Page 1

Service Manual

TSG 95

PAL/NTSC Signal Generator

070-8917-04

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved. T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PAR TICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

DECLARATION OF CONFORMITY

We

Tektronix, Inc.

Television Products Division

P.O. Box 500

Beaverton, Oregon U.S.A.

declare under our sole responsibility that the

TSG95 PAL/NTSC Signal Generator

to which this declaration relates is in conformity with the following standards:

EN50081-1, Generic Emission Standard

EN50082-1, Generic Immunity Standard

EN60555-2, Power Line Harmonics Standard

following the provisions of the Directive(s) of the Council of the European Union:

EMC Directive 89/366/EEC.

Original Declaration Of Conformity is on file with:

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

TSG 95 Service Manual

Page 6

TSG 95 Service Manual

Page 7

Table of Contents

List of Figures ii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Documentation 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Conditions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standard Compliance 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMI Compliance 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification Tables 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAL Waveform Diagrams 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NTSC Waveform Diagrams 1–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplying Power 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the TSG 95 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad and Display Conventions 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Definitions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Settings 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Settings 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Your TSG 95 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification and Adjustment Procedures 4–1. . . . . . . . . . .

Required Test Equipment 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Checklist 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedures 4–4. . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Checklist 4–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Hints 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Aids 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Utility Menu 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrective Maintenance 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Assemblies 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 6–1. . . . . . . . . . . . . . . . . . .

Column Descriptions 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cross Index – Mfr. Code Number To Manufacturer 6–3. . . . . . . . . . . . .

TSG 95 Service Manual

i

Page 8

Table of Contents

List of Figures

Replaceable Electrical Parts 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams and Circuit Board Illustrations 7–1. . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 8–1. . . . . . . . . . . . . . . . . .

Column Descriptions 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cross Index – Mfr. Code Number To Manufacturer 8–3. . . . . . . . . . . . .

Replaceable Mechanical Parts 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–1: PAL 75% Color Bars 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: PAL 100% Color Bars 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: PAL 75% Red and Red Field 1–15. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: PAL 100% Red 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: PAL Green Field 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: PAL Blue Field 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: PAL 50% Flat Field 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–8: PAL 100% Flat Field 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–9: PAL 0% Flat Field 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–10: PAL Convergence (vertical lines) 1–18. . . . . . . . . . . . . . . . . . .

Figure 1–11: PAL Convergence (horizontal lines) 1–19. . . . . . . . . . . . . . . . .

Figure 1–12: PAL 5 Step (Gray Scale) 1–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–13: PAL Modulated 5 Step 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–14: PAL Multiburst 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–15: PAL Reduced Sweep 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–16: PAL Pluge 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–17: PAL Matrix Signal — CCIR 17 1–22. . . . . . . . . . . . . . . . . . . . .

Figure 1–18: PAL Matrix Signal — CCIR Line 330 1–22. . . . . . . . . . . . . . . .

Figure 1–19: PAL Matrix Signal — CCIR Line 331 1–23. . . . . . . . . . . . . . . .

Figure 1–20: PAL Matrix Signal — CCIR 18 1–23. . . . . . . . . . . . . . . . . . . . .

Figure 1–21: PAL Matrix Signal — (Sin x)/x 1–24. . . . . . . . . . . . . . . . . . . . .

Figure 1–22: PAL Matrix Signal — 15 kHz Square Wave 1–24. . . . . . . . . . .

Figure 1–23: PAL Matrix Signal — Shallow Ramp 1–25. . . . . . . . . . . . . . . .

Figure 1–24: PAL Matrix Signal — UK ITS 1 1–25. . . . . . . . . . . . . . . . . . . .

Figure 1–25: PAL Matrix Signal — UK ITS 2 1–26. . . . . . . . . . . . . . . . . . . .

Figure 1–26: PAL Safe Area 1–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–27: SMPTE (NTSC) Color Bar Components 1–28. . . . . . . . . . . . . .

Figure 1–28: SMPTE (NTSC) Color Bars, Zero Setup 1–29. . . . . . . . . . . . . .

Figure 1–29: NTSC 75% Color Bars 1–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–30: NTSC 75% Color Bars, Zero Setup 1–30. . . . . . . . . . . . . . . . . .

ii TSG 95 Service Manual

Page 9

Table of Contents

Figure 1–31: NTSC Red Field 1–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–32: NTSC Red Field, Zero Setup 1–31. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–33: NTSC (Sin x)/x 1–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–34: NTSC 5 Step Staircase (Gray Scale) 1–32. . . . . . . . . . . . . . . . .

Figure 1–35: NTSC 0 IRE No Burst 1–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–36: NTSC 30 IRE and 50 IRE Flat Fields 1–33. . . . . . . . . . . . . . . .

Figure 1–37: NTSC Black Burst 1–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–38: NTSC Black Burst, Zero Setup (and Bounce, Low) 1–34. . . . .

Figure 1–39: NTSC 100 IRE, Field Square Wave (and Bounce, High) 1–35.

Figure 1–40: NTSC Multiburst 1–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–41: NTSC Convergence Components 1–36. . . . . . . . . . . . . . . . . . .

Figure 1–42: NTC7 (NTSC) Composite 1–37. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–43: NTC7 (NTSC) Combination 1–37. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–44: FCC (NTSC) Composite 1–38. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–45: NTSC Cable Multiburst 1–38. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–46: NTSC Cable Sweep 1–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–47: NTSC Matrix 1–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–48: NTSC Safe Area 1–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: TSG95 Block Diagram 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: XLR Female to Mini XLR Male Adapter Cable/Pinout 4–2. .

Figure 4–2: A Setup for Verifying the Oscillator Frequency 4–8. . . . . . . .

Figure 4–3: VM700A Horizontal Timing Measurement Screen 4–9. . . . . .

Figure 4–4: VM700A Luminance “Non Linearity” Measurement Screen 4–10

Figure 4–5: VM700A “Multi Burst” Measurement Screen 4–12. . . . . . . . . .

Figure 4–6: VM700A Horizontal Timing Measurement Screen 4–14. . . . . .

Figure 4–7: VM700A Luminance “Non Linearity” Measurement Screen 4–16

Figure 4–8: VM700A Bar Level Measurement Screen 4–17. . . . . . . . . . . . .

Figure 4–9: VM700A “Multi Burst” Measurement Screen 4–19. . . . . . . . . .

Figure 4–10: VM700A Level Meter Screen 4–25. . . . . . . . . . . . . . . . . . . . . .

List of Tables

TSG 95 Service Manual

Table 1–1: General PAL Test Signal Characteristics 1–3. . . . . . . . . . . . . .

Table 1–2: Unique PAL Test Signal Characteristics 1–4. . . . . . . . . . . . . . .

Table 1–3: PAL Vertical Interval Test Signals (VITS) 1–6. . . . . . . . . . . . .

Table 1–4: General NTSC Test Signal Characteristics 1–7. . . . . . . . . . . . .

Table 1–5: Unique NTSC Test Signal Characteristics 1–8. . . . . . . . . . . . .

Table 1–6: NTSC and NTSC JAPAN VITS 1–12. . . . . . . . . . . . . . . . . . . . .

Table 1–7: Character Identification 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Audio Tone 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 10

Table of Contents

Table 1–9: Physical Characteristics 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Power Supply 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–11: Environmental Characteristics 1–13. . . . . . . . . . . . . . . . . . . . . .

Table 2–1: TSG 95 Video Test Signals 2–8. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Required Test Equipment 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

iv TSG 95 Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Replace Batteries Properly. Before replacing batteries, turn the instrument off and

disconnect the AC adapter.

Use only the size and type of batteries specified for this product. Be sure to

install the batteries in the proper polarity. Use care not to short battery terminals

together when replacing batteries.

When replacing alkaline batteries, all batteries should be replaced at the same

time.

Recharge Batteries Properly. Do not attempt to recharge alkaline batteries.

Do not attempt to recharge alkaline batteries.

Recharge NiCad batteries only in accordance with the instructions provided in

this manual. Do not continue recharging for longer periods than recommended in

the instructions.

Replace the NiCad battery pack if the batteries do not recharge within the recommended time, or if the operating time from a full charge seems significantly

shortened.

TSG 95 Service Manual

Use Proper AC Adapter. Use only the specified AC adapter provided with this

product to connect it to the mains (local AC) supply.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

v

Page 12

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Battery Recycling

CAUTION

Refer to Manual

Double

Insulated

This product contains a Nickel Cadmium (NiCd) battery, which must be recycled

or disposed of properly. For the location of a local battery recycler in the U.S. or

Canada, please contact:

RBRC (800) BATTERY

Rechargeable Battery Recycling Corp. (800) 227-7379

P.O. Box 141870 www.rbrc.com

Gainesville, Florida 32614

vi

TSG 95 Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Use the Proper Fuse

Use only the type and rating fuse specified for this product.

TSG 95 Service Manual

vii

Page 14

Service Safety Summary

viii

TSG 95 Service Manual

Page 15

Specifications

Introduction

The material in this section is organized into two main groupings: the specification tables and the supporting figures. The specification tables include:

H General signal characteristics and specifications.

H Signal level specifications.

H Power supply, physical, and environmental specifications.

The supporting figures (waveform diagrams and related data) follow the specification tables.

Reference Documentation

The following documents were used as references in the preparation of this specification:

Product Classification Environmental Test Summary, 13 June 1977;

Tektronix Standard 062-2853-00

Electromagnetic Compatibility Environmental Test, 31 March 1977;

Tektronix Standard 062-2866-00

Recommendations and reports of the CCIR, 1978; Transmission of Sound

Broadcasting and Television Signals Over Long Distances (CMTT)

IEEE Standard Dictionary of Electrical Terms, Second Edition (1977); IEEE

Standard 100-1977

Safety Standard for Electrical and Electronic Test, Measuring, Controlling,

and Related Equipment, February 1988; ANSI/ISA-S82.01

International Electrotechnical Commission Standard “Safety Requirements

for Electronic Measuring Apparatus”; IEC 348

Canadian Standards Association Electrical Standard for Electrical and

Electronic Measuring and Testing Equipment; CAN/CSA C22.2 No. 231

Standard for Electrical and Electronic Measuring and Testing Equipment,

Second Edition, July 21, 1980

TSG 95 Service Manual 1–1

Page 16

Specifications

Performance Conditions

The Performance Requirements are valid if the instrument has been adjusted at

approximately 25° C, is being operated within environmental limits (see Table

1–11), and has had a minimum warm-up of 20 minutes.

Safety Standard Compliance

The following safety standards apply to the TSG 95:

H ANSI S82 — Safety Standard for Electrical and Electronic Test, Measuring,

Controlling, and Related Equipment, 1988.

H CAN/CSA C22.2 No. 231 M89 — CSA Safety Requirements for Electrical

and Electronic Measuring and Test Equipment.

H IEC1010-1 — Safety Requirements for Electrical Equipment for Measure-

ment, Control, and Laboratory Use (1990).

EMI Compliance

H UL1244 — Standard for Electrical and Electronic Measuring and Testing

Equipment, Second Edition (1980).

The following electromagnetic interference (EMI) regulatory requirements are

applicable to the TSG 95:

H 47 CFR, Chapter 1 (FCC Rules), Part 15, Class A

H EN 50 081-1 Generic Emission Standard. Part 1: Residential, commercial

and light industry.

H EN 50 082-1 Generic Immunity Standard. Part 1: Residential, commercial

and light industry.

NOTE. Shielded cables were used in the certification of this instrument; therefore,

shielded cables are recommended to be used when operating. (EC 92)

1–2 TSG 95 Service Manual

Page 17

Specification Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

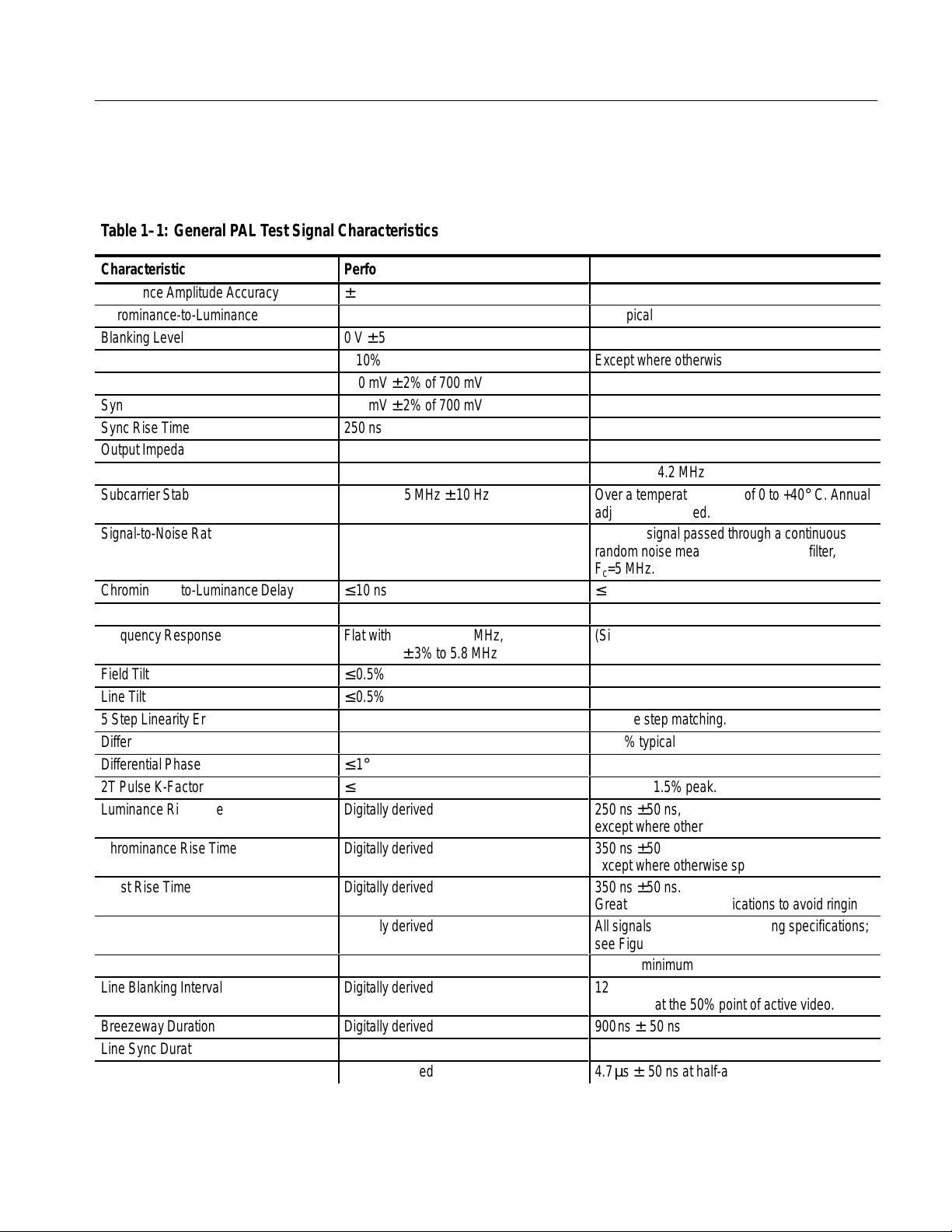

T able1–1: General PAL T est Signal Characteristics

Specifications

Characteristic

Luminance Amplitude Accuracy

Chrominance-to-Luminance Gain

Blanking Level

Rise Time Accuracy

Burst Amplitude

Sync Amplitude

Sync Rise Time

Output Impedance

Return Loss

Subcarrier Stability

Signal-to-Noise Ratio

ББББББББББ

ББББББББББ

Chrominance-to-Luminance Delay

SCH Phase

Frequency Response

Field Tilt

Line Tilt

5 Step Linearity Error

Differential Gain

Differential Phase

2T Pulse K-Factor

Luminance Rise Time

ББББББББББ

Chrominance Rise Time

Burst Rise Time

ББББББББББ

Line Timing

Front Porch Duration

Line Blanking Interval

ББББББББББ

Breezeway Duration

Line Sync Duration

Vertical Serration Duration

Performance Requirements

± 1% of 700 mV

± 2% of 700 mV

0 V ± 50 mV

± 10%

300 mV ± 2% of 700 mV

300 mV ± 2% of 700 mV

250 ns

4.43361875 MHz ± 10 Hz

БББББББББ

БББББББББ

≤ 10 ns

0° ± 5°

Flat within ± 2% to 4.8 MHz,

± 3% to 5.8 MHz

≤ 0.5%

≤ 0.5%

≤ 1%

≤ 1%

≤ 1°

≤ 0.5%

Digitally derived

БББББББББ

Digitally derived

Digitally derived

БББББББББ

Digitally derived

Digitally derived

Digitally derived

БББББББББ

Digitally derived

Digitally derived

Digitally derived

Supplemental Information

1% typical

Except where otherwise specified

75 Ω

≥ 36 dB at 4.2 MHz

Over a temperature range of 0 to +40° C. Annual

adjustment required.

