Page 1

Operating instructions

(Translation of the original operating instructions)

Caremaster 1 - IFA

Caremaster 2 - IFA

TEKA Absaug- und Entsorgungstechnologie GmbH, Industriestraße 13, D-46342 Velen,

Tel.: +49 2863-9282-0, E-Mail: info@teka.eu, www.teka.eu

1

Page 2

Table of contents

1 General 4

2 Description of the system elements 5

2.1 Illustration of the system elements 5

2.2 Functionality of the system 6

2.3 Intended use 6

3 Safety instructions 7

3.1 Definition of the hazard symbols 7

3.2 General safety instructions 7

4 Storage, transport and installation of the device 8

5 Commissioning 8

5.1 Connecting an extraction element 9

5.2 Electrical connection 9

6 Operating the system 10

6.1 Explanation of the operating elements 10

7 Maintenance 11

7.1 Reset to maintenance state 12

7.2 Replacing the prefilter mat 12

7.3 Replacing the particle filter 13

8 Dismantling / Disposal 14

9 Diagnostics and troubleshooting 15

10 List of spare parts 16

11 Technical data 17

12 EC declaration of conformity 18

13 Training protocol 19

14 Maintenance intervals 20

14.1 Usage-related maintenance 20

14.2 General maintenance 20

14.2.1 Visual inspection of the device 21

BA_Caremaster-1-und-2_IFA_170831 _EN

2

31.08.2017

Page 3

14.2.2 Functional test of the device 21

14.2.3 Electrical test of the electrical lines and earthing connections 22

BA_Caremaster-1-und-2_IFA_170831 _EN

3

31.08.2017

Page 4

1 General

Congratulations on purchasing the product from TEKA.

Our engineers ensure that our devices reflect the state of the art through continuous development.

Nevertheless, misuse or misconduct can endanger your safety. Please observe the following for a

successful use of the device:

Only authorised and instructed personnel can carry out transport, operation,

maintenance and repair of the device. The operator must ensure that the operating

personnel take note of these instructions.

Please read these instructions before operating the device, and observe the safety

precautions to avoid injury!

Store this manual in a safe place! These instructions are to be regarded as a component

of the product!

Adhere to all product notes!

Modifications or conversions that the operator carries out at the device without the

consent of the manufacturer, can lead to new safety hazards or to the loss of warranty

claims.

Observe the manufacturer’s instructions. Contact the manufacturer in case of any

uncertainty:

