Page 1

22051EISE

102 mm

47 mm

44

0

2

3

1

0

2

3

1

6

7

5 5

9

8

6 9

87

0832

0832-CPD-0199

B501AP

60°C

112.5g

-20°C

T4

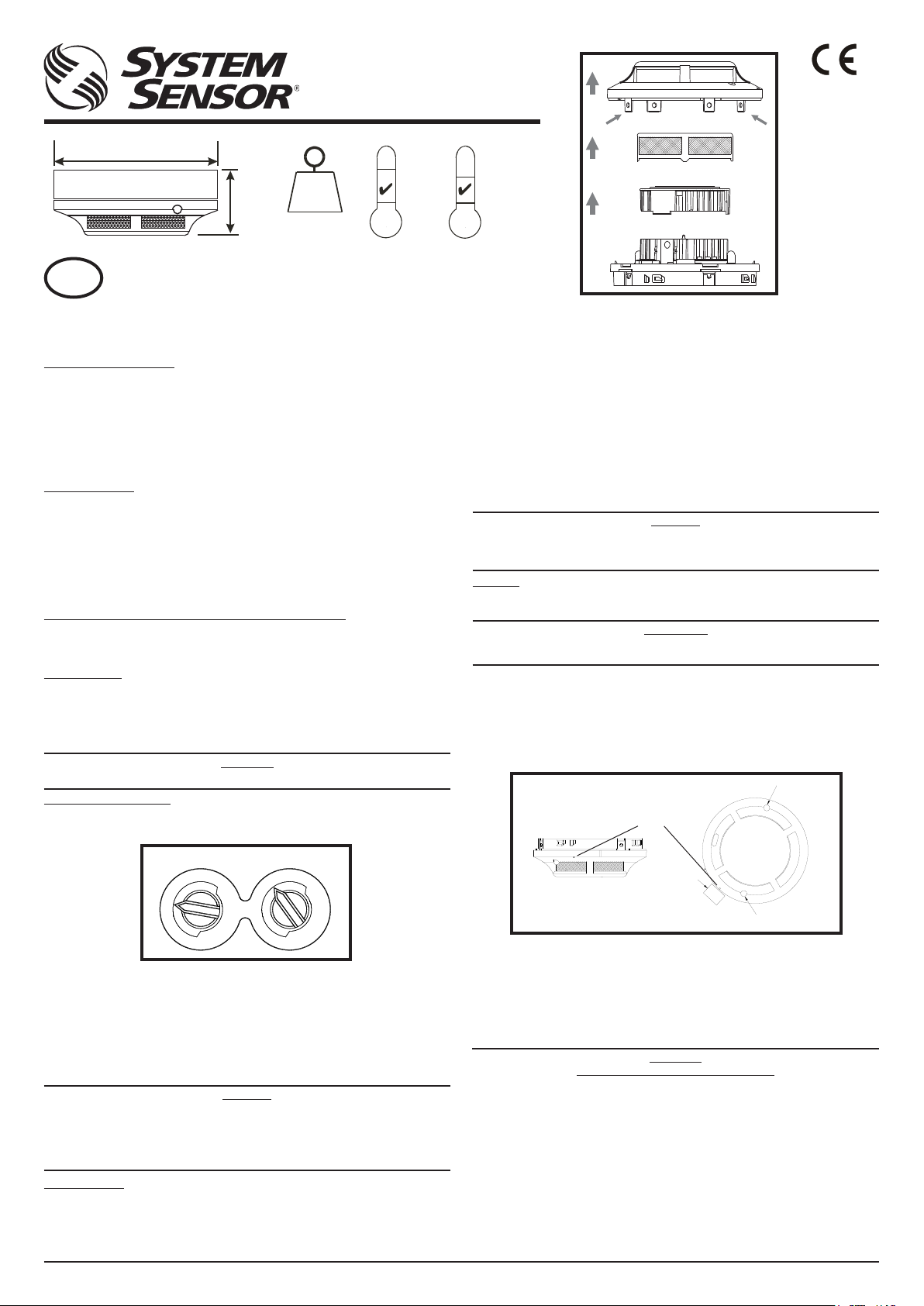

INSTALLATION AND MAINTENANCE INSTRUCTIONS

EN

FOR MODEL 22051EISE INTRINSICALLY SAFE

INTELLIGENT PHOTO ELECTRONIC SMOKE SENSOR

Before installing the sensor, please thoroughly read System Sensor Europe’s “Guide

to Intelligent Fire Systems”. Copies of this manual are available at no charge from

System Sensor.

