Page 1

SERVICE MANUAL

DVTV5190F

51CM TV DVD COMBO

FEB05 SERVDVTV5190

Page 2

.

CONTENTS

1. Safety precautions……………………………………………………………..……………3

2. TV block diagram……………………………………………………………………..…….4

3. Replacement of memory IC………………………………………………………….……5

4. Service adjustment……………………………………………………………..…………...5

5. ICs functional description…………………………………………………………………8

6. Test point waveform………………………………………………………………………10

7. All ICs voltages……………………………..……………………………………………….10

8. Purity / convergence adjustment………………………………………………………11

9. DVD maintenance…………………………………………………………………………13

10. List of Parts ………………………………………………………………………….…….14

11. Circuit diagram………………………………………………………………………Attached

12. Exploded view…………………………………………………………………Attached

2

Page 3

.

1. SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components especially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to those

used in the original circuits. Service should be performed by

qualified personnel only.

2. Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void the

manufacturer’s warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using

replacement components rated for higher voltage, wattage,

etc. Replacement parts which have these special safety

characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematics and by ( ! ) on

the parts list in Service manual. The use of a substitute

replacement which does not have the same safety

characteristics as the recommended replacement part

shown in the parts list of Service manual may cause shock,

fire, or other hazards

4. Don’t short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing. Some model’s power circuit is

partly different in the GND. The difference of the GND is

shown by the LIVE: ( ) side GND, ISOLATED

(NEUTRAL): ( ) side GND and EARTH: ( ) side GND.

Don’t short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure with a measuring apparatus (oscilloscope etc.) the

LIVE side GND and ISOLATED (NEUTRAL) side GND or

EARTH side GND at the same time. If above note will not be

kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See ADJUSTMENT OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform to

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive

high voltage conditions should be kept to a minimum, or

should be prevented. If severe arcing occurs, remove the AC

power immediately and determine the cause by visual

inspection (incorrect installation, cracked or melted high

voltage harness, poor soldering, etc.). To maintain the proper

minimum level of soft X-Ray emission, components in the

high voltage circuitry including the picture tube must be the

exact replacements or alternatives approved by the

manufacturer of the complete product.

7. Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ 2W

resistor to the anode button.

8. When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer’s replacement components.

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screw heads, earphone jack, control

shafts, etc.) to be sure the product is safe to operate without

danger of electrical shock.

10. The surface of the TV screen is coated with a thin film which

can easily be damaged. Be very careful with it when handle

the TV. Should the TV screen become soiled, wipe it with a

soft dry cloth. Never rub it forcefully. Never use any cleaner

or detergent on it.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second.

(…Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance

rated 200V or more, for a period of one second.)

This method of test requires test equipment not generally

found in the service trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

line isolation transformers during this check). Using a

“Leakage Current Tester”, measure the leakage current from

each exposed metal part of the cabinet, particularly any

exposed metal part having a return path to the chassis, to a

known good earth ground (water pipe, etc.). Any leakage

current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

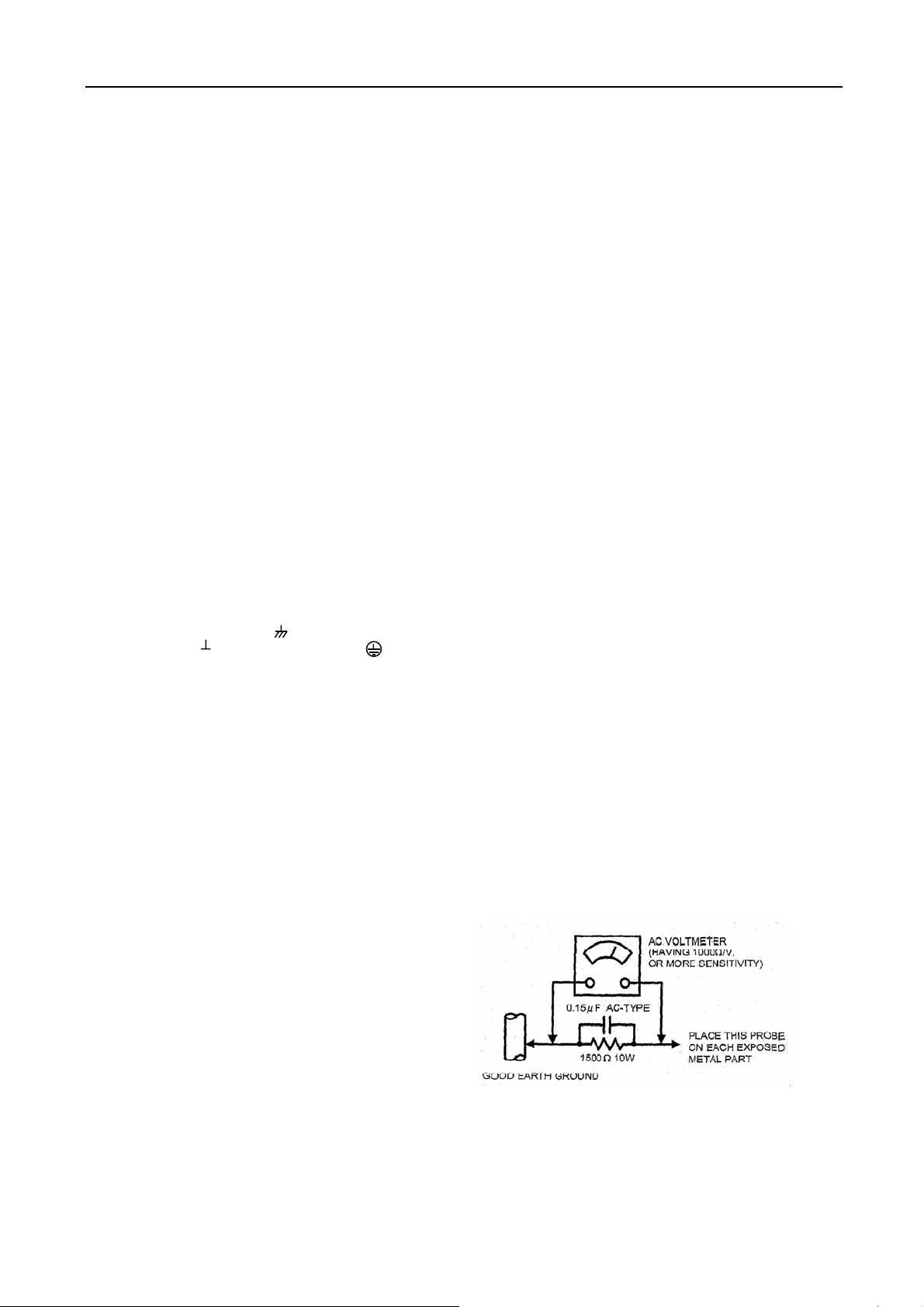

●Alternate Check Method

Plug the AC line cord directly into the AC outlet ( do not use

a line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in

the following manner. Connect a 1500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an

exposed metal part and a known good earth ground (water

pipe, etc.). Measure the AC voltage across the resistor with

the AC voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed metal part

having a return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.).

This corresponds to 0.2mA AC (r.m.s.)

3

Page 4

.

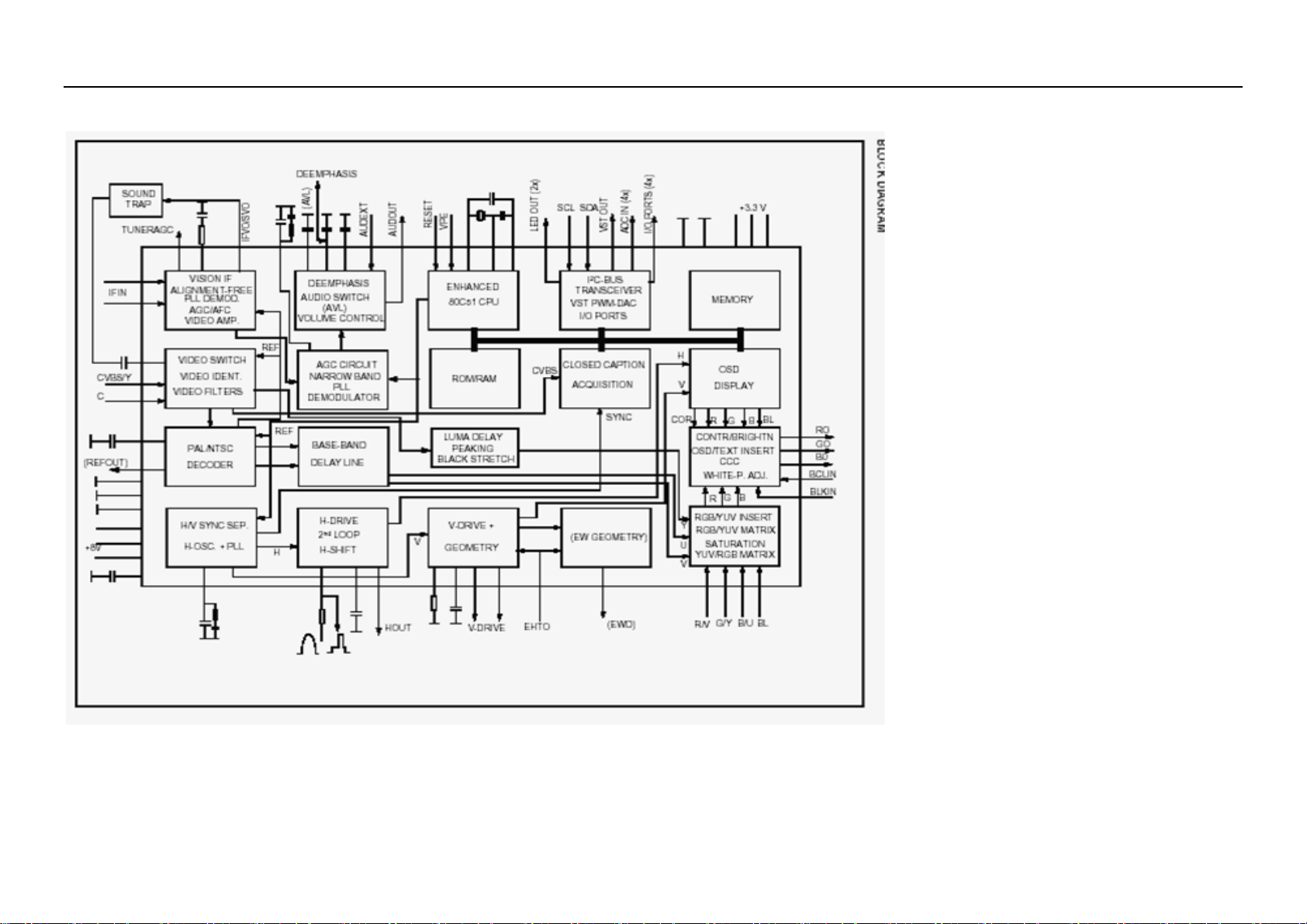

2. Block diagram TDA9370PS/N2 series with mono intercarrier sound demodulator

4

Page 5

3. REPLACEMENT OF MEMORY IC

1. MEMORY IC.

This TV uses memory IC. In the memory IC are memorized data for correctly operating the video and deflection

circuits.

2. PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from AC outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data values.

(3) Power On

Plug the power cord into the AC outlet and switch the power on.

(4) Check and set SYSTEM default value:

1) Press “MUTE” Æ “CALL” Æ “-\--“ Æ “CALL” Æ “MUTE” buttons in sequence to enter into factory

status.

2) If the memory IC haven’t been written with the initial data, press [Program+] / [Program-] to select item

INIT and press [VOLUME+] / [VOLUME-] to start initialize memory IC.

3) Check the setting value of the SYSTEM default value of Table below. If the value is different, select

items by [Program+] / [Program-] keys and set value by [VOLUME+] / [VOLUME-] keys.

4) Press “EXIT” button to return to the normal screen.

4. SERVICE ADJUSTMENT

Specific operation: use remote controller

Press “MUTE” Æ “CALL” Æ “-\--“ Æ “CALL” Æ “MUTE” buttons in sequence to enter into factory mode.

Press [Program+] / [Program-] to select items and press [VOLUME+] / [VOLUME-] key, to make data adjustment

of corresponding factory menus.

Press “EXIT” key to exit factory mode.

Focus adjustment

1. Receive a crosshatch signal.

2. While watching the screen, adjust the FOCUS VR on the FBT to make the vertical and horizontal lines as

fine and sharp as possible.

Geometrical adjustment

Receive PAL standard complete pattern signal.

Adjustment steps:

a) Adjust VSL, to the centre horizontal line just appears from half bottom shadow.

b) Adjust VAM, to get 92% of vertical picture contents would be displayed on CRT.

c) Adjust VSH, the centre horizontal line corresponds to CRT vertical centre.

d) Adjust SCL, to the linearity of P card field is in proper condition.

e) Adjust

Receive NTSC signal and repeat above adjustment.

AGC Adjustment

Receive 60dBµ (1mV) VH colour bar pattern signal.

Select TOP item.

Adjust value, to noise reduce gradually and just disappeared point.

CRT cut off and white balance adjustment

a) CRT cut off adjustment

b) White balance adjustment

HSH, to get the picture horizontal centre correspond to CRT horizontal centre.

1. Select item VG2B, then adjust value to 32.

2. PRESS “0” key, when the screen shows”VG2” adjust the SCREEN control on Fly back transformer to

make the screen show alternating flashing characters of “INSIDE HIGH INSIDE LOW”.

