Page 1

INSTA L L AT I O N

FLANGED

8 0 1 f L O w m e T e r

INSTALLATION, SpecIfIcATION, ANd wArrANTy INfOrmATION

Please read before installing this equipment. Failure to do so may void your warranty.

Installation

The 801 ow meter gives the best accuracy when there is a smooth, unobstructed

ow through it. To minimize turbulance, there should be at least twelve inches of

straight plumbing upstream from the ow meter and at least 6 inches of straight

plumbing downstream from the ow meter. Mount the ow meter in a location that

physically protects it from damage and allows liquid to drain away after the sprayer is

ushed and secured at the end of the operating day. A straight, vertical section of the

main boom supply line is the ideal location for the ow meter.

Keep the ow meter from lying in a low section of the sprayer plumbing. This is

particularly important in cold weather when water might freeze in the ow meter and

cause damage to the unit. It is also important when applying chemical suspensions

which may settle out and stall the ow meter turbine if they cannot drain away.

8 0 1 F L O W M E T E R

TeeJet

Before installing the ow meter insert, make sure there are no obstructions in the

insert cavity. Clearance at the bottom of the cavity is very close and over tightening

or compressing of foreign material in the cavity can cause damage to the ow meter

body. Turn the insert in until it is hand tight.

Prior to each day’s spraying, the ow meter should be inspected to ensure there are

no leaks around the attachment ttings. At the end of the day, care should be taken

to thoroughly ush the ow meter with clean water.

Make sure no water or sediment is trapped in the flow meter

The impeller type ow meters supplied by TeeJet Technologies are inherently rugged.

However, continued use over time will eventually wear the internal bearings and

shafts until the meter becomes inaccurate. Replacement kits are available to repair

the ow meters. Contact your TeeJet Technologies dealer for these parts.

