Page 1

Control

TECHNOLOGIES 834-P Sprayer

834-P Sprayer Control

User Guide (Y1.04)

ALARM

speed

pressure

MPH

min

RPM

Man

Auto

98-70028-R0

GPA

GPT

inch

gal/min

lbs/rot

@40psi

PROGRAM MODE push 3 sec.

1

2

SPEED

RPM

p/300ft

p/rot

PSI

MPH

min

RPM

3

834-P

SPRAYER CONTROL

On

4

5

adjust

value

Page 2

834-P Sprayer Control TECHNOLOGIES

Table of Contents

Normal Working Mode (GPT Mode) _____________________________________________________ 3

Introduction _______________________________________________________________________________ 3

Target Application Rate Display ______________________________________________________________ 3

Speed/RPM Display (GPT mode) ______________________________________________________________ 4

Pressure Display (GPT mode) ________________________________________________________________ 4

Normal Working Mode (GPA Mode)_____________________________________________________ 4

Introduction _______________________________________________________________________________ 4

Target Application Rate Display ______________________________________________________________ 5

Speed/RPM Display (GPA mode)______________________________________________________________ 6

Pressure Display (GPA mode) ________________________________________________________________ 6

Operating Instructions__________________________________________________________________ 7

The Spraying Operation _____________________________________________________________________ 7

Automatic Power Down_________________________________________________________________ 7

Alarms and Warnings ___________________________________________________________________ 8

Programming Guidelines _______________________________________________________________ 9

Console Programming (GPT Mode) ____________________________________________________ 10

System Setup Mode (GPT mode) ______________________________________________________ 11

Operating Mode___________________________________________________________________________ 11

Minimum RPM ____________________________________________________________________________ 11

Shaft Sensor Calibration ___________________________________________________________________ 12

Spray Tip Capacity ________________________________________________________________________ 12

Pounds Per Rotation_______________________________________________________________________ 12

Console Programming (GPA Mode)____________________________________________________ 13

System Setup Mode (GPA mode) ______________________________________________________ 14

Operating Mode___________________________________________________________________________ 14

Minimum MPH ____________________________________________________________________________ 14

Speed Sensor Calibration___________________________________________________________________ 15

Auto Calibration _________________________________________________________________________ 15

Radar _________________________________________________________________________________ 16

Manual Calculation_______________________________________________________________________ 16

Simulated Speed ________________________________________________________________________ 16

Spray Tip Capacity ________________________________________________________________________ 17

Swath Width______________________________________________________________________________ 17

98-70028-R0 2

Page 3

TECHNOLOGIES 834-P Sprayer Control

Normal Working Mode (GPT Mode)

Note: This section covers operation of the 834-P in Gallons Per Ton mode.

Operating instructions for Gallons Per Acre mode can be found on page 6.

INTRODUCTION

In the Gallons Per Ton (GPT) normal working mode, the display can show three different

pieces of information indicated by the LED’s below the display e.g.:

Application rate in GPT

Shaft RPM

Pressure in PSI

Use of the keys during normal working mode is summarized as follows:

key is used to power ON and to select the information display

Auto/Man & key combination is used to power OFF (when not spraying)

+

and keys are used for changing the target application.

In manual mode the + and keys drive the regulating valve to adjust pressure.

