Page 1

Instruction Handbook

CX 8020

Large Format System

Page 2

Thank you for purchasing the Copier CX 8020.

This USER'S MANUAL contains functional and operational explanations for the CX 8020.

Please read this USER'S MANUAL carefully before using the Copier.

Please keep this USER'S MANUAL for future reference.

1. When this product is installed in North America.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

2. When this product is installed in Europe

This equipment complies with the requirements in Pub.22 of CISPR Rules for a Class B

computing device.

Operation of this equipment in a residential area may cause unacceptable interference to radio

and TV reception requiring the operator to take whatever steps are necessary to correct the

interference.

Do not install Machine around other electronic equipment or other precision instruments.

Other devices may be effected by electrical noise during operation.

If the Machine is installed near other electronic equipment, such as a TV or a radio,

interference to said equipment, such as noise or flickering, may occur.

Use a separate power line and install the COPIER as far as possible from said equipment.

This product meets the ENERGY STAR ® guidelines for energy efficiency.

The International ENERGY STAR ® Office Equipment Program is an international program that

promotes energy saving through the penetration of energy efficient computers and other office

equipment. The program backs the development and dissemination of products with functions that

effectively reduce energy consumption. It is an open system in which business proprietors can

participate voluntarily. The targeted products are office equipment such as computers, monitors,

printers, facsimiles, copiers, scanners, and multifunction devices. Their standards and logos are

uniform among participating nations.

The symbol shown indicates that this product conforms to Directive

2002/96/EC of the European Parliament and the council of 27 January

2003 on waste electrical and electronic equipment (WEEE) and does not

apply to countries outside of EU.

(1)

Page 3

Safety Warnings

The following warnings are very important in order to safely use this product.

These notes are important in preventing danger to the operator or operation of the machine.

The following symbols are found throughout the USER’S Manual and have the following meaning:

WARNING

This WARNING mark means that there is a possibility of death or serious

injury if you ignore or do not follow the said instruction.

CAUTION

This CAUTION mark means that there is a possibility of injury or physical

damage if you ignore or do not follow the said instruction.

When marked with this symbol, “DO NOT ATTEMPT”

When marked with this symbol, “pay close attention to”

(2)

Page 4

,

WARNING

Ground the product with a correct ground source or you may be electrically

shocked.

1. The Power source should be as follows:

2. Use a circuit with a dedicated breaker.

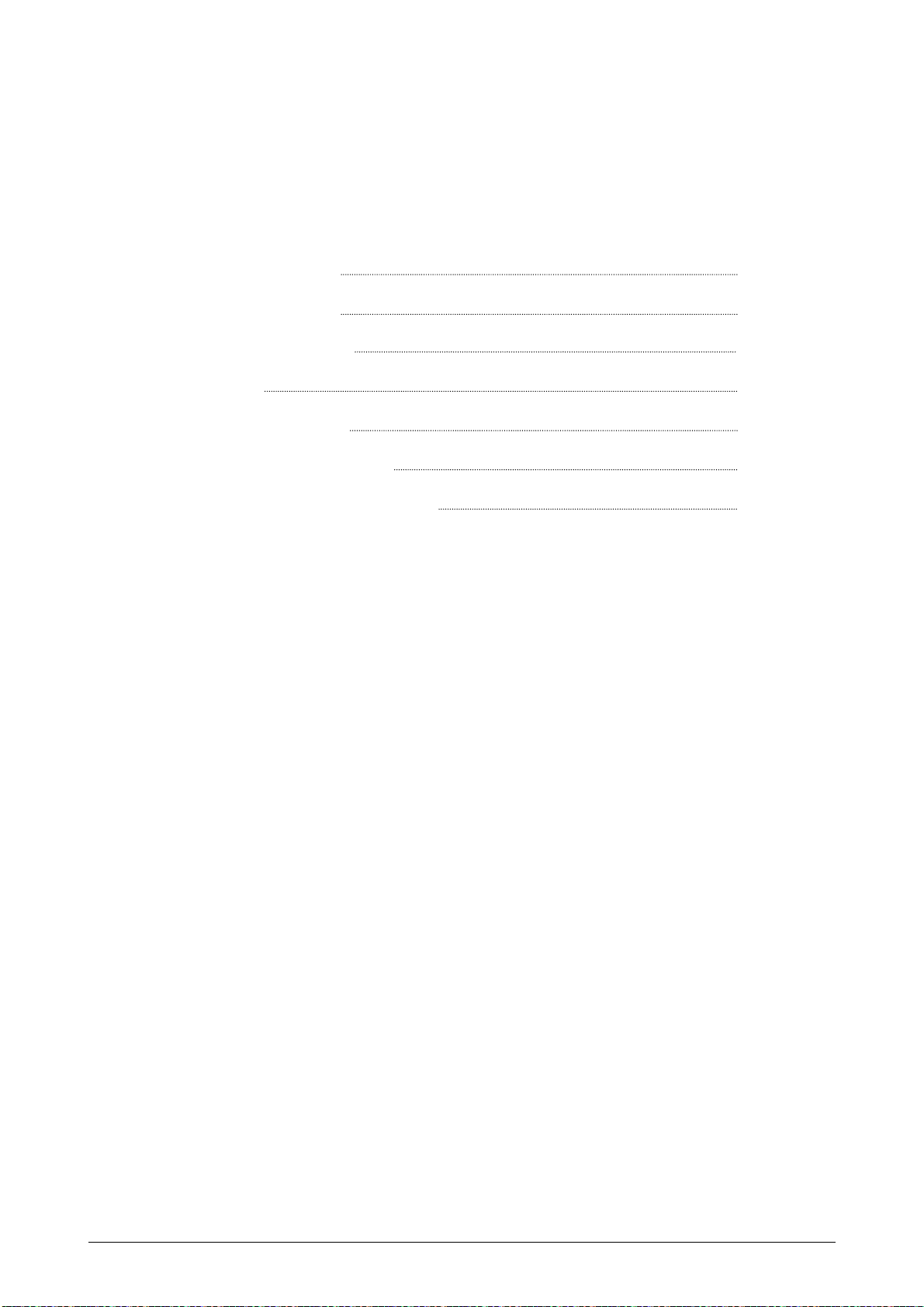

3. Install the product as close to the wall outlet as possible.

4. If you wish to move the machine, please contact your service personnel.

1. Do not remove the screw and do not open the cover if not instructed to

do so in this User’s Manual. If you ignore this warning, you may be burnt

or receive an electric shock due to a hot item or electrically charged part

inside of the printer.

2. Do not disassemble or tamper with the copier.

It may result in a fire or an electrical shock.

1. Do not plug in the machine into a multi-wire connector in which some

other equipment is plugged into.

It may cause a fire due to outlet overheating.

2. Do not damage the Power Cord by stepping on or placing heavy items

on it.

If the Power Cord is damaged, it may cause a fire or you may receive

an electric shock. REPLACE THE CORD IF DAMAGED!

1. Do not put a flower vase, a flowerpot or any water-filled item on the

product.

Spilt water could cause a fire or an electric shock.

2. If the product generates an abnormal smell or noise, turn it off and

unplug it from the wall electrical outlet immediately.

1. Do not throw toner (including wasted toner), toner cartridge and used

wasted toner bottle into a fire or other sources of heat, as it can

explode.

2. When you discard toner (including wasted toner), toner cartridge and

used wasted toner bottle

220-240V plus 6% or minus 10%, 50/60Hz, 10A

follow your service personnel’s instructions.

(3)

Page 5

CAUTION

Do not install the machine in a humidified room or a dusty room.

Also, do not install the machine on an unstable floor as injuries may occur.

1. Unplug the machine before you move it.

The power cord may be damaged and it may result in a fire or electric

shock.

Do not pull the cord when you unplug the machine as you may damage the

Power Cord.

There are hot items inside of the machine.

Take great care not to touch these items when you remove mis-fed media.

Ventilate the room well if you print in a small area.

2. If you do not use the machine for a long duration (holidays, company

shutdown) turn off and unplug the printer from the outlet for safety.

(4)

Page 6

TABLE OF CONTENTS

Chapter 1 Before Use

Page

1. 1 Installation Requirements 1- 2

1. 2 Originals Prohibited from Duplication 1- 3

1. 3 Features 1- 4

1. 4 Specifications 1- 5

1. 5 Specifications of Original 1- 6

1. 6 Specifications of Copying Paper 1- 8

1. 7 Storage of Copying Media 1- 9

1. 8 Appearance 1-10

1. 8. 1 Front View 1-10

1. 8. 2 Rear View 1-12

1. 8. 3 Operation Panel 1-13

Chapter 2 Basic Operation

Page

2. 1 Turning on the CX 8020 2- 2

2. 2 Turning off the CX 8020 2- 4

2. 3 Replacing the Roll Media 2- 5

2. 4 Adding the Toner 2- 9

2. 5 Copying with the Roll Media 2-13

2. 6 Copying with the Cut Sheet Media 2-16

2. 7 Replacing the Waste Toner Bottle 2-20

Chapter 3 Useful Functions

Page

3. 1 Initial Cut 3- 2

3. 2 Adjusting the Copy Density 3- 3

3. 3 Selecting the Cut Mode 3- 5

3. 4 Adjusting the Leading/Trailing Margin 3- 6

3. 5 Multiple Copy 3- 7

(5)

Page 7

3. 6 Power Saving Mode and Power OFF Mode 3-11

3. 6. 1 Power Saving Mode 3-11

3. 6. 1. 1 Power Saving Mode (Manual) 3-11

3. 6. 1. 2 Power Saving Mode (Automatic) 3-12

3. 6. 2 Power OFF Mode 3-13

3. 7 Dehumidifying the Roll Media 3-15

3. 8 Sample Copy 3-16

Chapter 4 Error Treatment

4. 1 Call Operator Errors 4- 2

4. 1. 1 Mis-feed Errors 4- 2

4. 1. 1. 1 Code “J0” : Original Mis-feed 4- 4

4. 1. 1. 2 Code “J1” : Paper Mis-feed at Paper Entrance Area 4- 5

4. 1. 1. 3 Code “J2” : Paper Mis-feed at Paper Turning Area 4- 7

4. 1. 1. 4 Code “J3” : Paper Mis-feed at Print Area or Copy Exit Area 4- 9

4. 1. 1. 5 Code “J4” : Incorrect insertion of Cut Sheet Paper 4-13

4. 1. 1. 6 Code “J5” : Mis-feed of cut sheet paper at Paper Turning Area 4-14

4. 1. 1. 7 Code “J6” : Mis-feed of cut sheet paper (Incorrect size) 4-17

4. 1. 2 Other Errors 4-20

4. 1. 2. 1 Roll Empty 4-20

4. 1. 2. 2 Toner Empty 4-20

4. 1. 2. 3 Waste Toner Full 4-21

4. 1. 2. 4 Incorrect set of original or cut sheet paper

(READY & WAIT Indicators flash simultaneously) 4-21

4. 2 Call Service Errors 4-22

Chapter 5 Cleaning and Checking

5. 1 Cleaning of Each Part 5- 2

5. 1. 1 Original Feeding Part 5- 2

5. 1. 2 Original Guide 5- 2

(6)

Page 8

Chapter 1

Before Use

Page

1. 1 Installation Requirements 1- 2

1. 2 Originals Prohibited from Duplication 1- 3

1. 3 Features 1- 4

1. 4 Specifications 1- 5

1. 5 Specifications of Original 1- 6

1. 6 Specifications of Copying Paper 1- 8

1. 7 Storage of Copying Media 1- 9

1. 8 Appearance 1-10

1. 8. 1 Front View 1-10

1. 8. 2 Rear View 1-12

1. 8. 3 Operation Panel 1-13

Chapter 1 Before Use 1-1

Page 9

1. 1 Installation Requirements

r

The following conditions are required for installation of the equipment.

1. Power source should be rated as follows.

220-240V plus 6% or minus 10%, 50/60Hz, 10A

2. The equipment must be on an exclusive circuit.

3. The outlet must be near the equipment and easily accessible.

1. Make sure to connect this equipment to a grounded outlet.

2. For PLUGGABLE EQUIPMENT, the socket-outlet shall be installed near

the equipment and shall be easily accessible.

The site temperature range = 10 to 30 degrees Centigrade, with the humidity between

20% to 80% RH. (NON CONDENSING)

Keep the machine away from water sources, boilers, humidifiers or refrigerators.

1. The installation site must not have open flames, dust or ammonia gases.

2. The equipment must not be exposed to the air vents from air conditioners.

It may affect the image quality.

3. The equipment should not be exposed to the direct sunlight.

Please draw curtains to block any sunlight.

Ozone will be generated while this equipment is use, although the quantity generated

is within safe levels. (see certifications)

Ventilate the room, if required.