Tel: +49 2863-9282-0

E-mail: info@teka.eu

BA_Caremaster-1-und-2_IFA_170831 _EN

4

31.08.2017

Page 5

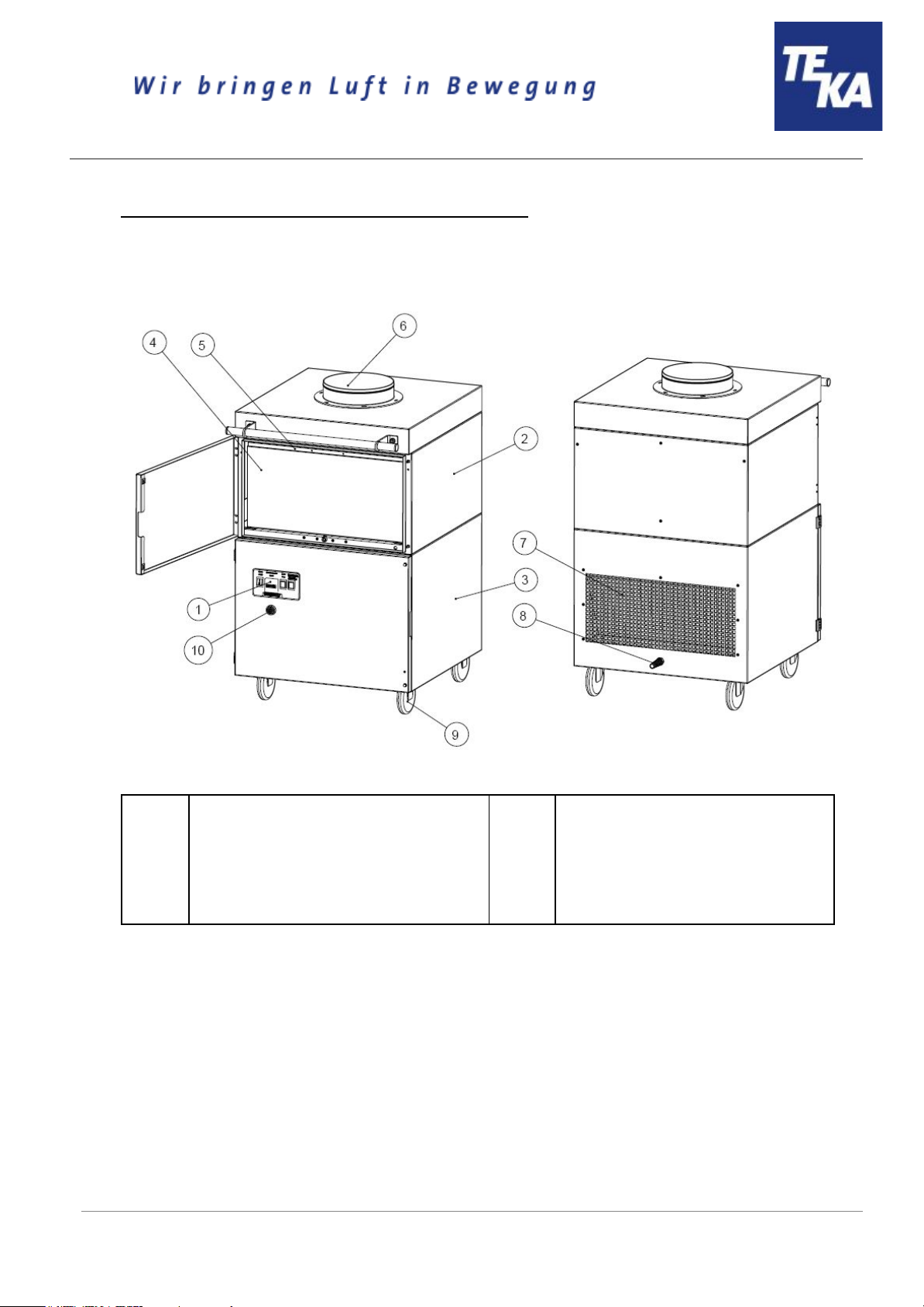

2 Description of the system elements

2.1 Illustration of the system elements

Z.Nr. 17012702

Pos.1

Pos.2

Pos.3

Pos.4

Pos.5

Operating panel of the control

Particle filter housing

Fan housing

Particle filter

Prefilter mat (into guide frame)

Pos.6

Pos.7

Pos.8

Pos.9

Pos.10

Suction nozzle (Caremaster 1: 1x,

Caremaster 2: 2x)

Exhaust grille

Mains cable with plug

Swivel castor

Signal horn

BA_Caremaster-1-und-2_IFA_170831 _EN

5

31.08.2017

Page 6

2.2 Functionality of the system

The filter unit serves to suck off and filter polluted air (according to the intended use). First of all, the

coarse particles are separated at the prefilter mat in the filter section of the unit. The subsequent particle

filter cleans even fine smokes and dusts. An automatic filter monitoring indicates when a cleaning or a

replacement of the filters is necessary. The purified air is led back into the working room.

2.3 Intended use

The filter unit is intended for extraction and filtration of dusts and fumes that result from thermal joining

and cutting of metals. The filter unit is amongst others suitable for separating welding smokes of

unalloyed and alloyed steels as well as of high-alloy chromium-nickel steels and therefore meets the

highest welding fume separation category “W3” according to DIN EN ISO 15012-1.