1. Receive a Black and White pattern.

2. Adjust WRP, WRG, WRB items to get colour temperature 9300K ±3 JND.

5

Page 6

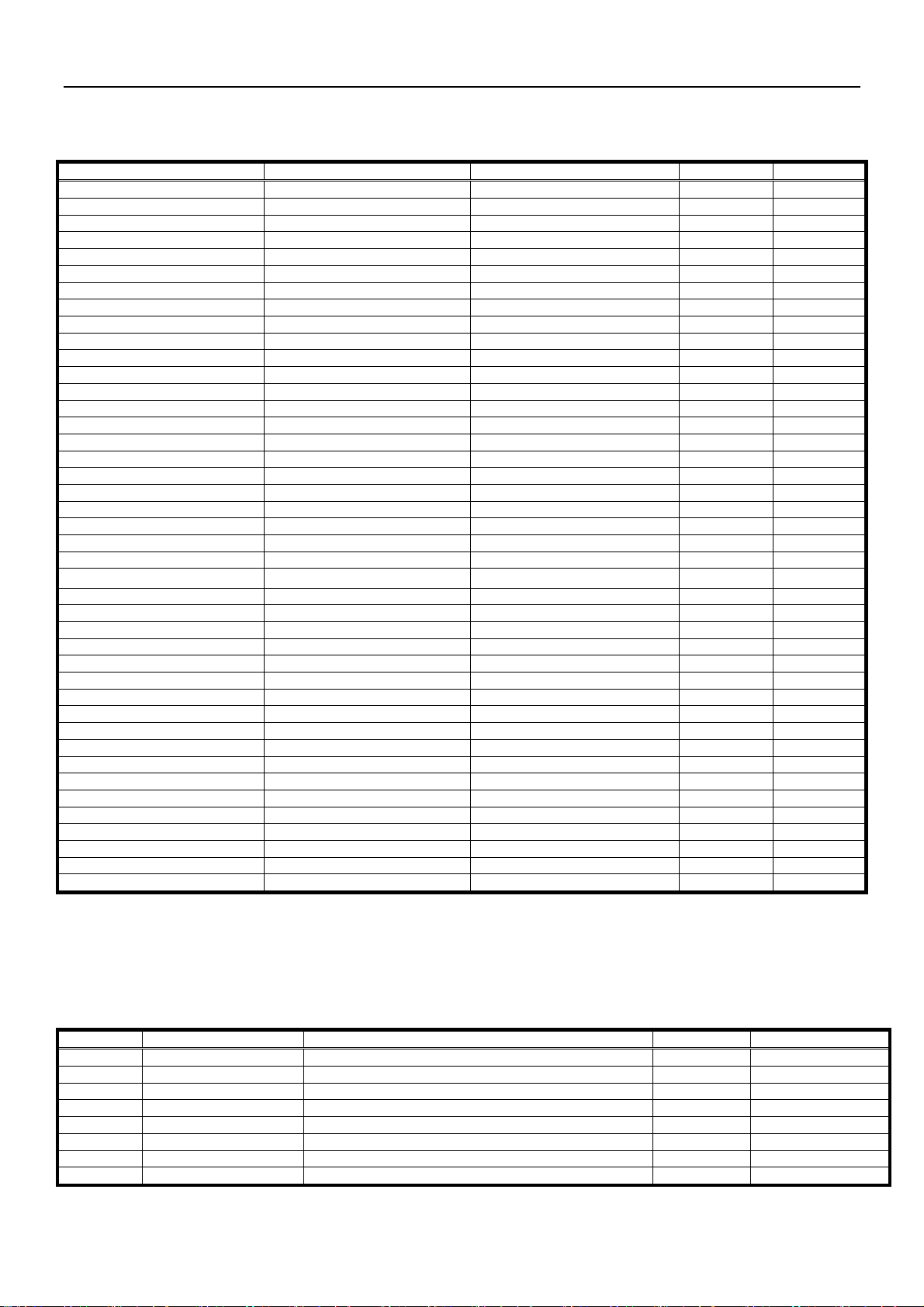

Adjustable Items

Direct access key Items Description Preset Remark

“1” 5/6HSH Horizontal shift ON A

“2” 5/6VSL Vertical slop 32 A

5/6VAM Vertical amplitude 23 A

5/6SCL S-correction 17 A

5/6VSH Vertical shift 27 A

5/6VOF OSD Vertical offset 37 A

HOF* OSD Horizontal offset 42 A

“3” RED Black level offset R 32 A

GRN Black level offset G 32 A

WPR White point R 30 A

WPG White point G 26 A

WPB White point B 38 A

“4” TOP AGC Take-over point 20 A

VOL Volume 42

9860 Sub-volume of TDA9860/59 18

HDOL Cathode drive level 59

AGC IF AGC speed 1

VG2B VG2 Brightness 42

IFFS 2

“5” Picture preset 1

0CON Listen: Contrast 0 A

0BRI Listen: Brightness 0 A

0COL Listen: Colour 50 A

0SHP Listen: Sharpness 50 A

1CON Soft: Contrast 45 A

1BRI Soft: Brightness 45 A

1COL Soft: Colour 50 A

1SHP Soft: Sharpness 50 A

“6” Picture preset 2

2CON Standard: Contrast 75 A

2BRI Standard: Brightness 50 A

2COL Standard: Colour 50 A

2SHP Standard: Sharpness 60 A

3CON Dynamic: Contrast 85 A

3BRI Dynamic: Brightness 60 A

3COL Dynamic: Colour 60 A

3SHP Dynamic: Sharpness 80 A

NOTE: THE ITEMS WITH REMARK “A” IS ADJUSTABLE DATA.

Optional data

1. OP1

Bit Function Description Preset Remark

Bit 0 VG2_MODE 1= 0 EA

Bit 1 YPRPB 1=Enable 1 EA

Bit 2 SUPERWOOFER Translucence OSD manual 1=Enable 0 EA

Bit 3 WOOFER_VOL 1=Enable (Can only be selected either RGB and DVD) 0 EA

Bit 4 AV2 1=Enable 1 EA

Bit 5 SVHS 1=Enable 0 EA

Bit 6 DVD 1=Enable 0 EA

Bit 7 RGB 1=Enable 1 EA

6

Page 7

2. OP2

Bit Function Description Preset Remark

Bit 7 FSL 1=21dBµV 0=26dBµV 0 EA

Bit 6 SOY 1=Enable 1 EA

Bit 5 ARABIC_SET 1=Enable 0 EA

Bit 4 FARSI_SET 1=Enable 0 EA

Bit 3 CYRILLIC_SET 0 EA

Bit 2 EUROUP_SET 1=Enable 1 EA

Bit 1 AUTO_SOUND 1 EA

Bit 0 AVL 1=Enable 1 EA

3. OP3

Bit Function Description Preset Remark

Bit 7 RUSSIA 1=Enable 0 EA

Bit 6 ITALY 1=Enable 0 EA

Bit 5 GERMANY 1=Enable 0 EA

Bit 4 FRANCE 1=Enable 0 EA

Bit 3 RUTKISH 1=Enable 0 EA

Bit 2 ARABIC 1=Enable 0 EA

Bit 1 FARSI 1=Enable 0 EA

Bit 0 ENGLISH 1=Enable 1 EA

4. OP4

Bit Function Description Preset Remark

Bit 6 HALFTONE 1=Enable 1 EA

Bit 5 IDENT_SENSITIVE 1 EA

Bit 4 HCO 1=Enable 0 EA

Bit 3 LOGO 1 EA

Bit 2 TILT 0 EA

Bit 1 SPANISH 1 EA

Bit 0 ROMANIA 0 EA

5. OP5

Bit Function Description Preset Remark

Bit 7 STORE_AV 1= Enable 1 EA

Bit 6 OSO 1= Enable 0 EA

Bit 5 SOFR_CHANGE 1=Enable 0 EA

Bit 4 FADE 1=Enable 0 EA

Bit 3 SOUND_M 1= Enable 0 EA

Bit 2 SOUND_I 1= Enable 0 EA

Bit 1 SOUND_BG 1=Enable With DVD select 1 1 EA

Bit 0 SOUND_DK 1=Enable 0 EA

6. OP6

Bit Function Description Preset Remark

Bit 7 RESERVE 1=Enable 0 EA

Bit 6 POR_WHEN_BLUE 1=Enable 1 EA

Bit 5 MENU_MIDLINE 1=Enable 1 EA

Bit 4 MENU_BLUE 1=Enable 1 EA

Bit 3 CHILDLOCK 1=Enable 1 EA

Bit 2 16_9 1=Enable 0 EA

Bit 1 BLUE_SCREEN 1=Enable 1 EA

Bit 0 LOGO_LISTEN 1 EA

7

Page 8

7. OP7

Bit Function Description Preset Remark

Bit 7 FMWS 1=Enable 1 EA

Bit 6 HOTEL 1=Enable 0 EA

Bit 5 PROG_ID 1=Enable 0 EA

Bit 4 LED 1=Enable 0 EA

Bit 3 TWIST 1=Enable 0 EA

Bit 2 BYELORUSSIAN 1=Enable 0 EA

Bit 1 UKRANIAN 1=Enable 0 EA

Bit 0 AV1 1=Enable 1 EA

8. OP8

Bit Function Description Preset Remark

Bit 6 DIRECT_SWITCH_ON 1=Enable 0 EA

Bit 5 INNER_DVD 1=Enable 1 EA

Bit 4 PROG_FREQ 1=Enable 0 EA

Bit 3 FAST_BAR 1=Enable 1 EA

Bit 2 AUSTRALIA 1=Enable 0 EA

Bit 1 FREQ 1=Enable 1 EA

Bit 0 9860 1=Enable 0 EA

Note:Don’t adjust any OPTION items, please inform the engineer about any change.

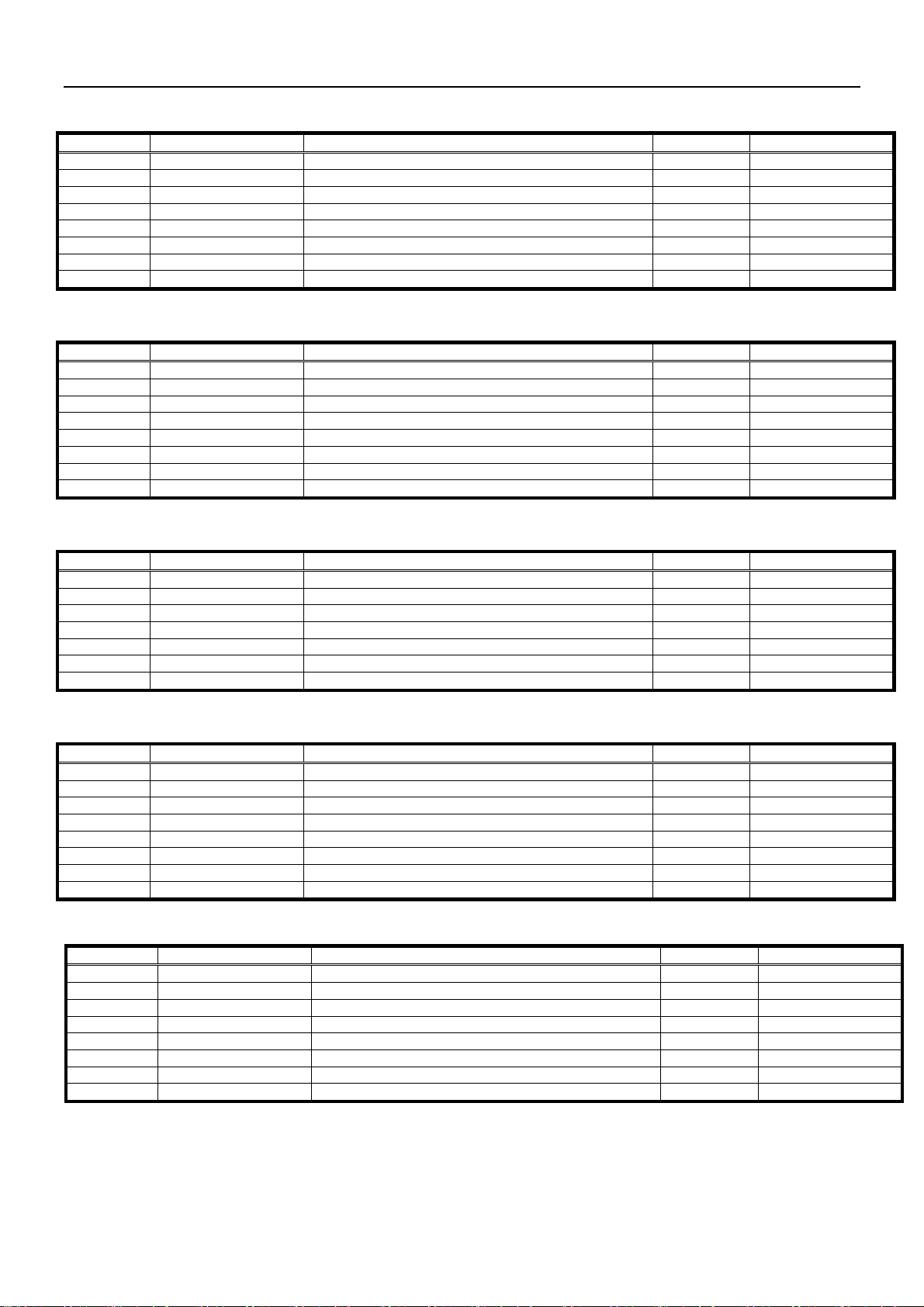

5. ICs functional description

1. N201 UOC TDA9370

SYMBOL PIN DESCRIPTION

STAND BY output. 1 In STAND BY mode, low level (Power OFF).

For Power ON this pin will be high.

