Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

1012 Ionization and 2012 Photoelectronic

Smoke Detectors

Smoke Detector Description

Smoke detectors are designed to provide early warning of developing fires

at a reasonable cost. They monitor the air and can sense smoke and can

provide precious minutes for you and your family to escape before a fire

spreads. Early warning fire detection is best achieved by the installation of

fire detection equipment in all rooms and areas of the household.

Model 1012 is a low-voltage ionization-type smoke detector. Model 2012 is

a low-voltage photoelectronic-type smoke detector. The detector is designed for open area protection in a residential building. Each detector has

a built-in relay which may be used to activate auxiliary devices such as

bells, horns, and door closers. The relay contacts automatically close eight

(8) seconds after the detector goes into alarm, and automatically resets

approximately five (5) seconds after the alarm stops. In addition, these

detectors can be interconnected, within one household, for a system of up

to twelve (12) smoke detectors per household. This way, when one smoke

detector sounds its alarm horn, it will cause all of the other connected

smoke detectors within the household to sound their alarm horns as well.

Installation in Australia Only

The installation temperature range for Australia is 5° to 45°C and has

been tested per the Australian Standard. Ignore installation temperatures

specified for all other applications when installing detectors in Australia.

Detectors should be installed by qualified technicians. Installation of a

main connected power supply unit must be performed by qualified electricians only. Ignore the power requirements in "Smoke Detector Requirements" listed below, as these apply to installation in the USA.

The primary

power should be provided by a power limited, supervised, panel type system. A rechargeable battery is required as a backup to the external power

supply in case of a mains failure. In standby operation, the

power limited

backup battery (fully charged) must be capable of providing uninterrupted power for at least 7 days to the system and all smoke alarms before

the panel gives the required low-battery signal. When the low-battery signal is given, the battery should be capable of providing power for another

7 days, after which the backup battery should have enough energy left to

allow a 4-minute alarm signal to be given by all connected smoke alarms.

• Smoke detectors will not sense a fire if the smoke does not reach

the sensor. In order for a smoke detector to sense smoke, it must be

installed in the immediate vicinity of the fire. In addition, smoke from

fires in chimneys, in walls, on roofs, in remote parts of the building, or

on another level from where the smoke detector is located, may not

reach the smoke detector quickly enough for occupants to escape unharmed. For this reason, installer shall install smoke detectors on

every level, in every sleeping area, and in every bedroom of the

household.

• Smoke detectors may not be heard. The alarm horn in this smoke de-

tector meets or exceeds current Underwriter's Laboratories standards.

However, if the smoke detector is not located in the same room as the

occupant, or if it is blocked by a closed door or normal noise, the

alarm horn may not be heard. In addition, sound sleepers, or persons

who are under the influence of drugs or alcohol may not hear the

alarm or be able to react to it. Therefore, locate this smoke detector,

which has a sounder rated at 85 dB at 10 feet, on every level, in every sleeping area, and in every bedroom of the household.

• In general, detectors may not always warn you about fires caused by

carelessness and safety hazards like smoking in bed, violent explosions, escaping gas, improper storage of flammable materials, overloaded electrical circuits, children playing with matches, or arson.

• Smoke detectors are not fool-proof. Like all electronic devices, smoke

detectors have limitations. No type of smoke detector can sense every kind of fire every time. In addition, smoke from slow, smoldering fires rises slowly and may not reach the smoke detector until

actual flame breaks out. This type of smoke may not reach the

smoke detector in time for occupants to escape unharmed.

• Smoke detectors are not a substitute for life or property insurance.

Though smoke detectors have been responsible for saving many lives,

they are not warranted or implied to protect lives or property in the

event of a fire.

• Smoke detectors have a limited life. They contain many parts. Any of

these parts could fail at any time. Repair or replace the smoke detector

immediately if the alarm horn does not sound when tested. Do not, in

any case, use a smoke detector for more than 10 years from the date

of original installation.

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

Smoke Detector Power Requirements (USA)

This smoke detector will not work without power.