GENERAL DESCRIPTION

Model 22051EISE is an intrinsically safe smoke detector that combines a photo

electronic sensing chamber with analogue addressable communications and is for use

in hazardous areas where potentially explosive atmospheres are likely to arise. The

classification of equipment required must be confirmed with your responsible authority.

The sensor communicates via a dedicated Galvanic Isolator Barrier with an IST200

Translator Module which relays the data to the Control Panel. Rotary decade switches

are provided for setting the sensor address.

Two LEDs on each sensor provide a local 360° visible sensor indication.

SPECIFICATIONS

Operating Voltage Range: 15 to 24 VDC

Max. Avg. Standby Current: 220 µA @20 VDC (One communication every 5

Max. Alarm Current (LED on): 3 mA @ 24 VDC

Operating Humidity Range: 10% to 93% Relative Humidity, Non-Condensing

Intrinsic Safety Rating: Ex ia IIC T5, T4

This detector has been independently tested and certified to EN54 part 7: 2000 and

BASEEFA approved for intrinsic safety.

ACCESSORIES (Available Separately from System Sensor)

IST200 Translator Module May drive up to 15 22051EISE sensors

Pepperl and Fuchs Y72221 Dedicated Galvanic Isolator Barriers for

WIRING GUIDE

Refer to the installation instructions supplied with the IST200 Translator Module, and

B501AP Base for wiring details.

Note 1: All wiring must conform to applicable local and national codes and regulations.

Note 2: Verify that all sensor bases are installed and that polarity of the wiring is

correct at each base.

Disconnect loop power before installing sensors. Notify proper authorities.

SENSOR INSTALLATION

1. Set the sensor address (see figure 2) by turning the two rotary switches, selecting a

number between 01and 99. Record the address on the label attached to the base.

Figure 2: Rotary Decade Address Switch

sec. With LED blink enabled)

22051EISE (drive up to 15 sensors).

WARNING

40°C

-20°C

T5

4. Remove the sensor screen. Pull the screen straight away from the sensing chamber

until it snaps out of place.

5. Remove the chamber cover by pulling it gently away from the sensing chamber until

it snaps out of place.

6. Use a vacuum cleaner and/or clean, compressed air to remove dust and debris

from the sensing chamber and sensing chamber cover.

7. Re-install the sensing chamber cover by aligning the arrow moulded on the cover

with the arrow printed on the circuit board and sliding the cover over the chamber,

gently pressing it home until it snaps into place.

8. Re-install the sensing chamber screen by sliding it over the sensing chamber.

Rotate the screen until the locating tabs on the bottom rim locate in the cutouts in

the chamber base, and the top of the screen is flush with the top of the chamber.

9. Re-install the sensor cover. Use the cover removal tabs and LEDs to align the cover

with the sensor. Snap the cover into place.

10. When all sensors have been cleaned, restore power to the loop and test the sensor(s)

as described under TESTING.

CAUTION

The Detector has a plastic enclosure that may present an electrostatic risk and

must not be installed in a position where it may be subject to a high dust-laden

air flow. Clean only with a damp cloth and do not rub.

TESTING

Sensors must be tested after installation and following periodic maintenance. Disable

the zone or system undergoing maintenance to prevent unwanted alarms.

IMPORTANT

If testing is carried out using non-intrinsically safe methods, it must be

conducted outside the hazardous area.

Test the sensors as follows:

Magnet Test Method

1. Test the sensor by positioning the test magnet (model M02-04-00 optional) against

the sensor body approximately 2cm from LED 1, indicated by a mark on the detector

cover as shown in figure 3.

2. Both LED’s on the detector should latch into alarm within 30 seconds, activating the

control panel.

