Page 1

SERVICE

MANUAL

Model 358 & 359

Thick Shake Dessert Machines

Service Manual

056788-S 8/27/10 (Original Publication)

(Updated 2/19/14)

Page 2

Page 3

Table of Contents

Section 1: Introduction 1...............................................

Safety 2.............................................................

Model 358 Specifications 4.............................................

Model 359 Specifications 5.............................................

Running Specifications 6...............................................

General Installation Instructions 7.......................................

Refrigerant 9.........................................................

Environmental Notices 10...............................................

Section 2: Controls & Systems 11........................................

Thermistor Control 12..................................................

Thermistor Curve 14...................................................

Refrigeration System 15................................................

Maintaining Quality 16..................................................

Section 3: Troubleshooting 17...........................................

Troubleshooting Thermistor Components 18..............................

General Troubleshooting Guide 19.......................................

Overrun 22............................................................

Section 4: General Service 23............................................

Evaporator Oil 24......................................................

Rear Bearing Unit Alignment 25..........................................

Pulley Alignment 26....................................................

Rear Shell Bearing 26..................................................

Beater Shaft Removal 26...............................................

Preventative Maintenance 27............................................

Models 358 & 359 Table of Contents

Page 4

Table of Contents - Page 2

Section 5: Parts 29......................................................

Parts Warranty Explanation 30...........................................

Model 358 Operator Parts 31............................................

Model 358 Exploded View 32............................................

Model 358 Shell Assembly 34...........................................

Model 358 Control A. (X66731-33) 35....................................

Model 358 Channel A.-Control (X63534) 36...............................

Models 358 & 359 Beater Door Assembly 38..............................

Model 359 Operator Parts 39............................................

Model 359 Exploded View 40............................................

Model 359 Shell Assembly 42...........................................

Model 359 Channel A.-Control (X65222) 43...............................

Model 359 Control A. (X65279-33) 44....................................

Models 358 & 359 Switch A.-Draw (X65212-SER) 45.......................

Models 358 & 359 Accessories 46.......................................

Parts List 47...........................................................

Wiring Diagrams 54....................................................

CAUTION: Information in this manual is intended to be used by Taylor Authorized

Service T echnicians only.

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

E August, 2010 Taylor (Original Publication)

(Updated March, 2011)

All rights reserved.

056788-S

The word Taylor and theCrown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents Models 358 & 359

Page 5

Section 1: Introduction

S Safety

S Specifications

S Running Specifications

S General Installation Instructions

S Refrigerant

S Environmental Notices

Models 358 & 359

1

Introduction

Page 6

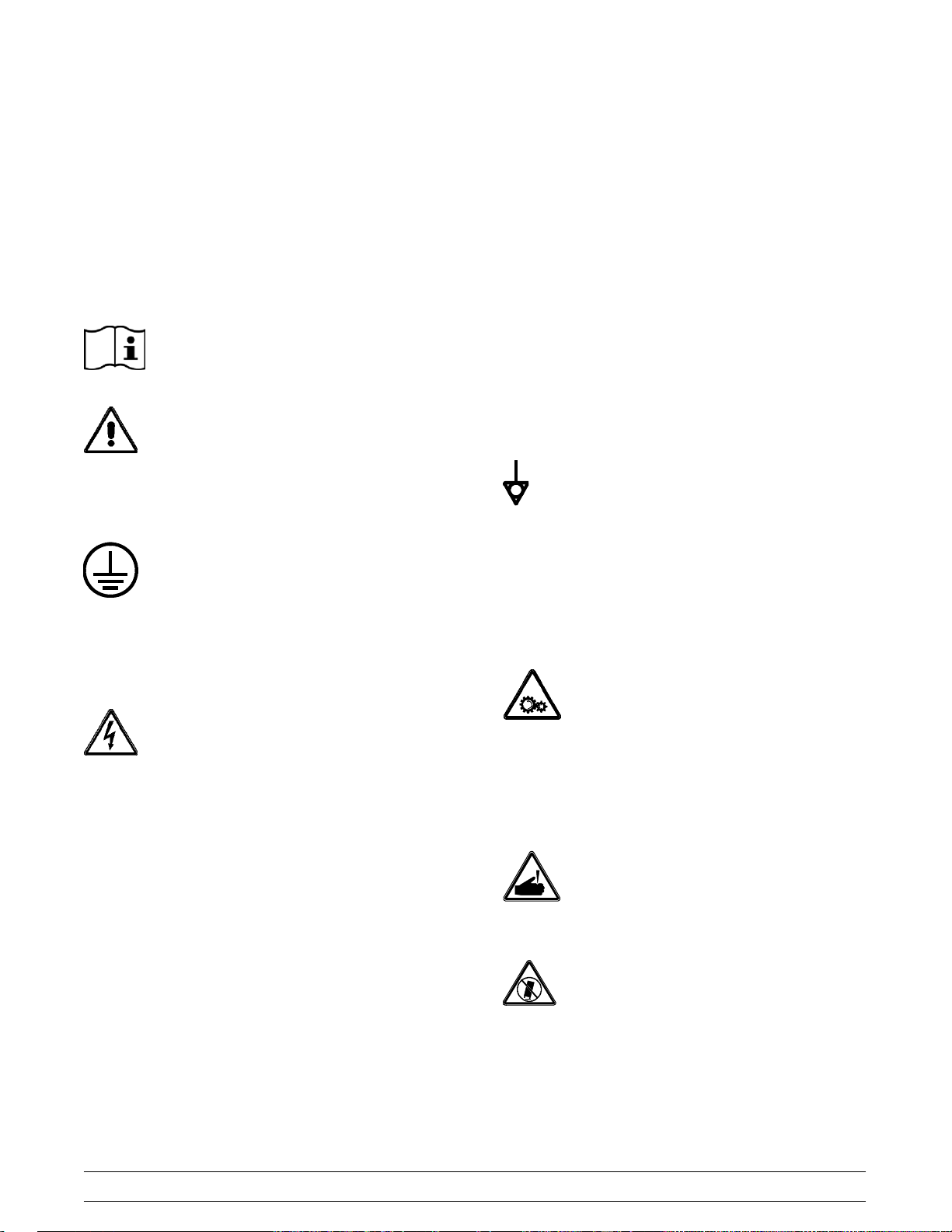

Safety

______________________________

We, at Taylor Company, are deeply committed to

manufacturing safe operating and serviceable

equipment. The many built-in safety features that

are part of all Taylor equipment are aimed at

protecting operators and trained service technicians

alike.

This manual is intended exclusively for

Taylor Company authorized service personnel.

DO NOT attempt to run the equipment

unless you have been properly trained to do so.

Failure to follow this instruction may result in

equipment damage, poor equipment performance,

health hazards, or personal injury.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! Do not operate this unit

unless it is properly grounded and all service panels

and access doors are restrained with screws. Failure

to do so can result in severe personal injury from

electrical shock!

protect against the leakage of current, and

be installed by authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord, (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

Failure to follow these instructions may result in

electrocution or damage to the unit.

This unit is provided with an equipotential

grounding lug that is to be properly attached to

either the rear of the frame or the under side of the

base pan near the entry hole for incoming power, by

the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021

of IEC 60417-1) on both the removable panel and

the equipment's frame, as well as on the diagram.

S DO NOT attempt any repairs unless the

main power supply to the unit has been

disconnected.

S DO NOT operate the unit with larger fuses

than specified on the data label.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected, not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

DO NOT remove the freezer door or any

internal operating parts (examples: beater, scraper

blades, etc.) unless all control switches are in the

OFF position. Failure to follow these instructions

may result in severe personal injury from hazardous

moving parts.

THIS UNIT HAS MANY SHARP EDGES

THAT CAN CAUSE SEVERE INJURIES.

This unit must be installed on a level

surface to avoid the hazard of tipping. Extreme care

should be taken in moving this equipment for any

reason.

Two or more people are required to safely move this

unit. Failure to comply may result in personal injury

or equipment damage.

Introduction

2

Models 358 & 359

Page 7

This unit must NOT beinstalledinanarea

where a water jet or hose can be used. NEVER use

a water jet or hose to rinse or clean this unit. Using a

water jet or hose on or around this equipment may

result in the electrocution of the user or damage to

the equipment.

Cleaning and sanitizing schedules are

governed by your state or local regulatory agencies

and must be followed accordingly. Please refer to

the cleaning section of the Operator Manual for the

proper procedure to clean this unit.

Models 358 & 359

3

Introduction

Page 8

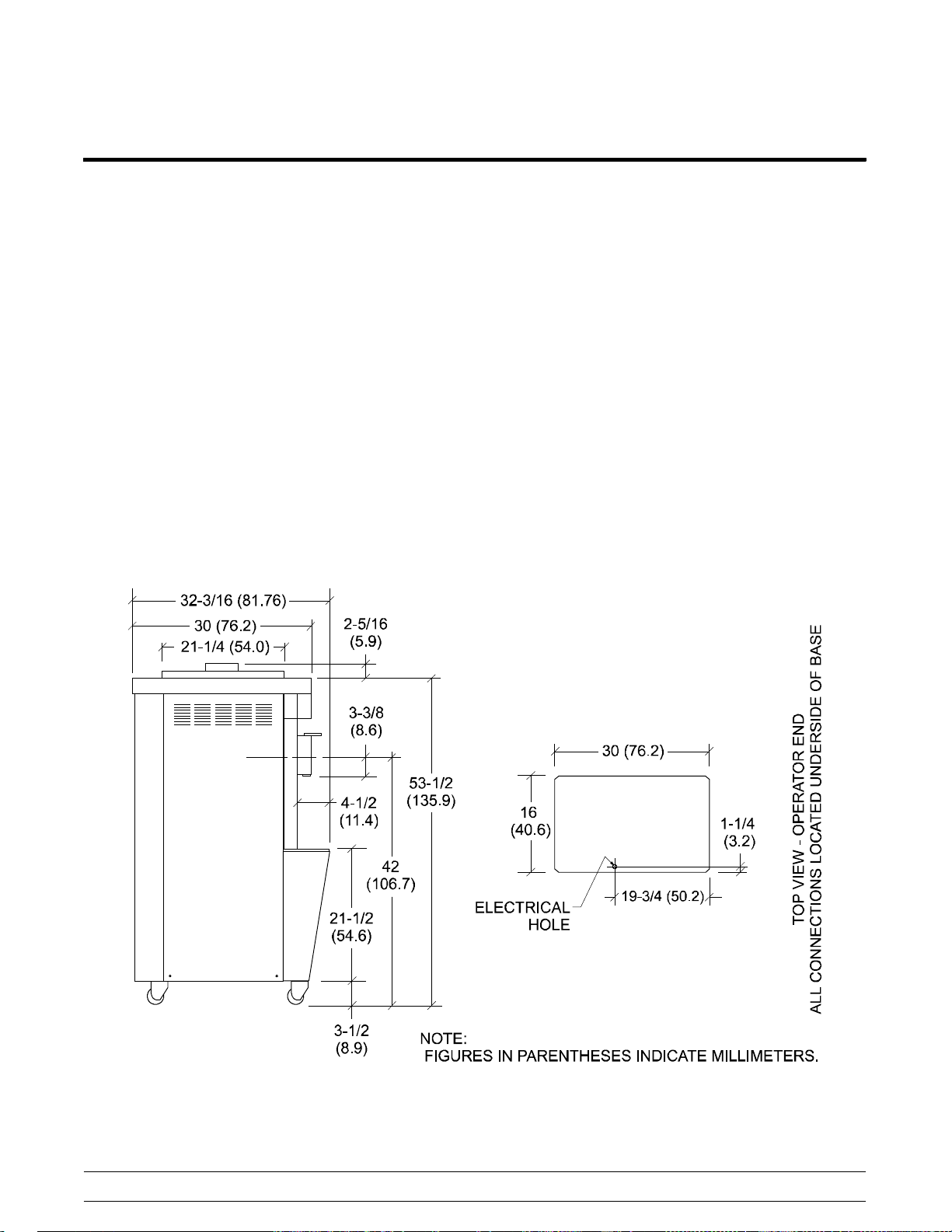

Model 358 Specifications

S Freezing Cylinder - One; 7 quart (6.6 liter)

capacity.