≥ 60 dB; signal passed through a continuous

БББББББББББ

random noise measurement low pass filter,

БББББББББББ

Fc=5 MHz.

≤ 5 ns typical

(Sin x)/x ± 1 dB to 5 MHz

Relative step matching.

≤ 0.5% typical

Ringing ≤ 1.5% peak.

250 ns ±50 ns,

except where otherwise specified.

БББББББББББ

350 ns ±50 ns,

except where otherwise specified.

350 ns ±50 ns.

БББББББББББ

Greater than BBC specifications to avoid ringing.

All signals comply with PAL timing specifications;

see Figures 1–1 through 1–25.

1.55 µs minimum

12.0µs ± 0.15 µs

БББББББББББ

Measured at the 50% point of active video.

900ns ± 50 ns

4.7µs ± 50 ns at half-amplitude

4.7µs ± 50 ns at half-amplitude

TSG 95 Service Manual 1–3

Page 18

Specifications

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

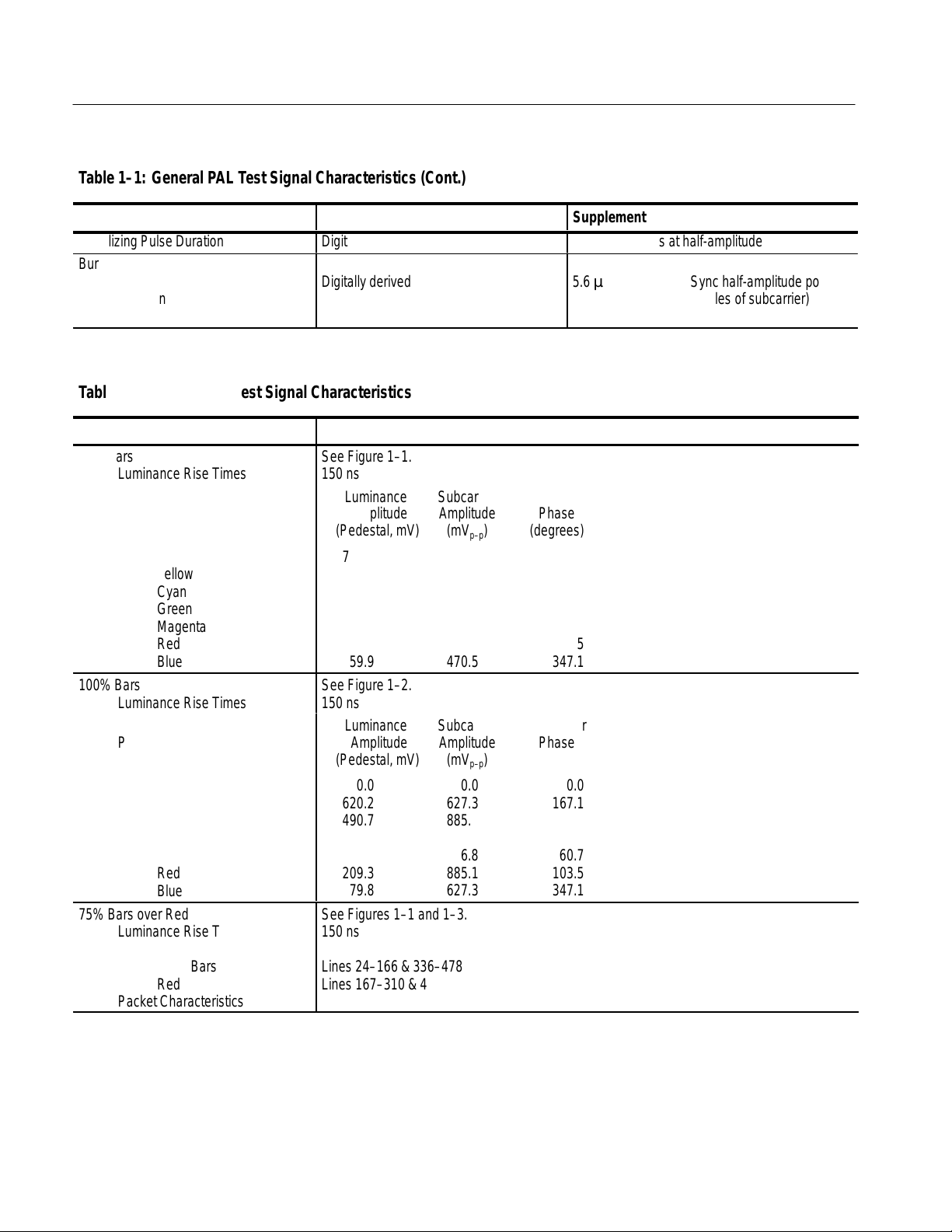

T able1–1: General PAL T est Signal Characteristics (Cont.)

Characteristic

Equalizing Pulse Duration

Performance Requirements

Digitally derived

Burst

БББББББББ

Delay from Sync

Duration

БББББББББ

БББББББББ

Digitally derived

БББББББББ

T able1–2: Unique PAL T est Signal Characteristics

Characteristic

75% Bars

БББББББББ

Luminance Rise Times

Packet Characteristics

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

White

Y ellow

Cyan

Green

Magenta

Red

Blue

100% Bars

Luminance Rise Times

БББББББББ

Packet Characteristics

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

White

Y ellow

Cyan

Green

Magenta

Red

Blue

75% Bars over Red

БББББББББ

Luminance Rise Times

Field Timing

БББББББББ

БББББББББ

БББББББББ

Color Bars

Red

Packet Characteristics

Information

See Figure 1–1.

БББББББББББББББББББББ

150 ns

Luminance Subcarrier Subcarrier

Amplitude Amplitude Phase

БББББББББББББББББББББ

(Pedestal, mV) (mV

БББББББББББББББББББББ

700.0 0.0 0.0

БББББББББББББББББББББ

465.1 470.5 167.1

БББББББББББББББББББББ

368.0 663.8 283.5

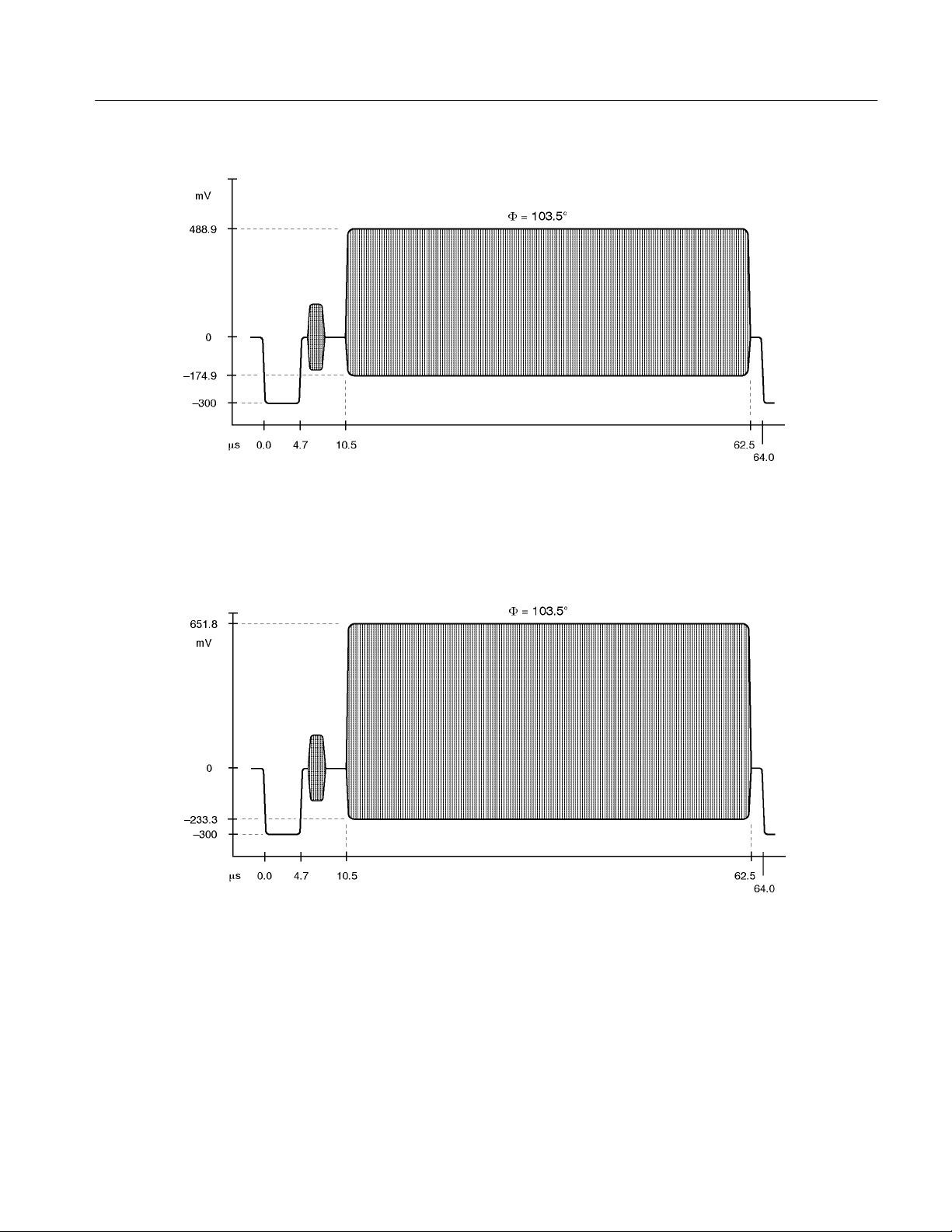

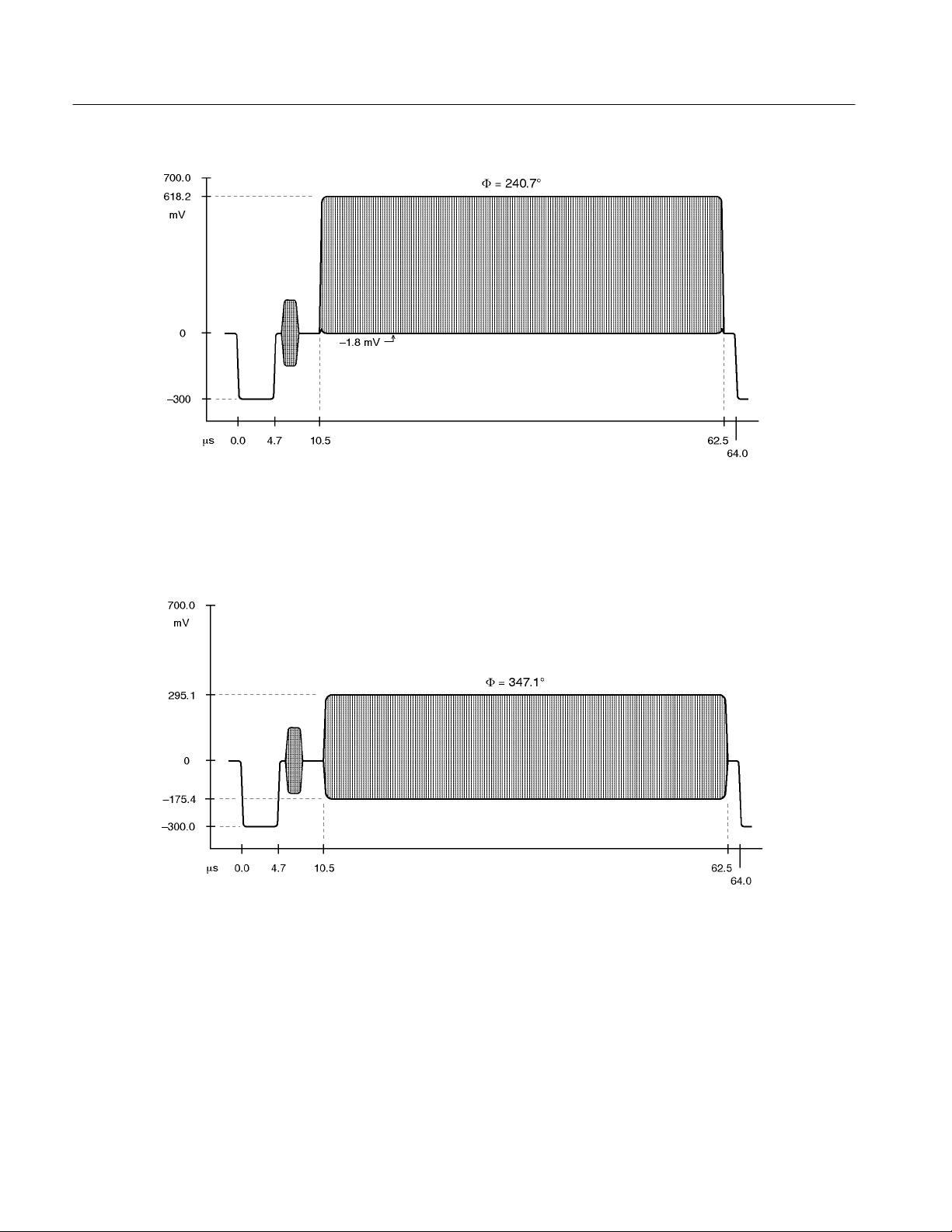

308.2 620.1 240.7

БББББББББББББББББББББ

216.8 620.1 60.7

БББББББББББББББББББББ

157.0 663.8 103.5

59.9 470.5 347.1

БББББББББББББББББББББ

See Figure 1–2.

150 ns

Luminance Subcarrier Subcarrier

БББББББББББББББББББББ

Amplitude Amplitude Phase

БББББББББББББББББББББ

(Pedestal, mV) (mV

БББББББББББББББББББББ

700.0 0.0 0.0

620.2 627.3 167.1

БББББББББББББББББББББ

490.7 885.1 283.5

БББББББББББББББББББББ

410.9 826.8 240.7

БББББББББББББББББББББ

289.1 826.8 60.7

209.3 885.1 103.5

БББББББББББББББББББББ

79.8 627.3 347.1

See Figures 1–1 and 1–3.