Figure 3: Test Magnet Position

Mark on Cover

Test Magnet

Figure 1: Cleaning

the Sensor

LED 2

TENS

2. Insert the sensor into the base and rotate it clockwise until it locks into place.

3. After all the sensors have been installed, apply power to the system.

4. Test the sensor as described under TESTING.

5. Reset the sensor by communication command from the panel.

Tamper-Resistance.

Model 22051EISE includes a feature that, when activated, prevents removal of the

sensor without the use of a tool. Refer to the installation instructions for the sensor

base for details of how to use this feature.

Dust covers help to protect units during shipping and when first installed.

They are not intended to provide complete protection against contamination

therefore sensors should be removed before construction, major re-decoration

or other dust producing work is started. Dust covers must be removed before

MAINTENANCE

Before cleaning, disable the system to prevent unwanted alarms:

1. Remove the sensor to be cleaned from the system.

2. Gently release each of the four cover removal tabs that hold the cover in place (see

figure 1) and remove the cover.

3. Vacuum the outside of the screen carefully without removing it.

system can be made operational.

CAUTION

UNITS

LED 1

Smoke Method

1. Using generated smoke, or synthetic smoke aerosol from an approved manufacturer

such as No Climb Products Ltd, subject the detector to controlled amounts of smoke

in accordance with local codes of practice and manufacturer recommendations.

2. Both LED’s on the detector should latch into alarm within 30 seconds, activating the

control panel.

After completion of the test notify the proper authorities that the system is operational.

WARNING

LIMITATIONS OF SMOKE DETECTORS

Smoke detectors must be used in conjunction with compatible equipment.

Smoke detectors will not sense fires which start where smoke does not reach the

detectors.

A detector may not detect a fire developing on another level of a building.

Smoke detectors also have sensing limitations. Consideration must be made of the

environment when selecting fire detectors.

Smoke detectors cannot last forever. Smoke detectors contain electronic par ts. Even

though detectors are made to last over 10 years, any of these parts could fail at any

time. Therefore, test your smoke detector system at least semiannually. Clean and take

care of your smoke detectors regularly. Taking care of the fire detection system you

have installed will significantly reduce your product liability risks.

Pittway Tecnologica Srl, Via Caboto 19/3, 34147 Trieste, ITALY I56-3310-003D200-51-00

Page 2

22051EISE System Diagram

0.083 4.2 55

0.65 12.6 210

2.15 33.6 444

SAFE AREA

Control

Panel

Safe area apparatus, which is

unspecified except that it must not be

supplied from or contain under normal

or abnormal conditions a source of

potential with respect to earth in excess

of 253 Vrms or 253 VDC

Maximum Permissible Capacitance,

Inductance and Impedance Figures Across

Terminals 1 and 2 on a B501AP Base

Capacitance µFInductance mHL/R Ratio

Group

IIC

IIB

IIA

IST200

Translator

Module

Table 1 Table 2

Shunt Zener

Diode Safety

Barrier or

Isolation

Barrier (see

Note 1.)

µH/Ohm

HAZARDOUS AREA

(See Note 2)

To Next

Detector(s)

4 (+)

1 (-)

2 (+)

B501AP

2 & 4 linked in base

22051EISE

Smoke Detector

II1G Ex ia IIC T5, T4

Baseefa08ATEX0278X

B501AP Pins Connection

1

2

4

-V IN, -V OUT

+V IN

+V OUT

Notes:

1. Any single channel shunt zener diode safety barrier or single channel of a

dual channel shunt zener diode safety barrier certified by Baseefa or any EEC

approved certification body to [EEx ia] IIC having the following or lower output

parameters:

Uz = 28V; Imax: out = 93.3 mA; Wmax: out = 0.66 W

In any safety barrier used, the output current must be limited by a resistor “R”,

such that Imax:out = Uz/R. Or any of the following isolation barriers may be

used:

P & F Smart Fire Detector Isolator Type KFDO-CS-Ex1.54-Y72221

One channel from: P & F Smart Fire Detector Isolator Type KFDO-CS-Ex2.54-

Y72222 (BAS00ATEX7087X)

2. The capacitance and either inductance or inductance/resistance (L/R) ratio of

the cable connected to the hazardous area terminals of barrier must not exceed

the values shown in Table 1.