This smoke detector is

only U.L. listed to be powered by System Sensor Part No. A77-727-01 (12volt DC power supply). The A77-727-01 must be permanently connected

to the building's 120-volt AC electrical supply per code. The A77-727-01

will not power the smoke detector if the AC power is cut off for any rea-

Where to Install Smoke Detectors

Warning: As a minimum requirement, smoke detectors must be installed

in accordance with the National Fire Protection Agency (NFPA) Standard

72 which defines the standards for the National Fire Alarm Code (National

Fire Protection Association, Batterymarch Park, MA 02269-9101). In addi-

tion, observe all local and national building and electrical codes.

son. The 12-volt DC power supply will only power the detector when 120volt AC power is present—it is not a power back-up source.

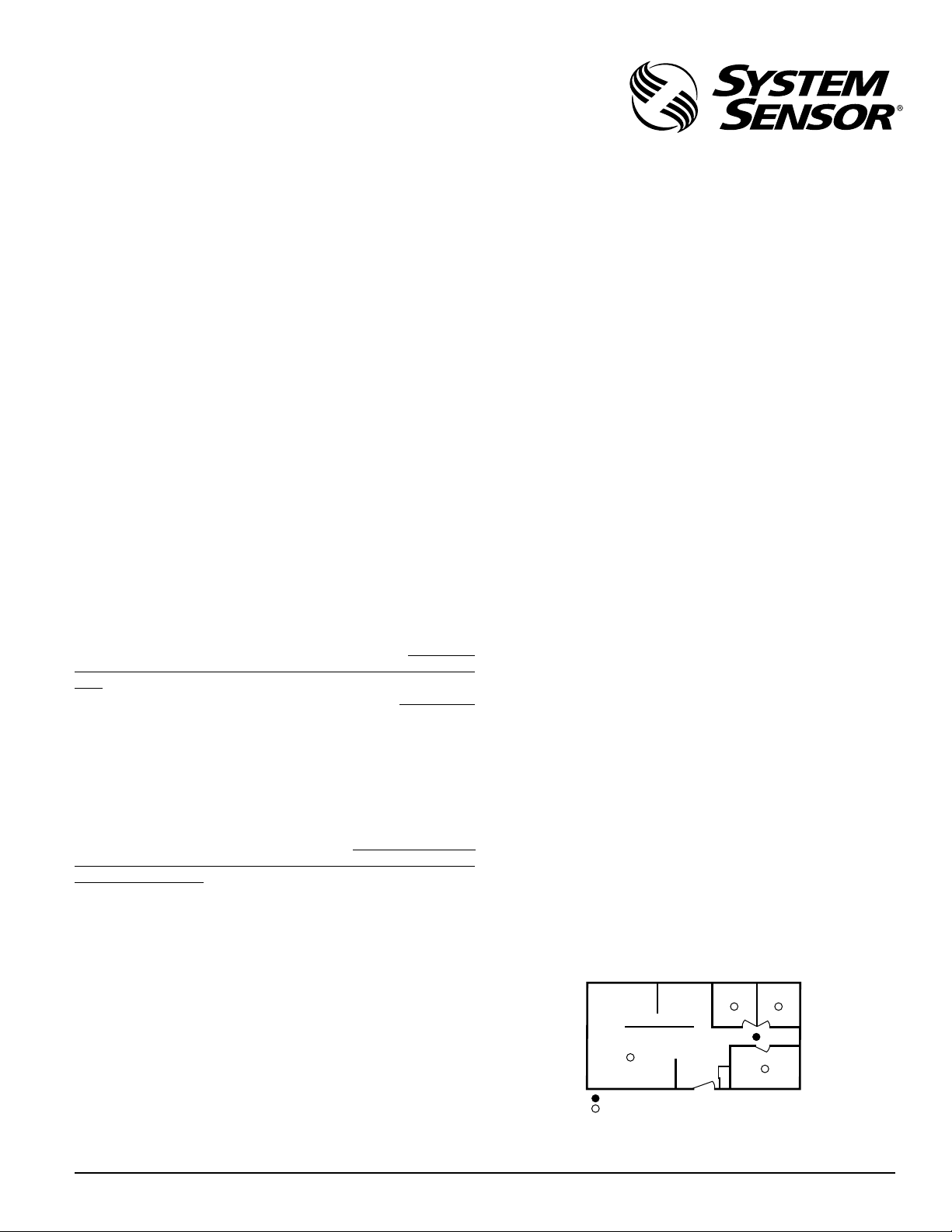

Proper Detector Location:

Figure 1: Recommended smoke detector protection for single-

Power input rating to the detector is 12VDC @ 0.02 amps. Input power to

the A77-727-01 power supply must be from a 24-hour 120V AC 60HZ circuit which cannot be turned off by a switch. Power supply and detector

floor residence with only one sleeping area

DINING ROOM KITCHEN BEDROOM BEDROOM

installation must conform to the electrical codes in your area and Article 760 of the National Electrical Code. It is recommended that wiring

be performed by a licensed electrician.

Smoke Detector Limitations

• This smoke detector is designed for residential use only. System

Sensor does not advise the use of this detector in multiple detector systems monitored by a central control. This detector is self-restoring and

SMOKE DETECTORS FOR MINIMUM PROTECTION

SMOKE DETECTORS FOR MORE PROTECTION AND

REQUIRED IN NEW CONSTRUCTION

BEDROOMLIVING ROOM

A78-1171-01

does not lock into an alarm condition.

D100-55-00 1 I56-733-10

Page 2

Figure 2: Recommended smoke detector protection for singlefloor residence with more than one sleeping area:

BEDROOM

KITCHENFAMILY ROOM

BEDROOM

DINING

ROOM

LIVING ROOM

BEDROOM

SMOKE DETECTORS FOR

MINIMUM PROTECTION

SMOKE DETECTORS FOR

MORE PROTECTION AND

REQUIRED IN NEW CONSTRUCTION

A78-1171-02

NFPA 72, Chapter 2, Section 2-2.1.1.1 states as follows: “Smoke detectors

shall be installed outside of each separate sleeping area in the immediate

vicinity of the bedrooms and on each additional story of the family living

• Rooms or areas that do not have smooth ceilings, or which have short,

transom-type walls coming down from the ceiling require additional

detectors.

• Install second-floor detectors on the ceiling at the top of the first-to-

second floor stairwell. Be sure no door or other obstruction blocks the

path of smoke to the detector.

