Page 1

xx

TCPA300/400 Amplifiers and

ZZZ

TCP303/305A/312A/404XL Current Probes

Compliance and Safety Instructions

www.tek.com

P071364301*

*

071-3643-01

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 3

Table of Contents

Important safety information ........................... .................................. ......................... 1

General safety summary ...................................................................................... 1

Service safety summary.. .................................. ................................ ................... 4

Terms in t hi

Symbols and terms on the product........................................................................... 5

Compliance information ........................................................................................... 6

EMC compliance (TCPA300/400 only)...... ................................ ............................... 6

Safety compliance ............................................................................................. 7

Environmental considerations ................................................................................ 9

Operati

Installation.......................................................................................................... 12

Operate the amplifier.................. .................................. ................................ .......... 17

Op

ng considerations ......................................................................................... 10

Product documentation..... ................................ ................................ .................. 11

Standard accessories.................. ................................ .................................. ...... 12

Optional accessories .......................... ................................ ................................ 13

System configuration ............................. ................................ ............................ 13

Conn

Power on the amplifier ....................................................................................... 15

Connect the probe to the amplifier ................................ ................................ .......... 16

LED indicators .................... .................................. ................................ .......... 18

Overload conditions .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... .... . . ..... . ..... . ..... . .. 19

erate the current probe......................................................................................... 20

Basic operation................................................................................................ 20

Operate the current probe slide.............................................................................. 21

Degauss and autobalance the current probe.......................................... ...................... 24

Use the ground lead........................................................................................... 25

Make DC current measurements............................................................................ 26

Make AC current measurements............................................................................ 28

s manual ... ................................ ................................ ....................... 4

ect the amplifier to an oscilloscope ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... .... . . ..... . ..... . .. 14

Amplifiers and Current Probes Compliance and Safety Instructions i

Page 4

Table of Contents

ii Amplifiers and Current Probes Compliance and Safety Instructions

Page 5

Important safety information

This manual contains information and warnings that must be followed by the user

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page 4, Service safety summary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

TCPA300/400 only: This product shall be used in accordance with local and

national codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

To avoid fire or

personal injury

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

Use proper power cord. TCPA300/400 only: Use only the power cord specified

for this product and certified for the country of use.

Do not use the provided power cord for other products.

Ground the product. TCPA300/400 only: This product is grounded through the

grounding conductor of the power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, make sure that the p roduct is properly

grounded.

Amplifiers and Current Probes Compliance and Safety Instructions 1

Page 6

Important safety information

Power disconne

from the power source. See instructions for the location. Do not position

the equipment so that it is difficult to operate the power cord; it must remain

accessible to the user at all times to allow for quick disconnection if needed.

Connect and disconnect properly. TCPA300/400 only: Do not connect or

disconnect

Use only current probes, test leads, and adapters supplied with the product, or

indicated

Observe all terminal ratings. TCPA300/400 only: To avoid fire or shock hazard,

observe all ratings and markings on the product. Consult the product manual for

further ratings information before making connections to the product.

Do not apply a potential to a ny terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not o

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

when powe r is present.

perate without covers. Do not operate this product with covers or panels

ct. TCPA300/400 only: The power cord disconnects the product

probes or test leads while they are connected to the circuit.

by Tektronix to be suitable for the product.

t operate with suspected failures. TCPA300/400 only: If you suspect that

Do no

there is damage to this product, have it inspected by qualified service personnel.

able the product if it is damaged. Do not use the product if it is damaged

Dis

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

Before use, inspect current probes, test leads, and accessories for mechanical

damage and replace when damaged. Do not use probes or test leads if they are

damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

2Amplifiers and Current Probes Compliance and Safety Instructions

Page 7

Important safety information

Probes and test leads

Provide proper

instructions in the manual for details on installing the product so it has proper

ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

Before conn

cord from the power connector to a properly grounded power outlet.

Keep finger

indicator on the probes.

Remove al

Use only correct Measurement Category (CAT), voltage, temperature, altitude,

and ampe

Beware of high voltages. Understand the voltage and current ratings for the probe

you are using and do not exceed those ratings.

The v oltage rating for the TCPA300/400 depends on the probe and your

application. Refer to the Specifications section of the manual for more

information.

ventilation. TCPA300/400 only: Refer to the installation

ecting probes or test leads to the TCPA300/400, connect the power

s behind the protective barrier, protective finger guard, or tactile

l probes, test leads and accessories that are not in use.

rage rated probes, test leads, and adapters for any measurement.

ect and disconnect properly. TCP303/305A/312A/404XL only: Connect

Conn

the probe output to the measurement product before connecting the probe to the

circuit under test. Connect the probe reference lead to the circuit under test

before connecting the probe input. Disconnect the probe input and the probe

reference lead from the circuit under test before disconnecting the probe from the

measurement product.

Connect and disconnect properly. De-energize the circuit under test before

connecting or disconnecting the current probe.

TCPA300/400 only: Connect the probe reference lead to earth ground only.

Do not connect a current probe to any wire that carries voltages or frequencies

above the current probe voltage rating.

Inspect the probe and accessories. Before each use, inspect probe and accessories

for damage (cuts, tears, or defects in the probe body, accessories, or cable jacket).

Disable and do not use the current probe if it is damaged. Do not use the product

if it is damaged or operates incorrectly.

Examine the exterior of the current probe before you use it. Look for cracks

or missing pieces.

Use only specified replacement parts.

Amplifiers and Current Probes Compliance and Safety Instructions 3

Page 8

Important safety information

Service safet

ysummary

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

service proc

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this

product un

present.

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

stre

edures. Read this Service safety summary and the General safety

less another person capable of rendering first aid and resuscitation is

ngth after performing a repair.

Termsinthismanual

se terms may appear in this manual:

The

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

4Amplifiers and Current Probes Compliance and Safety Instructions

Page 9

Important safety information

Symbols and te

Amplifiers

rms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

When this symbol is marked on the product, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

The following symbol(s) may appear on the TCPA300/400 amplifiers:

Probes

The following symbol(s) may appear on the TCP303/305A/312A/404XL current

probes:

Amplifiers and Current Probes Compliance and Safety Instructions 5

Page 10

Compliance information

Compliance in

formation

This section

lists the EMC (electromagnetic compliance), safety, and

environmental standards with which the instrument complies. This product is

intended for use by professionals and trained personnel only; it is not designed

for use in households or by children.

Questions about the following compliance information may be directed to the

following address:

Tektronix, Inc.

PO Box 500, MS 19-045

Beaverton, OR 97077, USA

www.tek.com

EMC compliance (TCPA300/400 only)

EU EMC Directive

Meets intent of Directive 2014/30/EU for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326-1, EN 61326-2-1. EMC requirements for electrical equipment for

measurement, control, and laboratory use.

1234

CISPR 11. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2. Electrostatic discharge immunity

IEC 61000-4-3. RF electromagnetic field immunity

IEC 61000-4-4. Electrical fast transient/burst immunity

IEC 61000-4-5. Power line surge immunity

IEC 61000-4-6. Conducted RF immunity

IEC 61000-4-11. Voltage dips and interruptions immunity

EN 61000-3-2. AC power line harmonic emissions

EN 61000-3-3. Voltage changes, fluctuations, and flicker

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

2

Emissions which exceed the levels required by t his s tandard may occur when this equipment is connected to a

test object.