3. The installation must comply with the appropriate national installation

requirements, e.g. in the U.K. to BSEN60079-14: 1997.

4. The electrical circuit in the hazardous area must be capable of withstanding

an A.C. test voltage of 500 VRMS to earth or frame of the equipment, for a

period of one minute without breakdown. This note does not apply when using

an isolation barrier.

R12-172-00, REV G

Please refer to control panel installation instructions for specific barrier/control panel

CAUTION

compatibility information.

0832

0832-CPD-0199

EC DECLARATION OF CONFORMITY

Date of issue: 07 November 2012

Pittway Tecnologica Srl

Manufacturer:

Product: 22051EIS

Bases: B501, B501AP

Description:

We hereby declare that the product identified above meets the requirements of the following EC

Directives and therefore qualify for free movement within markets comprising the European Union

(EU) and the European Economic Area (EEA):

EMC Directive 2004/108/EC

EU Construction Products Directive, 89/106/EEC

Conforms to: EN54 - 7: 2000 + A1: 2002 + A2:2006

Notified Body: BRE - LPCB

Notified Body Number: 0832

EC Certificate Number 0832-CPD-0199

ATEX 94/9/EEC

Conforms to:

Notified Body: Baseefa

Notified Body Number: 1180

Certificate Number Baseefa08ATEX0278X

Rating

For and on behalf of

Pittway Tecnologica S.r.l.

Marco Corti

Plant Manager

Via Caboto 19/3

34147 TRIESTE

Italy

E

Intrinsically Safe Analogue addressable photoelectric smoke detector

EN60079-0: 2006, EN60079-11: 2007

EN60079-26:2007

II 1G Ex ia IIC T5 / T4 Ga (-20°C ≤Ta≤ 40°C/60°C)

Pittway Tecnologica S.r.l.

a socio unico

Via Caboto 19/3

34147 TRIESTE (Italy)

Tel: +39-040-9490111

Fax: +39-040-382137

N. IVA IT 00744320326

Reg. Impr. TS n. 10331 Trib. TS

R.E.A. N. 97799

Cap.Soc. € 1.368.619,00 int. vers.

P.IVA e Cod. Fisc. 00744320326

Page 3

22051EISE

102 mm

47 mm

44

0

2

3

1

0

2

3

1

6

7

5 5

9

8

6 9

87

0832

0832-CPD-0199

B501AP

60°C

112.5g

-20°C

T4

INSTALLATIONS- UND WARTUNGSANLEITUNG FÜR

D

MODELL 22051EISE EIGENSICHERER INTELLIGENTER

OPTISCHER RAUCHMELDER

Bevor Sie mit der Installation des Brandmelders beginnen, lesen Sie bitte sorgfältig die

Anleitung zum Umgang mit intelligenten Brandmeldesystemen. Kopien dieser Anleitung

sind kostenlos bei System Sensor erhältlich.

ALLGEMEIN

Das Modell 22051EISE ist ein eigensicherer Rauchmelder, der eine optische

Sensorkammer mit einer analog adressierbaren Kommunikation verbindet und ist für

die Verwendung in Gefahrenbereichen, in denen mit einer explosiven Atmosphäre

gerechnet werden muss. Die Klassifizierung der erforderlichen Baugruppen muss den

Anforderungen der zuständigen Behörde entsprechen. Der Sensor kommunizier t über

eine geeignete galvanische Trennungsbarriere mit einem IST200 Übersetzermodul,

welches die Daten an das Bediengerät weiterleitet. Für die Einstellung der

Sensoradresse stehen Dekadendrehschalter zur Verfügung.

Die beiden LED ermöglichen eine optische Erkennung des Sensorzustandes im

Bereich von 360 Grad.

