Page 1

Instruction Handbook

CX 8036

Large Format System

Page 2

This USER GUIDE contains functional and operational details

There are many sections in this guide for Basic Functions and Advanced Operations. Please see

the TABLE OF CONTENTS.

Please read this USER GUIDE carefully before using the Printer.

Please keep this USER GUIDE for future reference.

1. When this product is installed in North America.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

2. When this product is installed in Europe

This equipment complies with the requirements in Pub.22 of CISPR Rules for a Class B

computing device.

Operation of this equipment in a residential area may cause unacceptable interference to radio

and TV reception requiring the operator to take whatever steps are necessary to correct the

interference.

Do not install Machine around other electronic equipment or other precision instruments.

Other devices may be effected by electrical noise during system operation.

If the machine is installed near other electronic equipment, such as a TV or a radio,

interference to the noted equipment, such as noise or flickering, may occur.

Use a dedicated power source and install the PRINTER as far as possible from the noted

equipment.

As an ENERGY STAR ® Partner, Katsuragawa Electric Co., Ltd. has determined

that this product meets the

The International

promotes energy saving through the penetration of energy efficient computers and other office

equipment. The program backs the development and dissemination of products with functions that

effectively reduce energy consumption. It is an open system in which business proprietors can

participate voluntarily. The targeted products are office equipment such as computers, monitors,

printers, facsimiles, copiers, scanners, and multifunction devices. Their standards and logos are

uniform among participating nations.

ENERGY STAR ® Office Equipment Program is an international program that

ENERGY STAR ® guidelines for energy efficiency.

of the Multifunction Printer.

(1)

Page 3

Safety

The following pages are very important in order to safely use this product.

These notes are important in preventing harm to the operator or the operation of the printer.

The following symbols are found throughout the USER GUIDE:

WARNING

This WARNING mark means that there is a possibility of death or serious

injury if you ignore or do not follow the instructions.

CAUTION

This CAUTION mark means that there is a possibility of injury or

damage, if you ignore or do not follow the instructions.

This symbol means , “DO NOT ATTEMPT”

This symbol means , “pay close attention to”

(2)

Page 4

WARNING

Ground the product with a proper ground source or you may be electrically

shocked.

1. The Power source should be:

2. Use a circuit with a dedicated breaker.

3. Install the product as close to the wall outlet as possible.

4. If you wish to move the printer, please contact your service personnel.

1. Do not remove the screw(s) or do not open the cover if not instructed to

do so in this User Guide. If you ignore this warning, you may be burnt

to a hot item or receive an electric shock due or electrically charged part

inside of the printer.

2. Do not disassemble or tamper with the printer.

It may result in a fire or an electrical shock.

1. Do not plug in the printer into a multi-wire connector in which some other

equipment is plugged into.

It may cause a fire due to outlet overheating.

2. Do not damage the Power Cord by stepping on or placing heavy items

on it.

If the Power Cord is damaged, it may cause a fire or you may receive

an electric shock. REPLACE THE CORD IF DAMAGED!

product. Spilt water could cause a fire or an electric shock.

2. If the product generates an abnormal smell or noise, turn it off and

unplug it from the wall electrical outlet immediately.

Do not throw the toner into a fire or other sources of heat, as it can

explode.

120V +6% or -10%, 50/60Hz, 15A or higher

1. Do not put a flower vase, a flowerpot or any other water-filled item on the

(3)

Page 5

CAUTION

Do not install the printer in a humidified room or a dusty room.

Also, do not install the printer on an unstable floor as injuries may occur.

1. Unplug the printer before you move it.

The power cord may be damaged and it may result in a fire or electric

shock.

Do not pull the cord when you unplug the printer as you may damage the

Power Cord.

There are hot items inside of the printer.

Take great care not to touch these items when you remove mis-fed media.

Ventilate the room well if installed in a small area.

2. If you do not use the printer for a long duration (holidays, company

shutdown) turn off and unplug the printer from the outlet for safety.

(4)

Page 6

TABLE OF CONTENTS

Section 1 Basic Printer Functions

Section 2 Copy Mode

Section 3 Scan Mode

Section 4 Job Info Mode

Section 5 Help – Configuration

Section 6 Windows Drivers

Section 7 AutoCAD Drivers

Section 8 KIP Request

Section 9 KIP PrintNet

Section 10 Reporting Package - PRP

Section 11 Connectivity

(5)

Page 7

Section 1

Basic Printer Functions

Page

1.0 Before System Use 1- 1

1.1 Installation Requirements 1- 2

1.2 Prohibited Originals 1- 3

1.3 Key Features 1- 4

1.4 Specifications 1- 5

1.5 Exterior Views 1- 8

1.5.1 Front View 1- 8

1.5.3 Rear View 1- 9

1.5.4 Operator Panel 1- 10

Copy Mode 1- 10

Scan Mode 1- 11

Job Info Screen 1- 12

? - Information / Help Screen 1- 13

1.6 Optional Accessories 1- 14

2.0 Operation Details 1- 15

2.1 Turning on

2.2 Turning off

2.3 Roll Media Replacement 1- 16

2.4 Toner Installation 1- 20

2.5 Cut Sheet Media Placement 1- 24

2.6 Emergency Stop of a Copy or Scan 1- 26

2.7 Dehumidify the Roll Media (option) 1- 27

3.0 Error Messages 1- 28

3.1 Operational Errors 1- 28

3. 1. 1 Paper mis-feed errors 1- 28

3. 1. 1. 1 Deck is jam / Feeding Jam 1- 28

3. 1. 1. 2 Manual Jam 1- 30

3. 1. 1. 3 Internal Transport Jam 1- 30

3. 1. 1. 4 Fuser Jam 1- 31

3. 1. 1. 5 Accessory Jam 1- 31

3. 1. 2 Others 1- 32

3. 1. 2. 1 Deck is open 1- 32

3. 1. 2. 2 Accessory Error 1- 32

3. 1. 2. 3 Manual Set 1- 32

3. 1. 2. 4 Cutter Set 1- 32

3. 1. 2. 5 Toner Empty 1- 33

3. 1. 2. 6 Paper Empty 1- 33

3. 1. 2. 7 Door opened during printing 1- 33

3.2 Call Service Errors 1- 34

1- 15

1- 16

Section 1 Basic Printer Functions 1-1

Page 8

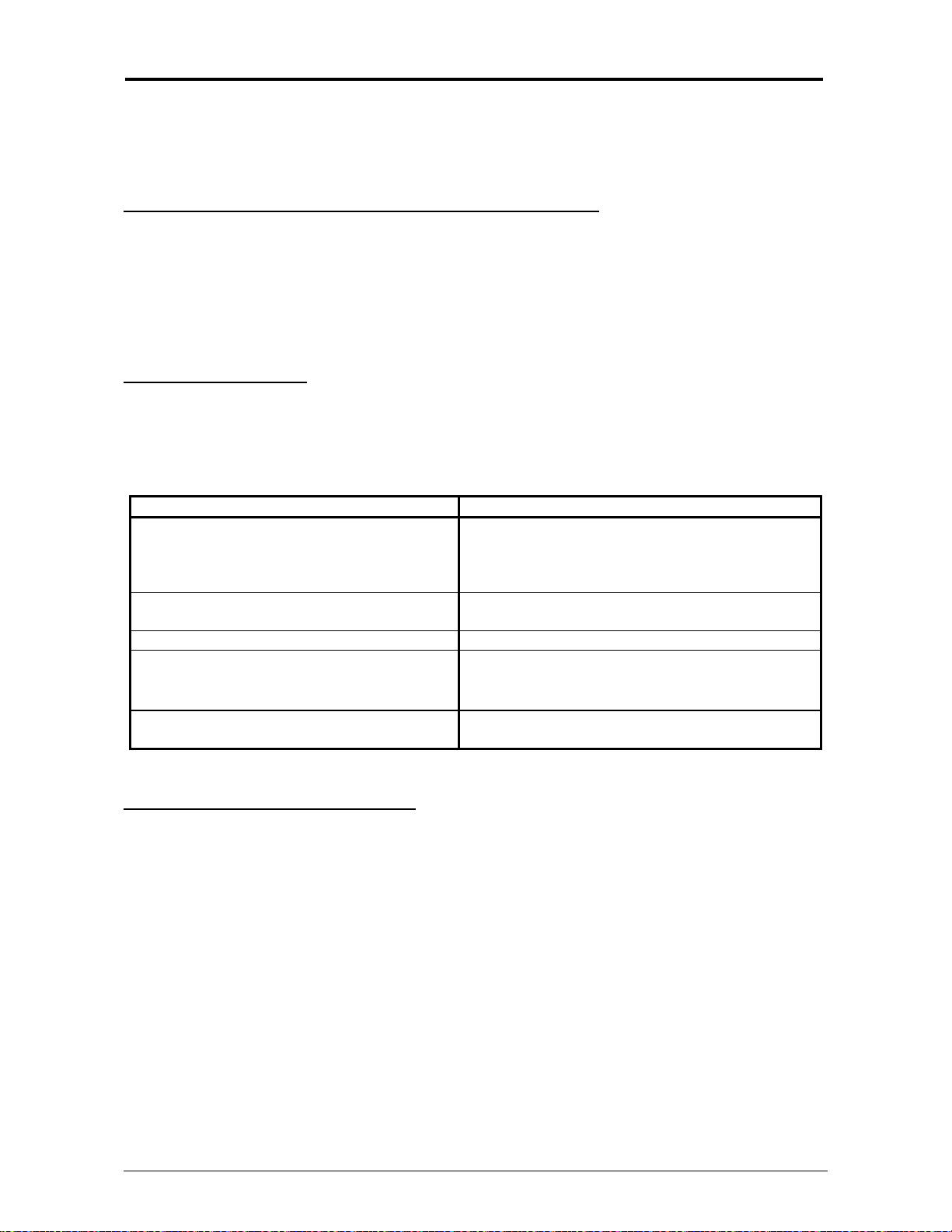

1. 1 Installation Requirements

The following conditions are required for the installation of the equipment.

1. Power source should be rated as:

120V +6% or -10%, 50/60Hz, 15A or higher

2. The equipment must be on a dedicated circuit.

3. The outlet must be near the equipment and easily accessible.

1. Make sure to connect this equipment to a properly grounded outlet.

2. The outlet shall be installed near the equipment and shall be easily accessible.

Site Environmental Conditions

Temperature Range

10 C to 30 C

50 F to 86 F

Humidity Range

20% to 85% RH. (NON CONDENSING)

Keep the printer away from water sources, boilers, humidifiers or refrigerators.

1. The installation site must not have any open flames, dust or ammonia gases.

2. The equipment must not be exposed to the air vents from heating/cooling systems.

3. The equipment should not be exposed to the direct sunlight.

Please draw curtains to block any sunlight.

When you open the printer (Upper Half), do not expose the Photoconductive Drum

to strong (intense) light as this will damage the Drum.

Ozone will be generated while this equipment is in use, although the quantity generated

is within all safe levels. (see certifications) Ventilate the room, if so required.

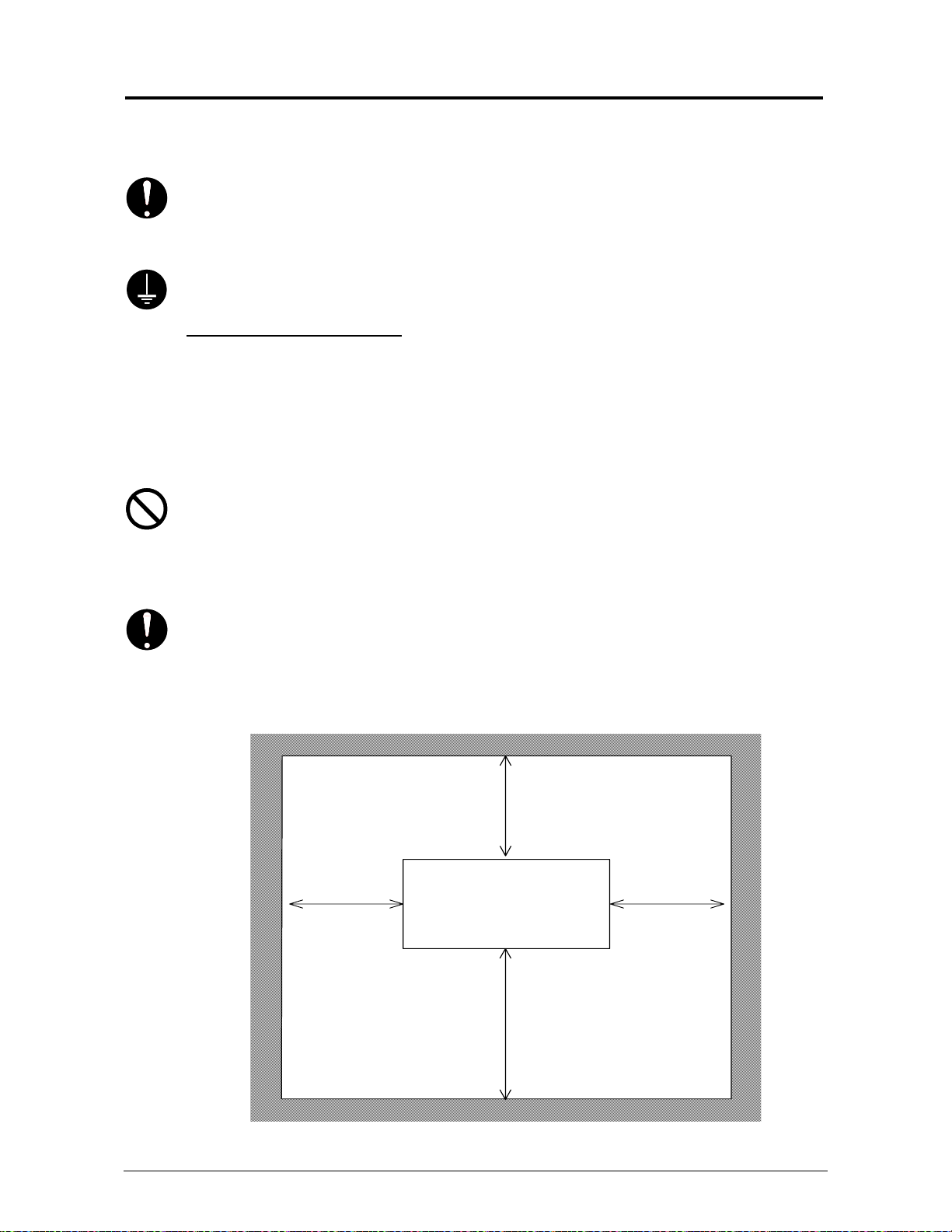

Keep ample space around the equipment to ensure comfortable operation.

(Refer to the following figure.) The floor must be level and the strength must be ample to

sustain the weight of the equipment.

45cm / 18”

or wider

60cm / 24” or larger

when the standard tray is installed

(Rear)

45cm / 18”

or wider

System

(Front)

80cm / 32” or larger

Section 1 Basic Printer Functions 1-2

Page 9

1. 2 Prohibited Originals

To duplicate or copy any type of document is not permitted! It may be illegal if you possess copies

of certain types of documents. We recommend you investigate if you have the legal right to copy /

scan a document prior to performing these functions.

Originals prohibited from copying / scanning (by law)

1. You cannot duplicate/copy Currency (Bill, Money, Bank Note, etc.), Government issued

Negotiable Instruments (National Bonds, Security, Local Debt Bonds, etc.).

2. You cannot duplicate/copy Foreign Currency or Foreign Negotiable Instruments.

3. You cannot duplicate/copy unused postal stamps or government postcards without

permission to replicate from the Government.

