Page 1

User Manual

TVS600 Series

Waveform Analyzers

(TVS621, TVS625, TVS641 & TVS645)

070-9283-01

This document applies for firmware version 1.5

and above.

Page 2

Copyright T ektronix, Inc. 1995. All rights reserved. Licensed software products are owned by Tektronix or its suppliers

and are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks, and IntelliFrame is a trademark of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of three (3) years from the date of shipment. If a product proves defective during this warranty period,

T ektronix, at its option, either will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

TVS600 Series Waveform Analyzers

meet the intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance

was demonstrated to the following specifications as listed in the official Journal of the

European Communities:

EN 50081–1 Emissions:

EN 55011 Radiated, Class A

EN 55011 Conducted, Class A

EN 60555–2 Power Harmonics

EN 50082–1 Immunity:

IEC 801–2 Electrostatic Discharge

IEC 801–3 RF Radiated

IEC 801–4 Fast Transients

Page 5

Table of Contents

Getting Started

Operating Basics

List of Figures xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety Summary xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual xxi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals xxi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Installation 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incoming Inspection Procedure 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the VXIbus Test System 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional T ests 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Cal 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

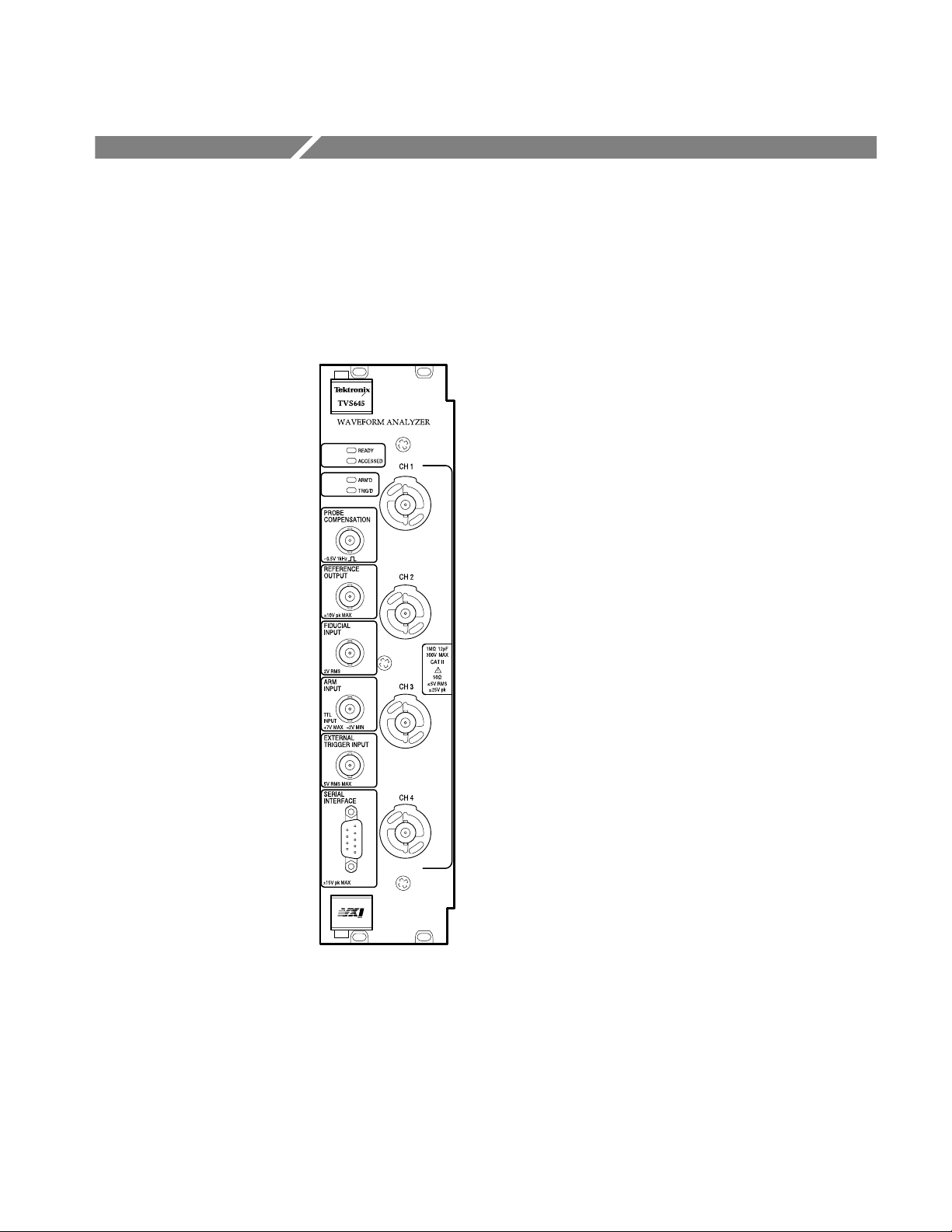

Connectors and Indicators 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Overview 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

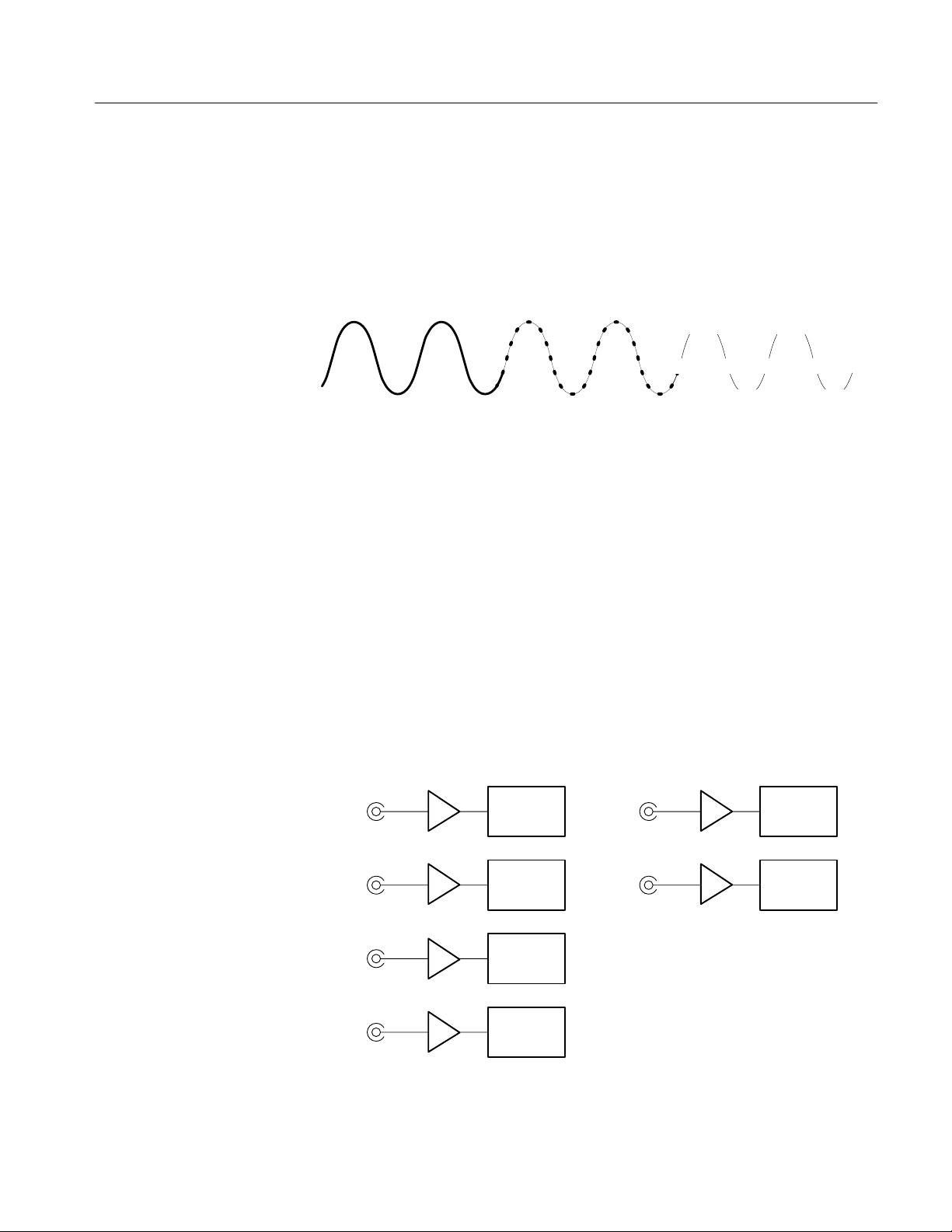

System Operation 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical Range and Offset 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculations 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fast Data Channel 2–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfer Formats 2–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument I/O 2–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VXIbus Interface 2–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232C Port 2–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tutorial 2–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1 — Instrument Setup 2–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 2 — Acquiring a Signal 2–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3 — Averaging and Enveloping a Signal 2–75. . . . . . . . . . . . . . . . . . . . . . .

Example 4 — Performing Basic Calculations 2–76. . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 5 — Performing Advanced Calculations 2–78. . . . . . . . . . . . . . . . . . . . . . .