БББББББББББББББББББББ

150 ns

БББББББББББББББББББББ

Lines 24–166 & 336–478

БББББББББББББББББББББ

Lines 167–310 & 479–622

БББББББББББББББББББББ

See 75% Bars, above.

) (degrees)

p–p

) (degrees)

p–p

Supplemental Information

2.35µs ± 50 ns at half-amplitude

БББББББББББ

5.6µs ± 50 ns from Sync half-amplitude point

2.25µs ± 0.1 µs (10 cycles of subcarrier)

БББББББББББ

1–4 TSG 95 Service Manual

Page 19

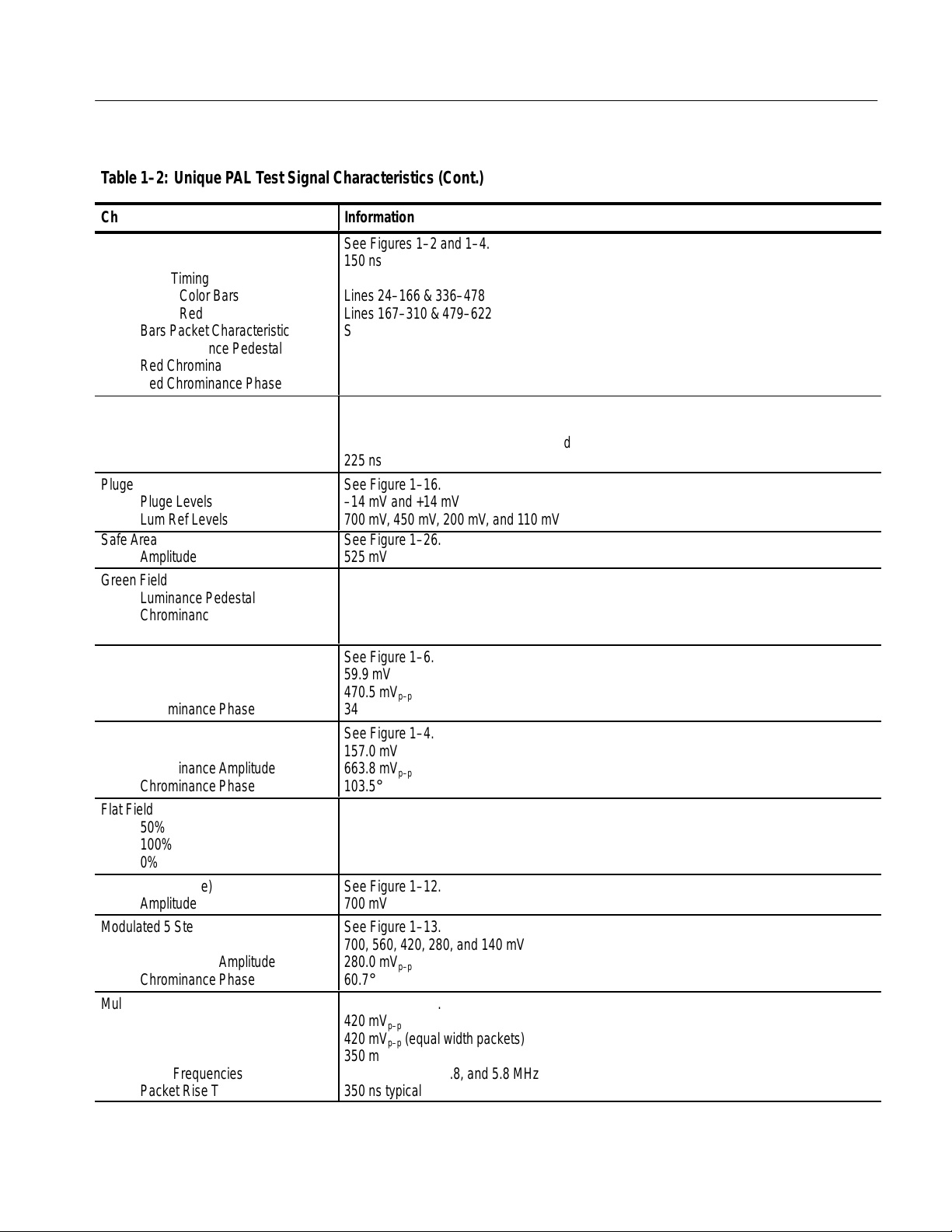

T able1–2: Unique PAL T est Signal Characteristics (Cont.)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Specifications

Characteristic

100% Bars over Red

ББББББББББ

Luminance Rise Times

Field Timing

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

Color Bars

Red

Bars Packet Characteristics

Red Luminance Pedestal

Red Chrominance Amplitude

Red Chrominance Phase

Convergence

ББББББББББ

Amplitude

Pattern

ББББББББББ

Pulse HAD

Pluge

ББББББББББ

Pluge Levels

Lum Ref Levels

ББББББББББ

Safe Area

Amplitude

Green Field

ББББББББББ

Luminance Pedestal

Chrominance Amplitude

ББББББББББ

Chrominance Phase

Blue Field

ББББББББББ

Luminance Pedestal

ББББББББББ

Chrominance Amplitude

Chrominance Phase

ББББББББББ

Red Field

Luminance Pedestal

ББББББББББ

Chrominance Amplitude

ББББББББББ

Chrominance Phase

Information

See Figures 1–2 and 1–4.

БББББББББББББББББББББ

150 ns

БББББББББББББББББББББ

Lines 24–166 & 336–478

БББББББББББББББББББББ

Lines 167–310 & 479–622

БББББББББББББББББББББ

See 100% Bars, above.

209.3 mV

БББББББББББББББББББББ

885.1 mV

103.5°

p–p

БББББББББББББББББББББ

See Figures 1–10 and 1–11.

БББББББББББББББББББББ

525.0 mV

19 vert. lines and 14 horiz. lines per field

БББББББББББББББББББББ

225 ns

See Figure 1–16.

БББББББББББББББББББББ

–14 mV and +14 mV

700 mV, 450 mV, 200 mV, and 110 mV

БББББББББББББББББББББ

See Figure 1–26.

525 mV

See Figure 1–5.

БББББББББББББББББББББ

308.2 mV

620.1 mV

БББББББББББББББББББББ

p–p

240.7°

See Figure 1–6.

БББББББББББББББББББББ

59.9 mV

БББББББББББББББББББББ

470.5 mV

347.1°

p–p

БББББББББББББББББББББ

See Figure 1–4.

157.0 mV

БББББББББББББББББББББ

663.8 mV

103.5°

p–p

БББББББББББББББББББББ

Flat Field

50%

ББББББББББ

100%

ББББББББББ

0%

5 Step (Gray Scale)

ББББББББББ

Amplitude

Modulated 5 Step

Luminance Amplitude

ББББББББББ

Chrominance Amplitude

ББББББББББ

Chrominance Phase

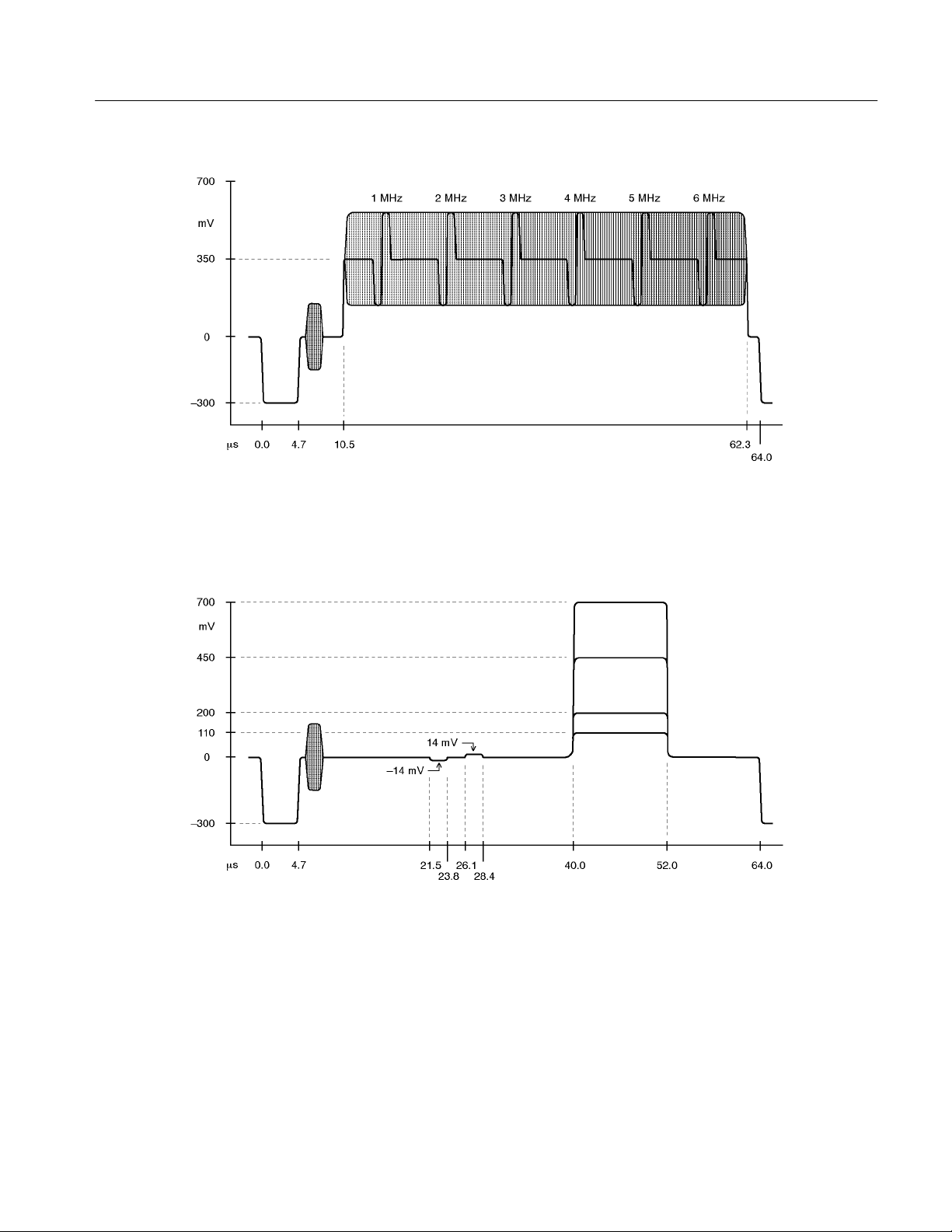

Multiburst

White Reference Bar Amplitude

ББББББББББ

Packet Amplitudes

ББББББББББ

Pedestal

ББББББББББ

Burst Frequencies

Packet Rise Time

ББББББББББ

TSG 95 Service Manual 1–5

350 mV; see Figure 1–7.

БББББББББББББББББББББ

700 mV; see Figure 1–8.

БББББББББББББББББББББ

0 mV; see Figure 1–9.

See Figure 1–12.

БББББББББББББББББББББ

700 mV

See Figure 1–13.

700, 560, 420, 280, and 140 mV

БББББББББББББББББББББ

280.0 mV

60.7°

p–p

БББББББББББББББББББББ

See Figure 1–14.

420 mV

БББББББББББББББББББББ

p–p

420 mV

350 mV

0.5, 1.0, 2.0, 4.0, 4.8, and 5.8 MHz

350 ns typical

(equal width packets)

p–p

БББББББББББББББББББББ

БББББББББББББББББББББ

БББББББББББББББББББББ

Page 20

Specifications

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

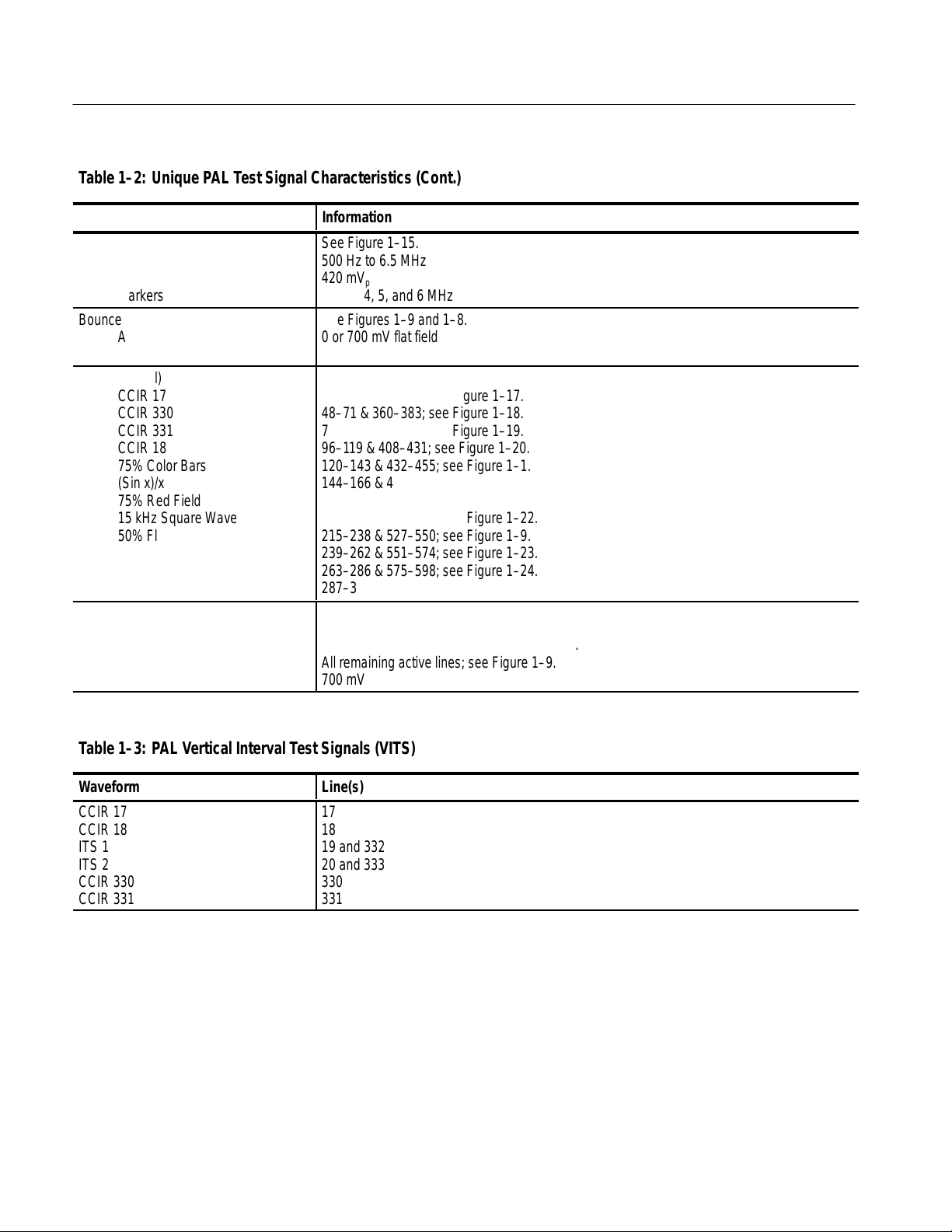

T able1–2: Unique PAL T est Signal Characteristics (Cont.)