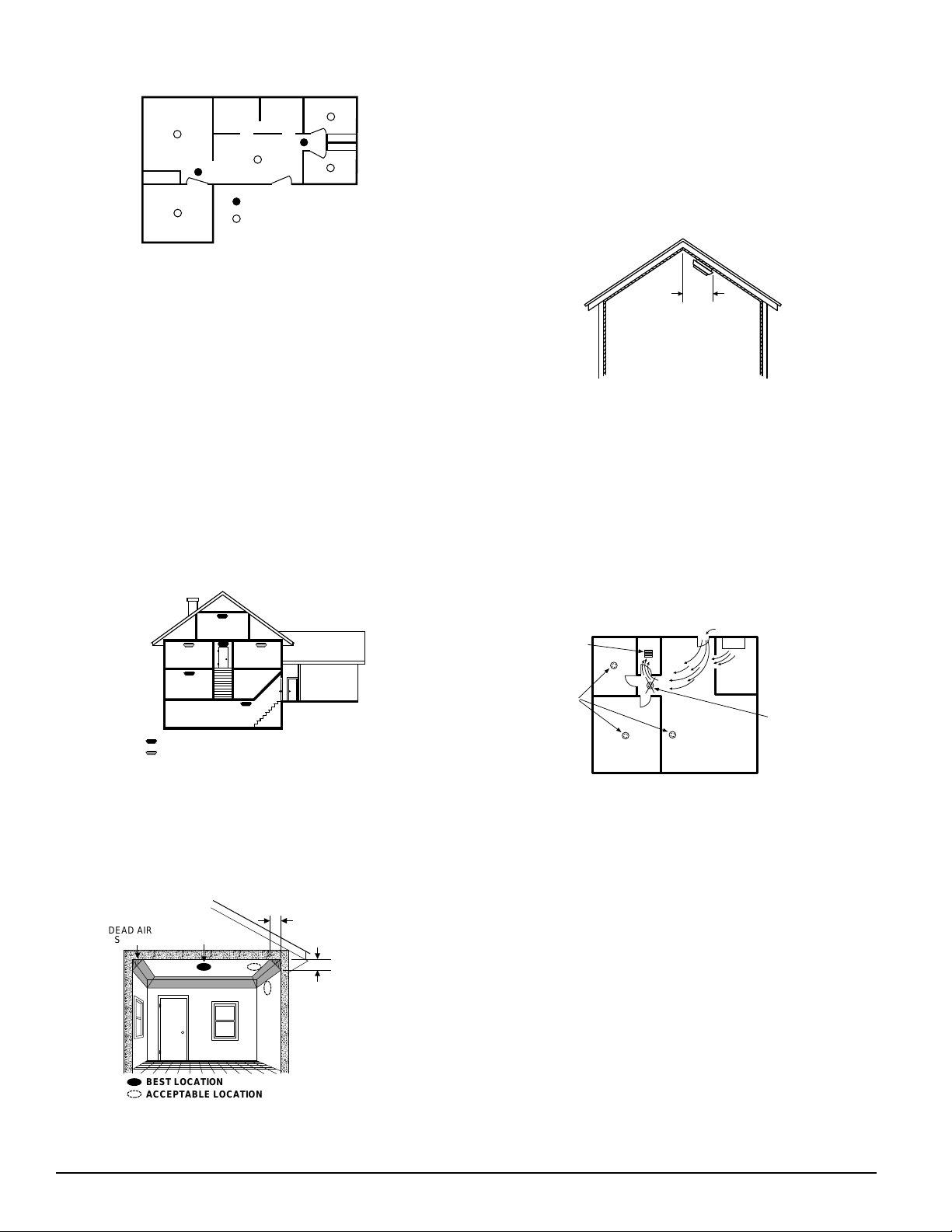

• In rooms with sloped, peaked, or gabled ceilings, install detectors 3

feet (0.9 meter) measured down on the slant from the highest point of

the ceiling. See Figure 5.

Figure 5: Recommended smoke detector location in rooms with

sloped, gabled or peaked ceilings:

HORIZONTAL

DISTANCE

FROM PEAK

3 FEET

(.9M)

unit, including basements and excluding crawl spaces and unfinished attics. In new construction, a smoke detector also shall be installed in each

sleeping room.”

The above NFPA standard is a minimum requirement for smoke detector installation. For better protection, we also require the installation

of a smoke detector inside every bedroom in existing construction.

• Install a minimum of two smoke detectors in any household, no

matter how small it is.

• Put a smoke detector in the hallway outside of every separate bedroom area. (See Figure 1.) A minimum of two detectors are required in

homes with two bedroom areas. (See Figure 2.)

• Put a smoke detector on every level of a multi-level residence. (See

Figure 3.)

• Install basement detectors on the ceiling at the bottom of the basement

stairwell. (See Figure 3.)

Figure 3: Recommended smoke detector protection for a multilevel residence:

Where Smoke Detectors Should NOT Be Installed

• In or near areas where combustion particles are normally present

such as kitchens; in garages where there are particles of combustion

in vehicle exhausts; near furnaces, hot water heaters, or gas space

heaters. Install detectors at least 20 feet (6 meters) away from kitchens and other areas where combustion particles are normally

present.

• On the ceiling in rooms next to kitchens where there is no transom

between the kitchen and these rooms. Instead, install the smoke detector on an inside wall, furthest from the kitchen (See Figure 6). Be sure

not to install smoke detectors within 4" of the ceiling or any corner or

more than 6" from the ceiling.

A78-1171-05

Figure 6: Recommended smoke detector locations to avoid air

BEDROOM

BEDROOM BEDROOM

BASEMENT

KITCHEN

GARAGE

A78-1171-03

LIVING

ROOM

SMOKE DETECTORS FOR MINIMUM PROTECTION

SMOKE DETECTORS FOR MORE PROTECTION AND

REQUIRED IN NEW CONSTRUCTION

• Install detectors on the ceiling as close to the center of the room as

possible. If this is not practical, install it on the ceiling no closer than 4

inches (10 cm) from any wall or corner. (See Figure 4.)

• If wall-mounting is permitted by local and state codes, and ceiling

mounting is not practical, install detectors on an inside wall between 4

and 6 inches (10 and 15 cm) from the ceiling. (See Figure 4.)