S Mix Hopper - One; 20 quart (18.9 liter)

capacity. Refrigerated and insulated.

S Beater Motor - One; 1.5 hp.

S Refrigeration Unit - One; approximately

9,500 btu/hr compressor. Refrigerant 404A.

S Electrical - Standard is 208/230-60-3;

however, other electrical characteristics are

available. Each unit requires electrical

service.*

Three Phase Maximum Fuse Size: 20A

Minimum Circuit Ampacity: 16A

*For exact electrical information, always refer

to the data label of the unit.

S Air Cooled - Clearance: 3” (76 mm) around

all sides.

S Dimensions -

Width: 16” (406 mm)

Depth: 30” (762 mm)

Height: 55-7/8” (1418 mm)

Floor Clearance: 3-1/2” (89 mm) mounted

on standard casters.

S Approximate Weights -

Net: 356 lbs. (161.5 kgs.)

Crated: 400 lbs. (181.4 kgs.)

Volume: 22.3 cu. ft. (.63 cu. m.)

Availability and specifications subject to change

without notice.

Introduction

Figure 1

4

Models 358 & 359

Page 9

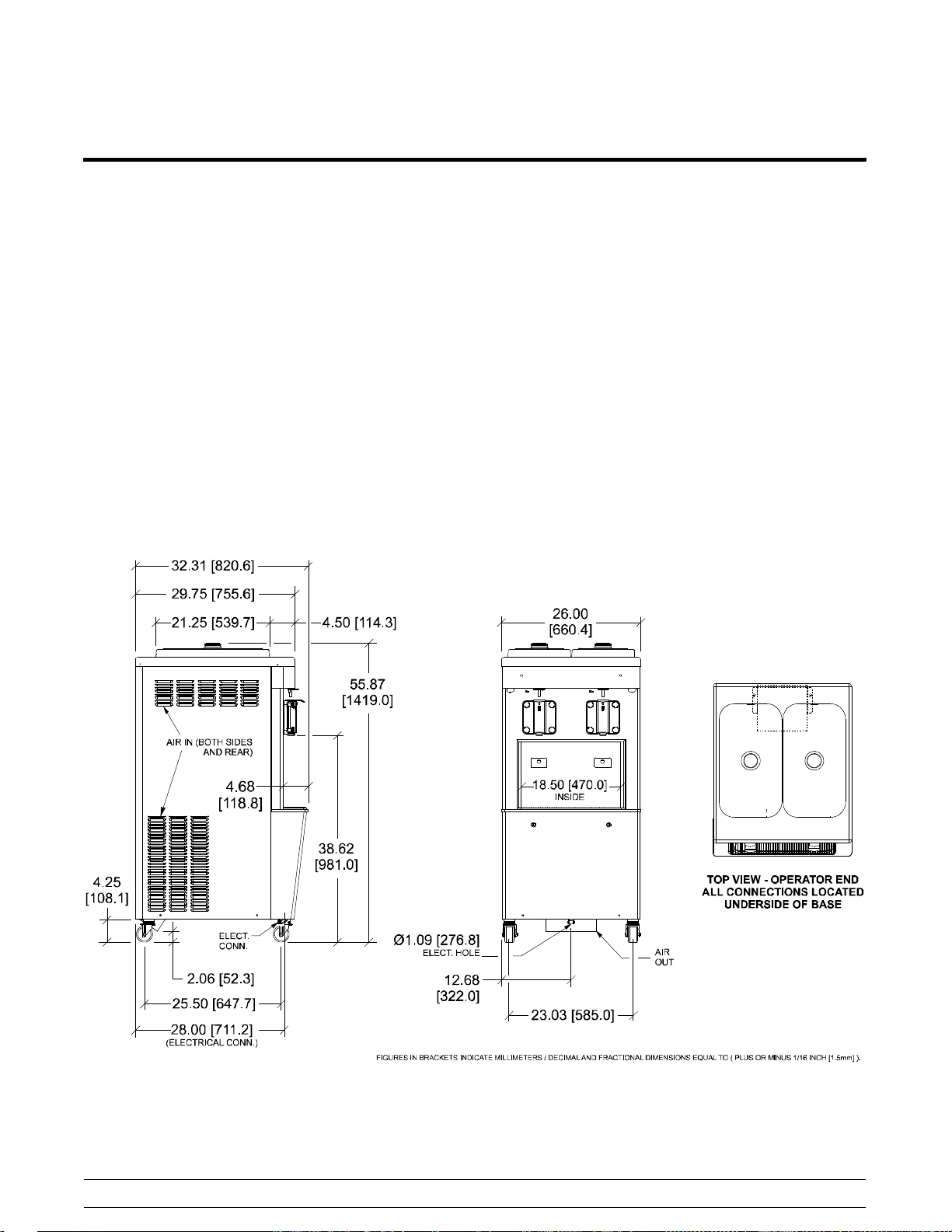

Model 359 Specifications

S Freezing Cylinder - Two; 7 quart (6.6 liter)

capacity.

S Mix Hopper - Two; 20 quart (18.9 liter)

capacity. Refrigerated and insulated.

S Beater Motor - Two; 1.5 hp.

S Refrigeration Unit - Two; approximately

9,500 btu/hr compressors. Refrigerant 404A.

S Electrical - Standard is 208/230-60-3;

however, other electrical characteristics are

available.

Each unit requires electrical service.*

Maximum Fuse Size: 35A

Minimum Circuit Ampacity: 30A

*For exact electrical information, always refer

to the data label of the unit.

S Air Cooled - Clearance: 3” (76 mm) around

all sides.

S Dimensions -

Width: 26” (660 mm)

Depth: 32-3/8” (822 mm)

Height: 55-7/8” (1418 mm)

Floor Clearance: 4-1/4” (108 mm) mounted

on standard casters.

S Approximate Weights -

Net: 580 lbs. (263.1 kgs.)

Crated: 673 lbs. (305.3 kgs.)

Volume: 41.1 cu. ft. (1.16 cu. m.)

Availability and specifications subject to change

without notice.

Models 358 & 359

Figure 2

5

140219

Introduction

Page 10

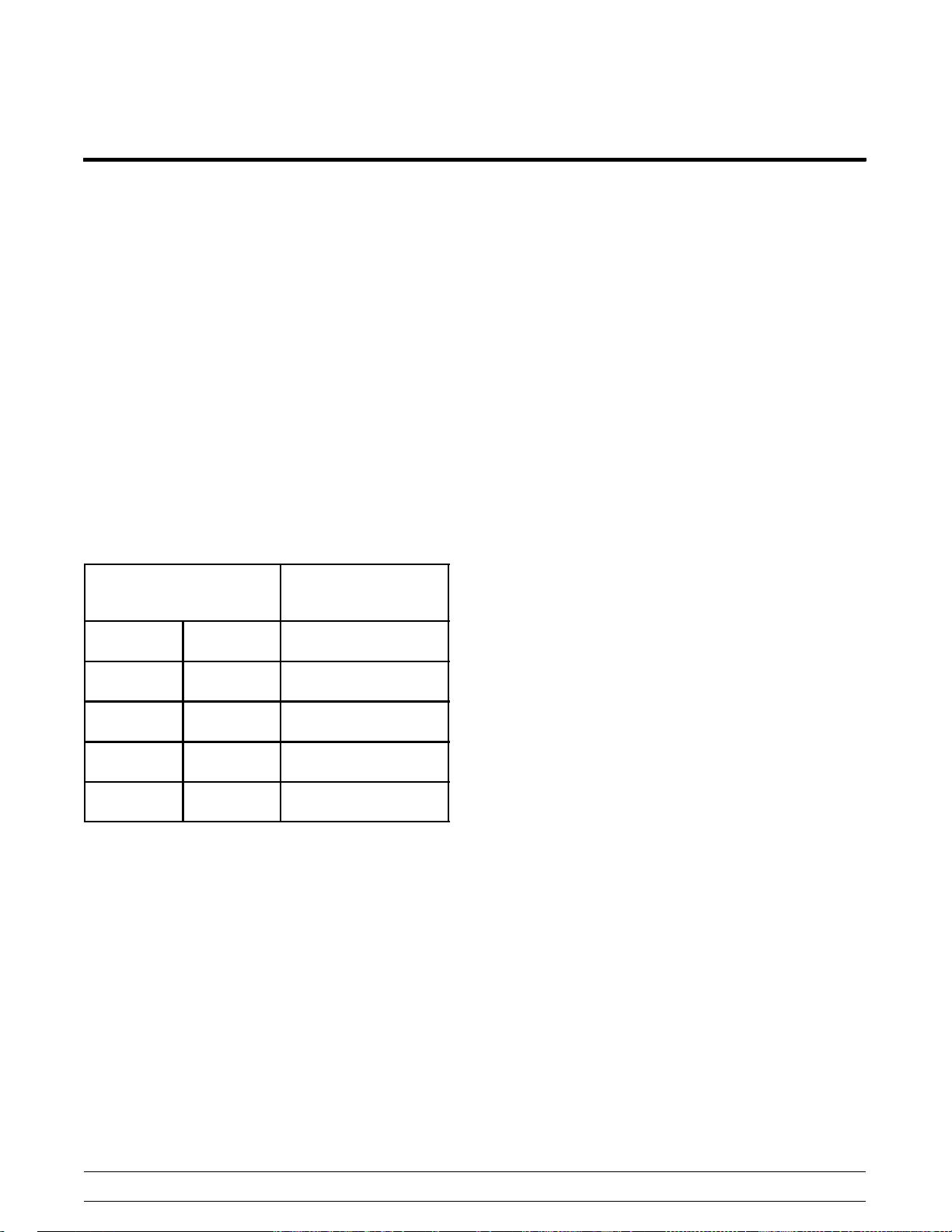

Running Specifications

Expansion Valve Setting

404A/HP62: 20 - 22 PSI (138 - 152 kPa)

Low Side Pressure

Low side pressure = expansion valve setting

To adjust the low side pressure, place the gauge on

the low side suction port at the compressor. With the

compressor running, turn the adjustment knob of the

automatic expansion valve clockwise to raise the low

side pressure and counterclockwise to lower the

pressure.

High Side Pressure

Air Cooled: The following chart indicates normal

operating head pressures at various ambient

temperatures:

Ambient Temperature Normal Operating Head

Pressures

F C PSI

70_ 21.1_ 240 -- 270

(1,655 -- 1,862 kPa)

80_ 26.7_ 270 -- 300

(1,862 -- 2,069 kPa)

90_ 32.2_ 300 -- 340

(2,069 -- 2,344 kPa)

100_ 37.8_ 340 -- 380

(2,344 -- 2,620 kPa)

Water Cooled: Thehighsidepressureforwater

cooled units is determined by the water valve. The

water valve is factory set to maintain a high pressure

of 235 PSI (1,620 kPa). To adjust the high pressure,

place the gauge on the high side access port. Turn

the adjustment knob on the water valve clockwise to

lower the high side pressure and counterclockwise

to raise the pressure.