Characteristic

60% Reduced Line Sweep

БББББББББ

Frequency

Amplitude

БББББББББ

Markers

Bounce

БББББББББ

Amplitude

БББББББББ

Rate

Matrix (Signal)

CCIR 17

БББББББББ

CCIR 330

БББББББББ

CCIR 331

CCIR 18

БББББББББ

75% Color Bars

БББББББББ

(Sin x)/x

БББББББББ

75% Red Field

15 kHz Square Wave

БББББББББ

50% Flat Field

БББББББББ

Shallow Ramp

БББББББББ

UK ITS 1

UK ITS 2

БББББББББ

Field Square Wave

Field Timing

БББББББББ

БББББББББ

Lines (White)

Lines at Blanking

Amplitude

Information

See Figure 1–15.

БББББББББББББББББББББ

500 Hz to 6.5 MHz

420 mV

p–p

БББББББББББББББББББББ

1, 2, 3, 4, 5, and 6 MHz

See Figures 1–9 and 1–8.

БББББББББББББББББББББ

0 or 700 mV flat field

БББББББББББББББББББББ

≈ 1.0 second high, ≈ 1.0 second low

(Lines)

24–47 & 336–359; see Figure 1–17.

БББББББББББББББББББББ

48–71 & 360–383; see Figure 1–18.

БББББББББББББББББББББ

72–95 & 384–407; see Figure 1–19.

96–1 19 & 408–431; see Figure 1–20.

БББББББББББББББББББББ

120–143 & 432–455; see Figure 1–1.

БББББББББББББББББББББ

144–166 & 456–478; see Figure 1–21.

БББББББББББББББББББББ

167–190 & 479–502; see Figure 1–3.

191–214 & 503–526; see Figure 1–22.

БББББББББББББББББББББ

215–238 & 527–550; see Figure 1–9.

БББББББББББББББББББББ

239–262 & 551–574; see Figure 1–23.

БББББББББББББББББББББ

263–286 & 575–598; see Figure 1–24.

287–310 & 599–622; see Figure 1–25.

БББББББББББББББББББББ

БББББББББББББББББББББ

Lines 89–244 (and 401–556); see Figure 1–8.

All remaining active lines; see Figure 1–9.

БББББББББББББББББББББ

700 mV

T able1–3: PAL Vertical Interval Test Signals (VITS)

БББББББББББББББББББББББББББББББ

Waveform

CCIR 17

CCIR 18

БББББББББ

ITS 1

БББББББББ

ITS 2

БББББББББ

CCIR 330

CCIR 331

БББББББББ

1–6 TSG 95 Service Manual

Line(s)

17

18

БББББББББББББББББББББ

19 and 332

БББББББББББББББББББББ

20 and 333

БББББББББББББББББББББ

330

331

БББББББББББББББББББББ

Page 21

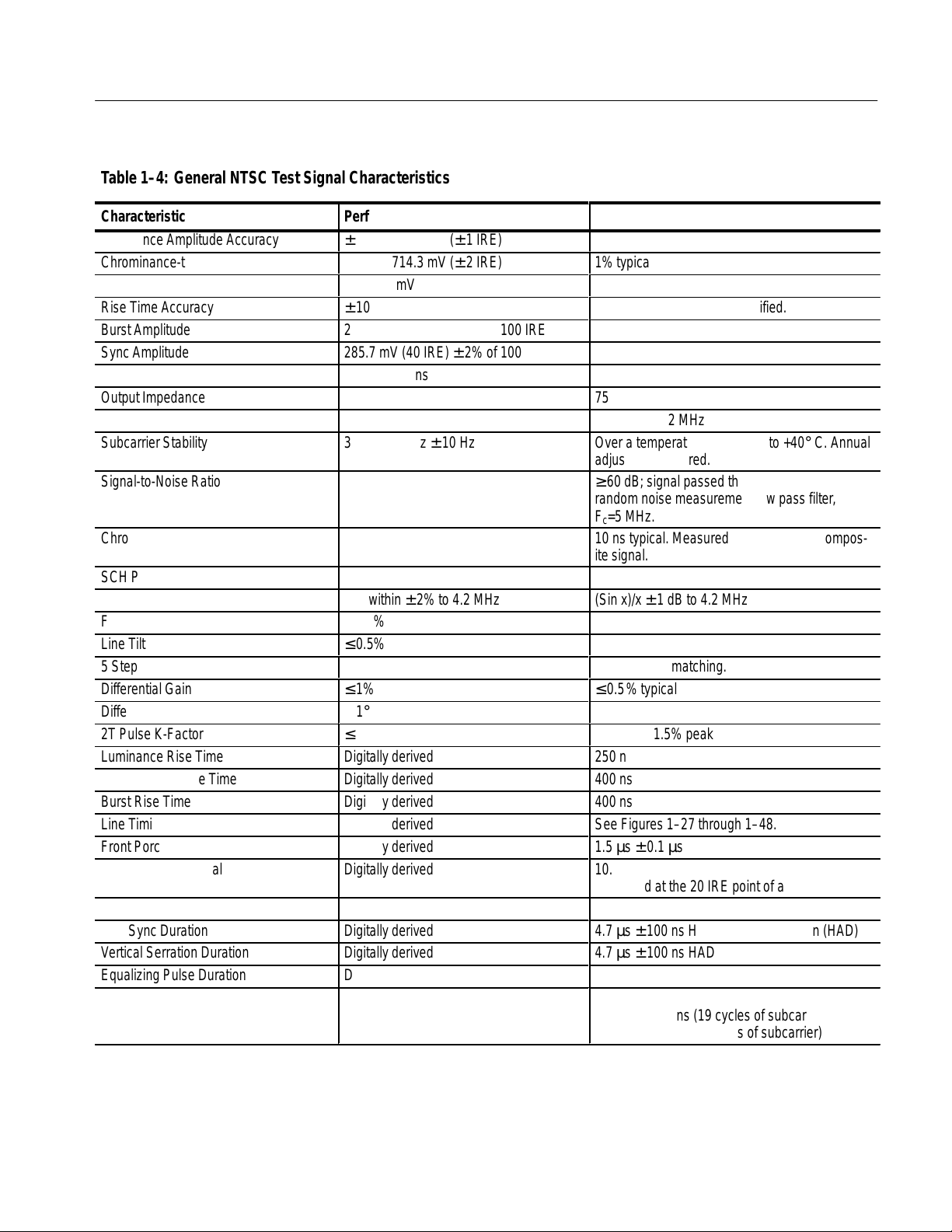

Table 1–4: General NTSC Test Signal Characteristics

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Specifications

Characteristic

Luminance Amplitude Accuracy

Chrominance-to-Luminance Gain

Blanking Level

Rise Time Accuracy

Burst Amplitude

Sync Amplitude

Sync Rise Time

Output Impedance

Return Loss

Subcarrier Stability

Signal-to-Noise Ratio

ББББББББББ

ББББББББББ

Chrominance-to-Luminance Delay

SCH Phase

Frequency Response

Field Tilt

Line Tilt

5 Step Linearity Error

Differential Gain

Differential Phase

2T Pulse K-Factor

Luminance Rise Time

Chrominance Rise Time

Burst Rise Time

Line Timing

Front Porch Duration

Line Blanking Interval

ББББББББББ

Breezeway Duration

Line Sync Duration

Vertical Serration Duration

Equalizing Pulse Duration

Burst

Delay from Sync

ББББББББББ

Duration

Performance Requirements

± 1% of 714.3 mV (± 1 IRE)

± 2% of 714.3 mV (± 2 IRE)

0 V ± 50 mV

± 10%

285.7 mV (40 IRE) ± 2% of 100 IRE

285.7 mV (40 IRE) ± 2% of 100 IRE

140 ns ± 20 ns

3.579545 MHz ± 10 Hz

БББББББББ

БББББББББ

≤ 15 ns

0° ± 5°

Flat within ± 2% to 4.2 MHz

≤ 0.5%

≤ 0.5%

≤ 1%

≤ 1%

≤ 1°

≤ 0.5%

Digitally derived

Digitally derived

Digitally derived

Digitally derived

Digitally derived

Digitally derived

БББББББББ

Digitally derived

Digitally derived

Digitally derived

Digitally derived

Digitally derived

БББББББББ

Supplemental Information

1% typical

Except where otherwise specified.

75 Ω

≥ 36 dB at 4.2 MHz

Over a temperature range of 0 to +40° C. Annual

adjustment required.

≥ 60 dB; signal passed through a continuous

БББББББББББ

random noise measurement low pass filter,

Fc=5 MHz.

БББББББББББ

10 ns typical. Measured with the NTC7 Composite signal.

(Sin x)/x ± 1 dB to 4.2 MHz

Relative step matching.

≤ 0.5% typical

Ringing ≤ 1.5% peak

250 ns

400 ns

400 ns

See Figures 1–27 through 1–48.

1.5 µs ± 0.1 µs

10.9 µs ± 0.2 µs

БББББББББББ

Measured at the 20 IRE point of active video.

600 ns ± 100 ns

4.7 µs ± 100 ns Half-amplitude duration (HAD)

4.7 µs ± 100 ns HAD

2.3 µs ± 100 ns HAD

5.308 µs ±35 ns (19 cycles of subcarrier)

БББББББББББ

2.51 µs ± 0.1 µs (9 cycles of subcarrier)

TSG 95 Service Manual 1–7

Page 22

Specifications

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

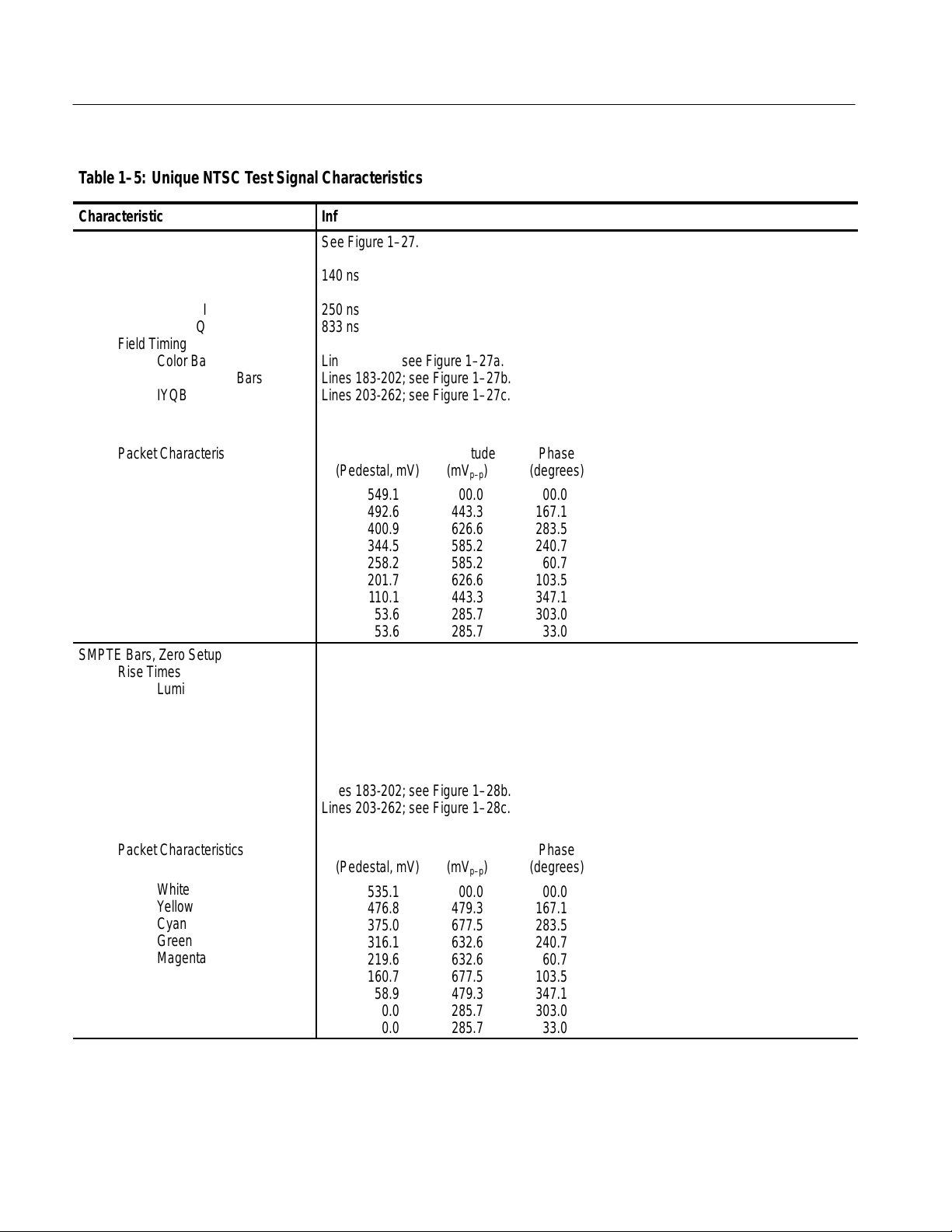

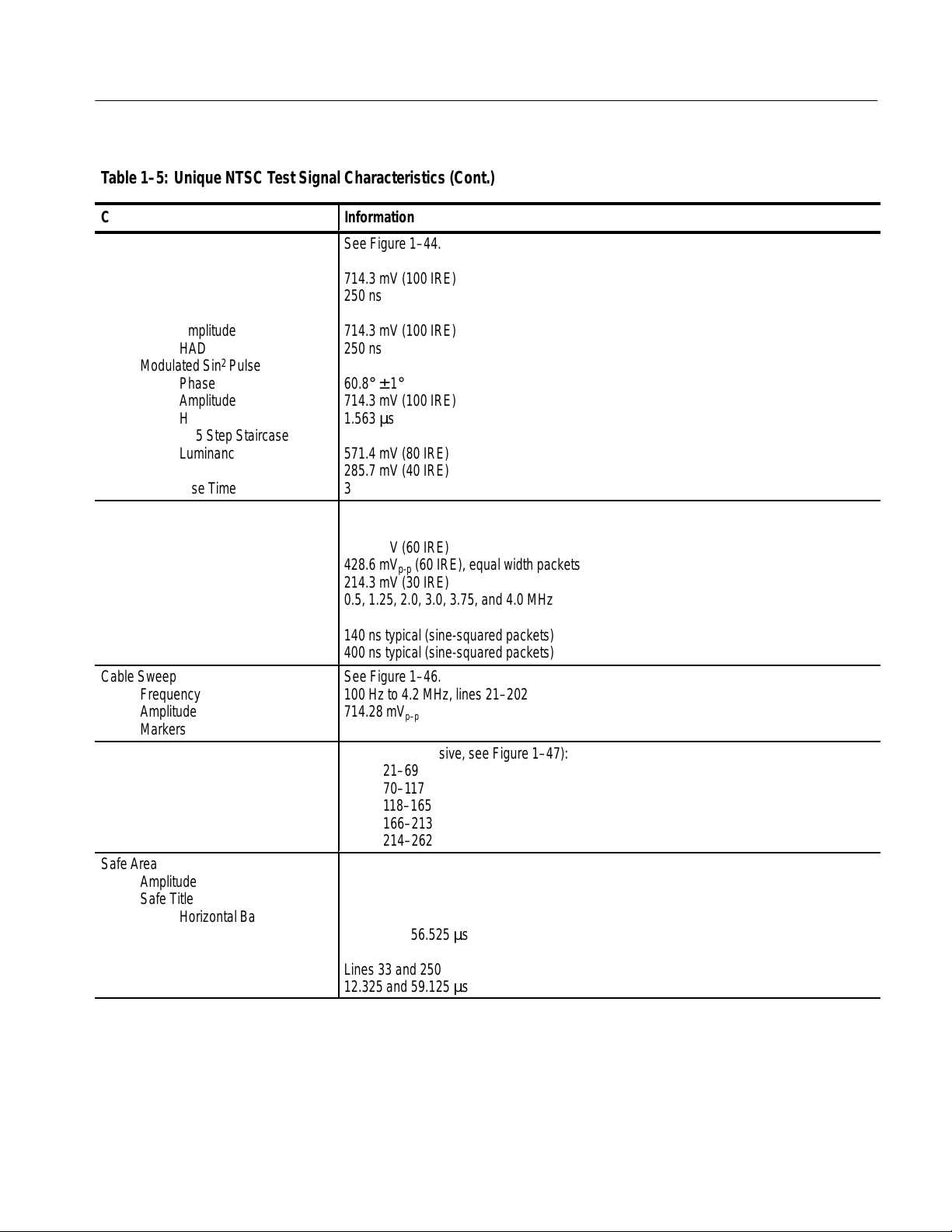

Table 1–5: Unique NTSC Test Signal Characteristics

Characteristic

SMPTE Bars

БББББББББ

Rise Times

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

Luminance

Chrominance

–I

Q

Field Timing

Color Bars

Reverse Blue Bars

IYQB

Packet Characteristics

White

Y ellow

Cyan

Green

Magenta

Red

Blue

–I

Q

SMPTE Bars, Zero Setup

БББББББББ

Rise Times

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

Luminance

Chrominance

–I

Q

Field Timing

Color Bars

Reverse Blue Bars

IYQB

Information

See Figure 1–27.

