “Figure 6.1 of the M101E Operators Manual (P/N 04470, REV. A)”.

User Notes:

2 05514 Rev A1

Page 9

M102E/M501 TRS SPECIFICATIONS, APPROVALS AND WARRANTY

(Addendum to M101E Manual - P/N 04740 Rev A)

2. SPECIFICATIONS, APPROVALS AND

WARRANTY

2.1. Specifications

There are no significant differences between the performance specifications for the M102E and the

M102E as listed in Section 2.1 of the M101E Manual - P/N 04740 Rev A.

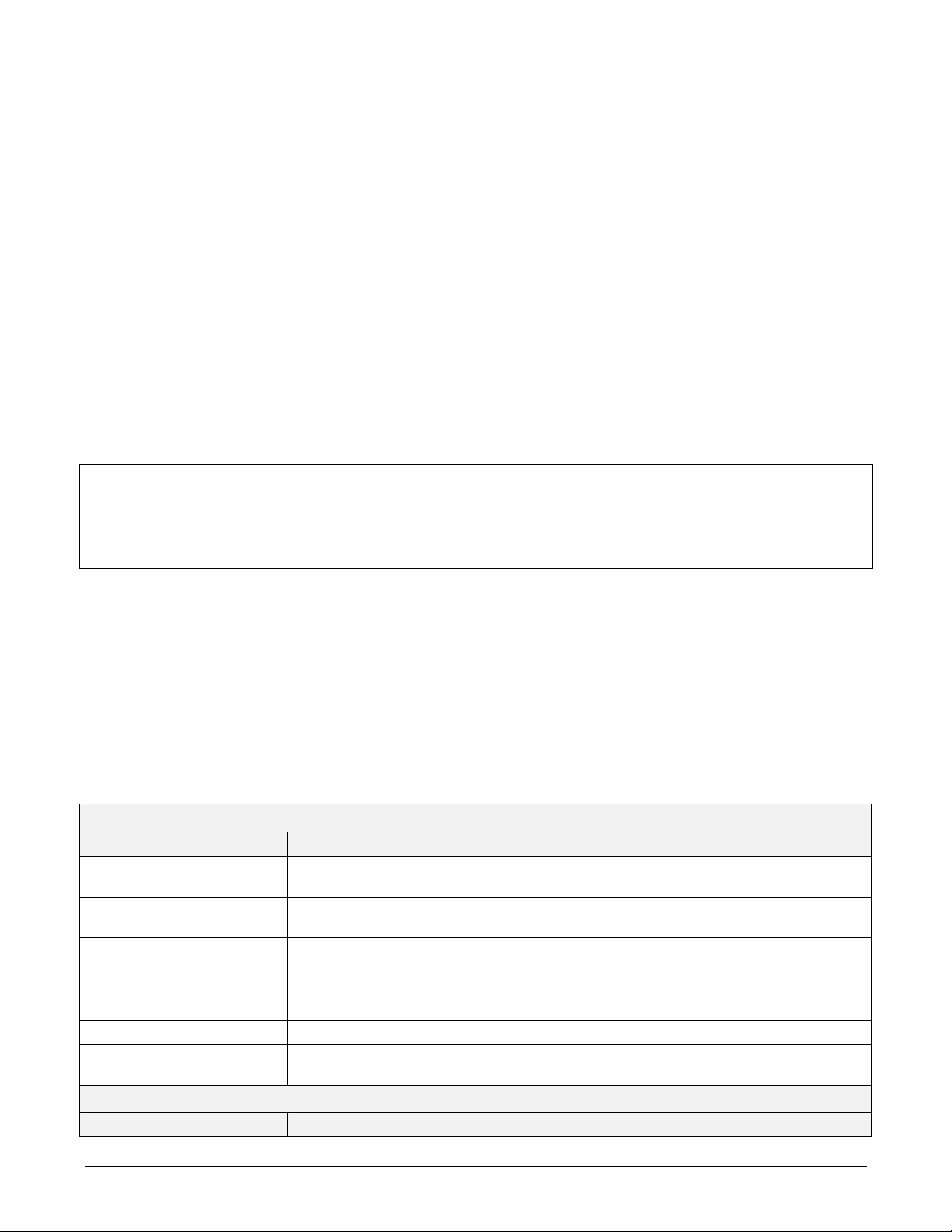

2.1.1. M501-TRS Specifications

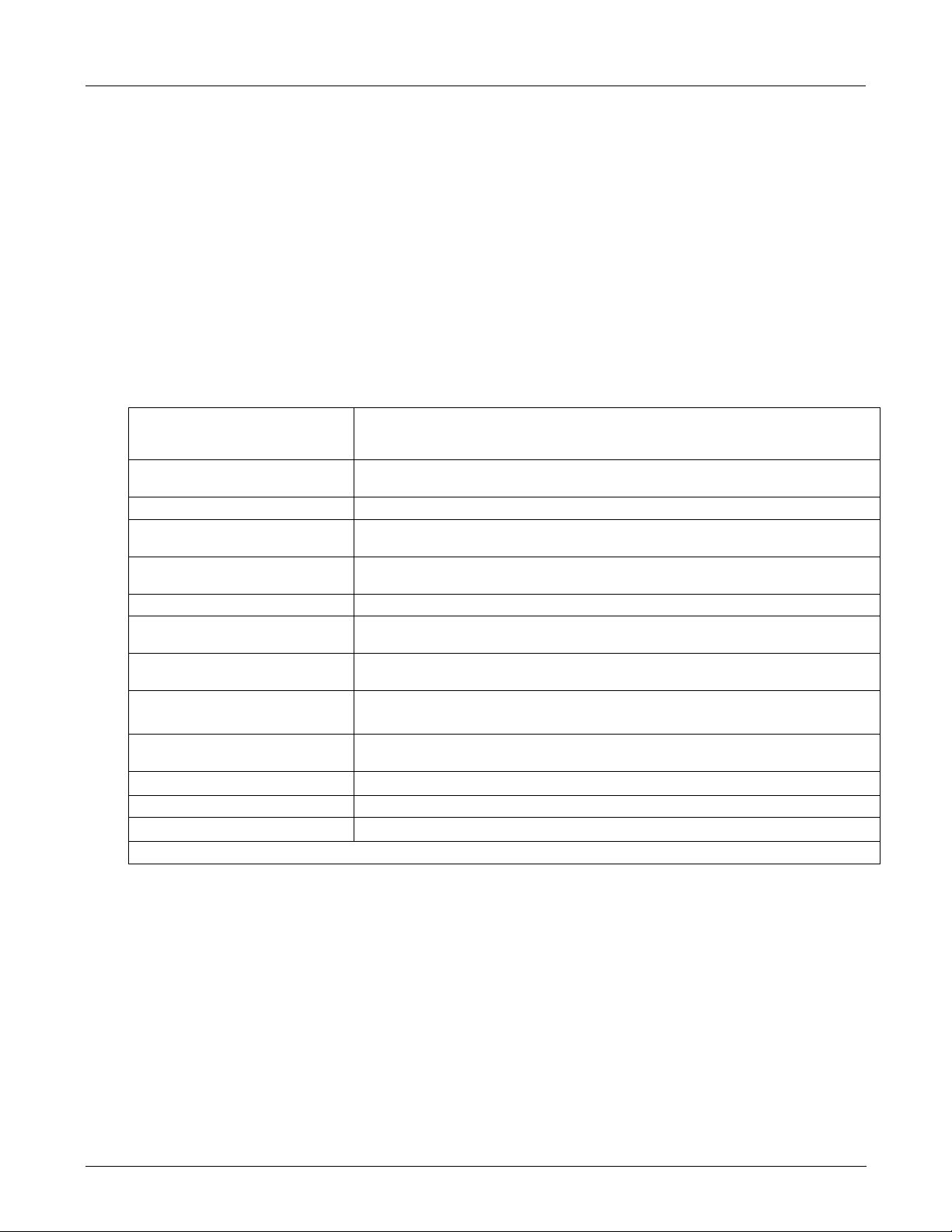

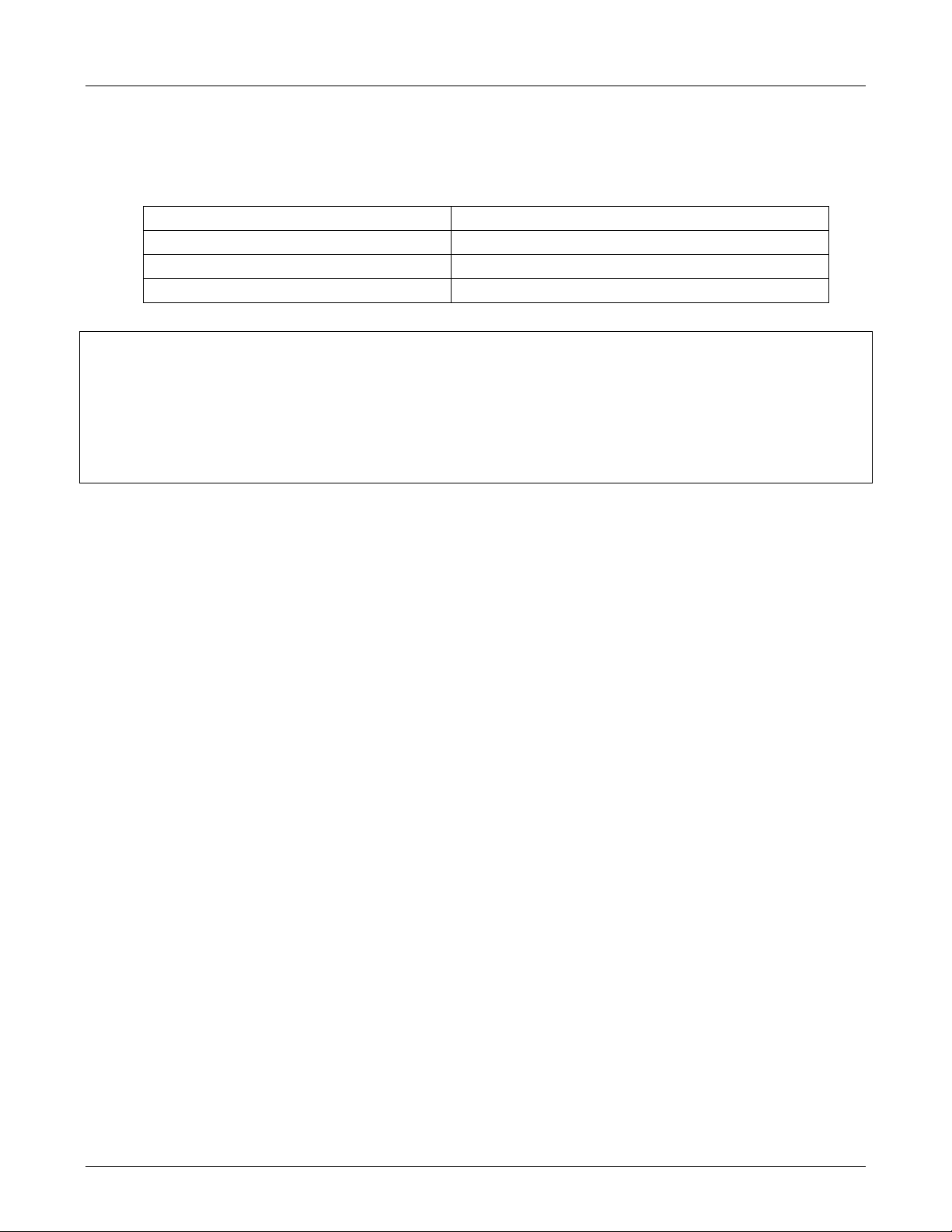

Table 2-1: Model 102E Basic Unit Specifications

S >95%

H

Minimum Converter Efficiency

Maximum TS Concentration for

specified conversion efficiency

Sample Flow Rate 650cc/min. ±10% - driven by M102E pneumatic system

Optimum Converter

Temperature

Maximum Converter

Temperature

Dimensions H x W x D 7" x 17" x 22" (178 mm x 432 mm x 559 mm)

Weight

AC Power Rating

Internal Alarms

Alarm Output Relay

Alarm Output Rating

Environmental Installation category (over-voltage category) II; Pollution degree 2

Certifications

For indoor use at altitudes ≤ 2000m only

2

COS >90%

CS

>90%

2

20 ppmv

1000°C (factory setup)

1100°C

16 lbs (8 kg)

26 lbs (12 kg) CE version

115 V, 50/60 Hz - 400 Watts;

230 V, 50/60 Hz - 575 Watts; CE Version

High Alarm Point: 1050°C

Low Alarm Point: 950°C

SPST - 1 point: Alarm output is energized should either the temperature

controller’s high or low internal alarm set points be activated.

