Page 1

XP -300

TM

Automated Hematology Analyzer

Quick Guide

Pre-operation Checks

Power On/Self Check

QC Analysis

Sample Processing

Reagent Replacement

Maintenance

Sysmex America, Inc. • Tel. 1-800-379-7639 • 1-800-3SYSMEX www.sysmex.com

Page 2

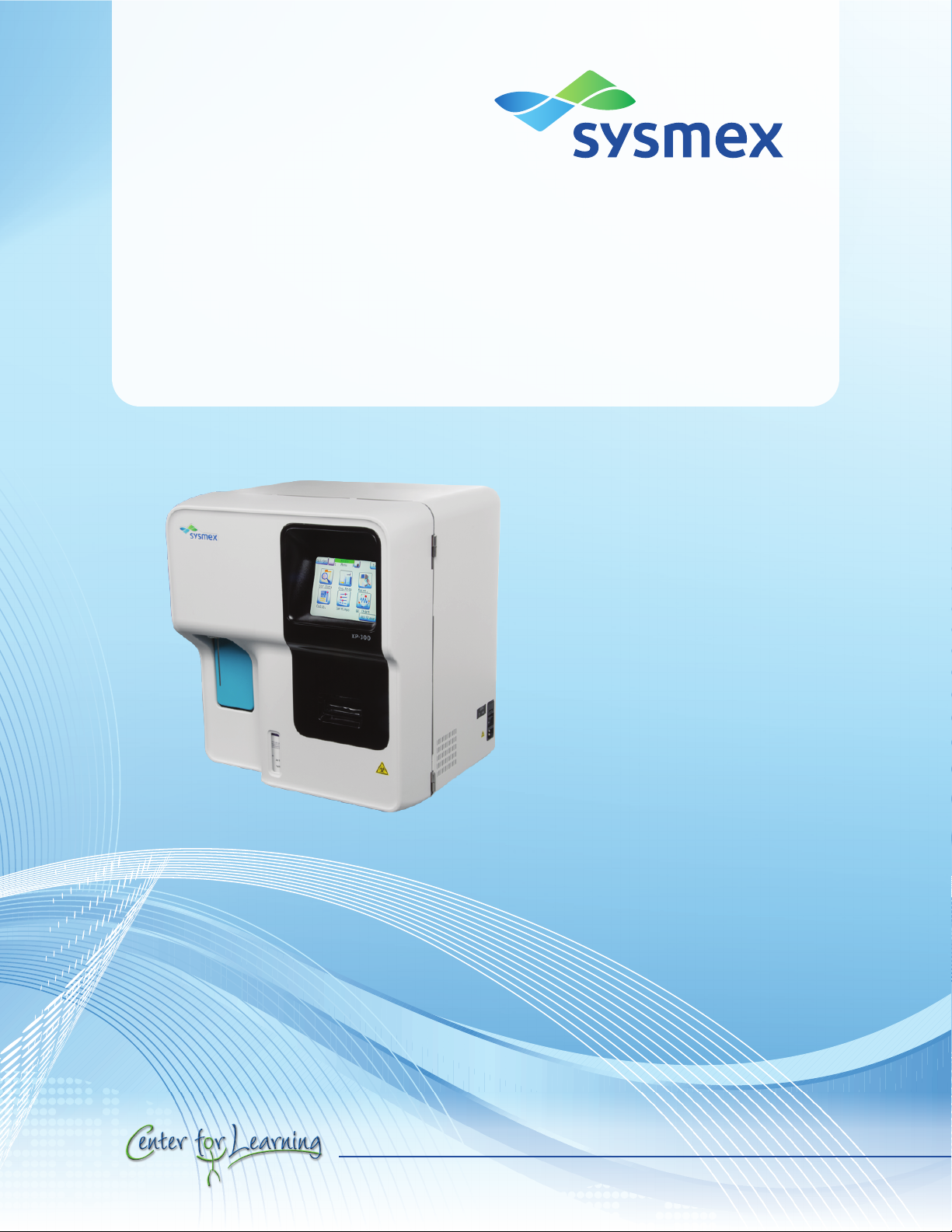

Daily Operating Procedures

Pre-Operation Checks

Verify the following before powering on the XP-300:

1. Check that the power cable is connected.

2. Check that there is sufficient printer paper.

3. Check pneumatic unit trap chamber for fluid. Empty if necessary.

4. If needed, discard any waste fluid in the waste container.

Power On/Self Check

1. Switch power on by pressing the power switch located on the right side of

the analyzer.