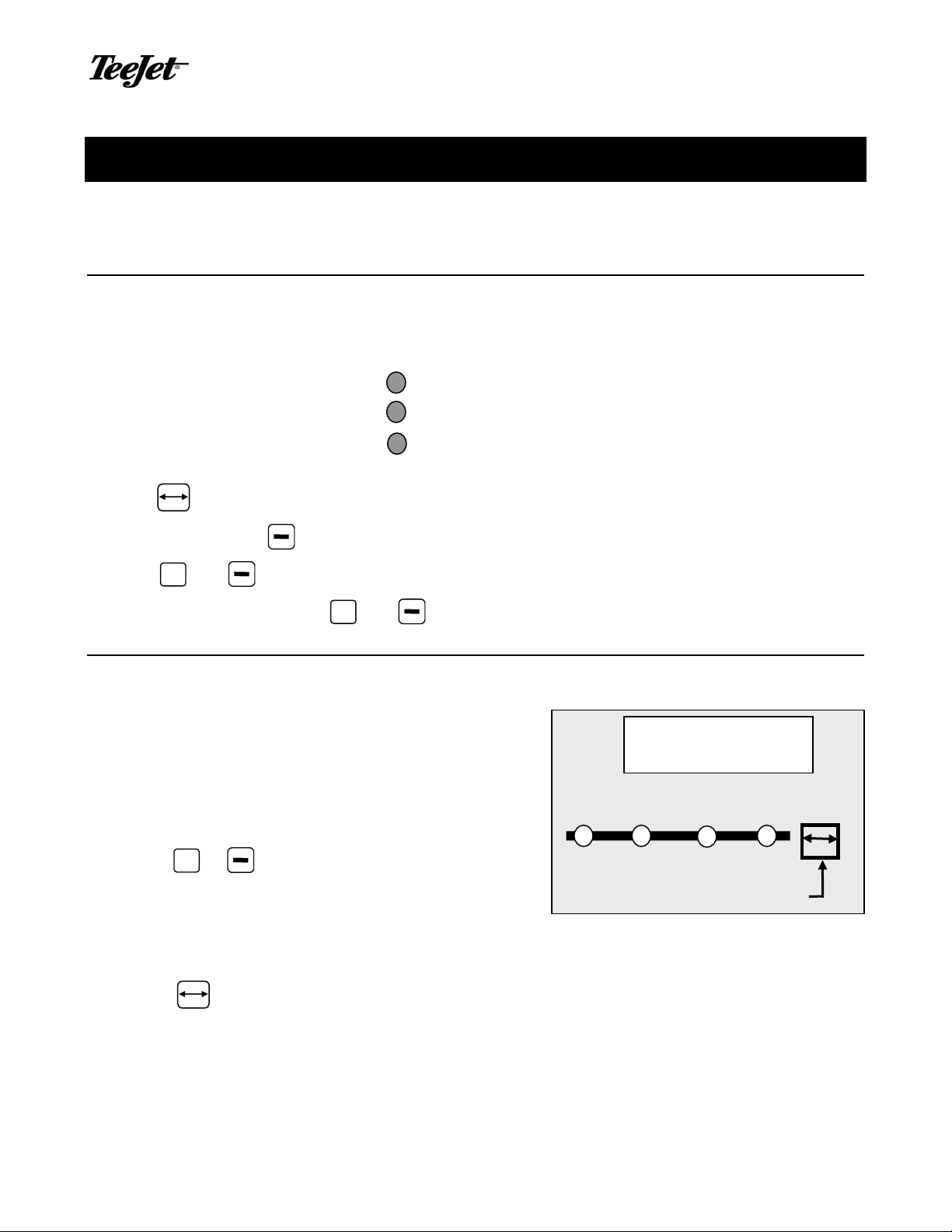

TARGET APPLICATION RATE DISPLAY

In this display the application rate in gallons per ton

(GPT) is shown. The target application rate will be

displayed any time the master boom switch is in the

off position (a "t" is on the display when the target

application rate is displayed). When the master

switch is on, no “t” is on the display and the actual

application rate is displayed.

+

Press the

application rate. This can be done before the

spraying operation begins with the Master

switch off or can be done on the go while spraying

in Auto mode.

Press the key to advance to the speed/rpm display.

