Page 1

Service Manual

TS200 TelScout

Access Network Analyzer

071-0070-02

This document applies to firmware version 2.00

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of purchase from an authorized T ektronix distributor. If

any such product proves defective during this warranty period, T ektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in exchange for the defective

product. Batteries are excluded from this warranty.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix,

shipping charges prepaid, and with a copy of customer proof of purchase. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the T ektronix service center is

located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE LISTED PRODUCTS IN

LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF

SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injury Precautions vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Terms and Symbols ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface

Preface xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assumptions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Servicing xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Will Find in this Manual xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Overview 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Functional Modules 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static-Sensitive Components 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls, Indicators, and Connectors 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display/Indicators 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectors 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification Tables 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TS200 Characteristic T ables 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories and Options 1–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 1–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Operating System Software 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Configuration Options 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TS200 Options 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TelScout TS200 Access Network Analyzer Service Manual

i

Page 6

Table of Contents

Theory of Operation

Block Diagram 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Descriptions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board A1 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board A2 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Assembly 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Battery 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC-to-DC External Adapter 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlight Inverter 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Required Equipment 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Port Configurations 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDR 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Crosstalk 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Dual Displays 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Pulse Widths and Heights 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Smoothing 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDR Distance Measurement Accuracy 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POTS 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Volts 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Volts 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loss and Slope 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Metallic Noise / Power Influence 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T one Generator 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VOM Ohms 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Fault Locator 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loop Current 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Longitudinal Balance 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitance (Open) Meter 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Dialer 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTMF Dialer 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Coils, 66 mH / 88 mH 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TS200 T est Record 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

ii

Inspection and Cleaning 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior Inspection 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior Cleaning 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interior Inspection 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interior Cleaning 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Downloading 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional T esting 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal / Installation Procedures 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly Procedures 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Longitudinal Balance Adjustment 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TelScout TS200 Access Network Analyzer

Service Manual

Page 7

Required Equipment 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup for Troubleshooting 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Replaceable Parts 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Servicing 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Modules 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire and Cable Assemblies 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Information

Multi-Test Fixture 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Count Load Coils 66 MH 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Count Load Coils 88 MH 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-T est Fixture Calibration and Performance Verification 6-5. . . . . . . . . . . . . . .

Index

Table of Contents

TelScout TS200 Access Network Analyzer Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 1–1: Front-Panel Controls, Indicators, and Connectors 1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Arrangement of the Readout Bar in TDR Mode 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: TS200 Block Diagram 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: TS200 with Standard Test Leads Attached 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: TDR Performance Checks 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: Verify 2 ns and 10 ns Pulse Widths and Heights 3–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–4: Example of Initial Pulse 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: Verify Pulse Widths / Heights ( 75 ns 340 ns and 3400 ns) 3–7. . . . . . . . . . . . . . . . . .

Figure 3–6: Example of Peak to Peak Pulse 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–7: Check TDR Distance Accuracy 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–8: Measure DC Volts 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–9: Loss Slope (T one Receiver) Performance Check 3–14. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–10: Psophometric / C-Message Filter Frequency 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–11: Measure Metallic Noise / Power Influence 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–12: Tone Generator Performance Check 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–13: VOM Ohm Performance Check 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–14: Resistance Fault Locator Performance Check 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–15: Sample Display to Verify Readouts 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–16: Loop Current Performance Check 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–17: Longitudinal Balance Performance Check 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–18: Open Capacitance Meter Performance Check 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–19: Pulse Dialer Performance Check 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–20: Typical Waveform for Dialer Performance Check 3–28. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–21: DTMF Dialer Performance Check 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–22: Load Coil Performance Checks 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Battery Removal 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Opening the TS200 Instrument 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: Disconnecting Circuit Board Assembly A1 Cable Attachments 4–7. . . . . . . . . . . . . .

Figure 4–4: Removing Circuit Board Assembly A1 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–5: Disconnecting Circuit Board Assembly A2 Cables 4–8. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Preparing to Remove Circuit Board Assembly A2 4–8. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Removing Circuit Board Assembly A2 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–8: Removing More Cable Assemblies 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–9: Removing the Speaker Cable Assembly 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TelScout TS200 Access Network Analyzer

Service Manual

Page 9

Table of Contents

Figure 4–10: Preparing to Remove the Support Plate Assembly 4–11. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–11: Removing the Support Plate Assembly 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–12: Disassemble the Support Plate; Remove DC–AC Converter Board A3 4–12. . . . . . .

Figure 4–13: Removing the LCD Display Module A4 Assembly 4–12. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: Removing the LCD Plate Assembly and Flex Circuit 4–13. . . . . . . . . . . . . . . . . . . . .

Figure 4–15: Disassembling the T op Case–half 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–16: Installing the Display Window 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–17: POTS Longitudinal Balance Adjustment 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: Exploded View, Replaceable Mechanical Parts 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Multi-T est Fixture Front Panel 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Multi-Test Fixture Schematics 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables

Table 1–1: TS200 Functional Modules 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–2: Environmental Performance Conditions 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–3: Certifications and Compliances 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–4: Safety Requirements 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–5: Reliability 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–6: Physical Characteristics 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–7: Base Product Characteristics 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–8: TDR Characteristics 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–9: POTS Characteristics 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–10: Load Coil TestWizard Characteristics 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–1: 2 ns and 10 ns Pulse Specifications 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–2: 75 ns, 340 ns, 3400 ns Pulse Specifications 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–3: Psophometric and C-Message Filter Frequency Responses 3–18. . . . . . . . . . . . . . . . . . .

T able 3–4: C–Message Noise and Power Influence Values 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–5: TelScout TS200 Test Record 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–1: Serial Cable Pinout Chart 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 6–1: Required Equipment for Calibration / Performance Verification 6–5. . . . . . . . . . . . . .

T able 6–2: Multi-Test Fixture Calibration and Performance Test Record 6–7. . . . . . . . . . . . . . . .

TelScout TS200 Access Network Analyzer Service Manual

v

Page 10

Table of Contents

vi

TelScout TS200 Access Network Analyzer

Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

CAUTION. Refer all repair problems to qualified service personnel. See

the Preface chapter for a list of phone numbers to call for service

information.

Injury Precautions

Power Source

The TS200 analyzer is designed to operate from an internal rechargeable

battery pack or an external battery charger/adapter. The internal power is

provided by a 9-cell, 3.5 Ah NiMH battery pack with an integral fuel

gage circuit. The external power source supplies 24 DC volts at 1.5 A to

the instrument.

Battery Pack

Do not expose the battery pack to fire or intense heat. Do not open or

mutilate the battery pack. Avoid contact with released electrolyte which

is corrosive and may damage eyes, skin, and clothing. Check with local

codes for special disposal instructions. Only the entire battery is

replaceable. Individual cells are not replaceable.

Always disconnect the test leads and turn off the instrument before

disconnecting the battery pack.

To reduce environmental pollution, the battery must be recycled.

Disconnect battery when stored for long periods of time.

CAUTION. Do not charge the battery in a gas-tight container.

Do not short the battery terminals.

Do not incinerate the battery.

Flush with water at once if contact is made with electrolyte.

TelScout TS200 Access Network Analyzer Service Manual

vii

Page 12

General Safety Summary

External Power

Use only the power charger/adapter that is specified for the TS200.

CAUTION. The power charger/adapter is not designed for outdoor use.

Use in an indoor environment only.

Grounding the Instrument

It is not necessary to ground the instrument during normal use. Cases are

non-conductive and internal voltages are not accessible to the operator.

Fuse

The TS200 contains a 1.5-amp, 30-volt, surface mounted self resetting

fuse on the TDR board. The fuse is not user replaceable.

Do Not Operate in Explosive Atmosphere

Do not operate the instrument in an explosive atmosphere unless it has

been specifically certified for such operation.

Do Not Remove Covers or Panels

To avoid personal injury, do not remove the instrument covers or panels,

nor operate the instrument without covers and panels in place. Refer

service to qualified service personnel.

Electromagnetic Emissions

The TS200 has been verified for compliance to FCC Class A and

European Union EMC.

Disposal of Batteries

This instrument contains a NiMH battery pack. Some states and/or local

jurisdictions might require special disposition/recycling of this type of

material in accordance with Hazardous Waste guidelines. Check your

local and state regulations prior to disposing of an old battery.

For the location of a local battery recycler in the U.S. or Canada, please

contact:

viii

RBRC (800) BATTERY

Rechargeable Battery Recycling Corp. (800) 227-7379

P.O. Box 141870 www.rbrc.com

Gainesville, Florida 32614

TelScout TS200 Access Network Analyzer Service Manual

Page 13

Safety Terms and Symbols

Terms in this Manual

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could

result in damage to this product or other property.

Terms on the Product

DANGER indicates an injury hazard immediately accessible as you read

the marking.

General Safety Summary

High Voltage

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product

DANGER

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

TelScout TS200 Access Network Analyzer Service Manual

ix

Page 14

General Safety Summary

x

TelScout TS200 Access Network Analyzer Service Manual

Page 15

Preface

Contacting Tektronix

This manual provides module level servicing information for the

TelScout TS200 Access Network Analyzer. It does not contain component-level service information. However, the Supplemental Information

chapter does contain component-level schematics of the multi-test

fixture which is required for performance verification testing.