Example 6 — Saving and Recalling Settings 2–79. . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 7 — Using Status and Events 2–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

i

Page 6

Table of Contents

Syntax and Commands

Command Syntax 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands and Queries 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE 488.2 Common Commands 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constructed Mnemonics 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Groups 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto-Advance Commands 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abort Commands 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arm Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A verage Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculate Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Commands 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Commands 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format Commands 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Commands 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initiate Commands 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Commands 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Commands 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Commands 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roscillator Commands 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sense Commands 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Commands 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sweep Commands 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Commands 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Commands 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trace Commands 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Commands 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Commands 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE 488.2 Commands 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AADVance Subsystem 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AADVance

AADVance? 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AADVance:COUNt

AADVance:COUNt? 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AADVance:RECord:COUNt

AADVance:RECord:COUNt? 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AADVance:RECord:STARt

AADVance:RECord:STARt? 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARM Subsystem 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARM:DEFine? (Query Only) 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARM:SOURce

ARM:SOURce? 3–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVERage Subsystem 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVERage

AVERage? 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVERage:COUNt

AVERage:COUNt? 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TVS600 Series Waveform Analyzers User Manual

Page 7

Table of Contents

AVERage:TYPE

AVERage:TYPE? 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate Subsystem 3–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:AAMList

CALCulate:AAMList? 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:AAMList:STATe

CALCulate:AAMList:STATe? 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:DATA? (Query Only) 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:DATA:PREamble? (Query Only) 3–47. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:DERivative:STATe

CALCulate:DERivative:STATe? 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FEED1

CALCulate:FEED1? 3–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FEED2

CALCulate:FEED2? 3–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FEED2:CONTEXT

CALCulate:FEED2:CONTEXT? 3–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency[:TYPE]

CALCulate:FILTer:FREQuency[:TYPE]? 3–54. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:CENTer

CALCulate:FILTer:FREQuency:CENTer? 3–55. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:HPASs

CALCulate:FILTer:FREQuency:HPASs? 3–57. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:LPASs

CALCulate:FILTer:FREQuency:LPASs? 3–58. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:SPAN

CALCulate:FILTer:FREQuency:SPAN? 3–59. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:SREJection

CALCulate:FILTer:FREQuency:SREJection? 3–60. . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:STARt

CALCulate:FILTer:FREQuency:STARt? 3–61. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:STATe

CALCulate:FILTer:FREQuency:STATe? 3–63. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:STOP

CALCulate:FILTer:FREQuency:STOP? 3–64. . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FILTer:FREQuency:TWIDth

CALCulate:FILTer:FREQuency:TWIDth? 3–65. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:FORMat

CALCulate:FORMat? 3–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:IMMediate

CALCulate:IMMediate? 3–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:INTegral:STATe

CALCulate:INTegral:STATe? 3–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:PATH

CALCulate:PATH? 3–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:PATH:EXPRession

CALCulate:PATH:EXPRession? 3–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:SMOothing

CALCulate:SMOothing? 3–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:SMOothing:POINts

CALCulate:SMOothing:POINts? 3–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:TRANsform:FREQuency:STATe

CALCulate:TRANsform:FREQuency:STATe? 3–75. . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

iii

Page 8

Table of Contents

CALCulate:TRANsform:FREQuency:WINDow

CALCulate:TRANsform:FREQuency:WINDow? 3–76. . . . . . . . . . . . . . . . . . . .

CALCulate:WMList

CALCulate:WMList? 3–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMList:STATe

CALCulate:WMList:STATe? 3–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:HIGH

CALCulate:WMParameter:HIGH? 3–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:HMEThod

CALCulate:WMParameter:HMEThod? 3–84. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:LOW

CALCulate:WMParameter:LOW? 3–85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:LMEThod

CALCulate:WMParameter:LMEThod? 3–86. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:HREFerence

CALCulate:WMParameter:HREFerence? 3–88. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:HREFerence:RELative

CALCulate:WMParameter:HREFerence:RELative? 3–89. . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:LREFerence

CALCulate:WMParameter:LREFerence? 3–90. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:LREFerence:RELative

CALCulate:WMParameter:LREFerence:RELative? 3–91. . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:MREFerence

CALCulate:WMParameter:MREFerence? 3–92. . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:MREFerence:HYSTeresis

CALCulate:WMParameter:MREFerence:HYSTeresis? 3–93. . . . . . . . . . . . . . . .

CALCulate:WMParameter:MREFerence:RELative

CALCulate:WMParameter:MREFerence:RELative? 3–94. . . . . . . . . . . . . . . . . .

CALCulate:WMParameter:RMEThod

CALCulate:WMParameter:RMEThod? 3–95. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration Subsystem 3–97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration

CALibration? 3–97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration:RESults? (Query Only) 3–98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration:RESults:VERBose? (Query Only) 3–99. . . . . . . . . . . . . . . . . . . . . . . . .

FORMat Subsystem 3–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat

FORMat? 3–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat:CALCulate

FORMat:CALCulate? 3–102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat:TRACe:AATS

FORMat:TRACe:AATS? 3–103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat:BORDer

FORMat:BORDer? 3–104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion and DATA Subsystems 3–105. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion[:ON]

FUNCtion[:ON]? 3–106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion[:ON]:ALL 3–107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion[:ON]:COUNt? (Query Only) 3–108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion:OFF

FUNCtion:OFF? 3–109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion:OFF:ALL 3–110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion:OFF:COUNt? (Query Only) 3–111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TVS600 Series Waveform Analyzers User Manual

Page 9

Table of Contents

FUNCtion:CONCurrent

FUNCtion:CONCurrent? 3–112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCtion:STATe

FUNCtion:STATe? 3–113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA? (Query Only) 3–114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA:PREamble? (Query Only) 3–115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate and ABORt Subsystems 3–117. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate 3–117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate:CONTinuous

INITiate:CONTinuous? 3–118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate:COUNt

INITiate:COUNt? 3–119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABORt 3–121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut Subsystem 3–123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut:COUPling

INPut:COUPling? 3–124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut:FILTer

INPut:FILTer? 3–125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut:FILTer:FREQuency

INPut:FILTer:FREQuency? 3–126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut:IMPedance

INPut:IMPedance? 3–127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut:PROTection:STATe

INPut:PROTection:STATe? 3–128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEMory Subsystem 3–131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEMory:DATA

MEMory:DATA? 3–131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEMory:NSTates? (Query Only) 3–133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEMory:STATe:CATalog? (Query Only) 3–134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEMory:STATe:DEFine? (Query Only) 3–135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut Subsystem 3–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:ECLTrg<n>

OUTPut:ECLTrg<n>? 3–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:ECLTrg<n>:POLarity

OUTPut:ECLTrg<n>:POLarity? 3–138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:ECLTrg<n>:SOURce

OUTPut:ECLTrg<n>:SOURce? 3–139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:PCOMpensate

OUTPut:PCOMpensate? 3–140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:PCOMpensate:FUNCtion

OUTPut:PCOMpensate:FUNCtion? 3–141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:REFerence

OUTPut:REFerence? 3–142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:REFerence:FUNCtion

OUTPut:REFerence:FUNCtion? 3–143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:TTLTrg<n>

OUTPut:TTLTrg<n>? 3–144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:TTLTrg<n>:POLarity

OUTPut:TTLTrg<n>:POLarity? 3–145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut:TTLTrg<n>:SOURce

OUTPut:TTLTrg<n>:SOURce? 3–146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROSCillator Subsystem 3–149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

v

Page 10

Table of Contents

ROSCillator:SOURce

ROSCillator:SOURce? 3–150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus Subsystem 3–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation? (Query Only) 3–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus:OPERation:CONDition? (Query Only) 3–153. . . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation:ENABle

STATus:OPERation:ENABle? 3–154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation:NTRansition

STATus:OPERation:NTRansition? 3–155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation:PTRansition

STATus:OPERation:PTRansition? 3–156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation:QENable:NTRansition

STATus:OPERation:QENable:NTRansition? 3–157. . . . . . . . . . . . . . . . . . . . . . . .

STATus:OPERation:QENable:PTRansition

STATus:OPERation:QENable:PTRansition? 3–158. . . . . . . . . . . . . . . . . . . . . . . .

STATus:PRESet 3–159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus:QUEStionable? (Query Only) 3–160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus:QUEStionable:CONDition? (Query Only) 3–161. . . . . . . . . . . . . . . . . . . . . .

STATus:QUEStionable:ENABle

STATus:QUEStionable:ENABle? 3–162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:QUEStionable:NTRansition

STATus:QUEStionable:NTRansition? 3–163. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:QUEStionable:PTRansition

STATus:QUEStionable:PTRansition? 3–164. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus:QUEStionable:QENable:NTRansition

STATus:QUEStionable:QENable:NTRansition? 3–165. . . . . . . . . . . . . . . . . . . . .

STATus:QUEStionable:QENable:PTRansition

STATus:QUEStionable:QENable:PTRansition? 3–166. . . . . . . . . . . . . . . . . . . . .

STATus:SESR:QENable

STATus:SESR:QENable? 3–168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep Subsystem 3–169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:OFFSet:POINts

SWEep:OFFSet:POINts? 3–170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:OFFSet:TIME

SWEep:OFFSet:TIME? 3–171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:OREFerence:LOCation

SWEep:OREFerence:LOCation? 3–173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:POINts

SWEep:POINts? 3–174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:TIME

SWEep:TIME? 3–176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEep:TINTerval

SWEep:TINTerval? 3–177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem Subsystem 3–179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:BAUD

SYSTem:COMMunicate:SERial:BAUD? 3–179. . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:CONTrol:DCD

SYSTem:COMMunicate:SERial:CONTrol:DCD? 3–180. . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:CONTrol:RTS

SYSTem:COMMunicate:SERial:CONTrol:RTS? 3–181. . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:ECHO

SYSTem:COMMunicate:SERial:ECHO? 3–182. . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

TVS600 Series Waveform Analyzers User Manual

Page 11

Table of Contents

SYSTem:COMMunicate:SERial:ERESponse

SYSTem:COMMunicate:SERial:ERESponse? 3–183. . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:LBUFfer

SYSTem:COMMunicate:SERial:LBUFfer? 3–184. . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:PACE

SYSTem:COMMunicate:SERial:PACE? 3–185. . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:PARity

SYSTem:COMMunicate:SERial:PARity? 3–186. . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:PRESet 3–187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:COMMunicate:SERial:SBITs

SYSTem:COMMunicate:SERial:SBITs? 3–188. . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:ERRor? (Query Only) 3–189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:ERRor:ALL? (Query Only) 3–190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:ERRor:CODE? (Query Only) 3–191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:ERRor:CODE:ALL? (Query Only) 3–192. . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:ERRor:COUNt? (Query Only) 3–193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:PROTect

SYSTem:PROTect? 3–193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:SECurity:IMMediate 3–194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:SET