3

Equipment may not meet the immunity req

probes are connected due to coupling of electromagnetic interference onto those leads/probes. To minimize the

influence of electromagnetic interference, minimize the loop area between the unshielded portions of signal and

associated return leads, and keep leads a s far away as possible from electromagnetic disturbance sources.

Twisting unshielded test leads together is an effective way to reduce loop area. For probes, keep the ground

uirements of applicable listed standards when test leads and/or test

6Amplifiers and Current Probes Compliance and Safety Instructions

Page 11

Compliance information

EMC compliance

Australia / New Zealand

Safety c

ompliance

EMC

return lead as s

accomplish this most effectively. In all cases, observe all safety instructions for the probes or leads used.

4

For complianc

impedance connection between the cable shield and the connector shell should be used.

hort as possible and close to the probe body. Some probes have accessory probe tip adapters to

e with the EMC standards listed here, high quality shielded interface cables that incorporate low

Meets the intent of Directive 2014/30/EU for Electromagnetic Compatibility

when it is use

d with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

Complies w

ith the EMC provision of the Radiocommunications Act per the

following standard, in accordance with ACMA:

EN 61326-

1 and EN 61326-2-1. Radiated and Conducted Emissions, Group 1,

Class A.

This section lists the safety standards with which the product complies and other

safety compliance information.

EU low v

oltage directive

U.S. nationally recognized

testing laboratory listing

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Union:

Low Voltage Directive 2014/35/EU.

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

EN 61010-2-032. (TCP303/305A/312A/404XL only) Particular requirements

for handheld current clamps for electrical measurement and test equipment.

UL 61010-1. (TCPA300/400 and TCP305A/312A only) Safety Requirements

for Electrical Equipment for Measurement, Control, and L aboratory Use –

Part 1: General Requirements.

UL 3111-1. (TCP303/404XL only) Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

UL 61010-2-032. (TCP305A/312A only) Particular requirements for

handheld current clamps for electrical measurement and test equipment.

IEC 3111-2-032. (TCP303/404XL only) Particular requirements for handheld

current clamps for electrical measurement and test equipment.

Amplifiers and Current Probes Compliance and Safety Instructions 7

Page 12

Compliance information

Canadian certification

Additional compliances

Equipment type

Safety class

Pollution degree

descriptions

CAN/CSA-C22.2

Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

CAN/CSA-C22.2 No. 61010-2-032. (TCP305A/312A only) Particular

requirements for handheld and hand manipulated current sensors for electrical

measurement and test equipment.

IEC 61010-1. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 1: General Requirements.

IEC 61010-2-032. (TCP303/305A/312A/404XL only) Particular

requirements for handheld current clamps for electrical measurement and

test equipment.

Test and measuring equipment.

TCPA300/400 only: Class 1 – grounded product.

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

No. 61010-1. Safety Requirements for Electrical

ollution degree rating

P

IP rating

Pollution degree 1. No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Pollution degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, o r snow. Typical outdoor locations.

Pollution degree 2 (as defined in IEC 61010-1). Rated for indoor, dry location

use only.

IP20 (as defined in IEC 60529).

8Amplifiers and Current Probes Compliance and Safety Instructions

Page 13

Compliance information

Measurement and

overvoltage category

descriptions

Mains overvoltage

Measurement te

from one or more of the following categories (see specific ratings marked on

the product and in the manual).

Category II. Circuits directly connected to the building wiring at utilization

points (socket outlets and similar points).

Category III. In the building wiring and distribution system.

Category IV

NOTE. Only mains power supply circuits have an overvoltage category rating.

Only measurement circuits have a measurement category rating. Other circuits

within the product do not have either rating.

TCPA300/400 only: Overvoltage category II (as defined in IEC 61010-1).

category rating

Environmental considerations

This section provides information about the environmental impact of the product.

rminals on this product may be rated for measuring mains voltages

. At the source of the electrical supply to the building.

Restriction of hazardous

substances

Product end-of-life

handling

Complies with RoHS2 Directive 2011/65/EU.

rve the following guidelines when recycling an instrument or component:

Obse

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

duce the use of natural resources, we encourage you to recycle this product in

re

an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

This symbol indicates that this product complies with the applicable European

nion requirements according to Directives 2012/19/EU and 2006/66/EC

U

on waste electrical and electronic equipment (WEEE) and batteries.

For information about recycling options, check the Tektronix Web site

www.tek.com/productrecycling).

(

Amplifiers and Current Probes Compliance and Safety Instructions 9

Page 14

Operating considerations

Operating con

Environmental

TCPA300 and TCPA400

power

siderations

Characteristic Probes and amplifiers

Temperature

Operating 0 to +50 °C (32 to 122 °F)

Nonoperating

Humidity

Operating 5 to 95% R.H. to +30 °C (86 °F)

Nonoperating

Altitude

Operating Up to 2000 m (6,560 ft.)

Nonoperating

Pollution degree 2, Indoor use only

cteristic

Chara

Input voltage

Maximum power 50 watts maximum

-40 to +75 °C (-40 to 167 °F)

5to85%R.H.+30to+50°C(86to122°F)

+30 to +46 °C (+86 to +115 °F) 0-90% RH

Up to 12,192 m (40,000 ft.)

00 and TCPA400 amplifiers

TCPA3

40 VAC, 47 Hz to 440 Hz, single phase

100–2

TCP312A and TCP305A

probes

Characteristic TCP312A probe TCP305A probe

Input current

Maximum input current

ratings

Maximum voltage on

bare wire

Maximum Amp·Second

product

0–50 A (Peak pulse) 0–50 A DC (Peak pulse)

10 A/V Range:

30 ADC (Continuous)

(Sinusoidal)

21 A

RMS

50 Apk (Peak pulse)

1 A/V Range:

5 ADC (Continuous)

3.5 A

50 Apk (Peak pulse)

150 V C AT II 150 V C AT II

1A/V-50A· μs

10 A/V - 500 A· μs

(Sinusoidal)

RMS

10 A/V Range:

50 ADC (Continuous)

35 A

50 Apk (Peak pulse)

5 A /V Range:

25 ADC (Continuous)

17.7 A

50 Apk (Peak pulse)

5 A/V - 500 A· μs

10 A/V - NA

(Sinusoidal)

RMS

(Sinusoidal)

RMS

10 Amplifiers and Current Probes Compliance and Safety Instructions

Page 15

Operating considerations

TCP303 and TCP

404XL

probes

Characteristic TCP303 probe TCP404XL probe

Input current

Maximum input

current ratings

0–500 A DC (Peak pulse) 0–750 A DC (Peak pulse)

50 A/V Range:

150 ADC (Cont

150 A

RMS

inuous)

(Sinusoidal)

500 Apk (Peak pulse)

1

1 A/mV Range:

500 ADC (Cont

inuous)

750 ADC (Noncontinuous)

500 A

750 Apk (Pea

(Sinusoidal)

RMS

k pulse)

5 A/V Range:

25 ADC (Continuous)

Sinusoidal)

RMS

(

17.7 A

500 Apk (Peak pulse)

Maximum v

oltage on

600 V

CAT I & II 600 V

RMS

CAT I & II

RMS

bare wire

Maximum Amp·Second

product

1

Control box derated to 100 Arms above 40 °C

2

WARNING: To reduce the risk of fire or burn, refer to TCP404XL Maximum Measurement Times for intermittent

operation in the TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual, Tektronix part

number 077-1183-xx, for maximum currents and duty cycles before use.