4. You cannot duplicate/copy Government issued revenue stamps or certificate stamps, which

are issued by Liquor Tax Acts or the Commodity Tax Acts.

Other Notable Items

1. You are warned by the government not to copy / scan, private issued securities (stock

certificate, draft, check, goods ticket, etc.), commutation ticket or book of tickets, excluding that

some specific companies can copy such originals it requires for its own business.

2. We recommend you not freely copy / scan government issued passports, public or private

issued licenses, automobile inspection certifications, ID and tickets (passes or meal).

Law To Reference Items Prohibited to Duplicate

Regulations to control fake currency and

bonds.

Control Law against Forged or Fake

Foreign Currency, Bill, Bank Note and Bond

Forged postal stamps control law Unused postal stamps or government postcards

Forged revenue stamp control law Government issued revenue stamps, and

Currency similarity securities Control Law Private issued securities (stock, draft, check,

Originals protected by Copyright

It is prohibited to copy / scan:

books, music, paintings, maps, drawings, movie and pictures which are protected

by copyright.

Currency (Bill, Money, Bank Note, etc.),

Government issued Negotiable Instruments

(National Bonds, Security, Local Debt Bonds,

etc.)

Foreign Currency or Foreign Negotiable

Instruments

certificate stamps prescribed by Liquor Tax Act

or Commodity Tax Act

goods ticket, etc.), commutation or book tickets

Section 1 Basic Printer Functions 1-3

Page 10

1. 3 Key Features

The system is a single footprint Multi-Function Printer which can copy, scan and print.

Advanced drivers and comprehensive print utilities make the

system. (some functions may be optional)

The scan and print speeds are up to 60mm/sec or up to 4 landscape “D” prints/minute.

KIP HDP technology generates no waste toner.

The combination of the KIP HDP Plus imaging system with mono-component minute toner

produces high definition lines, distinctive greyscale and consistent blacks.

The maximum paper width is 914mm or 36” wide, and the minimum is 279mm or 11”.The

maximum paper length is 3.6m or 11.8’ (with 36” paper), and the minimum is 210mm or 8.5”.

Up to 600dpi print and scan resolutions, with an advanced Image Process System, produces the

highest quality images.

Copier Features

• Easy Touch screen control panel

• Collated Sets copying

• Real-time image preview

• Recall/reprint previous jobs

• 600x600DPI copy quality

• Integrated Accounting and Reports for all copying, network printing, scanning

• Network ready copier

• Simple Operator assistance for every day tasks (toner replacement procedure)

• Image stamping

• All hardware/software included for instant upgrade from Digital Copier to Network

Printer to Scan-to-File system.

• Information center displays all support information, meter readings, and serial number.

Network Printer Features (Optional)

• Standard TCP/IP connectivity

• Direct support for vector file formats: HPGL1/2, HP-RTL, Calcomp 906/907

DWF format support

•

• Direct support for raster file formats: TIF Group 3/4, Cals Group 4, Uncompressed

Grayscale/Color TIF,

• Optional PDF format support: PS/PDF file format.

• Standard Windows Driver for KIP Script (PS output) and KIP-GL (HPGL/2,RTL output)

• Standard AutoCAD Drivers

• Unlimited site license of KIP Request allows users to group supported formats together

for printing collated sets.

• Integrated Accounting in all KIP Drivers/Request for all network printing.

•

Integrated Web Printing (web server)

• Open architecture ASCII Job Ticket for third party applications

Scan-to-File Features

• Scan directly to PDF, TIF Group 4, Cals Group 4

• Scan to file to FTP or personal inbox on the

• Selected resolution – up to 600 DPI optical

• Automatic original size recognition

• Retrieve scanned image files with KIP Request

system an advanced, easy to use

system

Section 1 Basic Printer Functions 1-4

Page 11

1. 4 Specifications

General

Subject Specification

Model CX8036

Configuration Console

Maximum power

consumption

Acoustic noise Idling Max. 52db

Ozone Max. 0.1ppm (Measurement method under UL Standard)

Dimensions 1240mm (W) x 600mm (D) x 1100mm (H) or

Weight 195 kg or 430 lbs (1 roll)

Environmental condition

for usage

Input power In U.S.A. : 120V plus/minus 10%, 50/60Hz, 10A

NOTE : specifications subject to change without notice

1500W (Including Scanner & IPS)

Printing Max. 60db

Impulse sound Max. 65db

49” x 24” x 44”

(Operation Panel is not included in these dimensions)

200 kg or 440 lbs (2 roll) (weights are estimated)

Temperature:

10 to 32 Centigrade or

50 to 86 Fahrenheit

Humidity:

20 to 85% RH

In Europe : 220-240V plus 6% or minus 10%, 50/60Hz, 6A

Section 1 Basic Printer Functions 1-5

Page 12

Printer

Subject Specification

Model CX8036

Configuration Console – Single Footprint

Printing method LED Array Electro-Photography

Photoreceptor Organic Photoconductive Drum

Print speed 60mm per second

(Metric) 2 A0 / minute

(Inch) 2 E or 4 D Landscape / minute

Print head LED Array – Calibrated

Resolution 600dpi x 600dpi

Print width Maximum 914mm or 36”

Minimum 279mm or 11”

Print length Maximum

(Standard) 3.6m or 11.8’

(Option) 24m or 75’

Minimum 210mm or 8.5”

NOTE

If the page is longer than 3.6m, image quality, function and

reliability are not guaranteed.

Warm up time Less than 5

First print time 24 seconds (D Landscape)

32 seconds (E)

Fusing method Heat - Pressure Rollers

Development method Dry, non-magnetic mono-component toner

Media Plain Paper 64 to 80g/m

2 -

US Bond (20lbs)

Tracing Paper US Vellum (20lbs)

Film 4 MIL

Recommend media for electro-photography process

Storage of consumables Store toner from 0 to 35 C ( 32 to 95 F ) and within the humidity

range from 10 to 85% RH.

NOTE : specifications subject to change without notice

Section 1 Basic Printer Functions 1-6

Page 13

Scanner

Subject Specification

Scanning method Contact Image Sensor (CIS) (5 – A4)

Light source LED

Setting of original Face up

Starting point of scan Center

Scan width Max. : 914.4mm or 36”

Min. : 275.0mm or 11”

Transportable original

width

Scan length Max. : 15,240mm or 50’ (Including the margin area)

Margin area 3mm from leading edge and trailing edge

Optical resolution 600dpi

Digital resolution Max. : 600dpi

Original transportation Sheet through type

Transportable original

thickness

NOTE : specifications subject to change without notice

Max. : 932.2mm or 36.7”

Min. : 275.0mm or 11”

Min. : 210mm or 8.5” (Including the margin area)

Min. : 100dpi

Max. : 0.65mm

Min. : 0.05mm

Section 1 Basic Printer Functions 1-7

Page 14

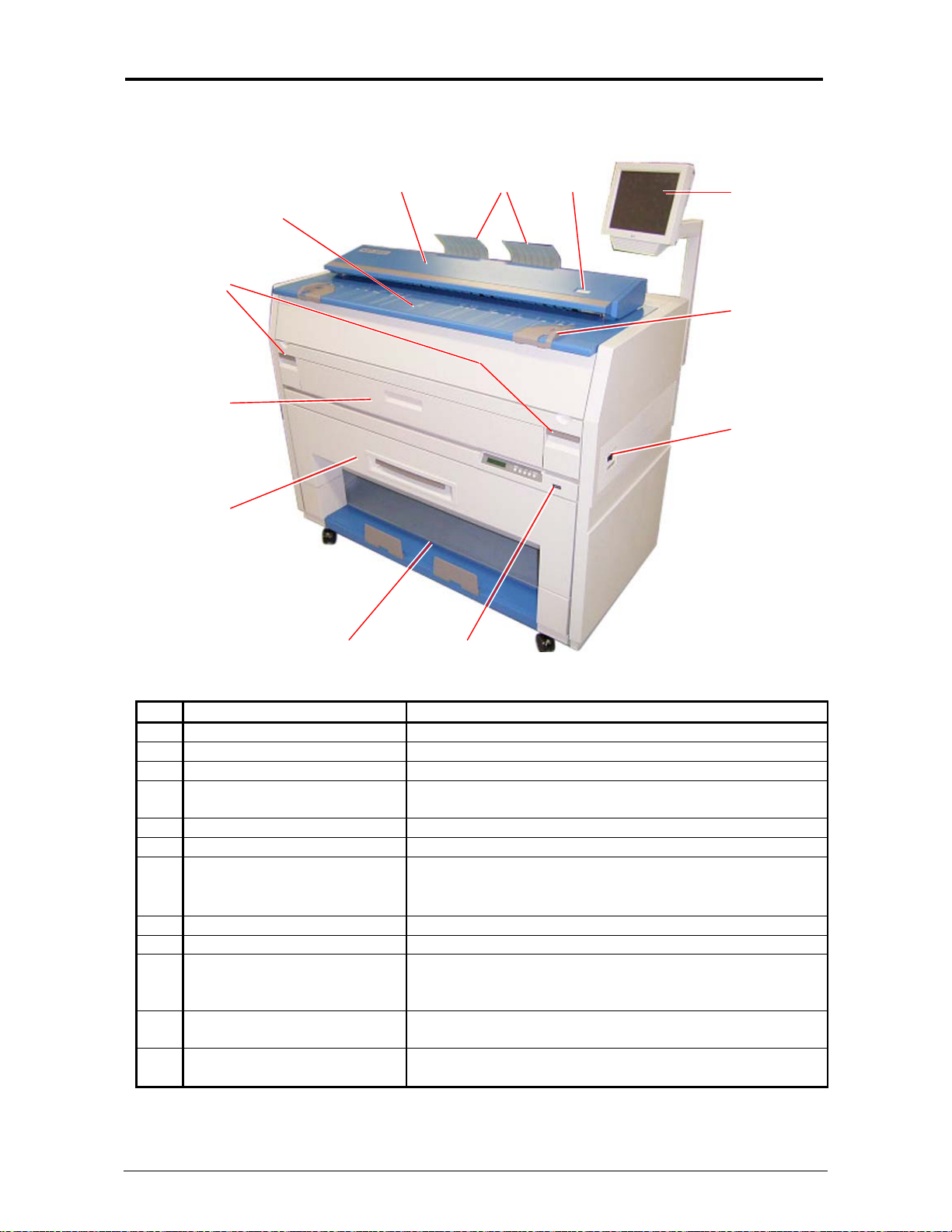

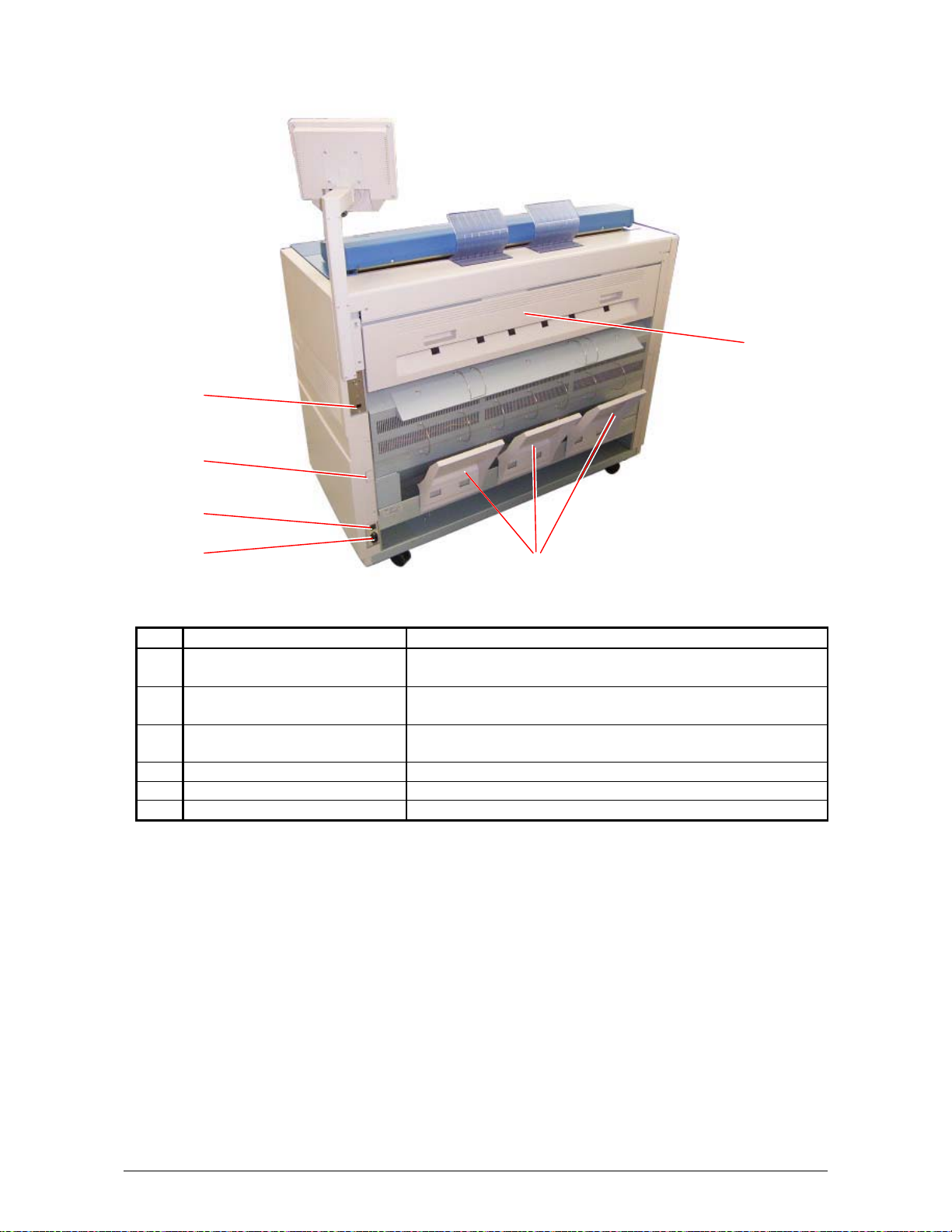

1. 5 Exterior Views

1. 5. 1 Front view

No. Name Function

1 Main Switch Turns on / off.

2 Original Guides Assists the user to feed originals into the scanner.

3 User Interface Operation Panel, with many user operations.

4 Emergency Stop Button Press this button when you would like to stop copying or

5 Original Return Guides Guides return the originals to the user.

6 Scanner Images the original for all scans or copies.

7 Original Table Open this cover to replace the Toner Cartridge.

8 Engine Unit Levers Press up on the handles to open the printer engine.

9 Cut Sheet - Bypass Feeds a sheet of cut sheet media.

10 Roll Deck Roll media installed here.

11 Print Tray Copies / prints are placed here. (standard configuration)

12 Counter Counts the total amount printed.

8

9

10

7

11

6

12

scanning in an emergency situation.

Place the original to feed into the Scanner to make a

scan or copy.

1 Roll - standard

2 Rolls - optional.

Optional Stacking / Folding devices are available

(also see Operational Panel - Info Screen)

45

3

2

1

Section 1 Basic Printer Functions 1-8

Page 15

1. 5. 2 Rear view

2

3

4

5

6

No. Name Function

1 Exit Cover Open the Exit Cover when you remove the paper

mis-fed inside of the Fuser Unit.

2 LAN Port Connect the LAN Cable here to connect the system to

the network. (Do not connect a telephone line.)

3 Dehumidify Heater Switch

(Option)

4 Inlet Socket Connect the Power Cord here.

5 Breaker It is possible to shut off supplying the AC power.

6 Print Guide Trays These trays guide the prints to the Print Tray.

Turn on the Dehumidify Heater with this switch when you

would like to dry the paper in the humid season.