The high side pressure switch is factory set at 440

PSI (3,034kPa) for 404A/HP62. In the event of a

water loss, this switch will sense a rise in pressure

and deactivate the unit.

EPR Valve Setting

The product temperature in the mix hopper is

maintained by the main refrigeration system and can

be adjusted by the EPR (evaporator pressure

regulator) valve. The EPR valve is factory set at 67 69 PSI (462 - 476 kPa) in order to maintain hopper

product temperature below 40_F(4_C). To adjust

the hopper temperature, place the gauge on the

access port at the inlet of the EPR valve. With the

compressor running, loosen the locking nut and turn

the adjustment screw (located on the top of the

valve) clockwise to raise hopper temperature and

counterclockwise to lower the temperature. When

the adjustment is complete, tighten the locking nut.

Introduction

6

Models 358 & 359

Page 11

General Installation Instructions

CAUTION: Only trained, authorized service

technicians should install this equipment. Failure to

comply will void the factory warranty.

The following are general installation instructions.

For complete installation details, please see the

checkout card.

This unit must be installed on a level

surface to avoid the hazard of tipping. Extreme care

should be taken in moving this equipment for any

reason.

Two or more people are required to safely move this

unit. Failure to comply may result in personal injury

or equipment damage.

ALL WIRING AND PLUMBING MUST

CONFORM TO NATIONAL AND LOCAL CODES.

INSTALL POTABLE WATER CONNECTION

WITH ADEQUATE BACK-FLOW

PROTECTION TO COMPLY WITH

APPLICABLE NATIONAL, STATE AND

LOCAL CODES.

Site Preparation

Review the area the unit is to be installed in before

uncrating the unit. Make sure that all possible

hazards to the user and the equipment have been

addressed.

Clearance: Air Cooled Units

Air cooled units require a minimum of 3” (76 mm) of

clearance around all sides of the unit. Failure to

allow for adequate clearance can reduce the

refrigeration capacity of the unit and possibly cause

damage to the compressor.

For Indoor Use Only: This unit is designed to

operate indoors, under normal ambient

temperatures of 70_ -75_F(21_ -24_C). The

machine has successfully performed in high ambient

temperatures of 104_(40_C) at reduced capacities.

This unit must NOT beinstalledinanarea

where a water jet or hose can be used. NEVER use

a water jet or hose to rinse or clean this unit. Using a

water jet or hose on or around this equipment may

result in the electrocution of the user or damage to

the equipment.

Uncrate the machine. Inspect the unit for damage.

Report any damage to the Taylor factory

immediately.

This piece of equipment is made in the USA and has

USA sizes of hardware. All metric conversions are

approximate and vary in size.

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only authorized Taylor service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE (Personal Protective

Equipment) is available and worn when

required during installation and service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

THIS UNIT HAS MANY SHARP EDGES

THAT CAN CAUSE SEVERE INJURIES.

Models 358 & 359

7

Introduction

Page 12

Electrical Connectio n s

In the United States, this equipment is

intended to be installed in accordance with the

National Electrical Code (NEC), ANSI/NFPA

70-1987. The purpose of the NEC code is the

practical safeguarding of persons and property from

hazards arising from the use of electricity. This code

contains provisions considered necessary for safety.

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Each machine requires one power supply. Check

the data label on the machine for fuse, circuit

ampacity and other electrical specifications. Refer to

the wiring diagram provided inside the control box

for proper power connections.

It is recommended that the machine be plugged into

an electrical surge protector for added protection

against power surges which could damage an

electrical/electronics component. An electrical surge

event may cause the unit to shut down. Such an

event would require service by a qualified service

technician if the machine was not adequately

protected. A good surge protector, as would

normally be used on a home computer, should be

adequate. They are available at most computer retail

outlets or electrical supply stores.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

Note: This unit is provided with an equipotential

grounding lug that is to be properly attached to

either the rear of the frame or the under side of the

base pan near the entry hole for incoming power, by

the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021

of IEC 60417-1) on both the removable panel and

the equipment's frame, as well as on the diagram.

S DO NOT operate the machine with larger

fuses than specified on the data label.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected, not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current, and

be installed by authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

Failure to follow these instructions may result in

electrocution or damage to the machine.

Introduction

8

Models 358 & 359

Page 13

Refrigerant

______________________________

Compressor Warranty Disclaimer

In consideration of our environment, Taylor proudly

uses only earth friendly HFC refrigerants. The HFC

refrigerant used in this unit is R404A. This

refrigerant is generally considered non-toxic and

non-flammable, with an Ozone Depleting Potential

(ODP) of zero (0).

However, any gas under pressure is potentially

hazardous and must be handled with caution.

NEVER fill any refrigerant cylinder completely with

liquid. Filling the cylinder to approximately 80% will

allow for normal expansion.

Refrigerant liquid sprayed onto the skin may

cause serious damage to tissue. Keep eyes and skin

protected. If refrigerant burns should occur, flush

immediately with cold water. If burns are severe,

apply ice packs and contact a physician

immediately.

Taylor reminds technicians to be cautious of

government laws regarding refrigerant recovery,

recycling, and reclaiming systems. If you have any

questions regarding these laws, please contact the

factory Service Department.

WARNING: R404A refrigerant used in

conjunction with polyolester oils is extremely

moisture absorbent. When opening a refrigeration

system, the maximum time the system is open must

not exceed 15 minutes. Cap all open tubing to

prevent humid air or water from being absorbed by

the oil.

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty

card accompanying this machine. However, due to

the Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed; thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should

be noted that in the event of ordinary service to this

machine's refrigeration system, only the refrigerant

specified on the affixed data label should be used.

The unauthorized use of alternate refrigerants will

void your compressor warranty. It will be the owners'

responsibility to make this fact known to any

technicians they employ.

It should be noted that Taylor does not warrant the

refrigerant used in its equipment. For example, if the

refrigerant is lost during the course of ordinary

service to this machine, Taylor has no obligation to

either supply or provide its replacement, either at

billable or unbillable terms. Taylor does have the

obligation to recommend a suitable replacement if

the original refrigerant is banned, obsoleted, or no

longer available during the five year warranty of the

compressor.

Taylor will continue to monitor the industry and test

new alternate refrigerants as they are being

developed. Should a new alternate prove, through

our testing, that it would be accepted as a drop-in

replacement, then the above disclaimer would

become null and void. To find out the current status

of an alternate refrigerant as it relates to your

compressor, call the local Taylor Distributor or the

Taylor Factory. Be prepared to provide the

model/serial number of the unit in question.

Models 358 & 359

9

Introduction

Page 14

Environmental Notices

______________________________

In consideration of our environment, Taylor proudly

uses only earth friendly HFC refrigerants. The HFC

refrigerant used in this unit is R404A. This

refrigerant is generally considered non-toxic and

non-flammable, with an Ozone Depleting Potential

(ODP) of zero (0).

However, any gas under pressure is potentially

hazardous and must be handled with caution.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

Introduction

10

Models 358 & 359

Page 15

Section 2: Controls & Systems

S Thermistor Control

S Thermistor Curve

S Refrigeration System

S Maintaining Quality

Models 358 & 359

11

Controls & Systems

Page 16

Thermistor Control

Function

The thermistor control maintains product

temperature in the freezing cylinder by monitoring

the resistance of the thermistor probe.

Thermistor Probe (038061--20)

The resistance value of the thermistor probe

corresponds with the product temperature in the

freezing cylinder. As the product becomes colder,

the probe resistance increases. As the product

becomes warmer, the probe resistance decreases.

Approximate probe resistance readings:

S 10,000 OHMS at room temperature

(77°F/25°C)

S 46,012 OHMS at product temperature

(20°F/-6.6°C)

Anticipator

The anticipator signals the thermistor control to

activate the refrigeration system whenever product

is drawn. As the draw valve is raised and the freezer

draw switch closes, continuity is created between

the thermistor control anticipator terminals. The

thermistor control relay will close within .5 seconds

to start the refrigeration system. The control set

point will shift 8°F (4.4°C) approximately 5 seconds

after the draw switch is released. The set point shift

will change 3.5°F (2°C) and remain in that state for

20 seconds. The set point will then return to its

original setting.

Setting Temperature

1. Position the thermistor fine adjustment at

mid-range. This will limit the fine adjustment

temperature range to ±2_F(±1_C).

2. Turn the coarse adjustment clockwise to the

coldest setting.

3. With the freezer correctly primed, place the

power switch in the “AUTO” position.

Operation

The thermistor probe is positioned in the bulb-well

located at the front of the freezing cylinder. The

thermistor control becomes operational when

powered by the 24 VAC transformer.

When the desired product is achieved (control

set-point), the thermistor control relay relaxes and

discontinues sending L1 power to the compressor

relay coil.

When the product in the freezing cylinder warms up

.5°F (.3°C) above the control set-point, the

thermistor control relay closes, sending L1 power to

the compressor relay coil. The refrigeration system

will run until the control set-point is achieved.

4. After the appropriate freezing time, test the

product temperature. When a sample portion

temperature is approximately 1_ above the

desired temperature setting, slowly turn the

coarse adjustment counterclockwise (warmer)

until the refrigeration system cycles off.

5. Allow the refrigeration system to cycle through

at least two “off” cycles. After the unit cycles

off, draw a sample of product and check the

temperature. Readjust the coarse adjustment

as required, but make only small adjustments.

Note: The anticipator automatically activates the

refrigeration system within 5 seconds after the draw

valve is opened. If several small samples are drawn,

the temperature may drift lower. To accurately set

the control, let the product temperature stabilize by

allowing the thermistor control to cycle the freezer

on and off by the control set-point, not the

anticipator.

Controls & Systems

12

Models 358 & 359

Page 17

Service Tips

If a problem arises with the thermistor control

assembly, identify and replace only the faulty

component. For example, if the probe is defective,

replace only the probe.

S A varistor must be connected to the

thermistor control 24 VAC terminals in order

to protect the control from voltage spikes

(varistor part number X31547).

S Fill the bulb-well with antifreeze before

installing the thermistor probe.

S Be sure the probe is installed completely

into the bottom of the bulb-well.

Note: Lower the probe to the point where the wires

extend from the probe and a resistance is felt. This

indicates the probe is installed completely in the

bottom of the bulb-well.

If the thermistor relay which starts the compressor

will not close, check the following items:

ELECTRICAL SHOCK AREA! USE CAUTION!

1. Make sure power is being supplied to the

freezer and that all operating switches are in

the correct position.

2. Using a voltmeter, check the voltage supply to

the thermistor control. The control requires 24

volts to operate.

If the thermistor relay which deactivates the

compressor will not open, check the following items:

ELECTRICAL SHOCK AREA! USE CAUTION!

1. Make sure the thermistor relay opens when the

freezer control switch is in the “OFF” position.

2. Make sure the thermistor probe is connected to

the correct probe terminals.

3. Using an ohmmeter, check the thermistor probe

for proper resistance. (Refer to the thermistor

curve chart on page 14 for proper readings.)