Three automatic rinse cycles are performed followed by a

background check.

Should any values fall outside of the acceptable limits, a maximum

of two extra background checks will be performed automatically.

Power

2. Record the background check on a daily checklist or keep a copy of the

printout for documentation. Compare the results to the acceptable

background limits.

Acceptable Background Limits

WBC ≤ 0.3 x 103/µL

RBC ≤ 0.02 x 106/µL

HGB ≤ 0.1 g/dL

PLT ≤ 10 x 103/µL

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 2

Page 3

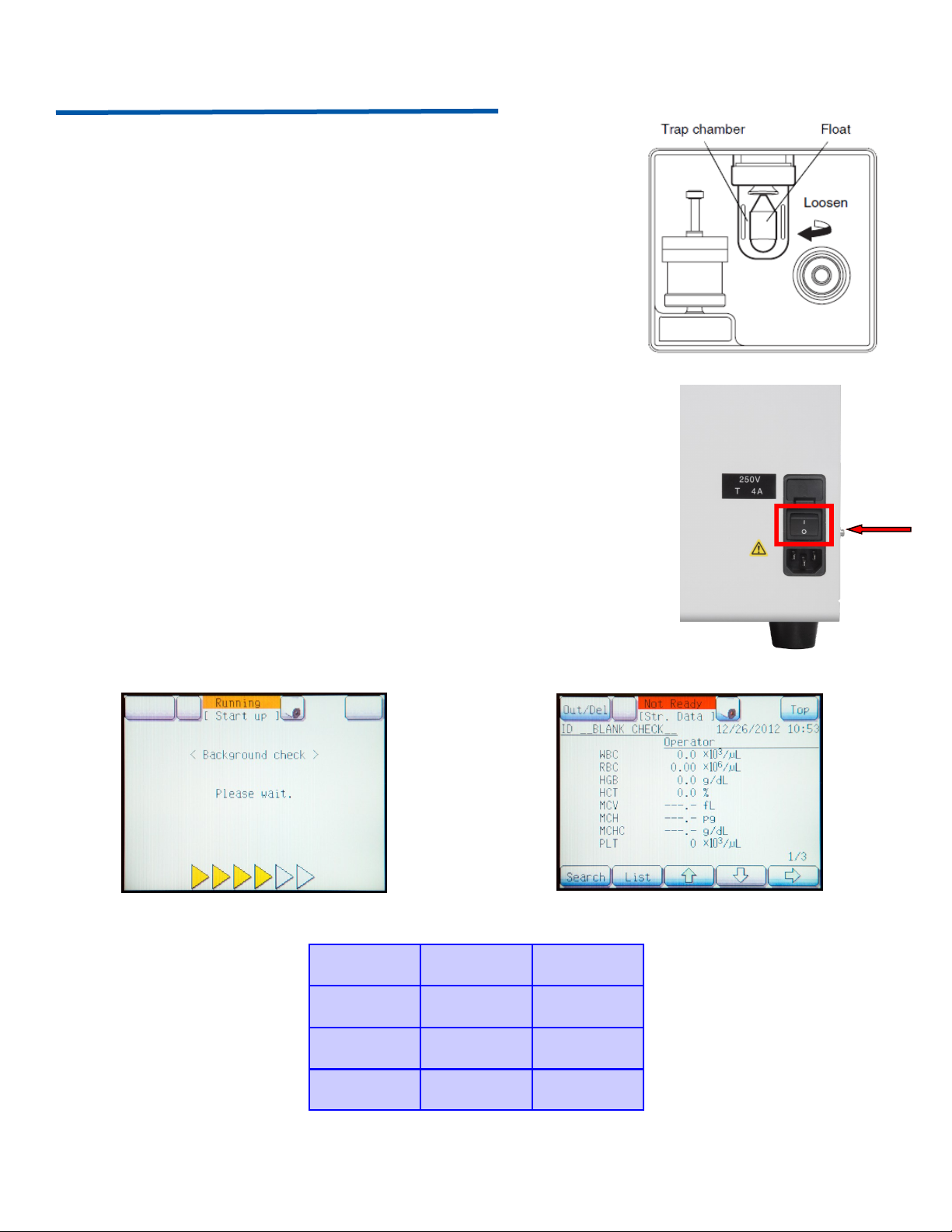

Quality Control Analysis

Running QC

1. Verify the XP-300 is at Ready.

2. Press the [QC] button.

3. Press the Quality Control file to be analyzed.

4. Mix the control blood according to the package insert.

5. Remove the cap and set control blood container to the sample probe.

6. Press the Start Switch.

7. When Analyzing is displayed and two beeps sound, remove the control

blood.

8. Use the [◄] and [►] buttons to scroll through pages.

9. Press [IP] to print to internal printer. Press [NG] to reject.

10. Touch [OK]

QC File Set-Up Barcoded Entry of Target and Limit Values

1. Press [QC] on the Main screen.

2. Select the correct file corresponding to the QC vial.

3. Press [Settings].

4. Scan lot from the assay sheet. Lot number loads automatically.

5. Manually enter the expiration date.

6. Using the [→], scroll to the PARAMETER page beginning with WBC.

7. Scan in WBC. TARGET and LIMIT Values load automatically.

8. Continue to scan in all parameters.

Note: Scroll to the right to advance the screen and input data for all parameters.

9. Press [Save].

10. Touch [OK]

11. Repeat steps 1-9 above to input QC data for the remaining levels of QC.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 3