1

Section 1 Basic Printer Functions 1-9

Page 16

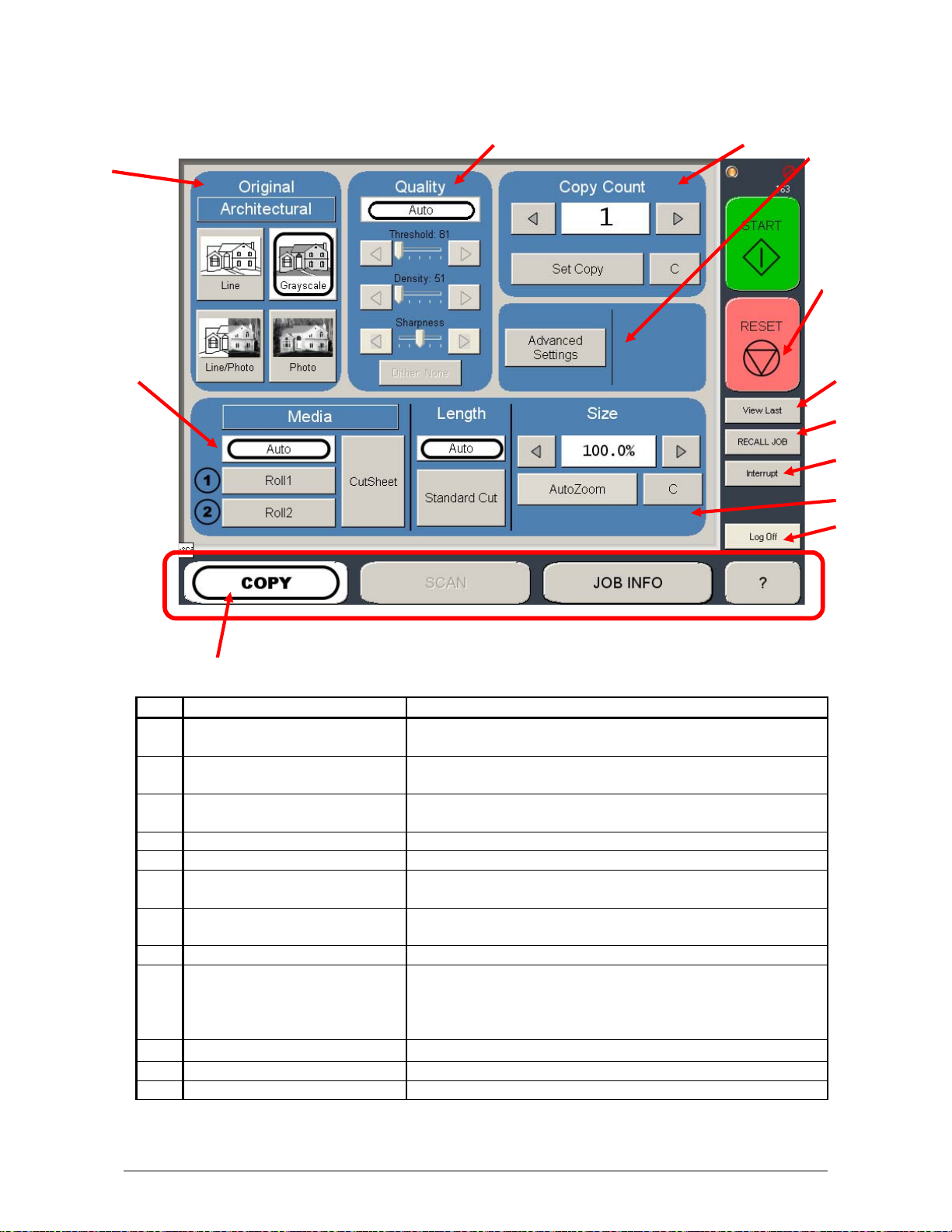

1. 5. 3 Operator Panel – User Interface Basic Screens

Copy Mode

3

2

No. Name Function

1 Mode Selects the “Mode” of the system. (Copy Mode for this

2 Media Displays Media type and quantity installed. Includes Cut

3 Original Type User Selects the type of original to copy. Also select

4 Quality Select Auto or Manual Image adjustments

5 Copy Count Select the quantity of prints and sets designation.

6 Advanced Settings Invert , mirror, stamps, folds, and edge adjustments

7 Reset Clears the image buffer and resets the system to default

8 View Last The last scan / job can be viewed

9 Recall Job Images can be recalled from the last job for reprint.

10 Interrupt Pauses the network print jobs to print any copy jobs

11 Zoom Manual and automatic zoom ratios set.

12 Log Off Displayed if Accounting enabled to Log off current user

45

6

7

8

9

10

11

12

1

screen shown)

Sheet Functions and Media Selection

Eng/Arch Modes here.

preformed / displayed in this button (sub screen)

settings.

Please note that a time limit may be set to recall or this

feature may be disabled by the administrator to prevent

any unauthorized copies.

Section 1 Basic Printer Functions 1-10

Page 17

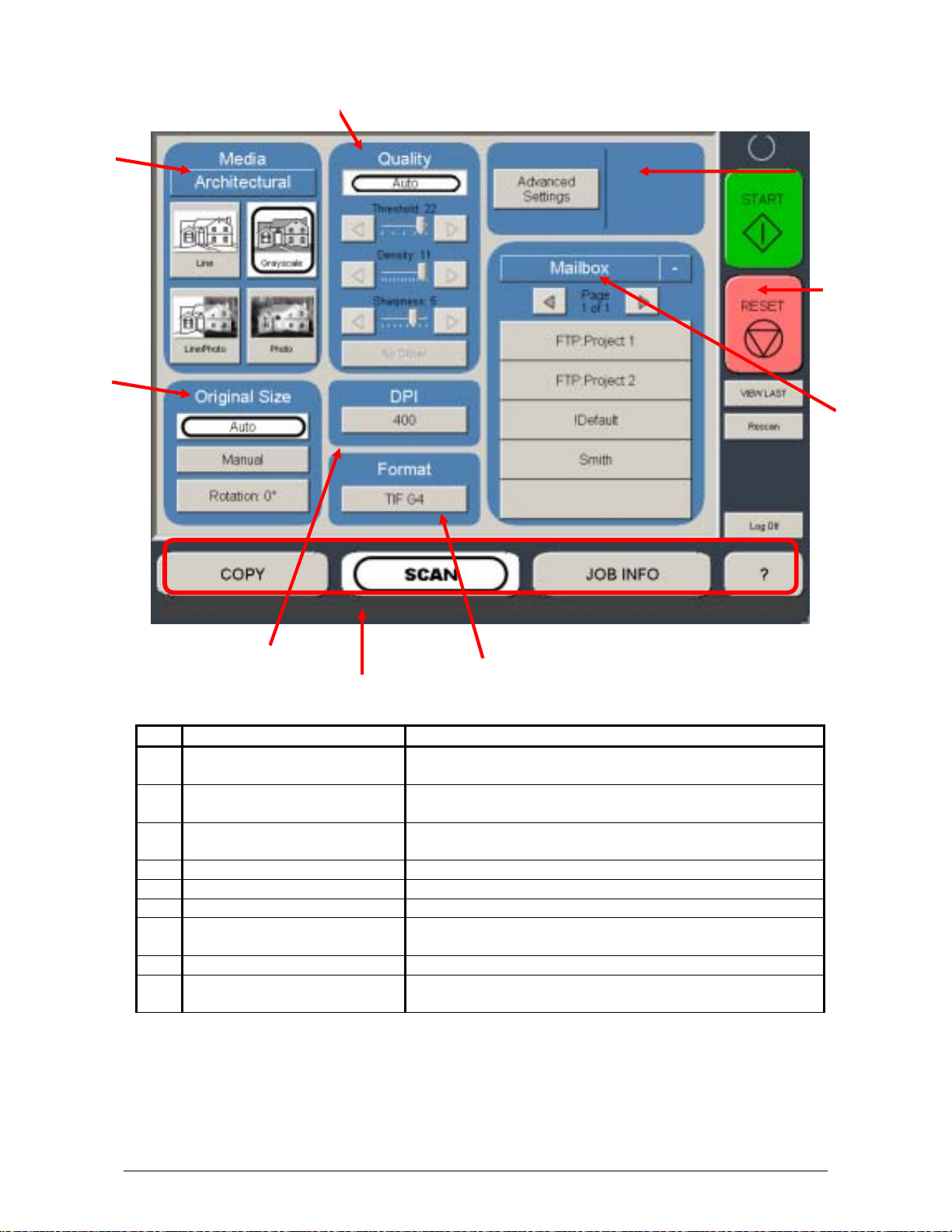

Scan Mode

4

2

3

7

8

9

No. Name Function

1 Mode Selects the “Mode” of the system. (Scan Mode for this

2 Original Size Use automatic settings or manually set width, length and

3 Original Type User Selects the type of original to copy. Also select

4 Quality Select Auto or Manual Image adjustments

5 Resolution Scroll through image resolution (DPI) of the scanner.

6 Format Scroll through file formats.

7 Advanced Settings Invert, mirror, stamps, and edge adjustments preformed

8 Reset Resets the system to default settings.

9 Mailbox Select where the image will be stored after the scan

5

6

1

screen shown)

rotation of the images.

Eng/Arch Mode selected here.

/ displayed in this button (sub screen)

(local setting, FTP etc.).

Section 1 Basic Printer Functions 1-11

Page 18

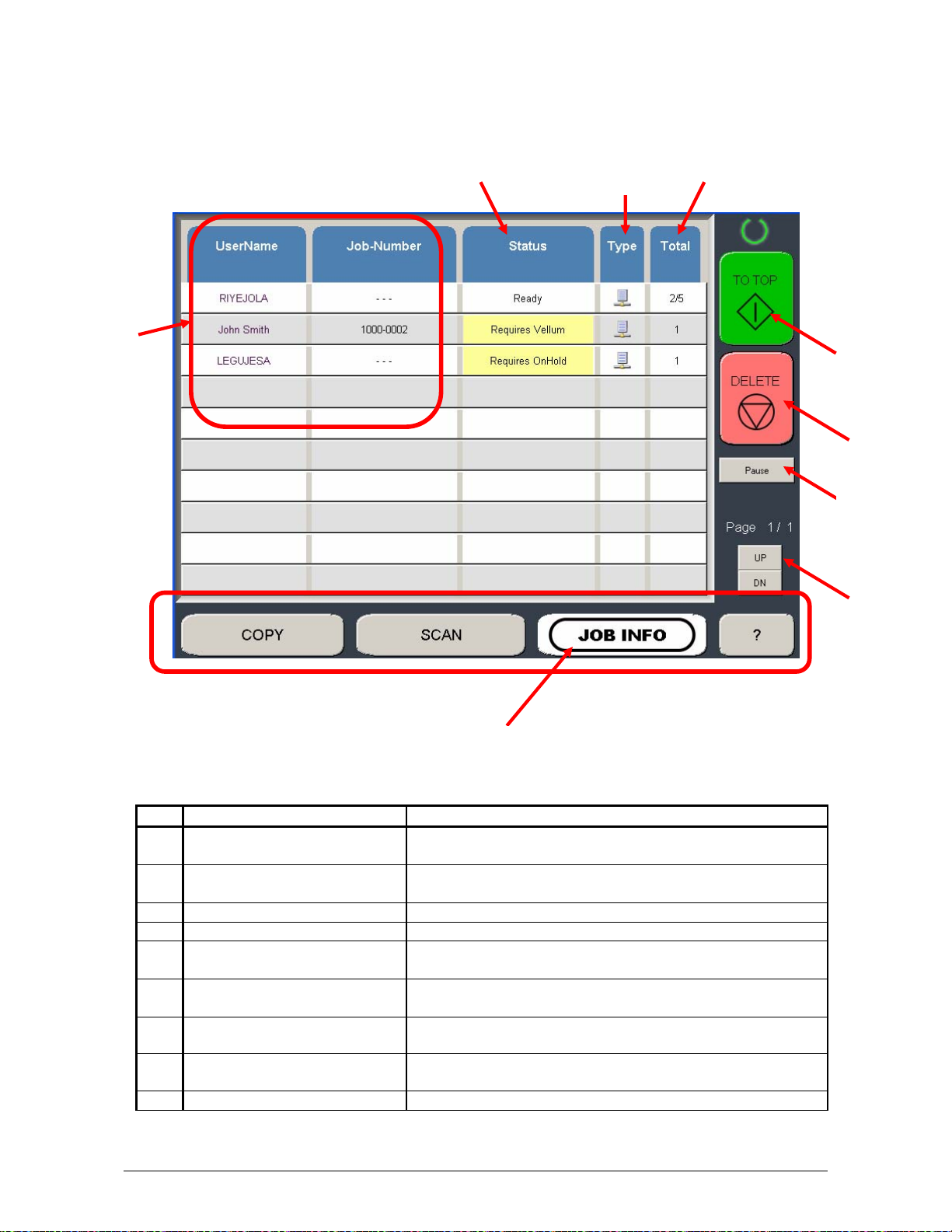

Job Info Screen

2

No. Name Function

1 Mode Selects the “Mode” of the system. (Job Mode for this

screen shown)

2 User Name – Job # Display the User and any user info of the job ID. A job

can be selected for other functions noted below.

3 Status Shows the current status of a job and media selection.

4 Type Displays a copy or network print job

5 Total Displays the total number of prints and current number

printed.

6 To Top After a job is selected (see #2) the position can be

changed to the next job printed.

7 Pause Pauses printer to allow media change, etc

3

1

4

5

6

8

7

9

8 Delete After a job is selected (see #2) it can be removed from

printing.