БББББББББББББББББББББ

140 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

250 ns

833 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

Lines 21-182; see Figure 1–27a.

БББББББББББББББББББББ

Lines 183-202; see Figure 1–27b.

Lines 203-262; see Figure 1–27c.

БББББББББББББББББББББ

Luminance Subcarrier Subcarrier

БББББББББББББББББББББ

Amplitude Amplitude Phase

(Pedestal, mV) (mV

БББББББББББББББББББББ

549.1 00.0 00.0

БББББББББББББББББББББ

492.6 443.3 167.1

БББББББББББББББББББББ

400.9 626.6 283.5

БББББББББББББББББББББ

344.5 585.2 240.7

258.2 585.2 60.7

БББББББББББББББББББББ

201.7 626.6 103.5

БББББББББББББББББББББ

110.1 443.3 347.1

53.6 285.7 303.0

БББББББББББББББББББББ

) (degrees)

p–p

53.6 285.7 33.0

See Figure 1–28.

БББББББББББББББББББББ

БББББББББББББББББББББ

140 ns

БББББББББББББББББББББ

250 ns

БББББББББББББББББББББ

833 ns

БББББББББББББББББББББ

Lines 21-182; see Figure 1–28.

БББББББББББББББББББББ

Lines 183-202; see Figure 1–28b.

БББББББББББББББББББББ

Lines 203-262; see Figure 1–28c.

Luminance Subcarrier Subcarrier

Packet Characteristics

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

1–8 TSG 95 Service Manual

White

Y ellow

Cyan

Green

Magenta

Red

Blue

–I

Q

Amplitude Amplitude Phase

БББББББББББББББББББББ

(Pedestal, mV) (mV

БББББББББББББББББББББ

535.1 00.0 00.0

БББББББББББББББББББББ

476.8 479.3 167.1

375.0 677.5 283.5

БББББББББББББББББББББ

316.1 632.6 240.7

БББББББББББББББББББББ

219.6 632.6 60.7

БББББББББББББББББББББ

160.7 677.5 103.5

58.9 479.3 347.1

БББББББББББББББББББББ

БББББББББББББББББББББ

0.0 285.7 303.0

0.0 285.7 33.0

) (degrees)

p–p

Page 23

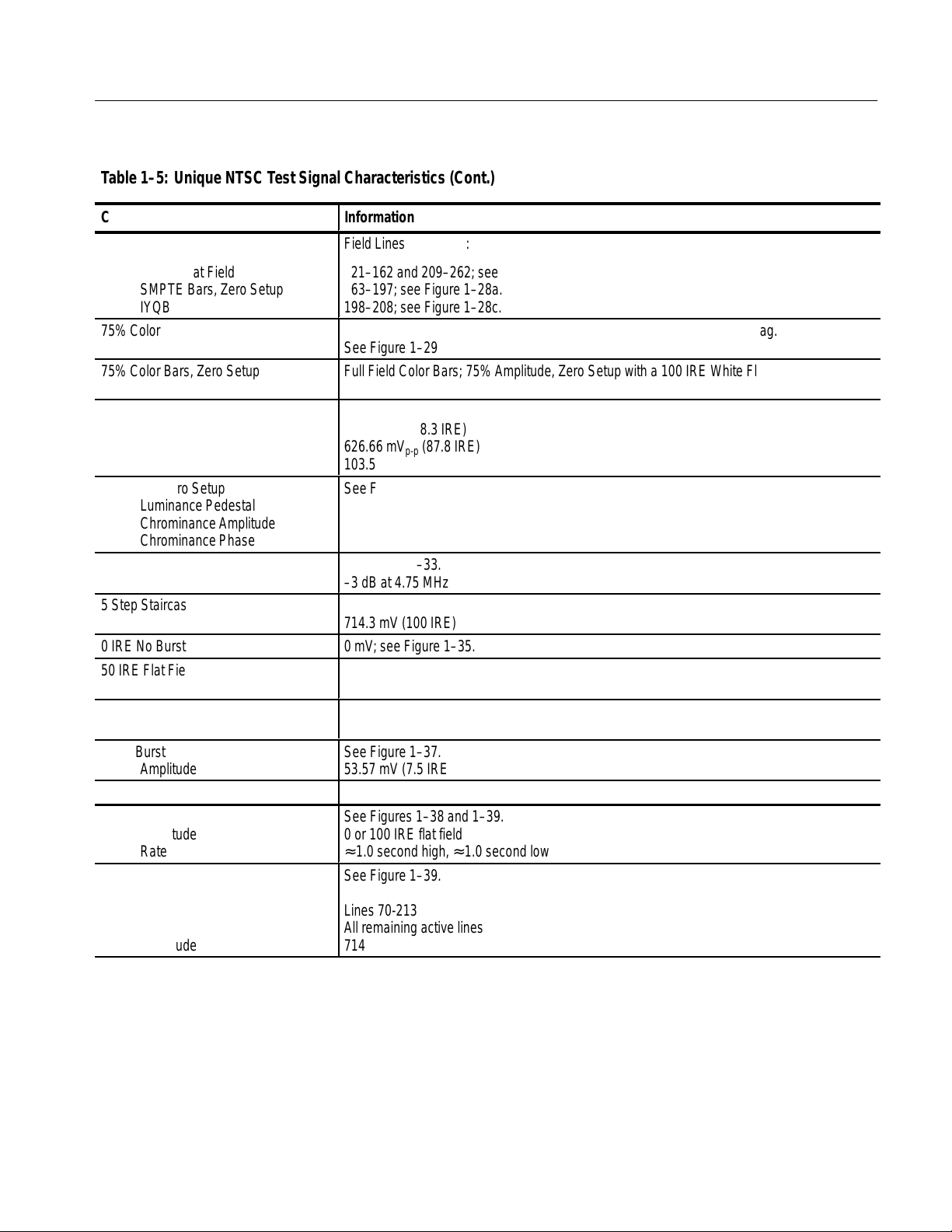

T able1–5: Unique NTSC Test Signal Characteristics (Cont.)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Specifications

Characteristic

SNG Bars (Matrix), Zero Setup Only

ББББББББББ

30 IRE Flat Field

ББББББББББ

SMPTE Bars, Zero Setup

ББББББББББ

IYQB

75% Color Bars

ББББББББББ

75% Color Bars, Zero Setup

ББББББББББ

Red Field

ББББББББББ

Luminance Pedestal

Chrominance Amplitude

ББББББББББ

Chrominance Phase

Red Field, Zero Setup

ББББББББББ

Luminance Pedestal

ББББББББББ

Chrominance Amplitude

Chrominance Phase

ББББББББББ

(Sin x)⁄x

Spectrum

5 Step Staircase

ББББББББББ

Amplitude

0 IRE No Burst

50 IRE Flat Field

ББББББББББ

Amplitude

100 IRE Flat Field

Amplitude

Black Burst

ББББББББББ

Amplitude

Black Burst, Zero Setup

Bounce

ББББББББББ

Amplitude

Rate

ББББББББББ

Field Square Wave

Field Timing

ББББББББББ

ББББББББББ

ББББББББББ

Lines (White)

Lines at Blanking

Amplitude

Information

Field Lines (inclusive):

БББББББББББББББББББББ

21–162 and 209–262; see Figure 1–36.

БББББББББББББББББББББ

163–197; see Figure 1–28a.

БББББББББББББББББББББ

198–208; see Figure 1–28c.

Full Field Color Bars; 75% Amplitude, 7.5% Setup with a 100 IRE White Flag.

See Figure 1–29

БББББББББББББББББББББ

Full Field Color Bars; 75% Amplitude, Zero Setup with a 100 IRE White Flag.

БББББББББББББББББББББ

See Figure 1–30.

See Figure 1–31.

БББББББББББББББББББББ

201.74 mV (28.3 IRE)

626.66 mV

БББББББББББББББББББББ

(87.8 IRE)

p-p

103.5_

See Figure 1–32.

БББББББББББББББББББББ

160.14 mV (22.4 IRE)

БББББББББББББББББББББ

677.08 mV

103.5_

БББББББББББББББББББББ

(94.8 IRE)

p-p

See Figure 1–33.

–3 dB at 4.75 MHz

See Figure 1–34.

БББББББББББББББББББББ

714.3 mV (100 IRE)

0 mV; see Figure 1–35.

See Figure 1–36.

БББББББББББББББББББББ

357.2 mV

See Figure 1–39.

714.3 mV

See Figure 1–37.

БББББББББББББББББББББ

53.57 mV (7.5 IRE)

0 mV (0 IRE); see Figure 1–38.

See Figures 1–38 and 1–39.

БББББББББББББББББББББ

0 or 100 IRE flat field

≈ 1.0 second high, ≈ 1.0 second low

БББББББББББББББББББББ

See Figure 1–39.

БББББББББББББББББББББ

Lines 70-213

БББББББББББББББББББББ

All remaining active lines

714.3 mV (100 IRE)

БББББББББББББББББББББ

TSG 95 Service Manual 1–9

Page 24

Specifications

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

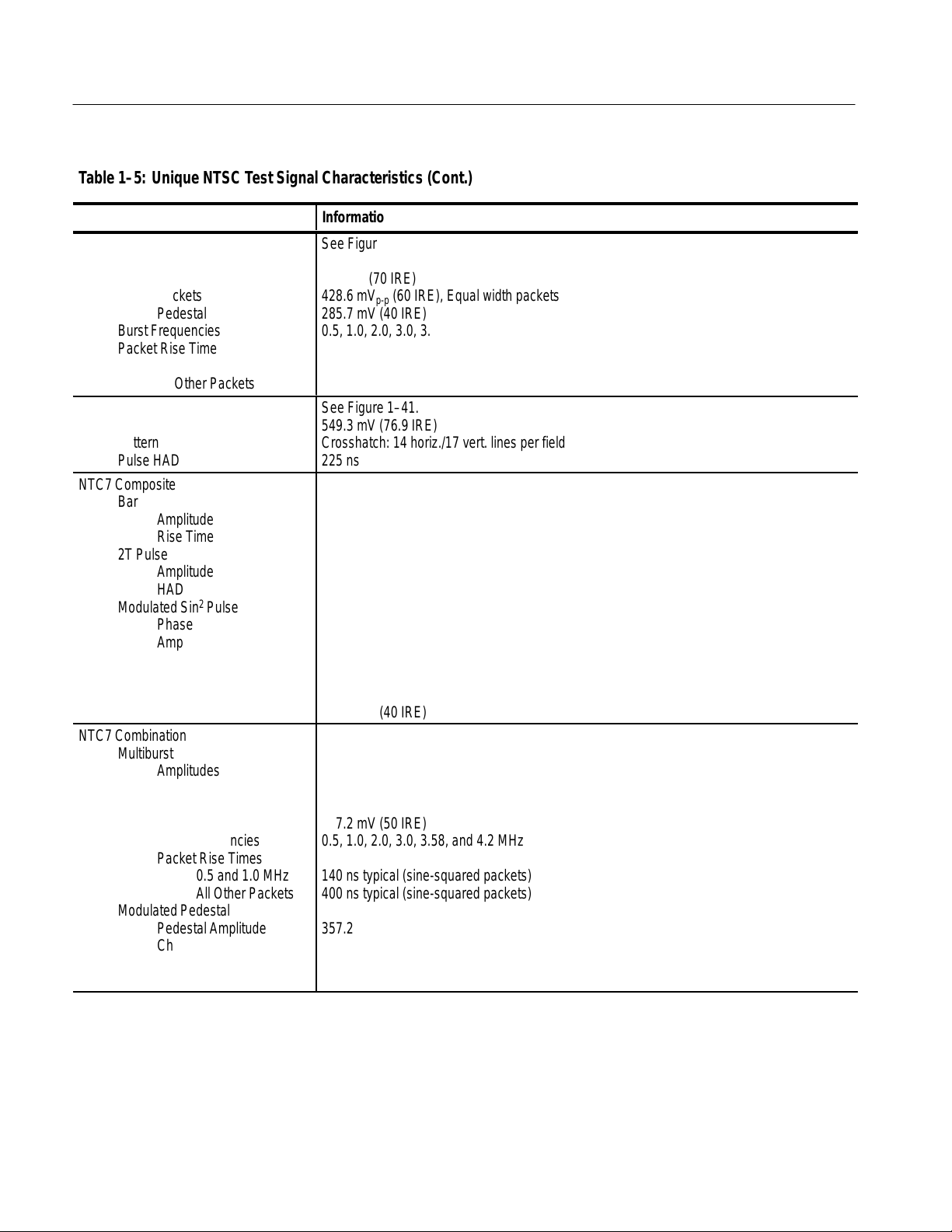

T able1–5: Unique NTSC Test Signal Characteristics (Cont.)