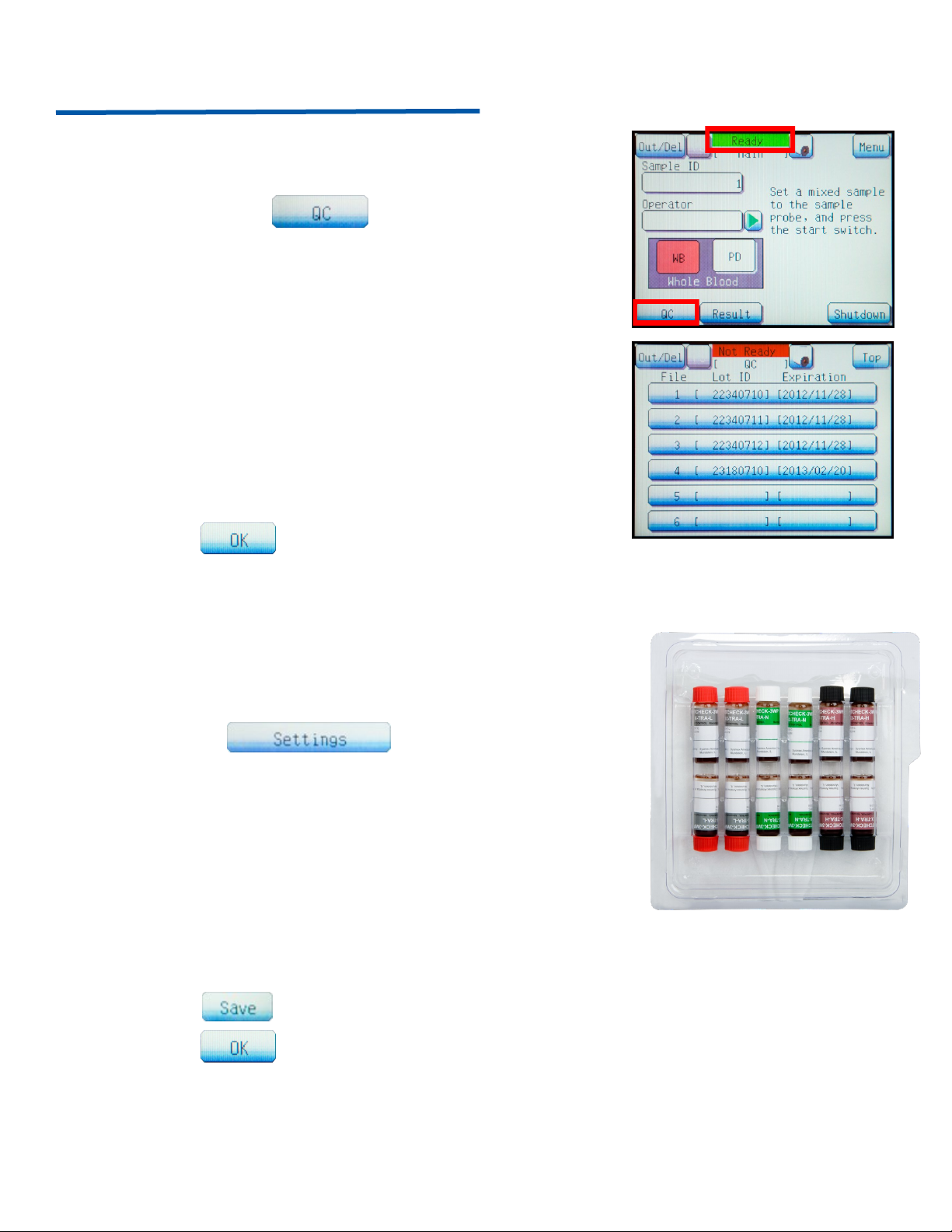

Page 4

Quality Control Analysis

Erasing a File for a New Lot of Controls

1. Verify the XP-300 is at Ready.

2. Press the [QC] button. The QC file list will be displayed.

3. Press the [Settings] button.

4. Press the [Clear] button.

5. Press [Enter].

6. Press [OK] to erase selected file.

7. Press [Cancel] to cancel file deletion.

Refer to the Sysmex XP-300 Resource and Validation Manual for more information about QC setup.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 4

Page 5

Sample Processing

Whole Blood (WB) Mode

1. Confirm that the XP-300 is Ready.

2. Press the [WB].

3. Press [Sample ID].

4. Enter the number using the panel keyboard, or the handheld barcode

reader.

5. Use the [C] key to clear incorrect entries.

6. Press [Ent.].

7. Mix the sample 10 times by gentle end to end inversion.

8. Remove the cap.

9. Set uncapped specimen to sample probe and press the Start Switch.

10. After the screen displays Analyzing and two audible beeps sound,

remove the sample tube.

Pre-Dilute (PD) Mode

1. Be sure the status display indicates 'Ready'.

2. Touch the [PD] button.

1

2

4

3

From Numerical Keys:

1. Touch the [Sample ID] display column on the Main screen (alphanumeric input dialog will appear).

2. Enter the Sample ID.

3. Touch the [Ent.] button.

Entering from Handheld Barcode Reader:

1. Touch the [Sample ID] display column on the Main screen (alphanumeric input dialog will appear).

2. Point and hold the barcode reader at the sample ID.

3. Press the button located on the bottom-side of the barcode reader.