WARNING

Improper use can damage parts and be a danger to life and limb!

The device must not be used for the extraction of oil-laden welding fume, explosive dust and

gases, hybrid mixtures, glowing or burning substances, gases, water, etc. The device must

not be operated in explosive zones.

BA_Caremaster-1-und-2_IFA_170831 _EN

6

31.08.2017

Page 7

3 Safety instructions

3.1 Definition of the hazard symbols

The device is constructed according to the state of the art and the recognised safety regulations.

Nevertheless, during use threats to life and limb of the user or other persons may arise. The impairment

of the machine or other property are also possible. In these instructions we warn by using corresponding

indications.

WARNING

WARNING

These instructions are made in case of risks that can lead to injury or death.

CAUTION

CAUTION

These instructions are made in case of risks that can lead to injury.

NOTICE

NOTICE

These instructions are made in case of risks that can lead to material damages.

Information notes are no hazard warnings; they call attention to useful information.

3.2 General safety instructions

WARNING

Dangers arising from improper use / unauthorised operations.

The operator must ensure that their authorised personnel are familiar with all the safety

indications in this manual in advance. The operator is responsible for ensuring that all work

is carried out by authorised and qualified personnel. We therefore recommend using the

training protocol on the last page for that purpose (see chapter “Training protocol”).

Laymen are allowed to operate the device after having received the necessary instructions.

But they are not allowed to carry out any installation, repair or maintenance work.

Dangers arising from fire.

In case of fire, if possible, switch the unit immediately off or disconnect it from the power

supply. Fire extinguishing measures which the operator is obliged to determine beforehand

must be initiated immediately.

WARNING

Dangers arising from electricity.

The operator must ensure that electrical plants and equipment are only built, modified and

maintained by a qualified electrician or under the direction and supervision of a qualified

electrician. Do not work on components if you are not sure that these are disconnected. If

necessary, disconnect the device from the electric power supply and secure it against

unauthorized restarting.

BA_Caremaster-1-und-2_IFA_170831 _EN

7

31.08.2017

Page 8

4 Storage, transport and installation of the device

WARNING

Risk of injury from tilting or unmounted components when stored or transported.

The device must be secured against tilting and slipping when it is stored or transported. Do

not stand under or next to the floating load. Lift trucks, forklift trucks and transport cranes

must have a sufficient minimum load bearing capacity. Pay attention to uneven grounds

during the transport. Avoid jerky pushing.

Dangers arising from titling or functional impairments at its destination.

The unit may only be set up on a suitable surface. The surface must be vibration-free and

horizontal. The operator must check the bearing capacity of the surface. As soon as the unit

has reached its intended destination, the brakes of the castors must be activated.

NOTICE

Damage or functional impairment of the unit due to climatic influences.

The unit must be stored in a dry place and protected against moisture during transport. As a

matter of principle, the filter unit is not designed to be installed outside.

5 Commissioning

WARNING

Dangers arising from a defective condition of the unit.

Make sure that the measures described in this chapter are completed before the

commissioning of the unit. All doors of the unit must be closed and all necessary connections

must be attached before turning the unit on. Do not operate the unit if any components are

defective, missing or damaged. Check the orderly condition of the unit before switching it on.

The unit must not be operated without a filter element.

NOTICE

Damaged supply lines.

Make sure that the supply lines are protected against damage by forklift trucks and similar

events. Protect all supply lines from heat, moisture, oil and sharp edges.

BA_Caremaster-1-und-2_IFA_170831 _EN

8

31.08.2017

Page 9

5.1 Connecting an extraction element

For extracting the contaminated air - according to the intended use - the provided extraction element

(e.g. suction arm, suction hose, ...) must be connected at the suction nozzle (see chapter 2.1).

The assembly of a suction arm is described in the separate operating manual.