4. Disconnect one wire to an anticipator terminal.

If the thermistor relay opens after

approximately 25 seconds, the problem is in the

anticipator wiring circuit.

When problems such as erratic product quality

occur, it is of utmost importance to determine if the

thermistor components are defective before

replacing them.

3. Using an ohmmeter, check probe resistance.

(Refer to the thermist or curve chart on page 14

for proper readings.)

Models 358 & 359

For a diagram of the thermistor control, see

page 18 (Troubleshooting Thermistor

Components).

13

Controls & Systems

Page 18

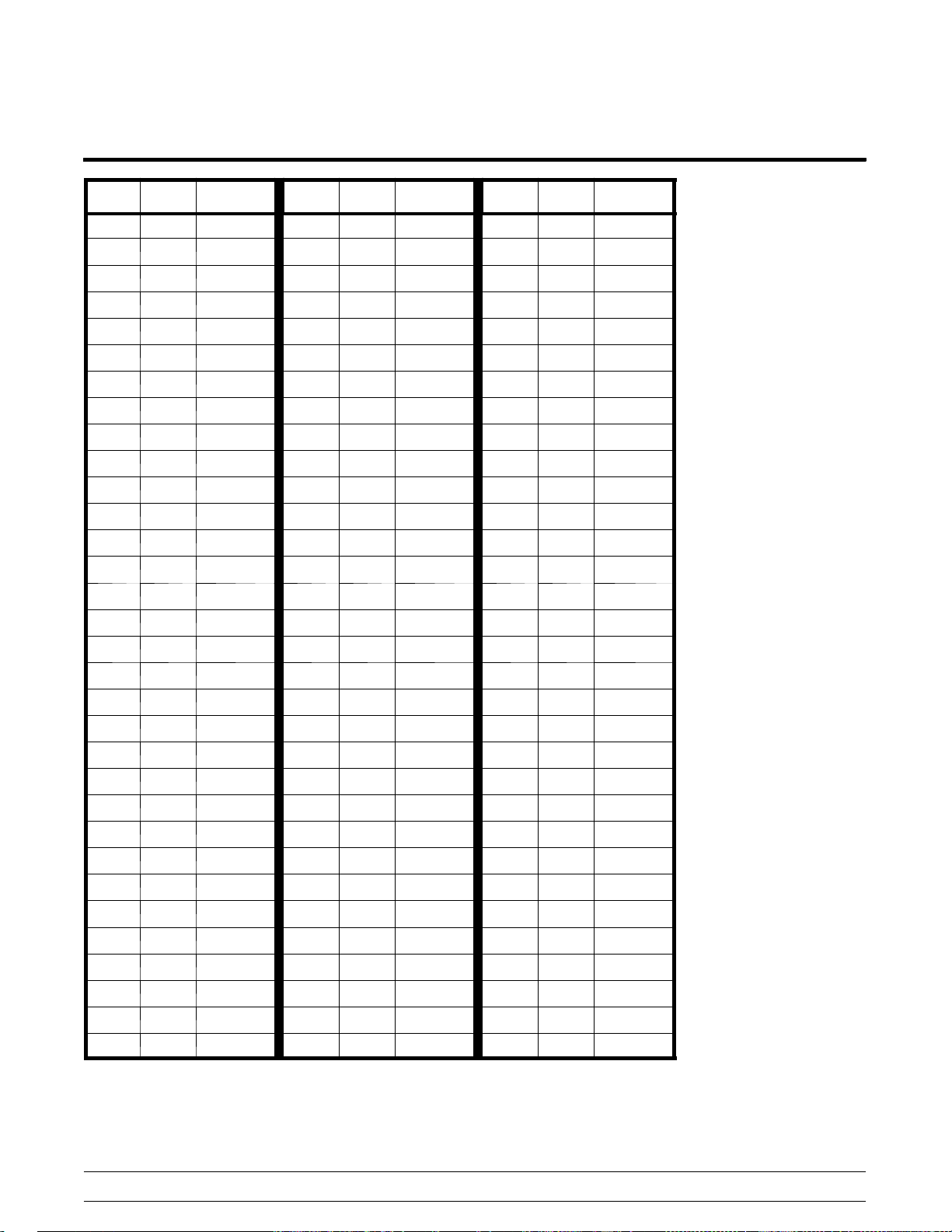

Thermistor Curve

F C KOHM F C KOHM F C KOHM

-10 -23.3 118.201 22 -5.5 43.530 54 12.2 17.915

-9 -22.7 114.394 23 -5.0 42.340 55 12.7 17.451

-8 -22.2 110.709 24 -4.4 41.136 56 13.3 16.998

-7 -21.6 107.143 25 -3.8 39.967 57 13.8 16.557

-6 -21.1 103.692 26 -3.3 38.830 58 14.4 16.128

-5 -20.5 100.352 27 -2.7 37.727 59 15.0 15.710

-4 -20.0 97.120 28 -2.2 36.654 60 15.5 15.315

-3 -19.4 94.085 29 -1.6 35.612 61 16.1 14.929

-2 -18.8 91.144 30 -1.1 34.599 62 16.6 14.554

-1 -18.3 88.296 31 -0.5 33.616 63 17.2 14.187

0 -17.7 85.536 32 0 32.660 64 17.7 13.830

1 -17.2 82.863 33 0.5 31.760 65 18.3 13.482

2 -16.6 80.273 34 1.1 30.885 66 18.8 13.143

3 -16.1 77.765 35 1.6 30.035 67 19.4 12.812

4 -15.5 75.334 36 2.2 29.207 68 20.0 12.490

5 -15.0 72.980 37 2.7 28.403 69 20.5 12.185

6 -14.4 70.627 38 3.3 27.620 70 21.1 11.888

7 -13.8 68.350 39 3.8 26.859 71 21.6 11.598

8 -13.3 66.147 40 4.4 26.120 72 22.2 11.315

9 -12.7 64.014 41 5.0 25.400 73 22.7 11.039

10 -12.2 61.951 42 5.5 24.721 74 23.3 10.769

11 -11.6 59.953 43 6.1 24.059 75 23.8 10.507

12 -11.1 58.021 44 6.6 23.416 76 24.4 10.250

13 -10.5 56.150 45 7.2 22.789 77 25.0 10.000

14 -10.0 54.340 46 7.7 22.180 78 25.5 9.763

15 -9.4 52.854 47 8.3 21.586 79 26.1 9.532

16 -8.8 51.409 48 8.8 21.009 80 26.6 9.306

17 -8.3 50.003 49 9.4 20.447 81 27.2 9.085

18 -7.7 48.636 50 10.0 19.900 82 27.7 8.870

19 -7.2 47.306 51 10.5 19.384 83 28.3 8.659

20 -6.6 46.012 52 11.1 18.881 84 28.8 8.454

21 -6.1 44.754 53 11.6 18.392 85 29.4 8.254

When checking a thermistor probe, firstdeterminethe temperature at the probe and find it on this chart, along with the correct

ohmmeter reading. If your ohmmeterreading varies from the correct reading,determine whether the difference is acceptable. If

a probe is faulty, the difference will be great.

Controls & Systems

14

Models 358 & 359

Page 19

Refrigeration System

Models 358 & 359

Figure 3

15

Controls & Systems

Page 20

Maintaining Quality

Operation Tips

To achieve the highest quality product, the following

are key operation procedures:

1. The machine should be primed with 2 gallons

(7.6 liters) of fresh mix. Rerun should be added

to the machine only before a rush period. One

part rerun mix should be mixed with two parts

fresh mix. Always skim the foam off the top of

the rerun. In addition, make certain that all

rerun is completely liquid before use; frozen

particles in the mix may plug the feed

assembly. To minimize beating time, start the

machine as close to opening time as possible.

2. Freeze down will take approximately 7 minutes.

Afterwards, the product should be 20_F

(-6.7_C) ± 1_.

3. It is possible to “outdraw” this unit. If the unit is

outdrawn, it should be given a chance to

recover, or inferior product will be served.

Outdrawing the unit can starve the cylinder of

mix and can cause mechanical damage.

Always make certain there is mix in the hopper.

4. If the unit is air cooled, the condenser must be

kept clean. A clogged condenser will result in

excessively long run times. The condenser

should be inspected regularly and brushed

clean when dirty.

5. Sharp and proper size scraper blades are of

critical importance. If the blades are nicked or

worn, they must be replaced, or poor scraping

and inefficient freezer operation will result.

6. O-rings and plastic scraper blades should be

replaced every three months. If at any time the

scraper blades are worn to less than 15/16”,

they should be replaced.

Controls & Systems

16

Models 358 & 359

Page 21

Section 3: Troubleshooting

S Troubleshooting Thermistor Components

S General Troubleshooting Guide

S Overrun

Models 358 & 359

17

Troubleshooting

Page 22

Troubleshooting Thermistor Components

Figure 4

Step 1

Power Switch in the “AUTO” Position

Using a voltmeter, check the two terminals

connecting the transformer wires to the controller.

There should be a reading of 24 volts (¦15%); if

not, the transformer is not receiving line voltage or

the transformer is faulty and should be replaced. If a

proper reading is obtained, proceed to the next step.

Step 2

Power Switch in the “AUTO” Position

Using a voltmeter, make certain L1 power is being

supplied to the common terminal of the controller. A

reading of the line voltage should be obtained. To

accomplish this, measure the voltage between the

common terminal and any L2 power source. If a

proper reading is not obtained, make sure there is

line voltage at the incoming power supply. If there is

incoming power, back track from the common

terminal (L1) and determine where L1 is being

interrupted and correct accordingly. If a proper

reading is obtained, proceed to the next step.

Step 3

Power Switch in the “AUTO” Position

Remove the probe wires from the controller. Place a

wire between the two probe terminals of the

controller to short the component. This should

activate the compressor. If this procedure does not

activate the compressor, check for line voltage. If

there is line voltage at the compressor contactor

coil, the controller is acceptable.

Step 4

Power Switch in the “OFF” Position

Check the probe resistance. Disconnect both the

white (yellow) and black wires at the control, and

measure their resistance with an ohmmeter. At room

temperature, a reading of approximately 10,000

ohms should be obtained. At product temperature, a

reading of approximately 46,000 ohms should be

obtained. If these readings are not obtained, replace

the probe. When replacing the probe, fill the

bulb-well with antifreeze. Connect the white (yellow)

wire to the white terminal and the black wire to the

black terminal.

Step 5

Power Switch in the “OFF” Position

Check the anticipator microswitch by removing the

wires connecting the switch to the controller and

check for continuity. If switch continuity exists when

the draw handle is raised, the switch is effective.

Continuity should break when the draw handle is

lowered.

Troubleshooting

18

Models 358 & 359

Page 23

General Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

1. No freezer operation with power

switch in the “AUTO” position.

2. With the power switch in the

“AUTO” position, the beater motor

runs, but the compressor does

not operate.

3. Unit short cycles. a. Cycling on high pressurecut-out.

a. Unit unplugged. a. Plug main power cord in the wall

b. Fuse blown or circuit breaker in the

“OFF” position.

c. The beater motor is out on reset. c. Place the control switch in the

a. The compressor internal overload

has been tripped.

b. Compressor is burned out. b. Replace the compressor.

c. Compressor is improperly wired. c. Check wiring against diagram on

d. Low line voltage. d. Check the line voltage at terminal

e. Single-phasingcompressor

contactor.

Cut in: 404A: 340 PSI (2,344 kPa.)