Characteristic

Multiburst

БББББББББ

Amplitudes

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

White Reference Bar

Packets

Pedestal

Burst Frequencies

Packet Rise Time

0.5 MHz

All Other Packets

Convergence

БББББББББ

Amplitude

Pattern

БББББББББ

Pulse HAD

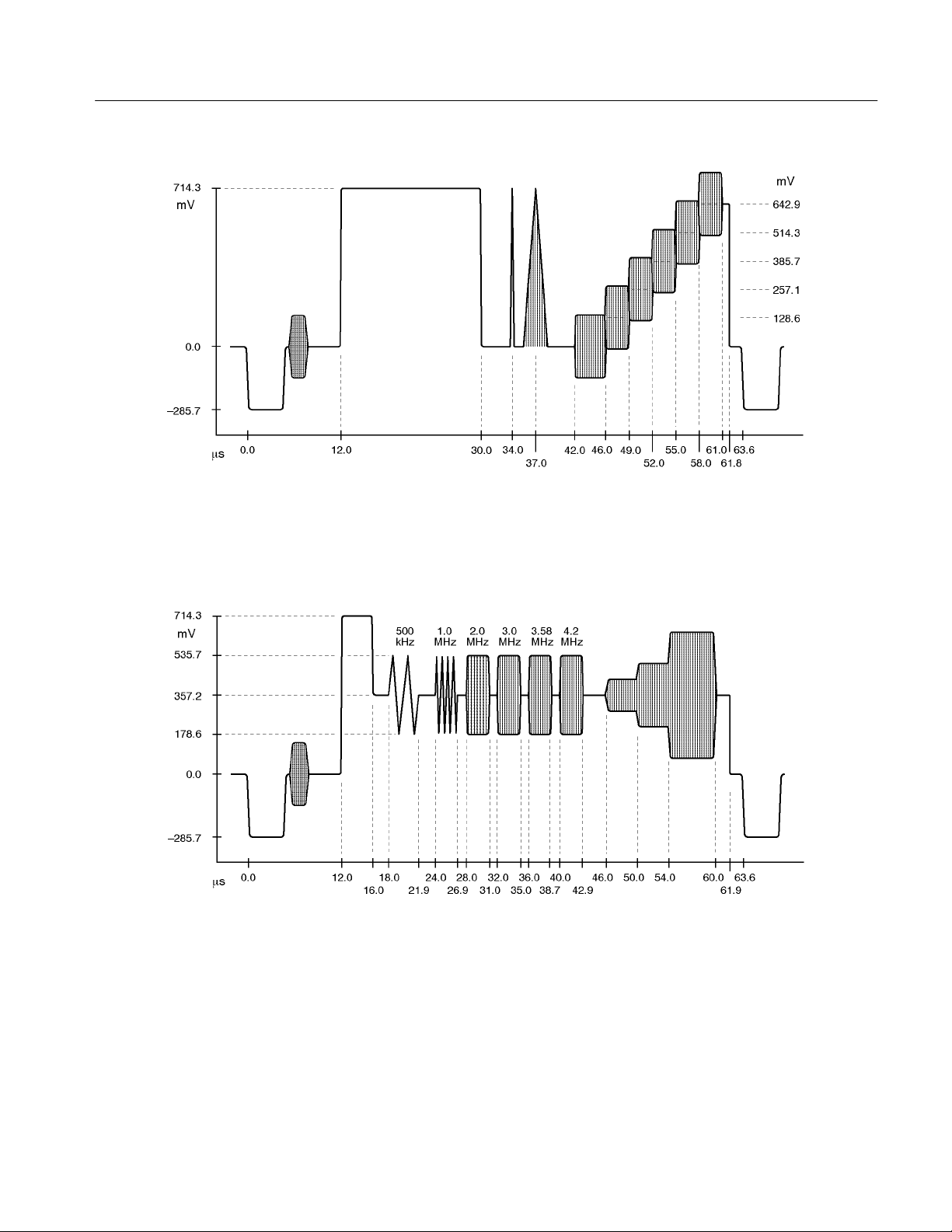

NTC7 Composite

БББББББББ

Bar

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

Amplitude

Rise Time

2T Pulse

Amplitude

HAD

2

Modulated Sin

Pulse

Phase

Amplitude

HAD

Modulate 5 Step Staircase

Luminance

Chrominance

NTC7 Combination

Multiburst

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

1–10 TSG 95 Service Manual

Amplitudes

White Bar

Packets

Pedestal

Burst Frequencies

Packet Rise Times

0.5 and 1.0 MHz

All Other Packets

Modulated Pedestal

Pedestal Amplitude

Chrominance Amplitudes

Phase

Rise Time

Information

See Figure 1–40.

БББББББББББББББББББББ

500 mV (70 IRE)

БББББББББББББББББББББ

428.6 mV

БББББББББББББББББББББ

285.7 mV (40 IRE)

БББББББББББББББББББББ

0.5, 1.0, 2.0, 3.0, 3.58, and 4.2 MHz

БББББББББББББББББББББ

140 ns typical (sine-squared packets)

БББББББББББББББББББББ

400 ns typical (sine-squared packets)

(60 IRE), Equal width packets

p-p

See Figure 1–41.

БББББББББББББББББББББ

549.3 mV (76.9 IRE)

Crosshatch: 14 horiz./17 vert. lines per field

БББББББББББББББББББББ

225 ns

See Figure 1–42.

БББББББББББББББББББББ

714.3 mV (100 IRE)

БББББББББББББББББББББ

125 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

714.3 mV (100 IRE)

250 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

60.8° ± 1°

БББББББББББББББББББББ

714.3 mV (100 IRE) at peak amplitude

1.563 µs

БББББББББББББББББББББ

БББББББББББББББББББББ

642.9 mV (90 IRE)

БББББББББББББББББББББ

285.7 mV (40 IRE)

See Figure 1–43.

БББББББББББББББББББББ

БББББББББББББББББББББ

714.3 mV (100 IRE)

357.2 mV (50 IRE)

БББББББББББББББББББББ

357.2 mV (50 IRE)

БББББББББББББББББББББ

0.5, 1.0, 2.0, 3.0, 3.58, and 4.2 MHz

БББББББББББББББББББББ

140 ns typical (sine-squared packets)

БББББББББББББББББББББ

400 ns typical (sine-squared packets)

БББББББББББББББББББББ

БББББББББББББББББББББ

357.2 mV (50 IRE)

142.9 mV (20 IRE), 285.7 mV (40 IRE), and 571.4 mV (80 IRE)

БББББББББББББББББББББ

90°

БББББББББББББББББББББ

400 ns

Page 25

T able1–5: Unique NTSC Test Signal Characteristics (Cont.)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Specifications

Characteristic

FCC Composite

ББББББББББ

Bar

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

Amplitude

Rise Time

2T Pulse

Amplitude

HAD

2

Modulated Sin

Pulse

Phase

Amplitude

HAD

Modulate 5 Step Staircase

Luminance

Chrominance

Rise Time

Cable Multiburst

ББББББББББ

Amplitudes

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

White Reference Bar

Packets

Pedestal

Burst Frequencies

Packet Rise Time

0.5 MHz

All Other Packets

Cable Sweep

ББББББББББ

Frequency

ББББББББББ

Amplitude

Markers

ББББББББББ

Matrix

NTC7 Composite

ББББББББББ

NTC7 Combination

Color Bars

ББББББББББ

(Sin x)/x

ББББББББББ

50 IRE Flat Field

Safe Area

ББББББББББ

Amplitude

Safe Title

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

TSG 95 Service Manual 1–11

Horizontal Bar

Vertical Timing

Safe Action

Horizontal Bar

Vertical Timing

Information

See Figure 1–44.

БББББББББББББББББББББ

714.3 mV (100 IRE)

БББББББББББББББББББББ

250 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

714.3 mV (100 IRE)

250 ns

БББББББББББББББББББББ

БББББББББББББББББББББ

60.8° ± 1°

БББББББББББББББББББББ

714.3 mV (100 IRE)

1.563 µs

БББББББББББББББББББББ

БББББББББББББББББББББ

571.4 mV (80 IRE)

285.7 mV (40 IRE)

БББББББББББББББББББББ

375 ns

See Figure 1–45.

БББББББББББББББББББББ

БББББББББББББББББББББ

428.6 mV (60 IRE)

428.6 mV

БББББББББББББББББББББ

214.3 mV (30 IRE)

БББББББББББББББББББББ

0.5, 1.25, 2.0, 3.0, 3.75, and 4.0 MHz

БББББББББББББББББББББ

140 ns typical (sine-squared packets)

БББББББББББББББББББББ

(60 IRE), equal width packets

p-p

400 ns typical (sine-squared packets)

See Figure 1–46.

БББББББББББББББББББББ

100 Hz to 4.2 MHz, lines 21–202

БББББББББББББББББББББ

714.28 mV

.5, 1, 2, 3, 3.75, and 4 MHz, lines 203–263

БББББББББББББББББББББ

(100 IRE)

p–p

Field Lines (inclusive, see Figure 1–47):

21–69

БББББББББББББББББББББ

70–1 17

118–165

БББББББББББББББББББББ

166–213

БББББББББББББББББББББ

214–262

See Figure 1–48.

БББББББББББББББББББББ

549.1 mV (76.9 IRE)

БББББББББББББББББББББ

Lines 45 and 238

БББББББББББББББББББББ

14.925 and 56.525 µs

БББББББББББББББББББББ

Lines 33 and 250

БББББББББББББББББББББ

12.325 and 59.125 µs

Page 26

Specifications

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

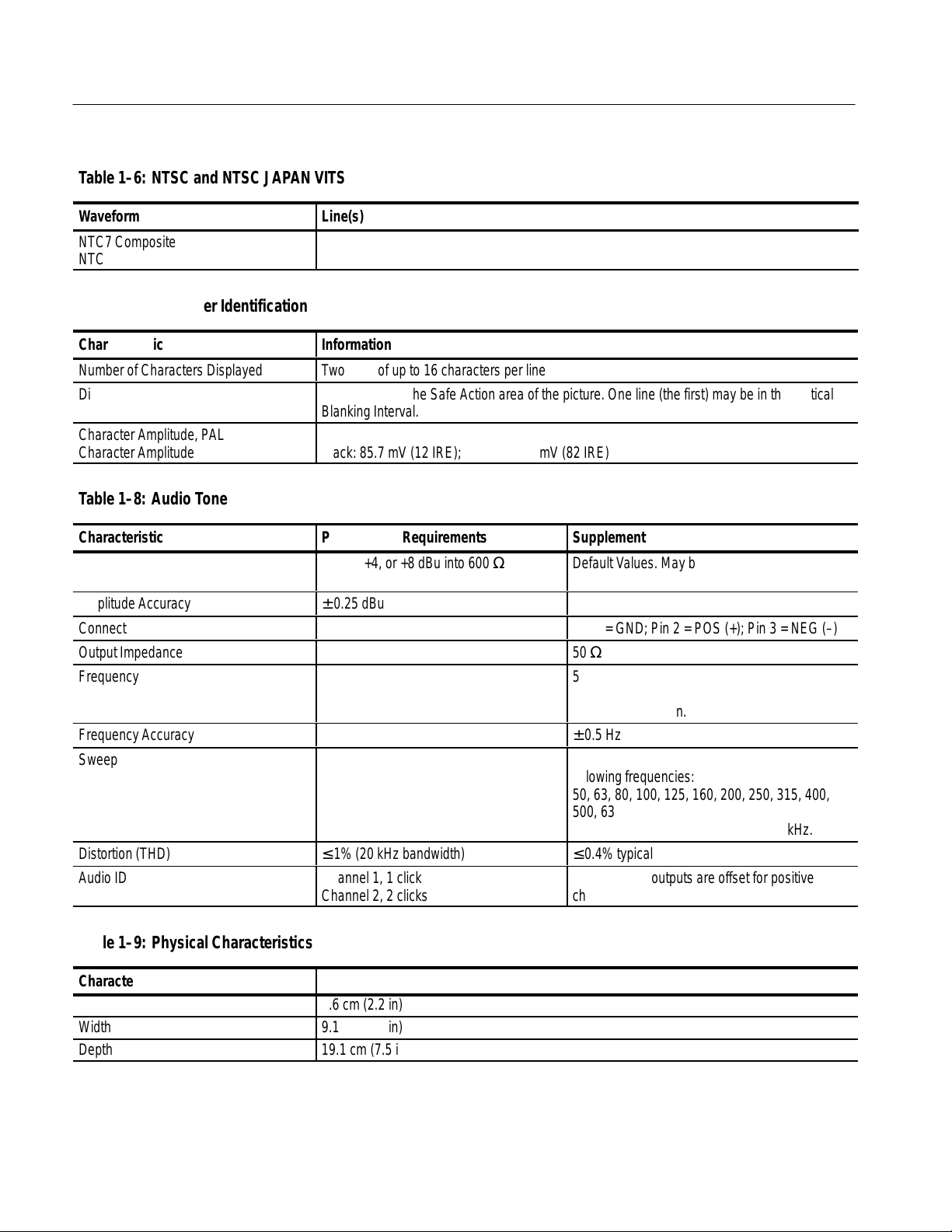

T able1–6: NTSC and NTSC JAPAN VITS

Waveform

NTC7 Composite

БББББББББ

NTC7 Combination

T able1–7: Character Identification

Characteristic

Number of Characters Displayed

Display Position

БББББББББ

Character Amplitude, PAL

БББББББББ

Character Amplitude, NTSC

T able1–8: Audio Tone

Characteristic

БББББББББ

Amplitude

Amplitude Accuracy

Connector Polarity

Output Impedance

Frequency

БББББББББ

БББББББББ

Frequency Accuracy

Sweep

БББББББББ

БББББББББ

БББББББББ

Distortion (THD)

Audio ID “click” (click ON)

Line(s)

17

БББББББББББББББББББББ

280

Information

Two lines of up to 16 characters per line

Movable within the Safe Action area of the picture. One line (the first) may be in the Vertical

БББББББББББББББББББББ

Blanking Interval.

Black: 105 mV; White: 630mV

БББББББББББББББББББББ

Black: 85.7 mV (12 IRE); White: 585.7 mV (82 IRE)

Performance Requirements

БББББББББ

–10, 0, +4, or +8 dBu into 600 Ω

Supplemental Information

БББББББББББ

Default Values. May be recalibrated by qualified

technicians.

± 0.25 dBu

Pin 1 = GND; Pin 2 = POS (+); Pin 3 = NEG (–)

50 Ω

БББББББББ

БББББББББ

50, 63, 125, 250, and 400 Hz; 1, 2, 4, 8, 10, 12.5,

БББББББББББ

16, and 20 kHz; Sweep; Three User frequencies

БББББББББББ

with 1 Hz resolution.

± 0.5 Hz

1 kHz for 5 s followed by 0.5 s at each of the

БББББББББ

БББББББББ

БББББББББ

≤ 1% (20 kHz bandwidth)

Channel1, 1 click

Channel 2, 2 clicks

following frequencies:

БББББББББББ

50, 63, 80, 100, 125, 160, 200, 250, 315, 400,

БББББББББББ

500, 630, and 800 Hz; then 1, 1.25, 1.6, 2, 2.5,

3.15, 4, 5, 6.3, 8, 10, 12.4, 16, and 20 kHz.

БББББББББББ

≤ 0.4% typical

Channel click outputs are offset for positive

channel identification.