When using a detection element with extraction hood, the extraction hood must track the welding seam,

possibly taking advantage of the thermally induced welding fume movements.

However, it is important to ensure that connections between the workpiece and the

extractor hood (and generally between the workpiece and filter device) are avoided, so that, if

necessary, the welding current cannot flow back through the protective conductor of the filter

device to the welding machine.

5.2 Electrical connection

NOTICE

Electric malfunction possible in cause of an incorrect power supply.

Pay attention to the admissible supply voltage. Please observe the specifications on the type

plate.

● Reconnect the mains cable (see chapter 2.1) to the power supply.

● Make sure that the fan impeller rotates in the required direction when switching it on for the first

time. If not, it results in a low extraction capacity. For visual inspection, there is a sticker

attached to the bottom of the dust collecting housing (see chapter 2.1). For the connection

points of 400V and 500V the rotating field might be incorrectly set and must be changed, if

necessary. Briefly switch the device on and off. The fan slowly starts running and the rotation

direction can be compared to the sticker.

When the fan rotates in the wrong direction, the extraction capacity is

reduced.

BA_Caremaster-1-und-2_IFA_170831 _EN

9

31.08.2017

Page 10

6 Operating the system

6.1 Explanation of the operating elements

Operating elements for the device control

Representa

tion

Designation

Description / function

ON-OFF-switch

By means of this switch, the device is switched on and off.

When the device is switched off, it is not

disconnected from the power supply.

Operating elements for status and error messages

Representa

tion

Designation

Description / function

Signal lamp “red”

Flashing up means that the air-flow rate of the device is not

sufficient anymore. Filter elements must be cleaned or

replaced.

When using extraction elements with a suction hood, it is

possible that the throttle valve(s) in the suction hood are

closed. In this case open the throttle valves.

Signal horn

Honking signals that the air-flow rate of the device is not

sufficient anymore. Filter elements must be cleaned or

replaced.

When using extraction elements with a suction hood, it is

possible that the throttle valve(s) in the suction hood are

closed. In this case open the throttle valves.

Indicator lamp “green”

Flashing up means that the device is in operation.

Operating hour counter

The number of operation hours during which the device was in

operation is shown.

BA_Caremaster-1-und-2_IFA_170831 _EN

10

31.08.2017

Page 11

7 Maintenance

In accordance with national regulations, the operator is obliged to carry out repeat and functional tests.

Unless otherwise specified by national regulations, we recommend regular visual inspections and

functional tests of the device as described in the chapter “Maintenance intervals”.

You find the chapter “Maintenance intervals” at the end of the document. The general

maintenance (visual inspection, etc.) is also explained there.

In the chapter “Maintenance intervals” there is information on the maintenance intervals of the filter

elements. But these are only recommendations. Depending on the application (multi-shift operation,

dust generation, ...) it may be necessary for the operator to change the maintenance intervals.

In this chapter the maintenance work which is caused by wear caused during operation is described.

WARNING

Work on the open system entails the risk of electrical shock or accidental restart the

system. Both pose a danger to life and limb.

When cleaning and servicing equipment during the replacement of parts or when changing

to another function, set the device to maintenance condition first (see chapter “Reset to

maintenance state”).

A recommissioning of the device must only occur if it is ensured that the device is

functionally equivalent to the original state.

CAUTION

Hazards to the respiratory tracts are possible due to contact with

contaminated filter elements.

All maintenance work must only be carried out in well-ventilated rooms and

while wearing an appropriate respiratory mask! We recommend: respiratory

protection half mask DIN EN 141/143 protection level P3. For all maintenance

work ensure a cautious handling of filter elements and components in order to

avoid whirling up dust.

The operator is obliged to store and dispose of the collected dust in accordance with national or

regional regulations. For all maintenance or cleaning work please refer to the applying

environmental regulations. Pollutants and filter elements must be disposed of or stored according

to the regulations as well. If you have any doubts, we recommend contacting a disposal

contractor in your area.