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: support@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please

leave a voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see

the Tektronix web site for a list of offices.

TelScout TS200 Access Network Analyzer Service Manual

xi

Page 16

Preface

Assumptions

Before Servicing

The procedures in this manual assume that you are a qualified electronics

technician and have a working knowledge of servicing procedures for

metallic time-domain reflectometry test equipment and POTS test

equipment.

The procedures also assume you are familiar with and practice clean,

static control measures.

To prevent injury to yourself or damage to equipment:

H You must be a qualified service person.

H Read the General Safety Summary at the beginning of this manual.

H Heed all warnings, cautions, and notes in this manual.

What You Will Find in this Manual

Section 1. Introduction. Contains product information, user information,

battery recharging and replacement information, instrument specifications, characteristic tables, accessories, and options.

Section 2. Theory of Operations. Shows the functional relationship of

the modules.

Section 3. Performance Verification. Checks TS200 performance to

verify correct operation after repairs and adjustments have been made.

Section 4. Maintenance. Includes:

H Inspection and cleaning of exterior, connectors, and test cables.

H Disassembly procedure to module level.

H Troubleshooting problems to module level.

H Resolving error messages displayed on the screen.

Section 5. Replaceable Parts. Lists and describes replaceable electrical

and mechanical parts.

Section 6: Supplemental Information. Multi-Test Fixture reference panel

and schematics. This fixture is for calibration and performance testing on

the TS200.

xii

TelScout TS200 Access Network Analyzer Service Manual

Page 17

Related Documents

Tektronix Service

Preface

The TelScout TS200 Series Access Network Analyzer User Manual

explains how to use the TS200 analyzer to test telephone cables. The

user manual is translated into ten languages. See Accessories.

Tektronix provides service to cover repair under warranty and post-warranty problems.

The TS200 Access Network Analyzer is warranted for one year. The

warranty appears at the beginning of this manual.

TelScout TS200 Access Network Analyzer Service Manual

xiii

Page 18

Preface

xiv

TelScout TS200 Access Network Analyzer Service Manual

Page 19

Introduction

Overview

The Functional Modules

This manual is used for servicing the TS200 to module level only. A module is

defined as a complete circuit board assembly or other electrical part that

performs a specific function.

When a problem is traced to a module, the usual corrective procedure is to

replace the module.

This manual does not contain:

H Component-level troubleshooting or calibration information.

H Information pertaining to component replacement or module repair.

H Circuit board schematics.

H Component-level electrical parts lists or information.

There are four functional modules in the TS200.

T able 1–1: TS200 Functional Modules

Module Module Name Function Assembly

POTS board Telephone service

TDR board Option 01 Assembly

Number

A1

measurements

A2

MTDR, power, control, external access

TelScout TS200 Access Network Analyzer Service Manual

1–1

Page 20

Introduction

T able 1–1: TS200 Functional Modules (Cont.)

Module Assembly

Static-Sensitive Components

CAUTION. All modules in the TS200 contain components that are sensitive to

electrostatic discharge (ESD).

When servicing the TS200, work only at a static-free work station, and practice

standard anti-static handling procedures.

FunctionModule Name

Power supply board DC–AC converter

for backlight

Display module Display (LCD)

assembly with backlight

Number

A3

A4

1–2

TelScout TS200 Access Network Analyzer Service Manual

Page 21

Operation

The following information describes the product and the operating features of the

product.

The Tektronix TS200 TelScout Access Network Analyzer consists of three

separate but related product configurations. The loop-test configurations include

a TDR unit, a POTS only unit, and a combined TDR and POTS unit. The TS200

allows customers to analyze and troubleshoot the access network for analog or

digital services. It is designed specifically for telephone access network

applications, including xDSL, ISDN, and POTS.

Controls, Indicators, and Connectors

The TS200 controls are described briefly in this chapter.

Introduction

Figure 1–1: Front-Panel Controls, Indicators, and Connectors

Display/Indicators

LCD Display

The display will convey three distinct kinds of information to the operator at all

times: operating mode (current status), softkey labels, and the data operating

TelScout TS200 Access Network Analyzer Service Manual

1–3

Page 22

Introduction

Display Organization: TDR

information. The measurement display shows numerical data in a readout bar at

the bottom of the data/information window.

The current operating mode of the instrument is displayed on the top status line

of the display, above the framed data window, which is above the bottom seven

lines reserved for softkey labels and dialog. When the instrument needs to

display additional information in a message to the operator, it will appear in the

dialog test box.

Current setting of

Velocity of Propagation

Pulse width in nanoseconds

(not visible in TestWizard

Zoom Off mode)

Distance from marker to cursor

(if marker is set and not visible

in TestWizard mode)

Vp 60.0 ft12 dB0.660 GAIN 12 dB PW 5 ns

Current gain setting in decibels

(not visible in TestWizard

Zoom Off mode)

Figure 1–2: Arrangement of the Readout Bar in TDR Mode

Vp: Velocity of Propagation. In Auto TDR and TestWizard, this is set in the

selection of the cable type being used. In Manual TDR, this can be changed from

the measurement display.

GAIN: This is set with (Y B) while no softkey is active. The visual result of

increasing the gain is to increase the height of the displayed waveform. It might

also bring out an event that is barely noticeable.

PW: Pulse width is shown in the Readout Bar when the measurement display is

in Auto or Manual TDR mode. PW is selectable in Manual TDR through the

Pulse softkey. In the Auto TDR or TestWizard modes, the pulse width selection

is automatically made by the instrument and is dependent on the distance from

the instrument, cable dielectric, etc.

ERL DIST

Current return loss in dB

(RL or ERL)

n

Distance to clip end

of test leads to current

cursor location

1–4

RL or ERL: RL is the Return Loss and ERL is the Event Loss. This box can be

turned off from the More Setups menu.

TelScout TS200 Access Network Analyzer Service Manual

Page 23

n

Display Organization:

POTS

Introduction

n: The delta symbol indicates a difference-distance. When a marker (◆) is

placed on the waveform display, the instrument calculates the distance from the

marker to the current cursor location and displays the number in this box. If no

marker is placed, this box is not shown.

DIST: This is always the distance from the clip end of the test leads to the current

cursor location. Distance to the cursor can be shown in feet, meters, or nanoseconds.

Display organizations vary for POTS measurements. The current operating mode

of the instrument is displayed on the top status line of the display, above the

framed data window, which is above the bottom seven lines reserved for softkey

labels and dialog. When the instrument needs to display additional information

in a message to the operator, it will appear in the dialog test box.

Indicators

NiMH Battery icons

Full charge

3/4 charge

1/2 charge

1/4 charge

Recharge now

ACĆDC adapter/

charger in use

Alkaline Battery icons

Full charge

3/4 charge

1/2 charge

1/4 charge

Near Empty

AC-DC adapter/charger ico

Power On / Off Indicator: A five-level battery-status indicator, located in the

upper right corner of all displays, shows the battery-charge level. A low-battery/

power-off message is displayed when the battery level is too low for safe

operation (the dialog box will indicate low batt and the audible warning beeps

when the low battery message is first displayed). When this happens, connect the

charger/adapter to the instrument. If alkaline batteries are being used, replace all

ten cells at the same time. If you are using a NiMH battery pack, you can

continue using the TS200 on AC power while the battery is recharging. The

NiMH battery should be fully discharged and then fully recharged periodically.

Speaker On / Off Indicator: An icon is located on the display just to the left of

the power indicator. It will show that the speaker is currently either on or off.

TelScout TS200 Access Network Analyzer Service Manual

1–5

Page 24

Introduction

Controls

All operator controls are elastomeric-technology push buttons.

Hard Buttons

POWER: This button turns the TS200 on and off.

HELP: Pressing HELP displays detailed information about the current

operation being performed by the TS200. The HELP function provides

information on the operation of each of the instrument controls.

The help displays are context-sensitive pop-up windows that overlay the current

display when you press the HELP button. In each of the measurement modes,

the help display describes the current mode and provides access to additional

help on how to use the front-panel controls.

Press HELP a second time to remove the help display.

In selected menus, Lesson softkeys are available, which provide tutorial

information about using the TS200, Auto TDR, Manual TDR, cable selection,

printing, and transferring data.

TestWizard: Pressing the TestWizard button initiates a simplified measurement

mode for TDR, POTS, xDSL, or Load Coil.

TestWizard TDR measurement mode prompts the user for any required

information. It requires minimal decisions on the user’s part and displays a

mosaic waveform with all significant events (at or above the predefined

threshold) marked and numbered.

TestWizard POTS measurement mode has five sequential displays, with the

option of continuing from one display to the next or going back to the previous

test. The xDSL TestWizard measurement mode has a single display with the

most common tests used for xDSL line qualifications. The Load Coil TestWizard

detects and locates up to two missing load coils on a properly spaced line.

BACKLIGHT: Press this button to switch the display backlight on and off. The

default at power-up is with the backlight off. Press the backlight button to turn

on the backlight. The backlight stays on as long as the user continues to press

buttons or softkeys.