Cut out: 404A: 440 PSI (3,034 kPa.)

receptacle.

b. Replace the fuse or place breaker

in the “ON” position.

“OFF” position and press the reset

button firmly. Place the power

switch in the “WASH” position and

observe the freezer's performance.

Resume normal operation.

a. Allow the internal overload to cool.

Check for high head pressure,

refrigerant overcharge, stuck

pistons, or tight bearings.

compressor.

block. Locate cause of voltage

drop.

e. Replace the compressor contactor.

a. Check the water supply (water-

cooled units only) and make sure

the condenser is clean. Check for

potentialrefrigerant overcharge.

4. Compressor hums intermittently,

but will not start.Cycling on

overload.

5. Product too stiff. a. Temperaturecontrol is set too cold. a. See the “ThermistorControl”

6. Product too soft. a. Temperature control set too warm. a. See the “Thermistor Control”

7. Head pressure too low. a. Shortage of refrigerant. a. Locate and repair leak. Recover

Models 358 & 359

a. Compressor is improperly wired. a. Check wiring against the diagram.

b. Low line voltage. b. Check the main line voltage and

locate the voltage drop.

c. Relay contacts not closing. c. Check by operating manually.

Replace defective relay.

section in this manual to reset the

control.

b. Inadequate mix in the hopper. b. Fill hopper with mix.

section in this manual to reset the

control.

the refrigerant,evacuate, and

charge the system.

b. Water valve stuck open (water

cooled unit).

19

b. Clear or replace the valve.

Troubleshooting

Page 24

PROBLEM PROBABLE CAUSE REMEDY

8. Hot liquidline. a. Shortageof refrigerant. a. Repairleak and recharge system.

9. Frosted liquid line. a. Restricteddryer or tubing. a. Replace or remove restrictions.

10.No product being dispensed. a. Control switch is in the “OFF”

position.

b. Freeze-up in the mix feed tube. b. Adjust hopper temperature by

c. Beater motor is out on reset. c. Place the control switch in the

d. Incorrectbeater rotation. (Rotation

should be clockwise when viewed

from the front of the unit.)

e. Circuitbreaker out. e. Check breaker or fuse.

f. Faulty draw switch. f. Repair or replace switch.

g. Inadequate mix in the hopper. g. Fill the hopper with mix.

11.Scored freezingcylinder walls. a. Missing or worn front bearing on the

freezerdoor.

b. Bent beater assembly. b. Replace beaterand correct the

12.Product is not feeding into the

freezingcylinder.

13.Drive shaft is stuck in the drive

coupling.

14.Excessive mix leakage through

the rear of the unit into the drip

pan.

15.Beater assembly works forward. a. Refrigerant shortage. a. Locate and repair leak.

16.Freezer door works loose. a. Handscrews are not tightly installed

a. Inadequate mix in the hopper. a. Fill the hopper with mix.

b. Freeze-up in the mix inlet hole. b. Adjust hopper temperature.

a. Mix and lubricant have collected in

the drive coupling.

b. Rounded corners of the drive shaft,

coupling, or both.

a. Worn or missing drive shaft boot

seal.

b. Inadequate lubrication of the drive

shaft boot seal.

c. Worn rear shell bearing. c. Replace bearing.

d. Drive shaft works forward. d. Check gear alignment and scraper

e. Wrong type of lubricant being used. e. Use lubricants recommended in the

b. Rear bearing unit is out of alignment. b. Align rear bearing unit.

or are damaged.

b. Beater assembly works forward. b. See previous problem.

a. Place the control switch in the

“AUTO” position.

readjusting the E.P.R. pressure.

“OFF” position, and press the reset

button firmly. Place the power

switch in the “WASH” position and

observe the freezer's performance.

Resume normal operation.

d. Reverse any two of the three

incoming power lines (three phase

units only).

a. Installor replace front bearing.

cause of insufficient mix in the

freezingcylinder.

a. Brush c lean rear shell bearing area

regularly.

b. Replace worn component(s).

a. Replace boot seal.

b. Lubricate the boot seal according

to the Operator's Manual.

blades. Make sure the beater is not

bent.

Operator's Manual.

a. Tighten or replace handscrews.

Troubleshooting

20

Models 358 & 359

Page 25

PROBLEM PROBABLE CAUSE REMEDY

17.Low overrun. a. Bad scraper blades. a. Replace blades.

b. Mix feed tube is not installed. b. Installfeed tube according to

instructions in the Operator's

Manual.

c. Beater rotates continually. c. Check for electrical short or faulty

power switch.

d. Long “ON” cycles. d. Make sure there is sufficient mix in

the hopper and that the condenser

is clean. Check the refrigerant

charge.

18.Leaking draw valve. a. Improperlubrication. a. Lubricate the draw valve according

to instructions in the Operator's

Manual.

b. Worn or nicked o-rings on valve. b. Replace o-rings.

c. Wrong lubricant being used. c. Use lubricants recommended in the

Operator's Manual.

19.Mix in the hopper is too cold. a. Temperature is out of adjustment. a. Adjust E.P.R. valve.

20.Mix in the hopper is too warm. a. Temperatureis out of adjustment. a. Adjust E.P.R. valve.

21.Compressor runs too long or

continuously.

b. Warm mix has been put in the

hopper.

c. Hopper cover not in position. c. Install cover properly.

a. Low refrigerant charge. a. Locate and repair the refrigerant

b. Worn or missing scraperblades. b. Replace scraper blades.

c. Inadequate air clearance. c. Provide 3” (76 mm) around all

d. Oil-loggedevaporator. d. Repair according to instructions on

e. Incorrectbeater rotation. e. Rotation should be counter-

f. Faulty expansion valve. f. Replace valve.

g. Dirty or faulty blower assembly. g. Clean, repairor replace the blower.

b. Mix added to the hopper should be

below 40_F. (4_C.)

leak.

sides of the unit.

page 24 of this manual.

clockwise.

Models 358 & 359

21

Troubleshooting

Page 26

Overrun

During the freezing process, mix is blended and

frozen with air. The frozen mix absorbs air and

therefore increases the volume of the mix.

Example: If 1 gallon of mix yields 1.5 gallons of

frozen product, the mix volume has been increased

by 50 percent. The overrun is then 50%.

Calculating Overrun

1. Place a cup on a scale and adjust the scale to

read “ZERO”.

Figure 5

4. Skim off the excess product at the brim of the

cup.

Figure 7

5. Place the cup of frozen product on the scale

and record the weight.

2. Fill the cup completely with unfrozen fresh mix

and weigh the cup of mix. Write down the

weight. Discard the liquid mix and rinse the cup.

Figure 6

3. After the freezer has completed a refrigeration

cycle, draw frozen product into the same cup.

As the cup fills, lightly pack the product to

prevent air pockets. Slightly overfill the cup and

then close the freezer draw valve.

Figure 8

6. Divide the unfrozen fresh mix weight by the

frozen product weight. The answer indicates

the increase in volume.

Unfrozen Fresh Mix Weight

Frozen Product Weight

Example:

1.50 = 50% Overrun

12 18.00

12

60

60

0

Troubleshooting

22

Models 358 & 359

Page 27

Section 4: General Service

S Evaporator Oil

S Rear Bearing Unit Alignment

S Aligning Pulleys

S Rear Shell Bearing

S Beater Shaft Removal

S Preventative Maintenance

Models 358 & 359

23

General Service

Page 28

Evaporator Oil

If the unit refrigeration cycle runs longer than

normal, this indicates a possible oil-logged

evaporator coil. An oil-logged evaporator is usually

caused by a bent beater, worn or bent scraper

blades, a faulty expansion valve, or an overcharge

of refrigerant.

To remove oil from an evaporator, follow these

steps:

1. Remove all mix and product from the freezer

and allow the freezing cylinder to warm slowly

to room temperature.

2. With the freezing cylinder fully assembled (i.e.,

beater and scraper blades in place), fill the

hopper with hot water and place the machine in

the “AUTO” mode.

3. Turn the automatic expansion valve clockwise

to approximately 10 PSI above its original

setting. This will increase the ability of the

refrigerant to flow across the evaporator.

4. Periodically pull the draw valve and check the

water temperature. When the water becomes

cool, draw the remainder of the cool water from

the machine. This will allow more hot water to

flow into the freezing cylinder.

Figure 9

The hot water will cause the refrigerant in the

freezing cylinder walls to “boil” rapidly, removing the

oil and returning it to the compressor.

Figure 10

5. Repeat the last step three times.

6. Adjust the automatic expansion valve setting to

its original setting:

R404A = 20 - 22 psi (138 - 152 kPa)

Important: Do Not Leave the Unit Unattended

During This Procedure!

General Service

24

Models 358 & 359

Page 29

Rear Bearing Unit Alignment

During rear bearing unit installation, it will be

necessary to properly align the new component.

Tools Required:

1. Hex Alignment (Shaft) - Part Number X14407.

Figure 11

2. Alignment Disc (Hub Assembly) - Part Number

X26415.

Procedure:

Step 1

Disconnect the main power supply to the freezer.

Step 2

Remove the belt and the direct drive pulley.

Step 3

Loosen the mounting bolts that secure the rear

bearing unit to the frame.

Step 4

Insert the alignment tool (shaft), hex end first,

through the freezing cylinder. Engage the hex end

firmly into the direct drive coupling.

Step 5

Slide the alignment disc onto the alignment tool

(shaft) and slide it 1 inch (25.4 mm) into the front of

the freezing cylinder.

Step 6

Evenly tighten the mounting bolts which hold the

rear bearing unit in place. Be sure the alignment tool

remains firmly engaged throughout the procedure.

Figure 12

Step 7

Tighten the mounting bolts that secure the gear unit

to the frame.

Step 8

Install the direct drive pulley and belts. Check for

proper pulley alignment. (See page 26.)

Step 9

Remove the alignment tools from the unit. Verify that

the drive shaft can be easily installed and removed

from the drive coupling.

Models 358 & 359

25

General Service

Page 30

Pulley Alignment

______________________________

Rear Shell Bearing

______________________________

Pulley alignment is to be performed only after proper

rear bearing unit alignment has been established.

1. Loosen the direct drive pulley.

2. Use a straight, flat bar and hold it firmly against

the large rear bearing unit pulley.

Figure 13

3. Adjust the direct drive pulley until it is flush with

the motor pulley.

Prior to installation, place silicone silastic around the

outer diameter of this area.

Figure 15

Beater Shaft Removal

______________________________

Beater Shaft Retriever Assembly

(Part No. X26533)

Figure 14

4. Tighten the direct drive pulley set screw.

If the belt does not fit within the groove of the

motor pulley, re-adjust the direct drive pulley

until a proper fit is achieved.

The beater shaft retriever is a device used to

remove a drive shaft from the drive coupling.

Figure 16

General Service

26

Models 358 & 359

Page 31

Preventative Maintenance

During Cleaning and Sanitizing:

Cleaning and sanitizing schedules are governed

by federal, state, or local regulatory agencies,

and must be followed accordingly. If the unit

has a “Standby mode”, it must not be used in

lieu of proper cleaning and sanitizing

procedures and frequencies set forth by the

ruling health authority. The following check

points should be stressed during the cleaning

and sanitizing operations.

CLEANING AND SANITIZING MUST BE

PERFORMED DAILY.

ALWAYS FOLLOW LOCAL HEALTH CODES.