SCL 2 I2C-bus clock line

SDA 3 I2C-bus data line

TUNING 4 tuning Voltage (Vt) PWM output

KEY 5 Control keys input

SYSTEM 6 TV system control

VOL 7 Sound Volume control PWM output

MUTE 8 Sound mute output

VSSC/P 9 Digit ground for µ-controller core and periphery

CTL 10 DVD power control

STANDBY 11 STANDBY control

VSSA 12 Analog ground of digital ground of TV-processor

SECPLL 13 Internally connected

VP2 14 2nd supply voltage TV-processor(+8V)

DECDIG 15 decoupling digital supply of TV-processor

PH2LF 16 Phase-2 filter

PH1LF 17 Phase-1 filter

GND3 18 Ground 3 for TV-processor

DECBG 19 Band gap decoupling

AVL/EWD 20 Automatic volume levelling

VDRB 21 Vertical drive B output

VDRA 22 Vertical drive A output

IFIN1 23 IF input 1

IFIN2 24 IF input 2

8

Page 9

IREF 25 Reference current input

VSC 26 Vertical sawtooth capacitor

TUNER AGC 27 Tuner AGC output

AUDEEM/SIFIN1 *1 28 Audio deemphasize or SIF input

DECSDEM/SIFIN2 29 Decoupling sound demodulator

GND2 30 Ground 2 for TV processor

SNDPLL/SIFAGC *1 31 Narrow band PLL filter

AVL 32 Automatic Volume Levelling

HOUT 33 Horizontal output

FBISO 34 Flyback input/sandcastle output

AUDEXT 35 External audio output

EHTO 36 EHT/over voltage protection input

PLL IF 37 IF-PLL loop filter

IFVO/SVO 38 IF video output / selected CVBS output

VP1 39 supply voltage TV processor

CVBS INT 40 internal CVBS input

GND1 41 ground for TV processor

CVBS/Y 42 CVBS/SVHS(Y) input

CHROMA 43 SVHS (C) input

AUDOUT 44 Audio output

INSSW2 45 YUV insertion input

R2/VIN 46 R input / V (R-Y) input / PR input

G2/YIN 47 G input / Y input

B2/UIN 48 B input / U (B-Y) input / PB input

BCLIN 49 Beam current limiter input

BLKIN 50 Black current input

RO 51 Red output

GO 52 Green output

BO 53 Blue output

VDDA 54 Analog supply of Closed Caption decoder and digital supply of TV-processor (3.3 V)

VPE 55 Ground

VDDC 56 Digital supply to core (3.3 V)

OSCGND 57 Oscillator ground supply

XTALIN 58 Crystal oscillator input

XTALOUT 59 Crystal oscillator output

RESET 60 Ground

VDDP 61 Digital supply to periphery (+3.3 V)

P1.0/INT1 62 AV1 / AV2 mode Output.

P1.1/T0 63 AV /S-VHS mode Output.

P1.2/INT0 64 Remote control signal input.

Note

Pin TV SVHS AV1 AV2

62 1 0 0 1

63 1 1 0 0

2. N902 24C08/PCF8598

PIN Function

1 GND

2 GND

3 Upper resistance

4 GND

5 SDA data wire

6 SCL clock wire

7 GND

8 +5V Power

3. N601: Sound power amplify (AN7522N)

Symbol PIN Function Symbol PIN Function

Vcc 1 Power supply GND 7 ground

Out 1 (+) 2 Ch 1 output (+) In 2 8 Ch 2 input

GND(out 1) 3 Ch 1Ground VOL 9 Volume Control

Out 1 (-) 4 Ch 1 output (-) Out 2 (-) 10 Ch 2 output (-)

Standby 5 Mute input GND(out 2) 11 Ch 2 Ground

9

Page 10

In 1 6 Ch 1 input Out 2 (+) 12 Ch 2 output (+)