SPEZIFIKATION

Betriebsspannungsbereich: 15 bis 24 VDC

Maximaler Durchschnittsruhestrom: 220 µA bei 20 VDC (Datenkommunikation alle 5

Maximaler Strom im Alarmfall: 3 mA bei 24 VDC (LED ein)

Bereich der Luftfeuchtigkeit: 10% bis 93% relative Feuchte, ohne Betauung

Einstufung der Eigensicherheit: Ex ia IIC T5 (40o to -20oC), T4 (60o to -20oC)

Dieser Melder wurde unabhängig getestet und gemäß den Anforderungen für

Eigensicherheit der EN54 Teil 7 (2000) und BASEEFA zertifiziert.

ZUBEHÖR (Optional erhältlich von System Sensor)

IST200 Übersetzermodul: Für bis zu 15 Sensoren 22051EISE

Pepperl und Fuchs Y72221: Geeignete Galvanische Trennung für Sensor

VERDRAHTUNG

Weitere Verdrahtungsdetails finden Sie in der mitgelieferten Installationsanleitung des

IST200 Übersetzermoduls sowie des B501AP Meldersockels.

HINWEIS: Die Verdrahtung muss den lokalen und nationalen Normen und

Anforderungen entsprechen.

HINWEIS: Stellen Sie sicher, dass alle Meldersockel angeschlossen sind und die

Polarität der Verdrahtung an jedem Sockel korrekt ist.

Melder nur im spannungsfreien Zustand installieren. Beachten Sie die

SENSOR INSTALLATION

1. Stellen Sie die Sensoradresse durch Drehen der beiden Drehschalter ein (siehe

Abb.2). Wählen Sie eine Adresse zwischen 01 und 99. Notieren Sie die Adresse

auf dem Aufkleber am Meldersockel.

2. Setzen Sie den Melder in den Meldersockel und drehen ihn im Uhrzeigersinn bis er

einrastet.

3. Nachdem alle Melder installiert sind schalten Sie die Spannungsversorgung ein.

4. Prüfen Sie den Melder wie im Abschnitt PRÜFUNG beschrieben.

5. Setzen Sie den Sensor mit Hilfe des Kommunikationsbefehls der Bedienkonsole

zurück.

Abb. 2: Rotary Decade Address Switch

Sekunden bei aktivierter blinkender LED)

22051EISE (bis zu 15 Sensoren 22051EISE).

WARNUNG

dazugehörigen Vorschriften.

40°C

-20°C

T5

WARTUNG

Zur Vermeidung von Fehlalarmen sollte das System bzw. die entsprechende

Meldergruppe vor den Wartungsarbeiten abgeschaltet werden.

1. Entfernen Sie den zu reinigenden Sensor aus dem System.

2. Lösen Sie behutsam jede der vier Halterungen und entfernen Sie die Abdeckung

(siehe Abb.1).

3. Saugen Sie vorsichtig die Außenseite des Schutzgitters ab ohne dieses zu entfernen.

4. Entfernen Sie das Schutzgitter indem Sie es gerade von der Sensorkammer abziehen.

5. Ziehen Sie die Abdeckung der Sensorkammer vorsichtig ab.

6. Verwenden Sie einen Staubsauger oder saubere Druckluft um Staub und

Ablagerungen von der Sensorkammer oder dem Sensorgehäuse zu entfernen.

7. Befestigen Sie die Abdeckung der Sensorkammer wieder auf der Platine in dem

Sie die Abdeckung an den Markierungspfeilen ausrichten und mit leichtem Druck

einrasten lassen.

8. Führen Sie das Schutzgitter über die Sensorkammer und drehen es, bis die

Befestigungspunkte am unteren Rand in die Aussparungen des Meldersockels

passen und die Oberseite bündig mit der Sensorkammer abschließt.

9 Montieren Sie das Sensorgehäuse, in dem Sie es an den vier Befestigungspunkten

und den LED ausrichten und mit leichtem Druck einrasten lassen.

10 Nachdem alle Sensoren gereinigt wurden, schalten Sie die Ringleitung wieder ein

und prüfen Sie alle Sensoren auf Funktion wie im Abschnitt PRÜFUNG beschrieben.