Troubleshooting Bacterial Count

j 1. Thoroughly clean and sanitize the machine

regularly, including complete disassembly and

brush cleaning.

j 2. Use all brushes supplied for thorough cleaning.

The brushes are specially designed to reach all

mix passageways.

j 3. Usethe white bristlebrush to clean the mixfeed

tube.

j 4. Use the black bristle brush to thoroughly clean

the rear shell bearing located at the rear of the

freezing cylinder. Be sure to have a generous

amount of cleaning solution on the brush.

j 5. IF LOCAL HEALTH CODES PERMIT THE

USE OF RERUN, make sure the mix rerun is

stored in a sanitized, covered, NSF approved

stainless steel rerun container and used the

following day. DO NOT prime the machine with

rerun. When using rerun, skim off the foam and

discard; then mix the rerun with fresh mix in a

ratio of 50/50 during the day's operation.

j 6. On a designated day of theweek, runthemix as

low as feasible and discard it after closing. This

will break the rerun cycle and reduce the

possibility of high bacteria and coliform counts.

j 7. Properly prepare the cleaning and sanitizing

solutions. Read and follow the label directions

carefully. Too strong of a solution may damage

the parts and too weak of a solution will not do

an adequate job of cleaning or sanitizing.

j 8. The temperature of the mix in the mix hopper

and walk-in cooler should be below 40_F.

(4.4_C.).

Regular Maintenance Checks

j 1. Rotate the scraper blades to allow both sides of

the knife edge to wear evenly. This will

contribute to self-sharpening and help maintain

fast, efficient freezing.

j 2. Replace scraper blades that are bent,

damaged, or worn smaller than 15/16”. Inspect

the condition of blades on a daily basis.

j 3. Before installing the beater, be certain that the

scraper blades are properly attached over the

beater pins.

j 4. Dispose of o-rings andsealsthat areworn, torn,

or fit too loosely, and replace with new ones.

Inspect all rubber parts daily.

j 5. Check the rear shell bearing for signs of wear

(excessive mix leakage in rear drip pan) andbe

certain it is properly cleaned. Inspect the rear

shell bearing monthly.

j 6. Using a screwdriver and cloth towel, keep the

female drive socket and the rear shell bearing

free of lubricant and mix deposits.

j 7. Follow all lubricating procedures as outlined in

the Operator Manual.

Models 358 & 359

27

General Service

Page 32

j 8. On air-cooled units, check the condenser filter

for an accumulation of dirt and lint. Dirty

condensers will reduce the efficiency and

capacity of the machine. The condensers

should be cleaned monthly.Remove the hood

to gain access to the condensers. Use a soft

brush to clean between the fins of the

condenser. Never use screwdrivers or other

metal probes to clean between the fins.

CAUTION: Always disconnect

electrical power prior to cleaning the

condenser. Failure to follow this

instruction may result in electrocution.

j 9. On water cooled units, check the water lines for

kinks or leaks. Kinks can occur when the

machineis movedback andforthfor cleaningor

maintenance purposes. Deteriorated or

cracked water lines should be replaced only by

an authorized Taylor service technician.

j 10. Inspect the drive shaft for wear and damage on

a monthly basis.

General Service

28

Models 358 & 359

Page 33

Section 5: Parts

S Parts Warranty Explanation

S Exploded Views

S Complete Parts List

S Wiring Diagrams

Models 358 & 359

29

Parts

Page 34

Parts Warranty Explanation

Class 103 Parts: The warranty for new equipment parts is one year from the original date of unit

installation, with a replacement parts warranty of three months.

Class 212 Parts: The warranty for new equipment parts is two years from the original date of unit

installation, with a replacement parts warranty of twelve months.

Class 512 Parts: The warranty for new equipment parts is five years from the original date of unit

installation, with a replacement parts warranty of twelve months.

Class 000 Parts: Wear Items - no warranty.

CAUTION: Warranty is valid only if the parts are authorized Taylor parts, purchased from an authorized

Taylor Distributor, and the required service work is provided by an authorized Taylor service technician.

Taylor reserves the right to deny warranty claims on equipment or parts if non-approvedpartsorrefrigerant

were installed in the machine, system modifications were performed beyond factory recommendations, or

it is determined that the failure was caused by neglect or abuse.

Parts

30

Models 358 & 359

Page 35

Model 358 Operator Parts

ITEM DESCRIPTION PART NO.

1 COVER A.-HOPPER INSUL X51658

2 TUBE-FEED-NONREVERS 015176-5

3 PANEL-REAR 046021

4 PANEL-SIDE *358* RIGHT 046023-SP1

5 FILTER A.-13 X 16-7/8 X 7/16 046044

6 STUD-NOSE CONE 054748

7 CHANNEL A.-CONTROL X63534

8 CASTER-SWIVEL 3/4 - 10 ST. 021279

Models 358 & 359

Figure 17

31

ITEM DESCRIPTION PART NO.

9 SCREW-1/4-20 X 5/8 SLOTTED 005542

10 CASTER-LOCKING SWIVEL 030307

11 PANEL-SERVICE 048267

12 PAN A.-DRIP X50879

13 SHIELD-SPLASH 066697

14 TRAY-DRIP 066696

15 PANEL-SIDE *358* LEFT 046022

Parts

Page 36

Model 358 Exploded View

Parts

Figure 18

32

Models 358 & 359

Page 37

358 Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 SHELL A.-INSULATED X45916-SER

1a BEARING-REAR SHELL-NICKL 031324

1b STUD-NOSE CONE 054748

2 O-RING-1/2 OD X .070 W 024278

3 PROBEA.-MIXOUT-SQHOLE X46024

4 SPACER-PROBE-SQ HOLE-7/8 041346

5 SPACER-PROBE-ROUND 5/8 046026

6 NUT-10-32 HEX MACHINE

SCREW

7 SCREW-5/16-18 X 7/8 SERR 017973

8 WASHER-5/16 USS FLAT CR3 000651

9 PULLEY-10J-11"PD-5/8BORE 025570

10 BELT-POLY V-450J10 044056

11 PULLEY-10J- 1.125PD-5/8BORE 028857

12 NUT-5/16-18 WHIZ FLANGE 017327

13 MOTOR-1.5 HP 021522-33

14 PULLEY-IDLER 3.00PD X 1.49" 054826

15 BOLT-IDLER PULLEY 046039

16 SCREW-SHOULDER 1/2 X 2 046048

17 SCREW-1/4-20X5/8SERR HWH 017522

18 NUT-1/4-20 WHIZ FLANGE LK 017523

19 NUT-3/8-16 WHIZ FLANGE LK 017329

20 BRACKET-IDLER ARM 045912

21 ARM A.-IDLER X64892

22 VALVE-ACCESS-1/4MFL X 3/8 053565

23 SWITCH-PRESSURE 405 PSI 052663

24 TEE-1/4S-COPPER 003949

25 DRYER-FILTER-HP62-3/8 048901

005598

ITEM DESCRIPTION PART NO.

26 VALVE-EPR 1/4S 022665

27 VALVE-ACCESS 1/4FL X 1/4 044404

28 SCREW-5/16-18 X 1-3/4 019691

29 KIT-MOUNTING-COMPRESSOR 052197

30 COMPRESSOR

CS18K6E-TF5-238

31 CASTER-3" SWV 3/4-10STM X1 021279

32 CASTER-3" SWV 3/4-10 STM

W/BRK

33 FILTER-AIR-13X16-7/8 X 7/16 046044

34 SCREW-10 X 3 /8 SLOT HEX 015582

35 SCREW-10-32 X 3/8 UNSL HWH 039381

36 NUT-1/4-20 WHIZ FLANGE LK 017523

37 SCREW-1/4-20 X 5/8 SERR 017522

38 CONDENSER-AC 12LX18H 019558

39 DUCTA.-EXHAUST X56398

40 SHROUD-CONDENSER 046000

41 FANA.-80 WATT X47180-27

42 SHROUDA.-FAN X45995

43 PANELA.-FRONT X45987

44 SCREW-6-32 X 3/8 SLTD 002201

45 CHANNELDETAIL SEE PG 36

46 PLATE-DEC 046010

47 COVER-BOX-SPLICE 046008

48 BOX-SPLICE 056402

49 GUIDE A.-DRIP PAN X45985

50 SCREW-10-32 X1/2 SERR HWH 020982

51 NUT-10-32 WHIZ FLANGE LK 020983

052397-33

030307

Models 358 & 359

33

Parts

Page 38

Model 358 Shell Assembly

ITEM DESCRIPTION PART NO.

1 SHELL A.-INSULATED

(INCLUDES ITEMS 1a-1c)

1a WASHER-BEARING LOCK 012864

1b NUT-BEARING 028991

1c GUIDE-DRIP SEAL 028992

2 ELBOW-1/4 PT-STREET-

BRASS

X45916-SER

035573

Parts

Figure 19

34

ITEM DESCRIPTION PART NO.

3 VALVE-EXP-AUTO-1/4S X1/4 046365

4 MOUNT A.-BEARING X54989

5 SCREW-5/16-18 X 7/8 SERR.

HWH

6 BEARING-UNIT-REAR 025629

7 SCREW-1/4-20 X 5/8

SERRATED HWH

017973

017522

Models 358 & 359

Page 39

Model 358 Control A. (X66731-33)

ITEM DESCRIPTION PART NO.

1 STARTER-3 PHASE 4 TO 6.5A 066794-33J

1a OVERLOAD-THERMAL 067461-3J

2 SCREW-8X1/4 SLTD HEX WASH 009894

3 RELAY-3 POLE-20A-208/240

50/60

066795-33

Models 358 & 359

Figure 20

35

ITEM DESCRIPTION PART NO.

4 CAPACITOR-RUN 4UF/440V 051785

5 BRACKET-CAPACITOR

1-1/4X2-1/16

6 SCREW-8-32X3/8UNSLTD HEX 041951

031205

Parts

Page 40

Model 358 Channel A.-Control (X63534)

Parts

Figure 21

36

Models 358 & 359

Page 41

358 Channel A.-Control (X63534) Parts Ident ificatio n

ITEM DESCRIPTION PART NO.

1 FILTER-CORCOM 2 VR1 032567

2 SCREW-8X1/4 SLTD HEX

WASH

3 CONTROL-THERMISTOR-MIX

LEVEL

4 SCREW-8-32X3/4 SLTD ROUND 016533

5 TRANS.-240V PR1/24V SEC 10 030132-27

6 SPACER-GRIP 051291

7 GRIP-THUMB 046009

009894

X63019-SER

ITEM DESCRIPTION PART NO.

8 SCREW-6-32X1/2 SLTD

BINDER

9 PLATE-DEC 046010

10 LIGHT-INDICATOR-RED 075724

11 NUT-6-32 NYLON INSERT

LOCK

12 SWITCH ASSEMBLY-DRAW X54278

13 SWITCH-TOGGLE 014464

022667

045716

Models 358 & 359

37

Parts

Page 42

Models 358 & 359 Beater Door Assembly

ITEM DESCRIPTION PART NO.

1 SEAL-DRIVESHAFT 032560

2 SHAFT-BEATER 033235

3 BEATER A.-7 QT. - 1 PIN X46233

4 BEARING-FRONT 013116

5 GASKET-DOOR-5.177 X 5 .938 016672

6 VALVE A.-DRAW X46028

Parts

Figure 22

38

ITEM DESCRIPTION PART NO.