9 Up/Down Scrolls through available pages in the queue.

Section 1 Basic Printer Functions 1-12

Page 19

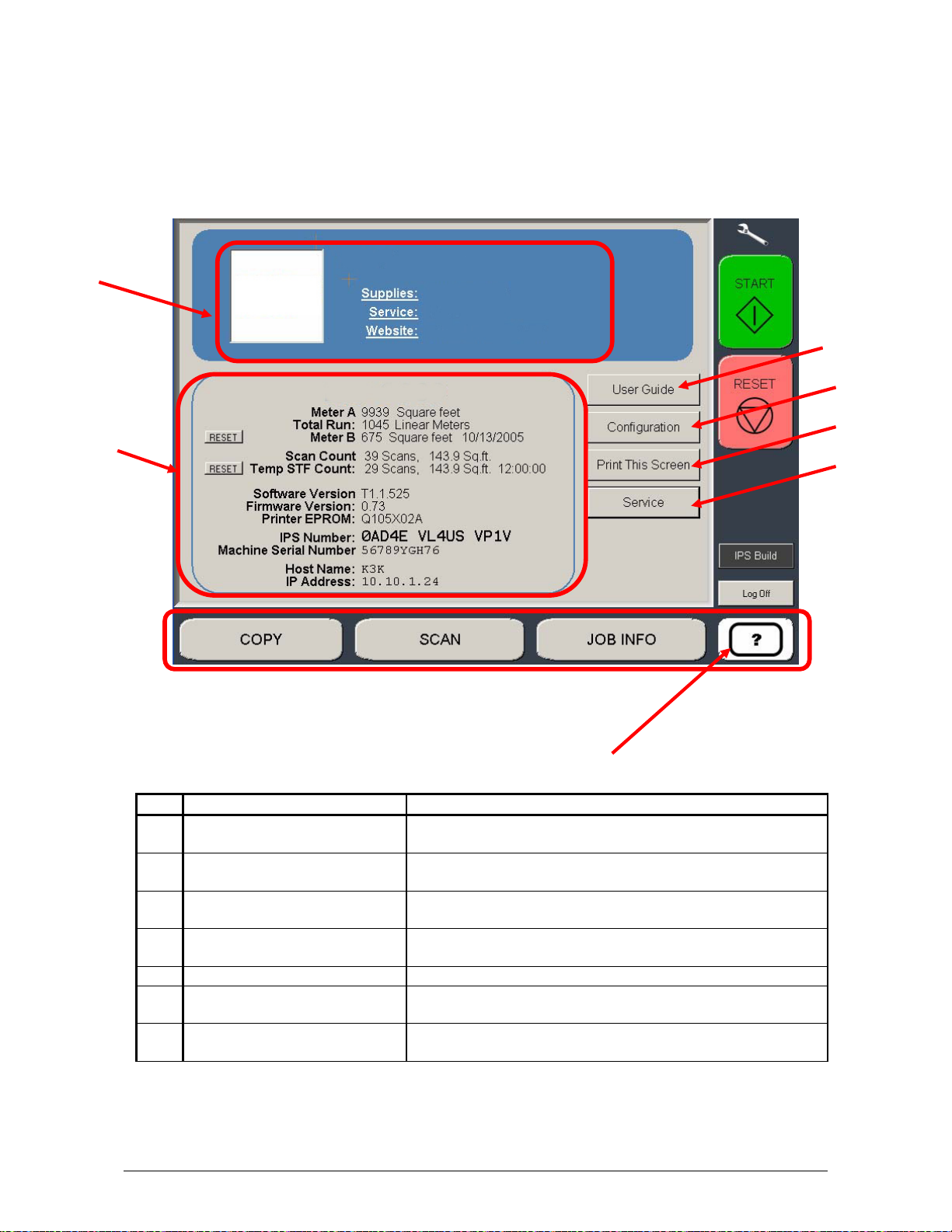

Information / Help Screen

3

2

No. Name Function

1 Mode Selects the “Mode” of the system. (Info/Help Mode for

2 Meter – Versions Display the current meter counts as well as all

3 Contact Shows the contact information for the Service and

4 User Guide User Guides for details on system functions and

5 Configurations Allows user “set up” of the system.

6 Print This Screen Allows the current screen with version and counter

7 Service Allows advanced “set up” of the system. Usually for

1

this screen shown)

Software/Firmware versions, IPS number, Host Name/IP

Supplies provider.

operations.

values to be prin

technical purposes only. Pass-code required.

ted on the system.

4

5

6

7

Section 1 Basic Printer Functions 1-13

Page 20

1. 6 Options - Accessories

Please contact your Authorized Reseller for the following options available:

1) Network Printing

Adds the functions of network printing (TCP/IP) from Windows and CAD applications. Includes

Windows/PS drivers, AutoDesk Drivers, “Request” job submission utility and “KIP PrintNet” for

web based submissions.

2) Scanning

Adds the function of scan to file, local drives or FTP sites in a variety of file formats.

3) PDF / PS Printing

Allows direct PDF and Postscript file format printing from various applications including

Request.

4) Roll Deck 2

Second roll of media for increased productivity

5) Print Trays - Slant Stacker

To accommodate a larger quantity of prints than the standard front print tray rearward stacking

systems are available

6) Folding (KIPFold)

For fan and crossfold functions as a copier, or network printer.

7) Dehumidifier

Roll Deck Dehumidifier for locations with excess or high humidity

options and accessories are subject to change without notice. Please contact your

All

local Authorized Reseller for details on current available options

.

.

Section 1 Basic Printer Functions 1-14

Page 21

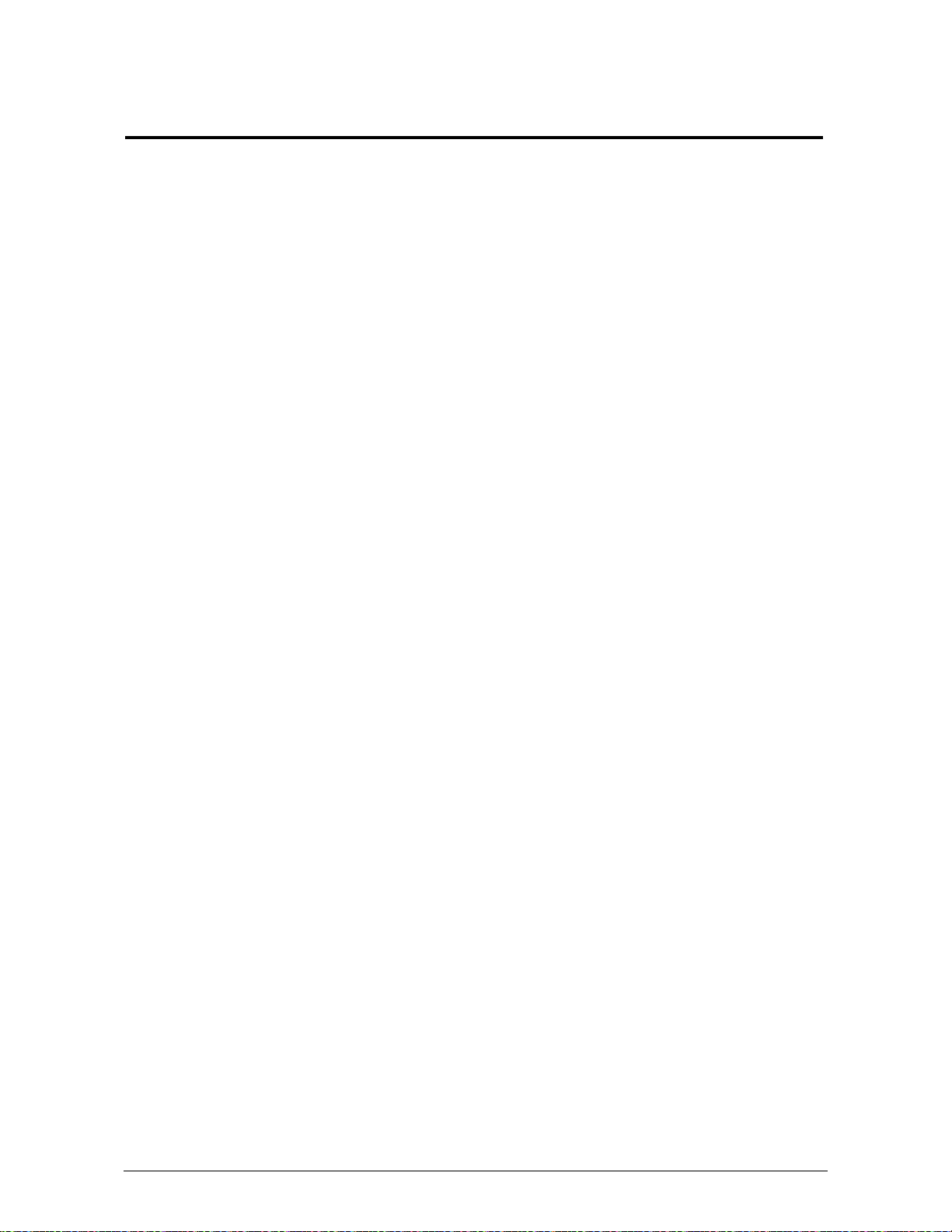

2. 1 Turning on

1. Ensure the

wall outlet.

WARNING

(1) Do not handle the Power Plug with wet hands, or you may receive an electrical shock.

(2) Make sure to ground the machine for your safety.

(3) Do not plug the printer into a multi-plug connector in which other devices are

plugged into. It may overheat the outlet and may result in a fire.

(4) The outlet must comply with 120V, plus 6% & minus 10%, 15A, and 50/60Hz

2. There is a Power Switch on the right side of

system.

Switch to the “ I ” position to turn

Power Switch

3. The Operation Panel commences to operate, and the Copy Mode Screen will appear in

approximately 1 minute. A Ready Indicator on the Copy Mode Screen will flash during the

warm up process.

Ready Indicator

4. When the Ready Indicator stops flashing, the

system is plugged into a dedicated

on the system.

system is ready to copy/scan/print.

Section 1 Basic Printer Functions 1-15

Page 22

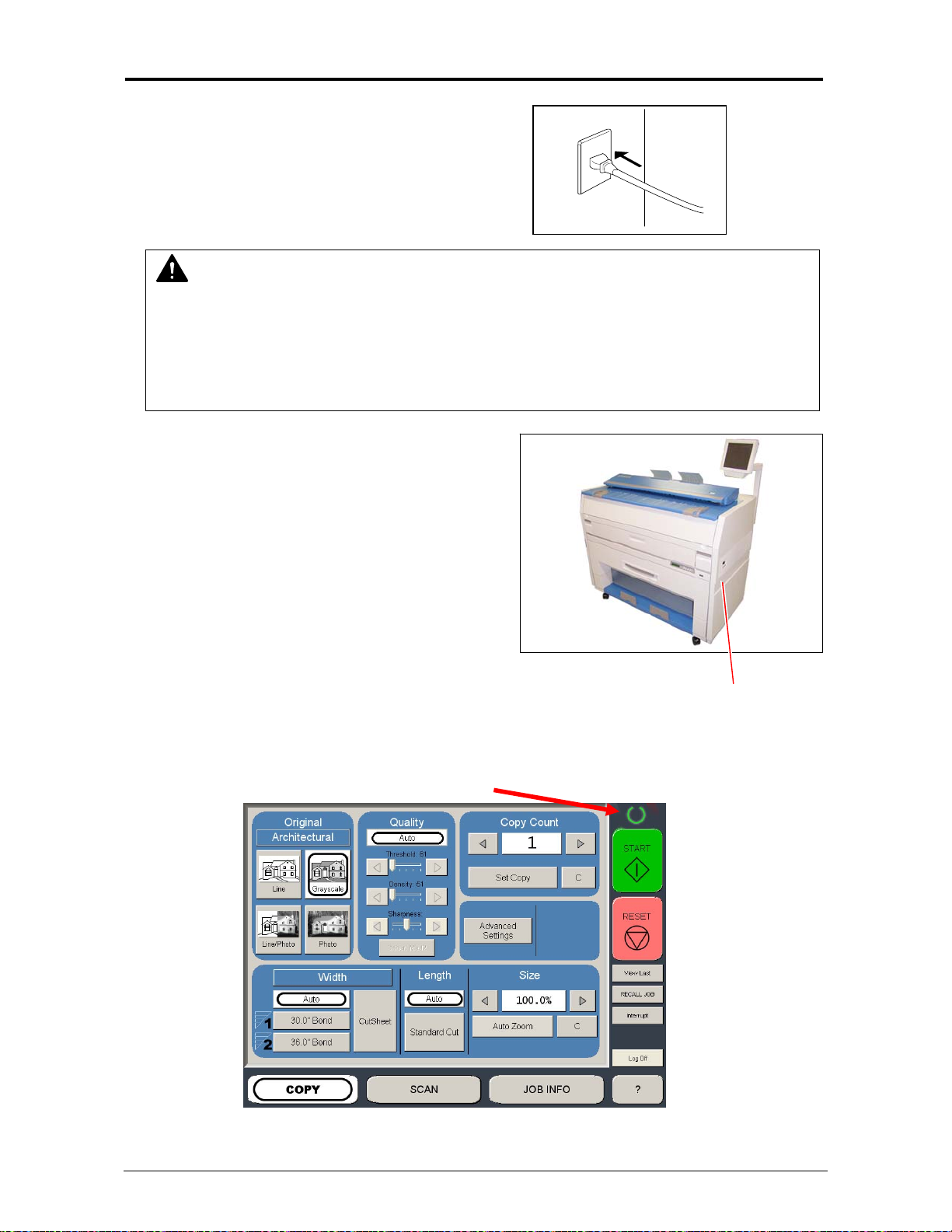

2. 2 Turning off

1. There is a Power Switch on the right side of

system.

Switch to the “ O ” position to turn off the

system.

Power Switch

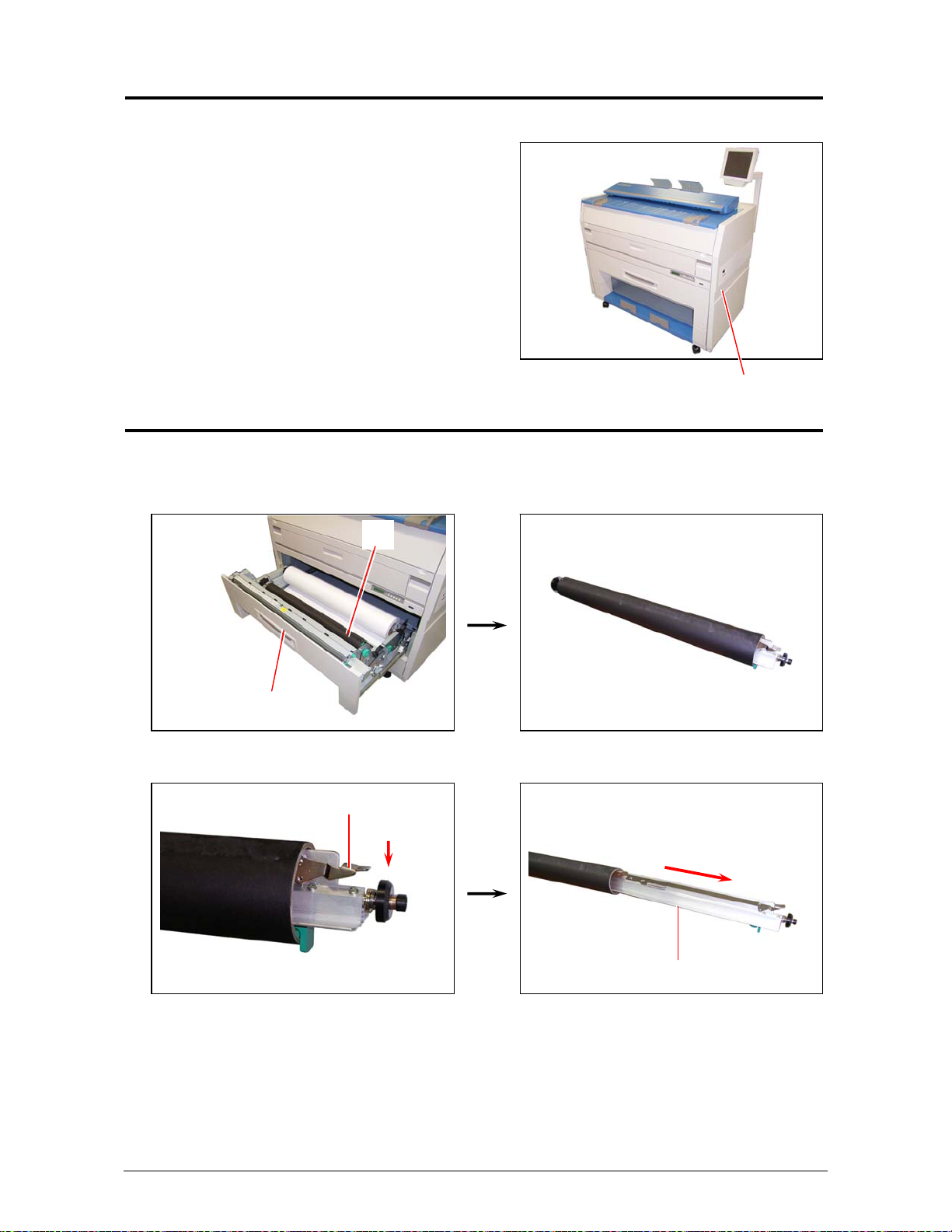

2. 3 Roll Media Replacement

1. Open the Roll Deck (1).

Remove the Spool (2) with the roll core from the Roll Deck.

2. Press down on the Lever (3) to release the core, and then pull out the Spool (2) from

the core.