220V AC/30V DC, 1A (resistive load)

IEC 1010-1 / 61010-1:93 (includes A1) + A2:95,

2.2. EPA Equivalency Designation

No EPA equivalency standards exist for TRS measurement, however, the M102E analyzer qualifies

for EPA equivalency designation as Reference Method Number EQSA-0495-100 per 40 CFR Part 53

when operated under the following conditions:

• Measurement Mode: SO2 single gas mode.

• Range: Any range from 50 parts per billion (ppb) to 10 parts per million (ppm).

o

• Ambient temperature range of 5

• Line voltage range of 105-125 VAC or 220-240 VAC, at 50 or 60 Hz.

05514 Rev A1 3

C to 40 oC.

Page 10

SPECIFICATIONS, APPROVALS AND WARRANTY M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

• Sample filter: Equipped with PTFE filter element in the internal filter assembly.

• Sample flow of 650 +/- 65 cc/min.

• Vacuum pump (internal or external) capable of 14"Hg Absolute pressure @ 1 slpm or

better.

• Software settings:

Dynamic span OFF

Dynamic zero OFF

Dilution factor OFF

AutoCal ON or OFF

Dual range ON or OFF

Auto-range ON or OFF

Temp/Pressure compensation ON

Under the designation, the analyzer may be operated with or without the following optional

equipment:

• Rack mount with chassis slides.

• Rack mount without slides, ears only.

• Zero/span valve options.

• Internal zero/span (IZS) option with either:

• SO

• SO

• 4-20mA isolated analog outputs.

• Status outputs.

• Control inputs.

• RS-232 output.

• Ethernet output.

• Zero air scrubber.

• 4-20mA, isolated output.

permeation tube - 0.4 ppm at 0.7 liter per minute; certified/uncertified.

2

permeation tube - 0.8 ppm at 0.7 liter per minute; certified/uncertified. Under the

2

designation, the IZS option cannot be used as the source of calibration.

2.3. CE Mark Compliance

See Section 2.3 of the M101E Manual - P/N 04740 Rev A

User Notes:

4 05514 Rev A1

Page 11

M102E/M501 TRS GETTING STARTED

(Addendum to M101E Manual - P/N 04740 Rev A)

3. GETTING STARTED

3.1. Unpacking the M102E

Unpack the M102E as per the directions ins Section 3.1 of the M101E Manual - P/N 04740 Rev A.

1. There are no shipping screws to be removed in the M102E.

3.2. Unpacking the M501-TRS

2. Inspect the shipping package for external damage. If damaged, please advise the shipper first,

then Teledyne Instruments.

3. Carefully remove the top cover of the converter and check for internal shipping damage.

• Remove the screws fastening the top cover to the unit (four per side).

• Lift the cover straight up.

CAUTION

Never disconnect electronic circuit boards, wiring harnesses or

4. Inspect the interior of the instrument to make sure all components are in good shape and

properly seated.

5. Check the connectors of the various internal wiring harnesses and pneumatic hoses to make

sure they are firmly and properly seated.

6. There are no shipping screws to be removed in the M501-TRS.

7. Replace the top cover.

The M501-TRS will not operate properly with the top cover removed.

electronic subassemblies while the unit is under power.

NOTE

The air cooling required to stabilize the temperature of the converter tube is dependent

on air flow patterns that only exist with the top cover in place.

Without the top cover in place, the thermal cutout may overheat and shut off the

heating element.

05514 Rev A1 5

Page 12

GETTING STARTED M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

3.2.1. M501-TRS Ventilation Clearance:

Whether the M501-TRS is set up on a bench or installed into an instrument rack, be sure to leave

sufficient ventilation clearance.

AREA MINIMUM REQUIRED CLEARANCE

Back of the instrument 10 cm / 4 inches

Sides of the instrument 2.5 cm / 1 inch

Above and below the instrument. 2.5 cm / 1 inch

NOTE

If the M501-TRS is installed in an instrument rack or any type of enclosure, make sure

that the rack/enclosure itself is adequately ventilated.

Failure to provide proper ventilation can result in the ambient temperature exceeding

the maximum operating temperature specification for the M102E (40°C)

6 05514 Rev A1

Page 13

M102E/M501 TRS GETTING STARTED

g

g Sy

/

y

(Addendum to M101E Manual - P/N 04740 Rev A)

3.3. Internal Layouts

Figures 3-1 & 3-3 supersede Figure 3-9 of the M101E Manual - P/N 04740 Rev A.

Front Panel

Reaction Cell

Hydrocarbon Scrubber

Hidden from view b eneath

Reaction Cell

ON/OFF

SWITCH

Particulate Filter

Pump Assy

UV Source Lap

230VAC

Transformer

(Option)

PMT Preamp PCA

PMT Housin

Rela

PMT Coolin

Board

IZS Permeation Tube and Oven

(+12 VDC)

stem

PS2

(Option)

Span/Cal Valves

PS1

(+5 VDC; ±15VDC)

(Option)

PC

104 Card

Rear Panel

Mother

Board

Vacuum

Manifold

Power Supply

UV Lamp

ON/OFF

SWITCH

Figure 3-1: M102E Internal Layout

Temperature

Controller

230VAC

Transformer

(Option)

Converter Tube Cover

Converter Heater located

underneath Cover

SO2

Scrubber

Converter Tube

Converter Heater

Control Relay

Alarm

Outputs

Figure 3-2: M501-TRS Internal Layout

05514 Rev A1 7

Page 14

GETTING STARTED M102E/M501 TRS

R

R

A

(Addendum to M101E Manual - P/N 04740 Rev A)