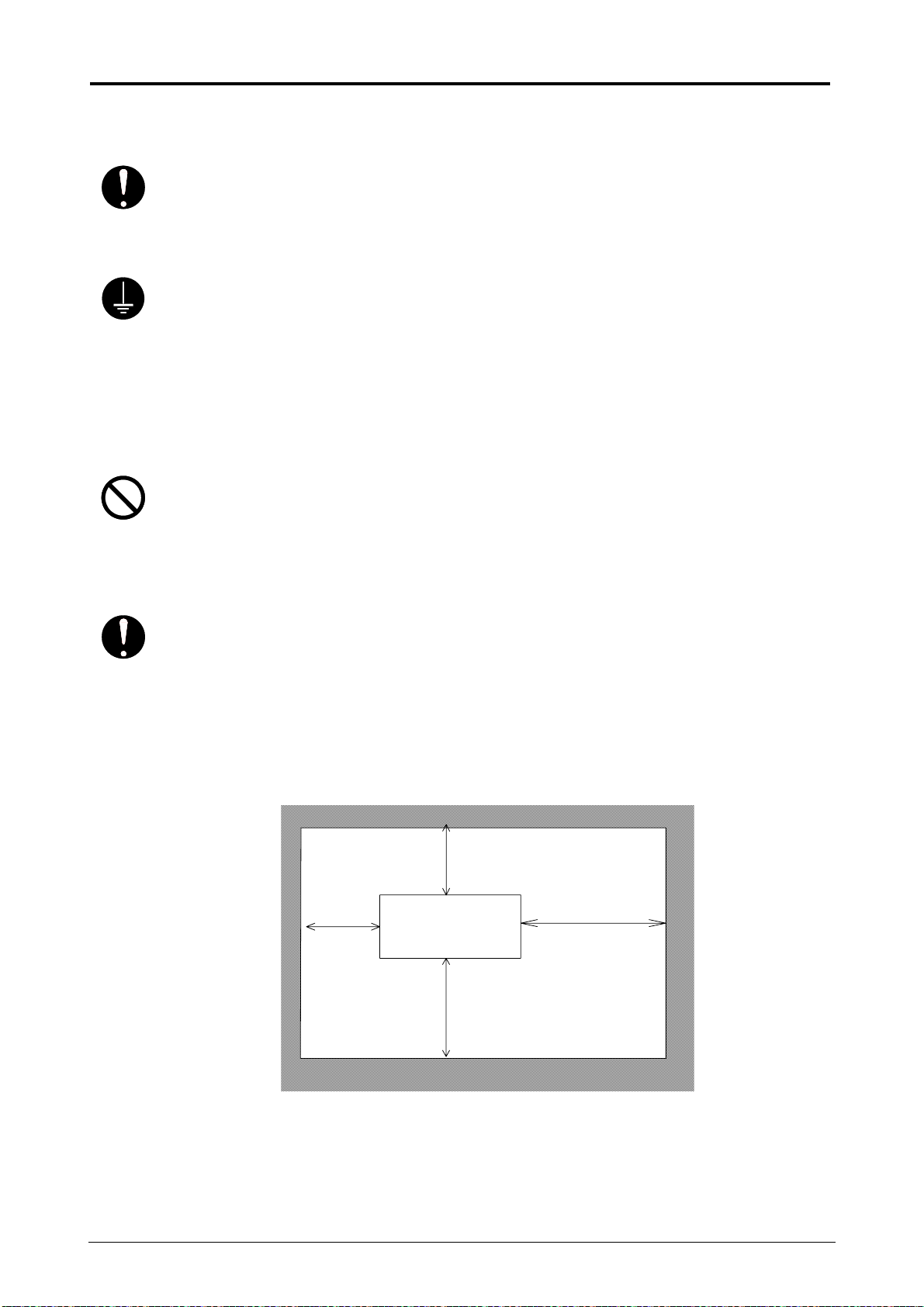

Keep ample room around the equipment to ensure comfortable operation.

(Refer to the following figure.)

The equipment must be levelled and the floor strength must be ample to sustain the

weight of the equipment.

(Rear side)

60cm or

wide

(Front side)

60cm or wider

CX 8020

120cm or wider

90cm or wider

Chapter 1 Before Use 1-2

Page 10

1. 2 Originals Prohibited from Duplication

It may not be allowed to copy every type of original.

You may be punished by the law if you possess the copy of some types of originals.

We recommend you to consider the following before you copy originals.

[Originals prohibited from copying by the law]

1. It is not allowed to copy Currency (Bill, Money, Bank Note, etc.), Government issued

Negotiable Instruments (National Bonds, Security, Local Debt Bonds, etc.).

2. It is not allowed to copy Foreign Currency or Foreign Negotiable Instruments.

3. It is not allowed to copy unused postal stamps or government postcards without permission

to make replica from Government.

4. It is not allowed to copy Government issued revenue stamps, certificate stamps which are

prescribed by Liquor Tax Act or the Commodity Tax Act.

[Special items]

1. It is warned by the government to copy private issued securities (stock certificate, draft,

check, goods ticket, etc.), commutation ticket or book of tickets, excluding that some specific

company copies such originals as many as it requires for its own business.

2. We recommend you do not copy freely originals such as government issued passport, public

or private issued licenses, automobile inspection certification, IDs and tickets like pass or

meal.

Reference Law Prohibited items to copy

Regulations to control fake currency and

Bond.

Control Law against Forged & faked

Foreign Currency, Bill, Bank Note and Bond

Forged postal stamps control law Unused postal stamps or government postcards

Forged revenue stamps control law Government issued revenue stamps, and

Currency similarity securities Control Law Private issued securities (stock, draft, check,

[Originals protected by the copyright]

It is prohibited to copy such originals as books, music, paintings, printed copy, maps, drawings,

movie and pictures which are protected by the copyright, except for personnel, family use or

similar purpose.

Currency (Bill, Money, Bank Note, etc.),

Government issued Negotiable Instruments

(National Bonds, Security, Local Debt Bonds,

etc.)

Foreign Currency or Foreign Negotiable

Instruments

certificate stamps prescribed by Liquor Tax Act

or Commodity Tax Act

goods ticket, etc.), commutation or book tickets

Chapter 1 Before Use 1-3

Page 11

1. 3 Features

1. 2 methods to feed media

CX 8020 can feed media by automatic roll paper feeding (1 roll) and manual cut sheet feed.

2. Cut Modes selection

2 Cut Modes are selectable; Standard Cut and Synchro Cut.

3. 2 copies/min. for A0 size

CX 8020 can make 2 A0 copies/minute.

4. Multiple Copy

It is possible to make a multiple copy up to 19 copies.

(We are unable to guarantee the accuracy of the Original feed, past 10 sheets during Multiple

Copy.)

5. Sample Copy is available.

CX 8020 has a Sample Copy function that allows to check the copy image in advance.

6. 14 kinds of Copy Density Level (including SL Mode) are available.

7. Adjustment of Leading Margin and Trailing Margin (40mm max.).

8. Easy Operation

a) Several kinds of operation such as original insertion, copy ejection and paper supply can be

made in front of the machine.

b) Toner is supplied by Toner Cartridge.

9. Environmentally Friendly Design

a) Power Saving Mode

(Satisfies the International

b) Succeeds a considerable reduction of hazardous substances on its components.

ENERGY STAR ® Office Equipment Program)

Chapter 1 Before Use 1-4

Page 12

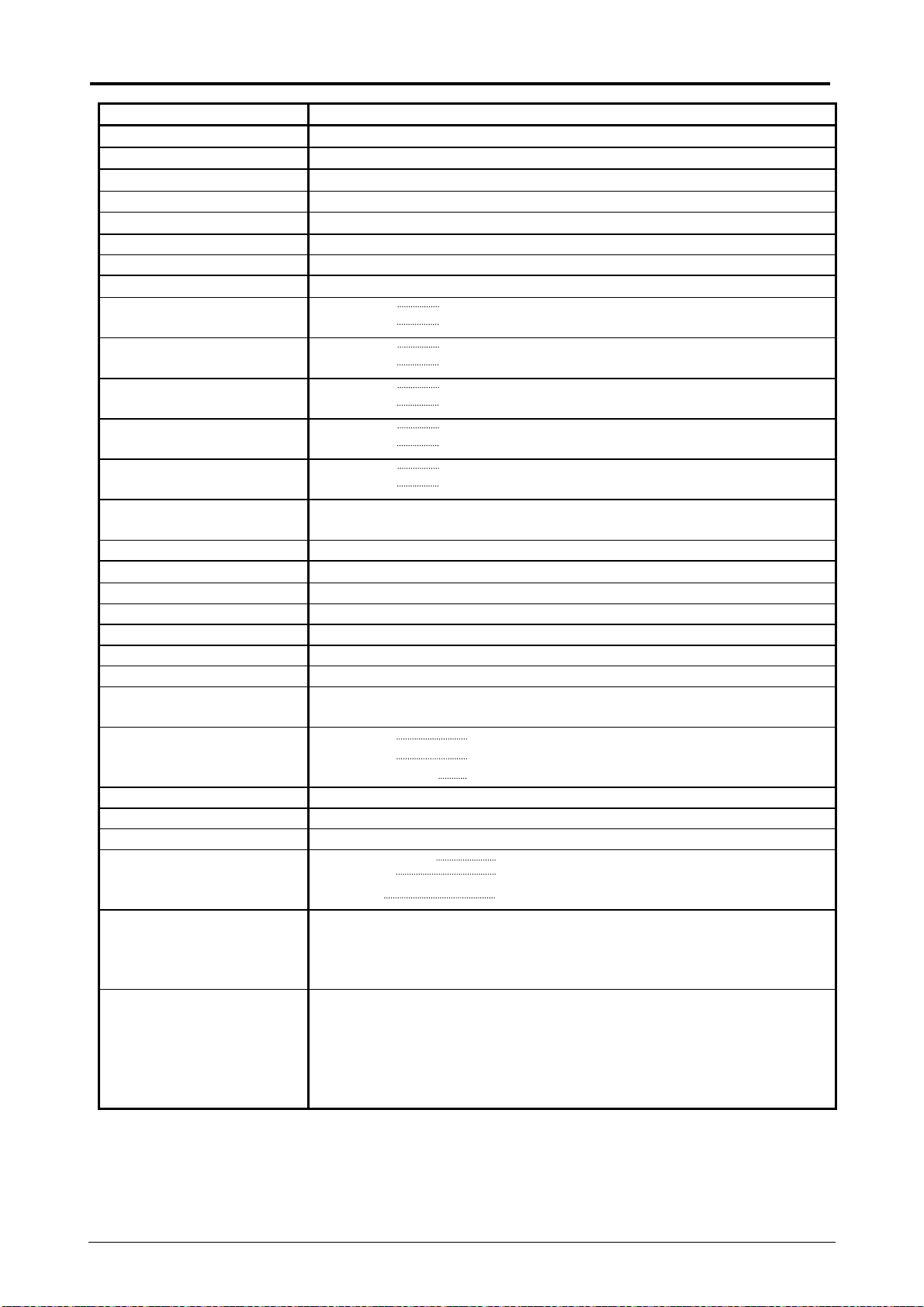

1. 4 Specifications

Subject Specification

Model CX 8020

Configuration Desk Top Type

Original Sheet through type

Photoconductor Organic Photoconductive Drum

Copy method Indirect Electrostatic System

Copy speed 60mm per second (1.5 copies (A0) / minute)

Light Source Fluorescent lamp

Kind of Original Sheet

Original thickness Maximum 0.2mm

Minimum 0.05mm

Original width Maximum 841mm

Minimum 210mm

Original length Maximum 3000mm

Minimum 297mm

Copying width Maximum 841

Minimum 210mm

Copying length Maximum 3000mm

Minimum 297mm

Warm up time Less than 8 minutes

First copy time 33 seconds (A0 size)

Media feeding method Automatic roll paper feeding & manual cut sheet paper feeding

Fusing method Heat Roller Fusing

Exposure method Lens array

Development method Dry (Mono-component)

Copy magnification ratio 1 : 1

Input power 220-240V plus 6% or minus 10%, 50/60Hz, 6.5A

Maximum power

consumption

Acoustic noise Stand by Max. 50db

Ozone Max. 0.1ppm (Measurement method under UL Standard)

Dimensions 1293mm (Width) x 460mm (Depth) x 580mm (Height)

Weight About 125kg

Media Plain Paper 64 to 80g/m2

Environmental condition

for usage

Storage of consumables (Media)

NOTE : The above specifications may change without notice.

o

(At 23

C, 60%RH, the rated voltage, and plain paper is used)

1600W

Printing Max. 55db

Impulse sound Max. 60db EN ISO7779

Vellum 64 to 80g/m

Film 120g/m

2

2

(Temperature)

10 to 30 degrees Centigrade

(Humidity)

20 to 80% RH

Wrap the media surely to shut out the humidity.

(Toner bottle)

Store the toner within the temperature range from 0 to

35 degrees Centigrade and within the humidity range from 10

to 85% RH.

Chapter 1 Before Use 1-5

Page 13

1. 5 Specifications of Original

The used original must satisfy the following specifications.