1

2

3

2

Section 1 Basic Printer Functions 1-16

Page 23

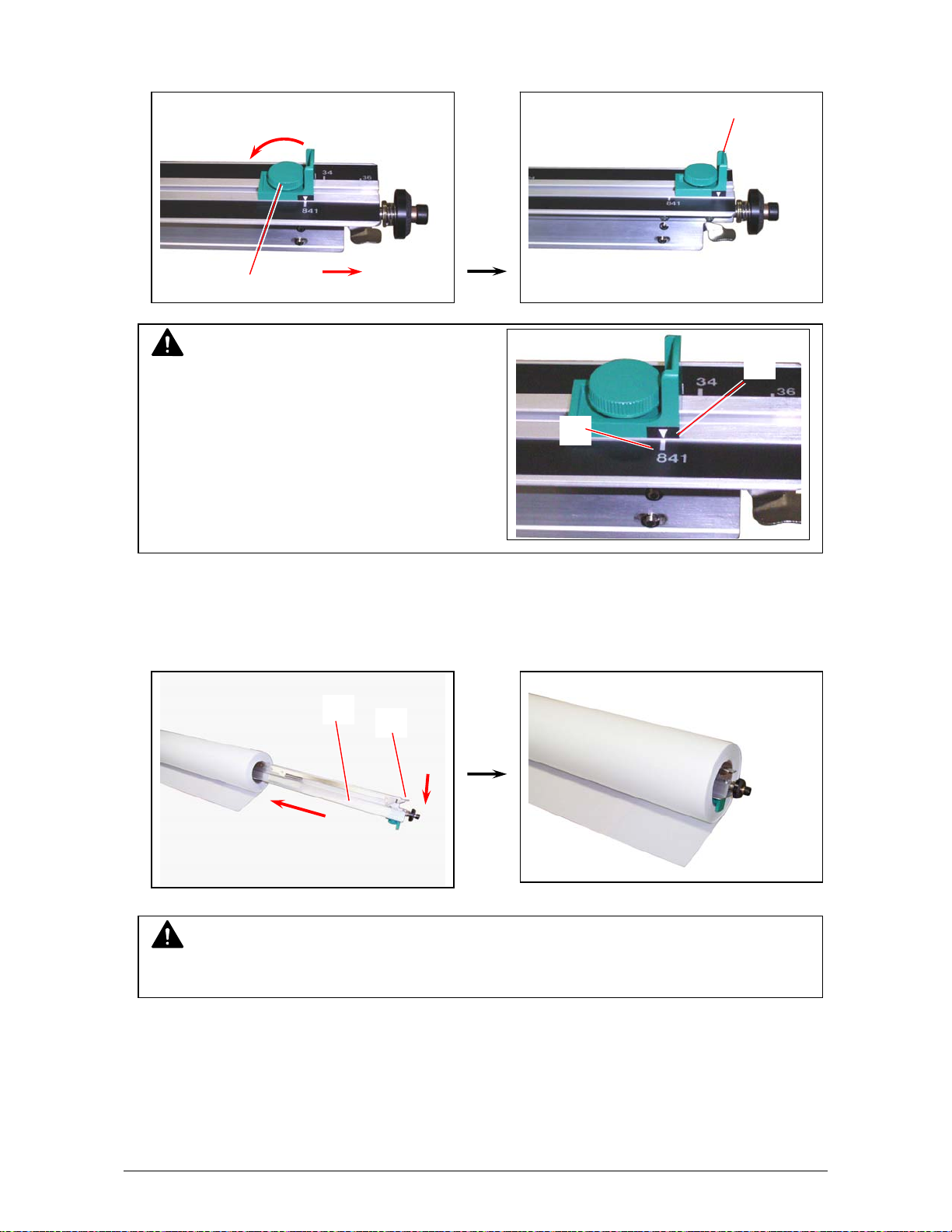

3. If so required, loosen the knob (4), slide the position of Paper Guide (5) according to the width

of media to be installed, and then secure the Paper Guide by tightening the knob.

NOTE

There are Size Guides (6) on the Spool.

The Paper Guide is provided with a triangle mark

(7), place the Paper Guide so that

the triangle aligns with the line of Size Guide.

4. Place a new roll on a table/desk or another stable flat surface. Pressing down the Lever (3),

insert the Roll Spool (2) into the core of new roll.

NOTE

Please note the unwinding direction of the media at this time. Please see diagrams.

4

6

2

3

5

7

Section 1 Basic Printer Functions 1-17

Page 24

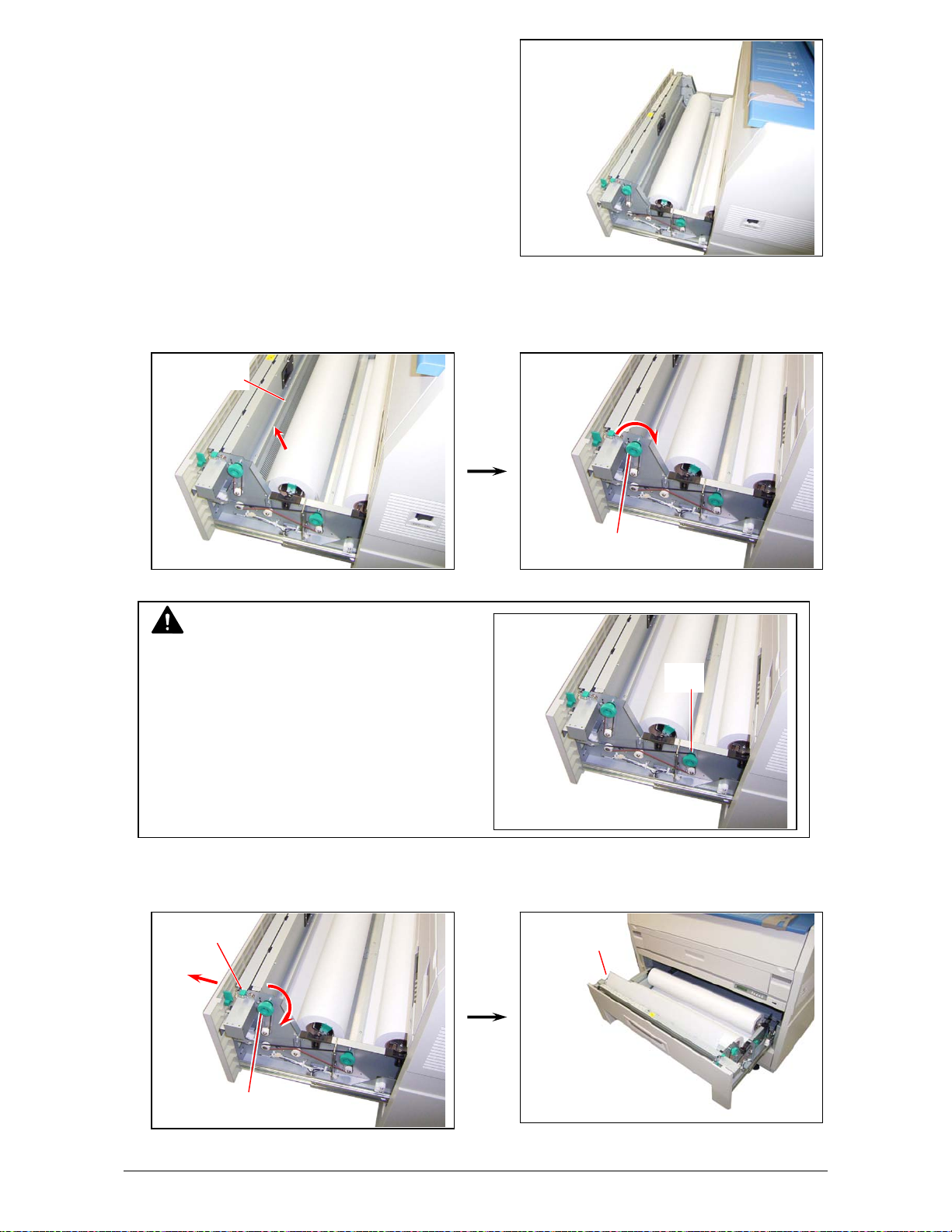

5. Place the Spool with new roll into the Roll Deck.

6. Insert the leading edge of the media under the Guide Plate (8) until the edge touches

the feeding roller.

Then rotate the Feeding Handle (9) clockwise so that the feeding rollers catch the roll

paper.

8

9

NOTE

In case of Roll 2, rotate the Feeding Handle

of Roll 2 (10).

10

7. When the feeding rollers catch the media, move the Lever (11) to the front side and rotate the

Paper Feeding Knob (9) until the leading edge comes out from the guides.

11

Leading edge

of roll paper

9

Section 1 Basic Printer Functions 1-18

Page 25

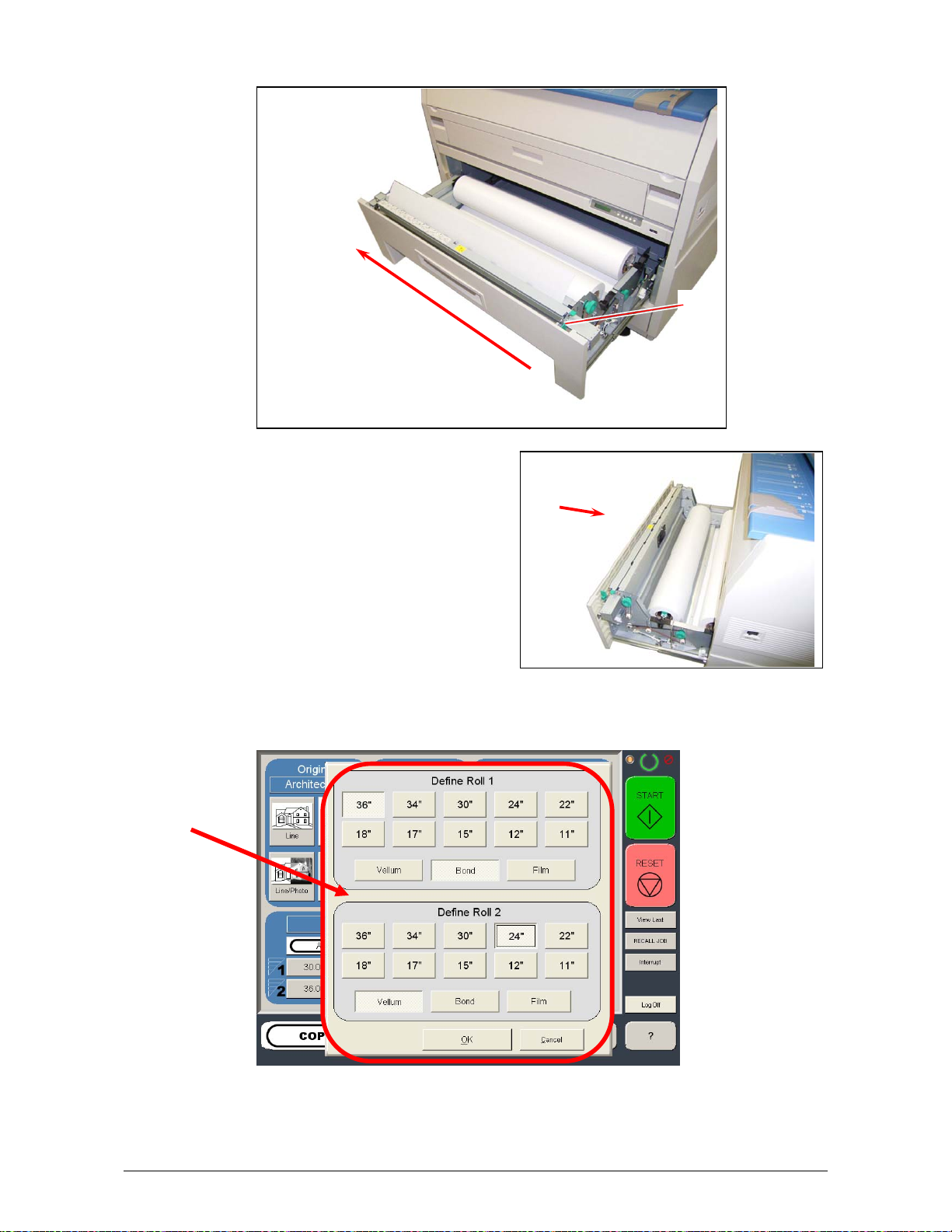

8. Slide the Cutter Handle (12) fully from one side to another side to cut the leading edge.

Remove the cut portion and discard.

10. Close the Roll Deck.

11. On the Operator Panel, a screen will automatically appear after the deck is closed to define the

media width and type. Please select the width, and type for each roll deck and then select the

“OK” button to confirm the selection.

12

Section 1 Basic Printer Functions 1-19

Page 26

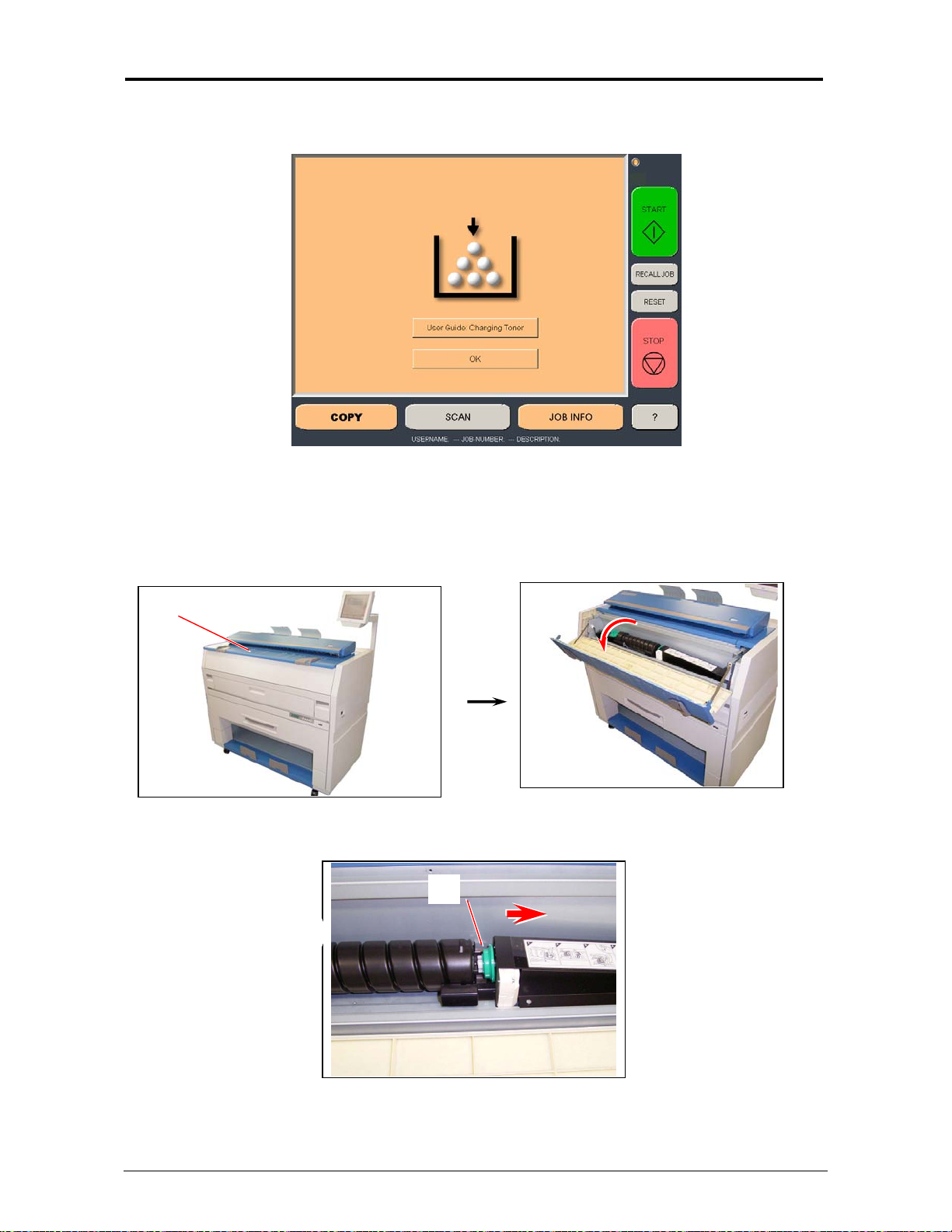

2. 4 Toner Installation

When toner installation is required, the Operator Panel will display a “Toner Required” screen