Das Meldergehäuse besteht aus Kunststoff und kann elektrostatisch

aufgeladen werden. Der Melder sollte deshalb nicht in einer Umgebung

installiert werden, in der mit einer staubhaltigen hohen Luftbewegung

gerechnet werden kann. Reinigung nur mit einem feuchten

PRÜFUNG

Die ordnungsgemäße Funktion der installierten Melder ist zu prüfen. Weiterhin ist eine

regelmäßige Wartung erforderlich. Zur Vermeidung von Fehlalarmen schalten Sie die

entsprechende Meldergruppe oder das System ab. Vor Beginn der Servicearbeiten sind

die entsprechenden Interventionskräfte und Beteiligten über die Ausser-betriebnahme

der Anlage zu informieren. Schalten Sie die Meldergruppen und Alarm-weiterleitung ab,

um unerwünschte Alarmmeldungen während der Wartung zu vermeiden.

Bei Prüfungen, die nicht den Methoden für eigensichere Baugruppen

entsprechen, muss die Durchführung außerhalb des

Prüfen Sie den Melder wie folgt:

Magnet Test (Option, Artikel-Nr. M02-04-00)

1. Um den Melder zu prüfen halten Sie den Testmagnet in einer Entfernung von ca.

2cm zur LED 1 direkt an die Markierung am Meldergehäuse (siehe Abb.3).

2. Beide LED sollten innerhalb von 30 Sekunden leuchten und die Alarmauslösung

lokal und an der Brandmelderzentrale anzeigen.

LED 2

ACHTUNG

Tuch ohne Scheuern.

WICHTIG:

Gefahrenbereiches erfolgen.

Abb.3: Position des Testmagneten

Abb.1:

Reinigung des

Rauchmelders

TENS

UNITS

Sabotageschutz / Entnahmesicherung

Der Meldersockel verfügt über eine Entnahmesicherung die das Entfernen des

Brandmelders aus dem Sockel nur mit Hilfe eines Werkzeuges zulässt. Beachten Sie

die Installationshinweise des Meldersockels für detaillierte Informationen zu diesem

Leistungsmerkmal.

Der Melder ist werkseitig mit einem Staubschutz vor Verschmutzung während

des Transportes oder der Erstinstallation geschützt. Ein vollständiger Schutz

gegen eine Verunreinigung ist dadurch nicht gewährleistet. Deshalb sollten die

Melder vor Beginn von Konstruktions-, umfangreichen Dekorationsarbeiten

oder sonstigen Aktivitäten mit Staubentwicklung entfernt werden. Zur

ordnungsgemäßen Funktion ist der Staubschutz vor der Inbetriebnahme des

ACHTUNG

Melders abzunehmen.

LED 1

Gehäusemarkierung

Testmagnet

Rauchmethode

1. Mit einem geeigneten Prüfgas eines zugelassenen Herstellers (z.B. von No Climb

Products Ltd.) wird der Rauchmelder durch eine kontrollierte Prüfgasmenge

ausgelöst. Hierbei sind die Herstellerempfehlungen und die lokalen Anforderungen

zu beachten.

2. Beide LED des Rauchmelders sollten innerhalb von 30 Sekunden leuchten und die

Alarmauslösung lokal und an der Brandmelderzentrale anzeigen.

WICHTIG

Informieren Sie nach Abschluss der Prüfung alle beteiligten Stellen wieder

über die Inbetriebnahme des Systems.

Pittway Tecnologica Srl, Via Caboto 19/3, 34147 Trieste, ITALY I56-3310-003D200-51-00

Page 4

EINSCHRÄNKUNGEN VON RAUCHMELDERN

0.65 12.6 210

2.15 33.6 444

ACHTUNG

Rauchmelder müssen mit kompatiblen Anlagen verwendet werden.

Rauchmelder erkennen keine Entstehungsbrände deren Rauch die Melder nicht erreicht.

Ein Rauchmelder kann keine Feuerentwicklung in anderen Gebäudebereichen erken-

nen.

Rauchmelder haben auch Einschränkungen in der Auslösung. Bei der Auswahl von

Brandmeldern müssen die Umgebungsbedingungen berücksichtigt werden.