Figure 4: Recommended smoke detector mounting locations:

DEAD AIR

SPACE

BEST IN CENTER

OF CEILING

NO CLOSER THAN 4

"

(10 cm)

FROM SIDE WALL

MOUNT ON WALL

AT LEAST 4

"

FROM CEILING

NO MORE

"

(15 cm)

THAN 6

FROM CEILING

(10 cm)

streams with combustion particles:

AIR RETURN

CORRECT

BEDROOM

BEDROOM

BATH

• In damp or very humid areas, or next to bathrooms with showers.

The moisture in humid air can enter the sensing chamber as water vapor, then cool and condense into droplets that cause a nuisance alarm.

Install detectors at least 5 feet (1.5 meters) away from bathrooms.

• In very cold or very hot rooms or areas. Operating temperature of the

smoke detector is 40°F to 100°F (4°C to 38°C).

• In dusty, dirty, or insect-infested areas. Dust and dirt can build up on

the detector’s sensing chamber and make it overly sensitive, or can

block openings to the sensing chamber and keep the detector from

sensing smoke.

• Near fresh air inlets or returns or excessively drafty areas. Air con-

ditioners, heaters, fans, and fresh air intakes and returns can drive

smoke away from smoke detectors, making the detectors less effective.

LIVING

ROOM

AIR INLET

STOVE

KITCHEN

INCORRECT

A78-1171-06

• In dead air spaces at the top of a peaked ceiling or wall/ceiling inter-

sect. Dead air may prevent smoke from reaching a detector.

• Near fluorescent light fixtures. Install detectors at least 10 feet (3

meters) away from such light fixtures.

BEST LOCATION

ACCEPTABLE LOCATION

A78-1171-04

• Put detectors at both ends of a bedroom hallway if the hallway is more

than 30 feet (9 meters) long. In addition, large rooms will require more

Installation Requirements

Warning: Electrical Shock Hazard. Turn off power at the main fuse box

or circuit breaker to the area of detector installation before beginning installation procedures.

• Mount detector to a 4-inch octagonal junction box only. Mount the 12

than a single detector if the room is over 900 square feet.

D100-55-00 2 I56-733-10

Page 3

Figure 7:

(+) (–)

POWER INPUT

GROUND

SIGNAL

(+) (–)

POWER INPUT

GROUND

SIGNAL

(+) (–)

POWER INPUT

GROUND

SIGNAL

RED

(+)

GRAY

(–)

POWERS UP TO

16 DETECTORS

A77-727-O1

12VDC POWER

SUPPLY

BLACK

BLACK

12OVAC

AUXILIARY

(+) (–)

POWER INPUT

AUXILIARY

8 UNITS

742

466

293

POWER INPUT

WIRE

GAUGE

14AWG

16AWG

18AWG

AUXILIARY

(+) (–)

AUXILIARY

1 UNIT

5000

3735

2349

GROUND

SIGNAL

2 UNITS

2970

1867

1174

POWER INPUT

INTERCONNECT UP TO

12 DETECTORS

3 UNITS

4 UNITS

1980

1485

1245

933

783

587

AUXILIARY

(+) (–)

AUXILIARY

5 UNITS

1188

747

469

GROUND

SIGNAL

6 UNITS

990

622

391

7 UNITS

848

533

335

Maximum power bus length in feet, given number of units (maximum per bus) and wire size.

Maximum interconnect bus length: 5,000 FT., No. 18AWG or larger dual conductor cable.

All wiring must conform to local electrical codes.

Relay contacts rating: 0.5A 30VDC; 0.5A 30VAC

Volt D.C. power supply to a 4" square junction box 2-1/8" deep only.

(If necessary, add an extension ring if the selected box does not have

adequate volume.) The power supply may be mounted remotely from

the detector.

• All wiring must be performed by a licensed electrician and installed in

compliance with the National Electrical Code, applicable local codes,

and any special requirements of the local authority having jurisdiction.

• Use only the specified wire gauge. Maximum interconnect bus length

is 5,000 feet, #18 AWG or larger two-conductor stranded cable.