Minimum Maximum Remarks

0.05mm 0.2mm In case of Single Copy Thickness

0.07mm 0.2mm In case of Multiple Copy

Width 210mm 841mm

Length 297mm 3,000mm

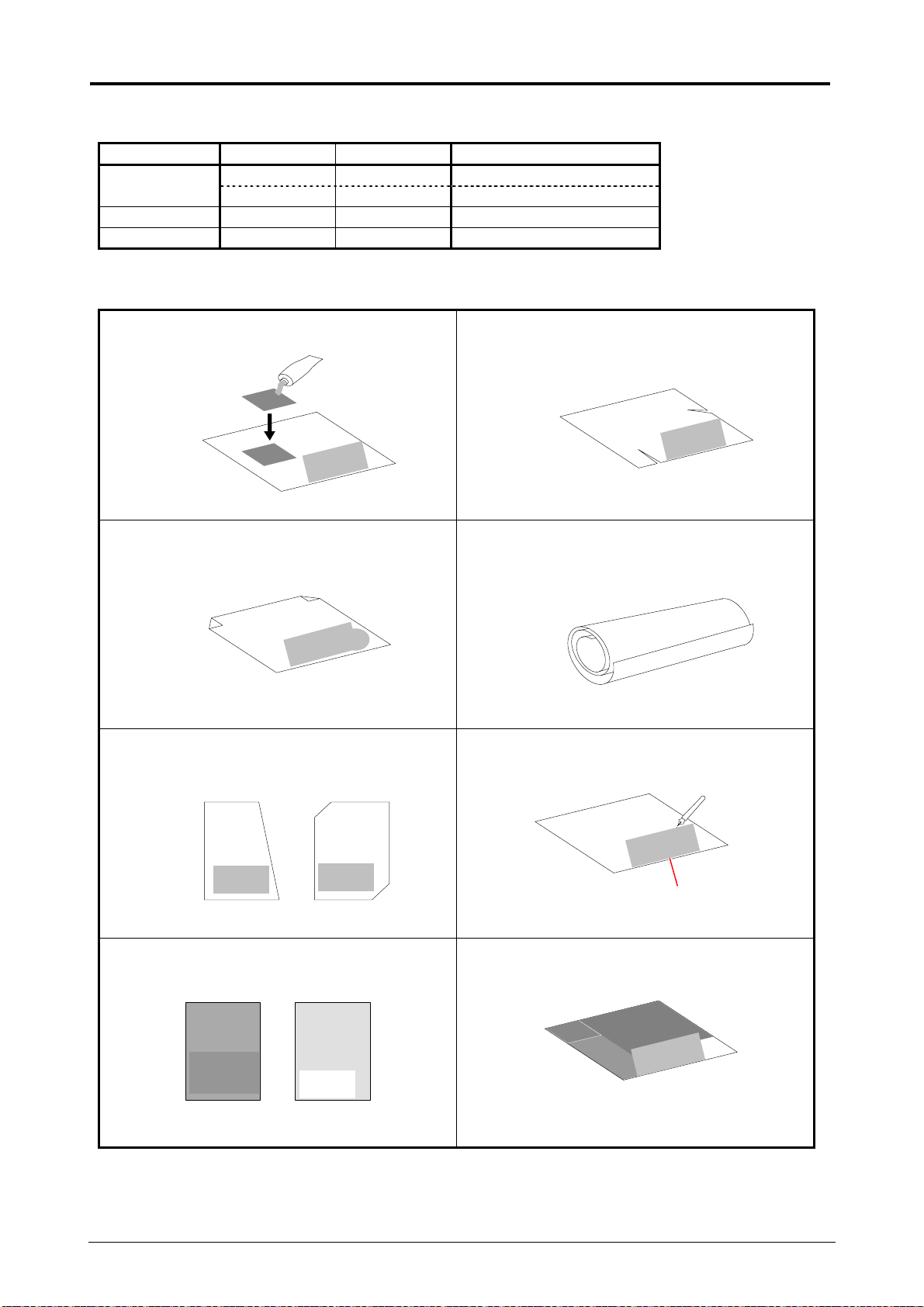

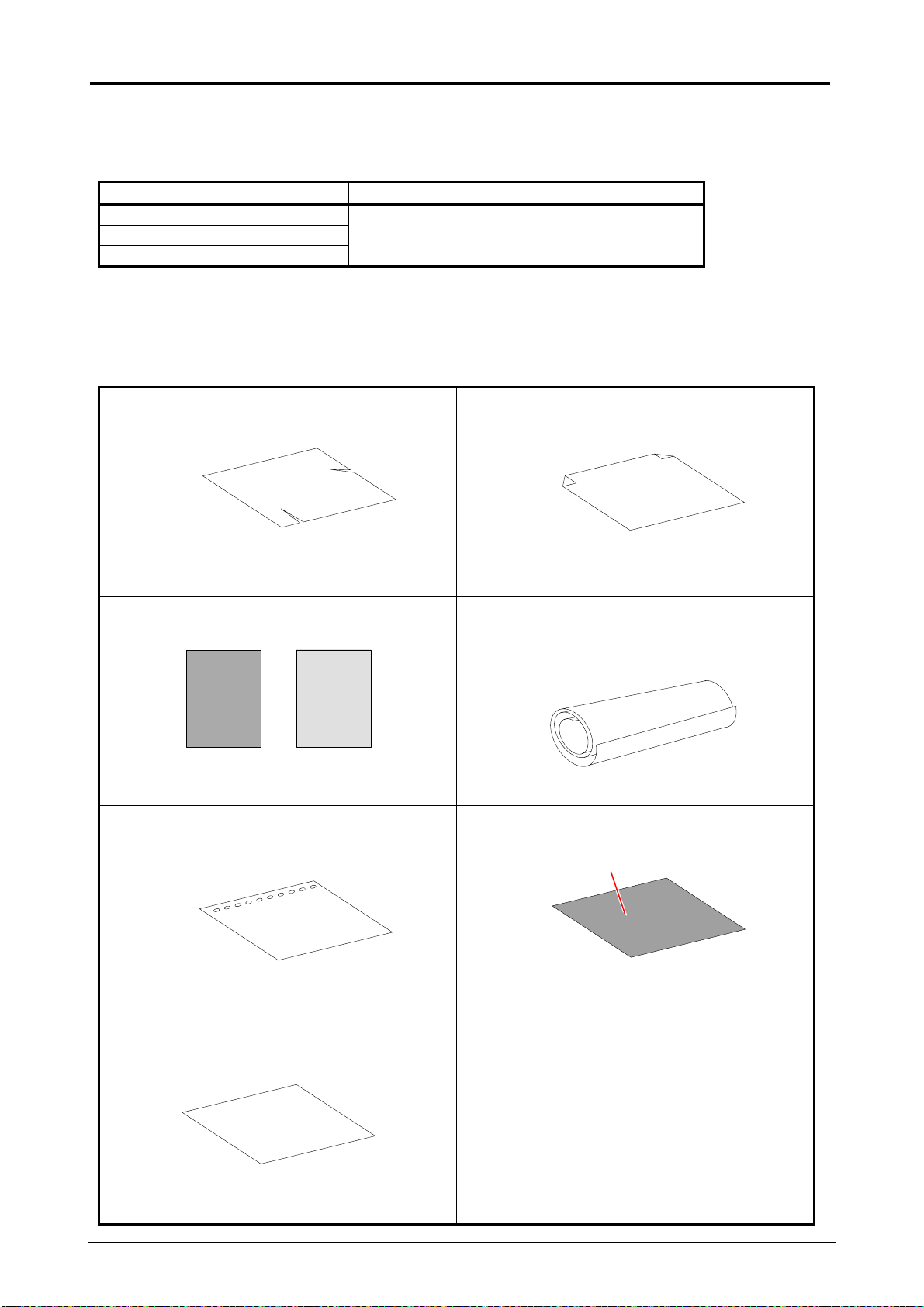

Also, do not use the following kinds of original, because you may damage the original or machine!

Sticked with paste Torn

Folded So much curled

Irregular shape (Not square) Wet (Ink is not dried)

KIP KIP

Made of metal or cloth Patched

Wet

Metal Cloth

KIP KIP

Chapter 1 Before Use 1-6

Page 14

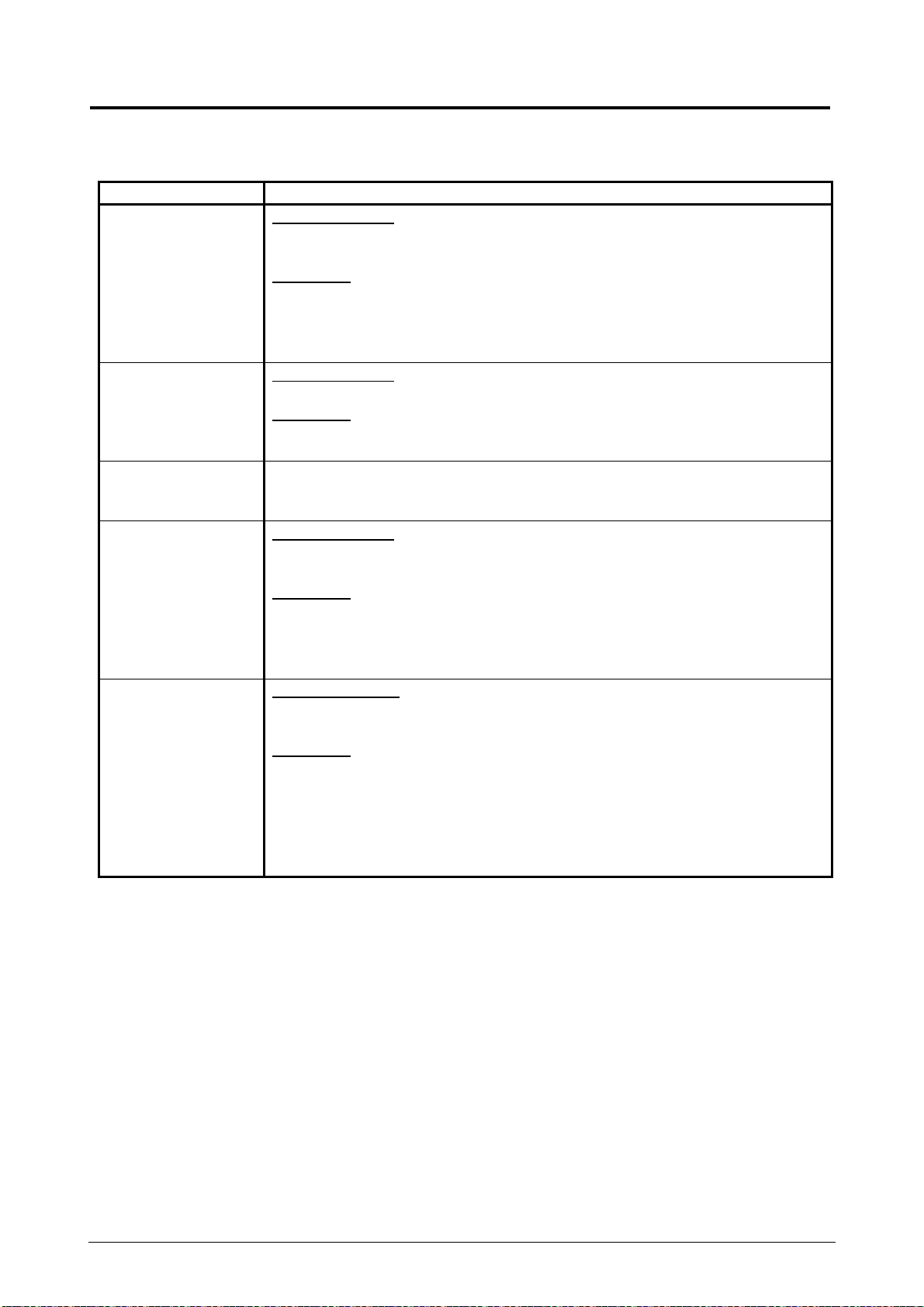

Clipped or stapled Rough surface (Carbon paper for example)

Clipped Stapled

Rough surface

KIP KIP

100Punched

Chapter 1 Before Use 1-7

Page 15

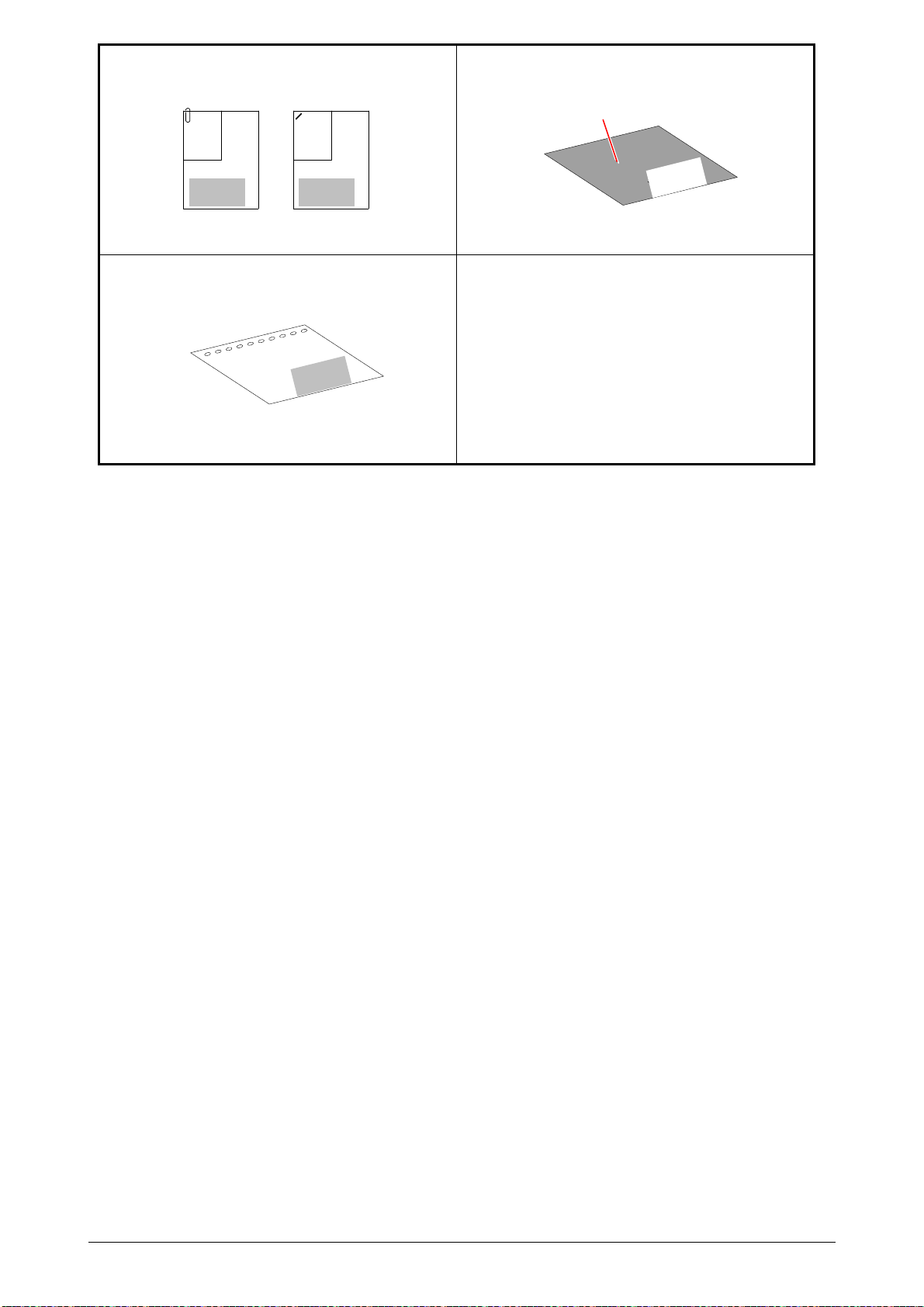

1. 6 Specifications of Copying Paper

The following sizes of paper are available for copying.

The maximum width is 914mm (36 inches) and the minimum is 216mm.

The maximum length is 3000mm, and the minimum is 279mm.

Type Weight Available Copying Sizes

Plain Paper 64 to 80g/m2

Vellum 64 to 80g/m2

Film 120g/m2

If the used paper does not satisfy the above specifications, it may cause such troubles as paper

mis-feed, defective image, etc.

Do not use the following kinds of paper because the paper mis-feed may occur.