5 A/V - 3000 A· μs

50 A/V - 15000 A· μs

NA

2

Product documentation

The following table lists the user documentation available for the products

covered by this document. These documents can be downloaded from the

Tektronix website (www.tek.com/downloads).

Tektronix

Document Language

TCPA300/400 Amplifiers and TCP303/305A/312A/404XL

English 071-3643-xx

Current Probes Compliance and Safety Instructions

(this document)

TCPA300/400 Amplifiers and TCP300A/400 Series

AC/DC Current Probes User Manual

English

Japanese

Russian

TCPA300/400 Amplifiers and TCP300A/400 Series

English 077-0323-xx

AC/DC Current Probes Service Manual

part number

077-1183-xx

077-1184-xx

077-0322-xx

Amplifiers and Current Probes Compliance and Safety Instructions 11

Page 16

Installation

Installation

The TCPA300 and TCPA400 current probe amplifiers let you use one probe to

simultaneously measure AC and DC current. The amplifiers convert the sensed

current into

oscilloscope. The amplifiers and associated probes provide these features:

a proportional voltage signal that you can measure directly with an

Standard accessories

Amplifiers

Simultaneo

High sensitivity

One-button autobalancing and probe degaussing

No adjustments needed to match a current probe to an individual amplifier

AC or DC coupling of signal

Direct scaling and unit readout on compatible TEKPROBE level II

oscilloscopes

The following accessories are shipped with the amplifiers and probes.

llowing accessories are shipped with the TCPA300 and TCPA400

The fo

amplifiers.

Powe

TEKPROBE Interconnect Cable

us DC and AC current measurements up to 750 A peak

r Cord (customer-chosen option)

Certificate of Traceable Calibration

Probes

12 Amplifiers and Current Probes Compliance and Safety Instructions

When you order a current probe, you will receive these accessories:

Probe cover (TCP303 and TCP404XL only)

robe ground lead, 6 inch length (TCP305A and TCP312A only)

P

Instruction Sheet

Certificate of Traceable Calibration

Page 17

Installation

Optional acce

ssories

You can order the following optional accessories for the amplifiers and probes.

One-turn 50 Ω HF current loop. Two versions are available; one for each

style of probe. The current loops are used in the performance verification

procedures for checking the performance of the TCPA300 Amplifier and

the compati

50 Ω feedthrough termination, 2 W (Tektronix part number 011-0049-xx)

50 Ω BNC-to-BNC coaxial cable (Tektronix part number 012-0117-xx)

TCPA Calibration Adapter. Use the TCPA Calibration Adapter to verify the

amplifier(s) performance independent of the current probes.

Travel Case. The travel case includes room to store one amplifier and two

current probes, along with related cables and adapters.

Deskew Fixture. This fixture converts the PROBE COMPENSATION output

or TRIGGER OUTPUT of the TDS5000 or TDS7000 into a set of test point

connections that allow you a convenient way to compensate for timing

rences between voltage and current probes.

diffe

ble probes.

System configuration

plete current measurement system consists of a current probe amplifier, a

Acom

compatible current probe, and an appropriate oscilloscope. (See Figure 1.)

Figure 1: Typical TCPA300/400 current measurement system

1. 50 Ω oscilloscope input — use the supplied TEKPROBE Interface Cable or

usea50Ω BNC cable, which is available as an optional accessory.

NOTE. If the oscilloscope only has a high-impedance input, you will need to add

a50Ω termination, which is available as an optional accessory.

Amplifiers and Current Probes Compliance and Safety Instructions 13

Page 18

Installation

TCPA300 and TCPA400

amplifiers

Current probes

Oscilloscope

The amplifier am

to a proportional voltage that is displayed on an oscilloscope or other similar

measuring device.

The followin

TCPA300 Amplifier:

TCP312A (30

TCP305A (50 A, 50 MHz)

TCP303 (150 A, 15 MHz)

The following Tektronix current probe is compatible with the TCPA400 Amplifier:

TCP404XL (750 A1,2MHz)

1

500 A continuous, 750 A DC derated with duty cycle

An oscilloscope displays the output from the current measuring system. A 50 Ω

s included to connect the amplifier to the oscilloscope input channel. A

cable i

TEKPROBE-to-TEKPROBE interface cable is also included for connecting to

TEKPROBE level II oscilloscopes.

plifies the current sensed by the probe and converts the current

g Tektronix current probes are compatible with the

A, 100 MHz)

If the oscilloscope does not have an input that can be set to 50 Ω impedance, you

need a feedthrough 50 Ω termination. This termination is available as a standard

accessory with your TCPA300 and TCPA400 Current Probe Amplifiers.

Connect the amplifier to an oscilloscope

You will need an oscilloscope to display the TCPA300 and TCPA400 measurement

output. To use the full dynamic range of the probe/amplifier combination, the

oscilloscope must be capable of displaying a vertical scale factor of 1 mV/div to

/div.

1V

If you are using a TEKPROBE II-compatible oscilloscope, use the supplied

EKPROBE-to-TEKPROBE interface cable to connect the amplifier OUTPUT

T

connector to your oscilloscope. Otherwise, use a 50 Ω BNC cable (available

as an optional accessory) to connect the amplifier OUTPUT connector to your

oscilloscope. (See Figure 1 on page 13.)

The input impedance of the oscilloscope channel must be 50 Ω, or you will

encounter slowed pulse response, increased aberrations, or incorrect DC

measurement amplitudes. If your oscilloscope provides only 1 M Ω inputs,

you need to attach a 50 Ω feed-through termination (available as an optional

accessory) between the oscilloscope input and the BNC cable. Do not install this

termination at the amplifier end of the BNC cable.

14 Amplifiers and Current Probes Compliance and Safety Instructions

Page 19

Installation

Power on the amplifier

To utilize the f

attached current probe, the oscilloscope bandwidth must be approximately five

times that of the current probe. For example, when using a TCP312A Current

Probe, the oscilloscope bandwidth must be at least 500 MHz. When using a

TCP305A Current Probe, the oscilloscope bandwidth must be at least 250 MHz.

After you have connected the amplifier to the oscilloscope, allow the equipment

to warm up to a stable t emperature; usually 20 minutes is required.

NOTE. To obtain accurate measurements, the input impedance of your

oscillosc

an oscilloscope input using a 50 Ω BNC cable, and that the oscilloscope input is

set to 50 Ω impedance.

1. Connect the power cord to the power input connector on the rear of the

amplifier, and then connect the power cord to your local mains supply

( 1 0 0 VA C t o 2 4 0 VA C , 5 0 H z to 40 0 Hz ) .

