Page 1

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

382

Item No. _______________________________

382

Serve non-dairy frozen beverages, like frozen cocktails,

frozen lemonade, fruit drinks, or other non-alcoholic drinks.

Requires separate remote refrigeration system for operation.

The RC25 remote refrigeration system is recommended to be

installed with the Model 382 for efficient operation. (See

RC25 specification for further details.)

Freezing Cylinder

One, 10 quart (9.5 liter).

Mix Hopper

One, 12 quart (11.4 liter). An adjustable setting in the refrigeration

system maintains mix temperatures in the hopper.

Indicator Lights

Add Mix light alerts the operator to add mix. When the Mix Out

light flashes, the unit shuts down automatically to prevent damage.

Automatic Consistency Control

Refrigeration is regulated by monitoring viscosity. Adjustable

control allows the operator to serve a wide variety of frozen

beverages from regular slush to cocktails, pre-mix or neutral base,

all at the desired thickness.

Continuous Auto Fill System

Mix supply to the hopper can be replenished automatically from a

remote mix delivery system customized to suit your business by

your local Taylor distributor. Mix delivery systems are available

based on volume needs for Bag-in-Box, other post-mix or pre-mix

products.

Flavor Cards

Four static cling flavor cards are provided: Frozen Drinks, Frozen

Cocktails, Frozen Fruit Drinks and Margaritas.

Lighted Display (Optional)

Optional lighted display backlights the flavor card and illuminates

the dispensing door area to draw attention to the product.

Features

Frozen Uncarbonated Beverage

(FUB) Dispenser

Single Flavor

Standard 18

SA4632

Page 2

382

382Frozen Uncarbonated Beverage (FUB) Dispenser

Electrical

One dedicated connection required. Manufactured to be permanently

connected. See the Electrical chart for proper electrical

specifications.

Beater Motor

One, 1/2 HP.

RC25 Refrigeration System (order separately)

One, 16,500 BTU/hr compressor. R404A. (BTUs may vary depending on

compressor used.) See RC25 Specification for further details.

For maximum capacity, connect one dispenser to each RC25. Two dispensers

may be connected to one refrigeration system; capacity may be reduced. The

maximum total length of refrigeration suction line is 150 feet (45.7 m).

Clearance

No air clearance is required.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Printed in U.S.A.

Weights lbs. kgs.

Net 160 72.6

Crated 185 83.9

cu. ft. cu. m.

Volume 14.5 0.40

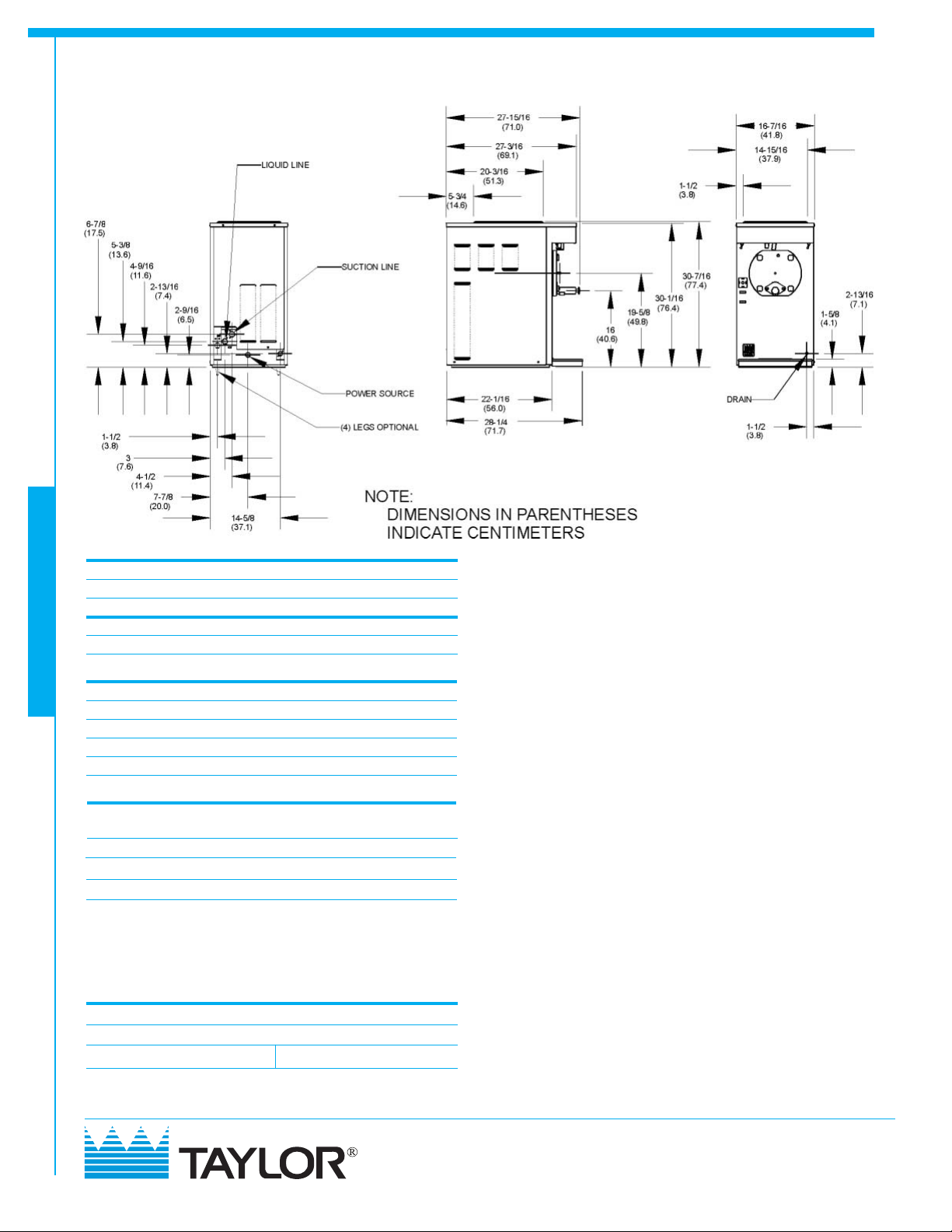

Dimensions in. mm.

Width 16-7/16 418

Depth 28-1/4 717

Height 30-7/16 773

Counter Clearance * *

*Designed to rest on a plastic pad directly on counter top.

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: nn Yes nnNo Cooling: nn Air nn Water nn NA

Options:_________________________________________________

_________________________________________________________

Customized Mix Delivery System

Legs for counter clearance

Lighted Display

Options

Specifications

051273-ADV

12/04

Continuing research results in steady improvements; therefore, these

specifications are subject to change without notice.

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W)

115/60/1 15 6 2P 3W

208-230/60/1 15 4 2P 3W

220-240/50/1 4 4 2P 3W

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Loading...

Loading...