SYSTem:SET? 3–195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em:VERSion? (Query Only) 3–196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST

TEST? 3–197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST:RESults? (Query Only) 3–198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST:RESults:VERBose? (Query Only) 3–199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe Subsystem 3–201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe? (Query Only) 3–202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:PREamble? (Query Only) 3–203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:CATalog? (Query Only) 3–205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:COPY 3–206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:FEED? (Query Only) 3–207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:LIST

TRACe:LIST? 3–208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe:POINts? (Query Only) 3–209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger[:A] Subsystem 3–211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:ATRigger

TRIGger:ATRigger? 3–211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:COUPling

TRIGger:COUPling? 3–212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:COUPling:<preset> 3–213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:DEFine? (Query Only) 3–214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:DELay

TRIGger:DELay? 3–215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:FILTer[:LPASs]

TRIGger:FILTer[:LPASs]? 3–216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:FILTer:HPASs

TRIGger:FILTer:HPASs? 3–217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:FILTer:NREJect

TRIGger:FILTer:NREJect? 3–218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

vii

Page 12

Table of Contents

TRIGger:HOLDoff:TIME

TRIGger:HOLDoff:TIME? 3–219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:LEVel

TRIGger:LEVel? 3–220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:SLOPe

TRIGger:SLOPe? 3–221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:SOURce

TRIGger:SOURce? 3–222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:TYPE

TRIGger:TYPE? 3–223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B Subsystem 3–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:COUPling

TRIGger:B:COUPling? 3–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:COUPling:<preset> 3–226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:SEQuence2:DEFine? (Query Only) 3–227. . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:DELay

TRIGger:B:DELay? 3–228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:ECOunt

TRIGger:B:ECOunt? 3–229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:FILTer[:LPASs]

TRIGger:B:FILTer[:LPASs]? 3–230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:FILTer:HPASs

TRIGger:B:FILTer:HPASs? 3–231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:FILTer:NREJect

TRIGger:B:FILTer:NREJect? 3–232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:LEVel

TRIGger:B:LEVel? 3–233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:SLOPe

TRIGger:B:SLOPe? 3–234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:B:SOURce

TRIGger:B:SOURce? 3–235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe Subsystem 3–237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:CLASs

TRIGger:PULSe:CLASs? 3–237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:GLITch:POLarity

TRIGger:PULSe:GLITch:POLarity? 3–238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:GLITch:QUALify

TRIGger:PULSe:GLITch:QUALify? 3–239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:GLITch:WIDTh

TRIGger:PULSe:GLITch:WIDTh? 3–240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:SOURce

TRIGger:PULSe:SOURce? 3–241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:THReshold

TRIGger:PULSe:THReshold? 3–242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:WIDTh:HLIMit

TRIGger:PULSe:WIDTh:HLIMit? 3–243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:WIDTh:LLIMit

TRIGger:PULSe:WIDTh:LLIMit? 3–244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:WIDTh:POLarity

TRIGger:PULSe:WIDTh:POLarity? 3–245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger:PULSe:WIDTh:QUALify

TRIGger:PULSe:WIDTh:QUALify? 3–246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VOLTage Subsystem 3–247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

TVS600 Series Waveform Analyzers User Manual

Page 13

Table of Contents

VOLTage:RANGe[:UPPer]

VOLTage:RANGe[:UPPer]? 3–248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VOLTage:RANGe:LOWer

VOLTage:RANGe:LOWer? 3–249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VOLTage:RANGe:OFFSet

VOLTage:RANGe:OFFSet? 3–251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VOLTage:RANGe:PTPeak

VOLTage:RANGe:PTPeak? 3–253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE 488.2 Common Commands 3–255. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*CAL? (Query Only) 3–255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*CLS 3–256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESE

*ESE? 3–257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESR? (Query Only) 3–258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*IDN? (Query Only) 3–259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*LRN? (Query Only) 3–260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*OPC

*OPC? 3–261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*OPT? (Query Only) 3–261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*PUD

*PUD? 3–262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*RCL 3–263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*RST 3–264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*SAV 3–264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*SRE

*SRE? 3–265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*STB? (Query Only) 3–266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*TRG 3–267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*TST? (Query Only) 3–268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*WAI 3–269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Events

Status and Events 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registers 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Queues 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Event Reporting Process 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization Methods 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Appendix A: Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification T ables A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Algorithms B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Variables B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Algorithms B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differentiation Algorithm B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integration Algorithm B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smooth Algorithm B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: ASCII Character Chart C–1. . . . . . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

ix

Page 14

Table of Contents

Glossary and Index

Appendix D: SCPI Conformance Information D–1. . . . . . . . . . . . . . . . . . .

x

TVS600 Series Waveform Analyzers User Manual

Page 15

List of Figures

Table of Contents

Figure 1–1: Logical Address Switches 1–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Module Retainer Screws and Ejector Mechanism 1–6. . . . . .

Figure 1–3: Example VXIbus Test System for the

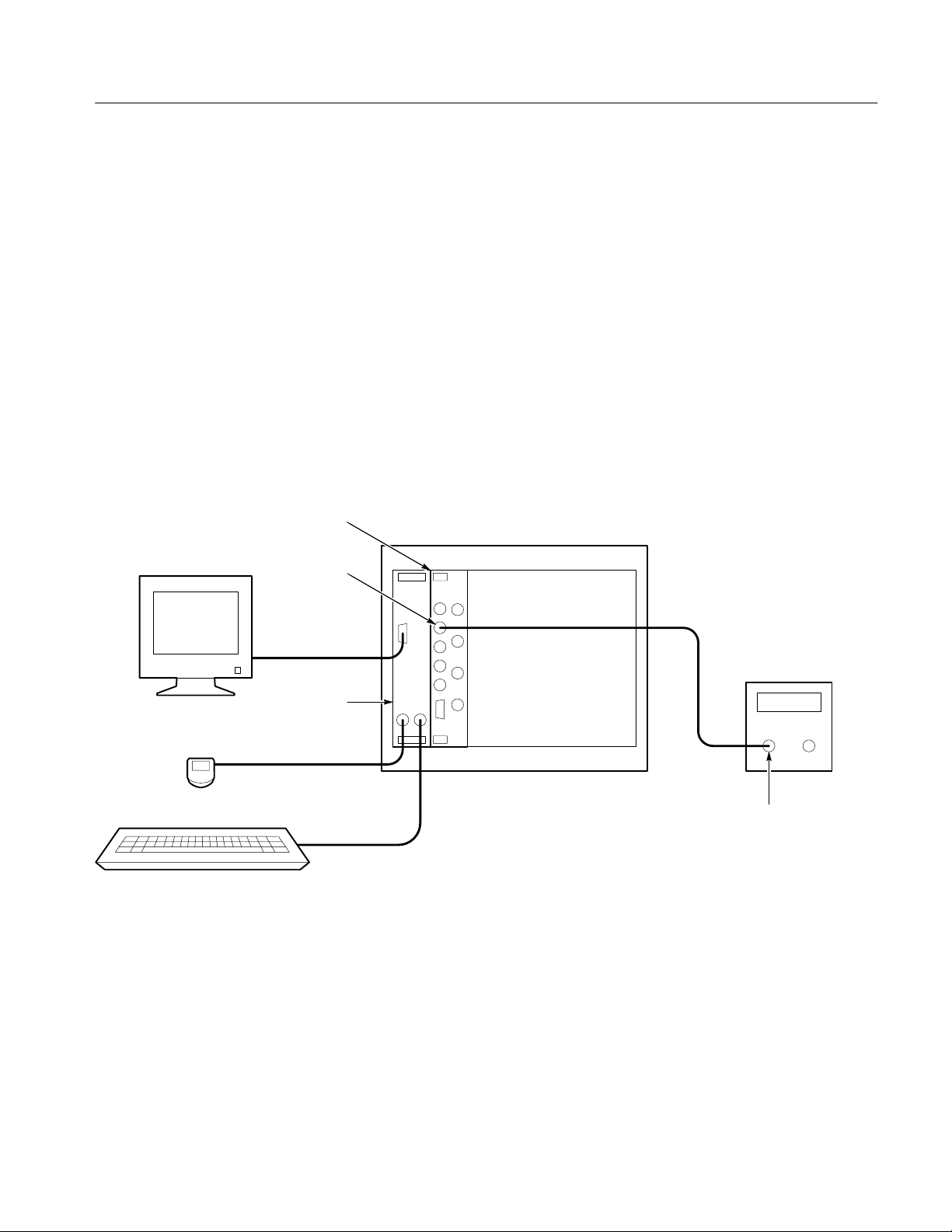

Incoming Inspection Procedure 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Time Reference Test Setup for Functional Tests 1–17. . . . . . .

Figure 1–5: Voltage Reference Test Setup for Functional Tests 1–19. . . . .