Torn Folded

A0, A1, A2, A3 and A4 size

Made of metal or cloth So much curled

(In case of the Cut Sheet Paper)

Metal Cloth

Punched Rough surface (Carbon paper for example)

Rough surface

OHP Film

Chapter 1 Before Use 1-8

Page 16

1. 7 Storage of Copying Media

According to the humidity of the installation place, store the copying media as follows.

Humidity level Possible trouble and treatment

Very low humidity Possible trouble

Any of “void of image” or “paper crease” may occur when you make a

copy with a plain paper or vellum.

Treatment

1. Turn on the air conditioner and the humidifier to humidify the room

air.

2. Remove the plain paper or vellum from the machine whenever you

finish copying, and keep it in a polyethylene bag.

Low Humidity Possible trouble

“Void of image” may occur when you make a copy with a vellum.

Treatment

Remove the vellum from the machine whenever you finish copying,

and keep it in a polyethylene bag.

40%RH to 70%RH Remove the paper from the machine every day in the evening, and keep

it in a polyethylene bag.

Then set it to the machine in the next morning.

High Humidity Possible trouble

“Void of image” may occur when you make a copy with a plain paper

or vellum.

Treatment

1. Turn on the Dehumidify Heater of CX 8020 to dehumidify the air in

the machine.

2. Remove the plain paper or vellum from the machine whenever you

finish copying, and keep it in a polyethylene bag.

Very High Humidity Possible Trouble

“Void of image” or “paper crease” may occur when you make a copy

with a plain paper or vellum.

Treatment

1. Turn on the Dehumidify Heater of CX 8020 to dehumidify the air in

the machine.

2. Turn on the air conditioner and the dehumidifier to dehumidify the

room air.

3. Remove the paper from the machine whenever you finish copying,

and keep it in a polyethylene bag.

Chapter 1 Before Use 1-9

Page 17

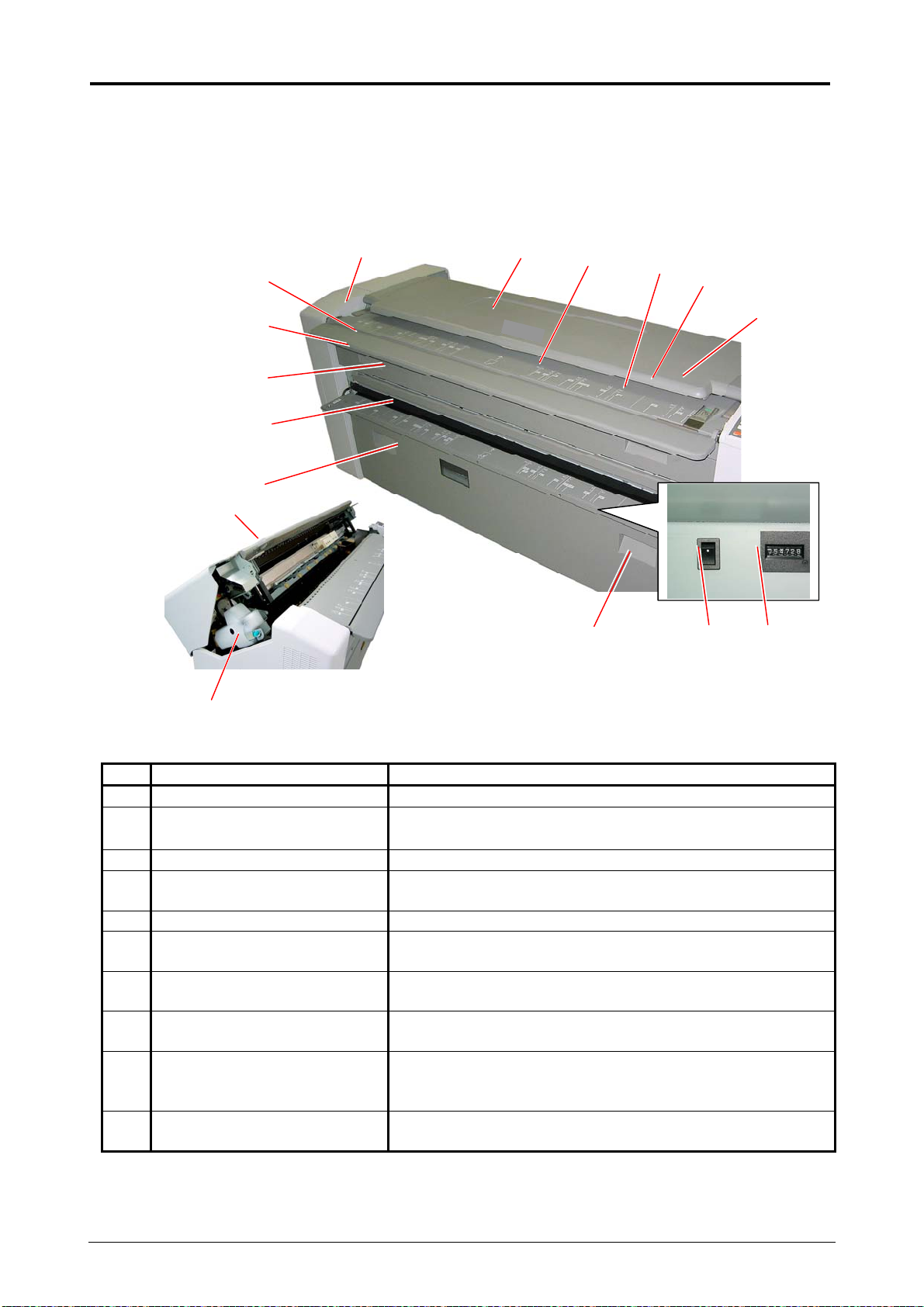

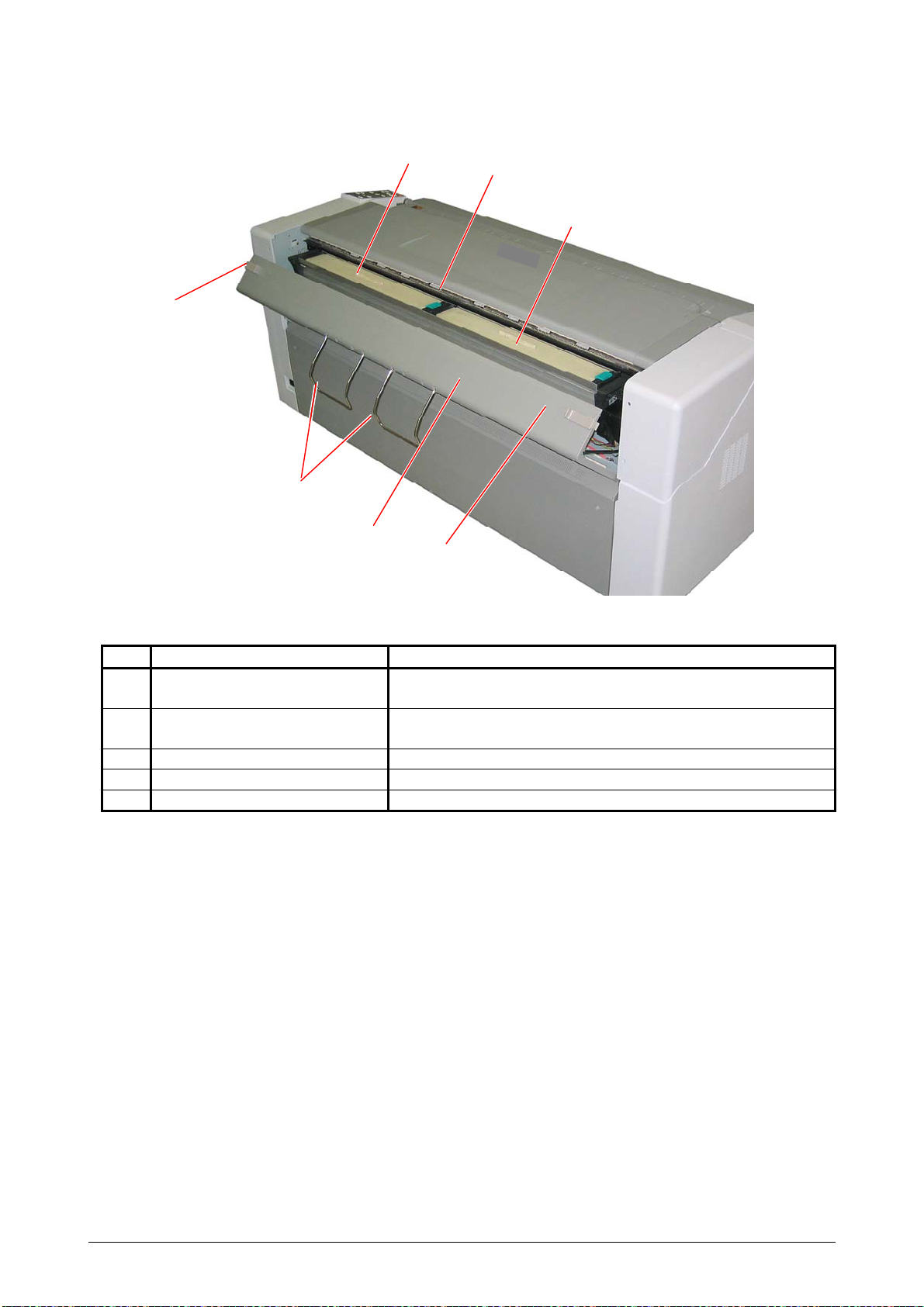

1. 8 Appearance

897

3

2

4

1. 8. 1 Front View

No. Name Function

1 Original Table Open the Original Table and put the original onto it.

2 Exit Cover Open the Exit Cover when you remove a mis-fed paper

3 Copy Exit Copies are ejected from the Copy Exit.

4 Bypass Feeder Table Open the Bypass Feeder Table when you make a copy

5 Front Door Open the Front Door when you replace the roll paper.

6 Upper Unit Open Lever Press down these levers to unlock and open the Upper

7 Original Feed Unit The Original is transported under the Original Transport

8 Original Feed Table Put the original on the Original Feed Table, and push it

9 Original Guide Move the Original Guide according to the width of

10 Operation Panel Several copying operations are available.

14

15

1

5

6

1

in the Fuser Unit.

with a cut sheet paper.

Unit.

Unit.

in for the scan.

original.

The original is transported along with it.

Refer to [1.8.3 Operation Panel] on the page 1-13.

6

1

1

1

Chapter 1 Before Use 1-10

Page 18

No. Name Function

11 Power Switch You can turn on/off the CX 8020.

12 Dehumidify Heater Switch You can turn on/off the Dehumidify Heater which

dehumidifies the roll paper in the machine.

13 Length Counter Total copy length is indicated. (1 count /1 meter)

14 Upper Unit Open the Upper Unit when you remove a mis-fed paper.

15 Waste Toner Bottle Waste toner is collected into this bottle.

Chapter 1 Before Use 1-11

Page 19

1. 8. 2 Rear View

1

No. Name Function

1 Toner Hatch Open Levers Pull both the Toner Hatch Open Levers inward to unlock

2 Developer Covers Remove these covers when you set a new Toner

3 Original Exit Original is ejected from here.

4 Original Receiver They receive the original after the ejection.

5 Toner Hatch Open the Toner Hatch when you supply the Toner.

4

2

5

1

and open the Toner Hatch.

Cartridge to supply the toner to the Developer Unit.

3

2

Chapter 1 Before Use 1-12

Page 20

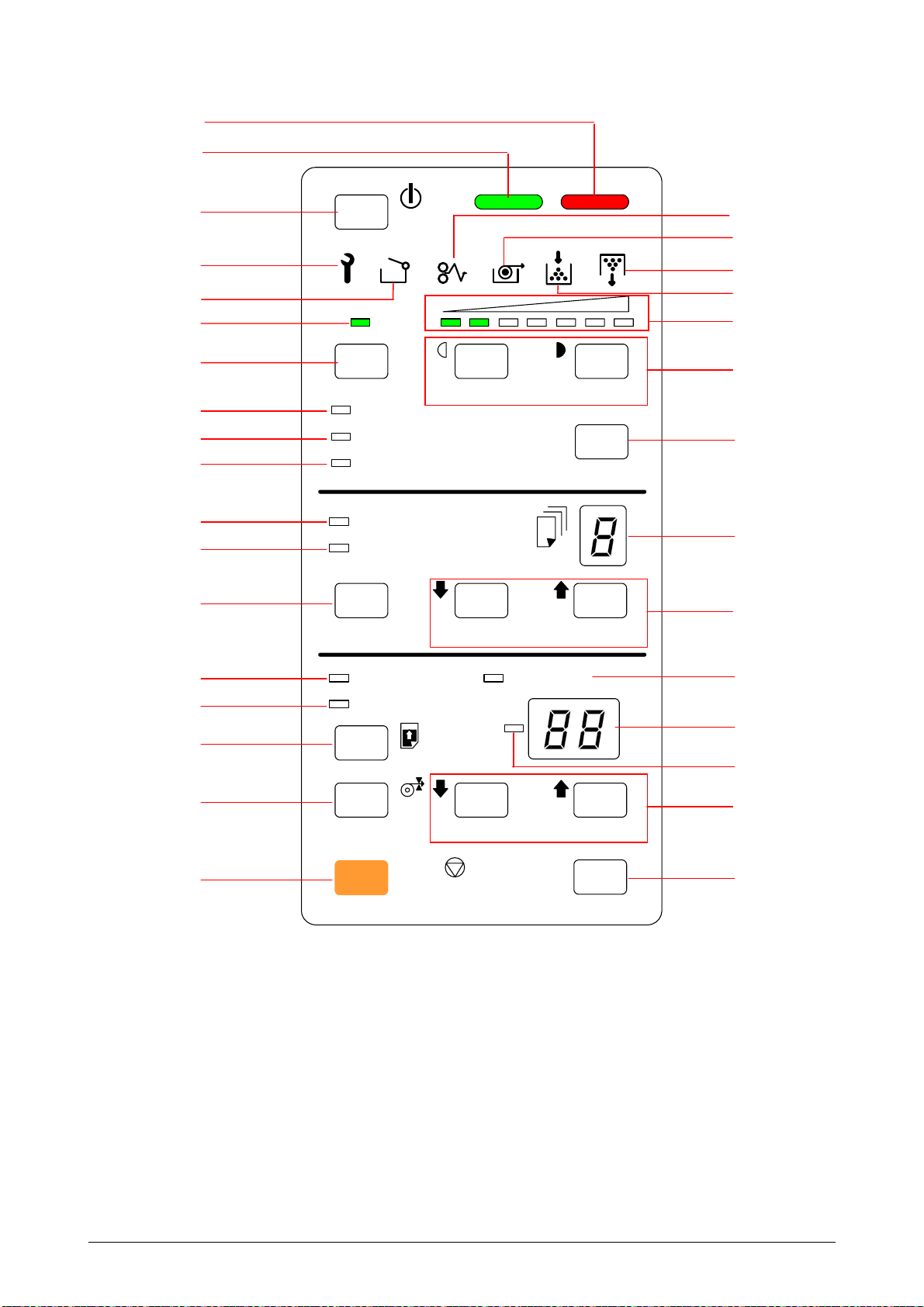

1. 8. 3 Operation Panel

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

STOP

ALL CLEAR

LIGHTER DARKER

MEDIA

CUT MODE

DECREASE INCREASE

C

CLEAR

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Chapter 1 Before Use 1-13

Page 21

No. Name Function

1 WAIT Indicator The WAIT Indicator lights when the CX 8020 is warming

up. (It is impossible to make a copy when it is lighting.)

