TeeJet LH665 VRT User Manual

OPERATORS MANUAL

FOR THE

LH 665 VRT

SERIAL APPLICATION CONTROL

LH No. 020-801-UK Version 1.00

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

1 INTRODUCTION

2 GENERAL OPERATION

3 APPLICATION CONTROL, OPERATION

APPLICATION CONTROL, ENCODE &

4

CALIBRATION

9 DGPS

11 DATA CARDS AND DATA MANAGEMENT

12 INDEX

Introduction

INTRODUCTION ..............................................................................................................1.3

MACHINE SETTING CHART ...........................................................................................1.5

NTRODUCTION

I

LH 665 VRT O

PERATORS MANUAL

1.2 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

INTRODUCTION

Congratulations on purchasing the LH 665 advanced DGPS computer.

The LH 665 is an advanced and reliable product, which, - if used in accordance

with this manual – will prove to be a reliable tool for many years to come.

Your new LH 665 is designed to be user friendly, which makes operation easy – in

the form of a large screen, and clearly marked back-lit keys. The LH 665 is

furthermore, upgradeable via a PCMCIA card, which ensures that you can

implement future developments without having to remove the unit from the vehicle.

The LH 665 can be used for yield monitoring as well as application control and

navigation purposes. The LH 665 can furthermore be used with DGPS for

precision farming purposes.

I

NTRODUCTION

This operator's manual is split up so that each function is described individually.

We recommend, that you start by reading the chapter concerning operating the

LH 665. After reading this chapter, You will feel more comfortable operating the

LH 665, which will give you a good foundation for delving further into the LH 665

as described in the remaining chapters describing the individual functions.

A machine-setting chart is included in this manual. This machine setting chart

contains information needed for correct operation and will, as a rule, be filled in by

the engineer when the unit is fitted.

LH A

GRO 1.3

NTRODUCTION

I

We have endeavoured to deliver a fault free product. To ensure optimal use of the

equipment we ask that great attention be paid when reading the manual. We are

more than happy to help should any queries arise, both when the product is used

for the first time and at any later date. Regarding responsibility for use of the

product we refer to our sales and delivery terms especially paragraph 7, which

follows:

7. Product usage.

LH 665 VRT O

• Any use of the product is at the sole risk of the buyer. The

buyer is therefore not entitled to any form for compensation

caused by, for example, any of the following:

• Disturbance to/from any electronic services or products that do

not confirm to the standards for CE marking,

• Missing or poor signal coverage or a succession hereof from

external transmitters/receivers, used by the buyer,

• Functional faults, which apply to or from a PC-program or PCequipment, not delivered by the seller,

PERATORS MANUAL

• Faults that may arise from the buyers negligence to react to

warnings and fault messages from the product, or which can be

traced to negligence and/or absent constant control of the work

carried out in comparison to the planned job.

7.2 When implementing any new equipment the buyer must take great care

and pay attention. Any doubts as to correct operation/use should

result in contacting the sellers service department.

This manual may not be altered, copied or manipulated in any way. Unoriginal

manuals can lead to operational faults damaging machines or crops as a

consequence thereof. LH Agro can therefore not be held responsible for damages

incurred, which can be traced to the use of unoriginal or manipulated manuals.

Original manuals can be requisitioned at any time from LH Agro.