Figure 2–1: TVS600 Front Panel 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

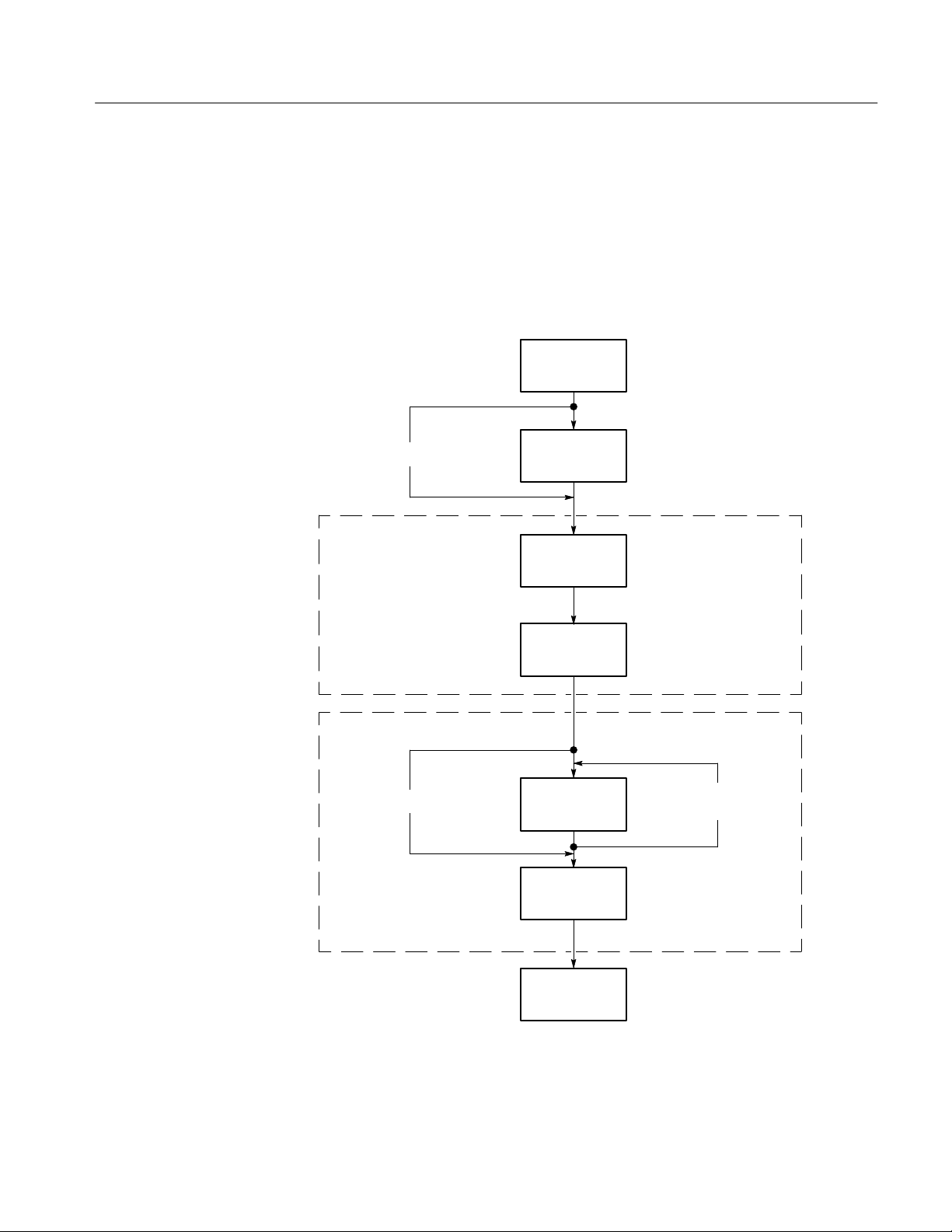

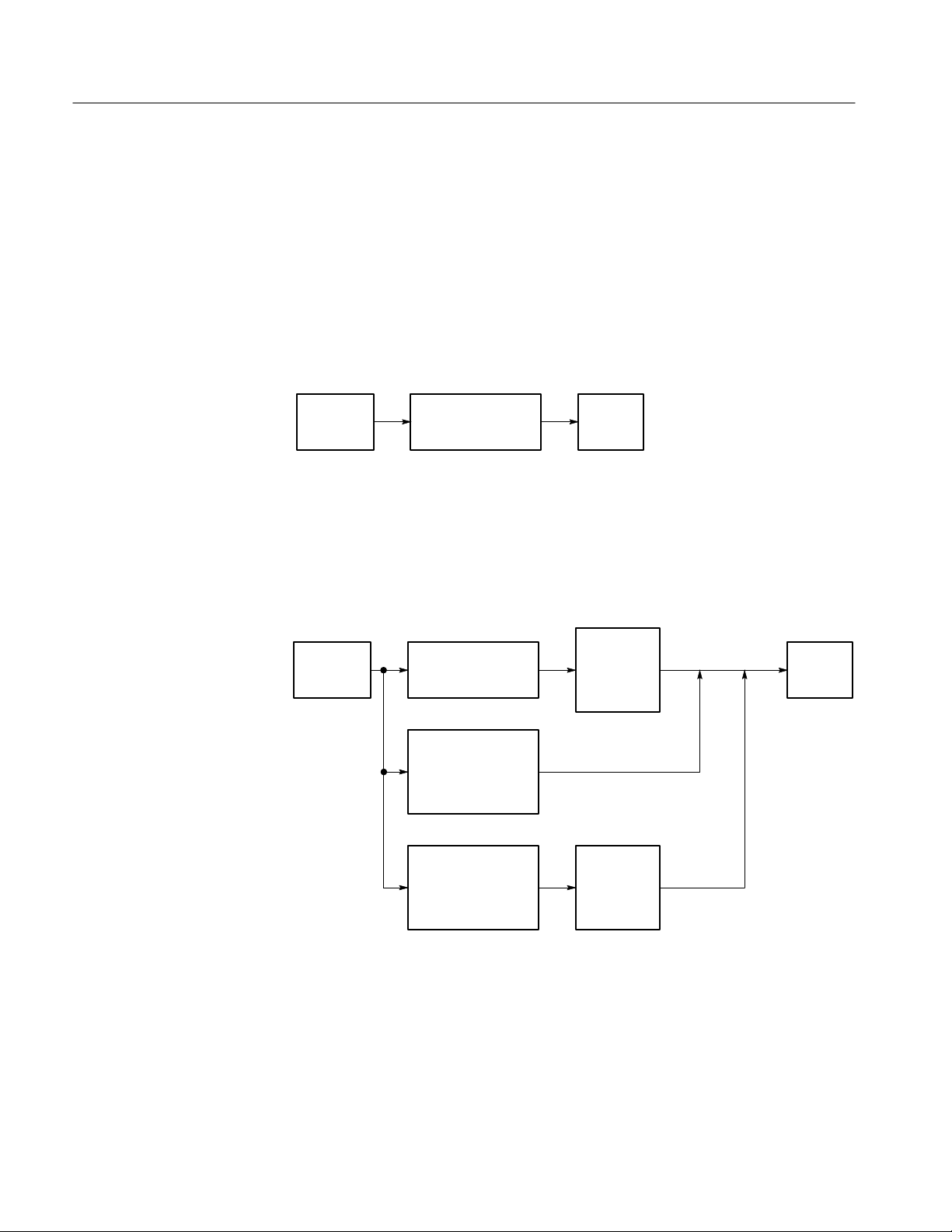

Figure 2–2: Instrument model showing root level nodes 2–8. . . . . . . . . . .

Figure 2–3: Digital acquisition showing sampling

and digitizing steps 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Digitizer configuration 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

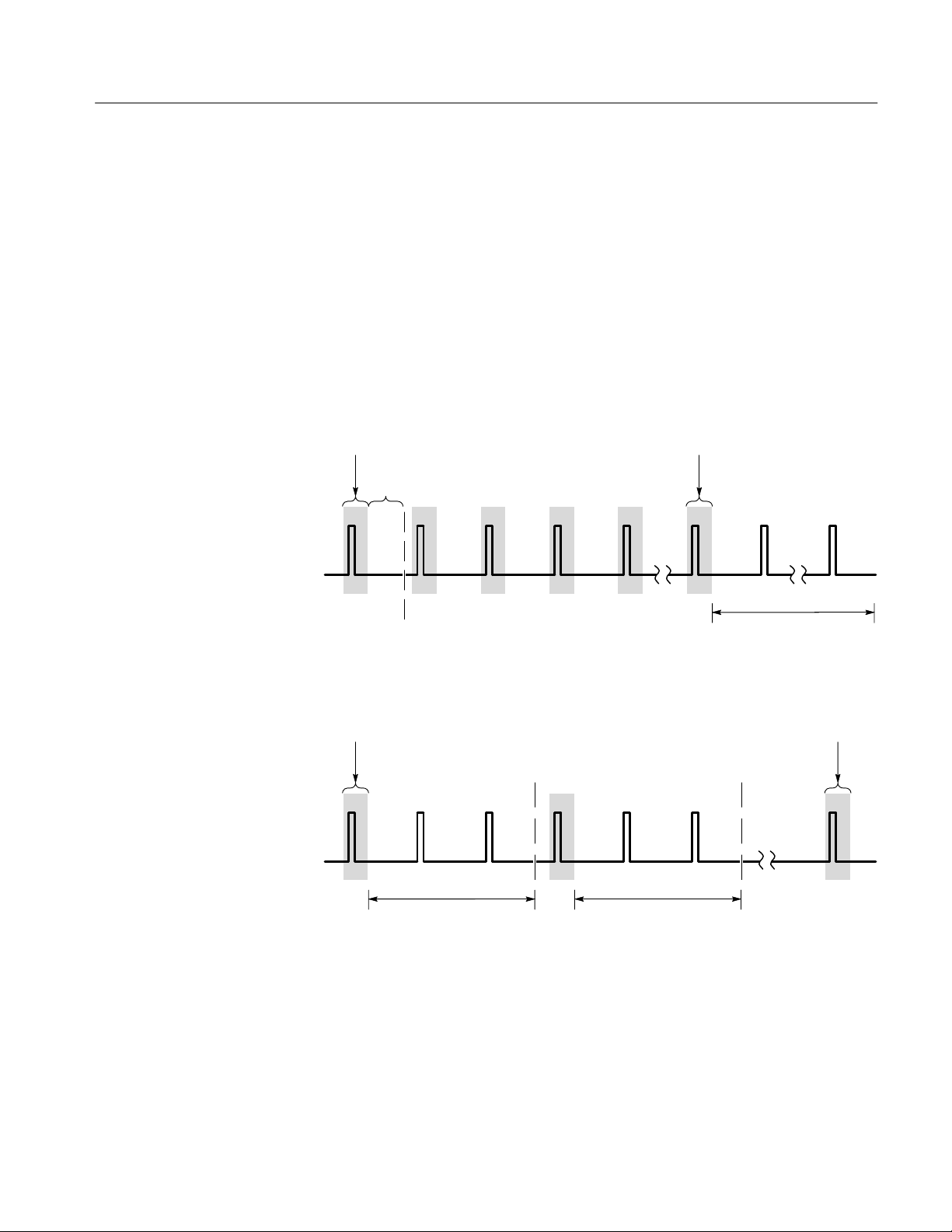

Figure 2–5: Digital sampling showing the sample interval,

trigger event, and pretrigger samples 2–10. . . . . . . . . . . . . . . . . . . . . . .