Also the WAIT Indicator flashes when the Original Guide

is not at the far right position. (It is impossible to make a

multiple copy in this case.)

2 READY Indicator The READY Indicator lights when the CX 8020 is

available for copying.

(It is put out when you start copying. It lights again when

a copy is completed.)

3 STAND BY Key Press the STAND BY to enter the Power Saving Mode.

Refer to [3.6 Power Saving Mode and Power OFF

Mode] on and after the page 3-11 as for the Power

Saving Mode.

4 Service Call Indicator Service Call Indicator lights when the CX 8020 has a

significant error or problem that a user can not fix by

him/herself.

Call your service personnel when it lights.

5 Door Open Indicator The Door Open Indicator lights when any of Upper Unit,

Exit Cover, Front Door or Toner Hatch is opened or not

locked firmly.

6 SL Indicator The SL Indicator lights when you select the SL (Strong

Light) Mode.

Refer to [3.2 Adjusting the Copy Density] on the page

3-3 as for the SL Mode.

7 SL Key Press the SL Key to select the SL Mode.

Refer to [3.2 Adjusting the Copy Density] on the page

3-3 as for the SL Mode.

8 FILM Indicator The FILM Indicator lights when the roll paper installed to

the machine is a film.

9 VELLUM/TRACING Indicator The VELLUM/TRACING Indicator lights when the roll

paper installed to the machine is a vellum (or tracing

paper).

10 PLAIN PAPER Indicator The PLAIN PAPER Indicator lights when the roll paper

installed to the machine is a plain paper.

11 ROLL PAPER Indicator The ROLL Indicator lights when the roll paper feeding

mode is selected.

12 CUT SHEET Indicator The CUT SHEET Indicator lights when the cut sheet

paper feeding mode is selected.

13 CLEAR Key (Copy number) Press the CLEAR Key (Copy number) to clear the

setting value of copy number.

14 LEAD EDGE Indicator This Indicator lights when the Leading Margin Setting is

selected.

15 TRAIL EDGE Indicator This Indicator lights when the Trailing Margin Setting is

selected.

16 LEAD/TRAIL Select Key Select either the Leading Margin Setting Mode or

Trailing Margin Setting Mode pressing the LEAD/TRAIL

Select Key.

17 Cut Mode Select Key Specify the Cut Mode pressing the Cut Mode Select

Key.

Chapter 1 Before Use 1-14

Page 22

No. Name Function

18 STOP/ALL CLEAR Key 1) Press the STOP/ALL CLEAR KEY to stop copying in

the middle.

2) Also press the STOP/ALL CLEAR KEY when the

machine is not copying to clear (initialize) all the

settings.

19 Mis-feed Indicator The Mis-feed Indicator lights when the copying paper or

original is mis-fed anywhere in the machine.

20 Roll Empty Indicator The Roll Empty Indicator lights when the roll paper is

emptied.

21 Wast Toner Full Indicator The Waste Toner Full Indicator lights when the Waste

Toner Bottle is filled with the toner (or when the Wasted

Toner Bottle is installed incorrectly).

22 Toner Empty Indicator The Toner Empty Indicator lights when the toner is

emptied.

23 Copy Density Indicator The selected level of Copy Density is indicated.

24 LIGHTER Key

DARKER Key

25 MEDIA Key Make the machine recognize the type of paper pressing

26 Copy Number Indicator The setting value of Copy Number is indicated.

27 DECREASE Key

INCREASE Key

(Copy Number)

28 CUT MODE Indicator The CUT MODE Indicator shows which Cut Mode is

29 Indication Part The Indication part indicates some kinds of information

30 Minus indicator The Minus Indicator lights when you input a minus value

31 DECREASE Key

INCREASE Key

(Leading/Trailing Margin)

32 Clear Key (Leading/Trailing

Margin)

Press these keys to adjust the copy density.

the MEDIA Key.

PLAIN PAPER Indicator, VELLUM/TRACING Indicator

and FILM Indicator lights orderly whenever you press

this key.

Increase or decrease the setting value of Copy Number

pressing these keys.

selected presently.

It lights when the Standard Cut Method is selected, and

it is put out when the Synchronous Cut Mode is selected.

such as the setting value of Leading/Trailing Margin, Cut

Mode and Error Codes.

for the Leading Margin setting.

a. Increase or decrease the setting value of

Leading/Trailing Margin pressing these keys.

b. Also change the Cut Length pressing these keys in

case you select the Standard Cut Mode.

Press the CLEAR Key (Leading*/Trailing Margin) to clear

the setting value of Leading/Trailing Margin.

Chapter 1 Before Use 1-15

Page 23

Chapter 2

Basic Operation

Page

2. 1 Turning on the CX 8020 2- 2

2. 2 Turning off the CX 8020 2- 4

2. 3 Replacing the Roll Media 2- 5

2. 4 Adding Toner 2- 9

2. 5 Copying with Roll Media 2-13

2. 6 Copying with Cut Sheet Media 2-16

2. 7 Replacing the Waste Toner Bottle 2-20

Chapter 2 Basic Operation 2-1

Page 24

2. 1 Turning on the CX 8020

1. Plug the CX 8020 into an exclusive wall outlet.

WARNING

(1) Do not handle the Power Plug with wet hands, or you may receive an electrical shock.

(2) Ground the printer for safety.

(3) Do not plug the printer into a multi-wiring connector in which other devices are

plugged. It may overheat the outlet and may result in a fire.

(4) outlet must satisfy 220-240V +6%/-10%, 50/60Hz and 10A.

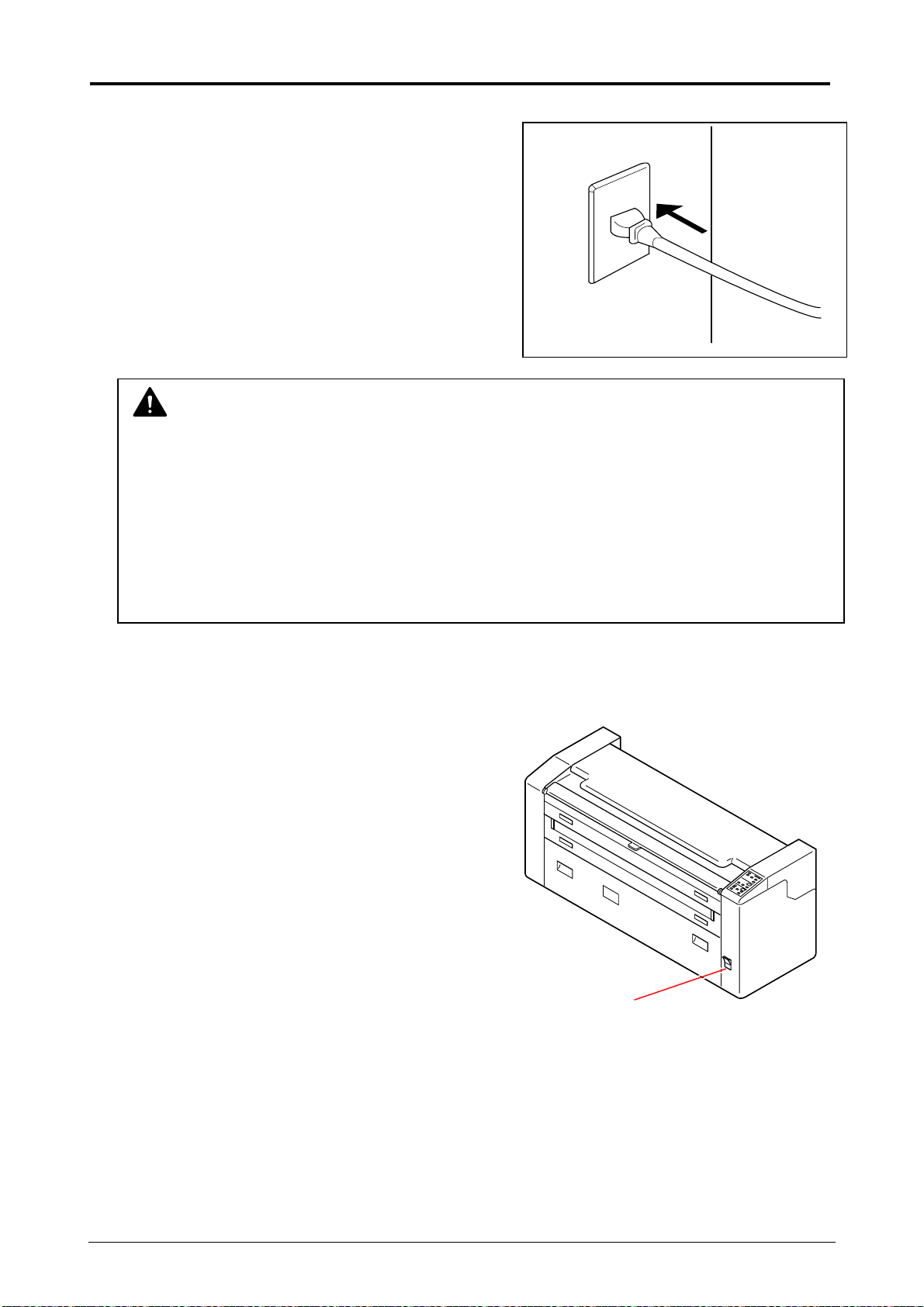

2. There is a Power Switch (1) on the right front side

of CX 8020.

Press its “ I ” side to turn on the CX 8020.

1

Chapter 2 Basic Operation 2-2

Page 25

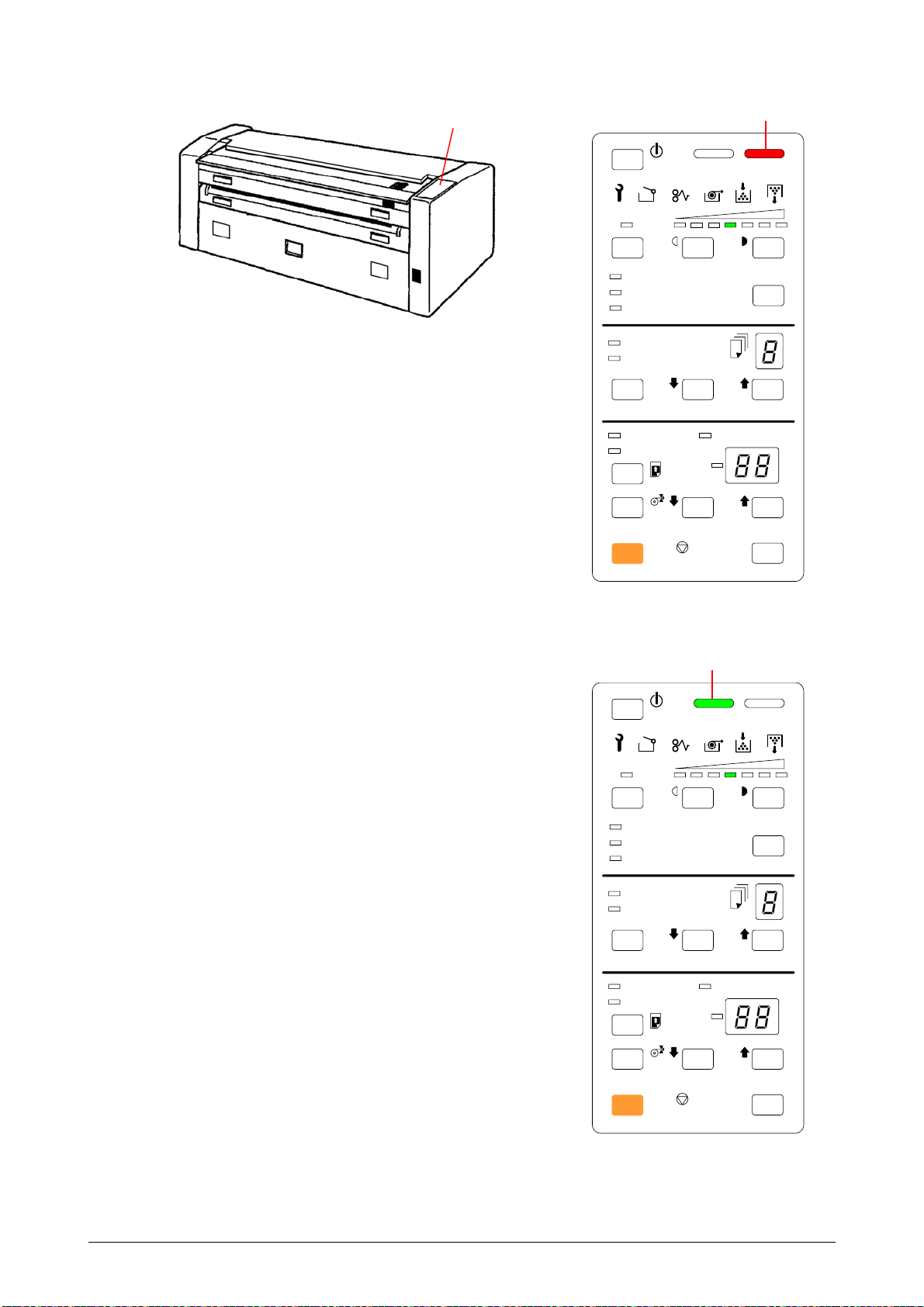

3. There is an Operation Panel (2) on the right top of the machine.

The WAIT Indicator (3) on the Operation Panel lights when the machine is warming up.