• The detector includes a tamper-resist feature that, when activated, re-

quires a tool for detector removal. The following detector installation

instructions include how to activate this feature.

GROUND

SIGNAL

9 UNITS

660

415

261

Figure 8:

Dimensions

1-3/4" high

5-1/2" base dia.

10 UNITS

594

373

234

AUXILIARY

ALARM RELAY

11 UNITS

540

339

213

MOUNTING

BRACKET

MOUNTING

SCREW

REMOVE

12 UNITS

495

311

195

A78-2187-01

MOUNTING

SCREW

FOR TAMPER RESIST

BREAK OFF TAB HERE

ALIGNMENT

ARROW

Installation Instructions

1. Turn off power at main service panel.

2. Using wire connectors, attach either black wire from power supply to

black AC power wire. Attach other black wire from power supply to

INSTALL

WHEN INSTALLING:

ALIGN ARROWS ON MTG.

BRACKET 1" TO THE

RIGHT OF THE NIB ON

THE DETECTOR. ROTATE

UNTIL ARROW AND NIB

LINE UP.

A78-2012-00

white AC neutral wire.

3. Using wire connectors, connect red and gray power supply output

wires to the bus line wires supplying power to the remote detectors.

(See Figure 7.) Use color-coded bus wires.

4. Mount power supply to junction box and cover junction box with a 4"

square box cover, using box mounting screws.

5. Install a junction box where you plan to install the detector. (See type

and size for junction box above.)

6. Install bus line wires from power supply output to junction box. Use

#14-18 AWG wire only. See Figure 7 to determine maximum power bus

length for wire size and number of interconnected detectors.

7. Connect color-coded DC power bus wires to power input screw terminals, located on detector back. If detectors will be interconnected or the

relay used, see following sections for specific installation instructions.

8. Remove detector from mounting bracket by turning the detector

counter-clockwise and pulling the detector away from the bracket.

9. Remove small tab on mounting bracket to activate tamper-resist feature, if desired. (To release a detector with this feature, push up on

locking tab with screwdriver while turning detector counterclockwise.)

10. Install mounting bracket to junction box.

11. Connect power wires to detector(s) as shown in Figure 8. Be sure to

tighten each terminal screw to secure wire in place. Tug wire to be sure

it is connected properly.

12. Attach smoke detector to mounting bracket by aligning arrows on side

of mounting bracket 1-inch to the right of the nib on the detector. Rotate until the arrow and nib line up. (See Figure 8).

13. After installing all detectors, turn on power at the main service panel.

14. Check for the green LED to flash about once every 30 to 40 seconds.

This means the detector is receiving power. Check all detectors.

Note: If the LED does not flash, power is not getting to the smoke detec-

tor. Check wiring. If LED still does not flash, return the smoke detector to the manufacturer for repair.

15.Test each detector in the system. (See “Testing” below for more detailed instructions.)

D100-55-00 3 I56-733-10

Page 4

LED

Figure 9:

WARNING: Never use an open flame of any kind to test the smoke detector. You may set fire to and damage the detector, as well as your home.

The built-in test switch accurately tests all detector functions, as required

by Underwriter's Laboratories.

• DANGER: If the alarm horn sounds a loud continuous sound and

you are not testing the detector, the detector has sensed smoke or

combustion particles in the air. THE ALARM HORN IS A WARNING

OF A POSSIBLY SERIOUS SITUATION. IT REQUIRES YOUR IMMEDIATE ATTENTION. See “What to Do In Case of Fire” section of this

PUSH RECESSED SWITCH

WITH A 0.1" max. DIAMETER TOOL

RECESSED TEST

SWITCH

manual.

Connecting Auxiliary Devices with Relay

This detector has a built-in relay which may be used to activate auxiliary

devices such as bells, horns, and door closers. The relay contacts automatically close approximately eight (8) seconds after the detector goes

into alarm, and automatically resets approximately five (5) seconds after

the alarm stops. For wiring refer to Figure 8. Auxiliary voltage and current

requirements must be within relay contact ratings and appropriate wiring

must be used.

How to Interconnect Detectors

NOTE:Interconnect smoke detectors within one household only. If detec-

tors are interconnected between households, nuisance alarms will

occur when a detector in another residence is tested.