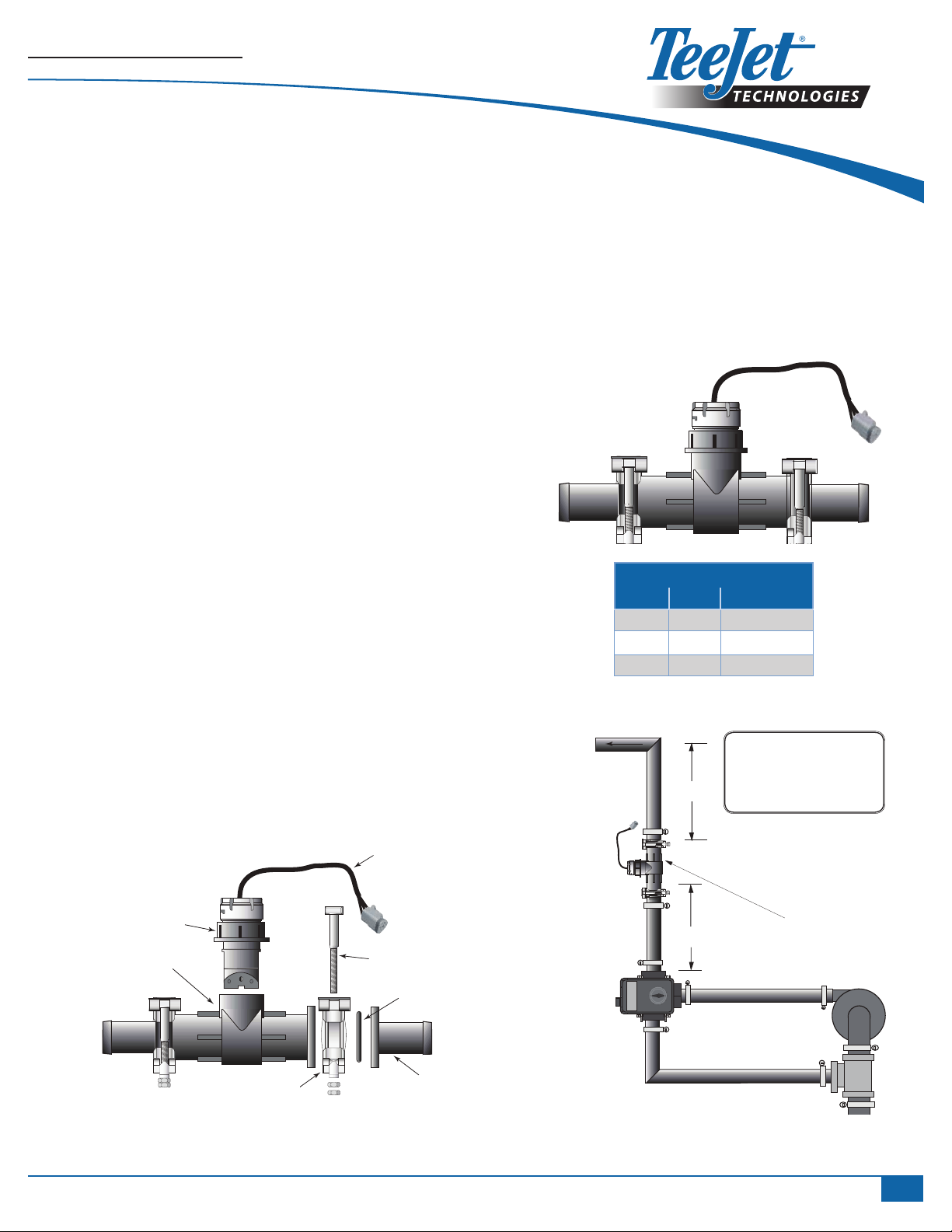

Sensor

Flow Meter

Insert

FLOW METER

SENSOR

Main Flow

MAIN

Meter Body

FLOW METER

BODY

Bolt

BOLT

O-Ring

O-RING

TeeJet

Hose

HOSE

Barb

BARB

Flanged

Clamp

To Booms

TO BOOMS

AUTO RANGE

Auto Range®

VALVE

Valve

Housing, Deutsch 3 Pos/Skts

Pin Out Color Function

A Red +12V

B White Signal

C Black Ground

NOTE: The ow meter must be

mounted to that it will drain

Meter must be mounted

completely when the sprayer

is not operating.

so that it will drain

> 6 inches

>6 inches

TeeJet

>12 inches

>12 inches

R

completely when the

sprayer is not operating

Pump Discharge

PUMP DISCHARGE

BYPASS LINE

Bypass Line

NOTE: The Flow

FLOW METER

Flow Meter

MAIN PRODUCT

Main Product

PUMP

Pump

www.teejet.com

Page 2

Specications

The 801 Flow Meter meets the following specications:

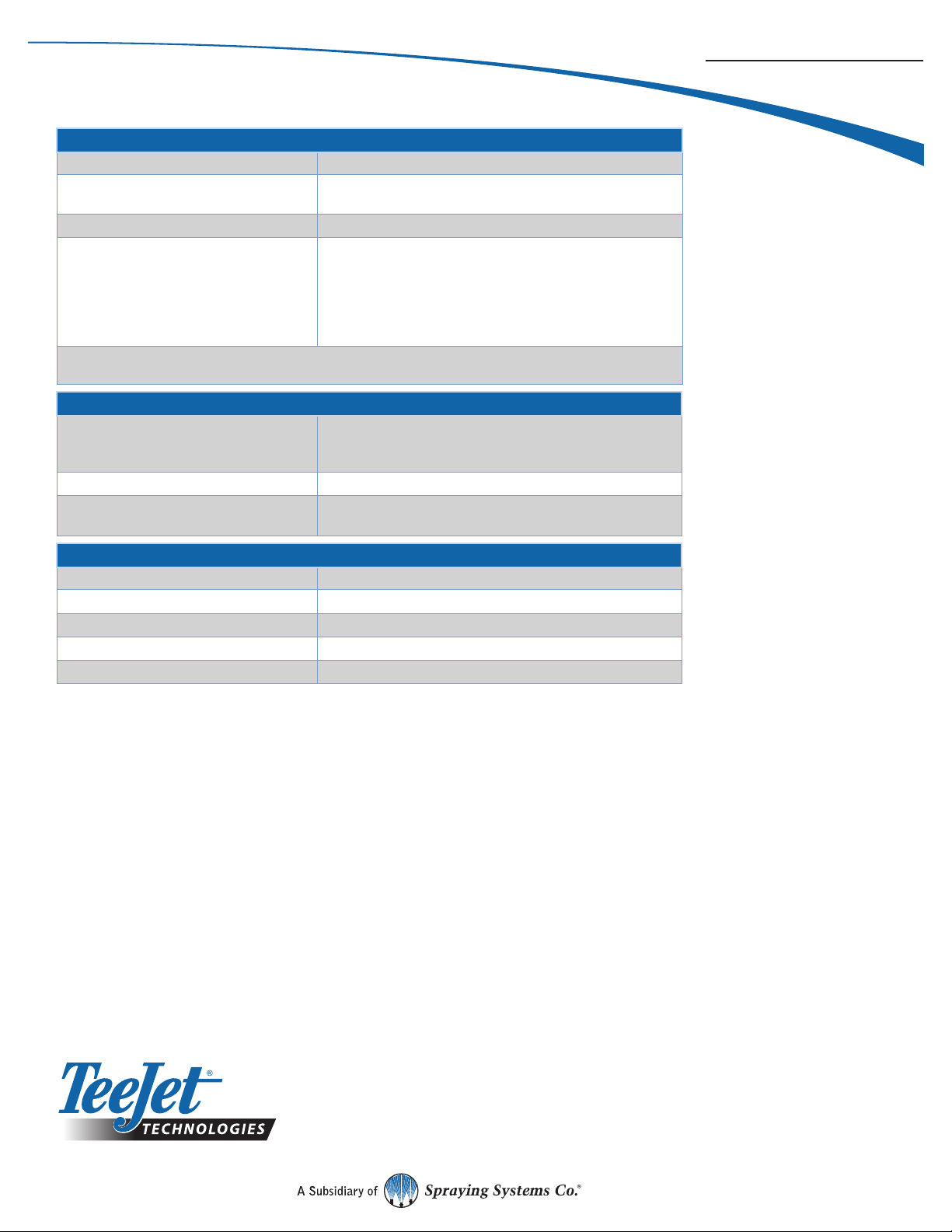

Measuring Data

Linearity at recommened ow range +/- 3.0%

Flow Range 2-60 GPM (7.5-225 LPM)

(3-30 GPM recommened for max life)

Maximum Working Pressure 300 PSI (20.7 Bar)

Pressure Drop 10 GPM (37.85 LPM) - NA

20 GPM (75.71 LPM) - 3 PSI (0.21 Bar)

30 GPM (113.56 LPM) - 7.5 PSI (0.52 Bar)

40 GPM (151.42 LPM) - 12.5 PSI (0.86 Bar)

50 GPM (189.27 LPM) - 19.5 PSI (1.34 Bar)

60 GPM (227.12 LPM) - 29 PSI (2.0 Bar)

Measuring range is partly dependent on the selected type and size of connectors.

The flow meter is bi-directional for mounting purposes.

Electrical Data

Sensor Open collector NPN

50% square wave

10-300 Hz in operating range

Calibration Number (Approximate) TeeJet Controller 82 pulses/liter, Mid-Tech 310 pulses/gallon

LED Indicators Green-Power

Orange-Signal

INSTA L L AT I O N

Measuring Data

Body & Insert 30% glass lled polypropylene

Shaft 410 hardened stainless steel

Turbine & Bearing Support 20% talc lled polypropylene

Bearing Sapphire

Bearing Housing 303 stainless steel

Warranty

The warranty on this equipment may be affected for the following reasons:

• Improper installation

• Obvious abuse

• Lack of, or improper maintenance

• Employed in a manner inconsistent with its intended use

• Used with chemicals that are incompatible with the materials which this product is made of

(See “Warranty and Limitations” statement in your controller manual for other limitations)

This ow meter is manufactured using some or all of the following materials:

• 303 Stainless Steel

• 410 Stainless Steel

• Polypropylene

TeeJet Technologies does not recommend metering any product that reacts with these materials and damage resulting from the use of such products will not be

covered under the warranty. Please contact your chemical supplier to verify that the chemicals you are using are compatible.

If you have any questions about installation or use, refer to the installation section of your manual or call your TeeJet Technologies dealer.

98-01087-R3

© TeeJet Technologies 2011

TeeJet Technologies

1801 Business Park Drive

Springeld, Illinois 62703 USA

Tel: (217) 747-0235 • Fax: (217) 753-8426

www.teejet.com

Loading...

Loading...