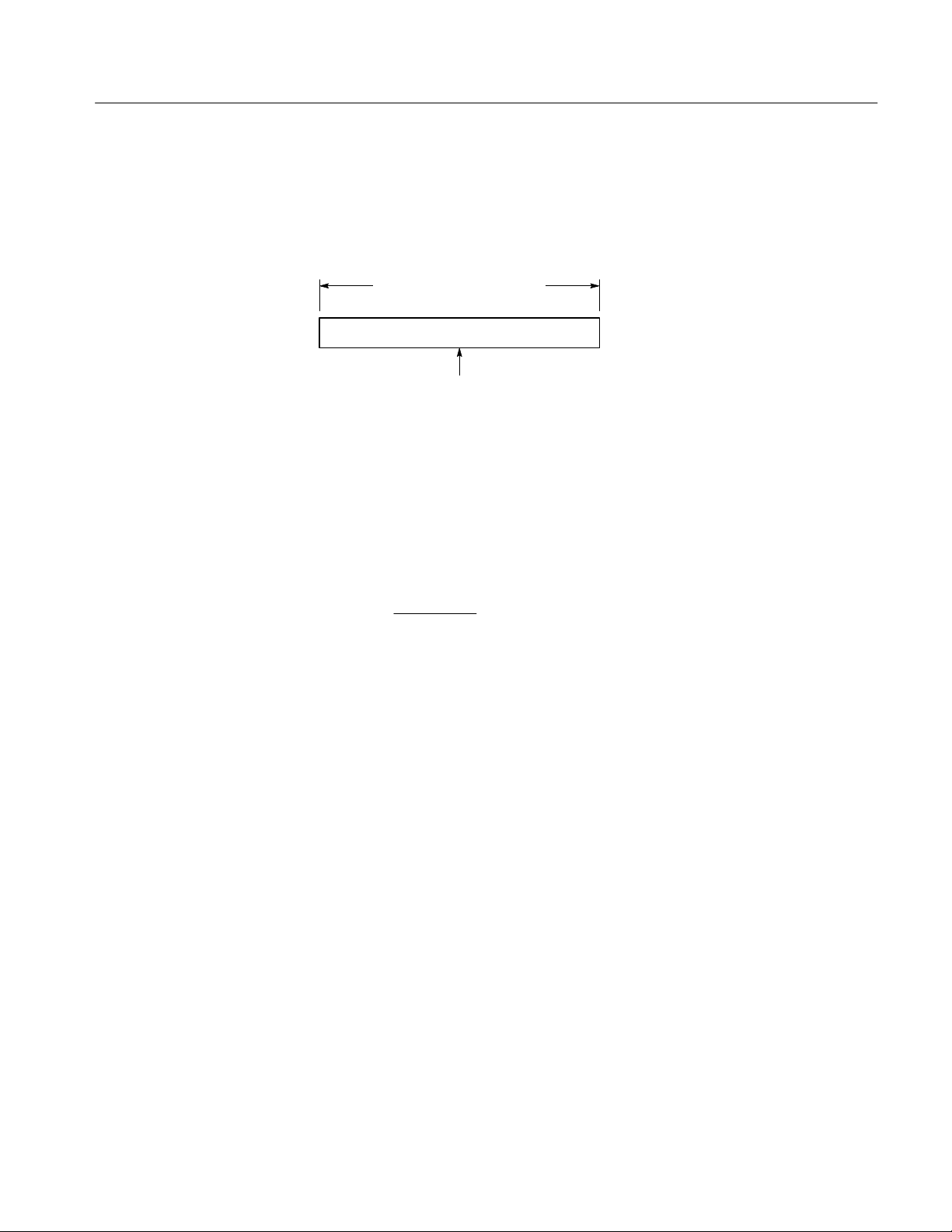

Figure 2–6: Positioning the waveform record relative

to the trigger point 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Real-time acquisition 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: The acquisition cycle 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–9: Comparison between auto-advance and INIT acquisition

looping 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

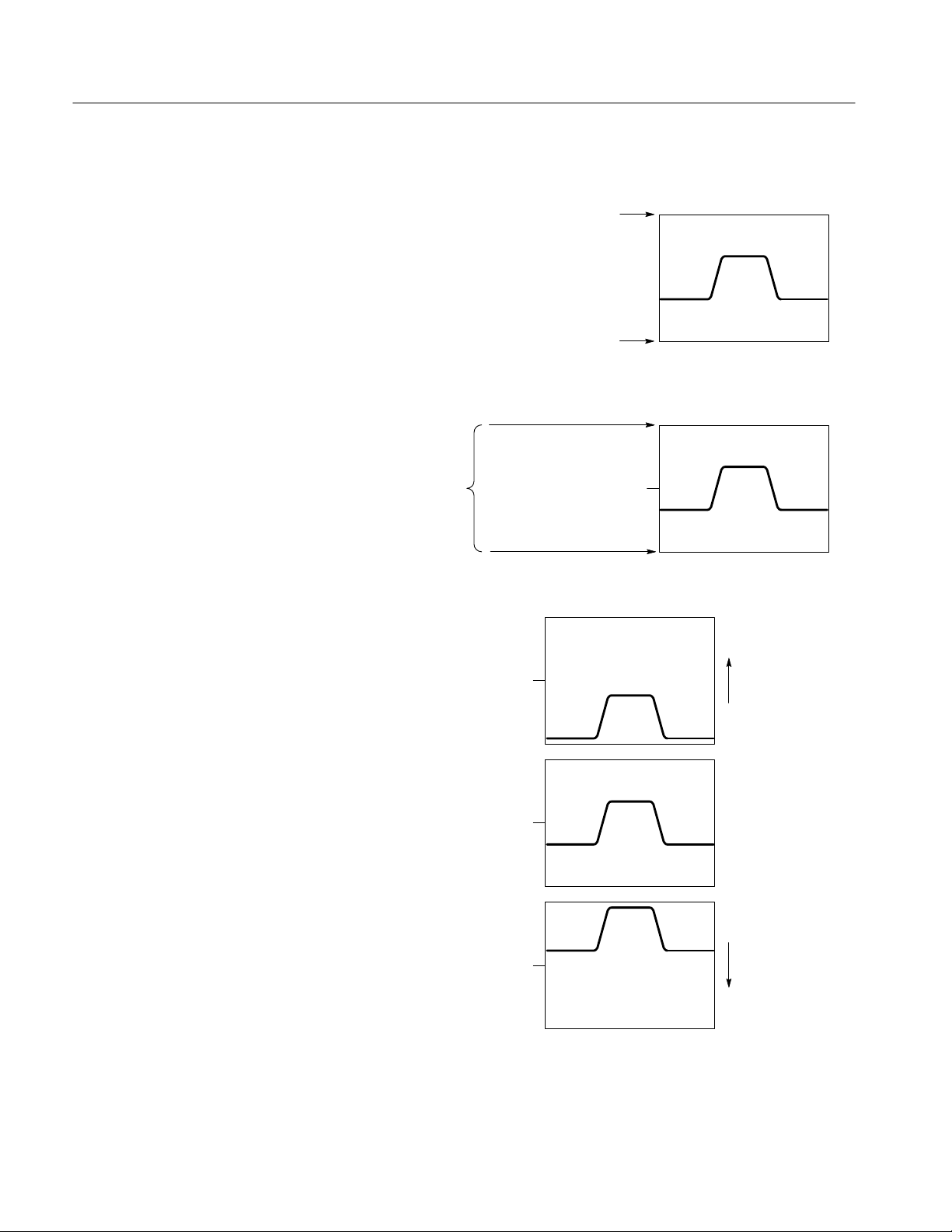

Figure 2–10: Setting vertical range and offset of input channels 2–20. . . .

Figure 2–11: The Arm/Trigger cycle 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–12: Slope and level define the trigger event 2–23. . . . . . . . . . . . .

Figure 2–13: Trigger holdoff time ensures valid triggering 2–24. . . . . . . .

Figure 2–14: Delayed runs after main 2–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–15: Delayed triggerable 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–16: How the delayed triggers work 2–27. . . . . . . . . . . . . . . . . . . .

Figure 2–17: Trigger holdoff time with trigger delay time 2–28. . . . . . . . .

Figure 2–18: Parameters for pulse triggering 2–29. . . . . . . . . . . . . . . . . . .

Figure 2–19: PATH definition for SCPI calculation model 2–32. . . . . . . . .

Figure 2–20: Zero phase reference point in FFT phase records 2–41. . . . .

Figure 2–21: How aliased frequencies corrupt an FFT transform 2–42. . .