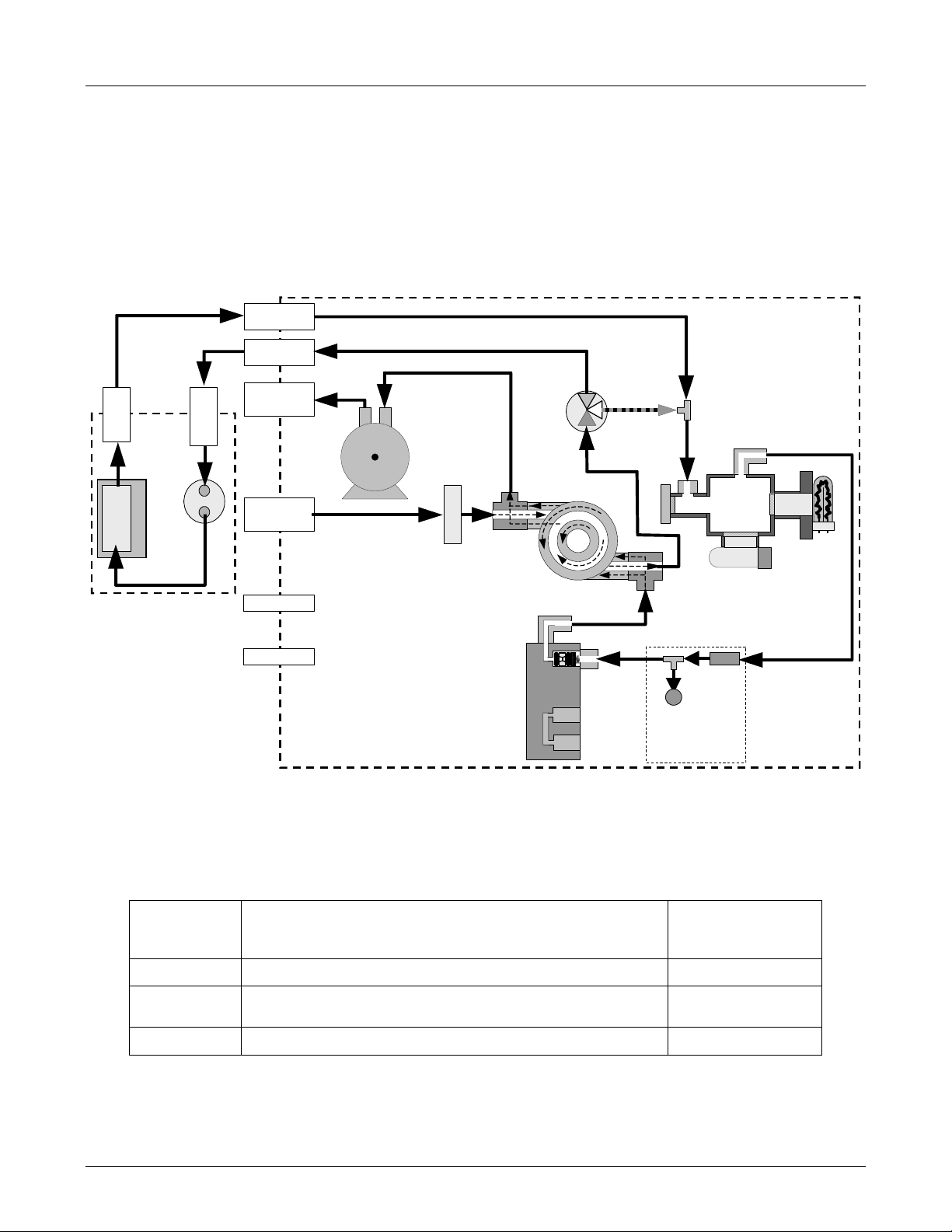

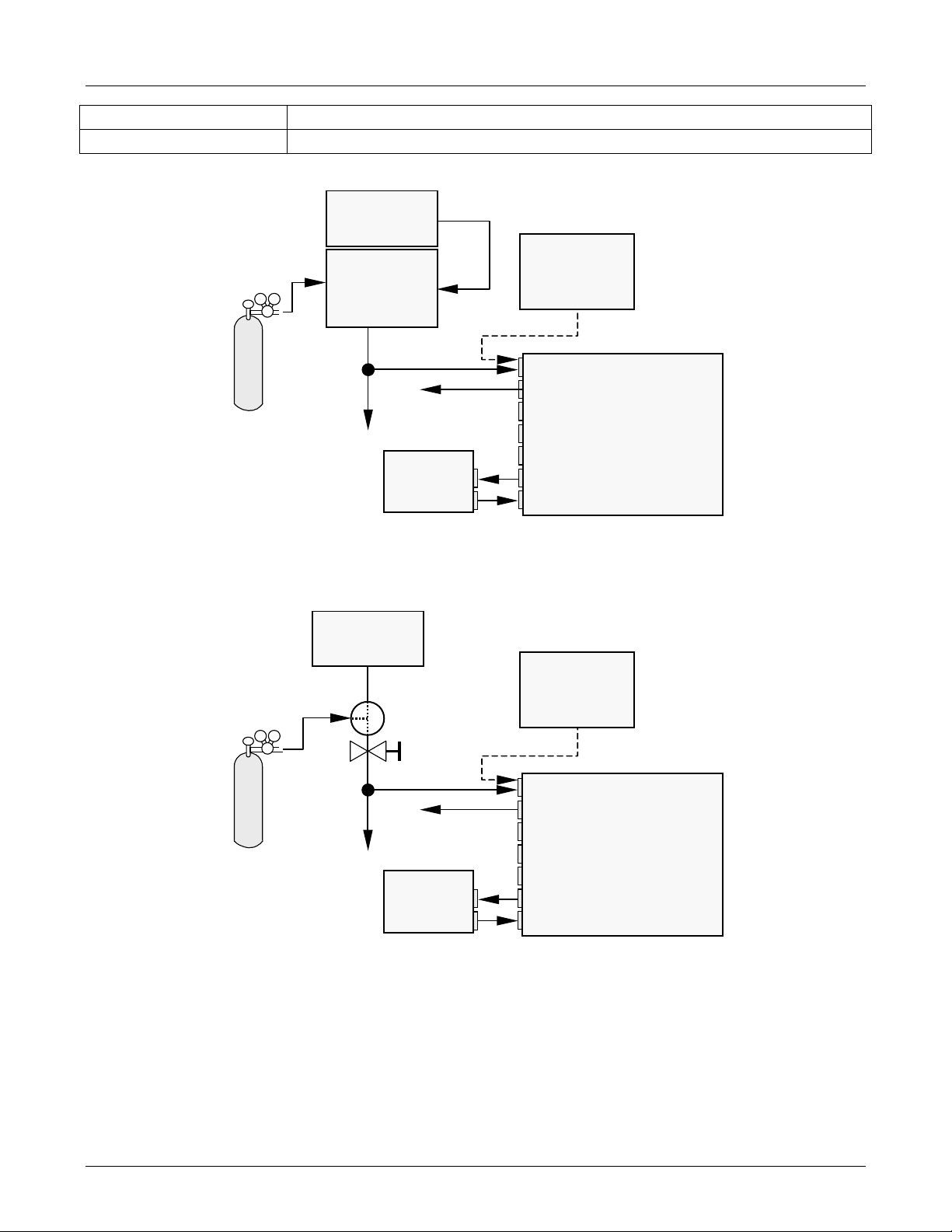

3.4. Internal Pneumatic Flow of the M102E & the

M501-TRS

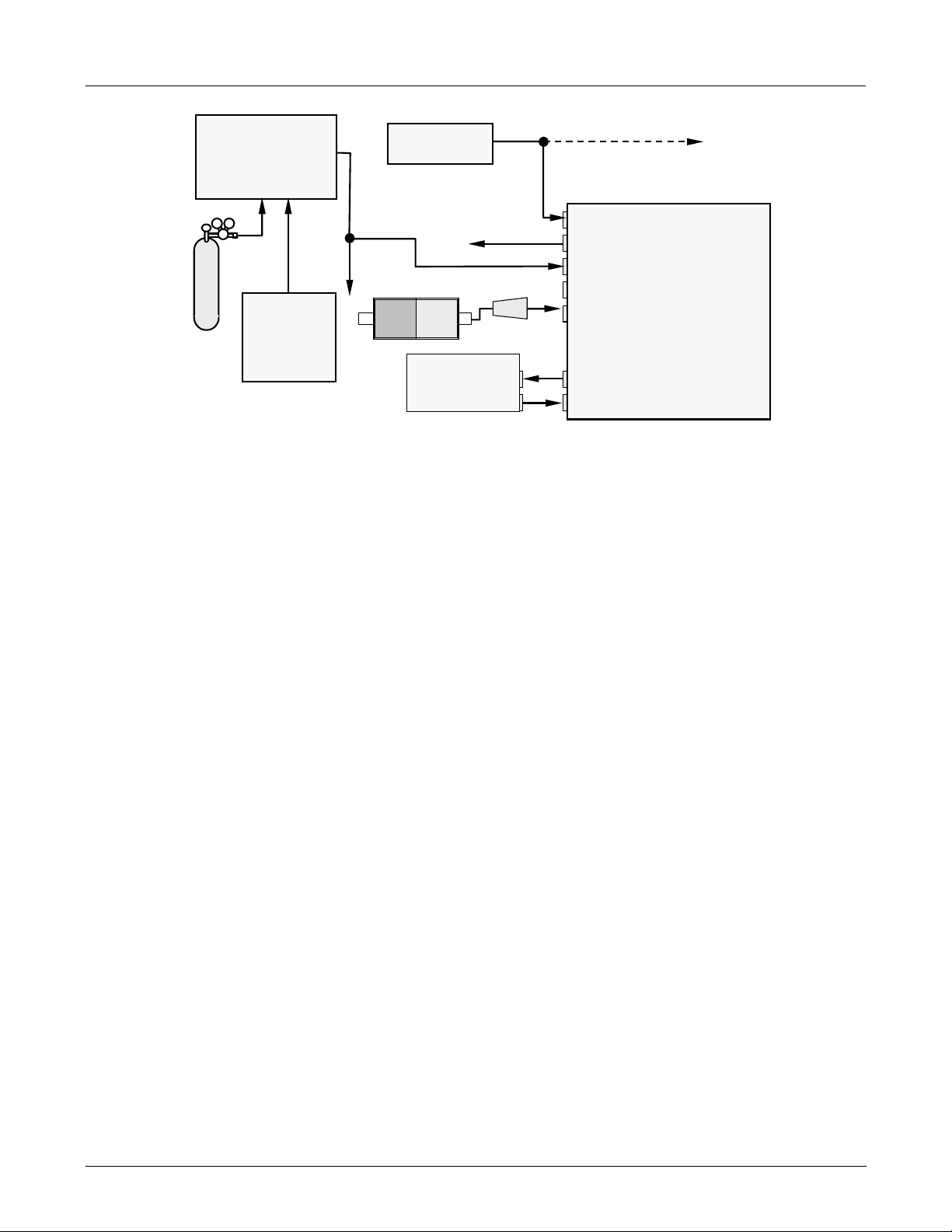

Figure 3-3 shows the internal pneumatic flow of the M102E in its Standard configuration. For

information on instruments in which one of the various zero/span valve options refer to Figures 52 and 5-3.

TO

ANALYZER

2

SO

Æ

TRS

CONVERTER OVEN

SO

FROM

ANALYZER

r

2

Scrubbe

FROM

CONVERTER

TO

CONVERTER

EXHAUST GAS

OUTLET

SAMPLE GAS

INLET

INSTRUMENT

M102E

CHASSIS

KICKER EXHAUST

PUMP

SAMPLE FILTER

TO PUMP

TRS / SO

2

MODE

VALVE

HYDROCARBON

SCRUBBER

(KICKER)

Gas Flow in SO

3

1

2

phase

2

of multigas mode or

when i n SO

2

measurement mode

SAMPLE

CHAMBER

PMT

UV

LAMP

M501-TRS

ZERO AIR INLET

SPAN GAS INLET

VACUUM MANIFOLD

EXHAUST TO OUTE

LAYER OF KICKE

FLOW

CONTROL

ASSY

SAMPLE

PRESSURE

SENSOR

FLOW / PRESSURE

SENSOR PC

FLOW

SENSOR

Figure 3-3: Internal Pneumatic Diagram of the M102E Standard Con figuration.

Switching Valve Operating Modes

2

Bypasses M501-TRS

CONNECTION

(FIG. 5-2)

2 Æ 3

2 Æ 1

- -

GAS

MODE

TRS

SO2

TRS –SO2

Table 3-1: TRS – SO

CONDITION OF TRS –SO2 SWITCHING VALVE VALVE PORT

Open to SO

Switches between above two states every 10 minutes.

Scrubber and Molybdenum Converter

2

Open to directly to Sample Chamber.

8 05514 Rev A1

Page 15

M102E/M501 TRS GETTING STARTED

(Addendum to M101E Manual - P/N 04740 Rev A)

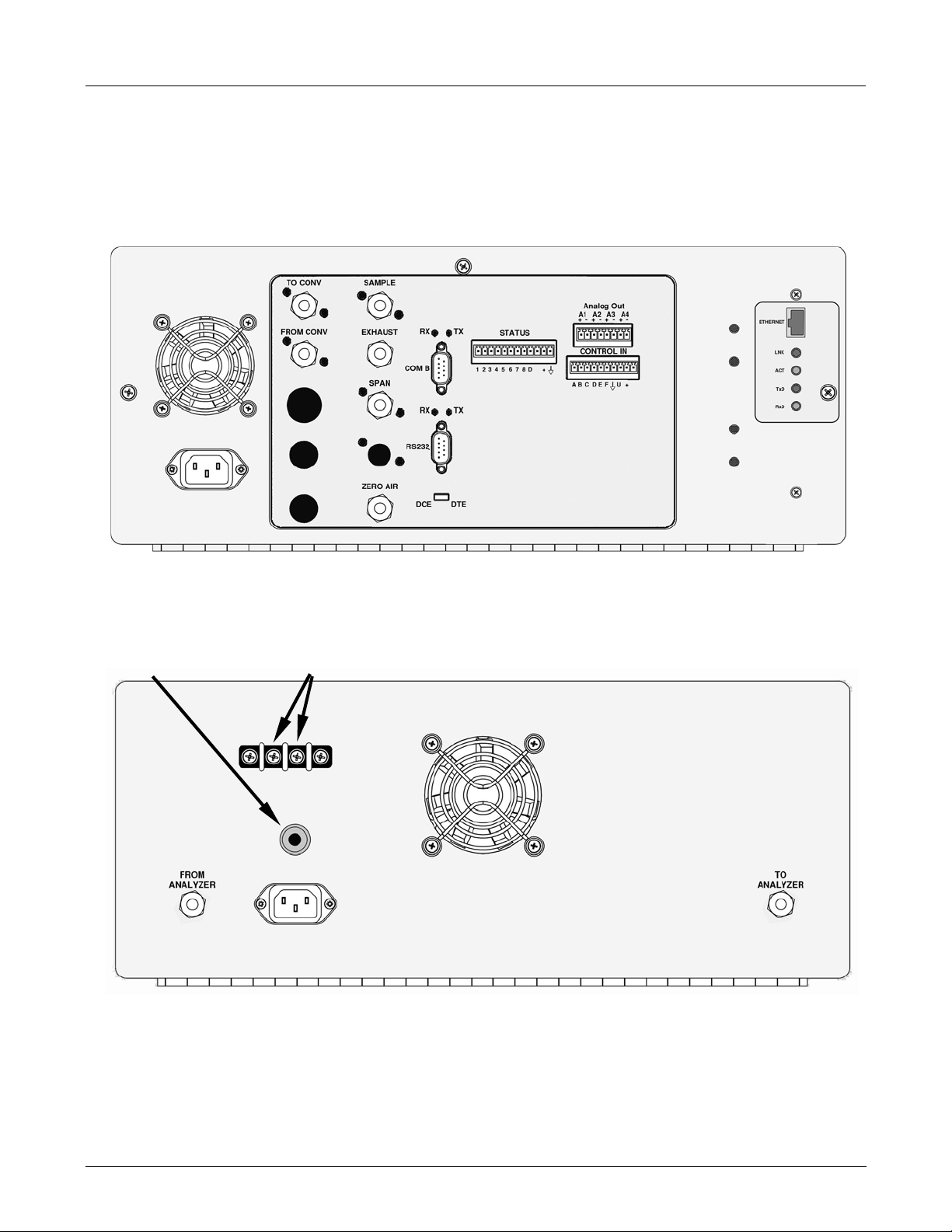

3.5. Rear Panel Layout for the M102E & M501-TRS

Figures 3-4 & 3-5 supersede Figure 3-2 of the M101E Manual - P/N 04740 Rev A.