BA_Caremaster-1-und-2_IFA_170831 _EN

11

31.08.2017

Page 12

7.1 Reset to maintenance state

● Switch off the unit. Unplug the mains plug. Secure the unit against unauthorized restarting

during maintenance.

● After completion of all maintenance work the unit can be reconnected to the power supply.

7.2 Replacing the prefilter mat

The prefilter mat is installed upstream to the particle filter and separates the coarse particles. This

extends the service life of the particle filter.

The prefilter mat must be changed after a certain number of operating hours. The time depends on the

amount of accumulated dust, and therefore cannot be determined beforehand. At the latest, the prefilter

mat must be changed when changing the particle filter.

CAUTION

Whirling up dust is possible.

The prefilter mat is a disposable filter element. Do not try to clean the filter element.

● Open the service door of the particle filter housing (see chapter 2.1).

● Lower the lifting device (A) by turning the clamping screw (B). Therefore, use the hexagon key

that is located on the right of the clamping screw.

● Carefully pull the insert frame (see chapter 2.1) out of the housing.

● Remove the prefilter mat from the insert frame and dispose of or store it according to the

regulations.

● Put a new prefilter mat into the insert frame.

Only use TEKA spare filters. Otherwise the proper functioning of the unit is

not guaranteed.

● Push the insert frame back into the particle filter housing.

● Elevate the lifting device by turning the clamping screw so that the insert frame is pressed

tightly against the above housing.

● Close the service door.

BA_Caremaster-1-und-2_IFA_170831 _EN

12

31.08.2017

Page 13

7.3 Replacing the particle filter

Replacing the particle filter is necessary when the device control signals the corresponding error. (see

chapter "Description of the control elements")

CAUTION

Whirling up dust is possible.

The particle filter is a disposable filter element. Do not try to clean the filter element.

When replacing the particle filter, the prefilter mat must be replaced as well.

● Open the service door of the particle filter housing (see chapter 2.1).

● Lower the lifting device (A) by turning the clamping screw (B). Therefore, use the hexagon key

that is located on the right of the clamping screw.

● Carefully pull the entire filter pack, incl. the particle filter (see chapter 2.1) out of the housing.

● Replace the particle filter.

Only use TEKA spare filters. Otherwise the proper functioning of the unit is

not guaranteed.

● Push the filter pack back into the filter housing. Make sure that the filter elements are inserted in

the correct order.

● Elevate the lifting device by turning the clamping screw so that the upper filter element is

pressed tightly against the above housing.

● Close the service door.

BA_Caremaster-1-und-2_IFA_170831 _EN

13

31.08.2017

Page 14

8 Dismantling / Disposal

Only authorised personnel may disassemble the machine.

WARNING

Dangers arising from electricity.

Before the dismantling of the machine it has to be disconnected from the power supply and

all supply lines.

CAUTION

Whirling up dust is possible due to the deposited dust.

During all work a suitable respiratory protection and protective clothing have to

be worn.

The operator is obliged to store and dispose of the collected dust in accordance with national or

regional regulations.

BA_Caremaster-1-und-2_IFA_170831 _EN

14

31.08.2017

Page 15

9 Diagnostics and troubleshooting

A list of possible system errors is provided in the table.

Faults indicated by control elements are explained in the chapter “Description of the control

elements”.

A recommissioning of the device must only occur if it is ensured that the system is functionally

equivalent to the original state. Repairs may only be carried out by TEKA personnel or, after

consultation with TEKA GmbH, by the personnel authorised by the operator.

Adhere to the instructions in the chapter "Safety instructions" and " Maintenance" when carrying out any

repairs. If in doubt, contact our TEKA service department:

Tel: +49 2863-9282-0

E-mail: info@teka.eu

Fault

Cause

Removal

System does not start.