With regards

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 96 96 25 00

Fax. +45 96 96 25 01

1.4 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

I

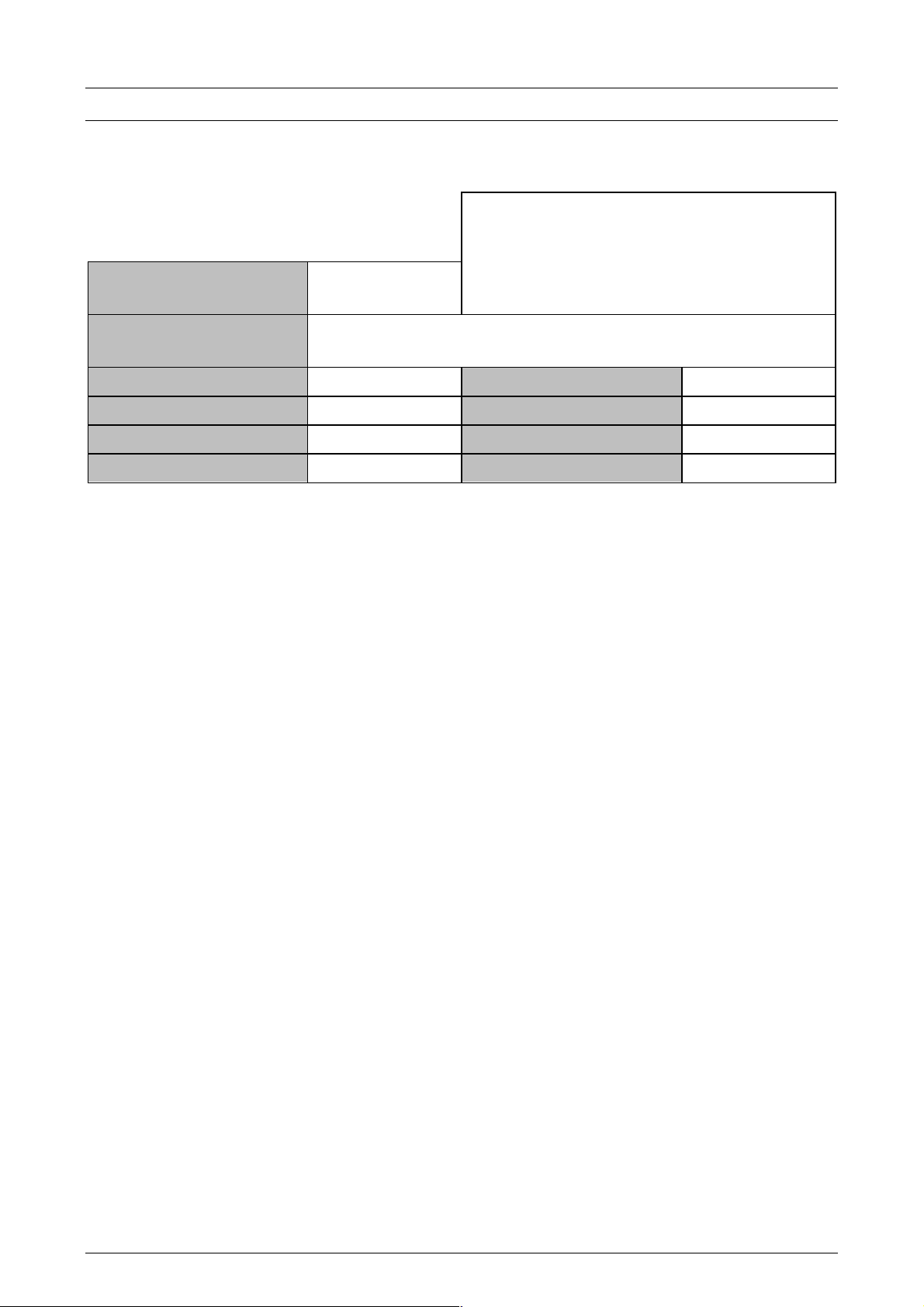

MACHINE SETTING CHART

Machine setting chart: Dealer:

NTRODUCTION

Fitting date:

(Not encoded)

Machine type:

(Not encoded)

Monitor –serial number: Box calibration:

GPS Check Sum OFF Volt calibration:

Primary speed sensor GPS Controller make:

Secondary speed sensor WHEEL Controller model:

! Ensure that the above settings are encoded before work commences.

LH A

GRO 1.5

NTRODUCTION

I

LH 665 VRT O

PERATORS MANUAL

1.6 LH A

GRO

General operation

OVERVIEW ......................................................................................................................2.2

OPERATING THE LH 665 ................................................................................................ 2.3

ON/OFF SWITCH (POS. 1)...................................................................................... 2.3

AREA OVERRIDE SWITCH (POS. 5)......................................................................2.3

THE SCREEN ..........................................................................................................2.3

USING THE KEYS ...................................................................................................2.3

ARROW KEYS (POS. 6)......................................................................................2.4

FUNCTION KEYS (POS. 4) .................................................................................2.4

MENU KEY (POS. 2) ...........................................................................................2.4

MENU SELECTION KEYS (POS. 3)....................................................................2.5

NOTES .............................................................................................................................2.6