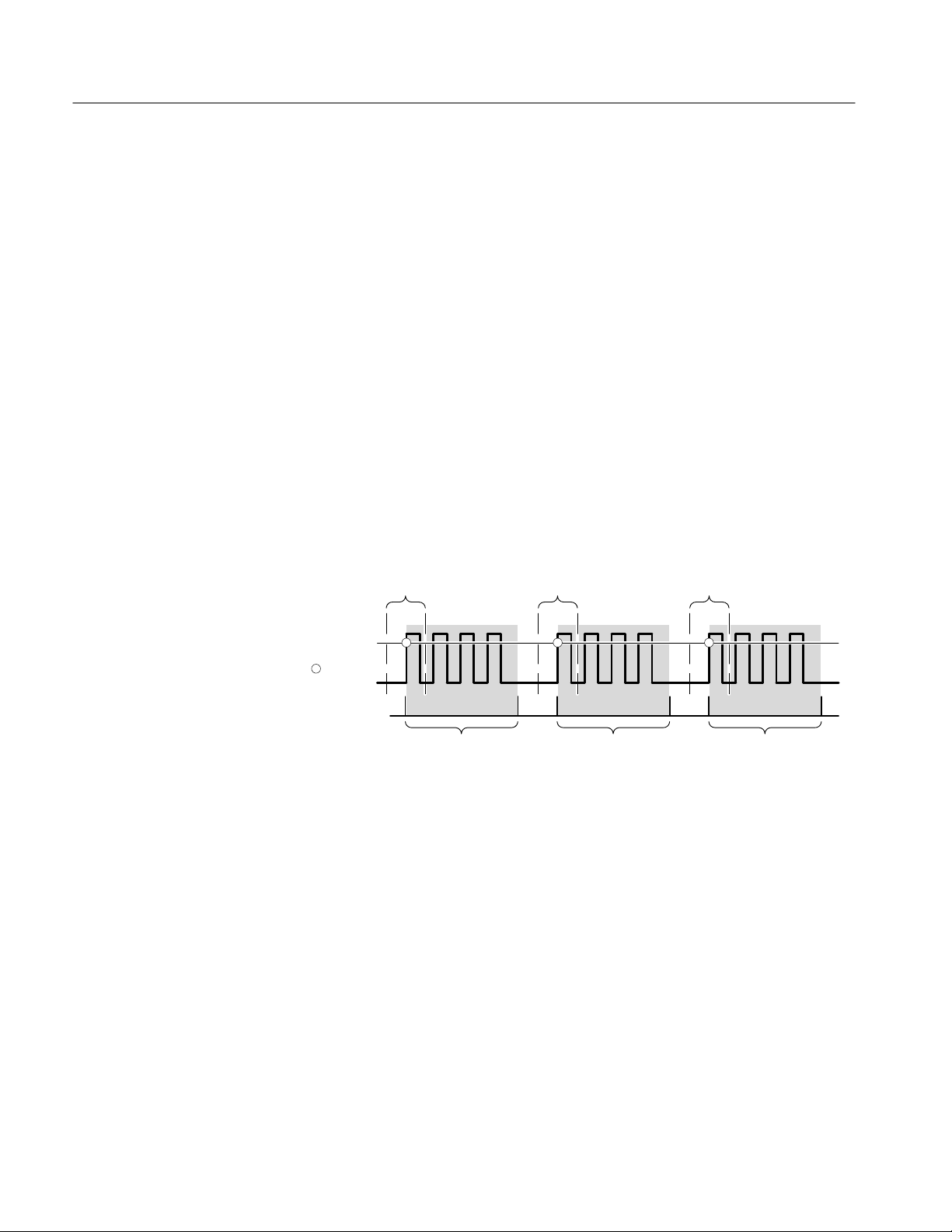

Figure 2–22: Windowing the FFT time domain record 2–43. . . . . . . . . . . .

Figure 2–23: FFT windows and bandpass characteristics 2–45. . . . . . . . . .

Figure 2–24: Parameters for the four digital filters 2–47. . . . . . . . . . . . . . .

Figure 2–25: Two methods of setting BPASs and NOTCh filters 2–48. . . .

Figure 2–26: Rejection level and transition slope for the digital filter 2–49

TVS600 Series Waveform Analyzers User Manual

xi

Page 16

Table of Contents

Figure 2–27: Binary transfer format 2–56. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–28: VXIbus Connectors P1 and P2 2–65. . . . . . . . . . . . . . . . . . . .

Figure 2–29: Pin assignments for the SERIAL INTERFACE (RS-232)

connector 2–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–30: Initial Equipment Setup for the Tutorial 2–72. . . . . . . . . . . .

Figure 2–31: Standard Event and Status Byte Registers 2–81. . . . . . . . . . .

Figure 3–1: Example of SCPI Subsystem Hierarchy Tree 3–1. . . . . . . . .

Figure 3–2: Example of Abbreviating a Command 3–3. . . . . . . . . . . . . . .

Figure 3–3: Example of Chaining Commands and Queries 3–4. . . . . . . .

Figure 3–4: Example of Omitting Root and Lower-level Nodes

in Chained Message 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: Instrument Model Showing Root-level Nodes

and Subsystems 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–6: AADVance Subsystem Hierarchy 3–29. . . . . . . . . . . . . . . . . . .

Figure 3–7: AADVance Subsystem Functional Model 3–29. . . . . . . . . . . . .

Figure 3–8: ARM Subsystem Hierarchy 3–35. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–9: AVERage Subsystem Hierarchy 3–39. . . . . . . . . . . . . . . . . . . .

Figure 3–10: AVERage Subsystem Functional Model 3–39. . . . . . . . . . . . .

Figure 3–11: CALCulate Subsystem Hierarchy 3–43. . . . . . . . . . . . . . . . . .

Figure 3–12: CALCulate Subsystem Functional Model 3–43. . . . . . . . . . .

Figure 3–13: CALibration Subsystem Hierarchy 3–97. . . . . . . . . . . . . . . .

Figure 3–14: FORMat Subsystem Hierarchy 3–101. . . . . . . . . . . . . . . . . . .

Figure 3–15: FUNCtion and DATA Hierarchy 3–105. . . . . . . . . . . . . . . . . . .

Figure 3–16: FUNCtion and DATA Functional Model 3–105. . . . . . . . . . . .

Figure 3–17: INITiate and ABORt Subsystem Hierarchy 3–117. . . . . . . . . .

Figure 3–18: INPut Subsystem Hierarchy 3–123. . . . . . . . . . . . . . . . . . . . . .

Figure 3–19: INPut Subsystem Functional Model 3–123. . . . . . . . . . . . . . . .

Figure 3–20: MEMory Subsystem Hierarchy 3–131. . . . . . . . . . . . . . . . . . .

Figure 3–21: OUTPut Subsystem Hierarchy 3–137. . . . . . . . . . . . . . . . . . . .

Figure 3–22: ROSCillator Subsystem 3–149. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–23: ROSCillator Subsystem Functional Model 3–149. . . . . . . . . .

Figure 3–24: STATus Subsystem Hierarchy 3–151. . . . . . . . . . . . . . . . . . . .

Figure 3–25: SWEep Subsystem Hierarchy 3–169. . . . . . . . . . . . . . . . . . . . .

Figure 3–26: SWEep Subsystem Functional Model 3–169. . . . . . . . . . . . . . .

Figure 3–27: SYSTem Subsystem Hierarchy 3–179. . . . . . . . . . . . . . . . . . . .

Figure 3–28: TEST Subsystem Hierarchy 3–197. . . . . . . . . . . . . . . . . . . . . .

Figure 3–29: TRACe Subsystem Hierarchy 3–201. . . . . . . . . . . . . . . . . . . . .

Figure 3–30: Functions of the TRACe Subsystem 3–201. . . . . . . . . . . . . . . .

Figure 3–31: TRIGger:A (SCPI SEQuence1) Subsystem Hierarchy 3–211.

xii

TVS600 Series Waveform Analyzers User Manual

Page 17

Table of Contents

Figure 3–32: TRIGger:B (SCPI SEQuence2) Subsystem Hierarchy 3–225.

Figure 3–33: TRIGger:PULSe Subsystem Hierarchy 3–237. . . . . . . . . . . . .

Figure 3–34: VOLTage Subsystem Hierarchy 3–247. . . . . . . . . . . . . . . . . . .

Figure 3–35: VOLTage Subsystem Functional Model 3–247. . . . . . . . . . . . .

Figure 3–36: IEEE 488.2 Common Command Syntax 3–255. . . . . . . . . . . .

Figure 4–1: SCPI & IEEE 488.2 Status and Event Registers 4–2. . . . . . .

Figure 4–2: Status and Event Reporting Process 4–10. . . . . . . . . . . . . . . . .

Figure B–1: MCross Calculations B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–2: Fall time B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–3: Rise Time B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–4: Transfer function H(f) for an ideal bandpass filter B–15. . . . .

Figure B–5: Transfer function for an ideal lowpass filter B–16. . . . . . . . . .

Figure B–6: Using a rectangular window to truncate the data

from Figure B–5 to a finite number of points B–17. . . . . . . . . . . . . . . .

Figure B–7: Lowpass filter transfer function obtained by truncating

the impulse response to just a few points B–18. . . . . . . . . . . . . . . . . . . .

Figure B–8: Using more points in the Lowpass filter results in a steeper

transition at the cutoff frequency B–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–9: Using many more points in the Lowpass filter results in a

quicker transition but a minimum attenuation of 21 dB B–19. . . . . . .

Figure B–10: Kaiser window with 200 points and b = 1, 5 and 20 B–20. . .

Figure B–11: Compare this result with Figure B–9 with the same

number of points but a rectangular window B–21. . . . . . . . . . . . . . . . .

Figure B–12: Filter specifications for a lowpass filter B–21. . . . . . . . . . . . .

Figure B–13: Filter specifications for a bandpass filter B–23. . . . . . . . . . . .

Figure B–14: Record resulting from convolving the filter impulse

response with the waveform record B–24. . . . . . . . . . . . . . . . . . . . . . . .

Figure B–15: Filter test signal with a 125 MHz signal modulating

a 10 MHz signal B–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–16: Test signal after being filtered with a lowpass filter B–25. . .

Figure B–17: View of the filtered record showing the first 5%

of the filtered data B–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

xiii

Page 18

Table of Contents

List of Tables

Table 1–1: Factory Default RS-232 Settings 1–14. . . . . . . . . . . . . . . . . . . .

Table 2–1: Trigger Sources and Compatibility 2–22. . . . . . . . . . . . . . . . . .