Plug power supply is missing or

incorrectly inserted.

Plug connector check power

supply / plug in correctly.

No power at outlet.

Check the mains, remove error if

possible.

Dust at the service door

of the filter housing.

The door is not correctly closed.

Close the door.

The seal between the service door and

filter housing is damaged.

The seal must be replaced.

Escape of dust at the hinge.

The hinge must be reoriented or

replaced.

Suction power too low

(smoke hardly

extracted).

Filter element is saturated.

Replace the filter package,

dispose of old filter properly!

Damage at the extraction elements.

Replace the extraction elements.

The motor rotates in the wrong

direction.

The rotating field of mains

connection point must be

changed.

Suction line contracted.

Check and fix.

Exhaust line contracted.

Check and fix.

The system is very noisy.

The motor rotates in the wrong

direction.

The rotating field of mains

connection point must be

changed.

The unit is untight.

Check and fix.

BA_Caremaster-1-und-2_IFA_170831 _EN

15

31.08.2017

Page 16

10 List of spare parts

Filter element

Article no.

Prefilter mat “M5” (10 pieces / 610 x 610 x 20 mm)

10032

Particle filter “H13” (610 x 610 x 292+6)

10030

Particle filter “F9” (610 x 610 x 292+6)

10029

Disposal elements

Article no.

PE-bag for the disposal of filter elements (4 pieces)

10030258

BA_Caremaster-1-und-2_IFA_170831 _EN

16

31.08.2017

Page 17

11 Technical data

Version

Caremaster 1 IFA

Caremaster 2 IFA

Supply voltage

V

230 / 400 / 500

230 / 400 / 500

Frequency

Hz

50

50

Type of current

Ph

1 / 3 / 3

1 / 3 / 3

engine power

kW

1,1

2,2

Air flow volume max.

m³/h

1270

2150

Air flow volume min.

m³/h

780

1600

Negative pressure max.

Pa

1800

2100

Protection class

IP54

IP54

ISO class F

F

Extraction performance

%

> 99

> 99

Welding fume extraction class

(according to EN ISO 15012-1)

W3

W3

Width

Depth

Height

mm

mm

mm

665

681

1050

665

681

1125

Weight

kg

115

120

Sound pressure level

dB(A)

72

74

Allowed ambient temperature

°C

+5 to +35

+5 to +35

Allowed max. humidity

%

70

70

BA_Caremaster-1-und-2_IFA_170831 _EN

17

31.08.2017

Page 18

12 EC declaration of conformity

according to the Machinery Directive 2006/42/EG, Annex II, 1 A

TEKA Absaug- und Entsorgungstechnologie GmbH

Industriestraße 13, D-46342 Velen

Tel.:+49 2863-9282-0 E-Mail: info@teka.eu Internet: www.teka.eu

Designation of the device: Caremaster 1 - IFA / Caremaster 2 - IFA

We hereby declare under our sole responsibility that the product mentioned above, from the serial

number A14500010011001 resp. the production number P28000010011001 on, conforms to the

following directives:

Machinery Directive: 2006/42/EG

Electromagnetic Compatibility: 2014/30/EC

This declaration will become void if the device is exposed to modifications that are not approved by the

manufacturer in written form.

Authorized representative for the technical documentation: Technical department, TEKA GmbH,

D-46342 Velen

(Jürgen Kemper, managing director)

Velen, 3rd january 2017

BA_Caremaster-1-und-2_IFA_170831 _EN

18

31.08.2017

Page 19

13 Training protocol

Designation of the device: Caremaster 1 - IFA / Caremaster 2 - IFA

(This form can be used by the operator to document the training of the employees. Training should be performed by

authorized personnel only. Refer to the instructions in Chapter "Safety Instructions")

By his signature, the employee confirms that he has been instructed regarding the following items:

Instruction

completed

Description of the device

Operation and application of the device

Explanation of the safety instructions

Behavior in case of fire

Explanation of the operation elements

Change and dedusting of the filter elements

Appropriate disposal

Maintenance works / Maintenance intervals

Name of the employee (legible)

Signature

Introduction through (legible):

Signature:

BA_Caremaster-1-und-2_IFA_170831 _EN

19

31.08.2017

Page 20

14 Maintenance intervals

14.1 Usage-related maintenance

The described maintenances become necessary through the demands of the system operations. The

maintenance intervals are recommendations. Depending on the application (multi-shift operation, dust

generation, ...) it may make sense for the operator to change the maintenance intervals.