or keys to select another target

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

MPH

RPM

On

3 98-70028-R0

Page 4

834-P Sprayer Control TECHNOLOGIES

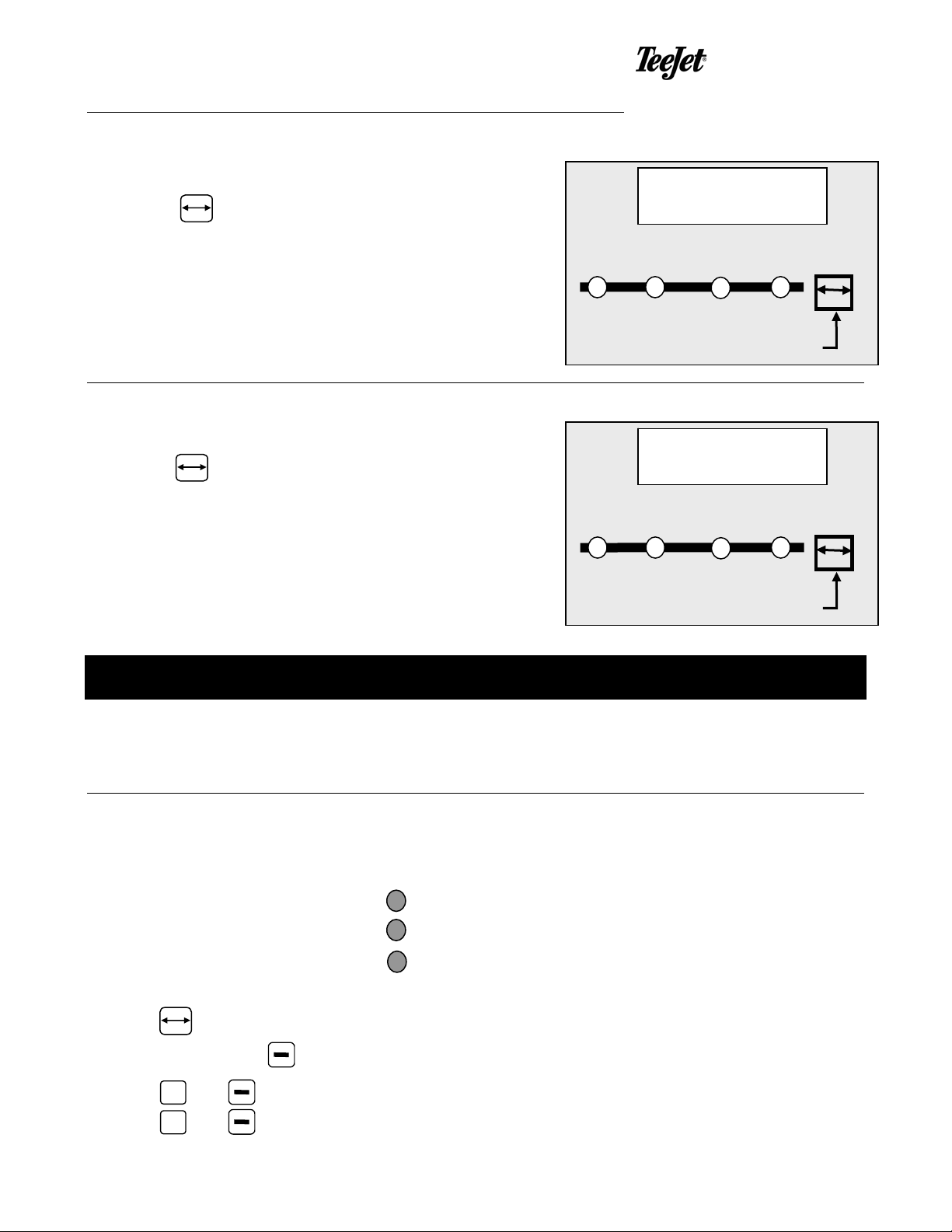

SPEED/RPM DISPLAY (GPT MODE)

In this display the shaft RPM is shown on the display.

Press the key to advance to the pressure display.

PRESSURE DISPLAY (GPT MODE)

In this display the pressure is shown in PSI.

Press the key to advance back to the rate display.

Normal Wor king Mode (GPA Mode)

tip

select

Inch

lbs/rot

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

min

MPH

RPM

MPH

RPM

On

On

Note: This section covers operation of the 834-P in Gallons Per Acre

mode. Instructions for Gallons Per Ton mode can be found on page 3.

INTRODUCTION

In the Gallons Per Acre (GPA) normal working mode, the display can show three different

pieces of information indicated by the LED’s below the display e.g.:

Application rate in GPA

Ground Speed

Pressure in PSI

Use of the keys during normal working mode is summarized as follows:

key is used to power ON and to select the information display

Auto/Man & key combination is used to power OFF (when not spraying)

+

98-70028-R0 4

and keys are used for changing the target application. In manual mode the

+

and keys drive the regulating valve to adjust pressure.