4. N301: Vertical output (TDA8357A)

Symbol PIN Function Symbol PIN Function

INV IN 1 Input PUMP UP 6 Pump up power

INV IN 2 Input V OUT 7 Vertical output

Vcc 3 Pump up power V PRO 8 Vertical protection

V OUT 4 Vertical output V FEEDBACK 9 Vertical feedback

GND 5 Ground

5. U101:Tuner

PIN Function PIN Function

1 AGC 7 +5V

2 vacant 8 vacant

3 Gnd 9 Vt 33V

4 SCL 10 Gnd

5 SDA 11 IF Out

6 +5V

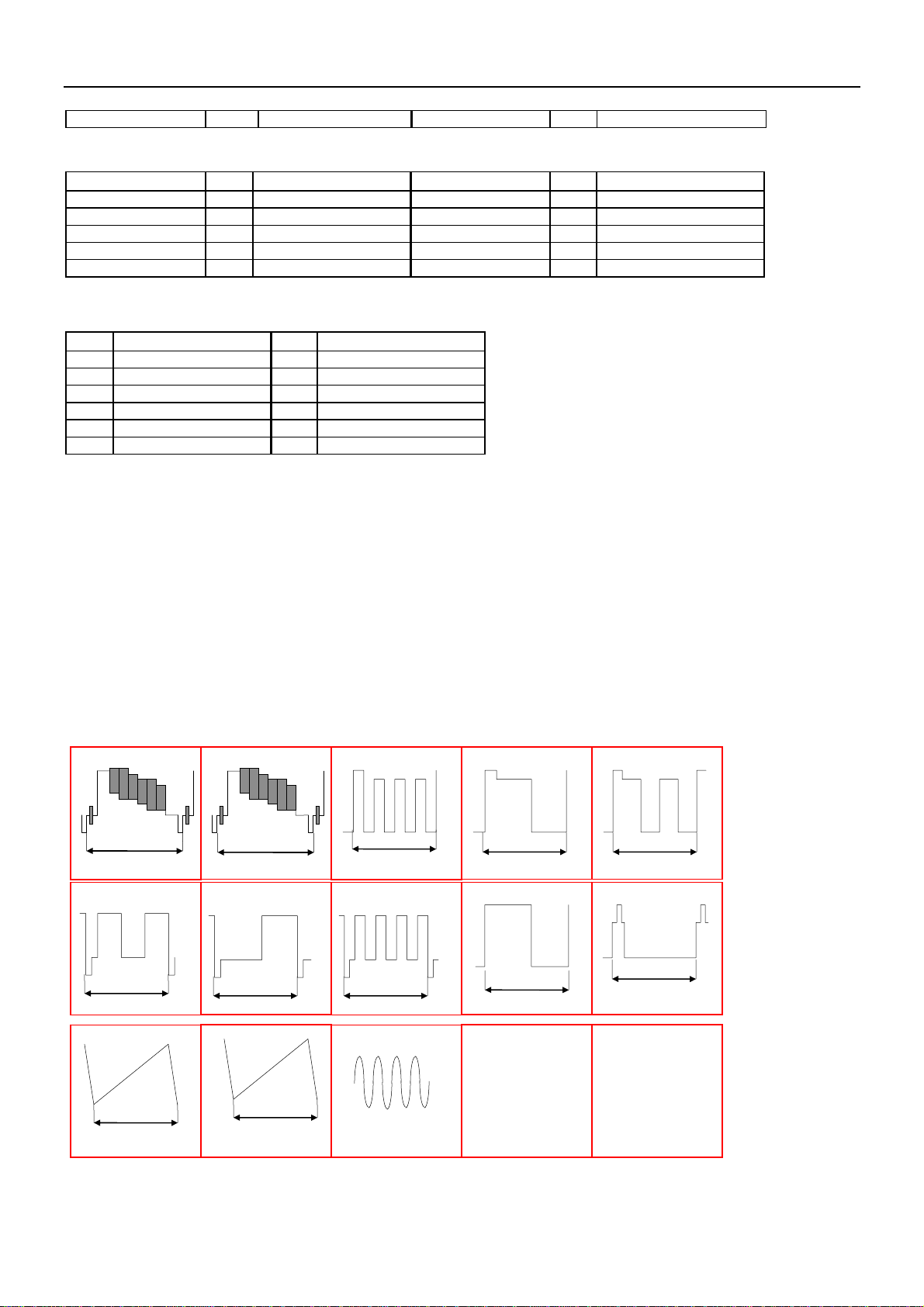

6. Test point Waveforms

2.6Vpp

H

TDA9370 PIN38

95Vpp

H

CRT KG CRT KR

1Vpp

V

TDA9370 PIN21 TDA9370 PIN22 TDA9370 PIN59

1.2Vpp

H

TDA9370 PIN40

95Vpp

H H

0.8Vpp

V

CRT KB

TDA9370PIN53

95Vpp

1.3Vpp

3.8Vpp

H

2.5Vpp

H H

TDA9370PIN52

0.9Vpp

H

TDA9370 PIN33

2.5Vpp

TDA9370 PIN51

TDA9370 PIN34

5Vpp

H

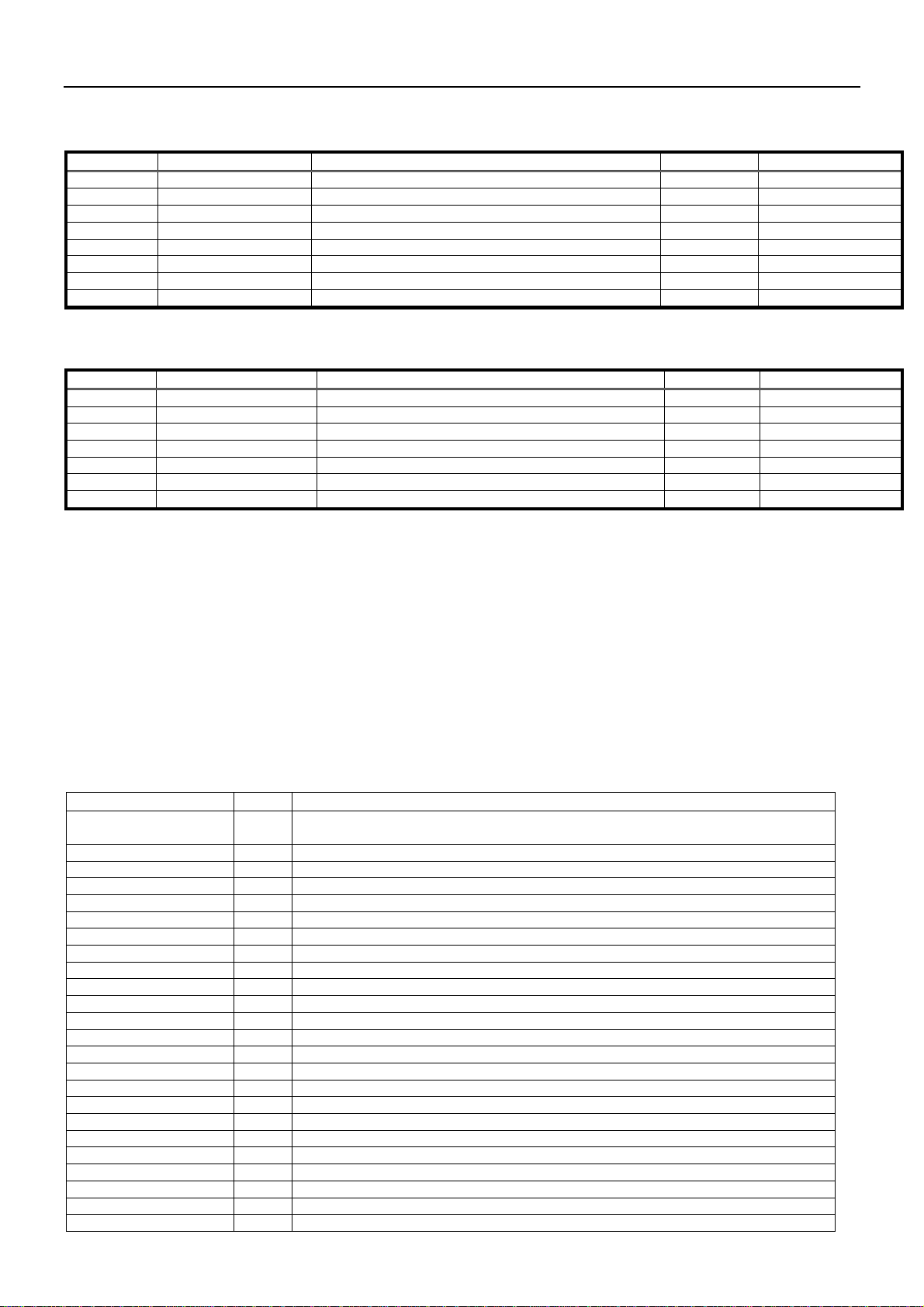

7. IC voltages

10

Page 11

TDA9370

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

V 0 3.8 3.6 3.3 3.5 4.4 5.1 1.8 0 0.18 0.17 0 2.3 8 5 3

PIN 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

V 4 0 4 0.5 0.7 0.8 1.9 1.9 3.9 3.8 1.6 3.2 2.3 0 2.3 0.2

PIN 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

V 0.5 0.3 0 1.7 2.4 3.4 8 3.9 0 3.3 0 3.6 1.4 2.5 2.5 2.5

PIN 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

V 1.9 5.0 2.4 2.4 2.4 3.1 0 3.2 0 1.8 1.7 0 3.2 5.1 3.3 5

TDA8357

PIN 1 2 3 4 5 6 7 8 9

V 0.8 0.7 16 6.9 0 43 7.2 0.3 7.2

AN 7522N

PIN 1 2 3 4 5 6 7 8 9 10 11 12

V 10 4.4 0 4.4 2.75 1.4 0 1.4 0.35 4.4 0 4.4

24C08/PCF8598

PIN 1 2 3 4 5 6 7 8

V 0 0 5.1 0 3.2 0 0 5.1

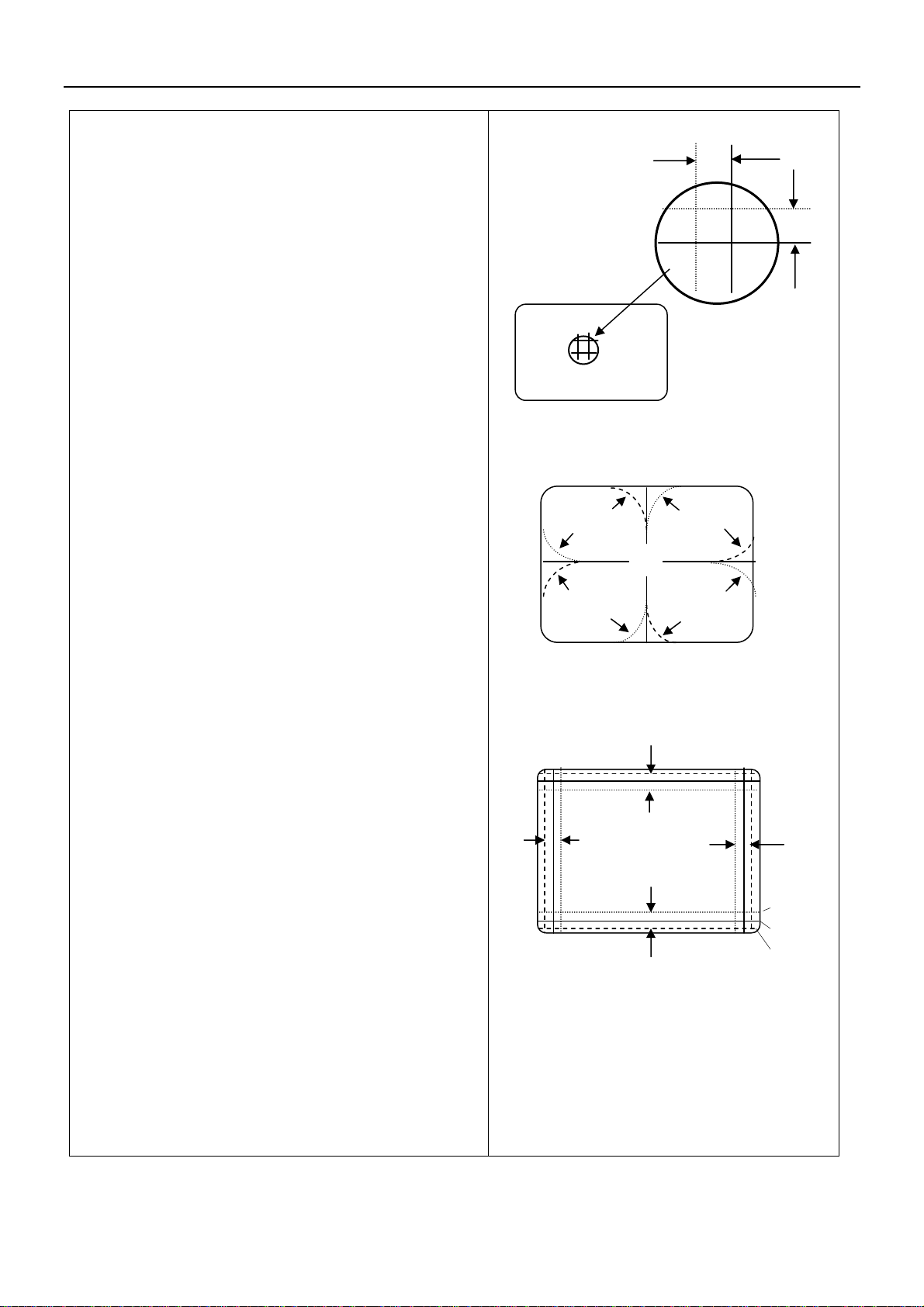

8. PURITY / CONVERGENCE ADJUSTMENT

11

Page 12

6

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3. Remove the wedges.

4. Input a green raster signal from the signal generator,

and turn the screen to green raster.

5. Move the deflection yoke backward.

6. Bring the long lug of the purity magnets on the short

lug and position them horizontally. (Fig2)

7. Adjust the gap between two lugs so that the GREEN

RASTER will come into the centre of the screen.

(Fig. 3)

8. Move the deflection yoke forward, and fix the position

of the deflection yoke so that the whole screen will

become green.

9. Insert the wedge to the top side of the deflection yoke

so that it will not move.

10. Input a crosshatch signal.

11. Verify that the screen is horizontal.

12.

Input red and blue raster signals, and make sure that

purity is properly adjusted.

Long lug

Short lug

WEDGE

DEFLECTION YOKE

P

CRT

P: PURITY MAGNET

4: 4-POLES

6: 6-POLES (convergence magnets)

4

P/C MAGNETS

(convergence magnets)

Fig. 1

PURITY MAGNETS

Bring the long lug over the short lug and

position them horizontally.

Fig. 2

(FRONT VIEW)

GREEN RASTER

CENTER

Fig. 3

12

Page 13

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4-pole convergence magnets overlap the red

and blue lines in the center of the screen (Fig. 1) and

turn them to magenta (red/blue).

3. Using 6-pole convergence magnets overlap the

magenta (red/blue) and green lines in the center of the

screen and turn them to white.

4. Repeat 2 and 3 above, and make the best

convergence.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflection yoke up and down and overlap

lines in the periphery. (Fig. 2)

2. Move the deflection yoke left to right and overlap the

lines in the periphery. (Fig. 3)

3. Repeat 1 and 2 above, and make the best

convergence.

After adjustment, fix the wedge at the original position.

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets with glue.

(FRONT VIEW)

Fig. 1

(FRONT VIEW)

RED GREEN BLUE

BLUE

GREEN GREEN

RED BLUE

BLUE GREEN RED

RED

Fig.2

(FRONT VIEW)

RED GREEN BLUE BLUE GREEN RED

RED

GREEN

BLUE

BLUE

GREEN

RED

Fig. 3

13

Page 14

9. DVD Part: Introduction of MTK1379 maintenance

1. Under normal power supply conditions, the maintenance plan for MT1379 mono-chip is: first the reset

circuit resets the MT1379, after the crystal oscillator circuit gave the clock signal to MT1379, MT1379 will

start the initialization check for Flash、E

start initialization check for 7Audio DAC, MT1336 and motor Driver.

2. If the all the a.m. parts are good, then MT1379 will send signal to motor Driver to drive the servo system,

pick up then to generate DVD light for collection, tracing the main shaft to check if there is any disc, and

confirm if it is CD format or DVD format disc. If the disc is in DVD format, the system will read the data

from the disc directly; if it is in CD format MT1336 will drive the CD laser to send out CD light and read the

data, the data then will be amplified through MT1336 and sent to MT1379 for data processing, released by

MPEG and resolved into video data and audio data, then they will be returned to analog signals through

VIDEO DAC、AUDIO DAC.

Decoder section

3. There is power supply, clock and reset, but the system does not work.

1) Check if all the address wires required for FLASH are exist, and if they are in normal status,

especially check if the A0~A15 of FLASH have normal signals, if there aren’t, then inspect MT1379

to see if there is faulty soldering. If there are normal signals at A0~A15, check if the address data

signal of MT1379 and SDRAM is normal. If it is normal, then check the signal at A16~A19 of

MT1379; if there are also signals, then check the 8 video data wires; it there is no signal, then

check the corresponding pins of MT1397 to see if there is any short circuit, break or faulty

soldering.

2) If all the a.m. conditions are good, but there is still no video signal output, then the filter circuit after

MT1379 shall be checked.

4. System in normal operation, but the audio has no sound.

1) Check if all the signals of DATA, MCLK, BCLK, LRCK and reset required by the Audio DAC are

exist, if there is signal missing, then check the signal line between MT1379 and Audio DAC. If the

line is connected properly, but there is no signal, then check if there is any welding problem at the

corresponding pins of MT1379. If it is still OK, it is probably the problem on MT1379 itself.

2) All the required signals are exist, while there is no audio output. Then you need to check the lower

passing amplifying circuit and the MUTE circuit at the back of Audio DAC. Also check if there is

any power supply to the Audio DAC.

3) Check if the power supply voltage required for playing is at normal level.

Servo Section

5. After the LOGO of the machine shows normally, there is no OSD display. This problem mainly is caused

by the abnormality between servo and MPEG, possible problems may be:

1) T1336 and its surrounding circuits have problems.

2) Servo part of MT1379 has problems.

6. OSD display is normal,while there is no action of servo part(feeding motor does not work, main shaft does

no turn, possible fault status are:

1) The corresponding signals giving by MT1379 to DMSO、FMSO are missing, the reason may be the

problem of MT1379 or the communication between MT1379 and motor Driver.

2) Not output from Motor Driver, the reason may be the problem on motor Driver or its corresponding

circuit.

7. Servo part in good status, while there is no pick up action(no light, no focus)

2

PROM、SDRAM, after everything is checked to be normal, it will

1) No light, check the power supply(power supply for pick up), or the light producing driving circuit to see

if they are in normal status.

2) No focus, check MT1379 to see if there is signal output from FOSO、TRSO.

Secondly, check motor driver to see if there is F+、F-、T+、T-signal output.

Thirdly, check the external corresponding circuit of the motor driver to see if there is any problem.

8. All the servo part has action, while it cannot read out the disc

1) Check MT1336 if there is RF net picture output, if there isn’t, then it must be the problem of MT1336

and external surrounding circuits, it there is output, then it might the problem of MT1369 and its

surrounding circuits.

14

Page 15

2) There is RF signal,but not in normal status,then check MT1336 and surrounding circuits.

3 )Everything is normal, but the disc cannot be read out, check MT1369 and its surrounding circuit

10. List of Parts

PART

LOCATION DESCRIPTION

FRONT CABINET ASS’Y BCJ7008-----Q 90806302 1

LENS MTAA7011AA--Q 90204520 1

SCREW SJ2824-87 ST3X10F 90600011 1

KEYS MTAA7012AA--Q 90204553 1

SCREW SJ2824-87 ST3X10F 90600011 3

SCREW SJ2838-87 ST3x12F 90600200 2

SWITCH BUTTON MTAA7013AA--Q

SPRING MTBH7004BC--Q 90100663 1

SPEAKER YDT0407-9AU-8W-8Ω

SPEAKER WIRE 90401453 2

SCREW SJ2824-87 ST3X8F 90600012 8

SCREW SJ2824-87 ST4X12F 90600015 2

WIRE ASS’Y D2006-12P-D2512-10P-TJC3-2P-350 90401676 1

FRONT AV CONNECTOR ASS’Y 90401336 1

DVD STAND MTAC7014AA--Q 90204556 1

SCREW SJ2824-87 ST3X12F 90600034 4

DVD ASS’Y DC005B 94006927 1

BACK CABINET MTFC7011AJ--Q 90204557 1

SCREW SJ2825-87 ST3X10F 90600037 1

AV LABEL 69.6X71.4

HIGH VOLTAGE SPACER TEM101 90200008 1

DVD DOOR MTAH7008AA--Q 90204558 1

POWER CORD CLIP MTAH7005AA--Q 90205627 1

SCREW SJ2824-87 SJ4X16F 90600023 8

SCREW SJ2824-87 SJ4X16F 90600023 2

TOP FOAM STAND MTEE7013AB--Q

BOTTOM FOAM STAND MTEE7014AB--Q

PLASTIC BRACKET MTFC1014AJ--Q 90806490 1

SCREW SJ2825-87 ST3X10F 90600037 6

UL POWER CORD JPRVVZ202XDFQ 90402120 1

040 PLASTIC CLIP MTAJ1001AG--Q 90200038 1

CRT ASS’Y 94005582 1

21" CRT A51LXR195X91JD 94004133 1

GROUNDING WIRE TJC1-1Y/2 90401291 1

DEGUASSING COIL HXC-54D 94500818 1

NUT M6 90600003 1

PARKAGING ASS’Y 90804858 1

RATING LABEL MTFB5364CA--Q 90205788 1

CARTON BOX 90505178 1

BATTERY 5# 94000105 2

DVD SHIELD(UP)

DVDSHIELD(DOWN)

90100709 1

90100710 1

15

NUMBER QTY

90204554

94008903

90204538

90503695

90503696

1

2

1

1

1

Page 16

PLASTIC BAG FOR USER MANUAL

REMOTE CONTROL

90204759

94009887

1

1

PLASTIC BAG FOR 21” COMPLETE SET 90500102 1

PLASTIC BAG FOR POWER CORD 90500018 1

USER MANUAL 90504553 1

TELESCOPIC MAST 94501185 1

MAIN BAORD ASS’Y 94008724 1

N301B HEAT SINK HEAT SINK 90100450 1

N301C IC TDA8357J 94401409 1

N301D SCREW ST3X8F SJ2831-87 90600097 1

V401B SCREW ST3X8F SJ2831-87 90600097 1

V401A HEAT SINK QHS-30184A 90100017 1

V401 TRANSISTOR 2SD2499 94401401 1

N801A HEAT SINK QHS-30184A 90100661 1

N801C IC KA5Q0765RTH-YDTU 94401392 1

N801D SCREW ST3X8F SJ2831-87 90600097 1

N802C IC L7809CS 94400808 1

N802B SCREW ST3X8F SJ2831-87 90600097 1

N802A HEAT SINK QHS-30184A 90100017 1

N601B IC AN7522N 94401684 1

N601A HEAT SINK QHS-30184A 90100665 1

N601C SCREW ST3X8F SJ2831-87 90600097 2

N804B IC KA278R05 94401923 1

N804A HEAT SINK MTBH4070BC--Q 90100443 1

N804C SCREW ST3X8F SJ2831-87 90600097 2

VD806 IC FFPF10U20STU 94401512 1

R625 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R110 METAL OXIDE RESISTOR RY16S-1W-33-J-05-E-A 94102578 1