T able1–9: Physical Characteristics

Characteristic

Height

Width

Depth

1–12 TSG 95 Service Manual

Information

5.6 cm (2.2 in)

9.1 cm (3.6 in)

19.1 cm (7.5 in)

Page 27

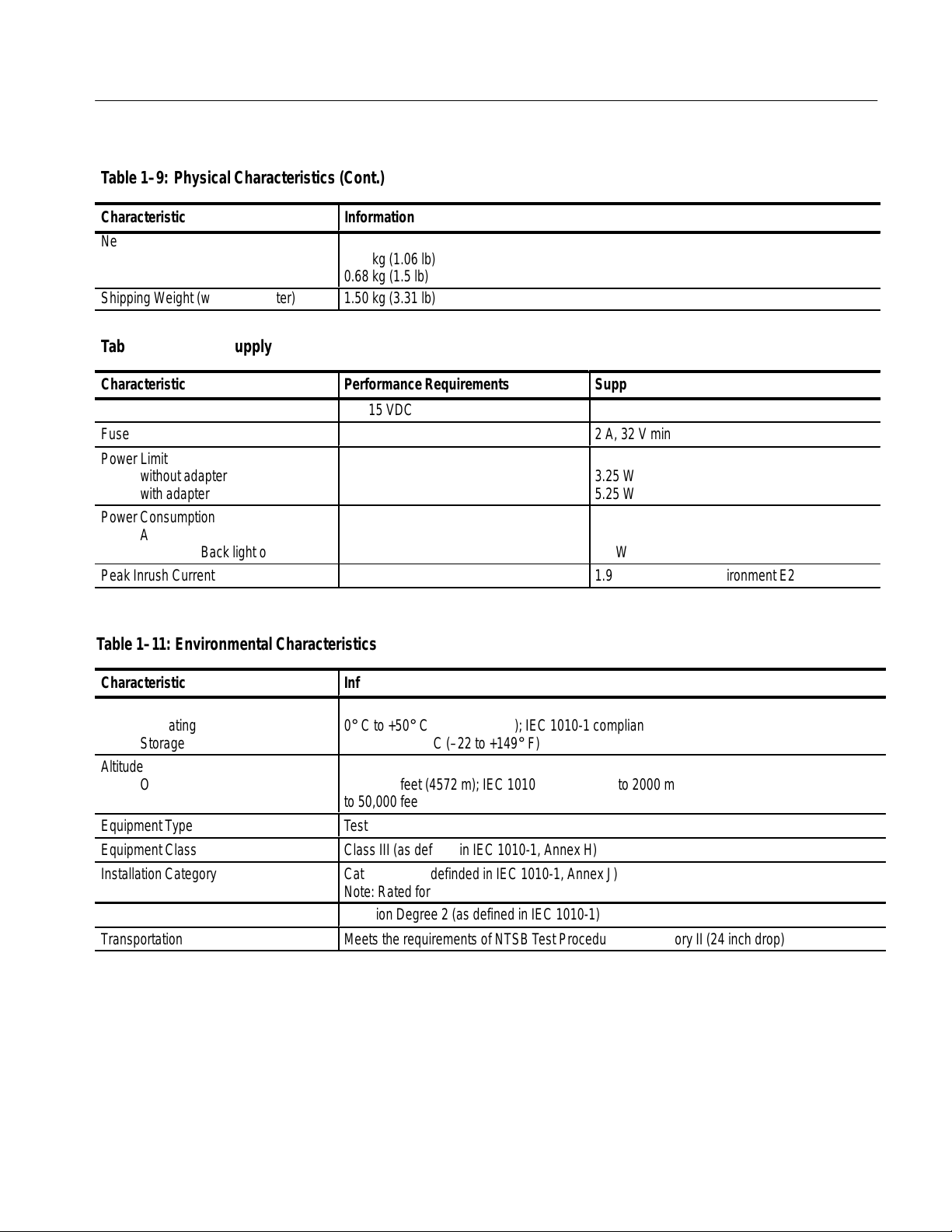

T able1–9: Physical Characteristics (Cont.)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Specifications

Characteristic

Information

Net Weight

ББББББББББ

TSG95

TSG95 with battery pack

ББББББББББ

Shipping Weight (with AC adapter)

БББББББББББББББББББББ

0.48 kg (1.06 lb)

0.68 kg (1.5 lb)

БББББББББББББББББББББ

1.50 kg (3.31 lb)

T able1–10:Power Supply

Characteristic

DC Input Range

Fuse

Power Limit

ББББББББББ

without adapter

with adapter

ББББББББББ

Power Consumption

Audio and Back light off

ББББББББББ

Audio and Back light on

Peak Inrush Current

Performance Requirements

9 to 15 VDC

БББББББББ

БББББББББ

БББББББББÁБББББББББББ

T able1–11: Environmental Characteristics

Supplemental Information

2 A, 32 V min

БББББББББББ

3.25 W

5.25 W

БББББББББББ

Typical (not charging):

2.0 W

2.5 W

1.95 A @230 VAC, Environment E2

Characteristic Information

Temperature

Operating

ББББББББББ

Storage

0° C to +50° C (32 to +122° F); IEC 1010-1 compliance to +40° C

ББББББББББББББББББББББ

–30° C to +65° C (–22 to +149° F)

Altitude

ББББББББББ

Operating

Storage

ББББББББББ

Equipment Type

Equipment Class

Installation Category

ББББББББББББББББББББББ

to 15,000 feet (4572 m); IEC 1010-1 compliance to 2000 m

to 50,000 feet (15420 m)

ББББББББББББББББББББББ

Test

Class III (as defined in IEC 1010-1, Annex H)

Category II (as definded in IEC 1010-1, Annex J)

Note: Rated for indoor use only.

Pollution Degree

Transportation

Pollution Degree 2 (as defined in IEC 1010-1)

Meets the requirements of NTSB Test Procedure 1A, category II (24 inch drop)

TSG 95 Service Manual 1–13

Page 28

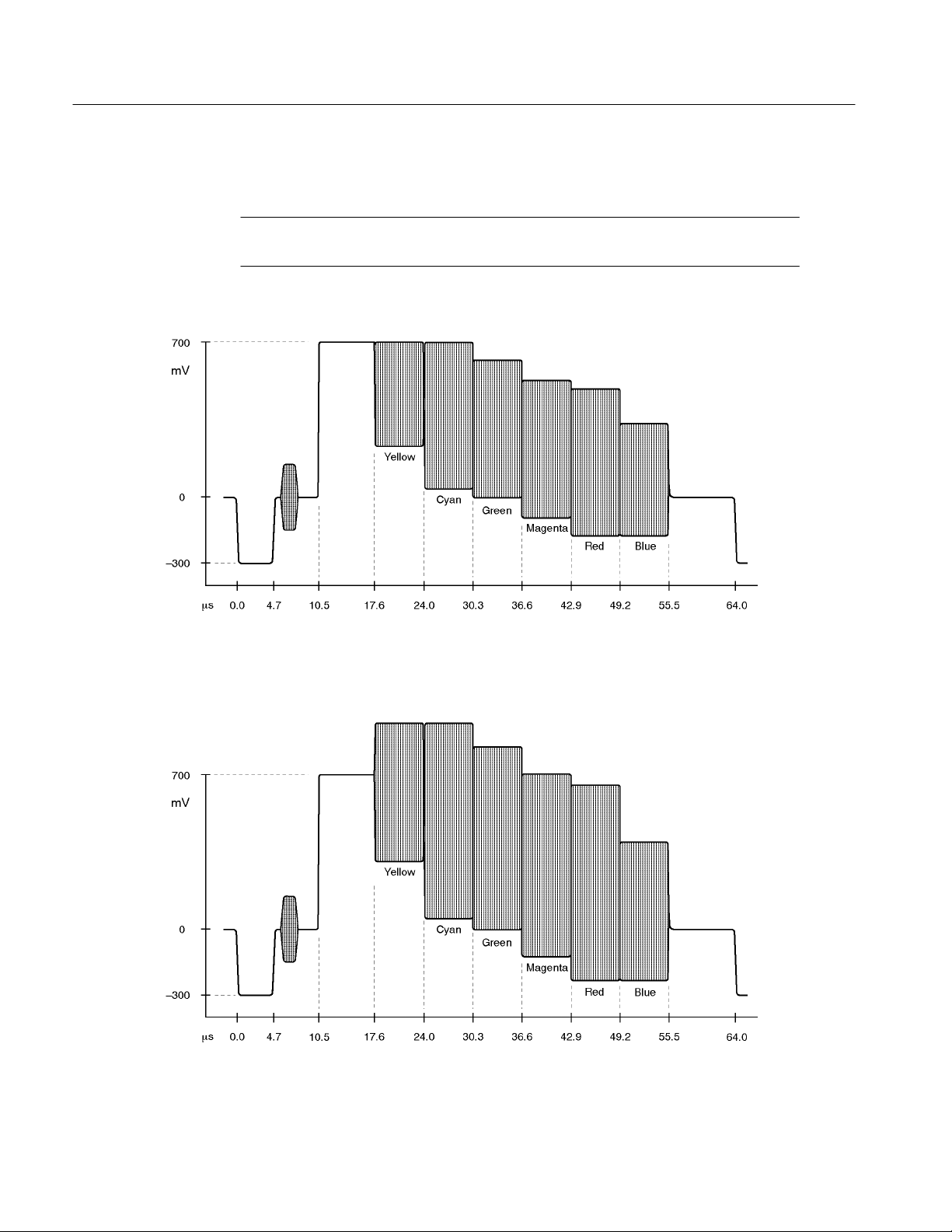

Specifications

PAL Waveform Diagrams

NOTE. Time references in the following waveform diagrams apply to the signal half-amplitude points or pulse peaks, unless indicated otherwise.

Figure 1–1: PAL 75% Color Bars

Figure 1–2: PAL 100% Color Bars

1–14 TSG 95 Service Manual

Page 29

Figure 1–3: PAL 75% Red and Red Field

Specifications

Figure 1–4: PAL 100% Red

TSG 95 Service Manual 1–15

Page 30

Specifications

Figure 1–5: PAL Green Field

Figure 1–6: PAL Blue Field

1–16 TSG 95 Service Manual

Page 31

Figure 1–7: PAL 50% Flat Field

Specifications

Figure 1–8: PAL 100% Flat Field

TSG 95 Service Manual 1–17

Page 32

Specifications

Figure 1–9: PAL 0% Flat Field

Figure 1–10: PAL Convergence (vertical lines)

1–18 TSG 95 Service Manual

Page 33

Figure 1–11: PAL Convergence (horizontal lines)

Specifications

Figure 1–12: PAL 5 Step (Gray Scale)

TSG 95 Service Manual 1–19

Page 34

Specifications

Figure 1–13: PAL Modulated 5 Step

Figure 1–14: PAL Multiburst

1–20 TSG 95 Service Manual

Page 35

Figure 1–15: PAL Reduced Sweep

Specifications

Figure 1–16: PAL Pluge

TSG 95 Service Manual 1–21

Page 36

Specifications

Figure 1–17: PAL Matrix Signal — CCIR 17

Figure 1–18: PAL Matrix Signal — CCIR Line 330

1–22 TSG 95 Service Manual

Page 37

Figure 1–19: PAL Matrix Signal — CCIR Line 331

Specifications

Figure 1–20: PAL Matrix Signal — CCIR 18

TSG 95 Service Manual 1–23

Page 38

Specifications

Figure 1–21: PAL Matrix Signal — (Sin x)/x

Figure 1–22: PAL Matrix Signal — 15 kHz Square W ave

1–24 TSG 95 Service Manual

Page 39

Figure 1–23: PAL Matrix Signal — Shallow Ramp

Specifications

Figure 1–24: PAL Matrix Signal — UK ITS 1

TSG 95 Service Manual 1–25

Page 40

Specifications

Figure 1–25: PAL Matrix Signal — UK ITS 2

1–26 TSG 95 Service Manual

Page 41

Specifications

Figure 1–26: PAL Safe Area

TSG 95 Service Manual 1–27

Page 42

Specifications

NTSC Waveform Diagrams

Figure 1–27: SMPTE (NTSC) Color Bar Components

1–28 TSG 95 Service Manual

Page 43

Specifications

Figure 1–28: SMPTE (NTSC) Color Bars, Zero Setup

TSG 95 Service Manual 1–29

Page 44

Specifications

Figure 1–29: NTSC 75% Color Bars

Figure 1–30: NTSC 75% Color Bars, Zero Setup

1–30 TSG 95 Service Manual

Page 45

Figure 1–31: NTSC Red Field

Specifications

Figure 1–32: NTSC Red Field, Zero Setup

TSG 95 Service Manual 1–31

Page 46

Specifications

Figure 1–33: NTSC (Sin x)/x

Figure 1–34: NTSC 5 Step Staircase (Gray Scale)

1–32 TSG 95 Service Manual

Page 47

Figure 1–35: NTSC 0 IRE No Burst

Specifications

Figure 1–36: NTSC 30 IRE (Zero Setup) and 50 IRE Flat Fields

TSG 95 Service Manual 1–33

Page 48

Specifications

Figure 1–37: NTSC Black Burst

Figure 1–38: NTSC Black Burst, Zero Setup (and Bounce, Low)

1–34 TSG 95 Service Manual

Page 49

Figure 1–39: NTSC 100 IRE, Field Square Wave (and Bounce, High)

Specifications

Figure 1–40: NTSC Multiburst

TSG 95 Service Manual 1–35

Page 50

Specifications

Figure 1–41: NTSC Convergence Components

1–36 TSG 95 Service Manual

Page 51

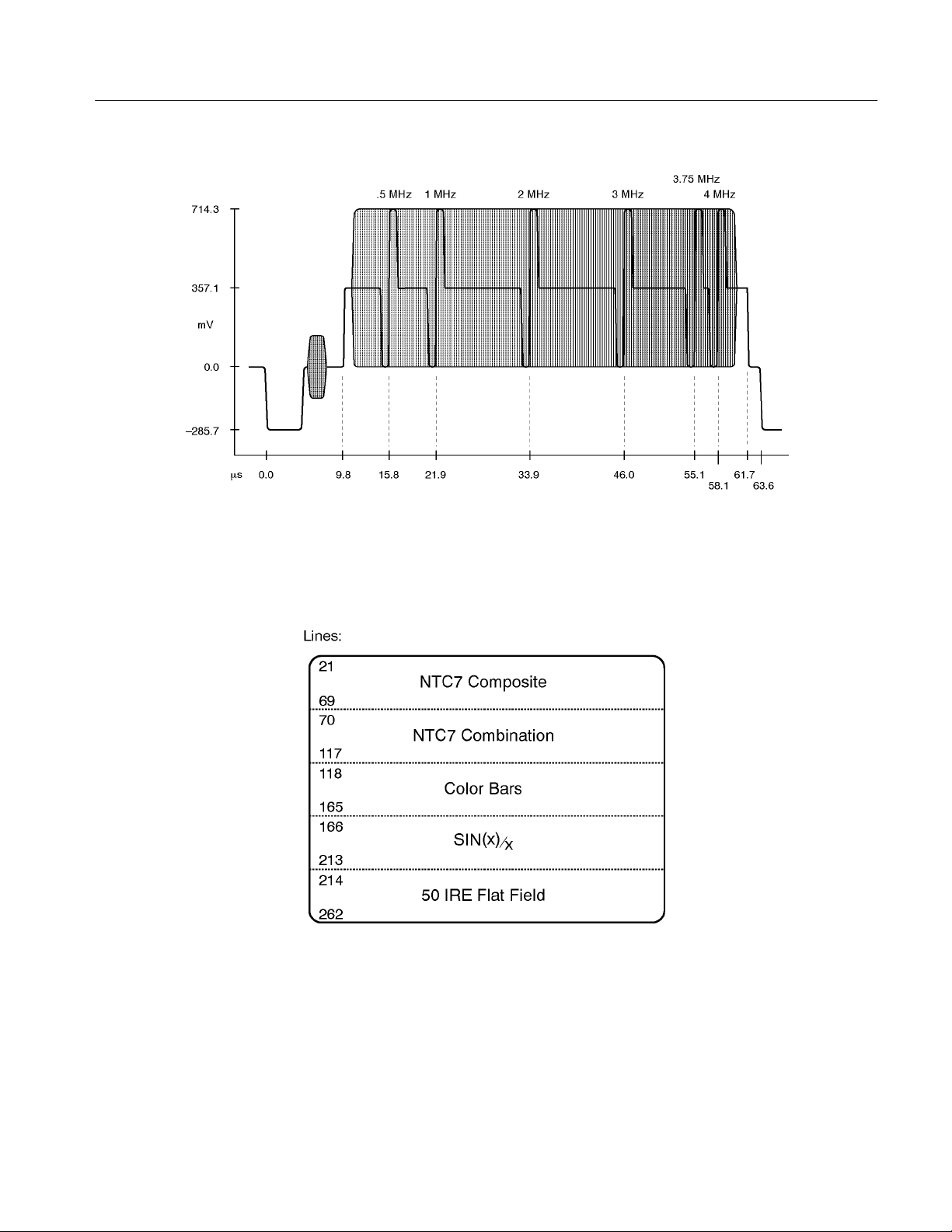

Figure 1–42: NTC7 (NTSC) Composite

Specifications

Figure 1–43: NTC7 (NTSC) Combination

TSG 95 Service Manual 1–37

Page 52

Specifications

Figure 1–44: FCC (NTSC) Composite

Figure 1–45: NTSC Cable Multiburst

1–38 TSG 95 Service Manual

Page 53

Figure 1–46: NTSC Cable Sweep

Specifications

Figure 1–47: NTSC Matrix

TSG 95 Service Manual 1–39

Page 54

Specifications

Figure 1–48: NTSC Safe Area

1–40 TSG 95 Service Manual

Page 55

Operating Information

This section duplicates material contained in the TSG 95 User manual (Tektronix

part number 070-8916-XX). This material is included for your convenience.