4. Make sure that the displayed sample ID is correct, and press the [Ent.] button.

Note: The analysis mode selected is maintained after completion of analysis, until it is switched to the other analysis

mode. Therefore, it may not be necessary to select the Mode before each run.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 5

Page 6

Histogram Flags

List of WBC error flags in order of priority

WL

T1

T2

F1

F2

F3

WU

RL

Relative frequency for LOWER discriminator (LD) exceeds the range. May be caused by the inclusion

of platelet clumps, large platelets, fibrin, etc.

Lower TROUGH Discriminator, that distinguishes lymphocytes and mixed cells, cannot be determined.

Higher TROUGH Discriminator, that distinguishes mixed cells and neutrophils, cannot be determined.

Small cell histogram error. Relative frequency for T1 exceeds the range.

Middle cell histogram error. Relative frequency for T1 or T2 exceeds the range.

Large cell histogram error. Relative frequency for T2 exceeds the range.

Relative frequency for UPPER discriminator (UD) exceeds the range. May be caused by lyse-resistant

red blood cells, or when numerous abnormal blood cells are present.

List of RBC error flags in order of priority

Relative frequency for LOWER discriminator (LD) exceeds the range. May be caused by changes in red

blood cell morphology, platelet clumps, or electrical noise.

RU

MP

DW

PL

PU

MP

DW

AG

Relative frequency for UPPER discriminator (UD) exceeds the range. May be caused by electrical

noise.

Two or more peaks in the histogram.