7 O-RING- 1-1/16 OD x .139 W 020571

8 DOOR-PARTIAL1 SPOUT X30272-SER

9 NUT-STUD 021508

10 CLIP-SCRAPER BLADE 8.75” 046238

11 BLADE-SCRAPERPLASTIC 046237

Models 358 & 359

Page 43

Model 359 Operator Parts

ITEM DESCRIPTION PART NO.

1 PANEL-SIDE-LEFT 065250

2 COVER ASSEMBLY-HOPPER X51658

3 TUBE-FEED-NONREVERSIBLE 015176-5

4 PANEL-REAR 065271

5 FILTER-AIR 18 L X 13.5 H X .70 052779-3

6 CASTER-3” SWIVEL 3/4-10STM 021279

7 PANEL-SIDE-RIGHT 065251

8 DEFLECTOR-AIR 065200

Models 358 & 359

Figure 23

39

ITEM DESCRIPTION PART NO.

9 SCREW-1/4-20 X 5/8 SLOTTED 005542

10 CASTER-3” SWV 3/4-10 LOCK 030307

11 PANEL-SERVICE FRONT 065268

12 TRAY-DRIP 19-5/8 L X 4-7/8 033812

13 SHIELD-SPLASH-WIRE 033813

14 PAN A.-DRIP X50879

15 STUD-NOSE CONE 054748

Parts

Page 44

Model 359 Exploded View

Parts

Figure 24

40

Models 358 & 359

Page 45

359 Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 SHELL A.-INSULATED X68132-SER

1a BEARING-REAR SHELL 031324

1b STUD-NOSE CONE 054748

2 BOLT-IDLER PULLEY 046039

3 PULLEY-IDLER 3.00PD X 1.49" 054826

4 ARM A.-IDLER X64892

5 BRACKET-IDLER ARM 045912

6 NUT-3/8-16 WHIZ FLANGE LOC 017329

7 NUT-1/4-20 WHIZ FLANGE LOC 017523

8 SCREW-1/4-20X5/8 SERRATED 017522

9 SCREW-SHOULDER 1/2D X 2"L 046048

10 PULLEY-10J-11"PD-5/8BORE 025570

11 BELT-POLY V-450J10 044056

12 PULLEY-10J-1.125PD-5/8BORE 028857

13 MOTOR-1.5 HP 021522-33

14 NUT-5/16-18 WHIZ FLANGE 017327

15 SCREW-5/16-18 X 7/8 SERR 017973

16 WASHER-5/16 USS FLAT CR3 000651

17 SCREW-10-32 X 1/2 SERR 020982

18 NUT-10-32 WHIZ FLANGE LOC 020983

19 GUIDE A.-DRIP PAN X45985

20 BLOWER A.-STD OUTPUT X53725-27

20a SCREEN-BLOWER 053729

21 SHROUD-TOP 056504

22 SCREW-10 X 3/8 SLOT HEX 015582

23 SHROUD-REAR 055943

24 CONDENSER-AC 12L X 18H X

3.12T-5RW

25 FILTER-AIR-18.00L X 13.50H 052779-3

26 GUIDE-FILTER 053784

27 SCREW-1/4-20 X 5/8 SERR 017522

28 NUT-1/4-20 WHIZ FLANGE LOC 017523

055813-1

ITEM DESCRIPTION PART NO.

29 SHROUD-FRONT 055944

30 SCREW-5/16-18 X1-3/4 019691

31 KIT-MOUNTING-COMPRESSOR 052197

32 NUT-5/16-18 WHIZ FLANGE 017327

33 COMPRESSOR

CS18K6E-TF5-238

34 VALVE-ACCESS-1/4MFL X 3/8 053565

35 SWITCH-PRESSURE 405 PSI 052663

36 TEE-1/4S-COPPER 003949

37 DRYER-FILTER-HP62-3/8X 1/4 048901

38 VALVE-EPR 1/4S 022665

39 VALVE-ACCESS 1/4FL X 1/4 044404

40 CASTER-3" SWV 3/4-10STM 021279

41 NUT-10-32 WHIZ FLANGE LOC 020983

42 DEFLECTOR-AIR 065200

43 CASTER-3" SWV 3/4-10 STM

W/BRK

44 SCREW-10-32X3/8 UNSL HWH 039381

45 COVER-BOX-SPLICE 046008

46 BOX-SPLICE 056402

47 CONTROL A. X65279-33

48 CHANNEL DETAIL SEE PAGE

49 PANEL A.-FRONT X65223

50 PLATE-DEC 065276

51 SCREW-6-32 X1/2 SLT BINDER 022667

52 CONDENSER-AC 12L X18H X

3.12T-5RW

53 O-RING-1/2ODX .070W 024278

54 PROBEA.-MIXOUT-SQHOLE X46024

55 SPACER-PROBE-SQ HOLE-7/8 041346

56 SPACER-PROBE-ROUND 5/8 046026

57 NUT-10-32 HEX MACHINE

SCREW

052397-33

030307

055813-2

005598

Models 358 & 359

41

Parts

Page 46

Model 359 Shell Assembly

ITEM DESCRIPTION PART NO.

1 SHELL A.-INSULATED

(INCLUDES ITEMS 1a-1c)

1a WASHER-BEARING LOCK 012864

1b NUT-BEARING 028991

1c GUIDE-DRIP SEAL 028992

X68132-SER

Parts

Figure 25

42

ITEM DESCRIPTION PART NO.

2 VALVE-EXP-AUTO-1/4S X1/4 046365

3 BEARING-UNIT-REAR 025629

4 SCREW-1/4-20X5/8 SERR. 017522

Models 358 & 359

Page 47

Model 359 Channel A.-Control (X65222)

ITEM DESCRIPTION PART NO.

1 SCREW-8X5/8 SLTD HEX HD B 039659

2 CONTROL-THERMISTOR-MIX

LEVEL

3 NUT-6-32 NYLON INSERT LOC 045716

4 SWITCH ASSEMBLY-DRAW X65212-SER

5 SCREW-8X1/4 SLTD HEX 009894

6 FILTER-CORCOM 2VR1 032567

7 TRANS.-240V PR1/24V SEC 10 030132-27

X63019-SER

Models 358 & 359

Figure 26

43

ITEM DESCRIPTION PART NO.

8 SWITCH-TOGGLE 014464

9 SPACER-GRIP 051291

10 SCREW-6-32X1/2SLT BINDER 022667

11 GRIP-THUMB 046009

12 LIGHT-INDICATOR-RED 075724

13 PLATE-DEC 065276

Parts

Page 48

Model 359 Control A. (X65279-33)

ITEM DESCRIPTION PART NO.

1 STARTER-3 PHASE 4 TO 6.5A 066794-33J

1a OVERLOAD-THERMAL 067461-3J

2 SCREW-8X1/4 SLTD HEX WASH 009894

3 RELAY-3 POLE-20A-208/240

50/60

4 RELAY-DPDT-20A-120/240/277V 026581-27

5 BRACKET-MOUNTING ACCESS

VALVE

066795-33

065340

Figure 27

ITEM DESCRIPTION PART NO.

6 LUG-GROUNDING 4-14GA

WIRE

7 NUT-1/4-20 WHIZ FLANGE LOC 017523

8 SCREW-1/4-20X5/8 SERRATED 017522

9 BUSHING-SNAP 11/16 ID X 7/8 010548

017667

Parts

44

Models 358 & 359

Page 49

Models 358 & 359 Switch A.-Draw (X65212-SER)

ITEM DESCRIPTION PART NO.

1 ROD-SWITCH 029135

2 SPRING-COMP.480 X.047 X 2.0 025452

3 WASHER-.380 X .625 X .094 085213

4 E-RING 5/16 SS 016422

5 BRACKET-SWITCH 054277

Models 358 & 359

Figure 28

45

ITEM DESCRIPTION PART NO.

6 NUT-PUSH ON-1/2 DIA. SHAFT 039735

7 INSULATOR-SWITCH 1/64 029099

8 SWITCH-PLUNGER-SPDT15A12

5-250V

032260

Parts

Page 50

Models 358 & 359 Accessories

ITEM DESCRIPTION PART NO.

KIT A.-TUNE UP *358* X46050

1

KIT A.-TUNE UP *359* X36356

2 BRUSH-REAR BEARING 013071

3 BRUSH-DOUBLE ENDED 013072

Parts

Figure 29

46

ITEM DESCRIPTION PART NO.

4 BRUSH-DRAW VALVE 014753

5 BRUSH-HOPPER 3” X 7” 023316

6 LUBRICANT-TAYLOR 4 OZ 047518

*7 SANITIZER-STERA-SHEEN SEE NOTE

*Note: A sample container of sanitizeris sent with the

unit. For reorders,order Stera Sheen part no. 055492

(100 packs) or Kay-5 part no. 041082 (125 packs).

Models 358 & 359

Page 51

Parts List

REMARKS

WARR.

CLASS

359

QTY.

358

QTY.