(in the “Copy” and “Job Info” Screens)

To replace the toner cartridge, please follow these steps:

Please note that the replacement procedure can also be displayed on the Operator Panel for

easier access, by pressing “User Guide : Changing Toner” on the screen)

1. Open the Toner Cover (1).

1

2. Slide the green Disk (2) to the right, to unlock the Toner Cartridge.

2

Section 1 Basic Printer Functions 1-20

Page 27

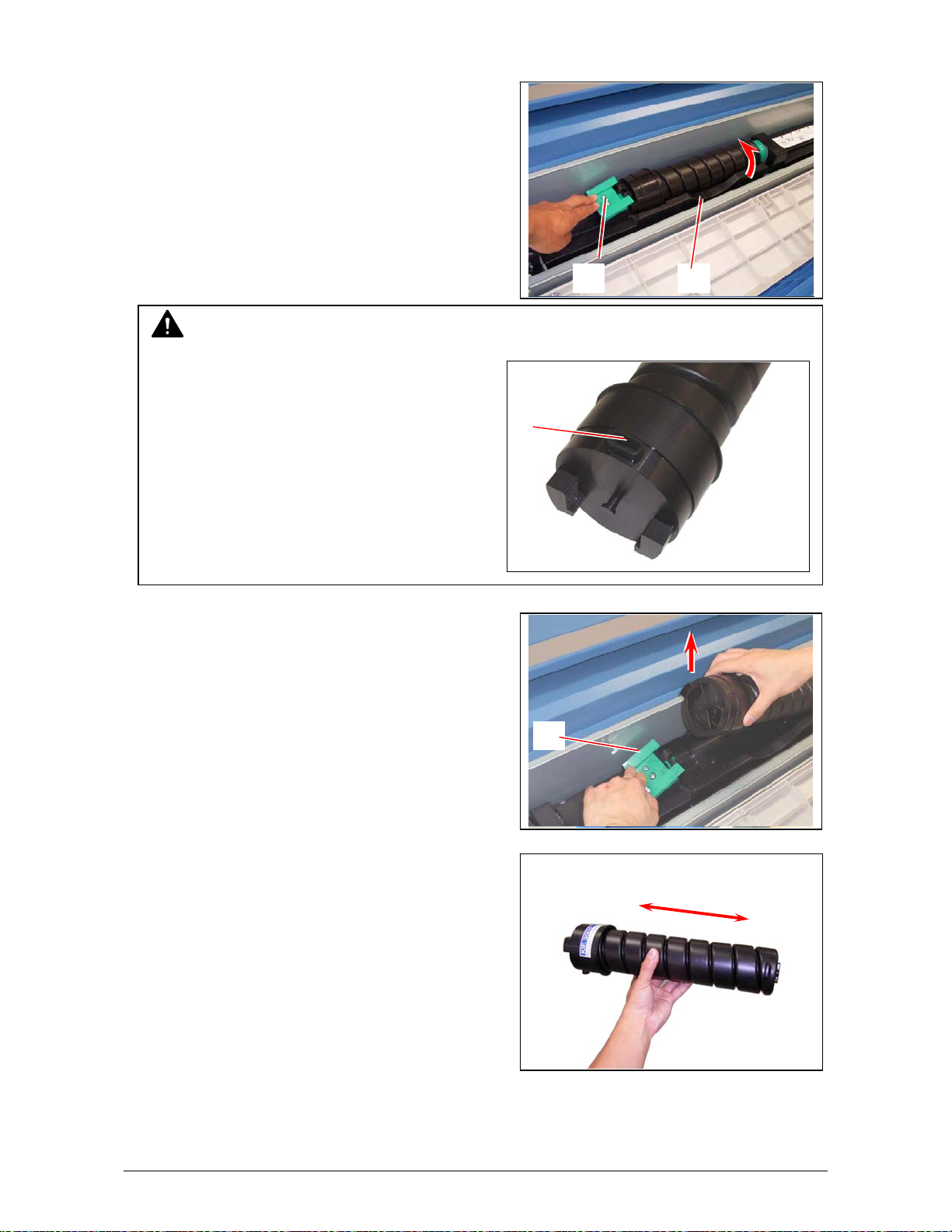

3. Pressing down on the Cartridge Lock Lever (3),

rotate the body of cartridge (4) in the arrow

direction several revolutions until it stops turning.

The cartridge is resealed by this procedure!

NOTE

If you remove the Toner Cartridge without

resealing the toner outlet (5) the toner

will drop from the toner outlet and it will

scatter into the machine or onto the floor!

4. Pressing down the Cartridge Lock Lever (3), lift

up on the left side of the Toner Cartridge, and

then remove the entire cartridge from the machine.

Discard the spent cartridge using local recycling

or waste management programs.

5. Shake a new Toner Cartridge several times from

left and right to loosen the toner.

3 4

5

3

Section 1 Basic Printer Functions 1-21

Page 28

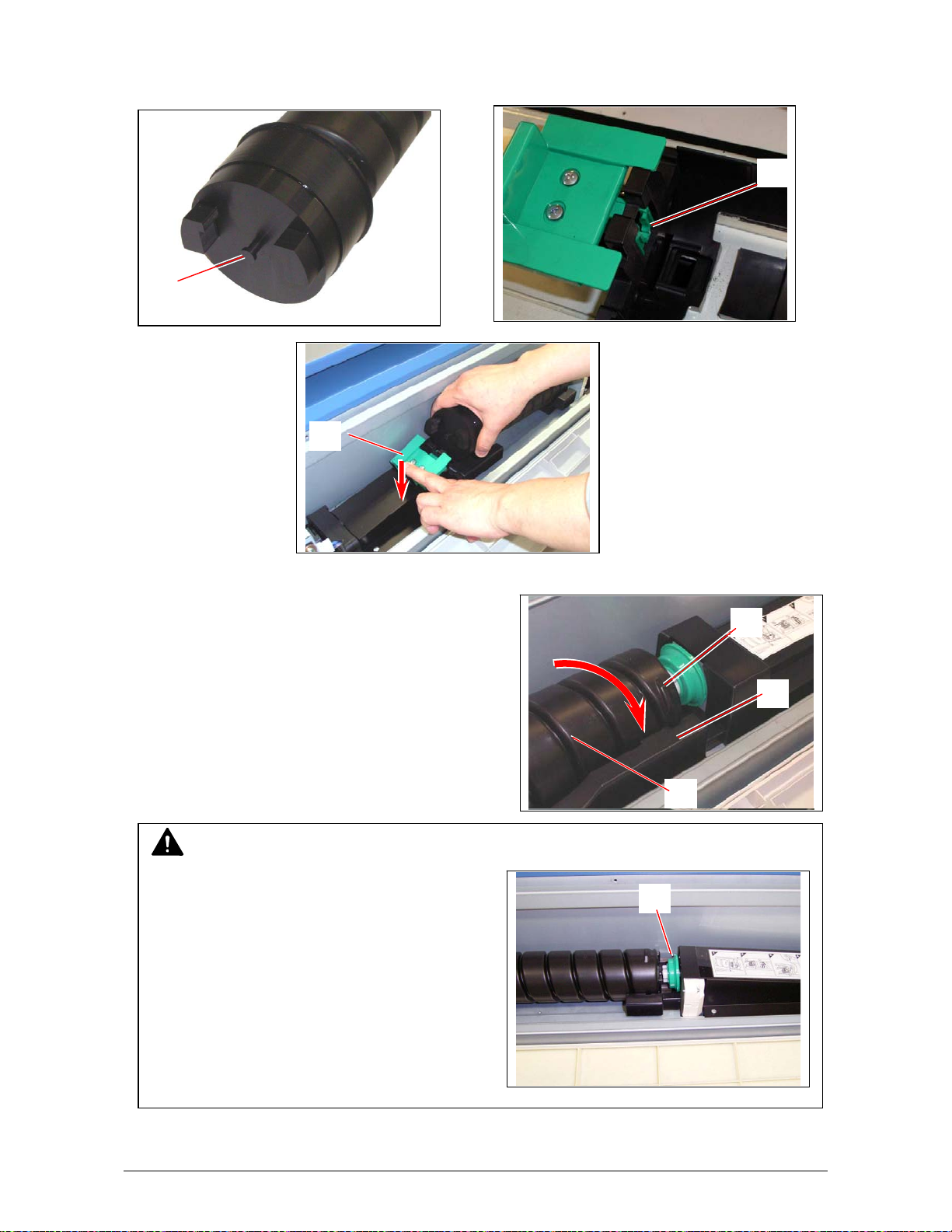

6. Locate the pin (6) of the left side of cartridge. While pressing down the Cartridge Lock Lever (3),

fit the pin to the groove (7)

7

6

3

7. Rotate the body of the cartridge (4) to the arrow’s

direction, several revolutions to open the toner

8

outlet.

Confirm that the projection (8) will fit into the

notches (9).

9

4

NOTE

It is not necessary to lock the cartridge with the

green Disk (2).

It will automatically lock after the

Toner Hatch is closed.

2

Section 1 Basic Printer Functions 1-22

Page 29

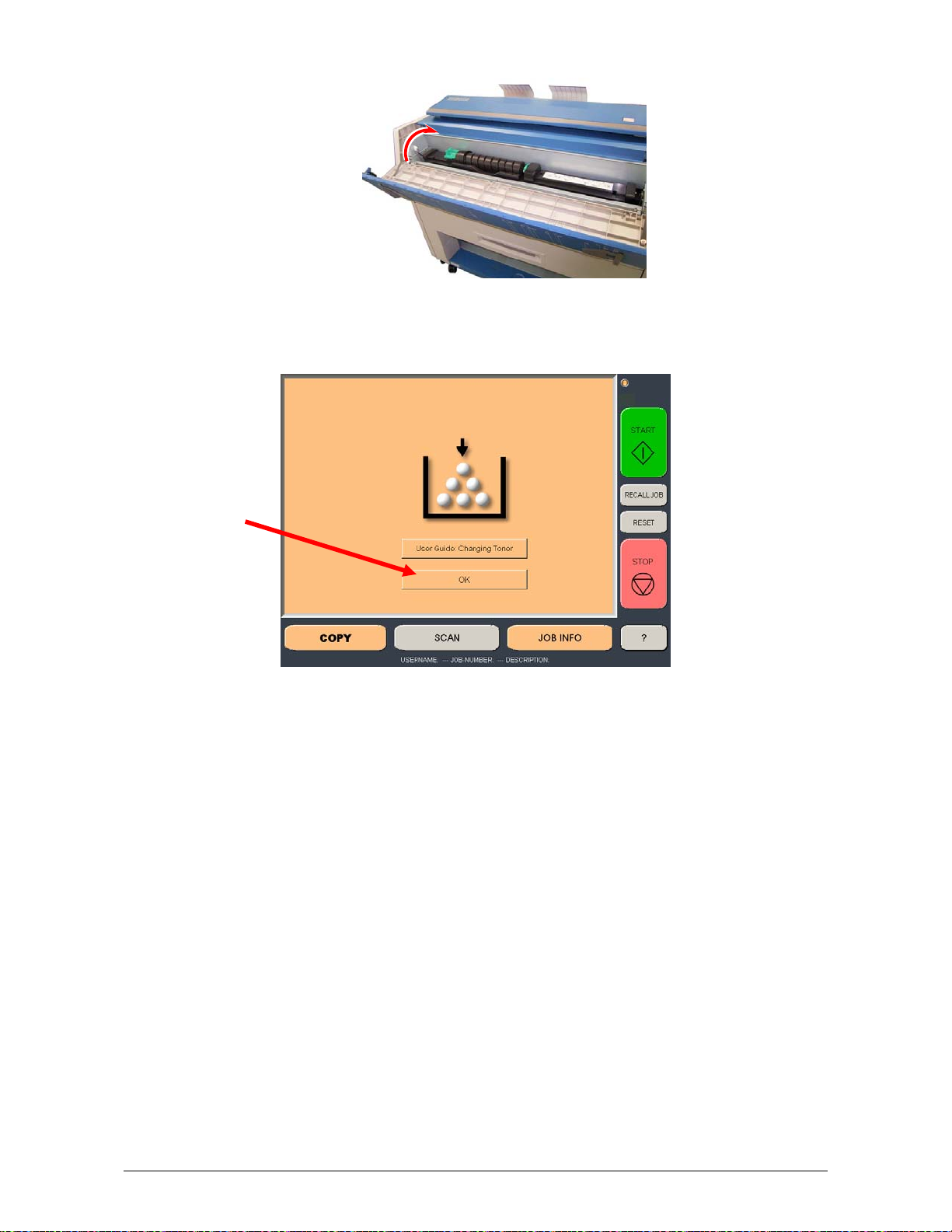

8. Close the Toner Cover.

9. Press “OK” on the Operator Panel to continue copying or printing.

Section 1 Basic Printer Functions 1-23

Page 30

2. 5 Cut Sheet Media Placement

1. Select Cut Sheet Bypass Button on the Operator Panel. (Copy Mode)

2. Select the size of the sheet, and the media type (not shown)

3. Or use “Custom” to select a width.

Section 1 Basic Printer Functions 1-24

Page 31

4. Select a standard length or use a “Custom Length”.

5. Confirm the cut sheet size by pressing enter.

6. Open the Cut Sheet Feeder (1).

1

Section 1 Basic Printer Functions 1-25

Page 32

6. There are size markings on the table.

Insert the cut sheet paper on the table along with the associated size mark, and then insert

it into the Feeder referencing the size marks.

When the paper is inserted far enough, the machine automatically sets the paper at the

proper position.

7. Continue with normal copy / print functions. See User Guide “Copy” or “Print” sections.

2. 6 Emergency Stop of a Copy or Scan

If ever so required, press the Stop Button (1) on the Scanner to immediately stop the original while

making a copy or a scan.

1

Section 1 Basic Printer Functions 1-26

Page 33

2. 7 Dehumidifying the Roll Media

If the printer is located in an environment where the humidity may effect the image quality, please

turn on the dehumidifiers.

1. Select Switch to “ I “ position

Dehumidifier switch

Dehumidifiers are an option for the

details.

NOTE

system. Please contact you local dealer for

Section 1 Basic Printer Functions 1-27

Page 34

3. 1 Operational Errors

3. 1. 1 Paper mis-feed Errors

In case of a paper jam, a message will be displayed on the Operator Panel as well as the

Technical LCD. One of the following messages will be displayed if an error does occur.

Roll Deck / Feeding Jam

Cut Sheet / Manual Jam

Internal Jam Resist Jam

Fuser Jam

Accessory Jam

3. 1. 1. 1 Deck jam / Feeding Jam

Either “Deck jam” or “Feeding Jam” is displayed when the roll paper is mis-fed in the Roll Deck.

1. Open the Roll Deck, and unwind the roll paper.

2. Insert the leading edge of media under the under the Guide Plate (2) until the edge touches

the feeding roller.

Then rotate the Feeding Knob (3) clockwise so that the feeding rollers catch the roll

paper.

2

3

Section 1 Basic Printer Functions 1-28

Page 35

NOTE

In case of Roll 2, rotate the Feeding Knob

of Roll 2 (4).