Page 5

TECHNOLOGIES 834-P Sprayer Control

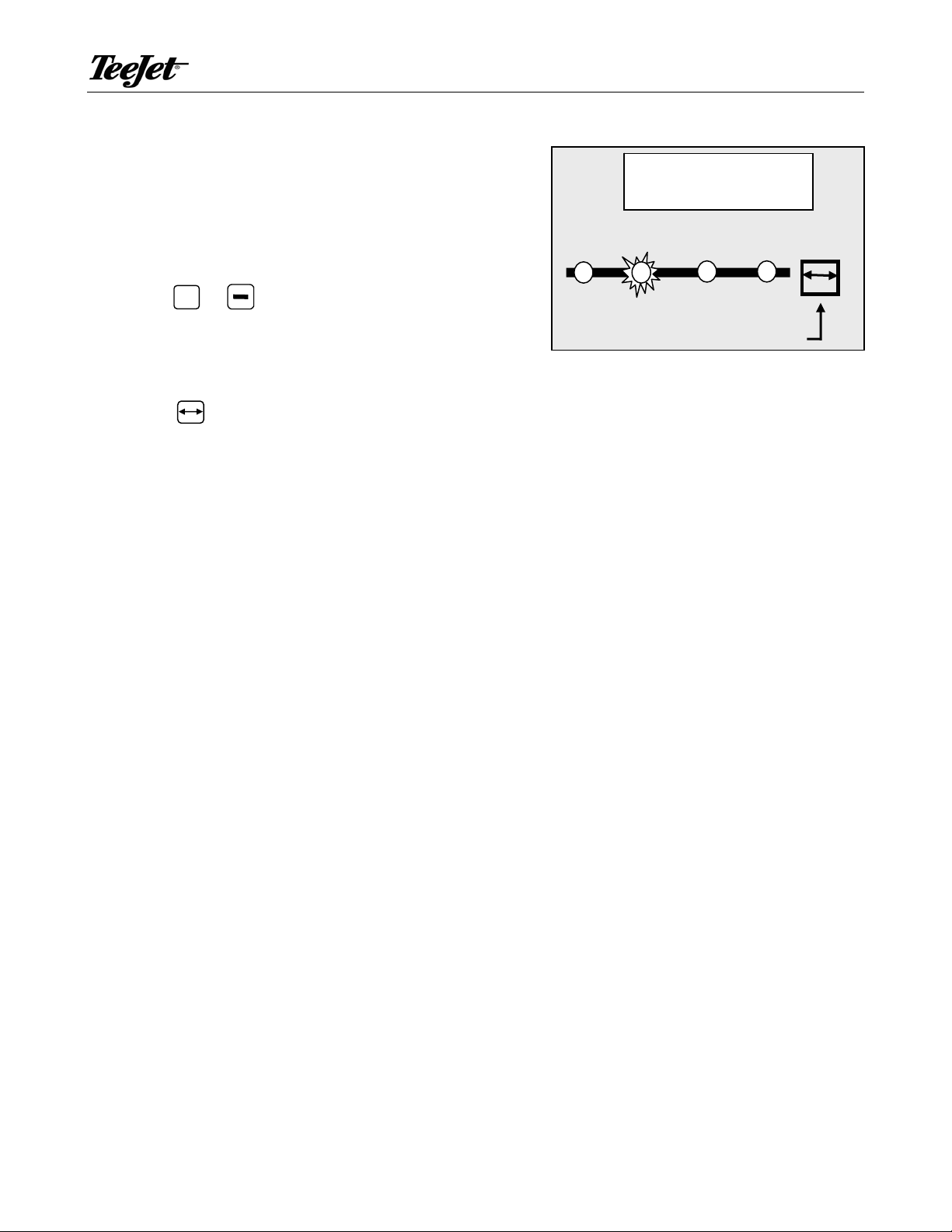

TARGET APPLICATION RATE DISPLAY

In this display the application rate in gallons per acre

(GPA) is shown. The target application rate will be

displayed any time the master boom switch is in the

off position (a "t" is on the display when the target

application rate is displayed). When the master

switch is on, no “t” is on the display and the actual

application rate is displayed.

Press the + or keys to select another target

application rate. This can be done before the

spraying operation begins with the Master

switch off or can be done on the go while spraying

in Auto mode.

Press the key to advance to the speed display.