R407 METAL OXIDE RESISTOR RY16S-1W-3.9K-J-12.5-E-A 94102667 1

R307 METAL OXIDE RESISTOR RY17S-2W-390-J-05-E-A 94100097 1

R414 METAL OXIDE RESISTOR RY17S-2W-1K-J-05-E-A 94102457 1

R413 METAL OXIDE RESISTOR RY17S-2W-7.5K-J-05-E-A 94100098 1

R810 METAL OXIDE RESISTOR RY17S-2W-18K-J-17.5-L-A 94102580 1

R802 METAL OXIDE RESISTOR RY17S-2W-33K-J-05-E-A 94100101 1

R801 METAL OXIDE RESISTOR RY17S-2W-33K-J-05-E-A 94100101 1

R501H

CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

C501 CERAMIC CAPACITOR CC1-B-500V-470PF-K-F05 94201264 1

C502 CERAMIC CAPACITOR CC1-B-500V-470PF-K-F05 94201264 1

R502

CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

R825 METAL OXIDE RESISTOR RY17S-2W-47K-J-05-E-A 94102581 1

R818 METAL OXIDE RESISTOR RY15S-1/2W-1.5K-J------T 94100085 1

R503

R505

R506

R820 FUSE RESISTOR

CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

FUSE RESISTOR RF10-2W-2.4Ω-J-A 94100704 1

FUSE RESISTOR

RF10-2W-68-J-05-E-A 94100128

RF10-2W-68Ω-J-05-C 94100128

1

R821 FUSE RESISTOR RF10-2W-1-J-05-E-A 94100125 1

R824 FUSE RESISTOR RF10-1/2W-1-J-05-E-A 94102583 1

R415 FUSE RESISTOR RF10-1/2W-1-J-05-E-A 94102583 1

R302 FUSE RESISTOR RF10-1/2W-10-J-05-E-A 94102668 1

R409 FUSE RESISTOR RF10-1/2W-0.22-J-05-E-A 94102584 1

R306 FUSE RESISTOR RF10-2W-0.68-J-05-E-A 94102586 1

R815 FUSE RESISTOR RF10-2W-0.18-J-15-L-A 94102669 1

R416 FUSE RESISTOR RF10-1/2W-68-J-12-L-A 94102591 1

DV801 TVR14561 94400806 1

P801 THERMISTOR MZ73-14RM270V 94400046 1

16

Page 17

RP801 THERMISTOR MF72-2-5Ω±N 94400047 1

C248 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C419 CERAMIC CAPACITOR CT1-B-2kV-681pF-K-07-A 94201373 1

C410 CERAMIC CAPACITOR CT1-B-2kV-681pF-K-07-A 94201373 1

C807 CERAMIC CAPACITOR CT1-B-2kV-561pF-K-07-A 94200067 1

C810 CERAMIC CAPACITOR CT1-B-500V-560pF-K-F05 94201449 1

C823 CERAMIC CAPACITOR CT81-400VAC-18B-2E4-332-M-10-C-A 94202412 1

C805 CAPACITOR CT1-B-1kV-1000pF-K-07-A 94201071 1

C849 CAPACITOR CL21X-63V-224-J------F 94201463 1

C216 CAPACITOR CL21X-63V-224-J------F 94201463 1

C414 CAPACITOR CL21X-400V-104-J-07-A-A 94200098 1

C227 CAPACITOR CBB13-50V-104-J-07-A-A 94200099 1

C416 CAPACITOR CBB21-400V-364-J-20-G-A 94200101 1

C409 CAPACITOR

CBB81-1.6KV-752-J-20-A-A 94200104

1

C802A CAPACITOR MKT61-275V-104-M-15-G-A 94200105 1

C222 ELECT. CAPACITOR CD110X-50V-1µF-M-F05 94200043 1

C236 ELECT. CAPACITOR CD110X-16V-22µF-M-F05 94201043 1

C846 ELECT. CAPACITOR CD110X-25V-1000µF-M-05-A 94201011 1

C811 ELECT. CAPACITOR CD110X-25V-2200µF-M-05-A 94201319 1

C610 ELECT. CAPACITOR CD110X-25V-1000µF-M-05-A 94201011 1

C304 ELECT. CAPACITOR CD263-100V-33uF-M-05-A 94202297 1

C418 ELECT. CAPACITOR CD263-100V-33uF-M-05-A 94202297 1

C808 ELECT. CAPACITOR CD263-160V-100µF-M-07-A 94200736 1

C411 ELECT. CAPACITOR CD288H-250V-22uF±20%-05-G-A 94201604 1

C801 ELECT. CAPACITOR CD293-400V-150µF-M-10-A 94201341 1

C852 ELECT. CAPACITOR CD110X-16V-1000µF-M-F05 94200802 1

N201 IC TDA9370PS/N2/A 94401831 1

N202 IC M24C08(BR24C08) 94400636 1

N202 IC PC817C 94400036 1

N703 IC TC4052BP 94400138 1

N805 IC KA78R12 94401924 1

N702 IC HEF4053 94400503 1

X201 CRYTAL JA12D-12MHZ-20PF 94600198 1

Z201 CERAMIC TRAP FILTER

XT5.5B 94600015 1

TU101 TUNER ENV56DB4G3 94003734 1

SF101 SAW FILTER

D1510C

94600292 1

F801 FUSE TSG-3.15A-250V 94000137 1

F801A FUSE CLIP FC503 90100021 1

F801B FUSE CLIP FC503 90100021 1

L401 LINEARITY COIL LX034 94501053 1

L801 LINE FILTER LCL-207 94500686 1

T444 FLYBACK TRANSFORMER

BSC25-0283G 94501054

1

T801 SWITCHING MODE TRANSFORMERBCK-07-DE7 94501146 1

T401 HORIZONTAL TRANSFORMER AA26-50001B 94500034 1

LW INDUCTOR

V999 CRT SOCKET

TK115 94401063

GZS10-2-BD 94300007

1

1

CN801 CONNECTOR SOCKET TJC1-2A 94300110 1

CN802 CONNECTOR SOCKET TJC2-2A 94300063 1

CN601 CONNECTOR SOCKET TJC3-2A 94300092 1

CN602 CONNECTOR SOCKET TJC3-2A 94300092 1

CN502 CONNECTOR SOCKET TJC3-3A 94300111 1

CN200 CONNECTOR SOCKET TJC3-3A 94300012 1

CN211 CONNECTOR SOCKET TJC3-3A 94300012 1

CN210 CONNECTOR SOCKET TJC3-5A 94300104 1

CN503 CONNECTOR SOCKET TJC3-5A 94300104 1

CN401 CONNECTOR SOCKET TJC1-4A 94300307 1

17

Page 18

CN809 CONNECTOR SOCKET TJC3-5A 94300104 1

VD802 DIODE T1R5GU41-12.5-M 94401993 1

VD803 DIODE T1R5GU41-12.5-M 94401993 1

C259 DIODE MTZJ5.1B------T 94400617 1

CN501 WIRE ASS’Y TJC3-5Y-750mm 90401725 1

CN502 WIRE ASS’Y TJC3-3Y-750mm 90401724 1

GT501 CONNECTOR SOCKET TJC1-1A 94300090 1

GT502 CONNECTOR SOCKET TJC1-1A 94300090 1

C503 CERAMIC CAPACITOR CC1-B-500V-470PF-K-F05 94201264 1

C705 CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C848 ELECT. CAPACITOR CD110X-25V-1000µF-M-05-A 94201011 1

CN702 WIRE ASS’Y 90401872 1

CN706 WIRE ASS’Y 90401670 1

CN703 CONNECTOR SOCKET TJC3-8A 94300106 1

S WIRE ASS’Y 90401672 1

CN810 WIRE ASS’Y TJC3-4A 90400514 1

CN807-CN808WIRE ASS’Y 90401671 1

G WIRE ASS’Y 150mm 90400064 1

DVD SCART SOCKET CS-103 94300457 1

MAIN PCB 91801280 91801280 1

R104 CARBON FILM RESISTOR RT13-1/6W-10-J------T 94100065 1

R752 CARBON FILM RESISTOR RT13-1/6W-10-J------T 94100065 1

R742 CARBON FILM RESISTOR RT13-1/6W-10-J------T 94100065 1

R216 CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

R103 CARBON FILM RESISTOR RT13-1/6W-100Ω-J-T52 94100017 1

R943 CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

R250 CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

R257 CARBON FILM RESISTOR RT13-1/6W-47-J------T 94100066 1

R258* CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R265 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R715 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R735 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R733 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R734 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

RS03 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

R718 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

RS01 CARBON FILM RESISTOR RT13-1/6W-75-J------T 94100067 1

RS02 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R208 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R209 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R210 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R230 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R235 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R236 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R237 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R245 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R252 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R743 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R744 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R745 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R740 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R741 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

W235 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

W236 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

18

Page 19

R280 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R281 CARBON FILM RESISTOR RT13-1/6W-100-J------T 94100017 1

R251 CARBON FILM RESISTOR RT13-1/6W-200-J------T 94100133 1

R263 CARBON FILM RESISTOR RT13-1/6W-200-J------T 94100133 1

R843 CARBON FILM RESISTOR RT13-1/6W-220-J------T 94100019 1

R817A CARBON FILM RESISTOR RT13-1/6W-220-J------T 94100019 1

R244 CARBON FILM RESISTOR RT13-1/6W-390-J------T 94100134 1

R255 CARBON FILM RESISTOR RT13-1/6W-430-J------T 94100069 1

R106 CARBON FILM RESISTOR RT13-1/6W-470-J------T 94100020 1

R256 CARBON FILM RESISTOR RT13-1/6W-470-J------T 94100020 1

R242 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R243 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R258 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R840 CARBON FILM RESISTOR RT13-1/6W-510-J------T 94100070 1

R227 CARBON FILM RESISTOR RT13-1/6W-1K-J--------T 94100023 1

R841 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R310 CARBON FILM RESISTOR RT13-1/6W-1.5K-J------T 94101350 1

R861 CARBON FILM RESISTOR RT13-1/6W-1.5K-J------T 94100025 1

R102 CARBON FILM RESISTOR RT13-1/6W-2.2KΩ-J-T52 94100026 1

R215 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R266 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R247 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R220 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R278 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R747 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R746 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R845 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R846 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R229 CARBON FILM RESISTOR RT13-1/6W-3.9K-J------T 94100071 1

R830 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R105 CARBON FILM RESISTOR RT13-1/6W-3.3K-J------T 94101328 1

R211 CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R212 CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R207 CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R262* CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R241 CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R623 CARBON FILM RESISTOR RT13-1/6W-4.7K-J------T 94100029 1

R605 CARBON FILM RESISTOR RT13-1/6W-5.6KΩ-J------T 94100721 1

R606 CARBON FILM RESISTOR RT13-1/6W-5.6KΩ-J------T 94100721 1

R610 CARBON FILM RESISTOR RT13-1/6W-5.6KΩ-J------T 94100721 1

R611 CARBON FILM RESISTOR RT13-1/6W-5.6KΩ-J------T 94100721 1

R213 CARBON FILM RESISTOR RT13-1/6W-6.2K-J------T 94100072 1

R848 CARBON FILM RESISTOR RT13-1/6W-15K-J------T 94100034 1

R847 CARBON FILM RESISTOR RT13-1/6W-15K-J------T 94100034 1

R248 CARBON FILM RESISTOR RT13-1/6W-6.8K-J------T 94100031 1

R246 CARBON FILM RESISTOR RT13-1/6W-8.2K-J------T 94100032 1

R860 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R862 CARBON FILM RESISTOR RT13-1/6W-15K-J------T 94100034 1

R218 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R214 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R218 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R831 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R620 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R622 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R738 CARBON FILM RESISTOR RT13-1/6W-220-J------T 94100019 1

R739 CARBON FILM RESISTOR RT13-1/6W-220-J------T 94100019 1

19

Page 20

R849 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R833 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R832 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R850 CARBON FILM RESISTOR RT13-1/6W-10K-J------T 94100033 1