1–6

The backlight automatically turns off, using the specified default time from the

More Setups menu, after the user stops pressing any buttons (one minute is the

TS200 default, but it is user adjustable).

The user can turn the backlight on again by pressing the Backlight button.

TelScout TS200 Access Network Analyzer Service Manual

Page 25

Scroll Controls

Softkeys

Introduction

SPEAKER: Press this button to turn on/off the speaker. You can perform

operations eliminating unwanted sounds and alerts.

In the lower right area of the front panel is a five-button group (up-down-leftright-center). The arrow buttons serve the functions of moving the cursor left and

right across the displayed waveform or changing values (A "), scrolling

through a menu or changing values (Y B), and scrolling pages (

These buttons have an accelerated repeating function when operated with

continued pressure.

There are six softkeys across the bottom of the LCD and two at the right side.

These are called softkeys because their labels are displayed on the LCD. Their

functions vary according to the instrument function.

◆ + Y B).

The softkeys are used in three different ways: function change, item selection,

and item toggle.

In the function change use, the softkey is briefly displayed in reverse video

(black box around white letters) until the function or mode change is complete.

After the function or mode change, the softkey label returns to normal, possibly

with a different label. An example of this type of operation is: changing from

measurement mode to setup mode.

In item selection, the softkey label is displayed in reverse video when the key is

pressed and remains in that state until pressed again or a different softkey is

pressed. Usually, pressing an item-selection softkey enables the up and down

arrow keys to change the value of the selected item. Examples of item selections

are: span, pulse, vertical position, and Vp in the manual measurement mode;

baud rate in the printer setup mode. Value changes might also be displayed in

another manner, such as the distance scale change when

is pressed in Auto TDR mode.

Cable

In item toggle, the softkey label toggles from an on to off to on form. Whichever

is active at the moment will be shown in reverse video. An example of this is:

Zoom On / Zoom Off.

More Cable or Less

TelScout TS200 Access Network Analyzer Service Manual

1–7

Page 26

Introduction

Connectors

AC–DC Adapter/Charger: This connector provides a jack for connecting to the

battery charger/adapter.

Black

Red

Green

Yellow

Instrument Settings

TEST: This connector consists of two standard-size banana jacks (one red, one

black) for connecting to the test pair of the cable under test.

REFERENCE: This connector consists of two standard-size banana jacks (one

yellow, one green) for connecting to the reference pair of the cable under test.

Serial Port: This connector provides a subminiature DB-9 IBM PC-AT-compatible serial port. Use this connector to connect a printer, and to transfer data

between the TS200 and an IBM PC (or compatible).

When you power on the instrument, the TS200 shows a display indicating that

the initialization sequence is in progress. The instrument returns to the same

settings in place when the power was last turned off, except for the following

setups:

PowerĆon Test Type, Auto Event Locator Threshold, and Smoothing.

1–8

TelScout TS200 Access Network Analyzer Service Manual

Page 27

Specification Tables

Introduction

T able 1–2: Environmental Performance Conditions

REQUIREMENT SPECIFICATION

Temperature

Operational Specs, Guaranteed

Humidity Operating: 10 to 95% RH, non-condensing

Altitude Operating: 10,000 ft (4.6 km)

Shock Operating: 50 g. Survives impact shock of 6.5 feet (2 m)

Drop, free fall, non-operating Surface to concrete, 12 drops @ 2 m

EMC Complies with national standards

Water / Rain Drip Proof

Operating: –15° C to +60° C

Non-operating: –30° C to +65° C

0° C to +45° C

Non-operating: 10 to 95% RH, non-condensing

Non-operating: 50,000 ft (15.2 km)

to concrete in standard soft case.

T able 1–3: Certifications and Compliances

REQUIREMENT SPECIFICATION

EC Declaration of Conformity Meets intent of Directive 89/366/EEC for Electromagnetic

Compatibility and Low Voltage Directive 73/23/EEC for

Product Safety . Compliance was demonstrated to the

following specifications as listed in the Official Journal of

the European Union:

EMC Directive 89/336/EEC:

EN 55011 Class A Radiated & Conducted Emissions

IEC 1000-3-2 Powerline Harmonic Emission

IEC 1000-4-2 Electrostatic Discharge Immunity

IEC 1000-4-3 RF Radiated Immunity

IEC 1000-4-4 Electrical Fast Transit Immunity

IEC 1000-4-6 RF Conducted Immunity

IEC 1000-4-11 Powerline Interruptions

Low Voltage Directive 73/23/EEC, amended by

93/69/EEC:

EN 61010-1:1993 Safety requirements for electrical

equipment for measurement control and laboratory use

EN 61010-2-031:1994 Particular requirements for

hand-held probe assemblies for electrical measurement

and test equipment

FCC Compliance Emissions comply with FCC Code of Federal Regula-

tions 47, Part 15, Subpart B, Class A Limits

TelScout TS200 Access Network Analyzer Service Manual

1–9

Page 28

Introduction

T able 1–3: Certifications and Compliances (Cont.)

REQUIREMENT SPECIFICATION

Certifications EMC (Australia/New Zealand):

Complies with EMC provision of Radio Communications

Act per the following standard(s):

AN/NZS 2064.1/2 Industrial, Scientific, and Medical

Equipment: 1992

UL 3111-1 Standard for Electrical Measuring and Test

Equipment

Installation (overvoltage) category CA T II Local level, appliances, and portable equipment

T able 1–4: Safety Requirements

REQUIREMENT SPECIFICATION

CSA CAN/CSA-C22.2 No. 1010.1 EN 61010-1

UL UL 3111-1

T able 1–5: Reliability

REQUIREMENT SPECIFICATION

MTBF >40 khours (TDR only)

>24 khours (POTS & TDR)

MTTR <0.5 hours to module level

T able 1–6: Physical Characteristics

REQUIREMENT SPECIFICATION

Size (max) 10 inches (254 mm) wide

8.5 inches (216 mm) high

2.75 inches (70 mm) deep

Weight (max) 5.4 lbs. (2.4 kg) fully configured

Waveform Capacity Minimum of 20 waveforms

1–10

TelScout TS200 Access Network Analyzer Service Manual

Page 29

T able 1–7: Base Product Characteristics

REQUIREMENT SPECIFICATION

Power Source:

Internal Batt

Charger Circuits Charge time: 4 hours at 25° C/77° F (full discharge to

PS Input/Output External input, charger jack, current input limit: 1.5 A, 18

AC adapter/charger Output: 5.5 mm OD, 2.1 mm ID plug, center +, sleeve –

System Load:

Base product only 24 V IN, 360 mA

Base product + POTS 24 V IN, 400 mA

POTS only 24 V IN, 400 mA

4 hours continued operation (with backlight off), 8 hours

at 50% duty cycle, meets UL safety requirements

90% capacity)

to 25 VDC

Input: 90-255 VAC, 47-63 Hz

Introduction

TelScout TS200 Access Network Analyzer Service Manual

1–11

Page 30

Introduction

TS200 Characteristic Tables

T able 1–8: TDR Characteristics

REQUIREMENT SPECIFICATION SUPPLEMENTAL INFORMA TION

Pulse Width

2 ns:

75 ns:

10 ns:

340 ns:

3400 ns:

typical

typical

12 ns "20%

+30%, –15%

+15%, –25%

Measured at the end of test leads with 105 W "2 W

termination. Measured differentially with oscilloscope

Pulse Height

2 ns

10 ns:

75 ns:

340 ns:

3400 ns:

Pulse Shape

short range

long range

Distance Accuracy

Test Interface Port Parameters

Impedance

Port Over-voltage Protection

1.55 V typical

4.44 V typical

8 V typical

18 V Pk-Pk typical

28 V Pk-Pk typical

0.1% "300 ps "Vp uncertainty

"cursor resolution

105 W typical

Measured at the end of test leads with 105 W "2 W

termination. Measured differentially with oscilloscope

2 ns, 10 ns, 75 ns: 1/2 sine

340 ns, 3400 ns: 1/2 sine with line charge compensation

Verified with digital delay generator.

Range: 5 ft to >50 kft

Resolution: 0.5 ft @ Vp 1.0

Cursor resolution: 0.33% of selected range

Designed to work on standard telephone twisted pair

wire, copper, or aluminum

400 VDC + AC peak at power line frequency; no damage

with application up to 30 seconds duration

Two Pairs

TestWizard Event Marking

Wire Diameter

Range

Accuracy

1–12

22 AWG

0 – 8,000 ft

@ 1000 kft "100 ft typical

TelScout TS200 Access Network Analyzer Service Manual

Tests for crosstalk; compares two pairs

Marks multiple events. Accuracy is defined as marking a

0 dB known event while marking no non-cable-structure

events.

Page 31

T able 1–8: TDR Characteristics (Cont.)