2. To allow for proper ventilation, place the rear panel of the amplifier at least

2 inches away from any obstructions. Set the amplifier on the bottom rubber

, and keep papers and other items away from the bottom of the amplifier

feet

which could restrict airflow and cause overheating.

ull bandwidth capability of the TCPA300 and TCPA400 and

ope must be 50 Ω. Make sure your amplifier OUTPUT is connected to

3. Pres

NOTE. The amplifier stores the power state it is in when the power cord is

unplugged. If you do not put the amplifier into STANDBY mode before unplugging

it, the amplifier will power on immediately when you plug it in again.

4. Degauss the probe before taking measurements. For more information, refer

NOTE. The amplifier stores the power state it is in when the power cord is

unplugged. If you do not put the amplifier into STANDBY mode before unplugging

it, the amplifier will power on immediately when you plug it in again.

When you connect a probe to the amplifier, the amplifier uses detection circuitry

to indicate probe conditions such as noncompatible probe type and probe open.

s the ON/STANDBY button on the amplifier front panel. The amplifier

goes through a self-test and cycles the front-panel LEDs.

to the TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes

User Manual, Tektronix part number 077-1183-xx, for additional instructions

on degaussing and performing a functional check.

Amplifiers and Current Probes Compliance and Safety Instructions 15

Page 20

Installation

Connect the pr

obe to the amplifier

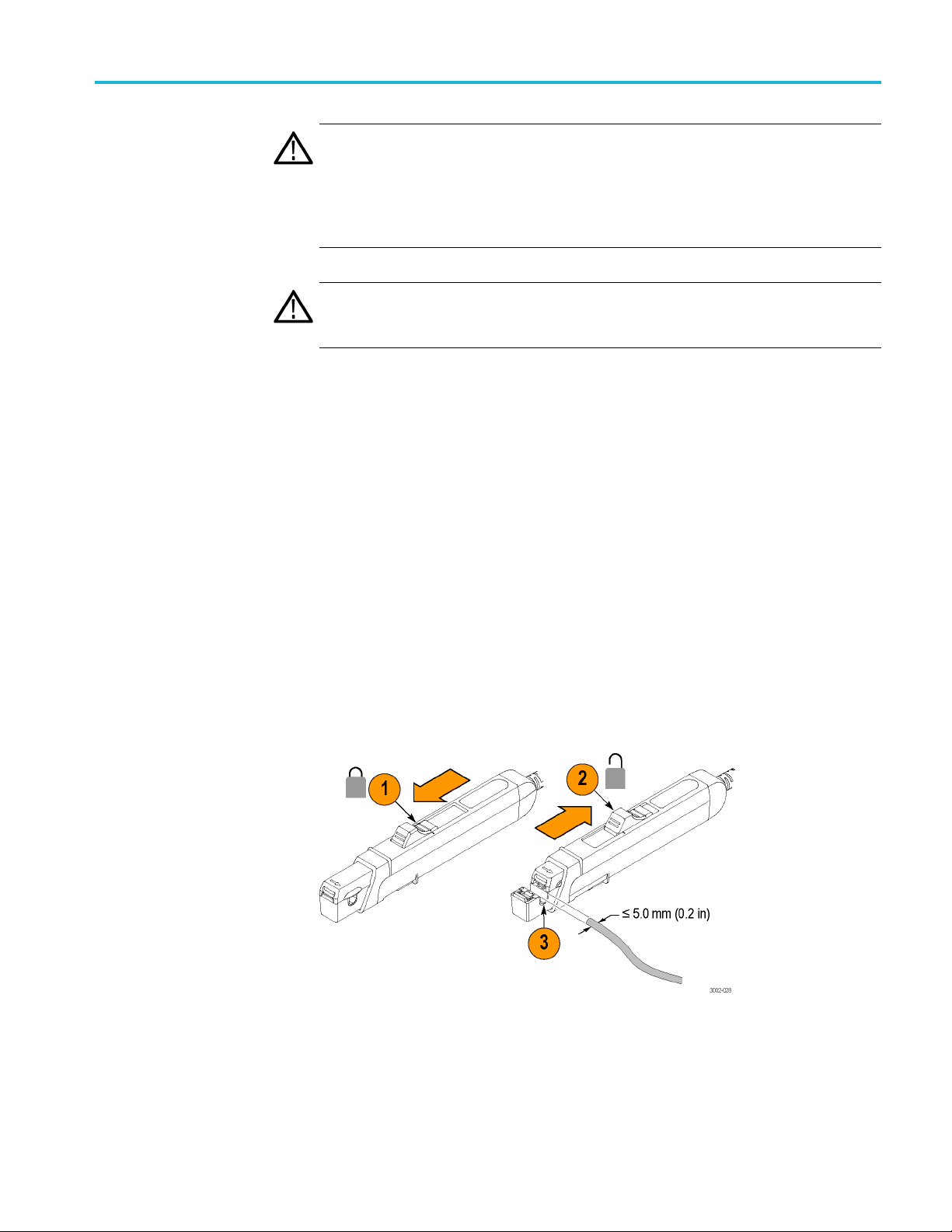

To connect a current probe to the amplifier input connector, do the following and

refer to the illustration. (See Figure 2.)

1. To connect the probe, align the red dots.

2. Push the probe connector in. Do not twist the connector.

3. To disconnect the probe, pull back the collar.

4. Pull out the connector.

Figure 2: Connecting and disconnecting a current probe to the amplifier

CAUTION. Handle current probes with care. Do not drop a probe or subject it to

ct, or the core may crack.

impa

Do not connect or disconnect a current probe while the probe is clamped around a

ve conductor, or the probe may suffer electrical damage.

li

If you connect a probe to the wrong amplifier, (for example, a TCP312A to a

PA400), the NONCOMPATIBLE PROBE TYPE LED illuminates. Disconnect

TC

the probe and use the correct amplifier. The TCPA400 amplifier accepts

TCP3XXA probes, but will only operate properly with TCP4XX probes.

Each current probe is calibrated before it is shipped, and should not require

further adjustment. If a probe requires adjustment, information is a vailable in the

service manual. The adjustment p rocedure must be performed only by qualified

service personnel. Contact your nearest Tektronix Service Center if you need

more assistan ce.

16 Amplifiers and Current Probes Compliance and Safety Instructions

Page 21

Operate the amplifier

Operate the am

plifier

The TCPA300 a

described below. Some seldom-used functions do not appear in the illustration.

These functions are discussed in the product user manual.

nd TCPA400 front-panel controls and connectors function as

Figure 3: Amplifier front panel (TCPA300 shown)

1. The PROBE DEGAUSS AUTOBALANCE button removes residual

magnetism from the attached current probe. A multi-color LED indicates the

status of the degauss circuit.

2. The MANUAL BALANCE buttons allow you to fine-adjust DC offset from

the amplifier. The adjacent LED lights when one of the buttons has been

pressed.

3. The four probe error lights indicate the following faults: PROBE OPEN,

OVERLOAD (current or temperature), NOT TERMINATED INTO 50 Ω and

ONCOMPATIBLE PROBE TYPE.

N

4. The ON/STANDBY button turns on power to the amplifier.

5. The TCPA300 and TCPA400 output appears at the OUTPUT connector.

Connect this to a 50 Ω input of your oscilloscope.