Particle distribution width error when the 20% frequency does not cross the histogram two times. The

peak is taken as 100%.

List of PLT error flags in order of priority

Relative frequency for LOWER discriminator (LD) exceeds the range. May be caused by electrical

noise.

Relative frequency for the UPPER discriminator (UD) exceeds the range. May be caused by electrical

noise, platelet clumps, etc.

Two or more peaks in the histogram.

Particle distribution width error when the 20% frequency does not cross the histogram two times. The

peak is taken as 100%.

The particle count equal to or less than the LD exceeds a prescribed range. Probable cause is platelet

agglutination, which does not alter the WBC count, but may result in decrease platelet count.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 6

Page 7

Reagent Replacement

Reagent Replacement

1. An error message will display on the screen when one of the reagents needs to be replaced.

2. Press the [Help] key to change to the replenishment operation.

3. Obtain a new container of the reagent. Check the expiration date.

4. Remove cap from new reagent bottle.

5. Remove cap from empty container, and pull the spout kit straight out to remove.

6. Insert the container spout kit straight into the new reagent bottle, and tighten the cap.

7. Press [1] to select [Asp. Reag.]

8. The reagent is aspirated and a background check is performed automatically.

9. Document the change in the Reagent Replenishment Record.

Reagent Name Volume Open Expiration Dating

CELLPACK

CELLPACK

STROMATOLYSER-WH™ 500mL 90 days

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

®

®

10L 60 days

20L 60 days

Page 7

Page 8

Maintenance

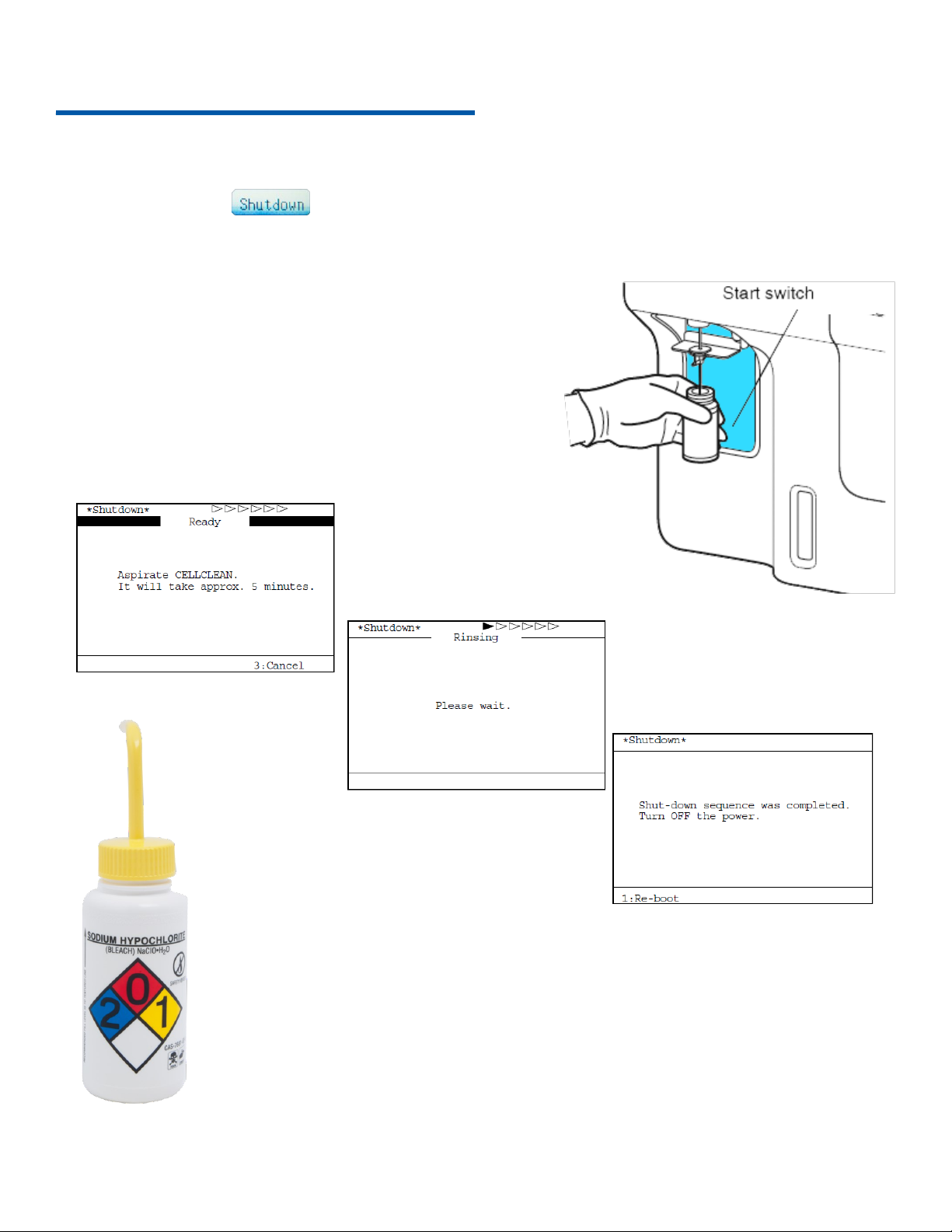

Shutdown—Daily Maintenance Procedure

Verify the XP-300 is at Ready.

1. Press [Shutdown].

2. Place a 5% filtered bleach solution to the sample probe and press the [Start Switch]. Continue to hold the bleach to

the probe while the analyzer is aspirating.

3. Remove the tube of bleach after two beeps.

Shutdown takes approximately five minutes.

4. When shutdown is complete, turn OFF main power switch on the

right side of the analyzer.

If the analyzer will be in use immediately following

shutdown, press [1] to re-boot.

Note: CELLCLEAN® = Filtered 5% Bleach (NaClO)