REQUIREMENT SUPPLEMENTAL INFORMATIONSPECIFICATION

Wire Diameter

Range

Accuracy

Receiver: Bandwidth 10 kHz – 200 MHz

Gain

22 AWG

@ 8,001 – 18,000 ft

@ 8,500 ft "850 ft typical

@19,500 ft "1,950 ft typical

Introduction

Range

System Noise Floor

0 dB to 72 dB

<1 cm noise

Steps of 6 dB, 6 dB, 8 dB

52 dB gain, 10 ns pulse, span >4000 ft, no connections

on test port, filter OFF

T able 1–9: POTS Characteristics

REQUIREMENT SPECIFICATION SUPPLEMENTAL INFORMA TION

VOM DC Volts

Range

Resolution

Accuracy

Impedance

Overload Protection

VOM Ohms (loop/insulation)

Test Voltage

Test Current

Range

Resolution

Accuracy

Range

Resolution

Accuracy

Range

Resolution

Accuracy

Range

Resolution

Accuracy

0 V to " 400 V

0.1 V

"(1% + 0.5 V)

>10 MW

400 V peak

<130 VDC open circuit

<1 mA short circuit

0 to 1 kW

0.1 W

"(0.9% + 1 W +1 count)

1 k to 100 kW

10 W

"(0.9% +1 count)

100 k to 1 MW

100 W

"(1% +1 count)

1 M to 100 MW

100 kW

"(6% +1 count)

The DCV function is designed to work on standard

telephone twisted pair wire. Voltage above 150 V is not

considered normal conditions.

TelScout TS200 Access Network Analyzer Service Manual

1–13

Page 32

Introduction

T able 1–9: POTS Characteristics (Cont.)

REQUIREMENT SUPPLEMENTAL INFORMATIONSPECIFICATION

Resistance Fault Locator

Distance Range

Resistance to Fault

Range

Resolution

Accuracy

Range

Resolution

Accuracy

Range

Resolution

Accuracy

0 to 60 km (200 k ft)

0.00 to 400 W

0.01 W

"(0.9% + 1 W +1 count)

400 to 4 kW

0.1 W

"(0.9% +1 count)

4 k to 40 kW

1 W

"(0.9% +1 count)

Designed to work on standard telephone twisted pair

wire, copper, or aluminum. Fault resistance <100 kW for

specified accuracy.

Accuracy specs only for fault resistance values <100 kW

Open Meter (measure fault dist to

open)

Accuracy

Distance Calculation

Range

Resolution

Range

Resolution

Open Meter Capacitance Measurement

Accuracy

Range

Resolution

Range

Resolution

Input Protection

VOM Loop Current Measurement

Range

Resolution

Accuracy

"1% @ 10 kft

0 to 1 kft

1 ft

1001 ft to 200 kft

10 ft

Range: 10 pF to 10 mF

"(1% + 50 pF + 1 count) up to

3.5 mF

10 pF to 10 nF

10 pF

10 nF to 10 mF

10 nF

400 Vp

0 to 300 mA

0.1 mA

"1% at 60 mA

Calculations assume no bridge taps or laterals. Accuracy

at 10 kft = "1% " uncertainty of capacitance per unit

length. Accuracy verified by capacitance meter

verification.

Up to 120 mA continuous measurement. Above 120 mA,

measurements are one-shot

= 430 W

Z

IN

1–14

TelScout TS200 Access Network Analyzer Service Manual

Page 33

T able 1–9: POTS Characteristics (Cont.)

REQUIREMENT SUPPLEMENTAL INFORMATIONSPECIFICATION

VOM Ohms-to-Distance Calculator

Introduction

Calculated distance resolution is 0.01 ft on all ranges

Range

Resolution

Range

Resolution

Range

Resolution

VOM Distance-to-Ohms Calculator

Range

Resolution

Longitudinal Balance

Range

Resolution

Accuracy

VOM Count Load Coils Counts up to 7 load coils on

0 to 99.99 W

0.01 W

100 to 999.9 W

0.1 W

1000 to 9999 W

1.0 W

0 to 200 kft

1 ft

40 to 62 dB

0.1 dB

"2 dB

properly loaded line using D66;

counts up to 6 load coils on

properly loaded line using H88

Calculated ohms resolution is 0.01 ohms on all ranges

Measure common mode impedance difference between

conductors

VOM AC Volts

Range

Resolution

Accuracy

Transmission Tests Power

Influence Meter (PI)

Range

Resolution

Accuracy

0 to 300 VAC

0.1 V

"(1% + 0.5 V)

40 to 100 dBrnC

0.1 dB

"2.0 dB + filter accuracy

TelScout TS200 Access Network Analyzer Service Manual

Identify hazardous voltage on line

50–60 Hz sinusoidal

The ACV function is designed to work on standard

telephone twisted pair . Voltage above 60 V is not

considered normal conditions.

Unfiltered PI measurements are converted to dBrnC

using NM measurements or default conversion factor.

Z

= 10 MW

IN

C message filter, 60 Hz PI filter

Psophometric filter , 50 Hz PI filter

1–15

Page 34

Introduction

T able 1–9: POTS Characteristics (Cont.)

REQUIREMENT SUPPLEMENTAL INFORMATIONSPECIFICATION

Transmission Test Metallic Noise

Measurement (NM)

No filter used when PI exceeds 4.5 V

rm

Range

Resolution

Accuracy

Transmission Tests Loss

Frequency

Range

Resolution

Accuracy 20 Hz – 20 kHz

Level

Range

Resolution

Accuracy

300 Hz – 4.5 kHz

40 kHz

196 kHz

Transmission Tests Dial Phone Number

DTMF

Pulse

Store #

10 to 50 dBrnC

0.1 dB

"2.0 dB + filter accuracy

20 Hz to 200 kHz

1 Hz

"2 Hz at 0 dBm

–40 dBm to + 10 dBm

0.1 dB

"0.5 dB

"2.0 dB

"4.0 dB

ZIN = 600 W

Tone receiver

20 Hz to 20 kHz: dBm referenced to 600 W

>20 kHz: dBm referenced to 135 W

POTS

ISDN

ADSL

Meets TR-TSY - 000450

10 pps, make/break ratio 39/61 and 33/67 supported

25 numbers, up to 12 digits each

Transmission Tests Generate Tone

Frequency

Range

Resolution

Accuracy 20 Hz – 20 kHz

Level

Range

Resolution

Accuracy 300 Hz – 4.5 kHz

ID Tone (Trace Tone)

Level

Accuracy

1–16

Up to 5 user-programmed frequencies

20 Hz to 64 kHz; 40 kHz (ISDN)

1 Hz

"2 Hz

–40 dBm to + 10 dBm

1 dB

"0.5 dB above –25 dBm

–40 dBm to +10 dBm

577.5 Hz "1 Hz;

Continuous/Intermittent

TelScout TS200 Access Network Analyzer Service Manual

20 Hz to 20 kHz: Z

577.5 Hz ID tone

20 Hz to 65 kHz: Z

= 600 W

Z

out

= 135 W

Z

out

= 600 W except 135 W for

out

= 135 W

out

Page 35

T able 1–9: POTS Characteristics (Cont.)

REQUIREMENT SUPPLEMENTAL INFORMATIONSPECIFICATION

Transmission Tests Slope

Frequency

Range

Resolution

Accuracy (300 Hz – 4.5 kHz)

Level

Range

Resolution

Accuracy

300 Hz – 4.5 kHz

40 kHz

196 kHz

20 Hz – 200 kHz and 40 kHz

(ISDN) and 196 kHz (DSL)

1 Hz

"2 Hz @ 0 dBm

–40 dBm to + 10 dBm

0.1 dBm

"0.5 dB

"2.0 dB

"4.0 dB

Introduction

Displayed ranges are: 0 to 5 kHz

0 to 100 kHz

0 to 200 kHz

VOM Ringers

Range

Resolution

Accuracy

Counts number of C4 ringer

equivalents

0 to 5

0.1

"0.5

Ringer equivalence programmable from 0.2 mF to 2 mF

per ringer. Accuracy verified by capacitance meter.

TelScout TS200 Access Network Analyzer Service Manual

1–17

Page 36

Introduction

T able 1–10: Load Coil TestWizard Characteristics

REQUIREMENT SPECIFICATION SUPPLEMENTAL INFORMA TION

Load Coil Test Wizard Software version 2.0 and above.

Number of load coils Maximum: 12

Minimum: 0

Number of missing load coils 0, 1 or 2 Specification assured by software.

Loop span – single wire diameter,

resistance design rules

Load span – single wire diameter,

unigauge design rules

Loop span – mixed wire diameter 0 to 1500 W loop resistance

Wire types supported 19 AWG (0.91 mm) copper

19 AWG: 0 to 70 kft

22 AWG: 0 to 37 kft

24 AWG: 0 to 25 kft

26 AWG: 0 to 15 kft

26 AWG: 0 to 30 kft Unigauge design rule summary:

22 AWG (0.65 mm) copper

24 AWG (0.51 mm) copper

26 AWG (0.40 mm) copper

1

H88 load coils, properly spaced.

Specification assured by software and performance

verification of tone generator and tone receiver.

Resistance design rule summary:

D Loop resistance below 1300 W

D 3 kft between CO and first load coil

D 6 kft between load coils

D end section between 3 kft and 15 kft, including

bridge tap

D no bridge taps between load coils

D no loaded bridge taps

D 26 gauge wire

D no gauge changes

D 15 kft between CO and first load coil

D 6 kft between load coils

D end section between 3 kft and 15 kft

Aluminum wire will perform similar to its copper

equivalent based on resistance.