R238 CARBON FILM RESISTOR RT13-1/6W-1K-J------T 94100023 1

R311 CARBON FILM RESISTOR RT13-1/6W-12K-J------T 94100073 1

R219 CARBON FILM RESISTOR RT13-1/6W-15K-J------T 94100034 1

R226 CARBON FILM RESISTOR RT13-1/6W-15K-J------T 94100034 1

R249 CARBON FILM RESISTOR RT13-1/6W-20K-J------T 94100074 1

R274 CARBON FILM RESISTOR RT13-1/6W-22K-J------T 94100779 1

R276 CARBON FILM RESISTOR RT13-1/6W-27K-J------T 94100780 1

W610 CARBON FILM RESISTOR RT13-1/6W-56K-J------T 94100038 1

R275 CARBON FILM RESISTOR RT13-1/6W-270K-J------T 94100943 1

R273 CARBON FILM RESISTOR RT13-1/6W-33K-J------T 94100036 1

R621 CARBON FILM RESISTOR RT13-1/6W-33K-J------T 94100036 1

R851 CARBON FILM RESISTOR RT13-1/6W-33K-J------T 94100036 1

R233 CARBON FILM RESISTOR RT13-1/6W-36KΩ-J 94100767 1

R261 CARBON FILM RESISTOR RT13-1/6W-68K-J------T 94100039 1

R277 CARBON FILM RESISTOR RT13-1/6W-100K-J------T 94100077 1

R303 CARBON FILM RESISTOR RT13-1/6W-100K-J------T 94100077 1

R314 CARBON FILM RESISTOR RT13-1/6W-270K-J------T 94100943 1

R407 METAL OXIDE RESISTOR RY15S-1/2W-0.39-J------T 94100079 1

R408 METAL OXIDE RESISTOR RY15S-1/2W-33-J------T 94100080 1

R403 METAL OXIDE RESISTOR RY15S-1/2W-270-J------T 94100083 1

R406 METAL OXIDE RESISTOR RY15S-1/2W-330-J------T 94102592 1

R809 METAL OXIDE RESISTOR RY15S-1/2W-39K-J------T 94102161 1

R822 METAL OXIDE RESISTOR RY15S-1/2W-470K-J------T 94100090 1

R823 METAL OXIDE RESISTOR RY15S-1/2W-470K-J------T 94100090 1

R807 RESISTOR RS11-1/2W-3.3M-K------T 94100103 1

RX801 RESISTOR RS11-1/2W-3.3M-K------T 94100103 1

R260 METAL FILM RESISTOR RJ13-1/6W-9.1K-J------T 94100106 1

R262 METAL FILM RESISTOR RJ13-1/6W-9.1K-J------T 94100106 1

R259 METAL FILM RESISTOR RJ13-1/6W-100K-J------T 94102210 1

R228 METAL FILM RESISTOR RJ13-1/6W-39K-G------T 94101159 1

R312 METAL FILM RESISTOR RJ15X-1/2W-2.2KΩ-F-T52 94102527 1

R313 METAL FILM RESISTOR RJ15X-1/2W-2.2KΩ-F-T52 94102527 1

R308 METAL FILM RESISTOR RJ15S-1/2W-1.5-F------T 94101353 1

R305 METAL FILM RESISTOR RJ15S-1/2W-1.3-F------T 94102593 1

R803 METAL FILM RESISTOR RJ15S-1/2W-390Ω±1%-----T 94102526 1

R805 METAL FILM RESISTOR RJ15S-1/2W-600-J------T 94102162 1

R819 METAL FILM RESISTOR RJ15S-1/2W-1K-F------T52 94101354 1

R420 METAL FILM RESISTOR RJ15S-1/2W-232K-F------T 94102851 1

R816 METAL FILM RESISTOR RJ15S-1/2W-123K-F------T 94102595 1

R817 METAL FILM RESISTOR RJ15S-1/2W-2.49K-F-J 94101355 1

C417 CERAMIC CAPACITOR CT1-B-500V-330pF-K-F05 94202282 1

C403 CERAMIC CAPACITOR CT1-B-500V-470pF-K-F05 94201264 1

C402 CERAMIC CAPACITOR CT1-B-500V-560pF-K-F05 94201449 1

C847 CERAMIC CAPACITOR CT1-B-500V-560pF-K-F05 94201449 1

C845 CERAMIC CAPACITOR CT1-B-500V-560pF-K-F05 94201449 1

C239 CERAMIC CAPACITOR CC1-CH-63V-33pF-J-F05 94201124 1

C240 CERAMIC CAPACITOR CC1-CH-63V-33pF-J-F05 94201124 1

C208 CERAMIC CAPACITOR CC1-CH-63V-56pF-J-F05 94201228 1

C209 CERAMIC CAPACITOR CC1-CH-63V-56pF-J-F05 94201228 1

C804 CERAMIC CAPACITOR CT1-B-63V-3900PF-K-F05 94202277 1

C218 CERAMIC CAPACITOR CT1-B-63V-2200pF-K-F05 94200760 1

C249 CERAMIC CAPACITOR CC1-CH-63V-150PF-J-F05 94200715 1

20

Page 21

C232 CERAMIC CAPACITOR CC1-CH-63V-330PF-J-F05 94202373 1

C231 CERAMIC CAPACITOR CT1-B-63V-1000pF-K-F05 94200981 1

C234 CERAMIC CAPACITOR CT1-B-63V-1000pF-K-F05 94200981 1

C110 CERAMIC CAPACITOR CT1-B-63V-1000pF-K-F05 94200981 1

C229 CERAMIC CAPACITOR CT1-B-63V-3300PF-K-F05 94201178 1

C221 CERAMIC CAPACITOR CT1-B-63V-4700PF-K-F05 94201039 1

C603 CERAMIC CAPACITOR CT1-B-63V-4700PF-K-F05 94201039 1

C611 CERAMIC CAPACITOR CT1-B-63V-4700PF-K-F05 94201039 1

C111 CERAMIC CAPACITOR CT1-2F4-63V-0.01µF-Z------F 94201040 1

C207 CERAMIC CAPACITOR CT1-B-63V-0.01µF-K-F05 94201040 1

C225 CERAMIC CAPACITOR CT1-B-63V-0.01µF-K-F05 94201040 1

C226 CERAMIC CAPACITOR CT1-B-63V-0.01µF-K-F05 94201040 1

C228 CERAMIC CAPACITOR CT1-F-63V-0.022µF-Z-F05 94201448 1

C254 CERAMIC CAPACITOR CT1-F-63V-0.022µF-Z-F05 94201448 1

C101 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C202 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C220 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C223 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C237 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C242 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C243 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C244 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C245 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C256 CERAMIC CAPACITOR CS1-F-63V-0.1µF-Z-F05 94201617 1

C306 CAPACITOR CL11-63V-0.047µF-J-F05 94201458 1

CS01 CAPACITOR CL11-63V-1000pF-J-F05 94201459 1

C803 CAPACITOR CL11-63V-0.047µF-J-F05 94201458 1

C217 CAPACITOR CL21X-63V-224-J------F 94201463 1

C850 CAPACITOR CL21X-63V-224-J------F 94201463 1

C725 CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C247 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C253 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C401 CAPACITOR CL21X-100V-103-J------F 94200095 1

C413 CAPACITOR CL23B-400V-472-J------F 94200097 1

C814 CAPACITOR CL21X-63V-104-J------F 94201462 1

C853 CAPACITOR CL21X-63V-104-J------F 94201462 1

C851 CAPACITOR CL21X-63V-104-J------F 94201462 1

C722 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C727 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C706 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C233 ELECT. CAPACITOR CD110X-50V-4.7µF-M-F05 94200751 1

C230 ELECT. CAPACITOR CD110X-16V-10µF-M-F05 94200008 1

C246 ELECT. CAPACITOR CD110X-16V-10µF-M-F05 94200008 1

C250 ELECT. CAPACITOR CD110X-16V-10µF-M-F05 94200008 1

C842 ELECT. CAPACITOR CD110X-16V-10µF-M-F05 94200008 1

C107 ELECT. CAPACITOR CD110X-16V-10µF-M-F05 94200008 1

C108 ELECT. CAPACITOR CD110X-16V-47µF-M-F05 94200988 1

C252 ELECT. CAPACITOR CD110X-16V-47µF-M-F05 94200988 1

C257 ELECT. CAPACITOR CD110X-16V-47µF-M-F05 94200988 1

C620 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C829 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C819 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C841 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C922 ELECT. CAPACITOR D110X-16V-100µF-M-F05 94200747 1

C219 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C854 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

21

Page 22

C241 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C255 ELECT. CAPACITOR CD110X-16V-100µF-M-F05 94200747 1