ENERAL OPERATION

S

G

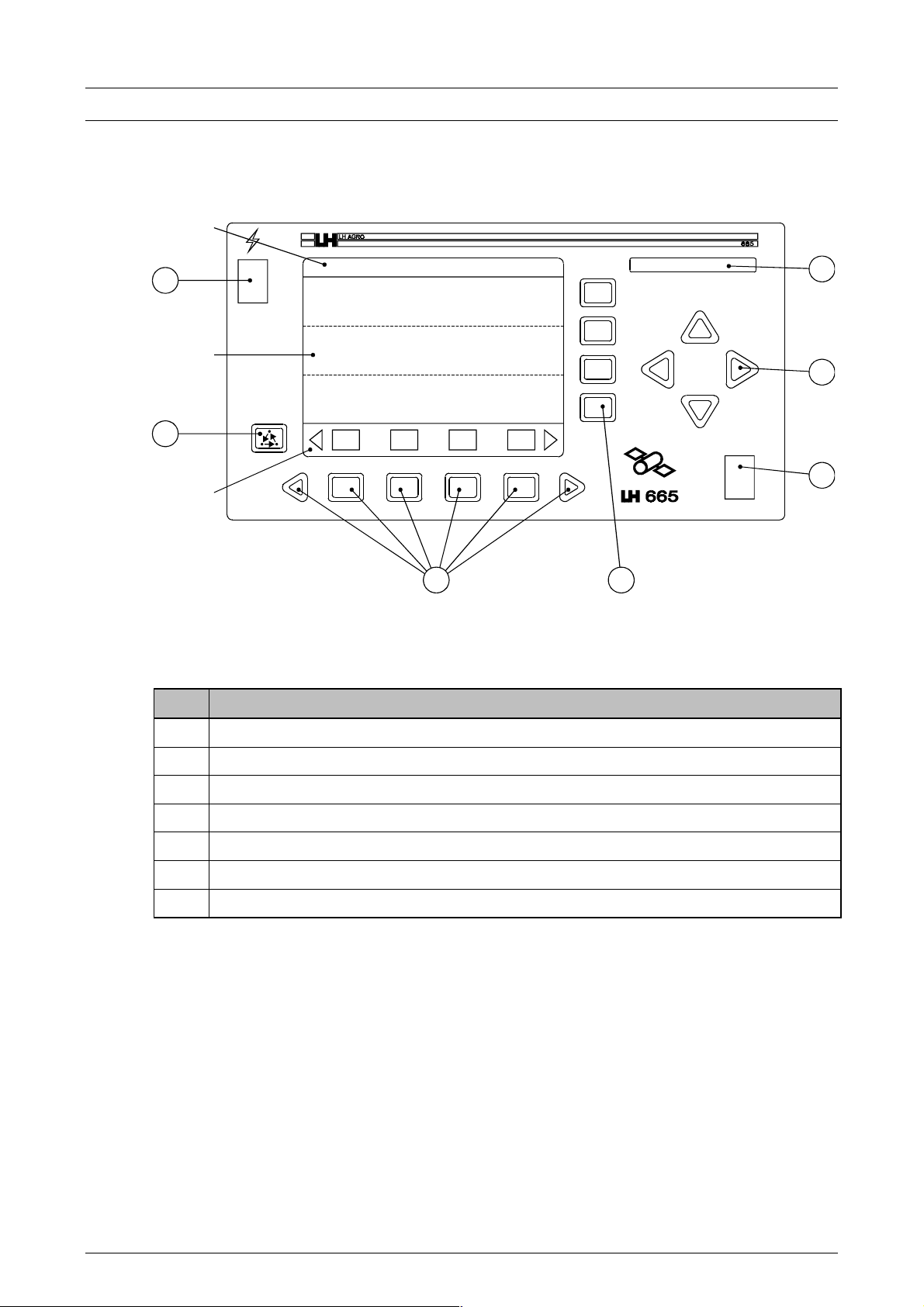

OVERVIEW

creen section A

LH 665 VRT O

PERATORS MANUAL

1

Screen section B

2

Screen section C

Pos. Description

3 4

7

6

5

1 ON/OFF switch.

2 Menu key.

3 Menu selection keys.

4 Function keys.

5 Arrow keys.

6 Area override switch.

7 PCMCIA –drive for data cards.

2.2 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

G

OPERATING THE LH 665

ON/OFF SWITCH (POS. 1)

The LH 665 is switched on and off with the switch positioned in the upper left-hand

corner. The computer will not react if the computer is switched off by mistake

whilst, e.g. copying data until the task is finished.

Note! The possibility to make a back up of data to a data card is given every

time the LH 665 is switched off. Copying the data to a data card is

necessary if the unit is used in connection with DGPS to produce field

maps. Press the COPY key if this is desired. If no backup is required

then simply press the CANCEL key.

AREA OVERRIDE SWITCH (POS. 5)

The switch in the lower right-hand corner is used for manually stopping the area

counter. The area counter status is shown on the display.

ENERAL OPERATION

Note! The computer controlling the implement is fitted with a sensor that

automatically starts and stops the area counter dependant on the

implement status. The manual area override switch should only be

used, therefore, when the signal from the automatic sensor is not

desired.

THE SCREEN

The screen is split into three sections. The top section (A) always shows the field,

load, DGPS status and the data card status.

The middle section (B) shows the functions selected using the function keys (pos.

4).

The lower section (C) shows the function of the menu selection keys (pos. 3); the

grain type being harvested and the area count status.

The middle section (B) can also be split into two using the SHOW/HIDE MAP key.

Pressing the SHOW MAP key will display a map of the field if DGPS equipment is

connected.

USING THE KEYS

The LH 665 is operated using “soft keys” (the function of the key changes in

relation to the operating program). There are four main groups; arrow keys,

function keys, menu key, menu selection keys.

LH A

GRO 2.3

ENERAL OPERATION

G

LH 665 VRT O

ARROW KEYS (POS. 6)

The UP, DOWN, LEFT and RIGHT arrow keys on the right-hand side of the panel

are used to select and alter a setting. The right and left arrow keys at the bottom of

the panel are used to page through the menu selections and are never used to

select or alter a setting.

An arrow symbol is displayed in the main operating screen next to the field or the

load; this symbol indicates what is altered by pressing the arrow keys.

FUNCTION KEYS (POS. 4)

PERATORS MANUAL

Screen section B on the LH 665 has four sub-sections. The function/information

displayed in these sections is determined with the function keys.

To alter the displayed function/information, the sub-section has to be selected. The

four sub-sections are next to the function keys and pressing one of the function

keys will highlight the section that corresponds to the function key.