5 Amp

Slow-Blow

Fuse

Figure 3-4: M102E Rear Panel Layout

Alarm Output

Connections

Figure 3-5: M501-TRS Rear Panel Layout

05514 Rev A1 9

Page 16

GETTING STARTED M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

3.6. Initial Setup

3.6.1. Electrical Connections:

The electrical connections for the M102E are the same as those described in Section 3.1.1 of the

M101E Manual - P/N 04740 Rev A except for the test channel analog output:

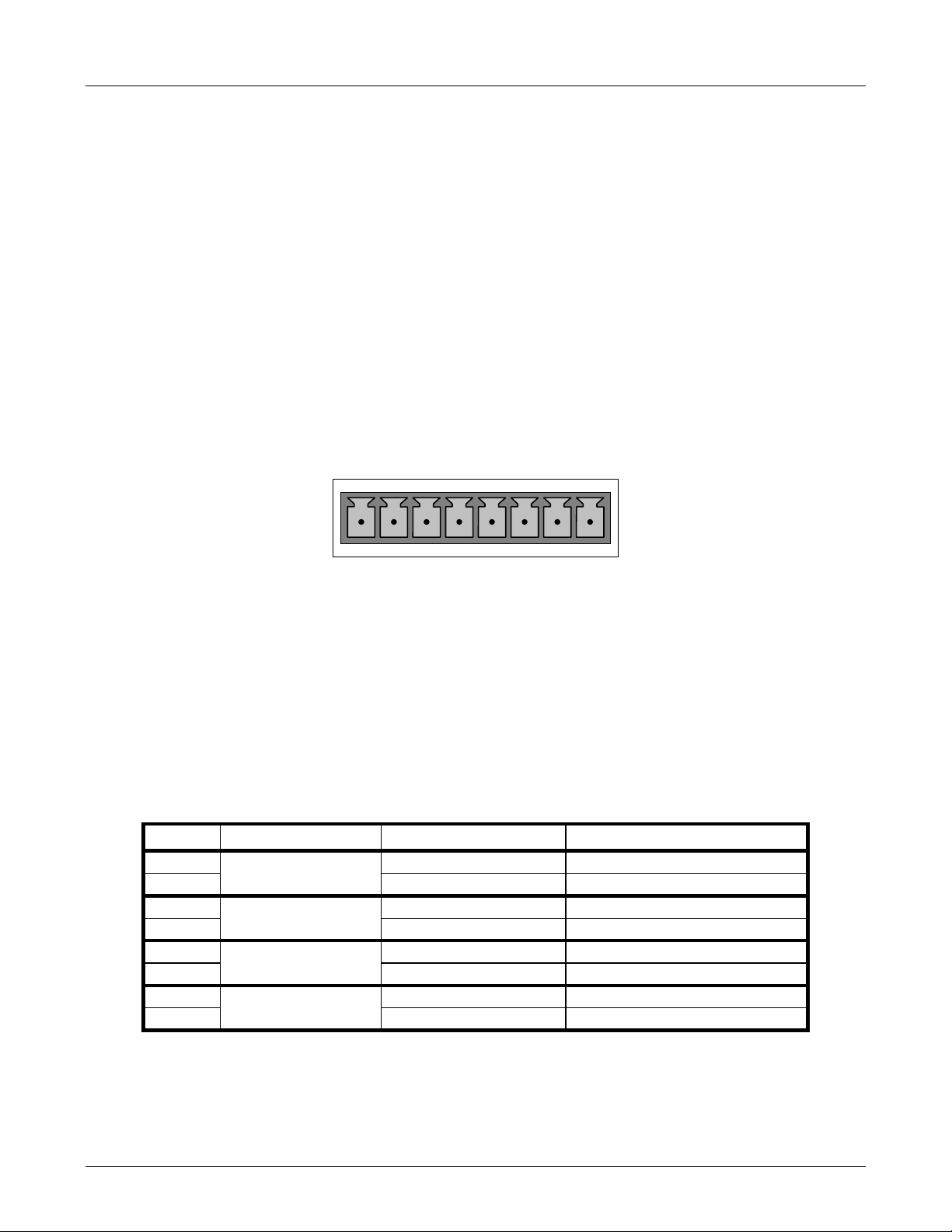

3.6.1.1. M102E Analog Output Connections

This section supercedes Section 3.1.1.1 of the M101E Manual - P/N 04740 Rev A.

Attach a strip chart recorder and/or data-logger to the appropriate contacts of the analog output

connecter on the rear panel of the analyzer.

A1 A2 A3 A4

+ - + - + - + -

ANALOG OUT

Figure 3-6: Analog Output Connector

The A1 and A2 channels output a signal that is proportional to the SO

concentration of the

2

sample gas.

The output, labeled A3 is special. It can be set by the user (see Section 6.9.10 of the M101E

Manual - P/N 04740 Rev A) to output any one of the parameters accessible through the <TST

TST> keys of the units sample display.

Pin-outs for the Analog Output connector at the rear panel of the instrument are:

Table 3–2: Analog output Pin Outs

PIN ANALOG OUTPUT VOLTAGE OUTPUT CURRENT LOOP OPTION

1 V Out I Out +

2

3 V Out I Out +

4

5 V Out I Out +

6

7 Not Available Not Available

8

A1

A2

A3

A4

Ground I Out -

Ground I Out -

Ground I Out -

Not Available Not Available

• The default analog output voltage setting of the M102E UV Fluorescence SO

Analyzer is 0

2

– 5 VDC with a range of 0 – 500 ppb.

10 05514 Rev A1

Page 17

M102E/M501 TRS GETTING STARTED

(Addendum to M101E Manual - P/N 04740 Rev A)

• TO change these settings, see Sections 6.9.4 and 6.7 of the M101E Manual - P/N 04740

Rev A respectively.

3.6.1.2. M501-TRS Alarm Output Connections

The rear panel of the M501-TRS includes a terminal strip by which connections can be made to

the converters internal temperature alarm for more information on this alarm see Section 6.5).

• Connect the input leads to your alarm-sensing device (e.g. datalogger) to the center two

pins of the alarm output connector (see Figure 3-5).

• Make sure the load does not exceed the rated capacity of the relay.

3.6.2. Pneumatic Connections:

This section supercedes the information contained in Section 3.1.2 of the M101E Manual

- P/N 04740 Rev A.

CAUTION

To prevent dust from getting into the analyzer, it was shipped with small plugs inserted

into each of the pneumatic fittings on the rear panel. Make sure that all dust plugs are

removed before attaching exhaust and supply gas lines.

Sample and calibration gases should only come into contact with PTFE (Teflon) or glass materials.

They should not come in contact with FEP or stainless steel materials.

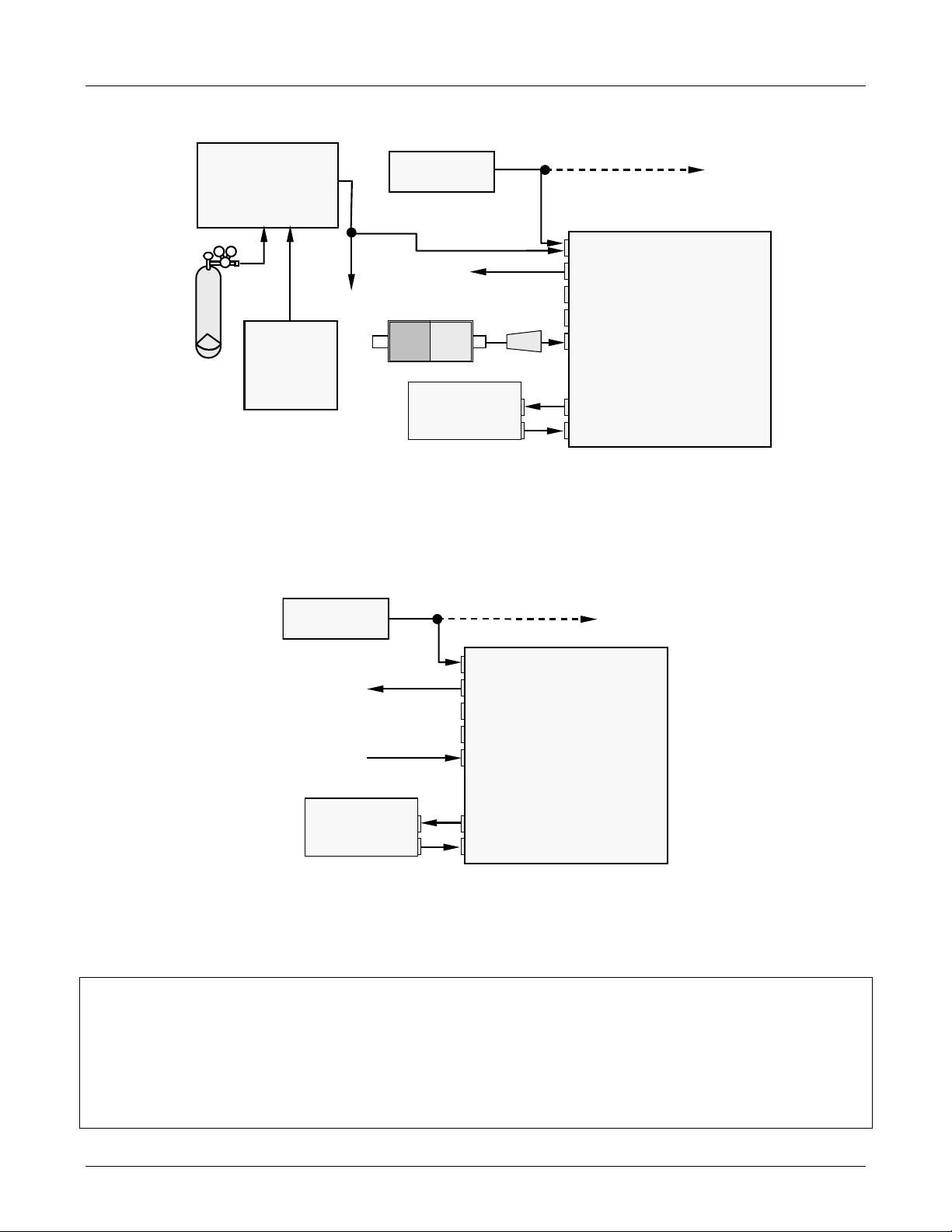

Figures 3-7 and 3-8 show the most common configurations for gas supply and exhaust lines to the

Model 102E Analyzer. Figures 3-9, 3-10 & 3-11 show the connections for units with valve options

installed.

Please refer to Figures 3-1 & 3.3 for the location of pneumatic connections at the rear panel of the

M102E and the M501-TRS.

Table 3-3: Inlet / Outlet Connector Nomenclature

M102E PNEMATIC CONNECTERS

REAR PANEL LABEL FUNCTION

SAMPLE

EXHAUST

SPAN

ZERO AIR

TO CONVERTER Sample gas leaves the M102E to be conditioned by the M501-TRS via this port.

FROM CONVERTER

Connects the sample gas to the analyzer. When operating the analyzer without

zero/span option, this is also the inlet for any calibration gases.

Exhausts the gas sampled by the analyzer. Connect to an outside area away

from people.

On units with zero/span/shutoff valve options installed, connect a gas line to

the source of calibrated span gas here.

On Units with zero/span valve or IZS option installed, this port connects the

zero air gas or the zero air cartridge to the analyzer.

Sample gas returns to the M102E after being conditioned by the M501-TRS via

this port.

M501-TRS PNEMATIC CONNECTERS

REAR PANEL LABEL FUNCTION

05514 Rev A1 11

Page 18

GETTING STARTED M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

FROM ANALYZER Sample gas enters the M501-TRS from the M102E via this port.

TO ANALYZER Sample gas leaves the M501-TRS to return to the M102E via this port.

Calibrated

span GAS

(At high

concentration)

MODEL 701

Zero Air

Generator

MODEL 700

Gas Dilutio n

Calibrator

(with Ozone

Bench Option)

VENT

M501-TRS

From Analyzer

To Analyzer

Source of

SAMPLE Gas

Removed

Calibration

Sample

Exhaust

Span

Zero Air

To Converter

From Converter

during

MODEL

102E

Figure 3-7: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator

MODEL 701

Zero Air

Calibrated

span GAS

Generator

Valve

Needle

valve to

control

flow

VENT

Source of

SAMPLE Gas

Removed

during

Calibration

Sample

Exhaust

Span

MODEL

102E

M501-TRS

From Analyzer

To Analyzer

Zero Air

To Converter

From Converter

Figure 3-8: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas

8. Attach the 1/4" exhaust line to the exhaust port.

12 05514 Rev A1

Page 19

M102E/M501 TRS GETTING STARTED

(Addendum to M101E Manual - P/N 04740 Rev A)

CAUTION

The exhaust from the instrument needs to be vented outside the

immediate area or shelter surrounding the instrument and conform to all

safety requirements using a maximum of 10 meters of 1/4” PTFE tubing.