17 AWG Al [ 19 AWG Cu

20 AWG Al [ 22 AWG Cu

22 AWG Al [ 24 AWG Cu

For other wire diameters not listed here, the TS200

will look for the closest match assuming the listed

diameters.

Cable capacitance

LA Option

All Options except LA

1

Considerations:

D H88 load coils, properly spaced (spacing tolerance: "120 ft typical, "500 ft maximum).

D Build-out network should be used when cable sections are shorter than design rules.

D Line meets either resistance design rules or unigauge design rules.

D Line passes all other fault tests.

D Termination is either an open circuit or an on-hook telephone.

D CO battery should be disconnected.

D For midspan tests, line should be opened at test point (test in one direction at a time).

1–18

13.7nF/kft (0.072 mF/mi, 45 nF/km)

15.7 nF/kft (0.083 mF/mi, 51.6 nF/km)

TelScout TS200 Access Network Analyzer Service Manual

Page 37

Accessories and Options

Standard Accessories

ACCESSORY TEKTRONIX PART NO.

Test lead set (red/black and green/yellow) 012–1552–xx

RFL strap (Options 02, 03) 346–0292–xx

Power Supply (36W, 100–250VAC, 47–63 Hz in; 24VDC, 1.5A

out)

Standard cord = N. American power cord, OR 161–0228–xx

Option 1C European power cord 161–0066–09

Option 2C United Kingdom power cord 161–0066–10

Option 3C Australian power cord 161–0066–11

Option 6C Japanese power cord 161–0288–xx

Auto adapter, cigarette lighter 012–1553–xx

Accessory pouch, soft 016–1690–xx

TS200 user manual

(includes all international language options)

Custom rechargeable battery pack (9 cell) 146–0126–xx

Alkaline battery holder 352–1071–xx

Introduction

119–6031–xx

071–0069–xx

Optional Accessories

ACCESSORY TEKTRONIX PART NO.

TS200 service manual 071–0070–xx

Custom rechargeable battery pack (9 cell) 146–0126–xx

Serial PC Cable (DB9 to DB9) 012–1379–xx

Cable, printer, RS232, DB9 female to DB25 male 012–1313–xx

MCT AP (PC software for TDR) MCTAP

Custom test lead set (Australian) 012–1558–xx

Hard Travel Case, black 016–1210–xx

D-Ring Hook 354–0745–xx

RFL strap 346–0292–xx

Waist strap 346–0202–xx

Coaxial Cable Adapter (75 Ω Banana to F type) 174–3525–xx

TelScout TS200 Access Network Analyzer Service Manual

1–19

Page 38

Introduction

Optional Operating

System Software

Instrument Configuration

Options

SOFTWARE TEKTRONIX PART

NUMBER

English 063–3306–xx

French 063–3307–xx

German 063–3308–xx

Spanish 063–3309–xx

Portuguese 063–3311–xx

Australian 063–3313–xx

Dutch 063–3315–xx

OPTION NUMBER INSTRUMENT INCLUDES:

01 TDR only

02 xDSL, ISDN, POTS

03 TDR, xDSL, ISDN, POTS (Option 01 + 02)

04 (Version 2.0 and

above)

LOAD COIL TESTWIZARD (only with Option 02 or Option 03)

TS200 Options

OPTION NUMBER INSTRUMENT INCLUDES:

L0 English language option

L1 French language option

L3 German language option

L4 Spanish language option

L6 Portuguese language option

LA Australian language option

LD Dutch language option

R3 Extended warranty option (3 years)

AU Custom T est Lead Set (Australian)

C3 Three year calibration services

D1 Calibration data report

D3 Three year calibration data reports (requires C3)

1–20

TelScout TS200 Access Network Analyzer Service Manual

Page 39

Theory of Operation

Block Diagram

Backlight

Inverter

Functional Descriptions

AC/DC

Adapter

Battery

Pack

RS232 PORT

CIRCUIT BOARD A2

(TDR)

CIRCUIT BOARD A1

(POTS)

Display

Keyboard

TEST PORT

REFERENCE PORT

Figure 2–1: TS200 Block Diagram

The TS200 consists of two circuit boards, noted as CIRCUIT BOARD A1 (TDR) and

CIRCUIT BOARD A2 (POTS), in the block diagram above.

Circuit Board A1

The A1 circuit board does all the POTS (Plain Old Telephone Service)

measurements. This board relies on the A2 TDR board for power, control, and

access to the external test leads and is mounted to A2 board using stand-off

posts. Board A1 contains an analog-to-digital converter along with circuits to

measure voltage, current, resistance, capacitance, frequency, tone amplitude,

noise, number of load coils, and longitudinal balance. The A1 POTS board

contains the pulse and DTMF dialing circuit, tone, generator, and a foreign

voltage detection circuit. The A1 circuit board also directs signals to the speaker.

Circuit Board A2

The A2 circuit board contains the Microprocessor, TDR circuits, display

controller, keyboard interface, power supply, and battery charging circuits. The

board connects to the display, backlight inverter, keyboard, printer port, beeper,

and to the A1 POTS board.

TelScout TS200 Access Network Analyzer Service Manual

2–1

Page 40

Theory of Operation

The A2 board routes signals on the test leads either to the TDR circuits on the

A2 board or to the A1 POTS board, depending on the measurement function

selected. The microprocessor adjusts the power supply voltage going to the

display to control the display contrast. The A2 board is mounted to the

aluminum LCD stiffener plate assembly.

Display Assembly

Keyboard

Battery

Optional Battery

The LCD is a VGA (640 X 480 pixel) display with a cold-cathode backlight

supported by a foam gasket and a rigid aluminum stiffener plate. The backlight

inverter attaches to the aluminum plate. Power for the display and backlight

inverter as well as LCD row and column data come from the A2 TDR board.

The keyboard assembly contains an elastomeric keypad, a polyester flex circuit,

and an aluminum support plate. The flex circuit connects to the A2 TDR board.

The standard battery is a 9-cell, 10.8 volt NiMH battery pack with built-in fuel

gauge, temperature sensor, and self-resetting fuse. The fuel gauge monitors

charge going into and out of the battery pack. The microprocessor on the A2

TDR board reads the data from the fuel gauge using a one-wire bi-directional

digital interface that is wired to the battery connector. The battery must go

through a complete charge/discharge/charge sequence periodically to recalibrate

the fuel gauge. Circuitry on the A2 TDR board controls battery charging. The

charging circuit monitors the temperature sensor inside the battery pack and the

voltage across the battery to determine when the battery is fully charged. The

start of a charge cycle is postponed if the battery temperature is above about

40° C. The A2 TDR board has a hardware shut-down circuit to prevent battery

cell reversal at 8 V.

A 10-cell, 15 volt AA battery holder can be used in place of the standard battery.

Standard AA-size alkaline cells are used in the optional battery holder. The

battery holder is designed for disposable batteries and does not connect to the

NiMH charging circuit. This prevents accidental charging of non-rechargeable

batteries. Optional battery life is short, so this pack should be used for

emergencies only.

2–2

AC-to-DC External

Adapter

Backlight Inverter

The AC-to-DC external power adapter accepts a wide range of input voltages and

frequencies. It outputs 24 Volts at up to 1.5 Amp. Different power cords are

available to allow the adapter to connect to various power line outlets. The cable

from the adapter to the instrument has a 5.5 mm OD, 2.1 mm ID center positive

socket.

The backlight inverter receives 12 Volts from A1 TDR board and provides 1000

VAC to power the cold-cathode lamp LCD backlight. An insulating cover

prevents accidental contact with high voltage by service personnel. The TDR

board also provides digital signals to turn the backlight power on/off and adjust

the bright/dim setting.

TelScout TS200 Access Network Analyzer Service Manual

Page 41

Performance Verification

Performance verification verifies the operation of the TS200 analyzer to make

sure that it is operating properly and conforms to instrument specifications as

listed under Specifications in Section 1.

Performance verification should be done after an instrument has been serviced

and at 12-month intervals.

If you are unfamiliar with how the TS200 analyzer works, it may help to review

the TelScout TS200 Access Network Analyzer User Manual or on-line help

before doing the performance verifications.

NOTE. Throughout the PV typical equipment set-ups, test lead connections will

be represented by the letter T for tip (black), R for ring (red), and G for ground

(green).

Required Equipment

The following is required to verify that the TS200 is operating correctly. Some of

the equipment is Tektronix part numbered and can be ordered as an optional

accessory.

NOTE. The multi-test fixture is not available outside Tektronix Factory Service.

All procedures requiring the multi-test fixture must be performed at a Tektronix

service depot.

H AC adapter/charger

H One set of standard accessory test leads

H Tektronix 784C Oscilloscope or equivalent

H Two P6139A, 10:1 probes

H One P6245 FET probe

H TS200 multi-test fixture (with banana plugs and cable) (See Section 6)

H DMM frequency counter (using Keithley Instruments 2000 multimeter)

H DTMF ASCII Converter (using Black Box Corporation)

H 9100 Wavetek calibrator with Options 100, 600, & S251 or equivalent

H 50 W Coax test cable (10 feet or less)

TelScout TS200 Access Network Analyzer Service Manual

3–1

Page 42

Performance Verification

H BNC female to alligator clip adapter

H Telephone cable (4 to 5 feet)

H 105 W carbon composition resistor

H Amp meter

H BNC female to banana plugs adapter

H Power Supply capable of minimum output of -52.1 V @ 500 mA

Check Port Configurations

1. Press the POWER button to turn on the TS200.

2. On the power-up display, there is a symbol indicating whether the TS200 is

on AC or DC power. A battery icon is used for DC and an AC-adapter icon

is used for AC.