2

3

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

MEDIA

C

CUT MODE

DECREASE INCRE ASE

STOP

ALL CLEAR

C

CLEAR

4. The Ready Indicator (4) lights when the CX 8020 is ready.

4

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

LIGHTER DARKER

MEDIA

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

C

CLEAR

Chapter 2 Basic Operation 2-3

Page 26

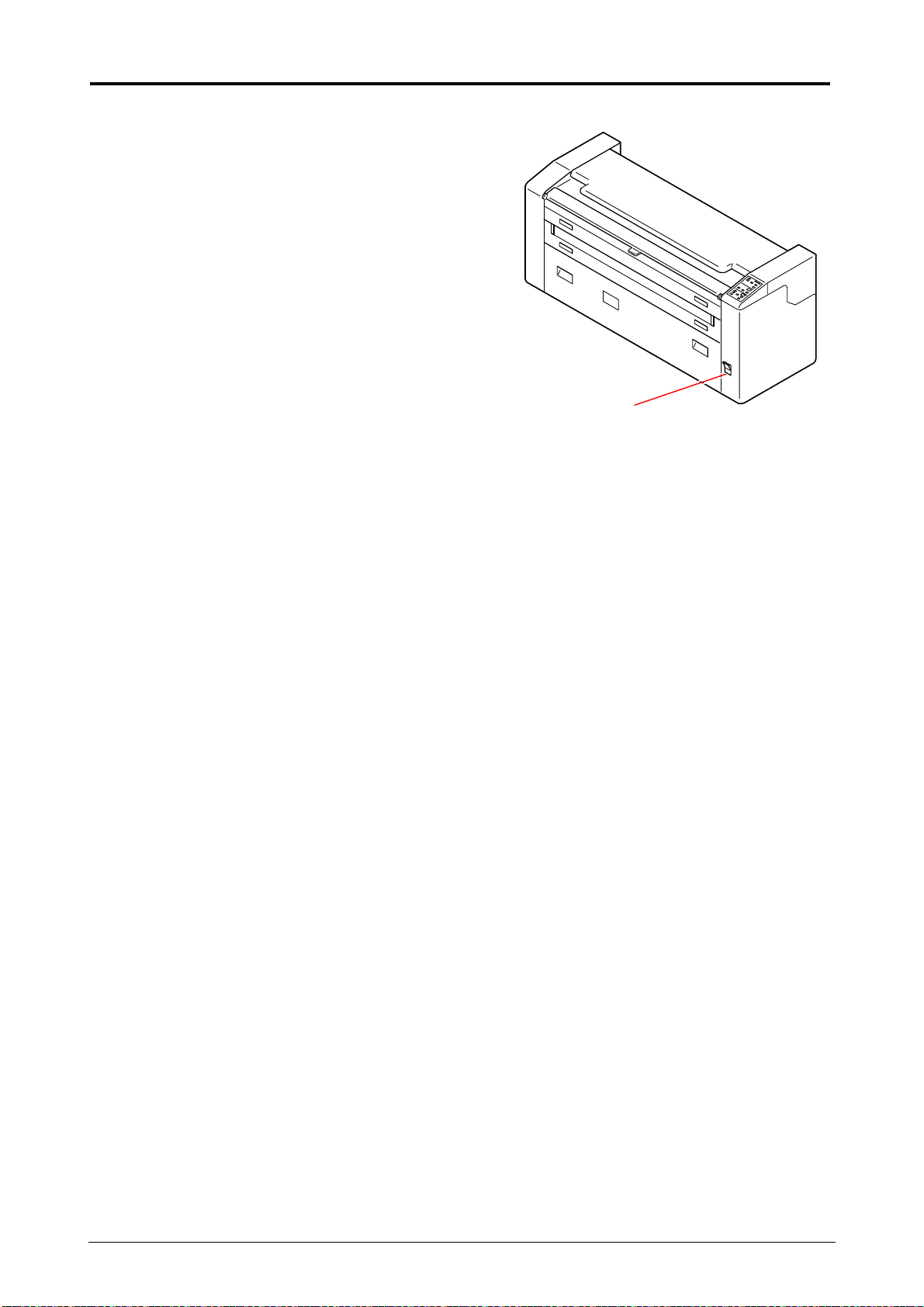

2. 2 Turning off the CX 8020

1. There is a Power Switch (1) on the right front side

of CX 8020.

Press its “O” side to turn off the CX 8020.

1

Chapter 2 Basic Operation 2-4

Page 27

2. 3 Replacing the Roll Media

1. Open the Front Door (1), and then pull out both the Spool Guides (2).

2. Lift up the core of roll paper with the Spool holding

its both sides.

3. Press down the Lock Lever (3) to unlock the core

of roll paper, and then pull out the Spool (4) from

the core.

1

2

4

3

Chapter 2 Basic Operation 2-5

Page 28

4. Insert the Spool into the new roll paper with pressing

down the Lock Lever (3).

And then align the side face of roll paper with the

concerning size mark (5) printed on the Spool.

When aligned, release your hand from the Lock

Lever (3) to lock the roll paper firmly.

5. Install the Spool with the new roll paper to the inner groove of the Spool Guides.

Then push in the Spool Guides.

NOTE

1. Return Spool Guide as shown in illustration.

2. Handle carefully as roll paper is heavy.

5

3

Chapter 2 Basic Operation 2-6

Page 29

6. Lift up the Feeding Roller Cover (6) until

it is locked.

7. Hold on the sides of the media about 30mm from the top leading edge, pulling the paper

outwards ( to keep the lead edge taught ) Feed the media straight up in between the rollers

noted . Insert the leading part (about 50mm) of the roll paper between the Feeding Roller

Cover (6) and the Roller (7).

And then bring down the Feeding Roller Cover (6).

8. Rewind the roll paper a little to remove any

slack in the roll paper.

NOTE

The roll paper may be transported with skew if the roll paper is loose.

6

6

7

6

6

7

Chapter 2 Basic Operation 2-7

Page 30

9. Close the Front Door.

NOTE

If the Feeding Roller Cover is not closed properly, the Front Door can not be closed.

10. Cut the leading part of roll paper by the Initial Cut.

(As for the detail of the Initial Cut, refer to [3.1 Initial Cut] on the page 3-2.)

Chapter 2 Basic Operation 2-8

Page 31

2. 4 Adding Toner

WARNING

There is combustible powder in the toner cartridge.

Do not burn up the used toner cartridge.

1. Pull both the Toner Hatch Open Levers (1) inward, and open the Toner Hatch (2).

2. Slide each green Hook (3) to the arrow mark, and remove each Developer Cover (4).

NOTE

If your hand or your clothing is soiled by toner, dust the toner.

If it is unable to dust it, wash the clothing with the cold water.

(Do not use the hot water at this time because the toner will soak into fibres.)

1

3

2

4

Chapter 2 Basic Operation 2-9

Page 32

3. Prepare 2 Toner Cartridges (5), and shake them

left and right several times while facing up its film

side.

4. One side of each Toner Cartridge has a tape (6)

which fixes the film.

Insert this side of each Toner Cartridge under the

holder (7).

5. Pulling the green Hook (3) toward the arrow mark, press down another side of cartridge.

The cartridge will be locked firmly if you release the Hook (3).

3

5

6

7

Chapter 2 Basic Operation 2-10

Page 33

6. Strip off the tape (6) which fixes the film (8), and then put the Holder (9) on the right end of the

Toner Cartridge as the following picture.

6 8 9 8

NOTE

Do not discard the tape (6) at this point of time because it will be used later.

7. Insert the Spool (10) to the holes of Holder (9),

while catching the film (8) between its pins.

Then rotate the Spool (10) clockwise to wind up

the film.

8. Fix the film roll (8) with the tape (6).

Rotate the Spool (10) a few revolutions counter clockwise, pull it out from the film roll, and then

discard the film roll.

9

6

8

10

8

10

Chapter 2 Basic Operation 2-11

Page 34

9. Pull each green Hook (3) toward the arrow mark

and remove each Toner Cartridge (5).

Discard the Toner Cartridge in a proper way.

11. Put back the Developer Covers (4).

12. Close the Toner Hatch (2).

2

3

5

4

Chapter 2 Basic Operation 2-12

Page 35

2. 5 Copying with Roll Media

1. Confirm that the Ready Indicator on the Operation Panel is lit.

Ready Indicator

2. If necessary, change such settings as Copy Density, Leading/Trailing Margin and so on.

(Refer to the pages in Chapter 3 as for the details of each setting.)

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

Chapter 2 Basic Operation 2-13

Page 36

3. Ensure that the Original Table (1) is open.

Move the Original Guide (2) according to the

width of original as needed.

NOTE

In case you will make a multiple copy, slide the Original Guide fully to the right after you

insert the original. Otherwise it is impossible to start multiple copy.

4. Put the original with face down on the Original Table,

and then insert it under the Original Feed Unit along

the Original Guide (2) until the leading edge touches

the feeding roller.

The Original is accepted, a little, remains a moment,

and then transported for the copy.

NOTE

Please wait for a moment if the WAIT Indicator is lighting, as it is impossible to make a copy

(If you set the original although the machine is warming up, both the READY indicator and

WAIT indicator flash at the same time.)

1

2

2

Chapter 2 Basic Operation 2-14

Page 37

5. The Original is ejected from the Original Exit

after the scan.

6. Copy is ejected from the Copy Exit.

Chapter 2 Basic Operation 2-15

Page 38

2. 6 Copying with Cut Sheet Media

NOTE

It is impossible to make a multiple copy by Cut Sheet Paper Feeding Mode.

1. Confirm that the Ready Indicator on the Operation Panel is lighting.

Ready Indicator

2. If necessary, change such settings as Copy Density, Leading/Trailing Margin and so on.

(Refer to Chapter 3 as for the details of each setting.)

3. Open both the Original Table (1) and the Bypass

Feeder Table (2).

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

1

2

Chapter 2 Basic Operation 2-16

Page 39

4. There are several Size Marks (3) on the

Bypass Feeder Table.

Align the edge of cut sheet paper with the

Size Marks (3), and insert the cut sheet

into the Bypass until it touches the feeding

roller.

Cut sheet paper is transported in a little, and then

awaits the original to be inserted.

NOTE

Normally the Roll Paper Feeding Mode is selected.

But if only you set the cut sheet paper the Cut Sheet Paper Feeding Mode is automatically

selected.

(The CUT SHEET Indicator on the Operation Panel automatically lights instead of ROLL

Indicator at this time.)

<Roll Paper Mode> <Cut Sheet Paper Mode>

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

CUT MODE

C

CLEAR

3

MEDIA

Chapter 2 Basic Operation 2-17

Page 40

5. Move the Original Guide (4) according to the width of

original.

6. Put the original with face down on the Original Table,

and then insert it under the Original Feed Unit along

the Original Guide (4) until the leading edge touches

the feeding roller.

The Original is transported a little, remains for a

moment, and then transported for the scan.

NOTE

Please wait for a moment if the WAIT Indicator is lighting, as it is impossible to make a copy

(If you set the original although the machine is warming up, both the READY indicator and

WAIT indicator flash at the same time.)

4

Chapter 2 Basic Operation 2-18

Page 41

7. The Original is ejected from the Original Exit

after the scan.

8. Copy is ejected from the Copy Exit.

NOTE

1. The paper feeding mode automatically changes from Cut Sheet Paper Feeding Mode to

Roll Paper Feeding Mode after the copy.

2. It is impossible to set multiple sheets in to the Bypass Feeder.

Please set it one at a time.

(When the previous cut sheet paper has been transported, the READY Indicator lights

and it becomes possible to set the next sheet. Note that you can not set the sheet

when the READY Indicator is out.)

Chapter 2 Basic Operation 2-19

Page 42

2. 7 Replacing the Waste Toner Bottle

WARNING

There is combustible powder in the wasted toner bottle.

Do not burn up the used wasted toner bottle.

NOTE

Do not reuse the wasted toner.

1. Press down the Upper Unit Open Levers (1) at both sides, and lift up the Upper Unit (2).

2. Loosen the Screw Knob (3), and remove the

Bracket of Wast Toner Bottle.

1

2

3

Chapter 2 Basic Operation 2-20

Page 43

3. Remove the Wast Toner Bottle (4) gently.

4. Install the new Waste Toner Bottle.

Then hold it with the Bracket and tighten the

Screw Knob (5).

5. Close the Upper Unit.

NOTE

1. If toner spill out from the bottle, clean with a wet cloth.

2. If your hand or your cloth is soiled with the toner, dust the toner.

If it is unable to dust it, wash the clothing with the cold water.

(Do not use the hot water because the toner will soak into fibre.)

3. Close the opening of Waste Toner Bottle with an Adhesive Tape, and put the bottle

into a vinyl bag. Keep it until the maintenance service comes.

5

4

Chapter 2 Basic Operation 2-21

Page 44

Chapter 3

Useful Functions

Page

3. 1 Initial Cut 3- 2

3. 2 Adjusting the Copy Density 3- 3

3. 3 Selecting the Cut Mode 3- 5

3. 4 Adjusting the Leading/Trailing Margin 3- 6

3. 5 Multiple Copy 3- 7

3. 6 Power Saving Mode and Power OFF Mode 3-11

3. 6. 1 Power Saving Mode 3-11

3. 6. 1. 1 Power Saving Mode (Manual) 3-11

3. 6. 1. 2 Power Saving Mode (Automatic) 3-12

3. 6. 2 Power OFF Mode 3-13

3. 7 Dehumidifying the Roll Media 3-15

3. 8 Sample Copy 3-16

Chapter 3 Useful Function 3-1

Page 45

3. 1 Initial Cut

In many cases the leading edge of a new roll paper is not straight but is rough (folded or torn).