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 8

Page 9

Maintenance

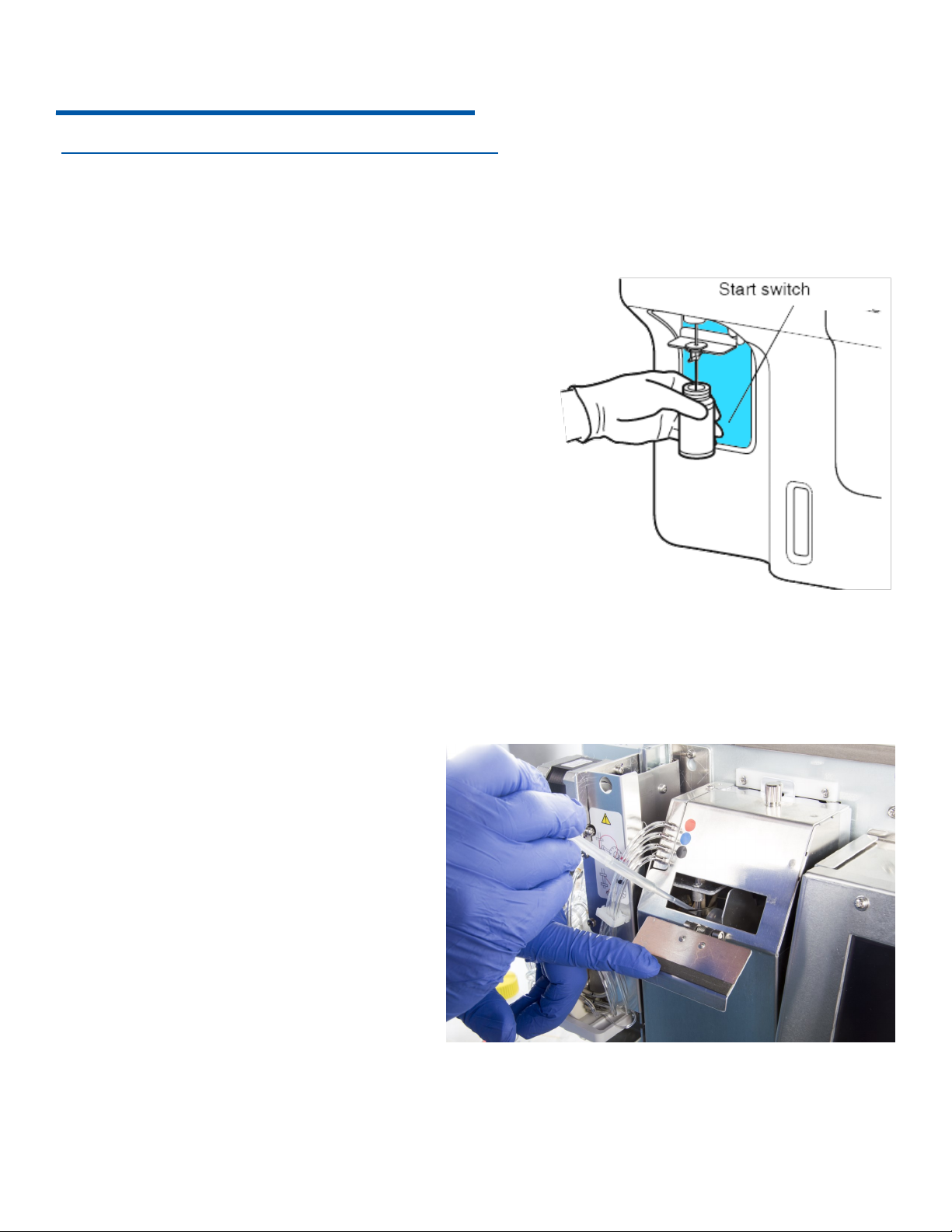

Weekly Maintenance

Clean the SRV tray

1. Turn off the power of the main unit and wait approximately 30

seconds.

2. Open the front cover of the main unit.

3. Remove the SRV tray.

4. Wash the SRV tray using tap water.

5. Make sure no contaminants remain, then wipe off water.

6. Replace the SRV tray to the original state.

7. Close the front cover of the main unit.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 9

Page 10

Maintenance

Monthly Maintenance/or Every 1,500 Samples

Clean Waste Chamber (Rinse Sequence)

When the power is turned on, a message is displayed once a month or every 1,500 samples to clean the waste

chamber. Sample analysis may continue without executing the operation by selecting [Cancel]. The message

will continue to appear at Start-Up until the operation is executed.

1. When this message displays, press [1] to select Exec. Clean.

2. Set a 5% filtered bleach solution to the sample probe and press

the Start Switch. Continue to hold the bleach to the probe while

the analyzer is aspirating.

3. Remove the tube after the two audible beeps.

Clean Waste Chamber Sequence takes approximately 15

minutes.

When the sequence is complete, the auto rinse and background

check are executed. Then the system returns to Ready. Verify

that no background error occurred. Should one occur, execute

the auto rinse.

Clean Transducer (Rinse Sequence)

When the power is turned on, a message is displayed once a month or every 1,500 samples to clean the

transducer. Sample analysis may continue without executing the operation by selecting [Cancel]. The message

will continue to appear at Start-Up until the operation is executed.

1. Open the front cover of the main unit.

2. Open the transducer cover.

3. Using the filler provided with the unit, pour

approximately 1 mL each of 5% filtered bleach into

the WBC and RBC transducer. Be careful not to

overfill.

4. Close the transducer cover.

5. Close the front cover of the main unit.

6. Press the Start Switch.

Clean Transducer Sequence takes

approximately 7 minutes.

When the cleaning is complete, the auto rinse and background check are executed. Then the system returns to

Ready. Verify that no background error occurs. Should one occur, execute the auto rinse.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 10