H Verify that the correct icon appears when the AC adapter is plugged into

the unit and removed.

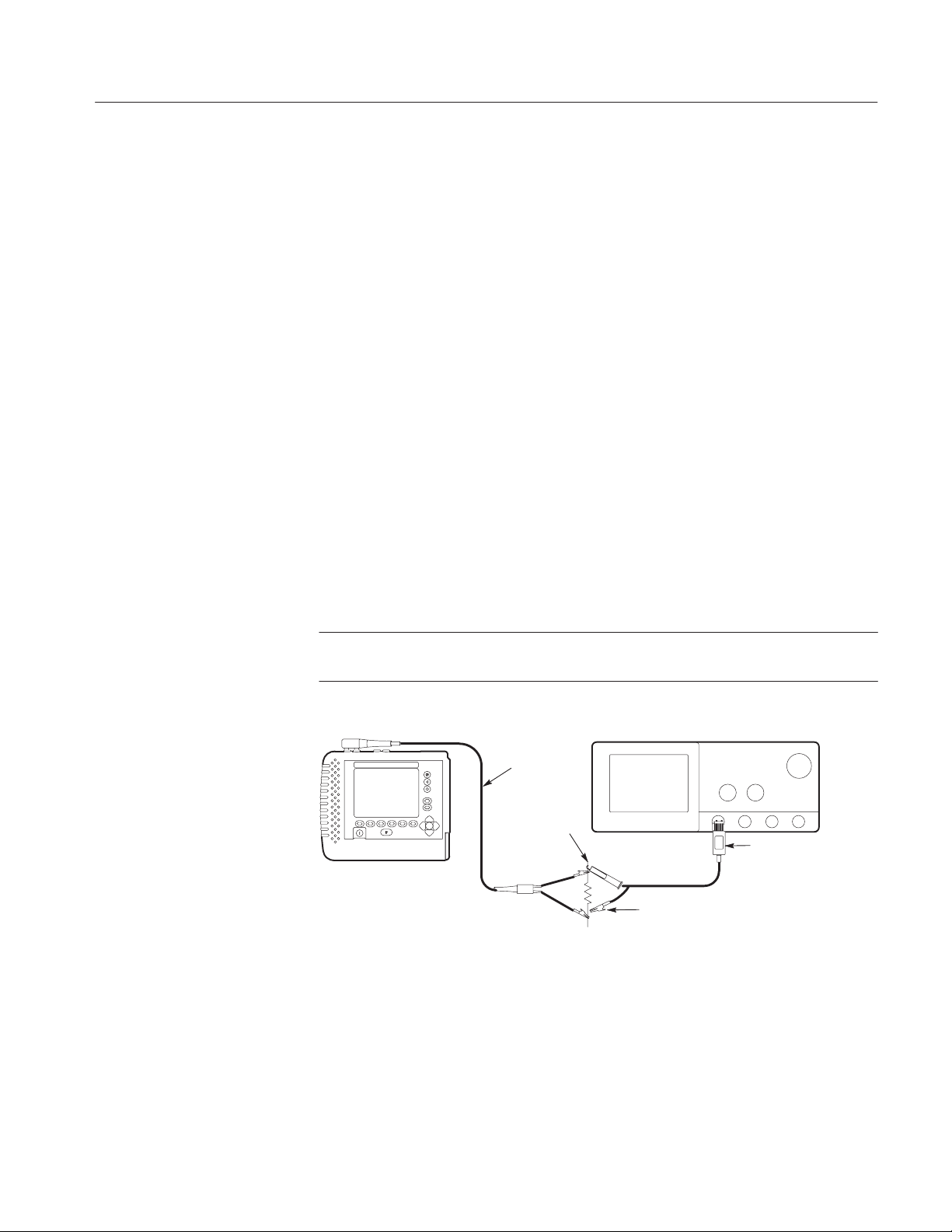

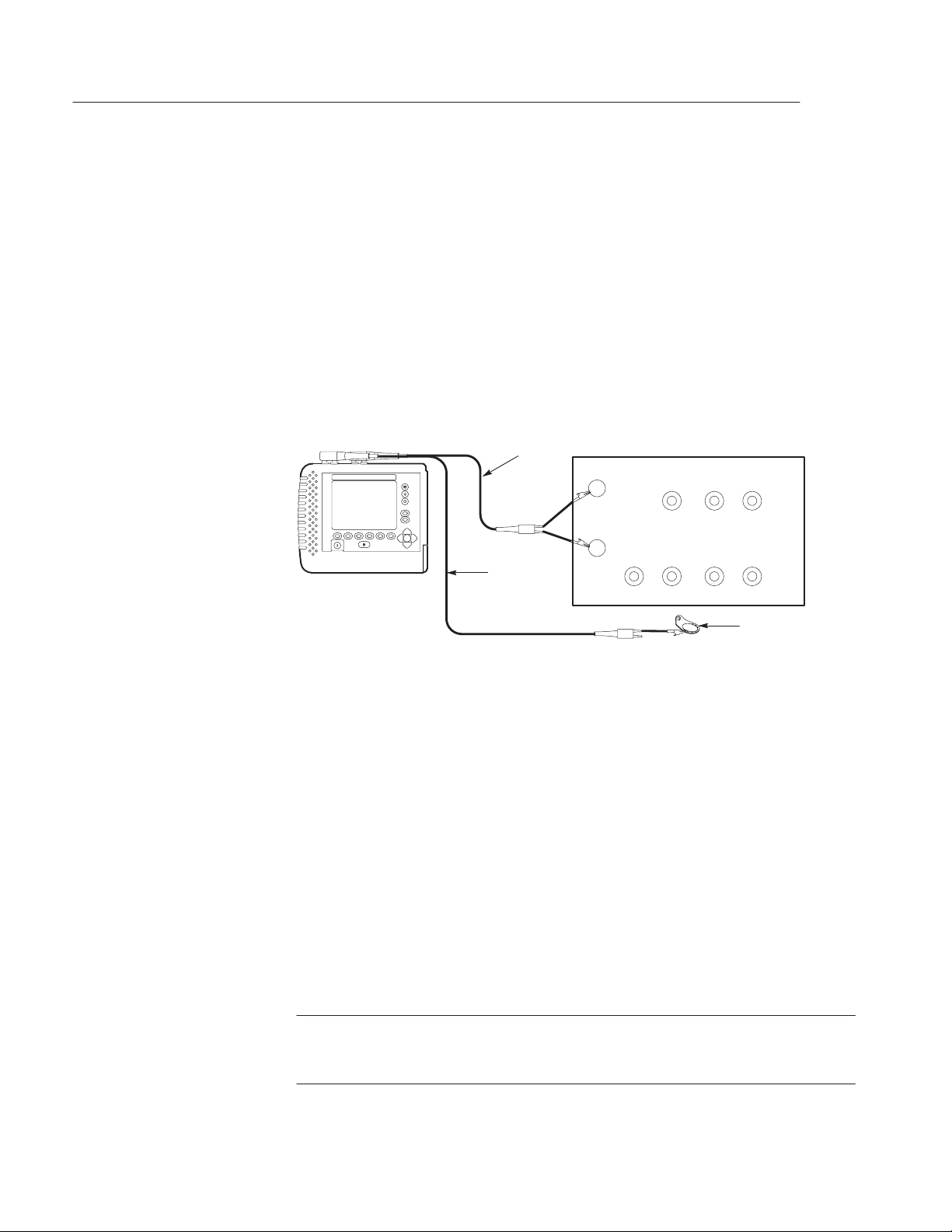

Test Port

Reference Port

TS200

Test Cable

Reference

Cable

Ring (Red)

Tip (Black)

Ring (yellow)

Tip (green)

Figure 3–1: TS200 with Standard Test Leads Attached

3. Plug the standard accessory port cables into the ports labelled TEST and

REFERENCE (red to red, black to black, yellow to yellow, and green to

green).

4. Press the

Reset to Defaults softkey.

Note: Each time the Reset to Defaults softkey is pressed, you will be prompted by

a screen display to verify your request to Reset to Defaults.

3–2

5. Press the

6. Press the

TDR softkey to view a waveform with test leads attached.

Setup softkey.

TelScout TS200 Access Network Analyzer Service Manual

Page 43

Performance Verification

7. Use the up and down arrow buttons to highlight your test cable type.

Also select the appropriate cable diameter and Vp before proceeding.

8. Press the More Setups softkey.

TDR

9. Use the

arrow buttons to highlight TDR Distance Units and change to

FEET.

10. Press the Previous Menu softkey.

11. Press the

Test Type softkey and highlight Auto TDR.