9. Attach the sample line to the sample inlet port. Ideally, the pressure of the sample gas should

be equal to ambient atmospheric pressure.

NOTE

Maximum pressure of any gas at the sample inlet should not exceed 1.5 in-Hg above

ambient pressure and ideally should equal ambient atmospheric pressure.

In applications where the sample gas is received from a pressurized manifold, a vent

must be provided to equalize the sample gas with ambient atmospheric pressure before

it enters the analyzer. The vented gas needs to be routed outsi de the immediate area or

shelter surrounding the instrument.

10. Attach zero air and span gas supply lines as appropriate (see Figures 3-5 & 3.5).

• Zero air and span gas inlets should supply their respective gases in excess of the 700

3

/min demand of the analyzer. Supply and vent lines should be of sufficient length and

cc

diameter to prevent back diffusion and pressure effects.

• For this type of analyzer, zero air and span gas are defined as follows:

SPAN GAS

• While it is possible to calibrate the M102E using SO

the analyzers gas measurement mode to SO

, Teledyne Instruments recommends that H2S

2

as the span calibration gas by setting

2

be used and that calibration operations be carried out with the analyzer’s TRS gas

measurement mode selected. Please note that verifying converter efficiency requires that

the instrument be calibrated on both TRS and SO

between the TRS and SO

• It is recommended that the H

modes.

2

S span gas be equal to 90% of the analyzer’s selected

2

, and the slope factors compared

2

reporting range.

• O2 is a quenching agent in fluorescent Sulfur analyzers. If the balance gas is pure

nitrogen, then false positive readings will result, both at zero and span. Therefore the user

should either use cylinders with zero air as the balance gas, or should use higher

concentration cylinders with an N2 balance, and dilute further with zero air using a

calibrator, such as the TAPI M700.

EXAMPLE: If the selected reporting rang is 0 ppb Æ 500 ppb, an appropriate span gas

concentration would be 450 ppb H

Cylinders of calibrated H

S gas traceable to NIST-Standard Reference Material specifications

2

S.

2

(also referred to as SRM’s or EPA protocol calibration gases) are commercially available. Table

3-4 lists specific NIST-SRM reference numbers for various concentrations of H

2

S.

05514 Rev A1 13

Page 20

GETTING STARTED M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

Table 3-4: NIST-SRM's Available for Traceability of H2S & SO2 Calibration Gases

NIST-SRM4 TYPE

2730

2731

Hydrogen sulfide in N

Hydrogen sulfide in N2

2

NOMINAL

CONCENTRATION

5000 ppb

20 ppm

ZERO AIR

• A gas that is similar in chemical composition to the earth’s atmosphere but without the

gas(es) being measured by the analyzer, in this case total reduced sulfur (TRS). While

TRS typically includes Hydrogen sulfide (H

(CH

and Methyl mercaptan (MeSH), CH4S many other gases fall into this category as

3)2S2

S), Dimethyl sulfide (CH3)2 , Dimethyl disulfide

2

well. In addition other interferent gases may be present in ambient air as well.

To ensure that high quality zero air is available a zero air generator such as the Teledyne

Instruments Model 701 should be used.

• If your analyzer is equipped with an IZS option, it is capable of creating zero air that is

adequate for performing informal calibration checks, but a zero air generator such as the

Teledyne Instruments Model 701 is still recommended for performing formal calibration

operations.

11. Once the appropriate pneumatic connections have been made, check all pneumatic fittings for

leaks using a procedure similar to that defined in Section 11.5.1 of the M101E Manual - P/N

04740 Rev A.

3.6.2.1. Connections with Internal Valve Options Installed

If your analyzer is equiped with either the zero/span valve option (Option 50) or the internal

zero/span option (Option 51), the pneumatic connections should be made as shown in

Figures 3-9; 3-10 & 3-11:

14 05514 Rev A1

Page 21

M102E/M501 TRS GETTING STARTED

p

p

r

r

(Addendum to M101E Manual - P/N 04740 Rev A)

Zero/Span Valves – Option 50

VENT if input is pressurized

le

Sam

Exhaust

S

an

Zero Air

To Converter

From Converter

MODEL

102E

MODEL 700

Gas Dilution Calibrator

(with O3 generator option)

Calibrated

SO

or H2S

2

gas

(At high

concentration)

VENT

MODEL 701

Zero Air

Generator

Source of

SAMPLE Gas

External Zero

Air Scrubber

M501-TRS

Filter

To Analyze

From Analyze

Figure 3-9: Basic Pneumatic Connections for Units with Zero/Span Valve Option

05514 Rev A1 15

Page 22

GETTING STARTED M102E/M501 TRS

p

r

r

p

(

)

p

r

(Addendum to M101E Manual - P/N 04740 Rev A)

MODEL 700

Gas Dilution Calibrator

(with O3 generator option)

Calibrated

H2S gas

(At high

concentration)

VENT

MODEL 701

Zero Air

Generator

Source of

SAMPLE Gas

External Zero

Air Scrubber

M501-TRS

To Analyze

From Analyze

Filter

VENT if input is pressurized

le

Sam

Exhaust

MODEL

102E

Zero Air

To Converter

From Converter

Figure 3-10: Pneumatic Connections for Formal Calibration of Units with an IZS Valve

Option

Source of

SAMPLE Gas

VENT if input is pressurized

Sam

Ambient

Air

M501-TRS

From Analyze

To Analyzer

le

Exhaust

S

an

Zero Air

To Converter

From Converter

MODEL

102E

Scrubber

Figure 3-11: Pneumatic Connections for Informal Calibration Checks of Units with IZS

Valve Option

NOTE

Gas flow must be maintained at all times for units with IZS Options installed. The IZS

option requires a permeation tube ( customer supplied ) which emits H2S. Insufficient

gas flow can build up H2S to levels that will damage the instrument.

Remove the permeation device when taking the analyzer out of operation.

16 05514 Rev A1

Page 23

M102E/M501 TRS GETTING STARTED

g

(Addendum to M101E Manual - P/N 04740 Rev A)

3.7. Initial Operation

3.7.1. Startup / Warm Up of the M102E

Startup procedures and warm up behavior of the M102E are identical to those described in

Sections 3.2.1 and 3.2.2 of the M101E Manual - P/N 04740 Rev A.

Possible Warning Messages at Start-Up

Warning messages for the M102E is the same as the list of warning messages included in

appendix A—3 of the M101E Manual - P/N 04740 Rev A with the exception that there is no CONV

TEMP WARNING (converter Temperature Warning).

3.7.2. Functional Check of the M102E

To performing an initial functional check of the M102E follow the steps contained in Section 3.2.4

of the M101E Manual - P/N 04740 Rev A.

Test Functions

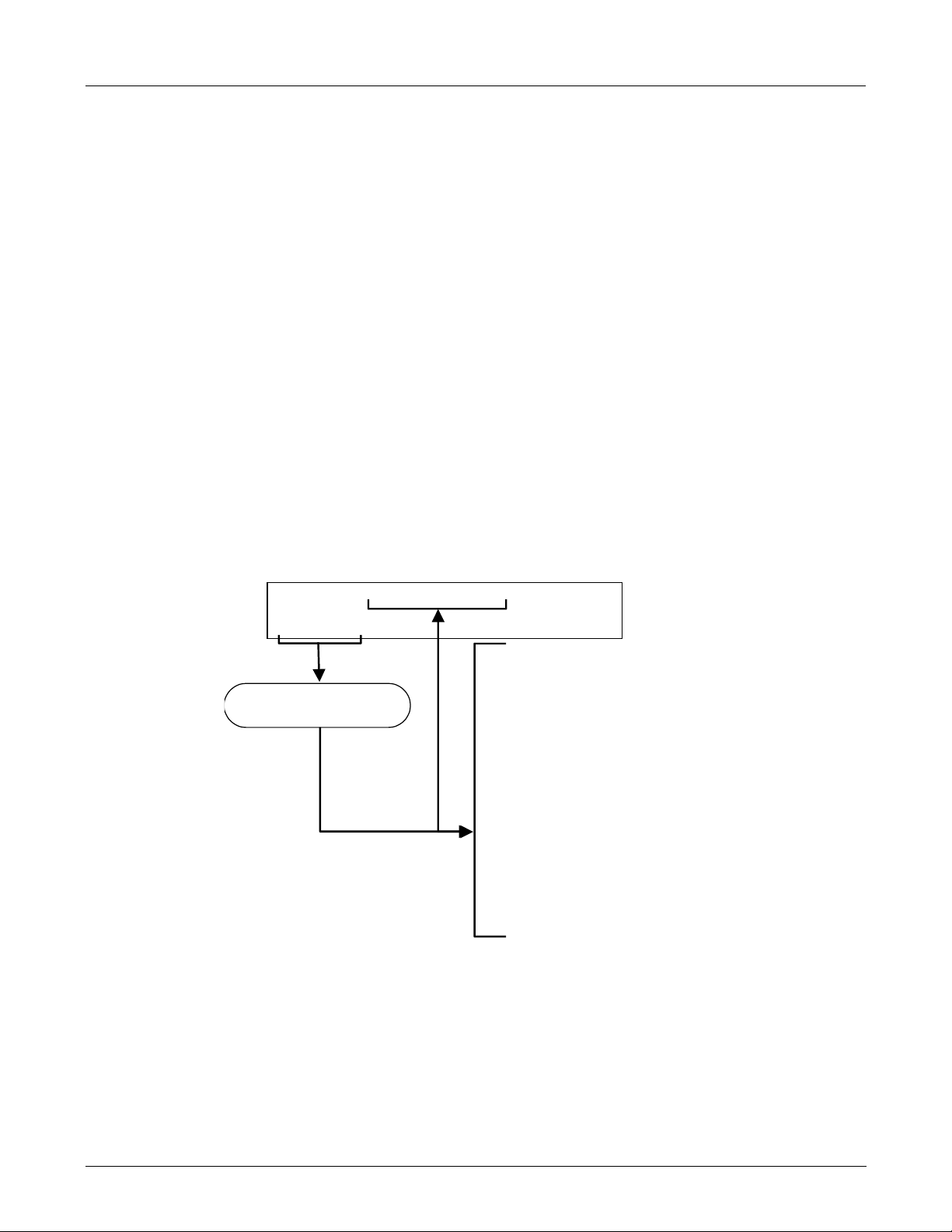

The following diagram supercedes the one found in Step 2 of Section 3.2.4 of the M101E Manual P/N 04740 Rev A.

SAMPLE RANGE = 500.0 PPB TRS = X.X

< TST TST > CAL SETUP

RANGE

TRS STB

PRES

Toggle <TST TST> keys to

scroll throu

1

Only appears if IZS option is

installed.

2

Only appears if analog output A4

is actively reporting a test function.

3

Shown as they appear when analyzer

is in TRS mode. In SO

h list of functions

mode appear as SO2 STB, SO2 OFFS &

2

SAMP FL

PMT

NORM PMT

UV LAMP

LAMP RATIO

STR. LGT

DARK PMT

DARK LAMP

TRS SLOPE

TRS OFFS

HVPS

RCELL TEMP

BOX TEMP

PMT TEMP

IZS TEMP

TEST

TIME

SO2 SLOPE. In multigas mode, both versions appear.

3

Refer to Section

6.2.1 of the M101E

3

Manual - P/N 04740

3

Rev A for definitions

of these test

functions.