Amplifiers and Current Probes Compliance and Safety Instructions 17

Page 22

Operate the amplifier

LED indicators

6. The current pro

bes connect to the TCPA300 and TCPA400 at the PROBE

INPUT connector.

7. The COUPLING b

utton selects AC or DC probe coupling, as indicated by

the LEDs.

8. The RANGE bu

tton toggles between the two scale factors that are available

for the attached probe (TCPA300 only). LEDs indicate the selected range.

Indicators Function

PROBE OPEN

OVERLOAD When lit, this LED indicates different overload conditions. (See page 19,

NOT

TERMIN

INTO 50 Ω

NONCOMPATIBLE

PROBE TYPE

ATED

When lit, t

must have the probe slide locked to degauss the probe or to accurately

measure current.

CAUTION:

that the probe slide is locked before you apply power to the circuit.

Overload conditions.)

When lit, this LED indicates that the T EKPROBE Interface able or BNC

cable f

on the oscilloscope. Switch the termination setting on the oscilloscope

to 50 Ω,orusea50Ω termination on the oscilloscope input.

NOTE. N

DEGAUSS AUTOBALANCE operation.

When l

amplifier is not designed to work with the amplifier. TCP3XX probes

only work with the TCPA300 Amplifier, and the TCP404XL probe only

works

his LED indicates that the current probe is unlocked. You

To reduce risk of fire when using bare conductors, ensure

rom the OUTPUT of the amplifier is not connected to a 50 Ω input

OT TERMINATED INTO 50 Ω is only detected during the

it, this LED indicates that the probe that is connected to the

with the TCPA400 Amplifi er.

18 Amplifiers and Current Probes Compliance and Safety Instructions

Page 23

Operate the amplifier

Overload cond

itions

LED color Overload condition Recommended action

Solid red

Flashing

red

Solid

orange

Flashing

red and

orange

All LEDs

flashing

1

Since c

Temperature shifts can also affect the probe accuracy; degauss the probe if the probe head or amplifier

temperature changes more than 5 °C.

Measured continuous

current is exceeding the

continuous current limit of

the probe.

Measured current waveform

has pulses that are

exceeding the limits of

the probe.

The operating temperature

of the probe or the amplifier

has been exceeded.

Both temperature and

current limits have been

exceeded.

Probe & amplifier thermal

shutdown has occurred.

urrent overloads can magnetize the probe, always degauss the probe after an overload condition.

Disconnect the probe from the current

source.

Reduce the current source amplitude or

use a higher probe current range or a

higher-rated current probe.

Disconnect the probe from current

source and allow time for the probe

head and amplifier to cool. Shorten the

measurement time duration or use a

higher-rated current probe.

Disconnect the probe from the current

source. Power-cycle the amplifier and

let the probe and amplifier adequately

cool down (typically 15 m inutes) before

taking measurements again. Shorten

the measurement time duration or use a

higher-rated current probe.

1

WAR NI NG . To avoid personal injury or equipment damage, do not exceed the

specified electrical limits of the TCPA300 and TCPA400 Amplifiers or any

applicable probe accessories.

Amplifiers and Current Probes Compliance and Safety Instructions 19

Page 24

Operate the current probe

Operate the cu

Basic operation

rrent probe

1. Connect the

amplifier.)

2. TCP305A and

(See page 25, Use the ground lead.)

3. Degauss t

probe.)

CAUTION. To prevent inaccurate measurements, always degauss the current probe

before taking measurements.

4. Insert a conductor into the probe. (See page 21, Operate the current probe

slide.)

5. Observe the amplifier and oscilloscope to make measurements.

probe to the amplifier. (See page 16, Connect the probe to the

TCP312A only: If desired, install the ground lead to the probe.

he probe. (See page 24, Degauss and autobalance the current

Operation precautions

WARNING. To prevent risk of electric shock or burn, keep your hands behind the

tactile barrier which indicates the limit of safe access.

CAUTION. To prevent risk of fire, do not connect or disconnect the current probe

to or from a live, uninsulated conductor. The core is not insulated. When you test

insulated circuits, remove power before you connect or disconnect the probe.

un

WARNING. These probes are not rated for bare-wire voltages above 150 V Cat II,

nd insulated-conductor voltages above 300 V Cat II. To reduce risk of electric

a

shock, do not take measurements with these probes on circuits with voltages

above these limits.

NOTE. An insulated conductor is any conductor that is surrounded by an

insulating material that is capable of isolating the voltage present on the

conductor. Lacquer coatings like those typically found on transformer windings

do not provide sufficient, reliable insulation for use with current probes. The

lacquer coating can be easily nicked or damaged, which compromises the

insulating capabilities of the lacquer coating.

20 Amplifiers and Current Probes Compliance and Safety Instructions

Page 25

CAUTION. To prevent damage to the TCP305A & TCP312A probes, do not drop

the probe, sub

insert insulated conductors larger than 5.0 mm (0.2 in) into the probe jaw or

damage may result. If the slider will not close around the conductors, do not

force the slide closed; either reduce the number of conductors, or use a smaller

conductor, if possible, without exceeding the amperage rating of the wire.

CAUTION. To reduce risk of fire, do not connect or disconnect the current probe to

or from a live, uninsulated conductor. The core is not insulated. Always remove

power before you c onnect or disconnect the probe to or from bare conductors.

To improve EMI rejection at high frequencies, use the optional ground lead. Refer

to the TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User

Manual,

Tektronix part number 077-1183-xx, for additional instructions.

Operate the current probe slide

Operate the current probe

ject it to physical shock or rapid temperature changes, and do not

TCP305A and TCP312A

slide operation

rrent probes each have a slide mechanism that opens and closes the probe

The cu

jaw. This allows you to clamp the probe around a conductor under test. The slide

must be locked closed to accurately measure current or to degauss the probe. If a

probe is unlocked, the PROBE OPEN indicator on the amplifier will light.

The current probes can be used to measure current on uninsulated wires. However,

the circuit must be de-energized when connecting or removing the current probe.