12. Press the Return to Test softkey.

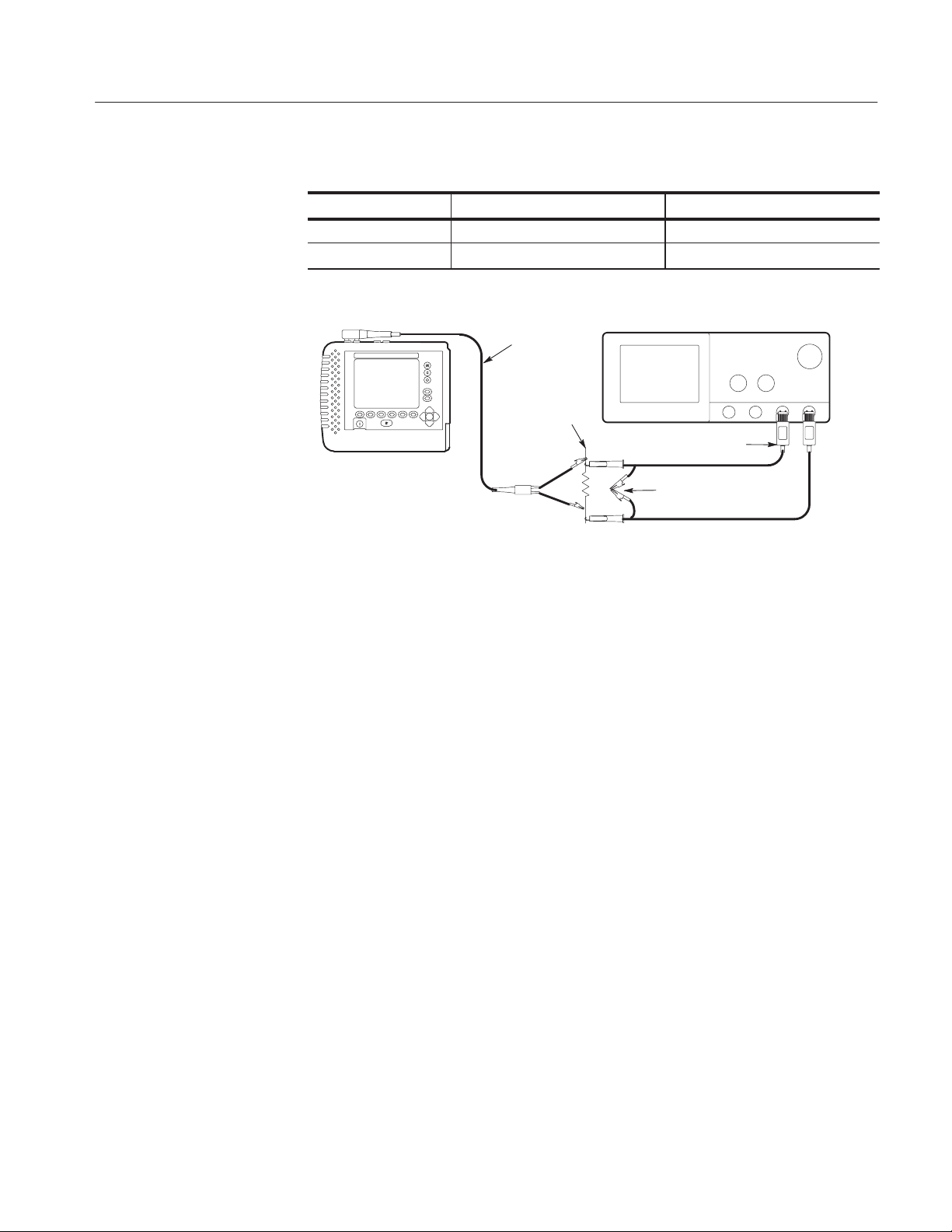

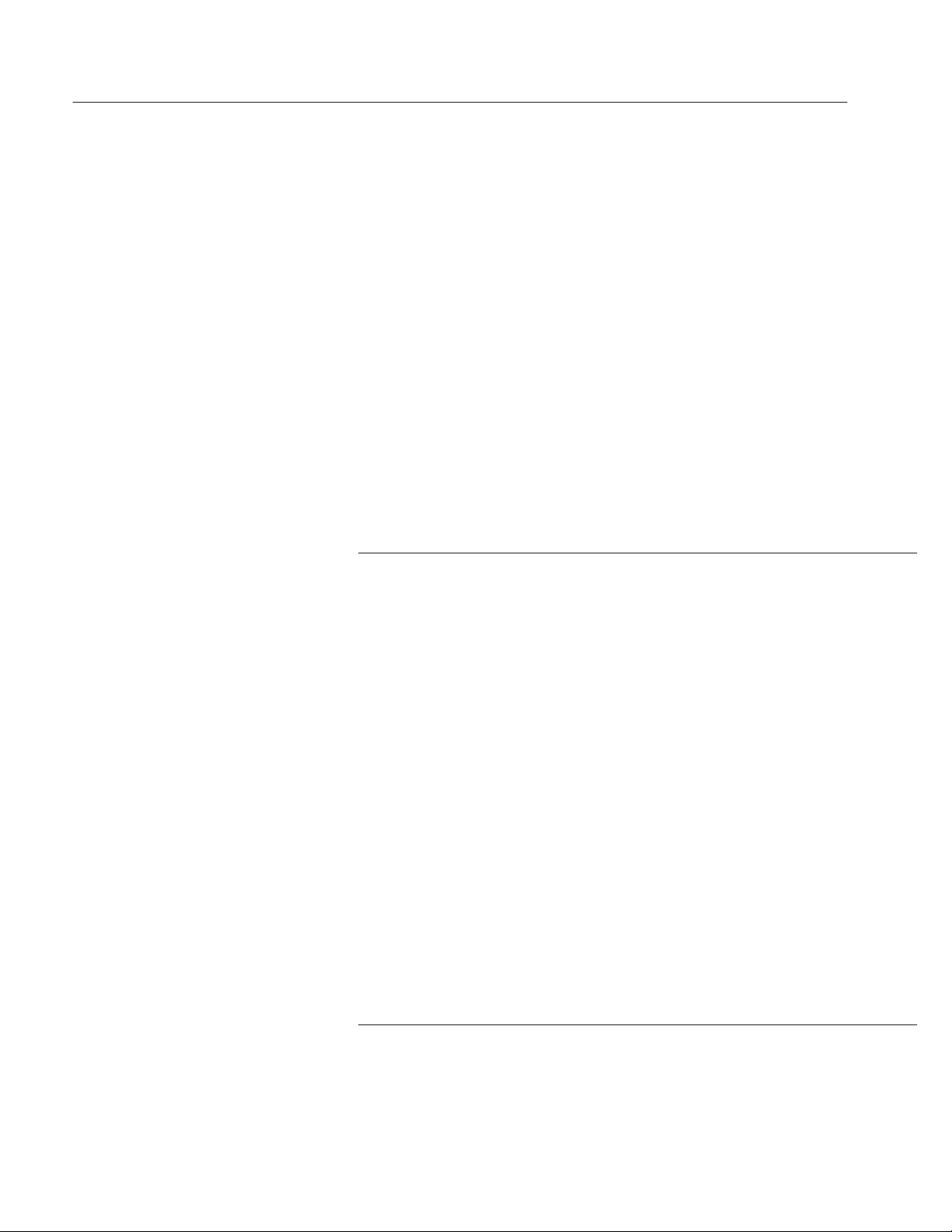

Reference

Cable

TS200

T

R

Test

Cable

Figure 3–2: TDR Performance Checks

TS200 Multi-Test Fixture

TT TT

T est Cable

RRRR

#1 #2

IN OUT IN OUT

T

R

Jumpers

Connected

13. Verify the

Zoom Off softkey is highlighted.

14. Connect all test leads to the test cable portion of the multi-test fixture (tip

to tip and ring to ring).

15. Connect jump wires as illustrated in Figure 3–2.

16. Press

the More Cable softkey until the end-of-cable reflection appears on

the display.

17. Press the Setup softkey.

18. Press the

Test Type softkey.

19. Use the up and down arrow buttons to highlight REFERENCE PAIR.

20. Press the

H Verify this waveform looks the same as the previous waveform.

Return to Test softkey.

TelScout TS200 Access Network Analyzer Service Manual

3–3

Page 44

Performance Verification

Check Distance Readouts

Check Crosstalk

21. Using the

left and right arrow buttons, move the cursor to the beginning

of the rising edge of the reflection.

H Verify distance readout (DIST) matches the cable length "10%.

NOTE. The setup consists of two 10-foot test cables plus the 1000-foot cable. The

instrument is set to zero distance at the end of the test leads, which negates the

leads on the selected port. However, the instrument is not using the test leads on

the other port for this particular test, so it will see the total cable length as 1010

feet. If your test cable is a different length, add the cable length plus 10 foot test

lead.

22. Press the

23. Press the

24. Use the

Setup softkey.

Test Type softkey.

up and down arrow buttons to highlight SPLIT AND CROSS-

TALK [TEST PAIR TO REFERENCE PAIR].

25. Press the

Return to Test softkey.

Check Dual Displays

26. Position the cursor near the leading edge of the pulse.

27. Press the

Zoom On softkey.