• Up to twelve 1012, 2012, and 2001LVRI detectors may be intercon-

nected so that if one detector senses smoke, all of them will sound an

alarm. After interconnecting the detectors, push the test switch on one

detector. The alarm horns on all of the other detectors should sound if

they are connected correctly.

• Connect the detectors together by connecting all the signal terminals

to each other and all ground terminals to each other. (See Figure 7.)

Use 18 guage (#18AWG) or larger two-conductor stranded wire.

• If detectors will not be interconnected, DO NOT use signal and

ground terminals.

• The LEDs on all smoke detectors should flash about 1 to 2 times per

minute when power is turned on to the detectors. Test detectors after

interconnection wiring is complete.

Cautionary Note: Test interconnection wiring after installation is com-

pleted. Test each unit in a system and make sure ALL other

units alarm. FAILURE TO OBSERVE ANY OF THESE CONDI-

TIONS CAN CAUSE SYSTEM MALFUNCTION AND/OR DAMAGE TO THE DETECTORS.

• The alarm could be caused by a nuisance situation. Cooking smoke or

a dusty furnace can cause the alarm to sound. If this happens, open a

window or fan the air to remove the smoke or dust. The alarm will

turn itself off as soon as the air is completely clear. DO NOT TURN

OFF POWER TO THE SMOKE DETECTOR. THIS WILL REMOVE

YOUR PROTECTION.

Monitoring Your Detector

Once the detector is powered, a green LED flashes about 1 to 2 times per

minute. This signals that the detector is receiving power and is in the detect mode. If the detector is not operating properly, the green LED will be

OFF. (If so, have the detector repaired or replaced immediately.) When the

smoke detector senses smoke, the green LED will flash rapidly. If the initiating smoke detector senses smoke and signals other interconnected

smoke detectors to sound their alarms, their LEDs will flash about 1 to 2

times per minute. See chart below for specific LED functions.

TABLE 1: DETECTOR STATUS

Detector Status Electronic Horn LED

Functioning Normally Silent Flashing about

Sounding Alarm; Beeping Continuously Flashing

Detecting Smoke (Steady Pulse) Rapidly

Sounding Alarm; Beeping Continuouslly 2012–Flashing about

Smoke Sensed by a (Steady Pulse) 1-2 times per minute

Connected Detector 1012–No flashing

1-2 times per minute

2001LVRI–No flashing

The detector will automatically return from Alarm to Normal state when

the reason for alarm, as the presence of smoke, is completely removed.

Cleaning and Maintenance

DANGER: Electrical Shock Hazard. Turn off power to the smoke detector

at the main service panel before cleaning the smoke detector.

Testing Information

• You should test your detector at least once a week to assure yourself of

its operation, as recommended by NFPA. Test the detector by firmly depressing the recessed test switch located on the detector cover (marked

“Push to Test”) with a 0.1 inch diameter tool such as an allen wrench

or small screwdriver FOR 20 SECONDS. (See Figure 9). The alarm

horn should sound, and the LED should flash rapidly.

• In an interconnected system, all of the detectors should sound their

alarm horns when any one of the test buttons is pushed. If the alarm

horn makes a continuous loud sound, the detector is working properly.

This is the only way to be sure the detector is working. Test the detector weekly. If the detector fails to test properly, have it repaired

or replaced immediately.

This smoke detector has been designed to be as maintenance-free as possible. However, regular testing (see “Testing” above) and periodic maintenance are necessary.

To clean the detector, turn off power and vacuum the outside of the detector with the soft brush attachment of a vacuum cleaner. Do this at least

once every year, preferably every six months. DO NOT ATTEMPT TO

CLEAN THE DETECTOR IN ANY OTHER WAY.

If the detector requires service, do not attempt to service it yourself; this

will void your warranty. Send the detector to: Repair Department, System

Sensor, 3825 Ohio Avenue, St. Charles, Illinois 60174. Enclose a note describing what is wrong with the detector.

Three-Year Limited Warranty

System Sensor warrants its enclosed smoke detector to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this smoke detector. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of

the smoke detector which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll

free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

D100-55-00 4 I56-733-10

© System Sensor 1996

Loading...

Loading...