Once a section has been highlighted, use the menu election keys to determine

which function/information the section will have. Pressing the lower arrow keys

pages through the available functions/information.

Some functions, e.g. working width, also display an arrow symbol on the righthand side of the function. This indicates that the function can be altered using the

ARROW UP/DOWN keys. Press the function key to the right of the function to

leave this function.

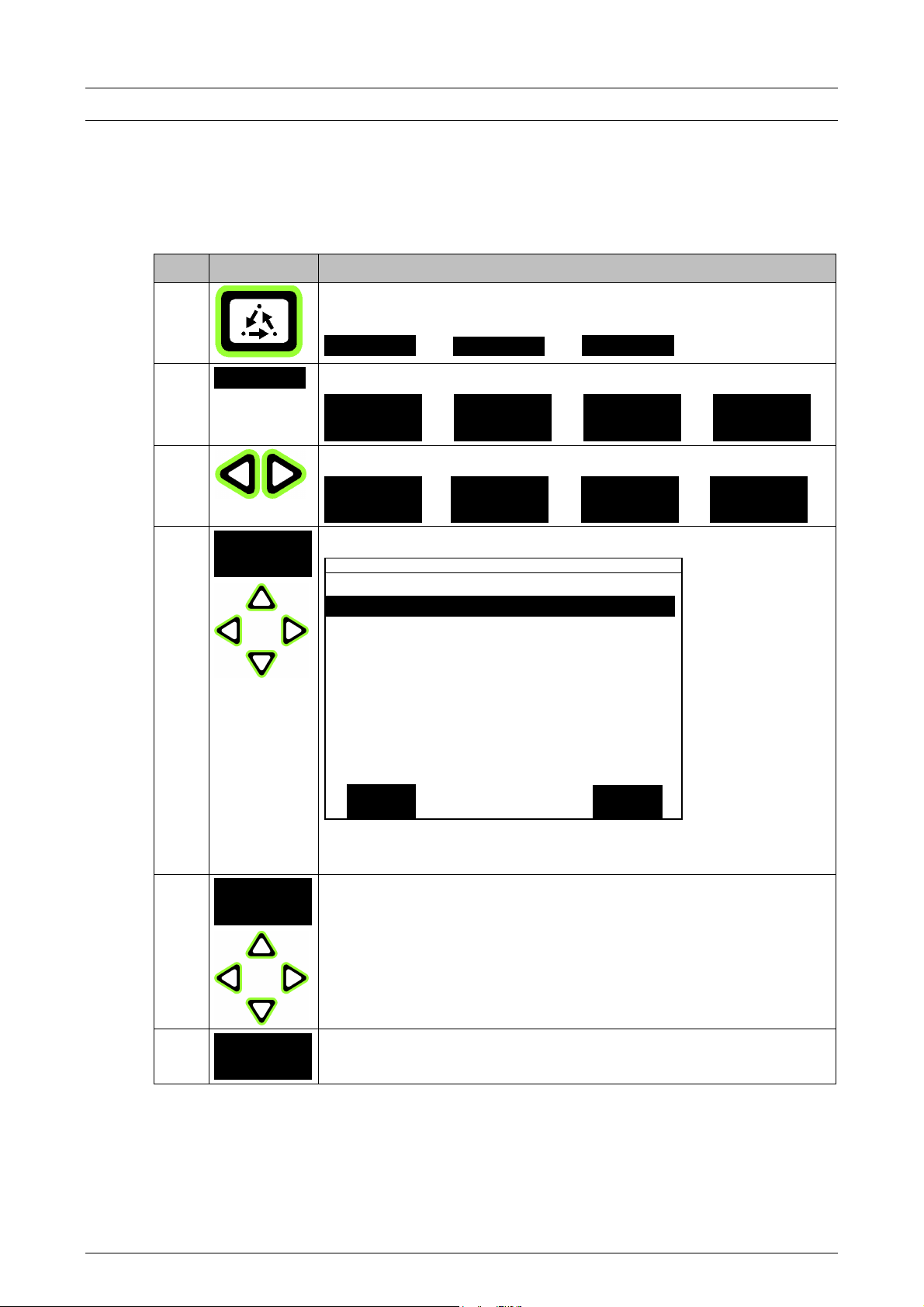

MENU KEY (POS. 2)

Repeatedly pressing the menu key alters the function of the menu keys. It is

possible to page through the available menus by pressing the MENU key.

Key Function

Repeatedly pressing this key pages through the following options:

FIELD LOAD OPTIONS HIDE MAP

CAL SETUP DIAG.

2.4 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

G

MENU SELECTION KEYS (POS. 3)

ENERAL OPERATION

The function of the menu selection keys alters depending on what is being done

on the computer.

The horizontal arrow keys at the bottom of the panel are used to display more

menu options. An arrow displayed over the lower arrow keys indicates that

pressing the arrow keys will display more options.