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

MPH

RPM

On

5 98-70028-R0

Page 6

834-P Sprayer Control TECHNOLOGIES

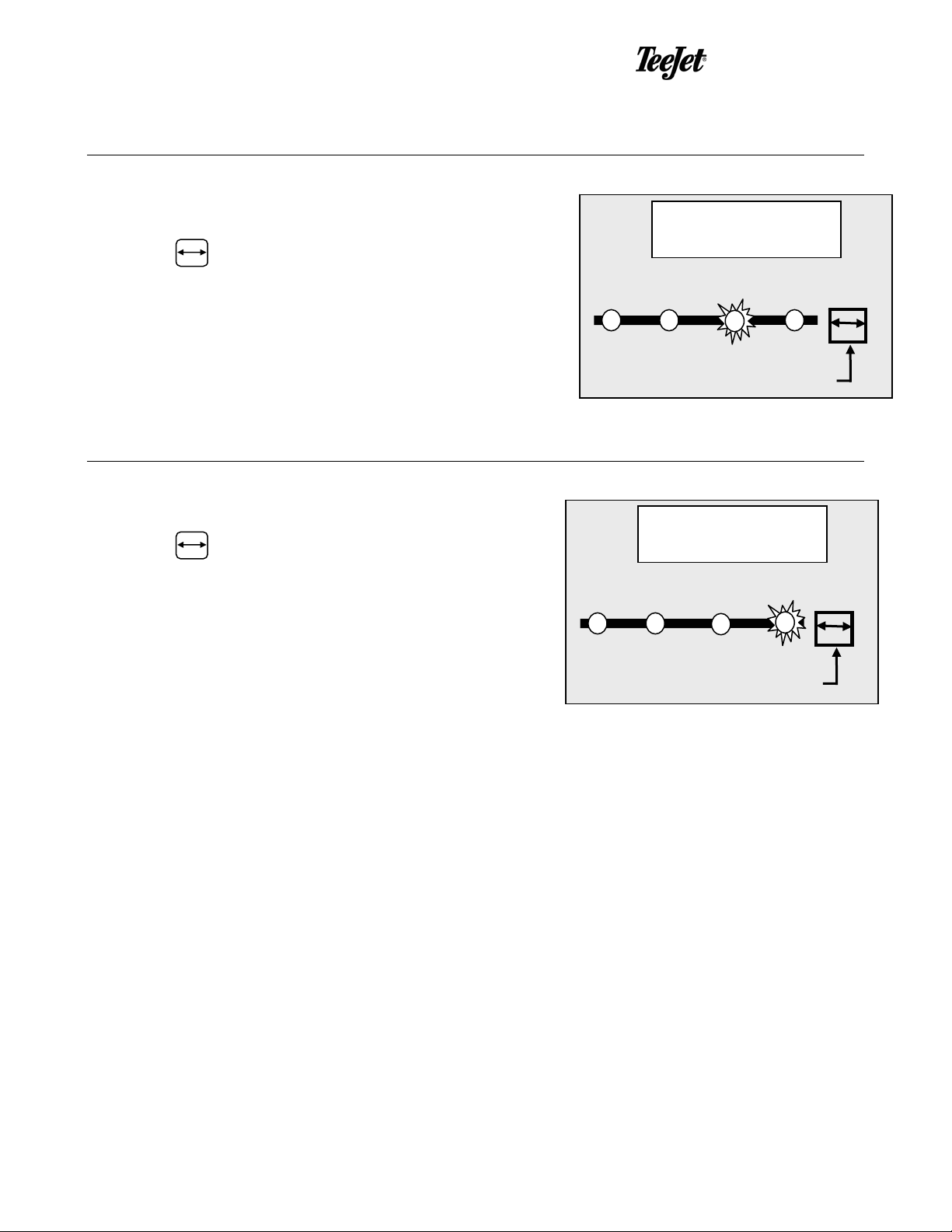

SPEED/RPM DISPLAY (GPA MODE)

In this display the vehicle speed is shown in MPH.

Press the key to advance to the pressure display.

PRESSURE DISPLAY (GPA MODE)

In this display the pressure is shown in PSI.

Press the key to advance back to the rate display.

tip

select

Inch

lbs/rot

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

min

MPH

RPM

MPH

RPM

On

On

98-70028-R0 6

Page 7

TECHNOLOGIES 834-P Sprayer Control

Operating Instructions

THE SPRAYING OPERATION

Fill the sprayer tank and thoroughly mix the chemical(s). Your application rate should be

determined as well as the spray tip you will be using, with the sprayer data programmed into

the computer.

Switch the computer on by pressing the key on the display panel.

While spraying with the Master switch “ON”, you can scroll through the different displays

using the key until the information you want is on the display :

♦ actual application rate in GPT or GPA

♦ vehicle speed in MPH or shaft RPM

♦ pressure in PSI

Adjust the target application rate with the + and

Switch the Master boom switch to “ON” position to start spraying. Maintain your usual vehicle

speed for spraying. Use the + or keys to boost the application rate if needed. Small

changes in vehicle speed are compensated by the automatic rate controller while spraying in

Auto mode. Manual mode allows the operator to manually adjust system pressure by using

the + and

If for any reason you need to stop, turn the MASTER BOOM SWITCH to “OFF.”

keys.

keys.