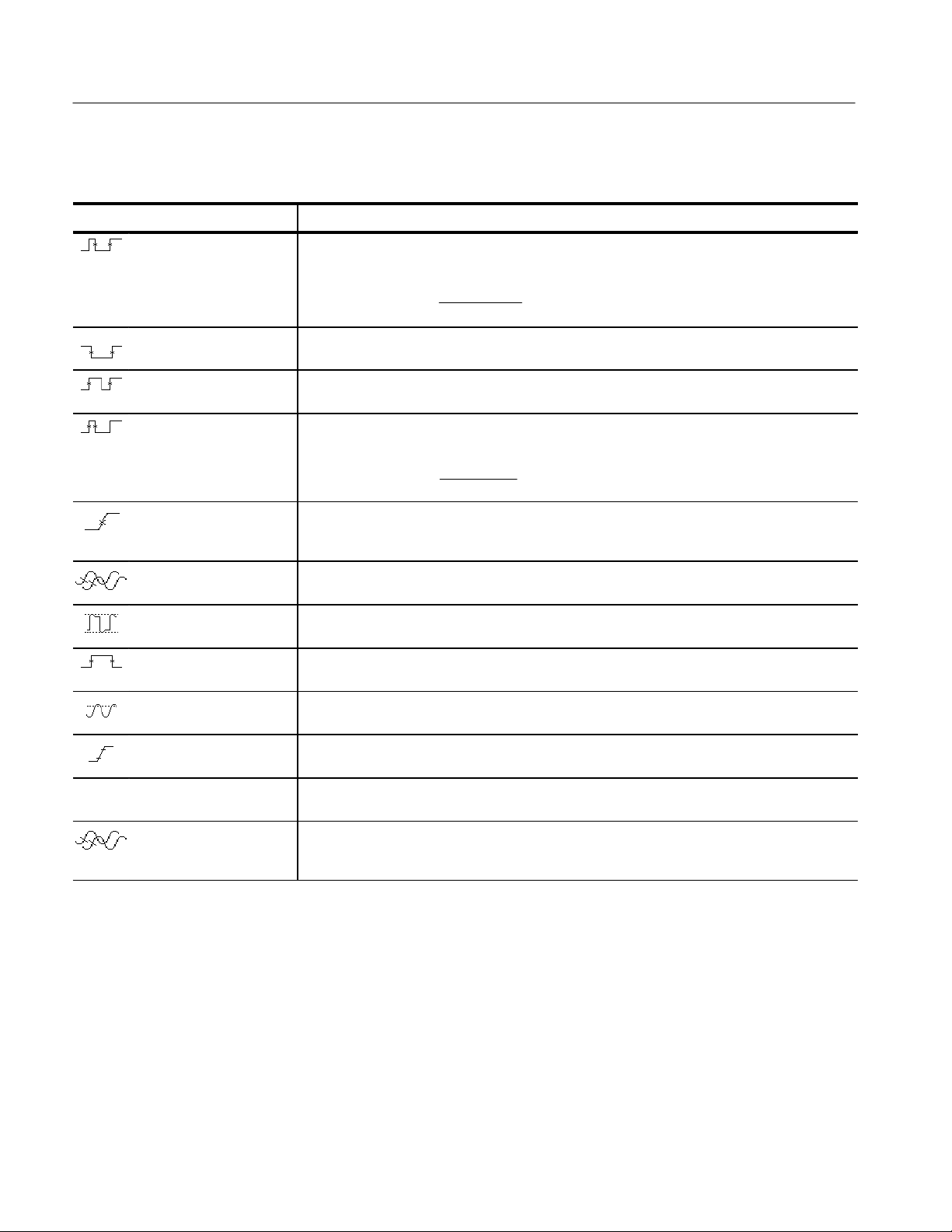

Table 2–2: Measurement Definitions 2–35. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Measurement Parameters 2–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Commands for Fast Data Channel and Associated

Functions 2–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: Waveform Preambles and Their Formats 2–58. . . . . . . . . . . . .

Table 2–6: Parameter Definitions for Preamble Elements 2–61. . . . . . . . .

Table 2–7: Trigger output lines and their default assignments 2–64. . . . .

Table 2–8: Left Slot P1 Pinout 2–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–9: Left Slot P2 Pinout 2–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–10: Right Slot P2 Pinout 2–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Parameter Types Used in Syntax Descriptions 3–2. . . . . . . . .

Table 3–2: BNF Symbols and Meanings 3–6. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Auto-advance Commands 3–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Abort Commands 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Arm Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–6: Average Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–7: Calculate Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–8: Calibration Commands 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–9: Data Commands 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–10: Format Commands 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: Function Commands 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–12: Initiate Commands 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–13: Input Commands 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–14: Memory Commands 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–15: Output Commands 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–16: Reference Oscillator Commands 3–17. . . . . . . . . . . . . . . . . . .

Table 3–17: Status Commands 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–18: Sweep Commands 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–19: System Commands 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–20: Test Commands 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–21: Trace Commands 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–22: Trigger Commands 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–23: Voltage Commands 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

TVS600 Series Waveform Analyzers User Manual

Page 19

Table of Contents

Table 3–24: IEEE 488.2 Common Commands 3–25. . . . . . . . . . . . . . . . . .

Table 3–25: Waveform Measurement Definitions 3–78. . . . . . . . . . . . . . . .

Table 3–26: The Operation Status Register 3–151. . . . . . . . . . . . . . . . . . . . .

Table 3–27: The Questionable Status Register 3–160. . . . . . . . . . . . . . . . . .

Table 3–28: Effects of :PRESet on Serial Port Parameters 3–187. . . . . . . .

Table 3–29: The Standard Event Status Register 3–258. . . . . . . . . . . . . . . .

Table 3–30: The Status Byte Register 3–266. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: The Status Byte Register 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: The Standard Event Status Register 4–4. . . . . . . . . . . . . . . . .

Table 4–3: The Operation Status Register 4–5. . . . . . . . . . . . . . . . . . . . . .

Table 4–4: Control Registers for the Operation Status Register 4–6. . . .

Table 4–5: The Questionable Status Register 4–7. . . . . . . . . . . . . . . . . . .

Table 4–6: Control Registers for the Questionable Status Register 4–7.

Table 4–7: Commands Associated with the Status Queue 4–8. . . . . . . . .

Table 4–8: Command Error Messages (Bit 5 in Standard Event

Status Register) 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–9: Execution Error Messages (Bit 4 in Standard Event

Status Register) 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–10: Device Dependent Error Messages (Bit 3 in Standard Event

Status Register) 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–11: System Events 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–12: Execution Warning Messages (Bit 3 in Standard Event

Status Register) 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–1: Comparison of Product Features A–1. . . . . . . . . . . . . . . . . . .

Table A–2: Signal Acquisition System A–2. . . . . . . . . . . . . . . . . . . . . . . . .

Table A–3: Timebase System A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–4: Trigger System A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–5: Front Panel Connectors A–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–6: VXI Interface A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–7: Power Distribution and Data Handling A–12. . . . . . . . . . . . . .

Table A–8: Environmental A–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–9: Certifications and Compliances A–13. . . . . . . . . . . . . . . . . . . . .

Table A–10: Mechanical A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C–1: ASCII Code Chart C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D–1: SCPI Conformance Information D–1. . . . . . . . . . . . . . . . . . . .

TVS600 Series Waveform Analyzers User Manual

xv

Page 20

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Avoid Electric Overload

Avoid Electric Shock

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in an

Explosive Atmosphere

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

To avoid injury or loss of life, do not connect or disconnect probes or test leads

while they are connected to a voltage source.

This product is indirectly grounded through the grounding conductor of the

mainframe power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

TVS600 Series Waveform Analyzers User Manual

xvii

Page 21

General Safety Summary

Product Damage Precautions

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product

Symbols on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

xviii

TVS600 Series Waveform Analyzers User Manual

Page 22

Certifications and Compliances

General Safety Summary

Safety Certification of

Plug-in or VXI Modules

Compliances

Overvoltage Category

For modules (plug-in or VXI) that are safety certified by Underwriters Laboratories, UL Listing applies only when the module is installed in a UL Listed

product.

For modules (plug-in or VXI) that have cUL or CSA approval, the approval

applies only when the module is installed in a cUL or CSA approved product.

Consult the product specifications for Overvoltage Category and Safety Class.

Overvoltage categories are defined as follows:

CAT III: Distribution level mains, fixed installation

CAT II: Local level mains, appliances, portable equipment

CAT I: Signal level, special equipment or parts of equipment, telecommunica-

tion, electronics

TVS600 Series Waveform Analyzers User Manual

xix

Page 23

Preface

About This Manual

This manual describes the capabilities of the TVS600 Series Waveform

Analyzers and how to use them in a programming environment. The TVS600

Series Waveform Analyzers, also referred to as the waveform analyzer, are

controlled through the use of SCPI (Standard Commands for Programmable

Instruments) derived commands and IEEE 488.2 Common Commands. This

manual describes how to use these commands to configure the waveform

analyzer and access information generated by it or stored within it.

This manual is composed of the following sections:

H Getting Started shows you how to configure and install your waveform

analyzer and provides an Incoming Inspection procedure.

H Operating Basics describes the front panel connectors, provides a functional

overview of product functions and presents a Tutorial on programming the

waveform analyzer.

Related Manuals

H Syntax and Commands defines the syntax used in command descriptions,

presents a list of all command subsystems, and presents detailed descriptions

of all programming commands.

H Status and Events describes how the status and Events Reporting system

operates and presents a list of all system errors.

H Appendices provides additional information including the Specifications,

Calculation algorithms, and SCPI conformance information.

The following documents are also available for the TVS600 Series Waveform

Analyzers:

H The TVS600 Series Waveform Analyzers Reference (Tektronix part number

070-9284-XX) provides an alphabetical listing of the programming

commands. This manual is a standard accessory.

H The TVS600 Series Waveform Analyzers Service Manual (Tektronix part

number 070-9285-XX) describes how to service the instrument to the

module level. This optional manual must be ordered separately.

TVS600 Series Waveform Analyzers User Manual

xxi

Page 24

Getting Started

Product Description

This chapter provides information that will help you get started using your

TVS600 Waveform Analyzer. This Chapter describes the waveform analyzer and

its options. This chapter also shows you how to configure and install the

waveform analyzer and the VXIplug&play software included with the product.

This chapter concludes with the Incoming Inspection procedure which verifies

basic operation and functionality.

The TVS600 Series Waveform Analyzers are a family of C-size, VXI modules

that provide high-speed signal acquisition, real-time measurements and Fast Data

Channel data transfer. Key features include:

H Fully programmable with an extensive SCPI command set and message

based interface

H Fast rearm capability with auto-advance acquisition mode

H Sample intervals as short as 200 ps/point with real time sampling

Accessories

H Acquisition modes such as auto-advance, envelope, and average

H A full compliment of internal triggering modes, including main, delayed,

edge and pulse triggering

H Trigger sources from input channels, front panel External Trigger, and VXI

backplane triggers

H Standard acquisition memory that allows 15,000 samples to be taken in

realtime acquisition mode and 30,000 samples in extended-realtime

acquisition mode.