Page 11

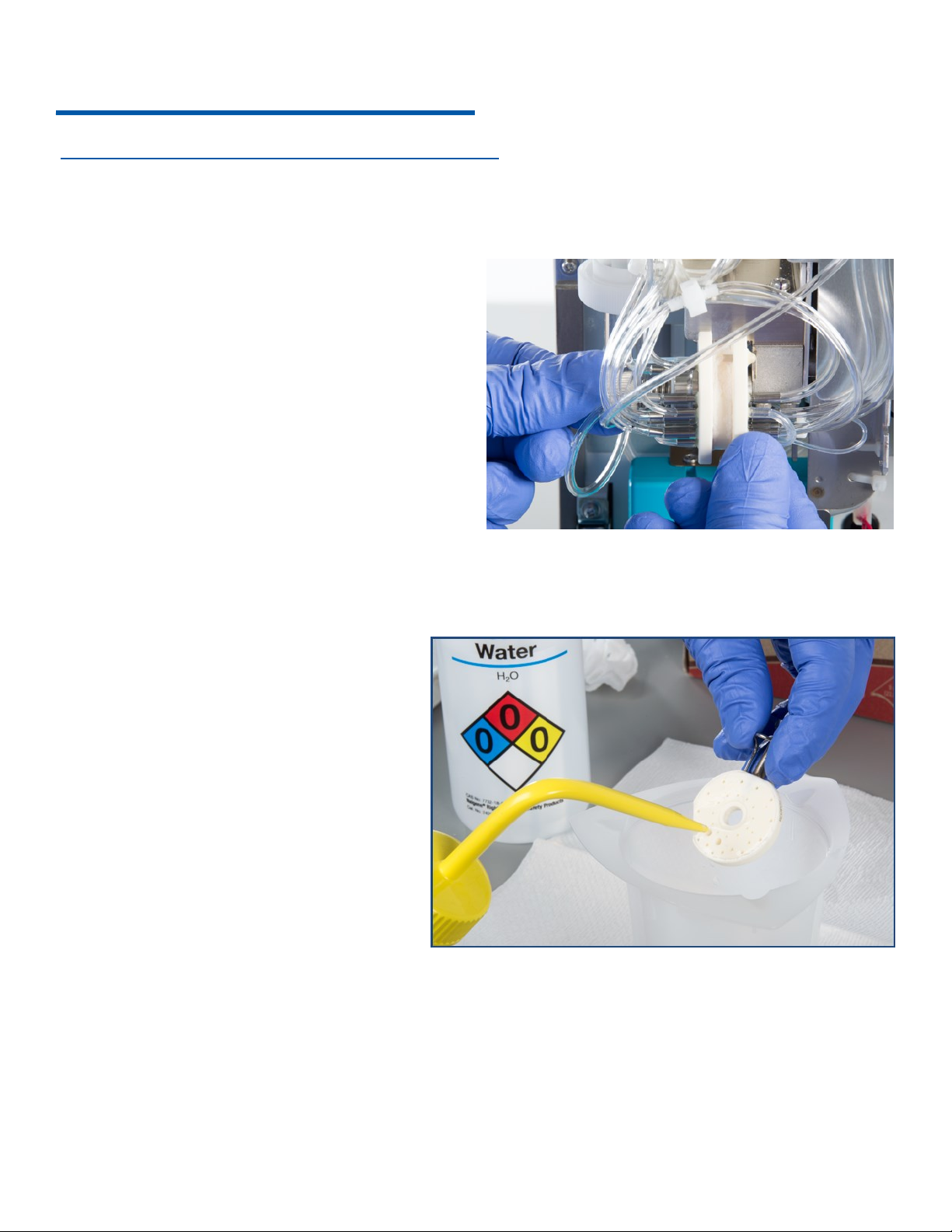

Maintenance

3-Month Maintenance/or Every 4,500 Samples

Clean the SRV

Once the counter reaches 4,500 or if three months have passed since the last maintenance, perform a SRV cleaning.

1. Touch the [OK] button on the menu screen.

2. Turn off the power of the main unit and wait

approximately 30 seconds.

3. Open the front cover of the main unit.

4. Remove the SRV tray.

5. Gently push down the rinse cup using both hands.

6. Remove the SRV fixing screw.

7. Remove entire SRV.

8. Remove the rotary valve.

9. Clean the rotary valve using distilled water or 1:10 dilution of 5% filtered bleach. After cleaning with 5% filtered

bleach, always rinse with distilled water.

10. Clean the contact surfaces of the fixed and

rotary valves using a gauze moistened with

distilled water.

11. Make sure the valve contact surfaces are

completely free from dirt or dust.

12. Assemble the SRV in the reverse order of

disassemble.

Note: Mount the rotary valve with the notch facing

upward and the metal knob coming between the

stoppers.

13. Replace the SRV tray to the original position and

gently push up the rinse cup to the top using

both hands.

14. Close the front cover of the main unit.

15. Turn on the main unit and make sure that a background error has not occurred.

16. Perform quality control and make sure the there is no functional problem.

XP-300 Quick Guide-Document Number 1051-CFL, Revision 2 June/2014

Page 11

Page 12

Loading...

Loading...