LH A

GRO 2.5

ENERAL OPERATION

G

NOTES

LH 665 VRT O

PERATORS MANUAL

2.6 LH A

GRO

Application control,

operation

THE APPLICATION CONTROL PROGRAM....................................................................3.2

DATA PER FIELD ....................................................................................................3.2

OPERATION.....................................................................................................................3.3

SETTING THE LH 665 TO APPLICATION CONTROL ............................................3.3

DEFINING FIELDS BEFORE START ...................................................................... 3.4

STARTING AND NAMING FIELDS..........................................................................3.5

START NEW FIELD .................................................................................................3.5

START NEW LOAD .................................................................................................3.6

USING LOAD NUMBERS ........................................................................................3.6

CHANGING BETWEEN THE ENCODED FIELD AND LOAD NUMBERS ...............3.7

CHANGE FIELD...................................................................................................3.7

CHANGE LOAD...................................................................................................3.7

SELECTING THE TARGET FILE............................................................................. 3.7

MARKERS................................................................................................................3.8

THE CONNECTION BETWEEN FIELD AND LOAD KEYS......................................3.9

FUNCTION KEYS .................................................................................................. 3.10

TARGET RATE..................................................................................................3.10

ACTUAL RATE ..................................................................................................3.10

AREA .................................................................................................................3.10

WORKING WIDTH.............................................................................................3.11

TOTAL UNITS.................................................................................................... 3.11

GROUND SPEED .............................................................................................. 3.11

AREA PER HOUR .............................................................................................3.11

DISTANCE.........................................................................................................3.11

TGT FILE RATE.................................................................................................3.12

GPS INFORMATION .........................................................................................3.12

LAT/LON ............................................................................................................3.12

COMPASS HEADING........................................................................................3.12

ELEVATION.......................................................................................................3.13

CARD INFORMATION.......................................................................................3.13

DATE/TIME........................................................................................................3.13

TARGET FILE....................................................................................................3.13

FIELD NAME......................................................................................................3.13

LOAD NAME......................................................................................................3.14

LIGHT BAR PASS NUMBER .............................................................................3.14

MAP ZOOM........................................................................................................3.14

DIAGNOSTICS ...............................................................................................................3.15

SYSTEM DIAGNOSTICS.......................................................................................3.15

SENSOR DIAGNOSTICS.......................................................................................3.16

GPS DIAGNOSTICS ..............................................................................................3.16

RAW NMEA............................................................................................................3.17

PPLICATION CONTROL

A

, OPERATION LH 665 VRT O

IMPORTANT

Correct encodement and calibration of the LH 665 are essential before

correct operation of the following functions.

The procedure for encoding and calibration of the LH 665 are described in the

respective chapters in this operator’s manual.

THE APPLICATION CONTROL PROGRAM

The most important functions for application control are:

Application rates

Area

PERATORS MANUAL

• Target rate

• Actual rate

• Average actual rate

• Total units

Forward speed

• Kilometres per hour

• Distance

Other functions

• Date and time

• Map zoom

DATA PER FIELD

• Area covered for the field

• Actual working width

• Hectare per hour

All application control data is connected to a field number, this is to ease data

registration.

• Each field has a number and can be given a name.

• Each field can use only one application task.

• Each field can be split into loads.

• Each load can be, e.g. a spreader full, a hopper load, etc.

• Each load has a number and can be given a name.

• The sum of, i.e. the area, the distance, etc. for each individual

load, is equal to the total for the field.

3.2 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

A

OPERATION

SETTING THE LH 665 TO APPLICATION CONTROL

The LH 665 may need setting up for application control. The following procedure

sets the computers “operating mode”.