Automatic Power Down

The TeeJet 834-P Sprayer Monitor has an automatic power down feature. With the Master

switch in the “OFF” position, the Console will automatically shut down after 10 minutes of no

inputs (when in normal working mode). This prevents possible battery drainage. Note that the

console will not power down while in programming mode.

You can also power down the controller by the following key combination: press

simultaneously the Auto and

with the Master switch OFF).

keys and the Console will power down immediately (only

Warning: Do not switch off the console by removing the main cable!

7 98-70028-R0

Page 8

834-P Sprayer Control TECHNOLOGIES

Alarms and Warnings

On the 834-P Console there are three LED's for indication of alarms or warnings.

• The Speed alarm LED flashes when no speed pulses are

received during spraying (Master in the ON position). This

indicates that there is something wrong with the speed sensor

or that you are standing still while spraying.

Note: When this alarm is triggered, the display will

automatically switch the application display to view

speed (if not currently viewing speed) and the speed

display will flash off and on as well. This allows the

operator to immediately determine the location of the

problem.

• The Pressure alarm LED flashes when the signal from the

pressure sensor is absent while spraying (Master in

the ON position). This indicates that the pressure sensor is

not working properly, or that the connection with the sensor

has been lost.

Note: When this alarm is triggered, the display will

automatically switch the application display to view

pressure (if not currently viewing pressure) and

the pressure display will flash off and on as well.

This allows the operator to immediately determine

the location of the problem.

• The minimum RPM/MPH LED is lit when the programmed

minimum speed or RPM has been reached. When this LED is lit,

the pump has been switched off.

Speed

Pressure

MPH

min

RPM

Speed

Pressure

MPH

min

RPM

Speed

98-70028-R0 8

Pressure

MPH

min

RPM

Page 9

TECHNOLOGIES 834-P Sprayer Control

Programming Guidelines

Make sure that all hardware components are properly installed and tested. Before you start

the programming process you should first check if the console and all sensors are working

properly.

Important Preliminary Information

Before you begin, we recommend that you review the following Programming Guidelines that

control the programming process:

The key is used to power the console ON

Auto & simultaneous key combination is used to power OFF (Master boom switch

must be in the off position)

Holding key for 3 seconds is used to enter programming mode

The white text above the indicator LEDs on the front panel refers the the data displayed

in normal working mode. Look at the white colored text labels whil in normal operating

mode.

The gold text below the indicator LEDs on the front panel refers to the value being set in

programming mode. Look at the gold colored text labels while in programming mode.

Pressing the key saves the current parameter and advances to the next

programming step during programming mode

The value of a parameter is changed with the + and keys. Holding the + or

key changes the parameter rapidly.

9 98-70028-R0

Page 10

834-P Sprayer Control TECHNOLOGIES

Console Programming (GPT Mode)

To begin the programming process:

Be sure the Master boom switch is “OFF.”

Turn console “ON” by pressing the key. When the control console is turned on, the

software version will be displayed for approximately 5 seconds. At the same time all

LED’s will be ON.

The software version and serial number of the console will be needed when calling for

support. The serial number is located on a sticker on the back of the console.

tip

select

GPA

GPT

SPEED

RPM

On

Inch

lbs/rot

Gal/min

@40 psi

P/300ft

P/rot

min

MPH

RPM

PROGRAM MODE push 3 sec.

Example: the software version is Y1.04.

After a short time the console will change to the target application rate display.

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

MPH

RPM

On

98-70028-R0 10

Page 11

TECHNOLOGIES 834-P Sprayer Control

System Setup Mode (GPT mode)

The System Setup Mode contains the programming steps that customize the controller to the

sprayer or sprayer components. These include calibration steps and parameters that, once

programmed, are not likely to change.

To enter the System Setup Mode:

First be sure that the console is ON (if not turn it on by pressing the key and wait

until the normal display is visible).

Ensure the Master boom switch is OFF.

Then press and hold the key for 3 seconds to enter the Program Mode.

OPERATING MODE

The 834-P can operate in either of two modes. They

are GPT (gallons per ton), used for pre-wetting

applications, or GPA (gallons per acre)used for

agricultural or anti-icing applications.