The Initial Cut is a useful function to straighten it by cutting off the leading part by 280mm long.

NOTE

The leading part of a roll media will be humidified if it is kept in the machine for a long term

without printing, which results in a defective image.

We recommend you to cut it off by the Initial Cut in this case as well.

1. Press and hold the LEAD/TRAIL Select Key (1), and then press the INCREASE Key (1) in the

Leading/Trailing Margin setting area.

NOTE

Initial Cut Mode is available only while the READY

Indicator (3) is lighting.

2. The roll paper is transported, its leading edge is cut off by

about 280mm long, and it is ejected from the Copy Exit.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

STOP

ALL CLEAR

3

LIGHTER DARKER

MEDIA

CUT MODE

DECREASE I NCREASE

C

CLEAR

21

Chapter 3 Useful Function 3-2

Page 46

3. 2 Adjusting the Copy Density

The CX 8020 has 14 levels of Copy Density.

It is possible to select your preferable one optionally from these 14 levels. (7 levels in Normal

Mode and also 7 levels in SL Mode) ( SL removes background )

The Copy Density is shown by both the Copy Density Indicator and SL Indicator.

The Copy Density Indicator has 7 selectable levels. The density of copy becomes darker if you

select the level on “more” right side. (On the contrary it becomes lighter if you select the one on

“more” left side.)

Also if you validate the SL Mode (Strong Light Mode which removes background), it becomes

possible to select 7 more levels which belong to the lighter category than Normal Mode. (These 14

levels are consecutive.)

SL Mode ON Normal Mode (SL Mode OFF)

Light (Consecutive) Dark

Reference

As the copy density becomes very light if you select the SL Mode, it will be beneficial if the

original has a very dark background like “dark blue print”.

SL SL

Darkest LevelLightest Level

Chapter 3 Useful Function 3-3

Page 47

1. Press the DARKER KEY (1) if you will make the copy

density darker.

On the contrary press the LIGHTER Key (2) if you will

make it lighter.

2. Press the SL Key (3) if you will validate the SL Mode.

The SL Indicator (4) lights when validated.

You can validate and invalidate the SL Mode alternately

whenever you press the SL Key.

3 2 4 1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

Chapter 3 Useful Function 3-4

Page 48

3. 3 Selecting the Cut Mode

You can specify the Cut Mode of roll media. Synchronous Cut and Standard Cut are selectable.

Reference

The roll paper is cut as long as the copy image if you select the Synchronous Cut.

Please select the Synchronous Cut when the size of copy image is not standard (as D size

or E size) because of original size, magnification and so on

The roll paper is cut by the standard size (length) as A0 or A2 if you select the Standard Cut.

Selectable standard sizes (length) are A4, A3, A2, A1, A0 size and 48 inches regardless of

the width of roll paper.

Please select the Standard Cut if the copy image is standard size.

(Or the printed copy sheet should be standard size even if the copy image is not so.)

1. Press the Cut Mode Select Key (1).

The CUT MODE Indicator (2) lights, and it becomes

possible to change the setting value indicated on the

Indication Part (3).

2. Change the setting value (Cut Length) pressing both

the DECREASE Key and INCREASE Key (4).

Selectable setting values are A4, A3, A2, A1, A0, 48

and “SC”.

“SC” means the Synchronous Cut, and others are

standard sizes.

.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

C

CLEAR

1 4

MEDIA

2

3

Chapter 3 Useful Function 3-5

Page 49

3. 4 Adjusting the Leading/Trailing Margin

You can provide the copy with a Leading/Trailing Margin.

NOTE

It is impossible to provide a Trailing Margin when you copy with a cut sheet paper.

1. Whenever you press the LEAD/TRAIL Select Key (1),

the LEAD EDGE Indicator (2) and the TRAIL EDGE

Indicator (3) light alternately.

It is possible to change the setting value of Leading

Margin indicated on the Indication Part (4) when the

LEAD EDGE Indicator is lighting.

Similarly it is possible to change that of Trailing Margin

when the TRAIL EDGE Indicator is lighting.

2. Change the setting value pressing both the INCREASE Key

and DECREASE Key (4).

The unit of setting is millimetre.

Setting ranges are as follows.

Leading Edge : +/- 40mm in 5mm increment

Trailing Edge : 0 to +40mm in 5mm increment

2

3

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

1 4

Chapter 3 Useful Function 3-6

Page 50

3. 5 Multiple Copy

It is possible to make a multiple copy.

The maximum Copy Number is 19.

NOTE

1. It is impossible to make a multiple copy by the Cut Sheet Paper Feeding Mode.

2. Note that it is unable to make a multiple copy if the original is 1.25m or longer.

1. Confirm that the Ready Indicator on the Operation Panel is lighting.

Ready Indicator

2. If necessary, change such settings as Copy Density, Leading/Trailing Margin and so on.

(Refer to Chapter 3 as for the details of each setting.)

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

Chapter 3 Useful Function 3-7

Page 51

3. Specify Copy Number pressing both the INCREASE Key

and the DECREASE Key (1).

STAND BY

The Copy Number Indicator (2) indicates the Copy

Number you specified.

SL

If you wish to cancel the multiple copy after specifying

the Copy Number, press the STOP/ALL CLEAR Key (3).

The multiple copy is cancelled and the Copy Number

becomes 1.

FILM

VELLUM/TRACING

PLAIN PAPER

LIGHTER DARKER

MEDIA

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE INCRE ASE

STOP

ALL CLEAR

C

CLEAR

3

1 2

NOTE

As the Copy Number Indicator has only one digit, 10 or larger number is shown by flashing

the indication.

Supposing “3” is indicated on the Copy Number Indicator, the Copy Number is 3 sheets if “3”

is lighting, and it is “13 sheets” if it is flashing.

3 sheets 13 sheets

(“3” is flashing.)

ROLL

CUT SHEET

C

CLEAR DECREASE I NCREASE

ROLL

CUT SHEET

C

CLEAR DECREASE I NCREASE

Chapter 3 Useful Function 3-8

Page 52

4. Open the Original Table (4).

Move the Original Guide (5) according to the

width of original as needed.

5. Put the original with face down on the Original

Table, and then insert it under the Original Feed

Unit along the Original Guide (5) until the leading

edge touches the feeding roller.

Then, slide the Original Guide (5) fully to the

right.

The Original is transported a little, remains a

moment, and then transported for the scan.

NOTE

If the Original Guide (5) is not at the far right position, the WAIT Indicator lights and it is

impossible to start the multiple copy.

6. The CX 8020 scans the original as many times as the Copy Number by transporting forward

and backward.

(If the Copy Number is “8”, for example, the original is scanned 8 times successively.)

4

5

5

Chapter 3 Useful Function 3-9

Page 53

7. The Original is ejected from the Copy Exit after

scanning.

8. Copies are ejected from the Copy Exit.

Chapter 3 Useful Function 3-10

Page 54

3. 6 Power Saving Mode and Power OFF

Mode

You can enable the Power Saving Mode or the Power OFF Mode to save the power consumption

when the CX 8020 is not used for a long time.

3. 6. 1 Power Saving Mode

The Power Saving Mode is the function to reduce the power consume when you do not make any

operation for some period although you leave the CX 8020 ON.

You can work the Power Saving Mode manually or automatically.

Reference

The purpose of Power Saving Mode is to reduce the power consumption by reducing the

temperature of the fuser.

If you do not make any copy for the time you specified in advance, the machine automatically

goes into the Power Saving Mode so not to consume the power.

Or it is possible for you to make the machine go into the Power Saving Mode manually at

any time you wi

The Power Saving Mode will be cancelled if you press either STAND BY Key or STOP / ALL

CLEAR Key.

However please understand it may take time to recover from the Power Saving Mode

because it is necessary to heat up the fuser again.

(Copy is not available until CX 8020 becomes ready.)

3. 6. 1. 1 Power Saving Mode (Manual)

1. Press the STAND BY Key (1).

The Power Saving Mode works, so all the indications on

the Operation Panel are out.

To cancel the Power Saving Mode, press either

STAND BY Key or STOP / ALL CLEAR Key.

sh.

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE INCRE ASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

Chapter 3 Useful Function 3-11

Page 55

3. 6. 1. 2 Power Saving Mode (Automatic)

The Power Saving Mode automatically works if you do not make any copy for you specified in

advance.

1. Press the STAND BY Key (1) for 3 seconds.

The Indication Part (2) indicates “LP” (at first).

2. If you press the DECREASE Key or the INCREASE

Key (3), the Indication Part (2) indicates “LP” and “OF”

alternately.

“LP” means the Power Saving Mode

“OF” means the Power OFF Mode

As you will specify the timer for the Power Saving Mode

from now, indicate “LP”.

3. Press the STAND BY Key (1).

The Indication Part (2) indicates the present setting

of the timer of the Power Saving Mode.

4. Change the setting of timer pressing DECREASE Key and INCREASE Key (3).

The selectable values are 10, 30, 1h (1 hour), 2h and 4h.

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE INCREASE

STOP

ALL CLEAR

CLEAR

C

3

NOTE

It is possible to cancel the setting if you press the STOP/ALL CLEAR Key (4) in the middle of

setting.

5. When you have finished all the settings, press the STAND BY Key (1).

If you leave the machine without any operation for the time you specified, the Power

Saving Mode works automatically.

To cancel the Power Saving Mode, press either STAND BY Key or STOP / ALL CLEAR Key.

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE INCRE ASE

STOP

ALL CLEAR

CUT MODE

DECREASE INCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

C

CLEAR

2

3

Chapter 3 Useful Function 3-12

Page 56

3. 6. 2 Power OFF Mode

The Power OFF Mode is the function to turn off the CX 8020 automatically if you do not make any

copies in the time you specified in advance.

Reference

The purpose of Power OFF Mode is not to consume any power by turning off the machine

automatically. It can save more power than the Power Saving Mode.

If you will make copies after the machine has been turned off by the Power OFF Mode, it is

necessary to turn on the machine again.

1. Press the STAND BY Key (1) for 3 seconds.

The Indication Part (2) indicates “LP” at first.

2. If you press the DECREASE Key or the INCREASE

Key (3), the Indication Part (2) indicates “LP” and “OF”

alternately.

“LP” means the Power Saving Mode

“OF” means the Power OFF Mode

As you will specify the timer for the Power OFF Mode,

indicate “OF”.

3. Press the STAND BY Key (1).

The Indication Part (2) indicates either “on” or “off”, which is

the present setting of the Power OFF Mode.

on Power OFF Mode works.

off Power OFF Mode does not work.

Select “on” pressing the DECREASE Key or the INCREASE

if you will make the Power OFF Mode work.

NOTE

If you select “off”, the setting is completed.

4. Press the STAND BY Key (1).

The Indication Part (2) indicates the present setting value of the timer specified to the Power

Saving Mode.

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCR

LEAD ED

TRAIL E

LIGHTER DARKER

C

GE

DGE

DECREASE INCRE ASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

EASE

2

3

Chapter 3 Useful Function 3-13

Page 57

5. Change the setting value of timer by pressing DECREASE Key and INCREASE Key (3).

The selectable values are 10, 30, 1h (1 hour), 2h and 4h.

LEAD EDGE

TRAIL EDGE

CUT MODE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE INCREASE

STOP

ALL CLEAR

CLEAR

DECREASE INCREASE

C

3

STOP

ALL CLEAR

C

CLEAR

NOTE

It is possible to cancel the setting if you press the STOP/ALL CLEAR Key (4) in the middle of

setting.

6. When you have finished all the settings, press the STAND BY Key (1).

If you leave the machine without any operation for the time you specified,

the CX 8020 is turned off automatically by the Power OFF Mode.

NOTE

If both the Power Saving Mode (Automatic) and the Power OFF Mode are ON, the Power

OFF Mode has the priority.

<Example 1>

Power Saving Mode Power OFF Mode

Timer 30 minutes 120 minutes

The Power Saving Mode works 30minutes later if you make no operation.

Then the Power OFF Mode works 90 minutes later since the Power Saving Mode has

worked.

<Example 2>

Power Saving Mode Power OFF Mode

Timer 60 minutes 60 minutes

The Power OFF Mode works 60minutes later if you make no operation, but the Power

Saving Mode does not work.

<Example 3>

Power Saving Mode Power OFF Mode

Timer 60 minutes 30 minutes

The Power OFF Mode works 30minutes later if you make no operation, but the Power

Saving Mode does not work.

Chapter 3 Useful Function 3-14

Page 58

3. 7 Dehumidifying the Roll Media

If the roll media has too much moisture, the toner may not be fixed correctly to the media.

And also, void of image, double feeding, creasing might occur.

If the room has humidity, turn on the Dehumidify Heater to dehumidify the interior of the

machine.

Open the Front Door (1), and the Dehumidify Heater Switch (2) appears.

Press “H” side of the switch to turn on the Dehumidify Heater.

1

2

Chapter 3 Useful Function 3-15

Page 59

3. 8 Sample Copy

Sample Copy is a function to copy only the leading part (about 280mm) of original for the purpose

to check the copy image in advance.

You can check the result of copy without consuming a great deal of toner or media if needed.

1. Press the DECREASE Key (1) when the Copy

Number Indicator (2) is indicating “1”.

The Copy Number Indicator (2) indicates “P”.

2. Set the Original to the CX 8020.

The original is transported about 280mm long for the Sample Copy, and then it is returned to

the front.