1

2

05514 Rev A1 17

Page 24

GETTING STARTED M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

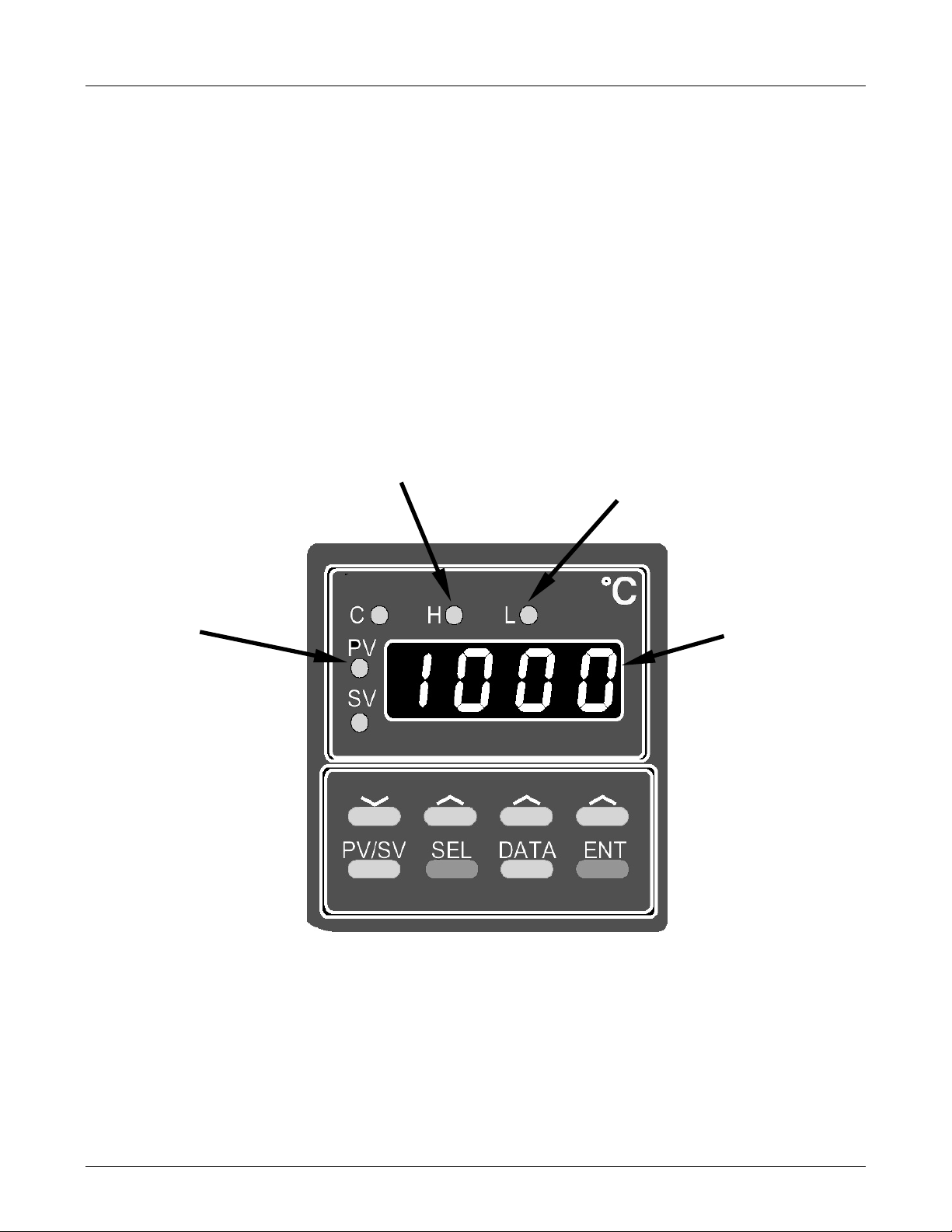

3.7.3. Startup / Warm Up of the M501-TRS

After electrical and pneumatic connections are made, turn on the instrument and pump power.

The exhaust fan should start.

The M501-TRS’ temperature controller is preprogrammed at the factory so no special setup

operation is required. The temperature controller (see Figure 3-12) should immediately come on

in operation mode: the current temperature of the converter oven should the display immediately

appear in the display area and the process

It may take as much as 30 minutes for the oven to reach its nominal operating temperature.

During that initial warm up period the high and low alarms and the M501-TRS single alarm output

are disabled. Both the internal alarms and the alarm output will be automatically enabled once

the converter oven temperature rises above the lower alarm limit.

value (PV) LED should be lit.

Process Variable

LED

High Alarm LED

Low Alarm LED

Display area

Figure 3-12: M501-TRS Temperature Controller Startup

18 05514 Rev A1

Page 25

M102E/M501 TRS GETTING STARTED

(Addendum to M101E Manual - P/N 04740 Rev A)

3.8. Initial Calibration

Initial calibration of the M102E should be performed with:

• Zero air supplied by a zero air generator such as the Teledyne Instruments’ M701;

• Calibrated H

• With external pneumatic connections as described in Figures 3-7 through 3-11 of this

addendum, and;

• Using the information and procedure included in Section 3.3 of the M101E Manual - P/N

04740 Rev A.

No initial calibration of the M501-TRS temperature controller is required.

Once you have completed the above set-up procedures, please fill out the quality

questionnaire that was shipped with your unit and return it to Teledyne Instruments.

This information is vital to our efforts in continuously improving our service and our

S span gas of the appropriate concentration:

2

NOTE

products. Thank you.

User Notes:

05514 Rev A1 19

Page 26

Page 27

M102E/M501 TRS OPTIONAL HARDWARE AND SOFTWARE

(Addendum to M101E Manual - P/N 04740 Rev A)

4. OPTIONAL HARDWARE AND SOFTWARE

This section includes descriptions of the hardware and software options available for the Model

102E analyzer and M501-TRS converter that are different from or not included in Chapter 5 of the

M101E Manual - P/N 04740 Rev A. For all other available options see that document.

For assistance with ordering these options please contact the sales department of Teledyne

Instruments at:

TOLL-FREE: 800-324-5190

TEL: +1 858-657-9800

FAX: +1 858-657-9816

E-MAIL: apisales@teledyne.com

WEB SITE: http://www.teledyne-api.com

4.1. Rack Mount Kits (Options 20a, 20b, 21, 22 & 81)

The following table supercedes the one included in Section 5.1 of the M101E Manual - P/N 04740

Rev A.

OPTION NUMBER DESCRIPTION

OPT 20A Rack mount brackets with 26 in. chassis slides.

OPT 20B Rack mount brackets with 24 in. chassis slides.

OPT 21 Rack mount brackets only

OPT 22 Rack Mount for M501-TRS

OPT 81 Rack Mount for M501-TRS with slides

4.2. Calibration Valves Options

4.2.1. Zero/Span Valves (Option 50) & Internal Zero/Span Gas

Generator (Option 51)

The description of the construction and operation for the zero span and IZS valve options for the

M102E TRS is identical to that information contained in Section 5.4of the M101E Manual - P/N

04740 Rev A.

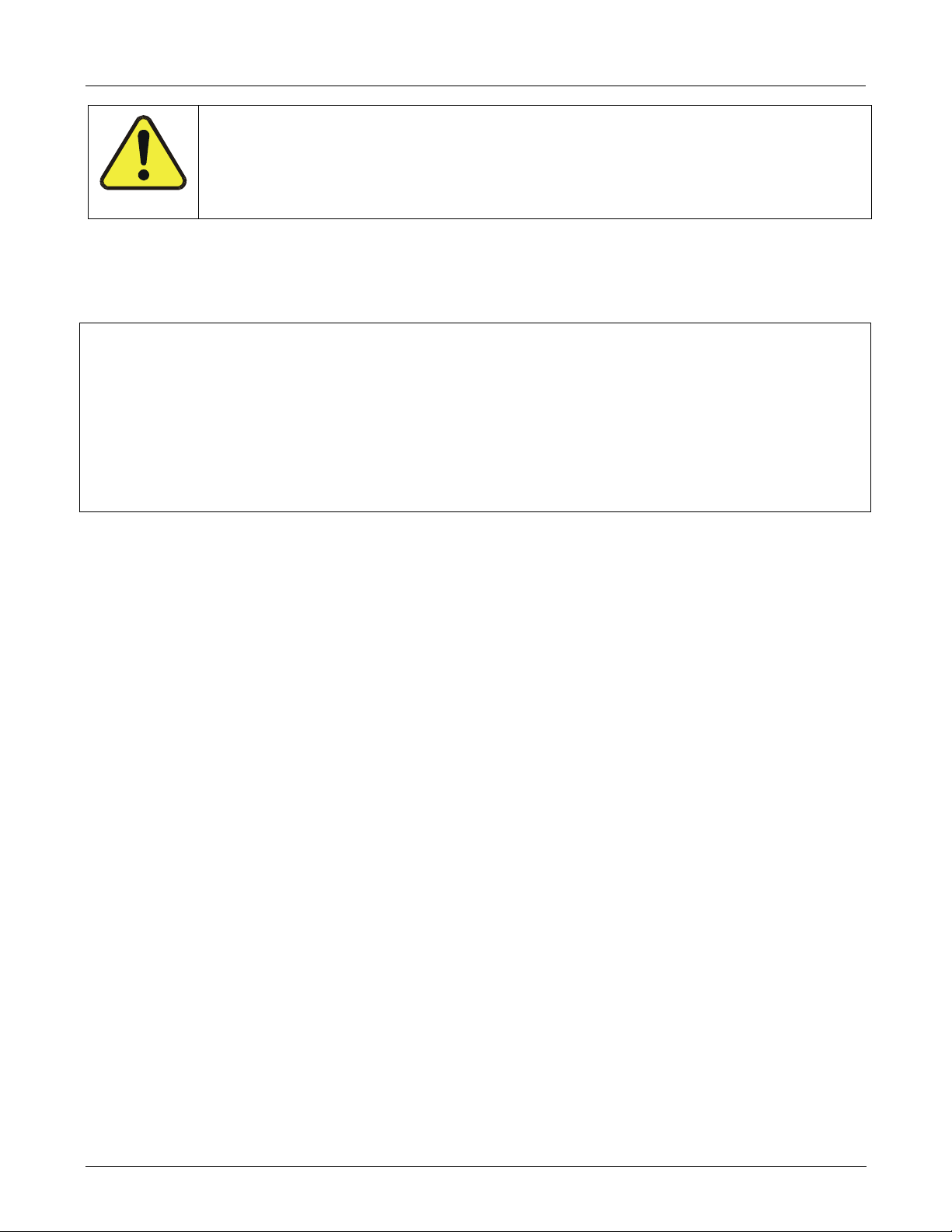

The internal pneumatic flow or the M102E with either of these options installed is however

different. See:

• Figure 4-1 for an illustration of the M102E internal gas flow with the zero/span valves

(option 50), and;

• Figure 4-2 for an illustration of the M102E internal gas flow with the IZS valve (option 1).

05514 Rev A1 21

Page 28

OPTIONAL HARDWARE AND SOFTWARE M102E/M501 TRS

V

R

R

A

(Addendum to M101E Manual - P/N 04740 Rev A)

TO

ANALYZER

2

TRS Æ SO

CONVERTER OVEN

2

SO

FROM

ANALYZER

Scrubber

FROM

CONVERTER

CONVERTER

EXHAUST GAS

OUTLET

M501-TRS

SAMPLE GAS

INLET

ZERO AIR INLET

SPAN GAS INLET

TO

PUMP

ZERO/SPAN

VALVE

3 2

1

3

1

SAMPLE FILTER

2

SAMPLE/CAL

KICKER EXHAUST

TO PUMP

ALVE

TRS / SO

2

MODE

VALVE

HYDROCARBON

SCRUBBER

(KICKER)

VACUUM MANIFOLD

Gas Flow in SO

of multigas mode or

3

1

when i n SO

2

measurement mode

EXHAUST TO OUTE

LAYER OF KICKE

FLOW

CONTROL

ASSY

phase

2

2

SAMPLE

PRESSURE

SENSOR

FLOW / PRESSURE

SENSOR PC

SAMPLE

CHAMBER

PMT

FLOW

SENSOR

M102E

INSTRUMENT

CHASSIS

UV

LAMP

Figure 4-1: Internal Pneumatic Diagram of the M102E With Z/S Option Installed.