Maintenance work must always be documented by means of a protocol.

The approach of the maintenance measures is described in chapter "Maintenance".

Maintenance work

Chapter

Maintenance interval

recommended by TEKA

determined by the operator

Replacing the particle filter

7.3

The saturation of the particle filter is automatically monitored by

the filter unit and thus is not subject to a maintenance interval.

The filter unit triggers an alarm when a replacement of the

particle filter is necessary.

Replacing the prefilter mat

(or check the degree of pollution)

7.2

monthly

14.2 General maintenance

The described maintenances are independent from the demands of the system operations.

The operator is obliged to carry out repeated inspections and functional tests according to national

regulations. If not otherwise covered by national regulations, the described maintenance intervals must

be respected.

Maintenance work must always be documented by means of a protocol.

Maintenance work

Chapter

Maintenance interval

Visual inspection of the device

14.2.1

weekly

Functional test of the device

14.2.2

monthly

Electrical test of the electrical lines and earthing connections

14.2.3

annually

BA_Caremaster-1-und-2_IFA_170831 _EN

20

31.08.2017

Page 21

14.2.1 Visual inspection of the device

Visual inspection: Observation that there are no visible safety-related defects.

WARNING

Danger arising from the ready to operate condition of the device.

Follow the procedure as described in the chapter “Set to maintenance state”.

The following steps must be carried out in the course of the visual inspection:

● Check if all required pipeline elements, cable connections and hoses are connected to the filter

unit

● Check all electrical earthing connections and cables for visible damages.

● Ensure that all parts are firmly connected.

● Check all connection points of the filter unit for escaping dust.

● Check all metal parts for corrosion or damages / changes of the coating.

● Check the inner filter area and the filter housing.

● Visual inspection of the control and operating elements as well as the outside running cables for

damages.

14.2.2 Functional test of the device

NOTICE

Possible material damage due to faulty condition of the unit.

Carry out a visual inspection before the functional test of the device as described in the

previous chapters.

The work as described in the chapter “Commissioning” must be finished.

The following steps must be carried out in the course of the functional test:

● Switch on the device.

● Pay attention to failures or error messages of the control unit. Also refer the separated

operating manual of the control unit.

● Pay attention to extraneous noises or vibrations during the device´s operation.

● A functional test should always be carried out with a connected / producing machine tool. Check

if the collection of the fume or dust is sufficient. (Visual inspection).

BA_Caremaster-1-und-2_IFA_170831 _EN

21

31.08.2017

Page 22

14.2.3 Electrical test of the electrical lines and earthing connections

WARNING

Danger arising from electricity.

The operator is responsible for ensuring that all work on electric components is carried out

by authorised and qualified personnel.

The device is subject to regular electrical checks by the operator of the device, and are subject to

national standards of the different countries.

The here recommended maintenance interval complies with the in Germany applying "Regulation 3 of

the German Social Accident Insurance - Electrical plants and equipment" (formerly known as BGV-A3).

The check must only be carried out by a qualified electrician or a person trained in electrics using

suitable measuring and test devices. The scope of testing and the methods must be in line with the

respective national standard. All contacts in the control cabinet must be checked for tight fit, and must

be readjusted if necessary.

BA_Caremaster-1-und-2_IFA_170831 _EN

22

31.08.2017

Loading...

Loading...