NUMBER

DESCRIPTION PART

BOOT-CAPACITOR-INSULATING 031314 1 000

CAPACITOR-RUN 7.5UF/370V 034749 1 103

MOTOR-FAN 208-230V 50/60 HZ 053481-27 1 103

+BRACKET-IDLER ARM 045912 1 2 103

+BOLT-IDLER PULLEY *358* 046039 1 2 103

+SCREW-SHOULDER 046048 1 2 000

ARM A.-IDLER*356* X64892 1 2 103

+ Available Separately, NNN = Not a Service Item

+SPRING-EXTENSION.500X.063X4.00 046046 1 2 103

Models 358 & 359 Parts List

BEARING-FRONT 013116 1 2 000

BEARING-REAR SHELL *NICK.PLATE 031324 1 2 000

+GUIDE-DRIP SEAL 028992 1 2 000

+NUT-BRASS BEARING 028991 1 2 000

+O-RING-1/2OD X .070W 024278 2 4 000

+WASHER-BEARING LOCK 012864 1 2 000

+BLADE-SCRAPER-PLASTIC 9-13/16L 046237 2 4 000

+CLIP-SCRAPER BLADE*8.75 INCH* 046238 2 4 103

BEARING-UNIT REAR 025629 1 2 103 DIRECT DRIVE UNIT

BEATER A.-7QT-1 PIN-SUPPORT X46233 1 2 103

BELT-POLY V-450J10 044056 1 2 000

BLOCK-TERMINAL 2P L1,L2 039422 1 103 208-230V 60HZ 1PH

BLOCK-TERMINAL 3P-L1,L2,L3 039423 1 1 103 208-230V 60HZ 3PH

BLOWER A. X53725-27 1 103

47

SCREEN-BLOWER 053729 1 103

BRUSH-DOUBLE ENDED-PUMP&FEED 013072 1 1 000

BRUSH-DRAW VALVE 1-1/2"OD X 3" 014753 1 1 000

BRUSH-MIX PUMP BODY-3"X7"WHITE 023316 1 1 000

BRUSH-REAR BRG 1IN.DX2IN.LGX14 013071 1 1 000

BUSHING-SNAP 11/16 ID X 7/8OD 010548 1 8 103

110318

110318

BUSHING-PANEL 013289 4 103

Page 52

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

+O-RING-1-1/16 OD X.139W 020571 2 4 000

+CAPACITOR-START-189-227UF/250 V 053106 1 103 208-230V 60HZ 1PH

+CAPACITOR-RUN- 35UF/440V 048132 1 103 208-230V 60HZ 1PH

+RELAY-START-COMPRESSOR 051957-27 1 103 208-230V 60HZ 1PH

+KIT-MOUNTING COMPRESSOR 052197 1 000

CAPACITOR-RUN- 4UF-440V 051785 1 103 CONDENSER FAN

CAPACITOR-RUN 7.5UF/370V 034749 1 103 BLOWER FAN

CASTER-LOCKING SWIVEL 3 IN. 030307 2 2 103

CASTER-SWV-3/4-10 ST. 3IN WHL 021279 2 2 103

COMPRESSOR CS18K6E 052397-27E 1 512 208-230V 60HZ 1PH - K0078823/UP COPELAWELD

+ Available Separately, NNN = Not a Service Item

Parts List Models 358 & 359

COMPRESSOR CS18K6E-TF5-238 052397-33 1 2 512 208-230V 60HZ 3PH

CONDENSER-AC-12LX18HX4.3-5ROW 019558 1 103

CONDENSER-AC 12LX18HX3.12T-5RW 055813-1 1 103

CONDENSER-AC 12LX18HX3.12T-5RW 055813-2 1 103

CONTROL-THERMISTOR-MIXLVL X63019-SER 1 2 103

48

COVER A.-HOPPER*358* X51658 1 2 103

DECAL-DEC-TAYLOR 358 056569 1 000

DECAL-DEC-TAYLOR 021872 1 000

DECAL-INST-CLNHPR 019029 1 1 000

DECAL-TROUBLESHOOTING 038374 1 000

DIAGRAM-WIRING *358* 063532-27 1 000 208-230V 60HZ 1PH

DIAGRAM-WIRING *358* 063532-33 1 000 208-230V 60HZ 3PH

DIAGRAM-WIRING *359* 065467-33 1 000

DOOR A.-1 SPT-7 QT X30272-SER 1 2 103

+GASKET-DOOR 5.177ID X 5.938OD 016672 1 2 000

+VALVE A.-DRAW *358* X46028 1 2 103

DRYER-FILTER-HP62-3/8 X 1/4S 048901 1 2 000

ELEMENT-HEATER 014174- 1 000 NO LONGER USED AFTER J5050000

FASTENER-CLIP 1/4-20 U-TYPE 045865 8 18 000

FILTER-AIR13X16-7/8X7/16 046044 1 000

Page 53

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

BEARING-FRONT 013116 2 000

GASKET-DOOR 5.177ID X 5.938O 016672 2 000

O-RING-.643 OD X .077W 018572 4 000

O-RING-1-1/16 OD X.139W 020571 4 000

SEAL-DRIVE SHAFT 032560 2 000

BEARING-FRONT 013116 1 000

GASKET-DOOR 5.177ID X 5.938OD 016672 1 000

O-RING-.643 OD X .077W 018572 2 000

O-RING-1-1/16 OD X.139W 020571 2 000

SEAL-DRIVE SHAFT 032560 1 000

TOOL- 0 -RING REMOVAL 048260-WHT 1 000

FILTER-AIR-18.00LX13.50HX.70W 052779-3 2 000

FILTER-CORCOM 2VR1 032567 1 2 000

GUIDE A.-DRIP PAN*358*W/SHROUD X68531 1 000 208-230V 60HZ 1PH

GUIDE A.-DRIP PAN *358*359 X45985 1 2 103 208-230V 60HZ 3PH

HARNESS A.-WIRE*358*BTR MTR X58286 1 103 208-230V 60HZ 1PH

HARNESS-WIRE-POWER*358* 059448-27 1 103 208-230V 60HZ 1PH

HARNESS-WIRE-POWER*358* 059448-33G 1 103 208-230V 60HZ 3PH

HARNESS-WIRE *359* COMPR 065506-G 2 103

HARNESS-WIRE *359* BTR MTR 065507 2 103

HARNESS-WIRE *359* CTRL BX/CHN 065508 2 103

HARNESS-WIRE *359* MAIN POWER 065509 1 103

HARNESS-WIRE *359* BLOWER 065512 1 103

KIT A.-WENDY'S*358*SPACER&GRIP X51432 1 103 DRAW SWITCH ASSEMBLY

KIT A.-TUNE UP*358* X46050 1 000

+ Available Separately, NNN = Not a Service Item

Models 358 & 359 Parts List

49

KIT A .-TUNE UP X36356 1 000

TOOL-O-RING REMOVAL-FREEZER 048260-WHT 1 000

LABEL-3PH MTR PROT/1PH C- 025949 1 1 000 208-230V 60HZ 3PH

LABEL-CK MTR ROTATE-CCW-M 046867 1 1 000 208-230V 60HZ 3PH

LABEL-DOOR-MOVE PART 032749 1 1 000

Page 54

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

+FAN-5 BLADE 12" PUSH 26DEG CCW 029771 1 103

+CAPACITOR-RUN 7.5UF/370V 034749 1 103

LABEL-SW-WASH/OFF/AUTO-SYMBOL 014502 1 2 000

LABEL-WARN-CONDENSER-SHARP 059287 1 3 000

LABEL-WARN-COVER 051433 5 5 000

LIGHT-AMBER 075724 1 2 103

LUBRICANT-TAYLOR 4 OZ. 047518 1 1 000

MAN-OPER 358/359 056788-M 1 1 000

MOTOR-1.5 HP 021522-27 1 212 208-230V 60HZ 1PH

MOTOR-1.5 HP 021522-33 1 2 212 208-230V 60HZ 3PH

MOTOR-FAN 80 WATT 1550 RPM CW 051744-27 1 103

MOTOR-FAN 208-230V 50/60 HZ 053481-27 1 103

NUT-STUD *GENERAL USAGE* 021508 4 8 103 HANDSCREWS

PAN A.-DRIP*358* X50879 1 2 103

PANEL A.-FRONT *358* X45987 1 103

PANEL-REAR *358* 046021 1 103

PANEL-SERVICE *358* 048267 1 103

PANEL-SIDE *358*LEFT 046022 1 103

PANEL-SIDE-RIGHT *358*AC 046023-SP1 1 103

PANEL A.-FRONT *359* X65223 1 103

PANEL-REAR *359* 065271 1 103

PANEL-SERVICE FRONT *359* 065268 1 103

PANEL-SIDE-LEFT *359* 065250 1 103

PANEL-SIDE-RIGHT *359* 065251 1 103

PLATE-DEC-358 046010 1 103

PLATE-DEC *359* 065276 1 103

PROBEA.-MIXOUT-SQUAREHOLE X46024 1 2 103

PROBE-THERMISTOR-BARREL-2%TOL 038061-BLK 1 2 103

PULLEY-10J- 1.125PD-5/8BORE 028857 1 2 103 BEATER MOTOR

PULLEY-10J-11"PD-5/8BORE 025570 1 2 103 GEAR

+ Available Separately, NNN = Not a Service Item

Parts List Models 358 & 359

50

Page 55

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

OVERLOAD-THERMAL-1P-6.3/10A 067461-1K 1 103

OVERLOAD-THERMAL-3P-4.0/6.5A 067461-3J 2 103

ACTUATOR-SWITCH 032247 1 103

BEARING-SWITCH 054385 2 103

BRACKET-SWITCH *358* 054277 1 103

E-RING 5/16 SS 016422 1 000

INSULATOR-SWITCH1/64 ARMITE 029099 1 000

ROD-SWITCH *350-1-450-1* 029135 1 103

SPRING-COMP.480X.047X2.00 SS 025452 1 103

SWITCH-PLUNGER-SPDT15A125-25 032260 2 103

ACTUATOR-SWITCH 032247 2 103

BEARING-SWITCH 054385 4 103

+BOLT-IDLER PULLEY *358* 046039 1 2 103

PULLEY-IDLER 3.00PD X 1.49" 054826 1 2 103

RELAY-3 POLE-20A-208/240 50/60 066795-33 1 2 103

RELAY-DPDT-20A-120/240/277V 026581-27 2 103

+ Available Separately, NNN = Not a Service Item

Models 358 & 359 Parts List

SANITIZER-STERA SHEEN -GREEN 055492 1 1 000

SHAFT-BEATER 033235 1 2 103

+SEAL-DRIVE SHAFT 032560 1 2 000

SHELL A.-INSULATED*358* X45916-SER 1 512

+STUD-NOSE CONE 054748 4 103

SHELL A.-INSULATEDDUAL *359 X68132 1 512

+STUD-NOSE CONE 054748 8 103

SHIELD-SPLASH 066697 1 103

SHIELD-SPLASH-WIRE-19-3/4 L 033813 1 103

STARTER-1 PHASE 6.3 TO 10 AMP 066794-27K 1 103 208-230V 60HZ 1PH

51

STARTER-3 PHASE 4 TO 6.5 AMP 066794-33J 1 2 103 208-230V 60HZ 3PH

SWITCH A.-DRAW *358* X51432 1 103

SWITCH A.-DRAW *359* X65212-SER 2 103

BRACKET-SWITCH *358* 054277 1 103

Page 56

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

E-RING 5/16 SS 016422 2 000

INSULATOR-SWITCH1/64 ARMITE 029099 2 000

ROD-SWITCH *350-1-450-1* 029135 2 103

SPRING-COMP.480X.047X2.00 SS 025452 2 103

SWITCH-PLUNGER-SPDT15A125-25 032260 4 103

+ Available Separately, NNN = Not a Service Item

Parts List Models 358 & 359

GUARD-POWER SWITCH 034830-1 1 2 103 K4013676/UP

SWITCH-PRESSURE 405 PSI-SOLD 052663 1 2 103 DISCHARGE LINE

SWITCH-TOGGLE-DPDT*ON-OFF-ON 014464 1 2 103 POWER

TRANS.-240V PR1/24V SEC 10 VA 030132-27 1 2 103

TRAY-DRIP 066696 1 103

SWITCH-PRESSURE 440 PSI-SOLDER 048230 1 103 H4102700/UP

SWITCH-PRESSURE 025749 1 103 H4102699/PRIOR

TRAY-DRIP-19-5/8 L X 4-7/8 033812 1 103

TUBE-CAPILLARY .021ID X 9 FT 020059 1 2 103 LINE A.-LIQUID

TUBE-FEED-NON REVERS 1/4 HOLE 015176-5 1 2 103 J7030970/UP

VALVE-ACCESS-1/4MFL X 3/8ODS 053565 2 4 103 ACCESS LINE - DISCHARGE LINES

VALVE-ACCESS 1/4FL X 1/4SOLDER 044404 1 2 103 EPR VALVE

VALVE-EPR 1/4S 022665 1 2 103

+BOOT-EXPANSION VALVE 050900 1 2 000

VALVE-EXP-AUTO-1/4SX1/4 FPT 046365 1 2 103 J4102700/UP

VALVE-ACCESS 1/4FL X 3/8SOLDER 043232 1 103 HEAT EXCHANGER

VALVE-ACCESS-1/4 MFLX1/4 S-90 047016 1 103 USE W/ 047519-27 COMPRESSOR

VALVE-ACCESS-1/4FLX5/16SOLDER 053026 1 103 USE W/ 047519-27F COMPRESSOR

52

Page 57

QTY.

QTY.

PART

CLASS

359

358

NUMBER

DESCRIPTION REMARKSWARR.

WATER COOLED

ACCUMULATOR-COPPER 2"DIA 10" 047062 1 103

ADAPTOR-3/8MP X 1/2 BARB- 011021 1 103

BLOWER-100 CFM 012796-27 1 103

CONDENSER-WC-COAX 048287 1 103