28. Reposition the cursor at the leading edge of the pulse.

29. Press the

H Verify the DIST readout is approximately 505 feet.

Zoom Off softkey.

NOTE. Because this test uses the same cable, testing from either end, and both

ports are alternately sending pulses into this cable, each port does not see the

end reflection of its own pulse but receives the pulse from the other port. This

fools it into seeing a crosstalk reflection halfway down the cable. Therefore, the

reflection will occur at one-half the length of the total cable, ± 2 feet. In this

example, 1010/2 = 505, ± 2 feet is 503 to 507 feet. If your test cable is a different

length, your display and result will be different.

30. Press the

31. Press the

Setup softkey.

Test Type softkey.

3–4

TelScout TS200 Access Network Analyzer Service Manual

Page 45

Performance Verification

32. Press the down arrow button to highlight TEST PAIR/REFERENCE

PAIR.

33. Press the Return to Test softkey.

H Verify there are two identical waveforms displayed on screen.

Verify Pulse Widths

and Heights

34. Press the

Setup softkey.

35. Press the Test Type softkey.

36. Press the

down arrow button to highlight TEST PAIR/DIFFERENCE/

REFERENCE PAIR.

37. Press the

H Verify the software has performed a difference calculation; view a third

Return to Test softkey.

waveform on screen.

38. Disconnect the test leads from the multi-test fixture.

39. Power off the TS200.

NOTE. Outgoing pulses will not be visible on the TS200 display. They can be

viewed on the oscilloscope display only.

TS200

784 Oscilloscope

Figure 3–3: Verify 2 ns and 10 ns Pulse Widths and Heights

Measure 2 ns and 10 ns Pulses

1. Power on the TS200 and the oscilloscope.

2. Connect a 105 Ω carbon composite resistor across the tip and ring of the

test cable.

TelScout TS200 Access Network Analyzer Service Manual

Test

Cable

105 W

T

R

Probe P6245

Probe

Ground

3–5

Page 46

Performance Verification

3. Connect the P6245 probe to Channel 1 of the oscilloscope.

4. Connect the probe tip to the test cable tip.

5. Connect the probe ground to the test cable ring.

6. Oscilloscope control settings:

Set the vertical scale on Channel 1 to 1V/Div

Set the horizontal scale on Channel 1 to 1 ns/Div

Press the Shift button

Press the Acquire Menu button

Press the Repetitive Signal Off button

Select Off (Real Time Only)

Press the Trigger Menu button

Set Trigger Source to Channel 1

Set the Trigger Slope to positive

Adjust trigger level for approximately 1 volt

Adjust horizontal scale to display the initial portion of the pulse ONLY

Press the Average button and set at 15

Press the Measure button

Select Positive width for measurement one

Select Max Positive for measurement two

Correct

Incorrect

Figure 3–4: Example of Initial Pulse

7. Press

8. Press

9. Press

TDR.

Setup.

Test Type.

10. Highlight Manual TDR.

11. Press

12. Press

13. Use the

H Verify the 2 ns pulse readings are within specifications.

14. Use the

Return to Test.

Pulse.

up and down arrow buttons to select 2 ns.

up and down arrow buttons to select 10 ns.

15. Measure the 10 ns pulse. Adjust the vertical and horizontal scales as

needed.

3–6

H Verify the 10 ns pulse readings are within specifications.

16. Disconnect the cables and remove the P6245 probe.

TelScout TS200 Access Network Analyzer Service Manual

Page 47

Performance Verification

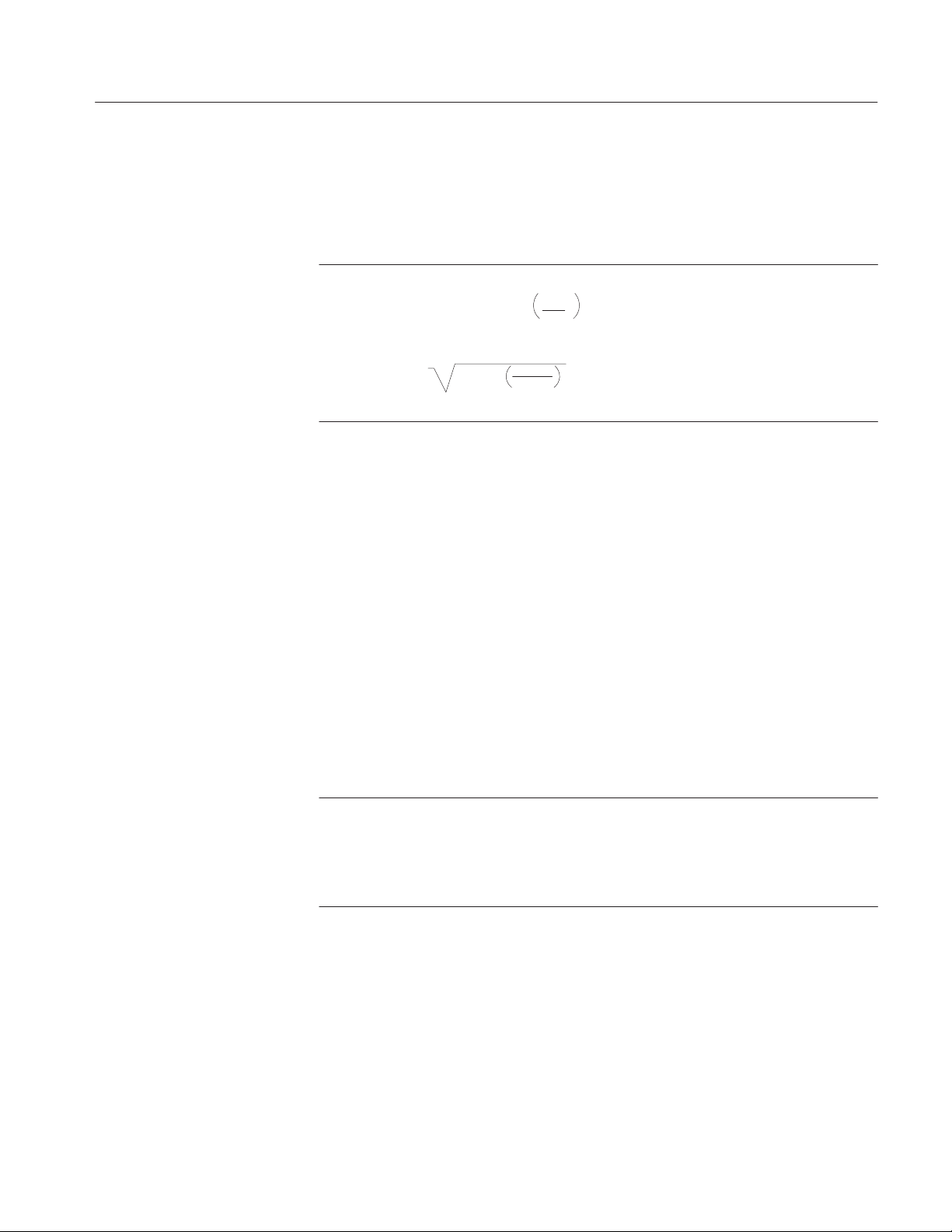

T able 3–1: 2 ns and 10 ns Pulse Specifications

MEASUREMENT PULSE WIDTH PULSE HEIGHT

2 ns 2 ns typical 1.55 V typical

10 ns 12 ns ±20% 4.44 V typical

TS200

Test

Cable

105 W

T

R

784 Oscilloscope

P6139A (2)

Probe

Grounds

Figure 3–5: Verify Pulse Widths / Heights ( 75 ns 340 ns and 3400 ns)

Measure the 75, 340 & 3400 ns Pulse

17. Connect a P6139A probe to oscilloscope Channels 3 and 4.

18. Connect the Channel 3 probe tip to the test cable tip.

19. Connect the Channel 4 probe tip to the test cable ring.

20. Connect both probe ground leads together.

21. Connect the probe ground leads to the outer sleeve of the AC adapter.

22. Connect a 105 W resistor as shown in the typical set-up illustration.

23. Oscilloscope control settings:

Turn on Channels 3 and 4 only

Set the vertical scale on Channels 3 and 4 to 2V/Div

Set the horizontal scale on Channels 3 and 4 to 25 ns/Div

Press the Shift button

Press the Acquire Menu button

Press the Repetitive Signal Off button

Select Off (Real Time Only)

Press the Vertical Menu button

Set Channel 3 and 4 input impedance to 1 MΩ

Press the Trigger Menu button

Set Trigger Source to Channel 3

Press the Math Ref button

TelScout TS200 Access Network Analyzer Service Manual

3–7

Page 48

Performance Verification

Select Change Math W/F Definition

Press the Dual Wfm Math button

Set 1st Source to Channel 3

Set 2nd Source to Channel 4

Set Operator to minus (–)

Select OK to Create Math Wfm

Turn off Channels 3 and 4

Press the Math Ref button

Press the Average button and set at 15

Increase the vertical scale of the math waveform to 2.5 V/Div

Pulse

Line Charge

Compensation

Figure 3–6: Example of Peak to Peak Pulse

24. Measure the pulse width at 50% amplitude.

25. Use the

H Verify the 75 ns pulse readings are within specifications.

26. Use the