C408 ELECT. CAPACITOR CD110X-25V-47µF-M-F05 94201113 1

C303 ELECT. CAPACITOR CD263-35V-100uF-M-F05 94200746 1

C102 ELECT. CAPACITOR CD110X-25V-220µF-M-F05 94200550 1

C820 ELECT. CAPACITOR CD110X-25V-220µF-M-F05 94200550 1

C238 ELECT. CAPACITOR CD110X-50V-1µF-M-F05 94200043 1

C750 ELECT. CAPACITOR CD110X-50V-1µF-M-F05 94200043 1

C621 ELECT. CAPACITOR CD110X-50V-1µF-M-F05 94200043 1

C740 ELECT. CAPACITOR CD110X-50V-1µF-M-F05 94200043 1

C224 ELECT. CAPACITOR CD110X-50V-2.2µF-M-F05 94200044 1

C258 ELECT. CAPACITOR CD110X-50V-2.2µF-M-F05 94200044 1

C201 ELECT. CAPACITOR CD110X-50V-10µF-M-F05 94200046 1

C802 ELECT. CAPACITOR CD110X-50V-47µF-M-F05 94200858 1

C404 ELECT. CAPACITOR CD263-25V-470uF-M-F05 94200729 1

C415 ELECT. CAPACITOR CD110-160V-1uF-M-F 94200993 1

C604 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

C612 ELECT. CAPACITOR CD71-50V-1uF-M-F05 94200994 1

L210 INDUCTOR LGA0203-5R6-K------T 94500020 1

L101 INDUCTOR LGA0203-1µH-K-T52 94500450 1

L102 INDUCTOR LGA0203-100-K------T 94500021 1

L202 INDUCTOR LGA0203-100-K------T 94500021 1

L206 INDUCTOR LGA0203-100-K------T 94500021 1

L207 INDUCTOR LGA0203-100-K------T 94500021 1

L208 INDUCTOR LGA0203-100-K------T 94500021 1

L306 INDUCTOR LGA0305-10uH-J-T52 94500264 1

L402 INDUCTOR LB3.5*5-2------F 94500027 1

L804 INDUCTOR LB3.5*6-3------T 94500028 1

DZ831 DIODE 1N4148------T 94400049 1

VD201 DIODE 1N4148------T 94400049 1

VD202 DIODE 1N4148------T 94400049 1

VD809 DIODE 1N4148------T 94400049 1

VD816 DIODE 1N4148------T 94400049 1

VD817 DIODE 1N4148------T 94400049 1

VD620 DIODE 1N4148------T 94400049 1

VD217 DIODE 1N4148------T 94400049 1

VD401 DIODE 1N4004-T52 94400473 1

VD402 DIODE 1N4004-T52 94400473 1

L209 DIODE 1N4004-T52 94400473 1

VD804 DIODE TB1206------T 94400052 1

VD403 DIODE TC2406------T 94400053 1

VD406 DIODE T1R5GU41------T 94400055 1

VD404 DIODE T1R5GU41------T 94400055 1

VD805 DIODE T1R5GU41------T 94400055 1

VD405 DIODE TTVR10G------T 94400056 1

VD810 DIODE TERB4304------T 94400059 1

DZ808 DIODE MTZJ3.9B------T 94400615 1

DZ205 DIODE MTZJ4.7B------T 94400616 1

DZ102 DIODE MTZJ5.1B------T 94400617 1

DZ402 DIODE MTZJ5.1B------T 94400617 1

DZ802 DIODE MTZJ5.1B------T 94400617 1

DZ101 DIODE MTZJ9.1B------T 94400493 1

DZ701 DIODE MTZJ9.1B------T 94400493 1

DZ702 DIODE MTZJ9.1B------T 94400493 1

DZ703 DIODE MTZJ9.1B------T 94400493 1

DZ807 DIODE MTZJ9.1B------T 94400493 1

22

Page 23

VD811 DIODE TRM11C--------T 94400453 1

VD812 DIODE TRM11C--------T 94400453 1

VD813 DIODE TRM11C--------T 94400453 1

VD814 DIODE TRM11C--------T 94400453 1

DZ303 DIODE MTZJ15C------T 94400372 1

DZ301 DIODE MTZJ22A------T 94400068 1

V101 TRANSISTOR

TRANSISTOR2SC2216(O)-05-D-A

94400405 1

V620 TRANSISTOR KSA539-YTA------F 94400203 1

V622 TRANSISTOR KSA539-YTA------F 94400203 1

V402 TRANSISTOR KSC2331-YTA------F 94400204 1

V206 TRANSISTOR KSC815-YTA------F 94400192 1

V208 TRANSISTOR KSC815-YTA------F 94400192 1

V212 TRANSISTOR KSC815-YTA------F 94400192 1

V213 TRANSISTOR KSC815-YTA------F 94400192 1

V621 TRANSISTOR KSC815-YTA------F 94400192 1

V801 TRANSISTOR KSC815-YTA------F 94400192 1

V802 TRANSISTOR KSC815-YTA------F 94400192 1

V803 TRANSISTOR KSC815-YTA------F 94400192 1

V804 TRANSISTOR KSC815-YTA------F 94400192 1

V806 TRANSISTOR KSC815-YTA------F 94400192 1

V807 TRANSISTOR KSC815-YTA------F 94400192 1

V805 TRANSISTOR 2SB764E 94401676 1

DZ201 IC KA33VTA------F 94400201 1

DZ803 IC KA431AZTA------F 94400200 1

R511 METAL OXIDE RESISTOR RY17-2W-18KΩ-J-20-D 94102168 1

R512 CARBON FILM RESISTOR RT13-1/6W-220-J------T

R513 CARBON FILM RESISTOR RT13-1/6W-390-J------T

R514

RESISTOR

RS11-1/2W-1.8K-K------T 94100102

94100019

94100019

1

1

1

R516 CARBON FILM RESISTOR RT13-1/6W-270-J------T 94100795 1

R521 METAL OXIDE RESISTOR RY17-2W-18KΩ-J-20-D 94102168 1

R522 CARBON FILM RESISTOR

RT13-1/6W-220-J------T 94100019

1

R523 CARBON FILM RESISTOR RT13-1/6W-390-J------T 94100134 1

R524 RESISTOR

RS11-1/2W-1.8K-K------T 94100102

1

C508 ELECT. CAPACITOR CD110X-250V-10µF-M-F05 94200728 1

C509 CERAMIC CAPACITOR CD110X-250V-4.7µF-M-F05 94200727 1

VD501 DIODE 1N4148------T 94400049 1

VD503 DIODE 1N4148------T 94400049 1

VD507 DIODE MTZJ8.2B--T 94400621 1

VD505 DIODE 1SS133T-72---------T 94400106 1

VD502 DIODE 1SS133T-72---------T 94400106 1

VD504 DIODE 1SS133T-72---------T 94400106 1

V511

V521

V531

V513

V523

V533

C510

C511

TRANSISTOR BF420 94400578 1

TRANSISTOR BF420 94400578 1

TRANSISTOR BF420 94400578 1

TRANSISTOR BF420 94400578 1

TRANSISTOR BF420 94400578 1

TRANSISTOR BF420 94400578 1

CERAMIC CAPACITOR CT1-B-2KV-1000PF-K-07-A 94200971 1

CERAMIC CAPACITOR

CT1-B-63V-1000pF-K-F05 94200981

1

R526 CARBON FILM RESISTOR RT13-1/6W-270-J------T 94100795 1

R527

METAL OXIDE RESISTOR

RY17S-2W-33K-J-05-E-A 94100101

1

R531 METAL OXIDE RESISTOR RY17-2W-18KΩ-J-20-D 94102168 1

R806 RESISTOR RS11-1/2W-3.3M-K------T 94100103 1

R532 CARBON FILM RESISTOR

RT13-1/6W-220-J------T 94100019

1

R533 CARBON FILM RESISTOR RT13-1/6W-390-J------T 94100134 1

R534

RESISTOR

RS11-1/2W-1.8K-K------T 94100102

23

1

Page 24

R536 CARBON FILM RESISTOR RT13-1/6W-270-J------T 94100795 1

R550 METAL OXIDE RESISTOR RY15S-1/2W-10M-J------T 94100091 1

V512

V522

V532

TRANSISTOR BF421 94400577 1

TRANSISTOR BF421 94400577 1

TRANSISTOR BF421 94400577 1

CC2 COAXIAL 94300460 1

CC1 WIRE ASS’Y 90401735 1

COAXIAL PCB 91801448 1

DVD INPUT PCB 0091800828V1.0 91800828 1

R001

R002

R003

C001

C002

C003

CN001

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

ELECT. CAPACITOR

ELECT. CAPACITOR

ELECT. CAPACITOR

CONNECTOR SOCKET

RT13-1/6W-120-J------T 94100942 1

RT13-1/6W-200-J------T 94100133 1

RT13-1/6W-100-J------T 94100017 1

CD110-16V-10uF±20%------F 94200008 1

CD110-16V-10uF±20%------F 94200008 1

CD110-16V-10uF±20%------F 94200008 1

TJC3-4AW 94300283 1

DVD AV CONNECTOR SOCKET AV9-3B04 94300393 1

LP01

A1001

CNT08

TV/AV

MENU

VV+

PP+

OPEN/CLOSE

PLAY

STOP

CN01

CN03

CN04

CN05

CN02

POWER

VD02

RD14

RD17

CONTROL BOARD ASS’Y

LED

REMOTE RECEIVER

AV CONNECTOR SOCKET

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

TACT SWITCH

CONNECTOR SOCKET

CONNECTOR SOCKET

WIRE ASS’Y

WIRE ASS’Y

WIRE ASS’Y

TACT SWITCH KFC-A06-1H-9 94008608 1

TRANSISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

94009500

TOL-30mRGdEHa 94401957

HS0038A 94000136

AV3-B03 94300018

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

K66T-1B-BL-6.5 94000480

TJC3-6A 94300107

TJC3-2P-260 90400915

300mm 90402080

230mm 90401673

TJC3-5Y-750mm 90401725

KSC815-YTA------F 94400192

RT13-1/6W-1K-J------T 94100023

RT13-1/6W-1K-J------T 94100023

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

CN08 WIRE ASS’Y 450mm 90401317 1

R01

R02

R03

R04

R05

RB06

RB07

R12

R11

R13

VD01

C13

CONTROL BOARD PCB

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

TRANSISTOR

CERAMIC CAPACITOR

0091801372V2.0 91801372

RT13-1/6W-470-J------T 94100020

RT13-1/6W-620-J------T 94100916

RT13-1/6W-1K-J------T 94100023

RT13-1/6W-1.2K-J------T 94100753

RT13-1/6W-1.8K-J------T 94100722

RT13-1/6W-10K-J------T 94100033

RT13-1/6W-10K-J------T 94100033

RT13-1/6W-100-J------T 94100017

RT13-1/6W-100-J------T 94100017

RT13-1/6W-10K-J------T 94100033

2SA1015 94400439

CT1-F-63V-0.01µF-Z-F05 94201040

24

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 25

C11

C12

ELECT. CAPACITOR

ELECT. CAPACITOR

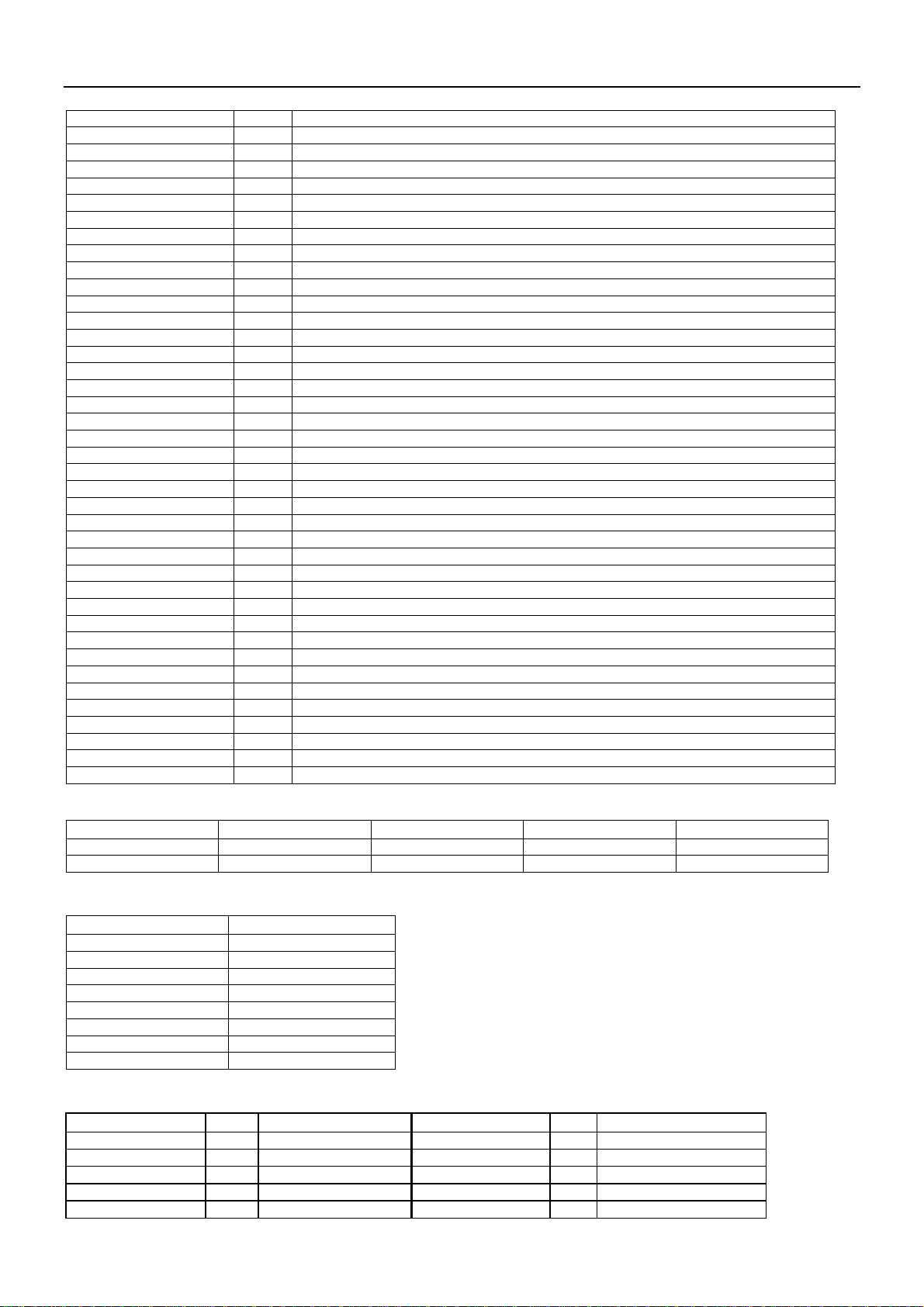

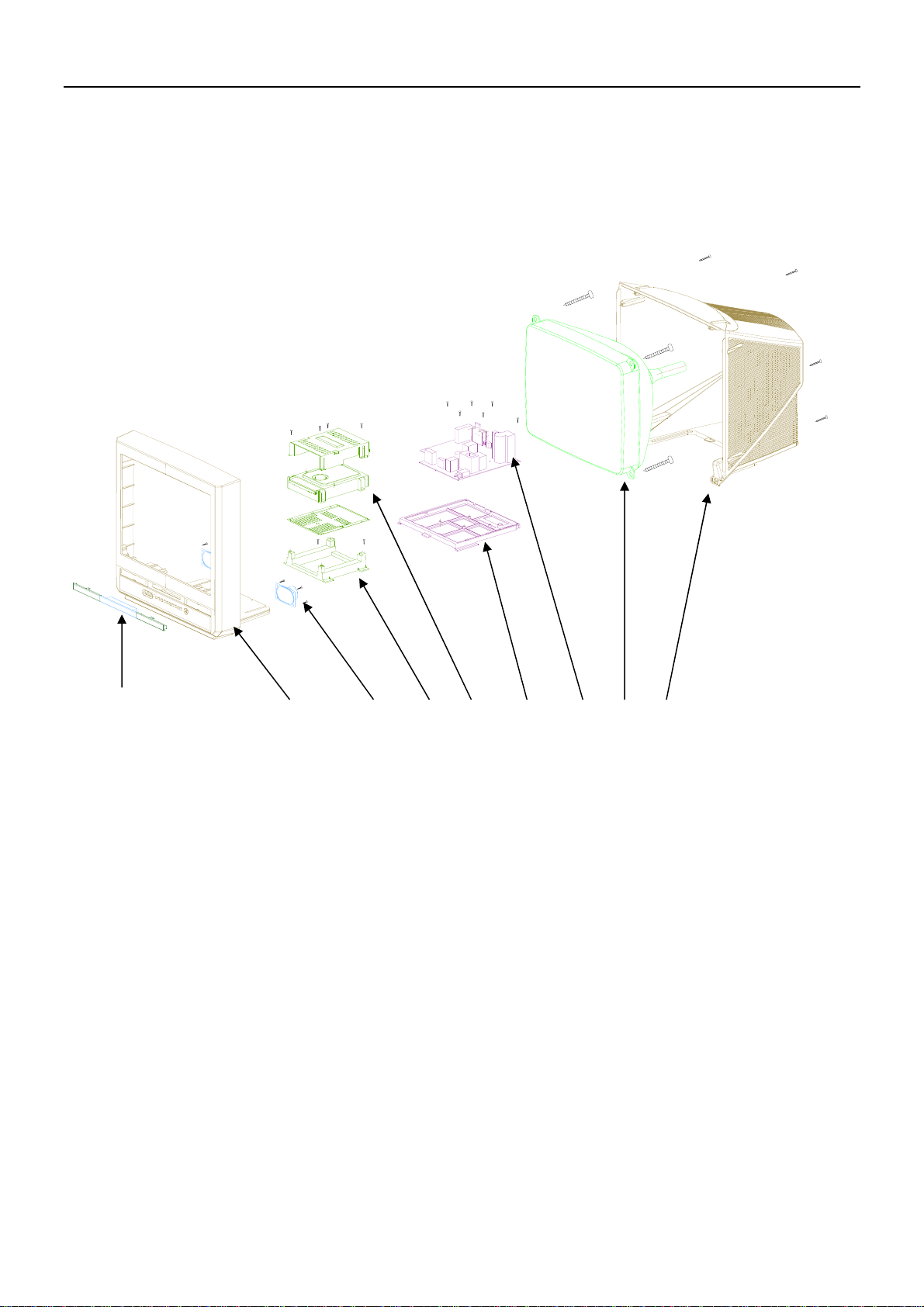

Exploed view

CD110X-16V-100µF-M-F05 94200747

CD110X-16V-47µF-M-F05 94200988

1

1

1 2 3 4 5 6 7 8 9

25

Page 26

Exploded view part list

NO. MATERIAL CODE PARTS NAME Q’TY REMARK

1 0090503696 Switch batton 1

2 0090204556 Front frame 1

3 0090204556 Dvd stand 1

4 0094006927 Dvd 1

5 0090204546

6 0094009819 Main board 1

7 0094000748 CRT 1

8 0094008903 Speaker 2

9 0090204557 Rear cover 1

Main board

stand

26

Exploded view part list

1

*

*

Page 27

W90DL-206--Q

P+

P-

TV/AV

63V-0.1µF

R104

R103

1/6W-22

RB04

1.2K

w236

1/6W-100

C101

250V/3.15A

F801

MKT61-275V-104

R801

33K

R802

33K

C801

MENU

RB02

RB03

620

1K

B+SCL SDA

NC

1/6W-100

C202

C102

DZ102

104