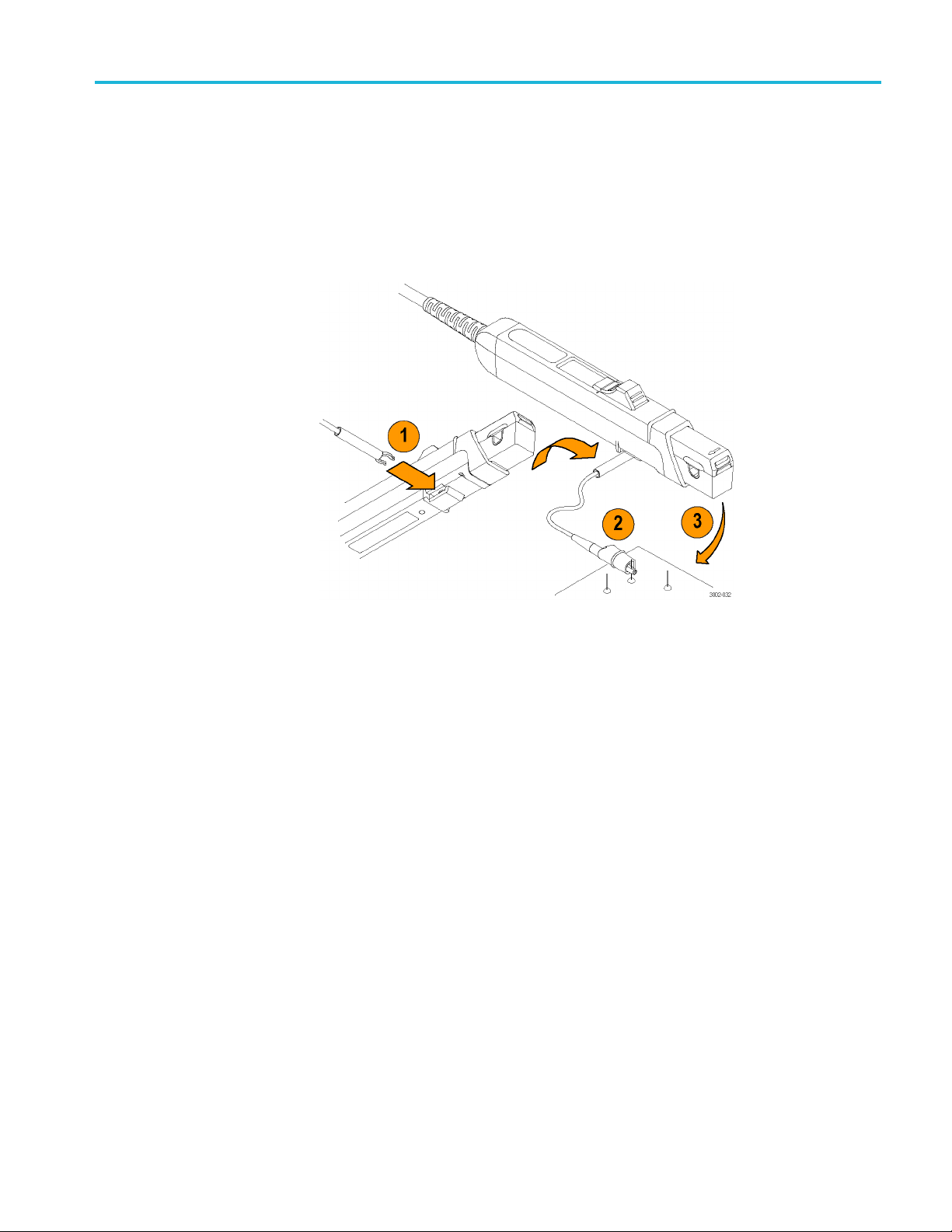

The slide operation of the TCP305A and TCP312A current probes is shown in the

following illustration.

Amplifiers and Current Probes Compliance and Safety Instructions 21

Page 26

Operate the current probe

To o perate t he p

1. To close (lock) the probe, push the slide forward until the detent snaps into

place.

NOTE. The slider must be in the closed (locked) position to degauss the probe.

2. To open (unl

3. Insert a 5 mm (0.2 in) diameter maximum conductor size into the jaw.

WARNING.

(0.2 in) diameter into the jaw.

4. Close th

measurements, keep your fingers behind the demarcations on the probe, and

away from the shaded area shown below.

robe:

ock) the probe, pull the slide back until the jaw is open.

To prevent probe damage, do not force conductors larger than 5 mm

e jaw around the conductor and lock the slider. When you are taking

RNING. Do not connect the current probe to any wire that carries voltages or

WA

currents that exceed the rating of the probes.

22 Amplifiers and Current Probes Compliance and Safety Instructions

Page 27

Operate the current probe

TCP303 and TCP404XL

slide operation

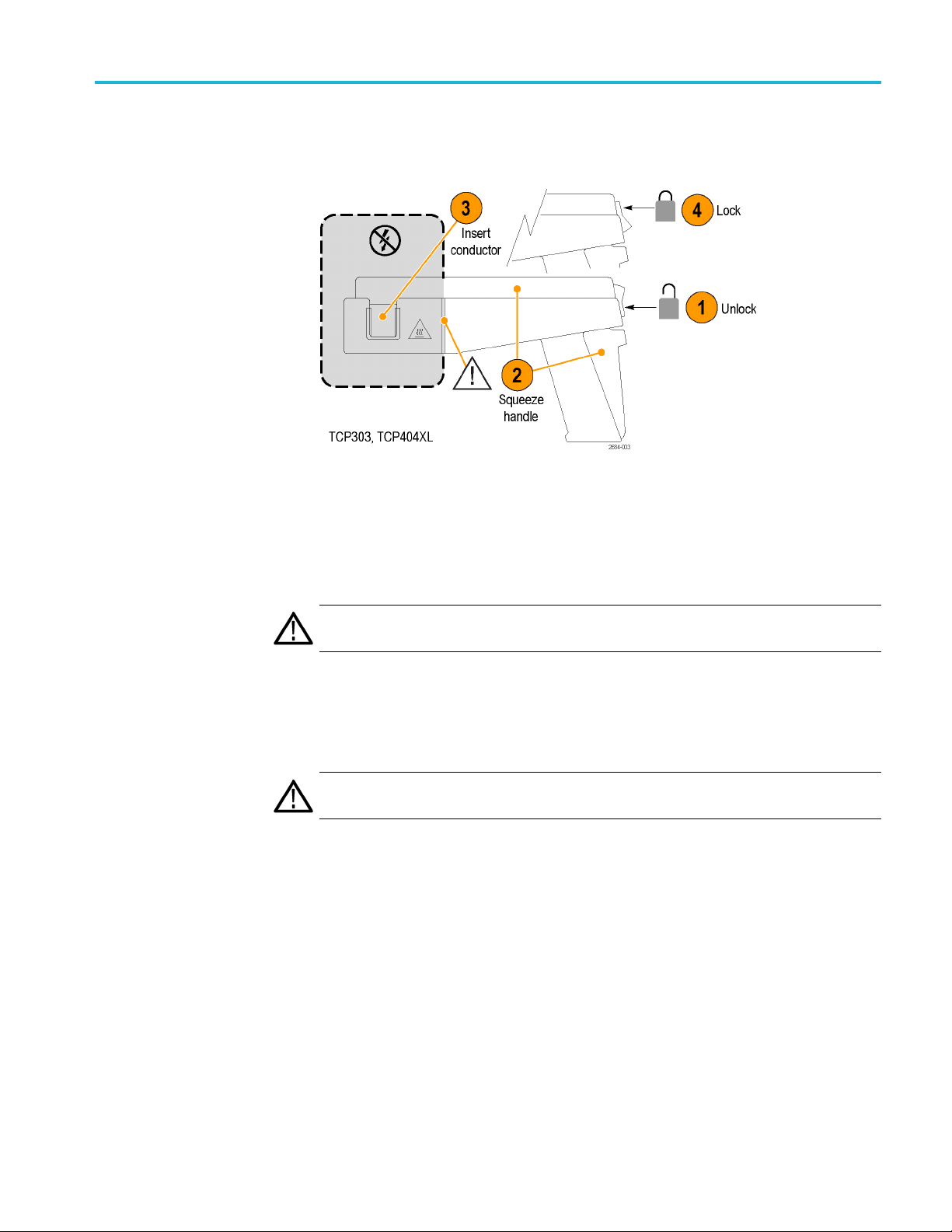

The slide opera

following illustration.