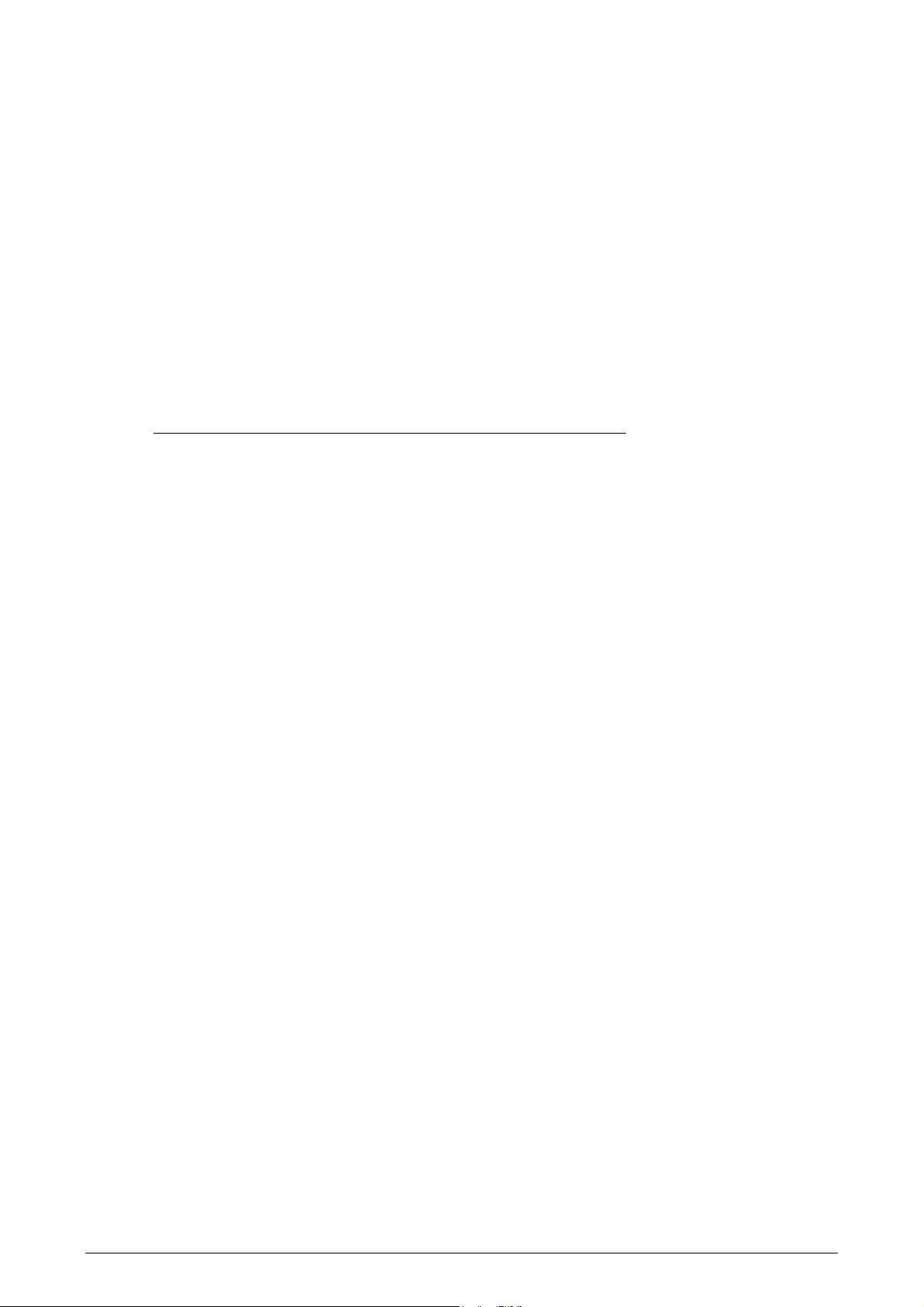

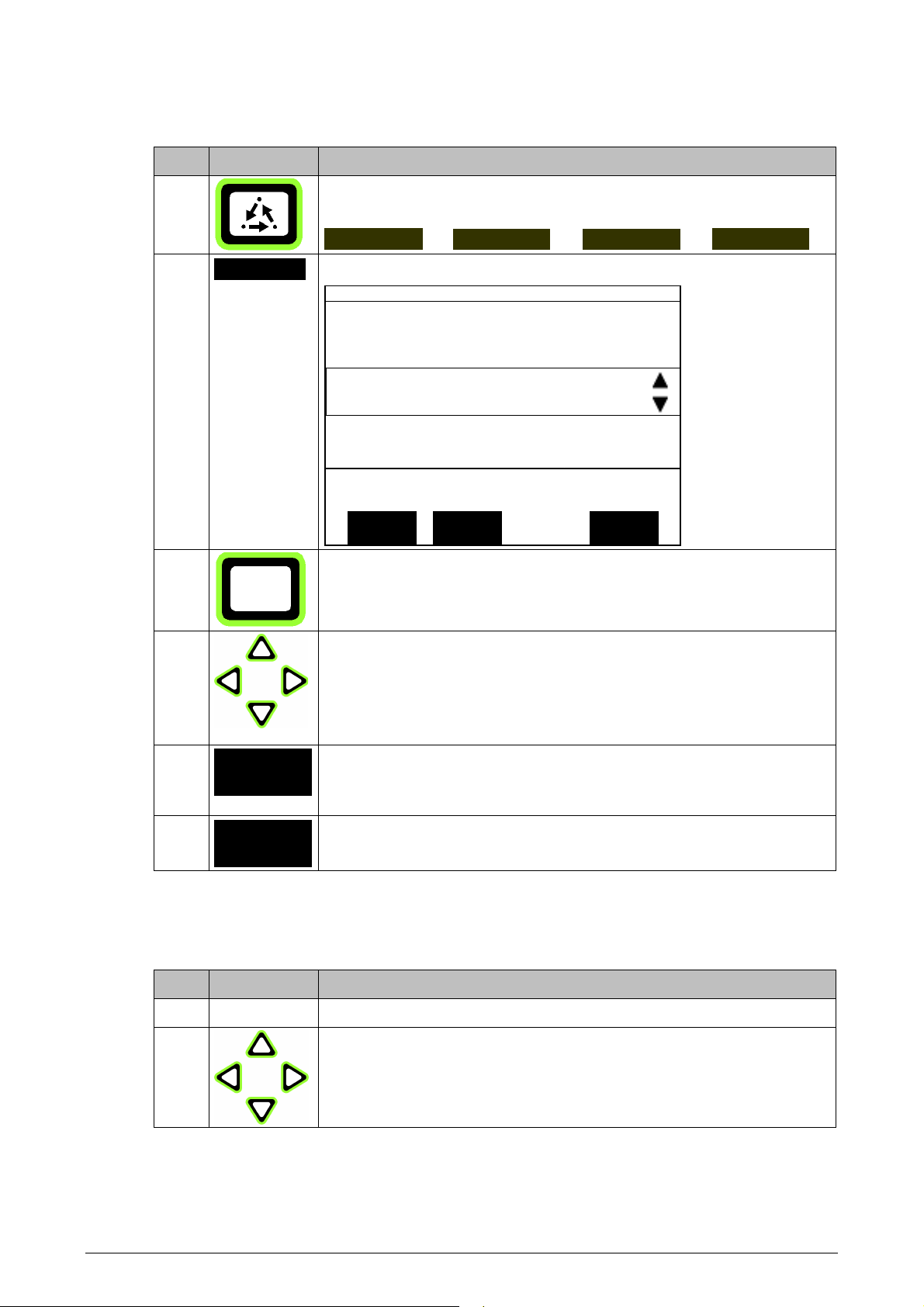

Step Key Procedure

PPLICATION CONTROL

, OPERATION

1

2

3

4

SETUP

CONSOLE

Press the MENU key until the following menu selection keys

appear at the bottom of the display (screen section C):

CAL SETUP

Press the SETUP key to display the following:

SWATH

MARKS CROP CARD

DIAG

Press the lower ARROW keys until the following is displayed:

LOAD VEHICLE MEMORY CONSOLE

Press the MONITOR key and this screen is displayed:

CONSOLE SETUP

Operating Mode APPLICATION RATE

Day/Month/Year 1/06/1999

Time 11:23

Serial Number 9800085

Box cal. 774

Voltage cal. 487

GPS Check Sum OFF

Field Marker input INTERNAL

EDIT

EXIT

Use the ARROW UP/DOWN keys to highlight Operating

Mode.

5

EDIT

Press the EDIT key and select APPLICATION RATE

using the ARROW UP/DOWN keys.

6

ACCEPT

When APPLICATION RATE has been selected under

Operating Mode press the ACCEPT key.

LH A

GRO 3.3

PPLICATION CONTROL

A

, OPERATION LH 665 VRT O

DEFINING FIELDS BEFORE START

It is practical to encode all fields (with names if required) before work commences.

Field numbers are controlled by the LH 665 and are shown on the upper left-hand

side of the display (screen section A) (F1:, F2:,etc). To the right of the field number

a name of max. 8 characters can be encoded (i.e. F1: TOPFIELD).

It is easiest to use the field numbers that are allocated in the farm’s field plans if

this is possible. In practice many fields in the field plans are split up into smaller

“part” fields and these lots are allocated an extra level, e.g. F1.1, F1.2, etc. In

these cases, the field name in the LH 665 can be utilised to organise the field

numbers in the LH 665 in relation to the field numbers in the field plans.

Example:

Field no. in the LH 665 Field name in the LH 665

F1: F1.1

F2 F1.2

PERATORS MANUAL

F3 F2

The field number encoded in the field name is the same as the field number in the

farm’s field plans.

255 fields can be stored in the LH 665. Do not start more fields than necessary in

the LH 665, as they cannot be deleted individually and take up space in the

memory.