The following table describes the state of each valve during the analyzer’s various operational

modes.

Table 4-1: Zero/Span Valve Operating States

MODE VALVE CONDITION VALVE PORT

CONNECTION

(FIG. 5-2)

SAMPLE

Zero/Span Open to ZERO AIR inlet

Sample/Cal Open to zero/span inlet

Sample/Cal Open to SAMPLE inlet

ZERO CAL

Zero/Span Open to ZERO AIR inlet

Sample/Cal Open to zero/span inlet

SPAN CAL

Zero/Span Open to SPAN GAS inlet

3 Æ 2

3 Æ 2

1 Æ 2

3 Æ 2

1 Æ 2

1 Æ 2

22 05514 Rev A1

Page 29

M102E/M501 TRS OPTIONAL HARDWARE AND SOFTWARE

A

R

V

(Addendum to M101E Manual - P/N 04740 Rev A)

`

TO

ANALYZER

2

TRS Æ SO

CONVERTER OVEN

ZERO AIR INLET

2

SO

FROM

TO

OUTLET

INLET

ZERO/SPAN

VALVE

3 2

PUMP

3

1

1

IZS

Permeation Tube

SO

Source

2

2

SAMPLE/CAL

SAMPLE

FILTER

ALVE

KICKER EXHAUST

TO PUMP

TRS / SO

VALVE

HYDROCARBON

SCRUBBER

(KICKER)

EXHAUST TO OUTER LAYE

MODE

VACUUM MANIFOLD

INSTRUMENT

when i n SO

phase

2

2

SAMPLE

PRESSURE

SENSOR

FLOW / PRESSURE

SENSOR PC

SAMPLE

CHAMBER

PMT

FLOW

SENSOR

Gas Flow in SO

of multigas mode or

3

2

1

2

measurement mode

OF KICKER

CRITICAL

FLOW

ORIFICE

CRITICAL

FLOW

ORIFICE

CONVERTER

CONVERTER

EXHAUST GAS

FROM

ANALYZER

r

Scrubbe

SAMPLE GAS

M501-TRS

ZERO AIR

SCRUBBER

M102E

CHASSIS

UV

LAMP

Figure 4-2: Internal Pneumatic Diagram of the M102E with IZS Options Installed.

The following table describes the state of each valve during the analyzer’s various operational

modes.

Table 4-2: IZS Valve Operating States

MODE VALVE CONDITION VALVE PORT

CONNECTIONS

SAMPLE

ZERO CAL

SPAN CAL

Sample/Cal Open to SAMPLE inlet

Zero/Span Open to ZERO AIR inlet

Sample/Cal Open to zero/span valve

Zero/Span Open to ZERO AIR inlet

Sample/Cal Open to zero/span valve

Zero/Span Open to SPAN GAS inlet

3 Æ 2

3 Æ 2

1 Æ 2

3 Æ 2

1 Æ 2

1 Æ 2

05514 Rev A1 23

Page 30

OPTIONAL HARDWARE AND SOFTWARE M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

4.3. Additional Manuals

4.3.1. Printed Manuals (P/N 049880000)

Additional printed copies of this addendum are available from Teledyne Instruments

4.3.2. Addendum on CD (Part number 049880200)

This addendum is also available on CD. The electronic document is stored in Adobe Systems Inc.

Portable Document Format (PDF) and is viewable with Adobe Acrobat Reader

downloadable for free at http://

The CD version of the addendum has many advantages:

Fully searchable text.

Hypertext links for figures, tables, table of contents and embedded references for quick access of

individual addendum portions.

A list of thumbnails, chapters and sections displayed at the left of the text.

Internet links embedded in the addendum will take you to the corresponding web site (requires an

internet connection).

www.adobe.com/

®

software,

User Notes:

24 05514 Rev A1

Page 31

M102E/M501 TRS M102E OPERATING INSTRUCTIONS

d

d

(Addendum to M101E Manual - P/N 04740 Rev A)

5. M102E OPERATING INSTRUCTIONS

NOTE

For the most part the operation instruction for the M102Eare the same as those

described in Chapter 6 of the M101E Manual - P/N 04740 Rev A with the exception that

the terms “TRS” & “total reduced sulfur” should be substituted for the t erms “H2S” &

“hydrogen sulfide” unless otherwise stated in this addendum.

5.1.1. M102E Analog Output Signals

The information contained in Section 6.7.1 of the M101E Manual - P/N 04740 Rev A is correct

except that the test channel output is located on analog output A3 rather than A4 .

ANALOG OUT

SO2 concentration

A1 A2 A3 A4

+ - + - + - + -

LOW range when

DUAL mode is selecte

outputs

Test Channel

HIGH range when

DUAL mode is selecte

Not Used

Figure 5-1: Analog Output Connector Key

NOTE

On analyzers with the SO2-TRS multigas gas measurement option available, the outputs

of A1 and A2 correspond to:

Output SO

2 SO2

– TRS TRS

Channel Mode Mode Mode

A1 ÅÆ SO2 ÅÆ SO2 ÅÆ TRS

A2 ÅÆ SO2 ÅÆ TRS ÅÆ TRS

As the instrument switches from TRS mode to SO2 mode and back, only the reporting

range and analog output associated with the gas currently being measured will be

active. The reporting range and analog output for the gas not being measured will

continue to report the last valid reading.

05514 Rev A1 25

Page 32

M102E OPERATING INSTRUCTIONS M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

The output, labeled A3 is special. It can be set by the user (see Section 6.9.10 of the M101E

Manual - P/N 04740 Rev A) to output many of the parameters accessible through the <TST TST >

keys of the units Sample Display.

Output A4 is not available on the Model 102E Analyzer.

5.1.2. Setting the M102E Gas Measurement Mode

Setting the gas measurement mode on the M102E is identical to the method described in Sections

6.8.1 of the M101E Manual - P/N 04740 Rev A except that the available measurement ranges are:

Table 5-1 M102E gas Measurement Modes

GAS

MODE

TRS

SO2

TRS –SO2

The sample gas stream is stripped of any ambient SO

chemical scrubber, then passed through a catalytic converter that

changes the TRS present into SO

UV Fluorescence method

The sample gas stream bypasses the SO

converter allowing the only ambient SO2 to be measured.

The switching valve alternates the gas stream between the two paths

at regular intervals allowing the instrument to measure both gases.

DESCRIPTION

which is then measured using the

2

Scrubber and catalytic

2

by a special

2

5.2. SETUP – DIAG: Using the Diagnostics Functions

5.2.1. M102E Analog I/O Configuration

The following table supercedes Table 6-11 of the M101E Manual - P/N 04740 Rev A

Table 5-2: Analog Output Pin Assignments

PIN ANALOG

OUTPUT

1 V Out I Out +

2

3 V Out I Out +

4

5 V Out not available

6

7-8

A1

A2

A3

A3

VOLTAGE

SIGNAL

Ground I Out -

Ground I Out -

Ground not available

Not Used Not Used

CURRENT

SIGNAL

See Figure 3-4 for a the location of the analog output connector on the instruments rear panel.

26 05514 Rev A1

Page 33

M102E/M501 TRS M102E OPERATING INSTRUCTIONS

(Addendum to M101E Manual - P/N 04740 Rev A)

5.2.2. M102E Test Channel Output

The following table supercedes Table 6-14 of the M101E Manual - P/N 04740 Rev A

Table 5-3: Test Parameters Available for Analog Output A4

TEST CHANNEL TEST PARAMETER RANGE 1

NONE Test channel is turned off

PMT READING 0-5000 mV

UV READING 0-5000 mV

SAMPLE PRESSURE 0-40 in-Hg-A

SAMPLE FLOW 0-1000 cm³/min

RCELL TEMP 0-70° C

CHASSIS TEMP 0-70° C

IZS TEMP 0-70° C

PMT TEMP 0-50° C

CHASSIS TEMP 0-70° C

HVPS VOLTAGE 0-5000 V

1

This refers to the voltage range of the parameter and

not the output signal of the test channel.

Once a TEST function is selected, the instrument begins to report a signal on the A36 output and

adds TEST= to the list of test functions viewable on the display (just before the TIME display).

5.3. SETUP – COMM: Setting Up the M102E’s

Communication Ports

5.3.1. M102E ID Code

The default ID code for all M102E analyzers is 102.

To edit the instrument’s ID code, see Section 6.10.1 of the M101E Manual - P/N 04740 Rev A.

5.3.2. M102E Ethernet Host Name

The default name for all Teledyne Instruments Model 102E analyzers is M102E.

To change the Ethernet Host Name see Section 6.10.6.4 of the M101E Manual - P/N 04740 Rev A.

05514 Rev A1 27

Page 34

M102E OPERATING INSTRUCTIONS M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

5.4. Remote Operation of the Analyzer

5.4.1. Control Inputs

The description of the control inputs in Section 6.12.1.2 of the M101E Manual - P/N 04740 Rev A

in correctly shows an external low span cal input. This is not correct. Neither the M102E nor the

M102E has an external low span cal input.

The following table and figures supercede Table 6-23 and Figures 6-18 & 6-19 of the M101E

Manual - P/N 04740 Rev A respectively.

Table 5-4: M102E Control Input Pin Assignments

INPUT STATUS CONDITION WHEN ENABLED

A External Zero Cal

B External Span Cal

C, D, E, & F Unused

Digital Ground Provided to ground an external device (e.g., recorder).

Zero calibration mode is activated. The mode field of the

display will read ZERO CAL R.

Span calibration mode is activated. The mode field of the

display will read SPAN CAL R.

U

+

DC Power For

Input Pull Ups

Internal +5v

Supply

Input for +5 VDC required to activate inputs A - F. This voltage

can be taken from an external source or from the “+” pin.

Internal source of +5V which can be used to activate inputs

when connected to pin U.

A B C D E F U

ZERO

SPAN

CONTROL IN

+

Figure 5-2: Control Inputs with local 5 V power supply

28 05514 Rev A1

Page 35

M102E/M501 TRS M102E OPERATING INSTRUCTIONS

(Addendum to M101E Manual - P/N 04740 Rev A)

CONTROL IN

A B C D E F U +

ZERO

SPAN

LOW SPAN

5 VDC Power

-

+

Supply

Figure 5-3: Control Inputs with external 5 V power supply

5.4.2. Using the M102E with a Hessen Protocol Network

5.4.2.1. M102E Hessen Protocol Gas ID List.

The default Hessen Gas Id’s for all M102E analyzers are:

Table 5-5: M102E Default Hessen Gas ID’s

Gas Type Hessen Gas ID

SO2 111

TRS 112

To edit the instrument’s ID code, see Section 6.12.4.6 of the M101E Manual - P/N 04740 Rev A.

05514 Rev A1 29

Page 36

M102E OPERATING INSTRUCTIONS M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

5.4.2.2. Setting Hessen Protocol Status Flags

The following table supercedes Table 6-29 of the M101E Manual - P/N 04740 Rev A/

Table 5-6: Default Hessen Status Bit Assignments

WARNING FLAGS

SAMPLE FLOW WARNING 0001

PMT DET WARNING 0002

UV LAMP WARNING 0002

HVPS WARNING 0004

DARK CAL WARNING 0008

RCELL TEMP WARNING 0010

IZS TEMP WARNING 0020

PMT TEMP WARNING 0040

CONV TEMP WARNING 1000

OPERATIONAL FLAGS

In Manual Calibration Mode 0200

In Zero Calibration Mode 0400

In Span Calibration Mode 0800

UNITS OF MEASURE FLAGS

UGM 0000

MGM 2000

PPB 4000

PPM 6000

SPARE/UNUSED BITS 0080, 0100, 1000,

UNASSIGNED FLAGS

Box Temp Warning Front Panel Warning

Sample Press Warning Analog Cal Warning

System Reset Cannot Dyn Zero

Rear Board Not Detected Cannot Dyn Span

Relay Board Warning Invalid Conc

STATUS FLAG NAME DEFAULT BIT

ASSIGNMENT

8000

User Notes:

30 05514 Rev A1

Page 37

M102E/M501 TRS M501-TRS OPERATING INSTRUCTIONS

V

(Addendum to M101E Manual - P/N 04740 Rev A)

6. M501-TRS OPERATING INSTRUCTIONS

CAUTION !