To operate the probe:

1. Press the bottom of the lock button to unlock the probe.

2. Squeeze the handle until the core is open.

3. Insert a 5 mm (0.2 in) diameter maximum conductor size into the jaw.

tion of the TCP303 and TCP404XL current probes is shown in the

WAR NI NG . To prevent probe damage, do not force conductors larger than 5 mm

(0.2 in) diameter into the jaw.

4. To close and lock the probe, release the squeeze handle and press the top of

the lock button. When you are taking measurements, keep your fingers behind

the demarcations on the probe, and away from the shaded area shown above.

WAR NI NG . Do not c onnect the current probe to any wire that carries voltages or

rents that exceed the rating of the probes.

cur

Amplifiers and Current Probes Compliance and Safety Instructions 23

Page 28

Operate the current probe

Degauss and autobalance the current probe

Degauss the probe to remove any residual magnetization from the probe core.

Such residual magnetization can induce measurement error. Autobalancing

removes unwanted DC offsets in the amplifier circuitry. Failure to degauss the

probe is a leading cause of measurement errors. The DEGAUSS LED flashes

until you de

To degauss the probe, disconnect the probe from the test circuit, or ensure that

the conduc

the amplifier PROBE DEGAUSS AUTOBALANCE button on the front panel of

the amplifier. To maintain measurement accuracy, degauss your probe in each of

these cases:

After you turn on the amplifier and allow a 20-minute warm-up period.

Before you connect the probe to a conductor.

gauss the probe.

tor under test has no power, close and lock the slide, and then press

Wheneve

Whenever you connect a new probe.

Whenever you subject the probe to a strong external magnetic field.

Periodically during normal use.

To degauss and autobalance a current probe, perform these steps:

1. Verify that the current probe is connected to the amplifier.

2. Rem

3. Lock the probe slide closed.

4. Press the amplifier PROBE DEGAUSS AUTOBALANCE button.

5. Wait about five seconds for the degauss procedure to complete.

The PROBE DEGAUSS AUTOBALANCE LED glows g reen when the

operation has successfully completed. If the LED is blinking orange, the degauss

operation is still in progress. If the LED is red, the operation failed, and the cause

of the failure needs to be found and fixed. (See page 17, Operate the amplifier.)

NOTE. The degauss procedure will fail if the amplifier is not properly connected

to an oscilloscope having 50 Ω input impedance. If this occurs, the NOT

TERMINATED INTO 50 Ω LED lights on the amplifier front panel.

r a current or thermal overload condition occurs.

ove the current probe from the conductor under test.

After you have completed the oscilloscope adjustments and the amplifier

degauss/autobalance procedure, your system is ready to measure current.

24 Amplifiers and Current Probes Compliance and Safety Instructions

Page 29

Use the ground lead

Operate the current probe

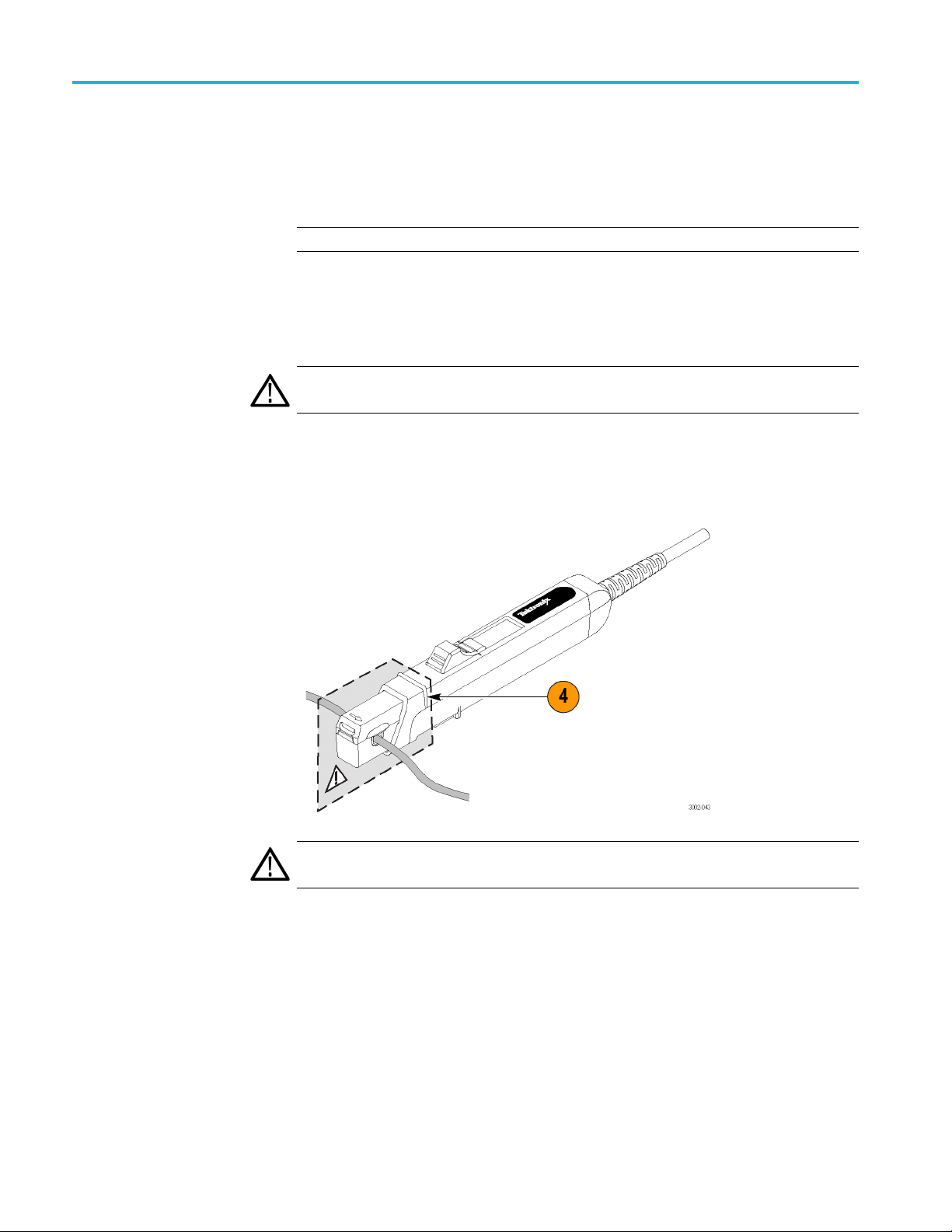

The TCP305A and TCP312A probes include a 6-inch ground lead. The ground

lead grounds the shield around the probe transformer at the probe end of the

cable. This allows you to move the ground connection closer to the circuit you are

measuring, thereby improving high frequency shielding. The ground lead clips

onto the gro

und connector on the bottom of the probe.

Figure 4: Connecting the ground lead

The ground lead on the current probes is intended to be used in high dV/dt

onments. The probes have a grounded shield between the conductor under

envir

test and the current sense transformer. Any capacitively-coupled current will then

flow in the ground instead of the transformer windings.