4

3. When the feeding rollers catch the paper, move the Lever (5) forward and rotate the

Feeding Knob (3) until the leading edge comes out from the guides.

5

Leading edge

of roll paper

3

4. Slide the Cutter Handle (6) fully from one side to another side to cut the media.

Remove the cut media.

6

Section 1 Basic Printer Functions 1-29

Page 36

3. 1. 1. 2 Cut Sheet / Manual Paper Jam

1. Carefully remove the paper by pulling as noted.

3. 1. 1. 3 Resist Jam / Internal Jam

1. Pull up the Engine Levers (1) to open the printer.

1

2. Remove any mi-fed paper.

Section 1 Basic Printer Functions 1-30

Page 37

3. 1. 1. 4 Fuser Jam

1. Open the Fuser Cover (1).

2. Remove the jam paper, by carefully pulling out the

back.

WARNING

There are extremely hot parts inside of the Heater Area.

Do not touch any parts in the Heater Unit, or you will be burnt!

Also note that the paper may be very hot as well.

NOTE

If you can not find the mis-fed paper inside of the Fuser, refer to [3. 1. 1. 3 Resist Jam /

Internal Jam] and follow the instructions.

1

3. 1. 1. 5 Optional Finisher Jam

The media is mis-fed in the optional finishing device such as a Stacker or Folder.

Remove the mis-fed paper referencing the User Guide of optional device.

Section 1 Basic Printer Functions 1-31

Page 38

3. 1. 2 Others

3. 1. 2. 1 Deck is open

This message is displayed when the Roll Deck is

opened.

Reopen and then close it firmly.

3. 1. 2. 2 Optional Finisher Jam

The media is mis-fed in the optional finishing device such as a Stacker or Folder.

Remove the mis-fed paper referencing the User Guide of optional device.

3. 1. 2. 3 Cut Sheet / Manual Set NG

This message is indicated when cut sheet media

has been set before the system is turned on.

Remove media from the Cut Sheet Feeder.

3. 1. 2. 4 Cutter Set NG

This message is indicated when the Cutter Knob is not in the correct position.

Open the Roll Deck, and then slide the Cutter Knob fully to the left or right until it stops.

Not correct (Not at the end) Correct (at the end)

Cutter Knob Cutter Knob

Roll Deck

Cut Sheet

Feeder

Section 1 Basic Printer Functions 1-32

Page 39

3. 1. 2. 5 Toner Empty

This message is indicated when the Toner Cartridge is

empty with the toner.

Replace the Toner Cartridge referencing

[2. 4 Replacement of Toner Cartridge]

3. 1. 2. 6 Paper Empty

This message is indicated when the roll paper is empty.

Replace media referencing

[2. 3 Replacement of Roll Paper].

3. 1. 2. 7 The door opened during printing

This message is indicated when the Roll Deck is opened

for some reason in the middle of printing.

Close the Roll Deck.

The paper usually will be mis-fed inside the

machine, please remove it.

Toner Cartridge

Roll paper

Roll Deck

Section 1 Basic Printer Functions 1-33

Page 40

3. 2 Call Service Errors

If the machine has the fatal error you will note one of the following Error Codes on the Technical

LCD panel. It is impossible for the user to resolve these errors.

PLEASE CONTACT YOUR

TO RESOLVE THESE ERRORS.

Code Error

E - 000 Fuser Low Temp

E - 001 Fuser Over Temp

E - 002 Fuser Low Temp

E - 003 Temp Not Rise

E - 010 Motor1 Error

E - 011 Motor2 Error

E - 012 Motor3 Error

E - 020 Counter Error

E - 031 1st Error

E - 032 AC Error

E - 033 Tr Error

E - 034 Bias Er ror

E - 040 Cutter Error

E - 050 FPGA Error

E - 070 Dev Error

If any of the above errors is displayed:

1. Turn off the printer, wait approximately one minute, and turn the printer on again.

2. If the same error code is displayed, turn off the printer, and then unplug the printer from the

wall outlet.

3. Contact your Authorized

Service Company.

AUTHERIZED SERVICE PERSONNEL

Section 1 Basic Printer Functions 1-34

Page 41

Section 2

Copy Mode

1. 0 Copy Mode............................................................................................................................ 3

1.1 Main Screen - General .................................................................................................... 3

1.2 Simple Copying............................................................................................................... 4

1.2.1 Select Copy Mode ....................................................................................................... 4

1.2.2 Select Size Mode ......................................................................................................... 4

1.2.3 Select Original Image Type ........................................................................................ 5

1.2.4 Cop y Count..................................................................................................................5

1.2.5 Media ............................................................................................................................ 6

1.2.6 Length .......................................................................................................................... 6

1.2.7 Size ...............................................................................................................................7

1.2.8 Insert Original..............................................................................................................7

2. 0 Operation Details.................................................................................................................8

1.3 Main Screen..................................................................................................................... 8

1.4 Original............................................................................................................................. 8

1.4.1 Original Size Mode ...................................................................................................... 8

1.4.2 Original Type ............................................................................................................... 9

1.5 Quality..............................................................................................................................9

1.5.1 Automatic.....................................................................................................................9

1.5.2 Threshold...................................................................................................................10

1.5.3 Density ....................................................................................................................... 10

1.5.4 Sharpness..................................................................................................................10

1.5.5 Dither..........................................................................................................................10

1.6 Copy Count....................................................................................................................10

1.6.1 Arrows - Count Increase / Decrease....................................................................... 11

1.6.2 Number Pad - Count Increase / Decrease............................................................... 11

1.6.3 Set Copy..................................................................................................................... 11

1.6.4 Clear ........................................................................................................................... 12

1.7 Advanced Settings.......................................................................................................13

1.7.1 Mirror..........................................................................................................................13

1.7.2 Invert........................................................................................................................... 13

1.7.3 Fold............................................................................................................................. 13

1.7.4 Stamp ......................................................................................................................... 14

1.7.5 Leading Edge Adjustment........................................................................................15

1.7.6 Trailing Edge Adjustment......................................................................................... 16

1.8 Width .............................................................................................................................. 16

1.8.1 Auto ............................................................................................................................ 17

1.8.2 Manual Roll Selection ............................................................................................... 17

1.8.3 Enabling Cutsheet..................................................................................................... 18

1.8.4 Cut Sheet.................................................................................................................... 18

1.8.5 Copying to Multiple Cutsheets.................................................................................19

1.8.6 Media Remaining....................................................................................................... 20

1.8.7 Installing Roll Media..................................................................................................20

1.9 Length ............................................................................................................................ 21

1.9.1 Auto ............................................................................................................................ 21

1.9.2 Standard..................................................................................................................... 21

1.10 Size – Zoom ................................................................................................................... 23

1.10.1 Preset Percentages...............................................................................................23

1.10.2 Percentage Key Pad.............................................................................................. 24

1.10.3 Page Size Zoom..................................................................................................... 24

Section 2 Copy Mode 2-1

Page 42

Auto Zoom ............................................................................................................. 25

1.10.4

1.10.5 Clear ....................................................................................................................... 26

1.11 Start................................................................................................................................26

1.12 View Last.......................................................................................................................26

1.13 Recall Job .....................................................................................................................26

1.14 Stop / Reset ................................................................................................................... 26

1.15 Interrupt ........................................................................................................................ 26

1.16 Rescan ........................................................................................................................... 27

1.17 Log Off ........................................................................................................................... 27

Section 2 Copy Mode 2-2

Page 43

1. 0 Copy Mode

1.1 Main Screen - General

3

2

No. Name Function

1 Mode Selects the “Mode” of the system. (Copy Mode for this

2 Media Displays Media type and quantity installed. Includes Cut

3 Original Type User Selects the type of original to copy. Also select

4 Quality Select Auto or Manual Image adjustments

5 Copy Count Select the quantity of prints and sets designation.

6 Advanced Settings Invert , mirror, stamps, folds, and edge adjustments

7 Reset Clears the image buffer and resets the system to default

8 View Last The last scan / job can be viewed

9 Recall Job Images can be recalled from the last job for reprint.

10 Interrupt Pauses the network print jobs to print any copy jobs

11 Zoom Manual and automatic zoom ratios set.

12 Log Off Displayed if Accounting enabled to Log off current user

13 Length Sets the length of the copy

1

4

13

screen shown)

Sheet Functions and Media Selection

Eng/Arch Modes here.

preformed / displayed in this button (sub screen)

settings.

Please note that a time limit may be set to recall or this

feature may be disabled by the administrator to prevent

any unauthorized copies.

5

6

7

8

9

10

11

12

Section 2 Copy Mode 2-3

Page 44

1.2 Simple Copying

To copy, pl ease follow these basic steps. The following chapters have details on

adjustments and parameters that the user can change to modify the copies as required.

1.2.1 Select Copy Mode

On the lower region of the Operator Panel select “COPY”.

1.2.2 Select Size Mode

Select whether the document is an engineering or architectural size document. This will

allow the automatic width detection to function.

Engineering widths = 34, 22, 17, 11, and 8.5 inches

Architecture widths = 36, 30, 24, 18, 12, and 9 inches

Section 2 Copy Mode 2-4

Page 45

1.2.3 Select Original Image Type

Set the original image type you will copy. The selections are:

Line - used for simple line documents

Line / Photo - used for a combination of lines & photos documents

Greyscale - used for a combination of lines & areas of shade (CAD) originals

Photo - used for photographic originals

This will allow automatic image quality adjustments for the scan.

1.2.4 Copy Count

Press the arrow buttons to scroll through the number of copies required or press on the

actual number to set the quantity with the number pad.

Section 2 Copy Mode 2-5

Page 46

1.2.5 Media

Selects automatic (for best possible fit) or manual roll selection.

or

1.2.6 Length

Select Auto for automatic cut length (to the length of the original) or Standard Cut for a

manual length. (a number pad will request the desired length to be entered)

Section 2 Copy Mode 2-6

Page 47

1.2.7 Size

Select

a) AutoZoom to automatically zoom to the width of paper or

b) press the arrow keys to scroll through presets ratios or

c) press on the Zoom number to enter a ratio on the key pad

1.2.8 Insert Original

Using the guides on the feed table, center the

original face up and insert the document.

Continue to push forward until the scanner accepts

the document.

The original will automatically commence to copy. While this occurs the image will be

displayed on the Operator Panel for your reference.

Section 2 Copy Mode 2-7

Page 48

2. 0 Operation Details

1.3 Main Screen

The main Copy screen is selected with the Copy Button.

It contains all user functions for copying. The following pages details the functions and

settings of each button and sub screens that can be used to adjust the copy mode

parameters to achieve the required result.

1.4 Original

This region allows the setting of the Size Mode (Engineering or Architectural) and the

original image type.

1.4.1 Original Size Mode

This button is used to select the Size Mode of Engineering or Architectural .

This will allow the automatic width detection system to determine the image width when an

original is placed in the scanner.

Engineering widths = 34, 22, 17, 11, and 8.5 inches

Architectural widths = 36, 30, 24, 18, 12, and 9 inches

Section 2 Copy Mode 2-8

Page 49

1.4.2 Original Type

There is a selection of four different predetermined original types. The selections are:

a) Line - used for simple line documents

b) Line / Photo - used for a combination of lines & photos documents

c) Greyscale - used for a combination of lines & areas of shade (CAD)

originals

d) Photo - used for photographic originals

Press the desired original setting from one of the four diagrams. This will allow automatic

image quality adjustments for the next scan. Please note that the selection will be

highlighted with a “black circle” and the icon will become white, as in the above example

“Greyscale”

1.5 Quality

This region is used to change the image quality settings from the automatic setting.

1.5.1 Automatic

For most copies, “Auto” should be selected. This will allow the copier to automatically

determine the best image settings without any user intervention (please also note

“Original” in 2.2)

Section 2 Copy Mode 2-9

Page 50

1.5.2 Threshold

To override the “Automatic” setting, “Threshold” can be adjusted.

Deselect “Auto” to enable “Threshold”.

When the arrows are pressed the threshold will be set to a desired

level. This will suppress or enhanc e the lines and images on the

original.

1.5.3 Density

To override the “Automatic” setting, “Density” can be adjusted.

Deselect “Auto” to enable “Density”.

When the arrows are pressed the background density will be set to

a desired level. This will suppress or enha nc e the background of

the original.

1.5.4 Sharpness

To override the “Automatic” setting, “Sharpness” can be adjusted.

Deselect “Auto” to enable “Sharpness”.

When the arrows are pressed the line sharpness will be increas ed

to remove rough lines or decreased when photos are copies to

allow smoother graduations.

1.5.5 Dither

To override the “Automatic” setting, “Dither” can be adjusted. Deselect “Auto” to enable

“Dither”.

By pressing the dither button,

a) None

b) Fine

c) Medium or

d) Course

dither of the image can occur. This will change how the dots are

arranged to create the final image of the copy. For fine lines a

“Course” dither pattern may be desired. For Photos “None” may be

desired.

1.6 Copy Count

In this region the number of copies, and set copy / collation can be set.

Section 2 Copy Mode 2-10

Page 51

1.6.1 Arrows - Count Increase / Decrease

Use the arrows to increase or decrease the total numbers of copies desired by one with

each press of the button.

In this example the arrow was press seven times to reach “8 copies”.

1.6.2 Number Pad - Count Increase / Decrease

Press the ”number of copies” value (which is a button) to set the desired number of copies

using a number pad. This will allow the quicker entry of the desired quantity if a larger

number is desired.

a) Press the numbers for the quantity

desired. (up to 999)

b) Select “Enter”

c) If an entry error was made press “C” to

start again

d) If you wish to close the screen without

changing the quantity press “Cancel”.

1.6.3 Set Copy

a) To enable collated sets or copy sets to be printed select the Set Copy button.

b) As originals are scanned , the total number in the set are displayed.

Section 2 Copy Mode 2-11

Page 52

c) Copying will not commence until the set is closed. To close a set, press the start

button. The set with the total number of copies will be printed.

An example of Set Copy:

3 originals with 3 sets or copies

1 2 3

Originals

.

Copies

1.6.4 Clear

Press the clear button to reset the quantity to “1”.

Section 2 Copy Mode 2-12

Page 53

1.7 Advanced Settings

The Advanced Setting button contains the additional

parameters on a sub screen:

a) Mirror

b) Invert

c) Fold (if optional device connected)

d) Stamp (Water Mark)

e) Lead Edge Adjustment

f) Trail Edge Adjustment

When any of the adjustments / selections are selected, the selections will now b e

displayed on the main Copy screen

1.7.1 Mirror

Select this button to “mirror” a scan. This can be utilized on originals that

may have the actual image on the reverse side such as older “sepia” or

“film” documents.

1.7.2 Invert

Select this button to change a region of white to black and visa versa of a

scanned document. This is normally used for “negative” documents or

“blue prints”.

1.7.3 Fold

Select “Fold” to display another sub screen. This will allow the selection of a “Fold Pattern”

to be applied to the copy.

a) use the Arrow buttons to scroll through the

available folds and then select the fold

from the list.

Section 2 Copy Mode 2-13

Page 54

b) The fold selected will be displayed in the button.

c) Select OK

NOTE

The list of “Folds” are loaded into Copy Mode by the

system administrator or key operator. They can not be

altered or modified in any manner on the

Operator Panel.

Please contact these persons for any additional stamps

that may be required.

Please see “KIP Request” for these functions.

An optional KIP Folder must be purchased to enable

these functions.

system

1.7.4 Stamp

Select “Stamp” to display another sub screen. This will allow the selection of a “Stamp” or

“Water Mark” to be placed on the scanned image. It will be imbedded into the image.

a) use the Arrow buttons to scroll through

the available stamps and then select the

stamp from the list.

b) The Stamp button will now display the stamp selected.

c) Select OK

Section 2 Copy Mode 2-14

Page 55

NOTE

The list of “Stamps” are loaded into Copy

Mode by the system administrator or key

operator. They can not be altered or

modified in any manner on the

Operator Panel.