Use the + or

keys to adjust this value. Once

the correct mode has been selected, press

the key to advance to the next step. If

operating in GPA mode, skip ahead to page 14.

MINIMUM RPM

The 834-P can be set to automatically switch off the

flow of liquid when the salt/sand auger shaft slows

below a minimum speed. This feature prevents

liquid from being applied when the salt/sand

spreader is switched off.

+

Use the

or

shaft RPM below which the pre-wetting spray should

be switched off.

keys to adjust this value to the

tip

select

Inch

lbs/rot

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

min

MPH

RPM

MPH

RPM

On

On

11 98-70028-R0

Page 12

834-P Sprayer Control TECHNOLOGIES

SHAFT SENSOR CALIBRATION

The shaft speed sensor needs to be calibrated in order to provide the proper speed reading.

The value for this step is the number of pulses generated by the shaft speed sensor in one

revolution. For example, if the shaft speed sensor is mounted to sense the teeth of a

sprocket, enter the number of teeth on that sprocket.

SPRAY TIP CAPACITY

Enter the combined capacity of all nozzles on the system. This should be measured in

Gallons Per Minute at 40 PSI. These capacities can be obtained from the nozzle

manufacturer’s catalog..

+

Use the

press the key to advance to the next step.

Example: Two 8004 nozzles would have a combined capacity of .8 GPM at 40 PSI.

or

keys to adjust this value. Once the correct units have been selected,

POUNDS PER ROTATION

In order to apply liquid at a fixed proporation to the dry material being applied, the controller

must be able to associate the amount of dry material applied with each rotation of the shaft.

To determine this number, operate the dry spreader. Allow the shaft to turn several

revolutions and weight the material applied. Divide the total weight by the number of shaft

rotations to determine pounds per rotation (lbs/rot).

Auto-Calibration

This value can be determined by an automatic calibration sequence. To perform this

operation:

+

a) Push the

b) Press the + key to start calibration.

c) Dispense exactly 100 lbs of material, then press

controller will automatically calculate the number of lbs/rot.

d) Press select key to accept value and conclude programming.

This concludes the programming of your 834-P for prewetting applications. The target

application rate in Gallons per Ton (GPT) can be set any time the master switch is off by

pressing the + or

and keys simultaneously. The display will show a blinking CAL.

+

again to stop calibration. The

keys.

98-70028-R0 12

Page 13

TECHNOLOGIES 834-P Sprayer Control

Console Programming (GPA Mode)

To begin the programming process:

Be sure the Master boom switch is “OFF.”

Turn console “ON” by pressing the key. When the control console is turned on, the

software version will be displayed for approximately 5 seconds. At the same time all

LED’s will be ON.

The software version and serial number of the console will be needed when calling for

support. The serial number is located on a sticker on the back of the console.

tip

select

GPA

GPT

SPEED

RPM

On

Inch

lbs/rot

Gal/min

@40 psi

P/300ft

P/rot

min

MPH

RPM

PROGRAM MODE push 3 sec.

Example: the software version is Y1.04.

After a short time the console will change to the target application rate display.

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

MPH

RPM

On

13 98-70028-R0

Page 14

834-P Sprayer Control TECHNOLOGIES

System Setup Mode (GPA mode)

The System Setup Mode contains the programming steps that customize the console to the

sprayer or sprayer components. These include calibration steps and parameters that, once

programmed, are not likely to change.

To enter the System Setup Mode:

First be sure that the console is ON (if not turn it on by pressing the key and wait

until the normal display is visible).

Ensure the Master boom switch is OFF.

Then press and hold the key for 3 seconds to enter the Program Mode.

OPERATING MODE

The 834-P can operate in either of two modes. They

are GPT (gallons per ton), used for pre-wetting

applications, or GPA (gallons per acre)used for

agricultural or anti-icing applications.

Use the + or

keys to adjust this value. Once

the correct mode has been selected, press

the key to advance to the next step. If

operating in GPT mode, see page 10.

MINIMUM MPH

The 834-P can be set to automatically switch off the

flow of liquid when the machine slows below a

minimum speed. This feature automatically prevents

liquid from being applied when the machine is

stopped.

tip

select

Inch

lbs/rot

tip

select

GPA

GPT

Gal/min

@40 psi

GPA

GPT

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

SPEED

RPM

min

MPH

RPM

On

On

Use the + or

machine speed below which spray should be

switched off.

keys to adjust this value to the

Inch

lbs/rot

Gal/min

@40 psi

PROGRAM MODE push 3 sec.