H Very fast calculation system for measurements, waveform math, and

waveform transforms.

This section lists the standard and optional accessories available for the TVS600

Series Waveform Analyzers.

In addition to the options described in this section, Tektronix offers maintenance

options that cover calibration and repair services. Contact your Tektronix

representative for details.

TVS600 Series Waveform Analyzers User Manual

1–1

Page 25

Getting Started

Standard Accessories

Optional Accessories

Configuration

The following accessories are shipped with the waveform analyzer:

H TVS600 Series Waveform Analyzers User Manual (Tektronix part number

070-9283-XX)

H TVS600 Series Waveform Analyzers Reference Manual (Tektronix part

number 070-9284-XX)

H TVS600 Series VXIplug&play Instrument Drivers (Tektronix part number

063-1874-XX)

The following accessories are available for use with the waveform analyzer:

H TVS600 Series Waveform Analyzers Service Manual (Tektronix part number

070-9285-XX)

You must configure the VXIbus module and the VXIbus mainframe before

installing the module. To configure the waveform analyzer, set its logical address

on the VXIbus. To configure your VXIbus mainframe, you set the Bus Grant and

Interrupt Acknowledge jumpers. This section describes how to perform the

necessary configuration.

Setting the Logical

Address

Every module within a VXIbus system must have a unique logical address; no

two modules can have the same address. On the waveform analyzer, you rotate

two switches on the rear panel to select the logical address. Refer to Figure 1–1

for the switch locations. You can select a static address or Dynamic Auto

Configuration. The default address is FF hexadecimal, which selects Dynamic

Auto Configuration.

1–2

TVS600 Series Waveform Analyzers User Manual

Page 26

Least-Significant

Digit

Most-Significant

Digit

Getting Started

Figure 1–1: Logical Address Switches

Static Logical Address Static logical address selections set the address to a fixed

value. The range for static addresses is from 01 to FE hexadecimal (1 to 254

decimal). A static logical address ensures that the waveform analyzer address

remains fixed for compatibility with systems that require a specific address

value. Remember that each device within your system must have a unique

address to avoid communication problems. The factory default address is

FF hexadecimal, which selects Dynamic Auto Configuration.

Dynamic Auto Configuration. With Dynamic Auto Configuration selected

(hexadecimal FF or decimal 255), the system resource manager automatically

sets the address to the next available value in your system. For example, if you

already have devices set to addresses 01 and 02, the resource manager might

automatically assign address 03 to the waveform analyzer at power on.

TVS600 Series Waveform Analyzers User Manual

1–3

Page 27

Getting Started

Configuring the VXIbus

Mainframe

This section describes how to install the waveform analyzer into a Tektronix

VXIbus mainframe. If you are installing the waveform analyzer into a different

mainframe, refer to the instruction manual for that mainframe for any pertinent

installation or capacity information.

V oltage, Current, and Cooling Requirements. You will find voltage, current, and

cooling requirements for the waveform analyzer in Appendix A, Specifications at

the following locations:

H Voltage and current requirements, see Table A–7 on page A–12

H Cooling requirements, see Table A–8 on page A–12

These requirements also appear on the left cover of the waveform analyzer. Be

sure your mainframe can supply adequate current and cooling to the waveform

analyzer and the other modules you plan to install into the same mainframe.

WARNING. Shock hazards exist due to high currents within the mainframe

compartment. Do not change configuration of the Bus Grant and Interrupt

Acknowledge jumpers unless you are qualified to do so. Consult your VXI

mainframe manual for safety warnings and configuration information.

Jumper Settings. Many VXIbus mainframes contain daisy-chain jumper straps

that you must configure before installing the waveform analyzer. The jumper

straps, located beside the P1 connectors, set up the Bus Grant (BG0-BG3) and

Interrupt Acknowledge (IACK) signals. If you are using a Tektronix mainframe,

the names of the jumper straps (BG0-BG3 and IACK) are often printed on the

circuit board facing the front of the mainframe. Access these jumpers from the

front of the mainframe.

Some VXIbus mainframes, such as the Tektronix VX1410 Intelliframe, have

an auto-configurable backplane with no mechanical jumpers. You do not need to

set jumpers on these VXIbus mainframes.

If your VXIbus mainframe has jumper straps, set the IACK and BG0–BG3

jumpers for the waveform analyzer as shown below:

H Remove the jumper straps for the left-most slot in which you will install the

waveform analyzer (retain the strap for future configurations).

H Keep the jumpers for the right-most slot installed in the mainframe.

For example, if you want to install the waveform analyzer into the third and

fourth mainframe slots, remove all jumper straps for the third slot and install

them into the fourth slot.

1–4

TVS600 Series Waveform Analyzers User Manual

Page 28

Installation

Getting Started

This section describes how to install the waveform analyzer into a VXIbus

mainframe and how to install the product software. For hardware configuration

information refer to Configuration on page 1–2.

Hardware Installation

You may install the waveform analyzer into any empty slot in the mainframe

except Slot 0. Be sure to set the logical address before installation (see Setting

the Logical Address on page 1–3).

CAUTION. If you install the waveform analyzer into a D-size mainframe, be sure

to connect the P1 and P2 connectors of the module to the P1 and P2 connectors

on the mainframe. Electrical damage will result when connecting the P1 and P2

connectors on the module to the P2 and P3 connectors on the mainframe.

To avoid damage, look for bent pins on P1 and P2 before installation.

Use the following installation procedure and Figure 1–2 to install the waveform

analyzer into the mainframe:

1. On the mainframe, set the power ON/STANDBY switch to OFF.

2. Insert the waveform analyzer into the mainframe top and bottom module

guides and push it partially into the mainframe (Figure 1–2). Then slide the

waveform analyzer into the mainframe as far as it will go without forcing it.

3. Be sure the front panel is flush with the front of the mainframe chassis. If so,

use a flat-blade screwdriver to install the top and bottom retainer screws.

Alternately tighten the screws, applying only a few turns at a time to fully

seat the module. If it is not flat, remove the module and check for mechanical problems with the VXIbus connector or the module enclosure.

TVS600 Series Waveform Analyzers User Manual

1–5

Page 29

Getting Started

Simultaneously

move handles apart

to eject module.

T op Retainer Screws

Bottom Retainer

Screws

Figure 1–2: Module Retainer Screws and Ejector Mechanism

Removal from VXIbus

Mainframe

Use the following procedure to remove the waveform analyzer from a Tektronix

VXIbus mainframe. If you are using a different mainframe, you may need to

modify this procedure. Refer to your mainframe manual for instructions.

1. On the mainframe, set the power ON/STANDBY switch to OFF.

2. Using a flat-blade screwdriver, loosen the top and bottom retainer screws

(Figure 1–2).

3. Grasp both handles of the waveform analyzer. At the same time, move the

top handle upward and the bottom handle downward to eject the waveform

analyzer.

4. Pull the waveform analyzer out of the mainframe.

1–6

TVS600 Series Waveform Analyzers User Manual

Page 30

Getting Started

Power-On Procedure

This section describes how to check that your waveform analyzer powers up

properly. Be certain that the waveform analyzer is properly configured before

applying power. Refer to Configuration on page 1–2.

1. Before applying power to your waveform analyzer and VXIbus system,

check the following items:

H Ensure that all VXIbus modules are properly installed.

H Check that all connected signal sources are set to an appropriate output

level to avoid damaging inputs on your waveform analyzer.

H Power up your controller, if it is external to the VXIbus mainframe.

2. Apply power to your VXIbus mainframe.

During power on, the waveform analyzer performs a self test to verify

functionality. The self test requires approximately five seconds to complete.

The front-panel ARM’D and TRIG’D indicators blink during the self test.

After testing successfully completes, the front panel READY indicator

should be on (green when lit).

NOTE. The READY indicator does not light if the power-on self test fails.

If your waveform analyzer does not pass the power on self test (READY

indicator does not light), power off the VXIbus mainframe and check that all

modules are fully seated in the VXIbus mainframe. If the problem persists,

remove the waveform analyzer and check that its address setting does not

conflict with another module. If failures continue, the module might require

service.

3. Once the power-on self tests are complete, the waveform analyzer recalls the

settings that were active when the waveform analyzer was powered off.

There is one exception: input protection is set ON, its reset value. Power-on

settings are stored in nonvolatile memory.

Most parameters have a default value that you can restore by sending the

command.

TVS600 Series Waveform Analyzers User Manual

1–7

Page 31

Getting Started

Software Installation

This section describes how to install the VXIplug&play WIN Framework

software that accompanies the TVS600 Series Waveform Analyzers User manual

(this manual). The product software includes the TVS600 Soft Front Panel

application and TVS600 device driver support library.

Description of the TVS600

VXIplug&play Software

The TVS600 VXIplug&play software provides a virtual front panel and a driver

that supports several programming environments. The TVS600 Soft Front Panel

(TKTVS600.EXE) is a tool that you can use to confirm that the waveform

analyzer is connected to the VXIbus. You can also access and control some of its

acquisition and measurement features. For detailed descriptions of the TVS600

Soft Front Panel and the device drivers, refer to the Windows on-line help

documents present with these applications.

The TVS600 VXIplug&play software includes a driver function library that

provides limited control of many instrument operations. The device driver

supports the following programming environments:

H National Instruments LabWindows/CVI for Windows

H National Instruments LabVIEW for Windows

H Microsoft Visual BASIC

H Microsoft Visual C

H Borland Turbo C

H Hewlett Packard HP-VEE

Other programming languages may also be used if they are compatible with

Windows 16 bit DLLs.

1–8

Driver Source Code. The driver library includes source code for the driver to help

you better understand driver functions and to allow you to compile them in your

programming environment. The source code conforms to ASCII C which may