Please contact these persons for any

additional stamps that may be required.

Please see “KIP Request” for these

functions.

system

1.7.5 Leading Edge Adjustment

The leading edge of a copy can be altered. ( +/- 4” )

a) additional void area can be placed on the lead edge of a scan or

b) image can be removed (such as a binding strip or a file hanger)

Leading Edge + Leading Edge -

Image

Scanner

Image

Scanner

Image

ScannerImage

Copy

Original

Scanner

Copy

Deleted image

Added margin

Original

To adjust the Leading Edge, use the arrows to denote the quantity you wish to add or

remove.

Section 2 Copy Mode 2-15

Page 56

1.7.6 Trailing Edge Adjustment

The trailing edge of each copy can be altered. ( +/- 4” )

c) additional void area can be placed on the bottom of a copy or

d) image can be removed (such as a binding strip or a file hanger)

Scanner

Image

Original

Trail edge + Trail Edge -

Image

Scanner

Copy

Deleted trailing image

Added trailing margin

Image

Scanner

Original

Image

Copy

1.8 Width

This region allows automatic or manual roll selection, roll size display, cut sheet media, the

roll amount remaining and to set the installed media type and width.

Section 2 Copy Mode 2-16

Page 57

1.8.1 Auto

This default setting allows the copier to automatically select the best media roll width to

print the image onto. It selects the roll noting the amount of image area to prevent surplus

media consumption. (applies to the option - two roll model)

Example:

22” original

36” and 24” bond media installed

Original is 22” wide

36” installed 24” Installed

excess non-imaged media has the best image to media fit

therefore this roll will be used

1.8.2 Manual Roll Selection

To select a roll deck. press the roll deck desired. Note that the roll information is displayed

in the roll deck button.

Section 2 Copy Mode 2-17

Page 58

1.8.3 Enabling Cutsheet

system is equipped with a cut sheet feeder that can be enabled in the configuration

The

of the user interface.

menu

This can be accomplished by following these steps

1. Select the (?) button in the bottom left corner of the user

interface.

2. Select the Configuration button from the Info/Help screen

3. Using the Left/Right arrows located at the bottom of the

page

scroll to page three (3).

4. From the Enable Cut Sheet “Yes” button.

1.8.4 Cut Sheet

To copy onto a cut sheet of media:

a) Select the CUT SHEET button on the main screen.

b) Select the Output Size of the actual cut sheet paper that will be inserted into the Cut

Sheet feeder.

Select desired settings from the main copy screen. Feed your original (s) into the

scanner.

Section 2 Copy Mode 2-18

Page 59

c) Open the Cut Sheet Feeder (1) and WAIT

until prompted by

the UI to

insert the Cut Sheet media.

1

d) There are size markings on the table.

Line up the original cut sheet on the feed table with the associated size marks.

When the paper is inserted far enough, the machine automatically sets the paper at

the proper position.

1.8.5 Copying to Multiple Cutsheets

1. Follow 1 through of the steps above (1.8. 4)

2. After a short period of time the Printer will beep notifying the user to insert the

cutsheet into the Cutsheet feeder, the Job Info button will also be flashing.

3. Once the cutsheet has been printed there will be a short pause and the printer will

start to beep again. Insert the next cutsheet into the printer

4. Continue for multiple s.

Note:

Only one cutsheet may be fed at a time and will time out after 3 minutes if no paper is

inserted.

Note:

DO NOT insert the cut sheet media into the feeder while printing from a roll deck, as this

may cause the printer to jam.

Section 2 Copy Mode 2-19

Page 60

1.8.6 Media Remaining

The installed roll information is displayed in the button of the particular roll deck. Beside

each deck is a volume of media that currently is left on the roll of media.

Indicators will display full, 3/4 ,1/2, 1/4 or empty

1.8.7 Installing Roll Media

When media is replaced or installed, a screen will automatically appear. This screen

allows the setting of the media type and width. Please see the BASIC PRINTER

FUNCTION ( Section 1 ) for the procedures to replace a roll of media.

a) if no changes are required, press cancel

b) if changes are required from the currently settings displayed, select the correct

media type and size for each deck and press OK.

This screen shows 36” bond for

deck one and 18” Vellum for deck two

Media types settings noted above can be changed at any time by pressing the Media

button on the main Copy Screen.

Section 2 Copy Mode 2-20

Page 61

1.9 Length

Two methods determine the length of the copy. These two methods are

Auto (may also be known as Syncro Cut or Automatic Cut ) and Standard Cut.

1.9.1 Auto

This mode allows the media length to be determined by the original

length. This also takes into consideration any enlargements or

reductions that are applied to an image as well, to prevent excess

media without image.

NOTE

Auto Length works in conjunction with Auto Roll

noted in 2.6.1.

1.9.2 Standard

This mode allows the media length to be determined by a standard length or a length set

manually by the user with a number pad.

a) select Standard Cut. A sub screen will appear. When Standard is used, the roll

must also be determined.

- If Auto Roll is selected in the Media region the following screen will appear,

prompting the media to be selected. Select the roll.

Section 2 Copy Mode 2-21

Page 62

- If a roll is already selected in Media, then the following screen appears now only

requesting the length.

b) Once the roll is determined (if so required)

the length can now be set.

- Standard Length

- Auto Length

- Custom Length

c) Standard Length – use an industry standard

length. Select the length and press Enter.

d) Auto Length – uses the length of the

original to determine the copy length.

Select and press Enter

Section 2 Copy Mode 2-22

Page 63

e) Custom Length – set the custom length in

the key pad and press enter

f) the cut length will now be displayed in the main Copy screen in the Standard Cut

button.

1.10 Size – Zoom

Image size / Zoom can be altered in this region of the operator panel. This

includes automatic zooming, predetermined percentages, or ratio calculations to page size,

and simply percentage increments.

1.10.1 Preset Percentages

The

system has several predetermined industry standard zoom p ercentages used for

quick access. These can be access with the arrow buttons.

Section 2 Copy Mode 2-23

Page 64

The pre-programmed percentages are:

50 - 66.7 - 70.7 - 100 - 141 - 150 - 200

1.10.2 Percentage Key Pad

To enter a percentage directly into the

a) press on the Percentage value displayed (the number is a button).

b) This will show a keypad to enter the value. (please note that the button Manual on

the side is a default).

c) Press the desired zoom v alue and press

enter

1.10.3 Page Size Zoom

To enter a zoom percentage based on pages sizes into the

system:

a) press on the Percentage value displayed (the number is

a button). This will show a keypad to enter the value.

system,

Section 2 Copy Mode 2-24

Page 65

b) Select Standard button.

c) Select the original page size by pressing onto the

original page size button.

d) Please note either Engineering or Architectural mode

can be utilized by pressing on the button below the

original page size.

e) Select the desired Copy page size. Again please note either Engineering or

Architectural mode can be utilized.

f) Press Enter to confirm your selections or Cancel to restart.

1.10.4 Auto Zoom

Press the Auto Zoom bottom to enable this function. Auto

Zoom features works in conjunction with the roll selected to

scale the image to the selected roll width.

a) if a roll is selected in the Media region the zoom

from the original will automatically fit the width of the

selected roll.

Section 2 Copy Mode 2-25

Page 66

b) If a roll is not selected (Auto is currently selected),

roll selection is requested prior to the function of

Auto Zoom. If cut sheet is used then it will use the

values set in the Cut Sheet button in Media.

1.10.5 Clear

To reset the percentage value to default, press the “C”

button.

1.11 Start

The copier is always set to “Auto Start”. That is when an originally is inserted

into the scanner it will start without other user intervention.

The start button is used when a job is recalled. The start button will “start” the

job if depressed after ‘Recall”. (the name will change to “Re-print”)

1.12 View Last

The last documented scanned to be copied be viewed.

1.13 Recall Job

The last set copy or single copy can be recalled to be resized or to switch

media type. After a job is recalled, make the required changes and then

press “Start”

1.14 Stop / Reset

This button has two functions.

1) Press the Stop button on the Operator Panel to stop the current scan.

After the original has been stopped, press the Stop button again to

eject the document from the scanner or open the scanner lid to remove

the original.

2) Press the Reset button to restore the “default settings” in Copy Mode. Some of the

default settings are determined in the Information / Help Screen of the

(see Copy Mode Configurations chapter)

system

1.15 Interrupt

Network printing can be interrupted between collated sets of documents.

Press the Interrupt button to pause the queue and allow a more urgent file

to be copied. For example if a file is needed right away and there is a job in the queue that

has 20 sheets and 10 sets are being printed this can be interrupted when one of the sets

finishes printing. After the urgent file is printed the sets will continue to print.

Section 2 Copy Mode 2-26

Page 67

1.16 Rescan

This button only appears when “Set Copy” mode in enabled. It allows a user to

rescan an original in a set as required. This may be due to skew or incorrect

image quality settings of the previous scan.

1.17 Log Off

This button only appears when “Accounting” functions are enabled. This

allows the current user to cease all

preformed the required copies.( after the code was entered to enable Coping)

Please note that the

seconds of no copy function activities by a user.

system also will automatically logoff from the current user after 180

system functions after the user has

Section 2 Copy Mode 2-27

Page 68

Section 2 Copy Mode 2-28

Page 69

Section 3

Scan Mode

1. 0 Scan Mode............................................................................................................................ 2

1.1 Main Screen..................................................................................................................... 2

1.2 Simple Scanning............................................................................................................. 3

1.2.1 Select Scan Mode....................................................................................................3

1.2.2 Select Size Mode ..................................................................................................... 3

1.2.3 Select Original Image Type ....................................................................................4

1.2.4 Select Format........................................................................................................... 4

1.2.5 Select Destination ................................................................................................... 5

1.2.6 Insert Original.......................................................................................................... 5

1.2.7 Retrieve the File....................................................................................................... 5

2. 0 Operation Details.................................................................................................................6

2.1 Main Screen..................................................................................................................... 6

2.2 Original............................................................................................................................. 6

2.2.1 Original Size Mode .................................................................................................. 6

2.2.2 Original Type ........................................................................................................... 7

2.3 Original Size .................................................................................................................... 7

2.3.1 Automatic Size.........................................................................................................7

2.3.2 Manual Size..............................................................................................................8

2.3.3 Hard Drive Space Monitor ...................................................................................... 9

2.3.4 Rotation..................................................................................................................10

2.4 Quality............................................................................................................................10

2.4.1 Automatic............................................................................................................... 10

2.4.2 Density ...................................................................................................................11

2.4.3 Sharpness.............................................................................................................. 11

2.4.4 Dither...................................................................................................................... 11

2.5 DPI ..................................................................................................................................11

2.6 Format............................................................................................................................ 12

2.7 Advanced Settings........................................................................................................12

2.7.1 Mirror...................................................................................................................... 13

2.7.2 Invert....................................................................................................................... 13

2.7.3 Stamp .....................................................................................................................13

2.7.4 Leading Edge Adjustment....................................................................................14

2.7.5 Trailing Edge Adjustment.....................................................................................15

2.8 Destination..................................................................................................................... 16

2.8.2 Setting a New Destination .................................................................................... 16

2.8.3 Removing a Destination .......................................................................................17

2.9 Start................................................................................................................................ 18

2.10 Reset / Stop ................................................................................................................... 18

2.11 Re-Scan.......................................................................................................................... 18

2.12 View Last.......................................................................................................................18

2.13 Log Off ........................................................................................................................... 18

Section 3 Scan Mode 3-1

Page 70

1. 0 Scan Mode

1.1 Main Screen

4

6

5

3

2

7

8

9

10

11

1

No. Name Function

1 Mode Selects the “Mode” of the system. (Scan Mode for

this screen shown)

2 Original Size Use automatic settings or manually set width, length

and rotation of the images.

3 Original Type User Selects the type of original to scan. Also select

either Eng/Arch Mode here.

4 Quality Select Auto or Manual image adjustments

5 DPI Scroll through final image resolution. (DPI)

6 Format Scroll through formats the scanned file will be saved

to.

7 Advanced Settings Invert, mirror, stamps, and edge adjustments

preformed / displayed in this button (sub screen)

8 Reset / Stop Resets the system to default settings. Stops a scan

in process

9 Destinatio n Select where the image will be stored after the scan

(local setting, FTP etc.).

10 View Last View the last scanned image

11 Rescan Rescans the last image (replaces)

Section 3 Scan Mode 3-2

Page 71

1.2 Simple Scanning

To scan to file please follow these basic steps.

The following chapters have details on adjustments and parameters that the user can

change to modify the scans.

1.2.1 Select Scan Mode

On the lower region of the Operator Panel select “SCAN”.

1.2.2 Select Size Mode

Select whether your document is an engineering or architectural size document. This will

allow automatic width detection to function.

Engineering widths = 34, 22, 17, 11, and 8.5 inches

Architecture widths = 36, 30, 24, 18, 12, and 9 inches

Section 3 Scan Mode 3-3

Page 72

1.2.3 Select Original Image Type

Set which Original Image type you will scan. The select ions are:

Line - used for simple line documents

Line / Photo - used for a combination of lin es & photos documents

Greyscale - used for a combination of lines & areas of shade (CAD) originals

Photo - used for photographic originals

This will allow automatic image quality adjustments for the scan.

1.2.4 Select Format

Press the button to scroll through the file formats available.

TIF-G4 - tif format Group 4 level compressed

TLC -

format compressed

CAL-G4 - Cals Group 4 level

PDF - PDF Level 3

Select the type you require which will save the file in this format.

Section 3 Scan Mode 3-4

Page 73

1.2.5 Select Destination

Select the location to where the file will be saved. Use the “Page Arrows” as required to

view other choices currently available.

NOTE

The choice of destinations are predetermined by the system administrator or key

operator. Please contact these persons for any additional locations that you may

require. The “Destination” button will allow for additional location entries.

1.2.6 Insert Original

Using the guides on the feed table, center the

original face up and insert the document.

Continue to push forward until the scanner

accepts the document.

The Original will automatically commence to scan. While this occurs the image will be

displayed on the Operator Panel for your reference.

1.2.7 Retrieve the File

Depending on the “Destination” you may now access your scan from a PC connected to

the LAN. This includes:

a) from a FTP site (using Microsoft Windows Internet Explorer or other FTP

software)

b) or from the “KIP IPS Mailbox” utilizing “KIP Request” to access the document.

Please see the User Guides of these applications for details on their function.

Section 3 Scan Mode 3-5

Page 74

2. 0 Operation Details

2.1 Main Screen

The main SCAN screen is selected with the Scan Button.

It contains all user functions for scanning to file. The following pages details the functions

and settings of each button and sub screens that can be used to adjust the scan

parameters to achieve the required result.

2.2 Original

This region allows the setting of the Size Mode (Engineering or Architectural) and the

Original Document type.

2.2.1 Original Size Mode

This button is used to select the Size Mode of Engineering or Arch itectural and Original

Image type.

Section 3 Scan Mode 3-6

Page 75

This will allow the automatic width detection system to determine the image width when an

original is placed in the scanner.

(Eng) Engineering widths = 34, 22, 17, 11, and 8.5 inches

(Arch) Architecture widths = 36, 30, 24, 18, 12, and 9 inches

2.2.2 Original Type

There is a selection of four different predetermined original types. The selections are:

a) Line - used for simple line documents

b) Line / Photo - used for a combination of lines & photos documents

c) Greyscale - used for a combination of lines & areas of shade (CAD)

originals

d) Photo - used for photographic originals