98-70028-R0 14

P/300ft

P/rot

min

MPH

RPM

Page 15

TECHNOLOGIES 834-P Sprayer Control

SPEED SENSOR CALIBRATION

Default = 250 pulses/300ft

The speed sensor needs to be calibrated in order to

provide the proper speed reading. The value for this

step is the number of pulses generated by the speed

sensor in 300 feet. For example, if the speed sensor

is mounted to sense lug bolts on a sprayer wheel,

this value would reflect the number of bolts passing

the sensor over a 300 foot distance.

Auto Calibration

The speed sensor can be automatically calibrated

by driving 300 feet. The console will automatically

detect a RADAR sensor (if used).

To start the auto calibration procedure, press

simultaneously on the + and

display now will show CAL.

Now you have to drive to the starting point of the

keys. The

tip

select

Inch

lbs/rot

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

SPEED

RPM

P/300ft

P/rot

min

MPH

RPM

min

MPH

RPM

On

On

300ft distance. Push the + key to start counting

speed pulses as you cross the start point.

Drive 300ft and press + again to stop the pulse

counting as you cross the finish point.

Note: During Auto Calibration the Man LED will flash.

The number now on the display is the number of

pulses corresponding to 300ft.

The auto calibration procedure can be escaped with

the key. The console will then return to the

previous calibration value.

Note: The auto speed calibration should be

repeated at least twice and an average of

the calibration numbers should be entered.

tip

select

Inch

lbs/rot

PROGRAM MODE push 3 sec.

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

PROGRAM MODE push 3 sec.

P/300ft

P/rot

min

MPH

RPM

On

15 98-70028-R0

Page 16

834-P Sprayer Control TECHNOLOGIES

×

Radar

A radar speed sensor will be indicated with an "r" on

the display e.g.

The "r" will automatically appear during the auto

calibration process when the console has determined

that a radar is being used. When manually entering

Tip

select

GPA

MPH

On

a radar calibration number the "r" must be turned on

by pushing the Auto/Man key. With this key you can

toggle between radar or wheel sensor. The calibration

value itself is adjusted with the + and

keys.

tip spacing

(inch)

speed cal

(pulses/300ft.)

PROGRAM MODE push 3 sec.

density

Manual Calculation

To manually calculate the proper value for Wheel Speed Sensor pulses, you need to know

the circumference of the wheel to which the sensor is mounted. It can be measured by

marking the tire and measuring the distance covered as that mark makes one full revolution.

Then use the following formula:

58

4600,3

=

248

×

#600,3

rotationperPulses

..

=

ge

InchInnceCircumfereWheel

Use the + or keys to adjust the value. Press the key to validate the value and

advance to the next programming step.

Note: The wheel calibration should be repeated if you are changing to another wheel

diameter.

Simulated Speed

If you enter 0 in the speed calibration step, then the console always works with a simulated

speed. This simulated speed can be used to test out the sprayer at stand still.

The simulated speed feature allows you to check out the sprayer at a certain speed without

actually moving the sprayer. This can be done prior to any spraying activity. The simulated

speed value can be changed with the

display in normal working mode.

+

and keys when the speed is shown on the

98-70028-R0 16

Page 17

TECHNOLOGIES 834-P Sprayer Control

SPRAY TIP CAPACITY

Enter the combined capacity of all nozzles on the system. This should be measured in

Gallons Per Minute at 40 PSI. These capacities can be obtained from the nozzle

manufacturer’s catalog.

Use the

+

or

keys to adjust this value. Once the correct units have been selected,

press the key to advance to the next step.

Example: Two 8004 nozzles would have a combined capacity of .8 GPM at 40 PSI.

SWATH WIDTH

Enter the total swath width of the sprayer in inches.

Use the

correct units have been selected, press the key to

advance to the next step.

+

or

keys to adjust this value. Once the

tip

select

Inch

lbs/rot

GPA

GPT

Gal/min

@40 psi

SPEED

RPM

P/300ft

P/rot

PROGRAM MODE push 3 sec.

min

MPH

RPM

On

17 98-70028-R0

Page 18

834-P Sprayer Control TECHNOLOGIES

Midwest Technologies Illinois, LLC

2864 Old Rochester Road

Springfield, IL 62703

98-70028-R0 18

Loading...

Loading...