DO NOT OPERATE WITHOUT THE COVER OF THE M501TS CONVERTER

INSTALLED.

OVEN TEMPERATURE WILL NOT REGULATE PROPERLY WITHOUT THE

COVER IN PLACE.

NOTE:

Changing the Converter temperature from the value preprogrammed at the factory may

have undesirable effects of TRS converters efficiency.

Do not change this value unless absolutely necessary or unless directed to do so by

Teledyne Instruments customer service.

6.1. Basic M501-TRS Controls

Control

Indicator

Process

alue (PV)

Indicator

High Alarm

indicator

Low Alarm

indicator

Main Display

100’s Digit

UP key

Set

Value (SV)

Indicator

DOWN key

PV/SV

Mode

Key

Program SELECT

Key

DATA key

10’s Digit

UP key

1’s Digit

UP key

ENTER key

Figure 6–1: M501-TRS Temperature Controls

05514 Rev A1 31

Page 38

M501-TRS OPERATING INSTRUCTIONS M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

Table 6-1: M501-TRS Temperature Controls and Definitions

NAME FUNCTION

Main Display A 4-digit, 7 segment LED display on which the current value of the PV and the

SV as well as error codes and programming parameters and data are all

displayed.

Process value

(PV) indicator

PV/SV Mode

key

Set value

Indicator

Program

SELECT key

DATA key Displays the current setting assigned to the parameter selected with the

ENTER key Once the value of a parameter is changed, press this key to store the new value

1’s Digit UP

key

10’s Digit UP

key

100’s Digit UP

key

DOWN key Decrements the numerical value by one digit of which ever display position (1,

Control

Indicator

High Alarm

Indicator

Low Alarm

Indicator

When lit indicates that the value on the main display is the process value (SV).

Toggling this key switches the main display between the PV and the SV.

When lit indicates that the value on the main display is the set value (SV).

To access the Primary Parameter Menu - Press and release this key once

To access the Secondary Parameter Menu - Press and hold this key for 3 sec.,

then release.

Repeatedly pressing this key scrolls though the list of available parameter for

whatever menu is selected in ascending order.

SEL/DOWN/100’s UP keys

in memory.

Press once to select the 1’s digit of the display when in numeric mode. Hold the

key down to continuously increment the 1’s digit. When “9” is reached the digit

loops back to “0”

Same as 1’s Digit UP key but for 10’s digit.

Same as 1’s Digit UP key but for 10o’s digit. When “9” is reached the digit loops

back to “0” and the 1000’s digit is incremented by one.

10, or 100) selected with by pressing the appropriate UP key.

In Program mode, where various parameters are displayed, repeatedly pressing

this key scrolls though the list of available parameter in descending order

Lit when the controller is actively controlling the heater temperature.

Lit when the PV equals or exceeds the upper alarm limit.

Lit when the PV equals or falls below the lower alarm limit.

6.2. To Display The Current Temperature:

If the Process value (PV) indicator is lit. the process value is currently being displayed.

If it is not lit Press the PV/SV mode key.

32 05514 Rev A1

Page 39

M102E/M501 TRS M501-TRS OPERATING INSTRUCTIONS

(Addendum to M101E Manual - P/N 04740 Rev A)

6.3. To Manually Adjust the Converter Oven

Temperature:

CAUTION !

DO NOT SET THE TEMPERATURE HIGHER THAN 1050OC

1. Set the main display to show the current value of the set variable by pressing the PV/SV mode

key.

2. To set each digit:

a. Press the up-arrow under that digit once. The digit will flash.

b. to increment that digit, press and hold the digit until the appropriate number is displayed.

c. To decrement that digit press and hold the DOWN key until the appropriate number is

displayed.

d. To increment/decrement the 1000’s digit it is necessary to adjust increment/decrement the

100’s digit up and down. Each time the 100’s digit passes “0” the 1000s digit will

increment or decrement correspondingly.

3. Once the desired value is reached, press the ENT key to store the new set value

4. Return the main display to process mode by pressing the PV/SV mode key once

EXAMPLE to change the set value from 950 to equal 1010.

ACTION RESULT

Press the PV/SV mode key The SV indicator will lit up and the display will

show 950.

Press the 10’s UP key once The 10’s digit will begin to blink

Press the DOWN key The 10’s digit will decrement from “5”. Release

the DOWN key when the 10’s digit reads “1”.

Press the 100’s UP Key once The 100’s digit will begin to blink

Press and hold the 100’s UP key The 100’s digit will increment from “9”. When it

passes “0” the 1000’s digit will increment to “1”.

Release the 100’s UP key.

-- The Display should now read “1010”

Press the ENTER key The new set value is recorded

Press the PV/SV mode key The current level of the process value will be

displayed.

05514 Rev A1 33

Page 40

M501-TRS OPERATING INSTRUCTIONS M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

6.4. Autotune the Temperature Controller:

The M501-TRS controller includes an auto tune feature which allows the controller to find and set

optimum values for various process control parameters so that the controller can establish and

maintain the converter oven at the temperature set value in the most stable and efficient manner.

NOTE

Before initiating the autotune feature make sure that the converter temperature oven

has reached a stable, constant temperature.

6.4.1. Initiating the Autotune Process:

1. Press the SELECT key once. The main display will show

2. Use the SELECT , DOWN or 100’s UP key to scroll through the primary menu parameters until

the display shows

3. Press the DATA key once. The display will show

4. Press the 1’s UP key once. The display will show

(AT =Autotune).

(zero = Off).

(1 = autotune based on set point value).

5. Press the ENTER key to begin the autotune process. A blinking decimal point will appear at the

bottom right-hand corner of the main display.

6. Wait until the blinking light stops. This may take up to 30 minutes.

7. The autotune process is finished. The autotune parameter value will automatically reset to

zero (off).

8. Press the PV/SV mode key to return to operational mode.

Note

The P-I-D parameters calculated by autotuning will be retained even if the power is lost.

However, if the power is turned off during the auto-tuning process, you must restart

autotuning.

34 05514 Rev A1

Page 41

M102E/M501 TRS M501-TRS OPERATING INSTRUCTIONS

(Addendum to M101E Manual - P/N 04740 Rev A)

6.4.2. Aborting the Autotune Process:

1. Press the DATA key once. The display will show (1).

2. Press the 1’s UP key once. The

3. Press the DOWN key once. The display will show

4. Press the ENTER key once.

5. Press the PV/SV mode key to return to operational mode.

Auto-tuning MUST to be repeated if there is a significant change in the set value.

If the temperature begins to oscillate excessively around the set value, it may be

necessary to repeat the autotune procedure.

will begin blinking

(zero).

Note

6.5. M501TRS Alarm Relay Adjustment

To set the High and Low Alarm points:

6. Press the SELECT key once. The main display will show

7. Use the SELECT , DOWN or 100’s UP key to scroll through the primary menu parameters until

the display shows either

(AL = Alarm Low) or

8. Press the DATA key once. The current value of the alarm limit will be displayed.

9. To set each digit:

a. Press the up-arrow under that digit once. The digit will flash.

b. To increment that digit, press and hold the digit until the appropriate number is displayed.

c. To decrement that digit press and hold the DOWN key until the appropriate number is

displayed.

d. To increment/decrement the 1000’s digit it is necessary to adjust increment/decrement the

100’s digit up and down. Each time the 100’s digit passes “0” the 1000s digit will

increment or decrement correspondingly.

(AH = High Alarm).

10. Once the desired value is reached, press the ENT key to store the new set value

11. Press the PV/SV mode key to return to operational mode.

05514 Rev A1 35

Page 42

Page 43

M102E/M501 TRS CALIBRATION PROCEDURES

(Addendum to M101E Manual - P/N 04740 Rev A)

7. CALIBRATION PROCEDURES

7.1. M102E Calibration

Calibration of the M102E should be performed according to the procedures described in Chapters

7 & 8 of the M101E Manual - P/N 04740 Rev A.

NOTE

It is recommended that the M102E be calibrated in TRS gas measurement mode using

H2S as a span gas.

If you are using the M102E for US-EPA controlled monitoring of SO2, see Chapter 8 of the M101E

Manual (P/N 04740 Rev A) for information on the EPA calibration protocol.

7.2. M501-TRS Calibration

The M501-TRS converter does not require field calibration.

USER NOTES:

05514 Rev A1 37

Page 44

Page 45

M102E/M501 TRS INSTRUMENT MAINTENANCE

(Addendum to M101E Manual - P/N 04740 Rev A)

8. INSTRUMENT MAINTENANCE

The following table supercedes Table 9-1 of the M101E Manual - P/N 04740 Rev A

Table 8-1: M102E Preventive Maintenance Schedule

ITEM ACTION FREQUENCY CAL

M501 SO2

scrubber

1

Particulate filter

Replace scrubber

material

Change particle

filter

As required Yes

Weekly

M101E

CHECK

No

MANUAL

SECTION

8.1.1.3 of

this

addendum

9.3.1

DATE PERFORMED

Verify test

functions

Zero/span check

1

Zero/span

calibration

1

External zero air

scrubber (option)

1

Perform flow

check

1

Sample

chamber optics

1

Critical flow

orifice & sintered

filters

Internal IZS

Permeation Tube

Perform

pneumatic leak

check

2

Pump

diaphragm

PMT sensor

hardware

calibration

1

These Items are required to maintain full warranty, all other items are strongly recommended.

2

A pump rebuild kit is available from Teledyne Instruments Customer Service including all instructions and required parts (see Appendix B for part numbers).

Review and

evaluate

Evaluate offset

and slope

Zero and span

calibration

Exchange

chemical

Check Flow Every 6 Months No 11.5.2

Clean windows

and filters

Replace

Replace Annually YES 9.3.2

Verify Leak Tight

Replace

Low-level

hardware

calibration

Weekly

Weekly -- 7.3, 7.6, 7.9

Every 3 months

Every 3 months

Annually or as

necessary

Annually

Annually or after

repairs involving

pneumatics

Every 2 years, or

as necessary

On PMT/ preamp

changes if

0.7 < SLOPE or

SLOPE >1.3

No Appendix C

--

No

Yes

Yes 9.3.7

Yes

Yes

Yes

7.2, 7.4, 7.5,

instruction in

diaphragm

7.7, 7,8

9.3.4

9.3.6

11.5.1

See

kit

11.6.3

05514 Rev A1 39

Page 46

INSTRUMENT MAINTENANCE M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

8.1. Additional and Updated Maintenance Procedures

The following procedures need to be performed regularly as part of the standard maintenance of

the Model 102E.

8.1.1. Maintaining the SO2 Scrubber

This section REPLACES Section 9.3.3 of the M101E Manual - P/N 04740 Rev A.

Unlike the M101E which includes an internal scrubber to remove SO

the H

S Æ SO2 conversion takes place, the M102E relies on the SO2 scrubber of the M501-TRS to

2

from the sample gas before

2

perform the same function.

The SO

sample gas before the TRS is converted to SO

scrubber of your M501-TRS utilizes a consumable compound to absorb SO2 from the

2

. This material must be replaced periodically in

2

order for the analyzer to continue measuring TRS accurately and reliability.

This material is capable of efficiently scrubbing SO

the SO

content of the sample gas is typically around 100 ppb, the scrubber will function for

2