Please check the User manual if you need additional information on any topic.

TSG 95 Service Manual 2–1

Page 56

Operating Information

Getting Started

Please read the following statements before using your new TSG 95, then see the

rest of the section for tips on supplying power, making preliminary settings, and

connecting the instrument.

CAUTION. Attempting to operate the TSG 95 with an improper AC adapter can

result in damage to the instrument. To avoid damage, USE ONLY AN APPROPRIATE DC POWER SOURCE: Voltage must be 9 to 15 VDC; the connector must have the NEGATIVE contact in the center; and open-circuit voltage of

the power source must not exceed 18 VDC.

For best results, use the AC adapter that is supplied with the instrument. If the

supplied adapter is incorrect for the local AC power supply, contact your nearest

Tektronix representative.

WARNING. Install or replace batteries only with the instrument switched OFF

and the AC adapter disconnected.

Supplying Power

Replace the batteries only with standard AA batteries (1.2–1.5 V, nominal), or

with a Tektronix rechargeable battery pack (p/n 119-4488-00).

If you use NiCad AA batteries or the optional battery pack, be sure to set the

battery type to “rechargeable” through the Utility menu (see page 2–6). Failure

to do so can result in damage to the batteries.

NOTE. Do not disconnect the AC adapter when the TSG 95 is switched on. Some

user settings may be lost, perhaps causing unexpected results the next time the

instrument is switched on.

If you have any questions regarding the operation of this instrument, please contact your nearest Tektronix representative or field office. In the United States and

Canada, you may also call the Tektronix information number, 1-800-TEK-WIDE

(1-800-835-9433), between 8:00 am and 5:00 pm Pacific time.

The TSG 95 is DC powered. You may power it with the standard AC adapter, the

optional 9.6 V NiCad battery pack, eight standard AA batteries, or a “BP” type

battery pack with the correct voltage and polarity. The external DC power connector is on the left side of the instrument.

2–2 TSG 95 Service Manual

Page 57

Operating Information

To install AA batteries or the battery pack, open the battery compartment of the

TSG 95 by pressing down on the cover and sliding it in the direction of the inscribed arrow, as shown above. When the cover tabs line up with the slots in the

case, lift the cover away from the instrument. Install batteries in alternating

directions as indicated by the graphic molded into the “floor” of the battery

compartment. If using the optional battery pack, take the time to identify both

contacts and install the pack properly.

When selecting a power source for your TSG 95, please remember:

H Attempting to use an improper AC adapter can damage the instrument. See

the Caution statement on the previous page.

H There is no need to remove the optional NiCad battery pack for recharging.

The TSG 95 will “trickle charge” the battery pack whenever the standard AC

adapter is used. Recharging the battery pack fully can take up to 16 hours.

NOTE. Charging will occur only if the adapter supplies at least 12V; make sure

that the adapter you use is appropriate for the local AC supply.

H AA batteries are not included with the instrument; obtain them locally.

Rechargeable AA batteries may be used, but they will NOT be recharged

automatically by the AC adapter. To recharge AA batteries, remove them

from the instrument and use an appropriate battery charger. For safety, read

and follow the battery charger instructions. Do NOT attempt to recharge

standard alkaline batteries. Remove Alkaline batteries when the instrument

will be stored or powered with the AC adapter for more than 30 days.

H After a minute with no key press, the TSG 95 will automatically switch to

lock out mode (as if you had pressed the Lock Out key); the display back

light will shut off to conserve battery charge. When you want to resume

keypad input, press Lock Out

to exit lock out mode.

H To guard against battery discharge if you forget to turn the TSG 95 off after

use, enable Auto Power Down through the Utility menu (see page 2–6).

TSG 95 Service Manual 2–3

Page 58

Operating Information

Connecting the TSG95

H The TSG 95 can sense low battery voltage. It will warn you when the charge

is sufficient for approximately ten more minutes of operation. The instrument will shut itself down when the battery voltage becomes too low for

reliable operation. For proper function of these features, the Battery Type

must be set correctly in the Utility menu. Please see “Setting the Battery

Type,” below.

The ON key toggles instrument power On and Off.

Connect the instrument to your equipment as you would any television test signal generator. Use 75W coaxial cable (for video) and be sure that the signal path

is properly terminated.

12

3

You may wish to confirm proper operation of your TSG 95—and gain familiarity

with it—by first connecting it directly to a video or waveform monitor.

Keypad and Display Conventions

Please see the Instruction card (p/n 070-8915-XX) supplied with your TSG 95

for a “tour” of the keypad and an explanation of the display symbols. For your

convenience, the following panels are excerpted from the card.

Pin 1 = GND

Pin 2 = POS (+)

Pin 3 = NEG (–)

2–4 TSG 95 Service Manual

Page 59

Definitions

Operating Information

There are two terms used in this manual that deserve a little explanation:

Signal Set. The group of signals that can be selected through the TSG95 keypad

at a given time. In the pre-programmed signal sets, all of the signals are the same

video standard. You may create a “User” signal set, however, that contains any

combination of PAL and NTSC signals assigned to the letter keys that you find

most convenient.

Preliminary Settings

Choose the Video

Standard/Signal Set

T one Level. One of four pre-defined audio output amplitudes that may be selected

through the Tone menu. The levels (1 through 4) are “named” –10, 0, +4, and +8

dBu and calibrated to those amplitudes when the TSG 95 is manufactured.

Qualified personnel with the appropriate equipment can rename and readjust the

levels within the ranges of –10 to –3 dBu and 0 to +10 dBu. See page 4–29, in

the Performance Verification and Adjustment section of this manual, for

instructions.

Once the TSG 95 is up and running, you should make some settings that depend

on how the instrument will be used. These settings are made through the Utility

menu. Invoke the Utility menu by holding Lock Out down while pressing the

ON key—then make the following configuration selections.

1. Use the

2. Select, with the

propriate to your application. The choices are: PAL; NTSC; NTSC JAPAN

(which includes NTSC signals with 0% Setup); and USER SIG SET (the

user-configurable signal set that can contain up to 26 signals of your

choice—see the User manual for more information).

Y and B keys to scroll to the SELECT STNDRD menu item.

A and " keys, the signal standard or “signal set” that is ap-

3. When the name of the desired signal set is displayed, continue to the Battery

Type, or press any rectangular key to exit the Utility menu and return to normal operation.

TSG 95 Service Manual 2–5

Page 60

Operating Information

Set the Battery Type

Enable (Disable)

Auto Power Down

While still in the Utility menu, use the

Y and B keys to scroll to the BATTERY

TYPE item.

1. Toggle to the selection that matches the type of battery you have installed in

your TSG 95 by pressing either

A or ". The choices are “rechargeable” and

“disposable.” Select rechargeable when using NiCad AA cells or the optional

battery pack; choose disposable when you are using common Alkaline AA

batteries, which cannot be recharged.

2. When the correct battery type is displayed, continue to Auto Power Down, or

press any rectangular key to exit the Utility menu and return to normal operation.

“Auto Power Down” will switch the instrument off when ten minutes have

passed without a key press. Enable this feature when using battery power and

operating in an environment in which unplanned shutdown of the TSG 95 is permissible.

1. While still in the Utility menu, use the

Y and B keys to scroll to the AUTO

PWR DOWN item.

2. Disable/enable Auto Power Down by pressing either

A or ". The new state

will be in effect when you return to normal operation. Enabled Auto Power

Down is indicated by a “rotating line” symbol in the upper-right corner of

the instrument LCD.

Other Settings

3. Use the

Y and B keys to access other Utility menu items, or press any rect-

angular key to exit the menu and resume normal operation.

There are other, less important TSG95 settings that are configured through the

Utility menu and its Calibration submenu. See “The Utility Menu,” beginning on

page 5–4 for more information.

2–6 TSG 95 Service Manual

Page 61

Using Your TSG95

Operating Information

Here is a list of what you can do with your TSG 95. Instructions for each use begin on the indicated page.

H Output either PAL or NTSC video test signals (page 2–8). You can

configure the instrument to generate:

H PAL signals

H NTSC signals

H “NTSC JAPAN” signals that have 0 IRE (instead of 7.5 IRE) setup

H A “User Signal Set” that can contain any combination of PAL, NTSC or

NTSC JAPAN signals that you find convenient.

See page 2–5 for information on choosing a video standard/signal set.

Directions for creating (or editing) your own User signal set appear in the

User manual.

H Generate audio tones (page 2–9). You may:

H Choose one of 13 discrete “factory” frequencies, or select a frequency

sweep that sweeps continuously from 50 Hz to 20 kHz (page 2–9)

H Designate three “User Tones” between 50 Hz and 20 kHz with a

resolution of 1 Hz (page 5–7), and later output one of these frequencies

H Select a factory-calibrated audio output level of –10, 0, +4, or +8 dBu

(page 2–9)

H Recalibrate the audio output to permit selection of any whole dB level

within the ranges of –10 to –3 dBu and 0 to +10 dBu (qualified service

technicians only—see page 4–29)

H Include channel-ID “clicks” in the audio output (page 2–10)

H Add an ID message to the video signal (pages 2–10), edit it (page 2–10), and

place it in the vertical interval or position it where desired in the active video

(page 2–10)

H Store up to eight ID messages for later use (page 2–11)

H Create a sequence of (up to four) stored ID messages that will cycle

continuously in the output (page 2–12)

H Save all the current instrument settings as a “Preset” for later recall (page

2–13)

TSG 95 Service Manual 2–7

Page 62

Operating Information

Á

Á

Á

Á

Á

Outputting Test Signals

1. Connect the TSG 95 to your system and make the appropriate preliminary

settings as described in the Getting Started section of this manual.

2. Switch the instrument on or return to normal operation by pressing either the

Bars or Other Signals key. By default, the instrument “powers up” with the

settings that were in effect when it was last switched off.

Table 2–1: TSG95 Video Test Signals

ББББББББББББББББББББББ

PAL

Signal Set

ББББББ

75% Bars

100% Bars

75% Bars/Red

100% Bars/Red

Convergence

Pluge

Safe Area

Green Field

Blue Field

Red Field

100% Flat Field

50% Flat Field

0% Flat Field

Multiburst

60% Sweep

5-Step

Mod. 5-Step

Matrix

Field Square Wave

Bounce

—

* These signals have 0 IRE setup and differ from the signals with the same name in the

NTSC signal set.

NTSC

Signal Set

ББББББ

SMPTE Bars

75% Bars

Convergence

Safe Area

Red Field

50IRE Flat Field

100IRE Flat Field

Black Burst

5-Step

Multiburst

NTC7 Composite

NTC7 Combination

FCC Composite

Cable Multiburst

Cable Sweep

SIN X/X

Matrix

0 IRE, no Burst

Field Square Wave

Bounce

—

NTSC JAPAN

Signal Set

ББББББ

SMPTE Bars*

75% Bars*

SNG Bars*

Convergence

Safe Area

Red Field*

50IRE Flat Field

100IRE Flat Field

Black Burst*

5-Step

Multiburst

NTC7 Composite

NTC7 Combination

FCC Composite

Cable Multiburst

Cable Sweep

SIN X/X

Matrix*

0 IRE, no Burst

Field Square Wave

Bounce

Key

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

Á

3. Select the desired test signal one of four ways:

H Press the Bars key repeatedly to select among the available color bars

signals. The signal will be output as soon as the name is displayed on the

TSG 95 LCD.

H Press the Other Signals key repeatedly to select among the “non-bars”

signals. Again, the signal will be output as soon as its name is displayed

on the LCD.

2–8 TSG 95 Service Manual

Page 63

Operating Information

Outputting Audio Tones

Selecting the Audio

Frequency

H Use the

Y and B keys to scroll through the full list of signals until you

get to the desired signal.

H Press the appropriate letter key (A through U) to “direct-select” the

signal. The available signals and their corresponding keys are listed in

Table 2–1.

H Toggle the audio output On/Off by pressing the Tone On/Off key.4

1. Enter the Tone menu (press Shift, then Tone On/Off). The first menu item is

TONE FREQ.

2. Use the

A and " keys to select the desired frequency. The choices are:

50, 63, 125, 250, and 400 Hz;

1, 2, 4, 8, 10, 12.5, 16, and 20 kHz;

USER1, USER2, USER3; and

SWEEP 50–20K (a 50 Hz–20 kHz sweep)

You may specify the USER# frequencies through the Utility/Calibration

menu; see page 5–7. (Note that there is no default value for USER3;

therefore, the USER3 choice will not appear in a new—or reset—instrument.)

Setting the Audio Tone

Level (Amplitude)

You can pause a sweep at any of its 27 frequency steps (listed in Table 1–8 in

the Characteristics section) by pressing Enter when in the TONE FREQ

menu item and SWEEP 50–20K is selected. The message SWEEP PAUSED

will appear on the display. You may find this capability useful for checking a

problem noticed at a particular frequency while sweeping. Press Enter a second time to resume the frequency sweep.

3. Tone frequencies are in effect as soon as they are indicated on the display.

Scroll down to other Audio menu items with the

B key, or exit the menu by

pressing any rectangular key.

1. In the Audio menu, use the

2. Use the

A and " keys to select the desired level. When manufactured, the

B or Y key to reach the TONE LEVEL item.

four TSG 95 tone levels are designated as –10, 0, +4, and +8 dBu and calibrated to those amplitudes. Qualified technicians may rename and recalibrate

the tone levels to any integer value within the ranges of –10 to –3 dBu and 0

to +10 dBu. See page 4–29 for instructions.

3. The new tone level will be in effect immediately. Scroll to other Audio menu

items with the

B or Y key, or exit the menu by pressing any rectangular key.

TSG 95 Service Manual 2–9

Page 64

Operating Information

Inserting Channel-ID

Clicks in the Audio

Inserting ID Messages

Editing ID Messages

When click is enabled, the instrument will insert a single click into channel 1,

and a double click into channel 2.

1. In the Audio menu, use the

2. Use the

A and " keys to toggle the ID clicks On/Off.

3. Scroll to other Audio menu items with the

B or Y key to reach the CLICK item.

B or Y key, or exit the menu by

pressing any rectangular key.

H Toggle the ID message or cycle on and off by pressing the ID On/Off key.

The status of the ID—on, off, or cyc (cycle)—is indicated on the second line

of the TSG 95 display, as shown in the next illustration.