25V-220µF

MTZJ5.1B

1/6W-10

DZ101

MTZJ9.1B

C108

16V-47µF

C111

63V-0.01µF

C109

R106

1/6W-470

L101

LGA0203-1µH

C802A

N801

KA5Q0765RTH-YDTU

4

VFB

VCC

SYNC

35

63V-3900PF

C804

VD804

TB1206

C802

50v-47u

C803

63V-0.047µF

TJC3-2Y

1

CNB02

RB01

CNB01

470

TJC3-2Y

2

GNDBT11IF

9

1083154672

w235

C201

10u

R104

SF101

D1510C

V101

BF370

SCL

SDA

SCL

SDA

A1-33V

DZ201

KA33V

C110

63V-1000pF

R105

R102

1/6W-13K

1/6W-2.2KΩ

SYSTEM

B4-12V

MUTE

C422

63V-104

SYSTEM

STAND BY

A7-8V

A7-8V

R840

1K

LD901

HTRYG9208

C823

332

R806

1/2W-3.3M

T801

BCK-07-DE7

1

。

L803

4

LB3.5*6

1

2

C805

1kV-1000pF

8

。

R805

VD809

1/2W-600

IN4148

R803

1/2W-390

9

VD810

TERB4304

PC801

PC817C

4

3

R212

R211

R220

R286

R278

R222

3.3K

3.3K

A6-5V

3.3K

3.3K

4.7K

4.7K

STANDBY

A5-3.3V

DZ259

MTZJ5.1B

R279

10K

R219

L202

10uH

50V-2.2µF

R281

39K

VD-N

R209

100

C209

R210

56

100

C208

56

R266

VT

3.3K

R216

47

C259

223

15K

C214

104

224

C216

C219

C220

104

100u

C217

224

C218

222

R226

C222

15K

1u

C221

472

C223

C224

104

2.2u

EWD

C225

C258

63V-0.01µF

C226

63V-0.01µF

R228

1/6W-39K

C227

50V-104

C228

63V-0.022µF

C230

R280

16V-10µF

39K

R229

1/6W-3.9K

C231

63V-1000pF

C232

63V-330PF

C233

VD-P

50V-4.7µF

A3-15.8

A5-3.3V

R841

1K

V805

2SB764(Y)

R821

R860

2W-1Ω

1/6W-10K

R861

1/6W-1.5K

R862

V806

1/6W-15K

POWER

KSC815

R820

2W-39Ω

R807

C807

1/2W-3.3M

2kV-561pF

C808

160V-100UF

VD802

10

T1R5GU41-12.5-M

。

C810

500V-560pF

12

。

14

VD805

C811

T1R5GU41

25V-2200µF

15

VD803

T1R5GU41

16

。

C845

C846

500V-560pF

25V-1000µF

17

VD806

。

18

FFPF10U20STU

C848

C847

1000UF

19

500V-560pF

R818

1

1/2W-1.5K

C814

R819

R809

63V-104

1/2W-1K

1/2W-39K

2

DZ803

KA431

SCL

SDA

1/6W-100

R208

A6-5V

R215

3.3K

1

2

3

461

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

R816

1/2W-123K

R817

1/2W-2.49K

R817A

1/6W-220

STANDBY

SCL

SDA

KEY

SYSTEM

MUTE

VOL

VSSC/P

CTL

STAND BY

VSSA

SEC.PLL

VP2

DECD/G

PH2.LF

PH1.LF

GND3

DEC.BG

V.BRA

IF.IN1

IF.IN2

I.REF

V.S.C.

AGC

AV.DEEM

DECS.DEM

GND2

SND.PLL

AVL

N802

L7809CS

C829

16V-100µF

R820A

2W-36Ω

DZ802

MTZ5.1B

R824

1/2W-1

50/220/330中选用

TDA9377

N201

INSS.W2(BL)

1N4148

63V-0.01µF

AV1/AV2

XTAL.OUT

OSC.GND

AUD.OUTV.DRB

IF.VO/SVO

MTZJ9.1B

1/6W-15K

R817A调整 可调

INT.REM

AV/SVHS

XTAL.IN

CHROMA

CVPS.INT

AUO.EXT

F.B.L.SO

DZ101

VD816

A6-5V

C207

64

C234

63V-1000pF

63

62

VDDP

C236

60

16V-22µF

RESET

59

X201

12M

58

57

56

VDD.C

55

VPE

54

VDD.A

C242

63V-0.1µF

53

B.OUT

52

G.OUT

51

R.OUT

50

BLK.IN

49

BCL.IN

C250

16V-10µF

48

B2/U.IN

47

G2/Y.IN

46

R2/V.IN

BL

45

44

43

42

CVBS/Y

41

GND1

40

39

VP1

C255

16V-100µF

38

R244

1/6W-390

37

PLL.IF

R276

1/6W-27K

36

EHTO

35

34

R245

1/6W-100

33

H.OUT

R263

1/6W-200

L209

IN4004

C108

16V-47µF

A6-5V

C819

16V-100µF

A3-14.73V

2W-18KR810

R849

1/6W-10K

V804

KSC815

R848

R847

1/6W-15K

V206

R214

1/6W-10K

KSC815

1整主电压,可在

CNT01

N202

24C08

RM201

A6-5V

1

8

Wp

VDD

HS0038A

NC

PTC

A2

SCL

SDA

5

R230

1/6W-100

AV1/AV2

C237

63V-0.1µF

R238

1/6W-1K

R248

1/6W-6.8K

1/6W-1K

C246

16V-10µF

C247

50V-1uF

R275

1/6W-270K

C256

63V-0.1µF

R246

1/6W-8.2K

C249

63V-150PF

R247

1/6W-3.3K

H-DRI

AV/SVHS

R241

1/6W-4.7K

R242

C239

33

C240

33

C254

63V-0.022µF

VSS

C241

16V-100µF

R274

1/6W-22K

R249

1/6W-20K

R259

1/6W-100K

4

L206

LGA0203-100

L207

LGA0203-100

L208

LGA0203-100

R235

1/6W-100

R236

1/6W-100

R237

1/6W-100

VD201

IN4148

R243

1/6W-1K

R264

470

R265

1/6W-75

C248

63V-0.1µF

H-SYNC ABL

R943

OUT

GND

VCC

47

C922

100U

AV1/AV2

N702

9

10

10

R746

R747

11

11

3.3K

3.3K

12

12

13

13

C740

1UF

14

14

CVBS/Y

15

15

A5-3.3V

CUT-OFF

A3-5V

R273

1/6W-33K

A7-8V

R277

1/6W-100K

V213

KSC815

R250

47

V209

KSC815

VD202

IN4148

V208

KSC815

DZ205

MTZJ4.7B

16

B-OUT

G-OUT

R-OUT

R752

2

1/6W-10

C750

21P-B

50V-1uF

21P-G

21P-R

R262*

1/6W-4.7K

CVBS/Y

1N4004

L211

V210

10uH

KSR2010

C252

47u

Z203

4.5MHz

R254

180

R253

510

R252

100

R251

R256

1/6W-200

1/6W-470

R255

C253

50V-1uF

1/6W-430

TJC3-10A

CN704

TJC-2A

Y-SVHS

R718

1/6W-75

A0R

A0L

V-OUT

HEF4053

8169

7

6

5

4

V2

3

2

1

YS

C706

50V-1uF

去功放

C-SVHS

L209

R257

47

C257

47u

V212

V-OUT

KSC815

R258*

W265

1/6W-75

1/6W-1K

V211

KSR1010

SYSTEM

A7-8V

A7-8V

B4-9V

A1-33V

A2-130V

A3-15.7V

A4-10.4V

DVD-5V

A6-5V

R213

1/6W-6.2K

POWER

STAND BY

RT02

100

AV2-VIN

R715

75

SL

A2L

V04

CNS01

RS03

YC

75

C722

50V-1uF

C727

50V-1uF

9

10

10

11

11

12

12

13

14

15

15

16

SL SR

HEATER

B1-180V

A4-10.4V

MUTE

POWER

A3-15.7V

AV1-VINAV1-ALAV1-AR

CT0175RS01

102

CNS02

CN200

AV1-V

C-SVHS

Cb Cr

Y

OUT

VIDEO

AV2-L

R704

1/6W-220

N703

HEF4052

8169

7

6

5

4

3

2

1

V03

去功放

高电平有效

VOL

V04

V03

CN703

AV1-AL

AV1-AR

C001

10u

C002

10u

C003

R001

R002

10u

120

R003

120

120

R703

AV2-R

1/6W-220

R708

C705

1/6W-220

50V-1uF

A1L

A1R

R707

C725

1/6W-220

50V-1uF

R218

R233

1/6W-36KΩ

1/6W-10KΩ

VD-P

1/6W-1.2K

VD-N

DZ301

MTZJ22A

H-SYNC

B4-16.5V

A3-15.8V

V402

H-DRI

KSC2331-Y

A2-115V

HEATER

B1-185V VIDEO

ABL

R531

16K

CN001

TJC3-4Y

V531

C2688

C502

330p

CN503

CN501

TJC-5

R501

R-OUT

47

G-OUT

R-OUT

R502

47

B-OUT

G-OUT

R503

GND

47

B-OUT

CUT-OFF

CN502

TJC-3

HEATER

5

1

2

6

180V

3

7

R506

68

8

C508

10uF

R527

33K

N601

AN7522N

VCC1OUT22GND3OUT24MUTE5INPUT6GND7INPUT8VOL9OUT110GND11OUT1

R815

2W-0.18

C610

1000u

V622

KSA539

+5V

低电平有效

R605

1/6W-5.6KΩ

INPUT

INPUT2VCC3OUT4GND5VFB6OUT7VO8VI

R314

DZ303

1/6W-270K

MTZJ15C

R312

R305

1/2W-1.3

R313

1/6W-1.3K

C304

C303

100V-33uF

35V-100uF

R303

1/6W-100K

VD402

IN4004

VD401

IN4004

R403

500V-560pF

1/2W-270

C402

C401

100V-103

N301

TDA8357J

AA26-50001B

R536

270

L306

LGA0305-10uH

T401

V533

R606

R532

BF423

V503

BF423

R505

2.8

1/6W-5.6KΩ

R302

1/2W-10

C422

104

220

R512

10K

1/6W-56K

C306

63V-0.047µF

R308

1/2W-1.5

SC

C511

100Pf

C415

160V-1uF

T444

BSC25-0283G

R420

1/2W-120K

FO

HV

B

G

R

G1

CRT

A51LXR195X91JD

C510

102K/2KV

C509

SCREEN

4.7uf

R550

10M

VD507

TC2406------T

GT501 1P

GT502 1P

SPEAKER

CN601

SPEAKER

CN602

V1

V2

CN401

TJC-4

H2

H1

TO CRT

HV

HV

FO

SC

FO

SC

TO CRT PCB SCREEN & FOCUS

10 11

ABL

C414

C411

104

250V-22uF

GT404

R534

1.8K

R522

R521

220

12k

V523

R524

BF422

V521

C2688

C503

470Pf

VD504

1N4148

VD505

1N4148

1.8K

R514

1.8K

R526

270

v522

BF423

R523

ZD501

390

R512

220

R511

18K

V511

C2688

C501

470Pf

BZX79C8V2

V513

BF422

V512

BF423

R516

270

R513

390

12

VD620

W610

C612

50V-1uF

R610

1/6W-5.6KΩ

2SD2499

R407

1/2W-0.39

1N4148

C620

R622

16V-100µF

1/6W-10K

v620

R620

KSA539

1/6W-10K

V621

R621

C611

63V-4700PF

C604

50V-1uF

R611

1/6W-5.6KΩ

9

w333

1/6W-12K

R306

2W 0.68

R311

1/6W-12K

R407

1W-3.9K

DZ402

MTZJ5.1B

VD403

TC2406

C418

100V 33u

B3-18.5V

C404

25V-470uF

V401

C410

2kV-681pF

R408

1/2W-33

L402

LB3.5*5

500V-470pF

C603

63V-4700PF

C417

VD404

T1R5GU41

R307*

2W 270

C403

500V-470pF

C409

1.6KV-752

1/6W-33K

1/6W-4.7K

Ly/50µH<R307*<Ly/20µH

R415

1/2W-1

R409

1/2W-0.22

C419

2KV-681pF

C413

400V-472

R623

LW

400uH/500uH

KSC815

C621

50V-1µF

C416

400V-364

VD406

TR5GU41

2W-7.5K

R413

L401

R414

LX034

2W-1K

8

46

9

16.5

6

7

HEATER

1

H-OUT

4

5

185v

3

B+

125v

VD405

TTVR10G

V-

V+

RB05

1.8K

TU101

ENV56DB4G3

AGC

C107

16V-10µF

R110

1W-33

L102

LGA0203-100

1/6W-10

R261

R262

VD217

1/6W-9.1K

1/6W-68K

1N4148

R260

R227

1/6W-9.1K

1/6W-1K

CN801

TJC1-2Y

DV801

TVR14561

VD814

TRM11C

L801

LCL-207

Rx801

1/2W-3.3M

CN802

TJC1-2Y

P801

MZ73-14RM270V

DEGUSS

VD811

TRM11C

VD812

TRM11C

RP801

MF72-2-5Ω±N

R822

1/2W-470K

150uF/400V

R823

1/2W-470K

旧底图总号

底图总号

日期签 名

格式

(3)

更改

标记

拟 制

于鲁东

审 核

标准化 等级标记 第 张共 张

批 准

制图 描图 幅面

:::

更改

标记

21F9K拉美通用

电路原理图

更改

日期日期签 名签 名签 名数量数量数量更改单号 更改单号 更改单号

标记

W90DL-206---Q

Loading...

Loading...