The Sample Copy about 280mm long is ejected from the Copy Exit.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

2

1

Chapter 3 Useful Function 3-16

Page 60

Chapter 4

Error Treatment

Page

4. 1 Call Operator Errors 4- 2

4. 1. 1 Mis-feed Errors 4- 2

4. 1. 1. 1 Code “J0” : Original Mis-feed 4- 4

4. 1. 1. 2 Code “J1” : Paper Mis-feed at Paper Entrance Area 4- 5

4. 1. 1. 3 Code “J2” : Paper Mis-feed at Paper Turning Area 4- 7

4. 1. 1. 4 Code “J3” : Paper Mis-feed at Print Area or Copy Exit Area 4- 9

4. 1. 1. 5 Code “J4” : Incorrect insertion of Cut Sheet Paper 4-13

4. 1. 1. 6 Code “J5” : Mis-feed of cut sheet paper at Paper Turning Area 4-14

4. 1. 1. 7 Code “J6” : Mis-feed of cut sheet paper (Incorrect size) 4-17

4. 1. 2 Other Errors 4-20

4. 1. 2. 1 Roll Empty 4-20

4. 1. 2. 2 Toner Empty 4-20

4. 1. 2. 3 Waste Toner Full 4-21

4. 1. 2. 4 Incorrect set of original or cut sheet paper

(READY & WAIT Indicators flash simultaneously) 4-21

4. 2 Call Service Errors 4-22

Chapter 4 Error Treatment 4-1

Page 61

4. 1 Call Operator Errors

4. 1. 1 Mis-feed Errors

If the copying paper or the original is mis-fed anywhere in the machine, the Mis-feed Indicator (1)

on the Operation Panel (2) lights to inform you of the error.

At the same time any Mis-feed Code (J0, J1, J2, J3, J4, J5 or J6) is indicated on the Indication Part

(3) to let you know where the mis-feed has occurred.

2

The following figure is the section of the CX 8020 which shows the location of each mis-feed.

(More detailed explanation for each code is described on the later pages.)

Rear

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

1

3

Front

Chapter 4 Error Treatment 4-2

Page 62

NOTE

(1) Carefully remove the mis-fed paper as its edge may be very sharp, or you may harm

your hand.

(2) Remove a necklace, a bracelet and a wristwatch from yourself before removing the

mis-fed paper.

Otherwise you may be burnt or get an electric shock when such metal accessory touches

the inside of the printer.

(3) The toner image is not fixed firmly if the paper did not reach the heater section.

Therefore be careful not to soil your cloth with the toner when you remove the mis-fed

paper.

Please dust the toner if your cloth is soiled.

If it is unable to dust it, wash the cloth with the cold water.

(Do not use the hot water at this time because the toner will soak into fibre.)

(4) The toner image is not fixed firmly if the paper did not reach the heater section.

Therefore be careful that the toner should not get into your eye, or be careful not to

inhale the toner.

(Please wash out with water if it gets into your eye or mouth.)

Chapter 4 Error Treatment 4-3

Page 63

4. 1. 1. 1 Code “J0” : Original Mis-feed

Mis-feed Code “J0” is indicated when the original is mis-fed

under the Original Feed Unit.

Rear

Front

Remove the mis-fed original in the following direction.

1. Open the Original Feed Unit (1), and remove the

original.

2. Close the Original Feed Unit (1).

NOTE

“J0” is also indicated if you cancel copying in the middle pressing the STOP/ALL CLEAR

Key.

Please remove the original in the above shown direction in this case.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

1

MEDIA

C

CLEAR

Chapter 4 Error Treatment 4-4

Page 64

4. 1. 1. 2 Code “J1” : Paper Mis-feed at Paper Entrance Area

Mis-feed Code “J1” is indicated when the paper is mis-fed at the

Paper Entrance Area.

Rear

Remove the mis-fed original in the following direction.

1. Open the Front Door (1).

2. Bring up the Feeding Roller Cover (2).

Front

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

CLEAR

2

MEDIA

C

1

Chapter 4 Error Treatment 4-5

Page 65

3. Rewind the roll paper completely.

Then, set the roll paper again.

NOTE

If it is difficult to set the paper again as its leading edge is folded or torn, cut it off by the

cutter or scissors.

4. Bring down the Feeding Roller Cover (2), and

close the Front Door (1).

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

2

1

Chapter 4 Error Treatment 4-6

Page 66

4. 1. 1. 3 Code “J2” : Paper Mis-feed at Paper Turning Area

Mis-feed Code “J2” is indicated when the paper is mis-fed at the

Paper Turning Area.

Rear

Remove the mis-fed original in the following direction.

1. Open the Front Door (1).

2. Bring up the Feeding Roller Cover (2).

Front

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE INCRE ASE

STOP

ALL CLEAR

2

MEDIA

CUT MODE

C

CLEAR

1

Chapter 4 Error Treatment 4-7

Page 67

3. Rewind the roll paper completely.

Then, set the roll paper again.

NOTE

If it is difficult to set the paper again as its leading edge is folded or torn, cut it off by the

cutter or scissors.

4. Bring down the Feeding Roller Cover (2), and

close the Front Door (1).

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

2

1

Chapter 4 Error Treatment 4-8

Page 68

4. 1. 1. 4 Code “J3” : Paper Mis-feed at Print Area or Copy Exit Area

Mis-feed Code “J3” is indicated in either of the following

cases.

(1) The paper is mis-fed at the Print Area.

(Print Area is between Drum and Fuser in the following

drawing.)

(2) The paper is mis-fed around the Copy Exit.

Rear

Front

Remove the mis-fed original in the following direction.

1. Open the Exit Cover (1), and check if you can find

the mis-fed paper.

Go to the following step “2” if you can find it.

Jump to the step “4” on the next page if you can

not find it.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

1

Chapter 4 Error Treatment 4-9

Page 69

2. Hold the mis-fed paper by both hands and pull it out

carefully without breaking.

NOTE

(1) Be careful not to touch on the Fuser Roller and the surrounding parts as they are very

hot. You will be burnt if you touch such parts.

(2) Be careful not to touch the Stripper Fingers as they are very sharp. Otherwise you may

be hurt.

3. Close the Exit Cover.

NOTE

It is recommended to make Initial Cut after removing the mis-fed paper, as the cut paper

will remove the toner dirt on the Heat Roller or some other parts.

(The copy may have some dirty image if you do not make it.)

Refer to [3. 1 Initial Cut] on the page 3-2 for the way of Initial Cut.

4. Open the Upper Unit (2).

2

Chapter 4 Error Treatment 4-10

Page 70

5. There are Levers (3) at both sides of the

Corner Transport Unit (4).

Pull both Levers (3) inward to open the Corner

Transport Unit (4) backward.

6. Remove the mis-fed paper gently.

NOTE

There is a Photoconductive Drum (large cylinder) on the bottom of the Upper Unit.

Do not touch the drum when you remove the mis-fed paper or when you

open/close the Corner Transport Unit!

Do not leave the Upper Unit open for a long period as the Photoconductive Drum is very

sensitive to light. (Direct sunlight is very harmful.)

That stated, remove the mis-feed media and then close the Upper Unit immediately after

the media is removed. Do not leave upper unit open!

If the Drum is damaged, you will have to replace it, as it is a very important part in

creating the print image.

3

4

3

Chapter 4 Error Treatment 4-11

Page 71

7. Close the Corner Transport Unit (4) and lock it moving the Levers (3) outward.

8. Close the Upper Unit finally.

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

Chapter 4 Error Treatment 4-12

Page 72

4. 1. 1. 5 Code “J4” : Incorrect insertion of Cut Sheet Paper

Mis-feed Code “J4” is indicated when you insert the cut sheet

paper to the Bypass Feeder mistakenly when the CX 8020 is

copying with the roll paper.

Rear

Front

Pull out the cut sheet paper from the Bypass Feeder.

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

CUT MODE

CLEAR

MEDIA

C

Chapter 4 Error Treatment 4-13

Page 73

4. 1. 1. 6 Code “J5” : Mis-feed of cut sheet paper at Paper Turning

Area

Mis-feed Code “J5” is indicated when the cut sheet paper is

mis-fed at the Paper Turning Area.

Rear

Front

Remove the mis-fed original in the following direction.

1. Open the Upper Unit (1).

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

Chapter 4 Error Treatment 4-14

Page 74

2. There are Levers (2) at both sides of the

Corner Transport Unit (3).

Pull both Levers (2) inward to open the Corner

Transport Unit (3) backward.

3. Remove the mis-fed paper gently.

NOTE

There is a Photoconductive Drum (large cylinder) on the bottom of the Upper Unit.

Do not touch the drum when you remove the mis-fed paper or when you

open/close the Corner Transport Unit!

Do not leave the Upper Unit open for a long period as the Photoconductive Drum is very

sensitive to light. (Direct sunlight is very harmful.)

That stated, remove the mis-feed media and then close the Upper Unit immediately after

the media is removed. Do not leave upper unit open!

If the Drum is damaged, you will have to replace it, as it is a very important part in

creating the print image.

2

3

2

Chapter 4 Error Treatment 4-15

Page 75

4. Close the Corner Transport Unit (3) and lock it moving the Levers (2) outward.

5. Close the Upper Unit finally.

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

Chapter 4 Error Treatment 4-16

Page 76

4. 1. 1. 7 Code “J6” : Mis-feed of cut sheet paper (Incorrect size)

Mis-feed Code “J6” is indicated when you set a cut sheet

paper of incorrect size.

(Incorrect size means shorter than 279mm or longer than

3 meters.)

Rear

Front

Remove the mis-fed original in the following direction.

1. Open the Upper Unit (1).

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

Chapter 4 Error Treatment 4-17

Page 77

2. There are Levers (2) at both sides of the

Corner Transport Unit (3).

Pull both Levers (2) inward to open the Corner

Transport Unit (3) backward.

3. Remove the mis-fed paper gently.

NOTE

There is a Photoconductive Drum (large cylinder) on the bottom of the Upper Unit.

Do not touch the drum when you remove the mis-fed paper or when you

open/close the Corner Transport Unit!

Do not leave the Upper Unit open for a long period as the Photoconductive Drum is very

sensitive to light. (Direct sunlight is very harmful.)

That stated, remove the mis-feed media and then close the Upper Unit immediately after

the media is removed. Do not leave upper unit open!

If the Drum is damaged, you will have to replace it, as it is a very important part in

creating the print image.

2

3

2

Chapter 4 Error Treatment 4-18

Page 78

4. Close the Corner Transport Unit (3) and lock it moving the Levers (2) outward.

5. Close the Upper Unit finally.

NOTE

Confirm that the Mis-feed Indicator is put out and the Paper Mis-feed Code disappears

after removing the mis-fed paper.

If the Mis-feed Indicator lights again, some more paper may be mis-fed anywhere in the

machine, so please check other areas as well.

Chapter 4 Error Treatment 4-19

Page 79

4. 1. 2 Other Errors

4. 1. 2. 1 Roll Empty

The Roll Empty Indicator (1) lights if the roll paper is emptied

in the middle of copying.

Please replace the roll paper making reference to

[2.3 Replacing the Roll Paper] on the page 2-5.

4. 1. 2. 2 Toner Empty

The Toner Empty Indicator (1) lights if the toner is emptied in

the middle of copying.

Please add the toner to the machine making reference to

[2.4 Add the Toner] on the page 2-9.

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

CUT MODE

C

CLEAR

Chapter 4 Error Treatment 4-20

Page 80

4. 1. 2. 3 Waste Toner Full

The Waste Toner Full Indicator (1) lights when the Waste

Toner Bottle is filled with the toner.

STAND BY

Replace the Waste Toner Bottle with the new one making

reference to [2.7 Replacing the Waste Toner Bottle] on the

SL

page 2-20.

FILM

VELLUM/TRACING

PLAIN PAPER

LIGHTER DARKER

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

CLEAR

4. 1. 2. 4 Incorrect set of original or cut sheet paper

(READY & WAIT Indicators flash simultaneously)

Both the READY Indicator (1) and the WAIT Indicator (2)

flash simultaneously if either original or cut sheet paper is

incorrectly set to the machine.

Remove the original/cut sheet paper and set it again correctly.

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

C

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

STOP

ALL CLEAR

1 2

LIGHTER DARKER

CUT MODE

DECREASE I NCREASE

CLEAR

1

MEDIA

C

MEDIA

C

Chapter 4 Error Treatment 4-21

Page 81

4. 2 Call Service Errors

If the machine has a fatal error, the Service Call Indicator (1)

lights to inform you of the error.

Also the Indication Part (2) indicates any of the following Error

Code.

Error Code Name of the error

E0 Fuser Error (High Temperature)

E1 Fuser Error (Low Temperature)

E2 EEPROM Error

E3 Cutter Error (Time Over)

E4 Cutter Error (Switch Abnormal)

E6 Pocket Door Error (Time Over)

E7 Pocket Door Error (Switch Abnormal)

E9 Exposure Lamp Error (Dark)

EA Exposure Lamp Error (Bright)

EC Counter Error

ED Developer Motor Error

EE Main Motor Error

EF Fuser Motor Error

It is impossible for the user to cure these errors to resolve these issues.

PLEASE CALL YOUR TRAINED SERVICE PERSONNEL TO RESOLVE THESE ERRORS.

If any of the above errors is displayed:

1) Turn off the machine, wait approximately 30 seconds, and then turn on the machine again.

2) If the same error code is displayed, turn off the machine, and then unplug the machine from

the wall outlet.

Call your service personnel.

1

STAND BY

SL

FILM

VELLUM/TRACING

PLAIN PAPER

ROLL

CUT SHEET

CLEAR DECREASE INCREASE

LEAD EDGE

TRAIL EDGE

LIGHTER DARKER

C

CUT MODE

DECREASE I NCREASE

STOP

ALL CLEAR

MEDIA

C

CLEAR

2

Chapter 4 Error Treatment 4-22

Page 82

Chapter 5

Cleaning and Checking

Page

5. 1 Cleaning of Each Part 5- 2

5. 1. 1 Original Feeding Part 5- 2

5. 1. 2 Original Guide 5- 2

Chapter 5 Cleaning and Checking 5-1

Page 83

5. 1 Cleaning of Each Part

The following parts tend to get dirt, so clean them once in a week.

(If they are dirty the copy quality will not be good.)

5. 1. 1 Original Feeding Part

1. Open the Original Feed Unit (1).