When you take high frequency measurements, connect the probe ground lead to

the probe ground connector and attach the alligator clip directly to RF ground to

improve EMI rejection at high frequencies (2 MHz and above). This will reduce

ringing and help bypass capacitively-coupled RF currents which can flow into

the probe cable. In some cases, it may be helpful to move the ground lead or

position the probe away from noise sources in the circuit under test.

re

Amplifiers and Current Probes Compliance and Safety Instructions 25

Page 30

Operate the current probe

Make DC curren

t measurements

To measure DC current, first degauss the probe. (See page 24, Degauss and

autobalance the current probe.)

1. Verify that the amplifier and the oscilloscope input coupling are set to DC,

and the input impedance is set to 50 Ω.

2. Lock the probe closed without a conductor passing through it.

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

4. Press the amplifier PROBE DEGAUSS AUTOBALANCE button.

The NOT TERMINATED INTO 50 Ω LED is lighted if impedance is not

50 Ω. If this is the case , make necessary changes. (For example, use a 50 Ω

termination.)

5. After the degauss/autobalance routine completes, adjust the ground reference

(if necessary) using the amplifier MANUAL BALANCE controls.

WARNING. The current probes can be used to measure current on uninsulated

. However, the circuit must be de-energized when connecting or removing

wires

the current probe.

26 Amplifiers and Current Probes Compliance and Safety Instructions

Page 31

Operate the current probe

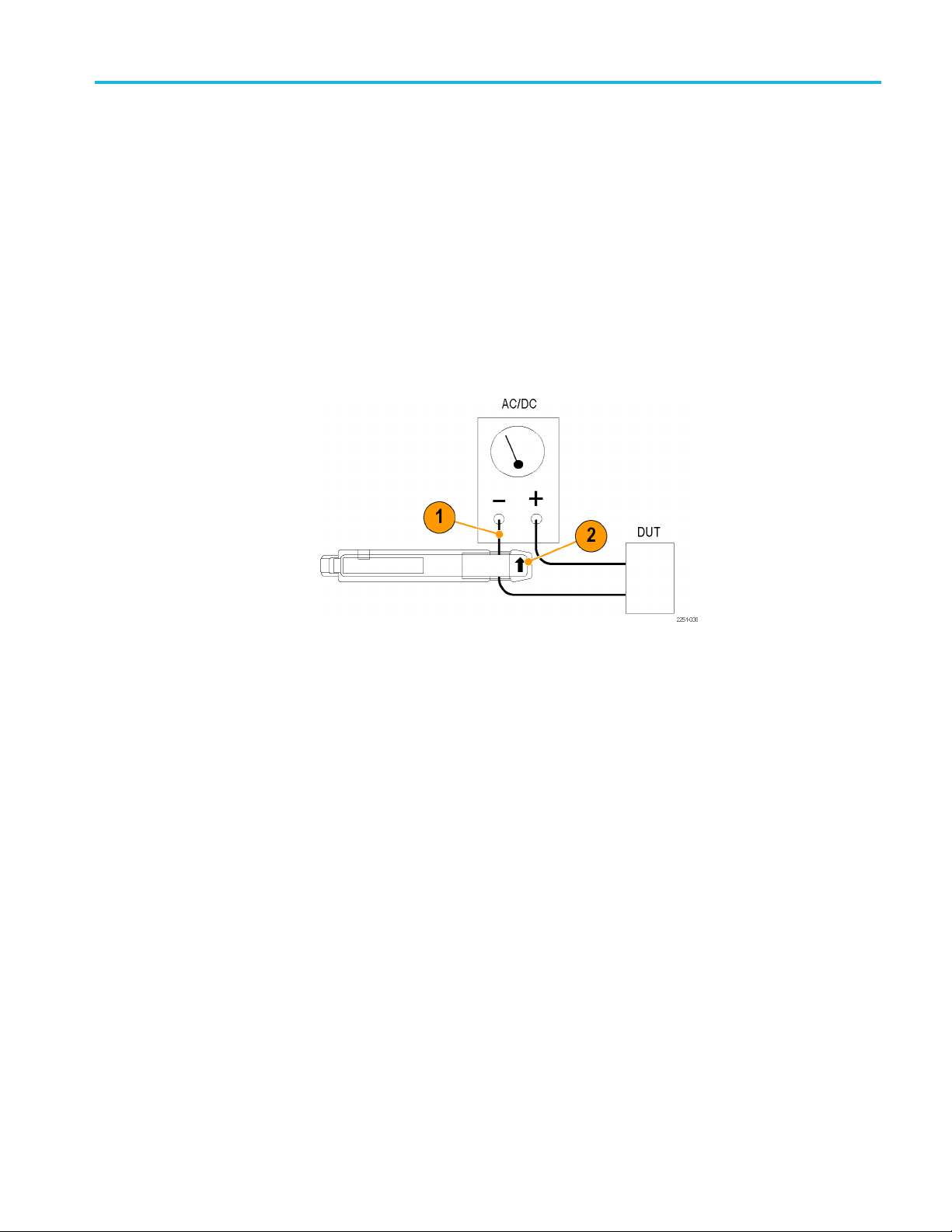

The current pro

Notice that the probe arrow points toward the negative terminal of the power

supplytoconf

To measure DC current, perform these steps:

1. Open the pro

then lock the slide.

2. For correct

the direction of conventional (positive to negative) current flow. Reversing

the flow will display the current waveform upside-down on the oscilloscope.

3. Adjust the oscilloscope time base, trigger, and gain as needed.

be is shown connected to a power supply line. (See Figure 5.)

orm to the conventional current flow of positive (+) to negative (-).

be slide, place the probe around the conductor under test, and

measurement polarity, make sure the probe arrow is pointing in

Figure 5: Arrow on current probe indicates conventional current flow

Amplifiers and Current Probes Compliance and Safety Instructions 27

Page 32

Operate the current probe

Make AC curren

t measurements

To measure AC current only, and remove the DC component of the current being

measured, follow the instructions below. These are identical to the instructions for

DC current me

1. Verify that the oscilloscope input coupling is set to DC, and the input

impedance i

amplifier is lit if impedance is not 50 Ω.)

2. Verify tha

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired g

4. Lock the probe closed without a conductor passing through it, and then press

the ampl

WARNING. The current probes can be used to measure current on uninsulated

wires. However, the circuit must be de-energized when connecting or removing

the current probe.

5. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will invert the displayed current waveform

on the oscilloscope.

asurements except that the amplifiercouplinginstep2issettoAC.

ssetto50Ω. (The NOT TERMINATED INTO 50 Ω LED on the

t the amplifier input coupling is AC.

raticule line.

ifier PROBE DEGAUSS AUTOBALANCE button.

E. Even when making AC current measurements, leave the oscilloscope

NOT

coupling on DC. Change only the amplifier coupling to AC. Using the oscilloscope

AC coupling may cause the amplifier to exceed its output dynamic range.

6. Adjust the oscilloscope time base and trigger as n eeded.

28 Amplifiers and Current Probes Compliance and Safety Instructions

Loading...

Loading...