Rauchmelder haben keine ewige Lebensdauer, da sie elektronische Bauteile enthalten. Selbst wenn robuste Melder für eine Betriebszeit von über 10 Jahren ausgelegt

sind, können Bauteile jederzeit ausfallen. Testen Sie deshalb mindestens halbjährlich Ihr

Meldersystem. Reinigen und inspizieren Sie die Brandmelder regelmässig. Inspektionen

des Brandmeldesystems reduzieren erheblich das Produkthaftungsrisiko.

Maximal zulässige Kapazität, Induktivität

und Impedanz Figures Über Terminals 1

und 2 auf einer B501AP meldersockel

Gruppe

IIC

IIB

IIA

Kapazität

µF

0.083 4.2 55

Induktivität

mH

Tabelle 1

L/R Verhältnis

µH/Ohm

B501AP Pin Anschluss

1

2

4

Hinweise:

1. Jede Einkanal-Shunt Zener Dioden Sicherheitsbarriere oder 1-Kanal einer Zweikanal-Shunt

Zener Dioden Sicherheitsbarriere zertifiziert durch Baseefa oder einer EEC zugelassenen

Einrichtung für [EEx ia] IIC müssen den folgenden Parameter oder dieser Mindestanforderung

entsprechen:

Uz = 28V; Imax: out = 93,3 mA; Wmax: out = 0,66 W

Für jede Sicherheitsbarriere muss der Ausgangstrom durch einen Widerstand “R” wie folgt

begrenzt werden: Imax:out = Uz/R.

Anderenfalls sind folgende Trenneinrichtungen (Barrieren) einzusetzen:

P & F Smart Fire Detector Isolator Type KFDO-CS-Ex1.54-Y72221 (BAS00ATEX7087x)

Ein Kanal von: P & F Smart Fire Detector Isolator Type KFDO-CS-Ex2.54-Y2222

(BAS00ATEX7087X)

2. Die Kapazität und Induktivität bzw. Das Induktivität/Widerstandsverhältnis (L/R) der Kabel im

Gefahrenbereich zwischen den Anschlussklemmen) dürfen die in Tabelle 1 gezeigten Werte

nicht überschreiten.

3. Die Installation muss den nationalen Anforderungen und Auflagen, z.B. der DIN VDE 0166,

DIN EN 60079, entsprechen.

4. Die elektrische Schaltung in Gefahrenbereichen muss einer Prüfung mit Wechselspannung

von 500 V~eff nach Masse oder dem Gehäuserahmen der Baugruppe für mindestens eine

Minute standhalten. Entfällt beim Einsatz einer Sicherheitsbarriere.

5. Das System muss dauerhaft gekennzeichnet werden. Die Kennzeichnung muss sich auf

oder in unmittelbarer Nähe der Typenkennzeichnung der elektrischen Einrichtung oder auf

der Schnittstelle zwischen den eigensicheren und nicht eigensicheren Stromkreis befinden.

Auf der Kennzeichnung sollte die Bezeichnung „Baseefa 03Y0182 und SYST der System”

aufgebracht werden.

22051EISE System Diagramm

Sicherer Bereich

Brandmelderzentrale

Sicheres Gerät, für das keine weitere technische

Spezifikation vorliegt, außer dass unter allen

Bedingungen (normal und außergewöhnlich) die

Spannung innerhalb des Gerätes den Wert von

253 V~eff bzw. 253 V DC nicht überschreiten darf

und kein Bezug zum Erdungspotential besteht.

IST200

Übersetzermodul

-V IN, -V OUT

+V IN

+V OUT

Tabelle 2

Shunt Zener

Diode,

Sicherheitsbarriere oder

Galvanische

Trenneinrichtung

(siehe Hinweis 1.)

Gefahrenbereich (Ex-Bereich)

(siehe Hinweis 2)

Zu weiteren

Melder(n)

4 (+)

1 (-)

2 (+)

B501AP

22051EISE

Rauchmelder

II1G Ex ia IIC T5, T4

Baseefa08ATEX0278X

R12-172-00, REV G

Die Kompatibilität von speziellen Kombinationen für Sicherheitsbarriere und

ACHTUNG

Brandmelderzentrale entnehmen Sie bitte der Anleitung der Brandmelderzentrale.

Loading...

Loading...