3.4 LH A

GRO

LH 665 VRT O

PERATORS MANUAL

A

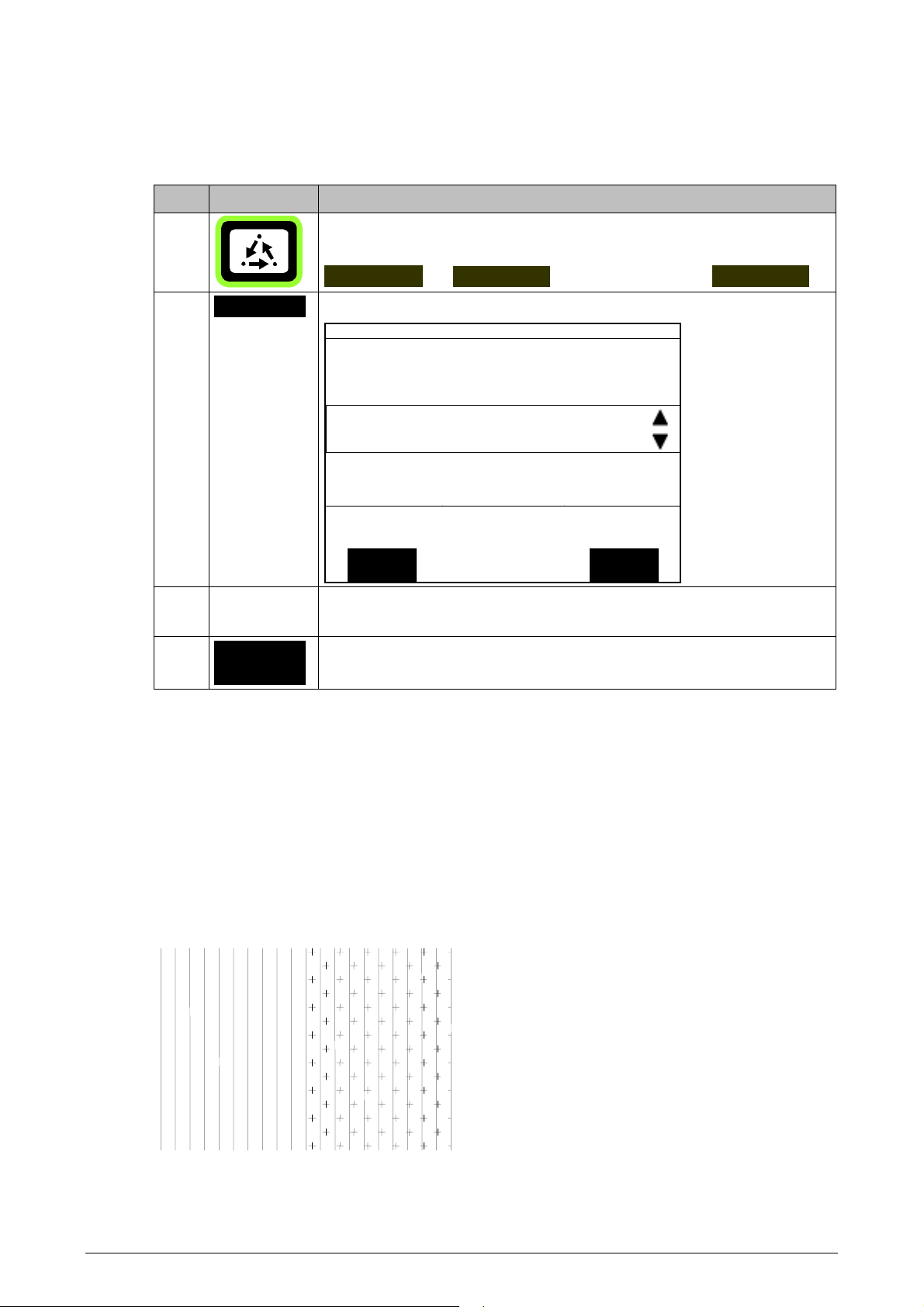

STARTING AND NAMING FIELDS

Step Key Procedure

PPLICATION CONTROL

, OPERATION

1

2

3

4

FIELD

Press the MENU key until the following menu selection keys

appear at the bottom of the display (screen section C):

FIELD LOAD OPTIONS HIDE MAP

Press the FIELD key twice to show the following screen:

F1: DG

F1:

PRESS

PRODUCT CONTROLLER CHANNEL

PRODUCT 1 LH 5000 N/A

ACCEPT CANCEL

ACTIVE FIELD

TO EDIT NAME

ACTIVE CONFIGURATION

VIEW

CONFIG

If there is not a rectangular box around the field section press

the function key to the right of the section.

Press the right ARROW key to move the cursor and use,

thereafter, the ARROW UP/DOWN keys to select the letter.

Move the cursor to the right using the right ARROW key. The

field name can have max. 8 characters. If the active

configuration is correct, press the ACCEPT key.

5

VIEW

CONFIG

If the configuration is incorrect and needs changing, press

the VIEW CONFIG key and follow the steps 4 to 7 as

described on page 3.7.

6

ACCEPT

Press the ACCEPT key.

START NEW FIELD

Step Key Procedure

1 Follow steps 1 – 3 as described above.

2

Press the ARROW UP key until CREATE NEW FIELD is

displayed. Name the field and select the correct crop type as

described above, press the ACCEPT key.

LH A

GRO 3.5

PPLICATION CONTROL

A

START NEW LOAD

The procedure for starting new loads is almost the same as described above for

starting new fields.

Step Key Procedure

, OPERATION LH 665 VRT O

PERATORS MANUAL

1

Press the MENU key until the following menu keys are

displayed at the bottom of the screen (screen section C).

FIELD LOAD MARKS

Press the LOAD key twice to display the following screen:

F1: L1: DG

L1:

PRESS

PRODUCT CONTROLLER CHANNEL

PRODUCT 1 LH 5000 N/A

ACCEPT CANCEL

ACTIVE LOAD

TO EDIT NAME

ACTIVE CONFIGURATION

2

LOAD

3 The loads can be named and the procedure for this is the

same as for naming fields.

4

ACCEPT

Press the ACCEPT key.

Note! We recommend creating new loads as the need arises and not like

fields before harvest.

USING LOAD NUMBERS

Typically the fields will be worked as one load. It is not necessary to split the fields

into loads unless it is required. The following example shows a field split into two

loads.

Example of a field split into two loads:

Load 1

Load 2

This example shows how it is possible to

split a field into two different loads.

The marked area (load 2) shows an area

of the field that was, e.g. wet.

3.6 LH A

GRO

Loading...

Loading...